Core-shell structure palladium-copper catalyst and preparation method thereof and catalytic application thereof

A core-shell structure and catalyst technology, applied in the field of core-shell structure palladium-copper catalyst and its preparation, can solve problems such as short lifespan, and achieve the effects of less by-products, lower cost and obvious selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

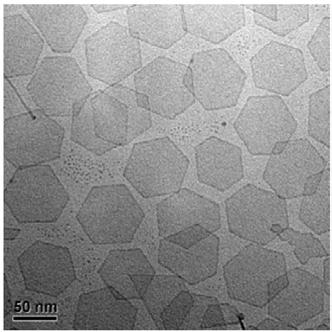

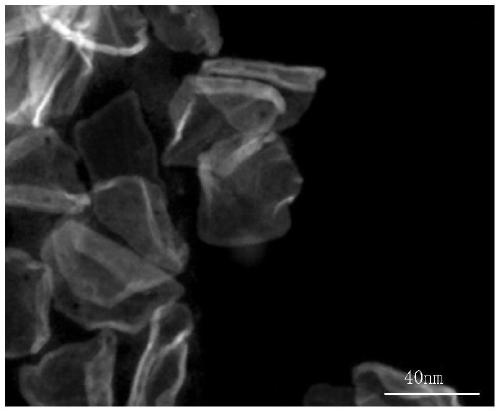

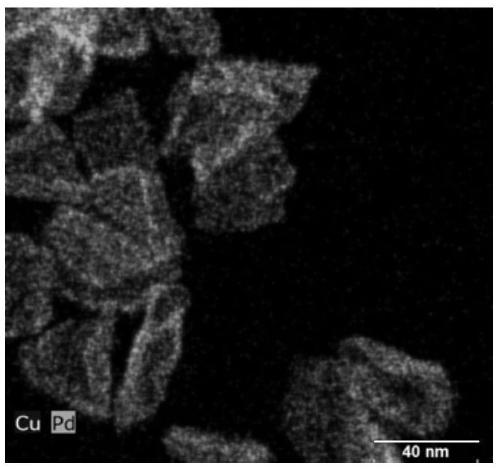

[0034] At 60 °C, a certain amount of Pd nanosheets was uniformly dispersed in 5 mL of aqueous solution, and transferred to a 25 mL two-necked bottle. After 40 minutes of passing through hydrogen gas, stop. While keeping the experimental device airtight, a certain amount of Cu(NO 3 ) 2 of aqueous solution. Continue to keep the experimental device airtight and stop after stirring for 1 h. The resulting reaction product was separated by centrifugation and washed several times with ethanol and acetone to be characterized and ready for use. According to the mass ratio of Pd and Cu elements, the obtained catalyst loadings are different. see results Figure 1~3 .

Embodiment 2

[0036] Wash the palladium-copper catalyst in Example 1 with ethanol for 3 times, dry, take 1 umol and disperse it in 10ml ethanol, disperse it ultrasonically, put it in a water bath at 30°C, add 2mmol phenylacetylene after stirring for 5min, and pass through 0.1MPa H 2 .

[0037] At the same time, the catalyst was recycled to examine its stability. see results Figure 4 with 7 .

Embodiment 3

[0039] Wash the same amount of Pd nanosheets before reacting with copper in Example 1 with ethanol for 3 times, dry, take 1 umol and disperse it in 10ml ethanol, ultrasonically disperse, put it in a 30°C water bath, add 2mmol phenylacetylene after stirring for 5min, pass 0.1MPaH 2 .

[0040] see results Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com