Light-emitting diode (LED) high-roof lamp

A technology for LED high bay lights and components, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc. Problems such as the service life of LED lamps, to achieve good heat dissipation effect, compact structure, easy to disassemble and replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

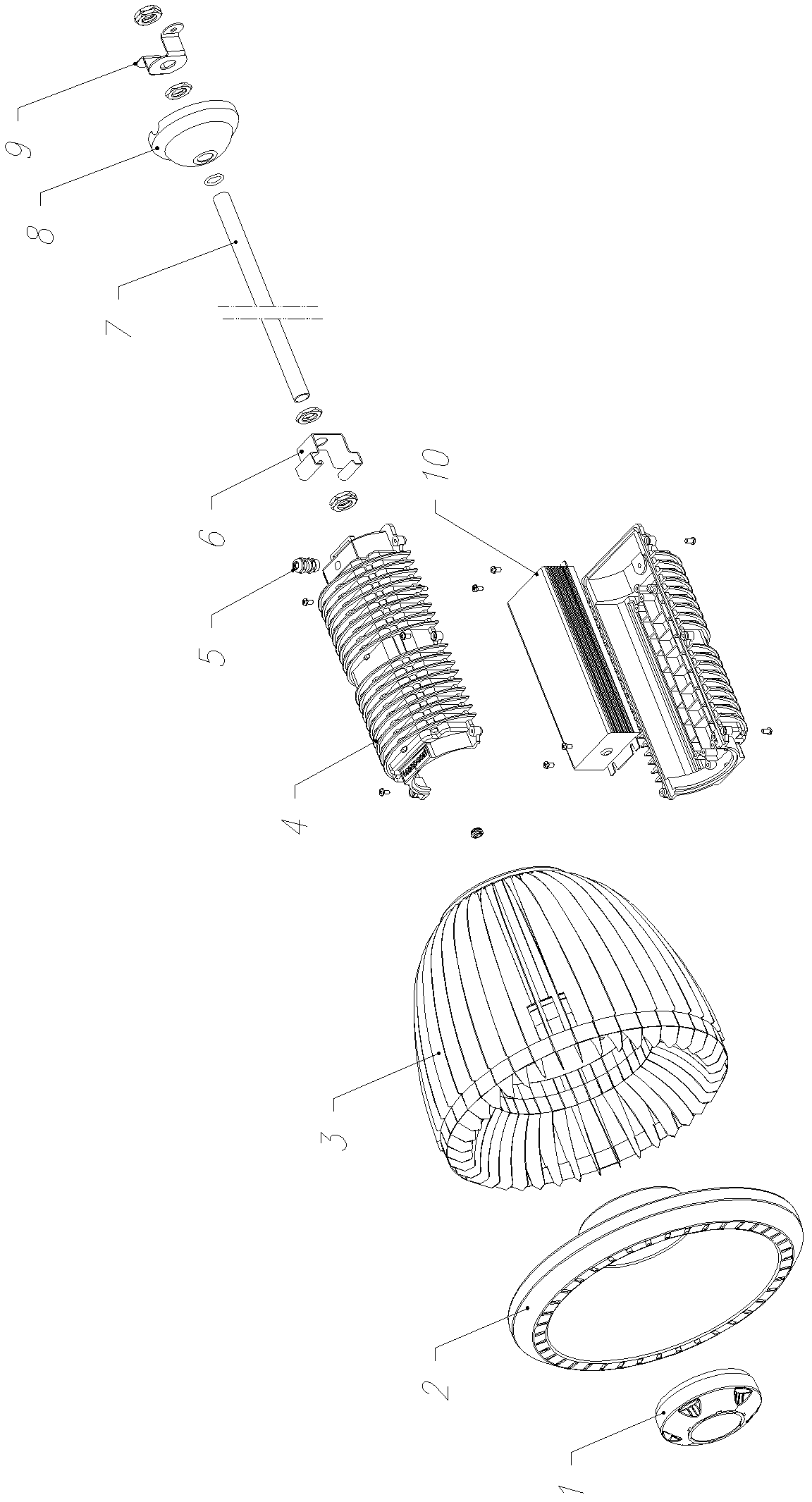

[0039] The implementation of the present invention will be described in detail below with drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

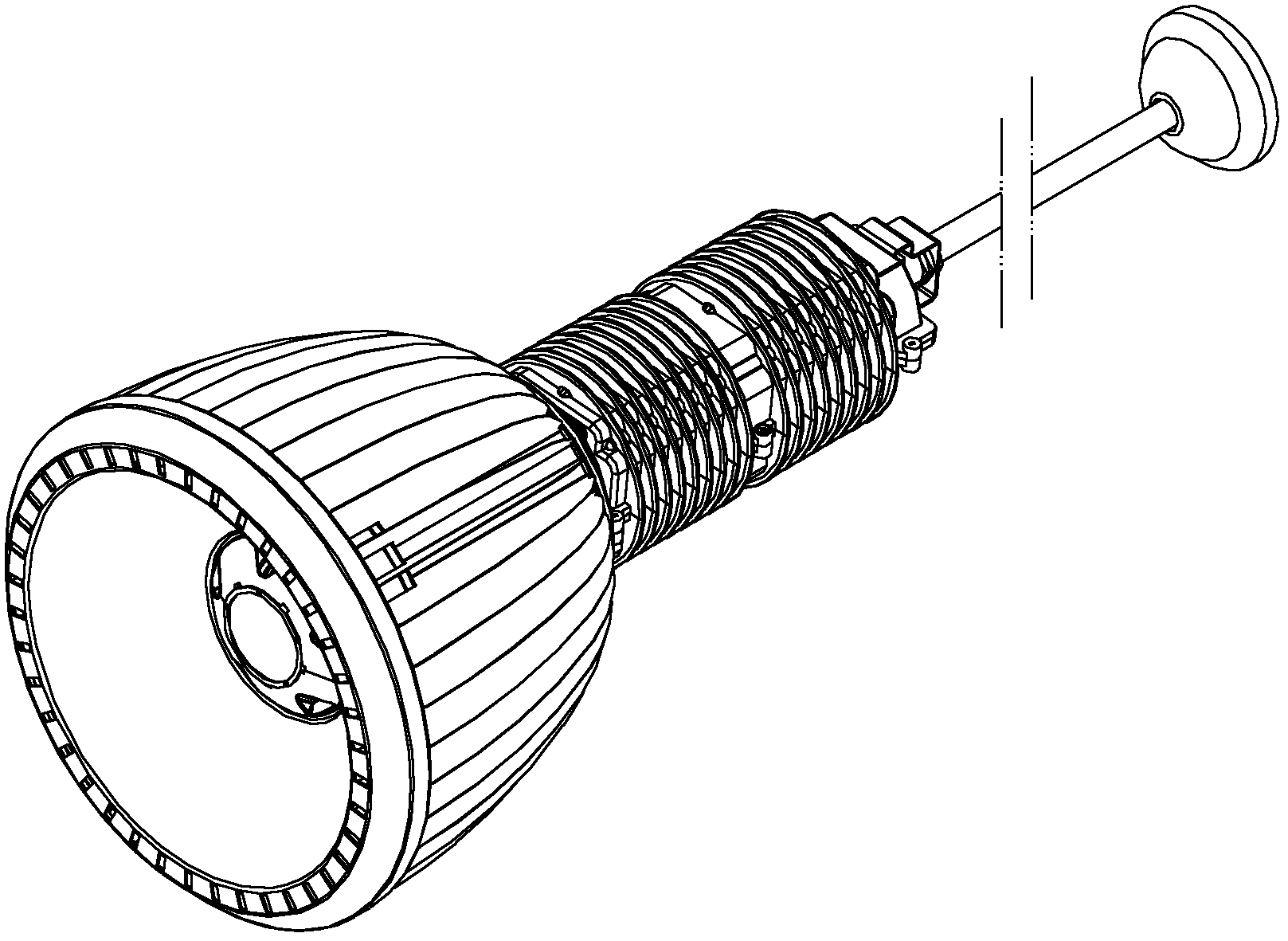

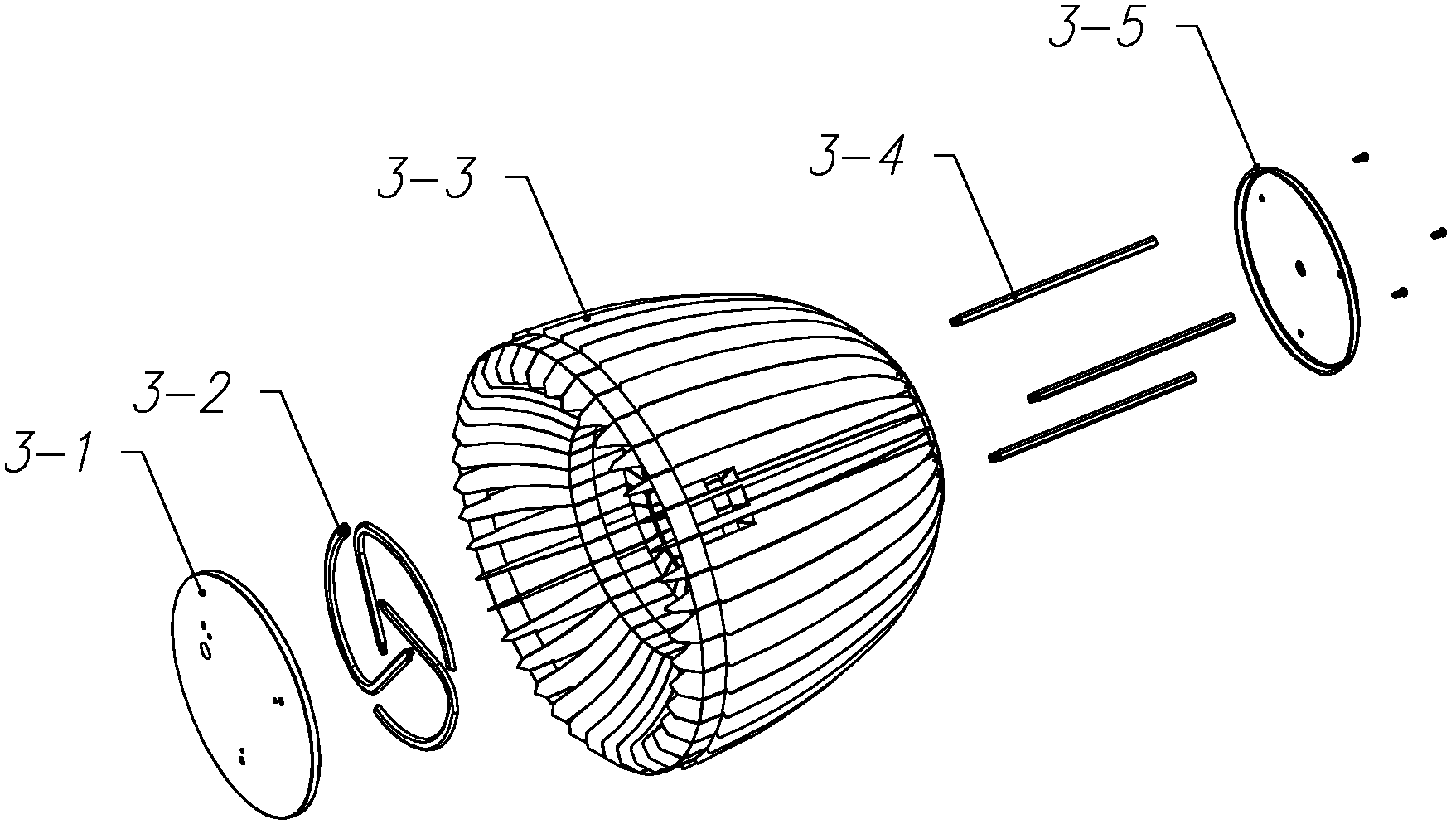

[0040] The core idea of the present invention is that the LED high bay light includes: a driver, a heat sink assembly and a light source assembly, wherein the heat sink assembly is a bowl-shaped structure, and the heat dissipation fins of the heat sink assembly are arranged in a circular array and mutually Fasten between them to form a bowl wall frame, the light source assembly is an integral package structure, fixed in the bowl belly surrounded by the bowl wall frame, and electrically and flexibly connected with the driver fixed at the bottom of the bowl structure.

[0041]The LED high bay light of the present invention will be described below with an embodiment.

[0042] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com