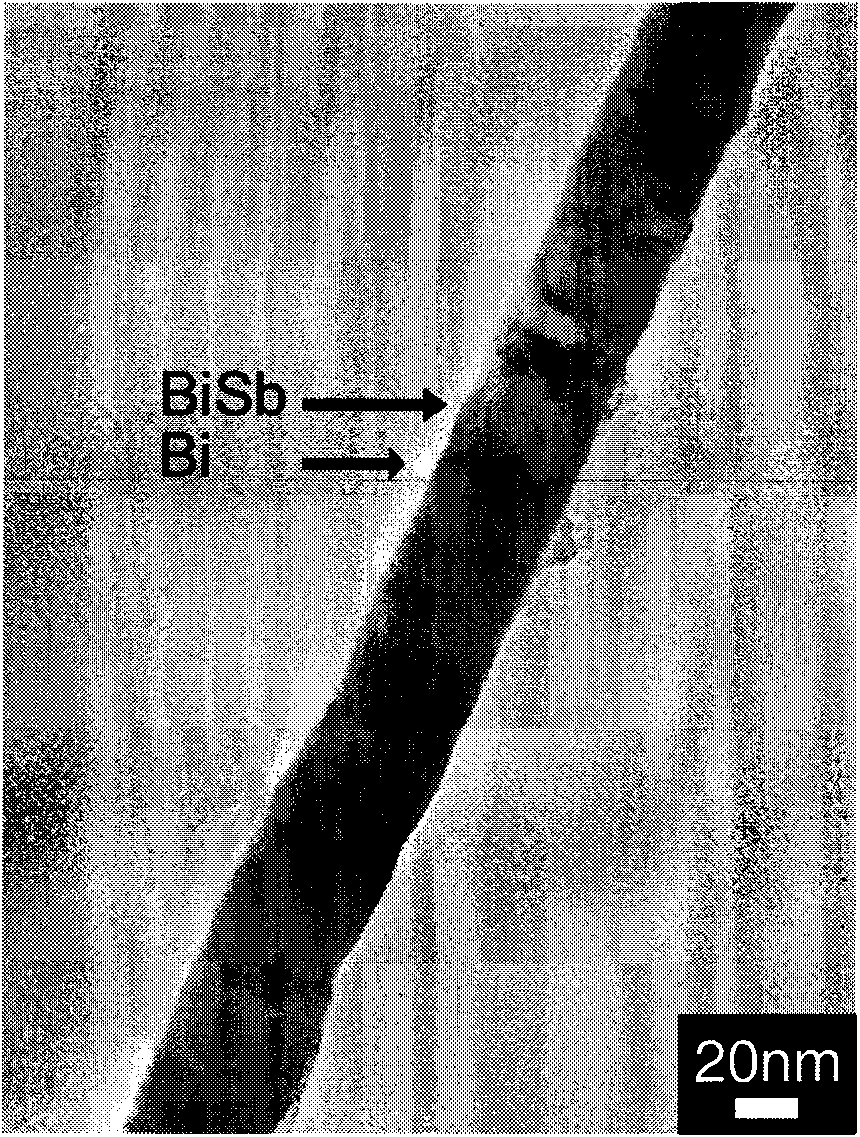

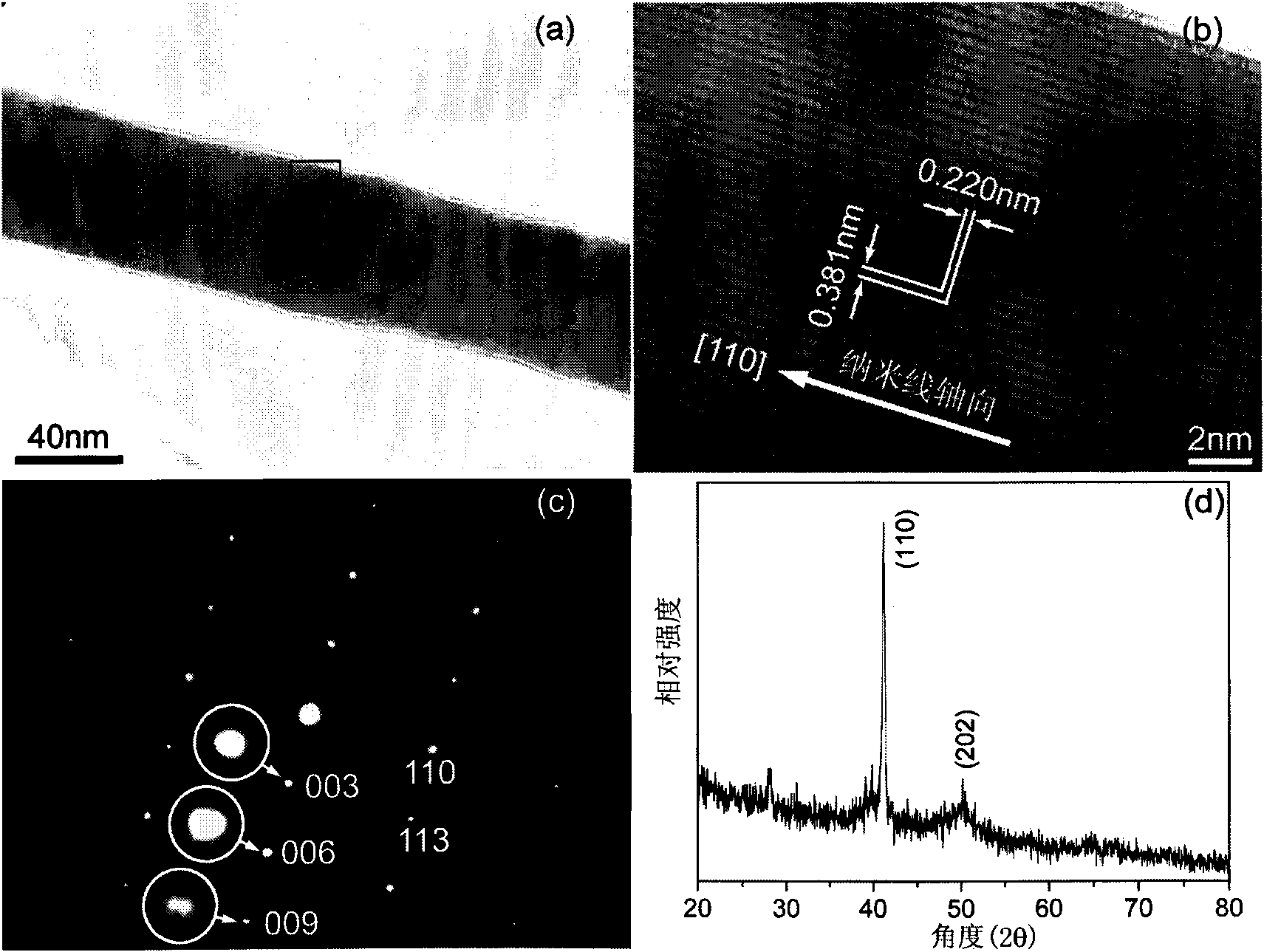

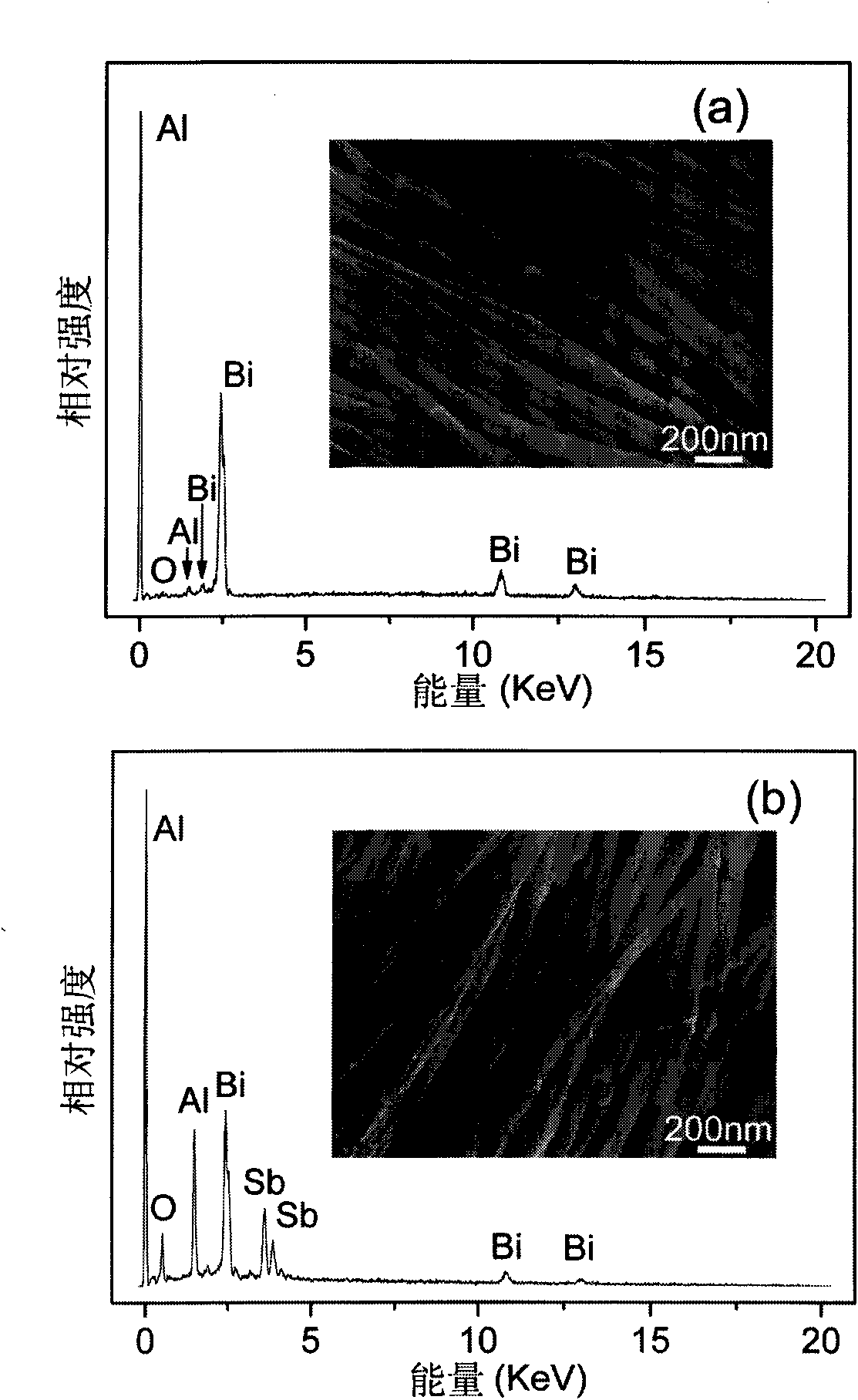

Bismuth/bismuth-antimony extensional superlattice nanowire and preparation method thereof

A nanowire and superlattice technology, which is applied in the field of superlattice nanowires and preparation, can solve the problem that bismuth/bismuth antimony epitaxial superlattice nanowires cannot be prepared, bismuth antimony nanowires are not disclosed, and bismuth/bismuth is not disclosed. The preparation steps of antimony epitaxial superlattice nanowires can achieve the effect of consistent preferred orientation, easy preparation method, and suitable for large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The specific steps of preparation are as follows: step 1, first dissolve bismuth chloride with a concentration of 0.02M and antimony chloride with a concentration of 0.06M in hydrochloric acid with a concentration of 0.08M to obtain a mixed solution. Then add the tartaric acid with the concentration of 0.25M, the citric acid with the concentration of 0.22M and the sodium chloride with the concentration of 0.1M successively in the mixed solution under stirring, add the glycerol with the concentration of 0.08M after it dissolves, and continue Stir for 1h. Afterwards, adjust the pH value to 0.8 with an alkaline solution to obtain an electrodeposition solution; wherein, the alkaline solution is a sodium hydroxide solution with a concentration of 0.05M (or ammonia water with a concentration of 0.1M). Step 2, use a porous alumina template coated with a gold film on one side as the cathode, place it in an electrodeposition solution at a temperature of 30°C, and conduct electro...

Embodiment 2

[0026] The specific steps of preparation are as follows: step 1, first dissolve bismuth chloride with a concentration of 0.03M and antimony chloride with a concentration of 0.07M in hydrochloric acid with a concentration of 0.09M to obtain a mixed solution. In the mixed solution under stirring, add successively the tartaric acid with the concentration of 0.26M, the citric acid with the concentration of 0.23M and the sodium chloride with the concentration of 0.11M. Stir for 2h. Afterwards, the pH value is adjusted to 0.81 with an alkaline solution to obtain an electrodeposition solution; wherein, the alkaline solution is a sodium hydroxide solution with a concentration of 0.05M. Step 2, use the porous alumina template coated with a gold film on one side as the cathode, place it in an electrodeposition solution with a temperature of 33°C, and conduct electrodeposition under a pulse voltage; wherein, the thickness of the gold film is 180nm, and the porous alumina template The po...

Embodiment 3

[0028] The specific steps of preparation are as follows: step 1, first dissolve bismuth chloride with a concentration of 0.04M and antimony chloride with a concentration of 0.08M in hydrochloric acid with a concentration of 0.1M to obtain a mixed solution. Then add tartaric acid with a concentration of 0.27M, citric acid with a concentration of 0.24M and sodium chloride with a concentration of 0.12M in the mixed solution under stirring. After it dissolves, add glycerol with a concentration of 0.1M, and continue Stir for 3h. Afterwards, the pH value is adjusted to 0.82 with an alkaline solution to obtain an electrodeposition solution; wherein, the alkaline solution is a sodium hydroxide solution with a concentration of 0.05M. Step 2, use a porous alumina template coated with a gold film on one side as the cathode, place it in an electrodeposition solution at a temperature of 35°C, and conduct electrodeposition under a pulse voltage; wherein, the thickness of the gold film is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com