Electric-conducting and heat-conducting thin-film component

A technology of thin film components, electrical conduction and heat conduction, applied in the direction of electrical components, electrical solid devices, semiconductor devices, etc., can solve the problems of incompetent thickness of parts, poor heat dissipation and temperature uniformity, etc., and achieve the reduction of thickness of parts, thin thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

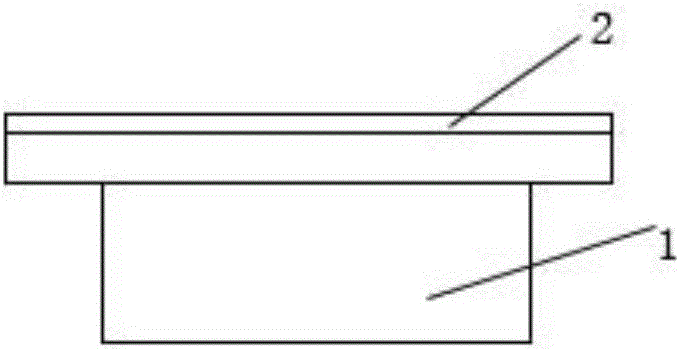

[0018] See figure 1 As shown, a conductive and heat-conducting film assembly includes a heat source 1 and a heat-conducting film 2 , and the heat-conducting film 2 covers the surface of the heat source 1 . The heat conducting film 2 is a synthetic material composed of graphene and / or metal.

[0019] The graphene material is carbon 60, carbon 70, graphene, carbon nanotubes, carbon fiber, graphite, diamond-like carbon or a thin film composed of at least one of the above materials. The metal is aluminum, copper, copper, brass, silver, gold, magnesium, zinc, iron, stainless steel, titanium or an alloy formed by at least one of the above metals. The synthetic material of the graphene material and metal is that the graphene material is grown on the metal surface, or the metal is deposited on the graphene material surface, or the graphene material is deposited on the metal surface, or the graphene material and the metal are mixed in any proportion formed film. The metal material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com