Patents

Literature

284results about How to "Increase the difficulty of the process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

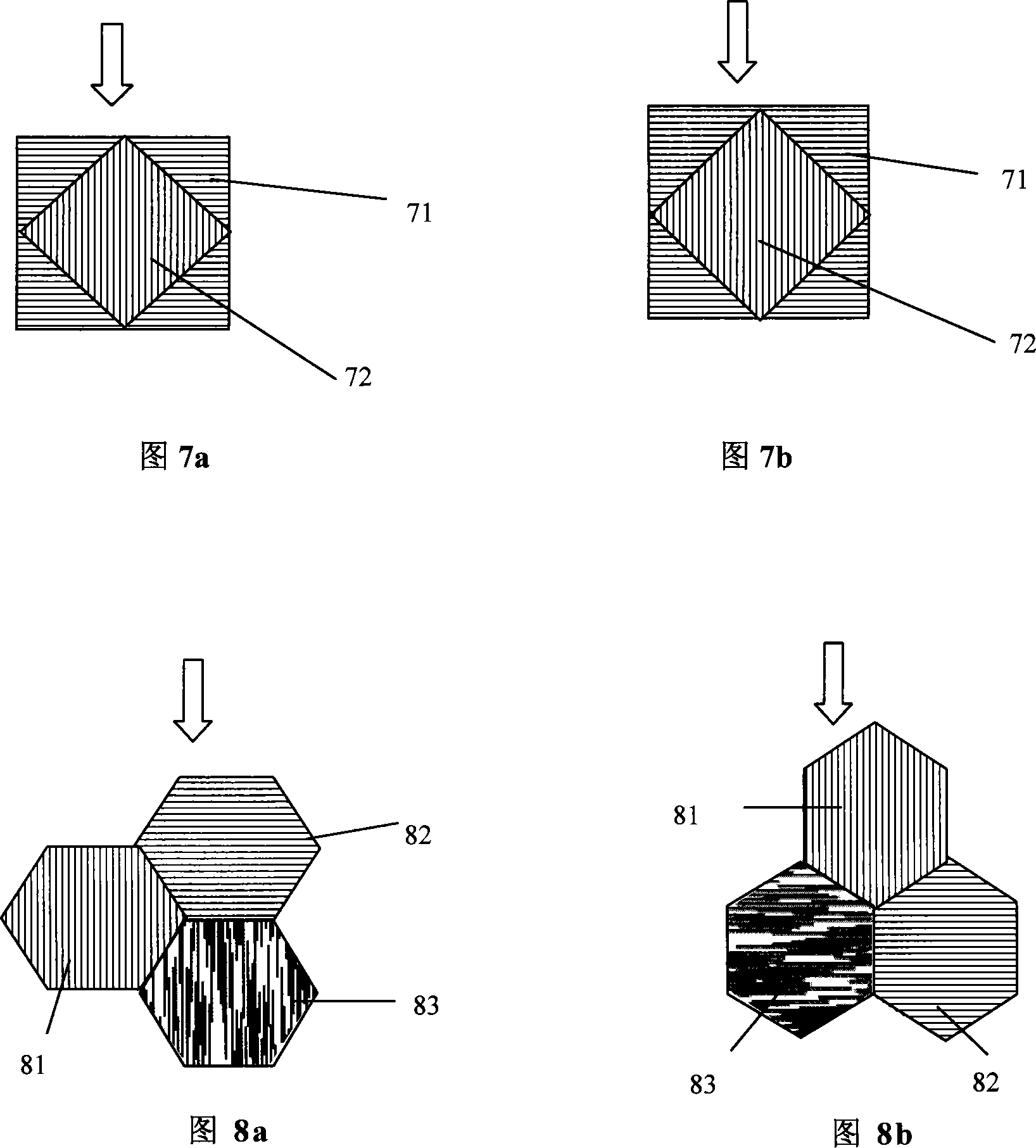

False proof structure for driving license and its identifying method

ActiveCN101161482AWith dynamic effectProminent visual featuresOther printing matterLight effect designsColor effectBody shape

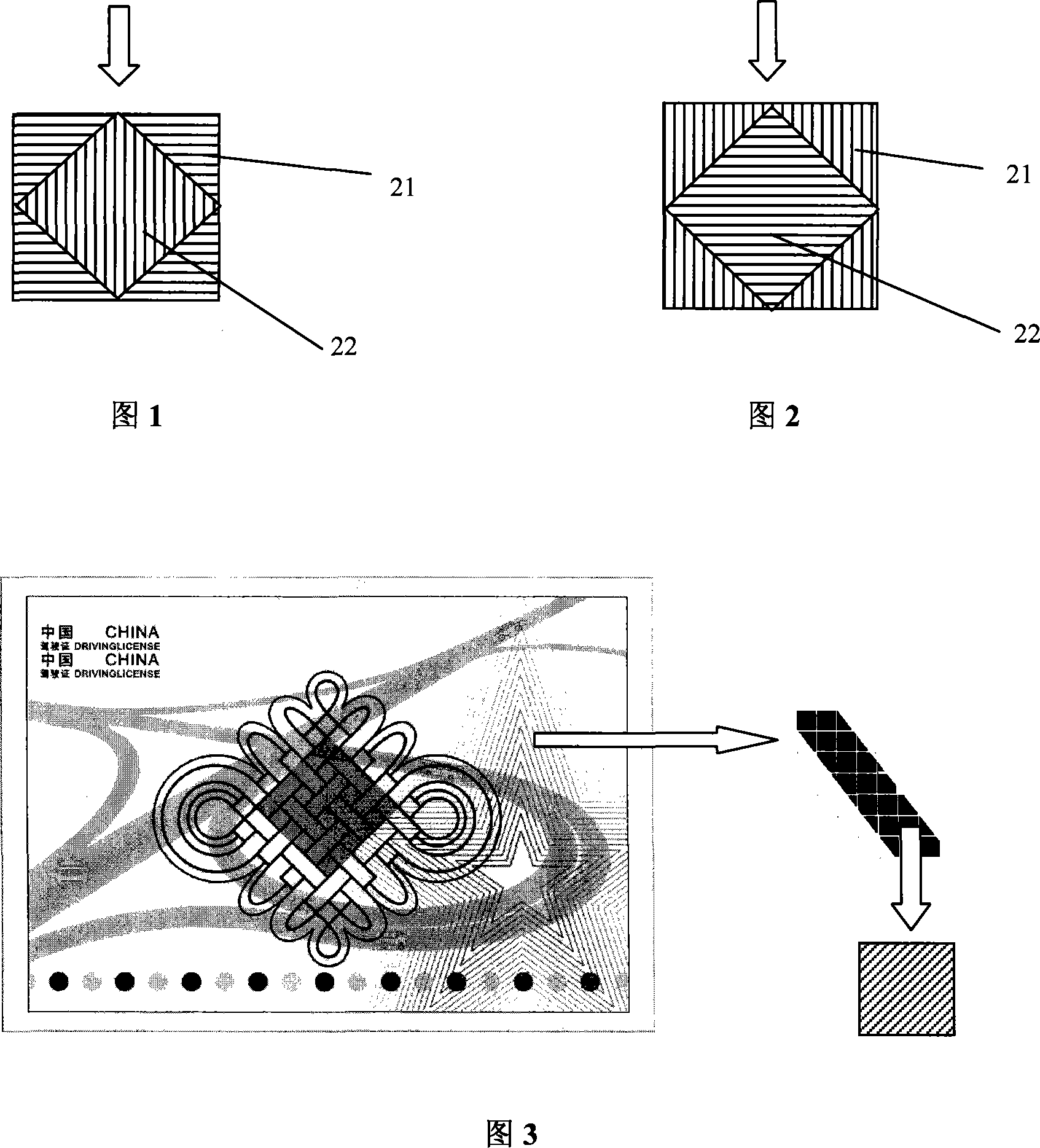

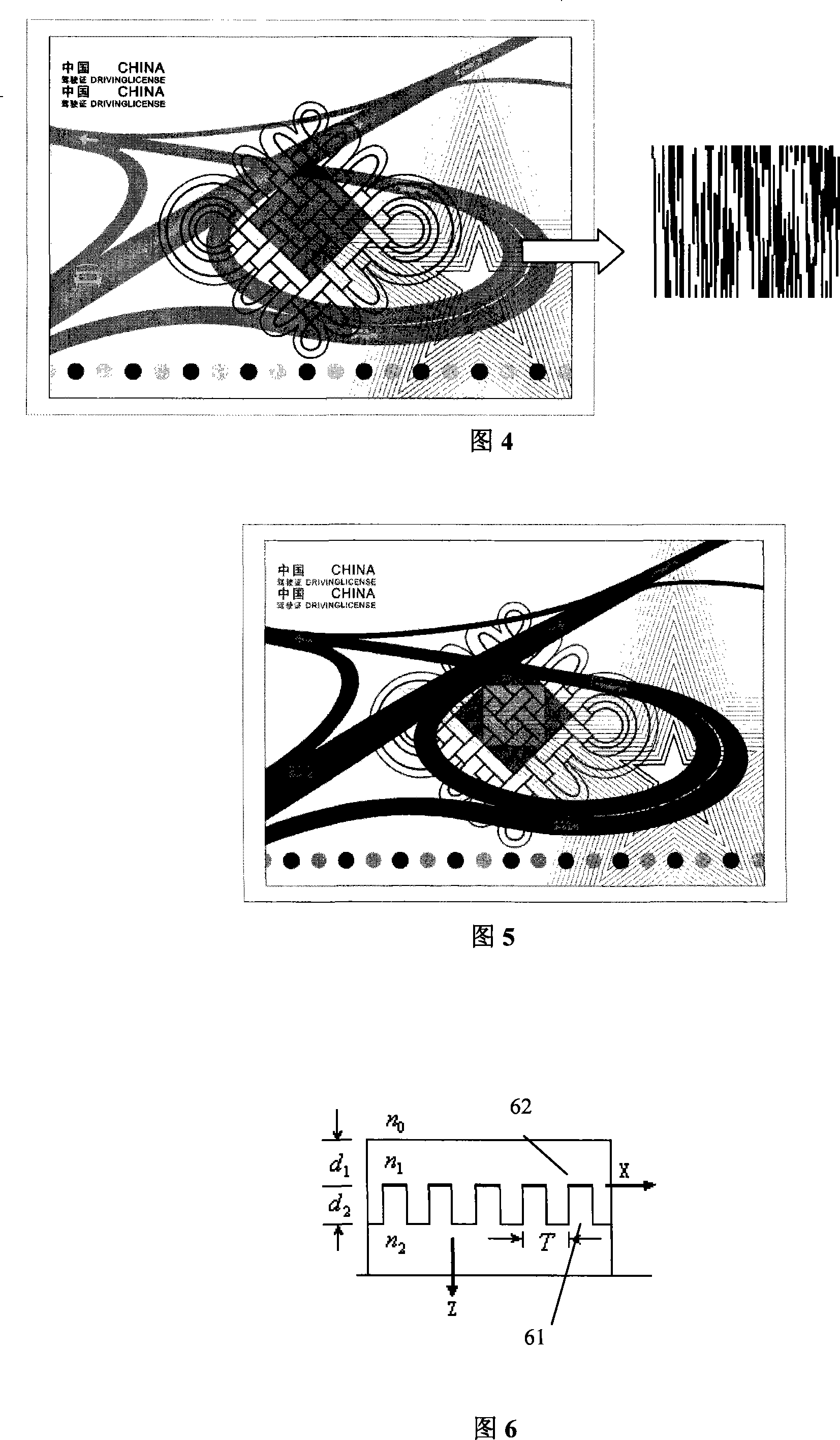

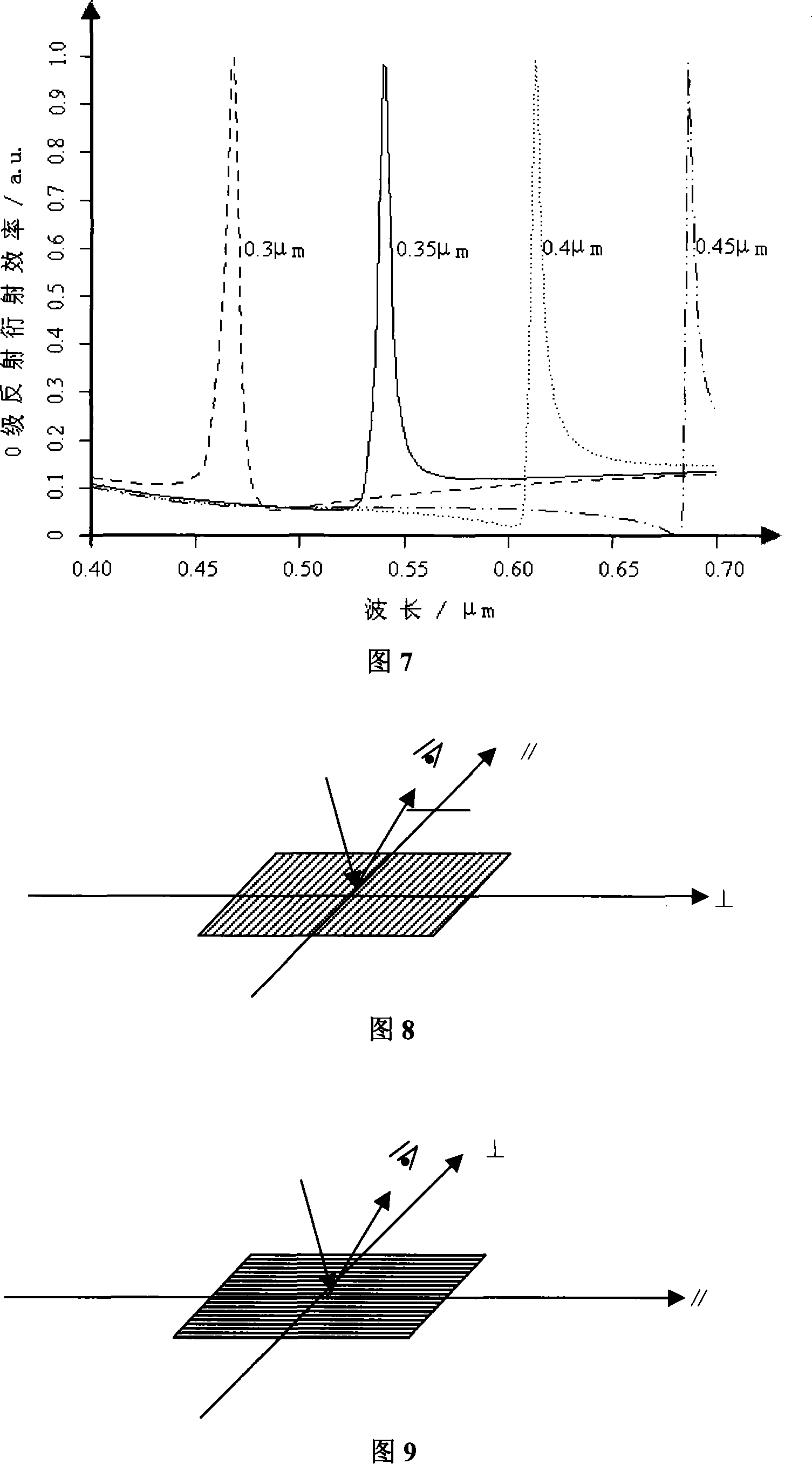

The invention discloses an anti-counterfeiting structure for driving card. The marked pattern composed of microstructure is set on the plastic packaged film of the card. The said marked pattern comprises at least three pattern area. A first pattern area is composed of sub-wavelength structure raster of orientated orthogonal structure and the double vision channel forms single color effect. A second pattern area is composed of light spot with body shape of square. The light spot shape of the pattern edge is determined by the outer outline of the pattern, with gliding property. The interference fringes are set in the light point. A third pattern area is composed of bar speckle microstructure, with oriented achromatization effect for white light reflection. The vision character of pattern is notable, easy to recognize in public places and conveniently and quickly distinguish the card. At the same time, the structure data is computed using rigid coupled wave. The said microstructure is produced using electron beam or laser interference optical lithography, and the means is advanced and the difficulty of technique is high with high safety.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY +1

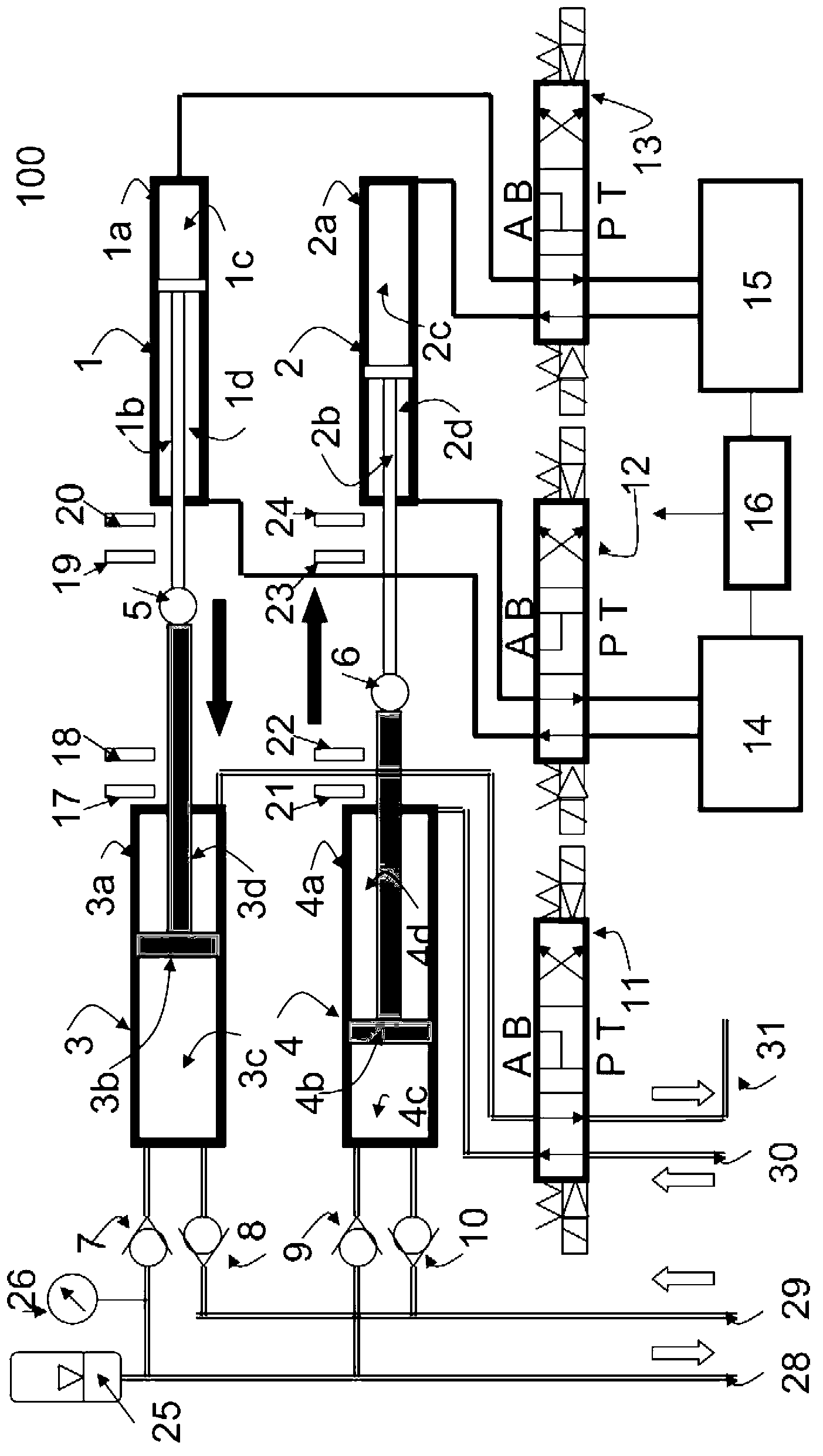

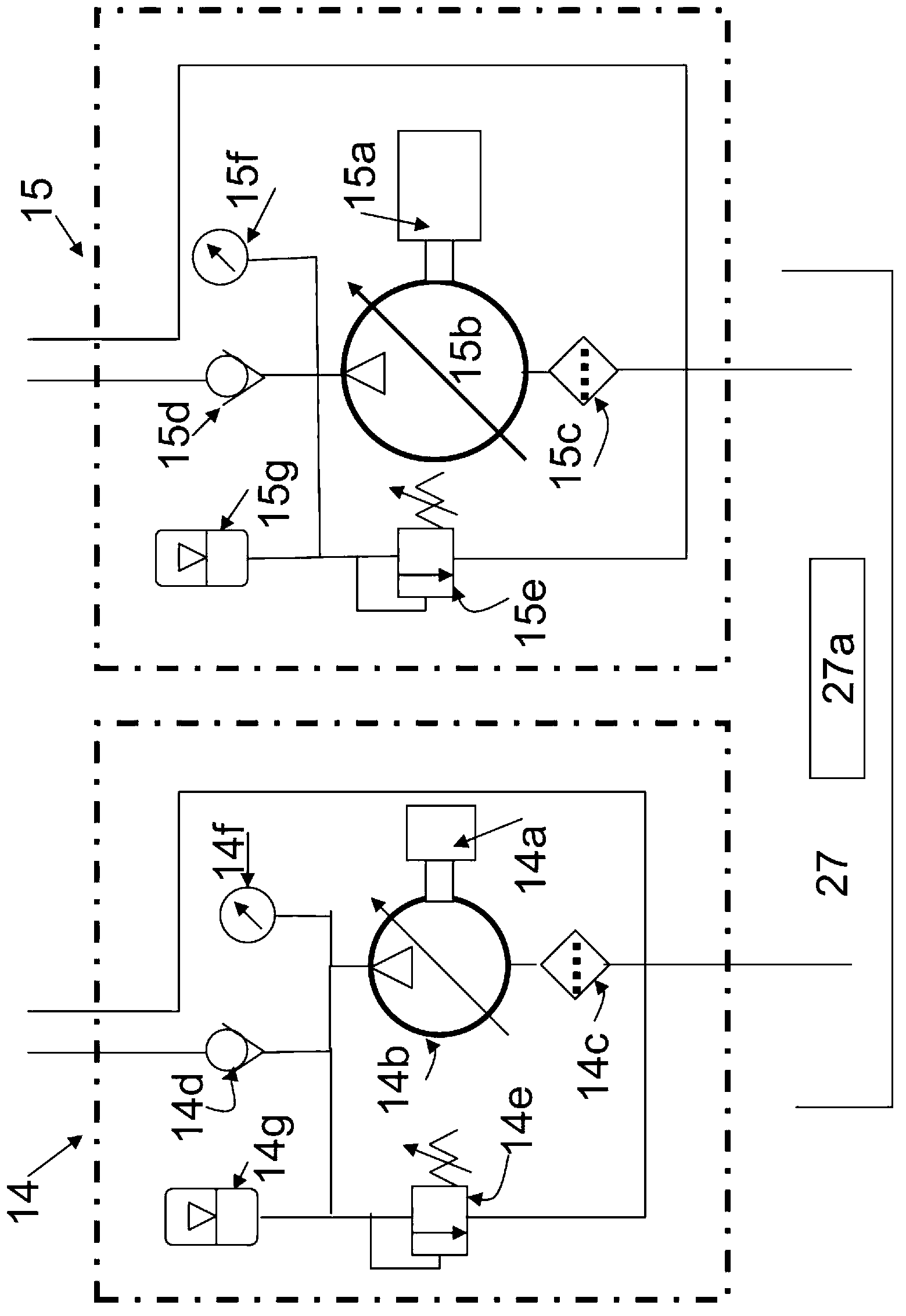

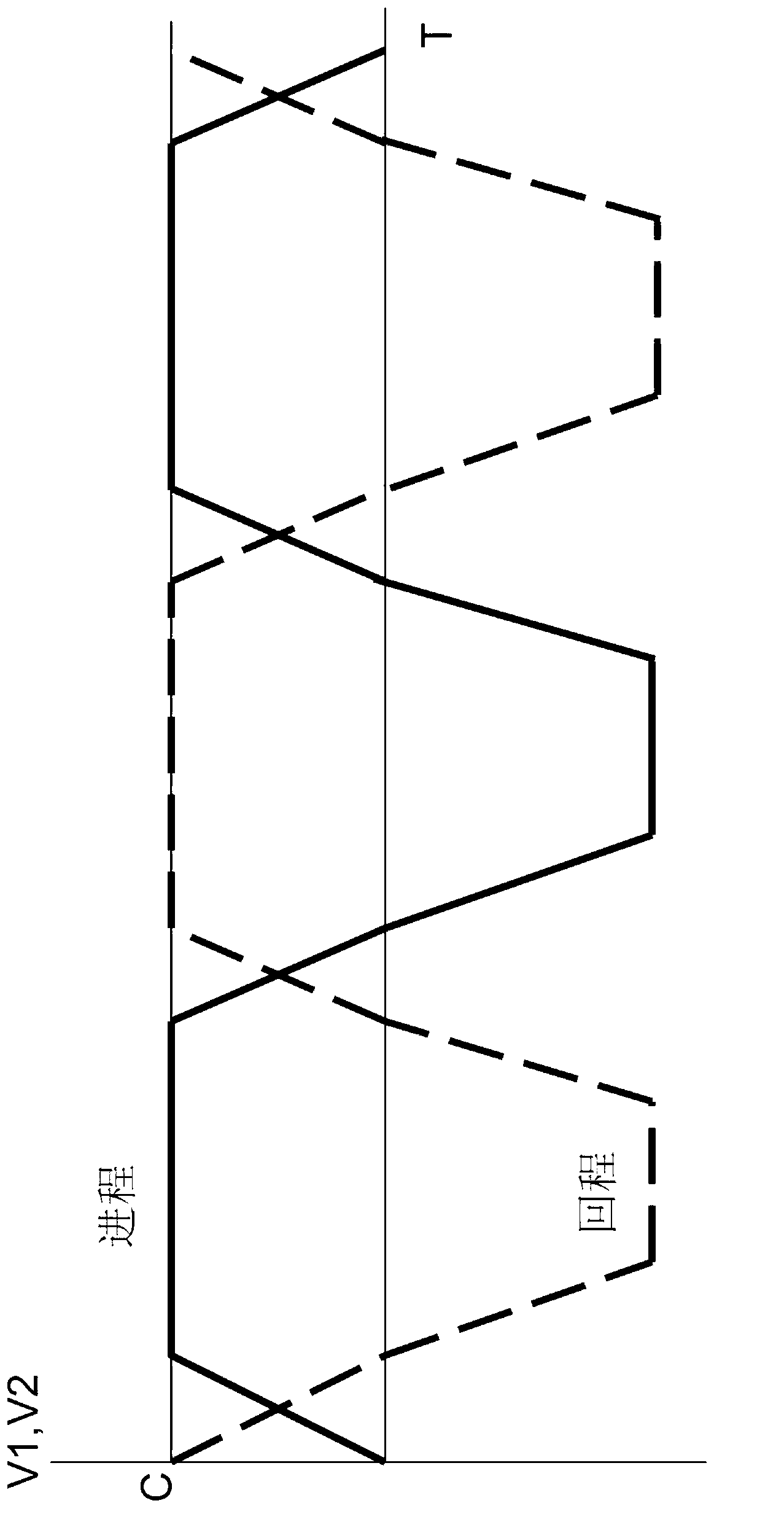

Membrane seawater desalination pressurization and energy recovery integrated method and device

ActiveCN102838186AReduce initial investment costHigh priceMembranesWater treatment parameter controlEngineeringEnergy recovery

The invention relates to a membrane seawater desalination pressurization and energy recovery integrated method and a membrane seawater desalination pressurization and energy recovery integrated device. Piston rods of single-rod seawater cylinders are connected with single-rod oil cylinders to form two or more working combined bodies which operate alternately; the oil cylinders drive the seawater cylinders to move back and forth; one piston cavities of the seawater cylinders suck high pressure strong brine in the process of moving forward and drain the high pressure strong brine in the returning process; and the other piston cavities of the seawater cylinders suck raw seawater in the returning process, pressurize the raw seawater in the process of moving forward and continuously and stably output the pressurized high pressure raw seawater to a reverse osmosis membrane modulus.

Owner:北京赛美环能科技有限公司

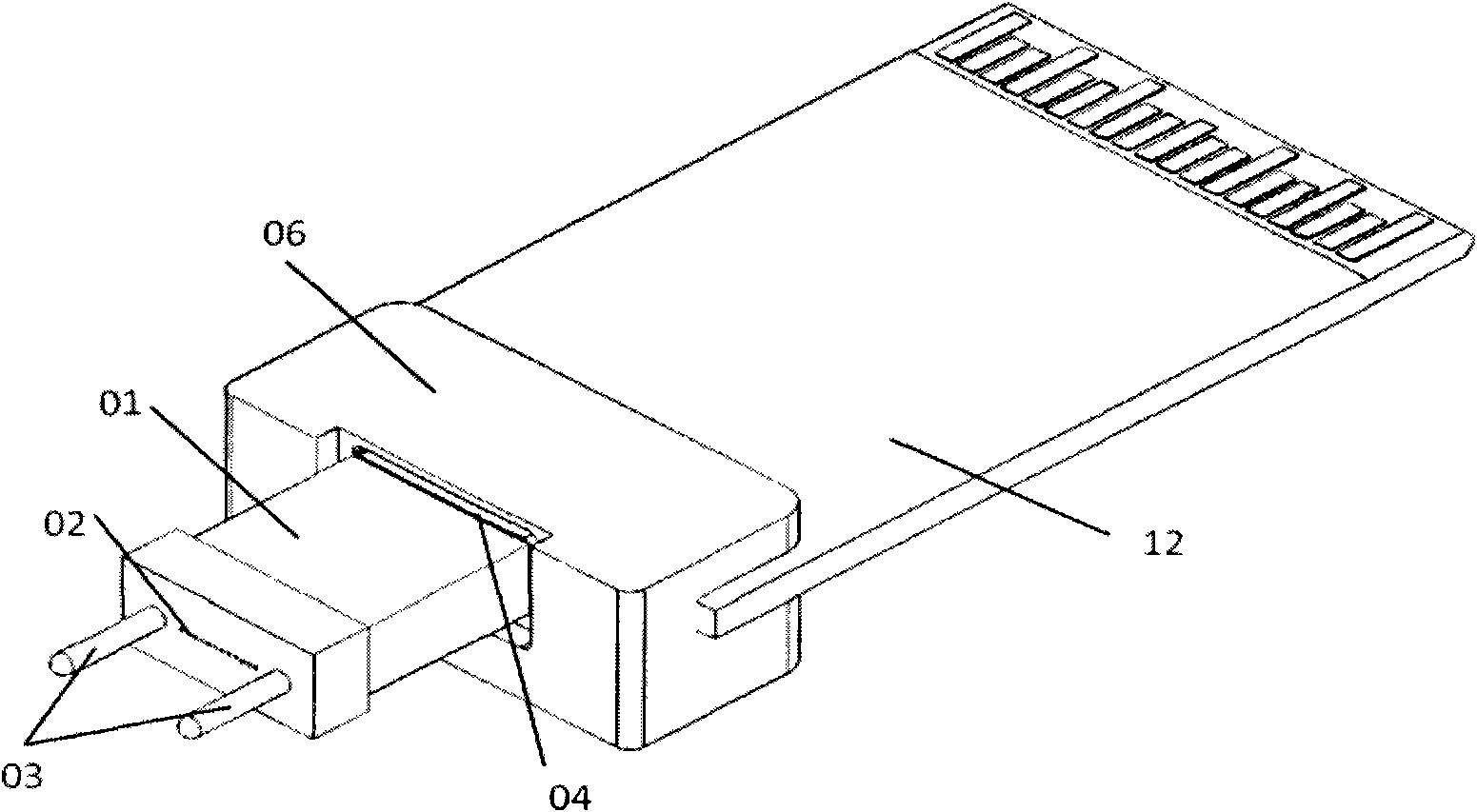

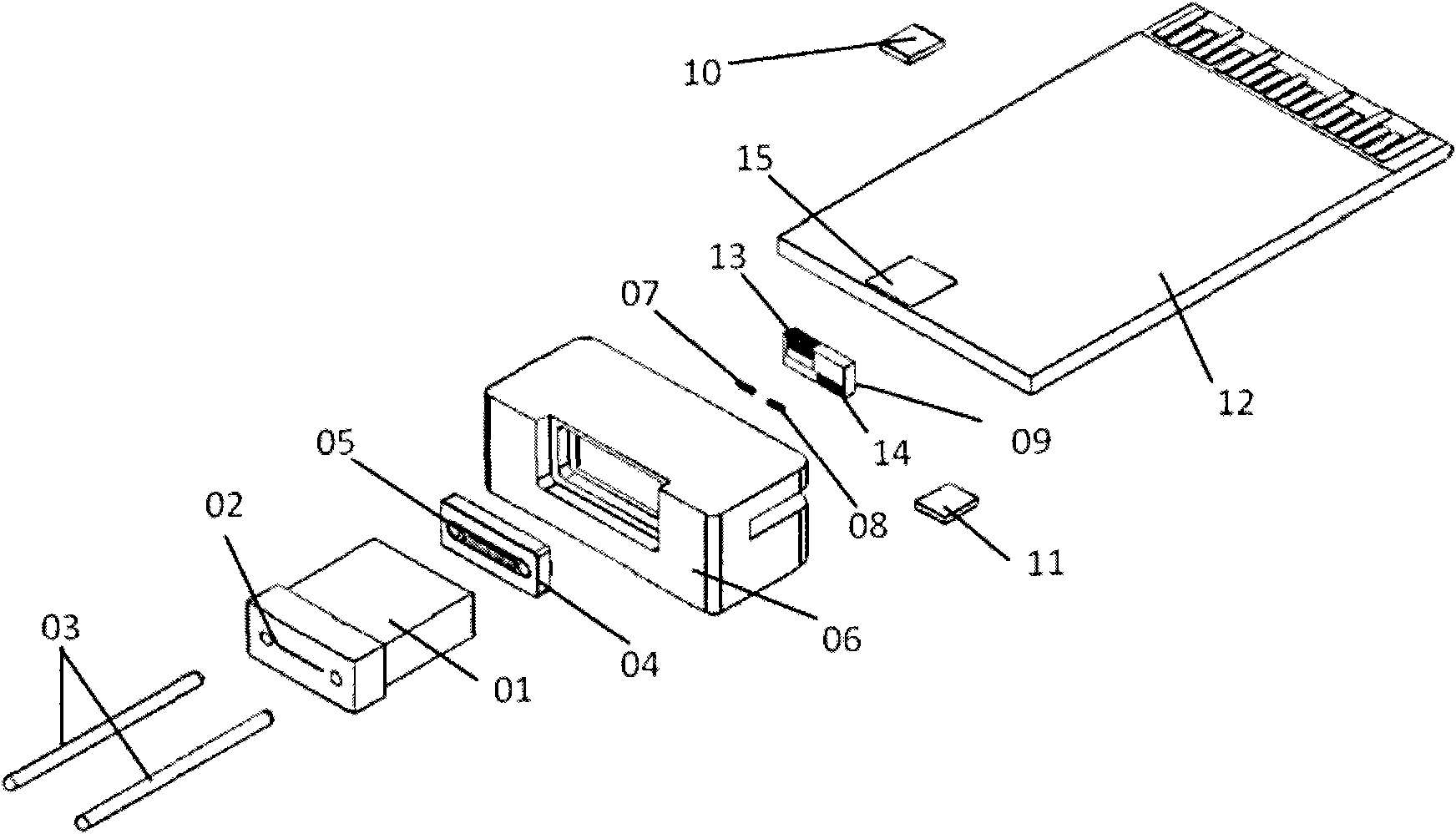

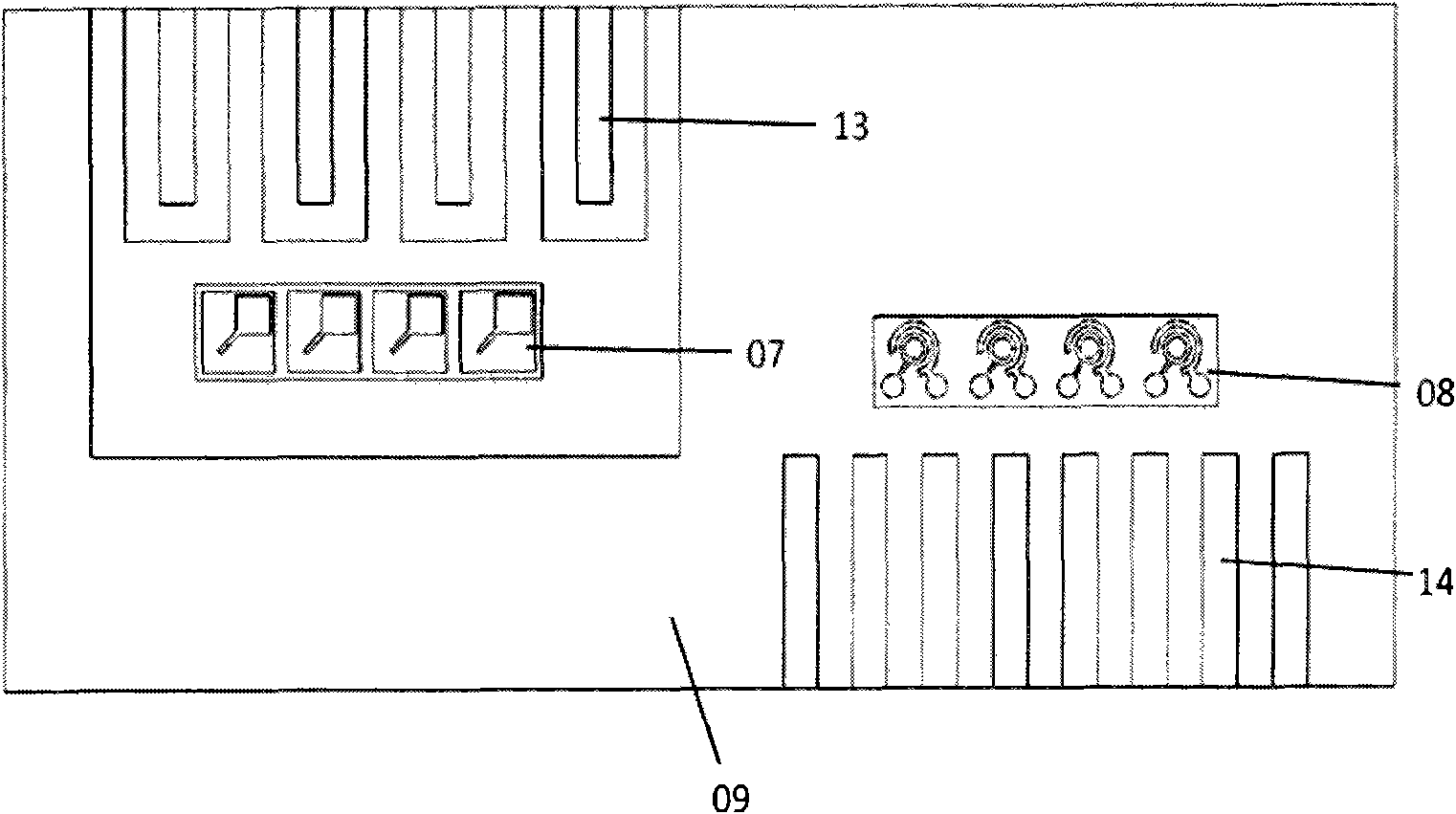

Light receiving and transmitting assembly for broadband parallel optics

InactiveCN102183829AReasonable distributionShorten the lengthCoupling light guidesFiber arrayOpto electronic

The invention relates to a light receiving and transmitting assembly for broadband parallel optics, which comprises an MT (Manual Transmission) type optical connector and a lens base butted with the MT type optical connector, wherein the MT type optical connector is internally provided with linearly and uniformly arranged optical fiber arrays, the lens base is internally embedded with linearly and uniformly arranged lens arrays, the lens arrays and the optical fiber arrays in the MT type optical connector are aligned and coupled; and a VCSEL (Vertical Cavity Surfaceemitting Laser) array and a PD (Photoelectric Detector) array are assembled on a substrate and respectively connected with a conductive gold wire in a routing manner, the substrate is fixed and attached on the side surface of a PCBA (Printed Circuit Board Assembly) support member in a routing connection manner, a laser drive chip and a detector TIA (Totally Integrated Automation) chip are respectively arranged on an upper surface electrode and a lower surface electrode of the PCBA support member, and the PCBA support member connected with the substrate is abutted with the MT type optical connector connected with the lens base. The invention has the advantages of increasing the coupling efficiency of photoelectric devices and optical fibers, remarkably improving elements on the aspects of flexibility, process difficulty and the like, and meeting demands on parallel light receiving and transmitting.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

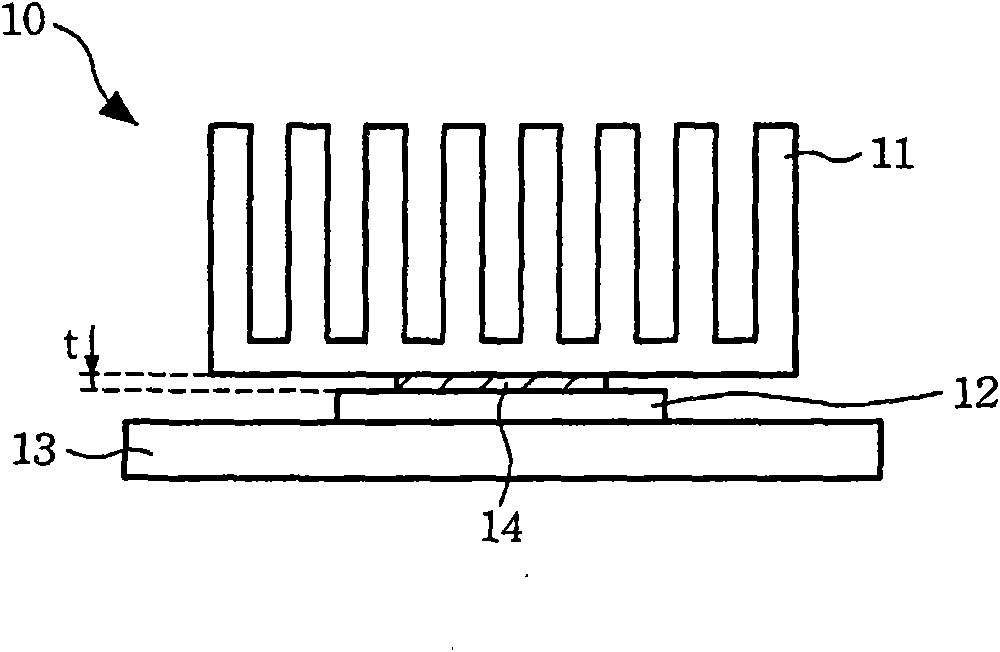

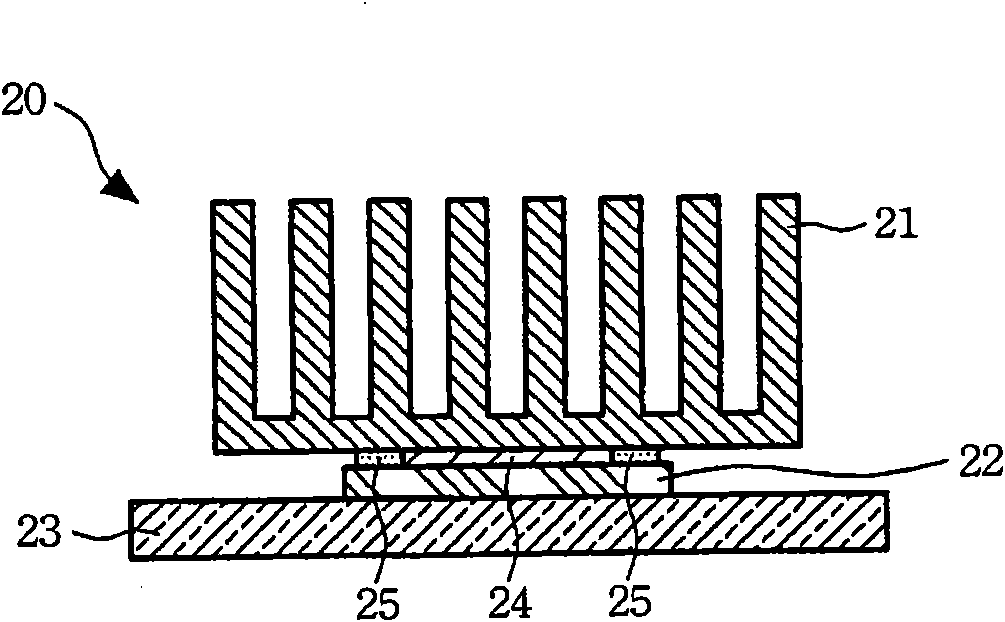

Heat radiation die set and radiation system applying phase change metal thermal interface material

InactiveCN101557697AAvoid the problem of liquid phase spillageAvoid spillingSemiconductor/solid-state device detailsSolid-state devicesElectronic componentPhase change

The invention relates to a heat radiation die set and a radiation system applying a phase change metal thermal interface material. The heat radiation die set and the heat radiation system can ensure that heat generated by the operation of an electronic element can be rapidly transmitted to outside environments. The heat radiation die set comprises a radiator and a phase change metal thermal interface material (TIM), wherein the radiator is arranged above the electronic element, and the bottom surface of the radiator is at least provided with a slot. The phase change metal thermal interface material is arranged between the electronic element and the bottom surface of the radiator, and is used as a thermal interface material between the electronic element and the radiator. When the phase change metal thermal interface material is melted by heating, part of hot melting liquid can flow into the slot so as to prevent the superfluous hot melting liquid from leaking out of a thermal interface.

Owner:萧复元

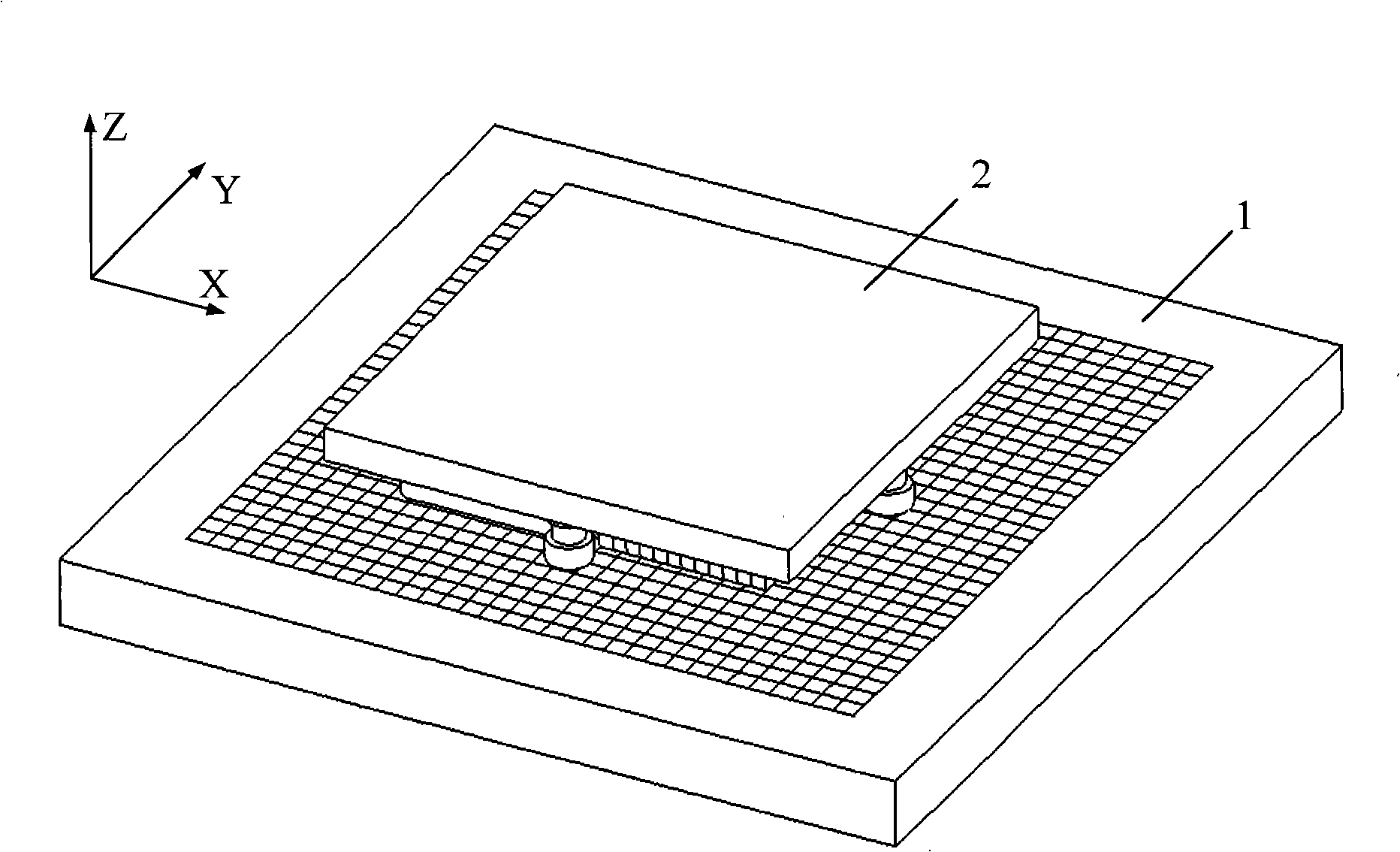

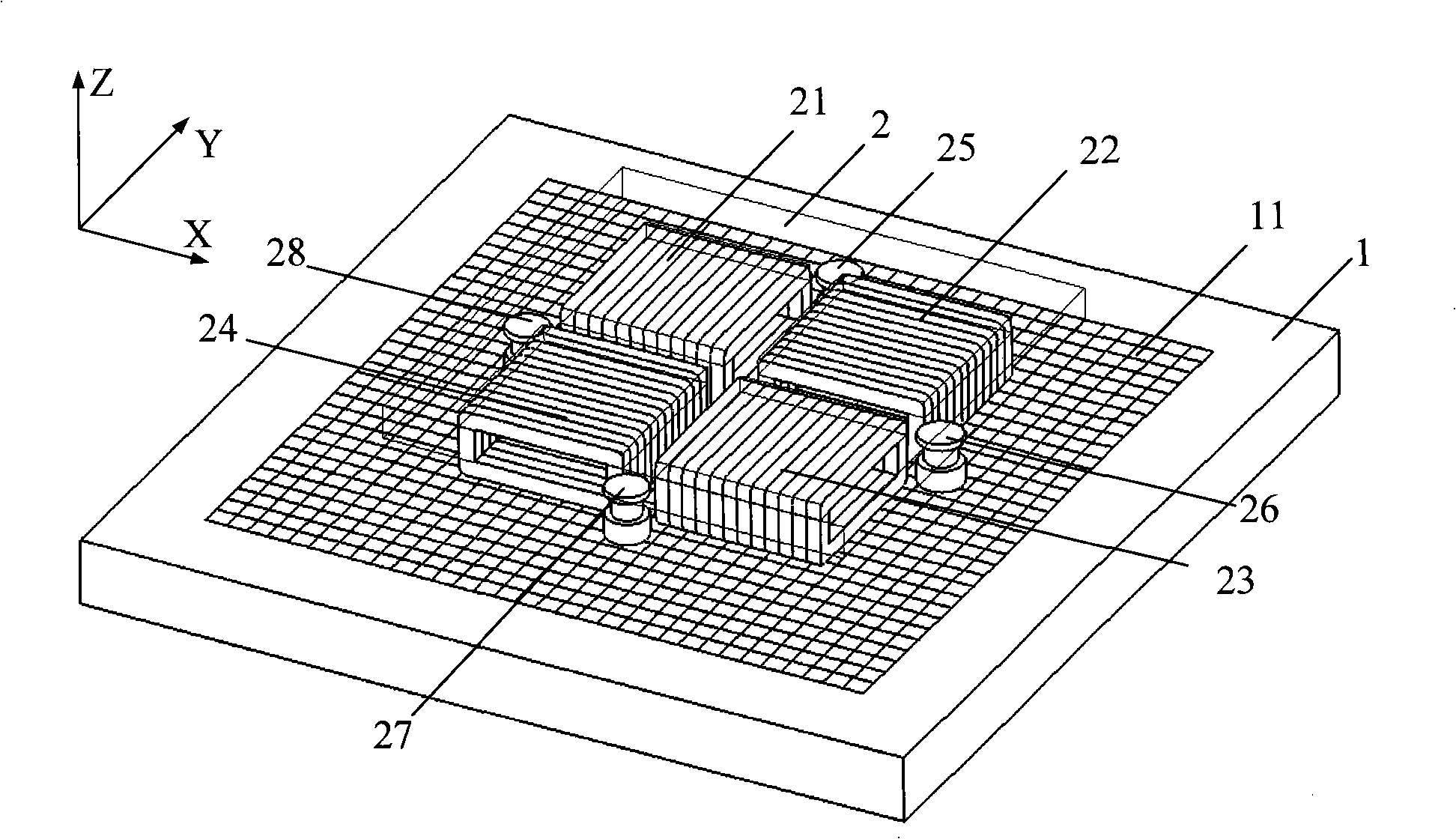

Gas-magnet mixing suspended planar motor with easily expanded horizontal stroke

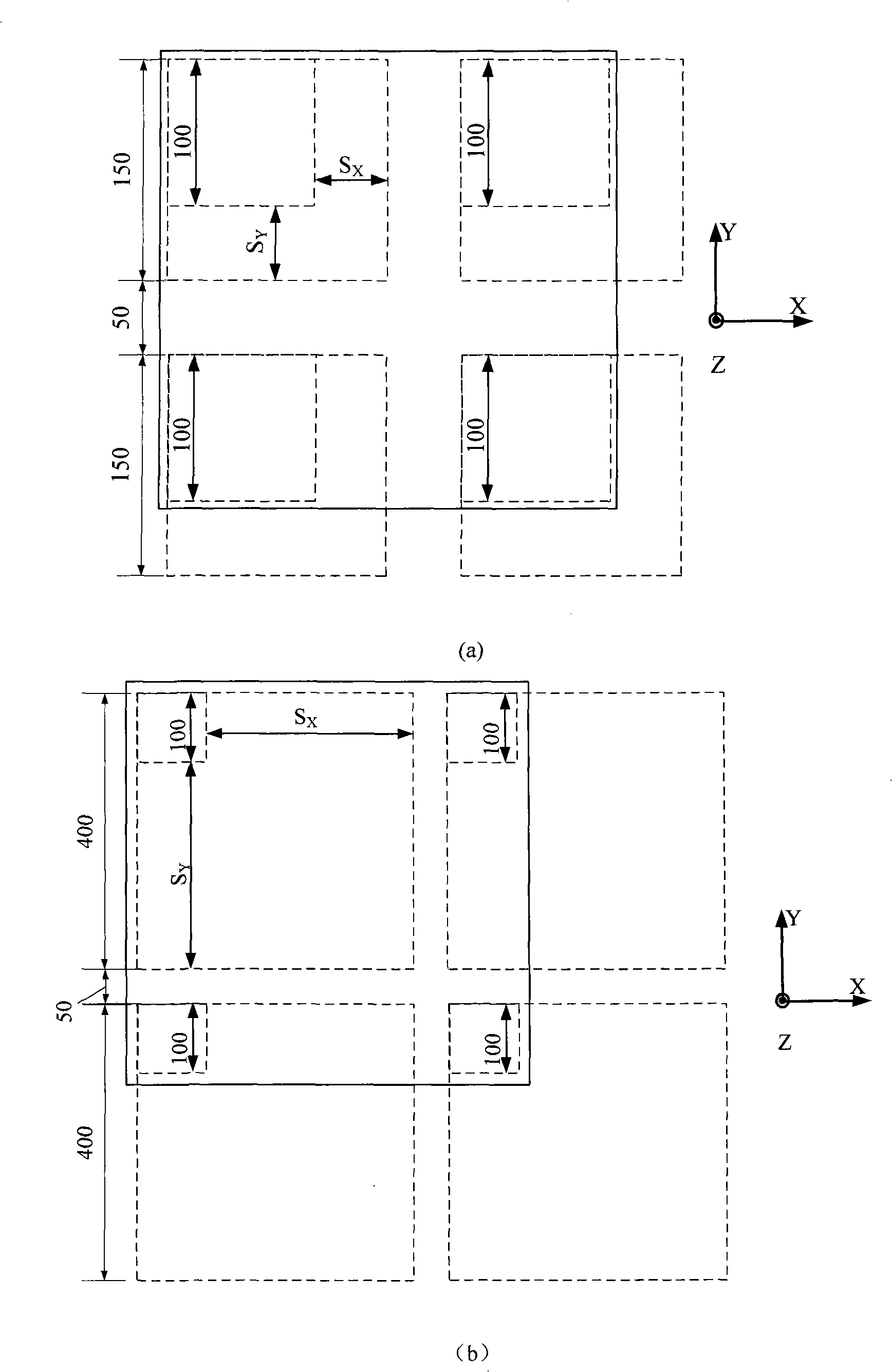

InactiveCN101527484ASimple mechanical structureReduce processing difficultySynchronous machinesMagnetic holding devicesClassical mechanicsMagnetic poles

The invention relates to a gas-magnet mixing suspended planar motor with easily expanded horizontal stroke, comprising a stator basal body arranged along a horizontal XY plane and a mover basal body suspended on the stator basal body and is parallel with the stator basal body. Two degrees of freedom Halbach permanent magnet arrays with wavelengths along the axis X and the axis Y directions are embedded on the surface of the stator basal body; each pair of magnetic poles of the two degrees of freedom Halbach permanent magnet arrays are formed by arraying first magnet to sixth magnet according to a four* four matrix; four corners of the lower surface of the mover basal body are respectively provided with a first thrust winding, a second thrust winding, a third thrust winding and a fourth thrust winding, wherein the wavelength direction of the first thrust winding and the third thrust winding are in the axis X direction; the wavelength direction of the second thrust winding and the fourth thrust winding are in the axis Y direction; four sides of the lower surface of the mover basal body are respectively provided with a first aerostatic bearing air-cushion, a second aerostatic bearing air-cushion, a third aerostatic bearing air-cushion and a fourth aerostatic bearing air-cushion.

Owner:SOUTHEAST UNIV

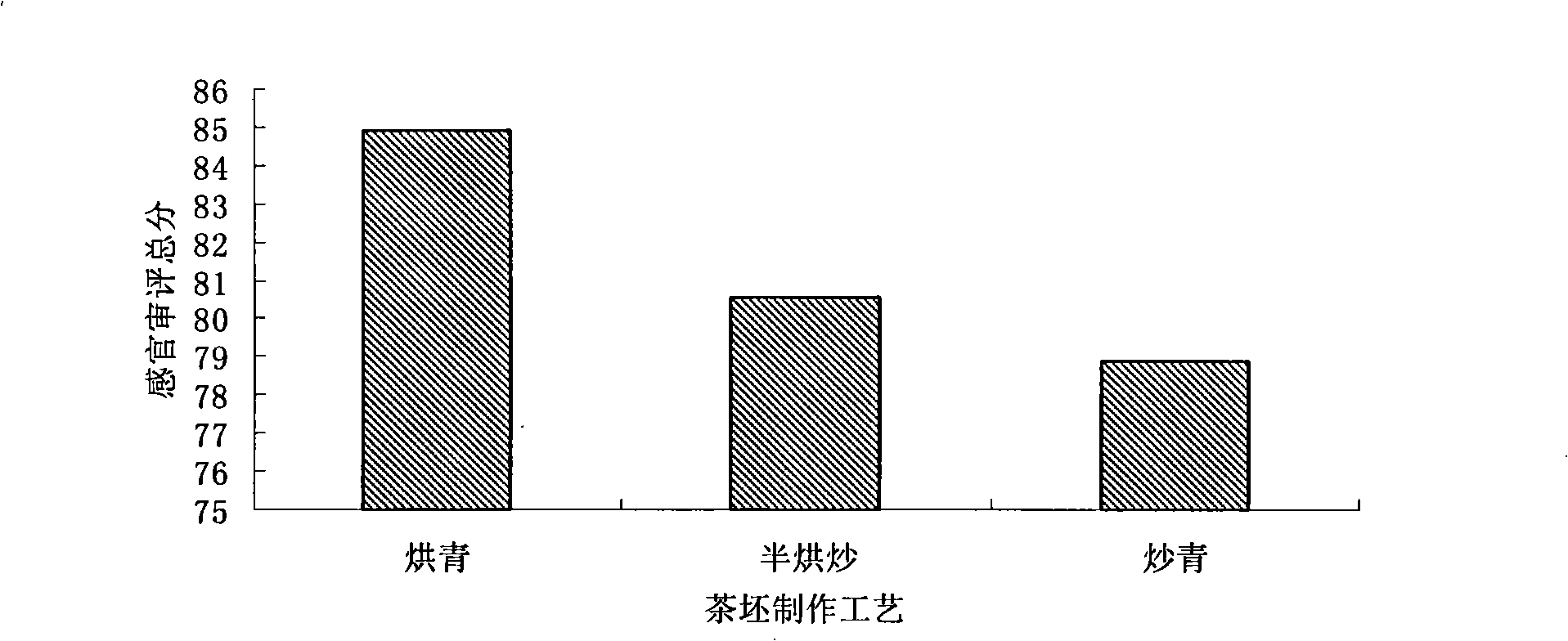

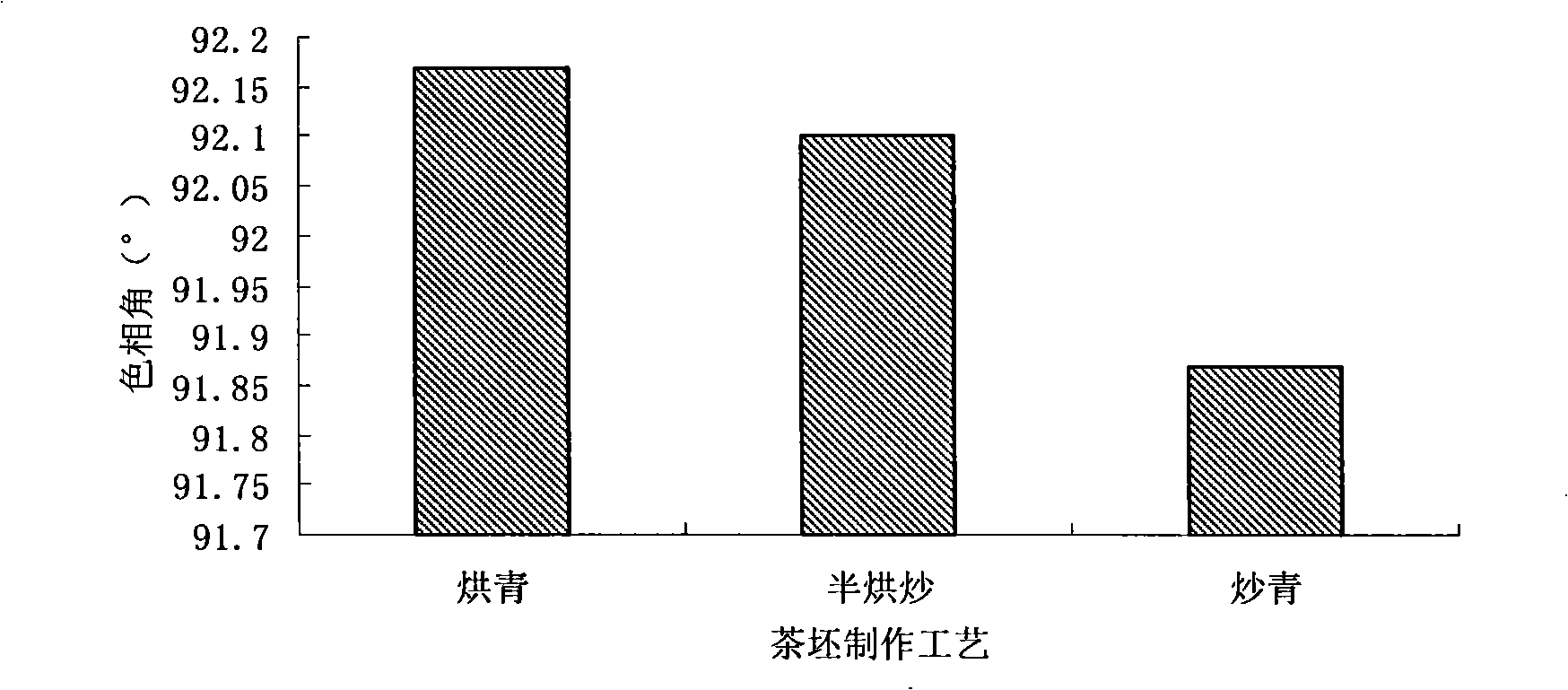

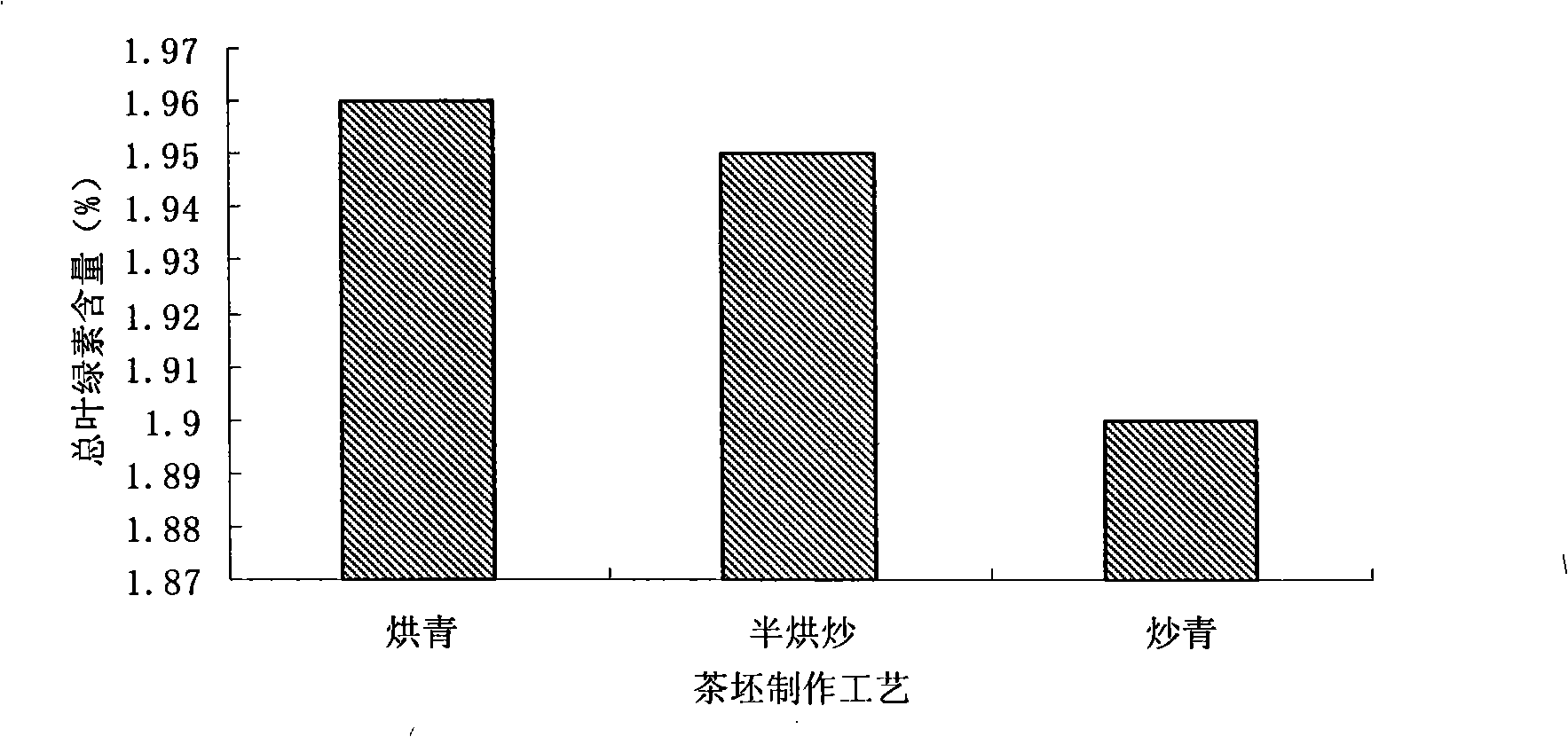

Production method of Japan allspice flower tea

InactiveCN101336663APromote structural adjustmentConducive to commercial productionPre-extraction tea treatmentFlavorWax

The invention belongs to the field of tea technology, which relates to a new preparation method of calyx canthus flower tea. The invention has the characters of plucking the fresh sprouts or leaves of tea tree, drying to premiere green tea, processing the tea with the two-scenting technology, aromatizing, scenting, drying and flowers-removing. The calyx canthus flower tea, which is the product of this invention, has the typical smell of calyx canthus flower, can keep fresh for a long time, the tea liquor has the color of light yellow and green with fresh flavor, the tea leaves bottom has the color of light yellow and green. The calyx canthus flower tea not only has the beautiful shape of good tea, but also has the light scent of calyx canthus flower, a novel flower tea is provided for customers.

Owner:HUAZHONG AGRI UNIV

Method for preprocessing stalk with alkali and ozone

InactiveCN101121175AImprove degradation rateLow costSolid waste disposalMacromolecular SubstancesPesticide

The invention belongs to the technical field of agricultural waste straw treatment, and specifically relates to a straw degradation pretreatment technology, which solves the problems of long processing time of existing straw biological or physical and chemical treatment methods, low degradation rate caused by difficult degradation of straw lignin and cellulose, etc. . Alkaline ozone pretreatment method of straw, mixing crushed straw with lime water, wherein straw (according to dry matter) accounts for 3%-15% of the total feed liquid, and lime accounts for 0.3%-1% of the total feed liquid , Introduce low-flux ozone into the mixed material liquid, and then let it stand. The invention kills all kinds of harmful bacteria carried in the straw, decomposes the pesticides that may remain in the straw, destroys the structure of the lignin and cellulose of the straw, and converts some macromolecular substances that are difficult to decompose into small molecules that are easy to degrade Substances, improve the degradation rate of lignin and cellulose in the straw during subsequent treatment, and speed up the subsequent treatment of straw.

Owner:上海特石生态科技有限公司

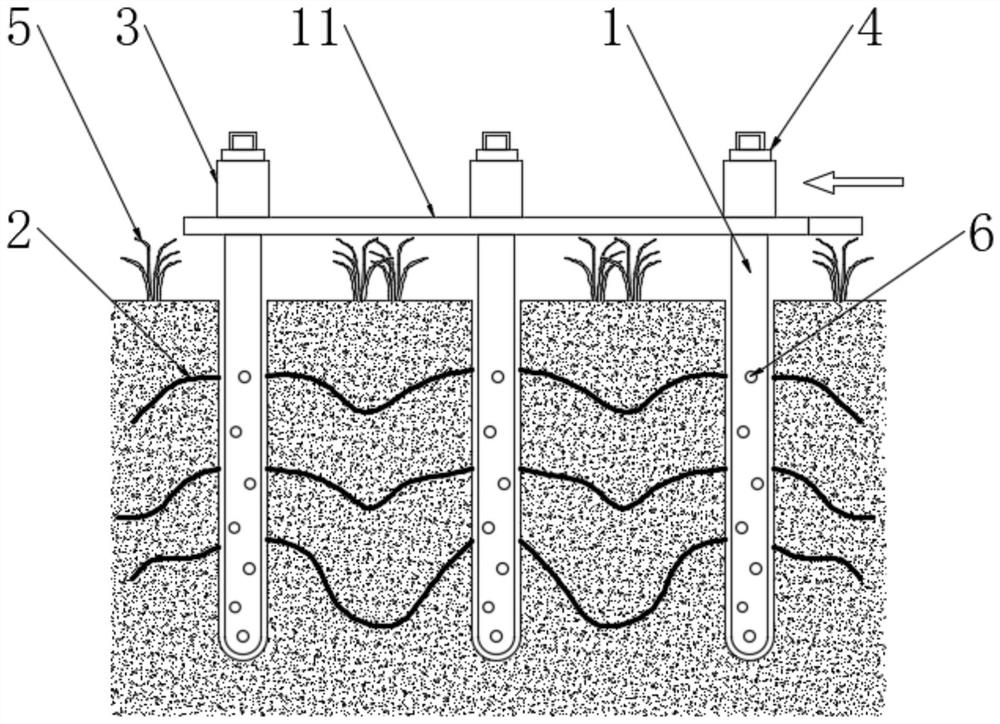

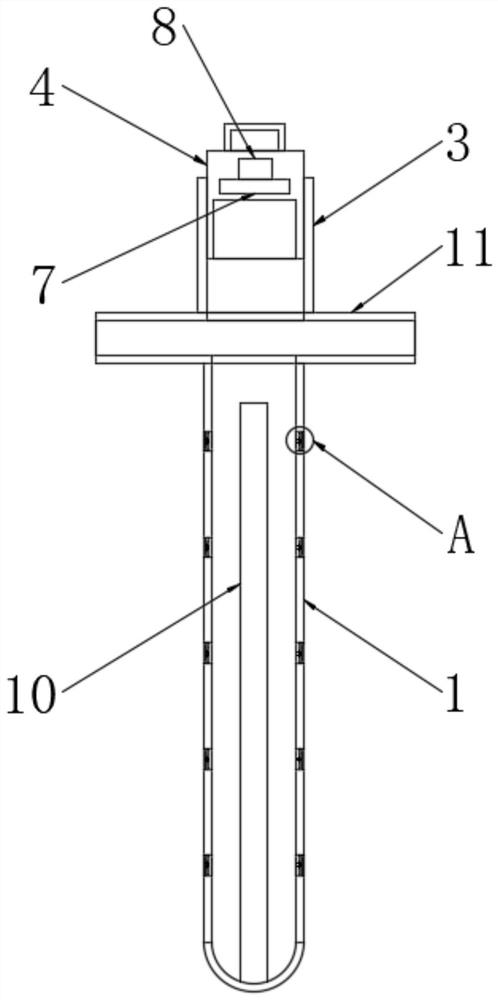

A parallel restoration method for farmland heavy metal pollution

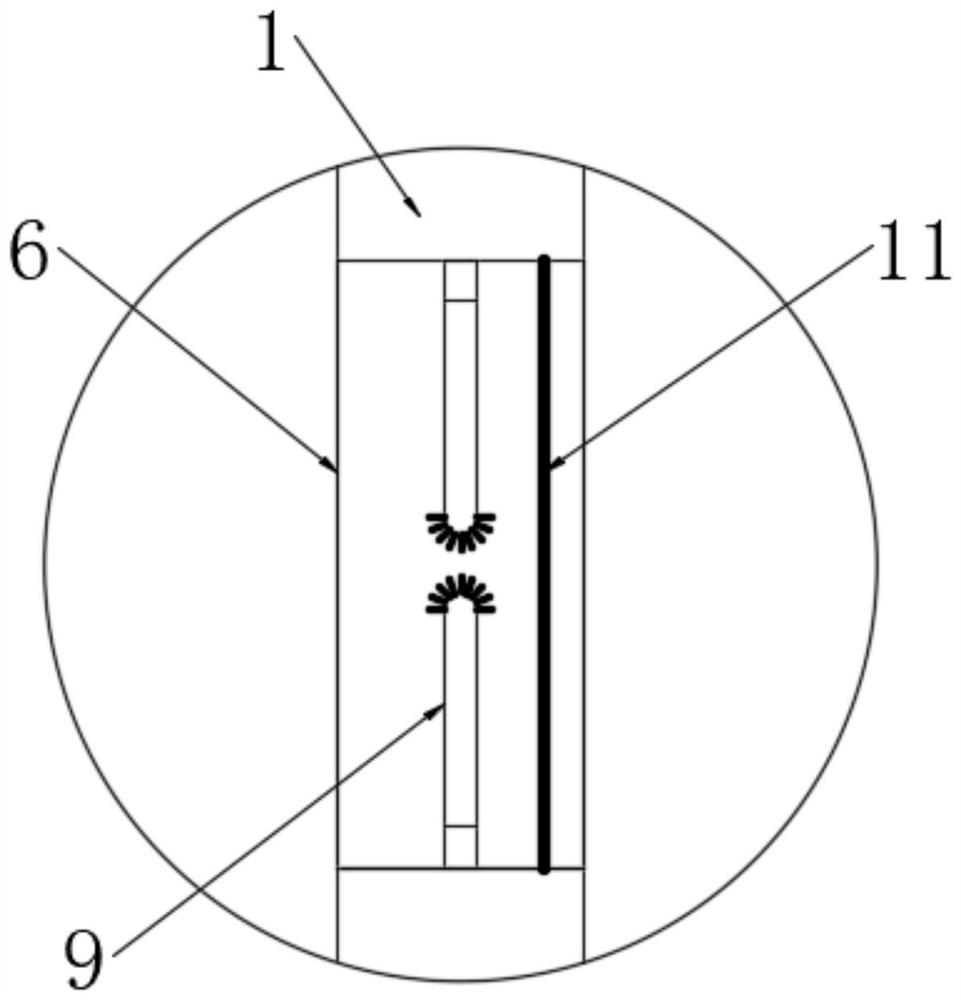

ActiveCN111589851BImprove propertiesImprove repair efficiencyContaminated soil reclamationSoil-working methodsMagnetic effectSoil science

The invention discloses a parallel restoration method for heavy metal pollution in farmland, which belongs to the technical field of heavy metal pollution restoration. It can be implemented by embedding repair rods in the soil, and uniformly discharging and collecting materials through the soil filter screen, so as to directly The way of water injection penetrates into the soil autonomously, and is doped with heavy metal scavenger and repair microspheres. The heavy metal scavenger uses the infiltration of water to capture the heavy metal ions in the soil and forms insoluble substances, while the repair microspheres infiltrate simultaneously In the process of peeling off the surface, the nutrients are continuously released into the soil to improve the soil properties. At the same time, the insoluble heavy metals are adsorbed and captured, and the magnetic effect of the repair microspheres is used to assist diffusion in the soil and intersect to form a tight repair. Finally, the residual repair microspheres and heavy metals are recovered through a magnetic field, which not only significantly reduces the cost of repair, but also greatly improves the efficiency and effect of repairing heavy metal pollution in farmland.

Owner:广西盎之然环保科技有限公司

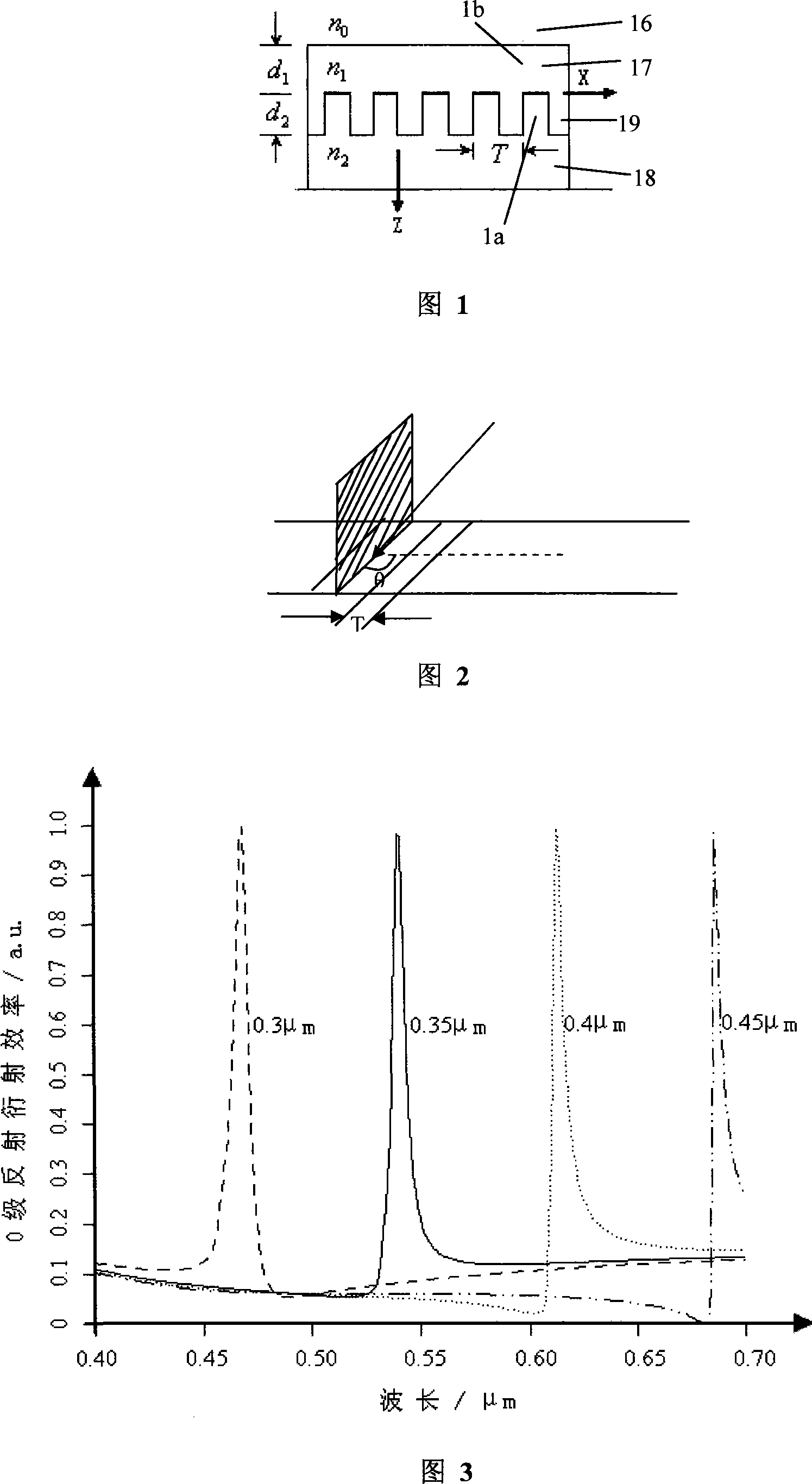

False proof structure used for card and certificate and its identifying method

InactiveCN101100156AProminent visual featuresEasy to identifyLight effect designsCharacter and pattern recognitionGratingRefractive index

The present invention discloses anti-fake structure for cards, and the anti-fake card is provided with mark pattern comprising raster structure and features that the mark pattern includes at least two kinds of pattern areas with orthogonally arranged raster structures to constitute double visual channels. The raster structures have period of 300-500 nm, slot depth of 50-150 nm and filled transparent high refractive index dielectric layer of 20-30 nm thickness and refractive index higher than 1.6. The pattern of the present invention has obvious visual characteristic capable of being recognized easily and convenient identification of the truth. The micro anti-fake structure has structural data calculated based on strict coupled wave theory, is made by means of advanced electronic beam or laser beam interference photoetching technology, and possesses high safety.

Owner:SVG TECH GRP CO LTD +1

Frequency-selective broadband waveguide slot antenna array

ActiveCN101557040AImprove electromagnetic compatibilitySuppress interferenceAntenna arraysWaveguide type devicesFrequency bandPhysics

The invention relates to a frequency-selective broadband waveguide slot antenna array which solves the problem that the existing waveguide slot antenna has poor capacity of resisting out-of-band interference. The frequency-selective broadband waveguide slot antenna array comprises a radiating waveguide, a feeding waveguide, a coaxial connector and a radiating slot. Both the radiating waveguide andthe feeding waveguide are rectangular metal ridge waveguide tubes with a ridge inside and terminals closed and the metal ridges are respectively positioned at the central line of the bottom edge; thecoaxial connector is positioned in the center of the lower edge of the feeding waveguide; the metal ridge of the feeding ridge waveguide between the coaxial connector and coupled slots at both sidesis symmetrically provided with more than three grooves and the overall structure of the grooves is battlement-shaped and forms two waveguide evanescent-mode filters; and the two waveguide evanescent-mode filters have the same structure and are respectively positioned on the straight waveguide sections of the two output arms of a 3dB power splitter. The frequency-selective broadband waveguide slotantenna array protects the antenna from the interference of signals out of the work frequency band and has the advantages of low loss, reduced weight, no additional equipment, high reliability and compact structure.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

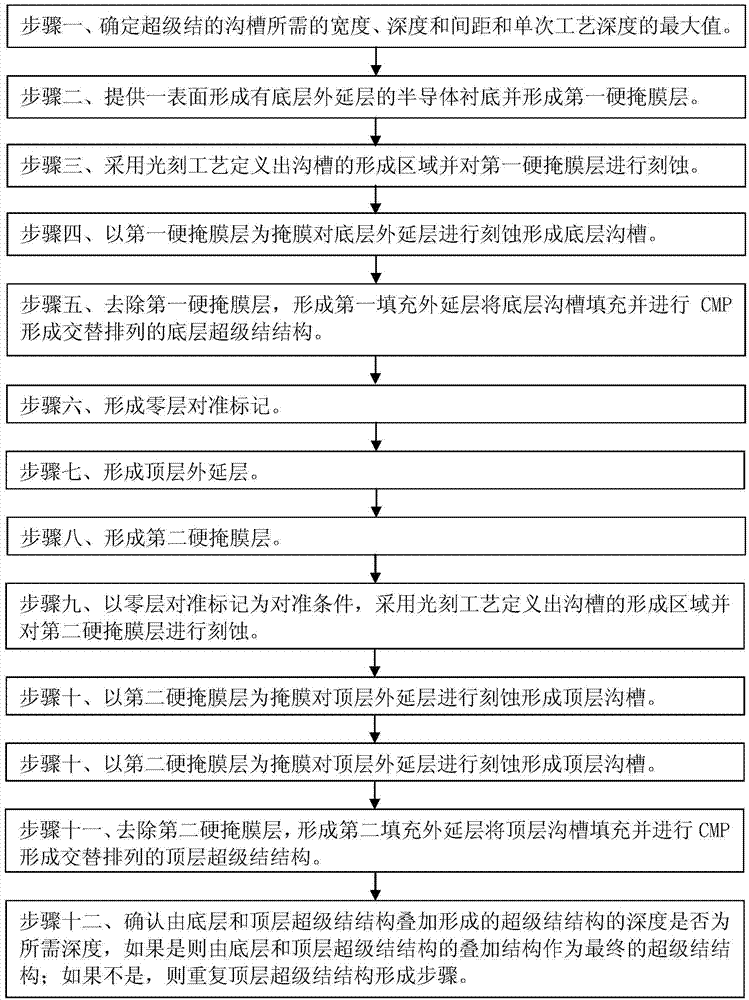

Manufacturing method of groove-type superjunction device

ActiveCN104779293AImprove in-plane uniformityImprove in-plane uniformity and increase trench aspect ratioSemiconductor/solid-state device manufacturingSemiconductor devicesSingle processEngineering

The invention discloses a manufacturing method of a groove-type superjunction device. The manufacturing method comprises the following steps as follows: determining groove size parameters and the maximum value of a single-process depth; providing a substrate, and forming a first hard mask layer; defining a groove forming region; etching a bottom epitaxial layer to form a bottom groove; removing the first hard mask layer, epitaxially filling the bottom groove, and performing CMP; forming a zero layer aligning mark; forming a top epitaxial layer; forming a second hard mask layer; with the zero layer aligning mark as a aligning condition, defining the groove forming region; etching the top epitaxial layer to form a top groove; removing the second hard mask layer, epitaxially filling the top groove, and performing CMP; checking whether the depth of a laminated superjunction structure reaches a required depth, if so, ending the manufacturing method, otherwise, repeating the top superjunction structure forming step. By the manufacturing method, reverse breakdown voltage of a superjunction device can be increased, the conduction resistance can be reduced, the existing equipment and the existing process can be utilized to the maximum extent.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

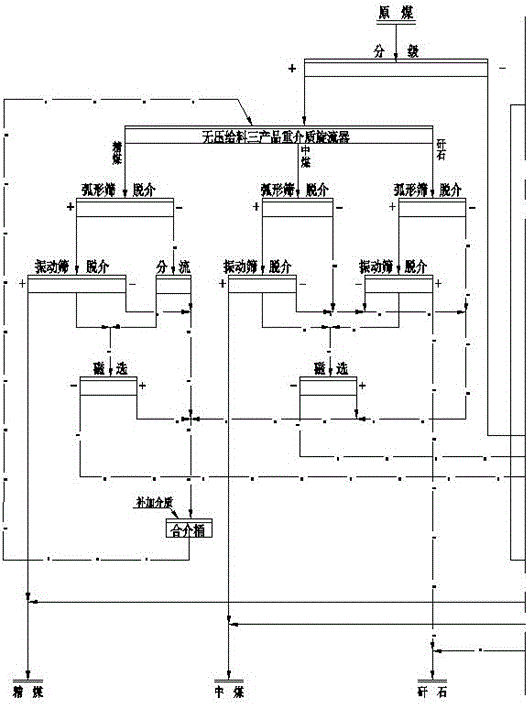

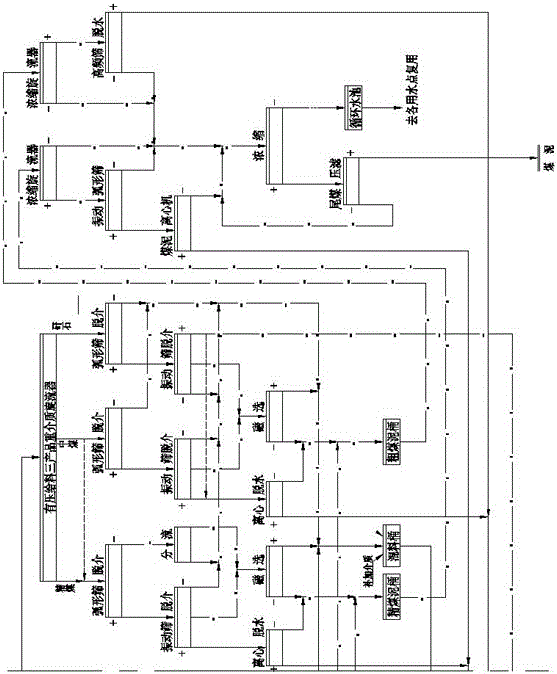

Steam coal all-grade selected and simplified heavy medium separation process

The invention discloses a steam coal all-grade selected and simplified heavy medium separation process. The process comprises classification; separation of coarse-particle coals; separation of fine-particle coals; medium and water removal of coarse-particle products; circulation, recovery and replenishing of coarse-particle coal mediums; medium and water removal of fine-particle products; and circulation, recovery and replenishing of fine-particle coal mediums. Coal slime is separated and recovered; after raw coals are classified, oversize products serve as the coarse-particle coals to enter a non-pressure three-product heavy medium cyclone for separation, and undersize products serve as the fine-particle coals to enter a pressure three-product heavy medium cyclone for separation; and after magnetic-separated tailing is concentrated, dehydrated and recovered, concentrate coal and medium coal products are doped. The coarse-particle coals are separated by the heavy-medium cyclone, so that the high-density separation of low-density suspension is realized, the separation density is reduced, the medium consumption is effectively reduced, and the wet mud removing link before separation of the fine-particle coals in a conventional process is saved; and the process is wide in application range, simple, convenient for operation, high in separation efficiency, flexible in product structure, low in production operation cost, low in capital investment and accordant with national environment protecting requirements.

Owner:TANGSHAN BRANCH COAL SCI ACAD

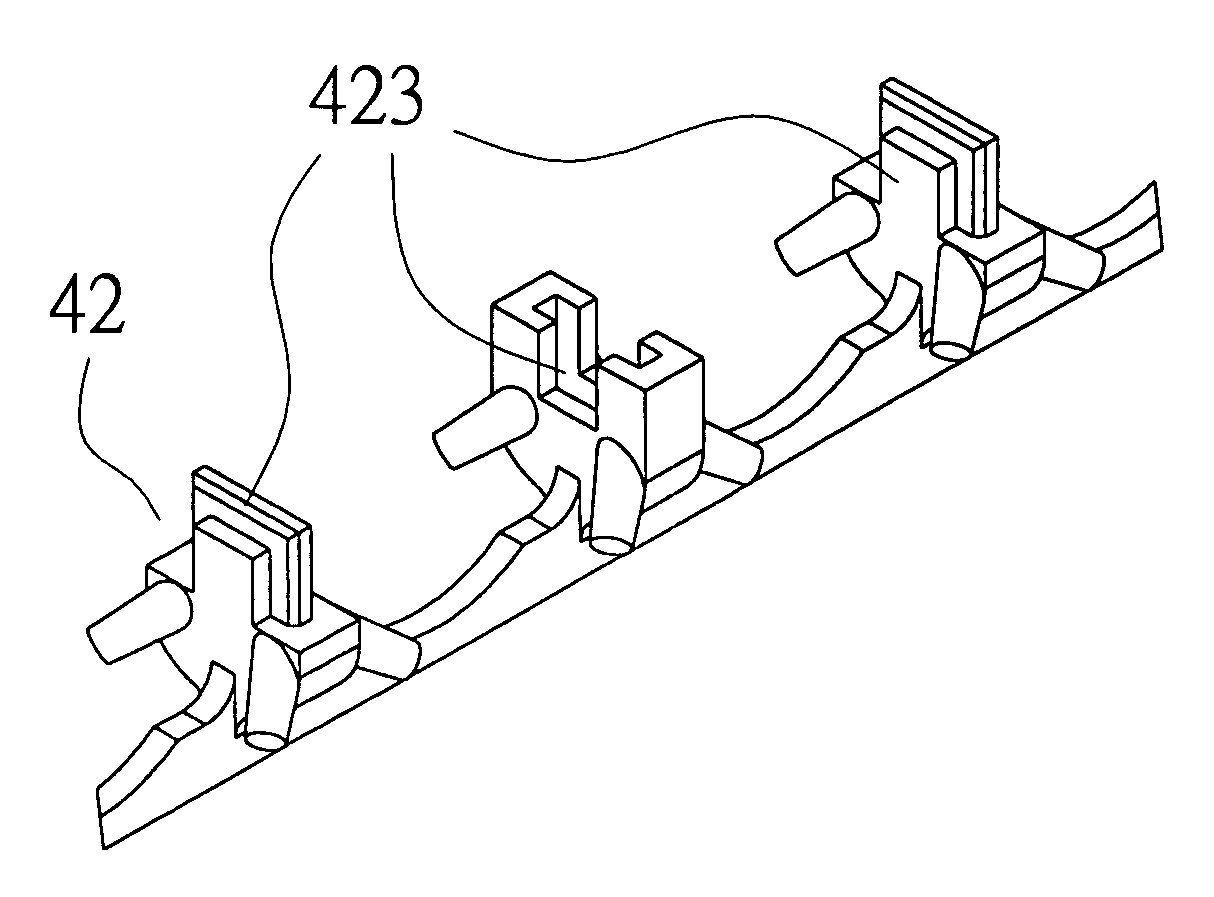

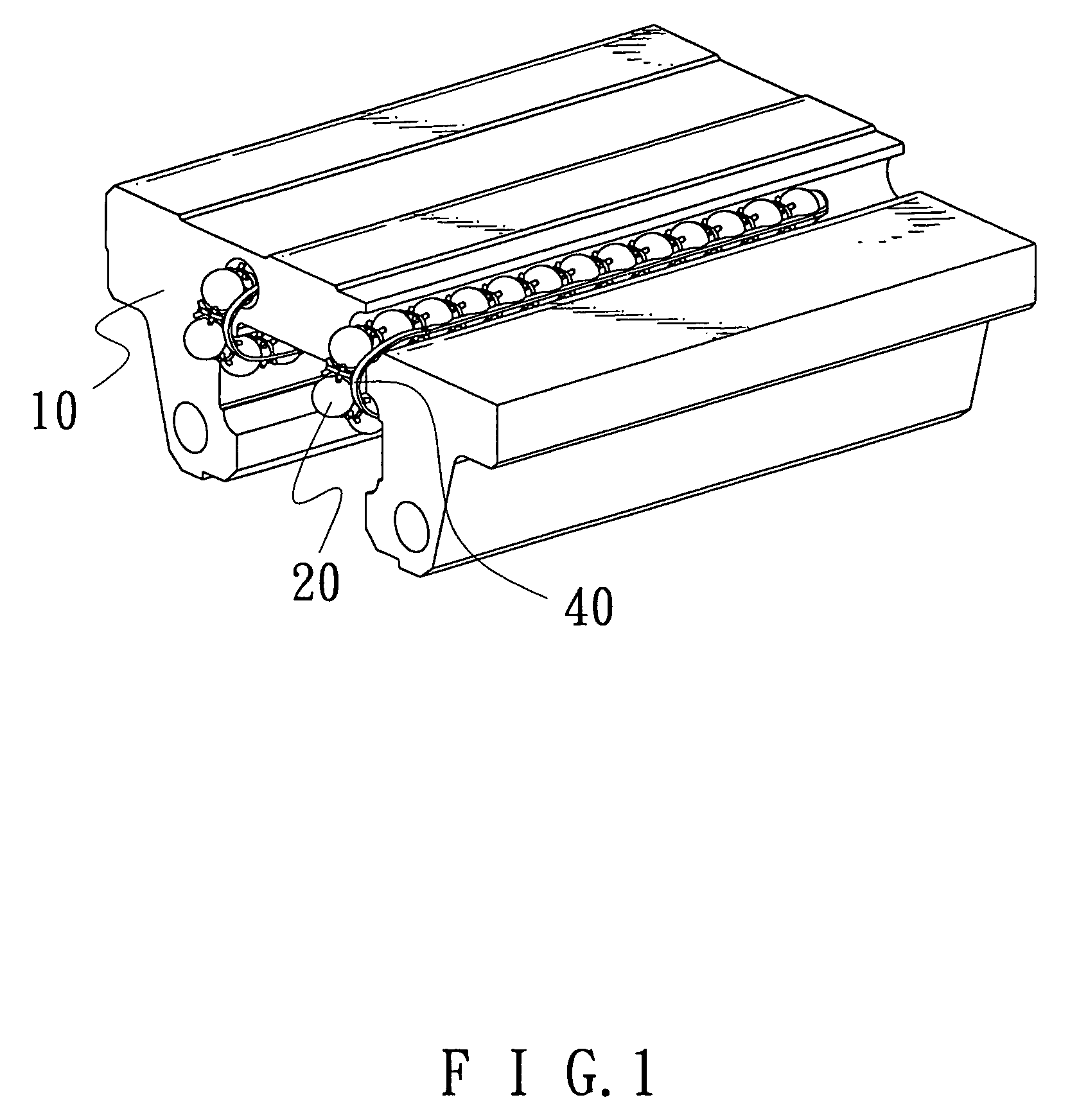

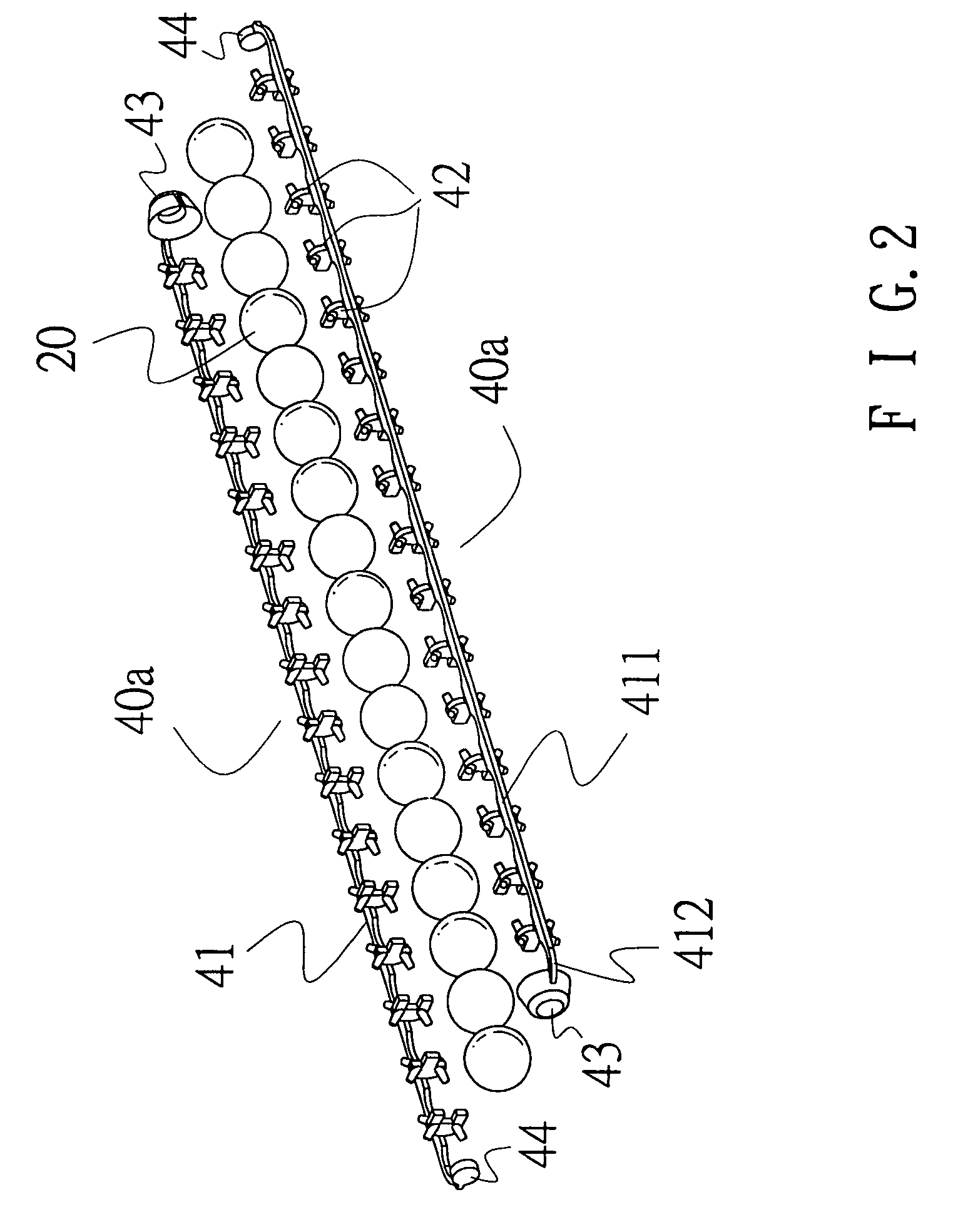

Clip-chain module of rolling unit

InactiveUS6966698B2Reduce frictionIncrease the difficulty of the processRolling contact bearingsLinear bearingsEngineeringMechanical engineering

Owner:HIWIN TECH

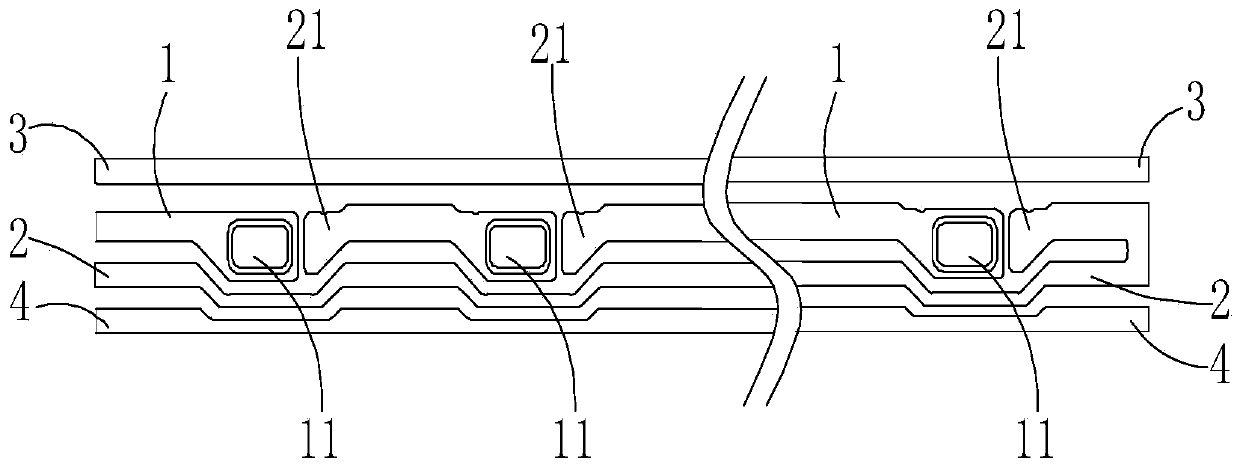

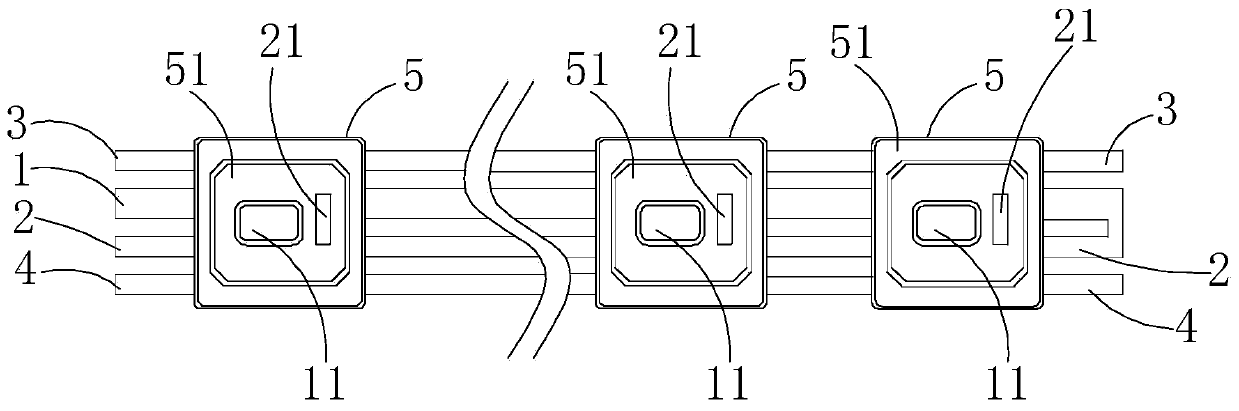

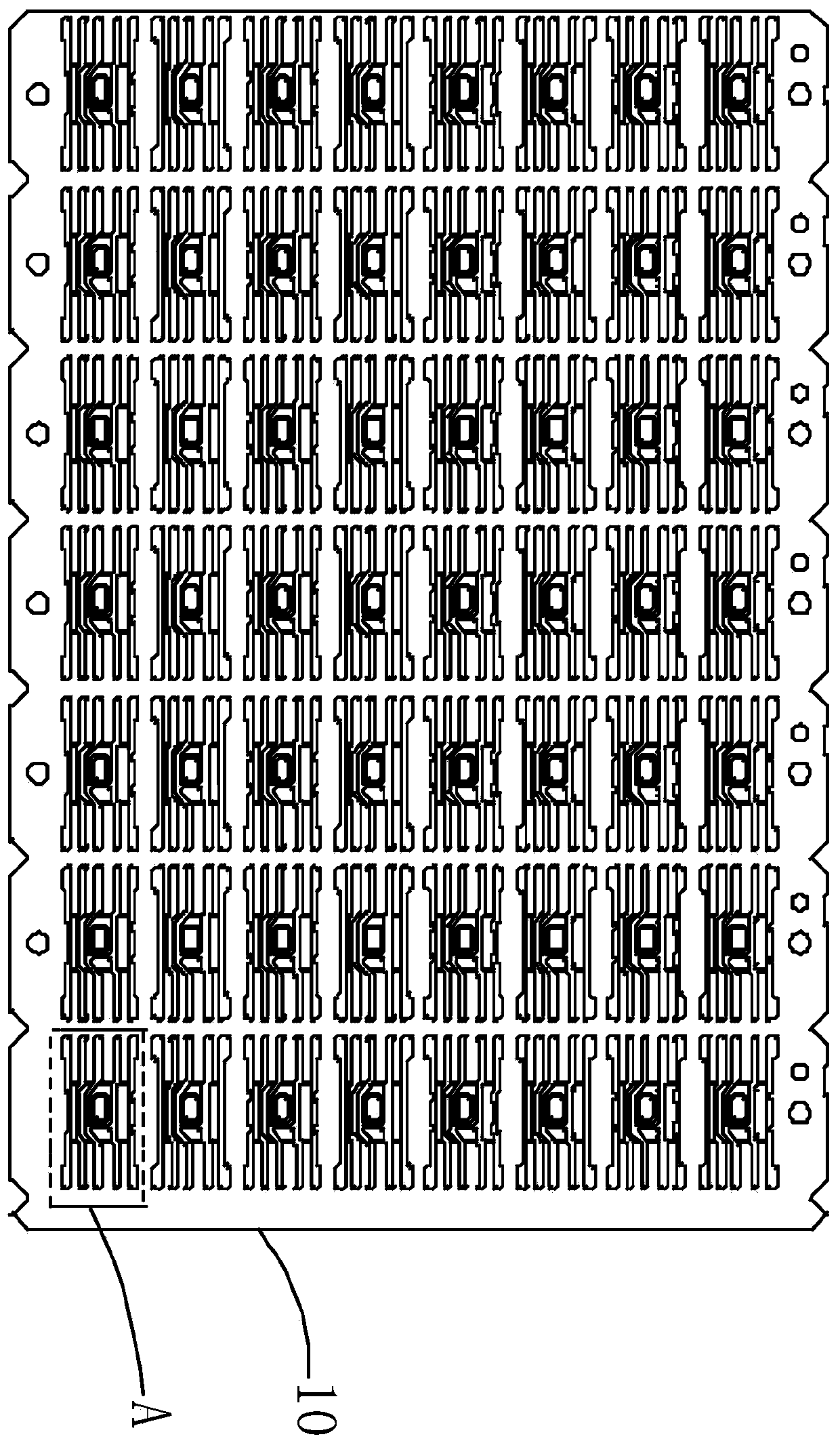

Modularized LED lamp strip and processing method thereof

InactiveCN103994359ALower the altitudeReduce manufacturing costElectric lightingSemiconductor devicesLED lampMechanical engineering

The invention discloses a modularized LED lamp strip and a manufacturing method thereof. The LED lamp strip comprises a positive pole metal wire and a negative pole metal wire, wherein the positive pole metal wire and the negative pole metal wire are connected with the input end of a rectifier. The LED lamp strip further comprises a positive pole metal base line and a negative pole metal base line, wherein the positive pole metal base line and the negative pole metal base line are connected with an LED chip and the output end of the rectifier, the positive pole metal wire, the negative pole metal wire, the positive pole metal base line and the negative pole metal base line are distributed in parallel, multiple plastic bases transversely wrapping the positive pole metal wire, the negative pole metal wire, the positive pole metal base line and the negative pole metal base line are arranged, the upper portions of the plastic bases are provided with a containing groove used for containing the LED chip, the bottom of the containing groove is exposed so that the positive pole metal base line and the negative pole metal base line of an electrode of the LED chip can be welded, and a light-pervious layer is further encapsulated on the surface, in the containing groove, of the LED chip. By means of the technical scheme, the height of an LED lamp can be effectively reduced, processing is easier, processing efficiency is higher, production cost is effectively lowered, troubles of externally connecting a power supply line are omitted, and application approximates to perfectness.

Owner:吴锦星 +1

Expanding and extruding connection method for mechanical connection of plastic pipes

InactiveCN102032413ALifetime SynchronizationFirmly connectedJoints with sealing surfacesPipe connection arrangementsEngineeringTensile ductility

The invention relates to an expanding and extruding connection method for mechanical connection of plastic pipes, specifically comprising the following steps of: (1) expanding the inner diameter of each plastic pipe connection part by 10-25 percent by using a pipe expander and utilizing the stretching ductility of the plastic pipes; and (2) connecting the plastic pipes by adopting a plastic expanding and extruding connector comprising a plastic connector and a plastic nut, sleeving the plastic nut on the plastic pipe, inserting an insertion part of the plastic connector to a connection part of the plastic pipes, fastening the plastic nut on an outer thread of the plastic connector, enabling ribbed edges to clamp the inner wall of the connection part of the plastic pipes, and storing an extruded deformation part of the plastic pipeline into a concave ring. The expanding and extruding connection method of the invention is convenient, concise and reliable to connect various plastic pipelines.

Owner:上海三山信邦科技有限公司

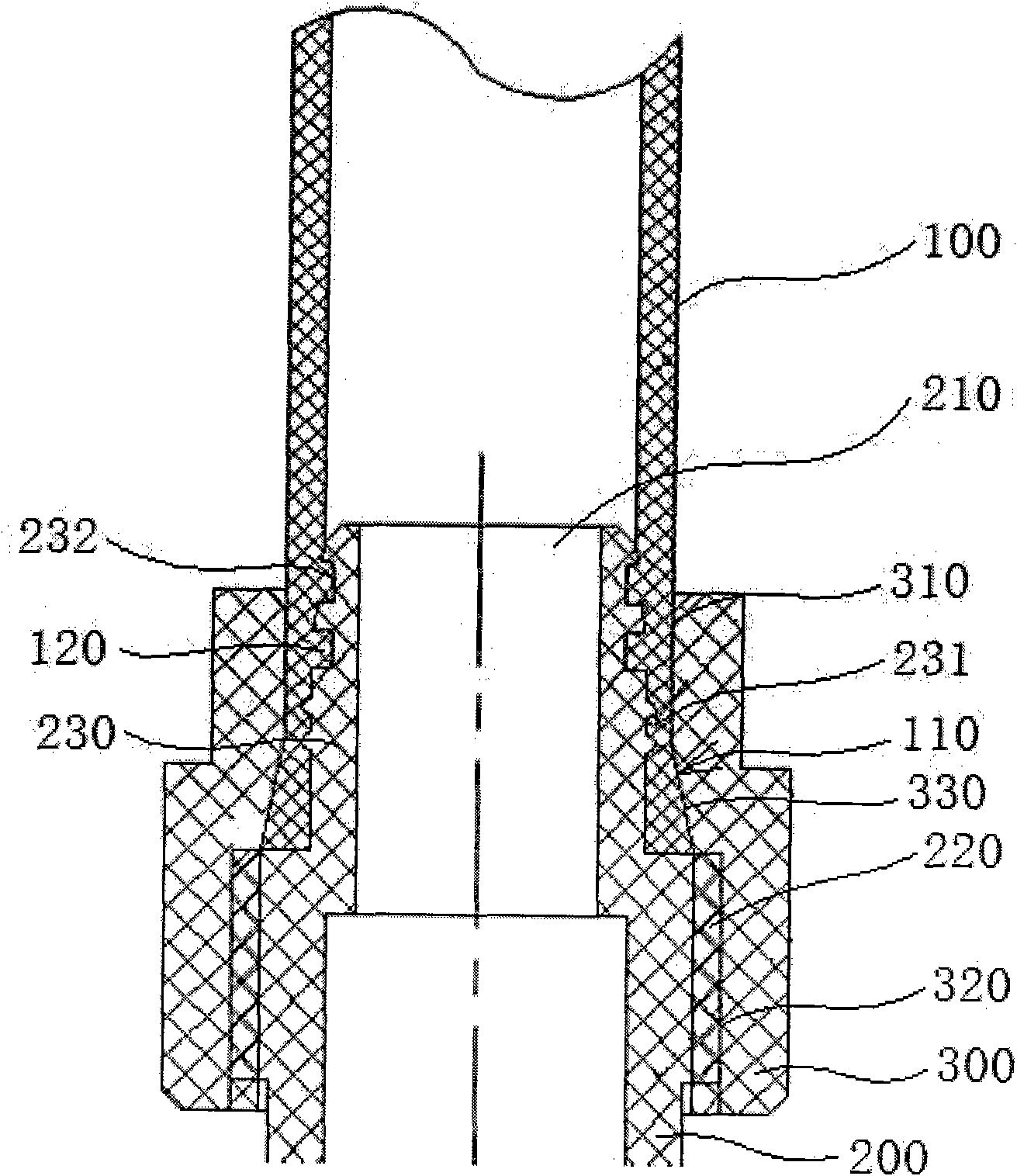

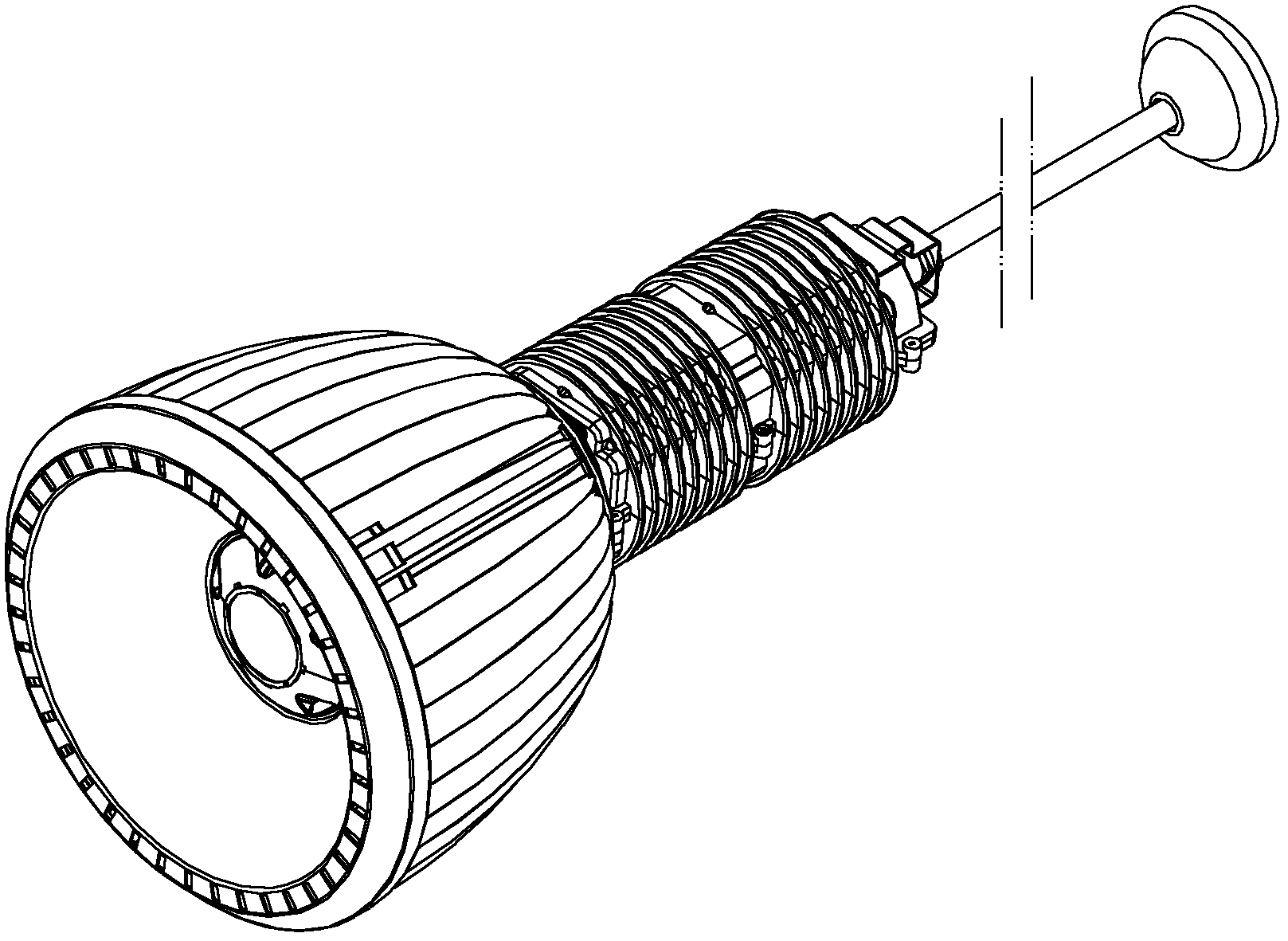

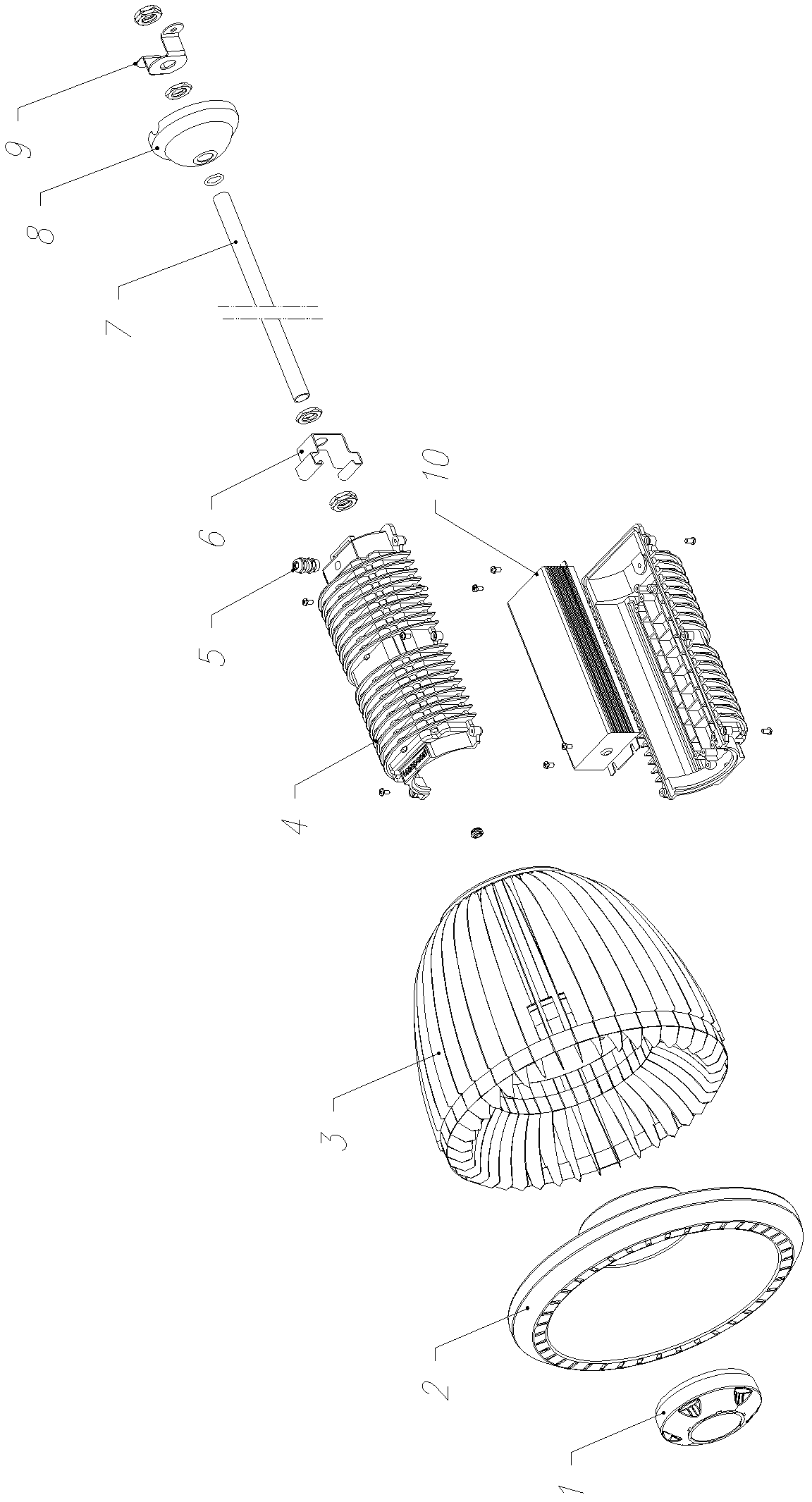

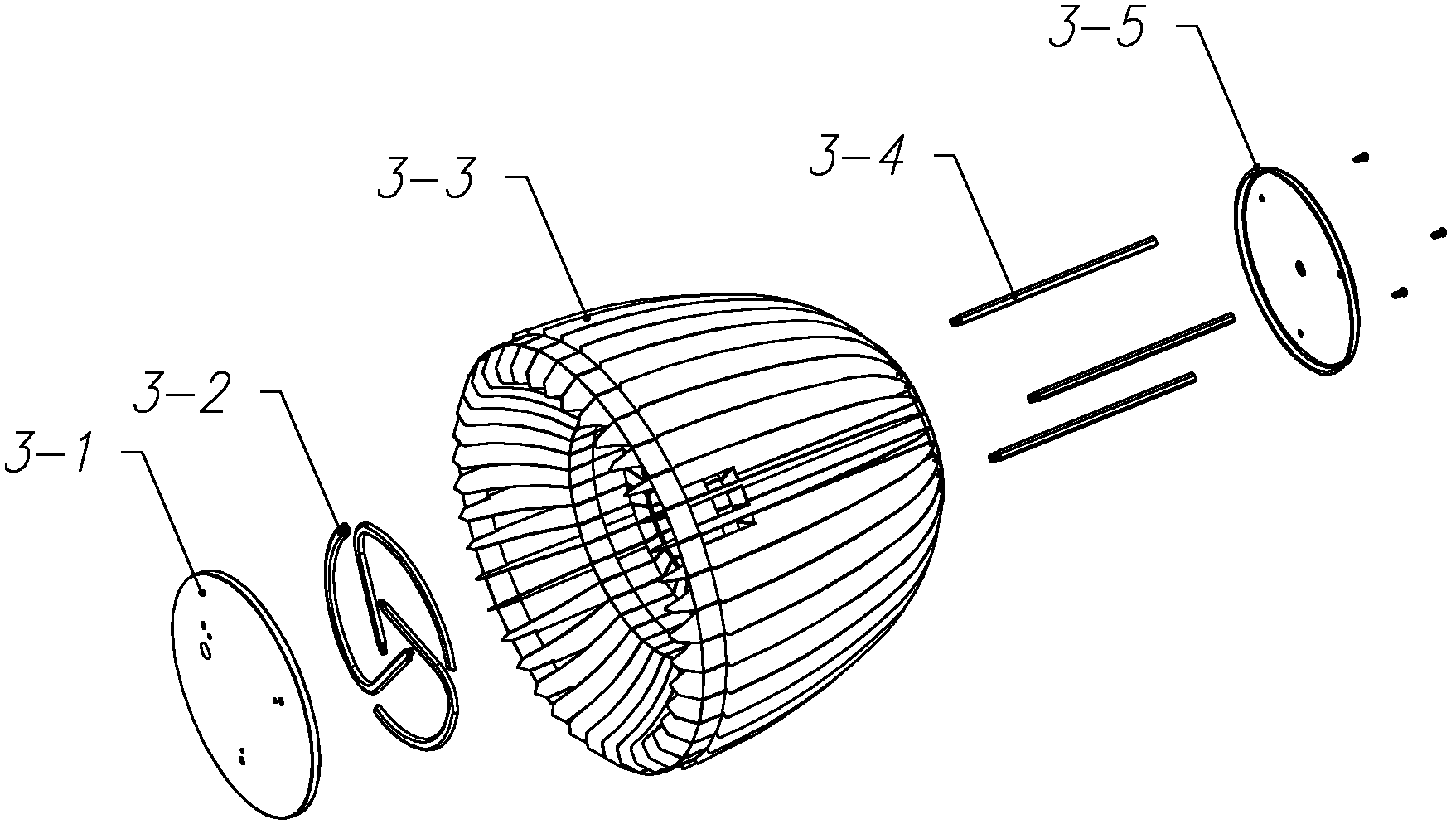

Light-emitting diode (LED) high-roof lamp

InactiveCN102494289AEasy to disassemble and replaceQuick releasePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

The invention discloses a light-emitting diode (LED) high-roof lamp, which comprises a driver, a radiator assembly and a light source assembly, wherein the radiator assembly has a bowl-shaped structure; radiating fins of the radiator assembly are arranged in a circumferential array and are buckled mutually to form a bowl wall frame; and the light source assembly has an integrally-encapsulated structure, is fixed to a bowl abdomen enclosed by the bowl wall frame and is electrically connected with the driver fixed to the bowl bottom of the bowl-shaped structure in a movable mode. According to the LED high-roof lamp, due to the utilization of a radiating structure of combining a heat conduction pipe and the radiating fins, a good radiating effect is ensured, and both the light source assembly and the radiator assembly are easy to disassemble and replace.

Owner:BEIJING LAMPEARL PHOTOELECTRIC

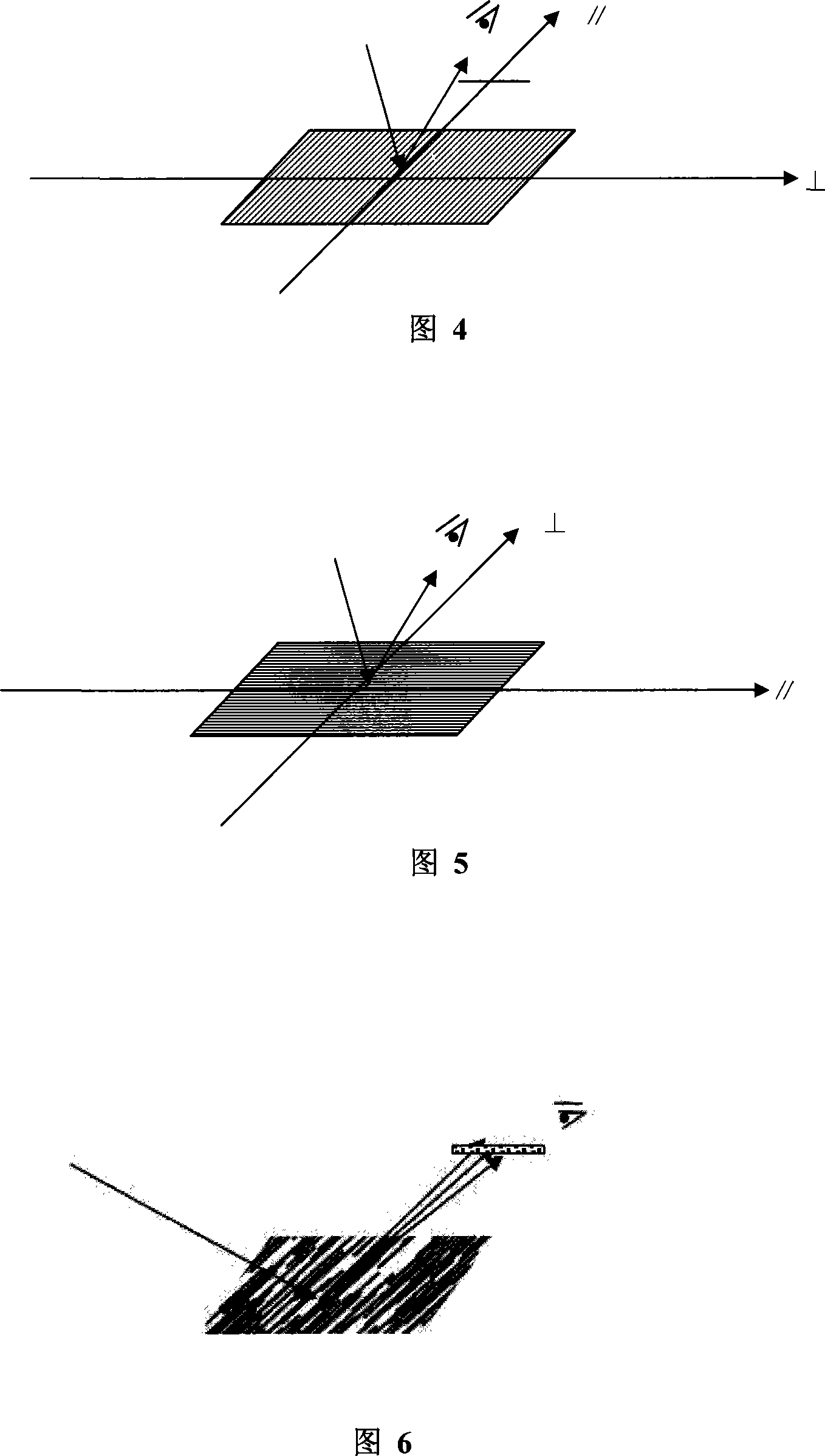

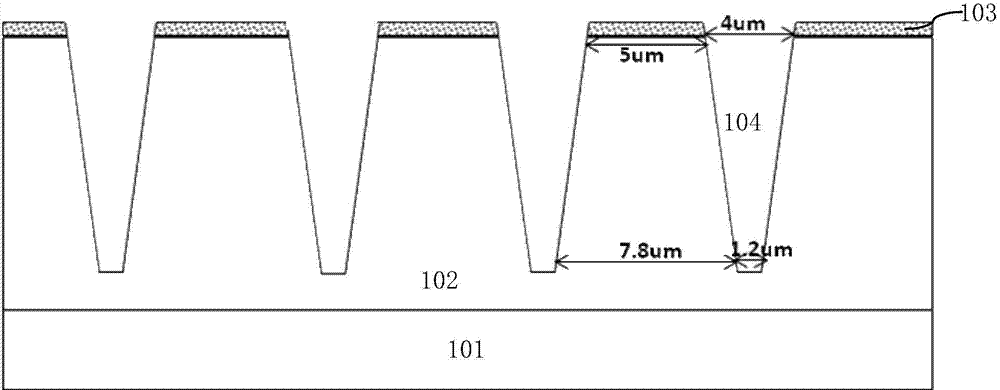

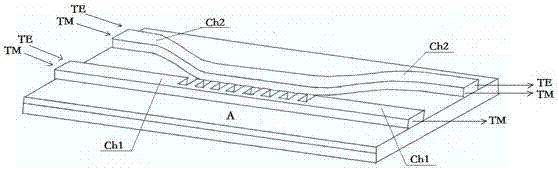

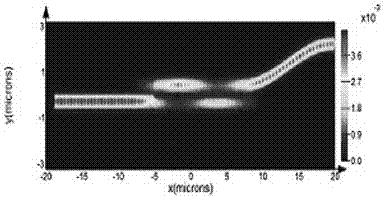

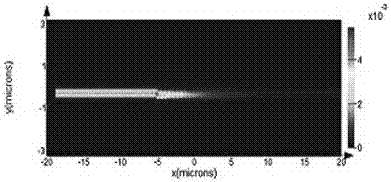

Directional coupling type TM polarizer and beam splitter based on sub-wavelength grating

ActiveCN106959485AHigh refractive indexHigh extinction ratioPolarising elementsHigh level techniquesBeam splitterGrating

The invention discloses a directional coupling type TM polarizer and a beam splitter based on sub-wavelength grating. A sub-wavelength grating is introduced to an asymmetric directional coupler, and a wave guide having a sub-wavelength grating is used as a channel 1, and another waveguide without the sub-wavelength grating is used as a channel 2. When an incident light beam is transmitted through the channel 1, a TE polarization state light is reflected by the sub-wavelength grating, and a TM polarization state light is coupled with a channel 2 for output by a sub-wavelength grating area, and a TM polarizer is realized. When the incident light beam is transmitted through the channel 2, the TE polarization state light is transmitted for the output by the channel 2, and the TM polarization state light is coupled with the channel 1 for the output by the sub-wavelength grating area, and a TE and TM polarization beam splitter is realized. By using one single device, the polarizer function and the beam splitter function are realized, and therefore an integration level of an optoelectronic device is greatly improved, a structure is simple, and is easy to design and produce.

Owner:NAT UNIV OF DEFENSE TECH

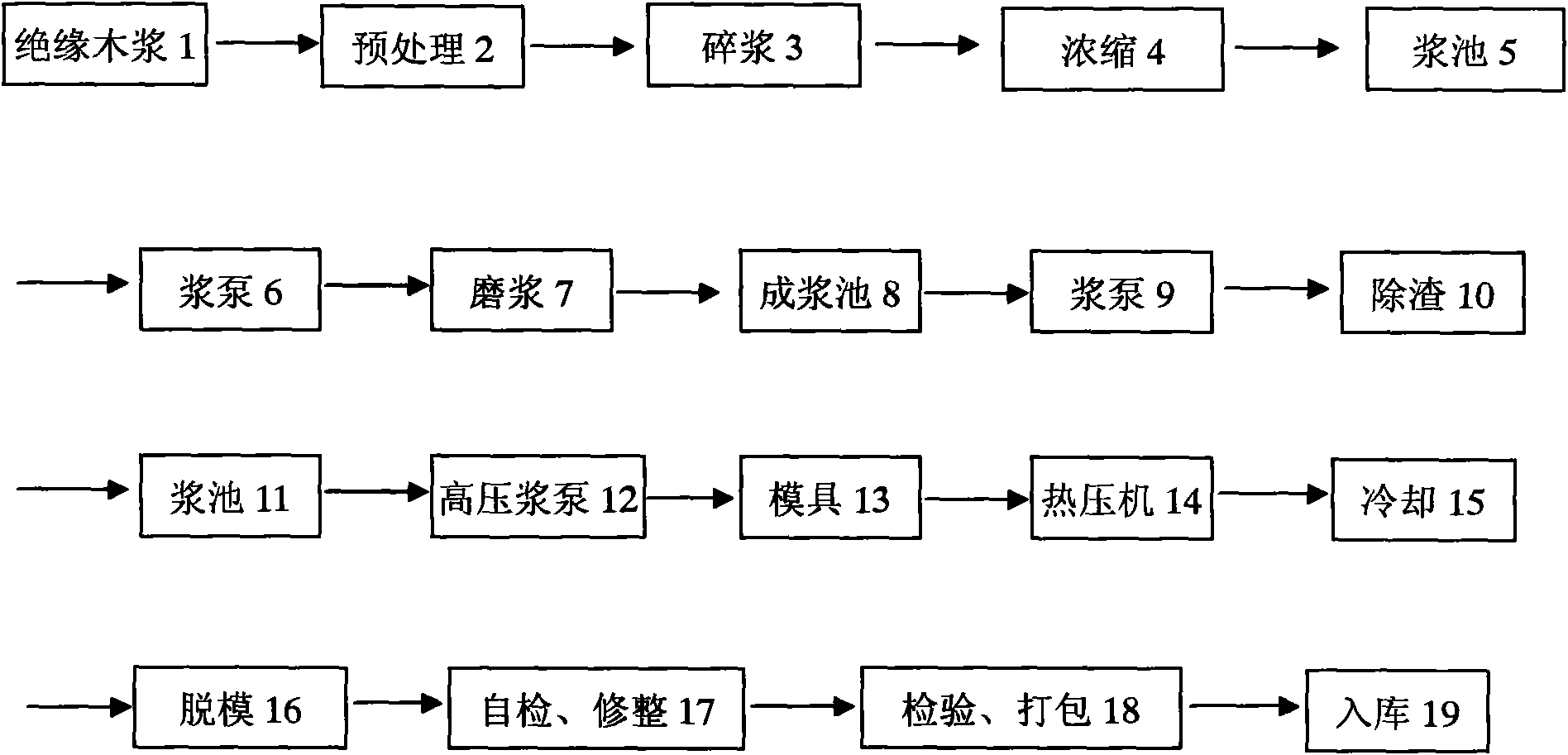

Process for producing transposed oxhorn cushion block of insulated coil of transformer

InactiveCN101783241AHigh fiber purityHigh oil absorptionFibreboardCoils manufactureInjection pressureTransformer

The invention belongs to a process for producing a transposed oxhorn cushion block of an insulated coil of a transformer, which comprises the following steps of: purifying and pre-treating a wood pulp; concentrating the pulp which is crushed through a pulper to have the concentration of 3.5-4.5 percent and enabling the pulp to enter a pulp pool; delivering the pulp to a pulp grinder through a pulp pump; feeding the pulp with 35-39 degrees SR of beating degree, 9-13g of wet weight and 1.3-1.5 percent of concentration into the pulp pool; again feeding the pulp into an effective deslagger through a pulp pump to enter a pulp pool; injecting the paper pulp into a forming mould through a high pressure pulp pump; stopping injecting the pulp when the injection pressure reaches 0.8-1.2MPa, and feeding the mould in which the pulp is injected into a hot press machine; and carrying out cooling, demoulding, self-check finishing, inspection package and warehouse entry after the paper pulp is dried and molded.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

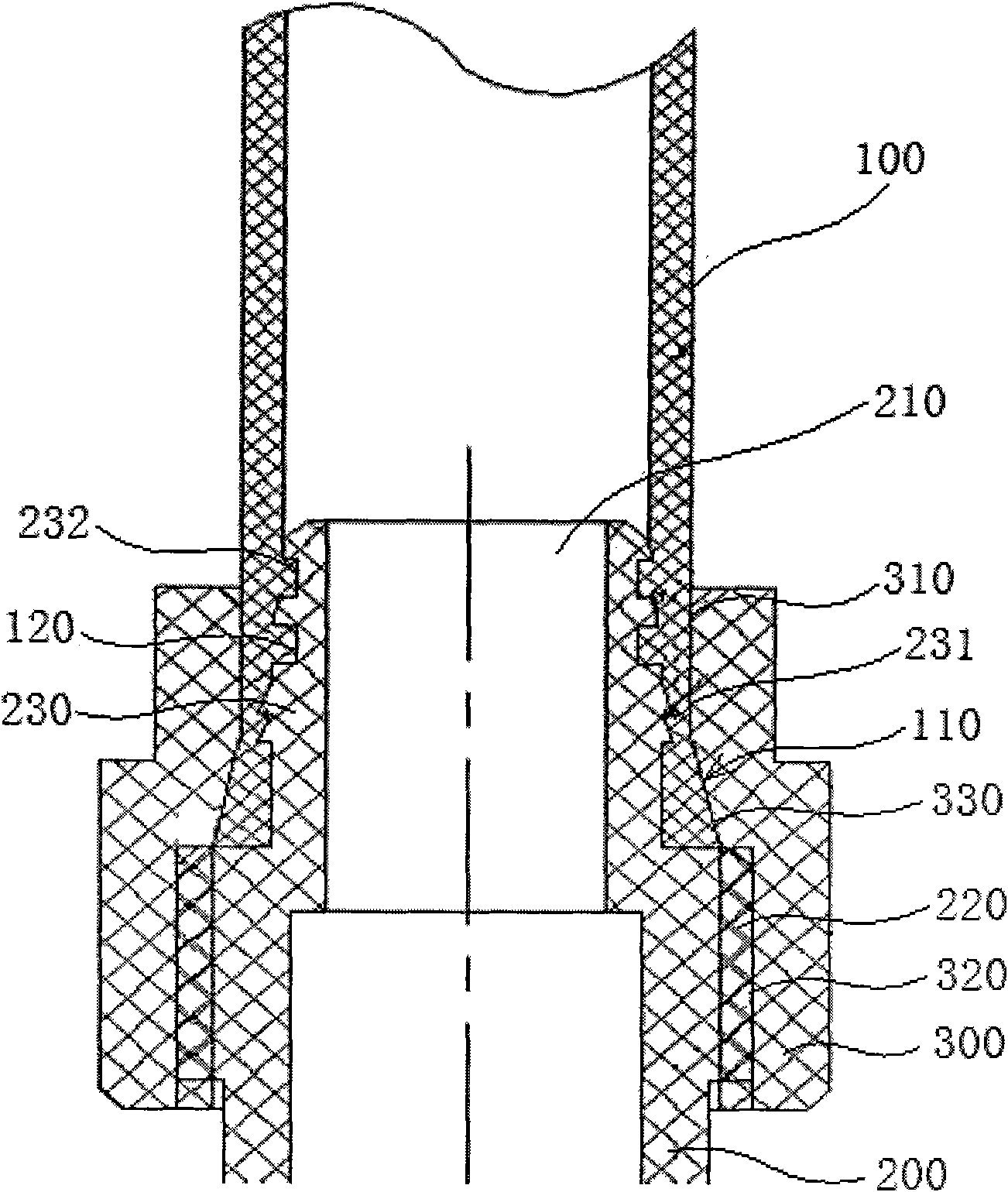

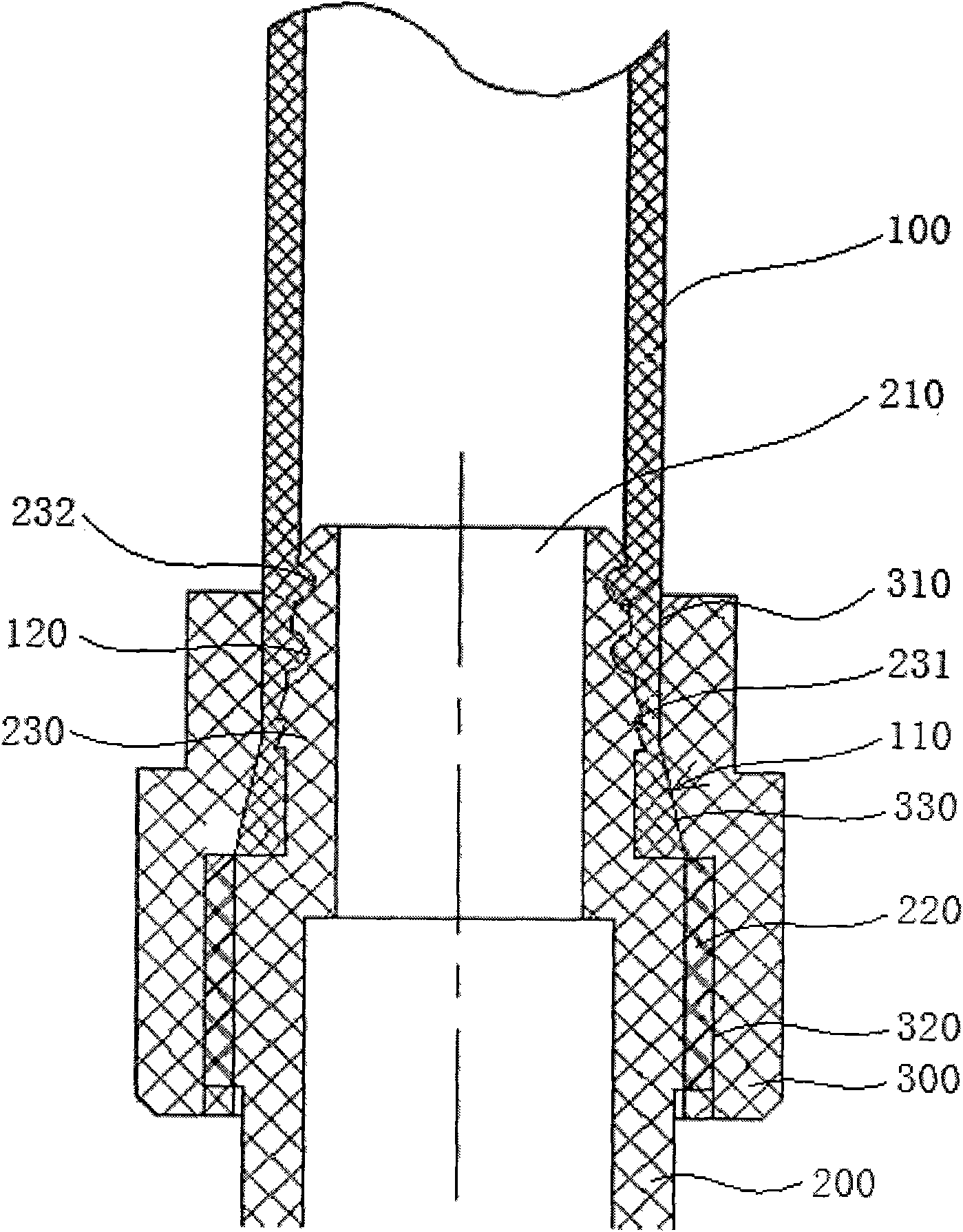

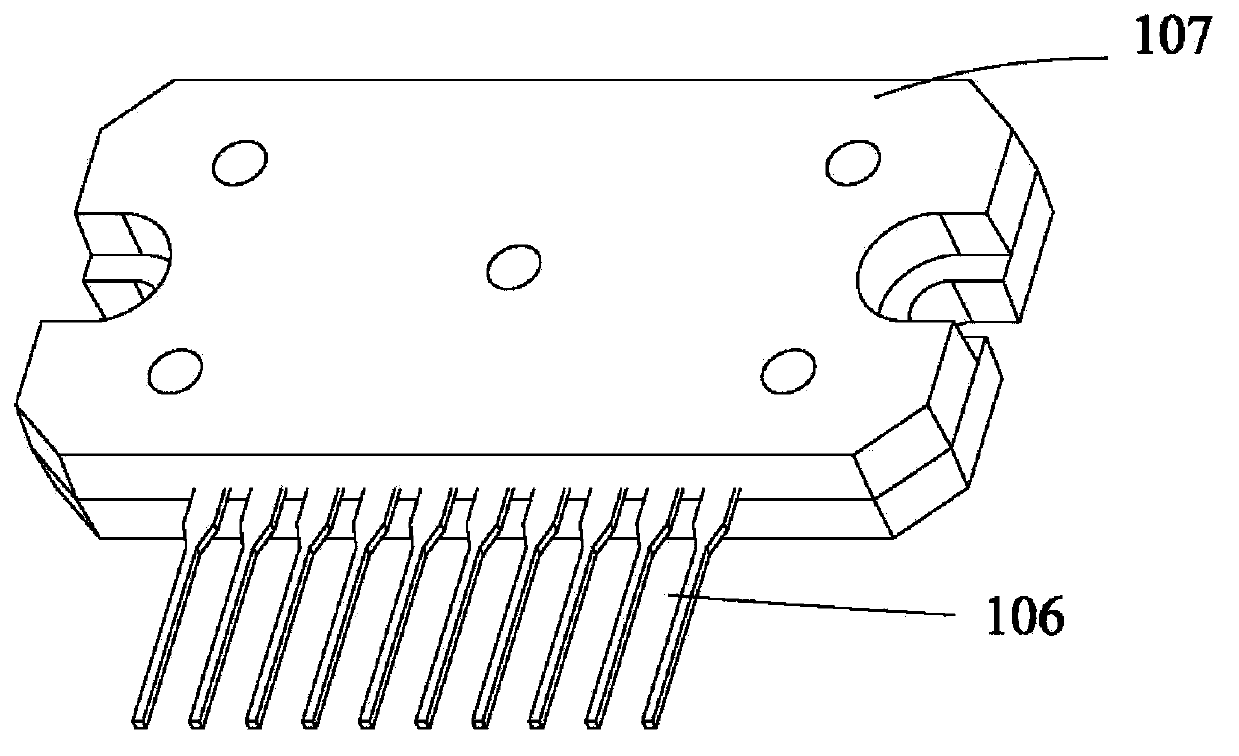

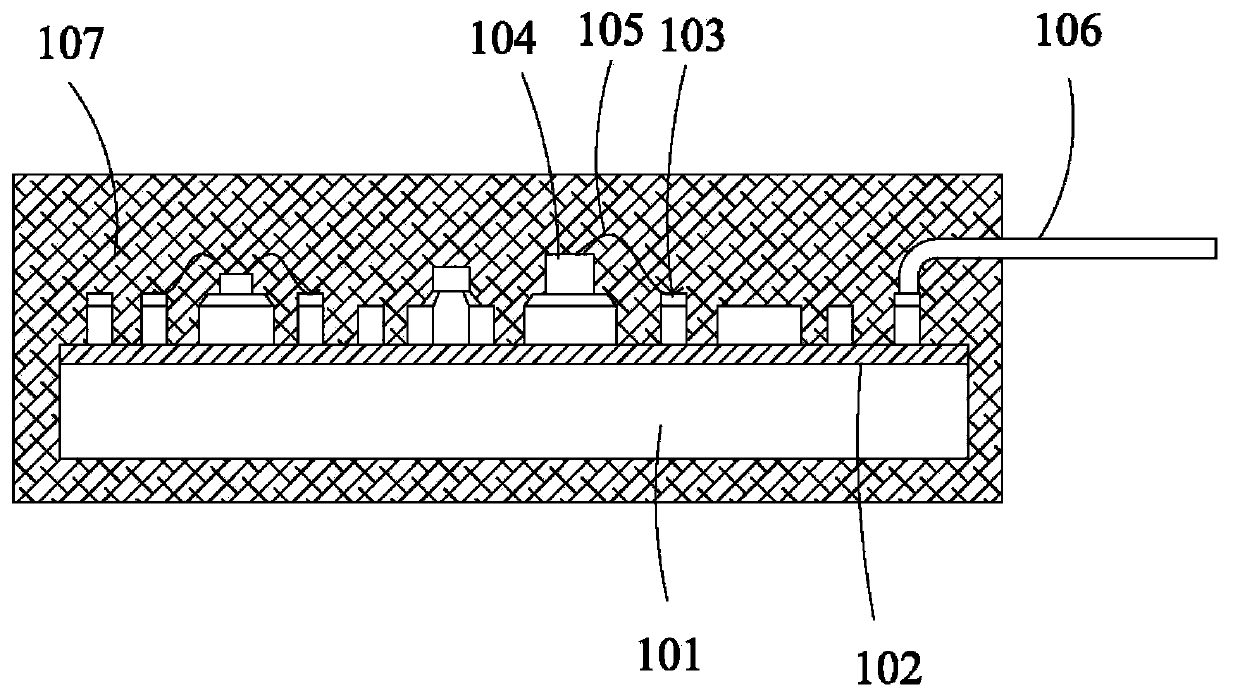

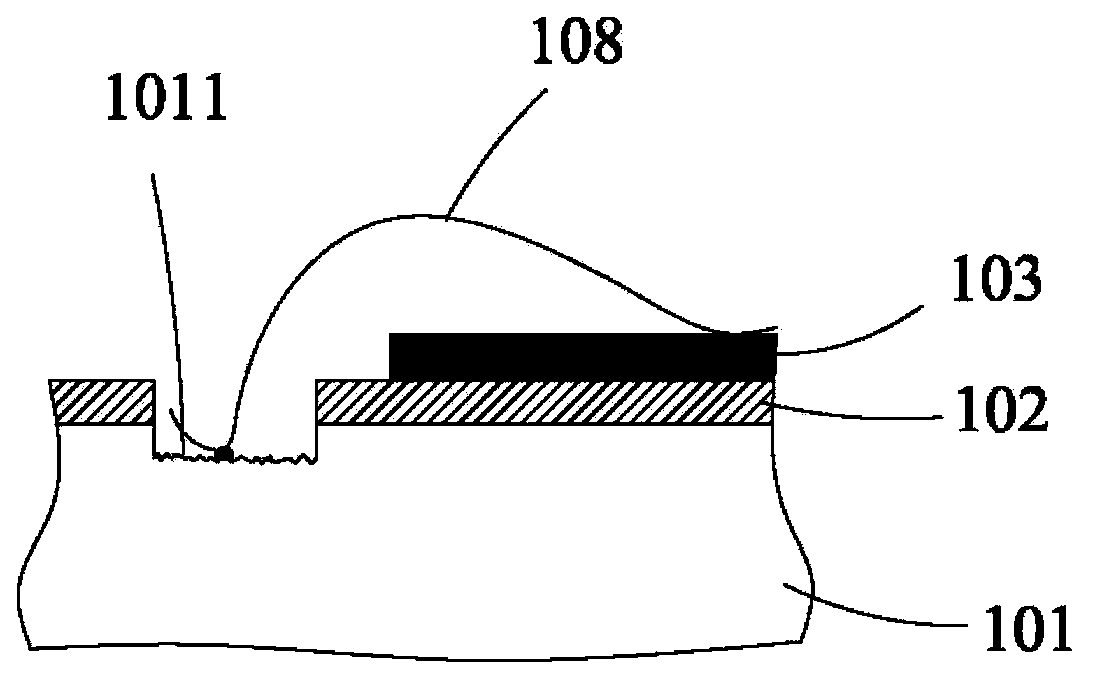

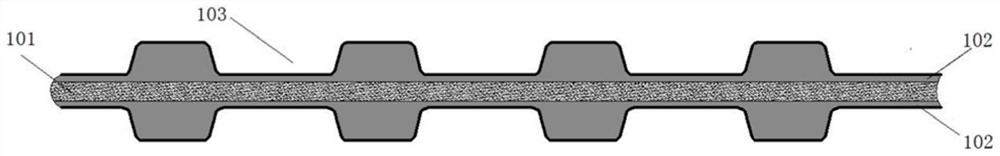

Intelligent power module and manufacturing method thereof

ActiveCN103633053AImprove adhesionLow costSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationComputer module

The invention belongs to the technical field of electronic devices and provides an intelligent power module and a manufacturing method thereof. The intelligent power module comprises a metal substrate, an insulating layer covering one surface of the metal substrate, a circuit wiring layer formed on the insulating layer, circuit elements which are configured at preset positions on the circuit wiring layer, and pins connected with the circuit wiring layer. The intelligent power module urther comprises a recessed hole which penetrates the insulating layer and extends to the metal substrate; the circuit wiring layer is connected with the bottom of the recessed hole through a metal wire; the recessed hole is filled with a cured conductive material; a tail portion of the metal wire, which is connected with the bottom of the recessed hole, is buried in the conductive material; and at least one surface of the metal substrate, which is provided with the circuit elements, is sealed. According to the intelligent power module of the invention, the recessed hole is filled with the conductive material, such that the connection of the metal wire and the bottom of the recessed hole can be realized by means of a bonding force of the metal wire and the recessed hole, and can be enhanced through the adhesive force of the conductive material, and therefore, reliable connection of the meal wire and the metal substrate can be realized, and the miniaturization of the module can be facilitated, and processing difficulty can be controlled, and cost can be decreased.

Owner:MIDEA GRP CO LTD

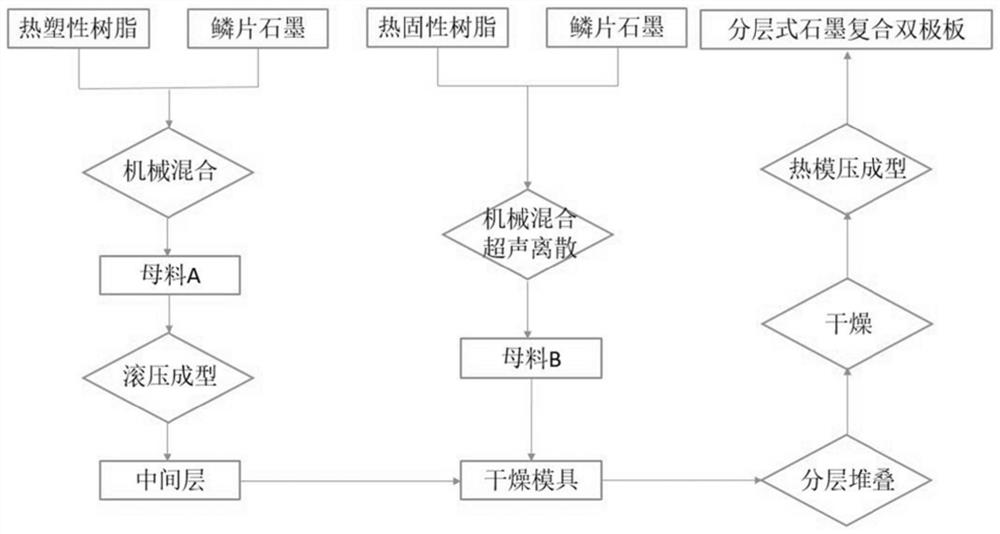

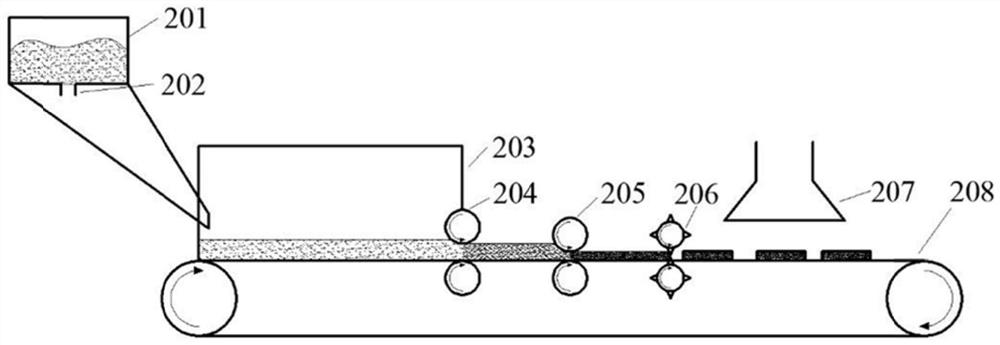

Layered graphite composite bipolar plate and preparation method thereof

PendingCN111883794AReduce molding difficultyAchieve structural strengthFinal product manufactureFuel cellsPolymer scienceThermoplastic composites

The invention relates to a layered graphite composite bipolar plate and a preparation method thereof. The layered graphite composite bipolar plate comprises a middle layer and surface layers arrangedat the two sides of the middle layer, the middle layer is a thermoplastic resin / graphite composite material plate, the surface layers are thermosetting resin / graphite composite material layers, and the outer surfaces of the surface layers are provided with flow channel structures. Compared with the prior art, the middle layer is made of the thermoplastic composite material, the feeding precision of the thermosetting composite material is improved in an auxiliary mode in the manufacturing process, and meanwhile the problem that the forming reliability of the thermosetting composite material islow under the high carbon content is solved; in addition, the middle layer with high resin content in the layered polar plate improves the bending strength and air tightness of the bipolar plate, andthe surface layer with high carbon content improves the conductivity of the bipolar plate; the overall performance of the bipolar plate is improved by means of respective optimization of different functional layers, and meanwhile, the preparation process is simple and convenient, is beneficial to batch production, and has a higher practical value.

Owner:TONGJI UNIV

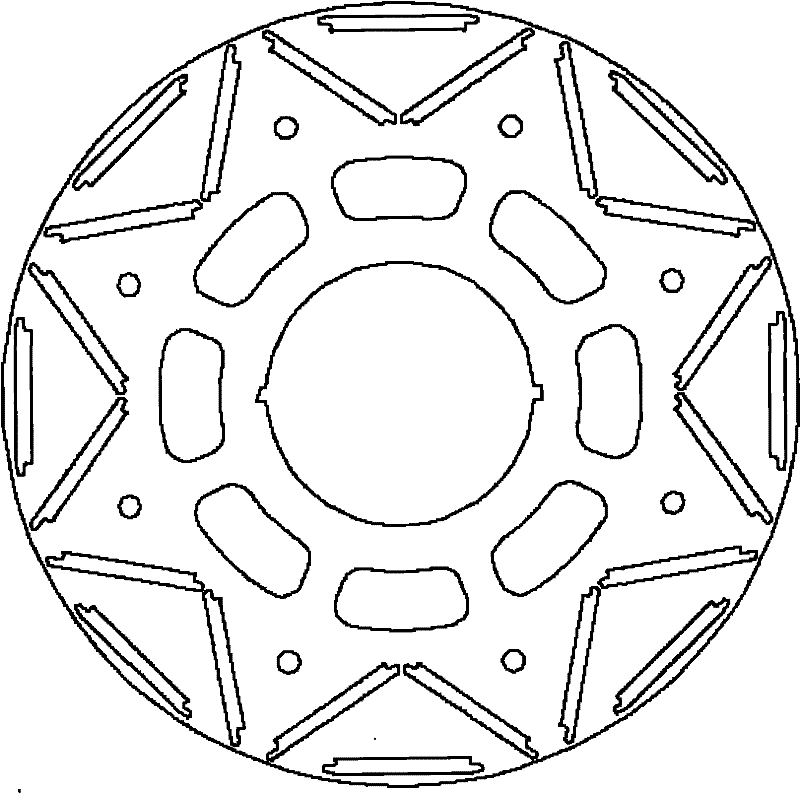

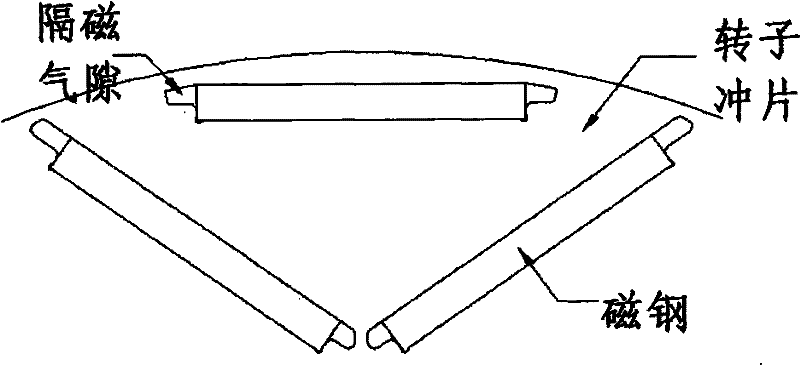

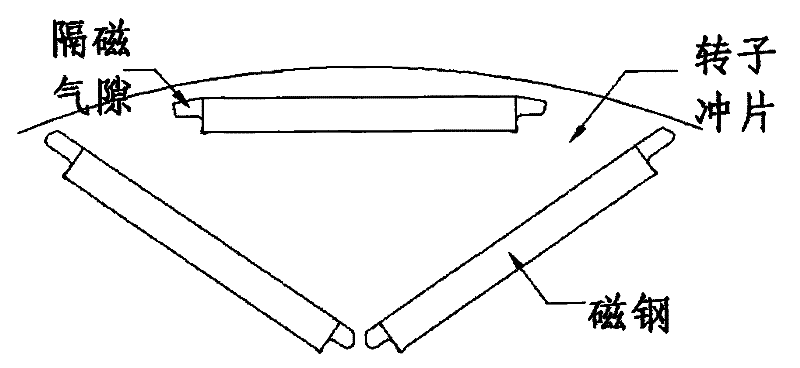

Novel multi-layer structure of rotor core

InactiveCN102214963AIncrease in sizeGuaranteed normal outputMagnetic circuit rotating partsWave formEngineering

The invention relates to a novel multi-layer structure of a rotor core. The novel multi-layer structure of the rotor core is formed by laminating punched silicon-steel sheets and embedding magnetic steel. During the design of a rotor, a double-layer structure is adopted, wherein the first layer comprises a piece of linear magnetic steel; and the second layer of magnetic steel has a V-shaped structure. Magnetic flux can be output to a largest extent by reasonably designing the length of the magnetic steel and distances between the respective magnetic steel, and the similarity of a counter potential wave form and a sine wave reaches 1.02 to 1.04. In a novel multi-layer embedded rotor sheet, on the basis of reserving the conventional advantages that a motor smoothly operates at a speed of 8,000 rpm, by the unique multi-layer structure of the rotor, the output of the magnetic flux of each electrode can be guaranteed to a largest extent, and the volume of the magnetic steel cannot be greatly increased.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

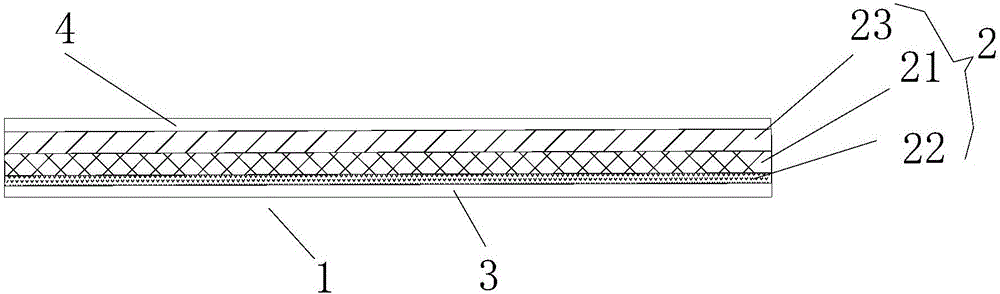

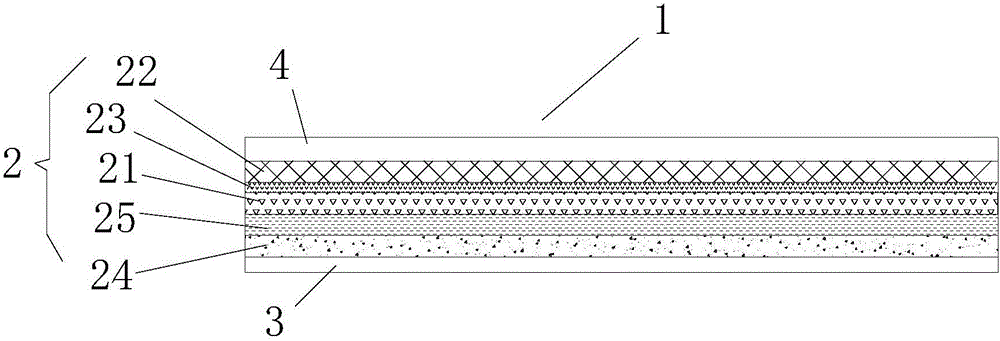

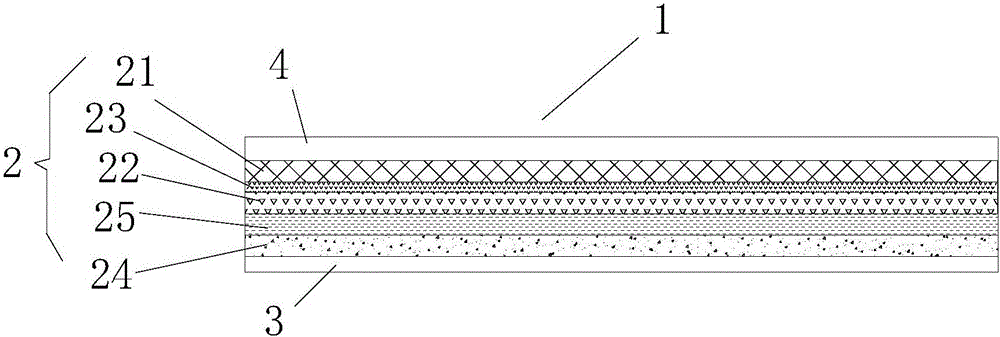

Heat-conducting and heat-dissipating film containing graphene

The invention relates to the technical field of a heat-conducting and heat-dissipating material, in particular to a heat-conducting and heat-dissipating film containing graphene. The heat-conducting and heat-dissipating film containing graphene comprises a heat-dissipating film body, wherein the heat-dissipating film body comprises a graphene composite film layer, the graphene composite film layer is formed by compositing a graphene layer and a base material through a bonding layer, the thickness of the graphene layer is in a range of 0.001-50.0 mu m, the purity of a graphene layer is in a range of 99.5%-99.99%, and a first adhesive layer and a second adhesive layer are arranged on the bottom surface and the top surface of the graphene composite film layer respectively. Compared with the prior art, the heat-conducting and heat-dissipating film containing graphene has the beneficial effects as follows: the heat-dissipating film body comprises the graphene composite film layer, the graphene composite film layer is formed by compositing the graphene layer and the base material through the bonding layer, and the heat-conducting and heat-dissipating film containing graphene has toughness, can be produced automatically and continuously, can be stored in a rolled manner, is convenient to use and good in heat-conducting and heat-dissipating effect, is fixed through bonding, and can be widely applied to heat conduction and heat dissipation of devices such as a laptop, a mobile phone, a television, a camera, an LED lamp, an automobile cooling fin and the like.

Owner:SHENZHEN LAIBIDE TECH CO LTD

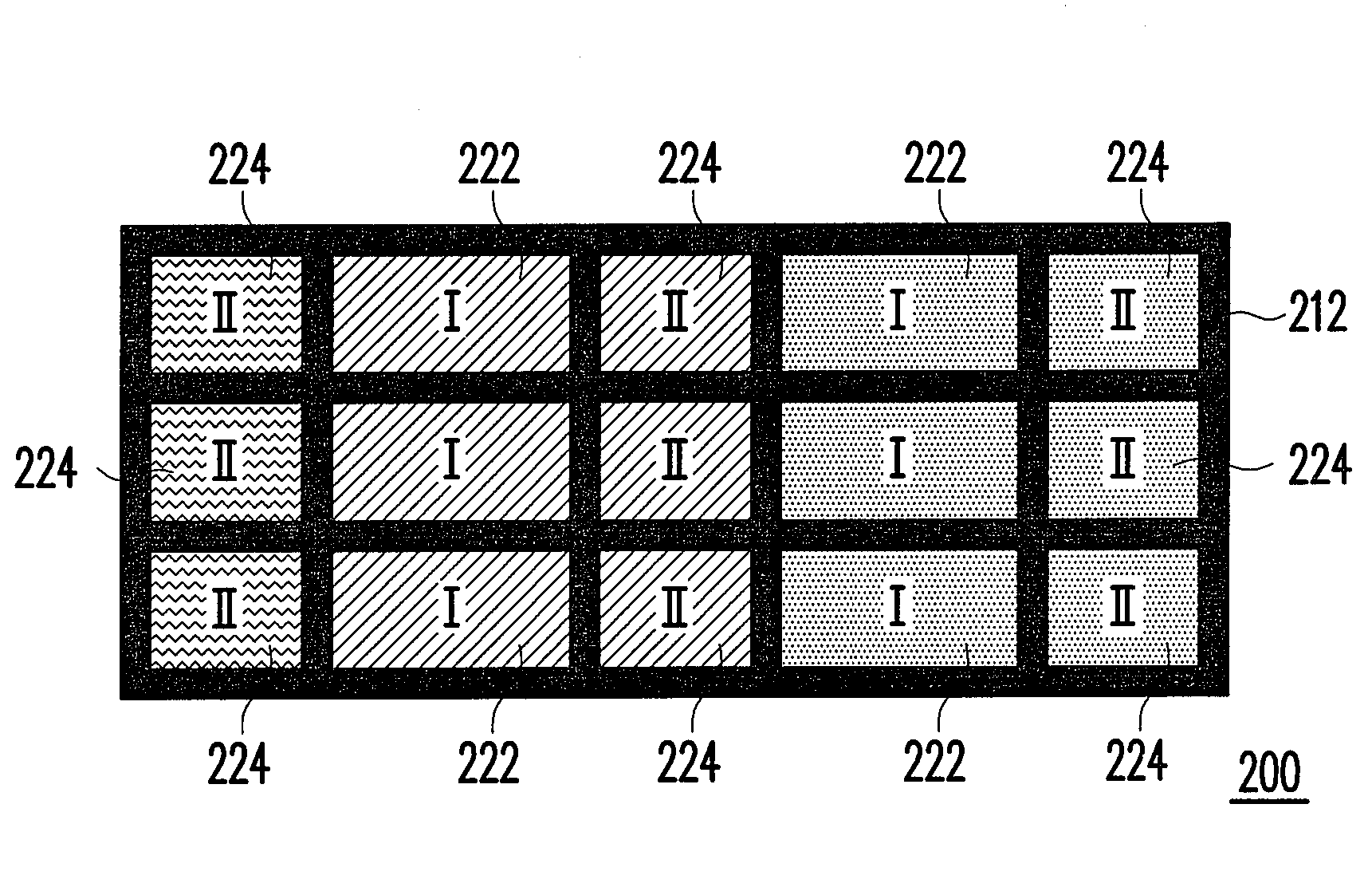

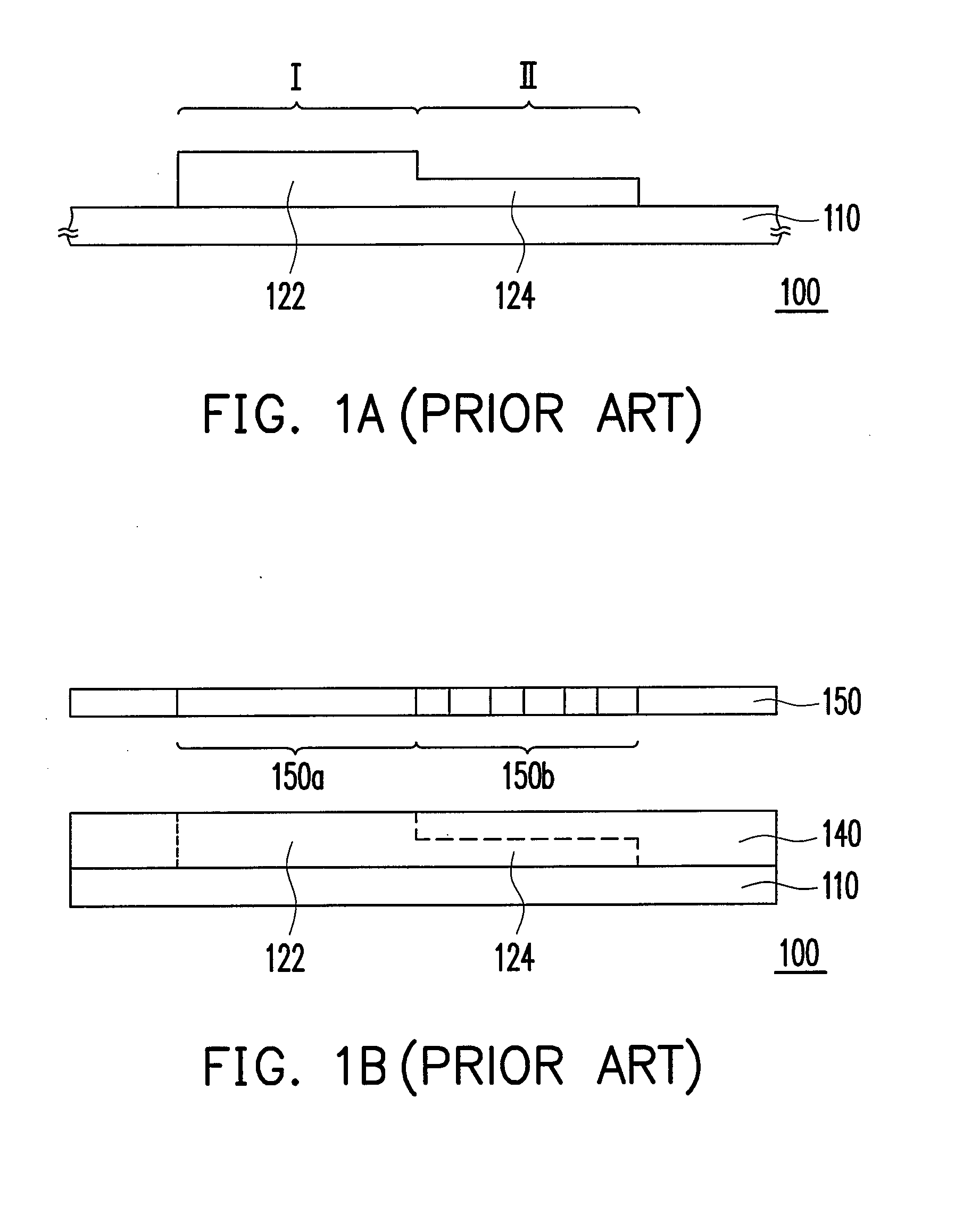

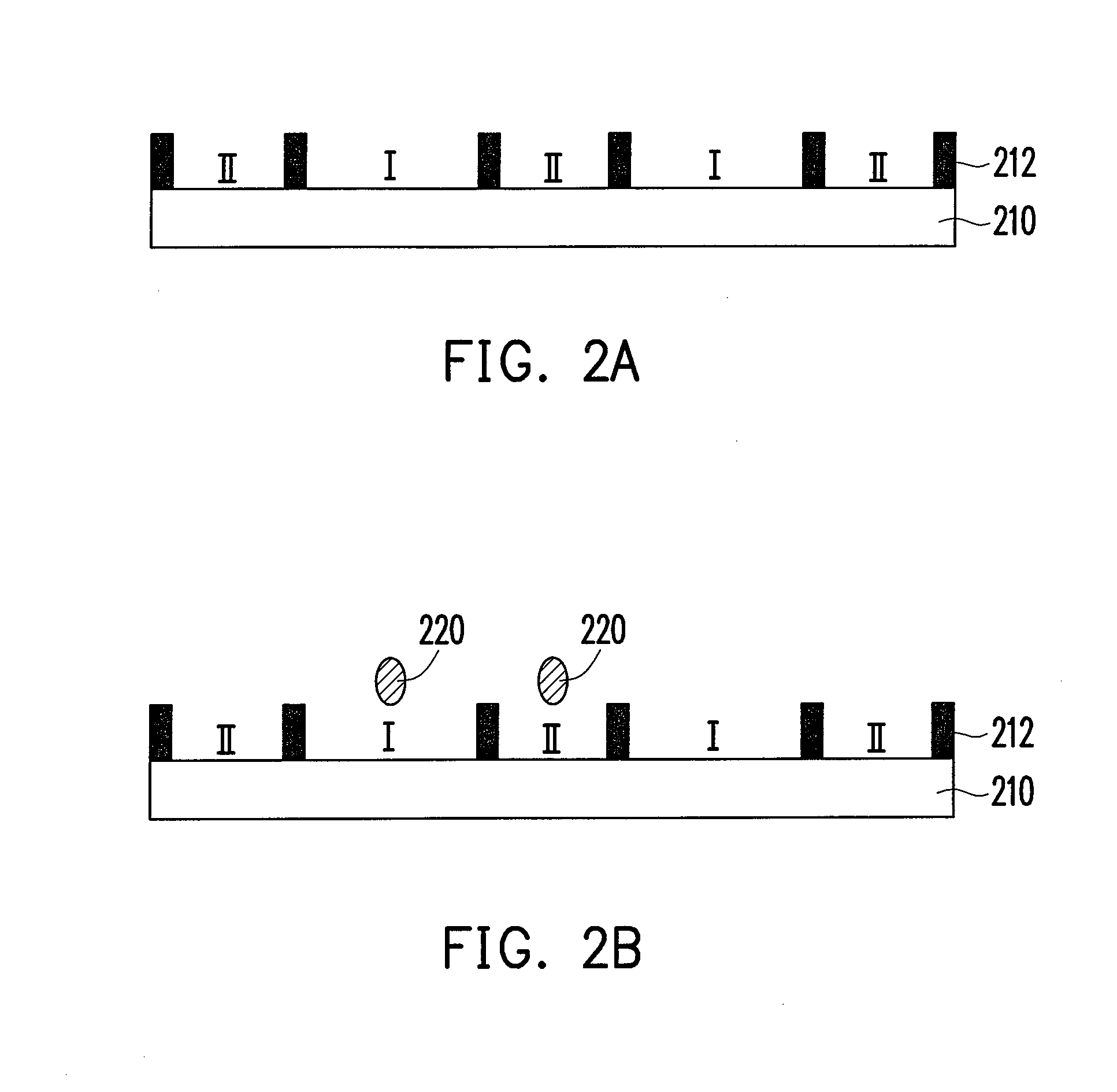

Method of manufacturing color filter

InactiveUS20080231681A1Easily controlImprove process windowPhotomechanical apparatusPattern printingLiquid-crystal displayColor filter array

A method of manufacturing a color filter is provided. First, a substrate is provided and then a partition, for example a black matrix, is formed on the substrate. The black matrix defines a plurality of first color filter areas and a plurality of second color filter areas corresponding to the first color filter areas on the substrate. Thereafter, a first color filter film and a second color filter film are formed in each of the first color filter areas and each of the second color filter areas corresponding thereto, respectively, such that a color filter is provided. The thickness of the first color filter film differs from the thickness of the second color filter film. Thus, images displayed by a transflective liquid crystal display with the aforementioned color filter have even colors.

Owner:AU OPTRONICS CORP

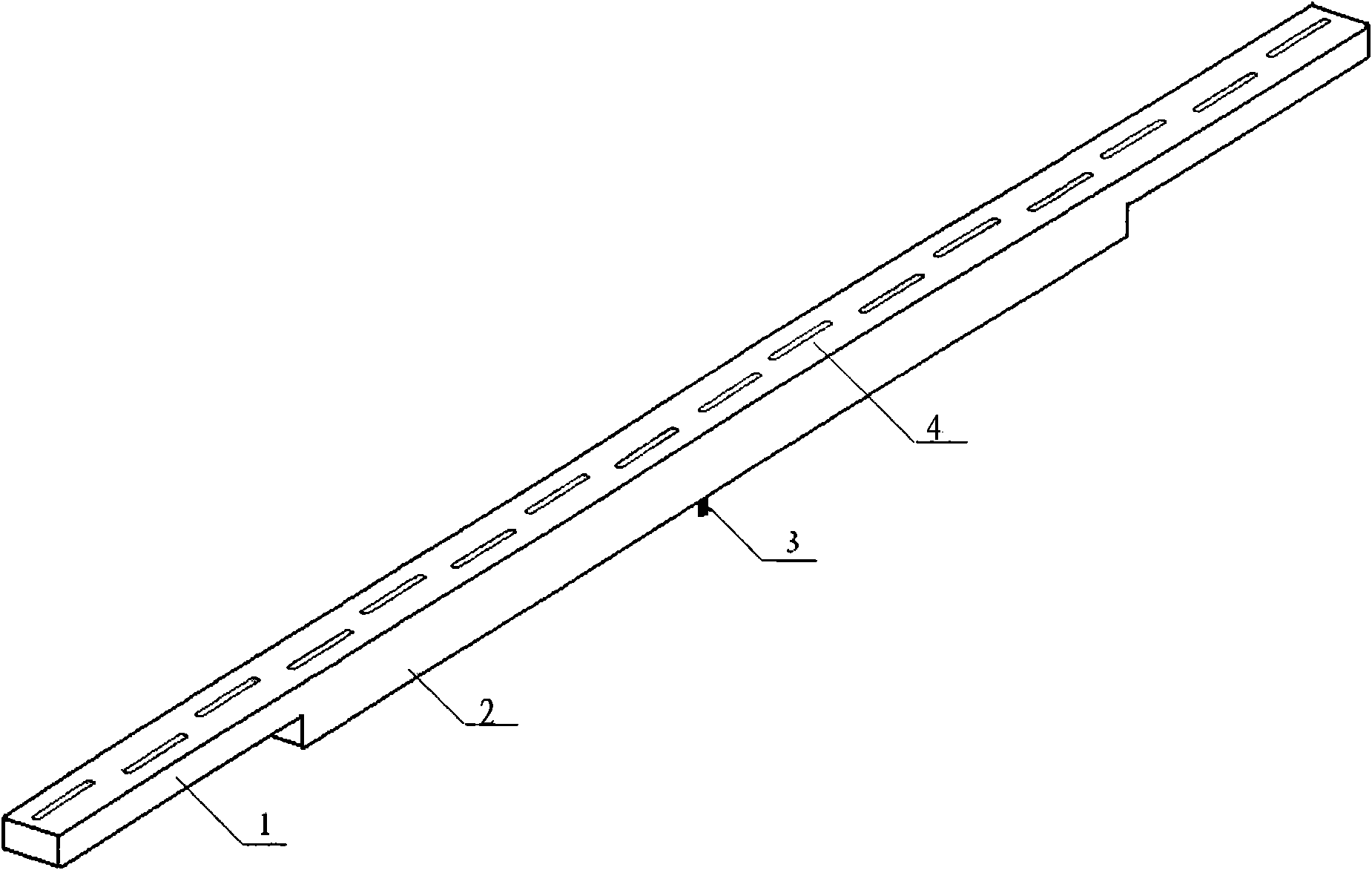

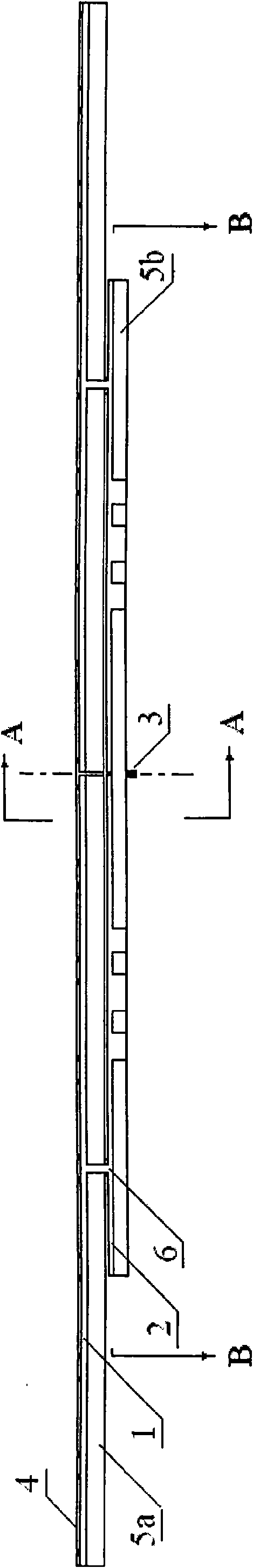

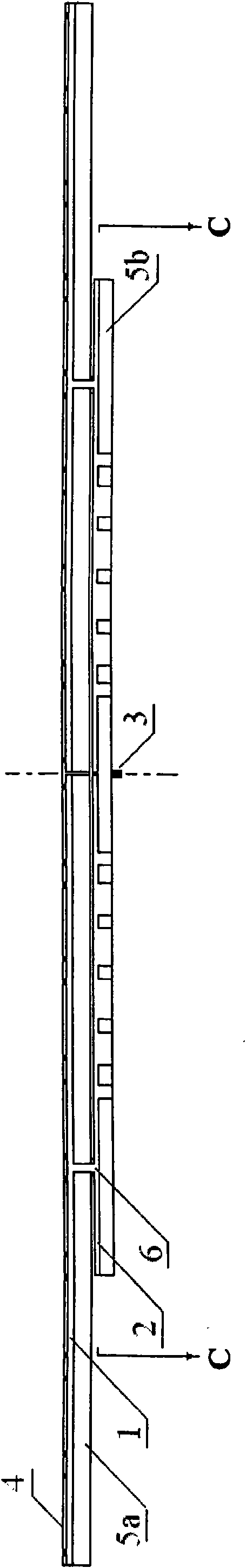

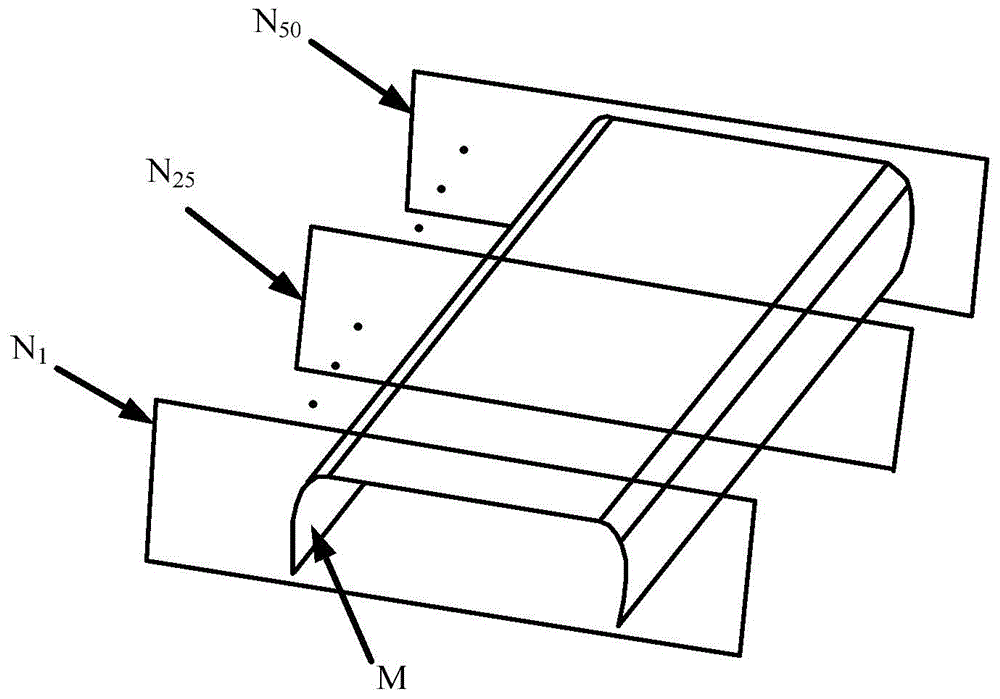

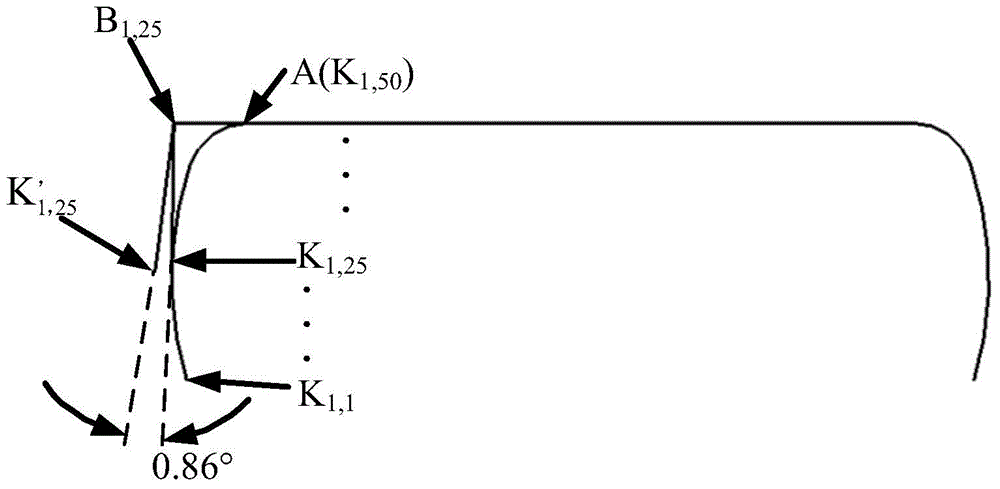

Method for designing die molded surface for forming groove-shaped part

InactiveCN104924633AIncrease the difficulty of the processIncrease the difficulty of assemblySurface fittingEngineering

Disclosed is a method for designing a die molded surface for forming a groove-shaped part. An inner molded surface M of the part is extracted, and section lines Pj of the extracted inner molded surface of the part are manufactured; the various section lines Pj are corrected sequentially through correction basis points, and new section lines are obtained; and surface fitting is carried out on the obtained section lines, and a new mold outer molded surface is obtained. The maximum deformation of the groove-shaped part formed through the mold outer molded surface determined through the method is reduced to 0.2mm from 1.5mm, and the design requirements of the part are met. Compared with the traditional technology, when the mold molded surface is designed, rebound deformation obtained after part deformation is considered in the method, and the problem that according to a traditional method, an inner molded surface of a composite material groove-shaped part is directly extracted to serve as the mold molded surface for manufacturing the composite material part, the part size cannot meet the design requirement is solved; and the mold repairing frequency of a follow-up mold is reduced, and therefore the production manufacturing cost is reduced, and the production efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Waterborne leveling agent for dyeing ultrafine fiber PU synthetic leather

The invention discloses a waterborne leveling agent for dyeing ultrafine fiber PU synthetic leather, which relates to the technical field of synthetic leather. The waterborne leveling agent is prepared from the following raw materials in parts by weight: 25 to 35 parts of methoxy polyethylene glycol, 10 to 15 parts of sodium polyacrylate, 1 to 5 parts of hydrogenated ricinoleic acid, 1 to 5 partsof gamma-polyglutamic acid, 1 to 5 parts of N-hydroxyethyl acrylamide, 0.5 to 3 parts of 2-Amino-2-(hydroxymethyl)-1,3-propanediol, 0.5 to 3 parts of povidoneK30, 0.05 to 0.5 part of vinyl trimethoxysilane, and 0.05 to 0.5 part of titanate coupling agent TMC-WT. The leveling agent of the invention belongs to the waterborne leveling agent; and by adopting the waterborne leveling agent, the staining rate of the dye on the synthetic leather can be significantly increased, the color difference can be reduced, the uniformity in dyeing the synthetic leather can be realized, a K / S value at 460nm isgreater than 4, and a DEcmc value is smaller than 0.3.

Owner:马多浩

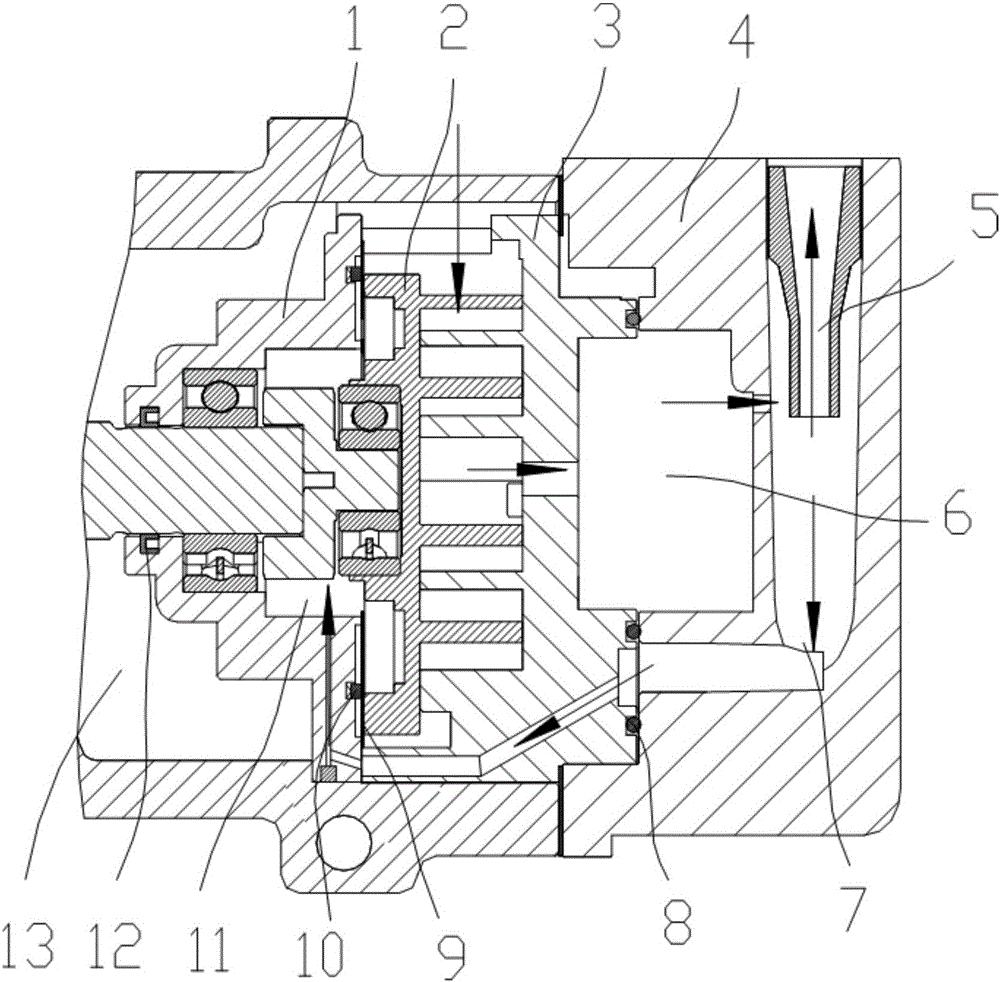

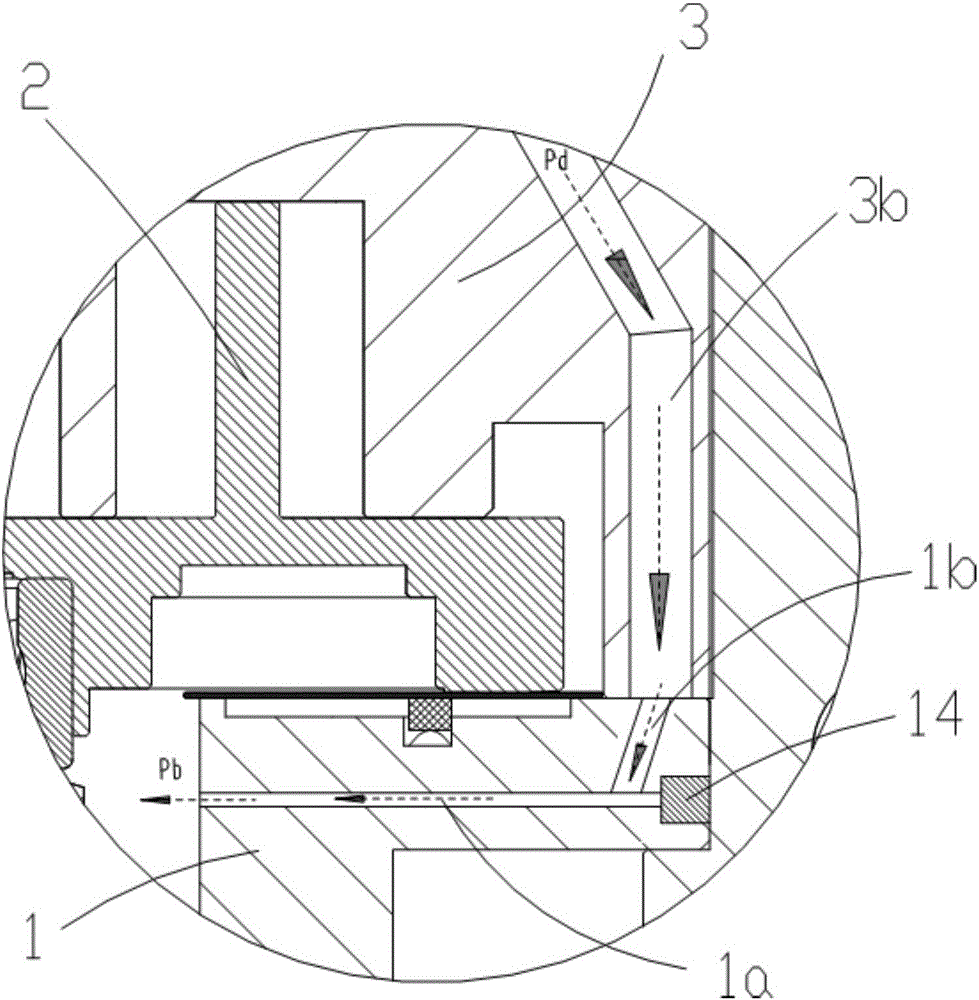

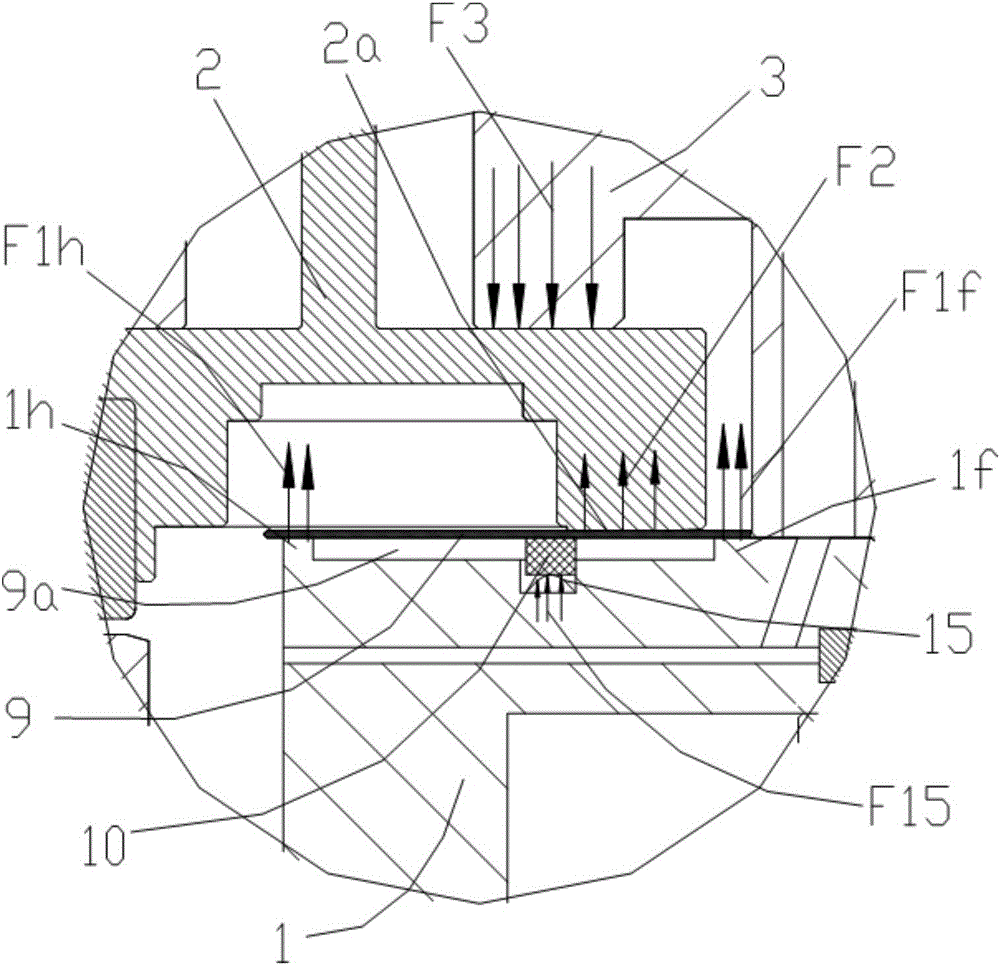

Scroll compressor

ActiveCN105840504AImprove processing strengthIncrease the difficulty of the processRotary piston pumpsRotary piston liquid enginesEngineeringScroll compressor

The invention discloses a scroll compressor. The scroll compressor comprises an upper support and an upper cover, wherein the upper support and the upper cover are connected. A movable scroll plate is arranged in the upper support and in the upper cover. A static scroll plate is coaxially arranged on the side, close to the upper cover, of the movable scroll plate. An elastic circular ring is coaxially arranged on the side, close to the upper support, of the movable scroll plate. The upper support is provided with an inner supporting part and an outer supporting part, wherein the inner supporting part and the outer supporting part are matched with the elastic circular ring. A suspended part is formed between the inner supporting part and the outer supporting part. A back pressure sealing groove is formed in the bottom face of the suspended part. A back pressure sealing ring tightly attached to the elastic circular ring is arranged in the back pressure sealing groove. A back pressure cavity and an air sucking cavity which communicate with the suspended part are formed in the upper support. An exhaust cavity communicating with the back pressure cavity is formed in the upper cover. A compression cavity communicating with the air sucking cavity and the exhaust cavity is formed between the movable scroll plate and the static scroll plate. The scroll compressor is sufficient and reliable in sealing effect, and the technology difficulty of a sealing structure of the scroll compressor is low.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

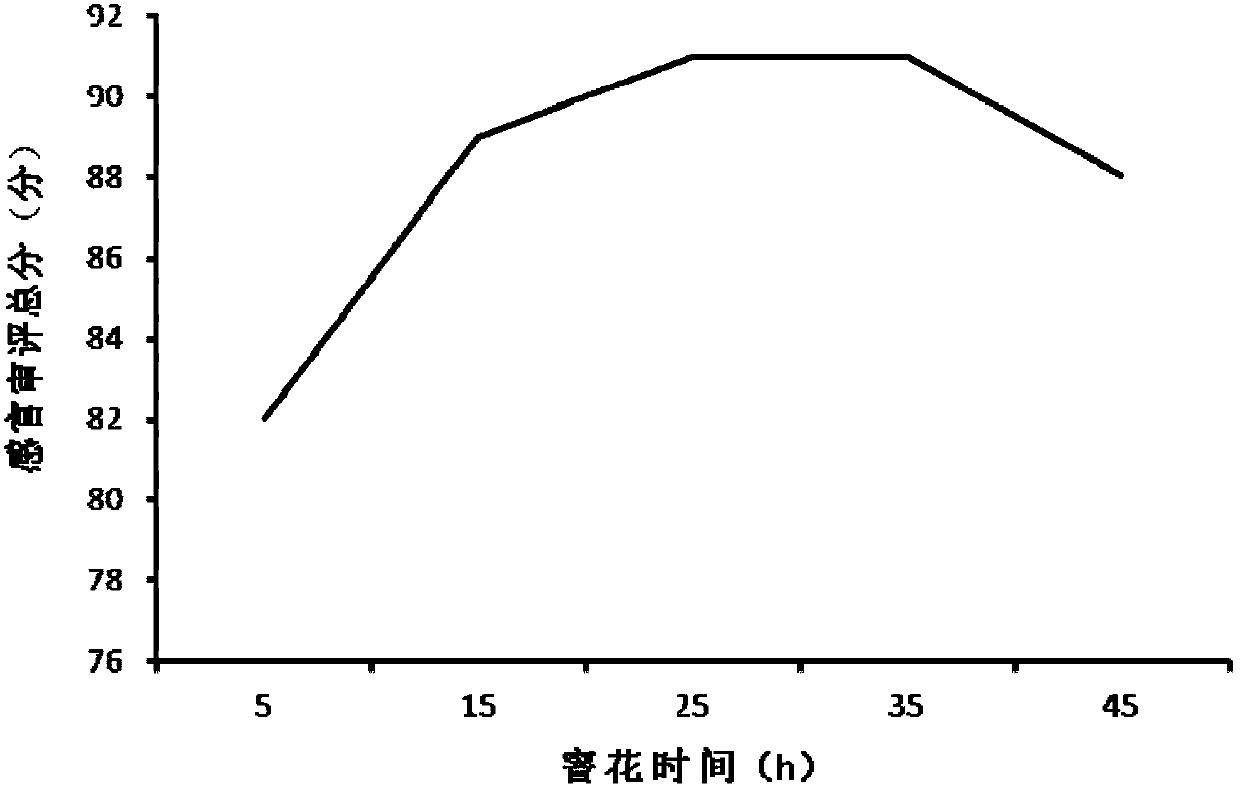

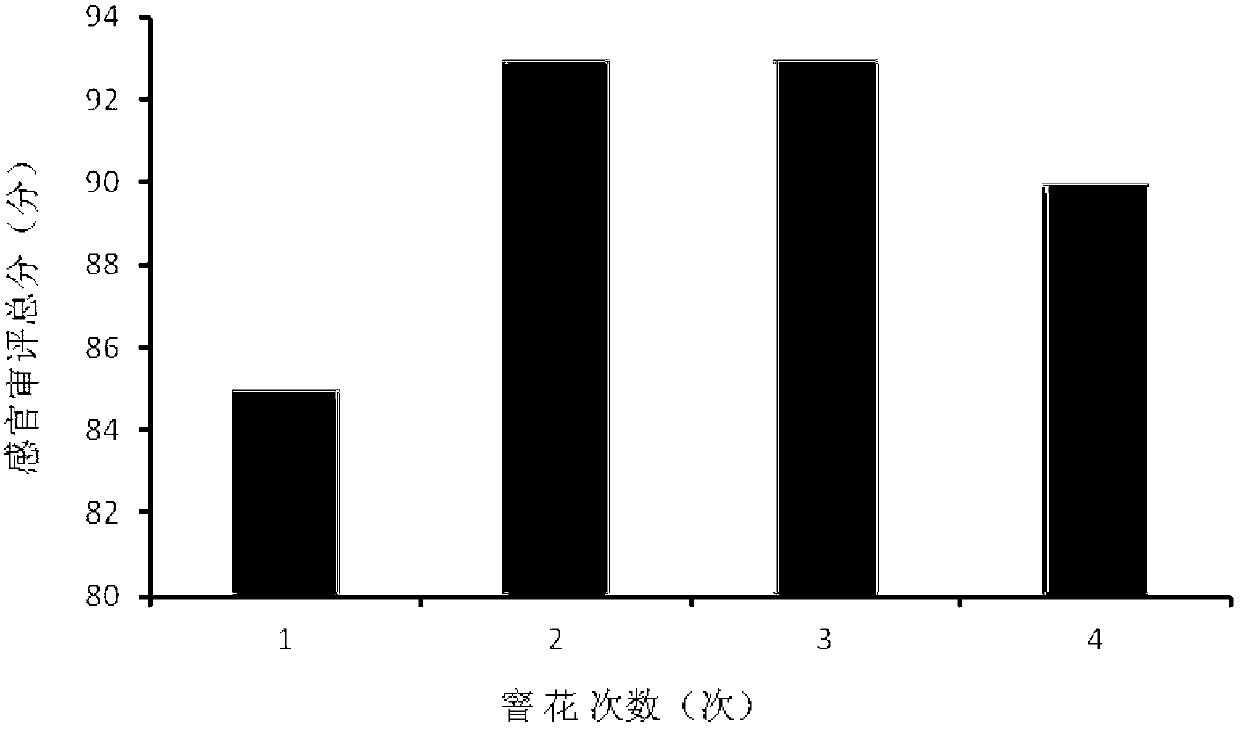

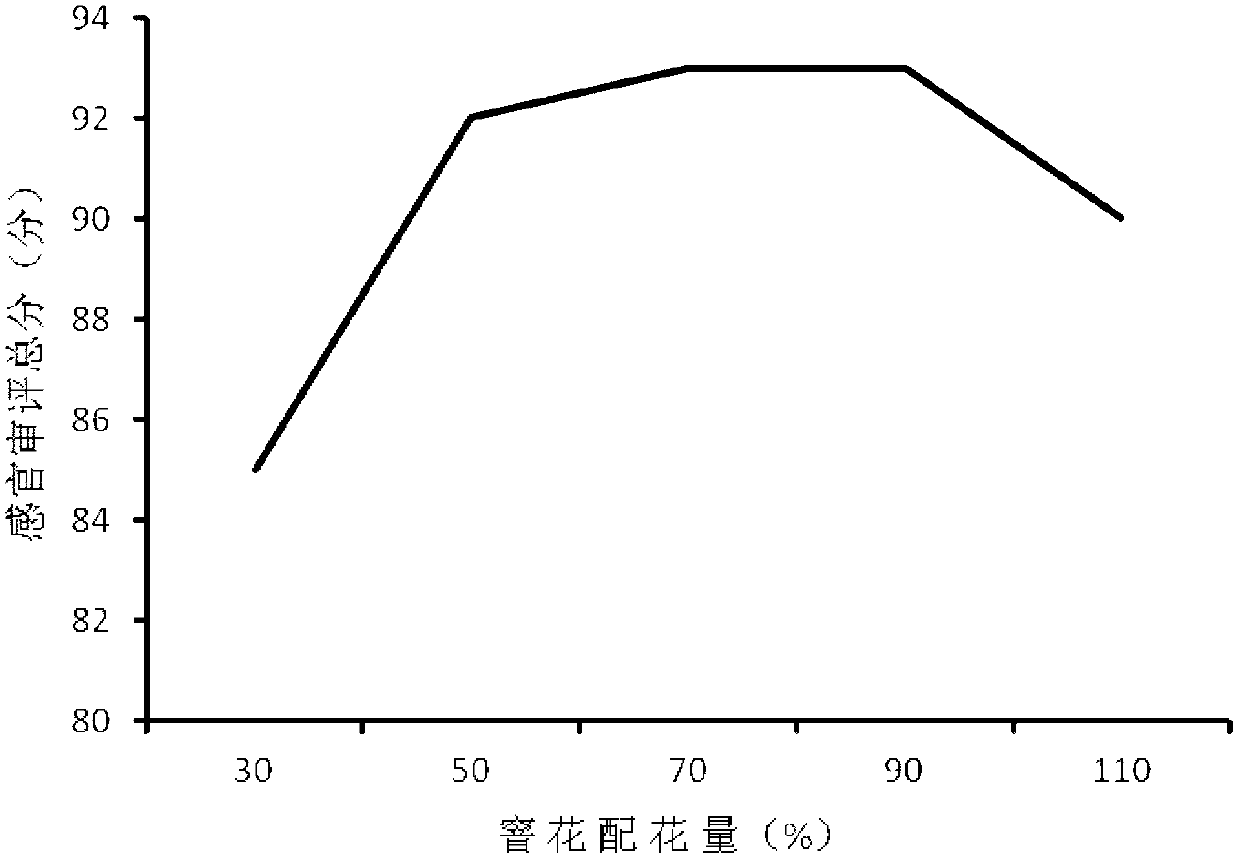

Method for preparing grapefruit scented tea

InactiveCN102763740AIncrease incomePromote incomePre-extraction tea treatmentAlcoholResource utilization

The invention belongs to technical field of tea science, and in particular relates to a novel method for preparing grapefruit scented tea. The method comprises the following steps of: processing a tea blank of baked green tea, screening grapefruit fresh flowers, scenting the flowers twice continuously, drying and the like. According to the method, processes of drying over repeated fire, ventilating and spreading for cooling in the conventional process for scented tea are eliminated, so that the time of scenting the flowers is shortened. According to the method, the tea blank of the high-gradebaked green tea is selected, and new flower scenting process parameters are adopted, so that the grapefruit scented tea is fresh, sweet and mellow, elegant and tasteful, fresh and mellow and lasting in flower charm; and the quality of the grapefruit scented tea is improved, so that the grapefruit scented tea is classified into the top ranks of tea products. According to the method, grapefruit flowers which are discarded by fruit growers in the 'flower thinning and fruit thinning' processes are utilized, so that the utilization rate of resources is improved, and the income increase of the fruit growers is promoted; the scenting season of the grapefruit scented tea follows the production season of spring tea, so that the second marketing peak can be formed after the spring tea marketing peak, the incomes of tea growers are improved, and the vigor of industry is improved.

Owner:HUAZHONG AGRI UNIV +2

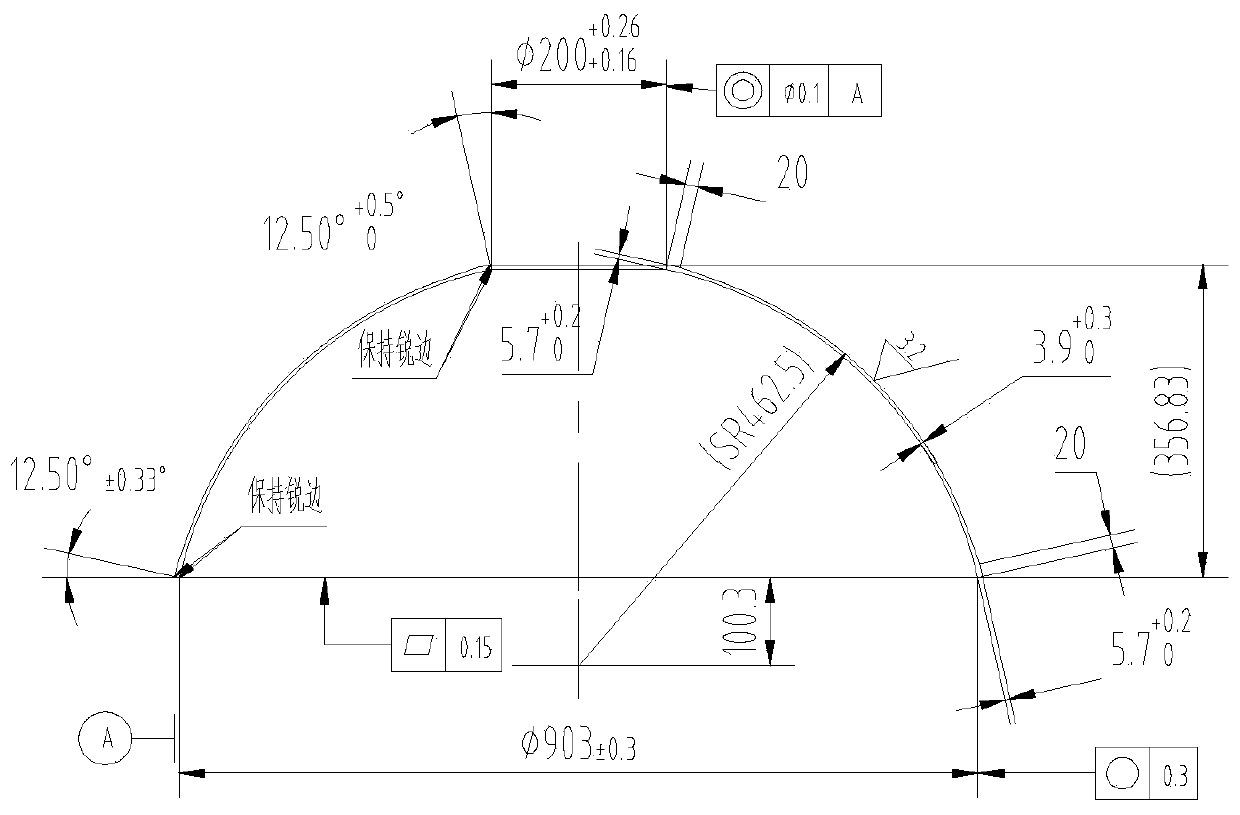

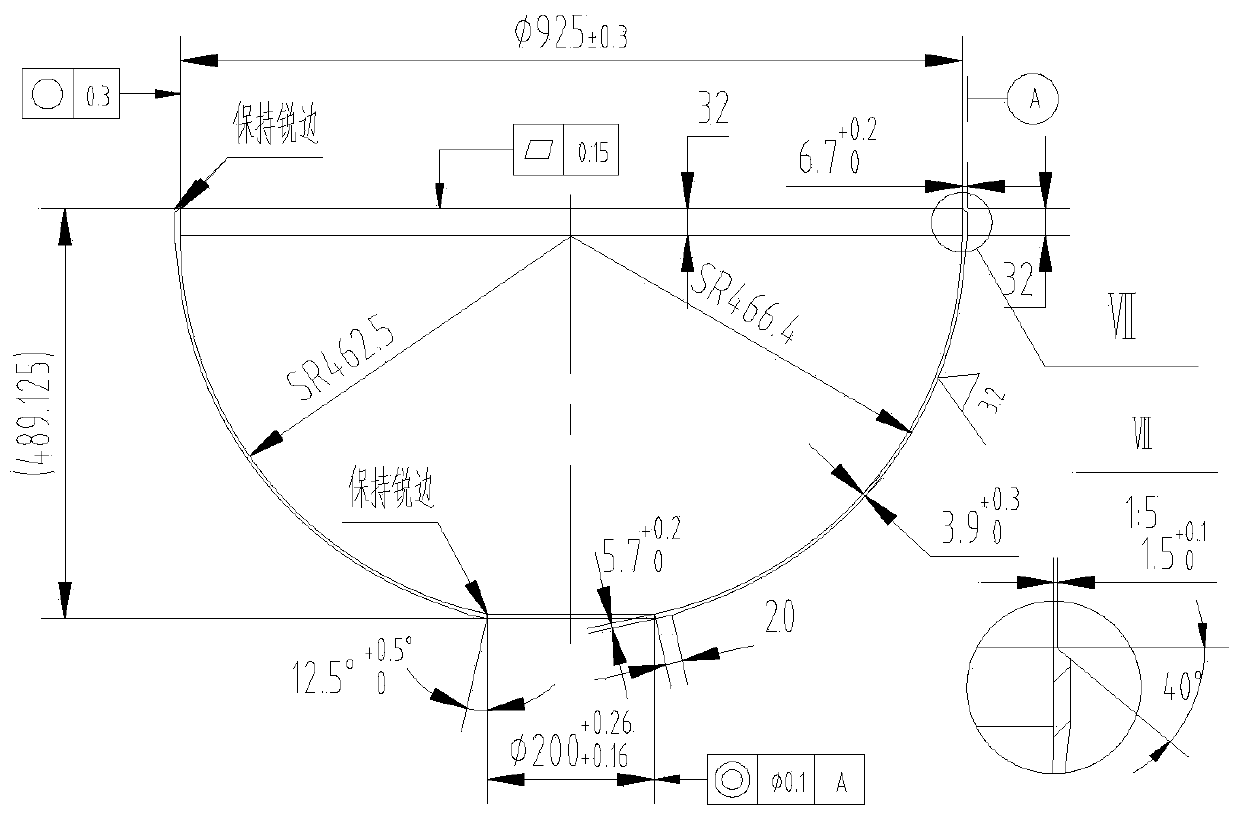

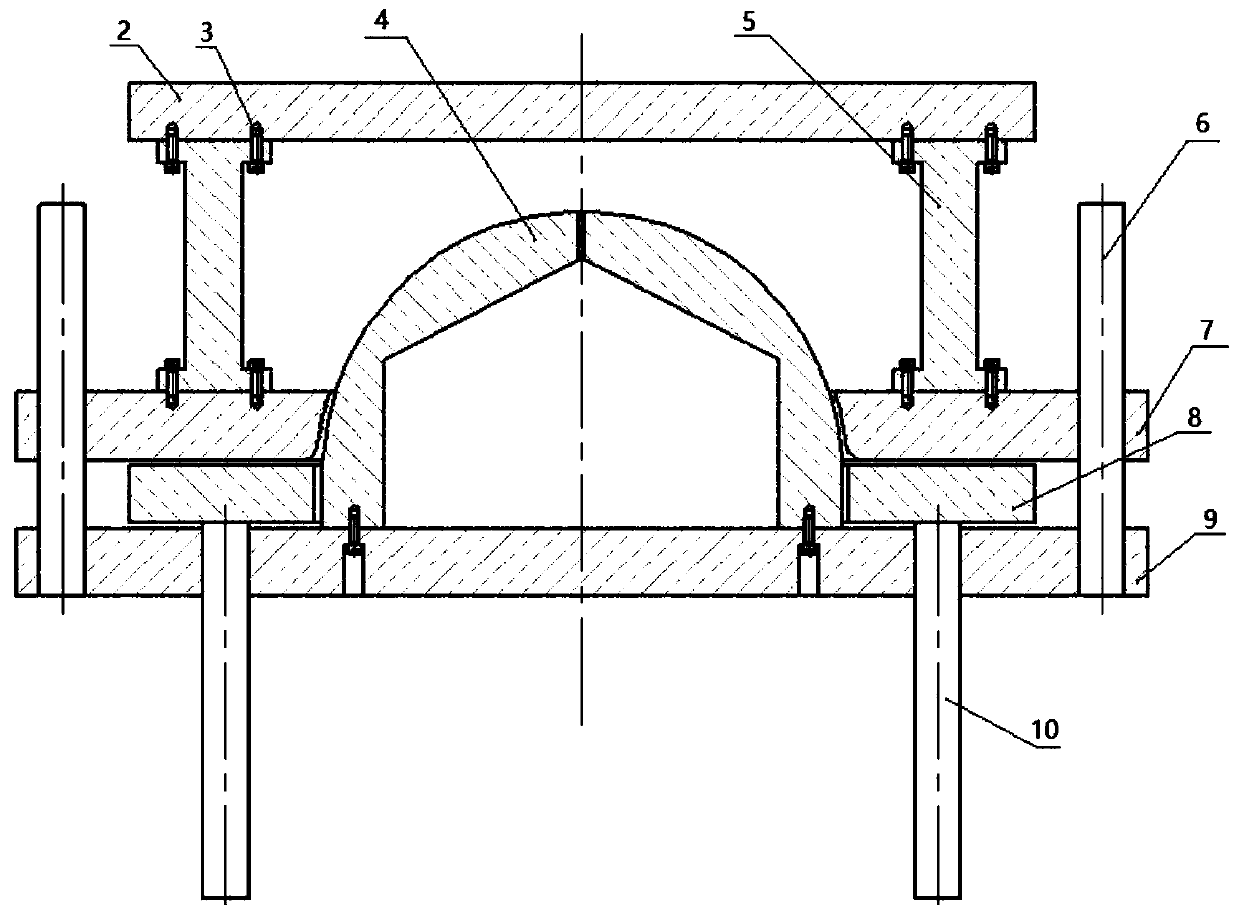

Machining process for precision forming of large thin-wall storage tank hemispheroid

The invention discloses a machining process for precision forming of a large thin-wall storage tank hemispheroid. The machining process comprises the steps of plasma gas cutting, punch forming, cutting, shaping, finish turning of an inner spherical surface, finish turning of an outer spherical surface and surface treatment. The diameter of the hemispheroid of a large thin-wall storage tank is phi925, the wall thickness of the hemispheroid is delta 3.9<0><+0.3>, the ovality of the hemispheroid is phi 0.3; and the diaphragm type storage tank is high in size requirement and high in numerical control machining difficulty, and particularly, the diaphragm type storage tank is made of aluminum alloy and is insufficient in strength and rigidity, large in machining deformation and high in machining difficulty, so that the diaphragm type storage tank is a hemispheroid with larger diameter, the surface linear speed changes along with changes of the height of a part, different main shaft rotatingspeeds need to be selected according to different annular belts during turning, and therefore the machining difficulty is further improved. According to the machining process, ultrasonic measurementand special tool expansion clamping are explored and adopted for numerical control machining, the wall thickness tolerance of an upper hemisphere and a lower hemisphere of the storage tank is 3.9<0><+0.3>, the ovality is phi 0.3, the tensile strength sigma b after heat treatment is larger than or equal to 340 MPa, and the elongation is larger than 10%.

Owner:贵州航天朝阳科技有限责任公司

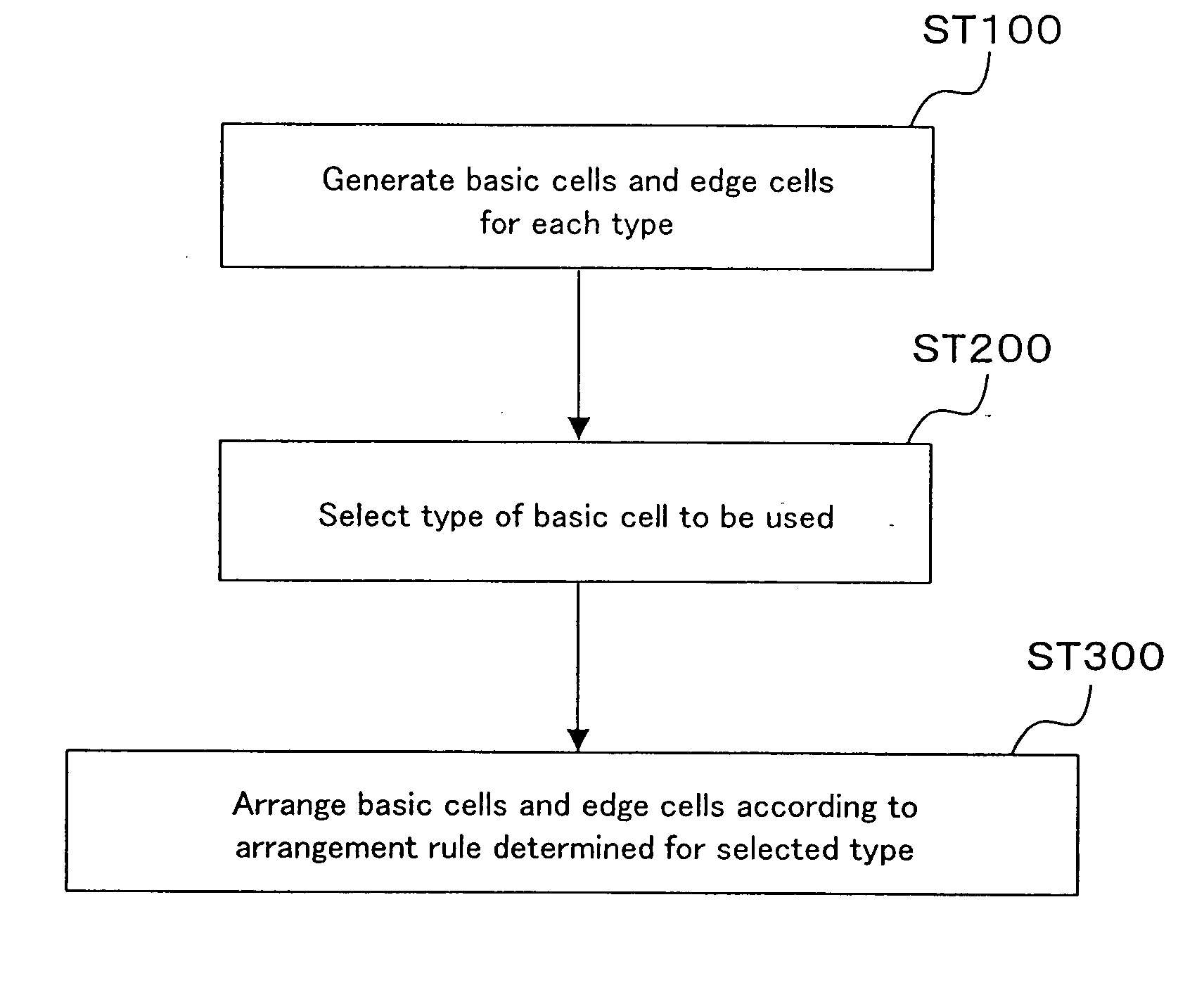

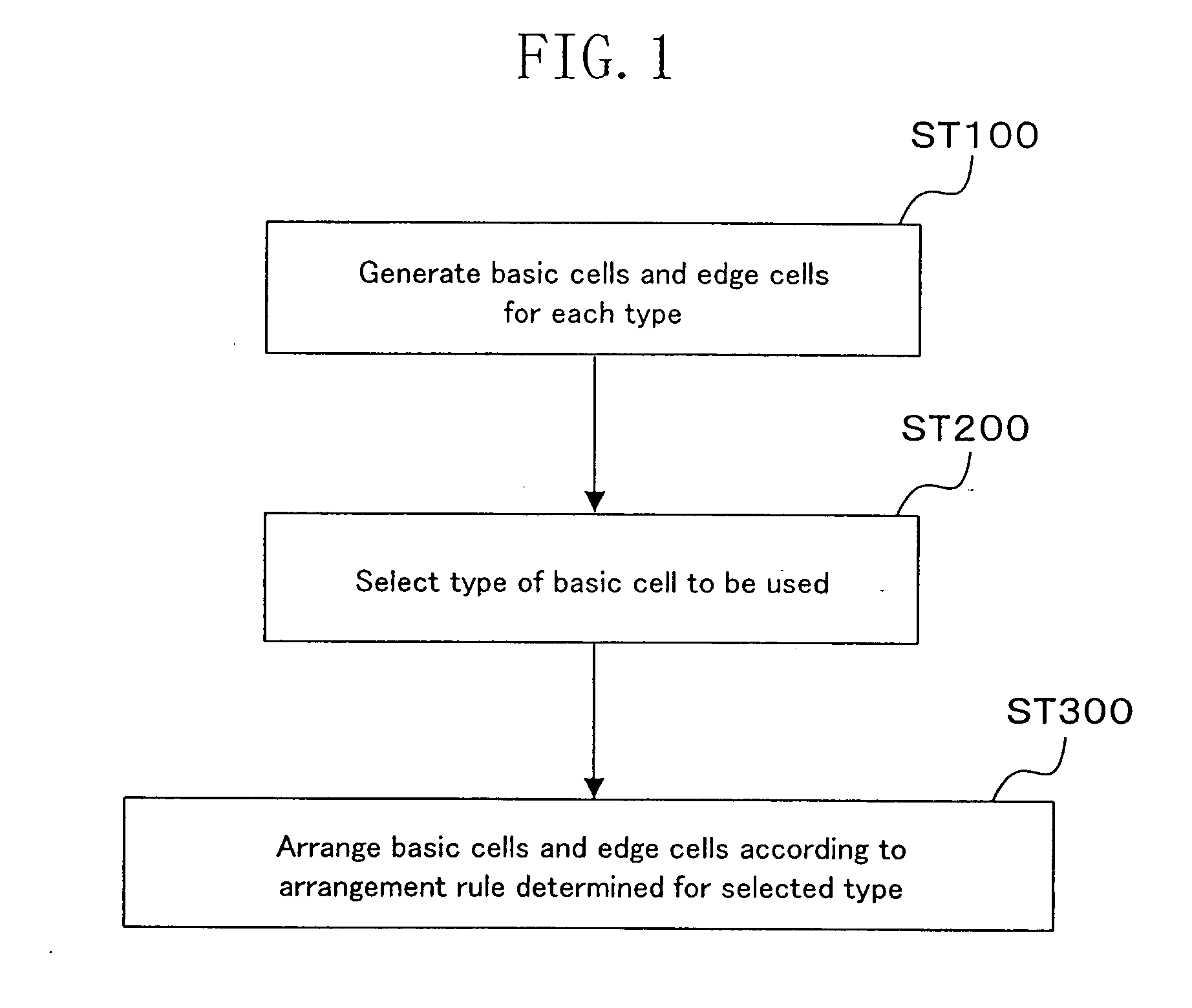

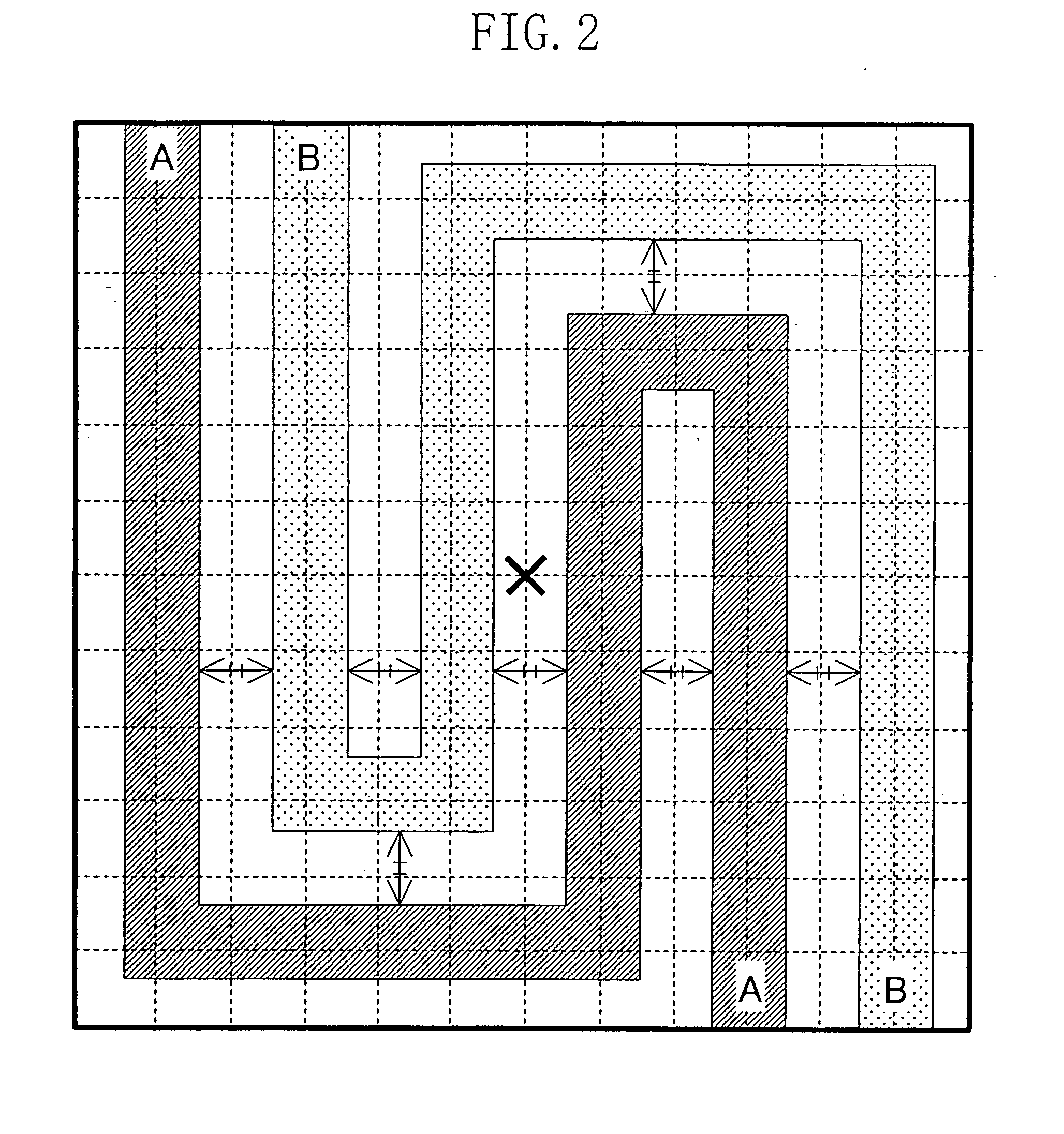

Basic cell, edge cell, wiring shape, wiring method, and shield wiring structure

ActiveUS20070162884A1Doubles processing time requiredIncrease the difficulty of the processSemiconductor/solid-state device detailsSolid-state devicesEdge cellElectrical and Electronics engineering

A basic cell of the present invention comprises a plurality of wires which constitute a wiring route of 90°, one ends of the plurality of wires being on one of opposite sides, and the other ends of the plurality of wires being on the other one of the opposite sides, wherein: each of the one ends of the plurality of wires is point-symmetric to any of the other ends of the plurality of wires with respect to the center of the area of the basic cell; and routes of the plurality of wires do not cross one another.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

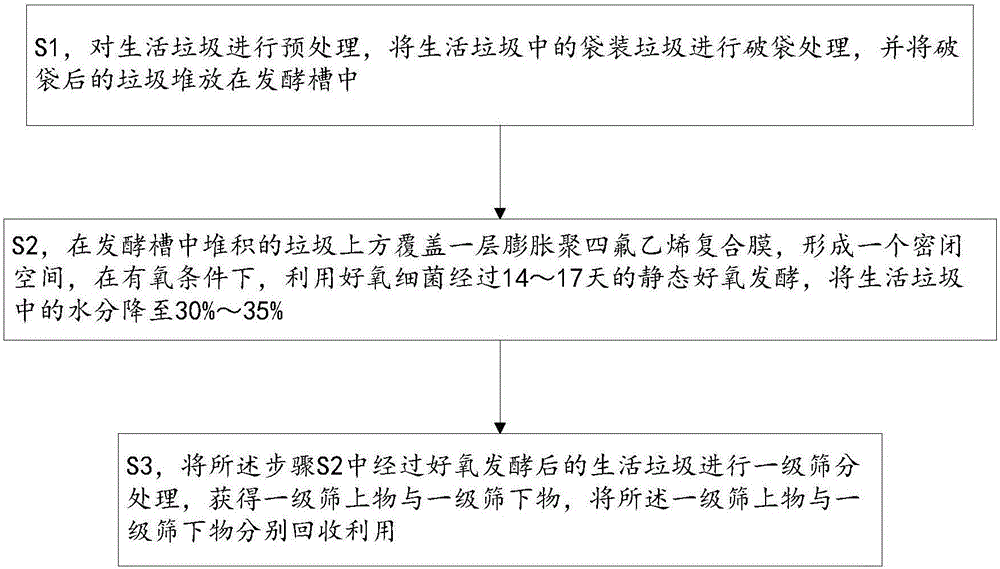

Household waste handling method

The invention discloses a domestic garbage treatment method and relates to the technical field of solid waste disposal. The domestic waste treatment method includes the following steps: S1, pretreating the domestic waste, breaking the bagged waste in the domestic waste, and stacking the broken bag in a fermentation tank; S2, fermenting The garbage accumulated in the tank is covered with a layer of expanded polytetrafluoroethylene composite film to form a closed space. Under aerobic conditions, aerobic bacteria are used for 14 to 17 days of static aerobic fermentation to reduce the moisture in domestic garbage. to 30% to 35%; S3, performing primary sieving treatment on the domestic garbage after aerobic fermentation in the step S2 to obtain the first-level sieve and the first-level sieve, and the first-level sieve The material and the undersize of the primary sieve are recycled separately. The beneficial effect of the invention is that the domestic waste can be decomposed and dried at low cost, the water content in the domestic waste can be reduced, the process is simplified, and the system investment and operation cost are reduced.

Owner:HUNAN VARY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com