Solder-resisting photosensitive resin composition, printed wiring board and preparation technology of printed wiring board

A technology for printed circuit boards and photosensitive resins, which is applied in the photoengraving process of pattern surface, printed circuit, printed circuit manufacturing, etc. There are problems such as air bubbles and poor solder mask performance, achieving good exposure performance and thickness uniformity, shortening exposure time, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Making solder resist photosensitive film

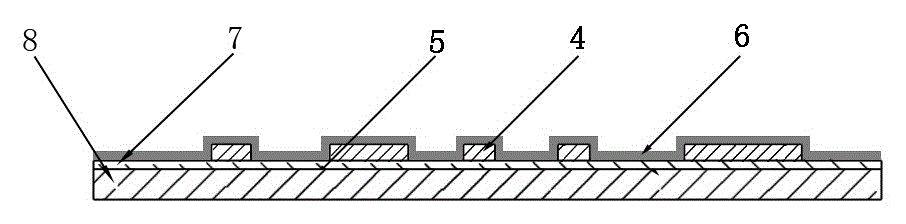

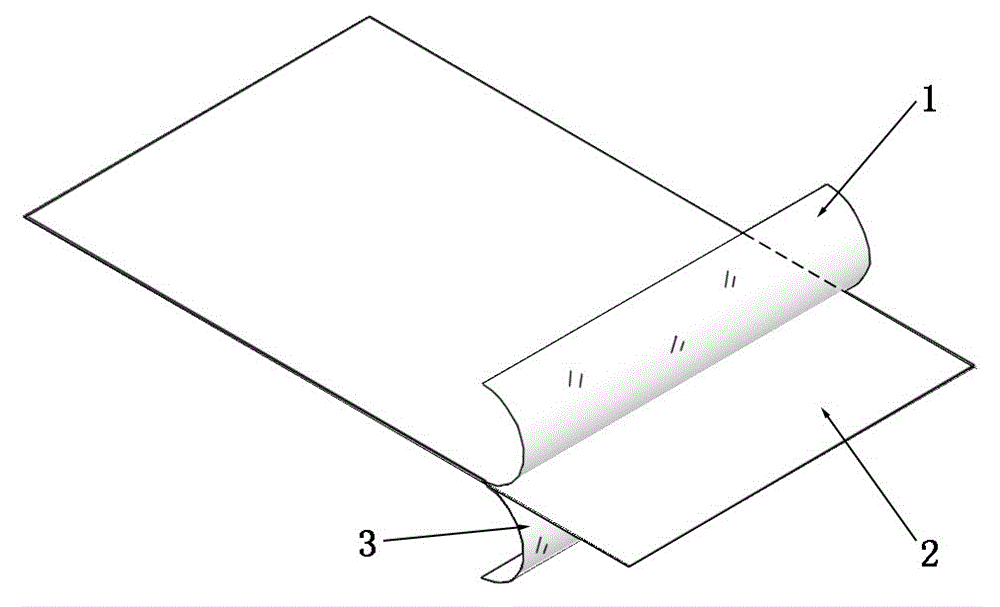

[0035] Such as figure 1 As shown, the prepared solder resist photosensitive dry film is composed of a three-layer structure of PE film 1, solder resist photosensitive dry film 2 and PET film 3. The specific production process is as follows:

[0036] a. Weighing

[0037] Binder (polystyrene resin 10g, polystyrene butadiene resin 2g), epoxy resin (polyurethane modified epoxy resin 32g), monomer (pentaerythritol triacrylate 13g), photoinitiator (xylenone 13g), Additives (5g of benzotriazole, 5g of triethylene glycol diacetate, 9g of polypropylene, 7g of ethylene (equivalent to about 5.6L)), dyes (4g of malachite green).

[0038] b. Premix polystyrene, polystyrene butadiene resin, pentaerythritol triacrylate, xylenone, benzotriazole, triethylene glycol diacetate, and polypropylene, and then add them to polyurethane modified epoxy resin , to obtain the mixed material, then dissolve the ethylene into the mixed material while vi...

experiment example

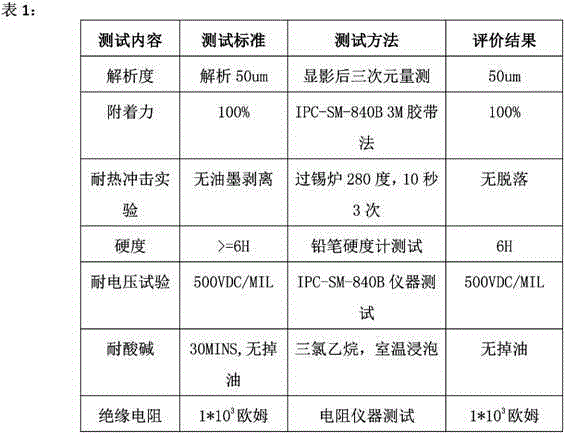

[0056] The performance of the dry film solder mask of the circuit board prepared in Example 1 and Comparative Example 1 is detected and compared, and the results are shown in Table 2 below:

[0057]

[0058] From the data comparison of the test items in Table 2, it can be seen that the solder resist layer formed by the dry film of the present invention using ultraviolet light curing is superior to thermal curing in terms of film thickness uniformity, resolution, and hardness.

Embodiment 2

[0060] Compared with Example 1, the coating thickness in step c is 15 μm, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com