Determination method for elastic constants of monocrystalline high temperature alloy

A technology of elastic constant and measurement method, which is applied in the direction of measuring device, analysis of solid with sound wave/ultrasonic wave/infrasonic wave, material analysis with sound wave/ultrasonic wave/infrasonic wave, etc. It can solve the difficulty of sample processing and the complex process of elastic constant of single crystal alloy , the large size of the material plate, etc., to achieve the effect of easy growth of single crystal, simple measurement process and data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

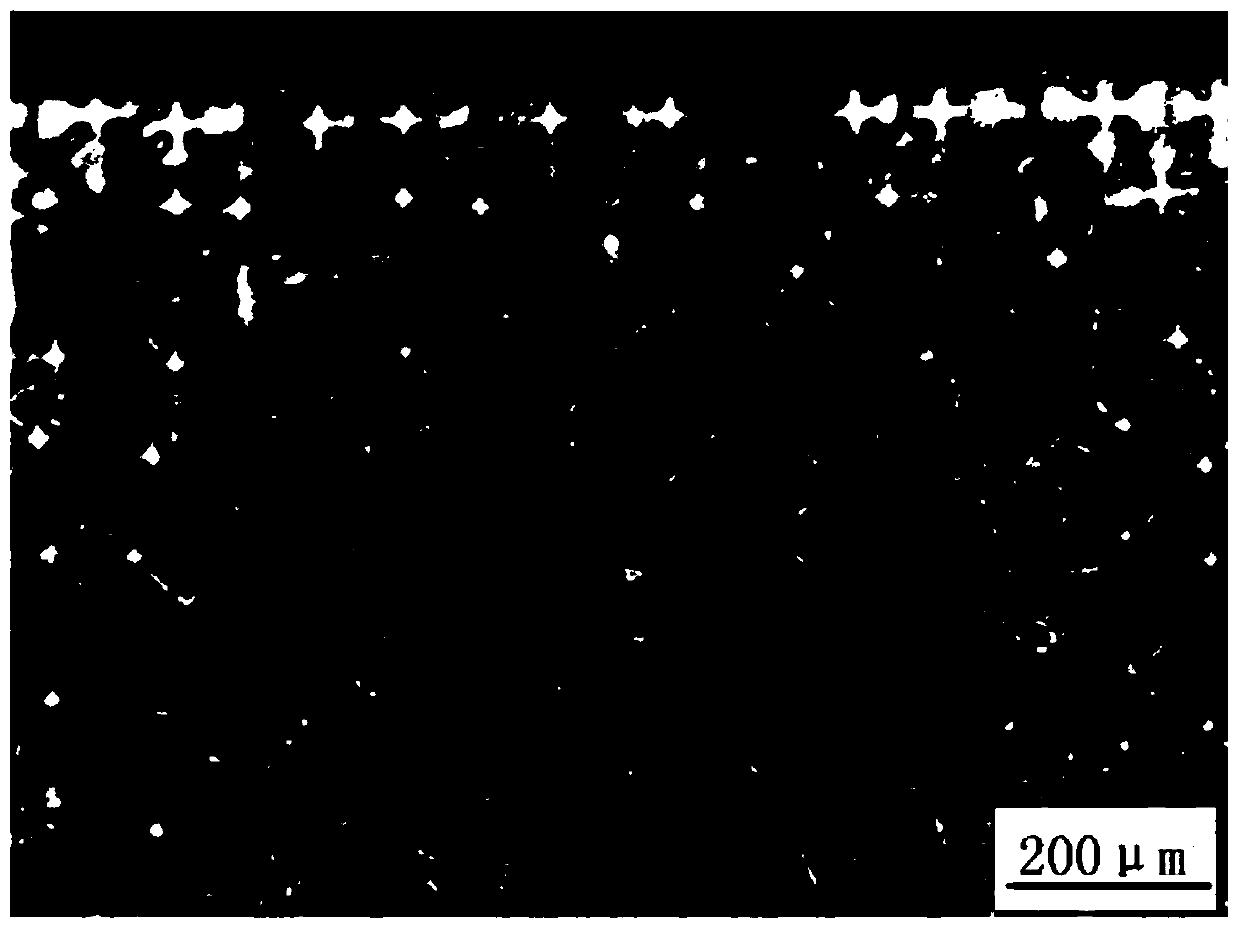

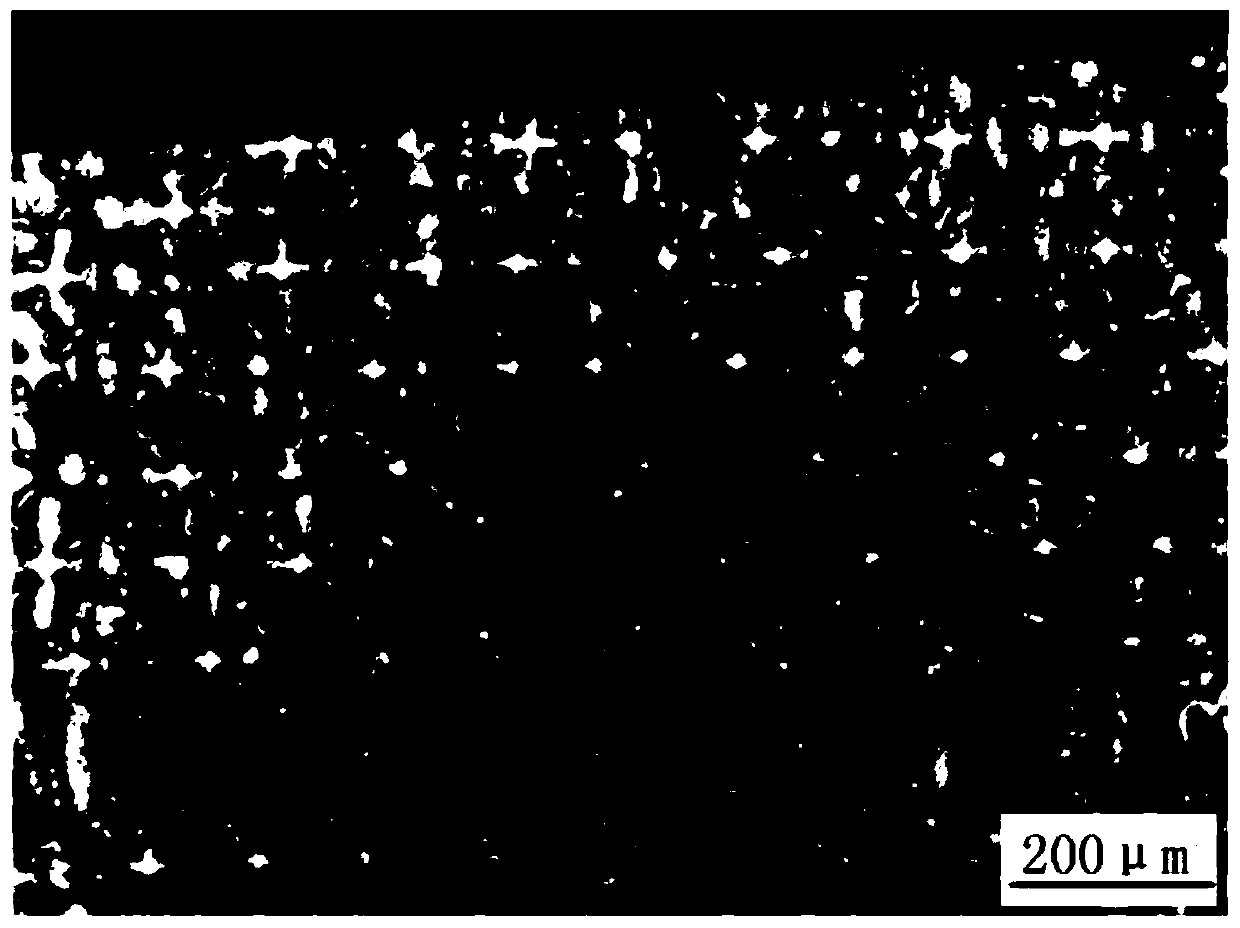

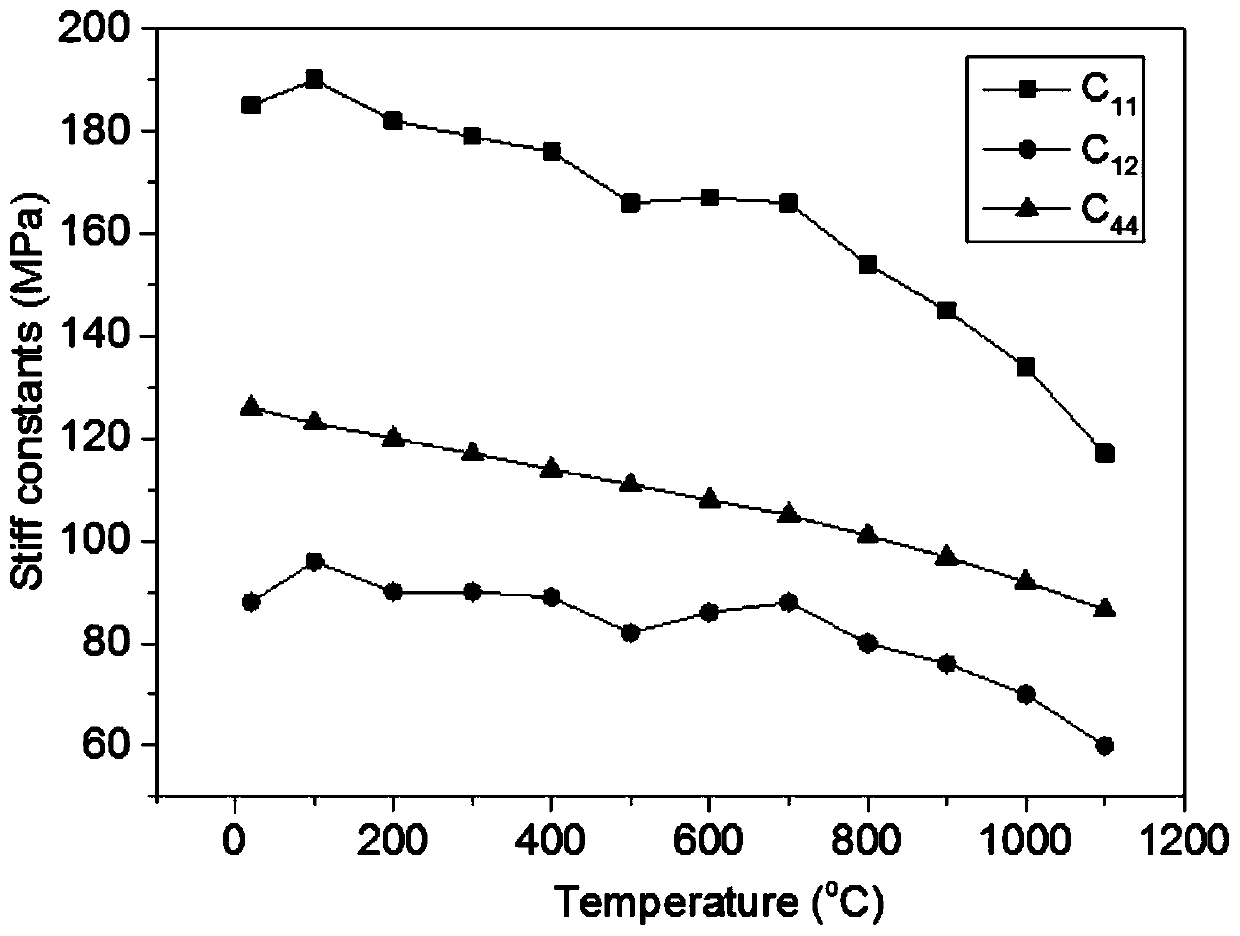

[0041] The first-generation single crystal superalloy (DD413) was used as the experimental material, and a single crystal material plate with specific primary and secondary orientations was grown by the seed crystal method in an industrial large-scale dual-zone heating ZGD-15 vacuum single crystal furnace. There are two different orientations of the single crystal plate, and the orientations of the seed crystals are: - and -.

[0042] 1. Cut cylindrical seed crystals with a diameter of 10mm and a height of 12mm and a base plane width of 8mm from the [001] single crystal superalloy rod produced by the crystal selection method, and the orientations are respectively the above two orientations. After the firing of the ceramic shell is completed, the seed crystal is placed in its seed crystal cavity, and the master alloy with the same composition is used as the experimental material for directional solidification to obtain a single crystal growing in the direction of the set seed cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com