Heat-conducting and heat-dissipating film containing graphene

A technology of heat dissipation film and graphene, applied in layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of fragile particle dust, low tensile strength, inconvenient installation and use, etc., to achieve Thin thickness, high processing difficulty, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

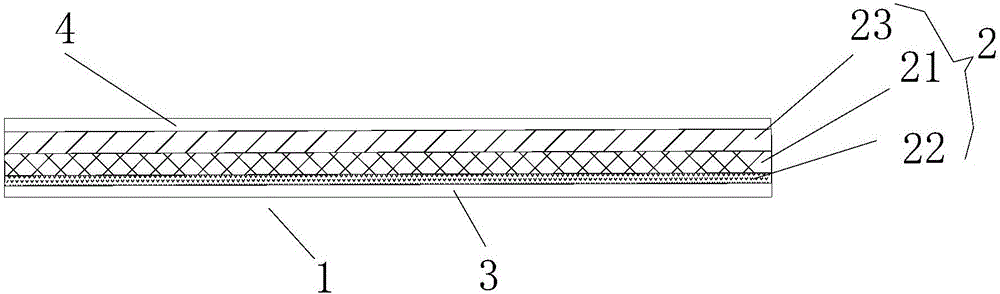

[0025] Such as figure 1 As shown, the graphene heat-conducting and heat-dissipating film includes a heat-dissipating film body 1, and the heat-dissipating film body 1 includes a graphene composite film layer 2, and the graphene composite film layer 2 includes a graphene layer 21 and a first substrate 22, so The first substrate 22 and the graphene layer 21 are composited by the first adhesive layer 23, the thickness of the graphene layer 21 is 0.001 μm, and the purity of the graphene layer 21 is 99.5%. The bottom surface and the top surface of the graphene composite film layer 2 are respectively provided with a first adhesive layer 3 and a second adhesive layer 4 . Through the first adhesive layer 3 and the second adhesive layer 4, it is convenient to be fixed with the heat generating body that needs to dissipate heat.

[0026] Preferably, the first base material 22 is copper foil, and the thickness of the first base material 22 is 0.001 μm. Copper foil has good calendering p...

Embodiment 2

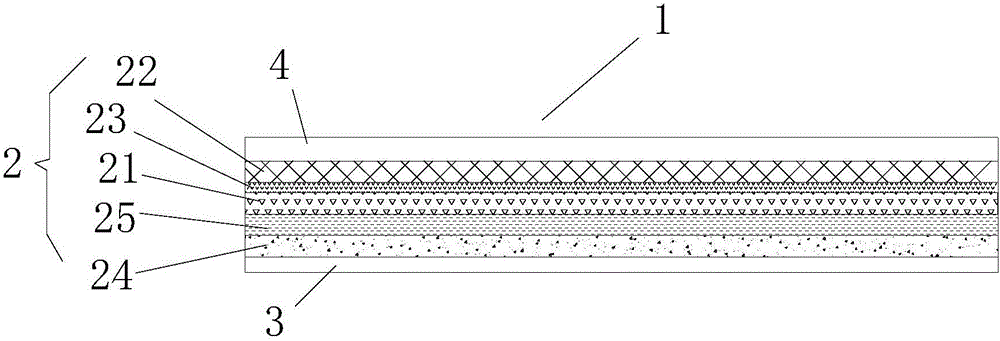

[0033] Such as figure 2 As shown, the graphene heat-conducting and heat-dissipating film includes a heat-dissipating film body 1, and the graphene composite film layer 2 includes a graphene layer 21, a first substrate 22 and a second substrate 24, and the first substrate 22 and the The graphene layer 21 is bonded to each other by the first bonding layer 23, and the second substrate 24 and the graphene layer 21 are composited by the second bonding layer 25. The graphene layer 2 The thickness is 2 μm, and the purity of the graphene layer 2 is 99.9%. Wherein, the graphene layer 2 is high-purity graphene, and the bottom surface and the top surface of the graphene composite film layer 2 are respectively provided with a first adhesive layer 3 and a second adhesive layer 4 .

[0034] Preferably, the first substrate 22 and the second substrate 24 are aluminum foil, and the thickness of the first substrate is 2 μm.

[0035] Preferably, the first bonding layer 23 and the second bondi...

Embodiment 3

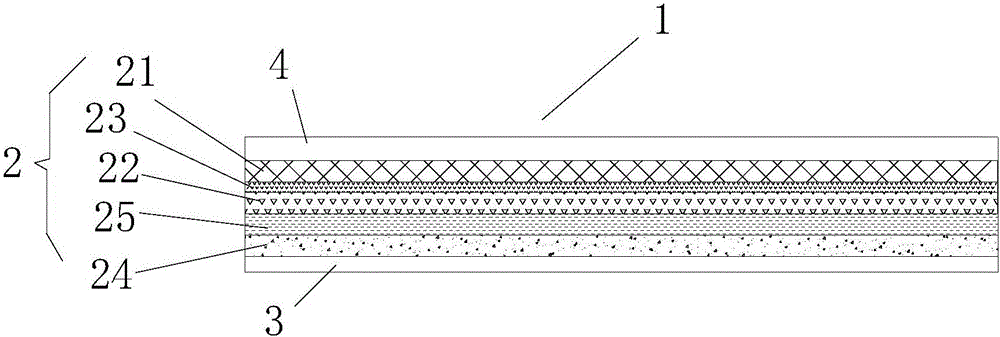

[0042] Such as image 3 As shown, the graphene heat-conducting and heat-dissipating film includes a heat-dissipating film body 1, and the graphene composite film layer 2 includes a first graphene layer 21, a first base material layer 22 and a second graphene layer 24, and the first graphite The graphene layer 21 and the first substrate 22 are bonded together by a first adhesive layer 23, and the second graphene layer 24 and the first substrate 22 are composited by a second adhesive layer 25 , the thickness of the first graphene layer 21 and the second graphene layer 24 is 1 μm, the purity of the first graphene layer 21 and the second graphene layer 24 is 99.7%, and the graphene The bottom surface and the top surface of the composite film layer 2 are respectively provided with a first adhesive layer 3 and a second adhesive layer 4 .

[0043] Preferably, the first substrate 22 is a PI plastic film, and the thickness of the first substrate 22 is 1000 μm. PI plastic film has exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com