Immersion type thin plate and frame film filter

A membrane filter, plate and frame technology, applied in the field of immersed thin plate and frame membrane filters, can solve the problems of reduced water production efficiency, increased manufacturing cost, increased filter thickness and weight, etc., to increase convenience and save costs. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

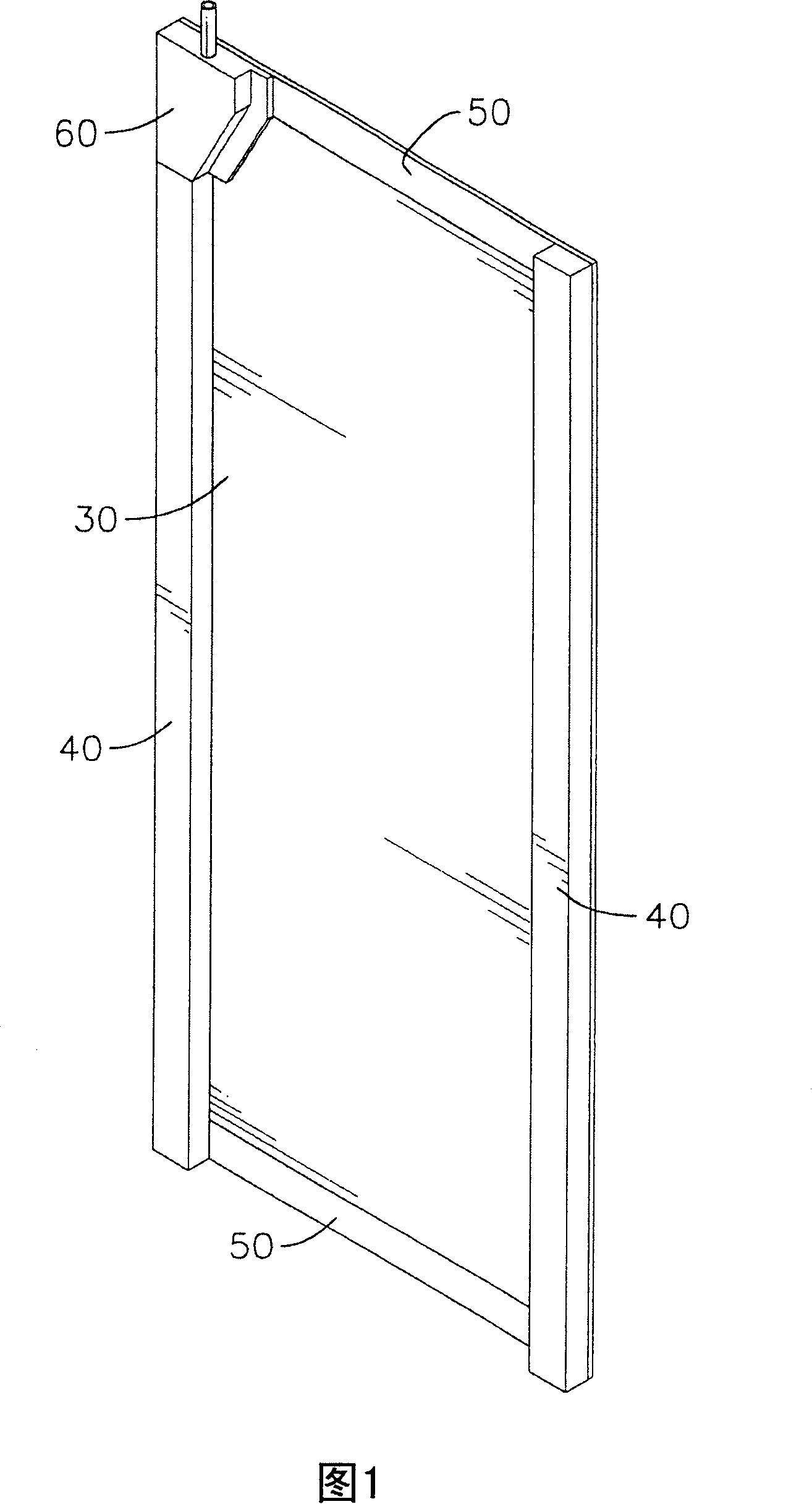

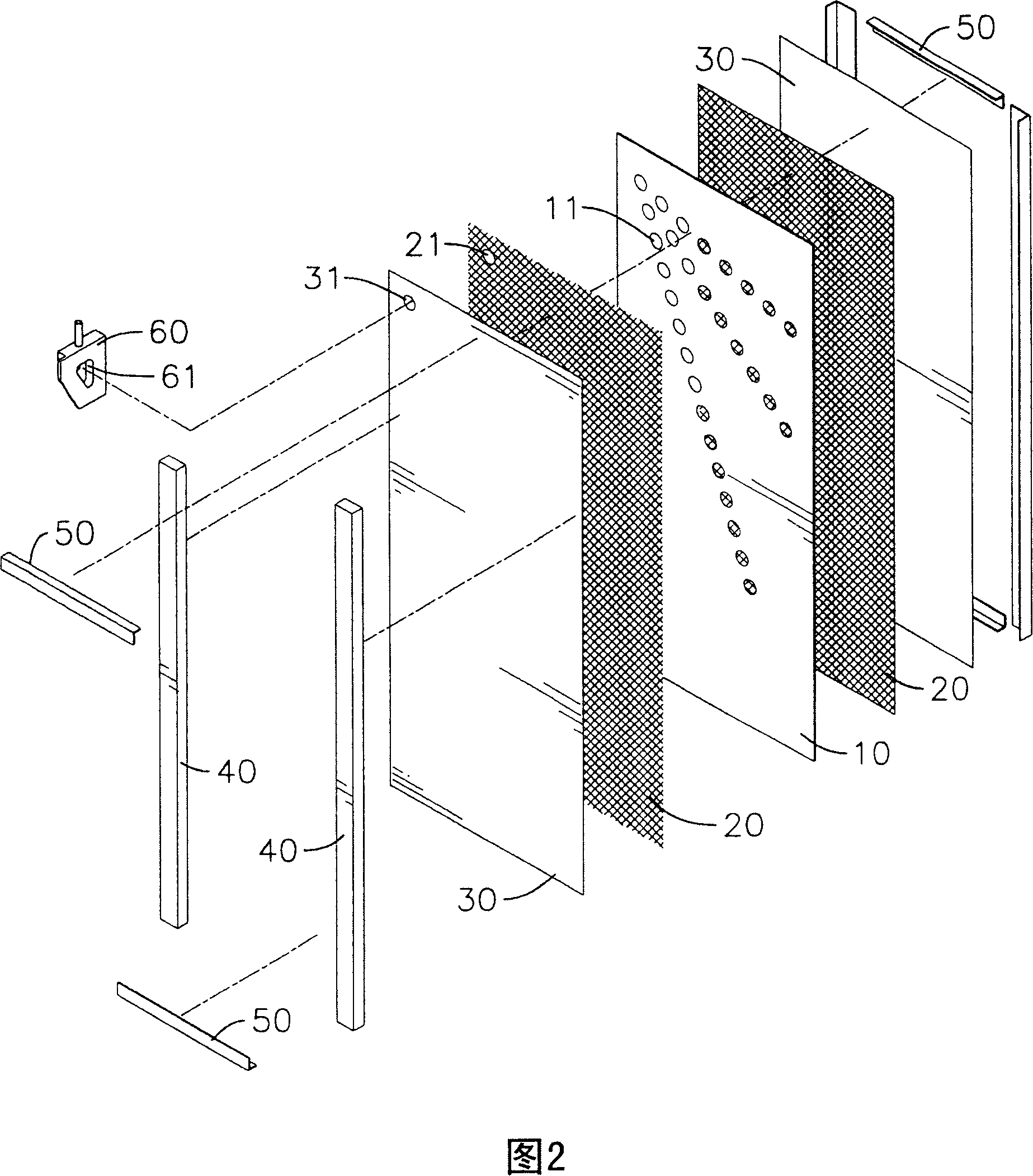

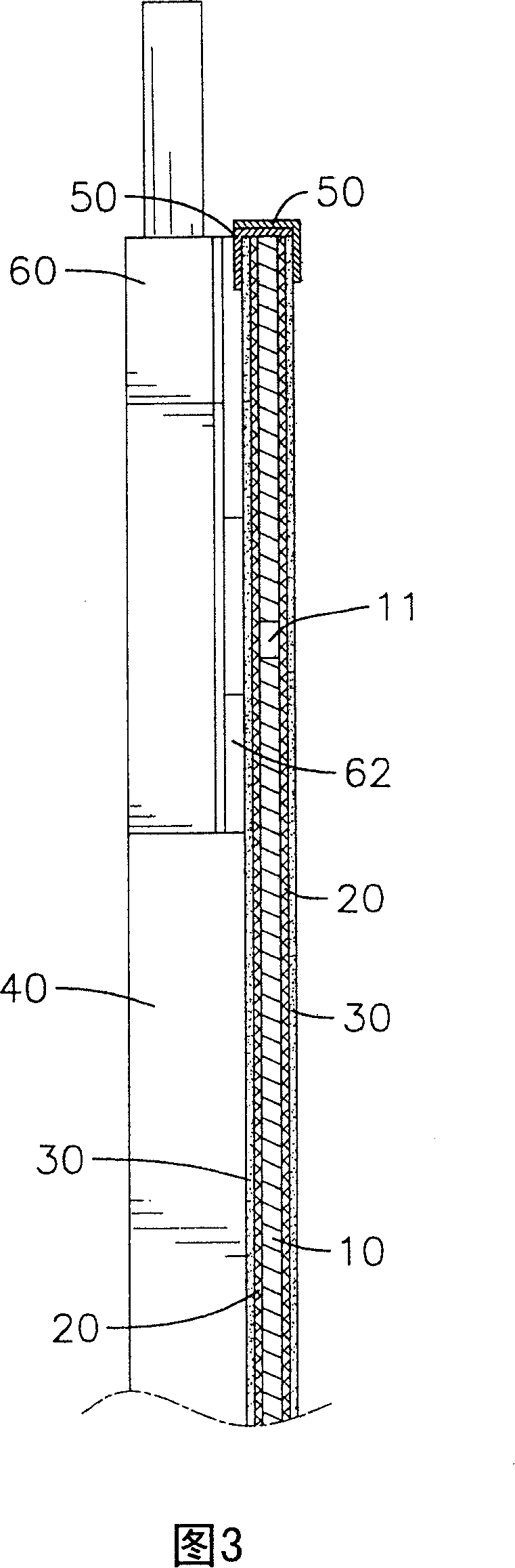

[0032] Please refer to Fig. 1 and shown in Fig. 2, the submerged thin plate-frame membrane filter provided by the present invention is made up of a thin plate-frame filter membrane and an aeration backwashing device, wherein the thin plate-frame filter membrane comprises Have:

[0033] A flat plate 10, which is a thin plastic plate, is provided with a plurality of perforations 11 through the plate body, and the plurality of perforations 11 are radially arranged around the corner where the water outlet plate 60 described later is located, which can increase the smooth flow of water;

[0034] Two conducting parts 20, which are in the shape of a net, are respectively attached to the two sides of the plate 10, and one of the conducting parts 20 has a through hole 21 at the corner;

[0035] The second filter membrane 30 has a plurality of filter holes with a pore diameter of 0.01 to 0.5 microns to filter impurities in water, and its adjacent center is attached to the back of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com