Backlight module and display with same

A technology for a backlight module and a display, which is applied to instruments, optics, light guides, etc., can solve the problem that light-emitting diodes increase the production cost of the direct-type backlight module 100, increase the power consumption of the direct-type backlight module 100, and cannot effectively improve the uniformity of the surface light source 102. and other problems, to achieve the effect of thickness and thickness, power saving and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

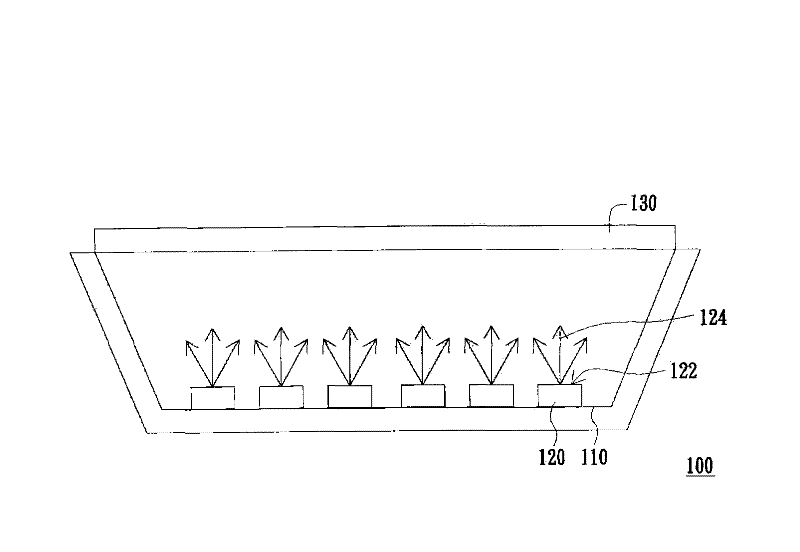

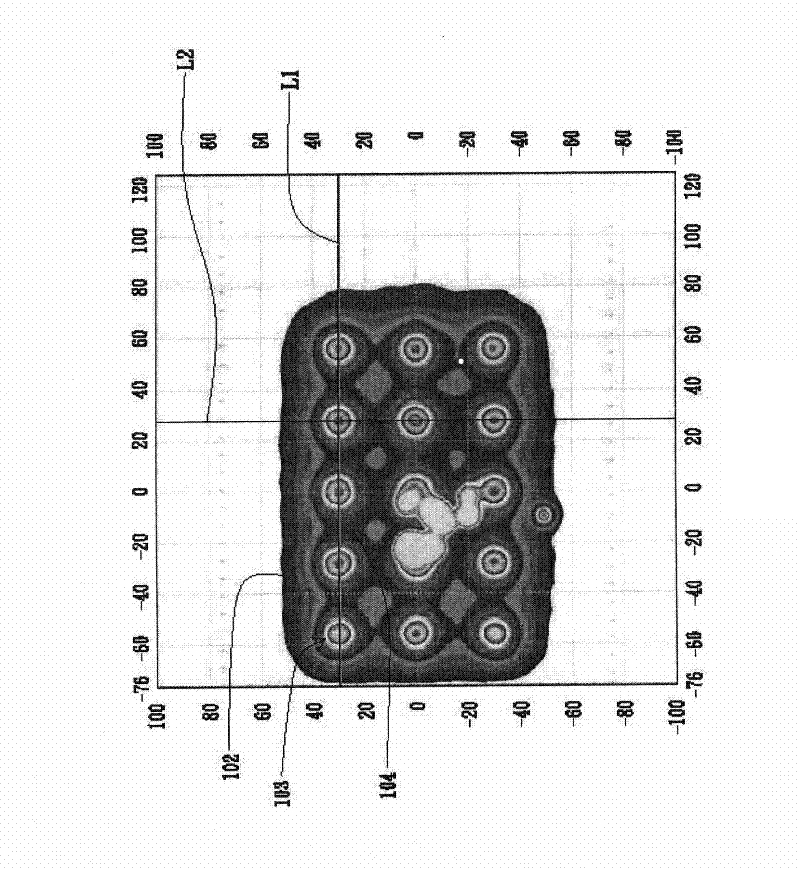

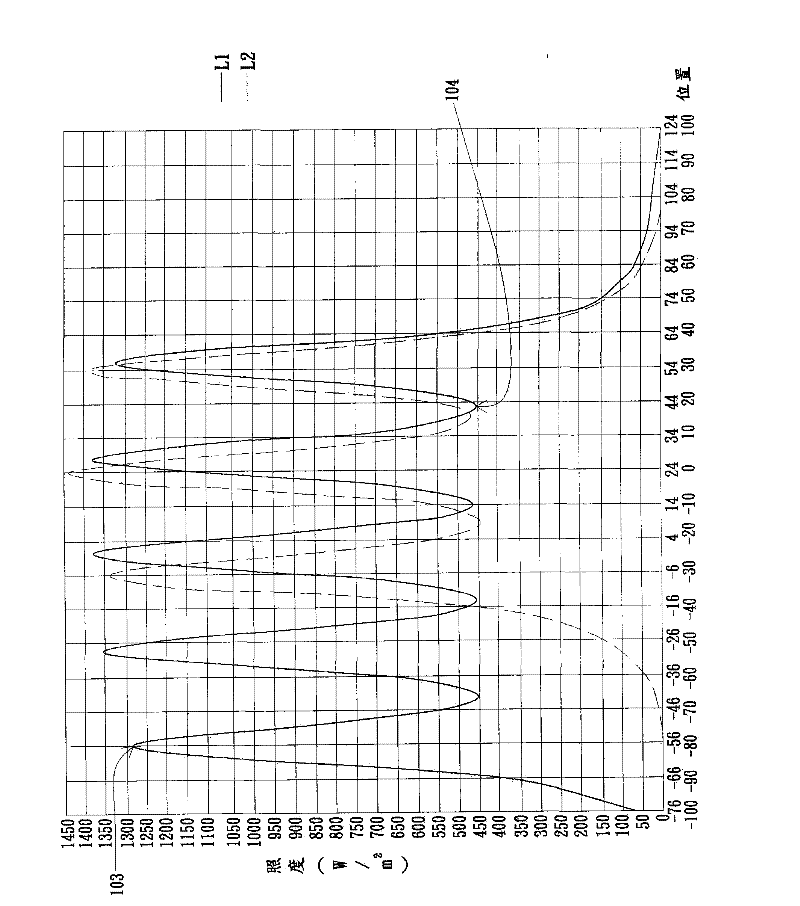

[0072] image 3 is a schematic diagram of a display according to an embodiment of the present invention, and Figure 4 yes image 3 A three-dimensional schematic diagram of some components of the middle backlight module. Please refer to image 3 and Figure 4 , the display 300 of this embodiment includes a display panel 310 and a backlight module 200 , wherein the backlight module 200 is disposed on one side of the display panel 310 to provide a surface light source to the display panel 310 . The display panel 310 can be a liquid crystal display panel, a flexible display panel or a touch panel, but not limited thereto.

[0073] The aforementioned backlight module 200 includes a backplane 210 , a plurality of light source groups 220 and a plurality of light guide elements 230 . The light source groups 220 are arranged at intervals on the backplane 210 , and each light source group 220 includes a plurality of point light sources 222 . The light guide elements 230 are dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com