Patents

Literature

143results about How to "Thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint and preparation method for same

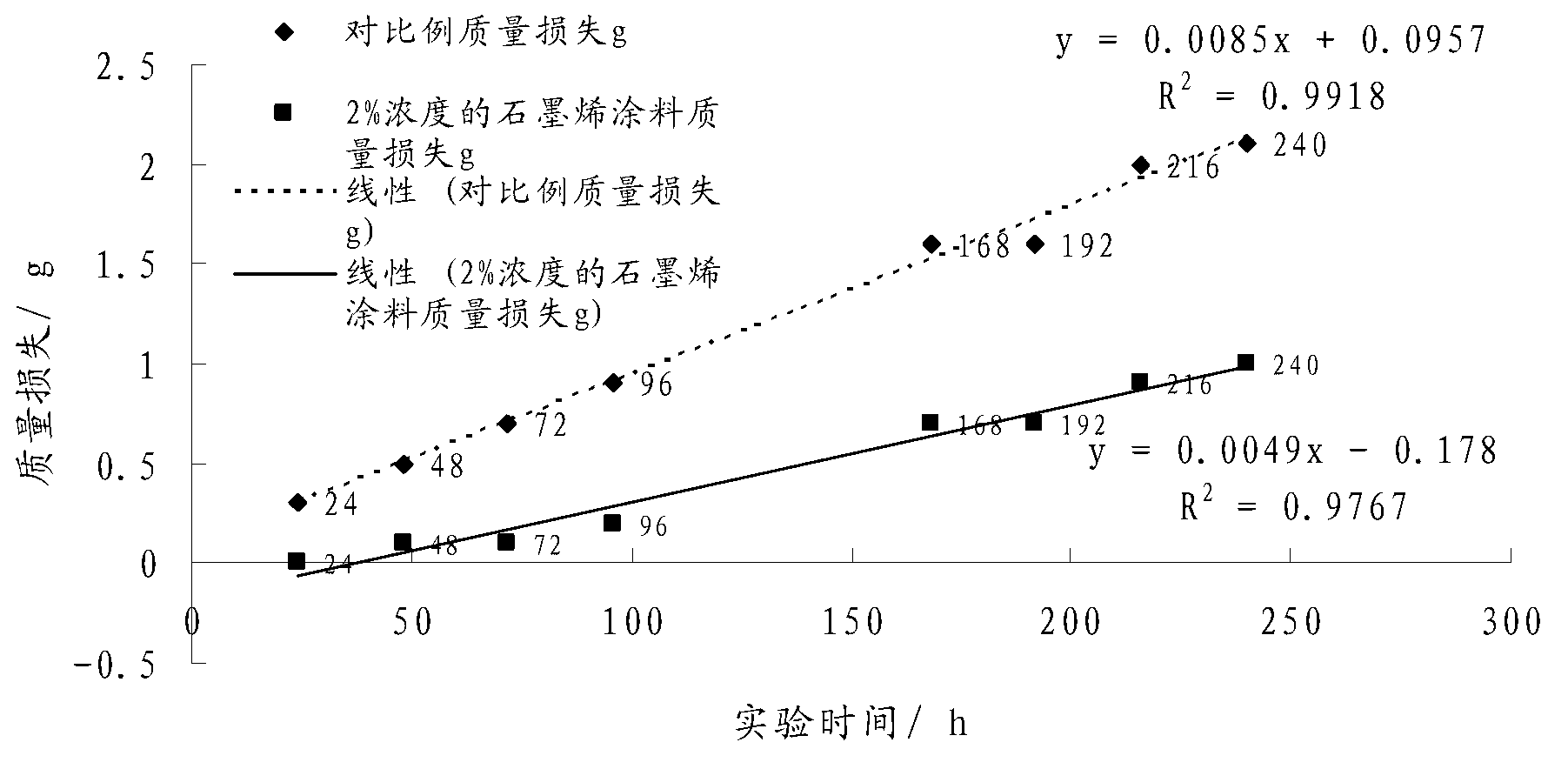

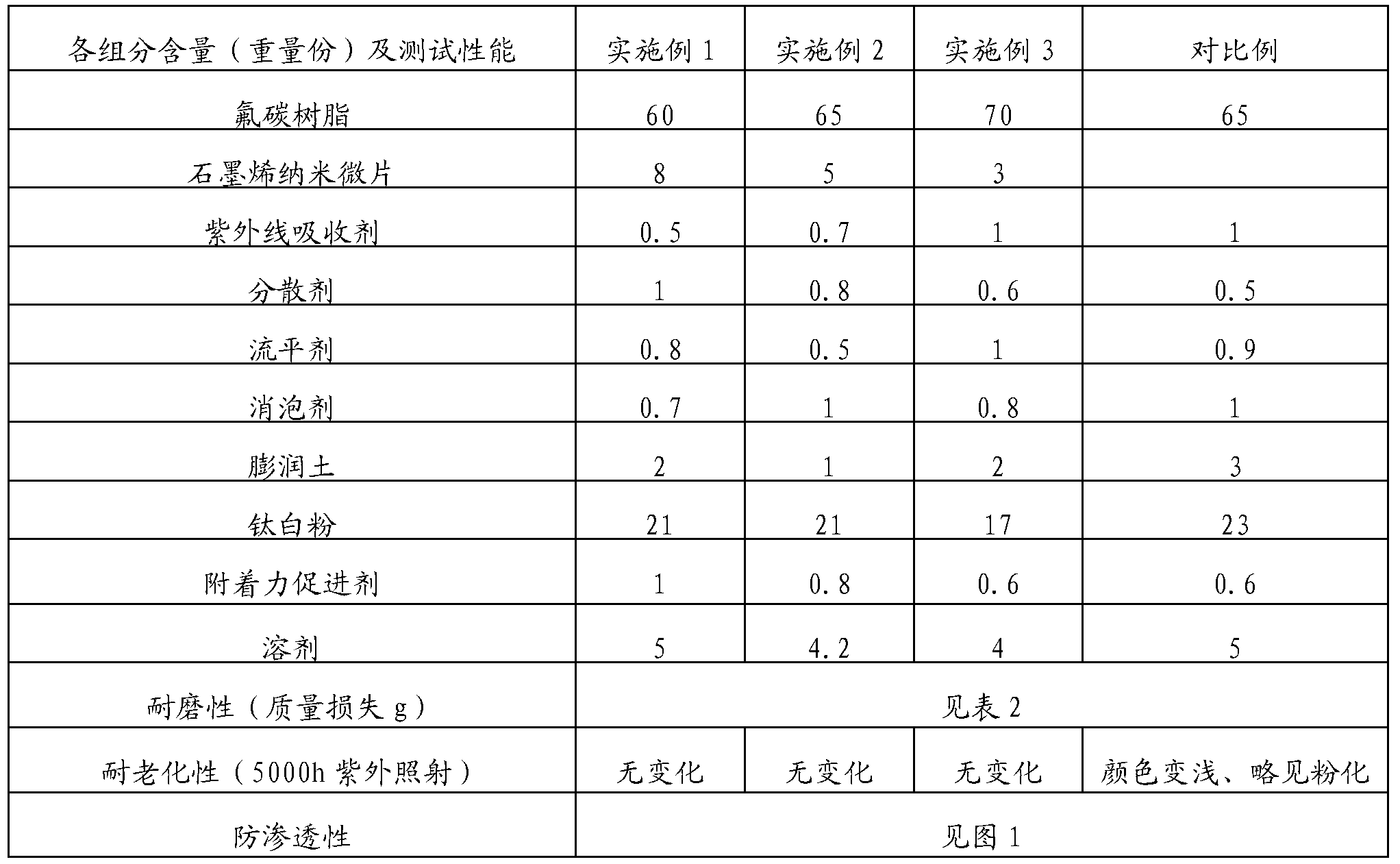

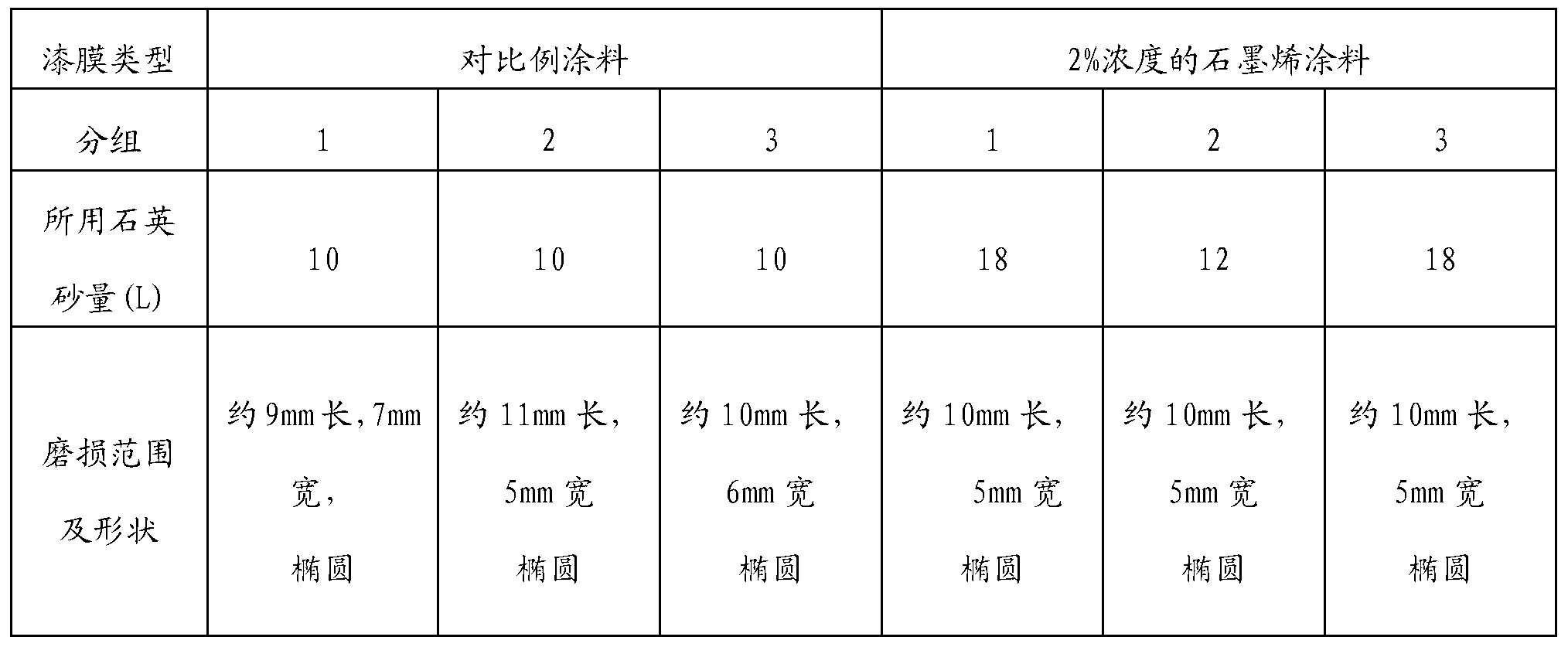

The invention provides a novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint and a preparation method for the same. The novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint is composed of an agent A and an agent B, wherein the agent A is composed of the following components in percentage by weight: 60-70% of fluorocarbon resin, 1-8% of graphene nanometre micro-sheets, 0-2% of an ultraviolet absorber, 0.5-1% of a dispersing agent, 0.5-1% of a levelling agent, 0.5-1% of a defoaming agent, 1-3% of bentonite, 20-25% of titanium dioxide, 0.5-1% of an adhesion promoter and 2-5% of a solvent; and the agent B is a curing agent used with the agent A. The preparation method provided by the invention is simple in operation and preparation processes; the prepared graphene anti-corrosion paint is excellent in wear-resistant, ageing-resistant, anti-bacteria and anti-corrosion performances; and moreover, graphene has no toxic and side effects, as well as is efficient and environment-friendly.

Owner:青岛科孚纳米技术有限公司

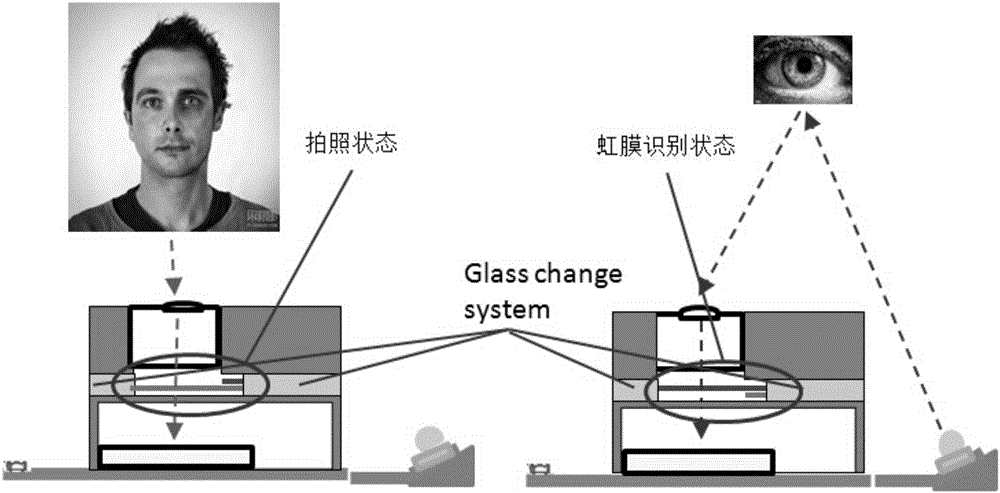

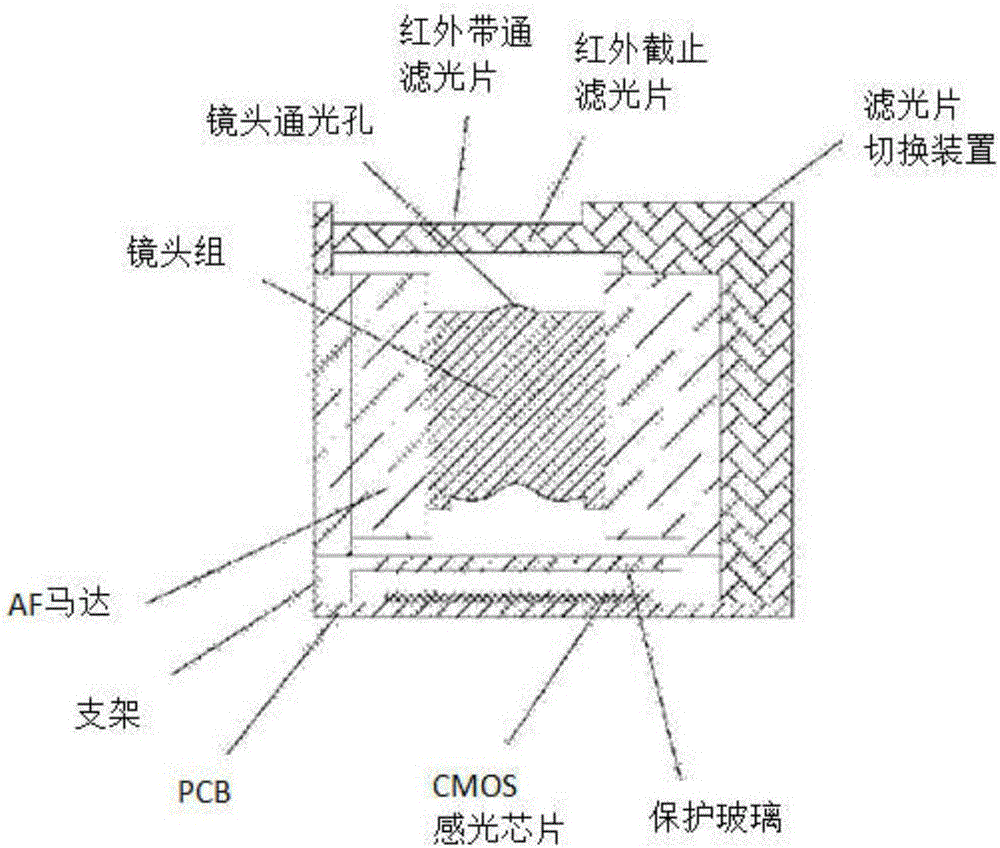

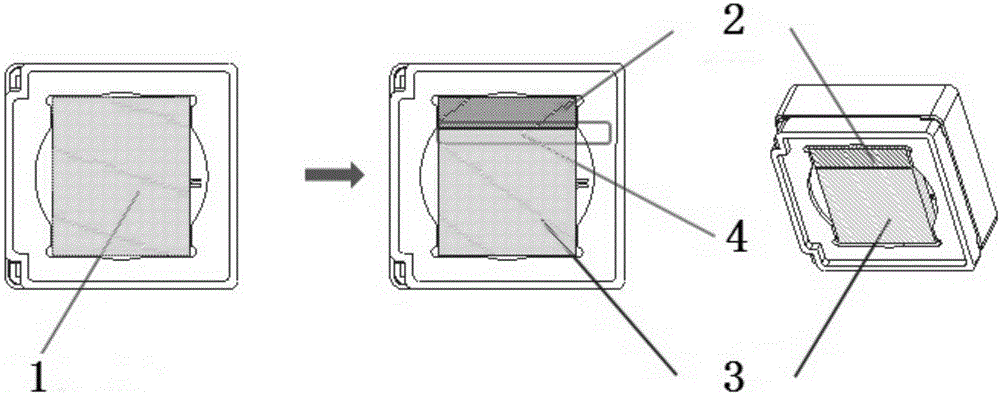

Iris recognition and photographing combined photographing module based on partition dual-pass optical filter

ActiveCN106454049ASmall sizeThinTelevision system detailsCharacter and pattern recognitionCamera lensVisible spectrum

The invention discloses an iris recognition and photographing combined photographing module based on a partition dual-pass optical filter. Optical filters capable of passing visible light (stopping infrared light) and transmitting the infrared light (stopping the visible light) are arranged between a lens light through hole and a photosensitive imaging chip of the photographing module, so light received on the photosensitive imaging chip is divided into a visible light area and an infrared light area, thereby realizing the iris recognition and photographing function combined photographing module. According to the module, the optical filter is formed by splicing a visible light transmitting (infrared light stopping) optical filter and an infrared light transmitting (visible light stopping) optical fiber, thereby forming the partition dual-pass optical filter, and the splicing part is processed to avoid light leakage.

Owner:WUXI HAOBANG HIGH TECH CO LTD

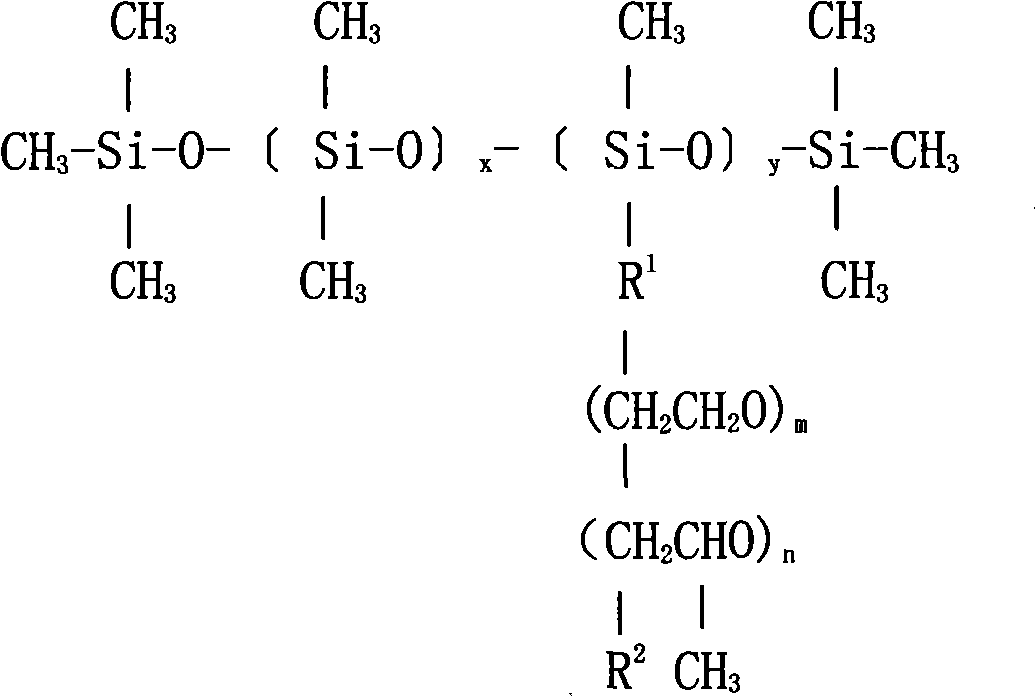

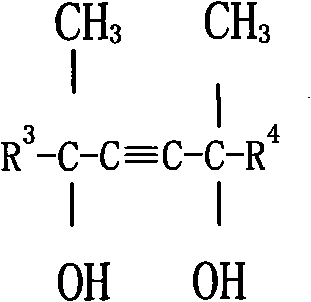

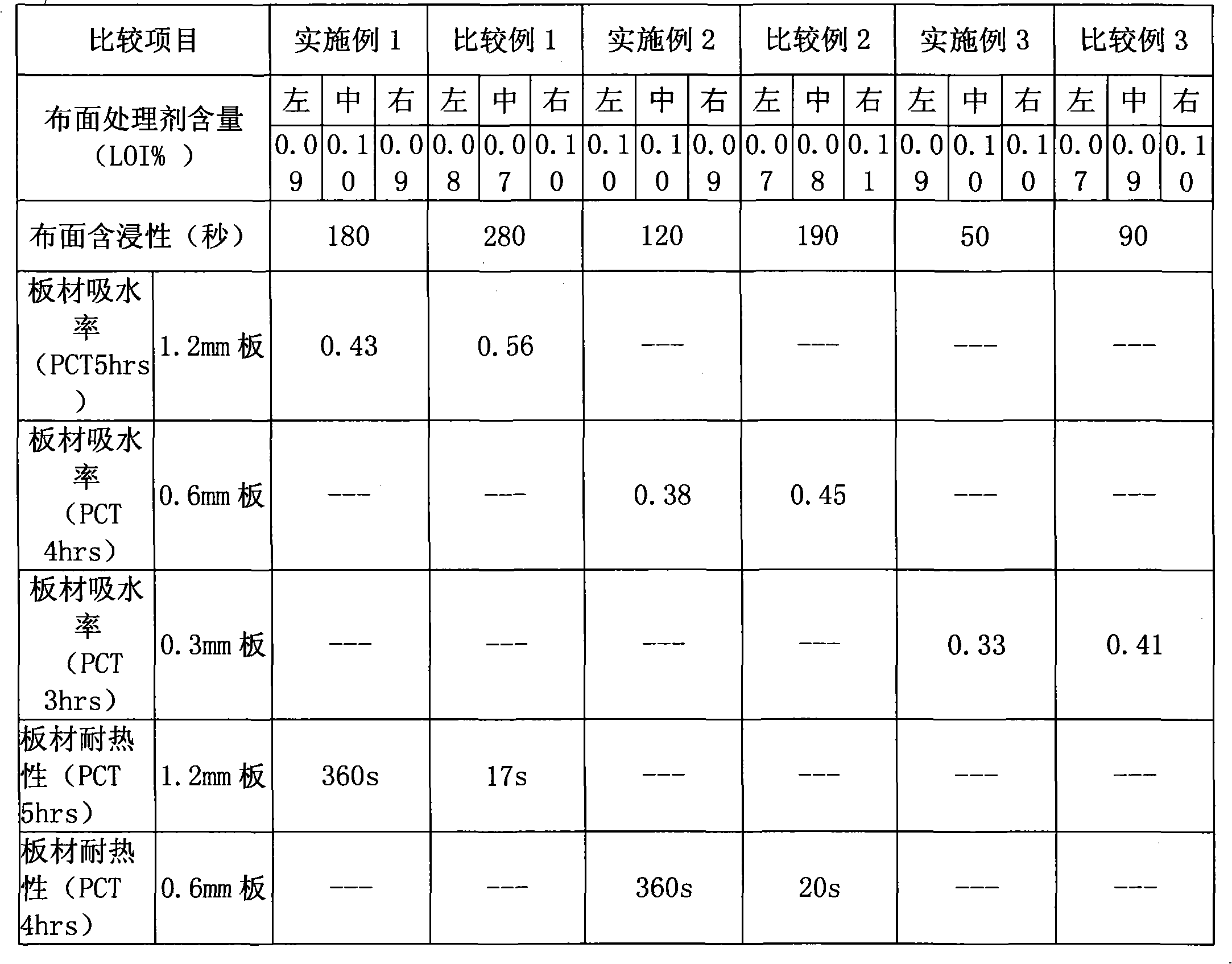

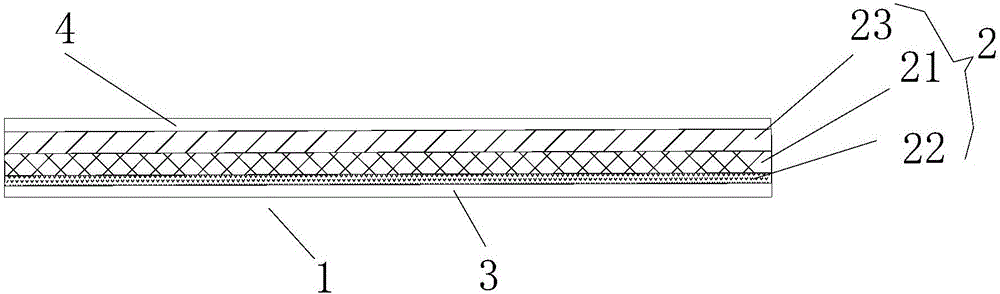

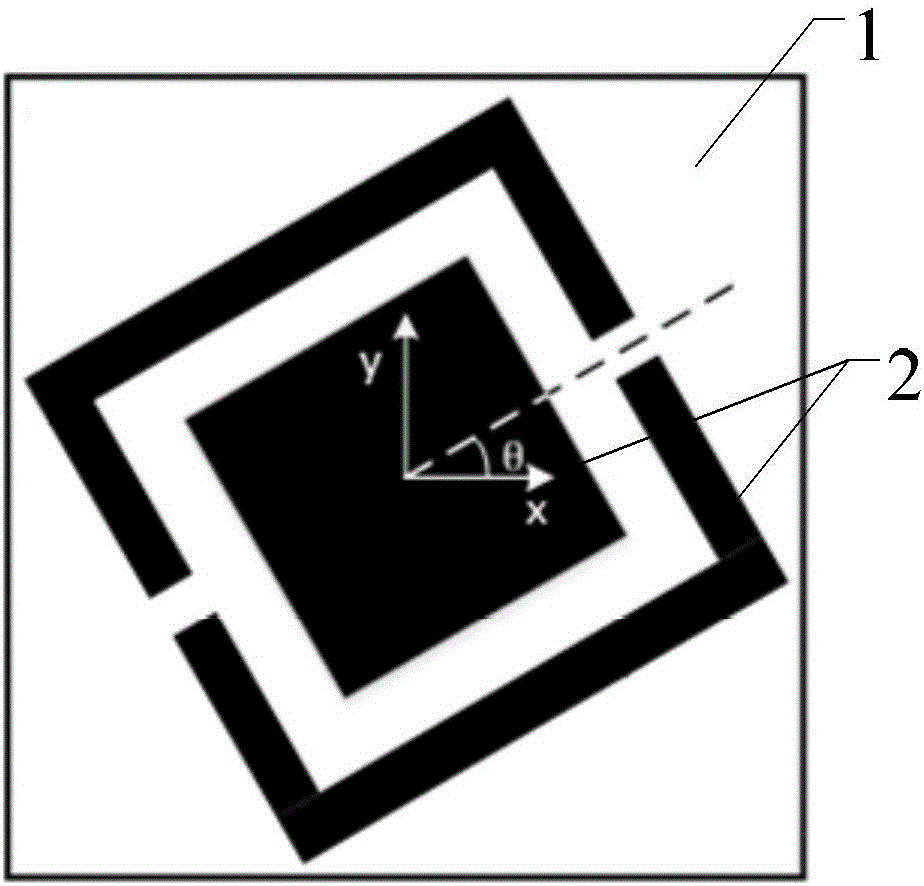

Surface treating agent for electronic-grade glass cloth and electronic-grade glass cloth surface produced by using the same

InactiveCN101864669AThinRapid infiltrationPrinted circuit detailsFibre treatmentGlass fiberAcetic acid

The invention relates to a surface treating agent applied to the technical field of the electronic-grade glass fiber cloth and an electronic-grade glass fiber cloth produced by using the surface treating agent. The surface treating agent comprises the following ingredients in weight percentage: 0.2 to 0.8% of silane coupling agent having general formula of (Y(CH2)nSiX3), 0.3 to 1.0% of acetic acid, 0.05 to 0.1% of surfactant I, 0.02 to 0.05% of surfactant II, and the balance of de-ionized water. The invention is applicable to the surface treating technology of the electronic-grade glass fiber cloth of the high-precision, high-uniformity and high performance printing circuit board; the electronic-grade glass cloth processed by the surface treating agent and the surface treating process has the advantages of thinness, homogenization and faster resin soakage and is suitable for the insulation reinforcing material of the printing circuit board; furthermore, the invention can be widely applied to the high-end products including mobile phone boards, notebook computers, navigation, automobiles, servers and the like.

Owner:SHANGHAI GRACE FABRIC

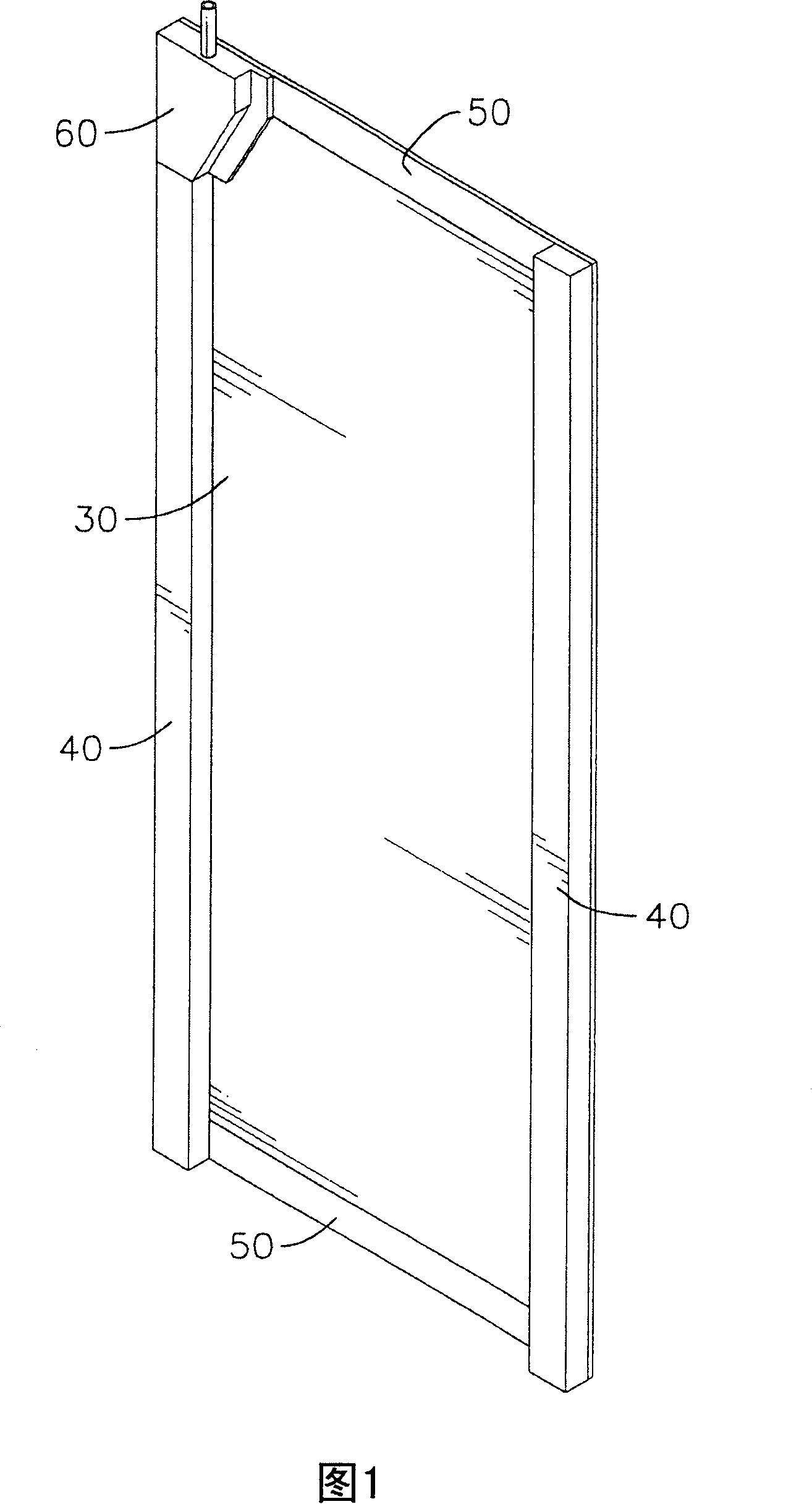

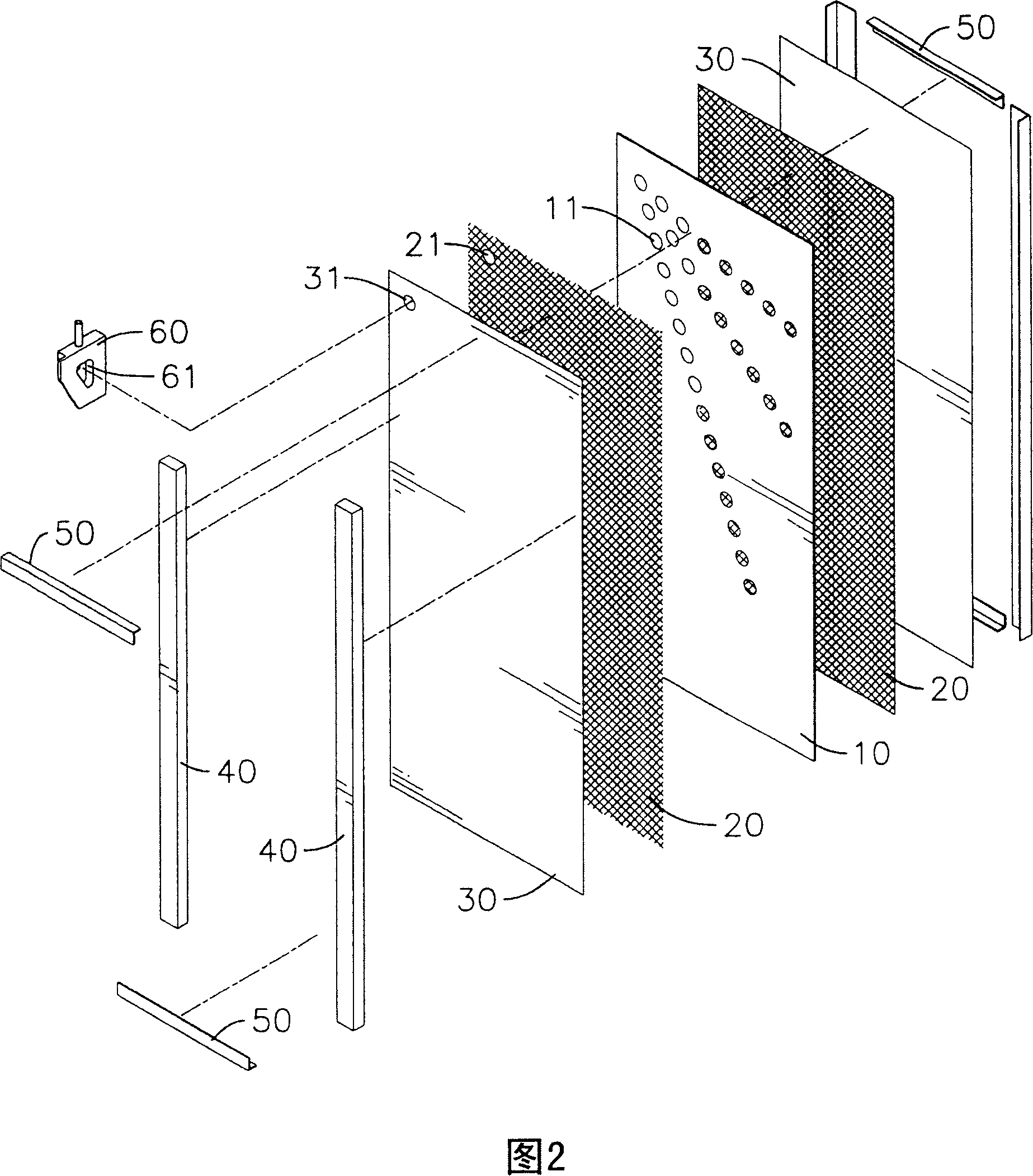

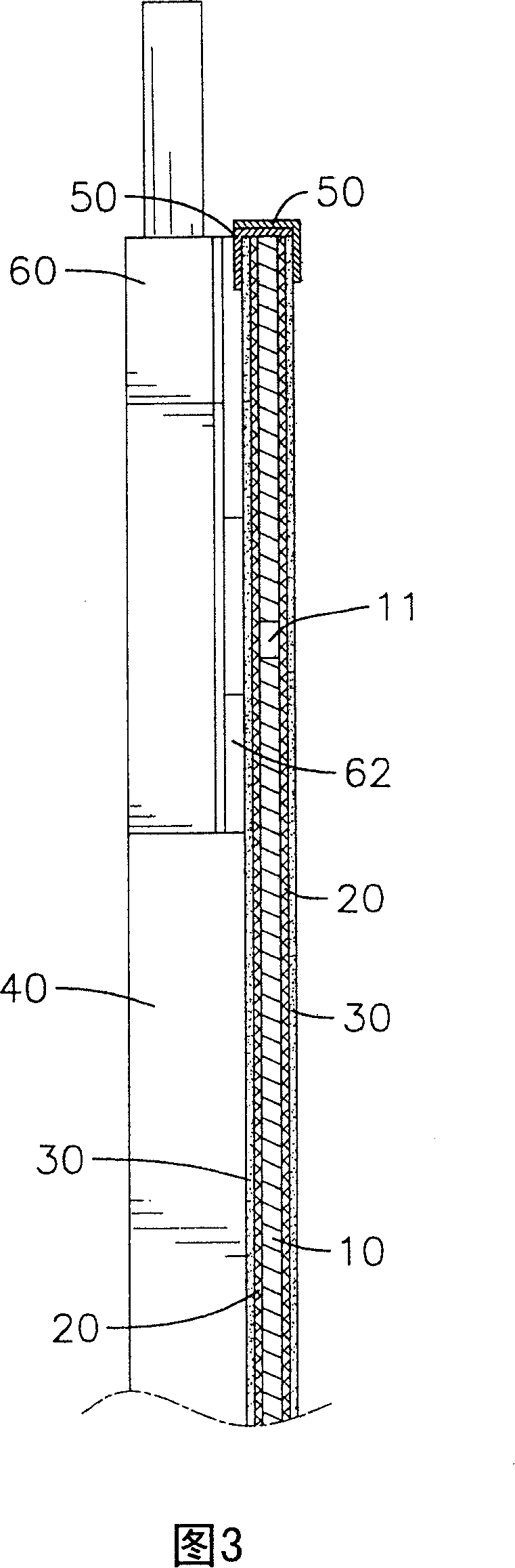

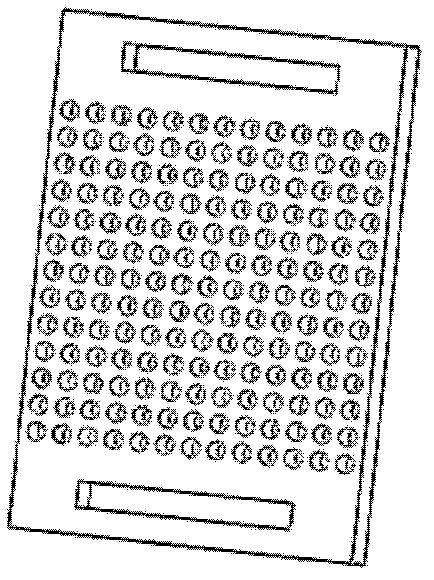

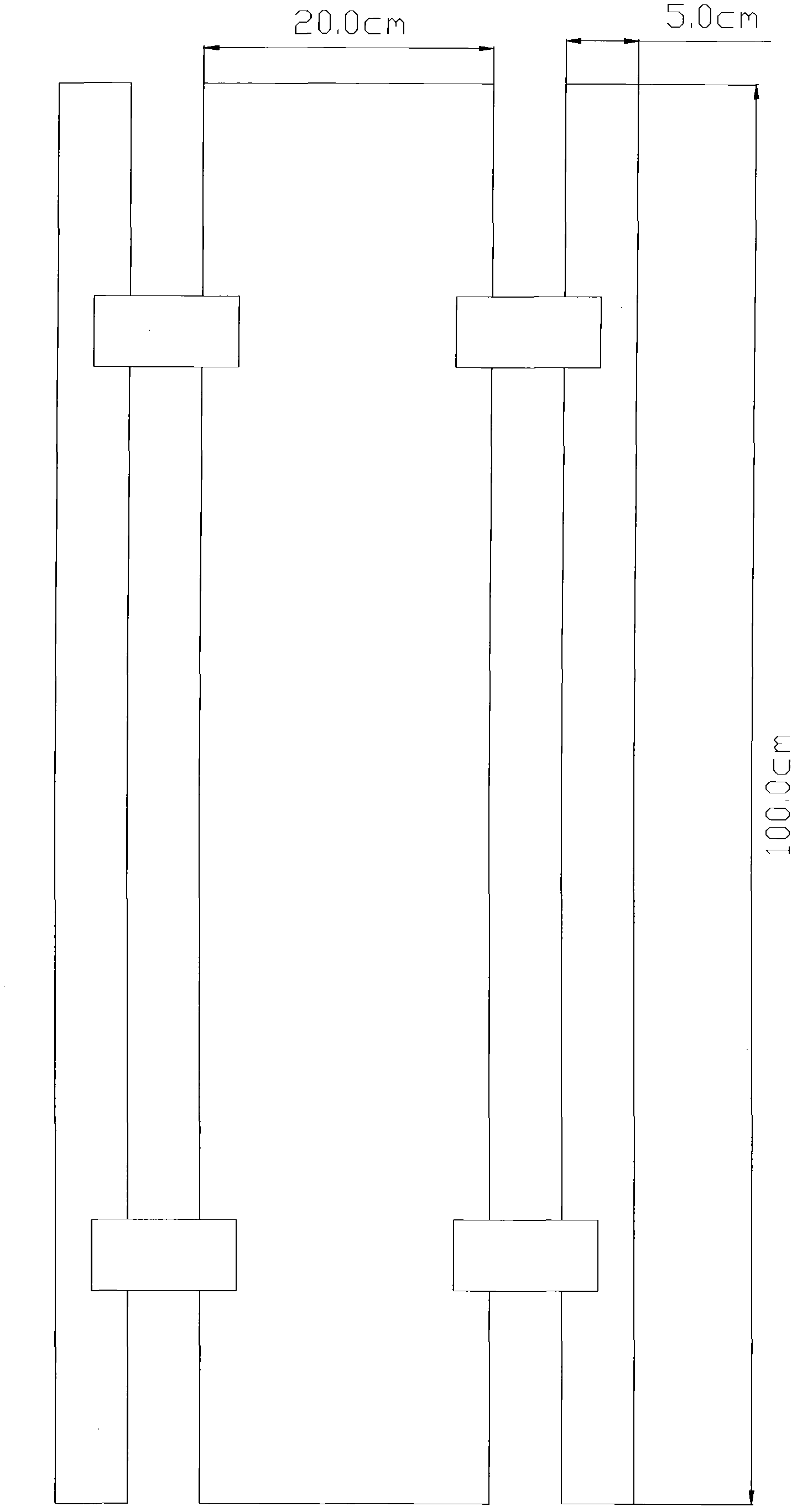

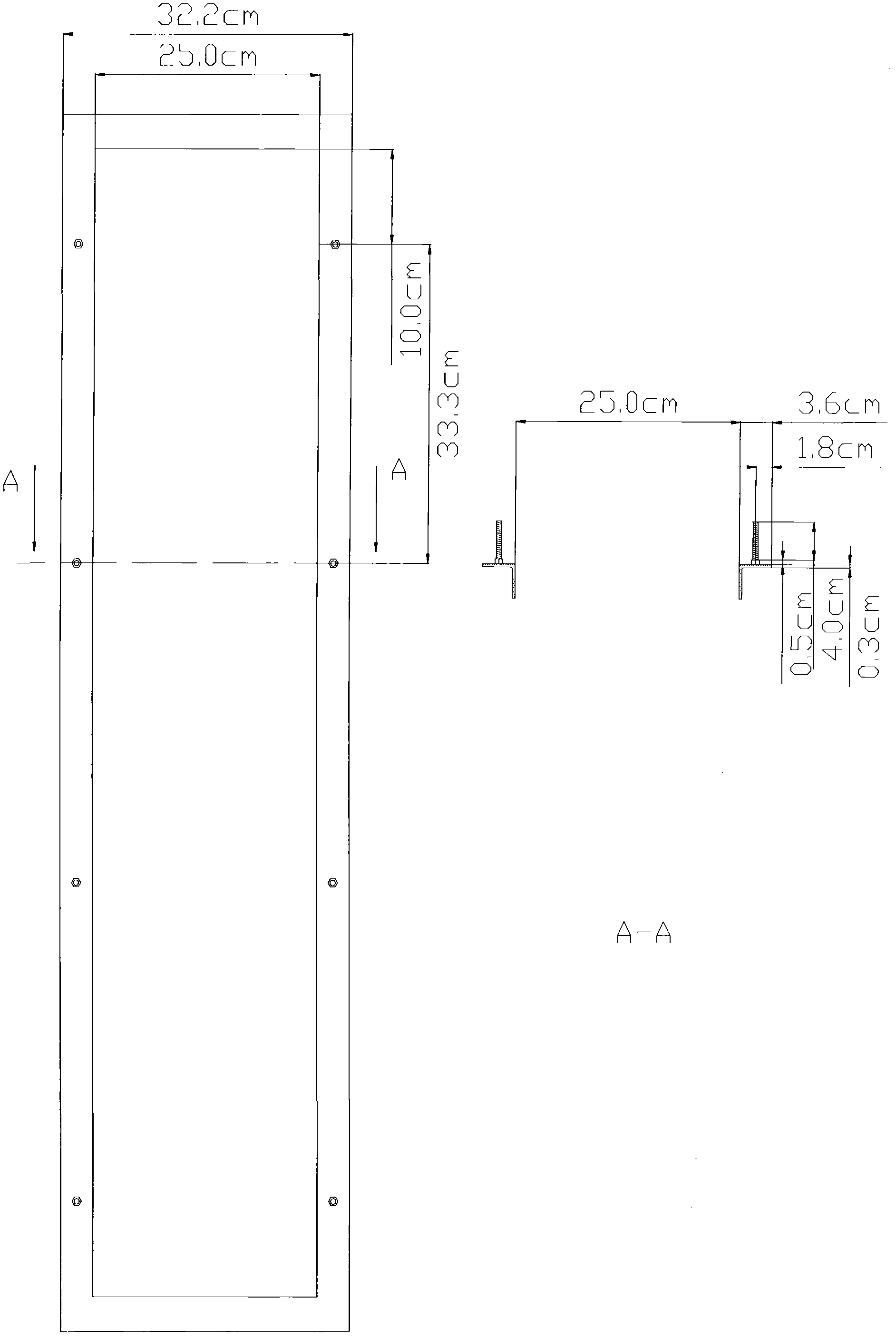

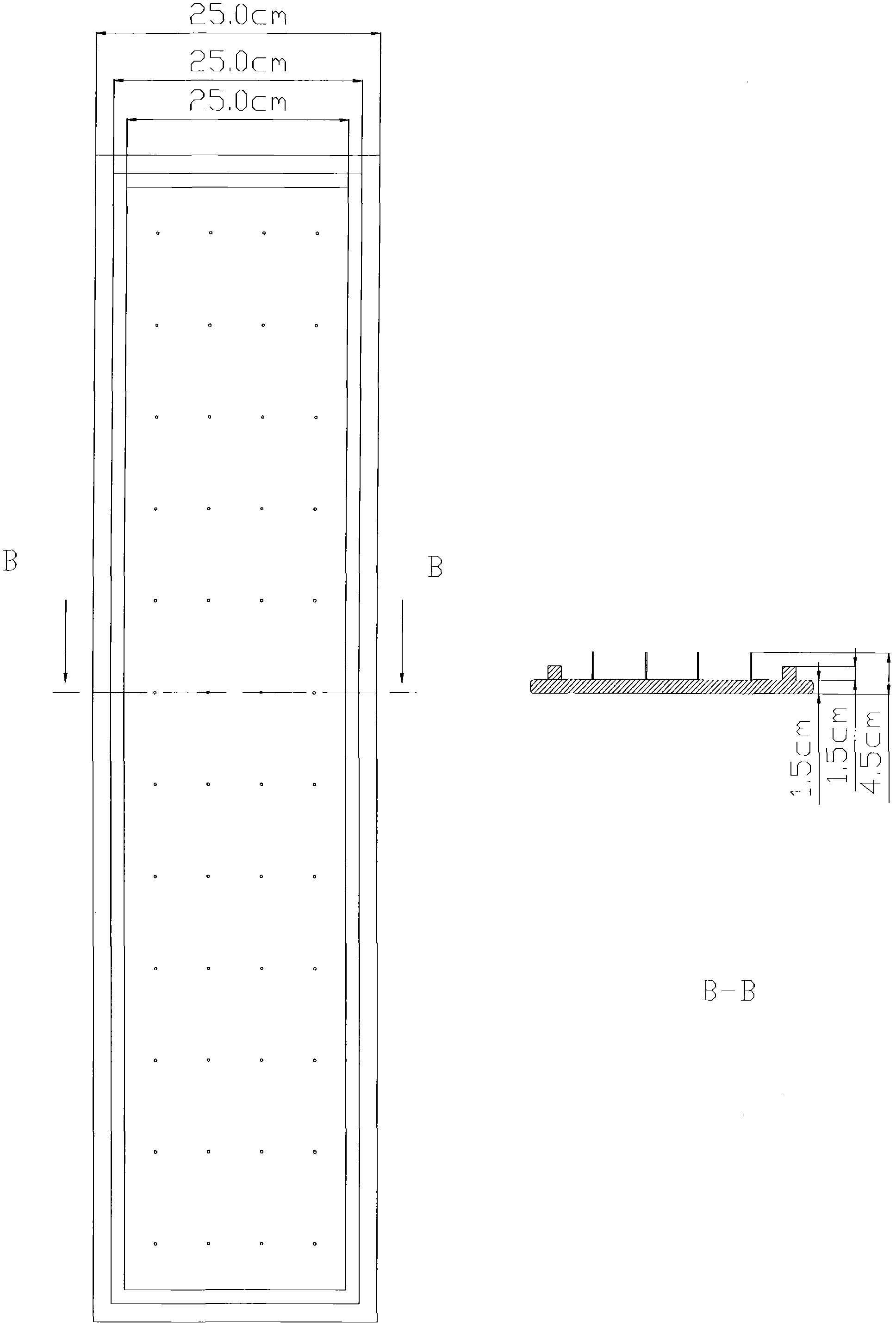

Immersion type thin plate and frame film filter

The invention relates to a soaking thin-walled plate frame membrane filter, which consists of one or a plurality of thin-walled plate frame membrane filter sheets and an aeration device below the filter sheet. The membrane filter sheet consists of a thin-walled panel, a conduction part and a filter membrane, all of which are bonded together. The invention is characterized in that at least two support strips are respectively arranged along two sides to form an asymmetrical framework on one surface of the invention, the vertical asymmetrical frames pressures each other closely to form a membrane chamber and two thin metal or plastic reinforcing strips are further arranged along two sides to be used as support. The soaking thin-walled plate frame membrane filter provided by the invention can be soaked in an original / waste sink and filters impurity in water, the aeration device is used for blocking reduction of the membrane and therefore, stable water production, bacteria filtering and reduction of slit index and turbidity can be realized.

Owner:长丰股份有限公司

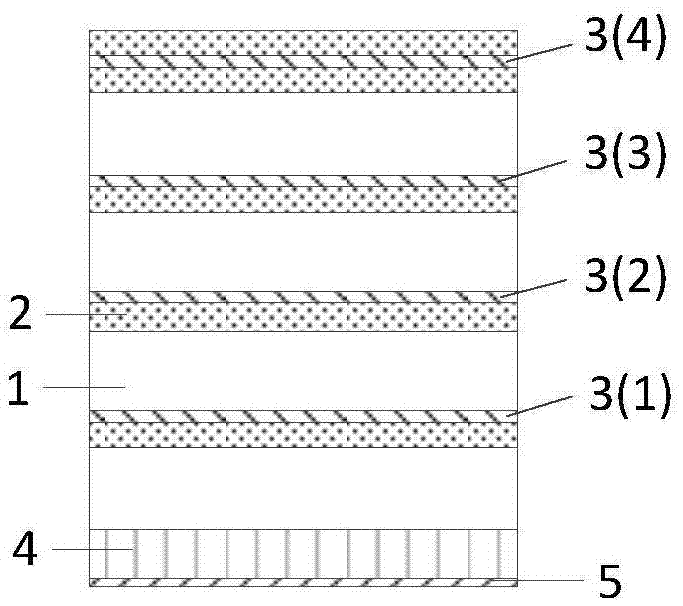

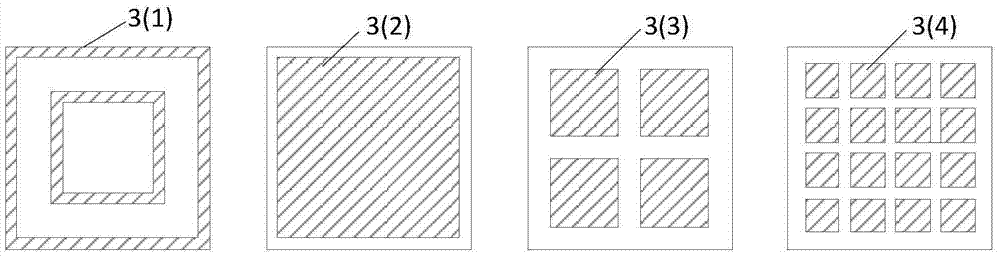

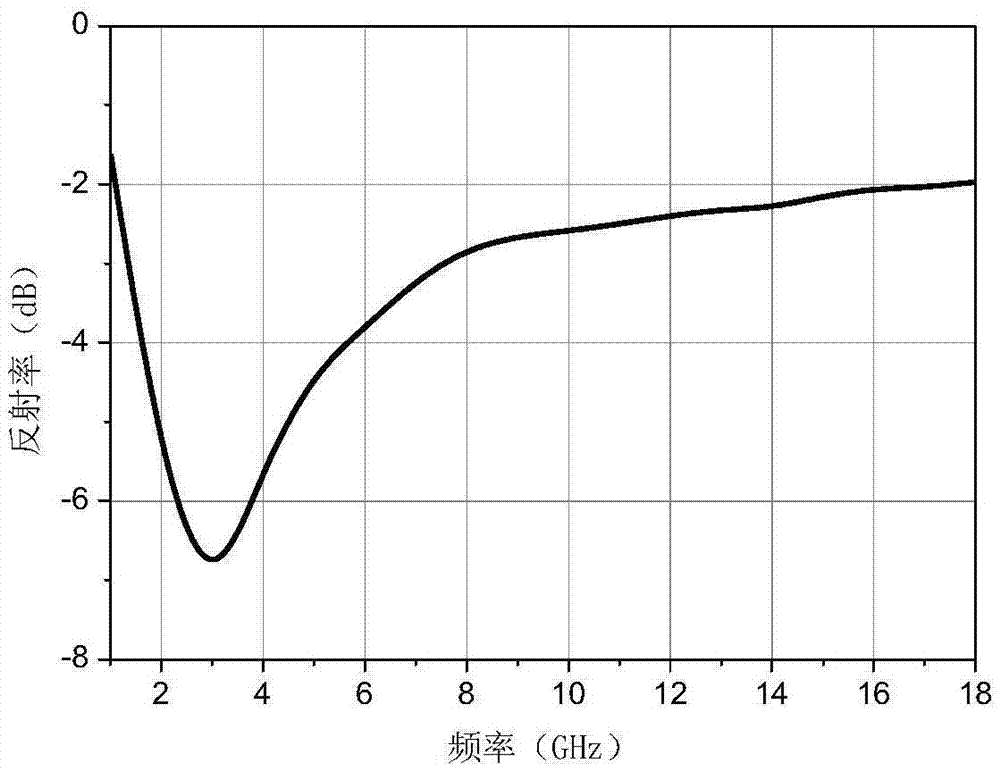

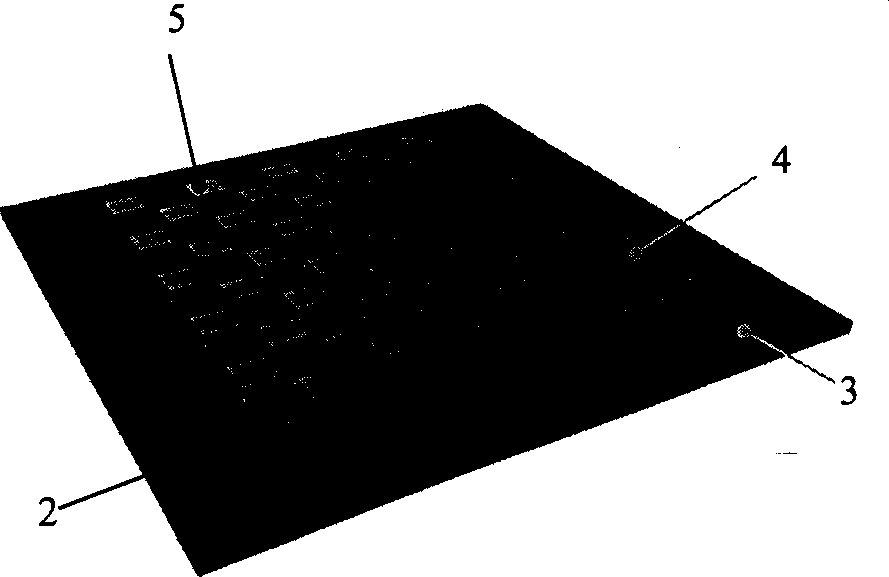

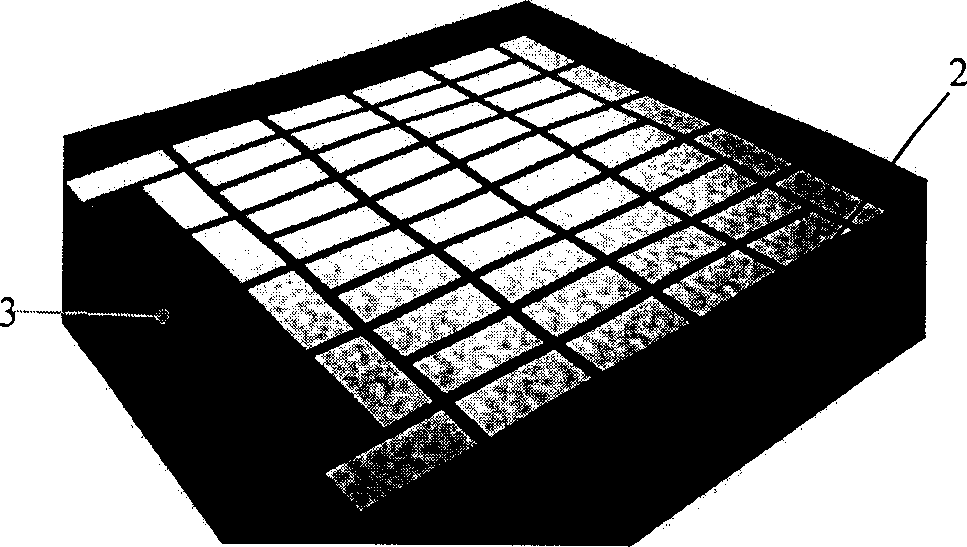

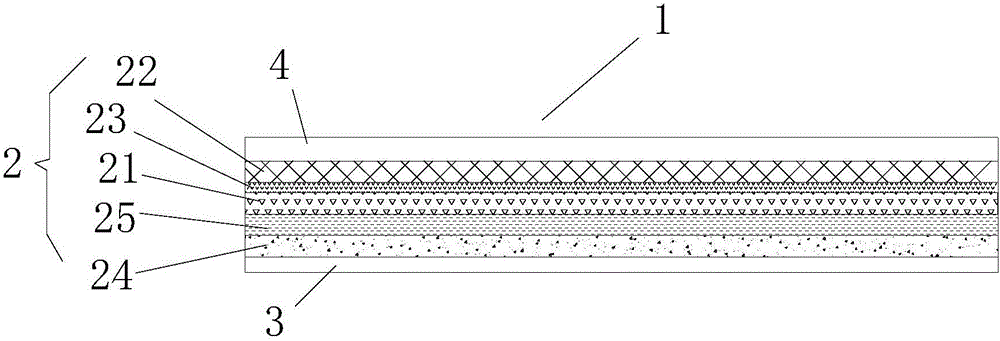

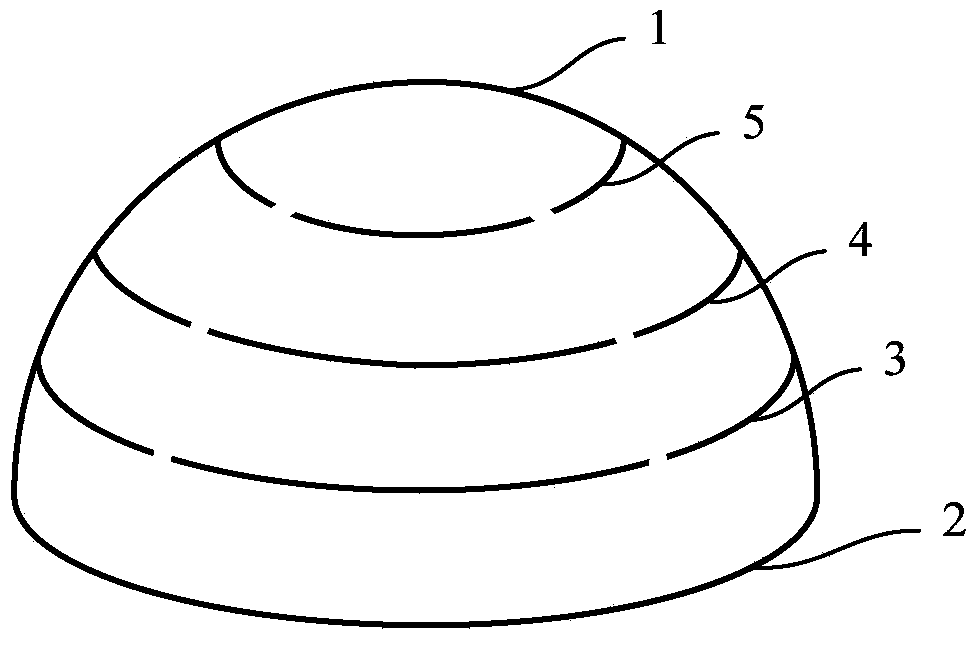

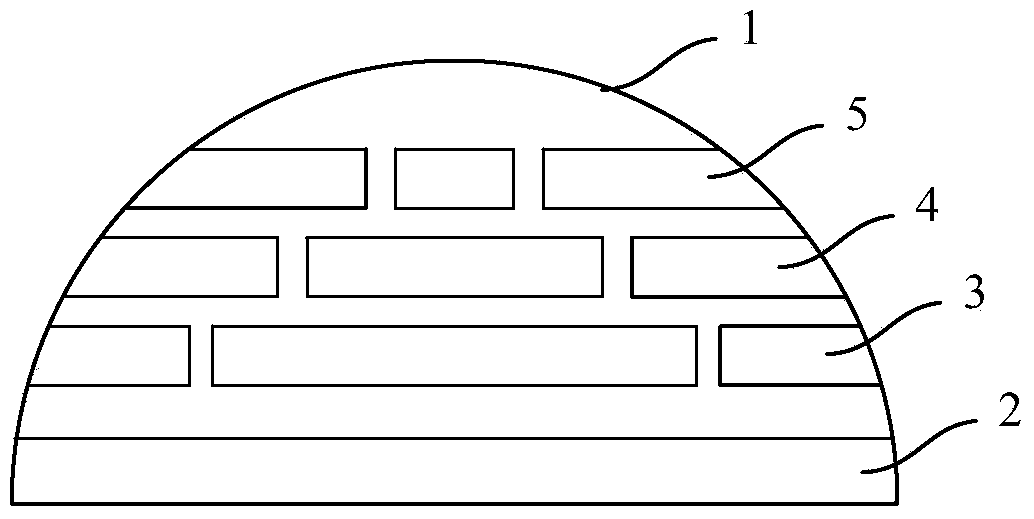

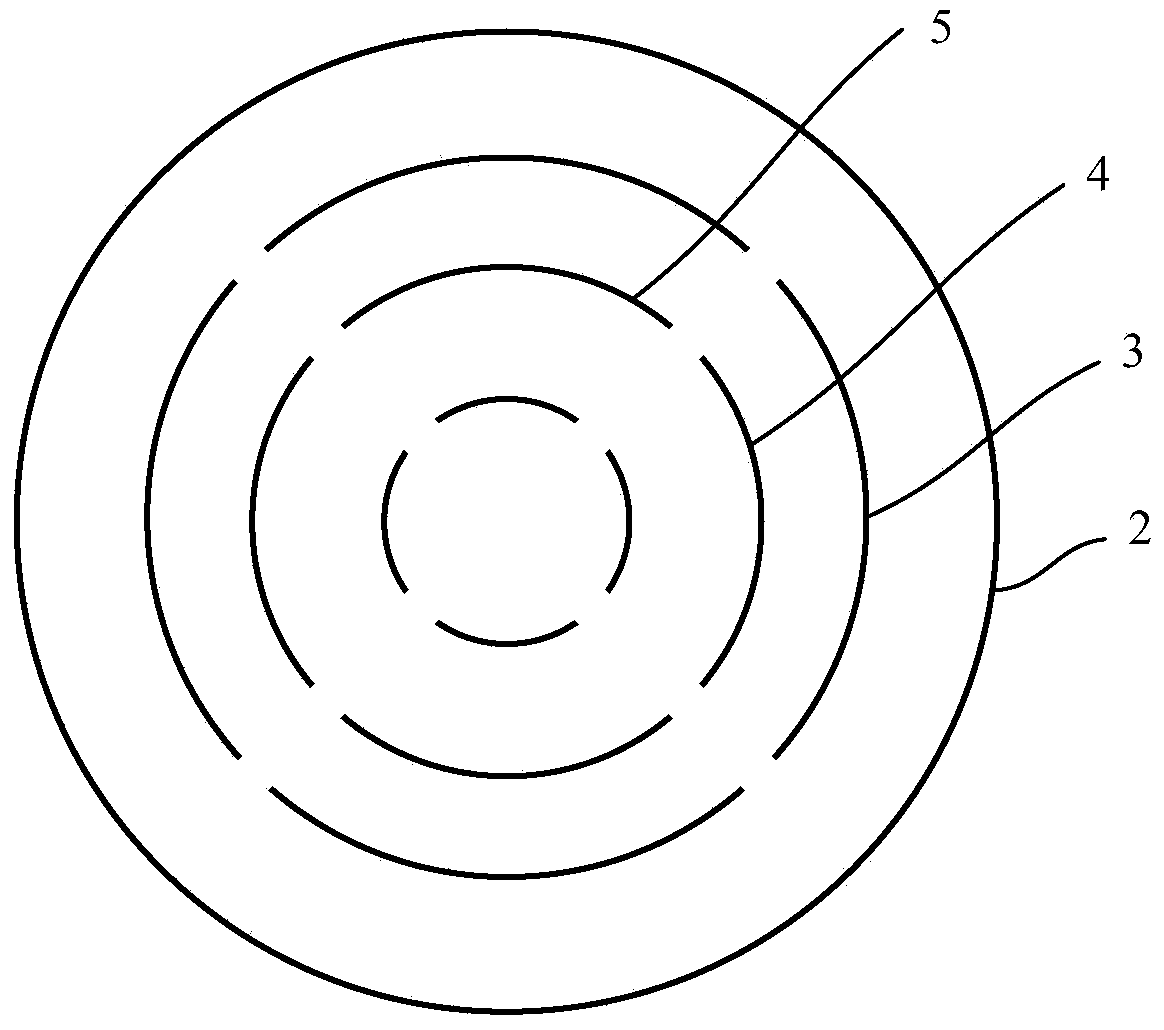

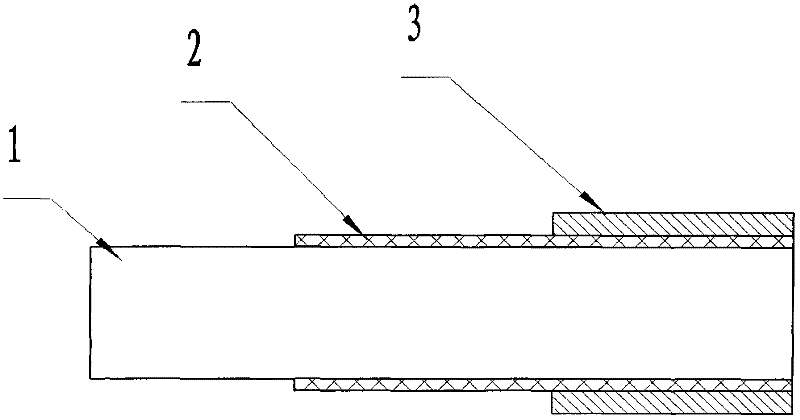

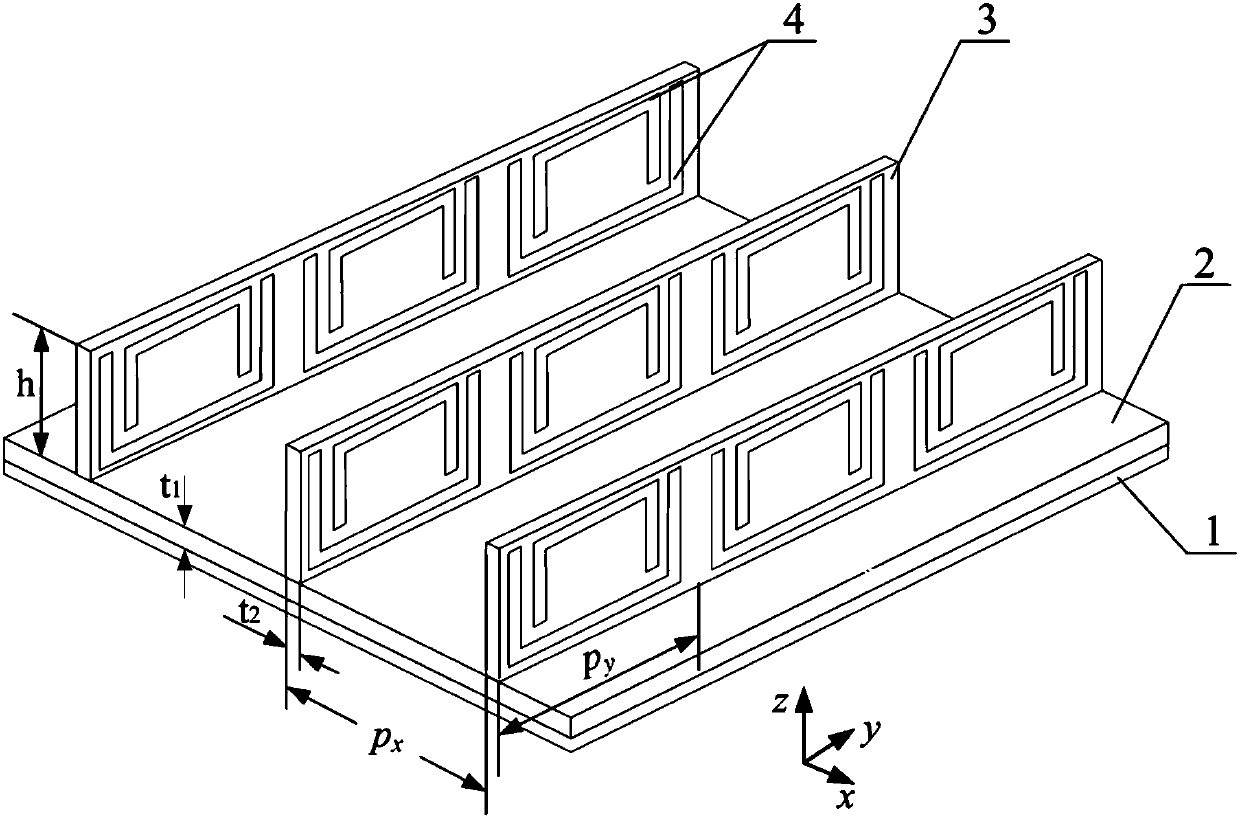

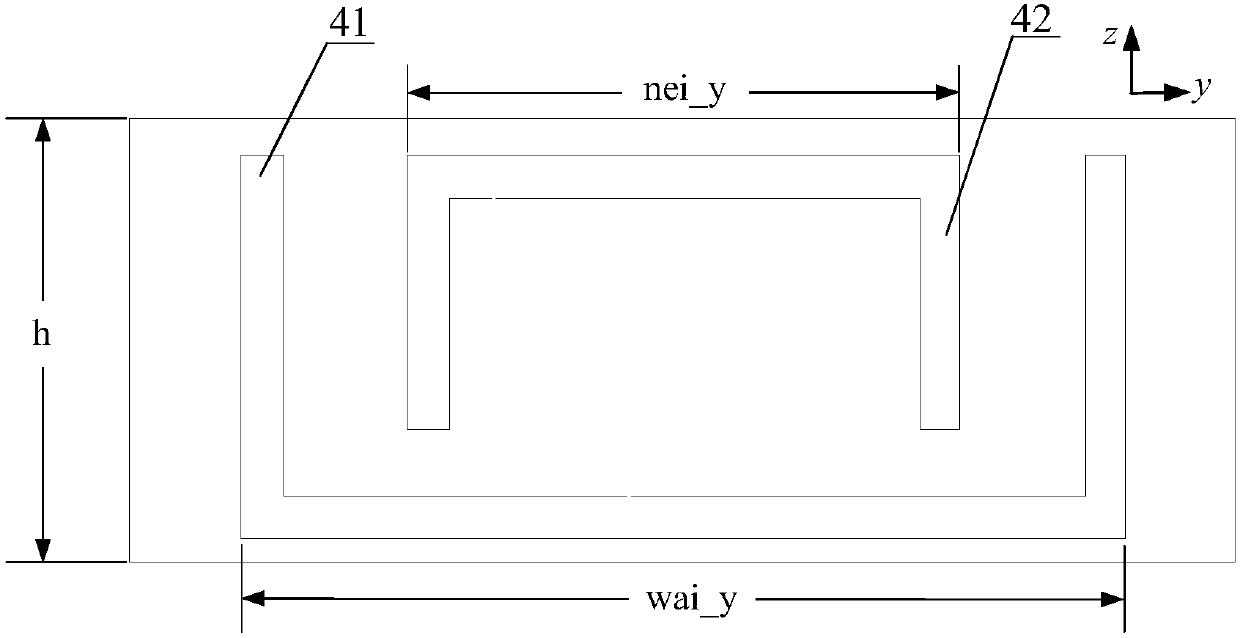

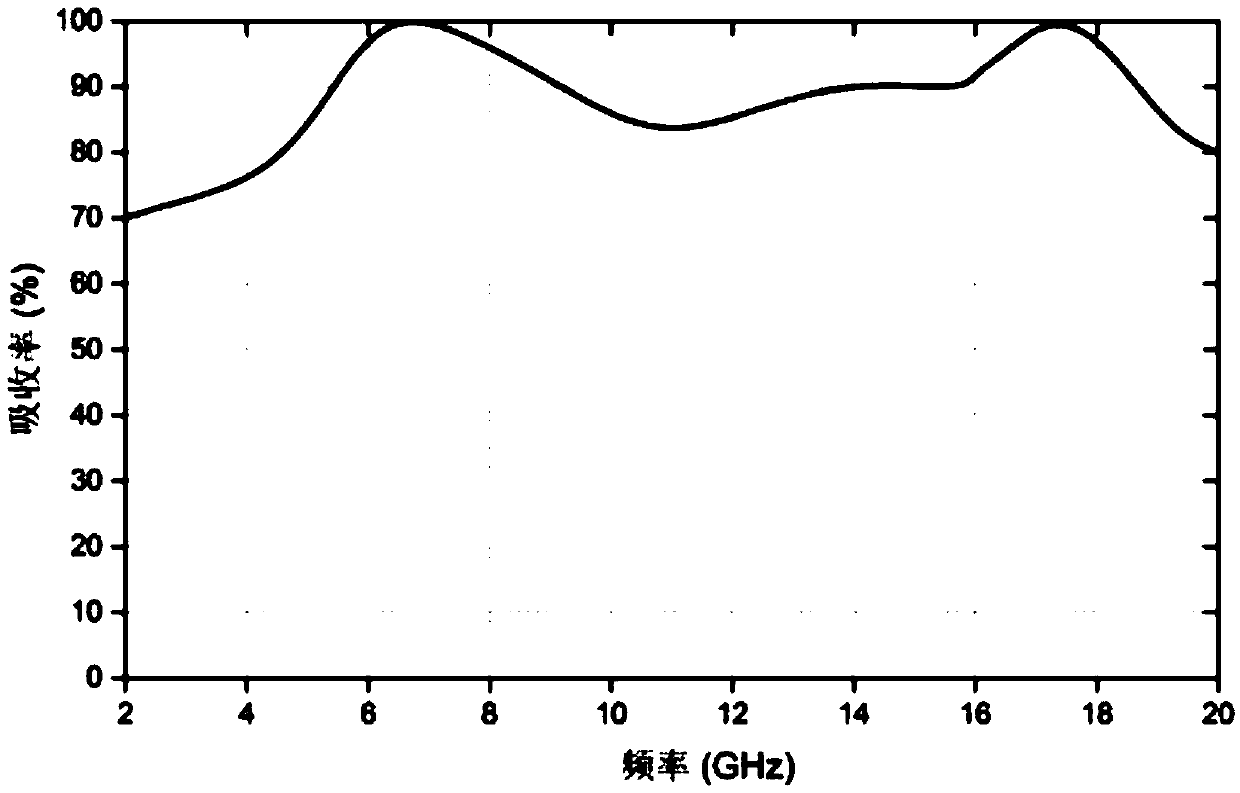

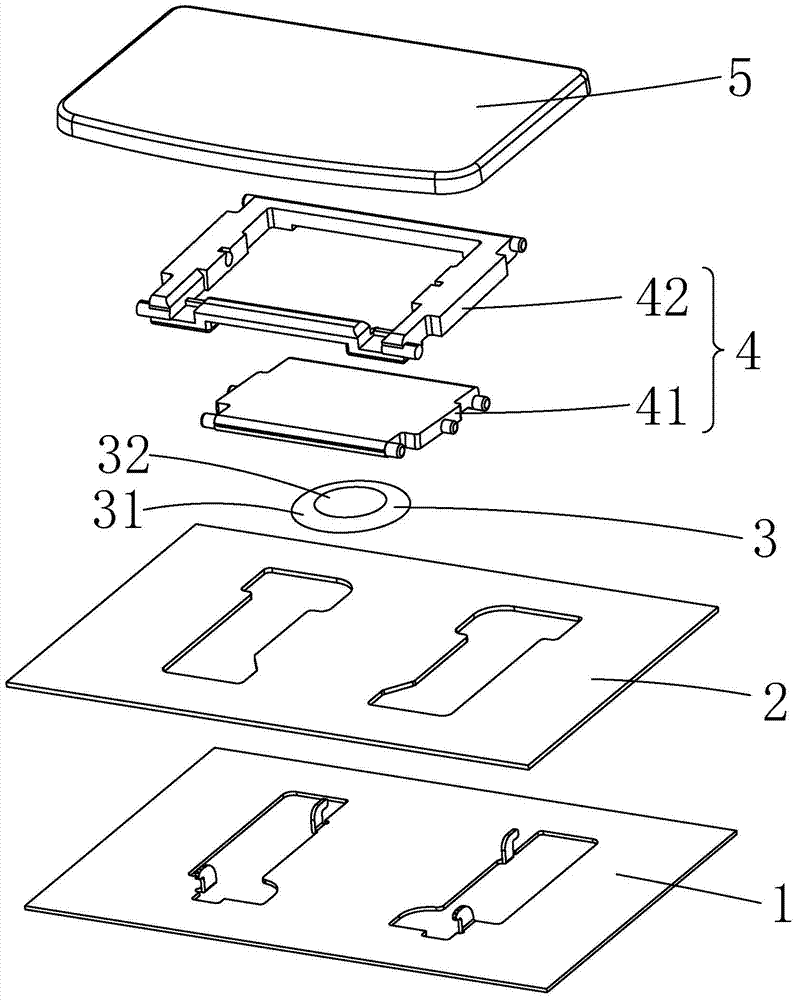

A metamaterial wave-absorbing structure based on a magnetic wave-absorbing material and multiple layers of resistive films

InactiveCN106856263AHigh strengthThinMagnetic/electric field screeningAntennasPhysicsDielectric substrate

The invention provides a metamaterial wave-absorbing structure based on a magnetic wave-absorbing material and multiple layers of resistive films. The metamaterial wave-absorbing structure comprises an array formed by a plurality of wave-absorbing units. Each wave-absorbing unit is formed by multiple layers of PMI foams (1), multiple layers of PET dielectric substrates (2), the multiple layers of resistive films (3(1)-3(4)), one layer of magnetic wave-absorbing material (4) and one layer of metal earth (5), which are stacked up alternately. Two kinds of wave-absorbing structures of the magnetic wave-absorbing material and the multiple layers of resistive films are combined, and thus contradiction of the composite wave-absorbing structure between thickness and low frequency wave-absorbing characteristic is tempered. The designed novel meta-material wave-absorbing structure is high in strength and thin in thickness, and has a good wave-absorbing effect within 1GHz-18GHz ultra-wide band.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

Production method of high elasticity stainless steel belt for touch switch

The invention relates to a production method of a high elasticity stainless steel belt for a touch switch, and in particular discloses a production method of the stainless steel belt which is used for manufacturing touch switches of electronic products such as mobile phones and computers. The production method is characterized by sequentially comprising steps such as a sorting, primary rolling, primary cleaning, primary annealing, secondary rolling, secondary cleaning, secondary annealing, tertiary rolling, tertiary cleaning, pulling rectification, high temperature relief annealing, anti-corrosive treatment, quartic cleaning and reverse pulling rectification. The stainless steel band produced by the method has the advantages of light weight, high hardness, low and stable force, long fatigue life, unified hand feeling and low roughness, and the stainless steel band can normally reserve and can avoid wasting and can meet operating requirements of elastic buttons of the electronic products such as the mobile phones and the computers, and the service lives of the elastic buttons are prolonged.

Owner:无锡华生精密材料股份有限公司

Micro temperature difference battery made of one-dimensional nanometer linear array structure thermo-electric material

InactiveCN1352468AReduce volumeThinThermoelectric device with peltier/seeback effectLinear arrayLamellar structure

The invention discloses a micro-thermoelectric cell made of thermal differential material with structure of one dimension linear array. The shape of the cell is like a platelet whose thickness is 20micron-3milimeter. The body of micro thermoelectric cell is composed of two boards: upper and lower boards with laminar structure in serial; C, B, A, B, C layers The upper boards is composed of C and Blayers. The lower layer is composed of C, B, and A layer. Layer A with thickness 5-50 micron is made of a thermal differential material containing a lot of P type of node and N type of node with structure of one dimension linear array. Layer B is a conducting material layer. Layer C is an encapsulation layer made of heat conducting insulated material. The invented micro-thermoelectric cell has advantages of compactness, thin thickness. It is especially suitable for being used in micro-module of high technological system.

Owner:TIANJIN UNIV

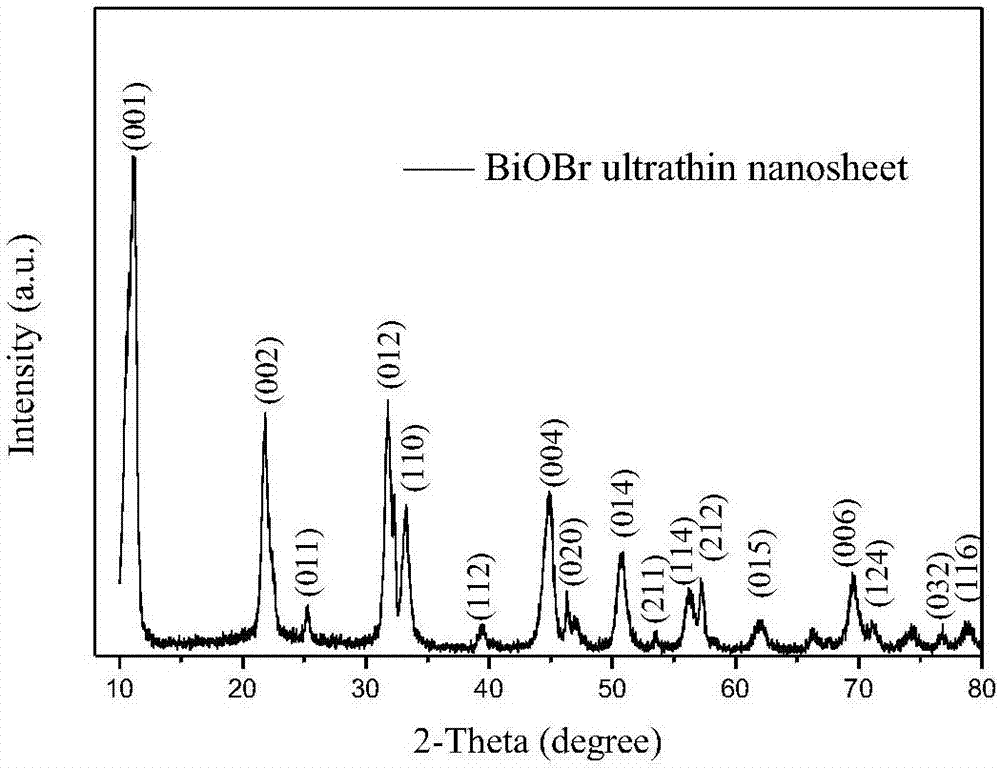

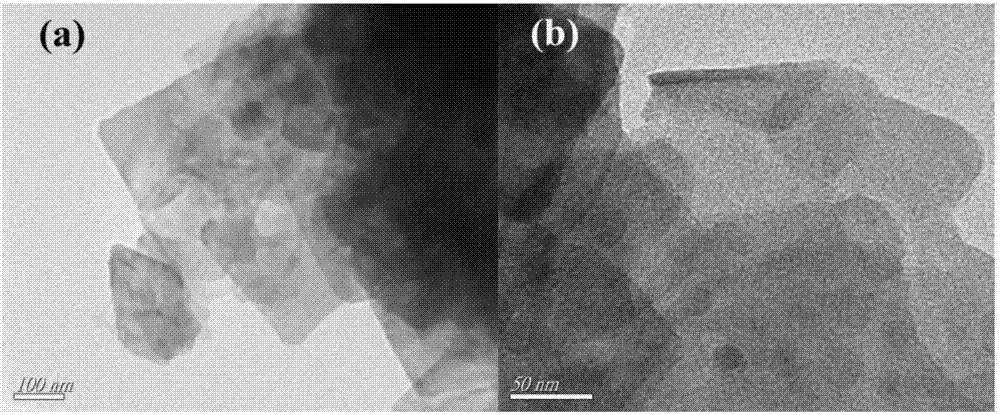

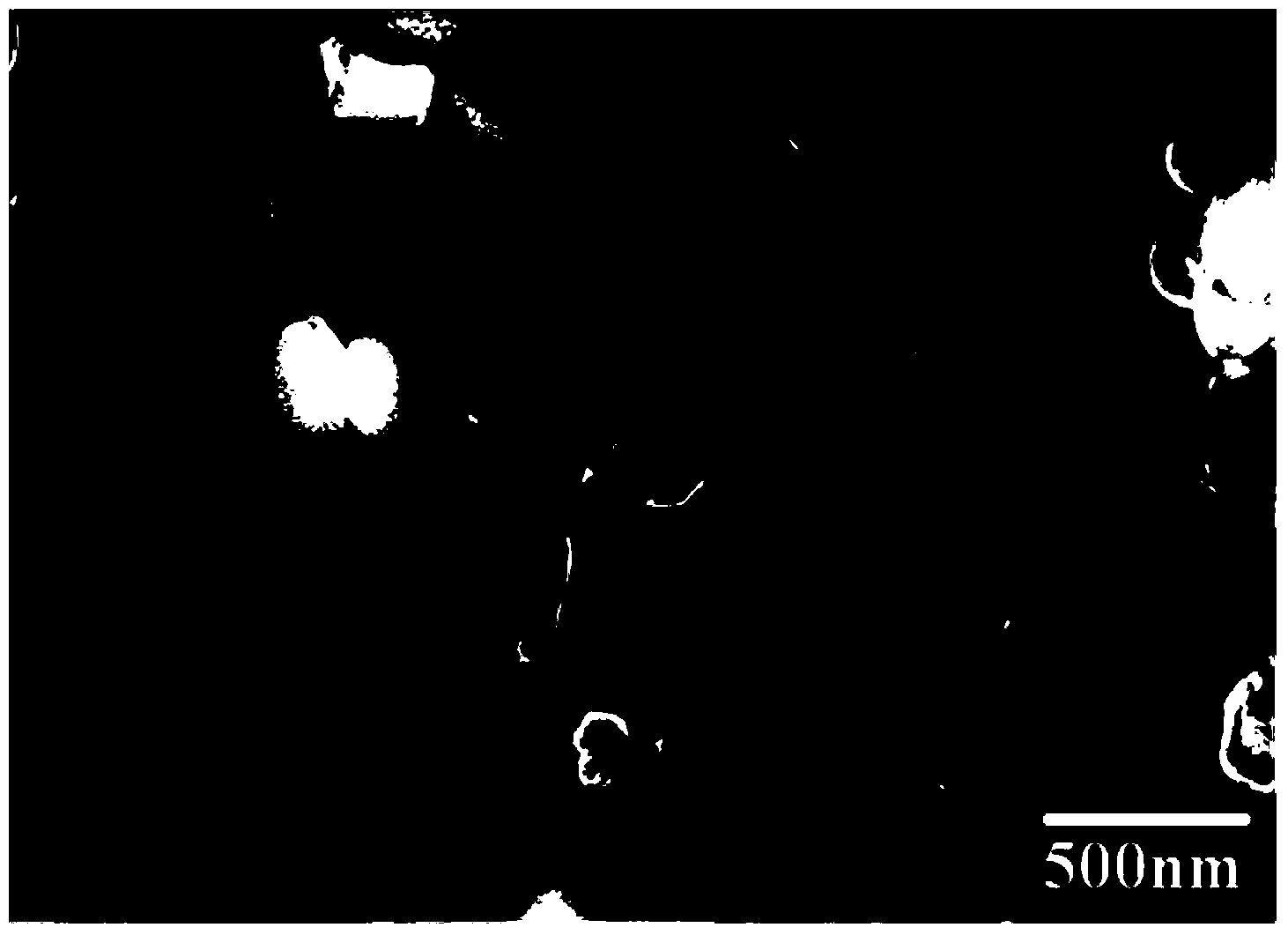

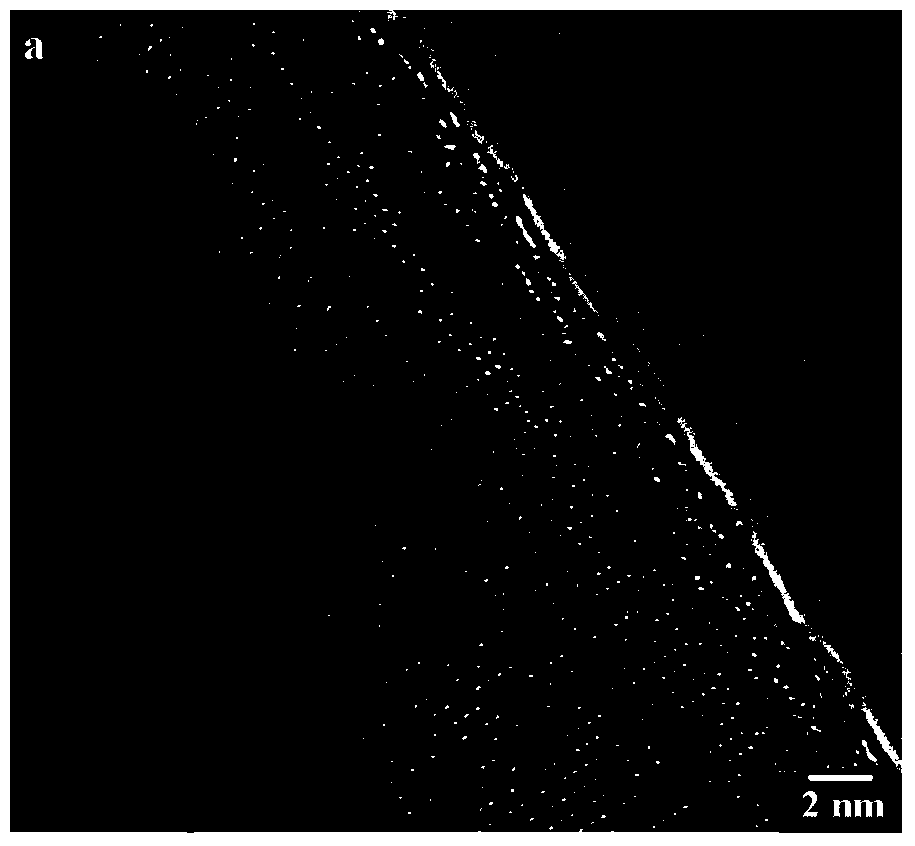

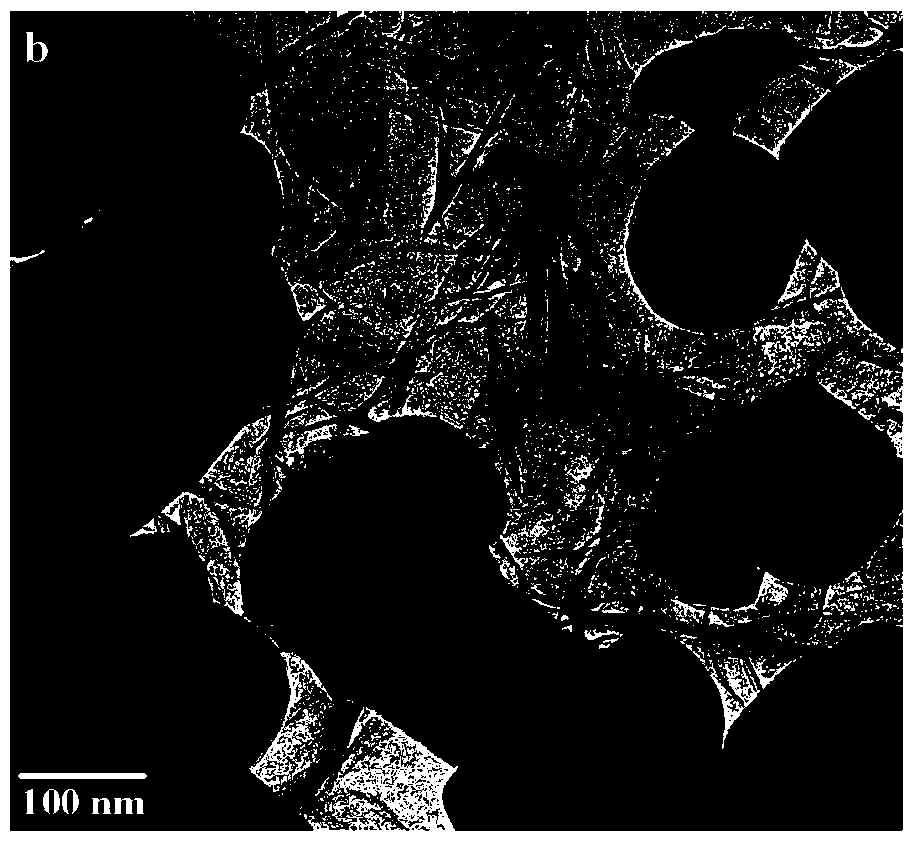

Method of synthesizing bismuth oxybromide ultrathin nanosheet photocatalyst at room temperature

InactiveCN107335452AThinGood dispersionPhysical/chemical process catalystsWater/sewage treatment by irradiationBromineIon

The invention belongs to the technical field of preparing nano-metallic materials with wet chemistry, and relates to a visible light responsive bismuth oxybromide ultrathin nanosheet material and a preparing method. A reaction type bromine ionic liquid and bismuth nitrate are adopted to serve as raw materials, and react in a mixed solution of water, ethyl alcohol and acetic acid to obtain a product. The product is filtered and washed, and dried in the air to obtain the bismuth oxybromide ultrathin nanosheet material. The method is conducted at room temperature, no extra energy supply is needed, and reaction in the whole synthesis process needs one hour. Ionic liquid type selection and dosage play a key role in forming the oxybromide ultrathin nanosheet. According to the synthesizing method, the thickness of the oxybromide ultrathin nanosheet material is 0.7-2 nm. A designed and synthesized oxybromide ultrathin nanosheet photocatalyst has an excellent photocatalysis characteristic, and can efficiently degrade organic pollutants when radiated by visible light of which the wave length is bigger than 400 nm. The method is simple in synthesizing route, and the whole technology process is easy to control.

Owner:JIANGSU UNIV

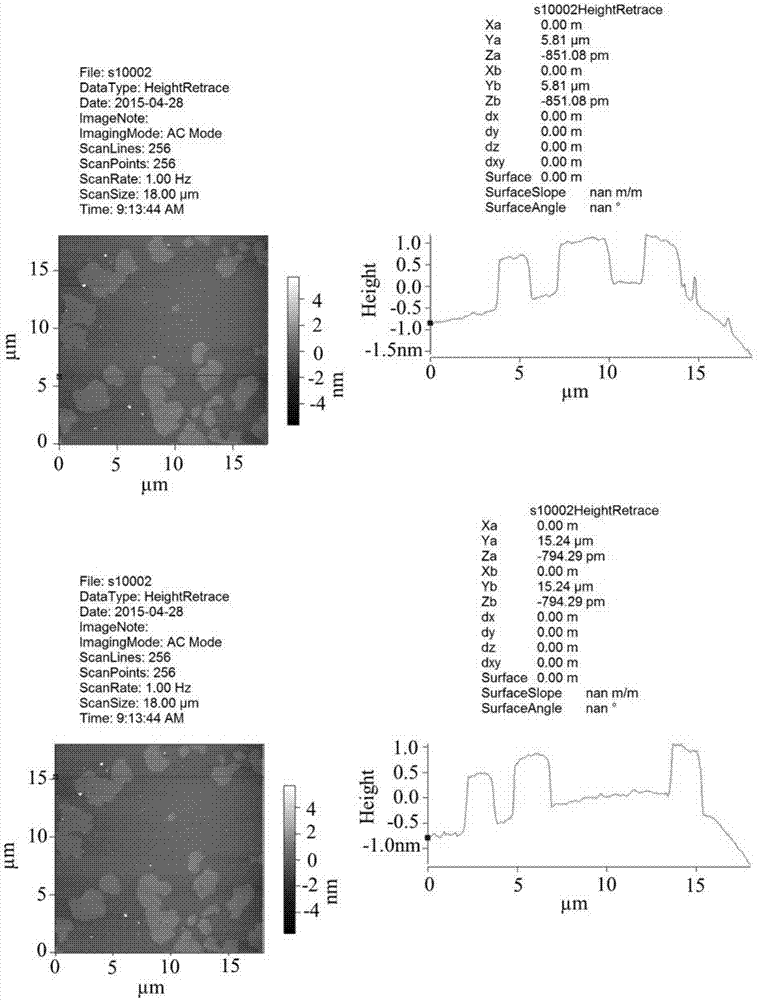

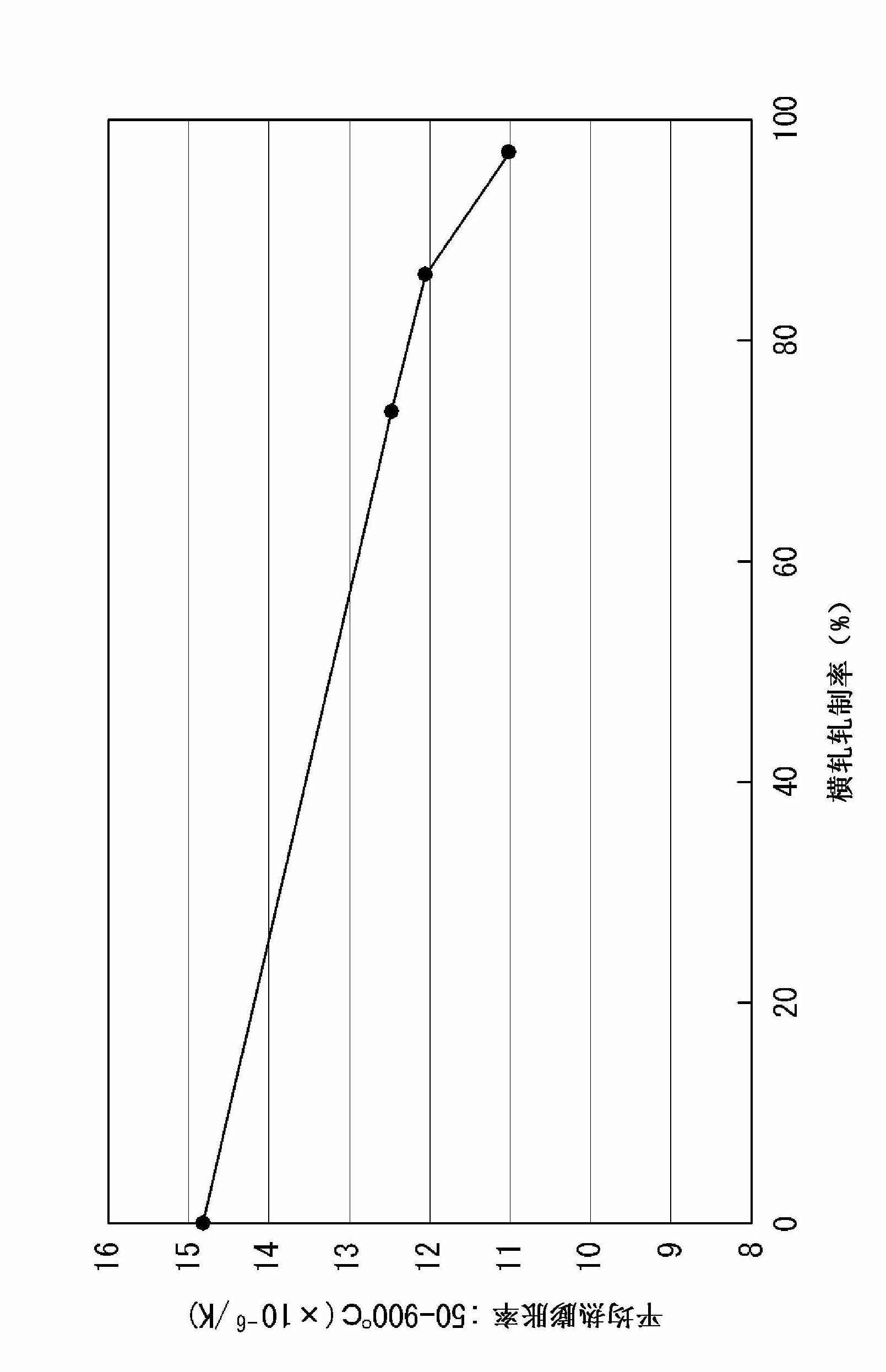

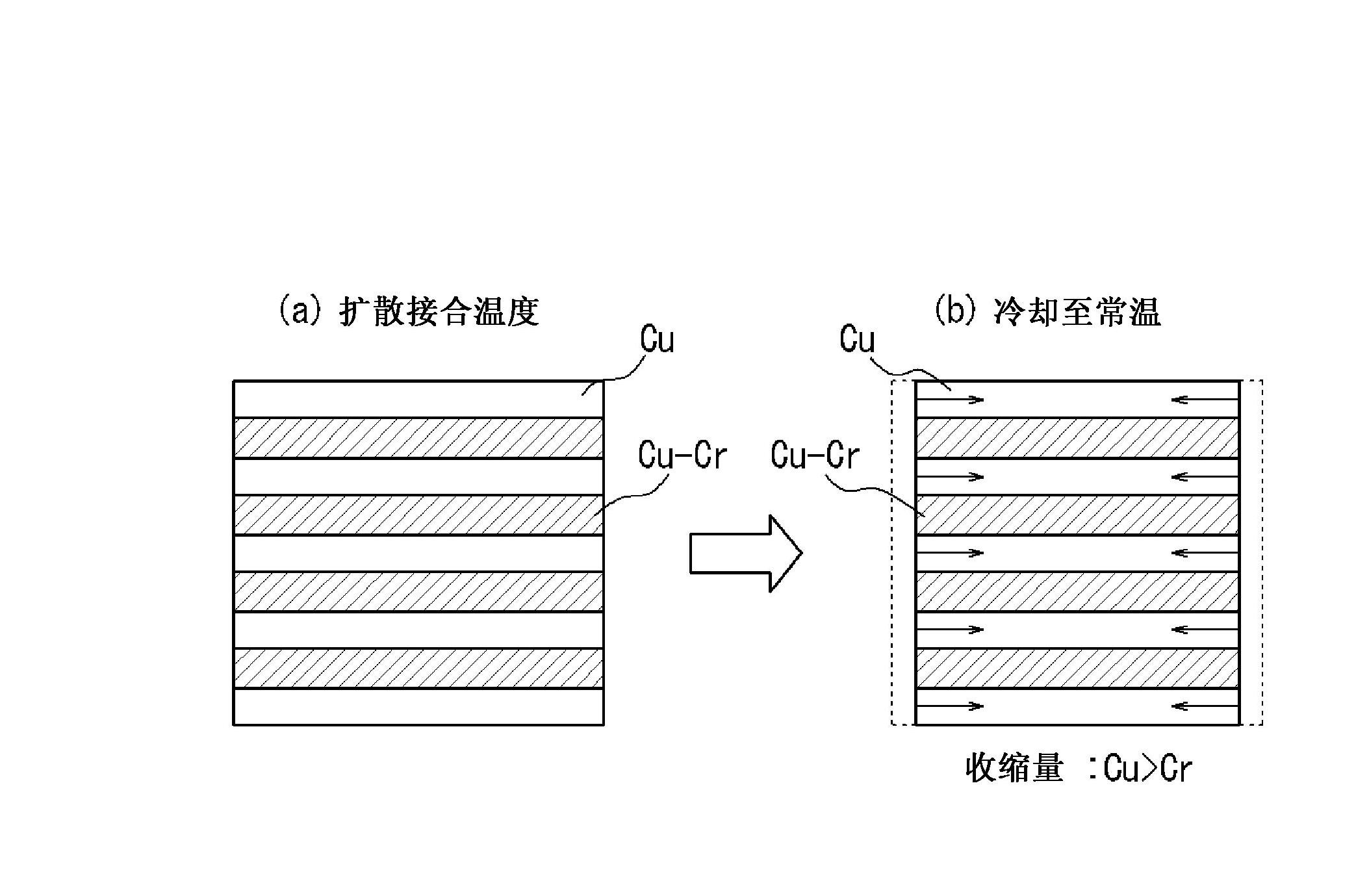

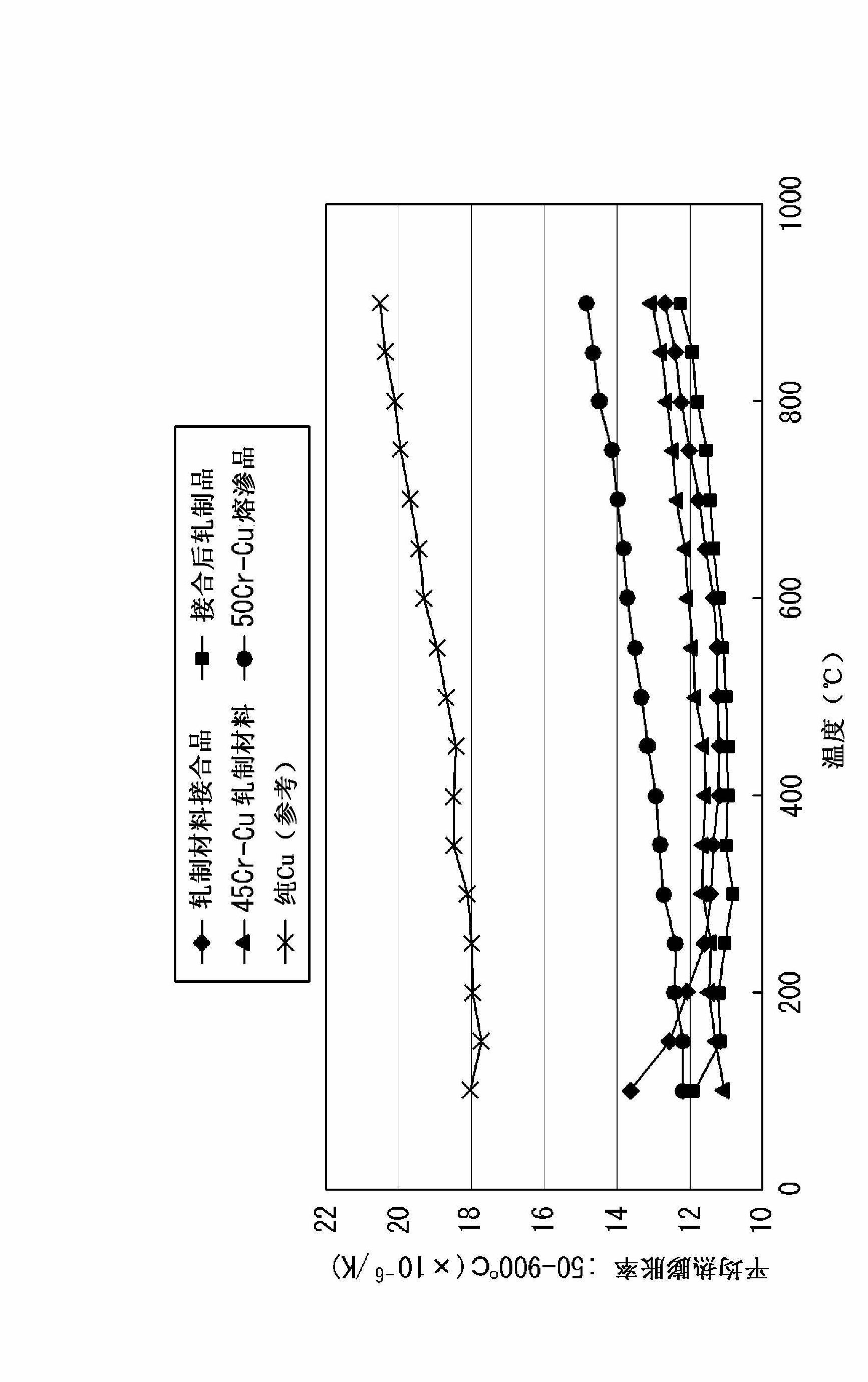

Heat sink for electronic device, and process for production thereof

ActiveCN102612745AGood thermal conductivityThinTransportation and packagingSemiconductor/solid-state device detailsHeat sinkMetallurgy

Disclosed is a heat sink for an electronic device, produced by joining a Cr-Cu alloy sheet comprising a Cu matrix and more than 30 mass% and not more than 80 mass% of Cr to a Cu sheet, and rolling the joined product, thereby producing a laminate having a Cr-Cu alloy layer and a Cu layer. The heat sink for an electronic device has low heat expansion properties, excellent heat conductivity particularly in the direction of thickness, and a reduced entire thickness.

Owner:JFE PRECISION CORP

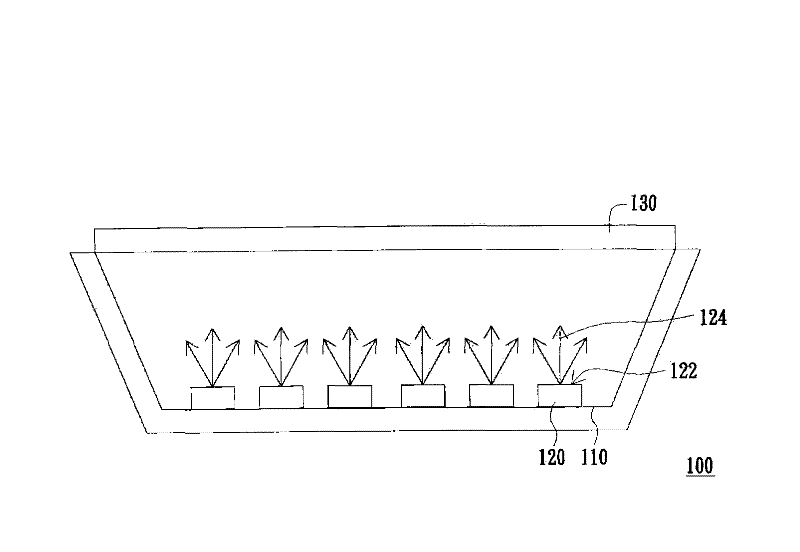

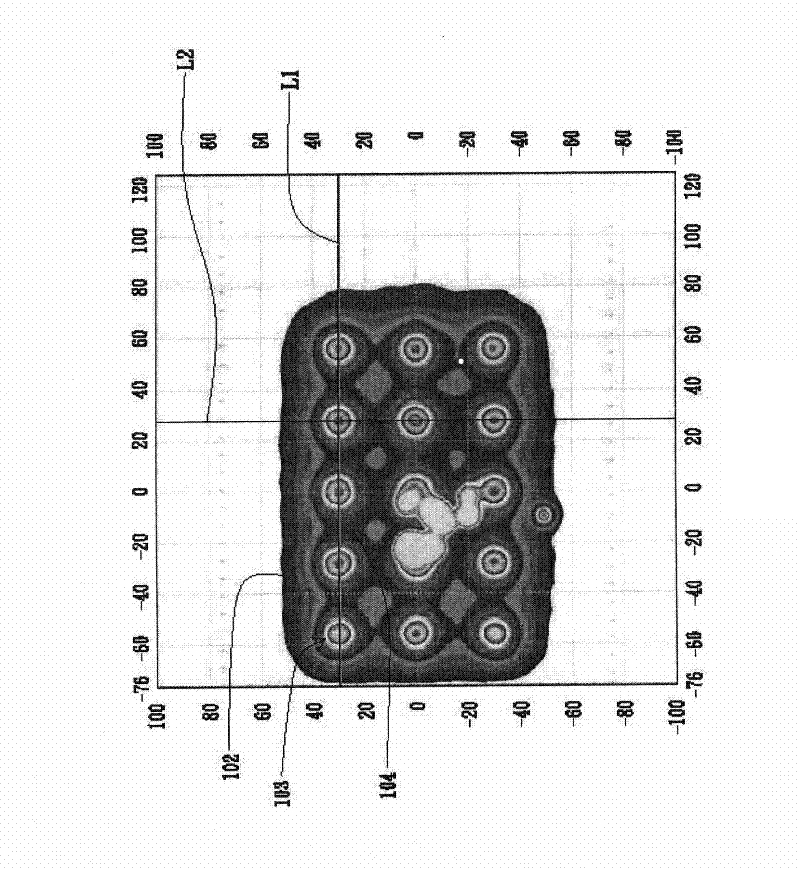

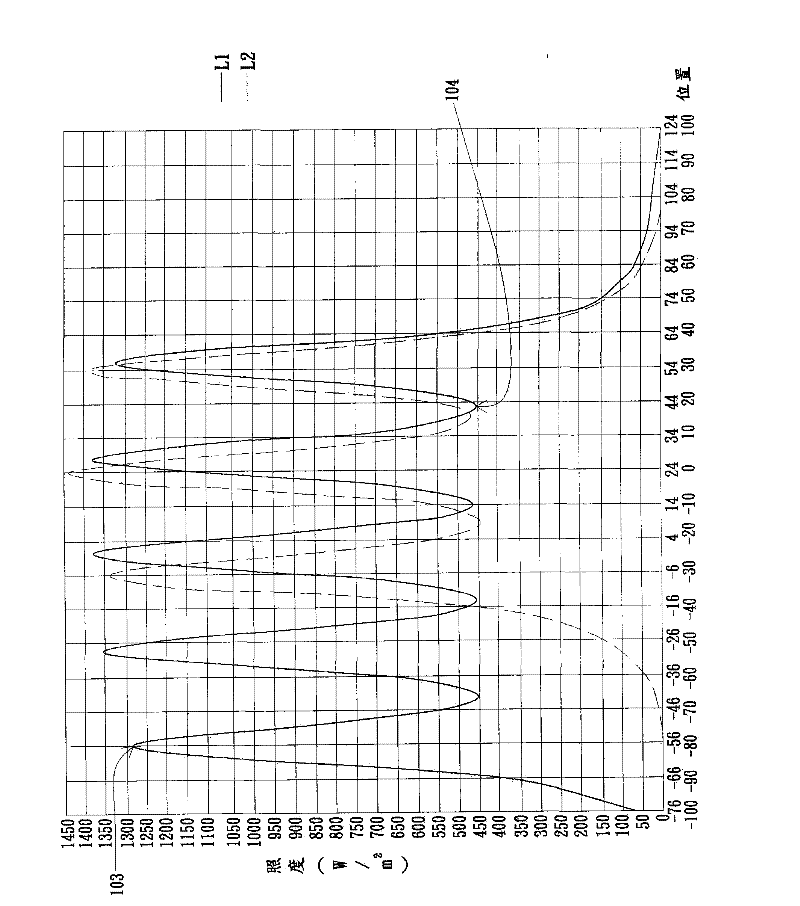

Backlight module and display with same

InactiveCN101749601AImprove uniformityThinMechanical apparatusPoint-like light sourcePower savingBackplane

The invention discloses a backlight module which comprises a back panel, a plurality of light source sets and a plurality of light guiding members. The light source sets are arranged on the back panel at intervals, and each light source set comprises a plurality of point light sources. The light guiding members are configured on the back panel and respectively located beside the light sources sets. Each light guiding member extends along a predetermined direction and is provided with a bottom surface, a first reflecting surface and a second reflecting surface. Each bottom surface faces the back panel, each first reflecting surface extends from the bottom face to the upside of the point light source of the corresponding light source set, and each first reflecting surface is a curved surface. Each second reflecting surface is connected between each bottom surface and each first reflecting surface. The luminous surfaces of the point light sources in each light source set face the first reflecting surface of the corresponding light guiding member. The backlight module has the advantages of thin thickness and power saving. In addition, the invention additionally provides a display with the backlight module.

Owner:AU OPTRONICS CORP

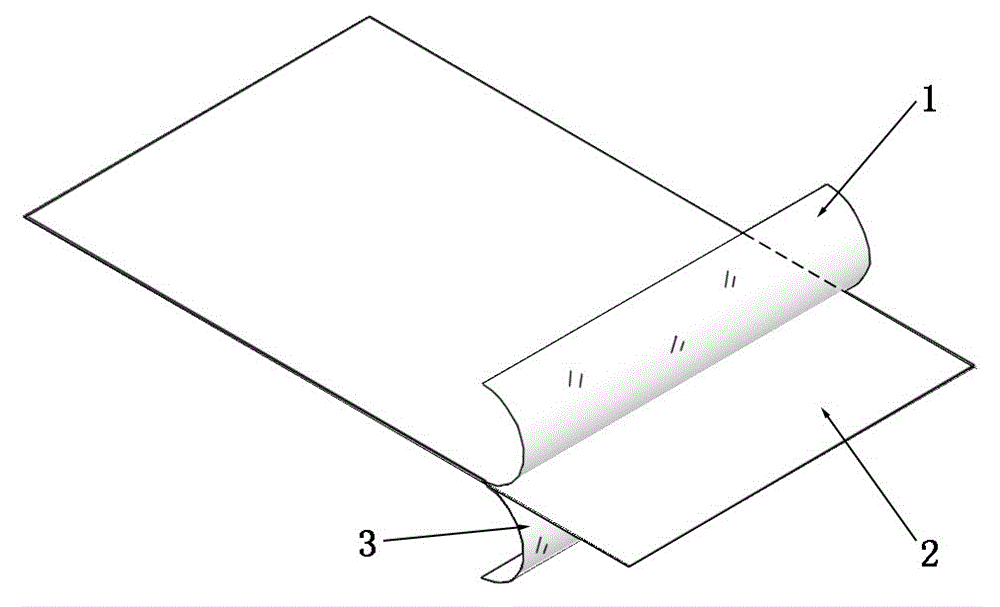

Heat-conducting and heat-dissipating film containing graphene

The invention relates to the technical field of a heat-conducting and heat-dissipating material, in particular to a heat-conducting and heat-dissipating film containing graphene. The heat-conducting and heat-dissipating film containing graphene comprises a heat-dissipating film body, wherein the heat-dissipating film body comprises a graphene composite film layer, the graphene composite film layer is formed by compositing a graphene layer and a base material through a bonding layer, the thickness of the graphene layer is in a range of 0.001-50.0 mu m, the purity of a graphene layer is in a range of 99.5%-99.99%, and a first adhesive layer and a second adhesive layer are arranged on the bottom surface and the top surface of the graphene composite film layer respectively. Compared with the prior art, the heat-conducting and heat-dissipating film containing graphene has the beneficial effects as follows: the heat-dissipating film body comprises the graphene composite film layer, the graphene composite film layer is formed by compositing the graphene layer and the base material through the bonding layer, and the heat-conducting and heat-dissipating film containing graphene has toughness, can be produced automatically and continuously, can be stored in a rolled manner, is convenient to use and good in heat-conducting and heat-dissipating effect, is fixed through bonding, and can be widely applied to heat conduction and heat dissipation of devices such as a laptop, a mobile phone, a television, a camera, an LED lamp, an automobile cooling fin and the like.

Owner:SHENZHEN LAIBIDE TECH CO LTD

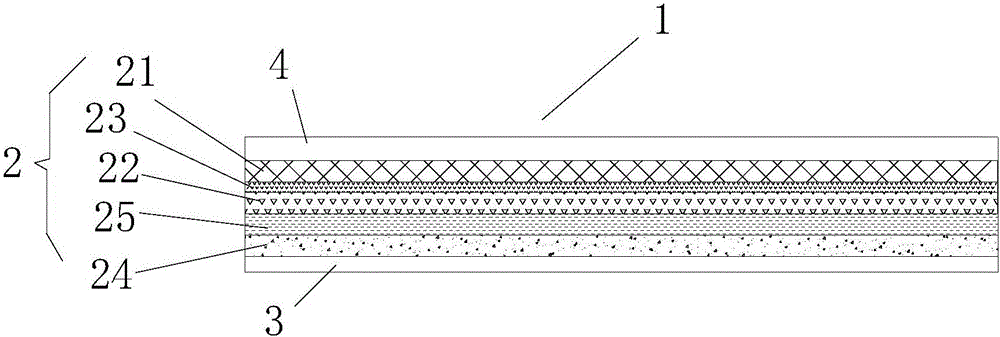

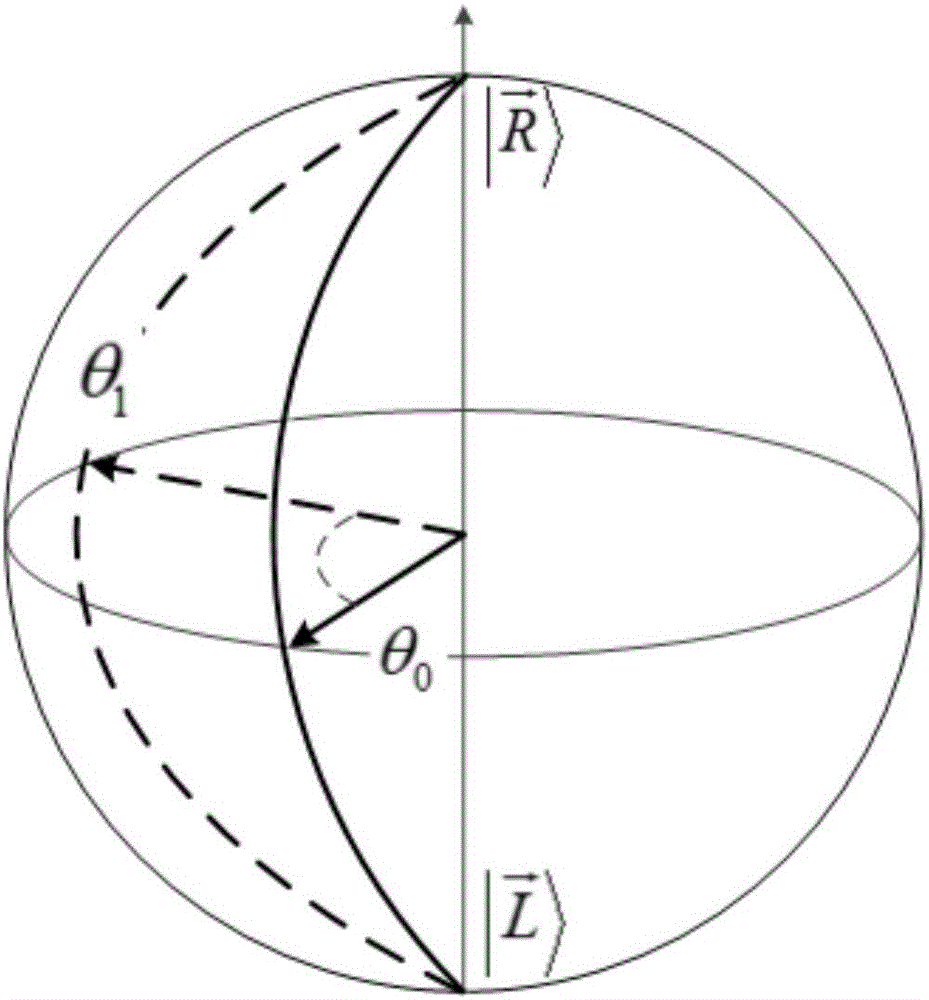

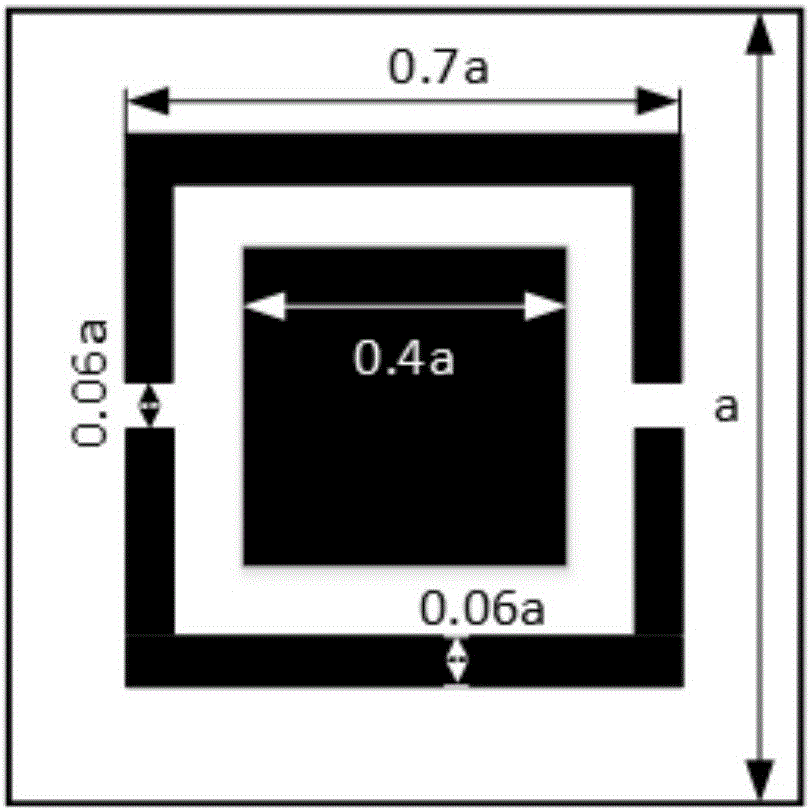

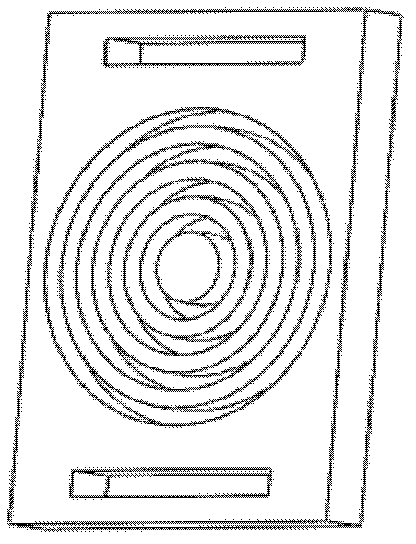

Lens and method for generating Bessel beam carrying orbital angular momentum based on super surface

The invention discloses a lens and a method for generating Bessel beam carrying orbital angular momentum based on a super surface, relates to a technology for generating the Bessel beam carrying the orbital angular momentum and solves the problems of high processing precision requirement, low energy utilization rate and poor integration effect of the conventional method for generating the Bessel beam. The lens comprises m*n phase mutation units which are periodically arranged, wherein each phase mutation unit comprises a substrate and a metal layer located on the surface of the substrate; the metal layer comprises two parts, wherein one part is a square metal layer arranged at the center of the substrate and the other part is a rectangular metal frame surrounding the square metal layer; a notch is arranged at the center of each of one group of opposite sides of the metal frame; one side of the substrate is taken as an x axis, an inclined angle between the connecting line of the center of the notch and the center of the substrate and the forward direction of the x axis is theta, (formula), circular polarized wave is vertically incident, and the transmission cross polarization wave is the Bessel beam carrying the orbital angular momentum. The lens and the method are suitable for generating the Bessel beam carrying the orbital angular momentum.

Owner:HARBIN INST OF TECH

Electric field detection device

The invention provides an electric field detection device which at least comprises a bearing body, a reference electrode layer arranged on the bearing body and at least three induction electrode layers arranged on the bearing body and located above the reference electrode layer. Each induction electrode layer comprises at least four induction electrodes evenly distributed. An independent electric field measurement circuit is formed by each induction electrode and the reference electrode layer. According to the electric field detection device, the induction electrodes distributed on multiple layers are adopted, the induction electrodes and the reference electrodes are all of a strip shape, and the strip-shaped electrodes are small in size, thin, capable of being integrated inside a cap easily and good in concealment performance. Meanwhile, due to the adoption of the induction electrodes distributed on multiple layers, the intensity of an electric field can be detected, the electric field can further be detected at multiple angles in multiple directions, and the direction of the electric field can be judged.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

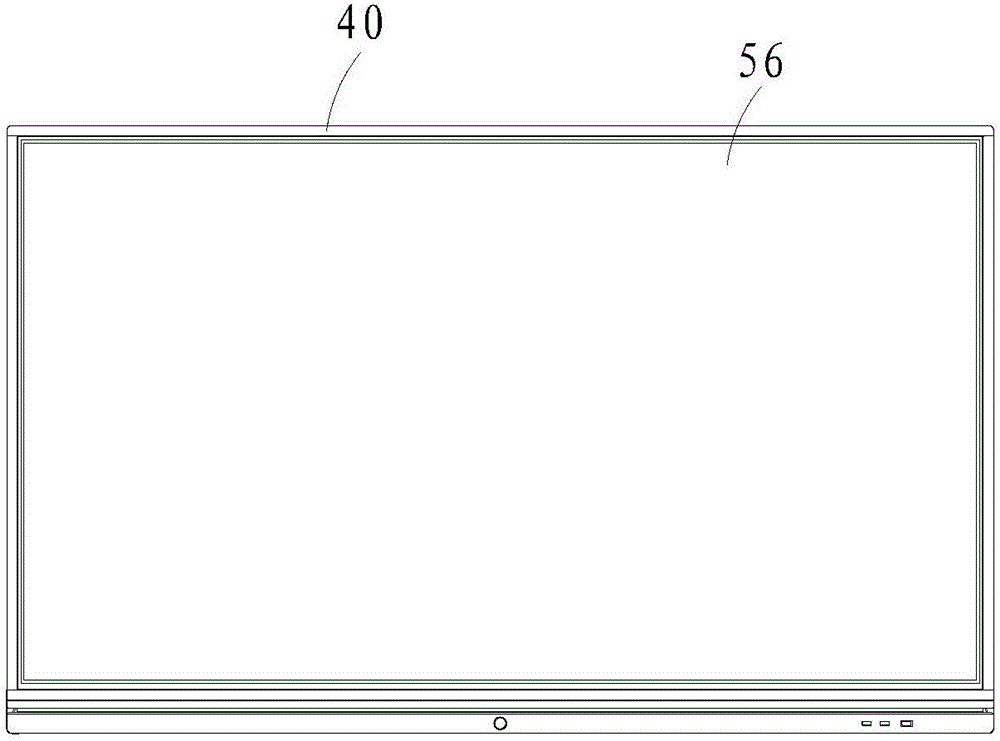

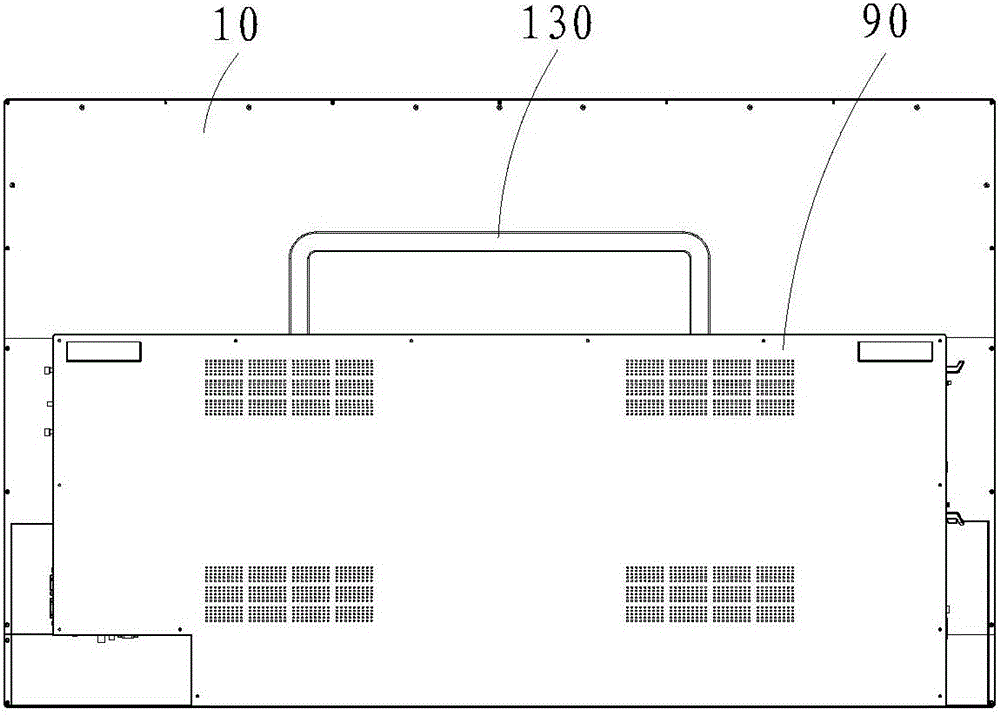

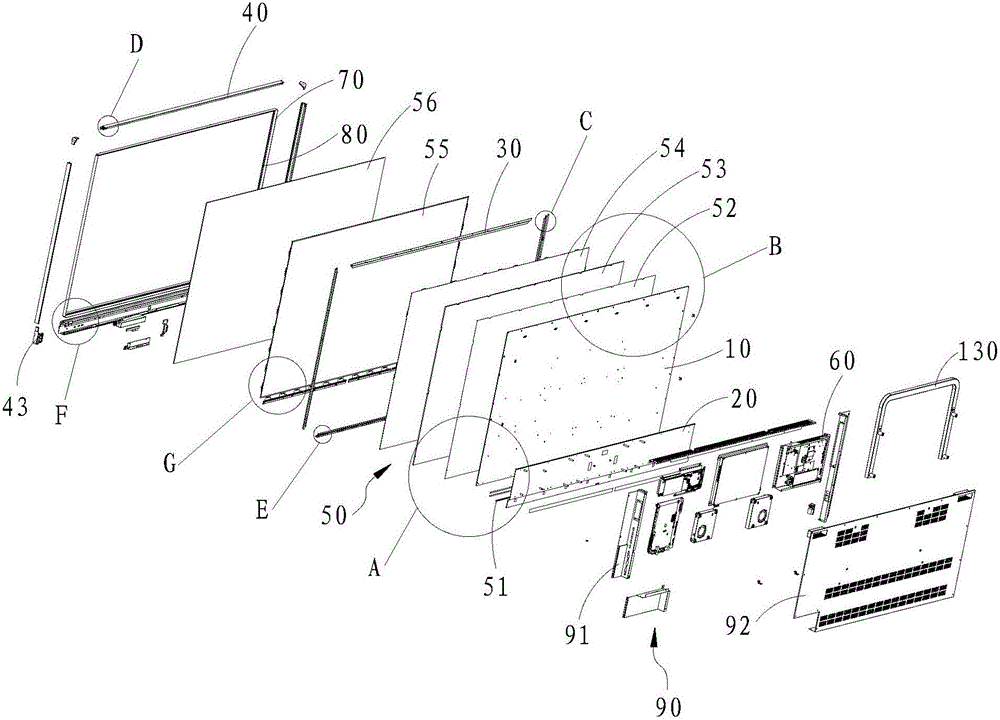

Interactive intelligent tablet

The invention discloses an interactive intelligent tablet. The interactive intelligent tablet comprises an aluminum-plastic backboard, a heat dissipation plate, a middle bezel component, an outer bezel component, a backlight module and a control unit, wherein the heat dissipation plate comprises a first plate body and a second plate body; the second plate body is located on the front side of the first plate body; the upper part of the second plate body is connected with the lower part of the first plate body; a light source mounting plate which extends to the front side is arranged at the lower end of the second plate body; the lower part of the aluminum-plastic backboard is mounted on a mounting surface formed by the front side surface of the first plate body and the upper end surface of the second plate body in a clinging manner; the front side surface of the aluminum-plastic backboard and the front side surface of the second plate body form a bearing basic surface for bearing the backlight module; and the back side surface of the aluminum-plastic backboard and the back side surface of the heat dissipation plate form a mounting basic surface for mounting the control unit. The interactive intelligent tablet is relatively small in thickness, relatively light in weight, good in heat dissipation effect and high in structural strength.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

Manufacture method of mica paper for capacitor

InactiveCN102651261AThinReduce volumeFixed capacitor detailsInsulating bodiesTension stressCapacitance

The invention belongs to the field of insulation materials and particularly relates to a manufacture method of mica paper for a capacitor. The manufacture method solves the technical problems that the dielectric intensity of mica paper produced by the existing method is low, and the mica paper is not suitable for producing small-sized and breakdown-resistant mica capacitance. The manufacture method of the mica paper comprises the following steps of a, mica raw material selection; b, roasting; c, chemical treatment; d, pulping; and e, papermaking. The mica paper for the capacitor prepared by the method has the advantages that the thickness is thin, the tension stress is high, the dielectric intensity is high, the mica paper can be used for producing small-sized and breakdown-resistant mica capacitance, and a new insulation material is provided for the electromechanical field.

Owner:SICHUAN MEIFENG MICA IND

Composite graphene electrode material and solid-phase catalysis preparation method thereof

The invention discloses a composite graphene electrode material. The material comprises an electrode material body and is characterized in that a graphene coating structure grows on the surface of the electrode material body in situ. The graphene coating structure is composed of a graphene close coating layer which is located on an electrode active material surface and a peripheral graphene conductive network and can improve the electrical conductivity of particles of the electrode material and the conductive connection among the particles. The invention also discloses a solid-phase catalysis preparation method for the composite graphene electrode material. The method comprises the steps of 1) mixing electrode materials, organic carbon source and catalyst precursors fully and uniformly as per the ratio of 200:(1-5):(5-30); 2) performing heat treatment on the mixture obtained through Step 1) in reducing atmosphere at 400-1000DEG C for 1-24 hours; 3) naturally cooling the mixture to the room temperature, performing porphyrizing and sieving, and finally obtaining the composite graphene electrode material. The method has the advantages of being low in cost and easy to implement and popularize.

Owner:SUZHOU UNIV

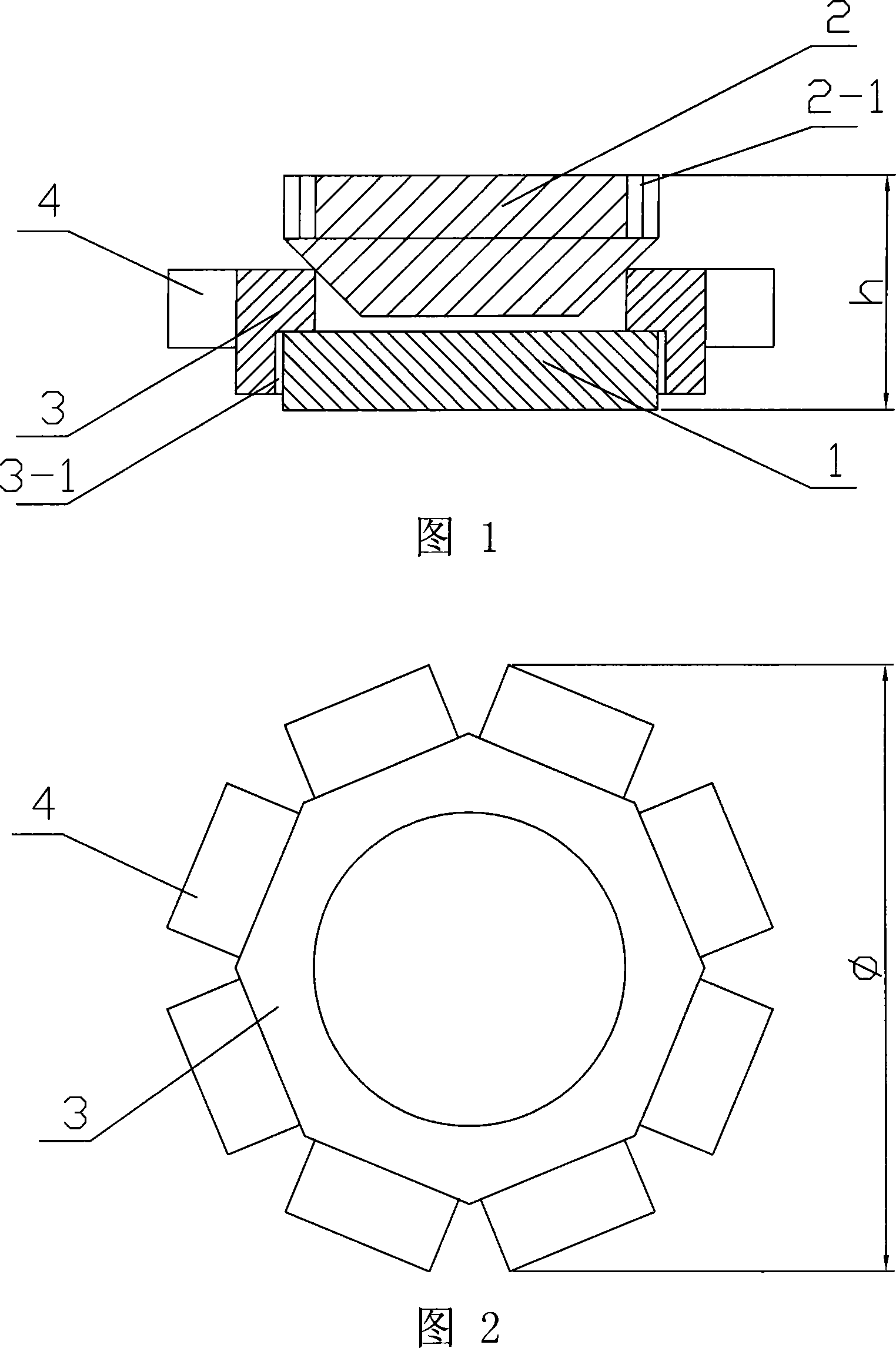

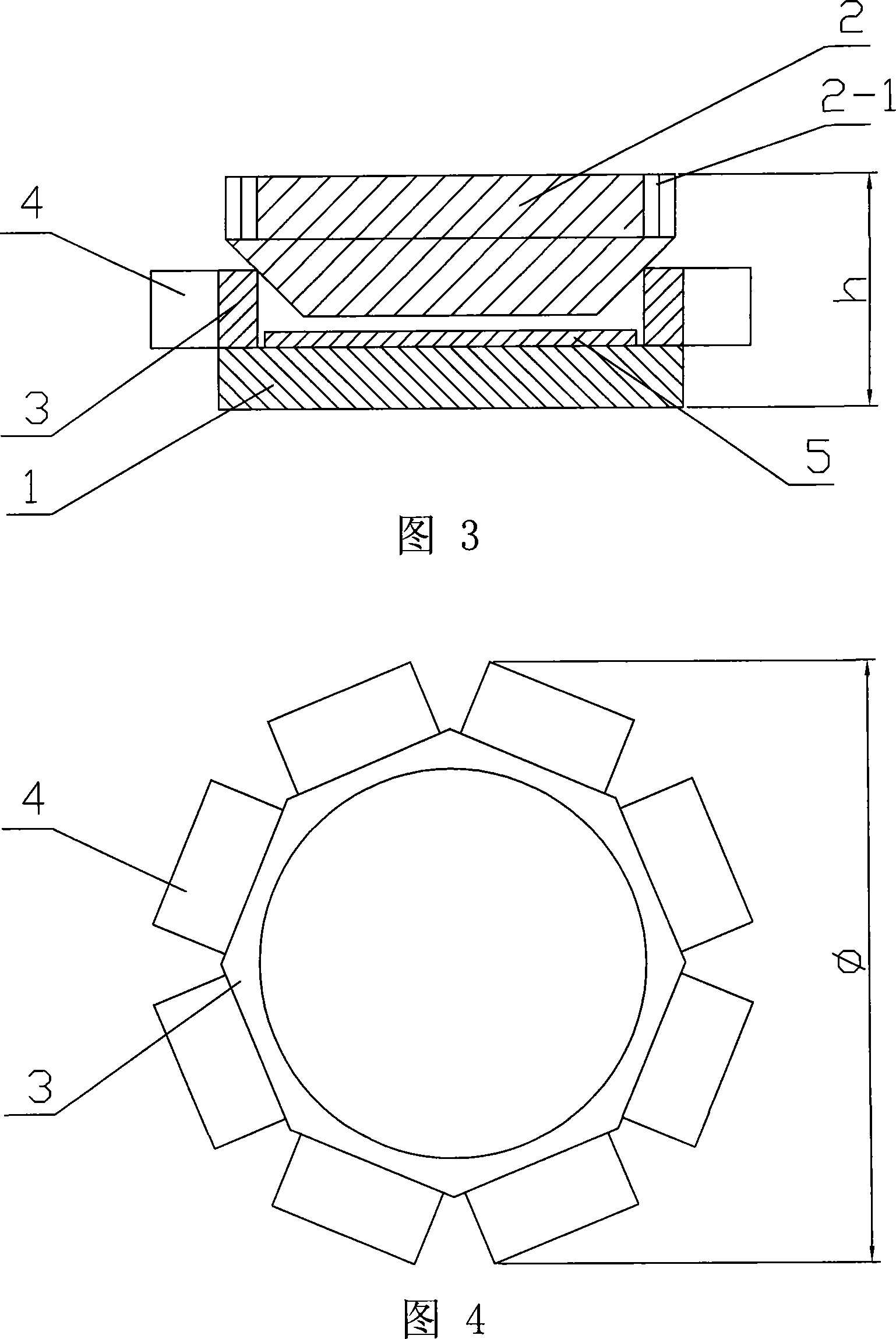

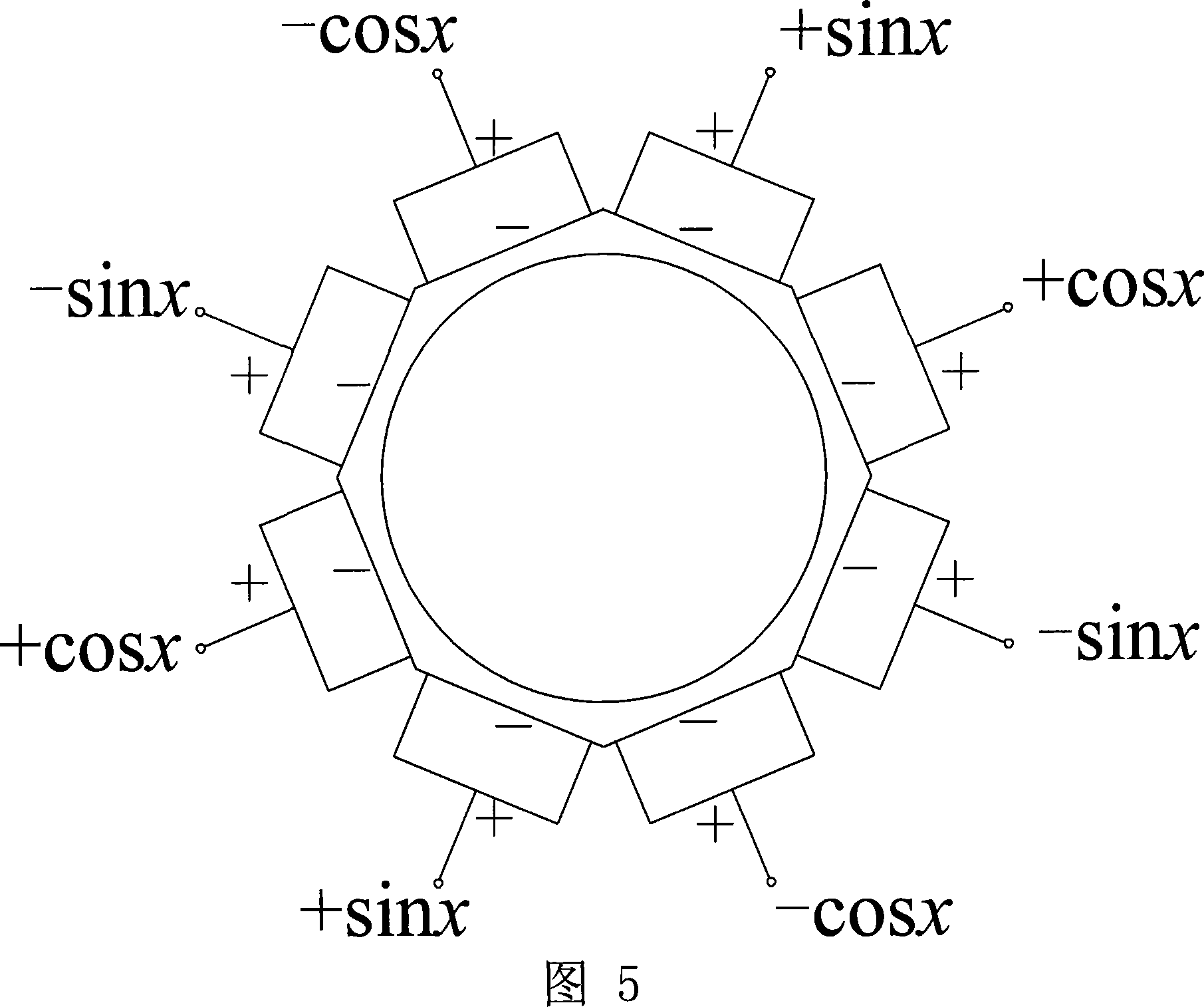

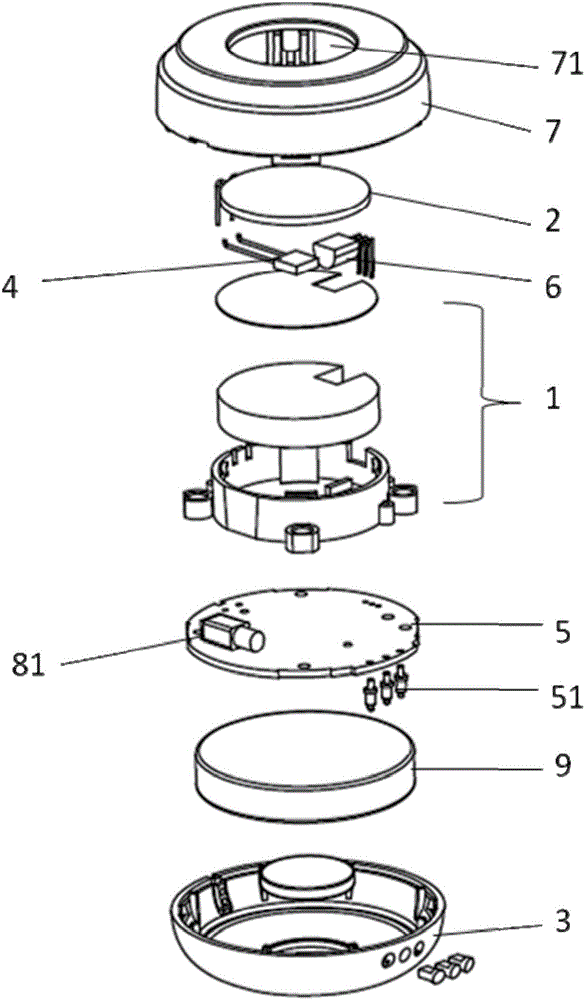

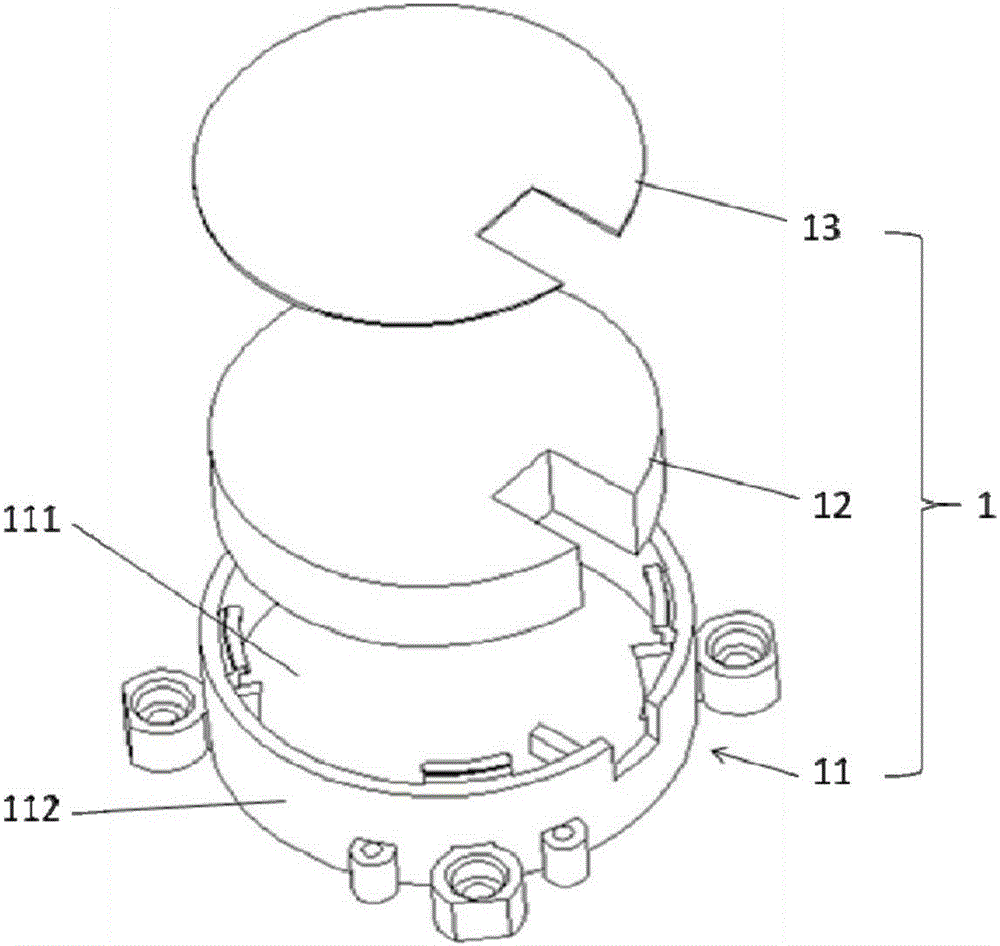

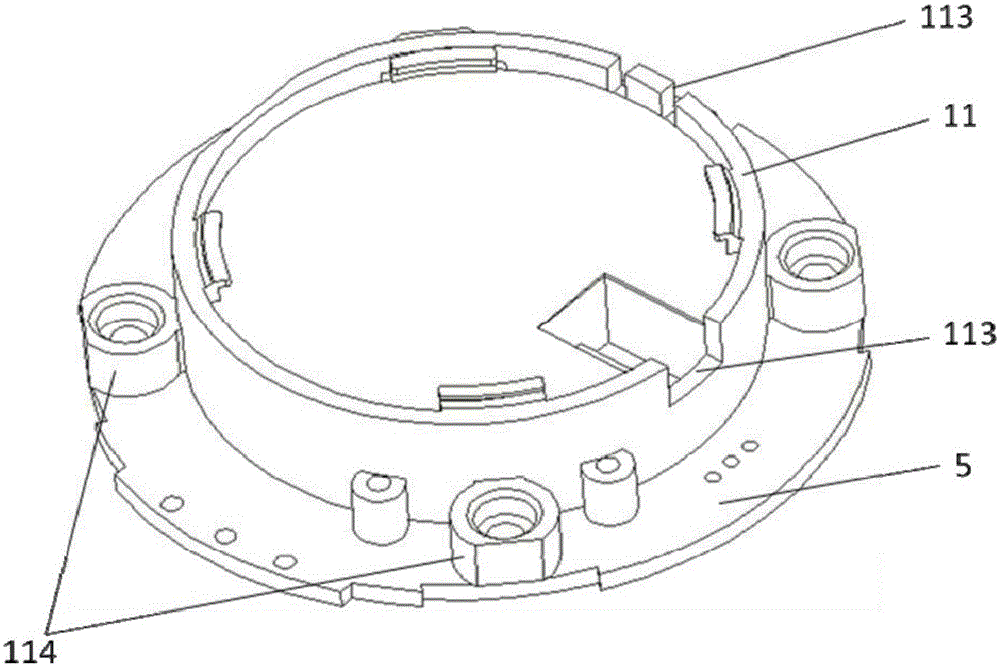

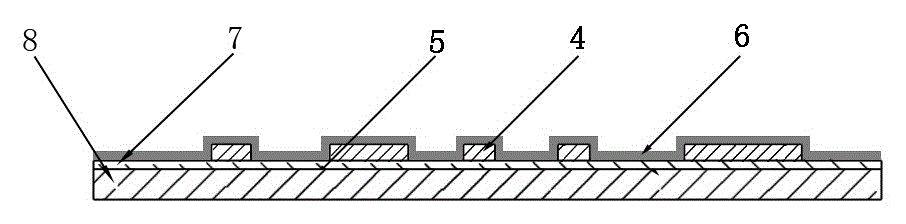

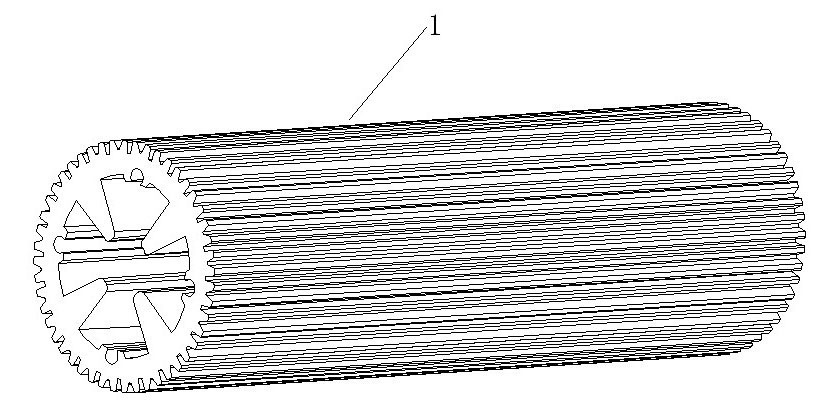

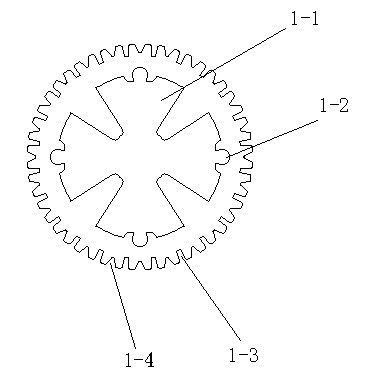

Pre-pressure device of magnetic force pressure enforcement and micro face ultrasonic electromotor based on this device

InactiveCN101170289AThinSimple pre-pressure devicePiezoelectric/electrostriction/magnetostriction machinesHollow cylinderMetal substrate

The invention discloses a pre-pressure device for magnetic pressure and a miniature in-plane ultrasonic motor using the device, which relates to the field of ultrasonic motors. The invention solves the shortcomings of the existing ultrasonic motors, which are large in radial direction, thick in axial direction and complex pre-pressure device. The pre-pressure device of magnetic force pressurization of the present invention adopts magnetic steel, and magnetic steel is circular sheet, and it fixes the stator bottom; Piezoelectric elements are respectively fixed on the eight edges of the metal base. The rotor is a conical frustum of magnetically conductive material. Gears are arranged on the edge of its upper bottom surface. The side wall of the rotor is lapped on the inner edge of the metal base of the stator. The magnetic force The magnetic attraction between the pressurized pre-compression device and the rotor provides the required pre-compression between the stator and the rotor. The invention has the advantages of thin thickness, simple pre-pressure device, miniaturization of the whole machine, easy processing of piezoelectric ceramics, low cost and good controllability, and is suitable for special occasions of thinning and miniaturization.

Owner:HARBIN INST OF TECH

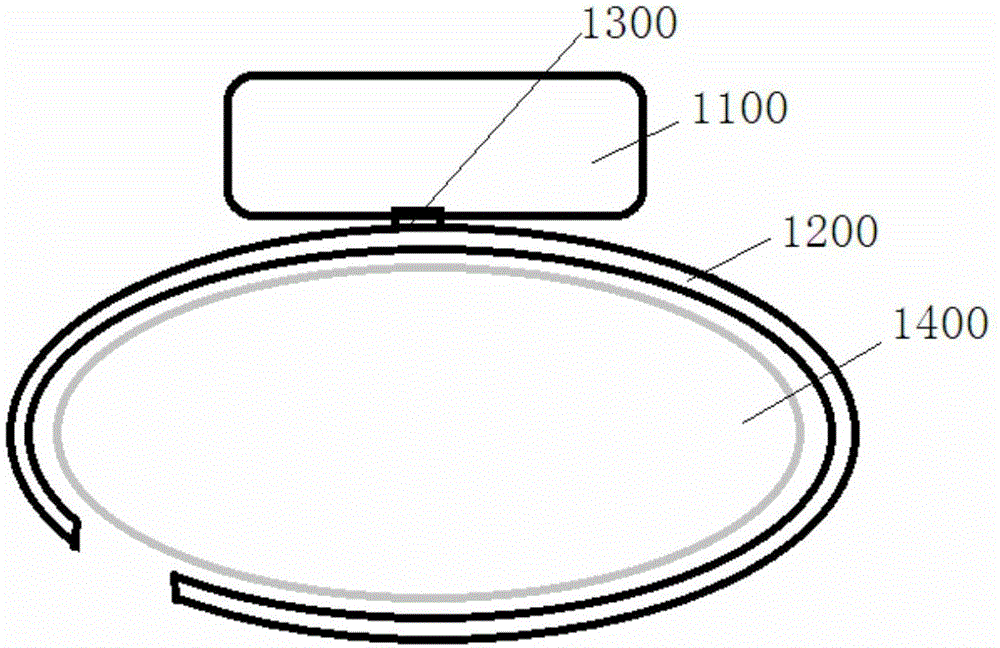

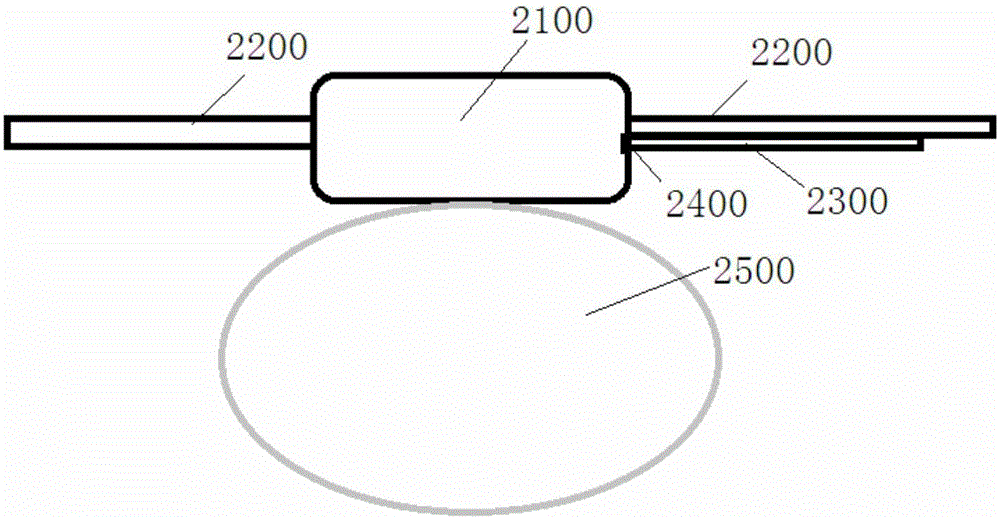

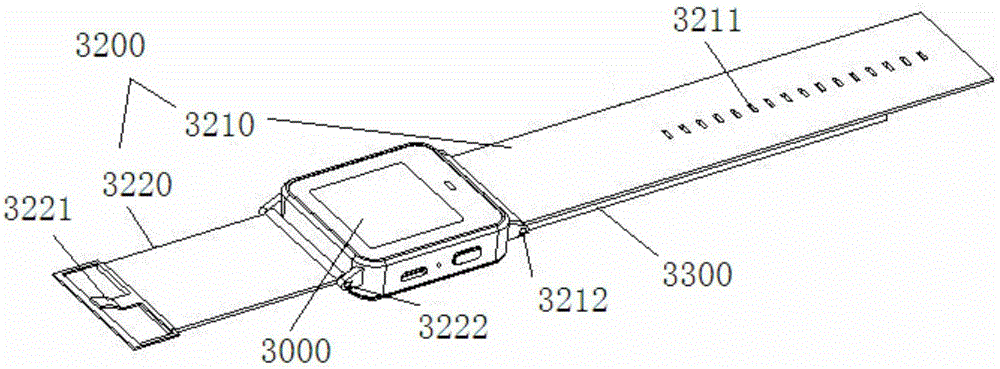

Watch type electronic sphygmomanometer

The invention discloses a watch type electronic sphygmomanomete. The watch type electronic sphygmomanomete comprises a sphygmomanometer main body, a watchband and a compression bag with an air bag, and the compression bag is arranged on the side, close to the wrist of a wearer, of the watchband; the sphygmomanometer main body is provided with a first side wall and a second side wall which are oppositely arranged, and the air bag in the compression bag is communicated with the sphygmomanometer main body at the first side wall to form a sphygmomanometer air channel. Due to the fact that an air channel connector of the air bag and the sphygmomanometer main body is arranged at the side of the sphygmomanometer main body, the thickness of the overall sphygmomanomete is decreased, the sphygmomanomete can be conveniently designed to be smaller, and the watchband does not need to pass through the position under the sphygmomanometer main body and can be connected with the two sides of the sphygmomanometer main body like an ordinary watch; the air bag is arranged on the side, close to the wrist of the wearer, of the watchband to avoid the sphygmomanometer main body, and therefore the overall watch type electronic sphygmomanomete is smaller in thickness and size and more convenient to carry.

Owner:SHENZHEN KINGYIELD TECH

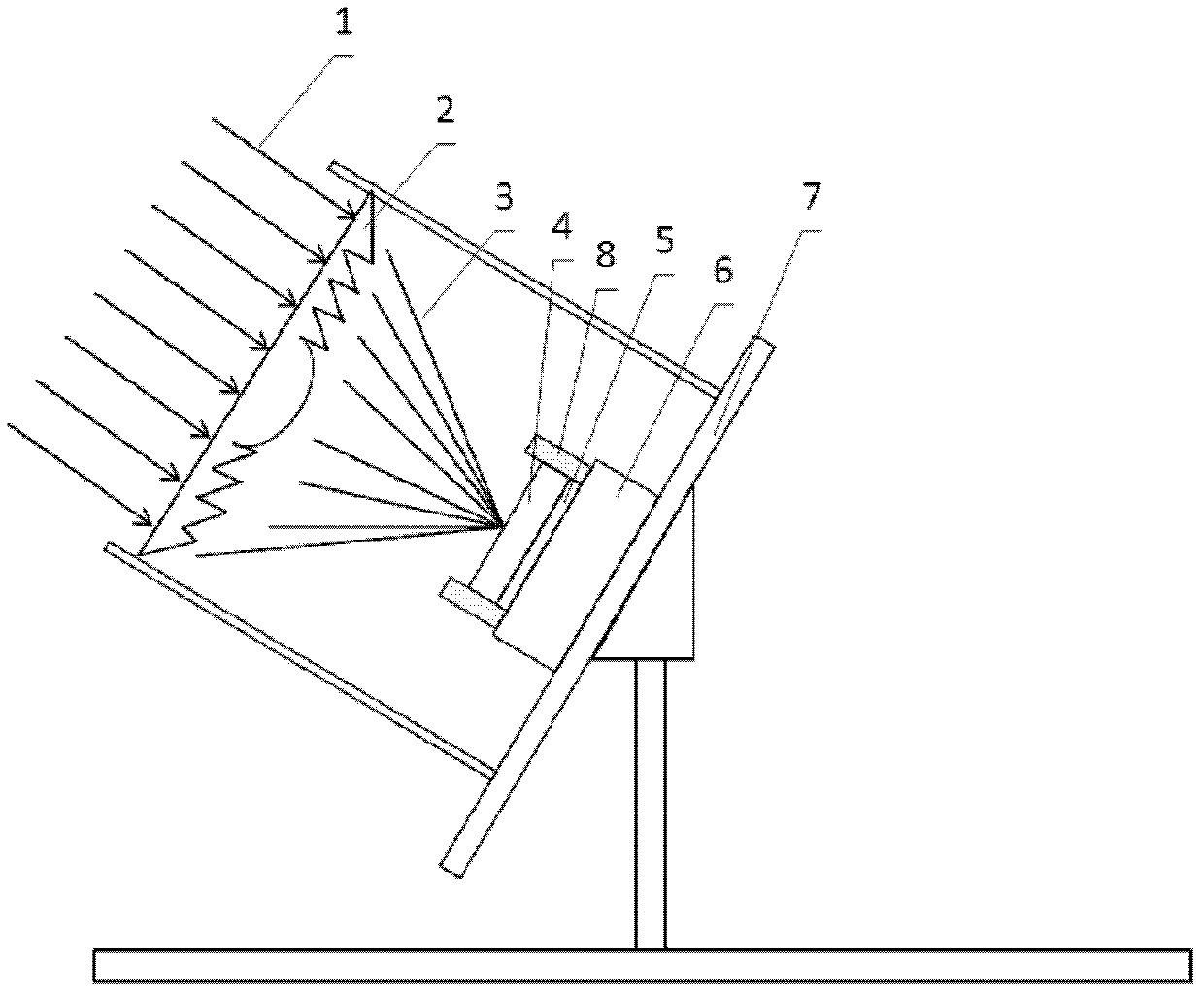

Focus solar temperature difference generating device

The invention discloses a focus solar temperature difference generating device, comprising a Fresnel focus lens, concentrators, a semiconductor temperature difference generating plate, water cooling systems and a support, wherein the Fresnel focus lens is fixed on the support, the semiconductor temperature difference generating plate is arranged on a light path of the Fresnel focus lens, the upper surface and the lower surface of the semiconductor temperature difference generating plate are respectively adhered with the concentrators and the water cooling systems, sunlight is incident to the Fresnel focus lens, is converged by the Fresnel focus lens and then is focused onto the concentrator, the concentrator converts light energy absorbed from the sunlight into heat energy, a high temperature terminal is formed on the upper surface of the semiconductor temperature difference generating plate, the water cooling systems form a low temperature terminal on the lower surface of the semiconductor temperature different generating plate, and electric energy can be obtained by virtue of temperature difference formed by the upper surface and the lower surface of the semiconductor temperature difference generating plate. The generating device can overcome the defect that solar energy density is low, a semiconductor temperature difference generating module is applied to the field of solar generating, and the generating device disclosed by the invention has simple system structure, high efficiency, low cost and strong practicability.

Owner:HUAZHONG UNIV OF SCI & TECH

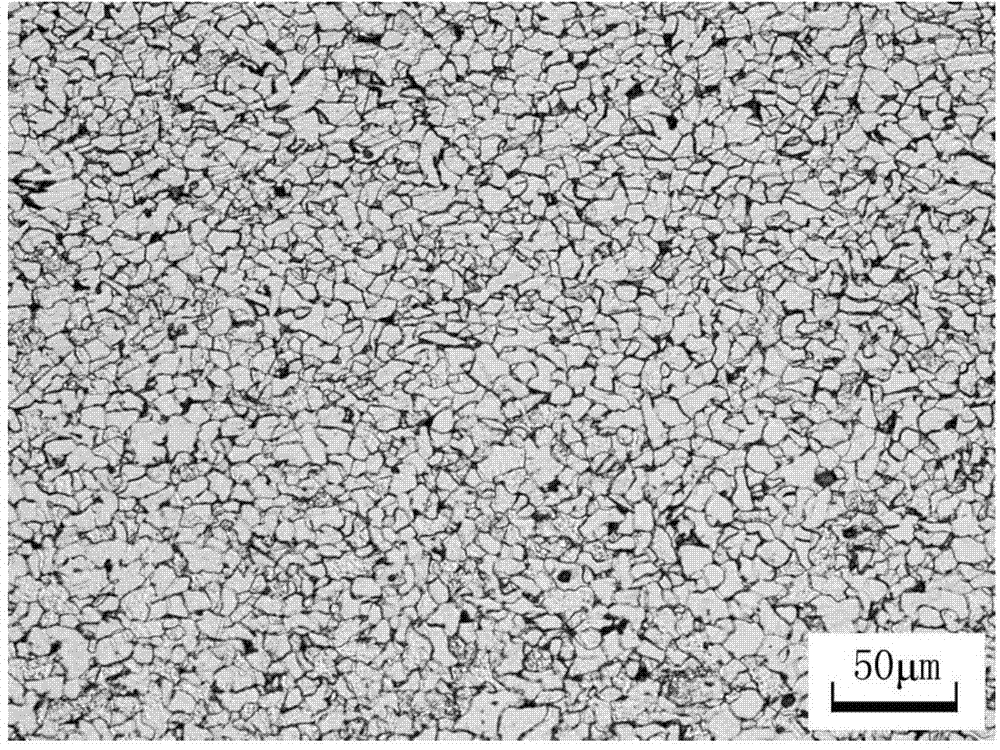

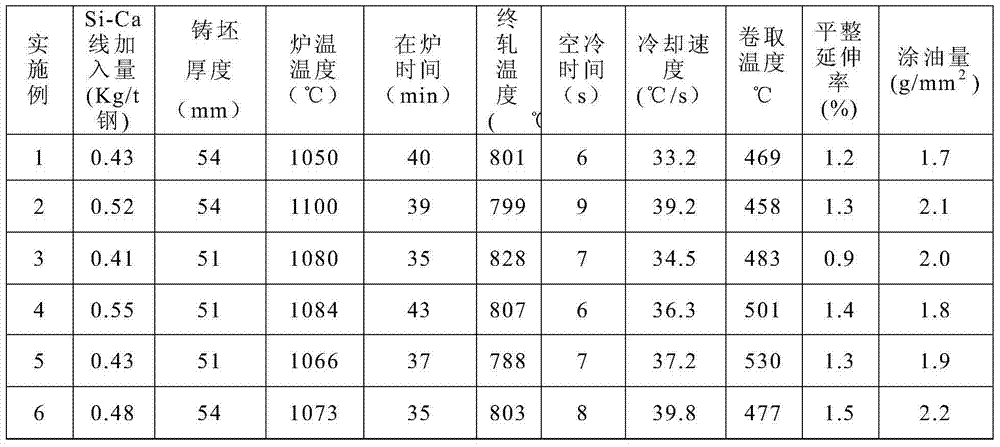

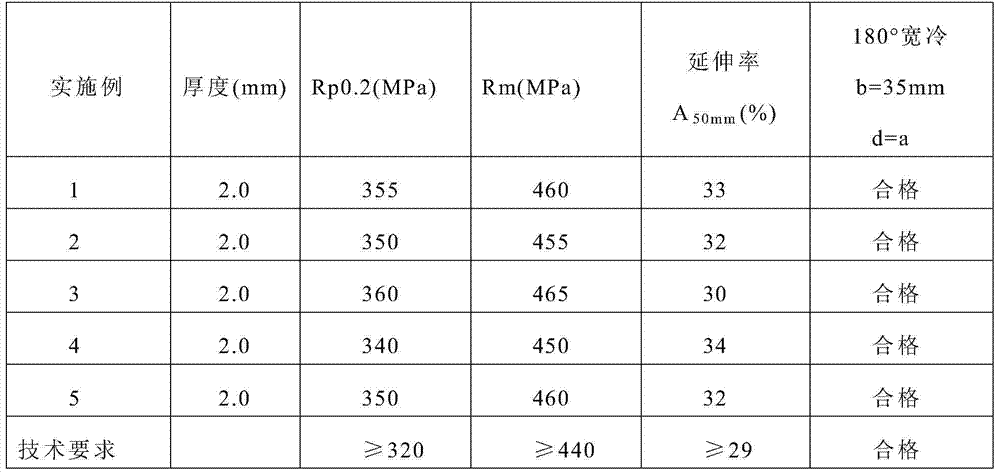

440MPa-tensile-strength hot-rolled high-strength steel sheet and production method thereof

The invention discloses a 440MPa-tensile-strength hot-rolled high-strength steel sheet and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.05-0.08% of C, 0.10-0.30% of Si, 0.60-1.20% of Mn, at most 0.025% of P, at most 0.012% of S, 0.01-0.03% of Nb, 0.01-0.03% of Als, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: desulfurizing molten iron, smelting in a converter, and carrying out alloying treatment; carrying out ladle furnace treatment while feeding a silico-calcium wire; carrying out continuous casting and continuous rolling; discharging the casting blank, and carrying out high-pressure water dephosphorization; carrying out seven-pass rolling; carrying out laminar cooling; coiling; carrying out acid washing; flattening; and finishing. The steel has the advantages of stable performance, high dimensional accuracy and favorable elongation percentage, can be used for passenger vehicles chassis, various reinforcing plates and other automobile structural members and safety members, and lowers the automobile production cost; and the production method has the advantages of low production cost and favorable adaptability to industrial production.

Owner:武汉钢铁有限公司

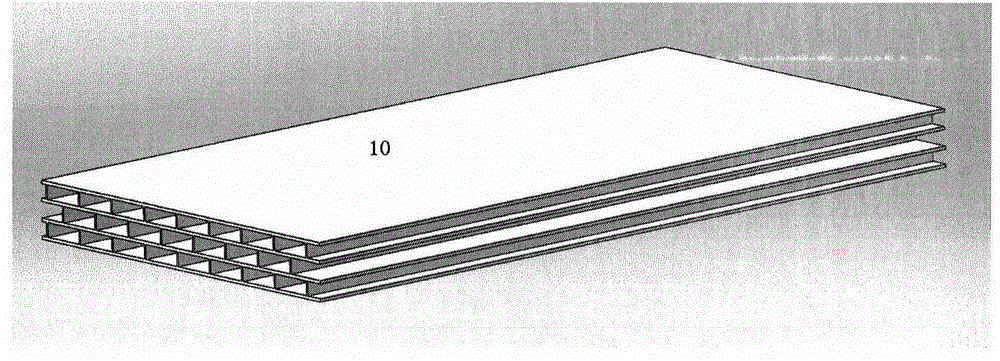

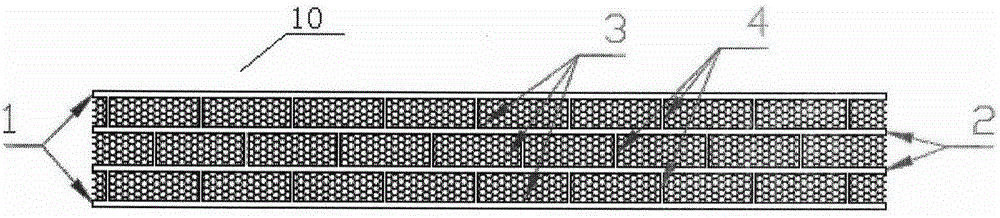

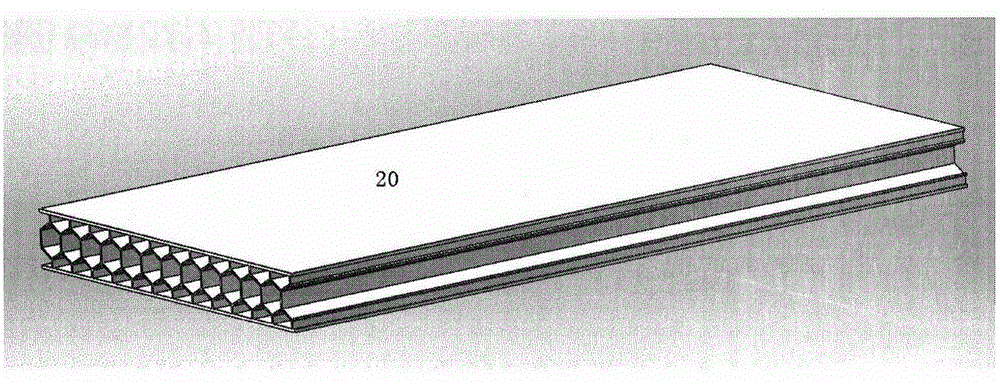

Multilayer composite grid sound barrier and application of multilayer composite grid sound barrier

InactiveCN105369923ALight in massImprove structural strengthHull panellingsFuselage insulationSound barrierIsolation layer

The invention provides a multilayer composite grid sound barrier. The multilayer composite grid sound barrier is of a multilayer composite three-dimensional structure, and comprises surface layers, a plurality of middle sound isolation layers and light-weight sandwich layers, wherein the surface layers are positioned on the surfaces of the two sides of the multilayer composite grid sound barrier; the middle sound isolation layers are positioned between the two surface layers; the light-weight sandwich layers are positioned between the surface layers and the middle sound isolation layers and between the middle sound isolation layers and fill gaps; the surface layers and the middle sound isolation layers are made of sound isolation materials or composite sound isolation materials; the light-weight sandwich layers are made of sound absorption material. The sound barrier also comprises keels; the keels are positioned between the surface layers and the middle sound isolation layers, connect the surface layers and the middle sound isolation layers and connect the middle sound isolation layers to form a three-dimensional grid structure; and the keels positioned at the two sides of the each middle sound isolation layer are not overlapped with the extension lines of the keels arranged at the other side of the middle sound isolation layer. The multilayer composite grid sound barrier has excellent sound isolation performance; meanwhile, good heat insulation performance is realized; the structure is firm, simple and reasonable; the weight is light; the thickness is small; the installation is convenient; the production and manufacturing process is simple; and the cost is low. The invention also provides application of the multilayer composite grid sound barrier.

Owner:北京谐声昊普声学技术有限公司

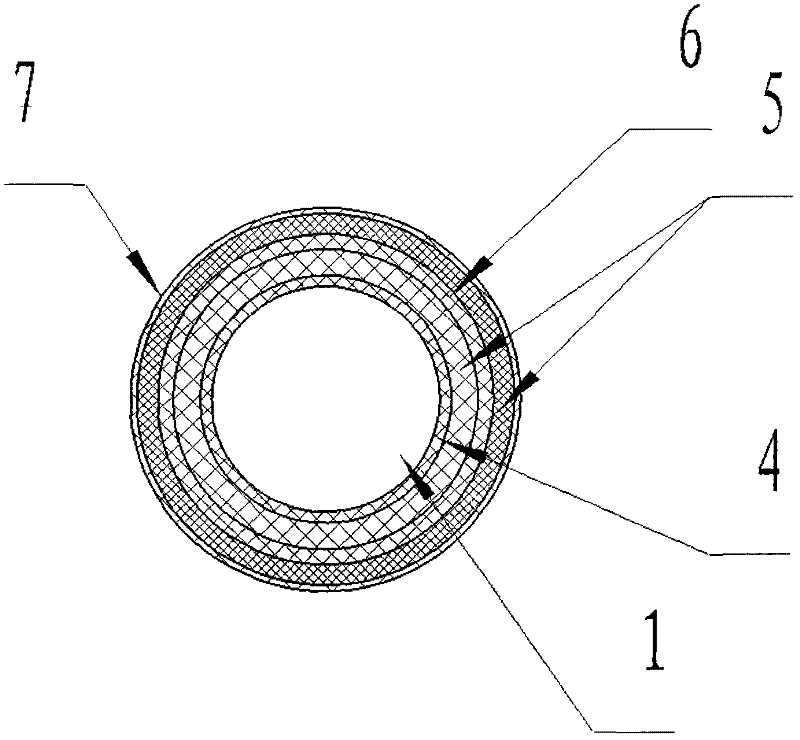

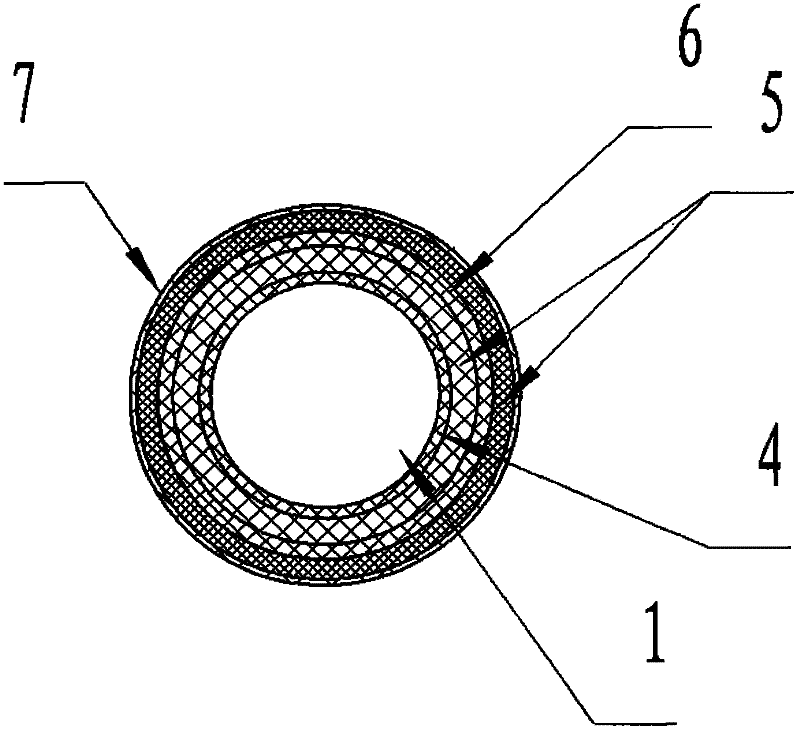

Silicone rubber composite rubber tube lined with polytetrafluoroethylene and manufacturing method thereof

ActiveCN102529181AExpand the scope of useThinLamination ancillary operationsSynthetic resin layered productsPlasma treatmentPolytetrafluoroethylene

The invention provides a silicone rubber composite rubber tube lined with polytetrafluoroethylene, comprising a polytetrafluoroethylene lining tube, a first silicone rubber layer, a reinforced layer and a second silicone rubber layer from inside to outside in sequence. The silicone rubber composite plastic tube solves the problems of low performance of the silicone rubber in oil resistance and solvent resistance, and greatly increases the use range of the silicone rubber tube. Additionally, the invention also provides a manufacturing method of the silicone rubber composite rubber tube, which improves the bonding property of the polytetrafluoroethylene lining tube with the silicone rubber by three methods, and comprises steps of: (1) performing plasma treatment to a polytetrafluoroethylene film belt; (2) tightly winding a layer of glass cloth on the outer surface of the polytetrafluoroethylene film belt after the polytetrafluoroethylene film belt is wound on a mould core so as to make the surface of the polytetrafluoroethylene film belt acquire the same textures to increase the surface area; (3) performing sodium-naphthalene-tetrahydrofuran solution to the outer surface of the shaped polytetrafluoroethylene lining tube to improve the surface polarity and the surface tension of the tube.

Owner:XIAMEN CHUANGXINYUAN RUBBER PROD

Wirelessly controlled moxibustion head

InactiveCN106361561AAvoid safety hazardsThinDevices for heating/cooling reflex pointsHeater elementsTreatment effectPrinted circuit board

The invention discloses a wirelessly controlled moxibustion head which comprises a casing composed of an upper casing and a lower casing. The wirelessly controlled moxibustion head further comprises a lithium battery, a printed circuit board (PCB) and a heating piece, wherein the lithium battery and the PCB are installed in the casing, and the heating piece is installed by being attached to a hollow opening at the center position of the lower casing. The moxibustion head further comprises a heat insulation structure which is arranged between the heating piece and the PCB and insulates heat emitted by the PCB, and the lithium battery is electrically connected with the heating piece through the PCB. The wirelessly controlled moxibustion head is flexible and convenient to use, easy to control, small in size, easy to carry and good in moxibustion therapy effect and can completely meet users' requirements for moving moxibustion therapy and high efficiency and convenience in the modern society.

Owner:SHENZHEN DR MOXIBUSTION MEDICAL SCI & TECH CO LTD

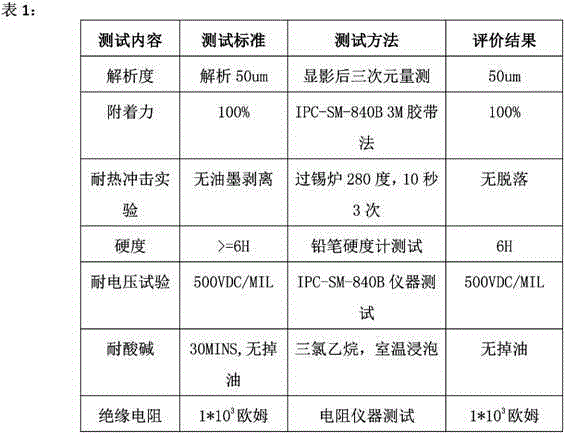

Solder-resisting photosensitive resin composition, printed wiring board and preparation technology of printed wiring board

PendingCN105137715AGood mechanical propertiesThinPrinted circuit detailsPrinted circuit manufactureSolder maskPhotoinitiator

The invention discloses a solder-resisting photosensitive resin composition, a printed wiring board using a solder-resisting photosensitive dry film, prepared from the solder-resisting photosensitive resin composition, as a solder mask, and a preparation technology of the printed wiring board. The solder-resisting photosensitive resin composition comprises the following components: 11-13 wt% of a binder, 29-32 wt% of epoxy resin, 11-14 wt% of monomer, 12-14 wt% of a photoinitiator, 25-29 wt% of an additive and 3.5-4.5 wt% of dye. The solder-resisting photosensitive dry film prepared from the solder-resisting photosensitive resin composition disclosed by the invention has the following advantages: (1) the mechanical property is excellent: the dry film is thinner and higher in strength and has excellent heat shock resistance; (2) the curing speed is high: the photosensitive dry film requires short time of exposure, can particularly ensure the manufacturing accuracy of the printed wiring board, and is applicable to manufacture of high-density wired circuit boards; (3) the photosensitive dry film is attached to the printed wiring board through the function of pressure and temperature and adopts a specific manufacturing technology, and no bubble exists between the solder mask and the circuit board.

Owner:河北盈丰电子科技有限公司

Soil monolith acquisition and production equipment and technology

InactiveCN102879240ALarge exhibition areaThinWithdrawing sample devicesPreparing sample for investigationSoil columnBonding strength

Soil monolith acquisition and production equipment and a technology belong to experimental research equipment for soil monolith acquisition and production and operational technical specification, and can well solve the problem that a soil sample is easy to crack and collapse, bonding strength of a produced sample is not high, mechanical material is easy to fall and soil structure is easy to destroy during sampling in the field by present equipment and technologies. The equipment provided by the invention is mainly composed of a soil sampling frame, a supporting auxiliary plate, a base plate, a cover plate, an auxiliary frame, gauze, a cementing agent and the like. Detailed implementation way of the invention comprises two stages of field sample acquisition and lab sample treatment, including more than 10 technical steps. By the adoption of the equipment and the technology to produce the soil monolith, original genetic state of an earth pillar can be retained to the maximum, and the earth pillar has characteristics of large stretching surface, thin thickness, light weight, high strength and the like.

Owner:陈杰 +1

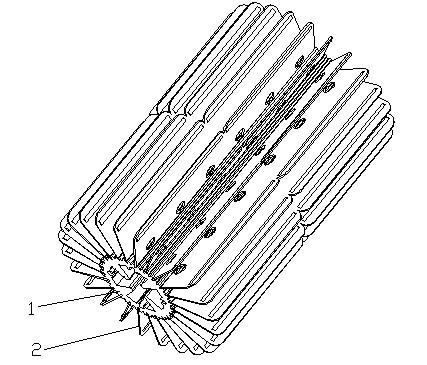

High-power LED illumination lamp metal radiator and manufacturing method

InactiveCN102128438AThinImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsHeat sinkEngineering

The invention relates to a high-power light emitting diode (LED) illumination lamp metal radiator and a manufacturing method. The radiator comprises a radiating shaft and radiating fins, wherein the radiating shaft is of a cylinder, the circle center of the cylinder is provided with a through hole, two end faces of the radiating shaft are correspondingly provided with positioning holes communicated at two ends, the circumferential surface of the radiating shaft is uniformly provided with a plurality of U-shaped insert slots and V-shaped pressing plate slots in the same number as the U-shaped insert slots, and the U-shaped insert slots and the V-shaped pressing plate slots are formed at intervals; the radiating fins are rectangular sheets, two angles at the upper ends of the radiating fins are symmetrical arc angles, and the surfaces of the radiating fins are provided with a plurality of rectangular reinforcing slots and a plurality of radiating holes; and the right-angled sides of a plurality of radiating fins are extruded into the plurality of U-shaped insert slots on the radiating shaft respectively. The radiator has the advantages that the radiating efficiency is improved, the weight and the volume are reduced and the consumption of raw materials is reduced. The radiator can directly replace the conventional incandescent lamp or energy-saving lamp, so the application range of the radiator is enlarged, the application of an LED illumination lamp is more convenient and the application range is wider.

Owner:TIANJIN ZHONGHUAN JINGRUI ELECTRONICS

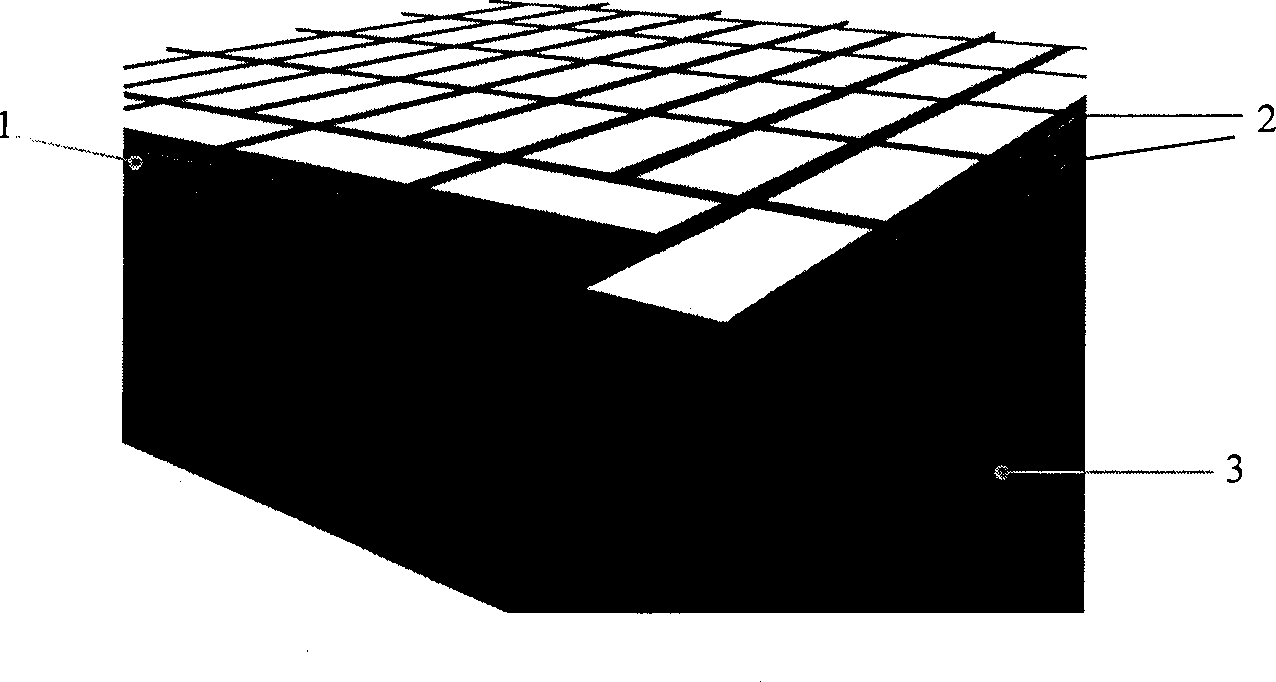

Three-dimensional metamaterial wave absorption body

PendingCN109994839AImprove survivability and penetration capabilitiesThinAntennasAbsorption effectMicrostructure

The invention discloses a three-dimensional metamaterial wave absorption body. The three-dimensional metamaterial wave absorption body comprises a reflection layer, a wave absorption layer and a plurality of metamaterial unit array layers, wherein the wave absorption layer is arranged above a surface of the top of the reflection layer, the plurality of metamaterial unit array layers are arranged on the wave absorption layer, contact edges of the plurality of metamaterial unit array layers and the wave absorption layer are arranged in parallel, each metamaterial unit array layer is divided intoa plurality of same metamaterial units, an artificial microstructure is attached onto a surface, facing the same direction, of each metamaterial unit. With the three-dimensional metamaterial wave absorption body disclosed by the technical scheme, the wave absorption material and the artificial microstructure form the three-dimensional metamaterial wave absorption body, a favorable wide-angle absorption effect is also achieved on the premise of achieving a favorable wide-frequency absorption effect, and the average wave absorption effect being 79.5% or above can be maintained within a 60-degree incident angle range.

Owner:KUANG CHI CUTTING EDGE TECH LTD

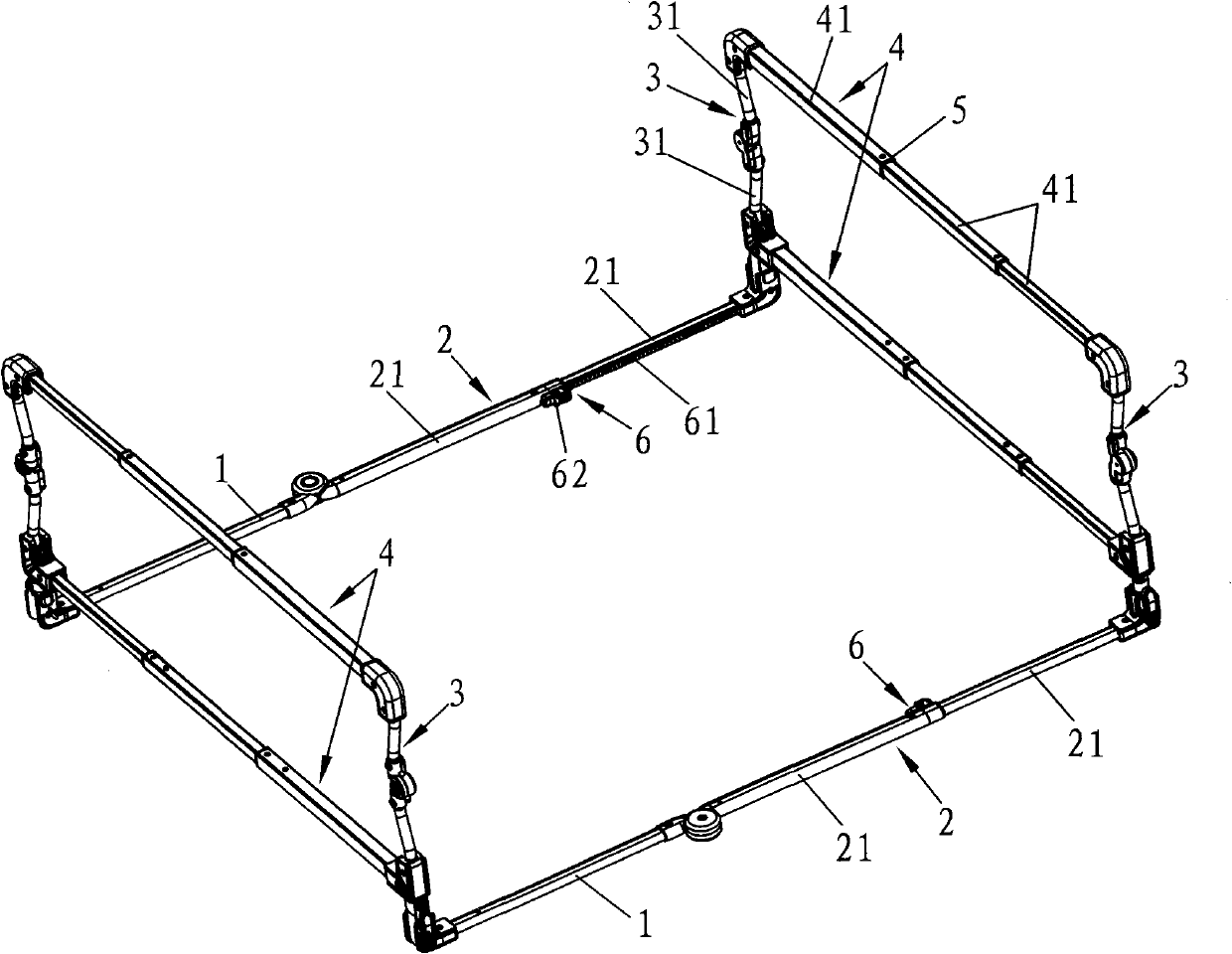

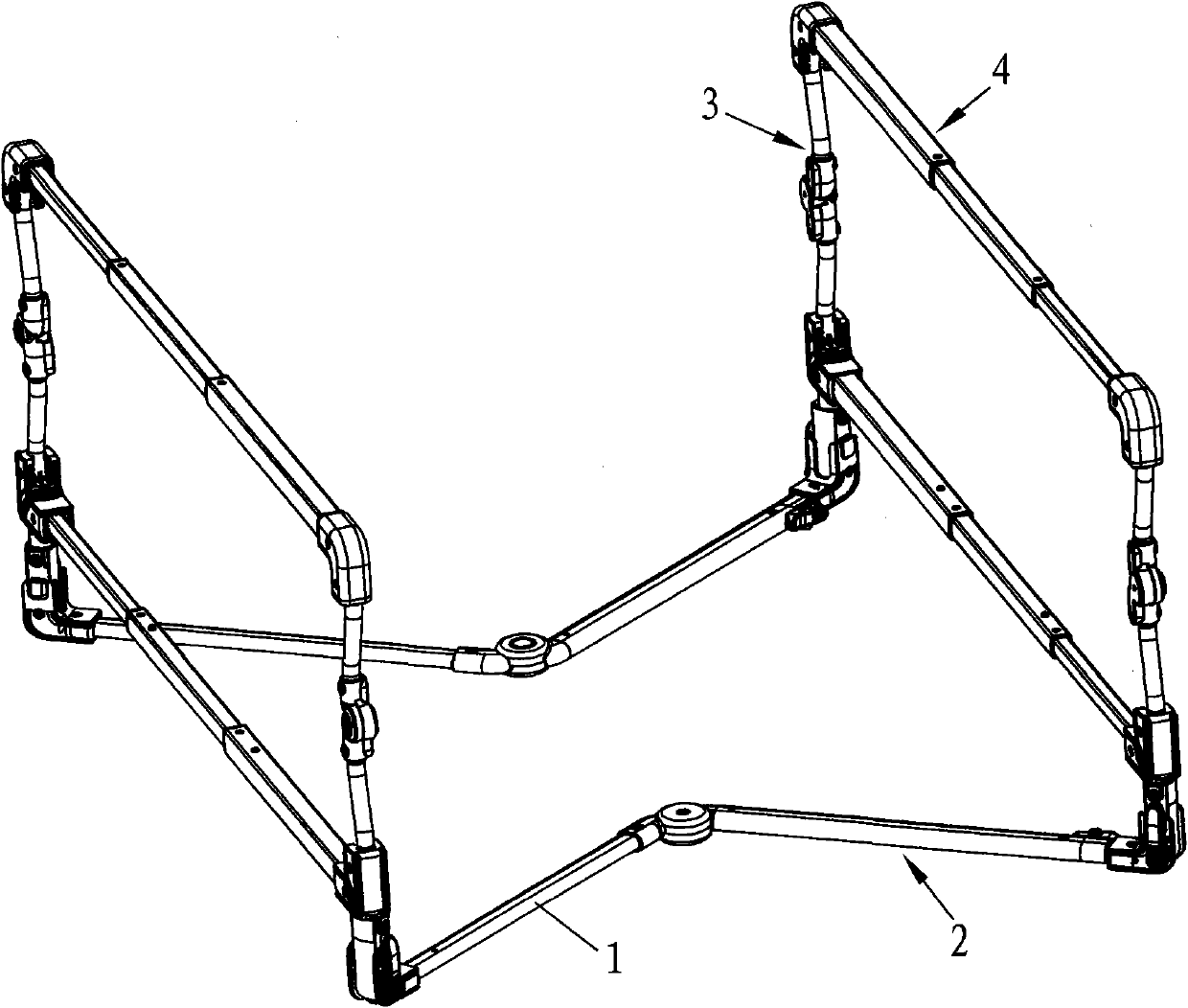

Folding type baby crib guardrail

Owner:陈瑞武

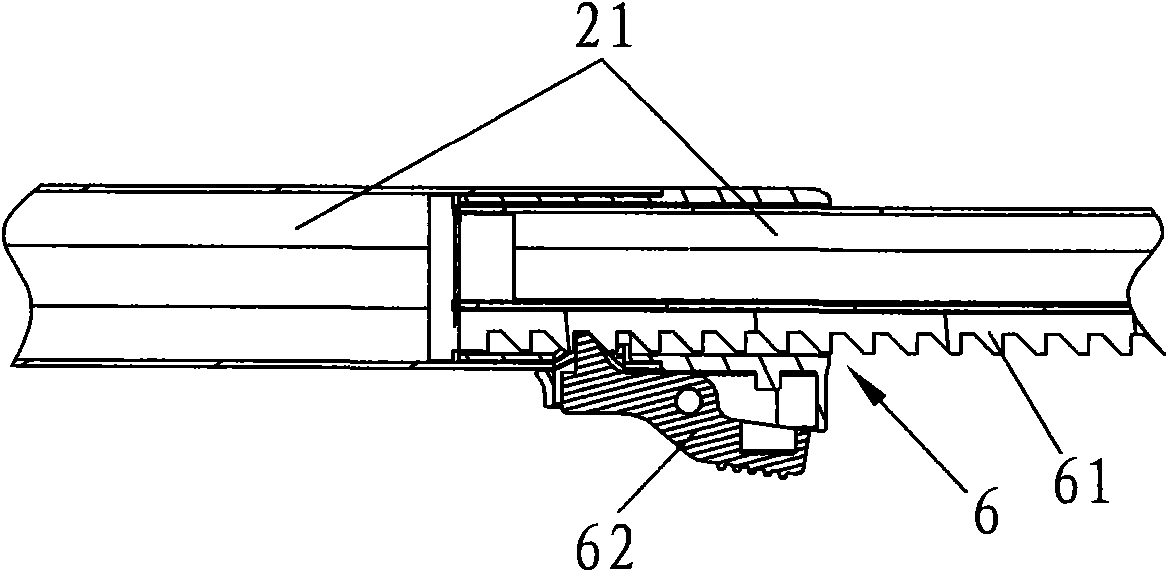

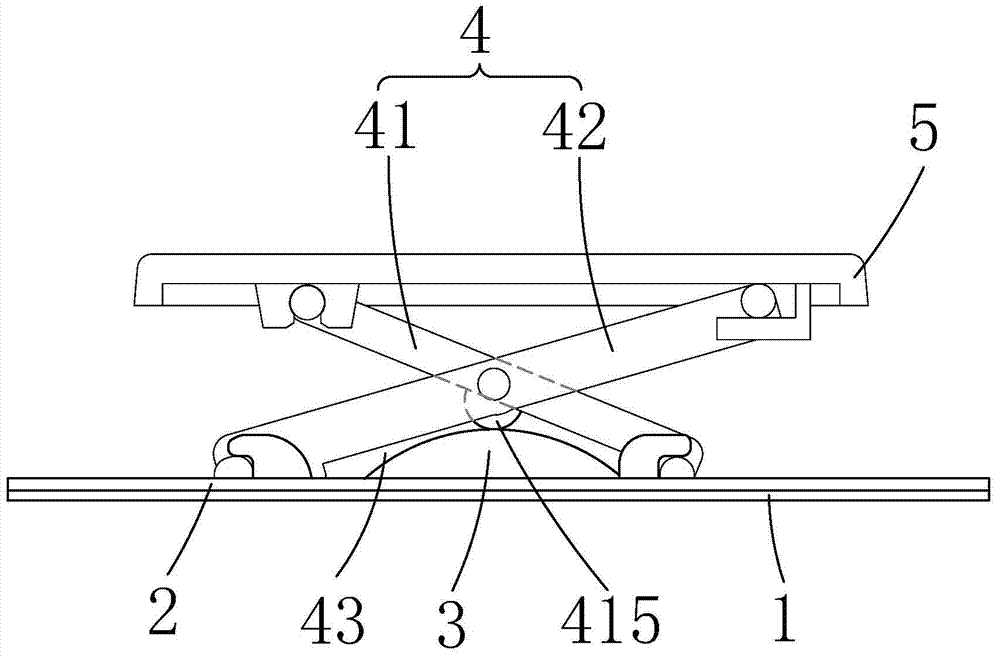

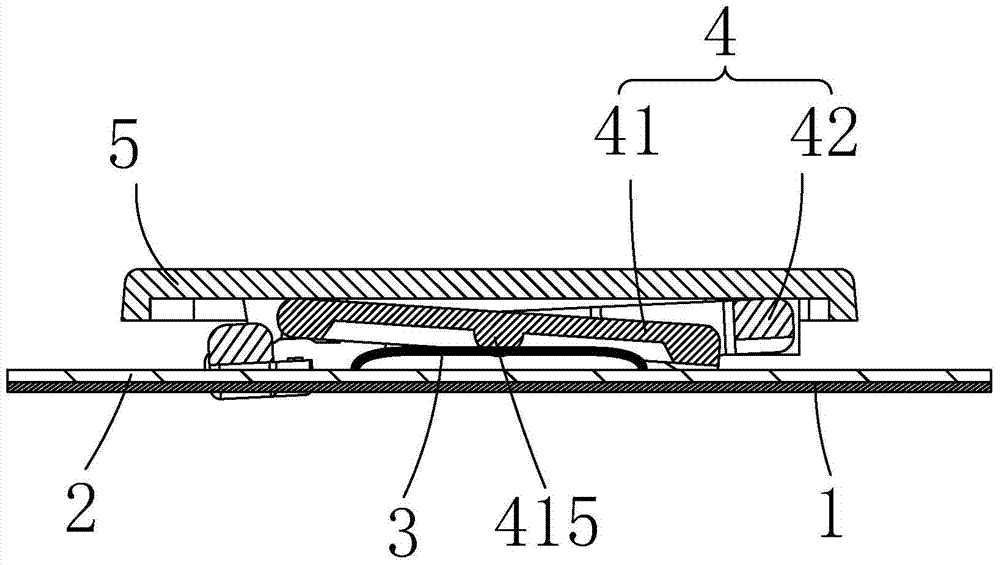

Scissor keyboard key structure

ActiveCN104851728AThinIncrease the itineraryEmergency casingsElectric switchesElectrical and Electronics engineeringKey pressing

The invention provides a scissor keyboard key structure, which comprises a base, a thin film circuit board arranged on the base, an elastic piece arranged on the thin film circuit board, a scissor support arranged above the elastic piece and arranged on the base, and a key cap arranged on the scissor support, wherein the scissor support comprises an inner support and an outer support in rotary connection onto the outer side of the inner support; the inner support and the outer support form a dual-lever structure; one side, facing the elastic piece, of the inner support is provided with a convex part; the thin film circuit board is provided with a circuit contact; and the elastic piece is arranged on the circuit contact in a corresponding covering mode. When the key cap is pressed, the convex part of the scissor support presses the elastic piece, and the elastic piece presses the thin film circuit board to enable the circuit contact of the thin film circuit board to be contacted and conducted. According to the scissor keyboard key structure provided by the invention, the overall key is thinner, the stroke is larger, the hand feeling is better, the striking force at each position of the key cap is small and balanced in the case of use, the use is comfortable, the sound is small, and the structure is simple.

Owner:SHENZHEN DOKING TECH CO LTD

Electric-conducting and heat-conducting thin-film component

PendingCN106783769AThinThe thickness of the machine part is reducedSemiconductor/solid-state device detailsSolid-state devicesHeat conducting

The invention discloses an electric-conducting and heat-conducting thin-film component. The electric-conducting and heat-conducting thin-film component comprises a heat source and a heat-conducting film, wherein the heat-conducting film is covered on the surface of the heat source. The heat-conducting thin-film material provided by the invention can achieve thinner thickness besides excellent heat-conducting property; the heat-conducting thin-film material can be adhered on the heat source, so that the entire parts thickness can be effectively reduced, but the radiating performance cannot be influenced.

Owner:上海增华电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com