Supercharger with electric motor

A supercharger and electric motor technology, which is applied in the direction of electric components, engine components, combustion engines, etc., can solve the problems of increased vehicle weight, large-scale equipment, narrowed flow path, etc., to improve compression efficiency and reliability , Cooling system simplification, effect of suppressing weight increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

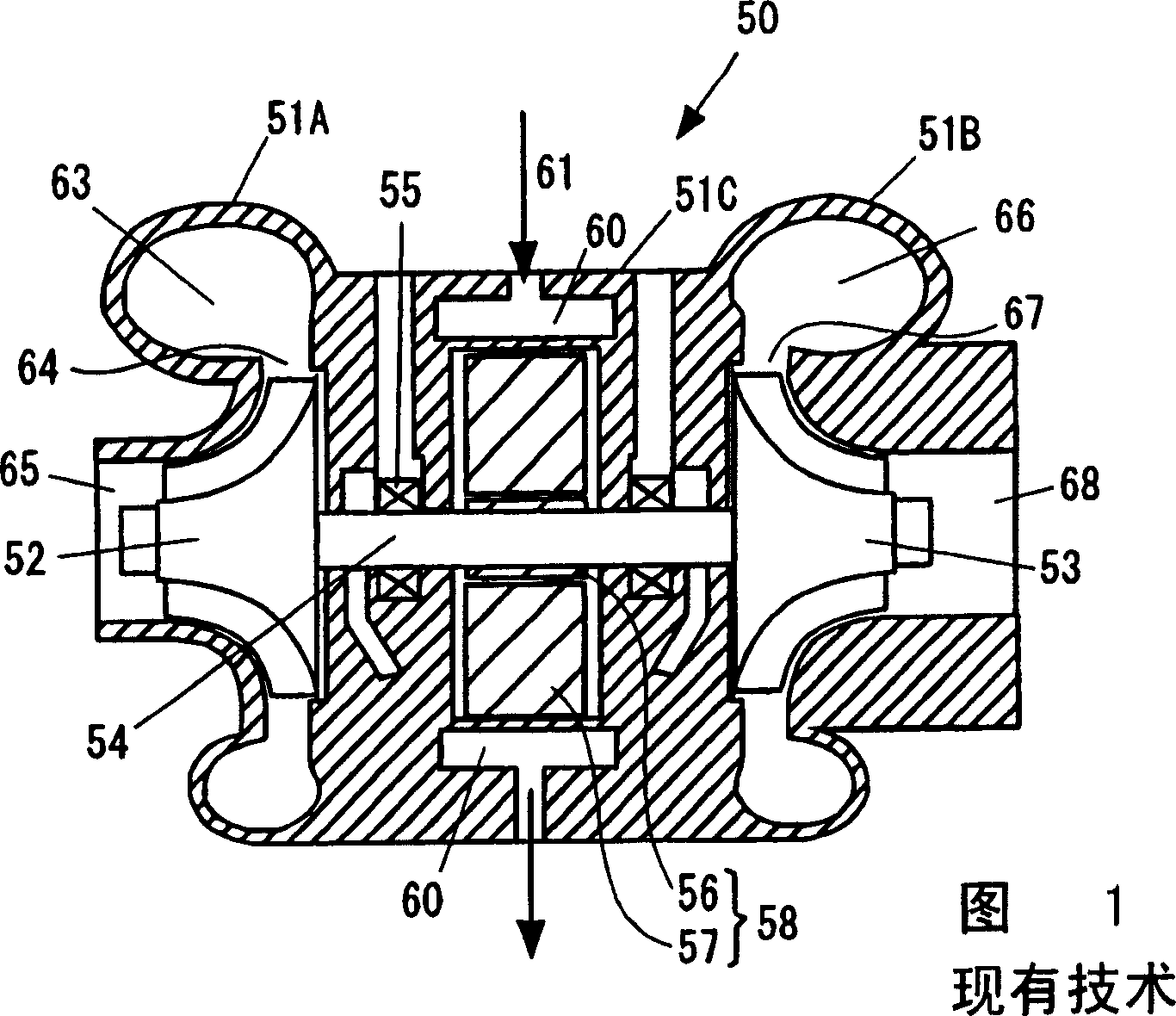

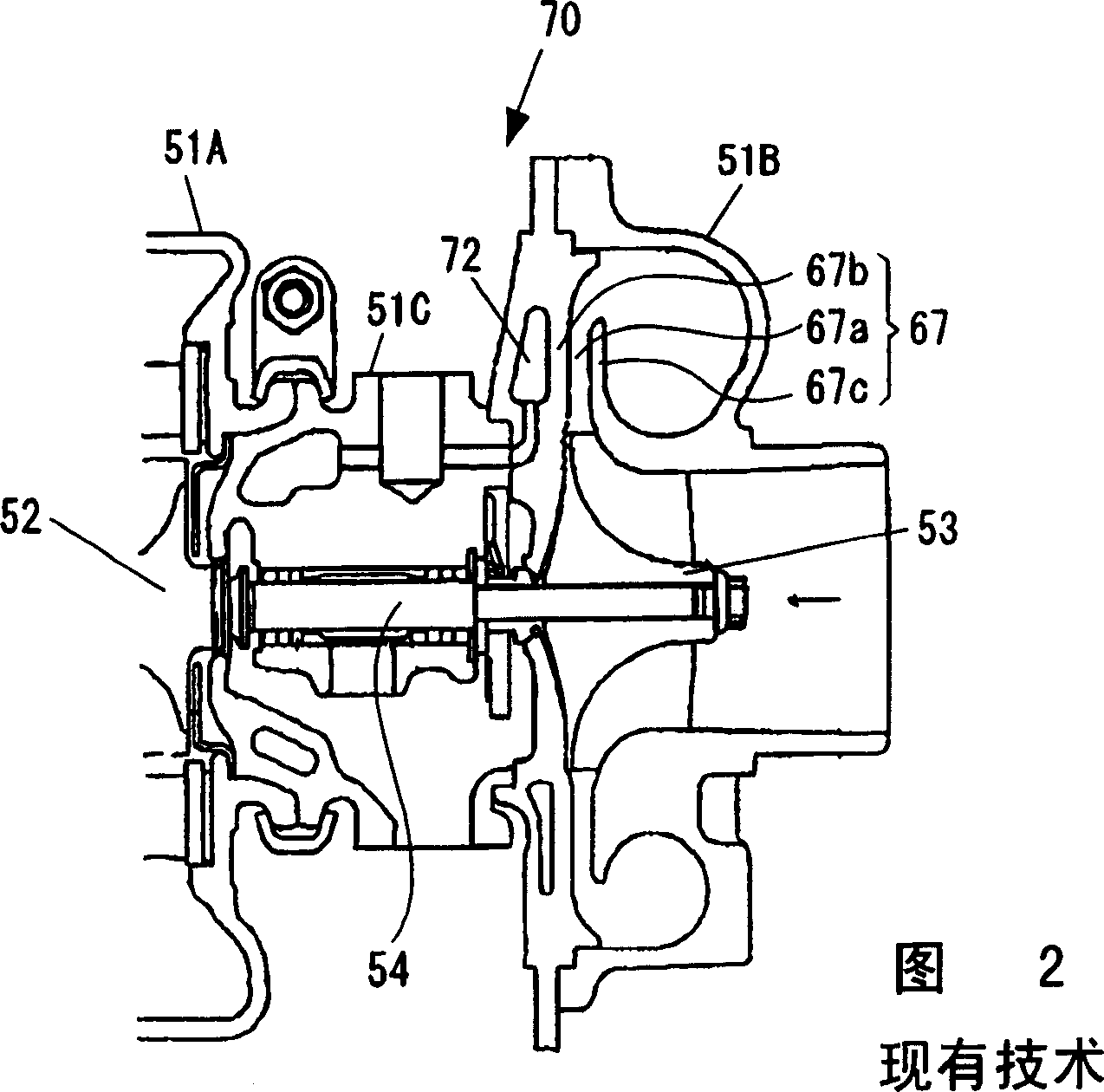

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

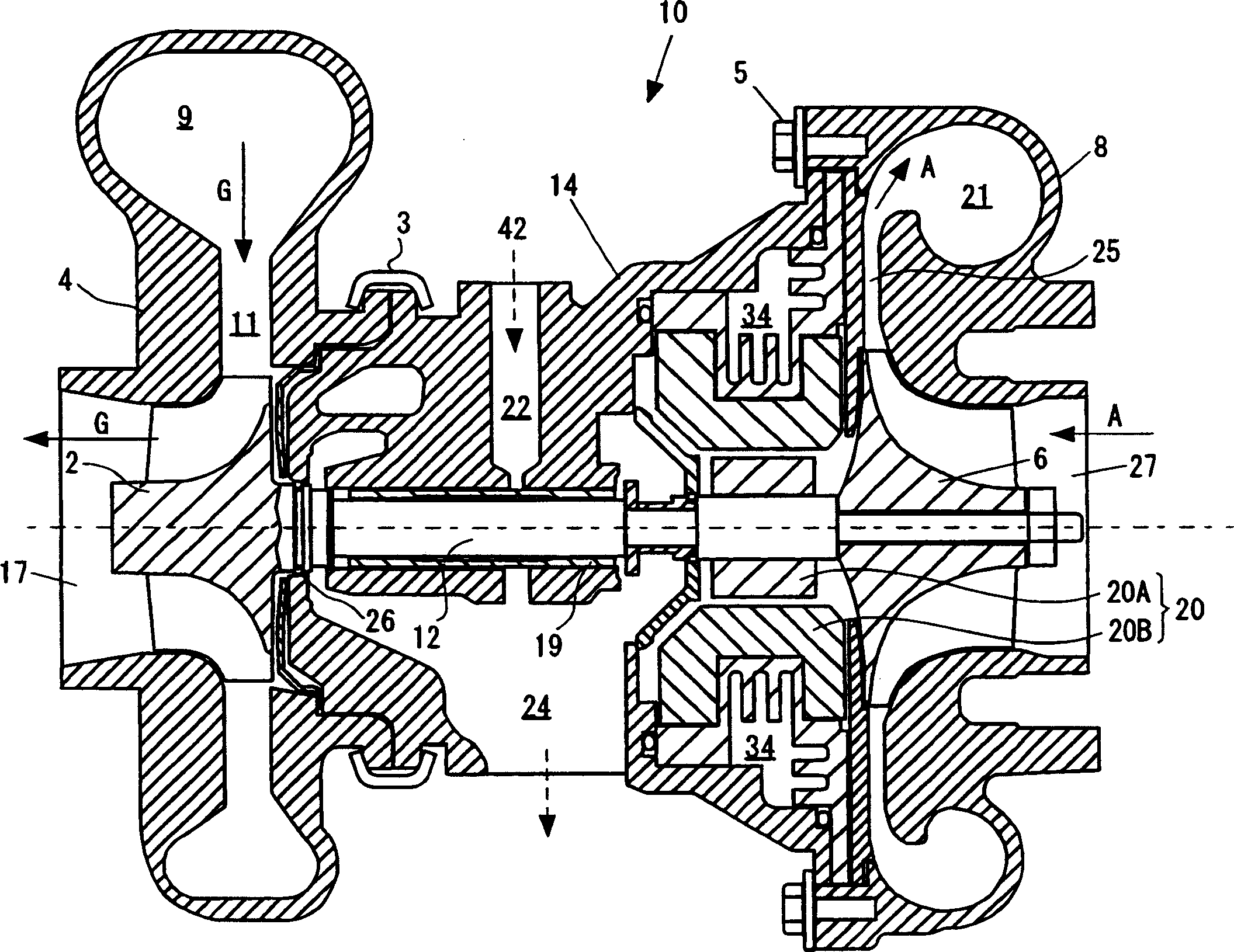

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the common part in each drawing, and repeated description is abbreviate|omitted.

[0025] image 3 It is a cross-sectional view of a supercharger with an electric motor according to an embodiment of the present invention. Such as image 3 As shown, this supercharger 10 with electric motor includes: turbine impeller 2; turbine housing 4; rotating shaft 12; compressor impeller 6; compressor housing 8;

[0026] Arranged on the exhaust passage side are a turbine impeller 2 that is rotationally driven by exhaust gas G of the internal combustion engine, and a turbine housing 4 that surrounds the turbine impeller 2 . The turbine housing 4 has a swirl chamber 9 formed around the turbine wheel 2 , and the swirl chamber 9 communicates with the turbine wheel 2 via an annular gas flow path 11 . In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com