Micro temperature difference battery made of one-dimensional nanometer linear array structure thermo-electric material

A technology of nanowire arrays and thermoelectric batteries, which is applied to thermoelectric devices that only use the Peltier or Seebeck effect, can solve the problems of low thermoelectric conversion rate, limited application range, and large volume of thermoelectric batteries, and achieve small volume and thin thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

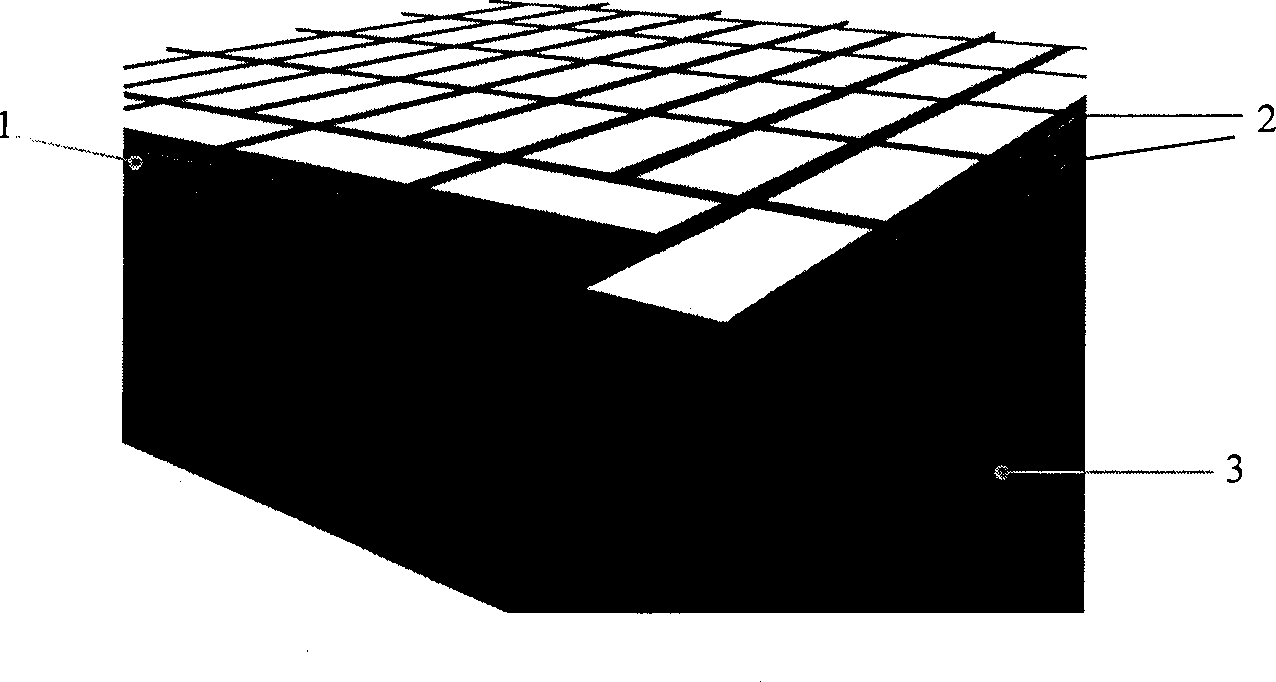

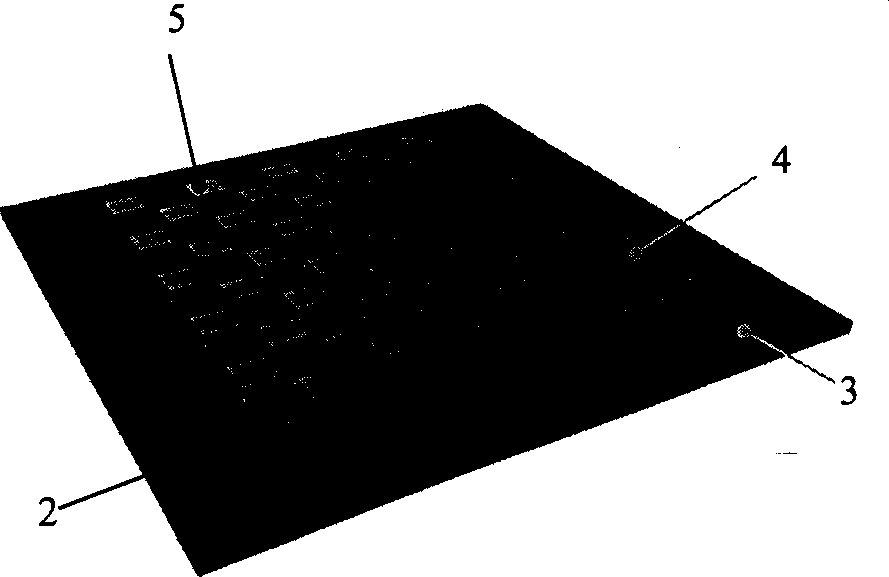

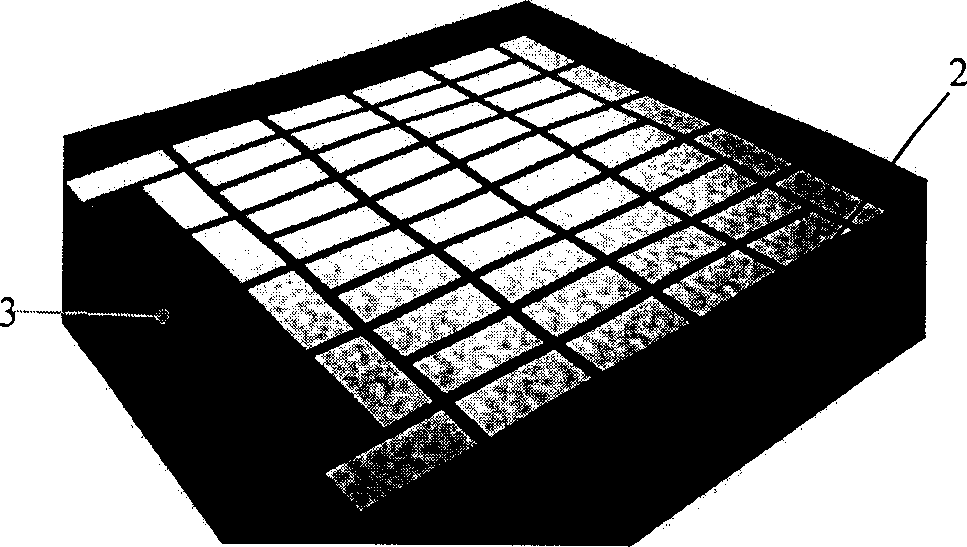

[0019] On the 100μm thick silicon wafer C layer, metal nickel is deposited by PVD method to form B layer. A layer of metallic aluminum is then deposited on top of the B layer. After a series of microelectronic processing procedures such as gluing, pre-baking, exposure of the P-type node area of the aluminum layer, development of the P-type node area, and post-baking on the aluminum layer, one-dimensional P Type nanowire micro temperature difference material. Then, the N-type node area of the aluminum layer is subjected to similar processes, such as exposure, N-type node area development, post-baking, and electrochemical technology is used to prepare a one-dimensional N-type nanowire micro-temperature difference material at the N-type node area. After the one-dimensional nanowire P-type node and N-type node are prepared on the metal aluminum layer through the above process, the microelectronic processing etching technology is used to etch the node spacing between the P-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com