Patents

Literature

42results about How to "Preparation high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

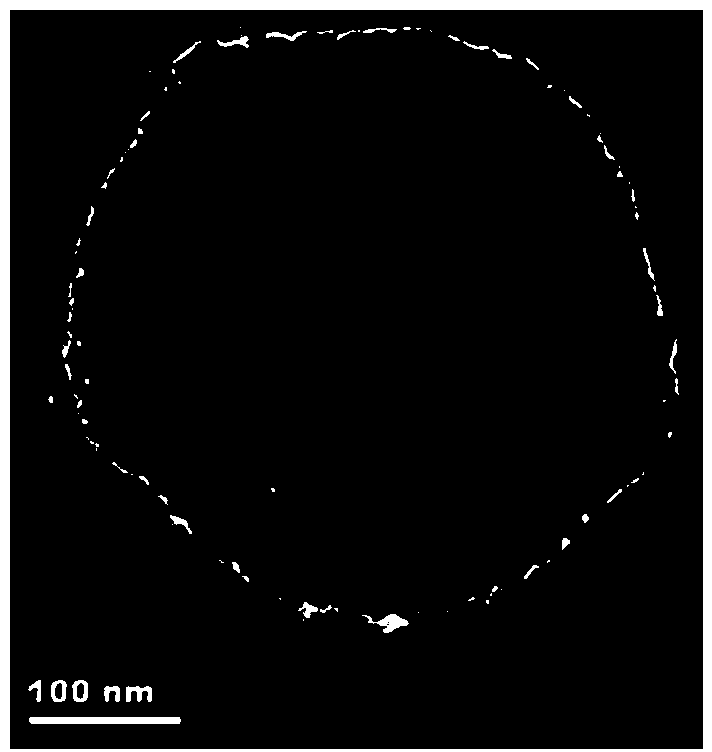

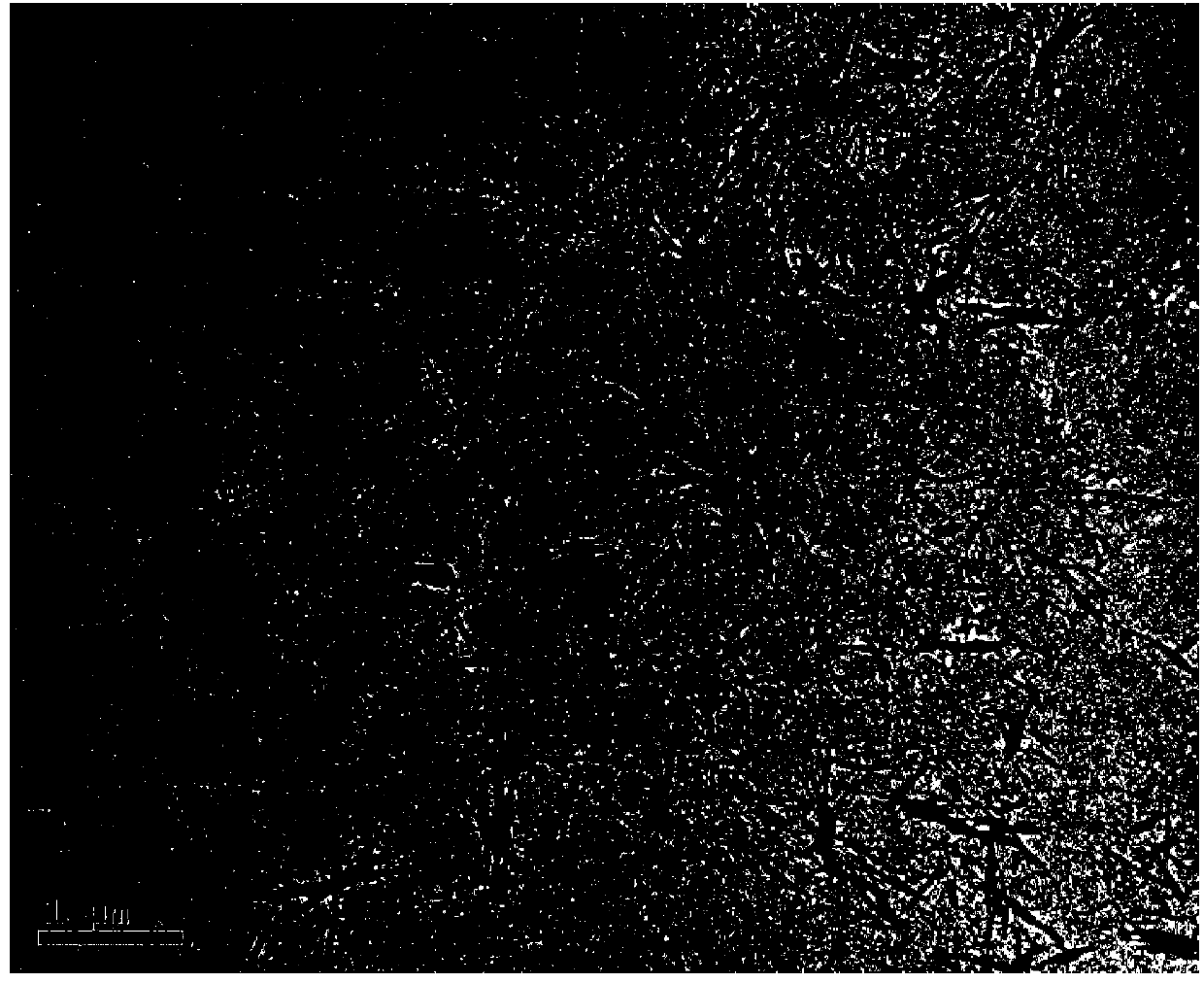

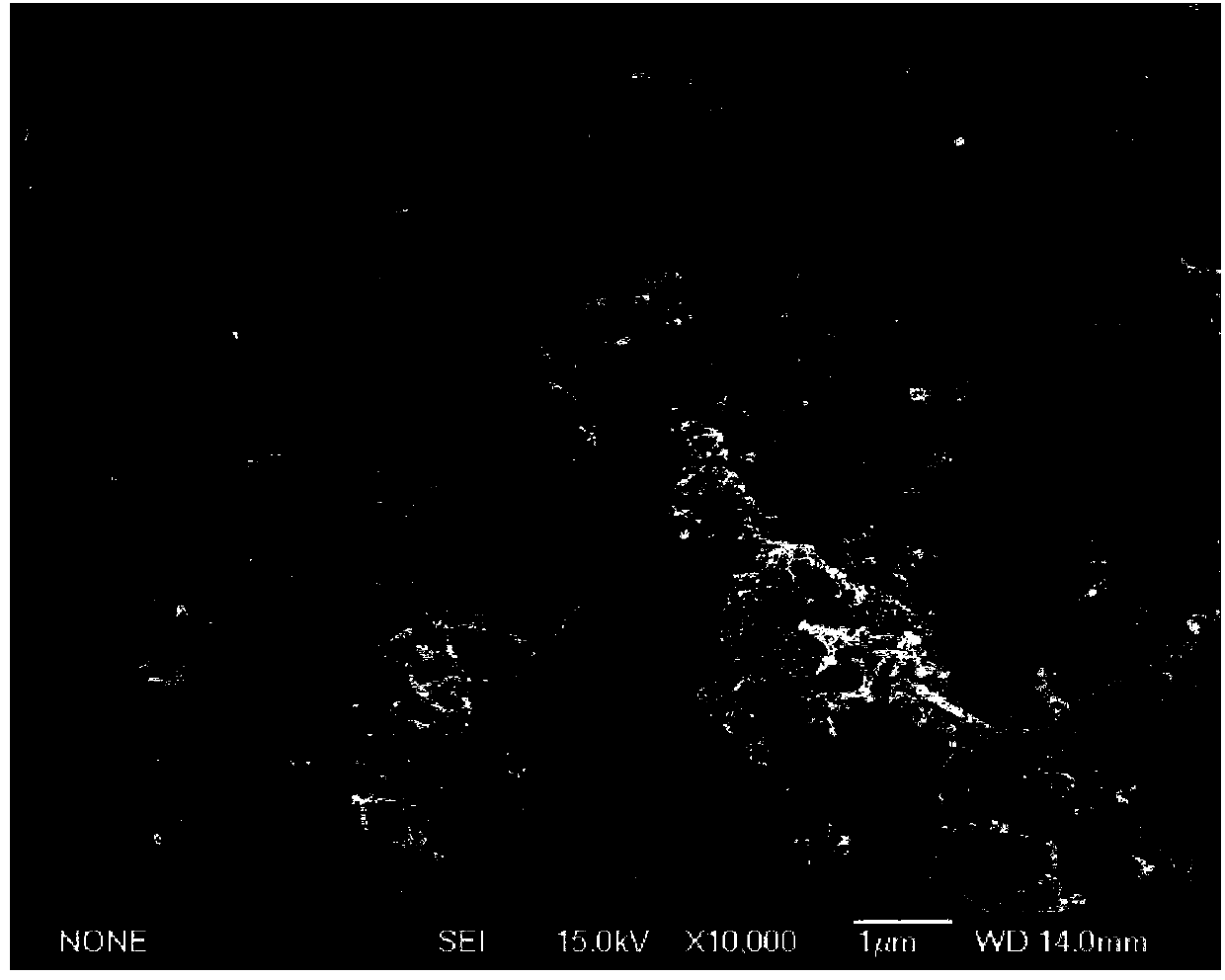

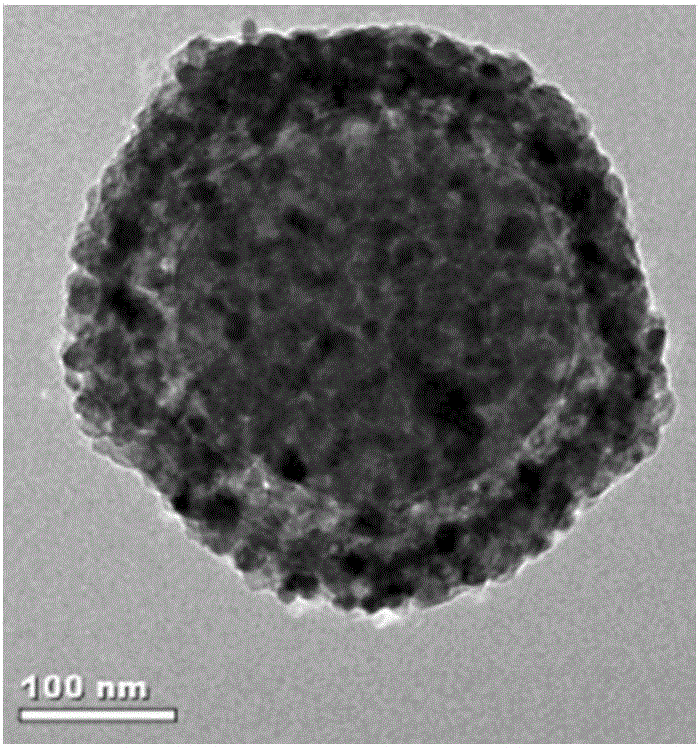

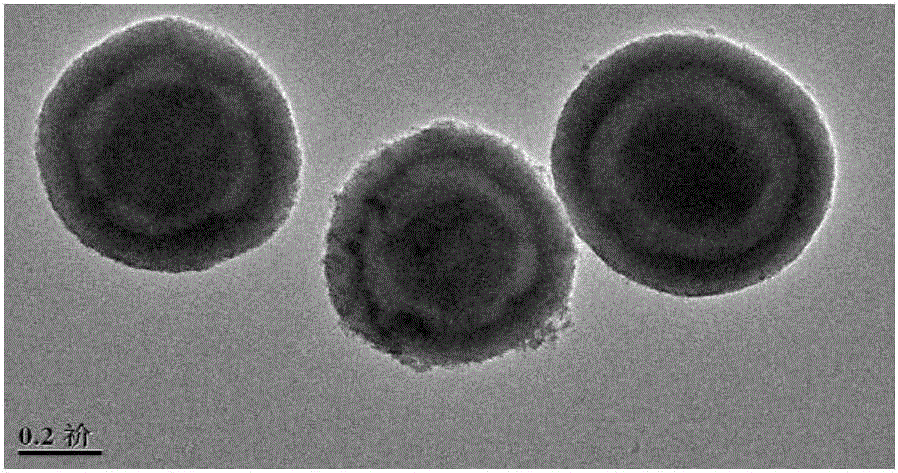

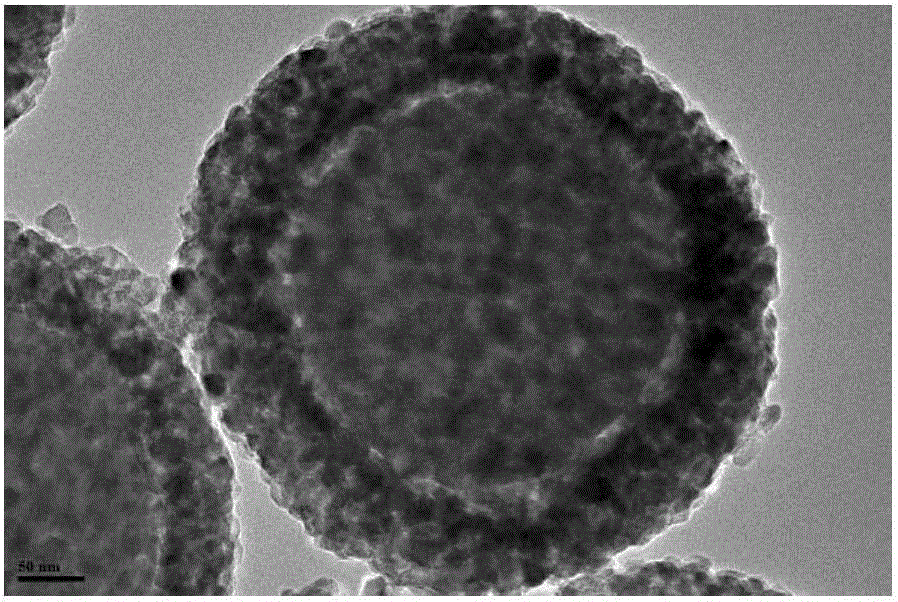

Yolk-eggshell-structured zeolite molecular sieve-mesoporous titanium oxide composite material and preparation method thereof

ActiveCN103894223APreparation highEasy to prepareCatalyst carriersMolecular sieve catalystsYolkPtru catalyst

The invention belongs to the technical fields of inorganic porous materials and catalysts and patricianly relates to a yolk-eggshell-structured zeolite molecular sieve-mesoporous titanium oxide composite material and a preparation method thereof. The composite material is characterized in that a yolk is made of zeolite molecular sieve materials, an eggshell is made of a mesoporous titanium oxide nanocrystal aggregate, and a size-adjustable cavity is formed between a zeolite molecular sieve and the mesoporous titanium oxide. The preparation method comprises the steps of wrapping a phenolic resin macromolecule layer or amorphous silicon dioxide on the outer surface of the zeolite molecular sieve, then wrapping a layer of amorphous silicon dioxide, forging to transform the titanium dioxide into crystallized titanium dioxide nanocrystals, and finally removing the phenolic resin macromolecule layer or the amorphous silicon dioxide, so as to obtain the targeted composite material. The method is simple and is easy to control. The composite material has a hierarchical pore structure and can be taken as a catalyst or a catalyst carrier for continuous reaction as well as an adsorption-catalysis composite material.

Owner:元颉新材料科技(浙江)有限公司

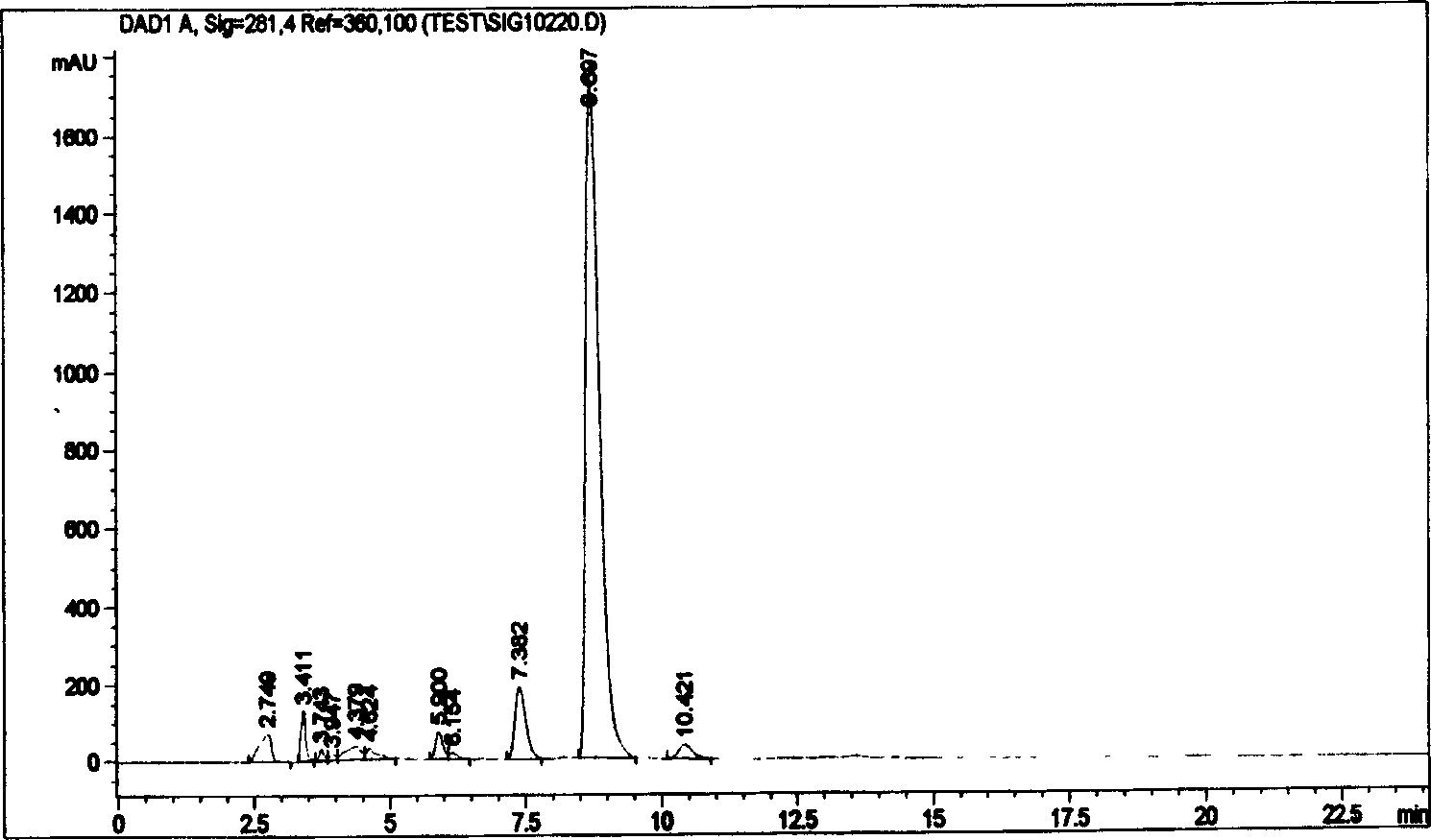

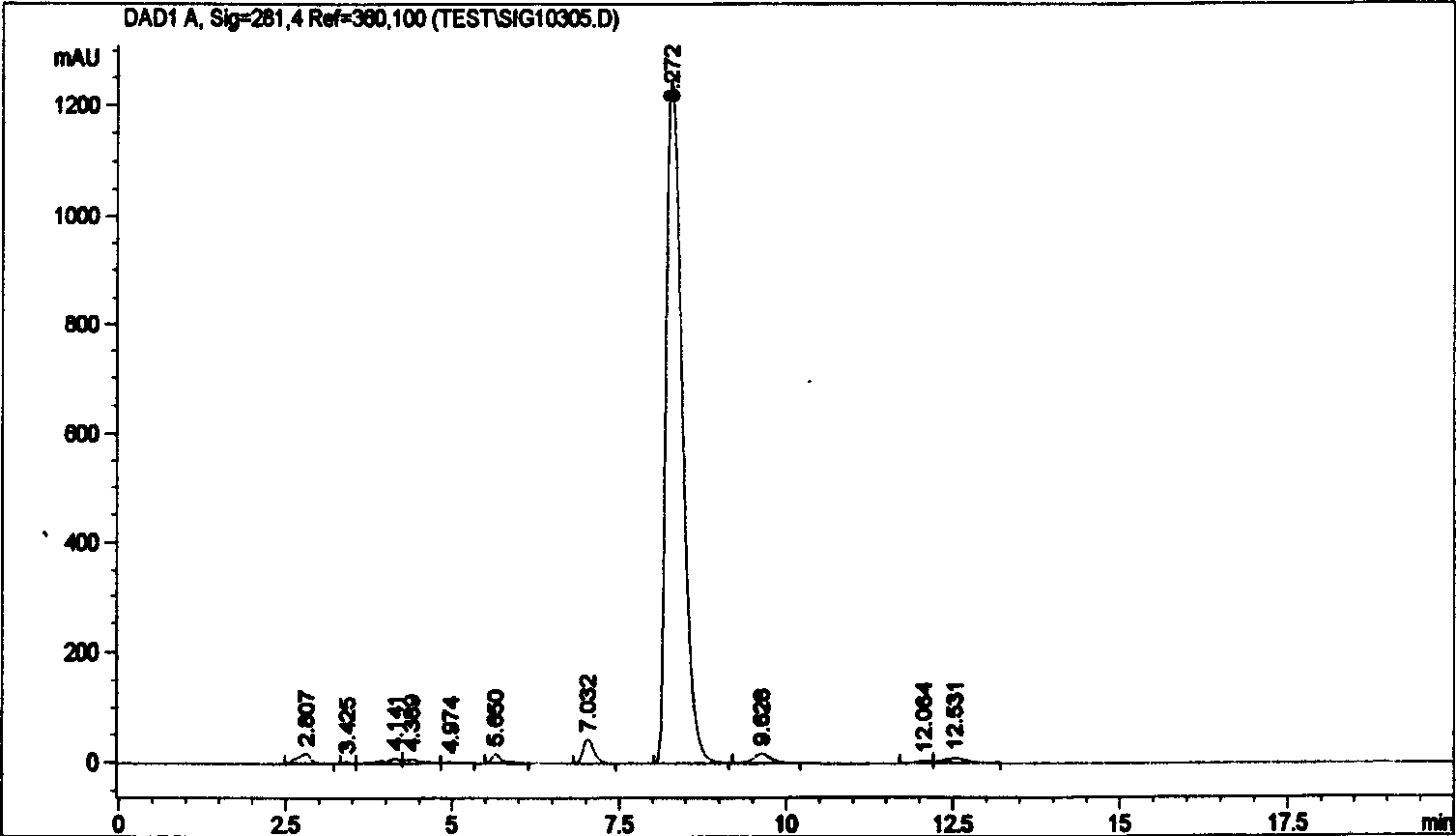

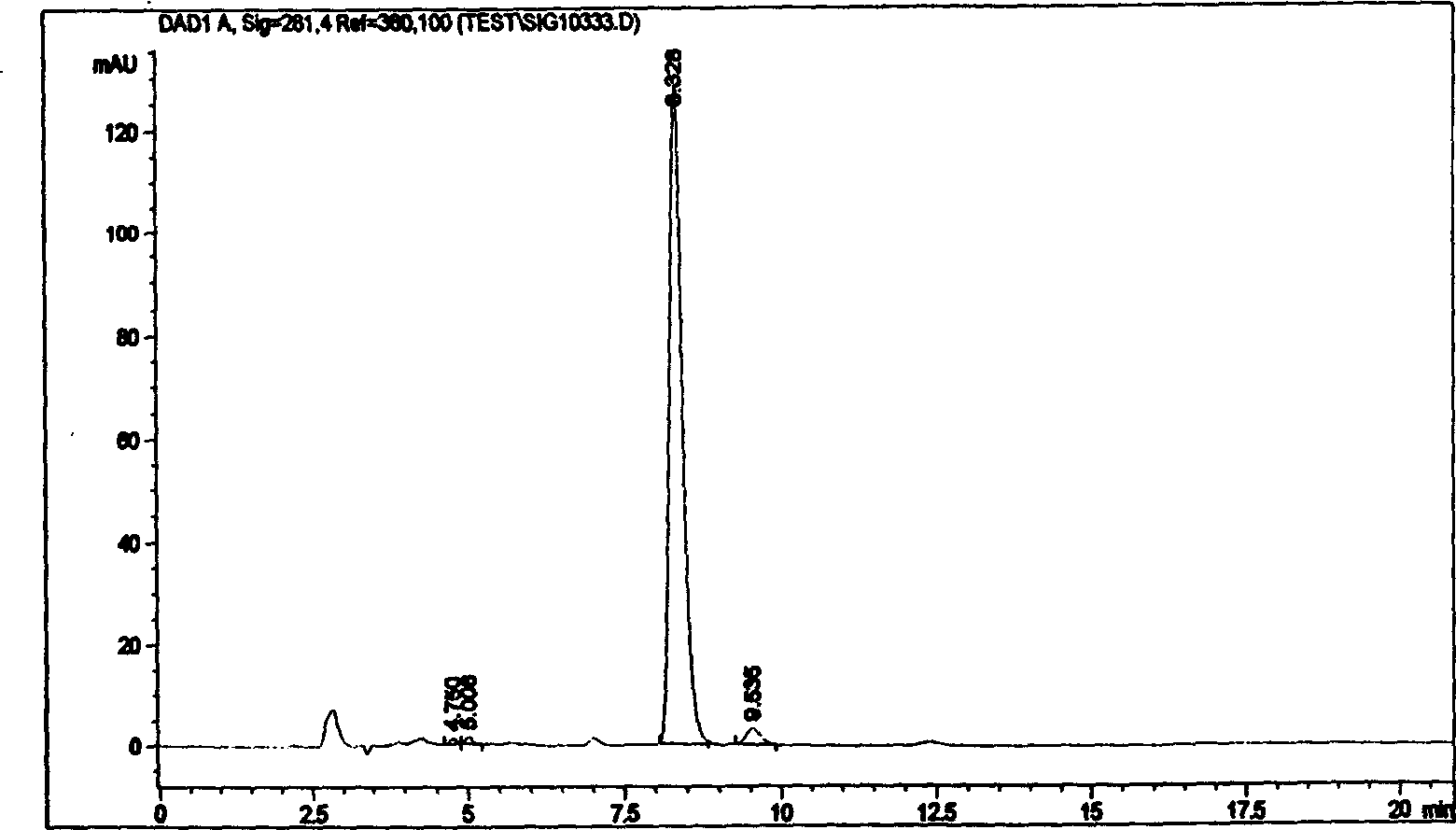

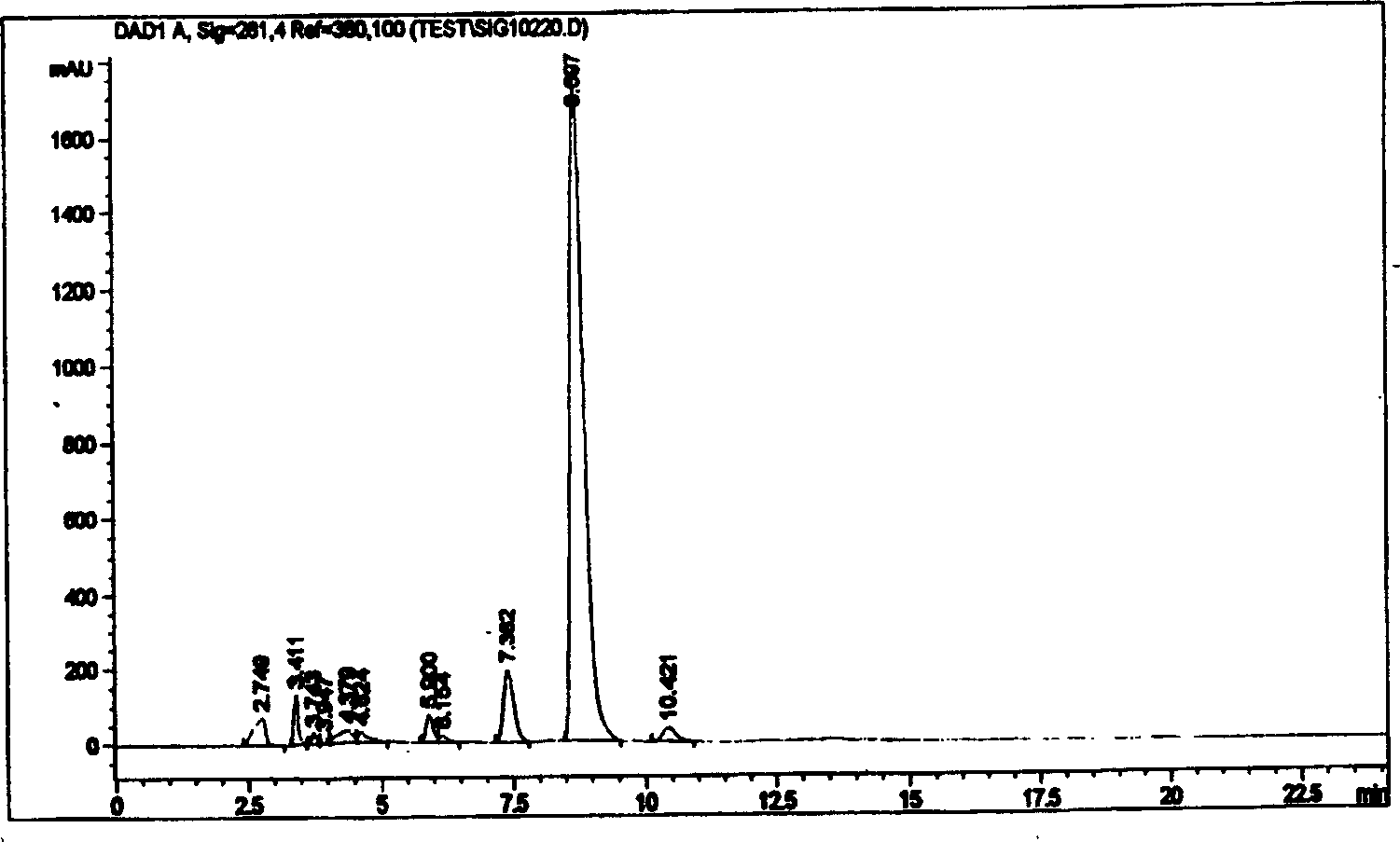

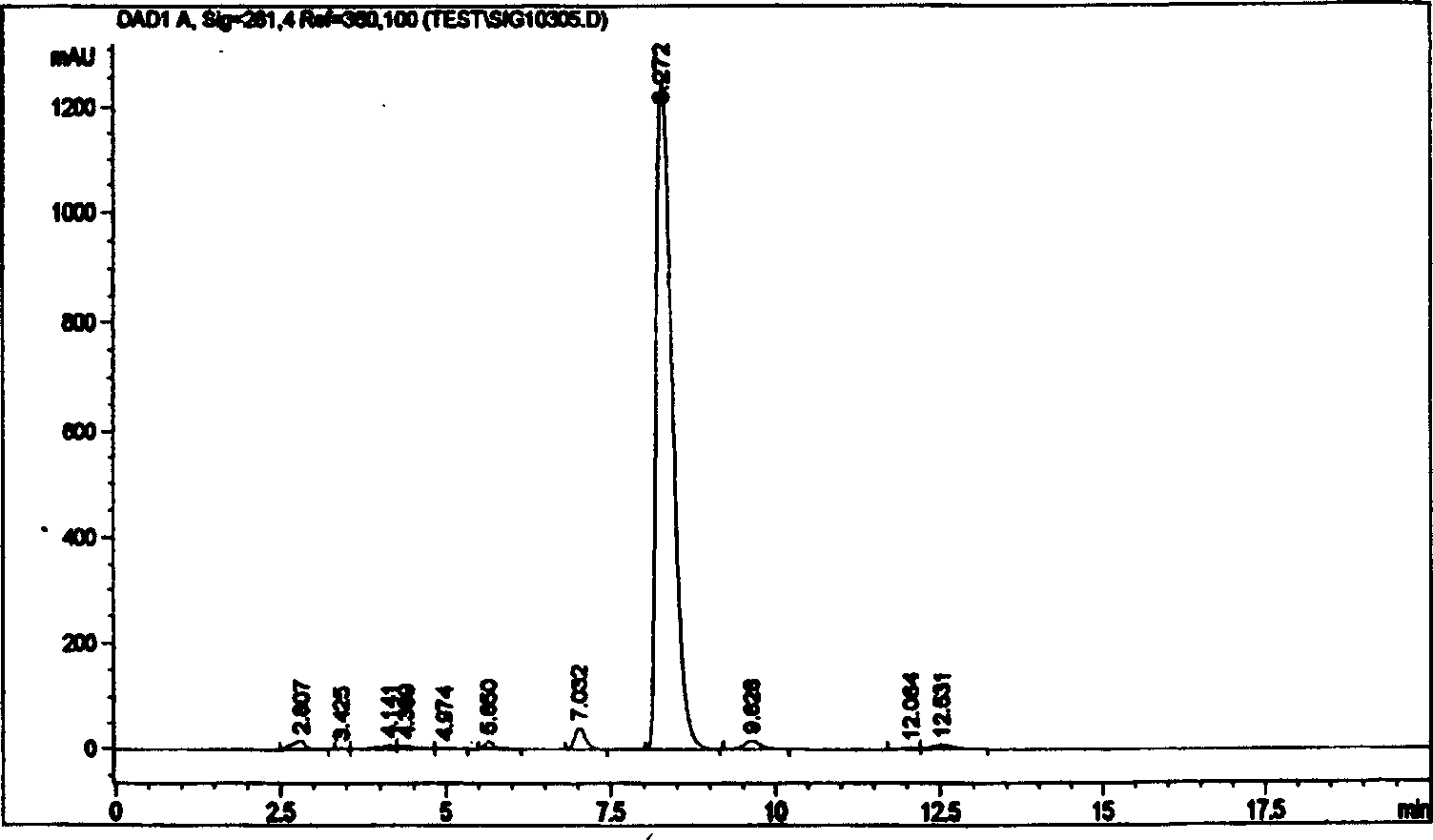

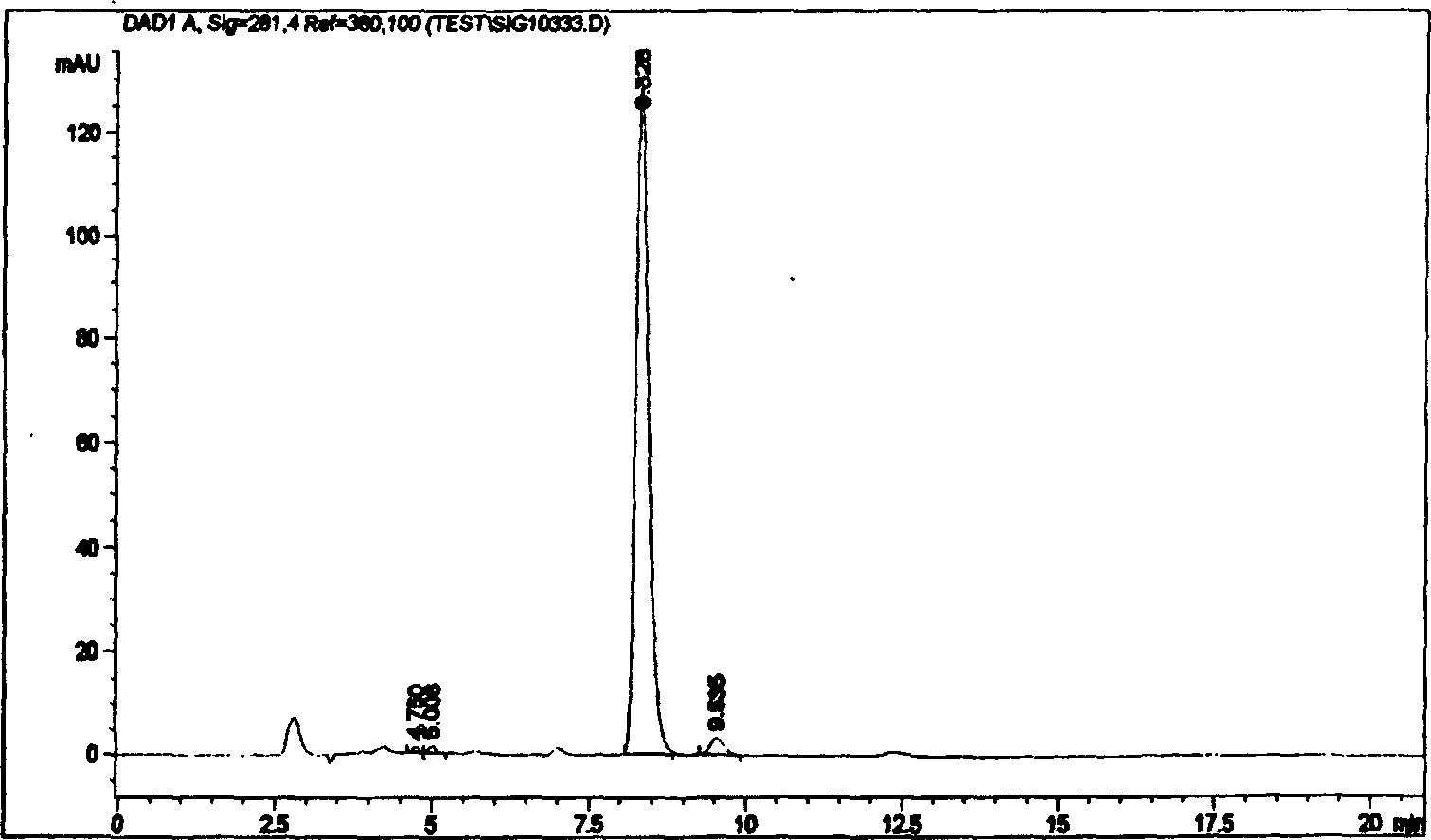

Technical method for extracting salvianolic acid B from radix salivae miltiorrhizae

The invention is a technical method to extract salvianolic acid B from tanshen, organically combining several methods to extract salvianolic acid B, to develop a new technique proper to separate and purify salvianolic acid B. It firstly extracts by water, then flocculates by chitosan, successively makes alcohol precipitation, then extracts by petroleum ether and acetic ester, respectively, and finally adopts silica gel column chromatography to obtain higher purity salvianolic acid B. It is applied to industrialized production.

Owner:EAST CHINA UNIV OF SCI & TECH

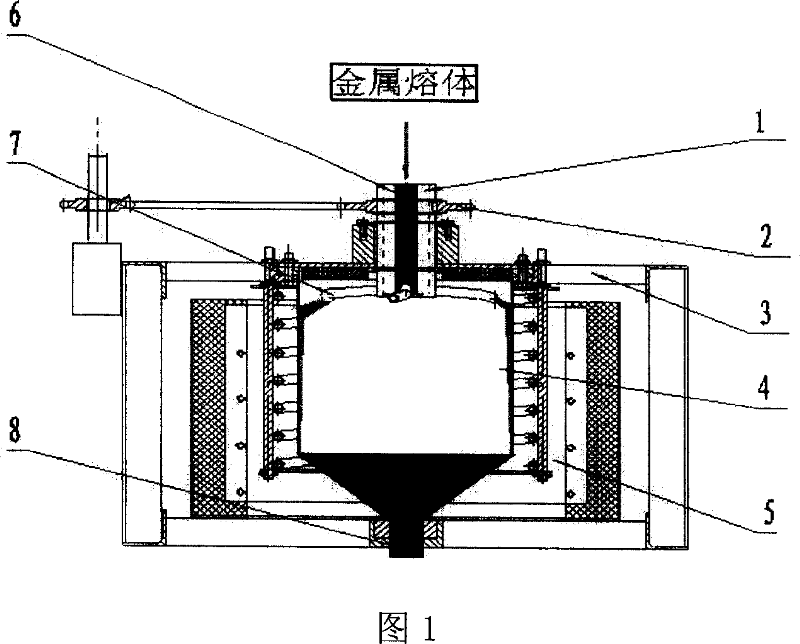

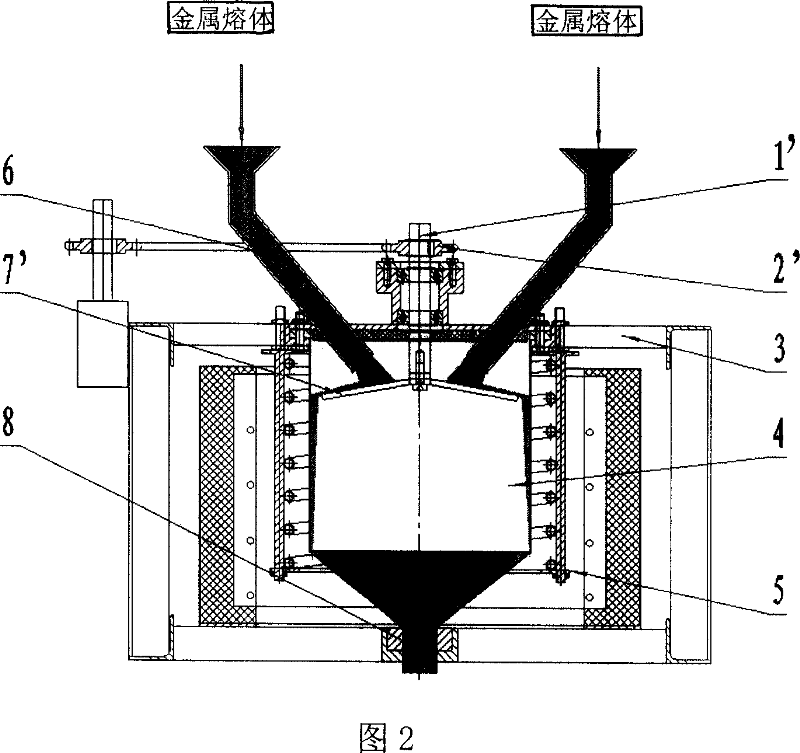

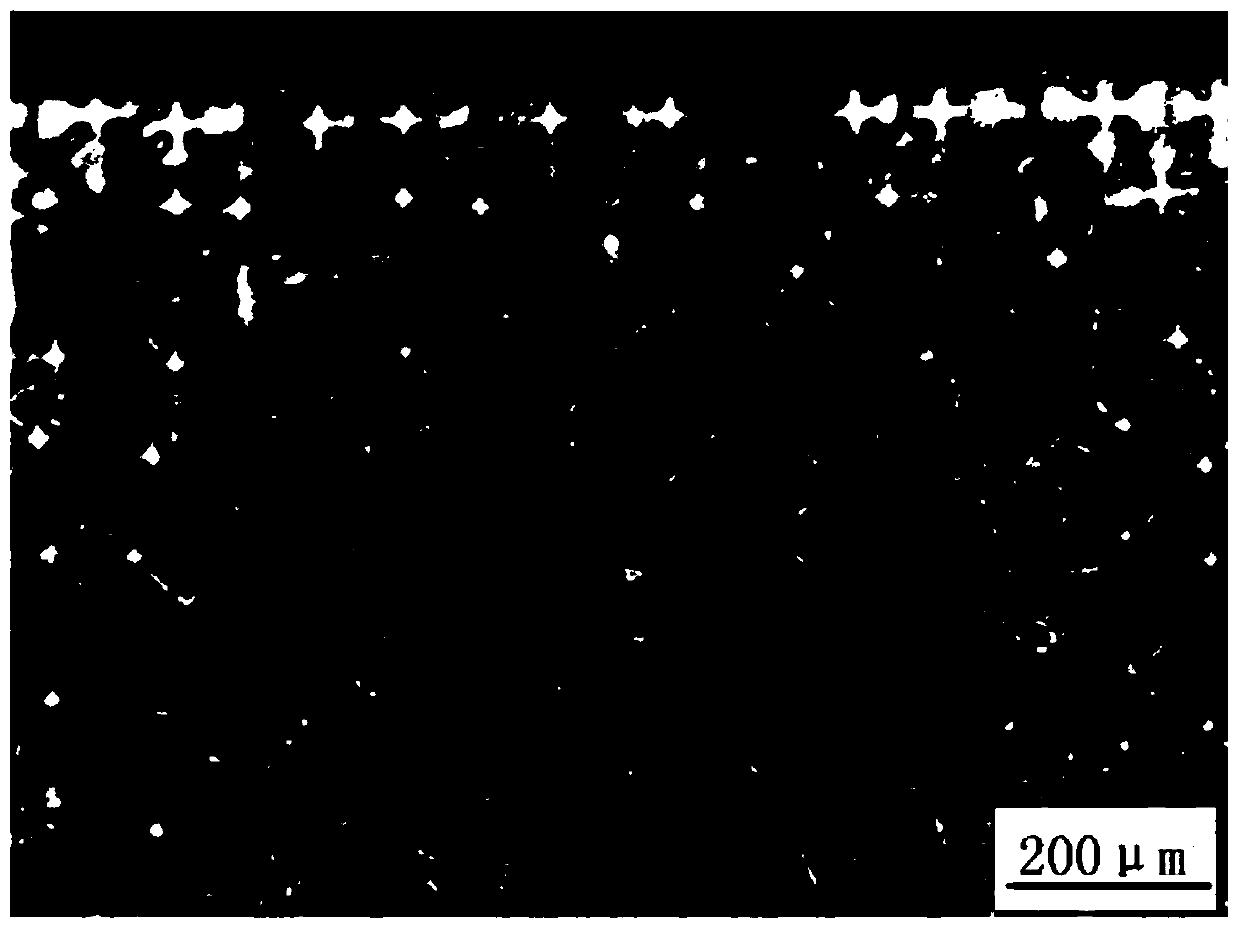

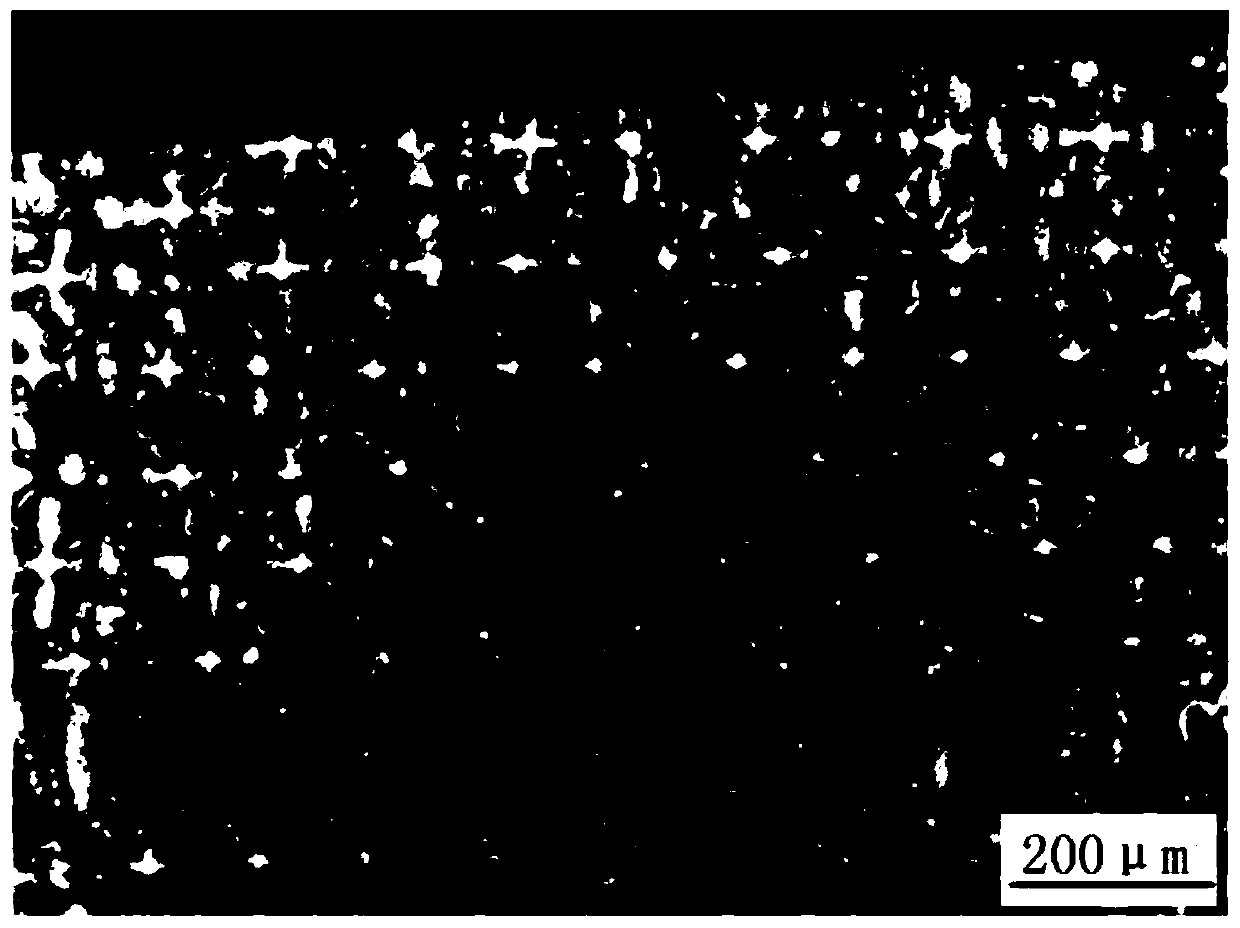

Method for preparing metal sizing agent by a compelling, equal-freezing and continuous method

The invention relates to a method for forced uniform solidified continuous preparing metal slurry, comprising that (1) melting overheat metal with the temperature more than the liquidus temperature about 0-100deg.C is poured into upper guide flow pipe; (2) the liquid metal flows into the melting deconcentrator and the liquid metal is injected on the inner round wall of melting deconcentrator; the temperature control system out of pulping room make the wall temperature of pulping room be controlled lower than the liquidus temperature about 0-100deg.C; the liquid metal is collected at the cone bottom to obtain the metal slurry with solid fraction smaller than 30%; the metal slurry flows out through the lower guide flow pipe and the temperature is controlled in -10-10deg.C of liquidus temperature; (3) the metal slurry flows into the collector or is sent into the common equipment such as die-casting, rolling and forging so on directly to carry rheological forming out and or is cast into the mould continuously to produce semi-solid continuous casting slab. The merit of invention is that the preparation of metal slurry is uniform, mass and continuous, and it can satisfy the demand of huge industrial production easily.

Owner:有研金属复材技术有限公司

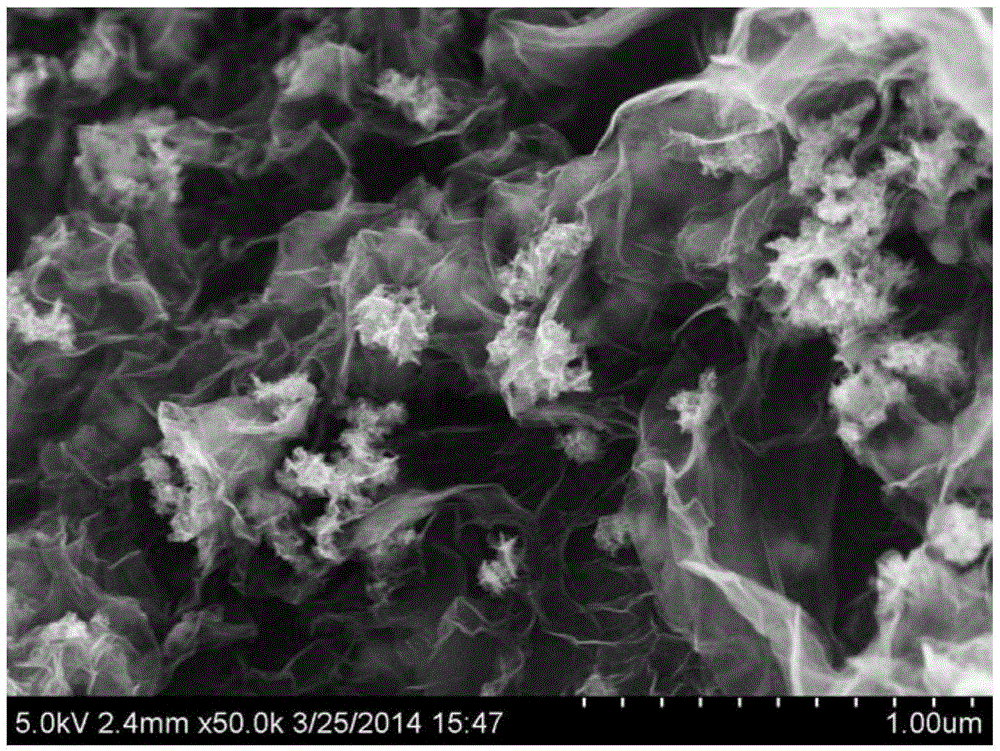

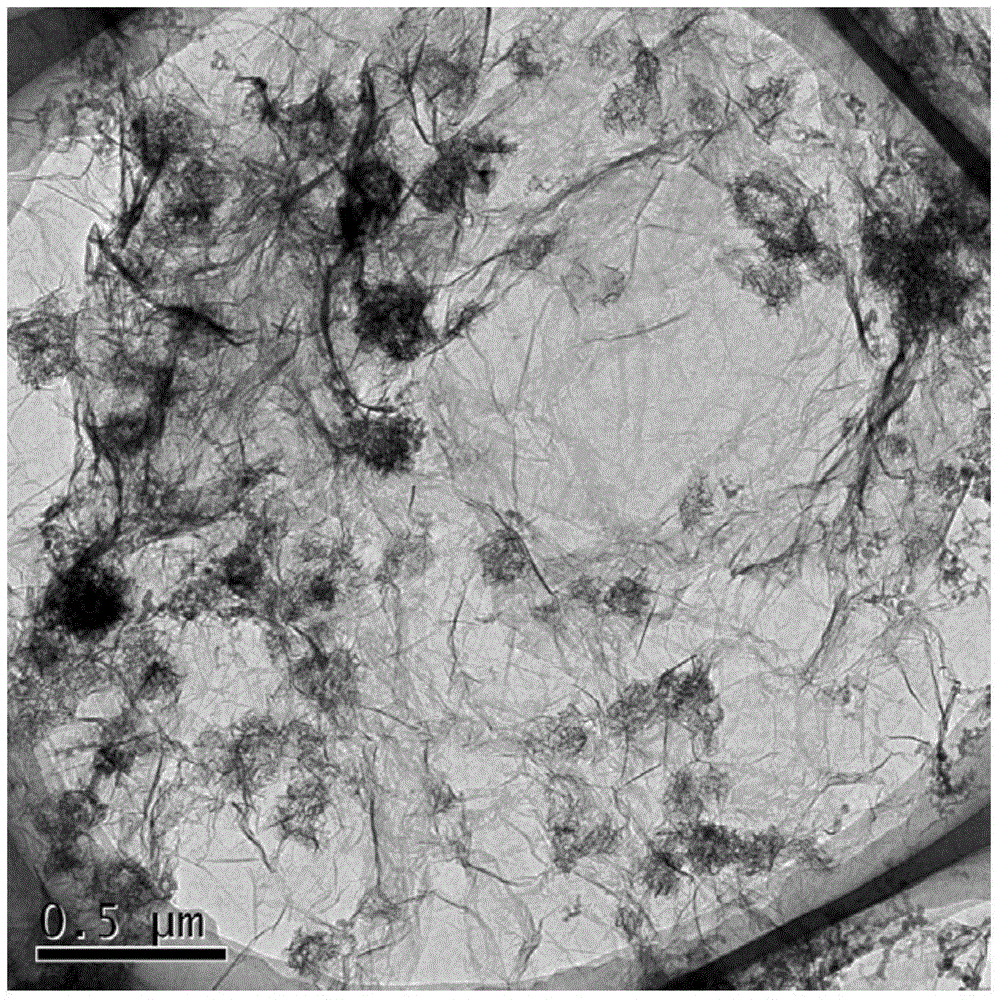

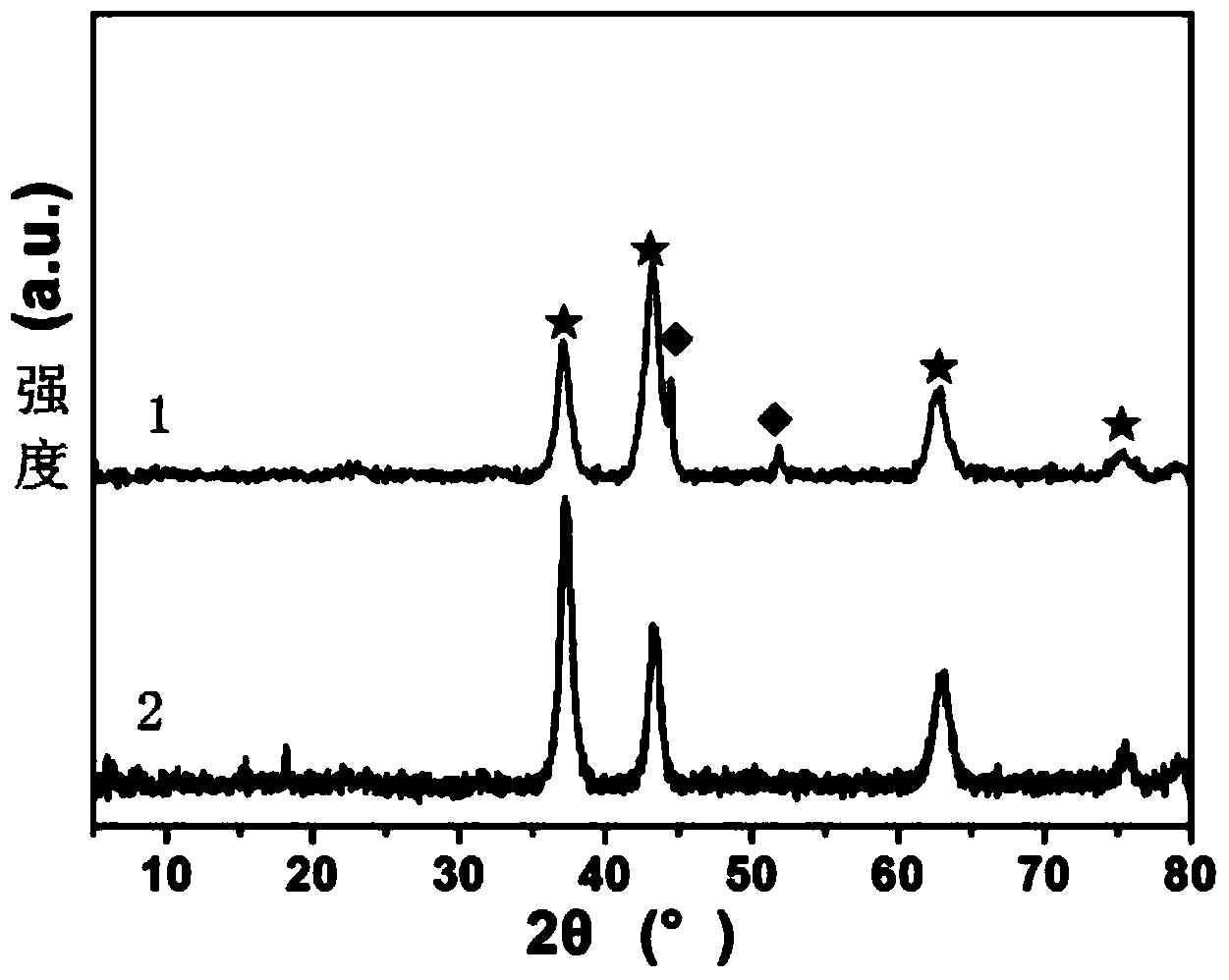

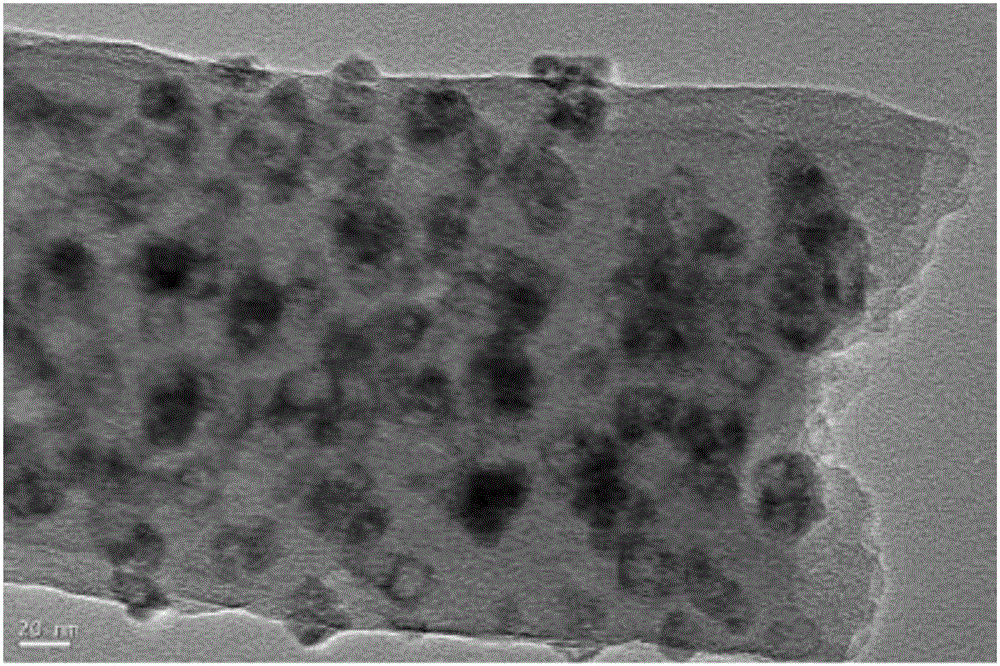

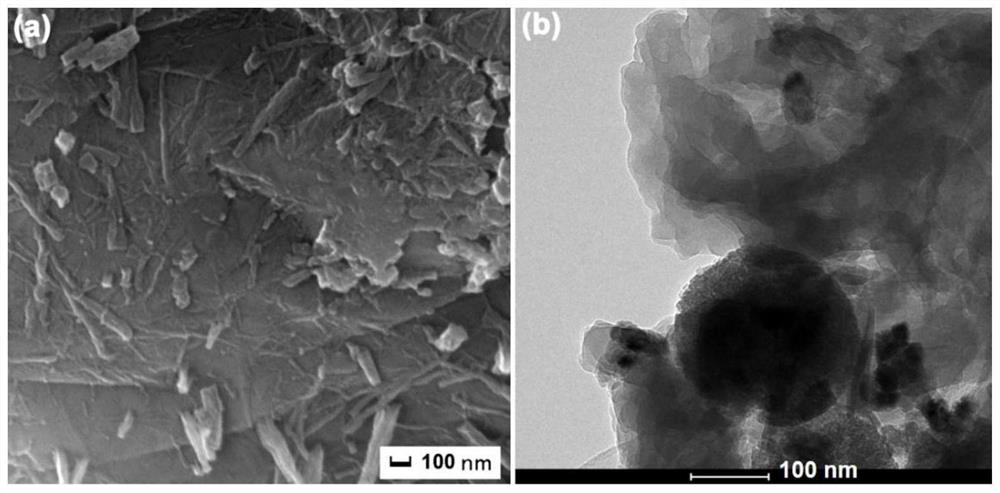

Graphene and nickel diselenide composite and preparation method thereof

InactiveCN105293475ASimple preparation processLow equipment requirementsMaterial nanotechnologySolventCvd graphene

The invention discloses a graphene and nickel diselenide composite and a preparation method thereof. The preparation method comprises the steps that a reducing agent is mixed with a graphene oxide solution, even stirring is conducted to form a brown solution, the brown solution is added into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and selenium containing matter and nickel containing inorganic salt are filled into the reaction kettle; the reaction kettle is closed to conduct the reaction; after the reaction is conducted, natural cooling is conducted, suction filtration is conducted on a mixture in the reaction kettle, repeated washing and suction filtration are conducted through distilled water and absolute ethyl alcohol, and the product is collected for storing after drying is conducted. According to the prepared graphene and nickel diselenide composite, nickel diselenide nanoparticles are wrapped with the graphene, nickel diselenide is closely combined with graphene sheets, and the composite has larger specific surface area. According to the graphene and nickel diselenide composite and the preparation method thereof, a simple solvothermal method is adopted, reduction of graphene oxide and preparation of the graphene oxide and the nickel diselenide composite are conducted synchronously, the technology is simple, the reaction temperature is low, the cost is low, the preparation method is green and controllable, and the graphene and nickel diselenide composite is suitable for industrial production.

Owner:JIANGNAN GRAPHENE RES INST

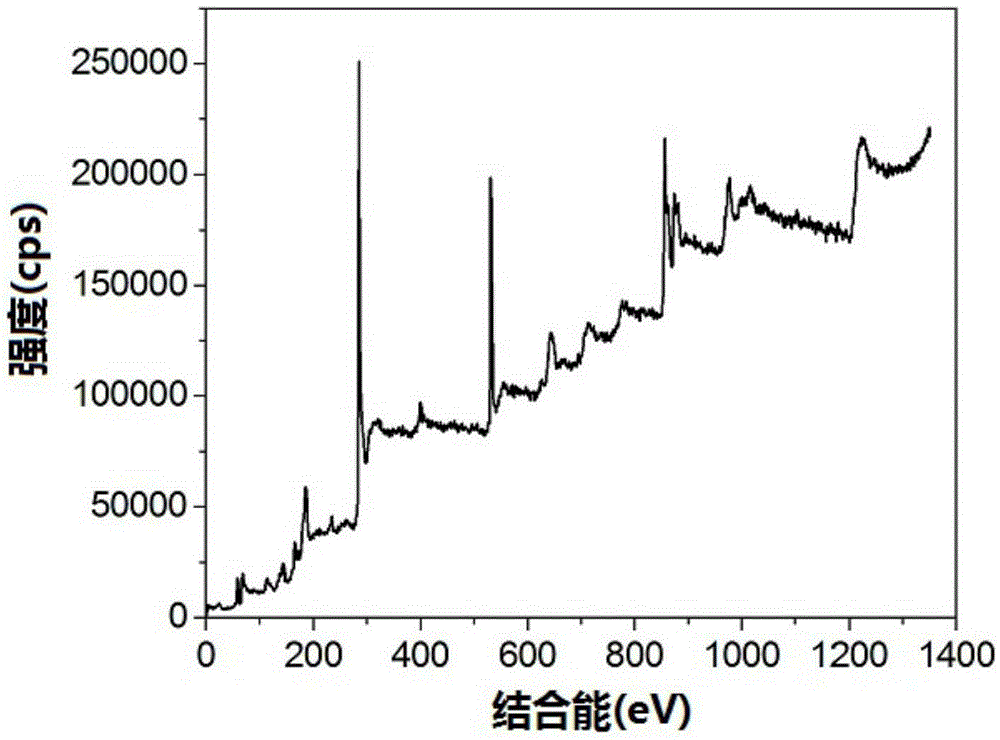

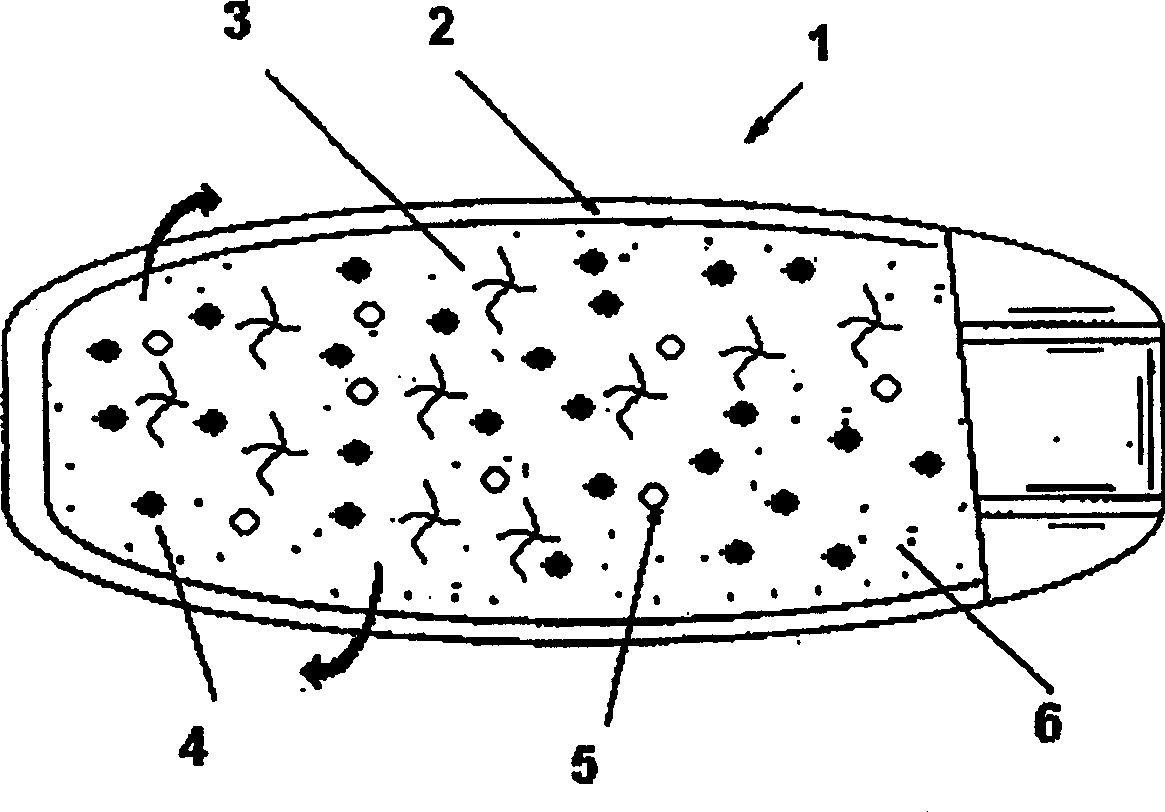

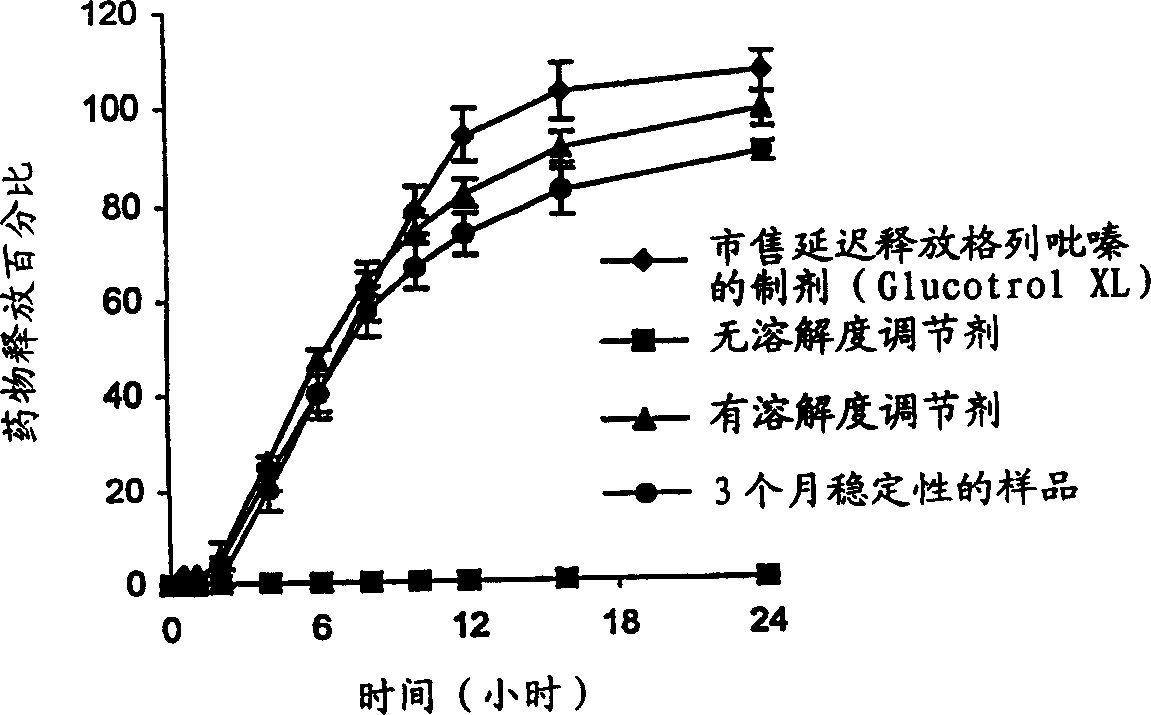

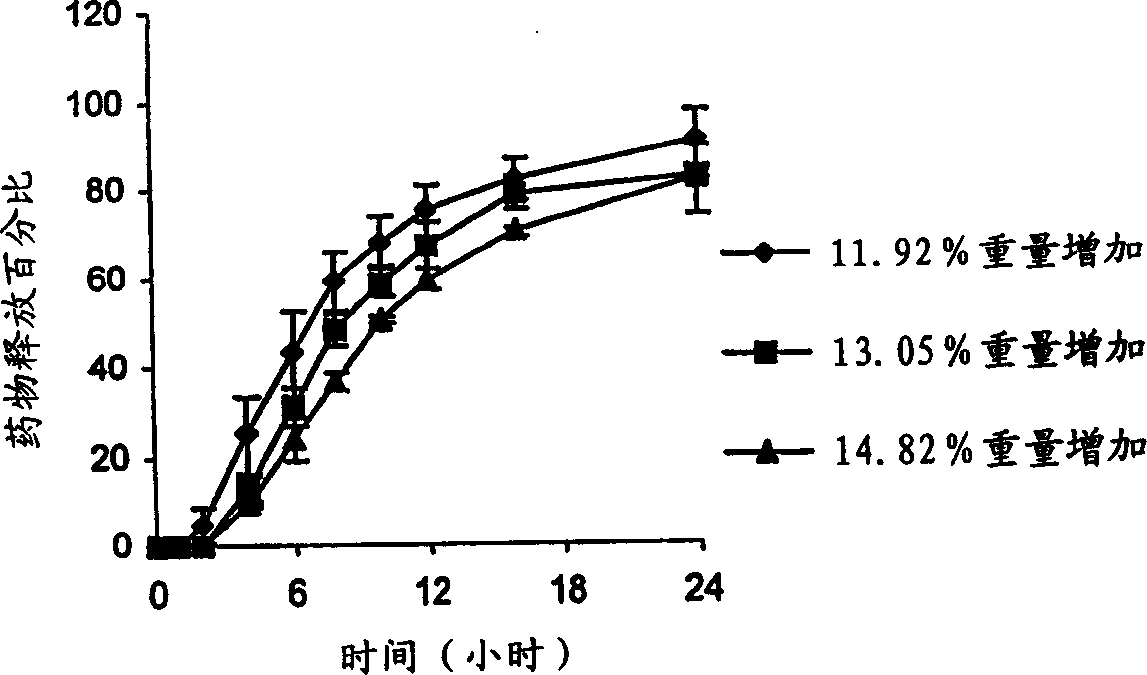

Pharmaceutical composition for sustained or continuous releasing therapeutic active components

InactiveCN1622799ADelayed treatment active ingredientsDelayed release of therapeutically active ingredientsAntibacterial agentsOrganic active ingredientsMedicinePlasticizer

A pharmaceutical composition useful for sustained / extended release of a therapeutically active ingredient to an environment of use, said composition comprises a tablet core composition consists of a therapeutically active ingredient that is weakly acidic in nature and has a limited solubility in the aqueous environment, said the therapeutically active ingredient is in immediate contact with the agents that are capable of improving the solubility of the agent within the core, for e.g., by changing the micro environmental pH of the core and the tablet core is surrounded by a release rate controlling membrane consisting of a semi-permeable membrane forming polymer, permeable membrane forming polymer, and at least one plasticizer capable of modulating the film formation properties of the polymers.

Owner:科学和工业研究委员会

Method for producing 5-hydroxymethyl furfural by chitin biomass

ActiveCN103121984AWide variety of sourcesRich reservesOrganic chemistryChlorideHydroxymethylfurfural

The invention discloses a method for producing 5-hydroxymethyl furfural by chitin biomass. The method comprises the steps of preparing a zinc chloride water solution of which mass concentration is 30-72%; evenly mixing the dried chitin biomass material, the zinc chloride water solution and a catalyst; reacting for 10 minutes to 10 hours after the reaction is finished at 60-140 DEG C, wherein the mass ratio of the chitin biomass material to the zinc chloride water solution is 1: (3-180); the mass ratio of the added catalyst to the chitin biomass material is 1: (1-50); extracting the 5-hydroxymethyl furfural from a reaction system by an organic extracting agent after the reaction is finished; then concentrating and drying the extracting agent, and crystallizing to obtain the 5-hydroxymethyl furfural product. The method has the advantages of being wide in source of the chitin biomass, abundant in storage, simple in operation process and high in obtained product purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of self-supporting two-dimensional transition metal/metal oxide mixed-phase nanosheet

InactiveCN104384527ASimple preparation processAvoid the detemplating processMaterial nanotechnologyIonSolvent

A preparation method of a self-supporting two-dimensional transition metal / metal oxide mixed-phase nanosheet relates to a preparation method of a two-dimensional nano material and solves the problems of complex technology, harsh reaction condition and poor electric conductibility of transition metal oxide in the conventional method for preparing the self-supporting two-dimensional transition metal / metal oxide mixed-phase nanosheet. The preparation method of the mixed-phase nanosheet comprises the following steps: firstly, inorganic transition metal salt, organic amine, alcohol and water are mixed to form a turbid liquid of an organic amine complex containing metal ions; secondly, the turbid liquid reacts under a high-temperature solvent thermal condition to generate a precursor of the metal / metal oxide mixed-phase nanosheet; finally, high-heat treatment is conducted under the protection of inert gas to control the crystallinity of the two-dimensional metal / metal oxide mixed-phase nanosheet. The preparation method provided by the invention has the advantages of simple technology and lower equipment requirement; the mixed-phase nanosheet prepared by the method has excellent electric conductibility.

Owner:HEILONGJIANG UNIV

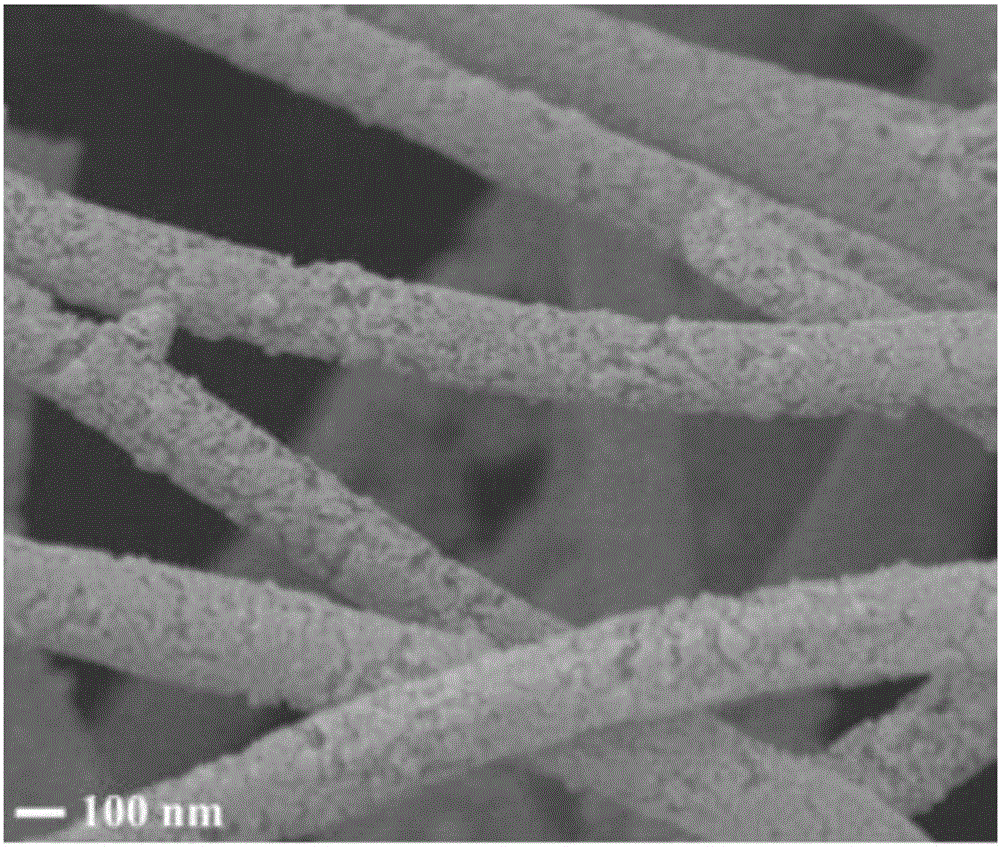

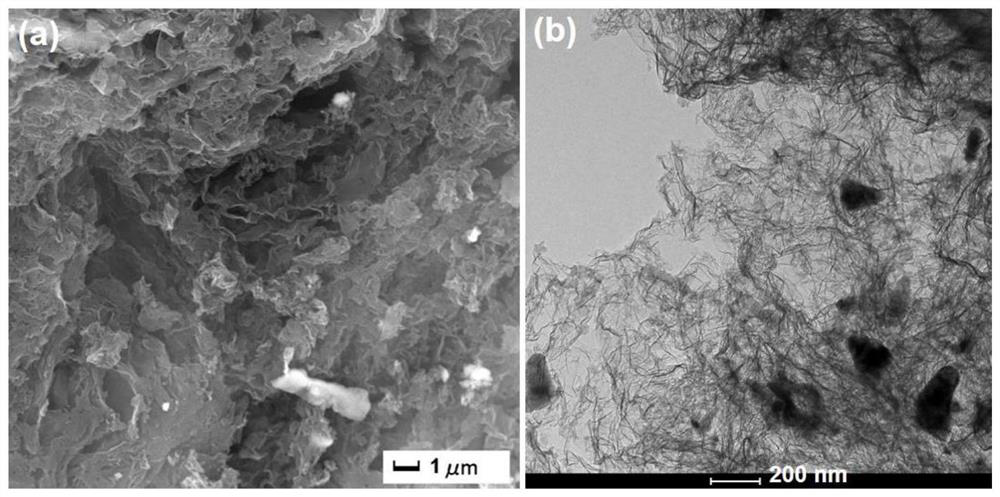

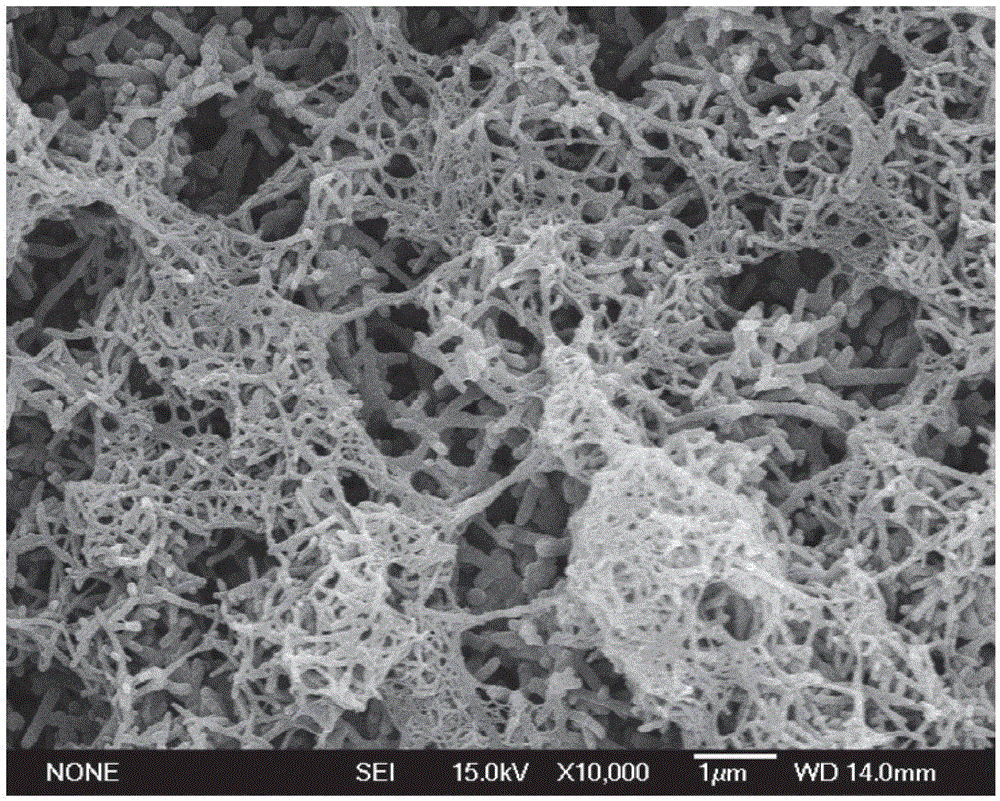

Preparation method and application of metal sulfide porous framework/graphene composite fiber

InactiveCN108456936AFlexibleEnsure Structural IntegrityCell electrodesSecondary cellsFiberMetallic sulfide

The invention discloses a preparation method of metal sulfide porous framework / graphene composite fiber. The metal sulfide porous framework / graphene composite fiber is obtained through calcination with a fiber-like compound prepared by compounding MOF crystal powder and graphene oxide as a precursor. The preparation method is simple to operate, conditions are mild, the shape is adjustable, the structure is controllable, component distribution is uniform, the structural integrity of a metal sulfide porous framework obtained with graphene and MOF crystals as templates is kept, excellent properties of graphene and properties of the metal sulfide porous framework are integrated, the fiber can be produced in batches or industrially produced, and the fiber serves as a lithium ion battery negative electrode material, is excellent in performance and has a good application prospect.

Owner:ZHEJIANG UNIV OF TECH

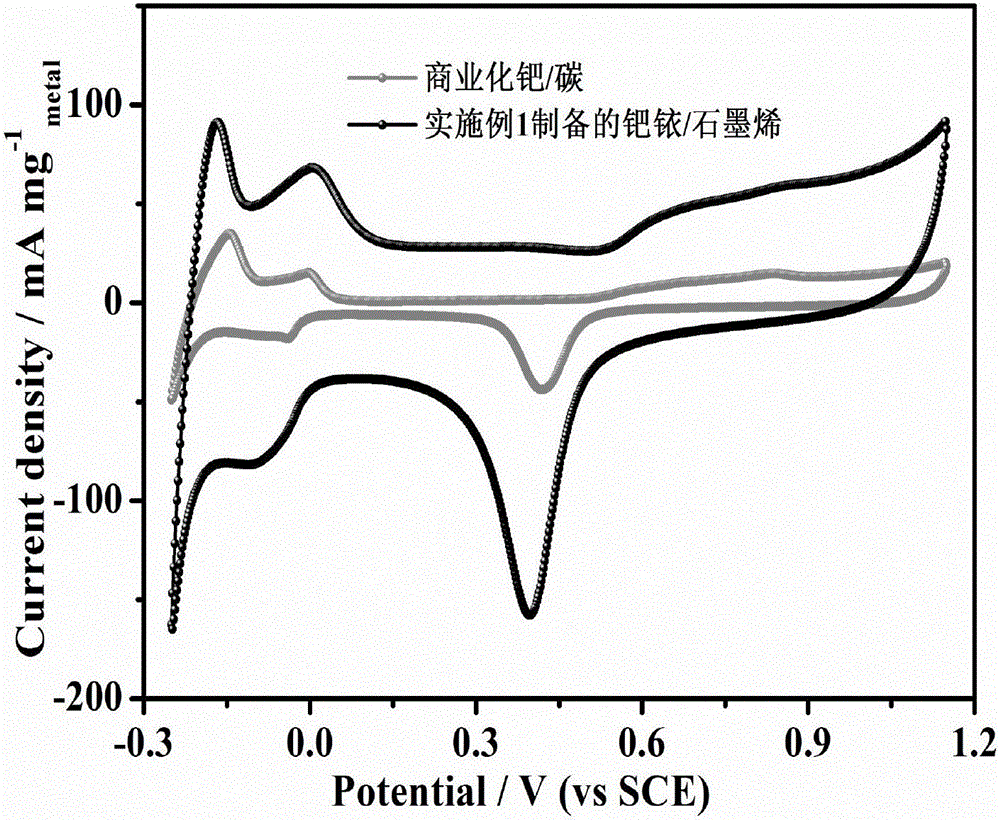

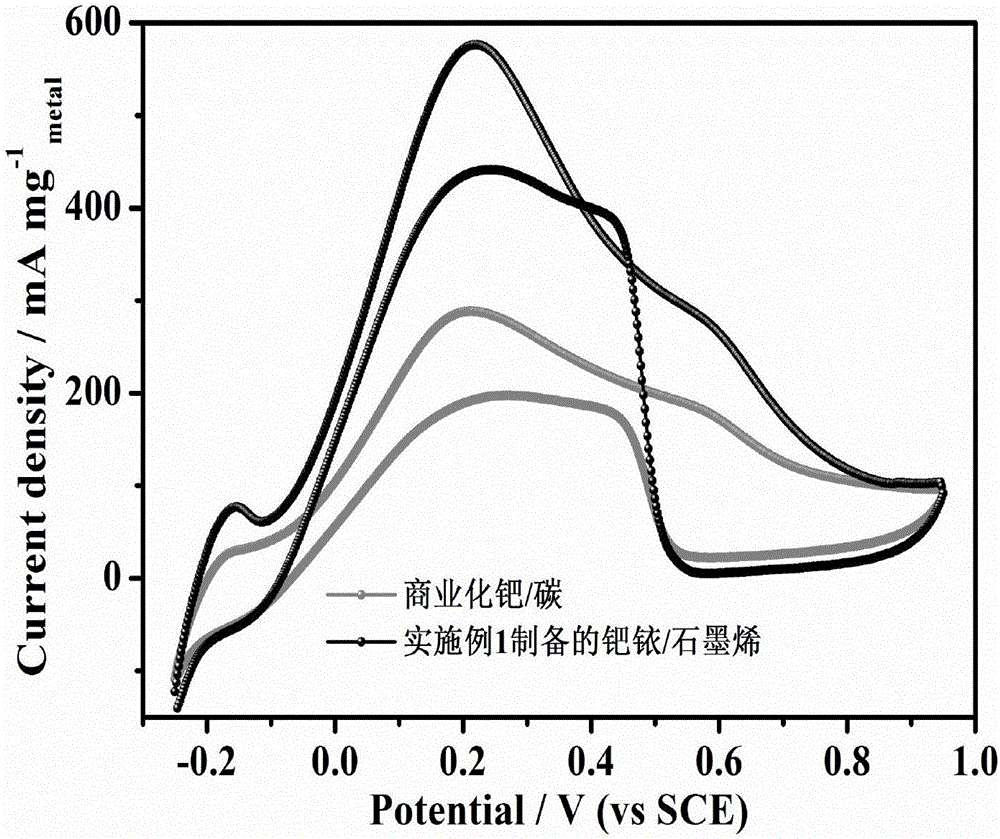

Method for preparing graphene-supported palladium-iridium nano-particle catalysts and formic acid oxidation electrocatalysis application of graphene-supported palladium-iridium nano-particle catalysts

InactiveCN107175105AEvenly dispersedLarge electrochemically active specific surface areaCell electrodesCatalyst activation/preparationIridiumElectrochemistry

The invention belongs to the field of technologies for preparing supported catalysts, and particularly relates to a method for preparing graphene-supported palladium-iridium nano-particle catalysts and formic acid oxidation electrocatalysis application of the graphene-supported palladium-iridium nano-particle catalysts. The method includes steps of 1), adding graphene into formic acid solution and ultrasonically uniformly mixing the graphene and the formic acid solution with each other; 2), uniformly dispersing mixed solution prepared from chloroiridic acid and sodium chloropalladate under ultrasonic conditions; 3), heating mixed solution obtained at the step 2); 4), quickly injecting mixed solution obtained at the step 3) into graphene and formic acid mixed solution obtained at the step 1) and carrying out ultrasonic treatment under sealed conditions; 5), cleaning obtained products and then drying the products. The method and the formic acid oxidation electrocatalysis application have the advantages that the graphene-supported palladium-iridium nano-particle catalysts have extremely large electrochemically active specific surface areas and are extremely high in formic acid oxidation catalytic activity, high-toxicity materials are omitted, and the method is easy and convenient to implement, high in repeatability and suitable for mass production.

Owner:QINGDAO UNIV

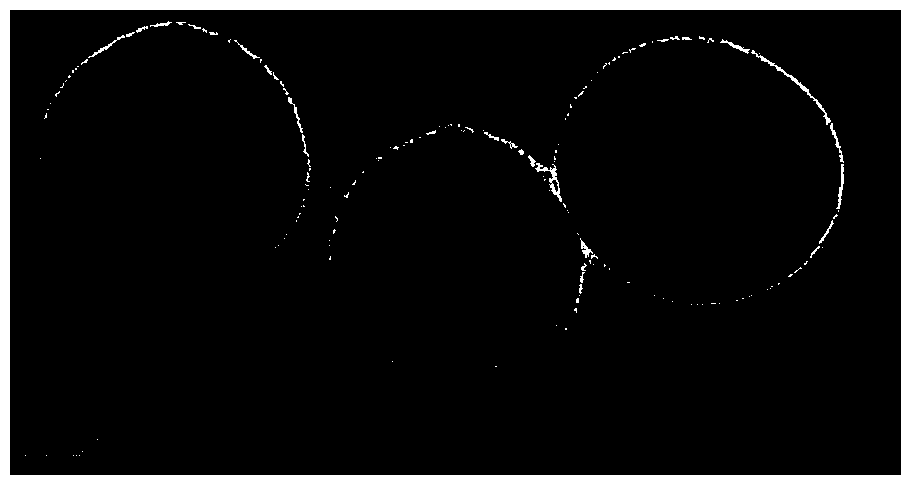

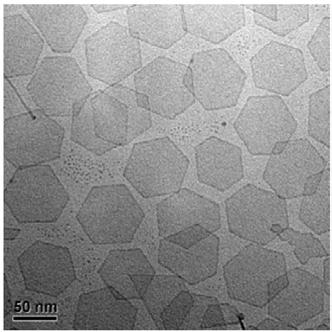

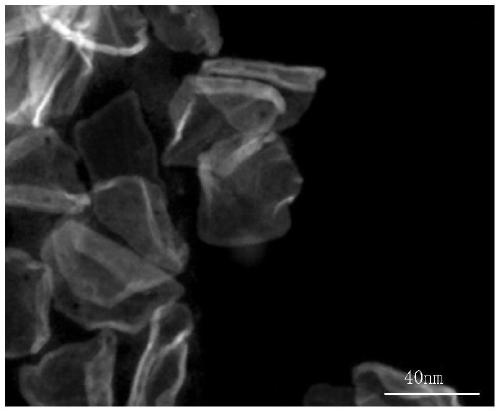

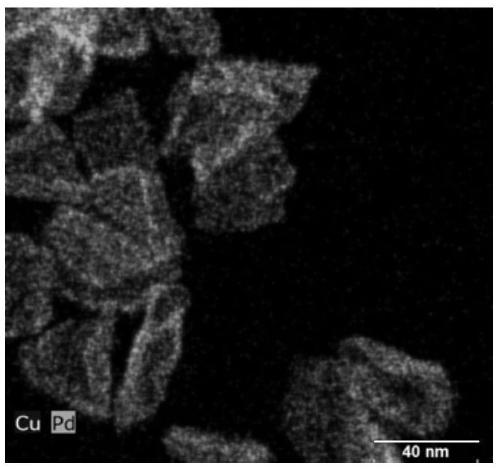

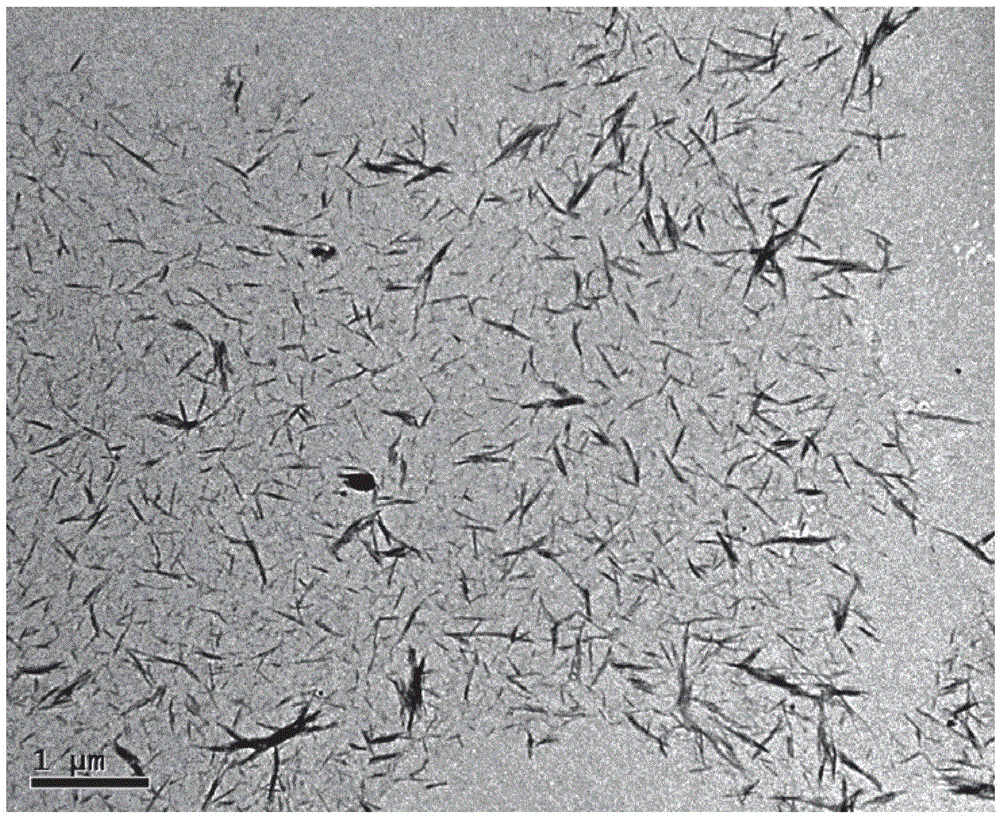

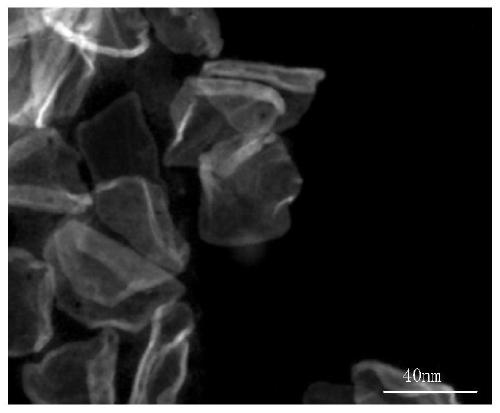

Core-shell structure palladium-copper catalyst and preparation method thereof and catalytic application thereof

ActiveCN109012694AInhibition of adsorptionRealize chemical functionHydrocarbon by hydrogenationCatalystsWater bathsPhenyl-acetylene

The invention discloses a core-shell structure palladium-copper catalyst and a preparation method thereof and catalytic application thereof, and belongs to the field of nanocatalysis. The core-shell structure palladium-copper catalyst comprises a palladium nanosheet and a copper shell layer coating the surface of the palladium nanosheet, wherein the palladium nanosheet has a size of 5 to 200 nm and a thickness of 0.5 to 3 nm; and the thickness of the copper shell is 0.1 to 10 nm. The palladium nanosheet is dispersed in water, hydrogen gas is introduced, after the reaction, an aqueous solutioncontaining copper ions is added, and sealing reaction is continued to obtain the core-shell structure palladium-copper catalyst. An catalytic application method is as follows: the core-shell structurepalladium-copper catalyst is collected by centrifugation, washed with ethanol and dried to obtain catalyst powder; the catalyst powder is dispersed in ethanol, phenylacetylene is added to a water bath and stirred, and H2 is introduced to react.

Owner:XIAMEN UNIV

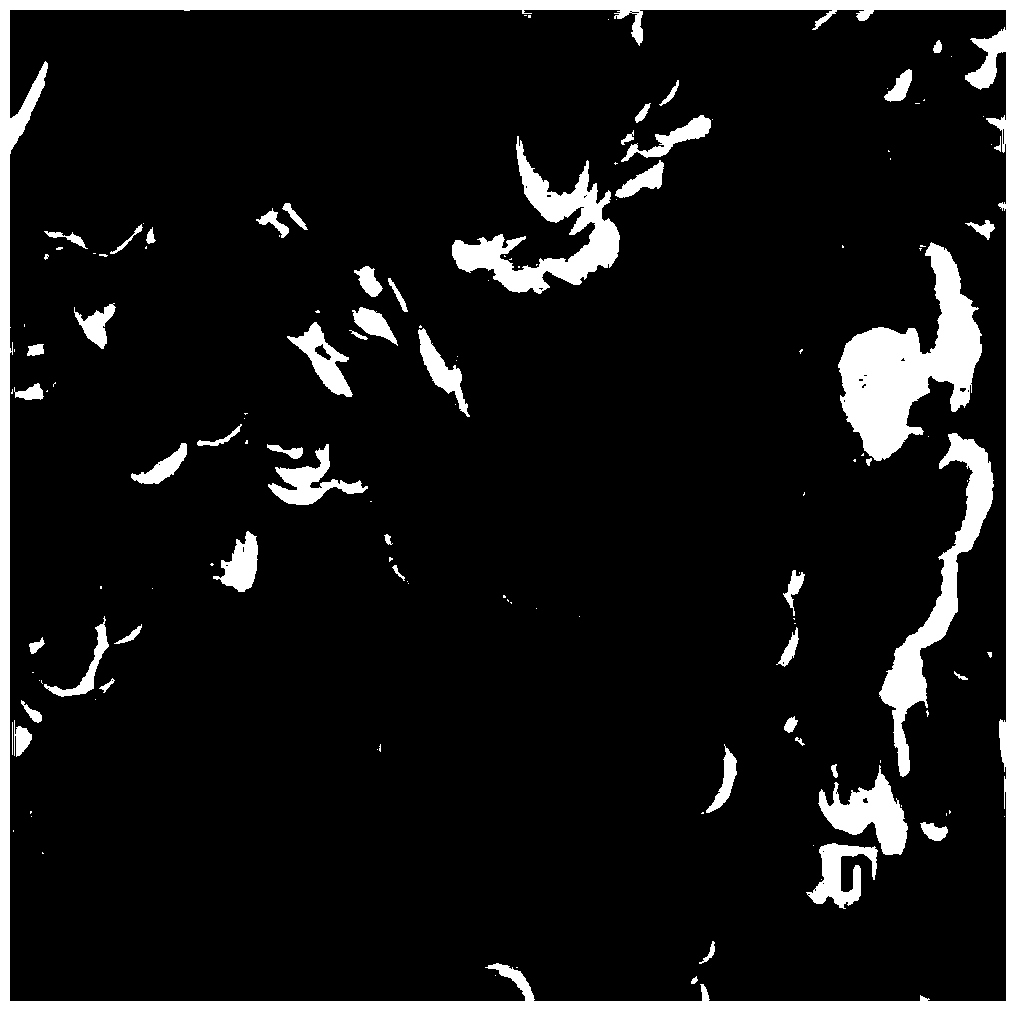

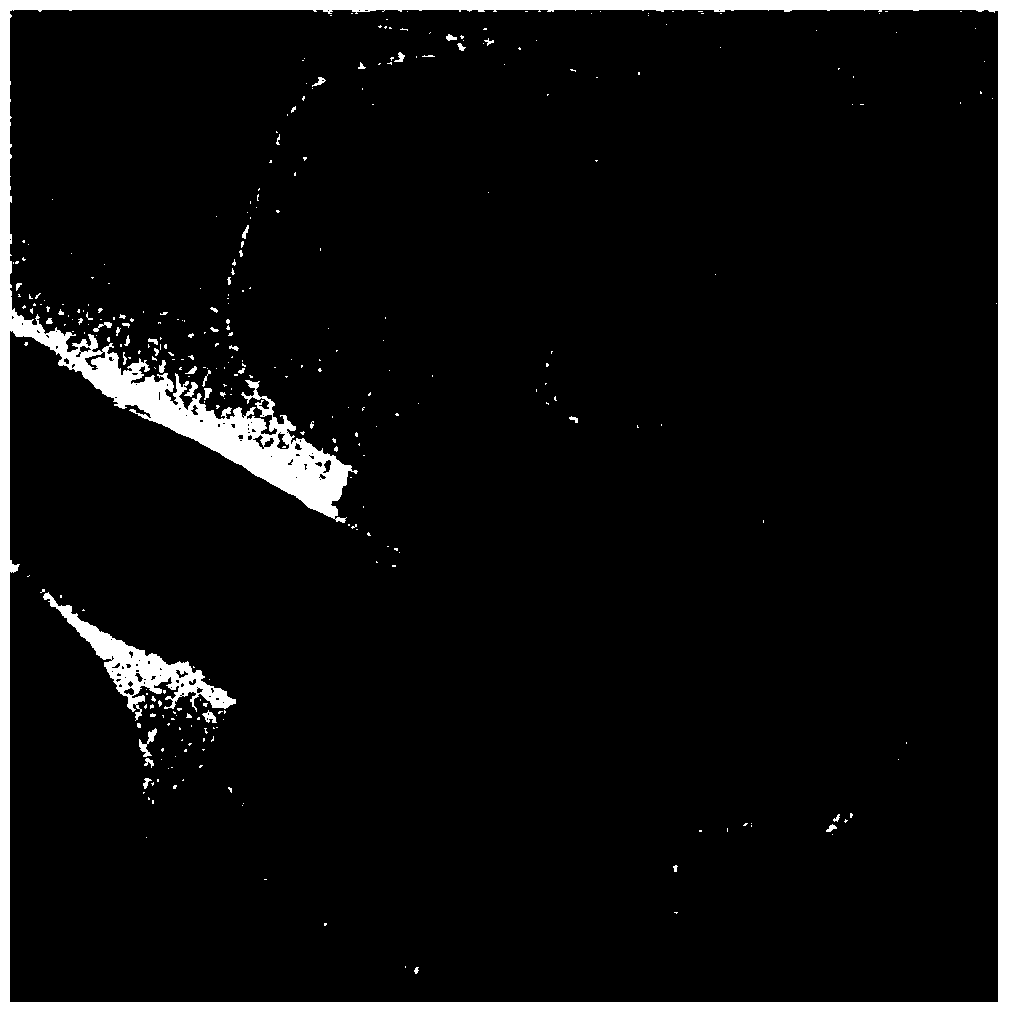

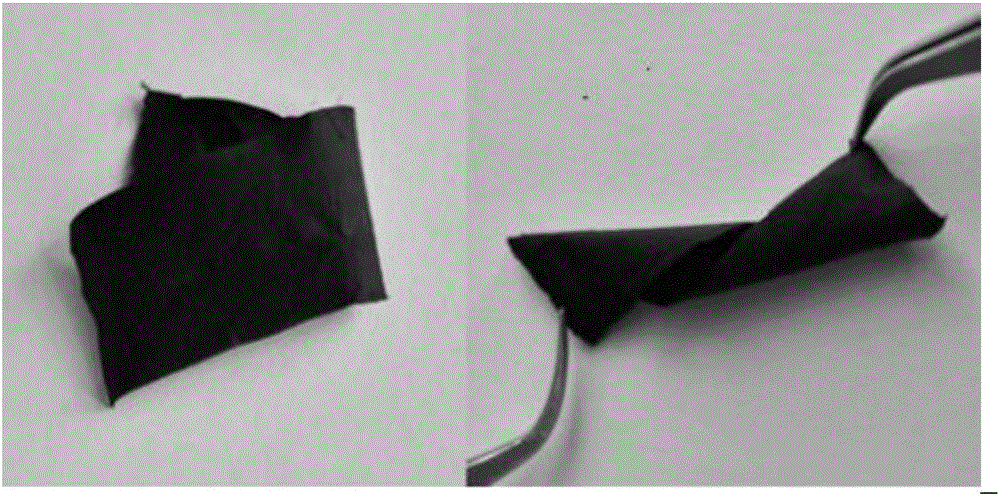

Method for preparing flexible iron sesquioxide/ferroferric oxide and nitrogen doped carbon composite nano-fibers

ActiveCN106811834AHigh yieldSimple processElectro-spinningArtifical filament manufactureFiberAir atmosphere

The invention relates to a method for preparing flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers. The method has the advantages that the problem of poor toughness and electric conductivity of existing metal oxide can be solved by the aid of the method; flexible macromolecules are used as supports and are subjected to composition with metal organic gel precursors with plasticity to obtain precursors, and the precursors are subjected to pyrolysis in inert atmosphere and air atmosphere to obtain the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers which are flexible metal oxide and nitrogen doped carbon composite nano-fibers; the problems of complicated and harsh conditions for preparing flexible metal oxide and carbon composite materials, high costs and difficulty in large-scale production at present can be solved by the aid of the method; raw materials for the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers are low in cost, processes for preparing the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers are simple, and the method is short in synthesis period, good in repeatability and high in yield, and industrial production can be facilitated; the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers can have characteristics of bendable properties and excellent electrochemical performance, accordingly, the method has an extremely broad application prospect in the field of wearable electronic devices, and the like.

Owner:NANKAI UNIV

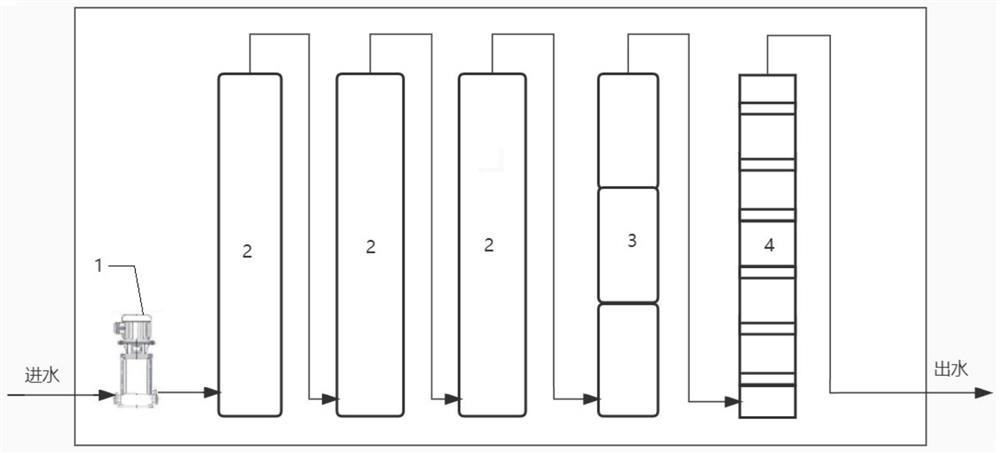

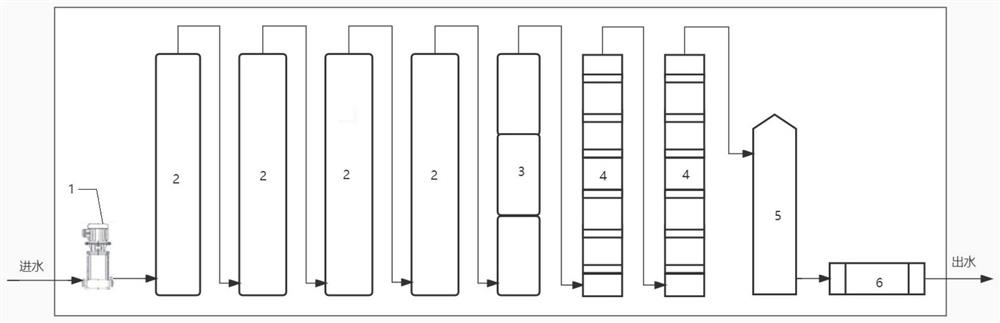

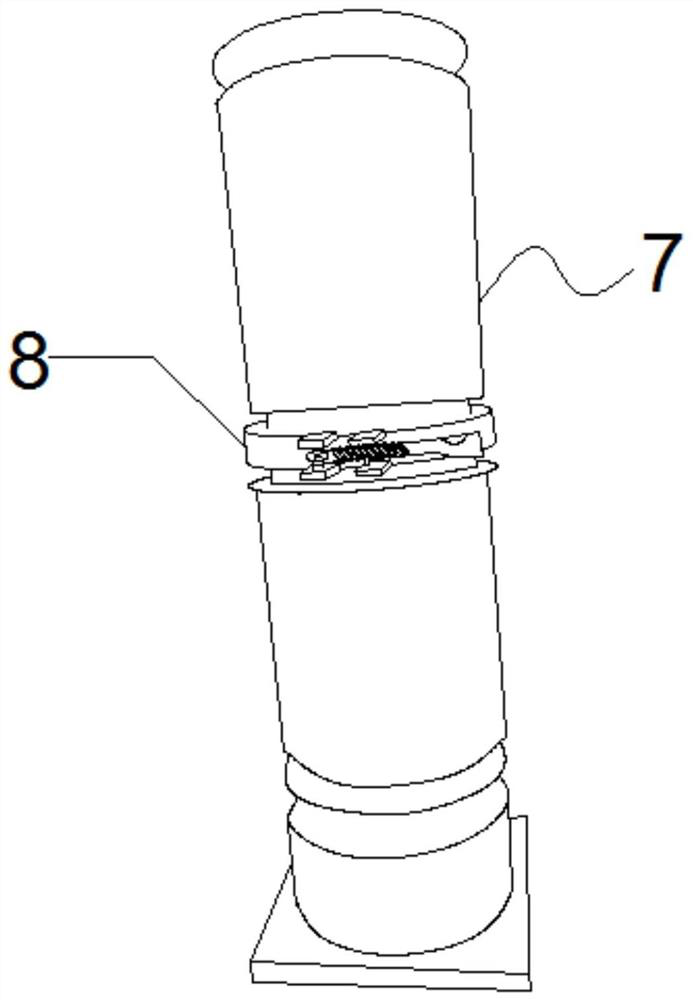

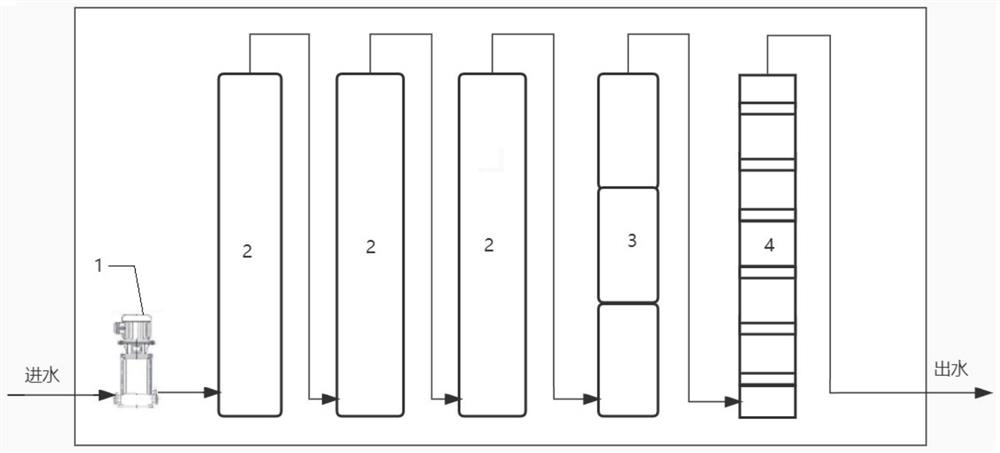

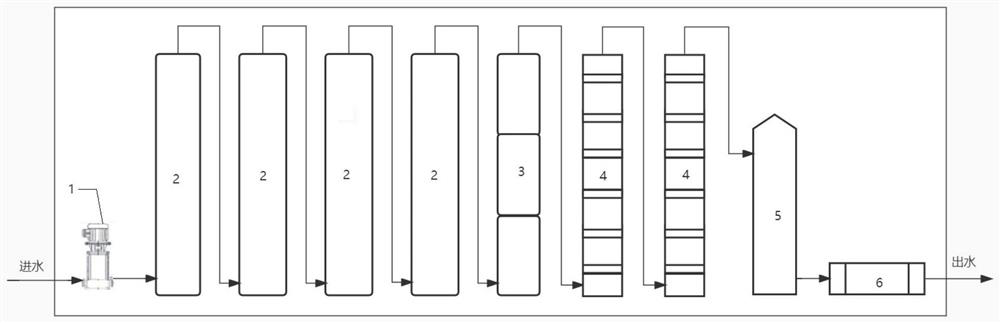

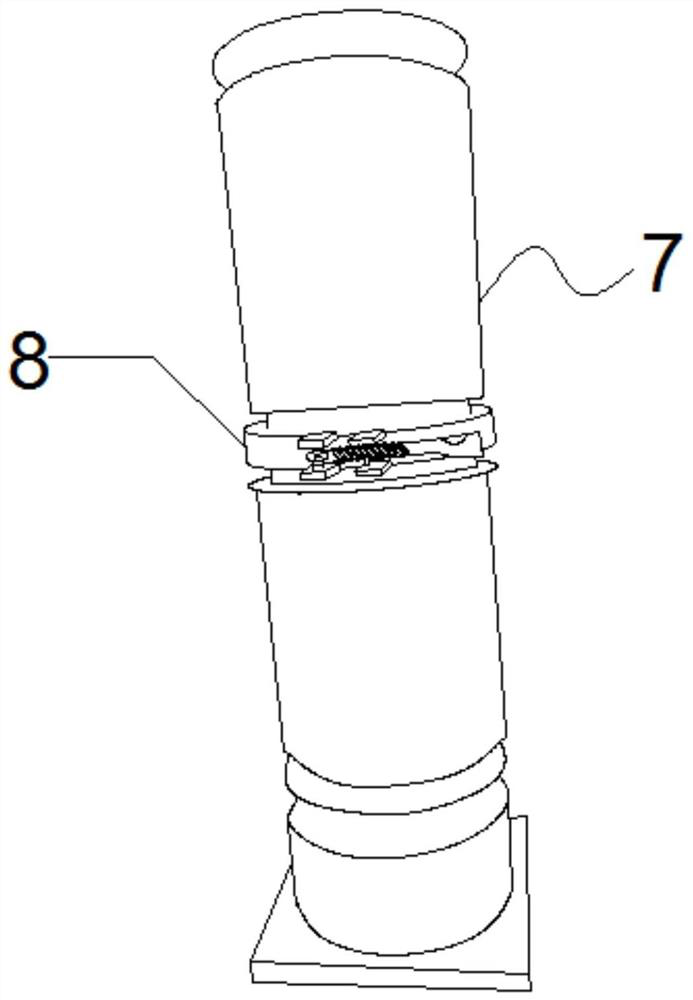

Active hydrogen generator

ActiveCN114315000APreparation highSafe preparationMultistage water/sewage treatmentData displayCeramic

The invention relates to an active hydrogen generator which is provided with a supercharging device, a water activating device, a hydrogen enriching device and an electron releasing device, and the supercharging device, the water activating device, the hydrogen enriching device and the electron releasing device are sequentially connected through a water supply pipe. The water activating device comprises a first filter cartridge, and energy spar and projectile natural ore are arranged in the first filter cartridge; the hydrogen-enriching device comprises a second filter cartridge; a combined multifunctional health-preserving hydrogen-enriching water sheet and a composite medical stone ceramic ball are arranged in the second filter cartridge; the electron release device comprises an inner ribbed tube, and a combined material composed of a composite tourmaline ceramic ball and an electrode metal band is placed in the inner ribbed tube. The active hydrogen generator can prepare a large amount of active hydrogen in a lasting, safe and environment-friendly manner, and third-party detection data shows that the content of the active hydrogen in water treated by the active hydrogen generator reaches 5-8 PPm.

Owner:北京氢润科技有限公司

Technical method for extracting salvianolic acid B from radix salivae miltiorrhizae

The invention is a technical method to extract salvianolic acid B from tanshen, organically combining several methods to extract salvianolic acid B, to develop a new technique proper to separate and purify salvianolic acid B. It firstly extracts by water, then flocculates by chitosan, successively makes alcohol precipitation, then extracts by petroleum ether and acetic ester, respectively, and finally adopts silica gel column chromatography to obtain higher purity salvianolic acid B. It is applied to industrialized production.

Owner:EAST CHINA UNIV OF SCI & TECH

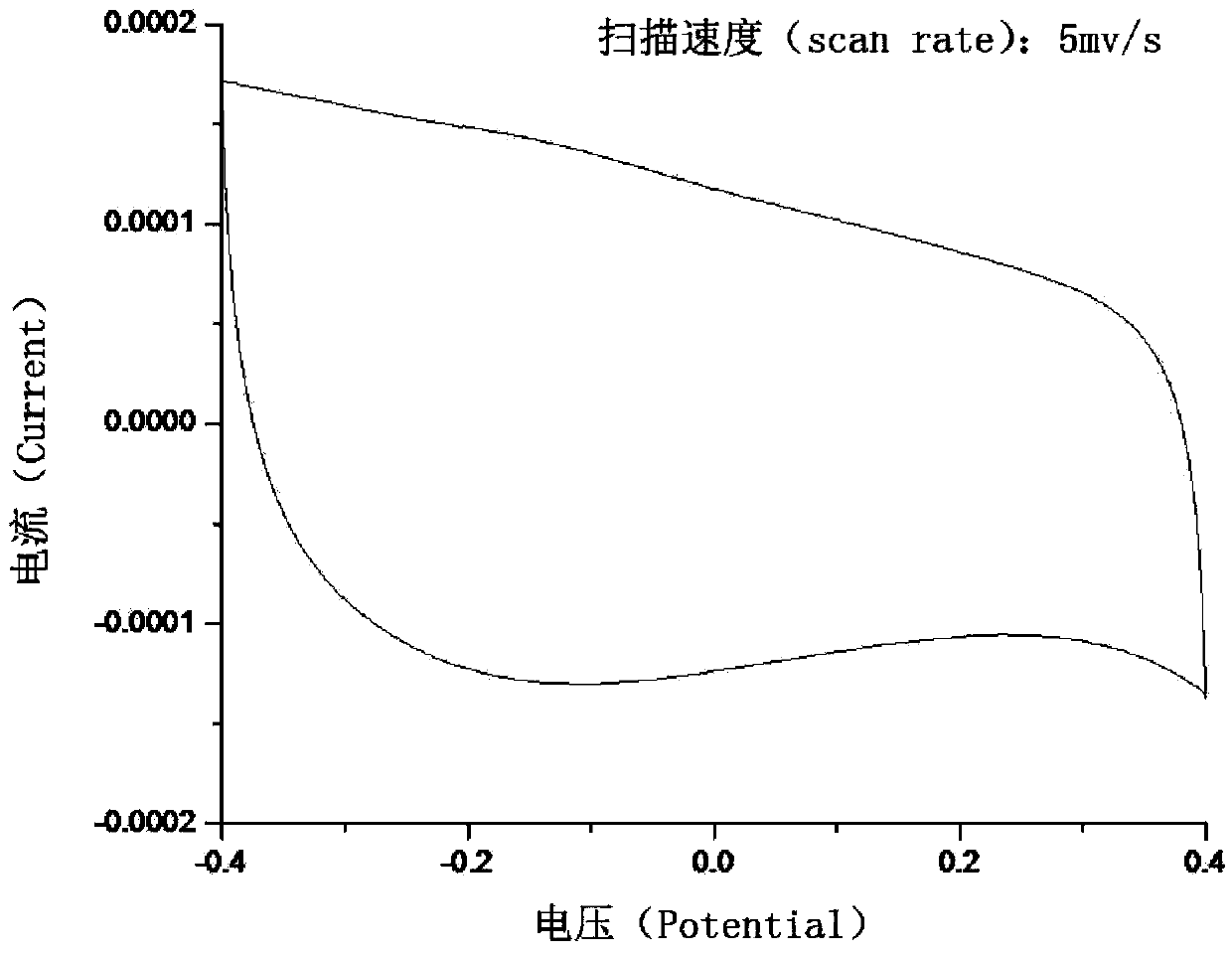

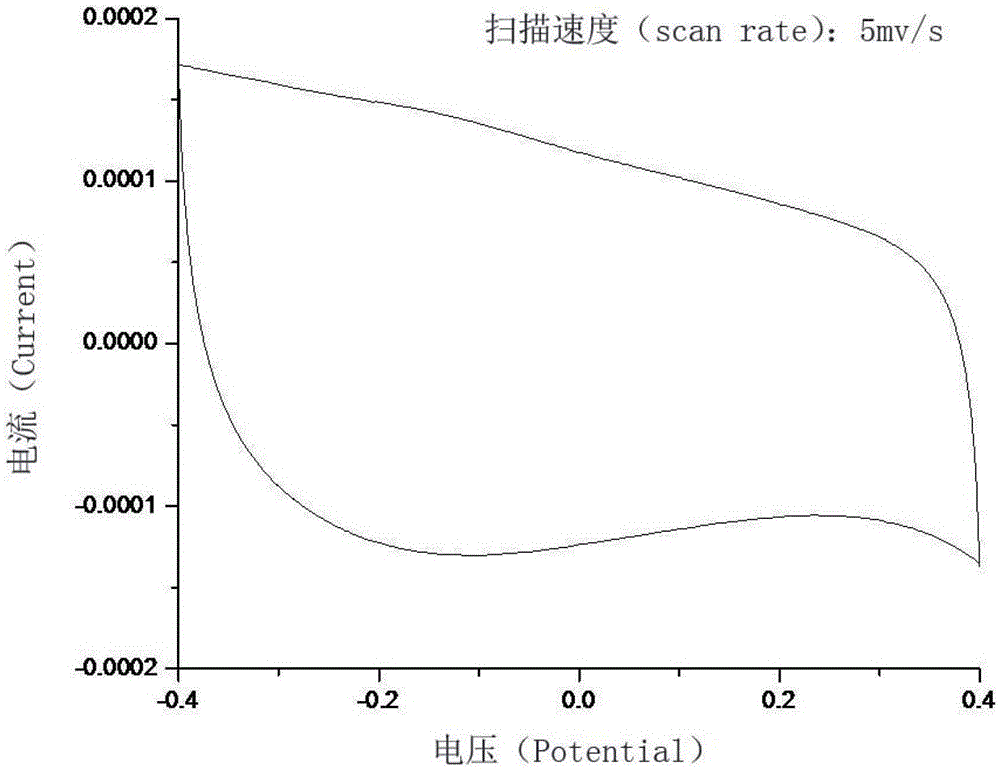

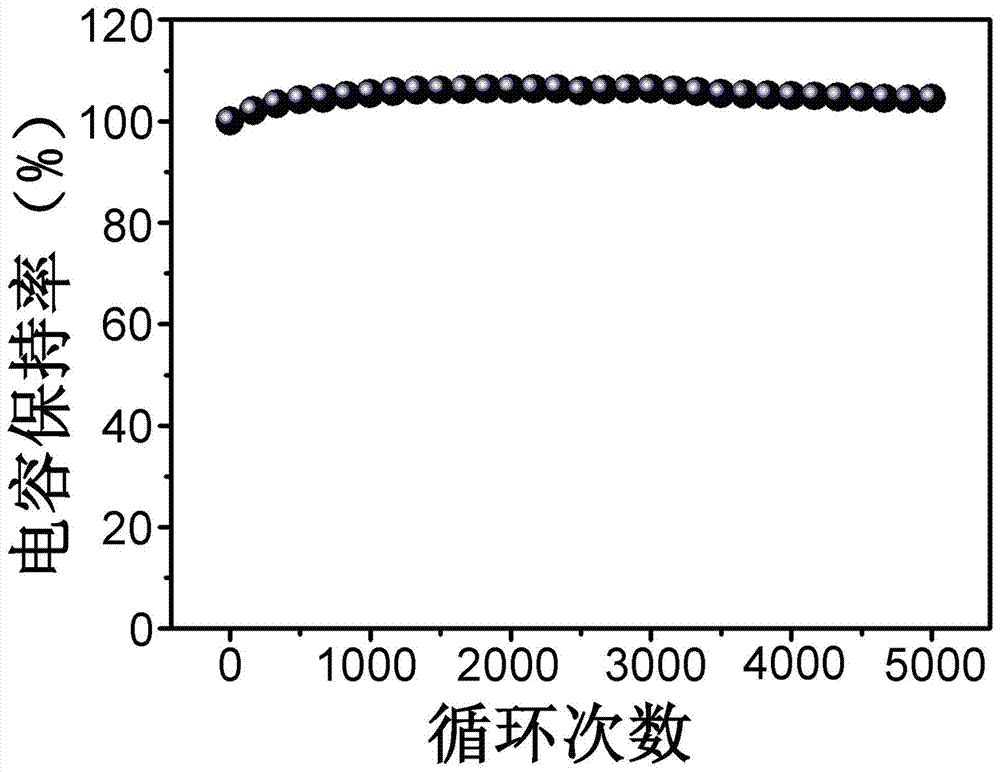

Preparation method for polypyrrole (PPy) and nano-crystalline celluloses (NCCs) compound film electrode material

ActiveCN103390510AExcellent electrochemical propertiesPreparation highHybrid/EDL manufactureCelluloseConductive polymer composite

The invention discloses a preparation method for a PPy and NCCs compound film electrode material. The preparation method is characterized by comprising the steps of performing pretreatment and hydrolysis on plant raw materials to obtain NCCs from the plant raw materials, mixing the obtained NCCs with pyrrole monomers to form an electrolytic solution, and obtaining the PPy and NCCs compound film electrode material through preparation by an electrochemical method. According to the preparation method, the PPy and NCCs compound film electrode material with the electrochemical property enhanced is obtained by using cheap plant raw materials or even waste plant raw materials; the preparation method is fast and environmentally friendly, mild in synthesis condition and low in cost. The preparation method can also be broadened to be applied to preparation of various conductive polymer composite materials, such as polyaniline, polyacetylene, polythiophene and poly-phenylene vinylene.

Owner:上海上惠纳米科技有限公司 +1

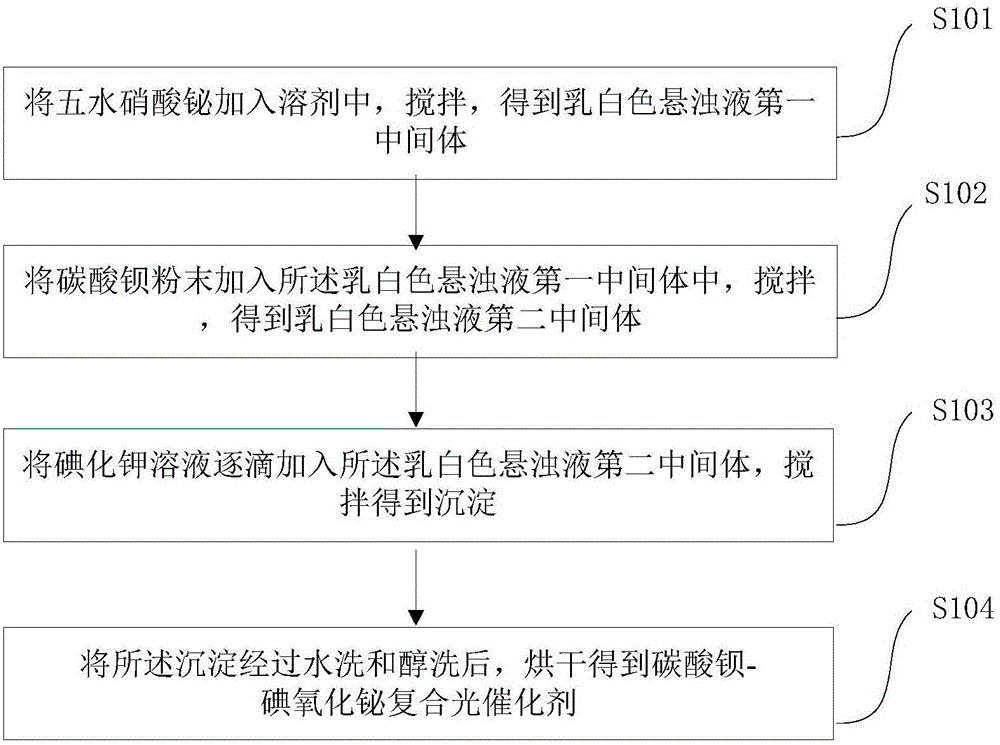

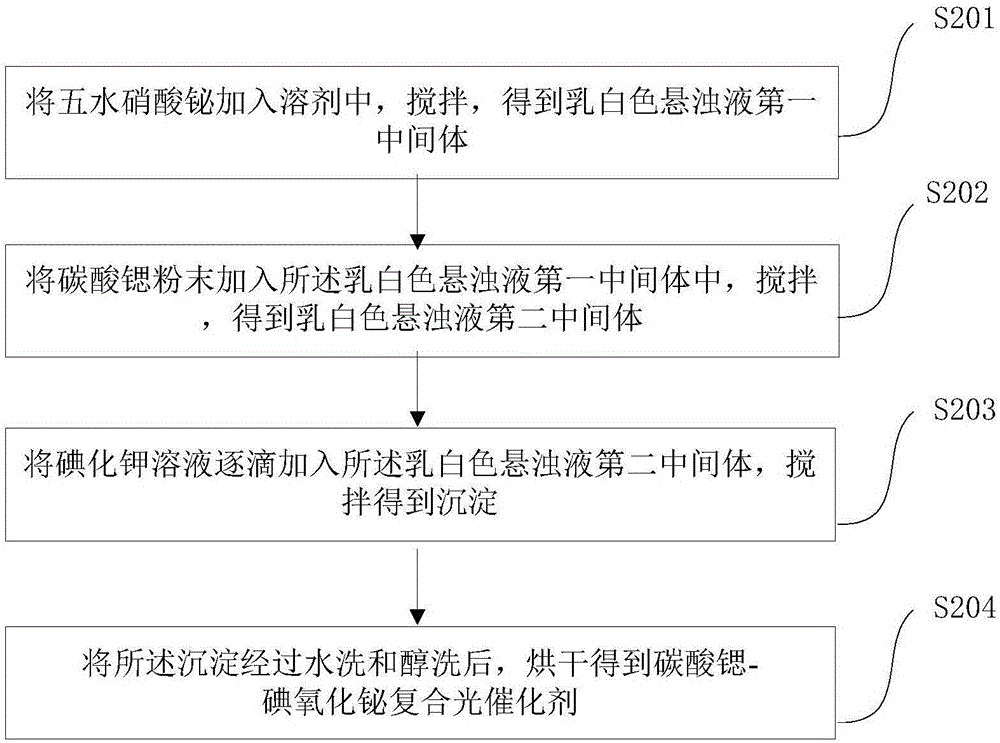

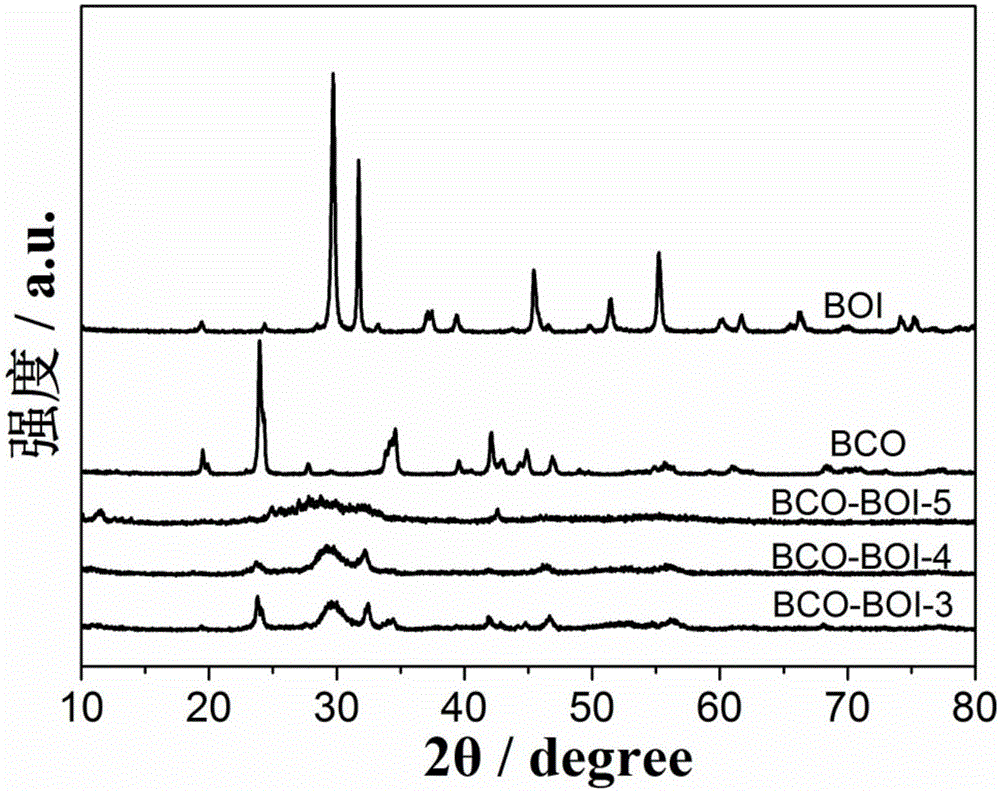

Carbonate-bismuth oxyiodide compound catalyst and preparation method thereof

InactiveCN106807424AImprove catalytic performanceEasy to separateGas treatmentPhysical/chemical process catalystsHeterojunctionStrontium carbonate

The invention provides a carbonate-bismuth oxyiodide compound catalyst and a preparation method thereof. The preparation method in the embodiment of the invention comprises the following steps: compounding barium carbonate or strontium carbonate with bismuth oxyiodide through a chemical precipitation method, and thus obtaining a barium carbonate-bismuth oxyiodide compound photo-catalyst or a strontium carbonate-bismuth oxyiodide compound photo-catalyst. According to the preparation method in the embodiment of the invention, a heterojunction formed by the prepared compound photo-catalyst has a matched energy gap, and is beneficial to separation and transmission of photo-induced electrons; photo-response is expanded to a visible region from an ultraviolet region, and the photo-absorption efficiency is improved; moreover, increased specific surface area is beneficial to adsorption of pollutants and generation of reaction sites, so that the catalyst has an excellent catalytic performance under visible light, and the preparation of the photo-catalytic material is expanded.

Owner:CHONGQING TECH & BUSINESS UNIV +1

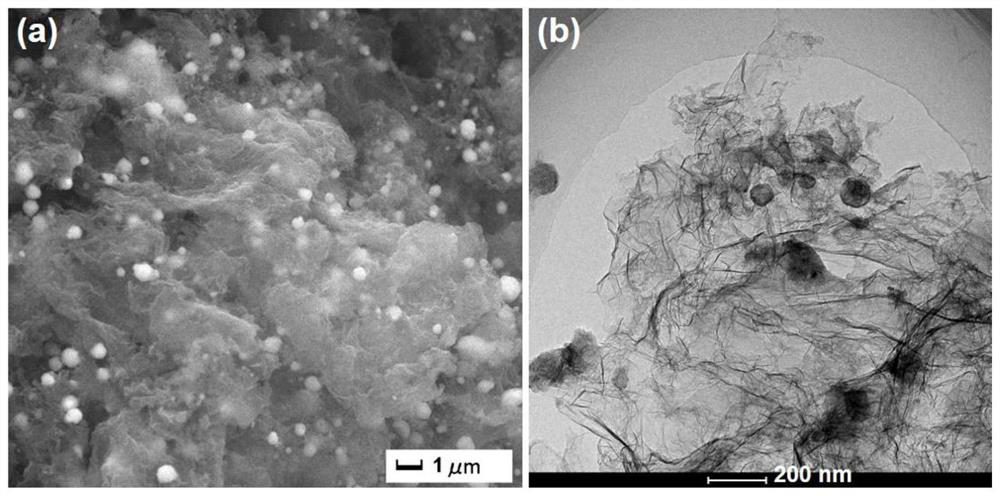

Porous graphene loaded ferrocobalt sulfide catalyst as well as preparation method and application thereof

PendingCN113764689AAvoid complex processesUniform particle sizeMaterial nanotechnologyCobalt sulfidesBattery electrodeFerrocobalt

The invention relates to a porous graphene loaded ferrocobalt sulfide catalyst as well as a preparation method and application thereof, and belongs to the technical field of clean energy nano materials and catalysis. Graphene oxide, melamine, formaldehyde, a cobalt source and an iron source are subjected to a hydrothermal reaction to prepare graphene hydrogel, and the graphene hydrogel and a sulfur source are fully mixed and then subjected to high-temperature heat treatment in a protective atmosphere to prepare the porous graphene loaded ferrocobalt sulfide powder material. The powder is subjected to acid pickling and secondary heat treatment to prepare the porous graphene loaded ferrocobalt sulfide nano-particles, the nano-particles are of a special core-shell structure, and the particle size is 21-24 nm. The material shows excellent catalytic activity and stability when being used as an oxygen reduction and oxygen evolution catalyst of an alkaline reaction system, and can be applied to electrode materials of fuel cells and zinc-air batteries.

Owner:JIANGSU UNIV

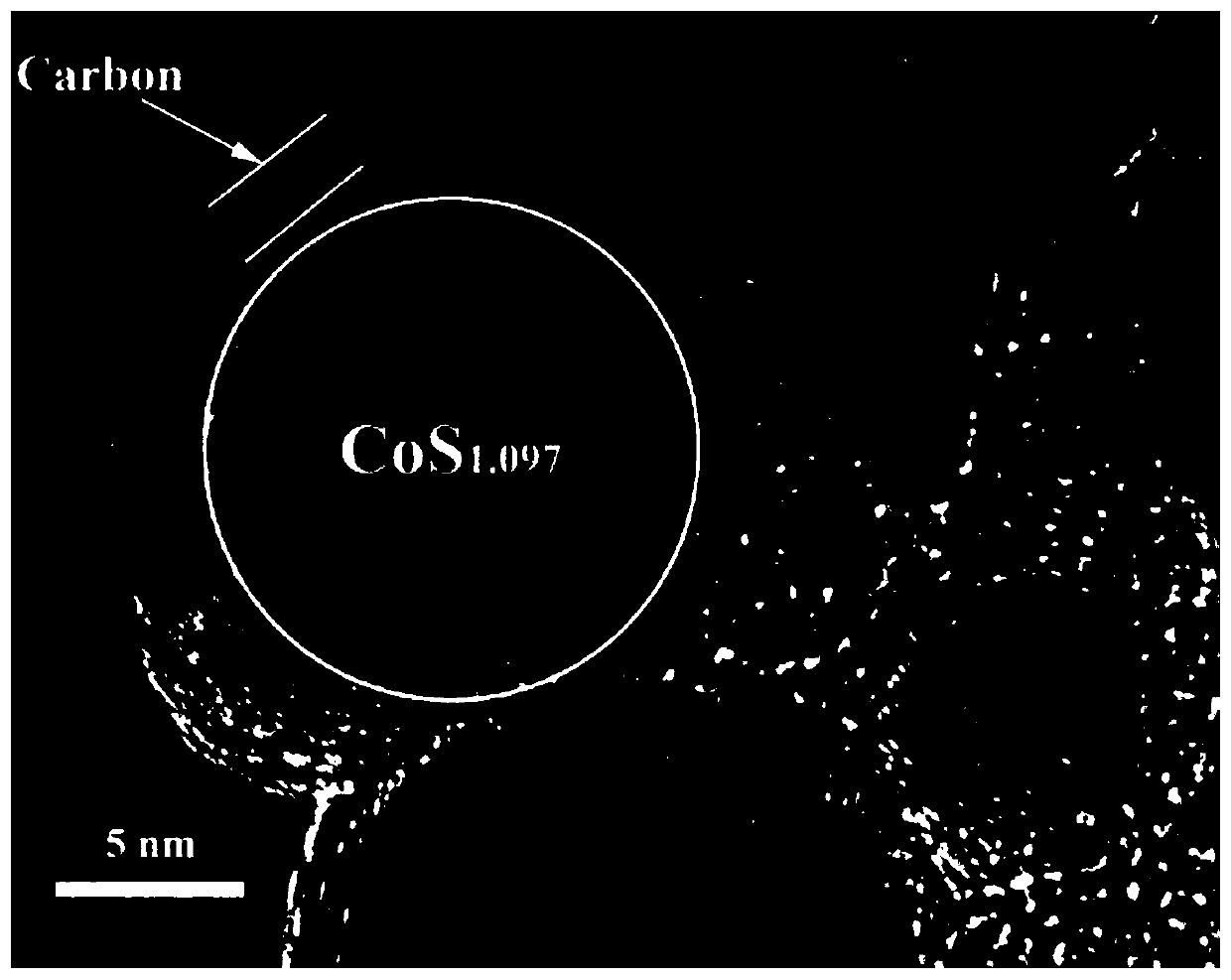

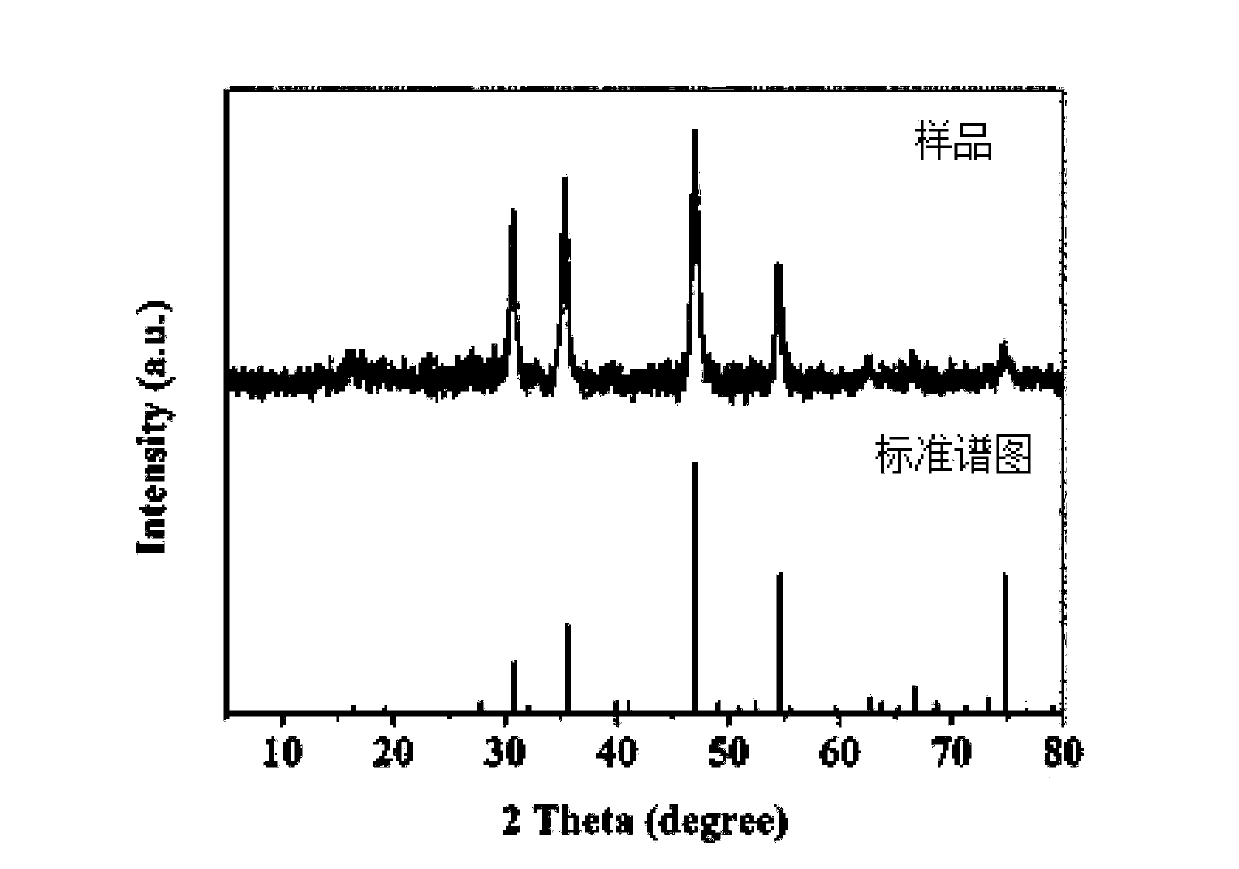

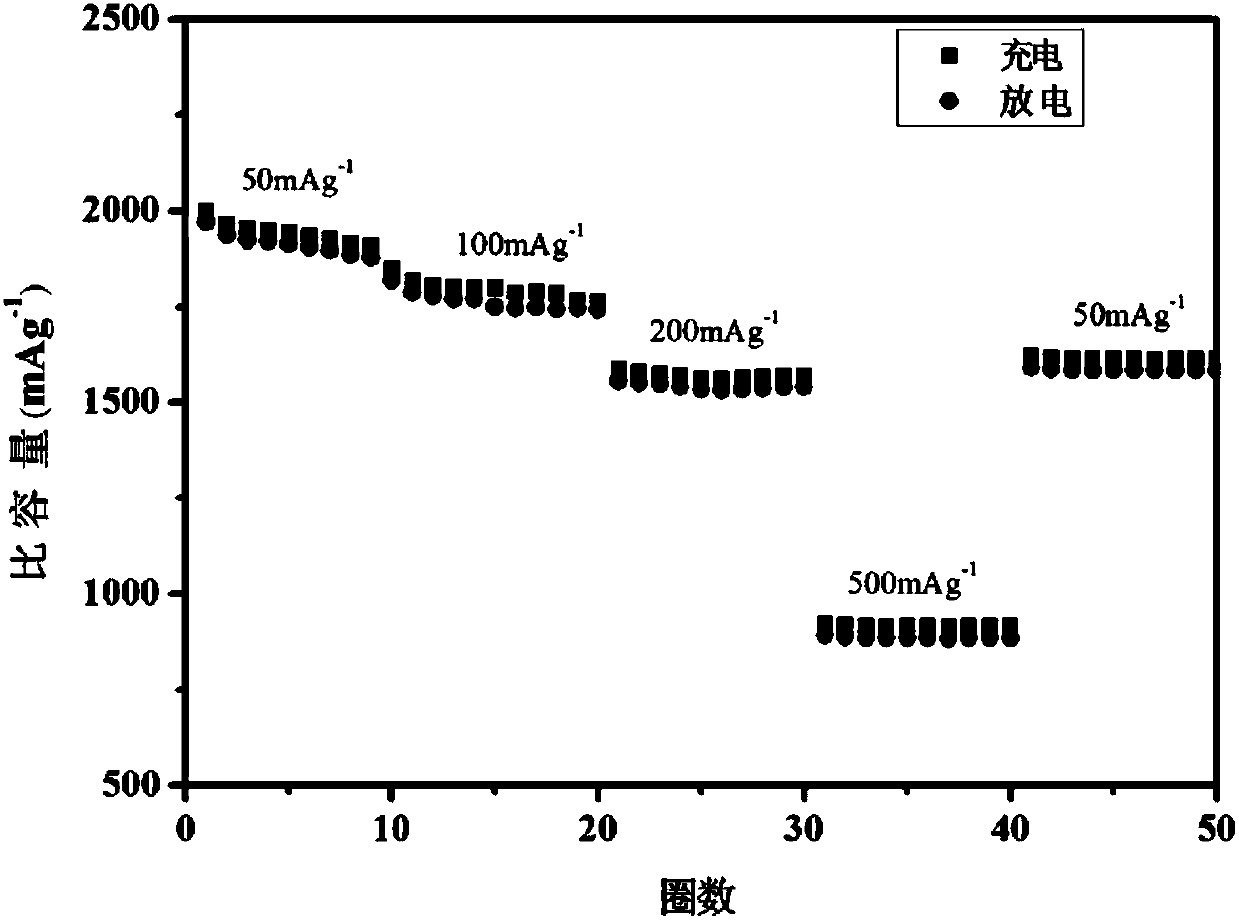

Cobalt sulfur compound/sulfur-doped carbon composite material preparation method

ActiveCN110400918AImprove electrochemical performanceSimple methodSecondary cellsNegative electrodesCarbon compositesMaterials preparation

The invention relates to a preparation method for synthesizing a cobalt sulfur compound / sulfur-doped carbon composite material based on a metal organic framework material. The metal organic frameworkmaterial (CoBDC) and different proportions of sulfur powder are uniformly mixed as a precursor, and the precursor is subjected to pyrolysis under an inert atmosphere to prepare the cobalt sulfur compound / sulfur-doped carbon composite material. The method has the advantages that the preparation process is simple, the synthesis cycle is short, the repeatability is good, the yield is high, industrialproduction is easy to realize and the like, and besides, the material has good electrochemical performance as a lithium ion battery negative electrode material, thereby having an extremely broad application prospect in the lithium ion battery field.

Owner:NANKAI UNIV

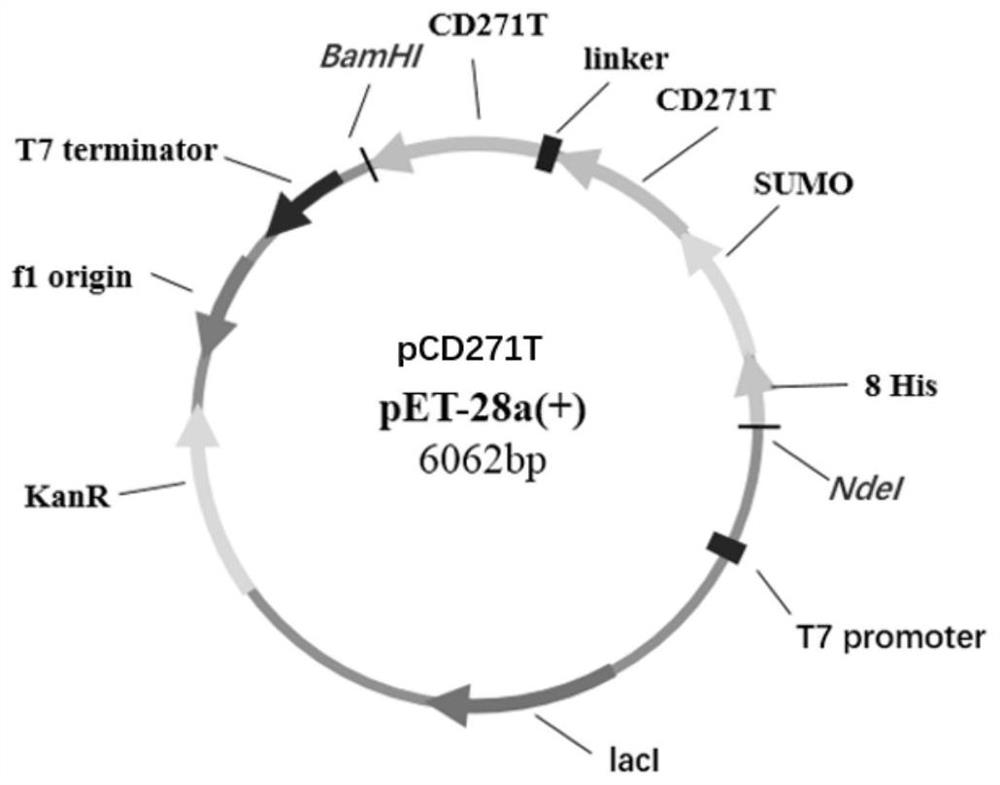

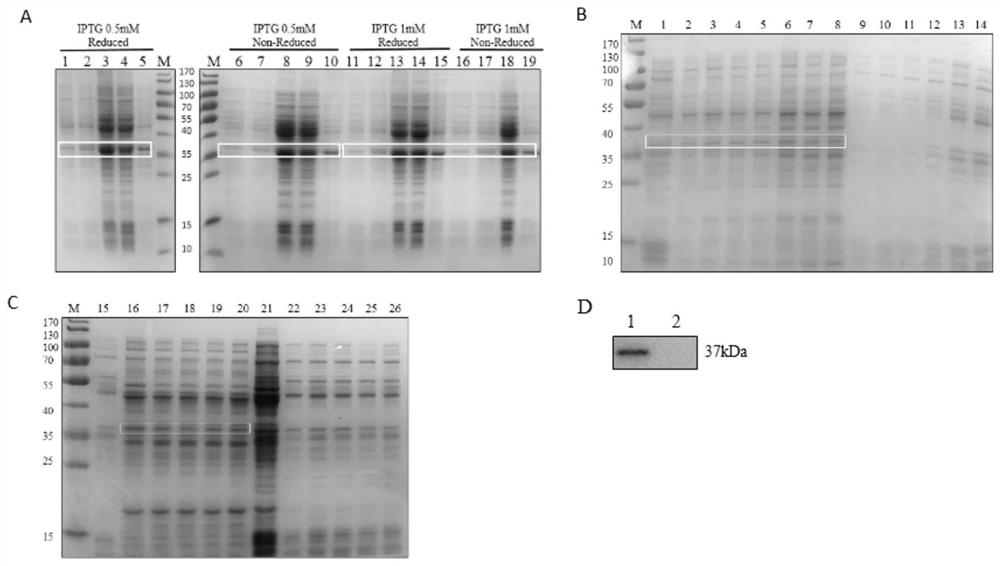

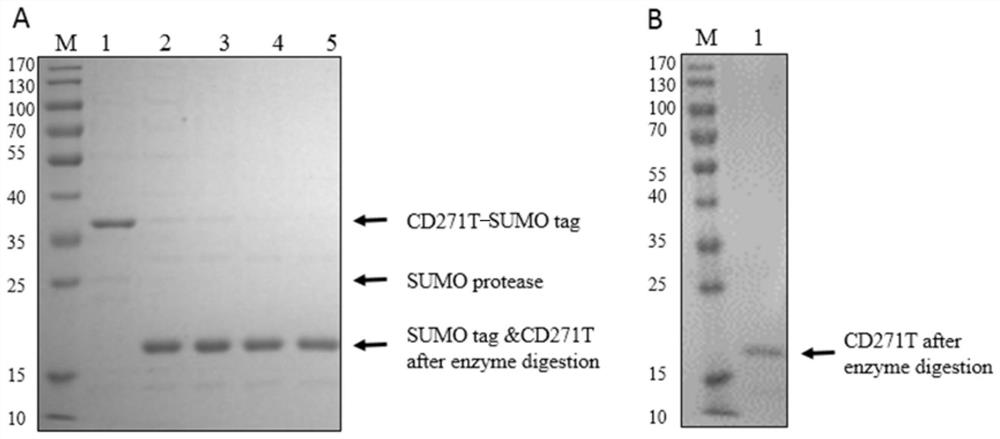

Novel antigen epitope based on CD271 and application thereof

The invention relates to a novel antigen epitope peptide based on CD271 and application of the novel antigen epitope peptide. The antigen epitope peptide is: (1) located in SEQ ID NO.1; or (2) is located in an amino acid sequence having at least 80% identity with the SEQ ID NO.1 sequence in (1); wherein SEQ ID NO.1 contains one or more antigen epitopes, and the length of the amino acid sequence of the antigen epitope peptide is 5-70% of the full length of the SEQ ID NO.1. An antibody, a nucleic acid aptamer, a vaccine, nanoparticles and the like targeting the antigen peptide can be stably combined with natural cells with CD271 protein. The antigen epitope peptide or nucleic acid, fusion protein, carrier or host cell and the like containing the antigen epitope peptide have important application significance in the fields of preparation of CD271 related detection reagents, disease treatment biological drugs, vaccines and the like.

Owner:苏州铂维生物科技有限公司

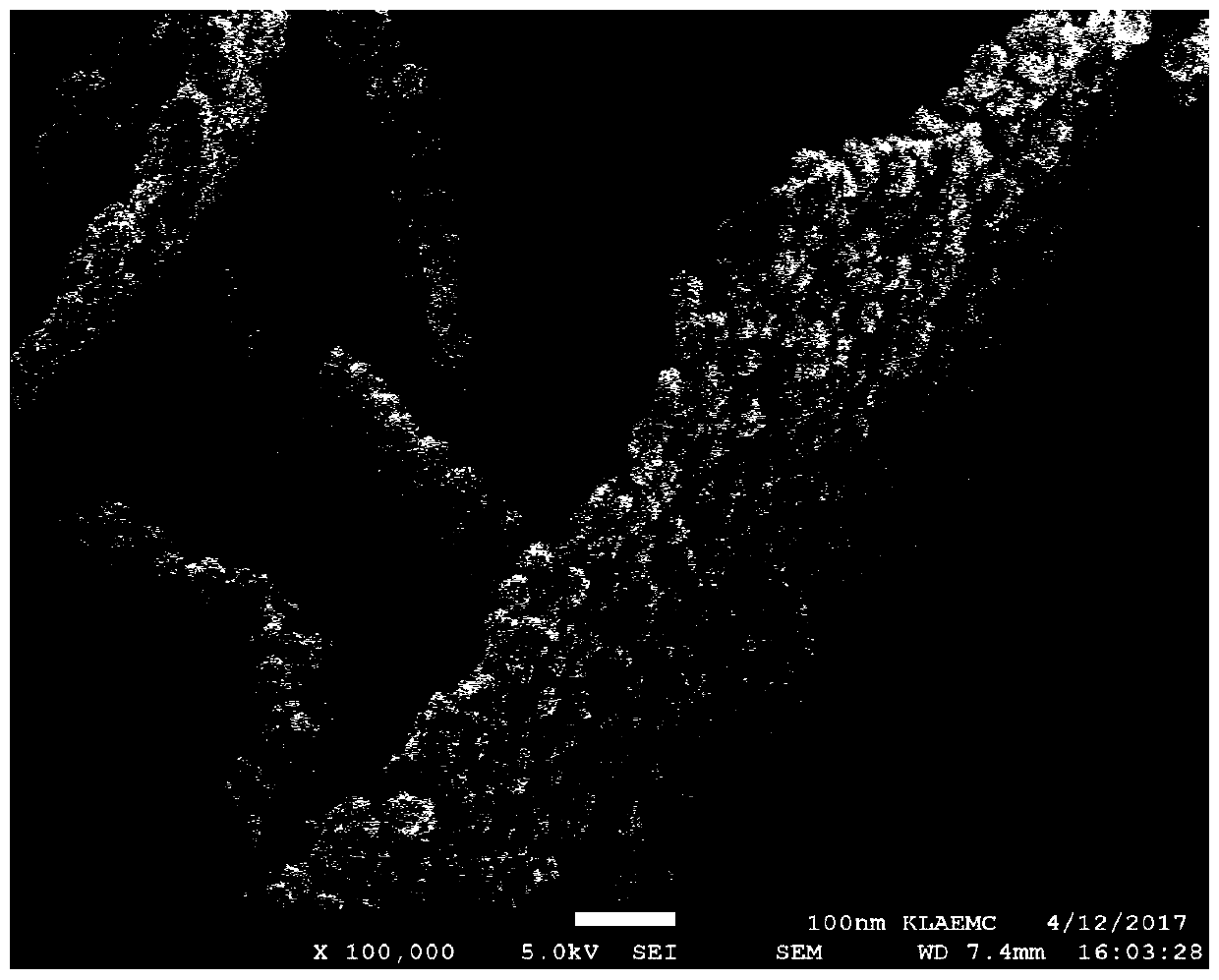

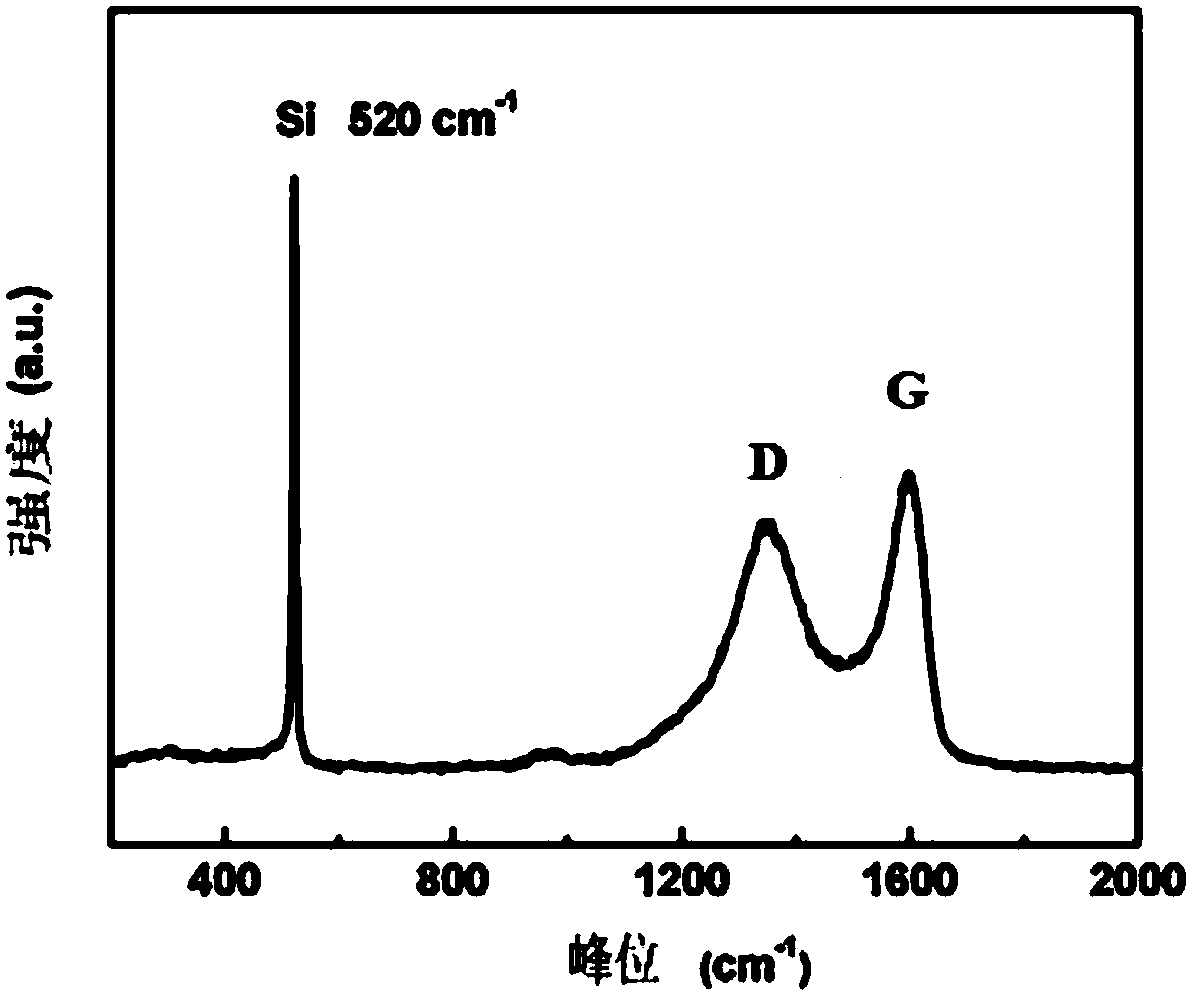

Preparation method of graphene-coated silicon particle composite material

InactiveCN107611376AInhibit synthesisAvoid processing powerMaterial nanotechnologyCell electrodesElectrochemistrySilicon particle

The invention provides a preparation method of a graphene-coated silicon particle composite material. The preparation method comprises the steps of 1, performing uniform mixing on carbon powder and asilicon-containing material and then performing pressing to prepare a carbon / silicon rod; 2, putting the carbon / silicon rod into electric arc equipment to be used as a negative electrode, inflating with H<2> and He<2>, adjusting the distance between the carbon / silicon rod and a positive electrode rod, and controlling current and performing arc discharge to prepare a product A; and 3, performing emulsification, ultrasonic processing, freezing and drying on the product A to obtain the graphene-coated silicon particle composite material. By taking the carbon powder and the silicon-containing material as the raw materials and by adopting the arc discharge method as the preparation means, silicon particles are intercalated between graphene layers so as to obtain the composite material; comparedwith the conventional method, the method disclosed in the invention is simple and convenient in process and low in cost; the material is uniform in appearance and stable in structure, so that the problems of silicon particle agglomeration and expansion can be solved; and compared with the similar silicon / graphene composite material, the graphene-coated silicon particle composite material shows higher electrochemical performance.

Owner:HARBIN ENG UNIV

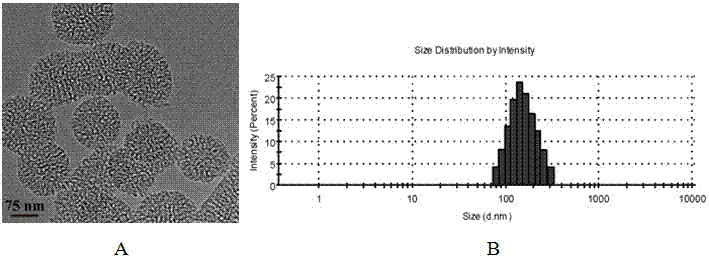

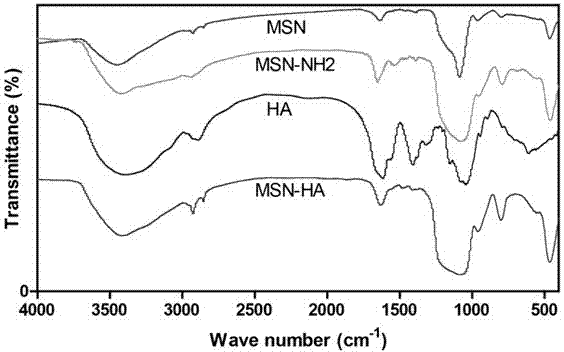

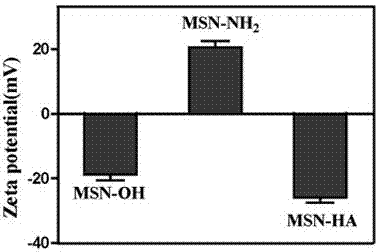

Paclitaxel/erlotinib-loaded mesoporous silica-hyaluronic acid hybrid targeted nano-particles

ActiveCN107970242AImprove anti-tumor effectIncrease uptakeOrganic active ingredientsPharmaceutical non-active ingredientsErlotinibNanoparticle

The invention discloses paclitaxel / erlotinib-loaded mesoporous silica-hyaluronic acid hybrid targeted nano-particles and application thereof to preparation of an anti-cancer drug. The targeted nano-particles are obtained by carrying out covalent coupling on hyaluronic acid to outer surfaces of mesoporous silica nano-particles after modifying the mesoporous silica nano-particles through surface amino functionlization and then mixing two types of mesoporous silica nano-particles in proportion after respectively loading paclitaxel and erlotinib into inner pore passages of the mesoporous silica nano-particles. According to the invention, not only can stability of the paclitaxel be improved, but also targeted drug delivery of paclitaxel / erlotinib can be implemented, and by combined use of the paclitaxel and the erlotinib, an effect of synergistically resisting to cancer metastasis is played.

Owner:FUZHOU UNIV

A preparation method of flexible ferric oxide/ferric oxide and nitrogen-doped carbon composite nanofiber

ActiveCN106811834BHigh yieldSimple processElectro-spinningArtifical filament manufactureCarbon compositesFiber

The invention relates to a method for preparing flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers. The method has the advantages that the problem of poor toughness and electric conductivity of existing metal oxide can be solved by the aid of the method; flexible macromolecules are used as supports and are subjected to composition with metal organic gel precursors with plasticity to obtain precursors, and the precursors are subjected to pyrolysis in inert atmosphere and air atmosphere to obtain the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers which are flexible metal oxide and nitrogen doped carbon composite nano-fibers; the problems of complicated and harsh conditions for preparing flexible metal oxide and carbon composite materials, high costs and difficulty in large-scale production at present can be solved by the aid of the method; raw materials for the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers are low in cost, processes for preparing the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers are simple, and the method is short in synthesis period, good in repeatability and high in yield, and industrial production can be facilitated; the flexible iron sesquioxide / ferroferric oxide and nitrogen doped carbon composite nano-fibers can have characteristics of bendable properties and excellent electrochemical performance, accordingly, the method has an extremely broad application prospect in the field of wearable electronic devices, and the like.

Owner:NANKAI UNIV

Preparation method of polypyrrole ppy nanocellulose nccs composite membrane electrode material

ActiveCN103390510BExcellent electrochemical propertiesPreparation highHybrid/EDL manufactureCelluloseConductive polymer composite

The invention discloses a preparation method for a PPy and NCCs compound film electrode material. The preparation method is characterized by comprising the steps of performing pretreatment and hydrolysis on plant raw materials to obtain NCCs from the plant raw materials, mixing the obtained NCCs with pyrrole monomers to form an electrolytic solution, and obtaining the PPy and NCCs compound film electrode material through preparation by an electrochemical method. According to the preparation method, the PPy and NCCs compound film electrode material with the electrochemical property enhanced is obtained by using cheap plant raw materials or even waste plant raw materials; the preparation method is fast and environmentally friendly, mild in synthesis condition and low in cost. The preparation method can also be broadened to be applied to preparation of various conductive polymer composite materials, such as polyaniline, polyacetylene, polythiophene and poly-phenylene vinylene.

Owner:上海上惠纳米科技有限公司 +1

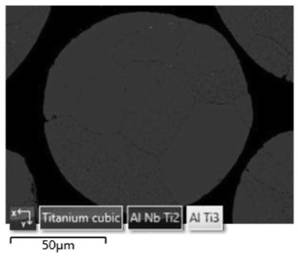

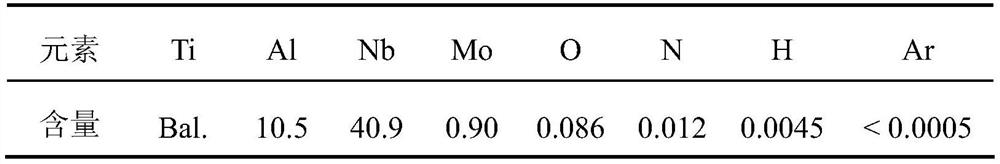

Preparation method of EBSD sample of Ti2AlNb alloy powder

PendingCN112697825AIncrease credibilityEasy to operateMaterial analysis using wave/particle radiationIon bombardmentCrucible

The invention discloses a preparation method of an EBSD sample of Ti2AlNb alloy powder, and belongs to the technical field of powder metallurgy titanium alloy processing. The method comprises the following steps: firstly, pouring a low-viscosity Surr embedding set and Ti2AlNb powder into a Ti-6Al-4V crucible, and uniformly mixing the low-viscosity Surr embedding set and the Ti2AlNb powder; then curing a mixture at 70 DEG C for 10 hours; and sequentially carrying out grinding and mechanical polishing, and then carrying out ion bombardment, cleaning and blow-drying to obtain the EBSD sample of the Ti2AlNb alloy powder. The method is simple, convenient and flexible to operate, high in EBSD experiment success rate, easy to popularize and wide in application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of core shell structure palladium copper catalyst and its preparation method and catalytic application

ActiveCN109012694BAchieving Precise Twisted Topography ControlChange electronic propertiesHydrocarbon by hydrogenationCatalystsPtru catalystCu2 ions

The invention discloses a core-shell structure palladium-copper catalyst and a preparation method thereof and catalytic application thereof, and belongs to the field of nanocatalysis. The core-shell structure palladium-copper catalyst comprises a palladium nanosheet and a copper shell layer coating the surface of the palladium nanosheet, wherein the palladium nanosheet has a size of 5 to 200 nm and a thickness of 0.5 to 3 nm; and the thickness of the copper shell is 0.1 to 10 nm. The palladium nanosheet is dispersed in water, hydrogen gas is introduced, after the reaction, an aqueous solutioncontaining copper ions is added, and sealing reaction is continued to obtain the core-shell structure palladium-copper catalyst. An catalytic application method is as follows: the core-shell structurepalladium-copper catalyst is collected by centrifugation, washed with ethanol and dried to obtain catalyst powder; the catalyst powder is dispersed in ethanol, phenylacetylene is added to a water bath and stirred, and H2 is introduced to react.

Owner:XIAMEN UNIV

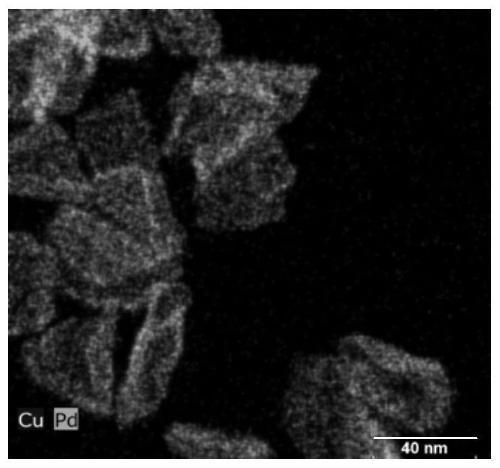

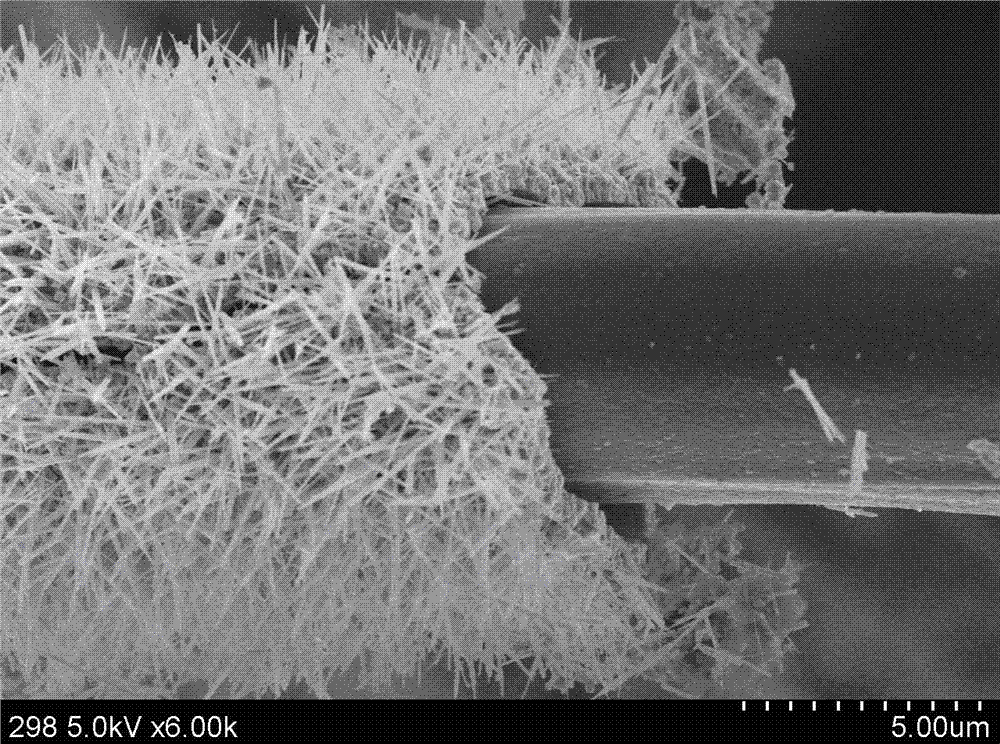

Activated carbon fiber for supercapacitor and preparation method thereof

ActiveCN105097302BImprove cycle stabilityImproved magnification performanceHybrid capacitor electrodesHybrid/EDL manufactureFiberMANGANESE ACETATE

Owner:JIANGSU SUTONG CARBON FIBER +1

Zeolite molecular sieve-mesoporous titanium oxide composite material with egg yolk-eggshell structure and preparation method thereof

ActiveCN103894223BPreparation highEasy to prepareCatalyst carriersMolecular sieve catalystsYolkPtru catalyst

The invention belongs to the technical field of inorganic porous materials and catalysts, in particular to a zeolite molecular sieve-mesoporous titanium oxide composite material with a high specific surface area egg yolk-eggshell structure and a preparation method thereof. The composite material uses zeolite molecular sieve materials as egg yolk, and mesoporous titanium dioxide nano crystal grain aggregates as eggshell, and there is a cavity with adjustable size between the zeolite molecular sieve and mesoporous titanium dioxide. The preparation method is to wrap a layer of phenolic resin macromolecule or amorphous silica on the surface of zeolite molecular sieve, and then wrap a layer of amorphous titanium dioxide, convert the titanium dioxide into crystalline titanium dioxide nanocrystals by calcining, and finally remove the phenolic resin polymer layer or amorphous silica to obtain the target composite material; the method is simple and the control is easy. The composite material has a multi-level porous structure and can be used as a catalyst or catalyst carrier for continuous reactions, and can also be used as an adsorption-catalysis composite material.

Owner:元颉新材料科技(浙江)有限公司

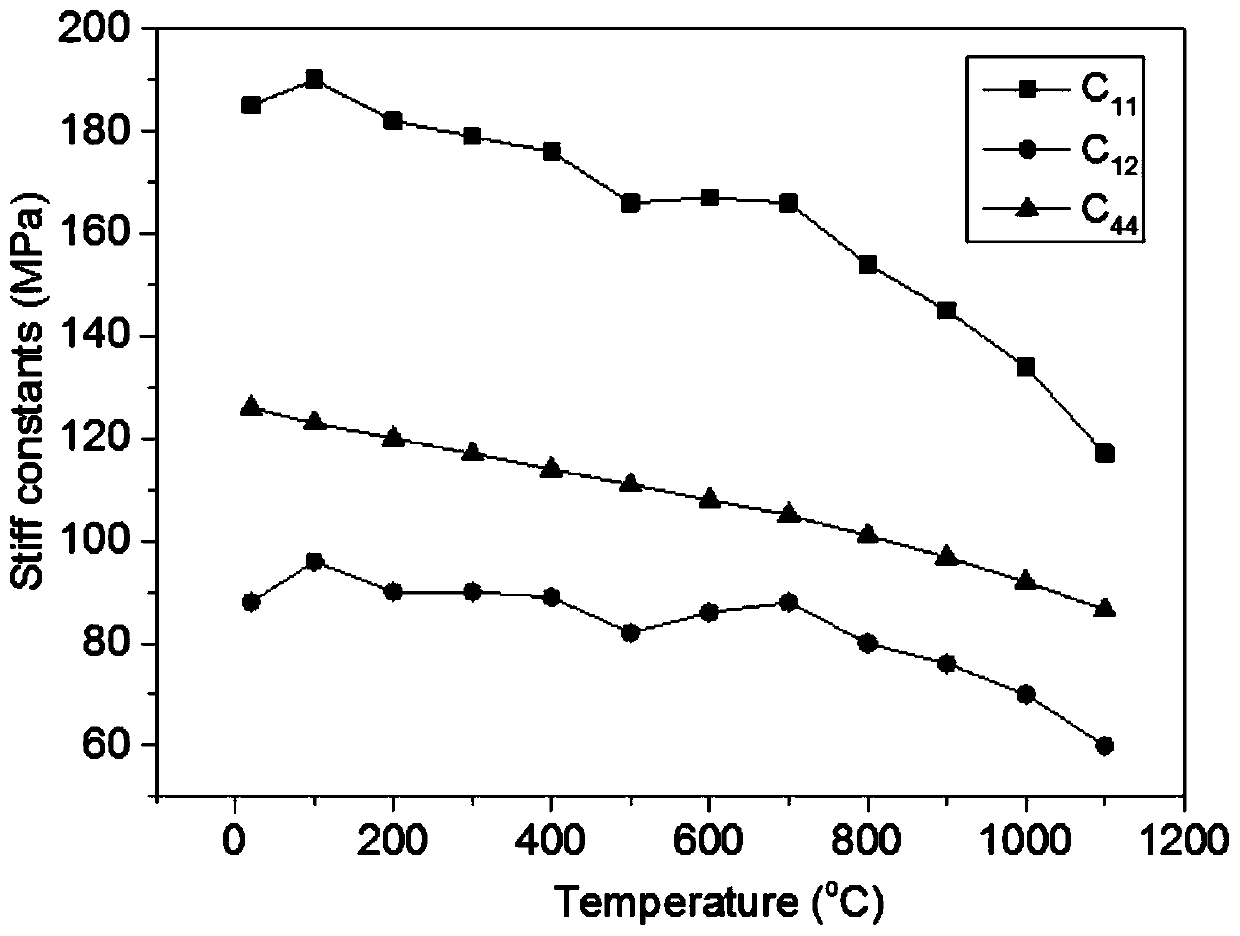

Determination method for elastic constants of monocrystalline high temperature alloy

ActiveCN110412126APromote growthSmall sizeAnalysing solids using sonic/ultrasonic/infrasonic wavesShear modulusResonance

The invention discloses a determination method for elastic constants of monocrystalline high temperature alloy, and belongs to the technical field of physical parameter determination of monocrystalline alloy. According to the method, two types of monocrystalline high temperature alloy plates with specific 3D orientations are prepared by a seed crystal method, first and second orientations of the first type of monocrystalline plate are (001) and (100) respectively, and first and second orientations of the second type of monocrystalline plate are (011) and (110) respectively. A rectangular elastic modulus sample whose length direction is in parallel with the primary orientation of the monocrystalline plate is cut from a material plate, and the young modulus E (001) and the shear modulus G(001)-(100) of the first type of sample and the shear modulus G (011)-(110) of the second type of sample are measured by a knock resonance method. The three elastic constants C11, C12 and C44 of the monocrystalline high temperature alloy can be simply calculated from the measured young modulus and two shear modulus.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

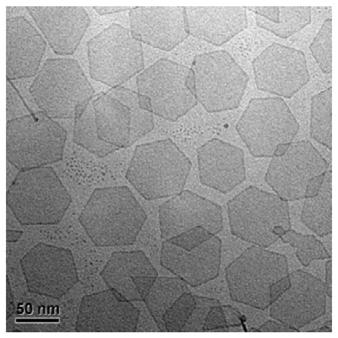

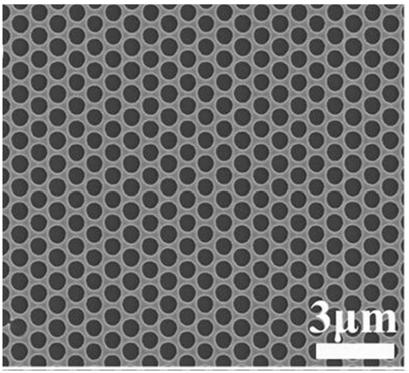

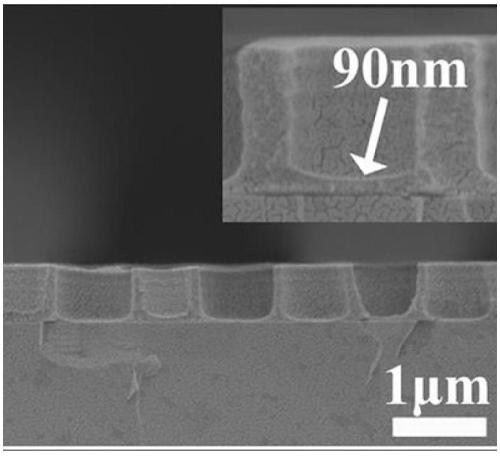

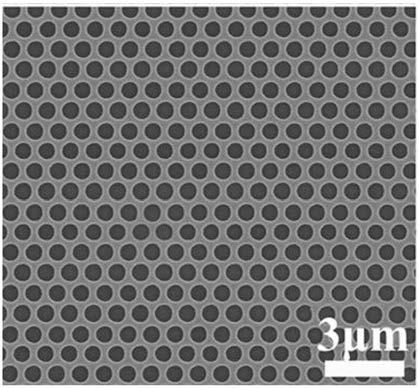

Fabrication method of large-area highly ordered porous oxide films based on soft nanoimprinting

The invention provides a preparation method of large-area highly-ordered porous oxide films based on nano soft embossing. The preparation method at least comprises the following steps: firstly copying a micro-nano-sized ordered structure of a mother template to a silica gel soft template, simultaneously providing a metal substrate and pretreating the metal substrate; then coating the surface of the metal substrate with an ultraviolet curing adhesive, carrying out nano embossing treatment on the ultraviolet curing adhesive by using the silica gel soft template, removing the silica gel soft template, and forming the micro-nano-sized ordered structure on the ultraviolet curing adhesive; subsequently taking the ultraviolet curing adhesive as a mask, transferring the micro-nano-sized ordered structure to the metal substrate by using an etching process and removing the residual ultraviolet curing adhesive; and forming a porous oxide film on the surface of the metal substrate by using an anodic oxidation method. The preparation method can be used for preparing large-area oxide films such as HOAAO and HOATO and the like; the method is efficient and convenient and is low in cost.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

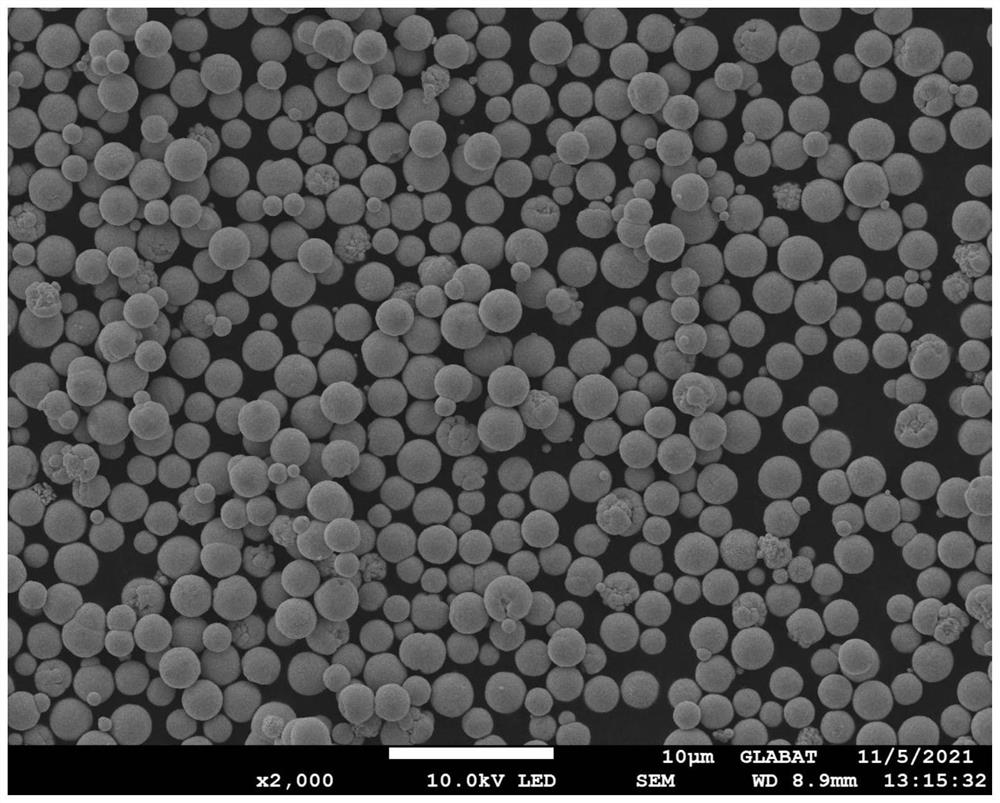

Method capable of continuously preparing micron-sized spherical gold powder

PendingCN114833334AHigh purityGood dispersionTransportation and packagingMetal-working apparatusCrystalliteMother liquor

The invention provides a method capable of continuously preparing micron-sized spherical gold powder with uniform particle size. According to the method, a rapid rotation nucleation method capable of effectively reducing interference of the external environment on gold grain nucleation is adopted, the gold-containing mother liquor and a reducing agent are introduced into a rapid rotation nucleation reactor at the same time, mass transfer reaction is rapidly completed in micro-nano liquid drops generated through high-speed rotation cutting, a huge amount of uniform crystal nuclei are formed, then the crystal nuclei are introduced into a rear reactor, and the gold-containing mother liquor is obtained. And the controllable growth of the spherical gold powder crystal grains is continuously completed until the spherical gold powder particles in the micron-sized particle size range are obtained, then the obtained micron-sized spherical gold powder precipitate is washed and dried, and the spherical gold powder with the uniform particle size can be obtained. The spherical gold powder which is high in purity, good in dispersity, smooth in surface and more uniform in particle size distribution compared with a common liquid phase reduction method can be continuously prepared through the method, and the average particle size D50 of the spherical gold powder ranges from 1 micrometer to 3 micrometers.

Owner:GRIMAT ENG INST CO LTD

An active hydrogen generator

ActiveCN114315000BPreparation highSafe preparationMultistage water/sewage treatmentMetal stripsHydrogen content

The present invention relates to an active hydrogen generator. The active hydrogen generator of the present invention is provided with a booster device, a live water device, a hydrogen enrichment device and an electronic release device. The booster device, the live water device, the hydrogen enrichment device and the electron release device Connected in sequence through a water supply pipe; the active water device includes a first filter cartridge, and the first filter cartridge is provided with energy spar and projectile natural ore; the hydrogen enrichment device includes a second filter cartridge, the second filter cartridge There are combined multifunctional health-preserving hydrogen-rich water tablets and composite medical stone ceramic balls inside; the electronic release device includes an inner rib tube, and a combination of composite tourmaline ceramic balls and electrode metal strips is placed in the inner rib tube. Material. The active hydrogen generator of the present invention can produce a large amount of active hydrogen in a durable, safe and environmentally friendly manner. According to third-party testing data, the active hydrogen content in the water treated by the active hydrogen generator of the present invention reaches 5-8PPm.

Owner:北京氢润科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com