Steering sensor capable of simultaneously measuring steering angle and torque

A technology of steering sensor and steering angle, which is applied in the field of sensors, can solve problems such as inability to measure steering torque, and achieve the effects of simple structure, convenient disassembly and replacement, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

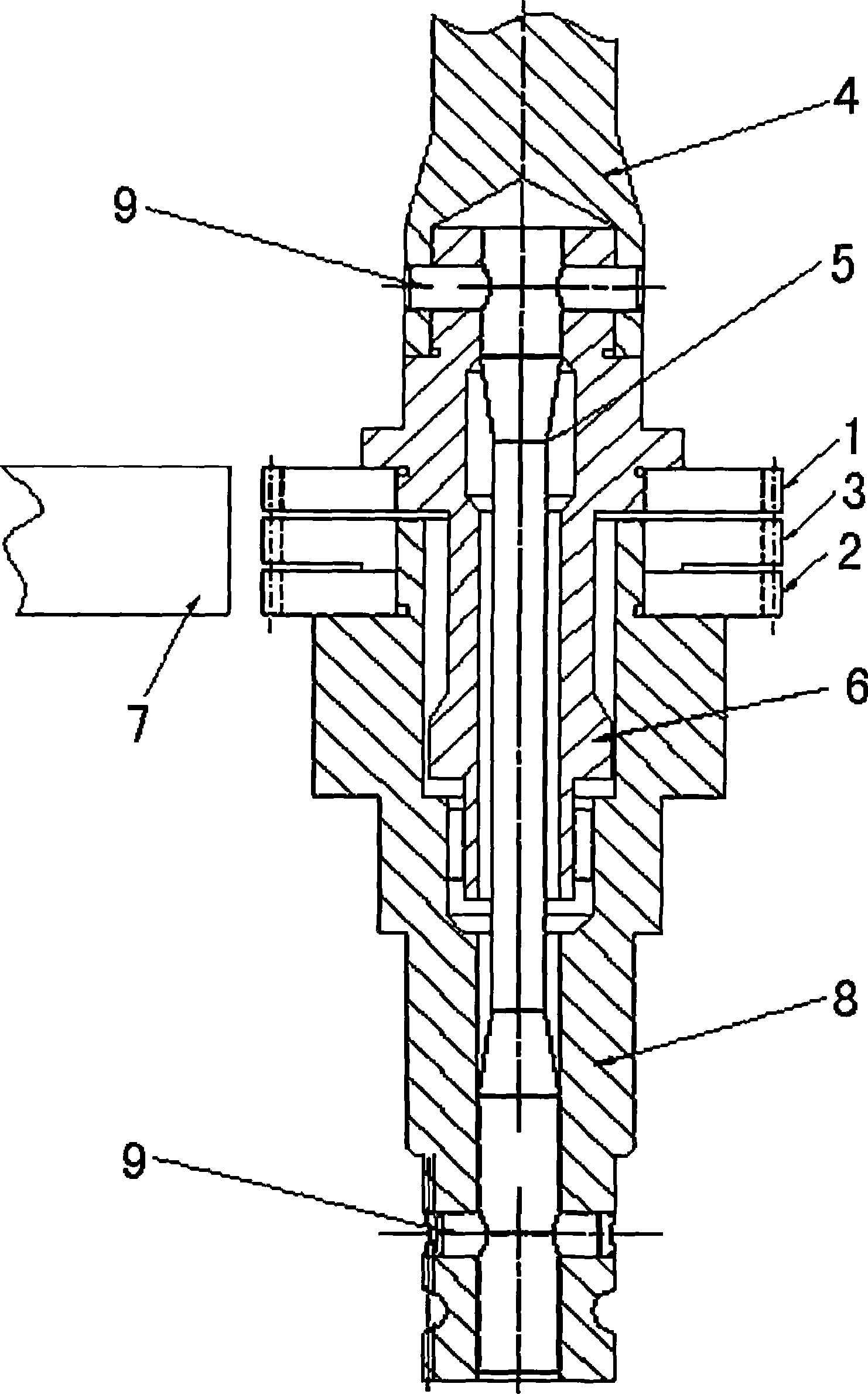

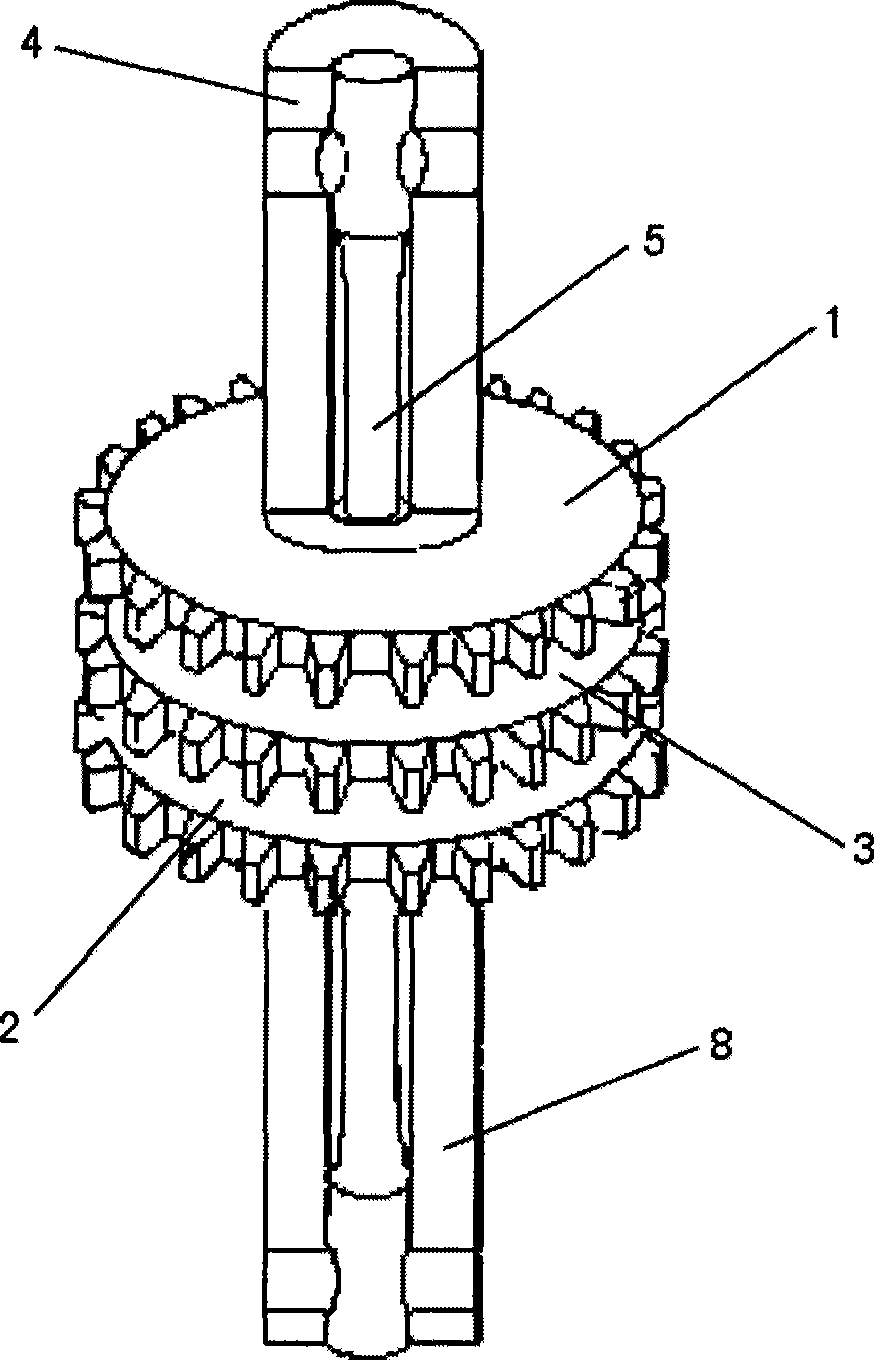

[0031] Such as figure 1 , 2 The shown embodiment of the steering sensor capable of simultaneously measuring steering angle and torque of the present invention includes an input shaft 4, an output shaft 8, a torsion bar 5, a first signal disc 1, a second signal disc 2, and a third signal Disc 3; one end of torsion bar 5 is connected with input shaft 4, and the other end is connected with output shaft 8. The first signal disc 1 is connected to the input shaft 4 ; the second signal disc 2 and the third signal disc 3 are connected to the output shaft 8 .

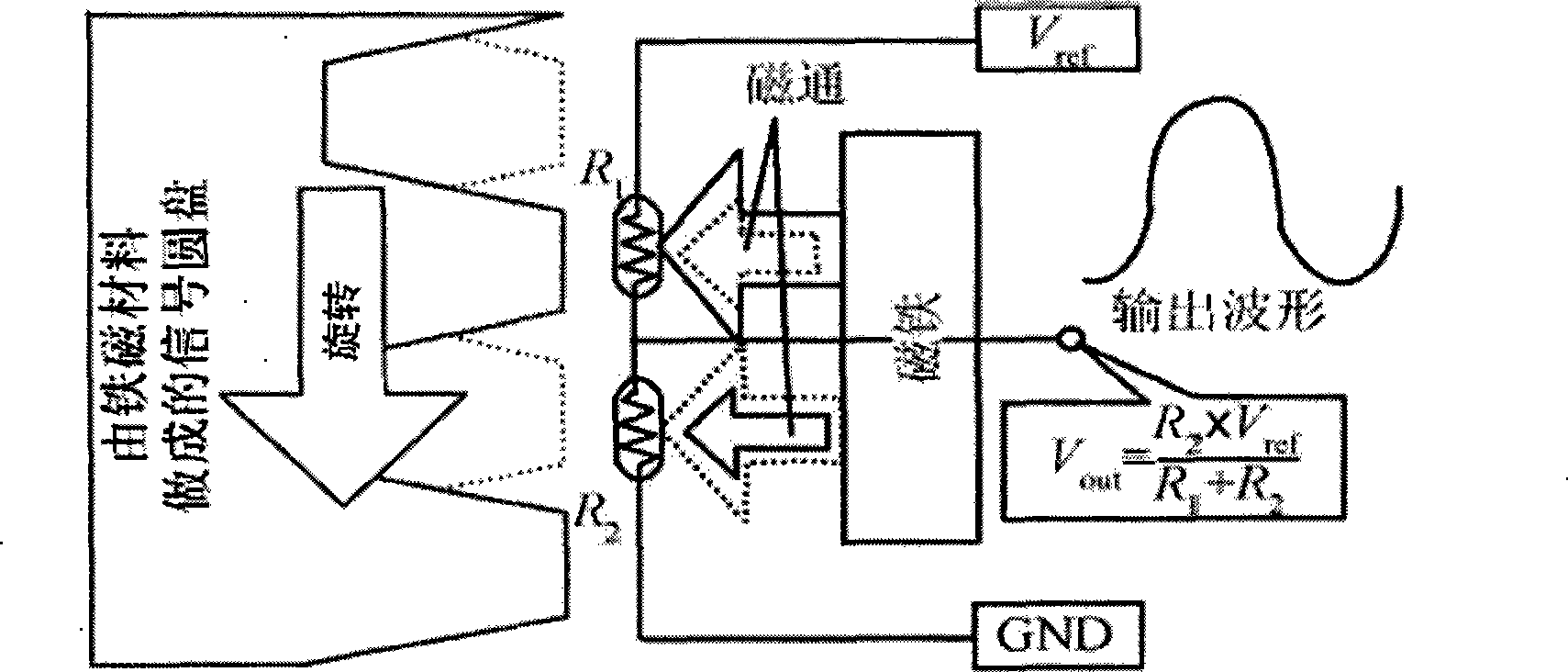

[0032] The above-mentioned three signal discs are gears made of ferromagnetic material, the number of teeth of the first signal disc and the second signal disc are the same, and the number of teeth is 36; the number of teeth of the second signal disc is higher than that of the third signal disc. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com