Vehicle seat frame

A seat frame and vehicle technology, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve problems such as directions that do not consider the load, and can not be said to effectively ensure the strength of the seat back frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

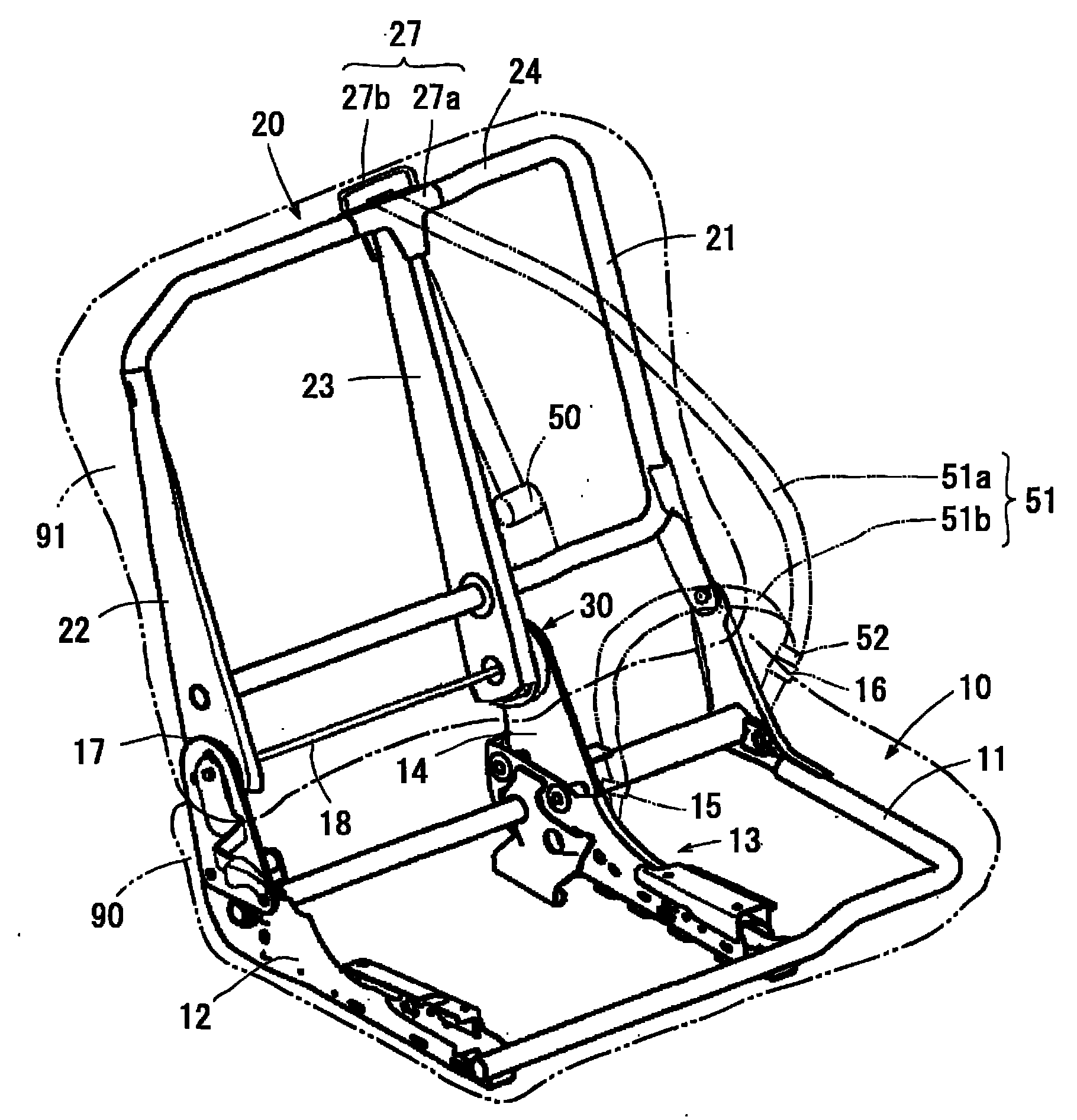

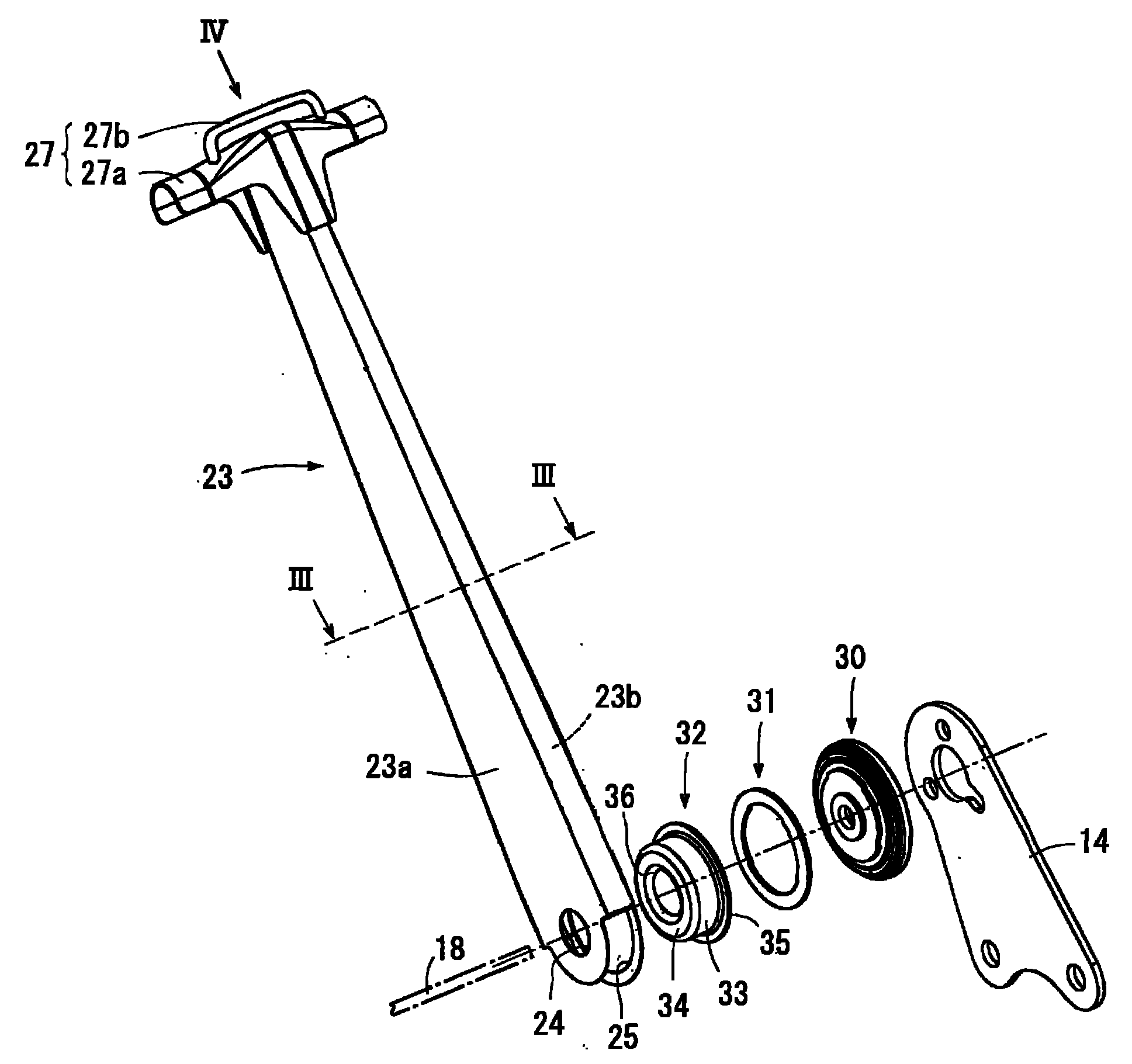

[0024] Hereinafter, embodiments in which the vehicle seat frame according to the present invention is embodied will be described with reference to the drawings. Such as figure 1 As shown, the vehicle seat frame of the embodiment is provided with: a seat cushion frame 10, which supports the seat cushion 90; a seat back frame 20, which supports the seat back 91; and a recliner 30, which adjusts the seat back 91. an angle with respect to the seat cushion 90 ; and the shoulder belt anchor 27 provided at the upper end of the seat back frame 20 . The shoulder belt anchor 27 is composed of a joint portion 27a and a belt guide portion 27b.

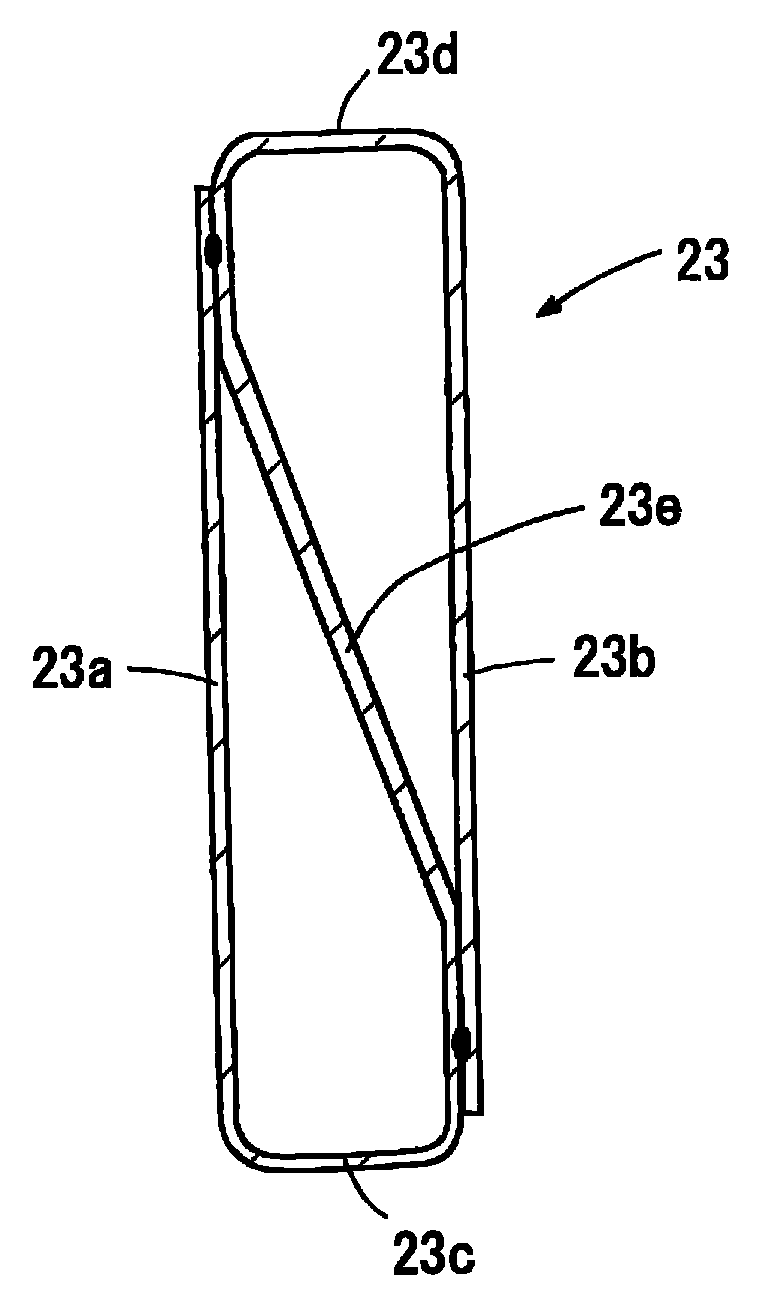

[0025] Back side frames 21 and 22 are arranged at both ends of the seat back frame 20 , and a hollow back middle frame 23 in the shape of a rectangular column is arranged at the center. The upper ends of the two back side frames 21 and 22 are connected by an upper pipe 24, and the center part of the upper pipe 24 and the upper end of the back m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com