Assembly type steel bridge and building method thereof

A prefabricated and bridge technology, which is applied in erecting/assembling bridges, bridge construction, bridges, etc., can solve the problems of complex assembly, insufficient stability, and installation structure that cannot meet the requirements of construction, and achieve rapid erection, reduce light pollution, The effect of good environmental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and examples.

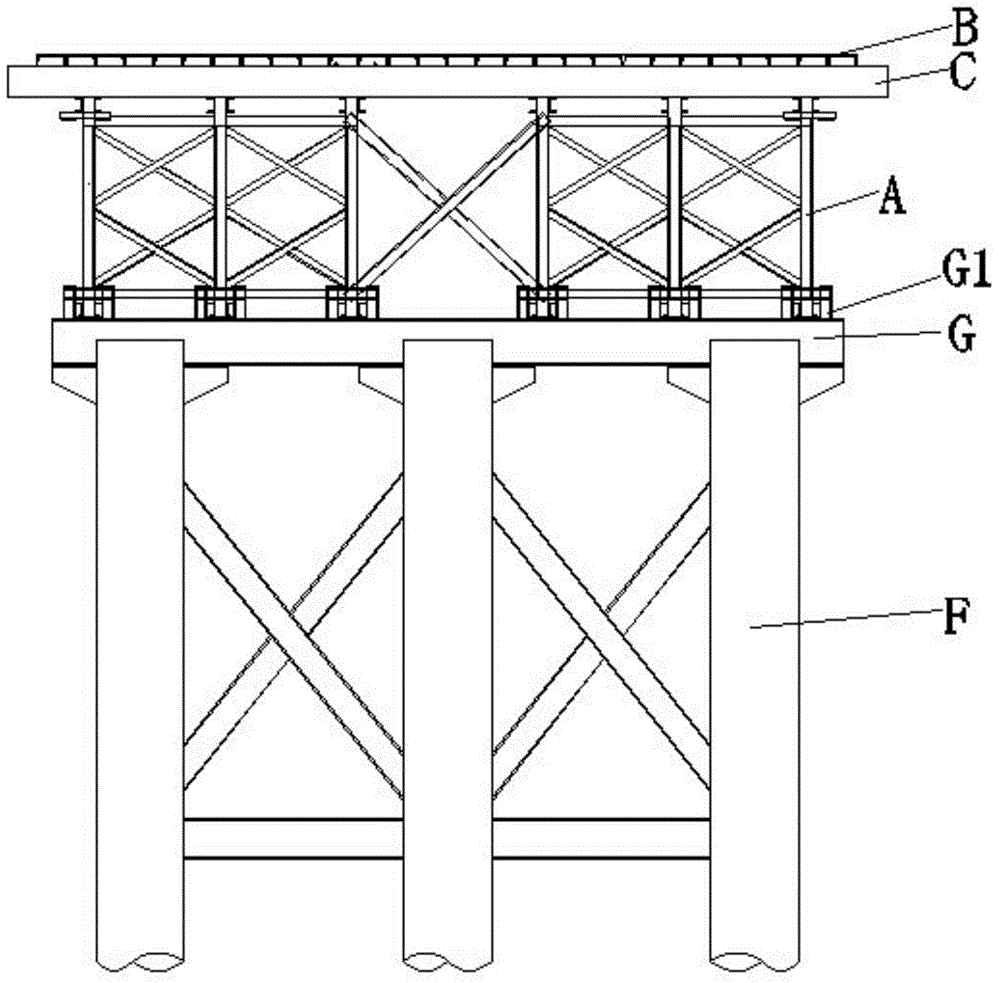

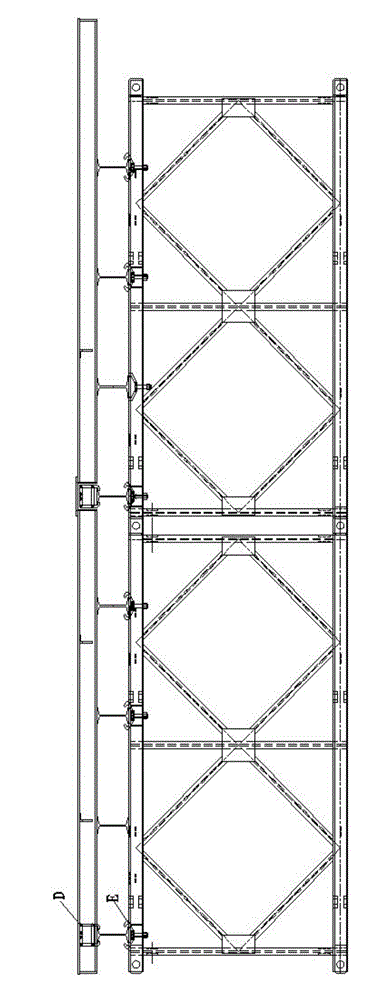

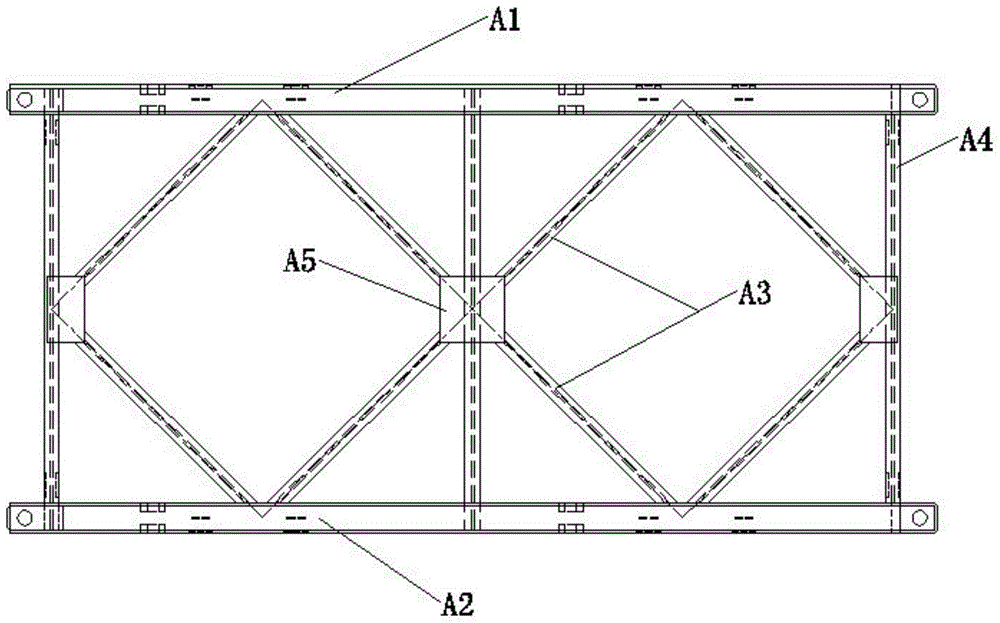

[0024] see Figure 1 to Figure 4 , a prefabricated steel bridge described in this embodiment includes a support frame A, a bridge deck B, an I-beam C, a bridge deck connector D, and an I-beam locking mechanism E; an I-beam is arranged above the support frame A C, the extension direction of I-beam C is perpendicular to the extension direction of support frame A, support frame A supports I-beam C, bridge deck B is laid on I-beam C, and support frame A and I-beam C adopt I-beam The locking mechanism E is fixedly installed, and the I-beam C and the bridge deck B are fixedly installed with the bridge deck connector D; the supporting frame A is composed of Bailey sheets, and the Bailey sheets include the upper beam A1, the lower beam A2, The oblique bar A3, the vertical bar A4, the decorative plate A5, the upper beam A1, the vertical bar A4, and the lower beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com