Carbonate-bismuth oxyiodide compound catalyst and preparation method thereof

A technology of bismuth iodide and catalyst, applied in the field of catalysis, can solve the problems of hindering the application of photocatalysis technology, low photon conversion efficiency, low solar energy utilization rate, etc., and achieve the effects of excellent catalytic performance, increased specific surface area, and increased light absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

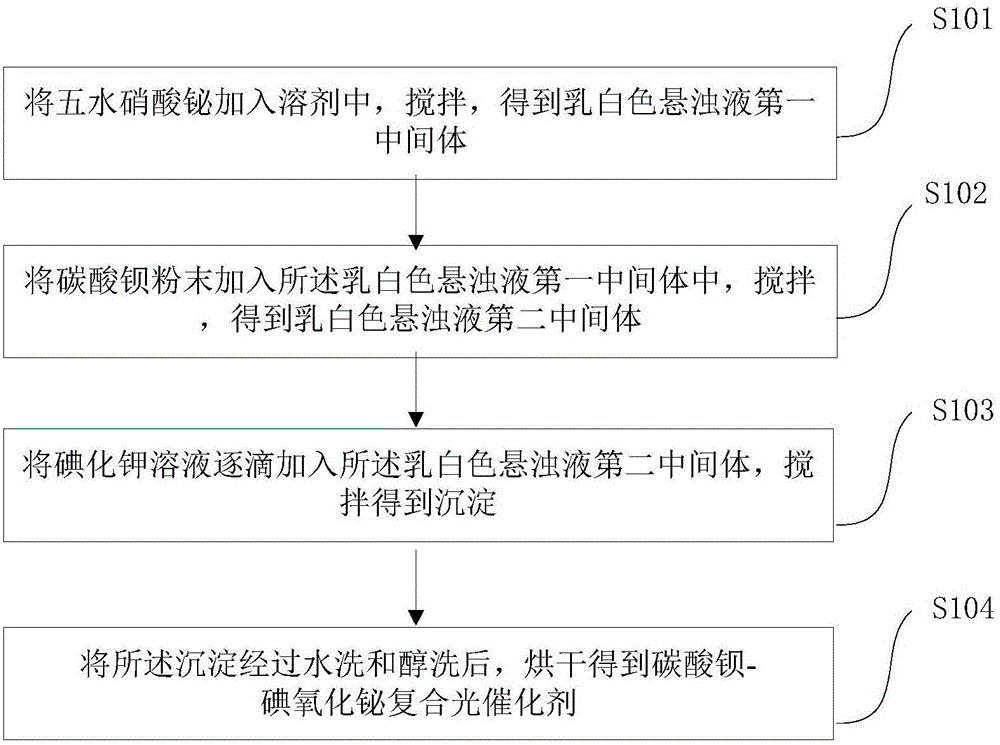

[0045]figure 1 The preparation method of a kind of barium carbonate-bismuth oxyiodide composite photocatalyst shown for the embodiment of the application, said method comprises:

[0046] S101 adding bismuth nitrate pentahydrate into the solvent and stirring to obtain the first intermediate of milky white suspension;

[0047] S102 adding barium carbonate powder into the first intermediate of the milky white suspension, and stirring to obtain the second intermediate of the milky white suspension;

[0048] S103 adding potassium iodide solution dropwise to the milky white suspension second intermediate, stirring to obtain a precipitate;

[0049] S104 washing the precipitate with water and alcohol, and drying to obtain a barium carbonate-bismuth oxyiodide composite photocatalyst.

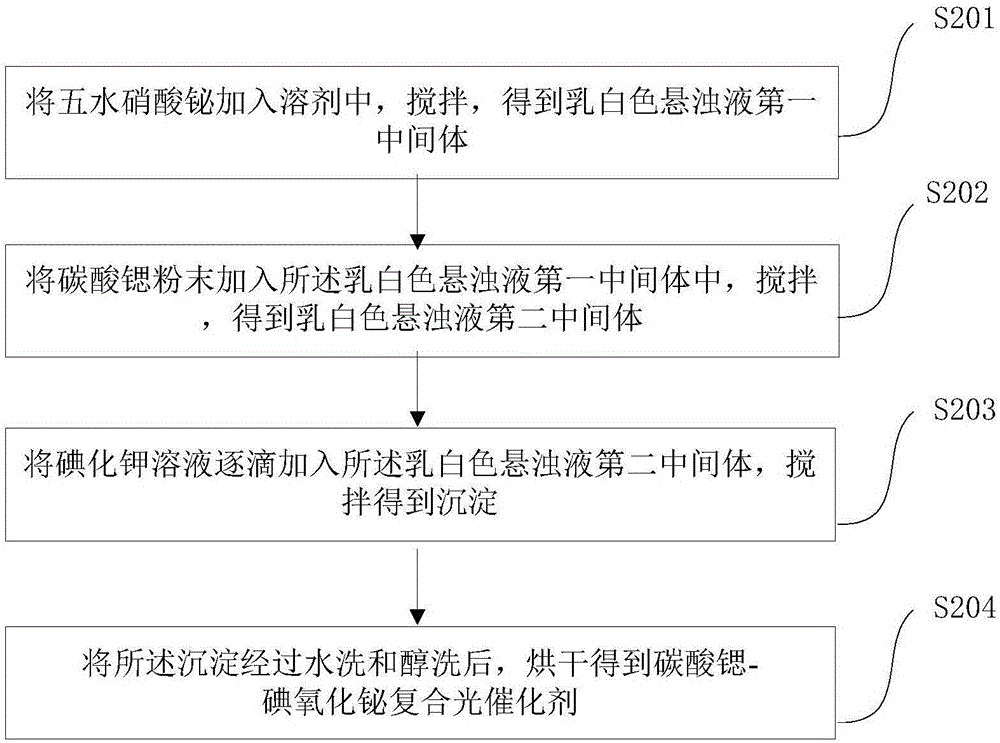

[0050] figure 2 The preparation method of a kind of strontium carbonate-bismuth oxyiodide composite photocatalyst shown for the embodiment of the present application, the method comprises:

[0051] S...

Embodiment 1

[0076] 1) After barium carbonate and bismuth nitrate pentahydrate were weighed according to the stoichiometric ratio of 6:3, bismuth nitrate pentahydrate was added to water and ethylene glycol mixed uniformly at a volume ratio of 9:1, and stirred for 30 minutes to obtain a milky white suspension. Turbid liquid first intermediate;

[0077] 2) adding pure-phase barium carbonate powder into the first intermediate of the milky white suspension, and stirring for 30 minutes to obtain the second intermediate of the milky white suspension;

[0078] 3) Add the dissolved potassium iodide solution dropwise to the second intermediate of the milky white suspension, stir for 2 hours, and then precipitate to obtain a barium carbonate-bismuth oxyiodide composite photocatalyst.

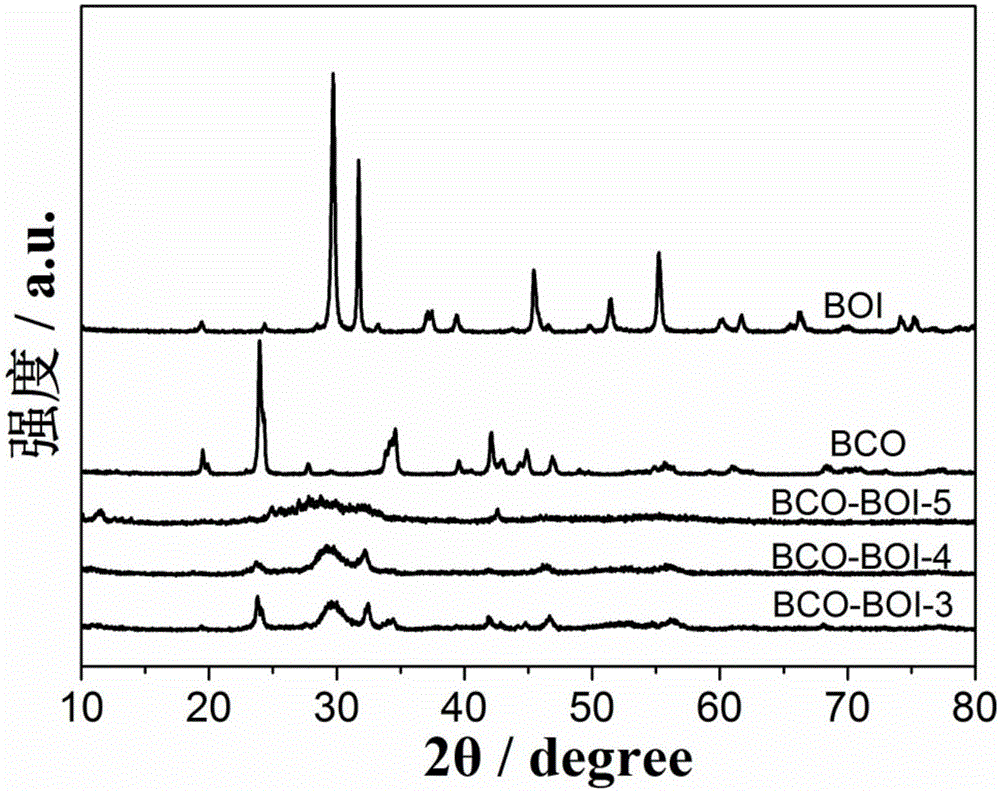

[0079] The barium carbonate and bismuth nitrate pentahydrate prepared in the examples of the present application were characterized by XRD, SEM, TEM, HRTEM, PL, UV-VisDRS, and XPS according to the barium carbonate-bis...

Embodiment 2

[0082] 1) After barium carbonate and bismuth nitrate pentahydrate were weighed according to the stoichiometric ratio of 6:4, bismuth nitrate pentahydrate was added to water and ethylene glycol mixed uniformly at a volume ratio of 9:1, and stirred for 30 minutes to obtain a milky white suspension. Turbid liquid first intermediate;

[0083] 2) adding pure-phase barium carbonate powder into the first intermediate of the milky white suspension, and stirring for 30 minutes to obtain the second intermediate of the milky white suspension;

[0084] 3) adding the dissolved potassium iodide solution dropwise to the second intermediate of the milky white suspension, stirring for 2 hours and then precipitating to obtain a barium carbonate-bismuth oxyiodide composite photocatalyst.

[0085] The characterization of the barium carbonate-bismuth oxyiodide composite photocatalyst with a stoichiometric ratio of 6:4 prepared by the barium carbonate and bismuth nitrate pentahydrate prepared in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com