Patents

Literature

202results about "Hull panellings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

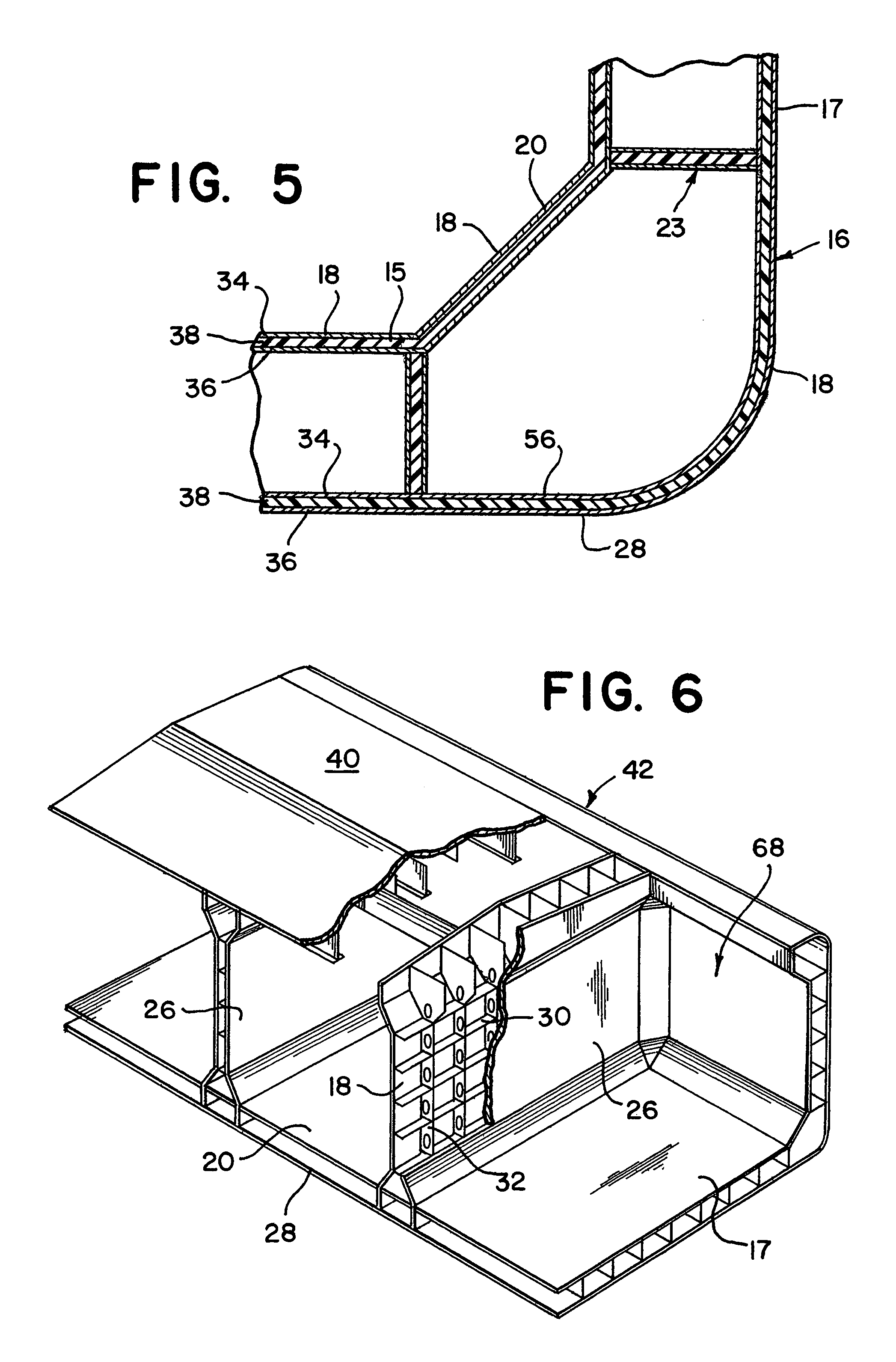

Sidewall panel integrated with insulation and air ducts

A mobile platform interior panel is provided that includes a body formed by a low pressure injection process and at least one of a duct and a layer of insulation integrated with the body. The low pressure injection process allows the duct and insulation to be integrated with the body simultaneously with the forming of the panel. More specifically, the duct is integrated with the panel by forming at least one internal cavity within the panel as the panel is formed. Additionally, the insulation is integrated with the panel by forming the panel using a low pressure injection material having desired insulative properties.

Owner:THE BOEING CO

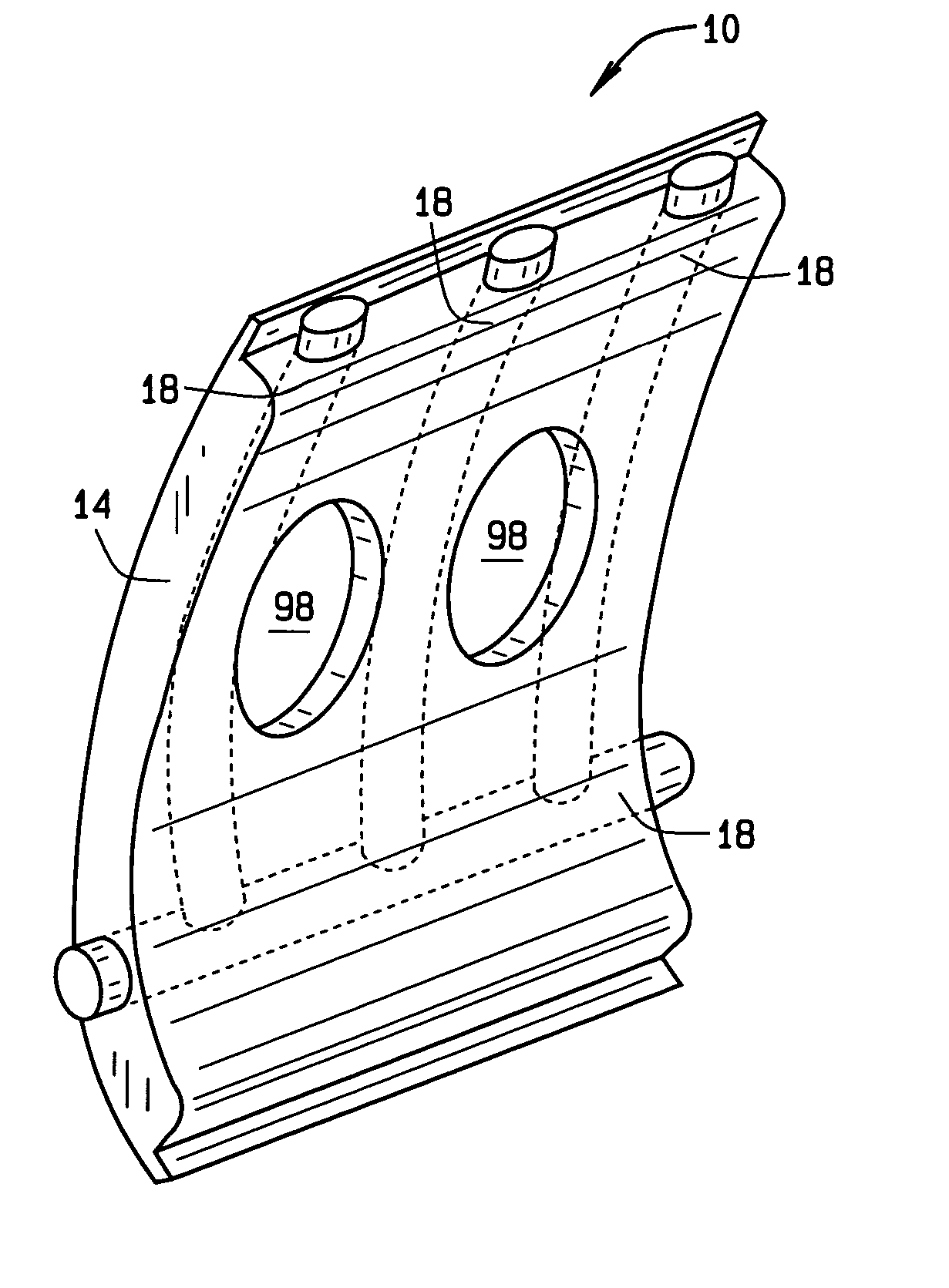

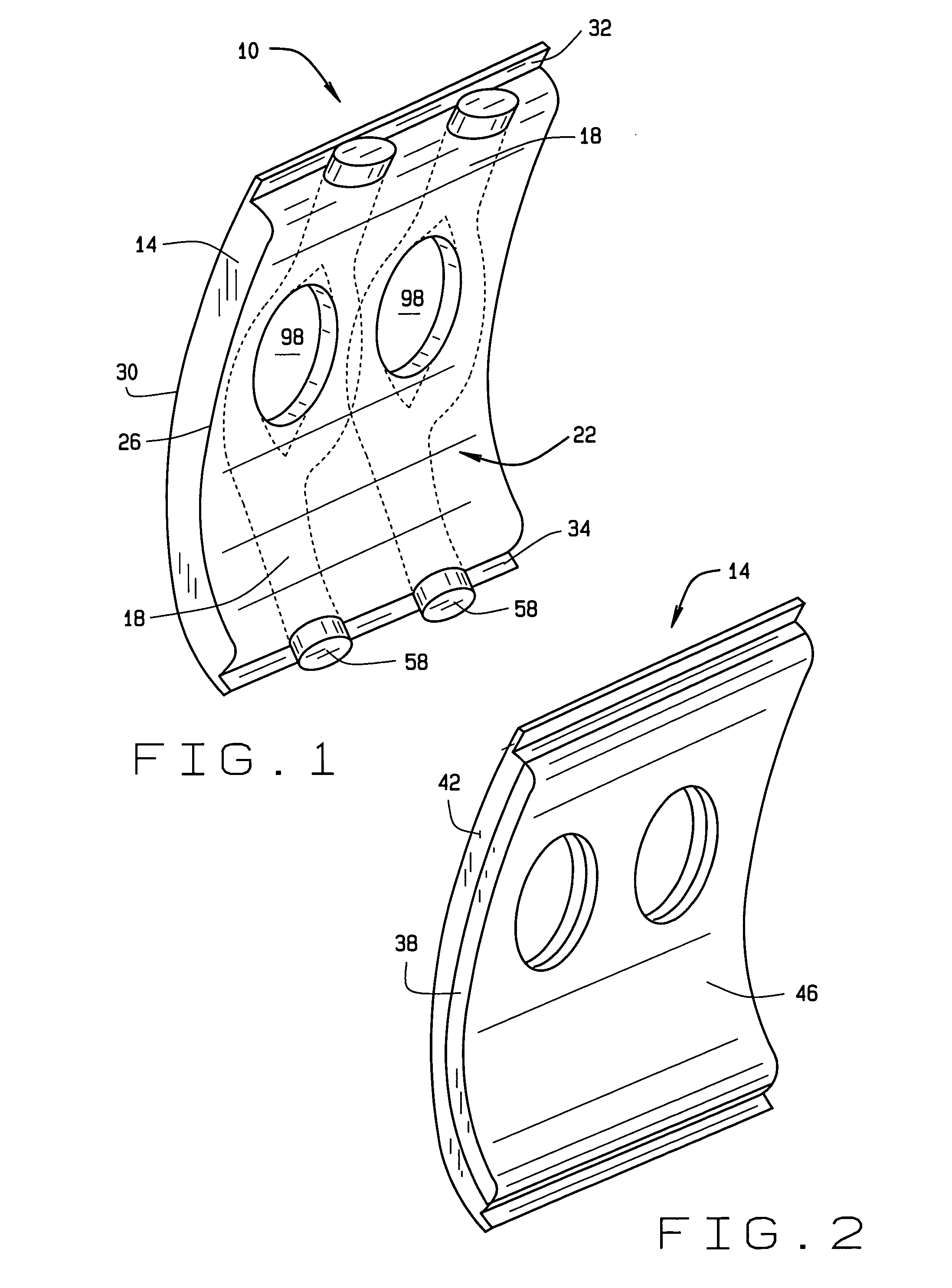

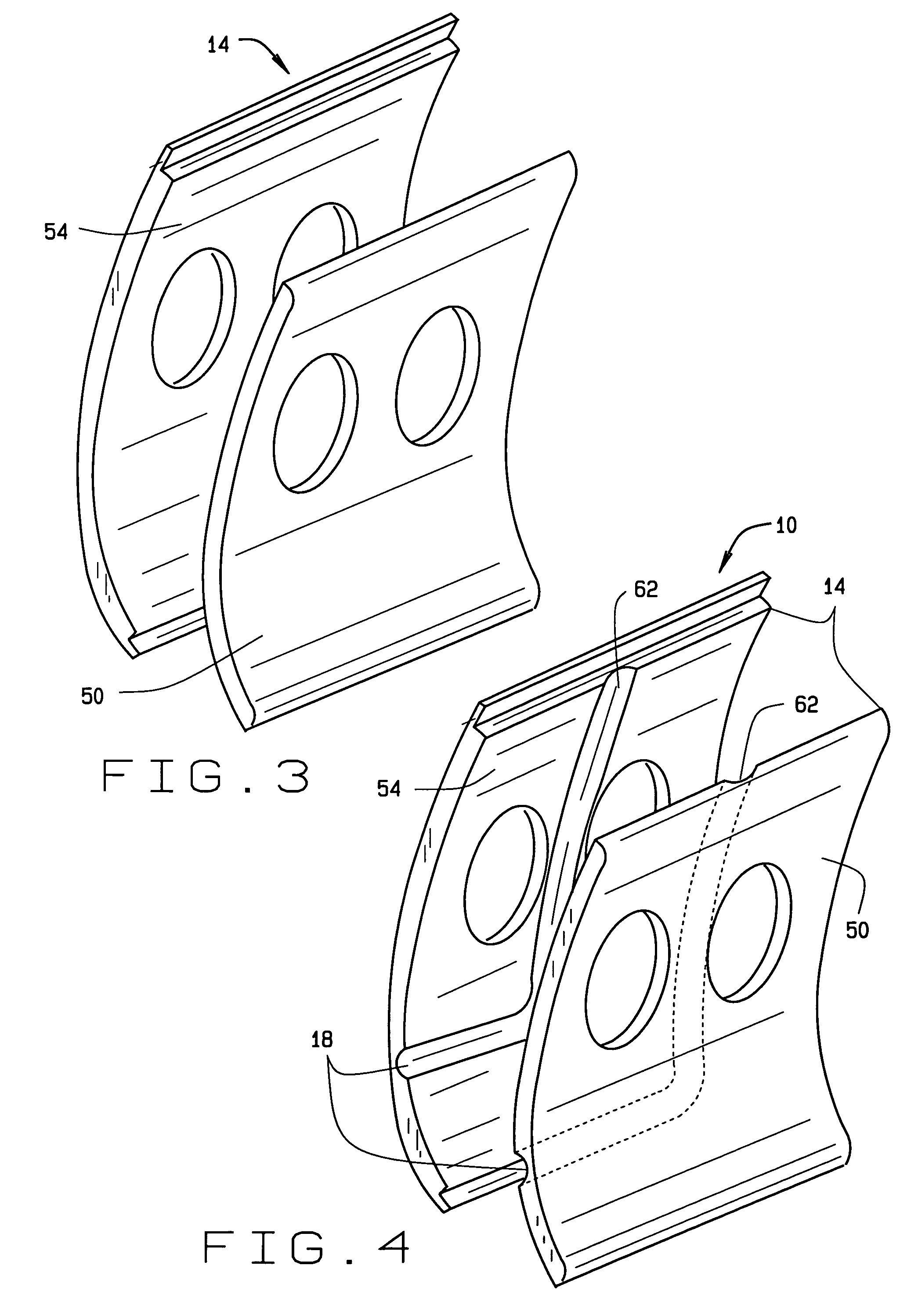

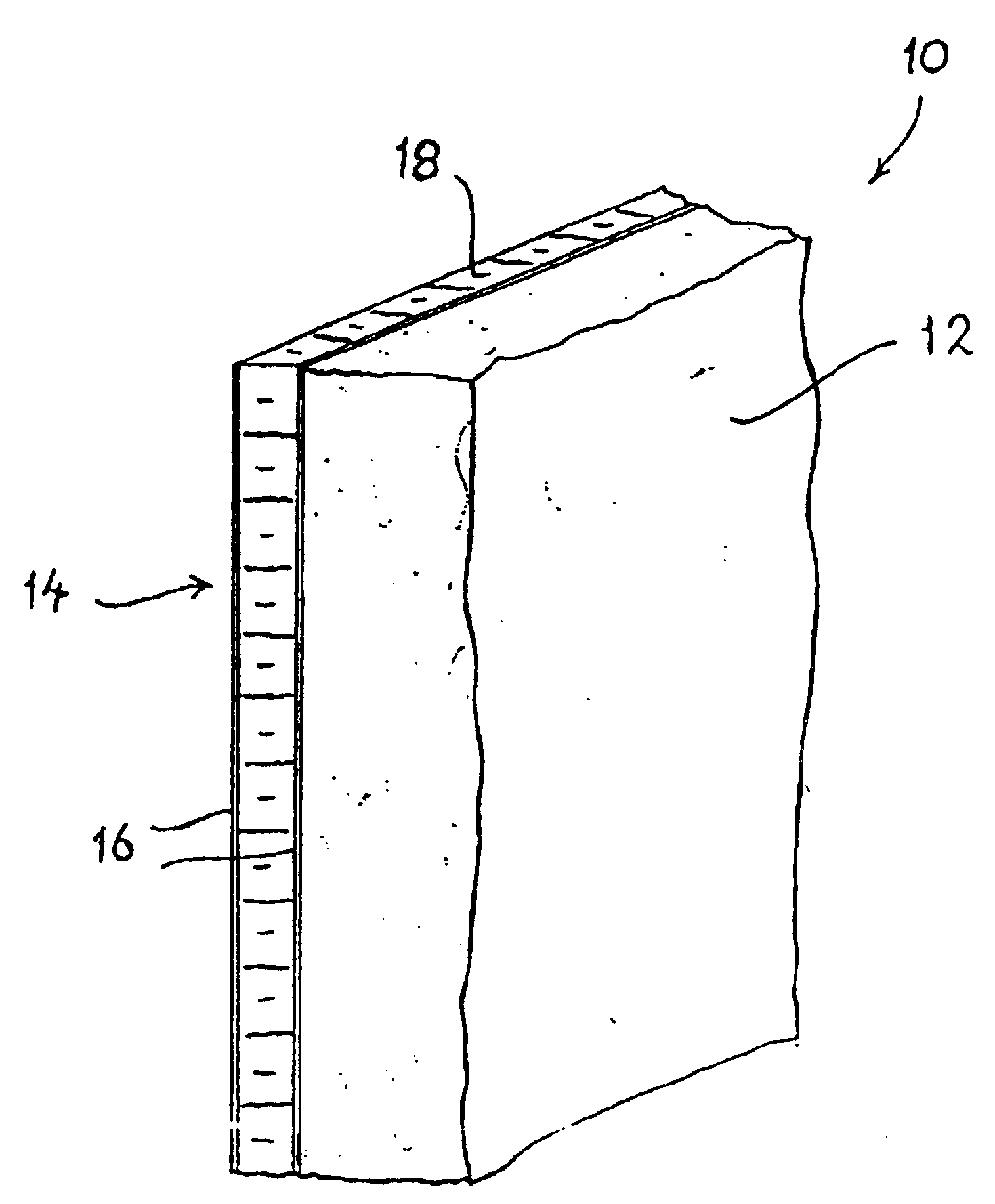

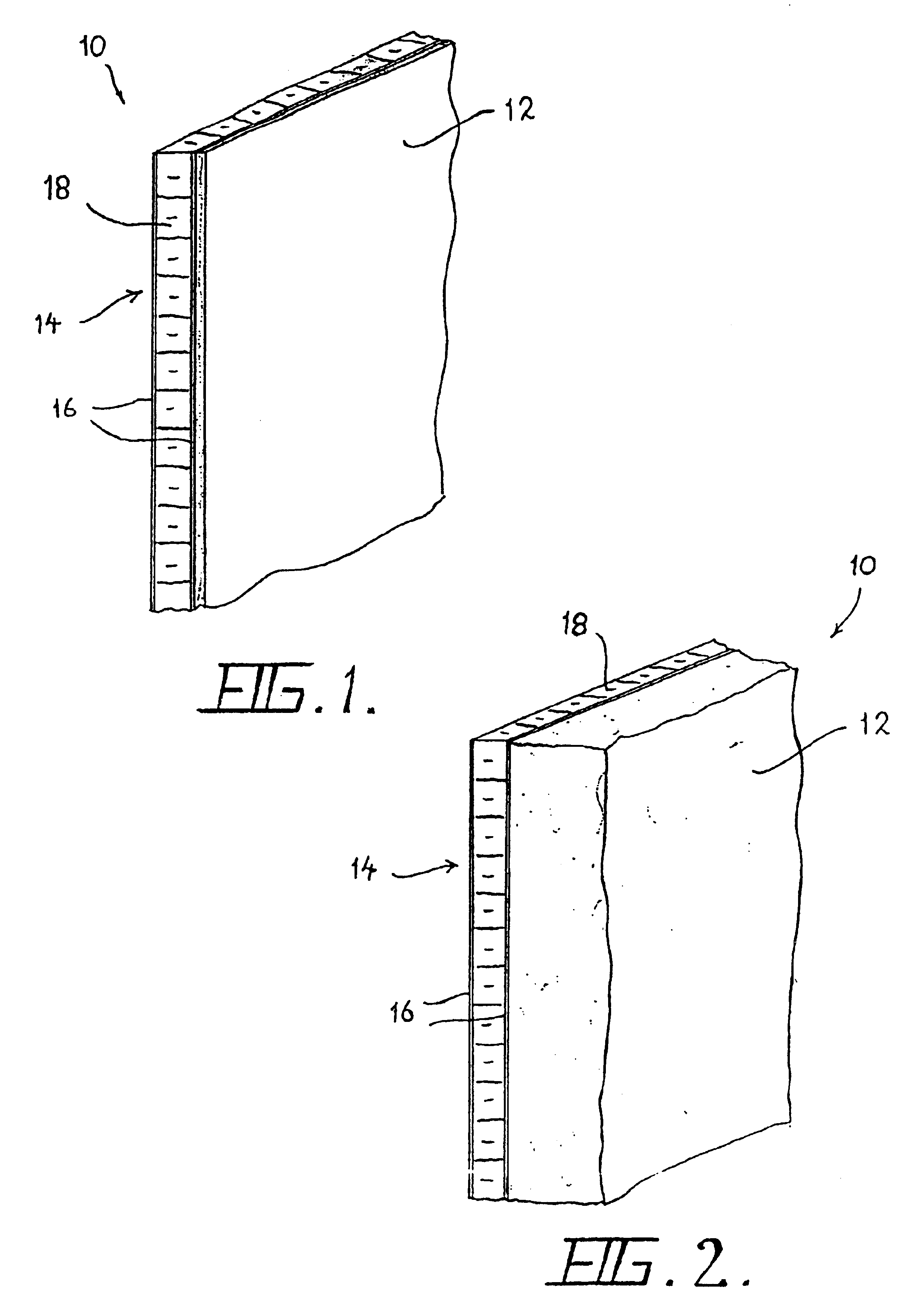

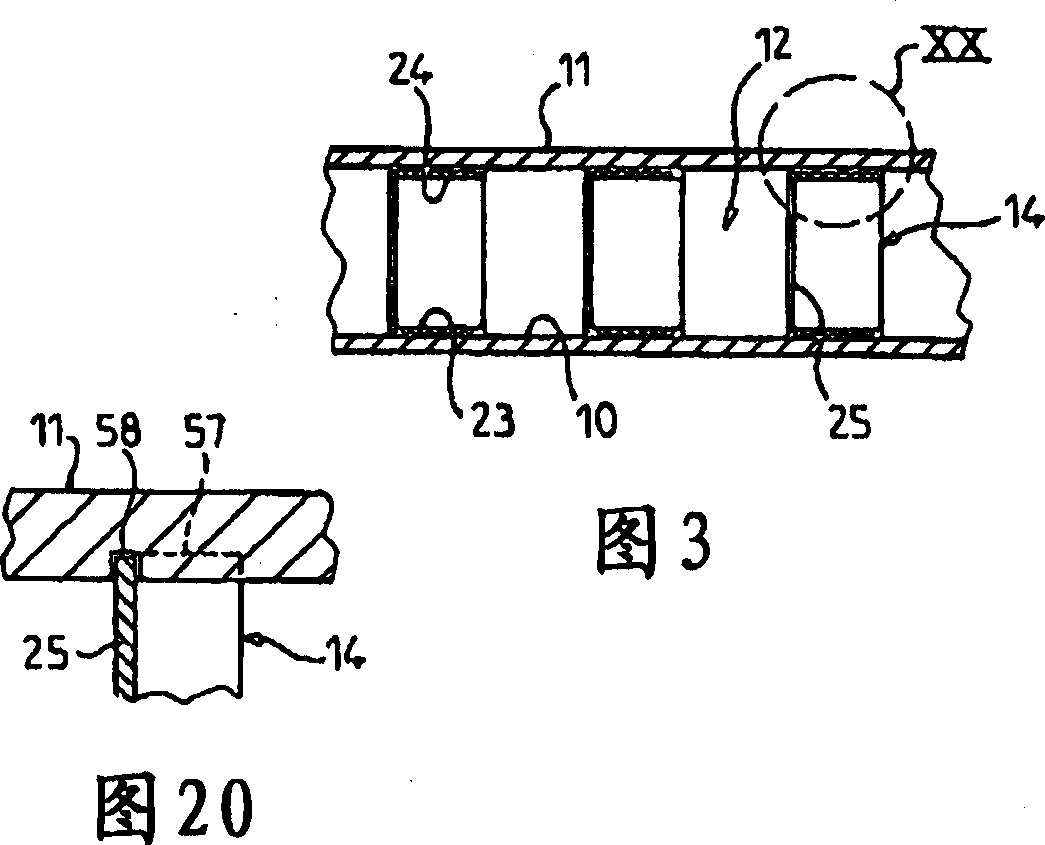

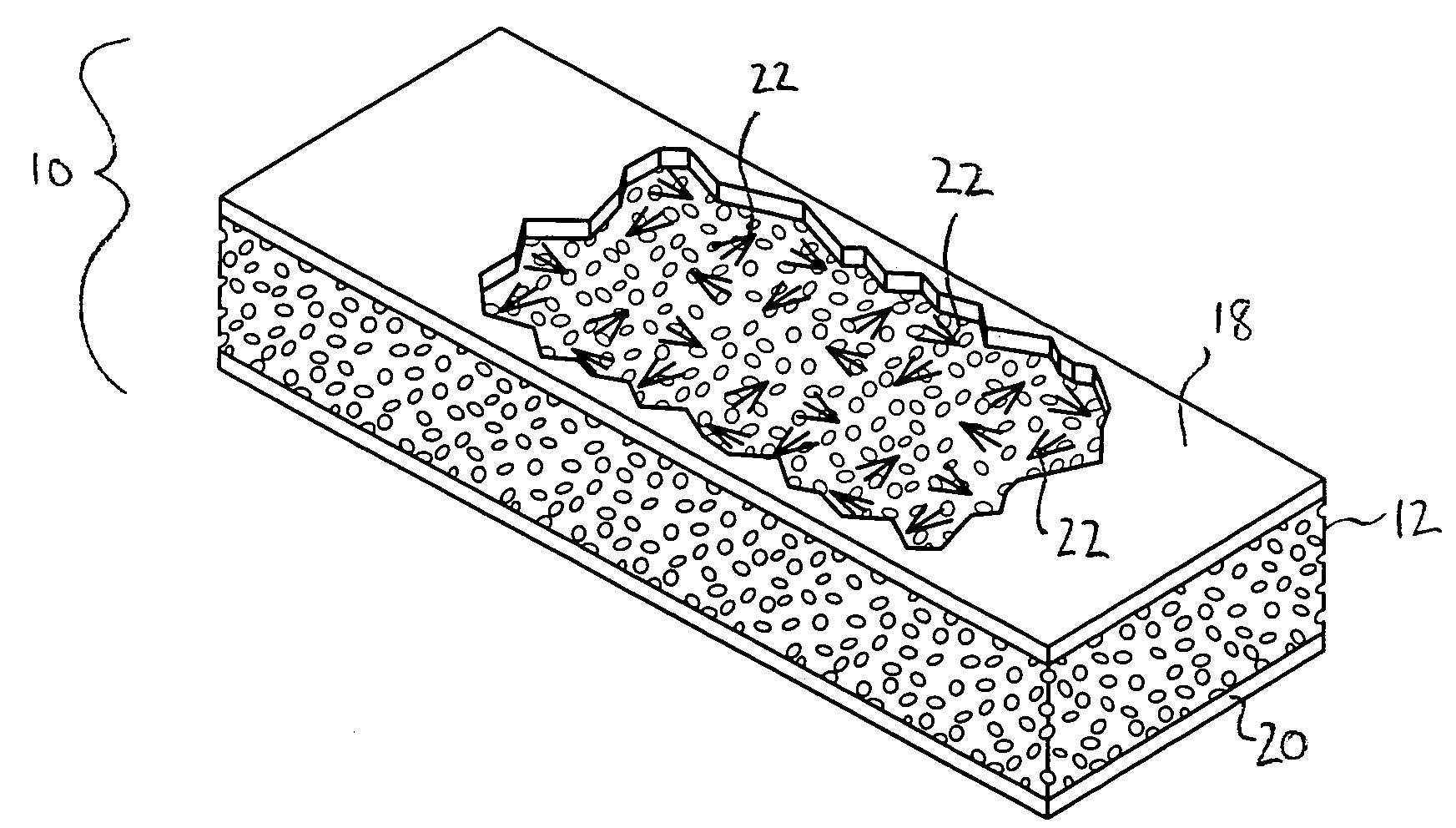

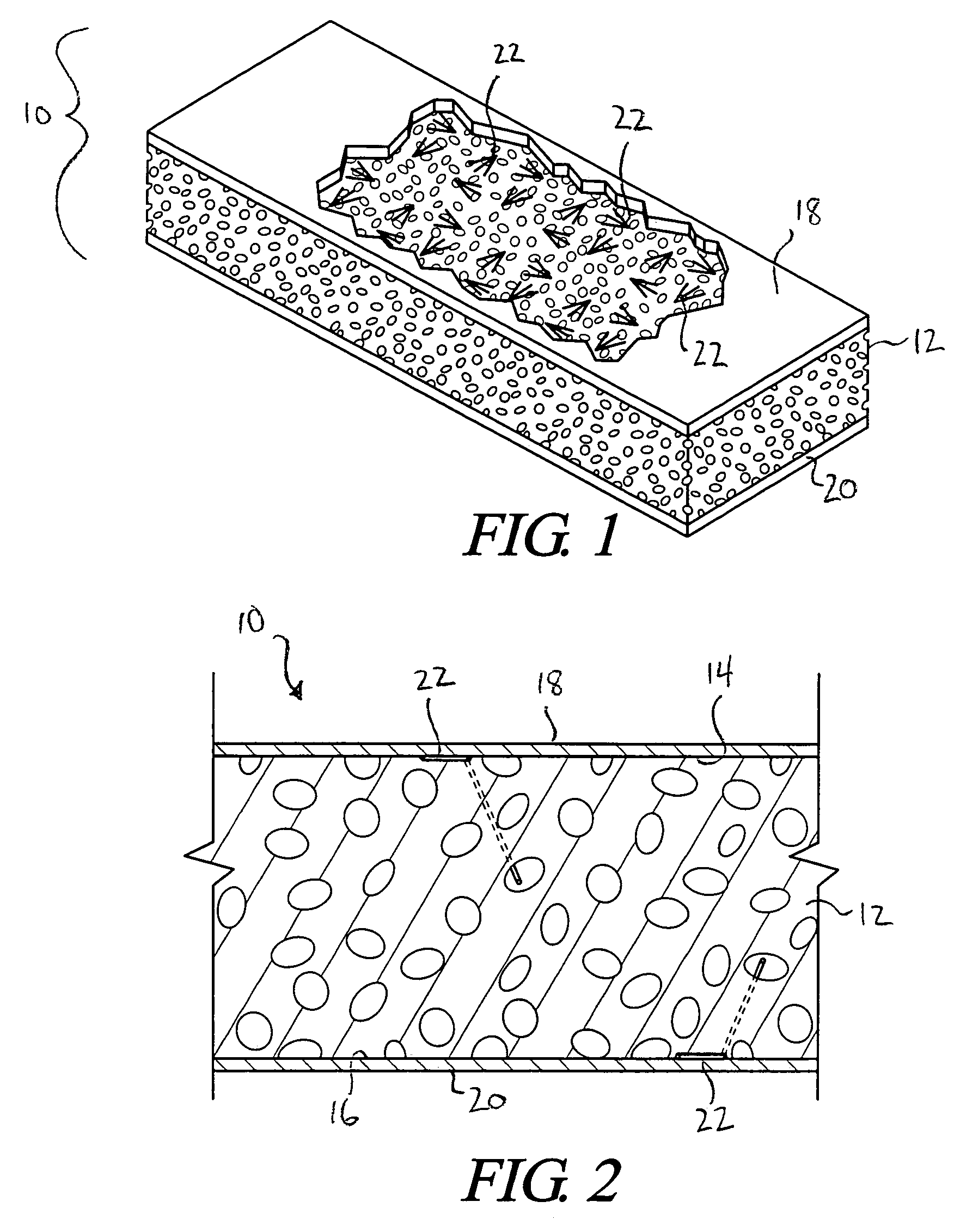

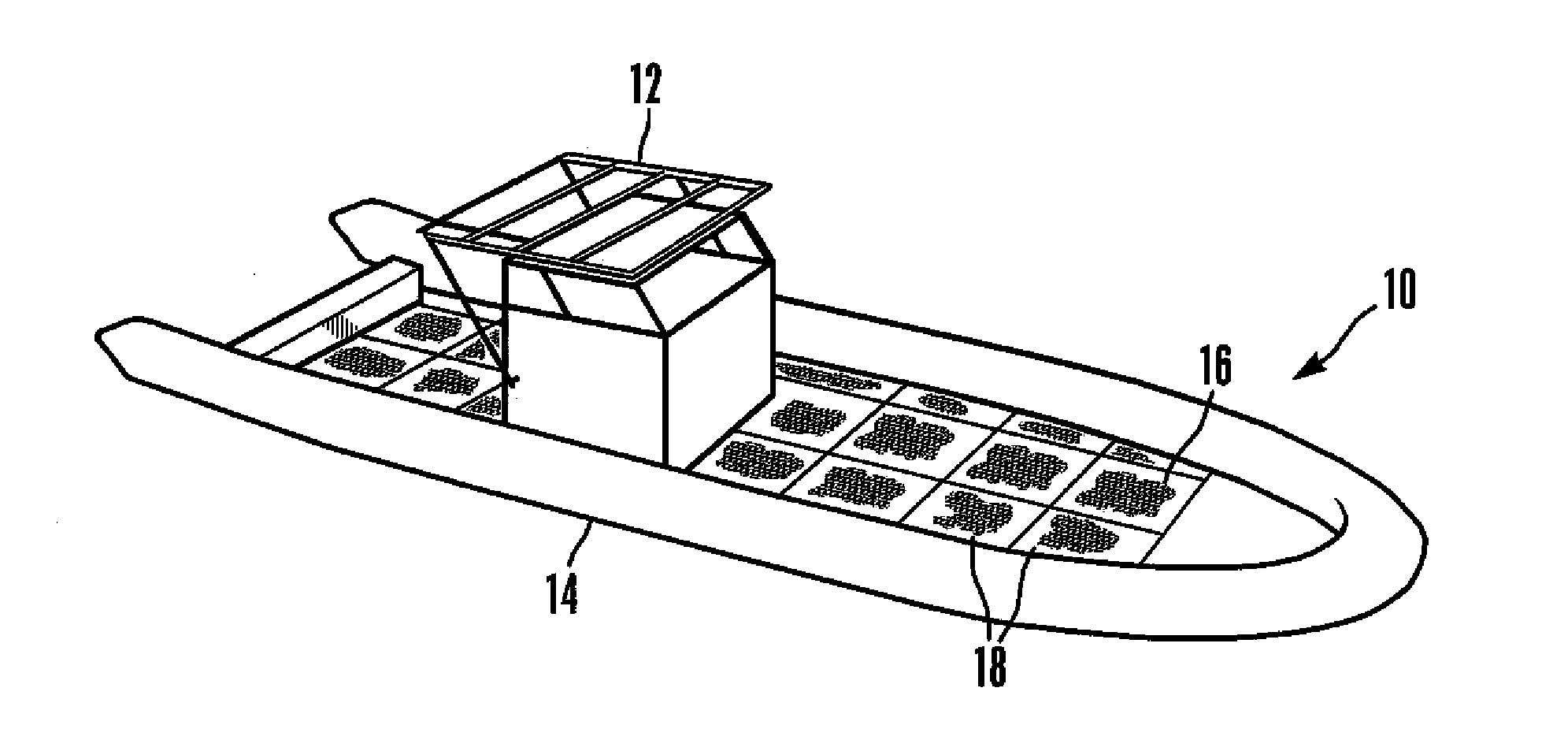

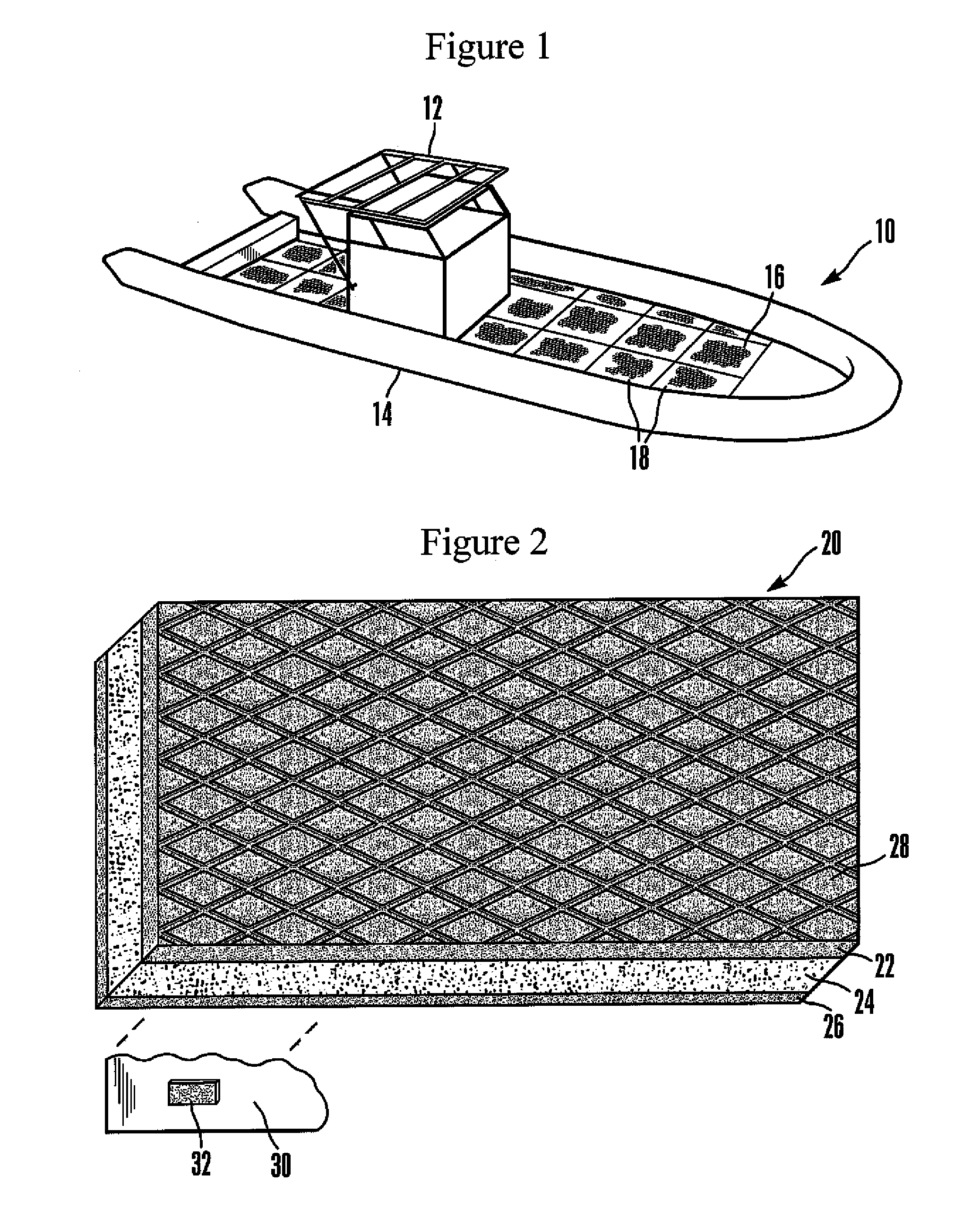

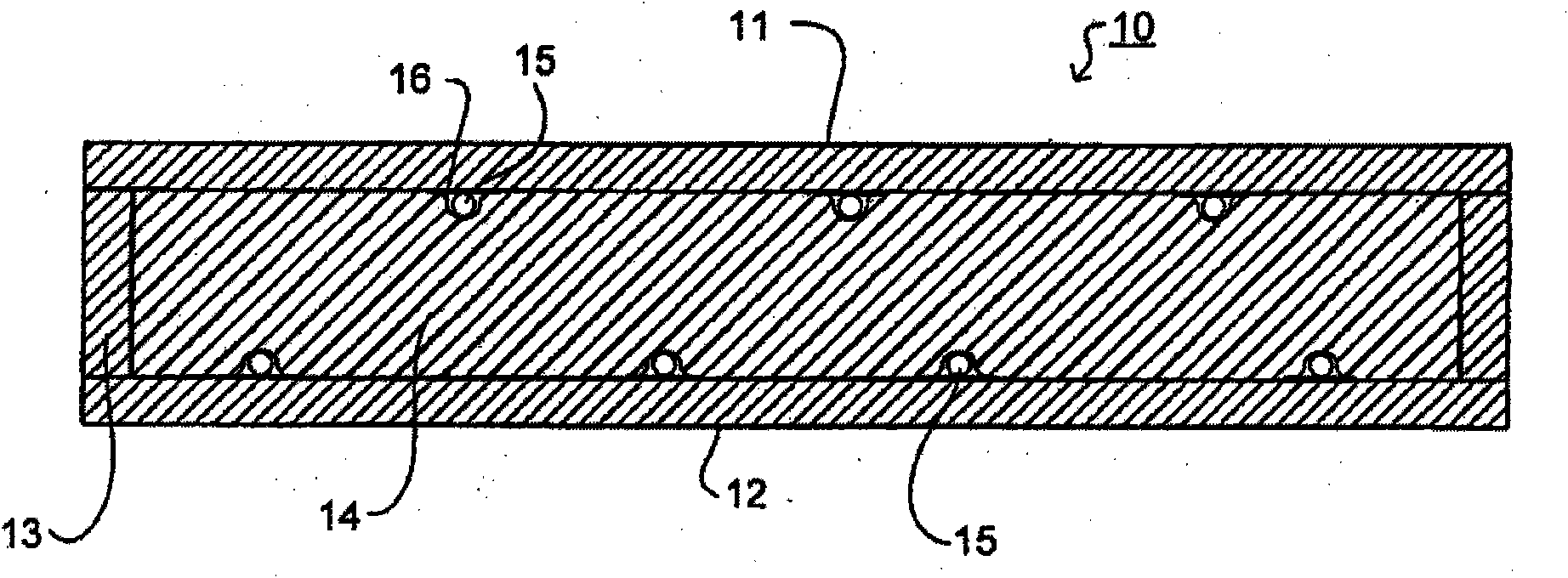

Fire barrier panel

A fire barrier panel of the kind suitable for lining car decks and engine rooms of high speed aluminum ferries is described. The panel (10) includes a relatively thin layer of inorganic insulating material (12) adhered to a lightweight support structure (14). The layer of inorganic insulating material may be an intumescent material made from mineral fibers. The decribed lightweight support structure (14) is a honeycomb panel having a honeycomb core (18) of non-combustible aluminum foil provided with two face skins made of glass reinforced plastics resin material (16). This construction of the honeycomb panel (14) is lightweight and has high stiffness and rigidity suitable for stiffening and supporting the insulating material into a rigid panel. The layer of intumescent material (12) supported on the panel expands when exposed to high temperatures to form a thick fire insulating barrier panel. Because the panels are self-supporting, and therefore support structures, installation costs are much lower than for prior art fire insulation systems.

Owner:ASHMERE HLDG

Fire barrier protection for airplanes comprising graphite films

ActiveUS20110114342A1Reduce weightLess outgassingArtificial islandsSynthetic resin layered productsJet aeroplaneMarine engineering

A fire barrier system for use in aircraft, ship or offshore drilling platform comprises a flexible graphite sheet. Methods of providing fire barrier protection in an aircraft, ship or offshore drilling platform comprise installing the described fire barrier system in the aircraft, ship or offshore drilling platform. Additionally, the fire barrier system when installed in the aircraft, ship or offshore drilling platform is described.

Owner:KANEKA CORP

Lng storage tank and constructing method thereof

InactiveCN1898124AMaintain liquid-tight propertiesAvoid breakingContainer filling methodsRailway vehiclesEngineeringStructural engineering

Disclosed is a liquid container adapted to store liquefied natural gas (LNG). The LNG storage container include a sealing wall directly contacting liquid contained in the tank and a structural wall, which is an exterior wall or inner structure integrated with the exterior wall. The container further includes a plurality of connectors mechanically connecting the sealing wall and the structural wall and an intermediate wall structure positioned between the structural wall and the interior wall. The intermediate wall structure is configured to move relative to at least one of the interior wall and the structural wall.

Owner:KC LNG TECH CO LTD ENTIRE RIGHT

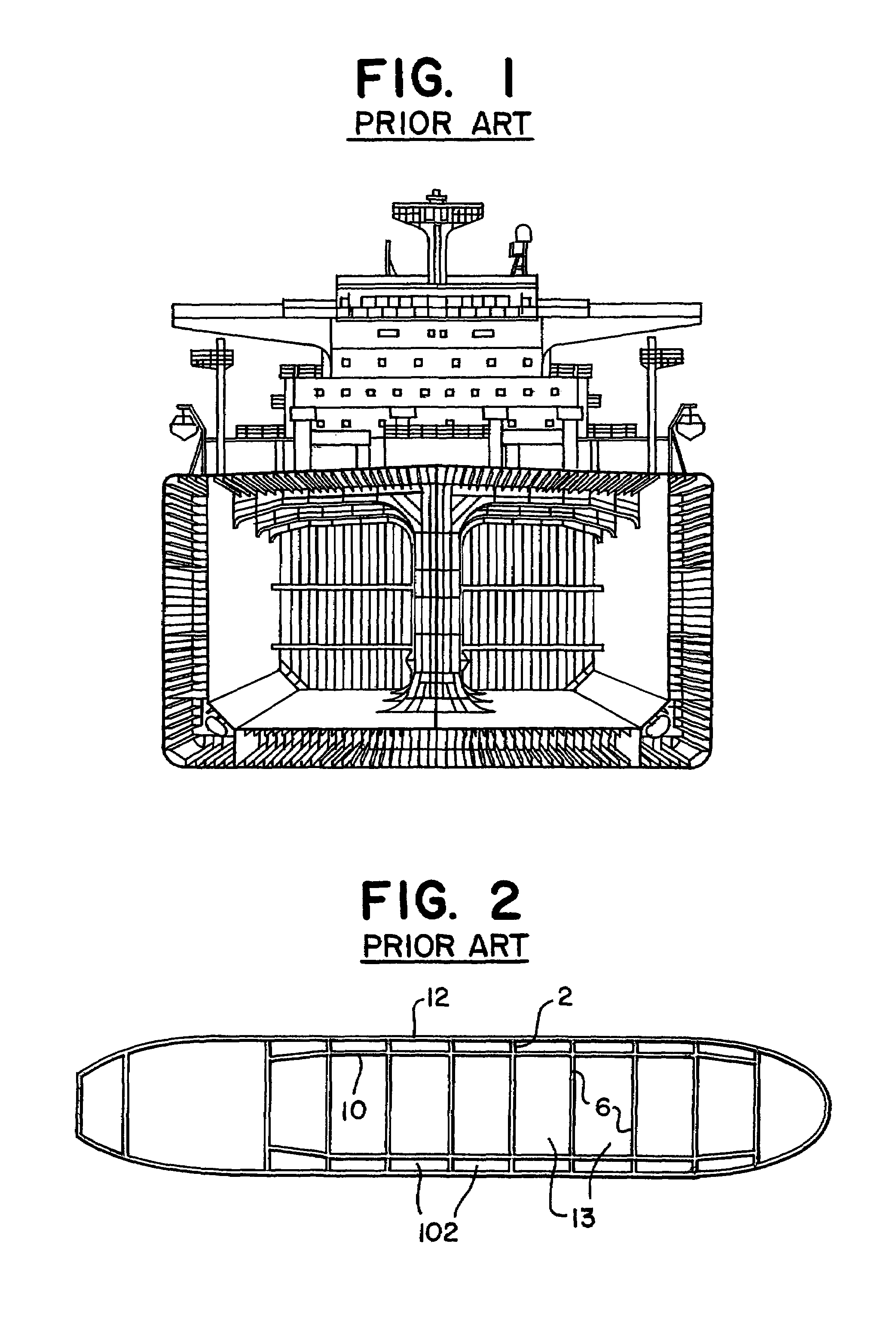

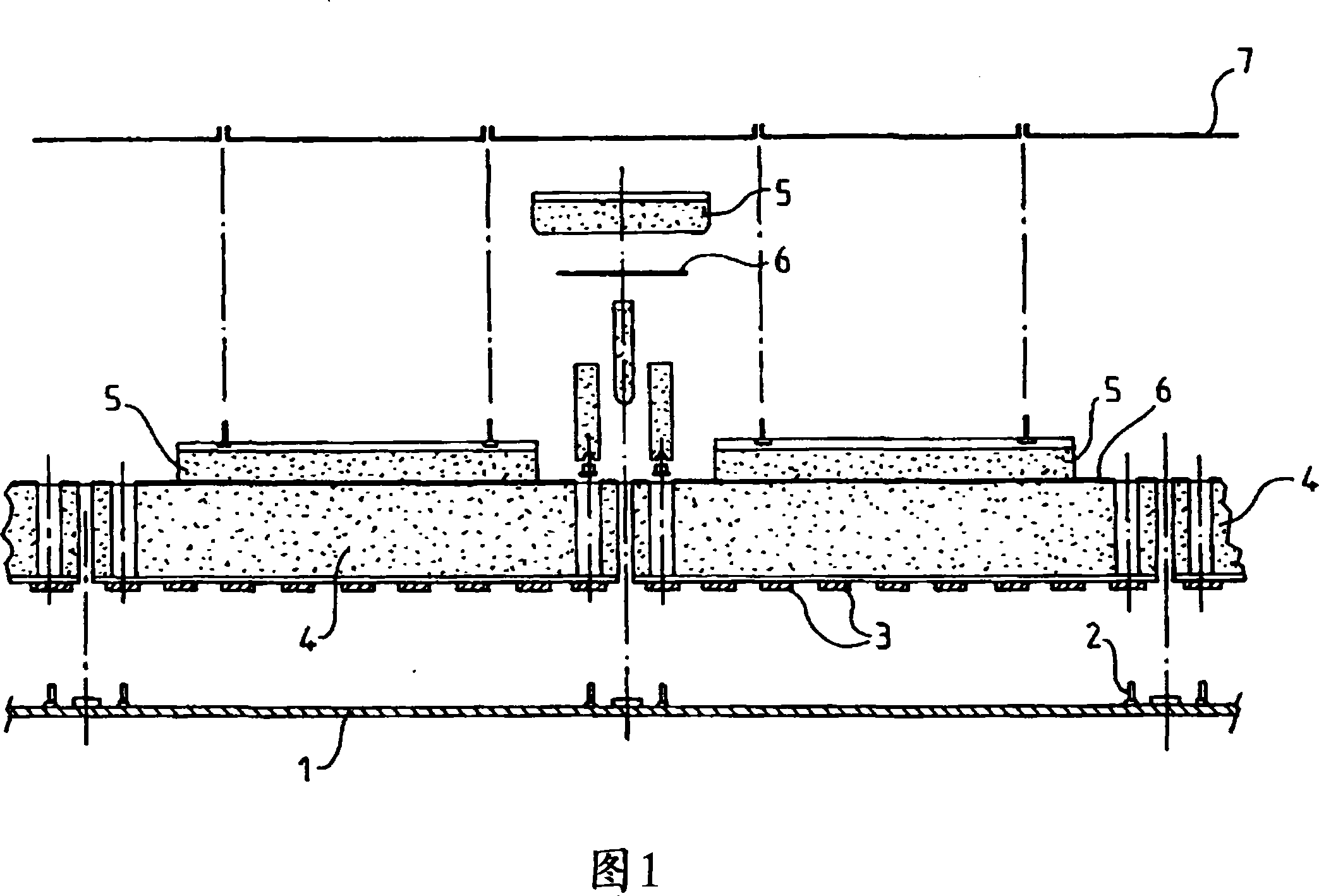

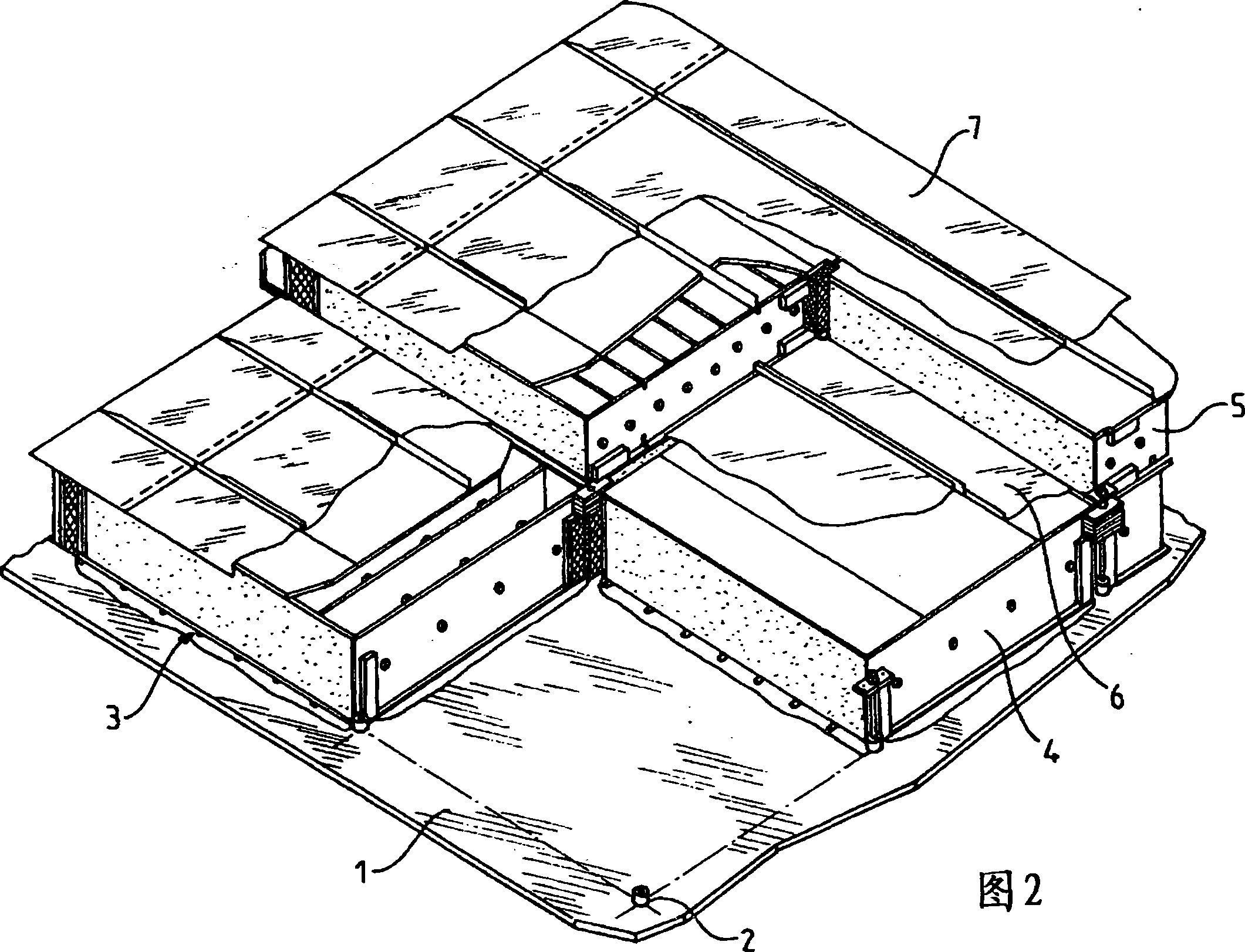

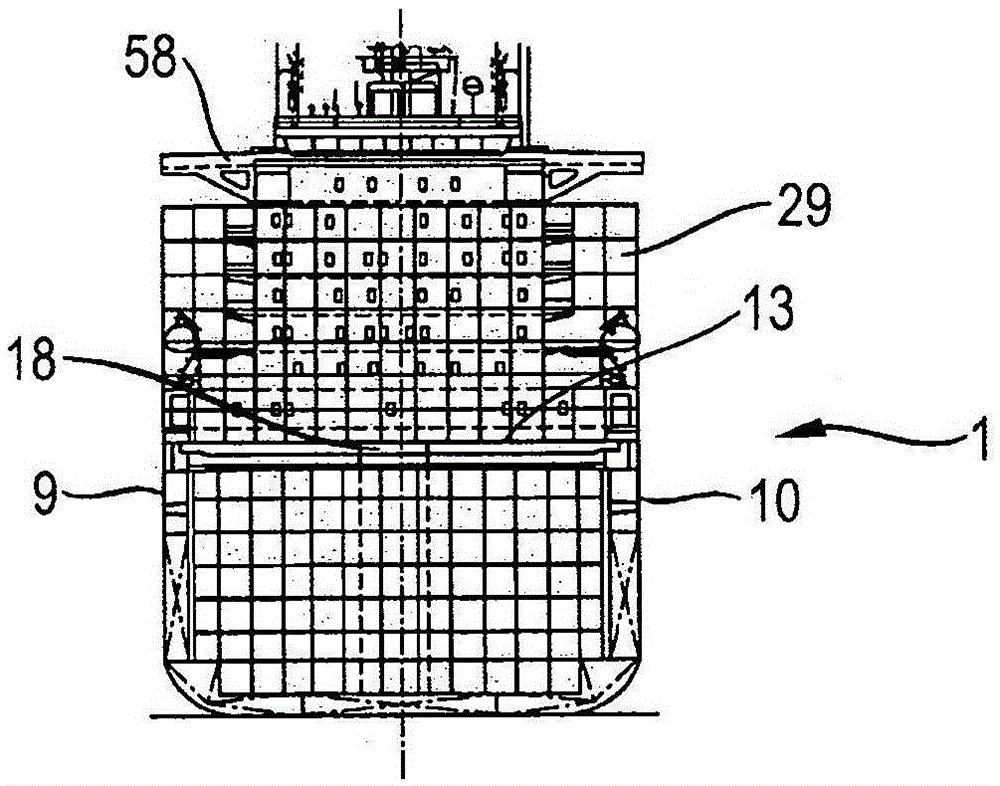

Sealed, thermally insulated tank incorporated into the load-bearing structure of a ship

Owner:GAZTRANSPORT & TECHNIGAZ

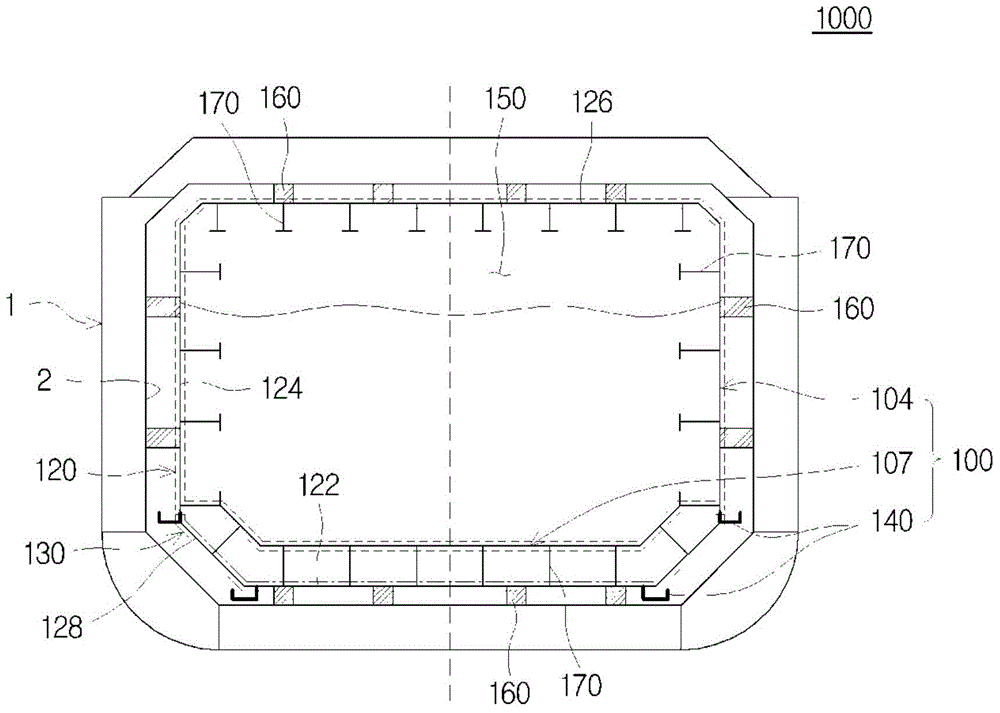

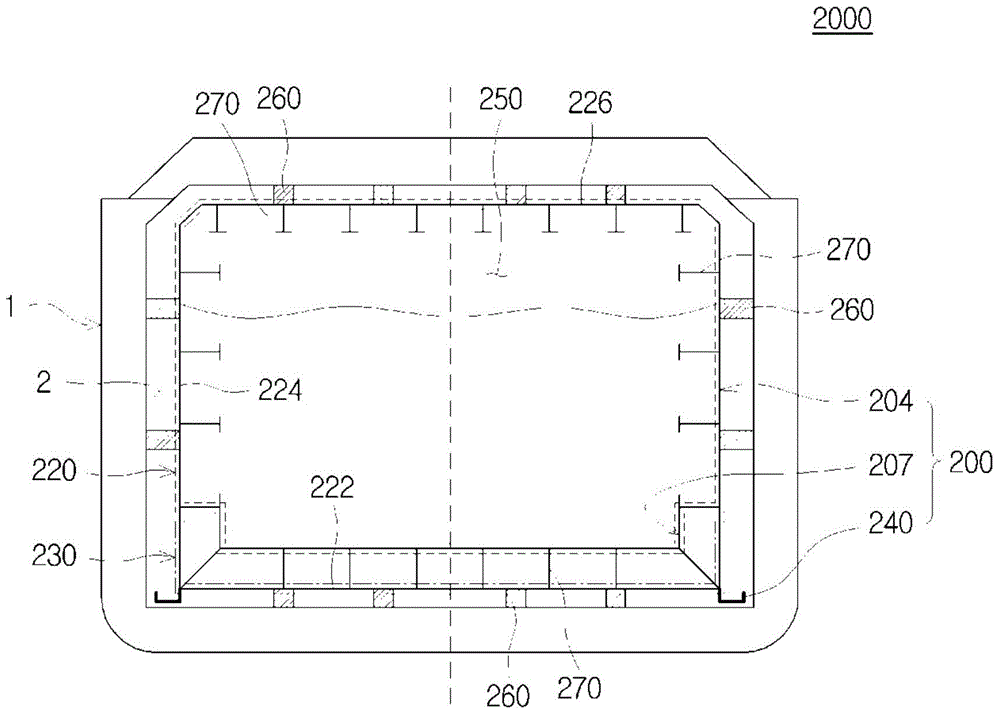

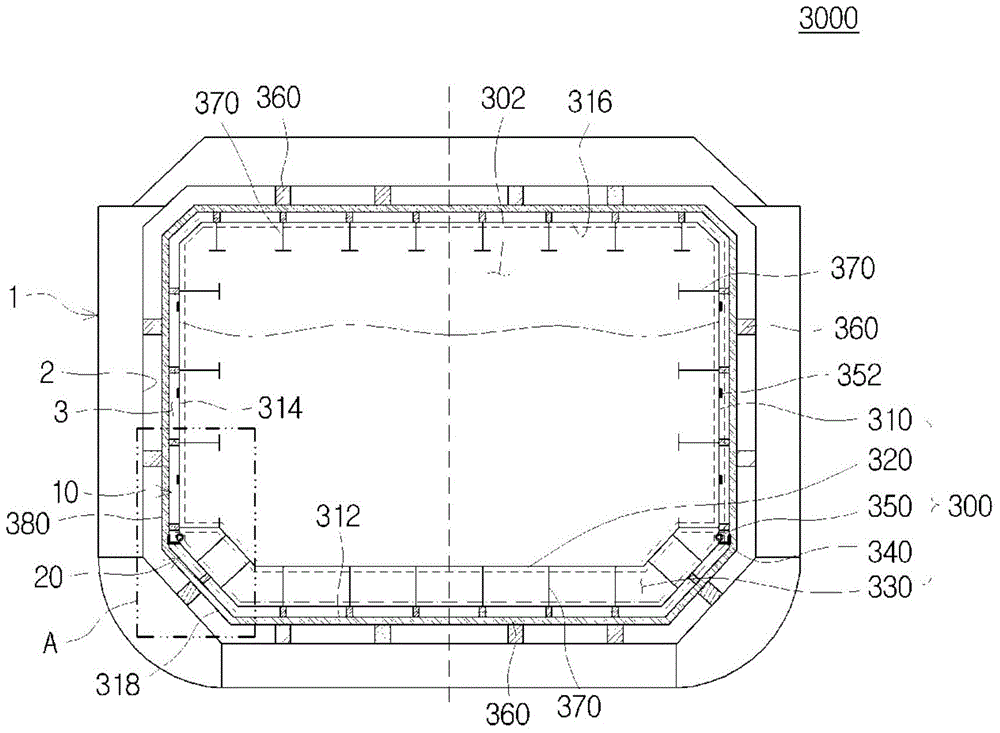

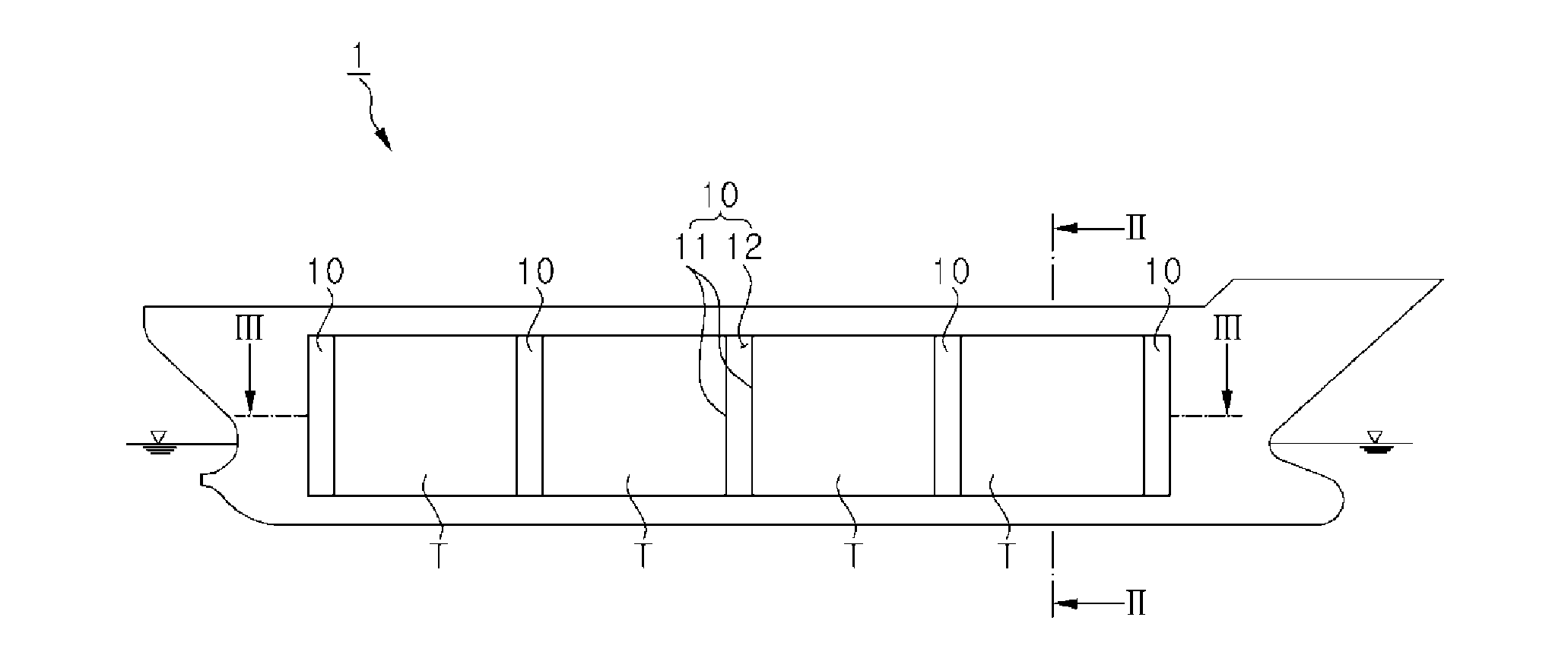

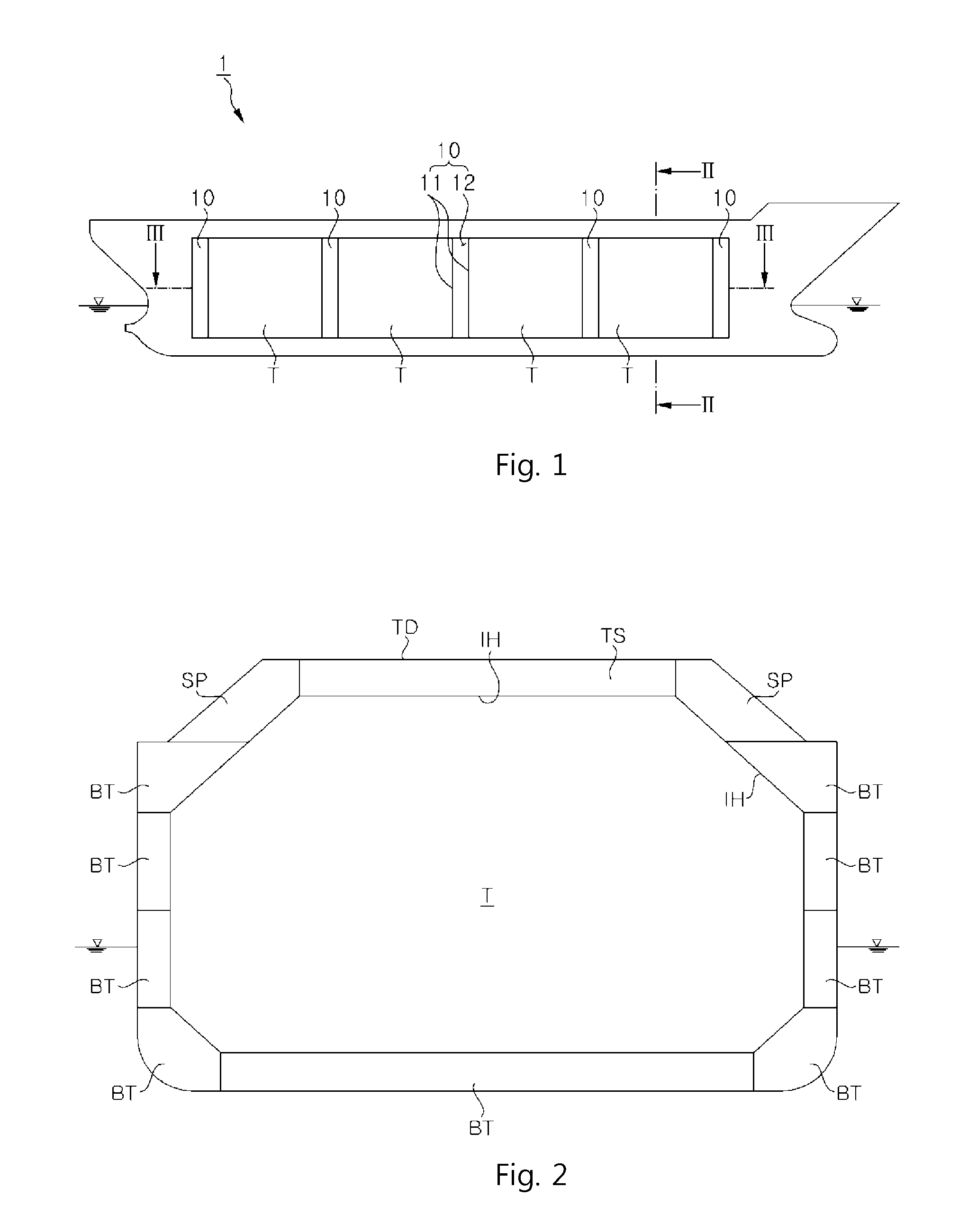

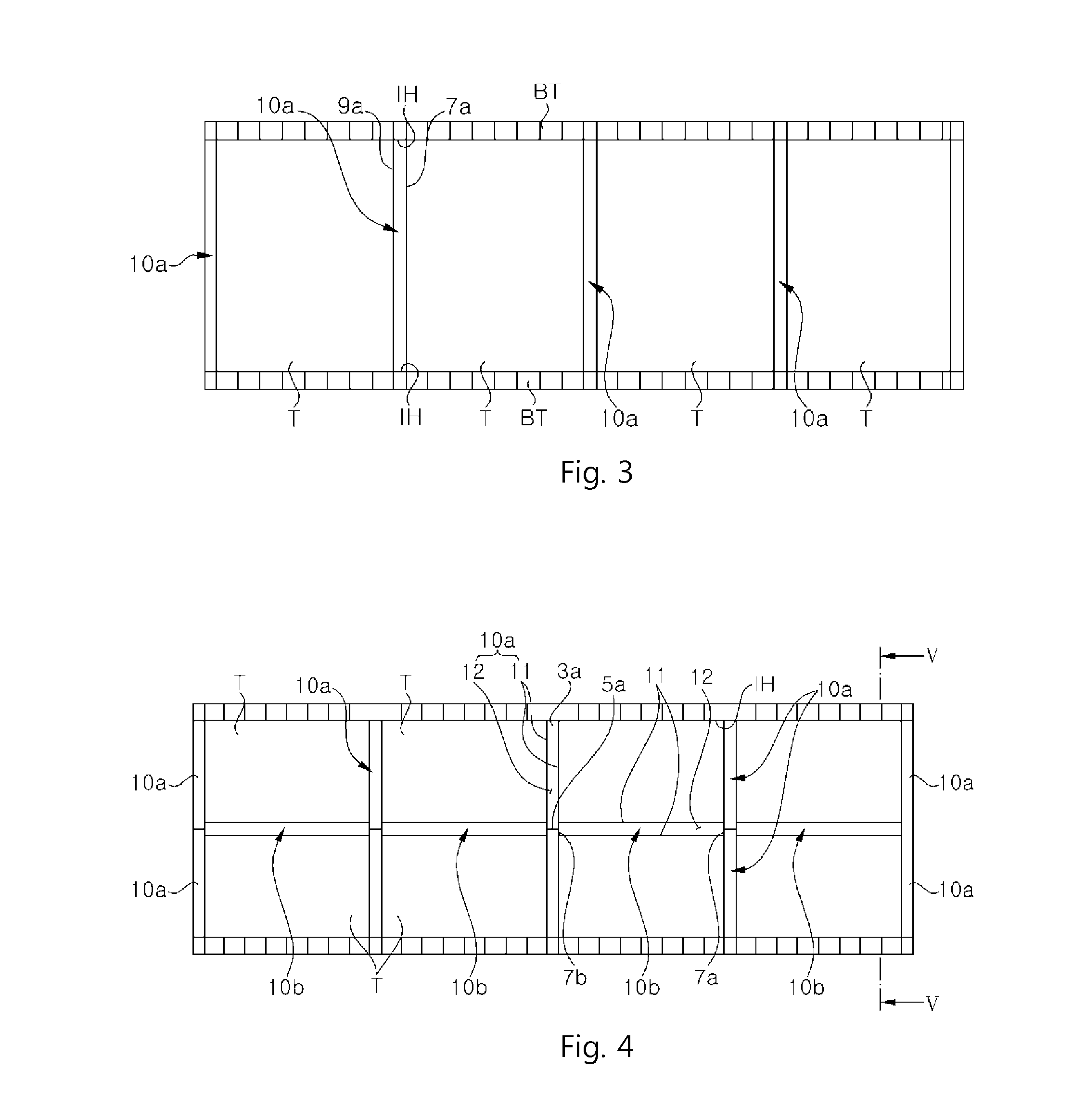

Storage tank for liquefied materials and ship comprising same

ActiveCN103562061APrevent leakageVessel geometry/arrangement/sizeVessel wallsMarine engineeringStorage tank

Disclosed are a storage tank for liquefied materials, and a ship comprising same. The storage tank for liquefied materials according to one embodiment of the present invention comprises: a main body which is installed within a hull of the ship such that a space is formed between said main body and said hull, and which has an interior with an accommodating space for accommodating a liquefied material therein; and a reinforcement plate which is installed in a lower portion of the interior of said main body such that the reinforcement plate is spaced apart from the bottom surface of said main body, so as to form the bottom of said accommodating space.

Owner:SAMSUNG HEAVY IND CO LTD

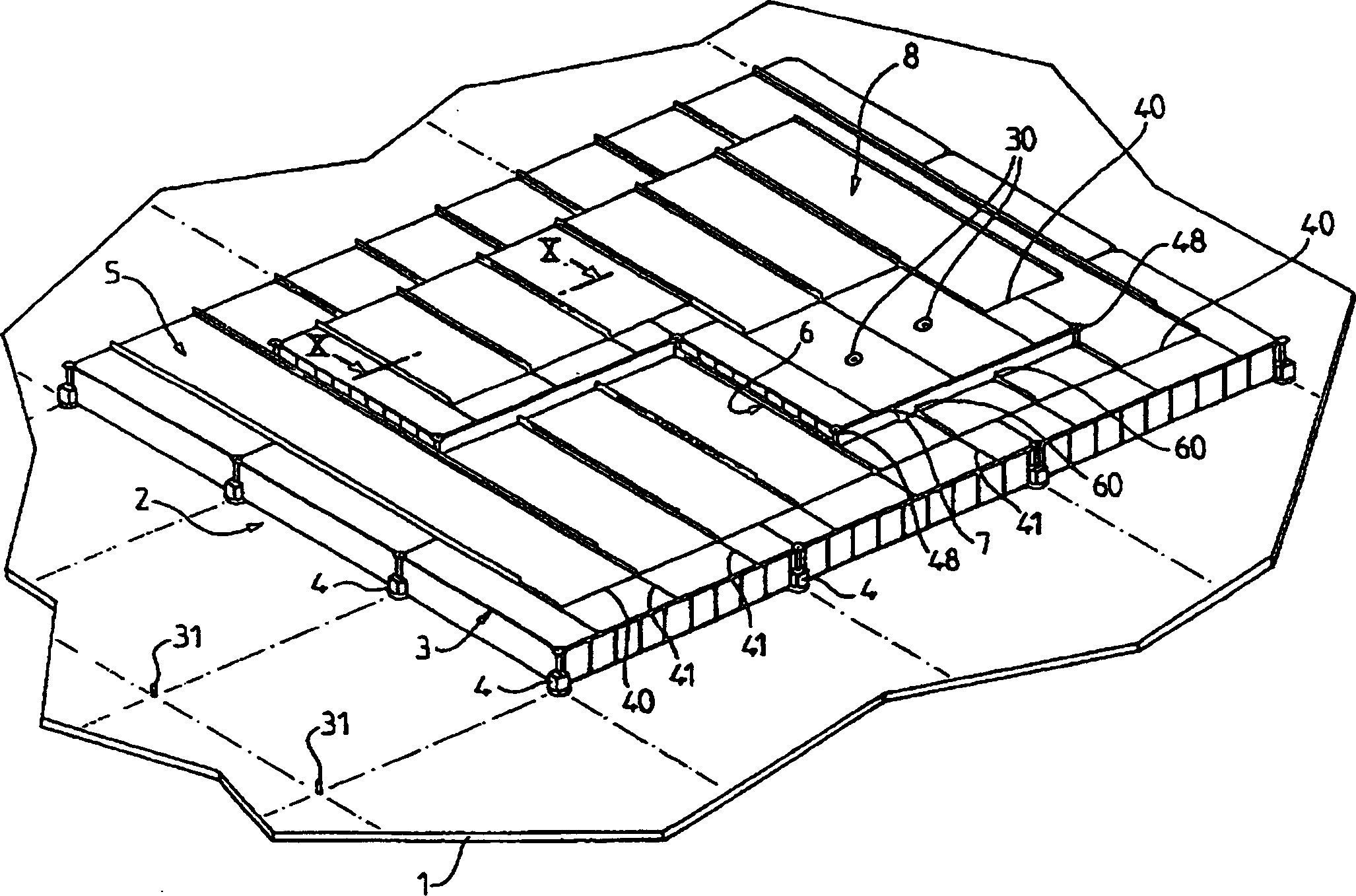

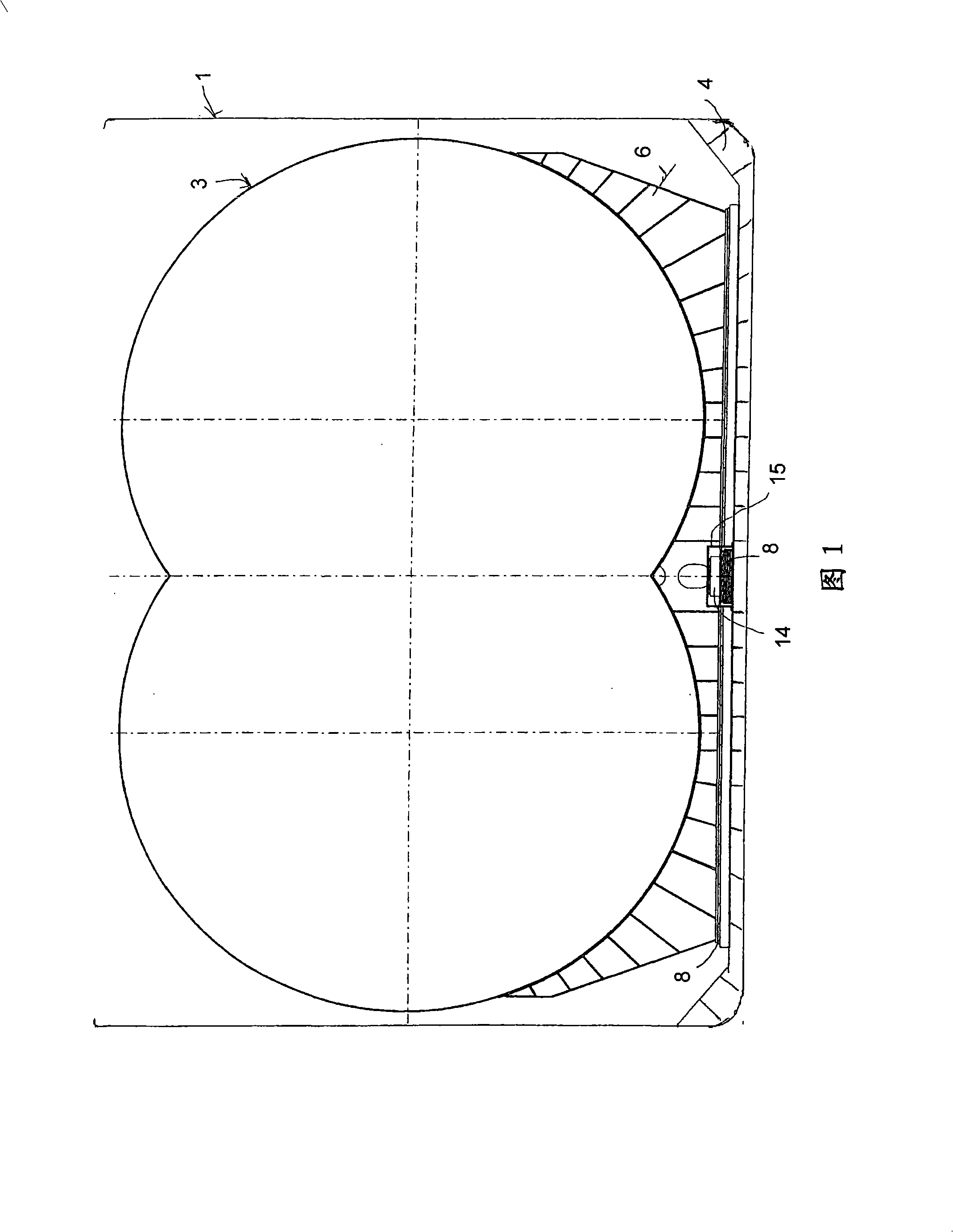

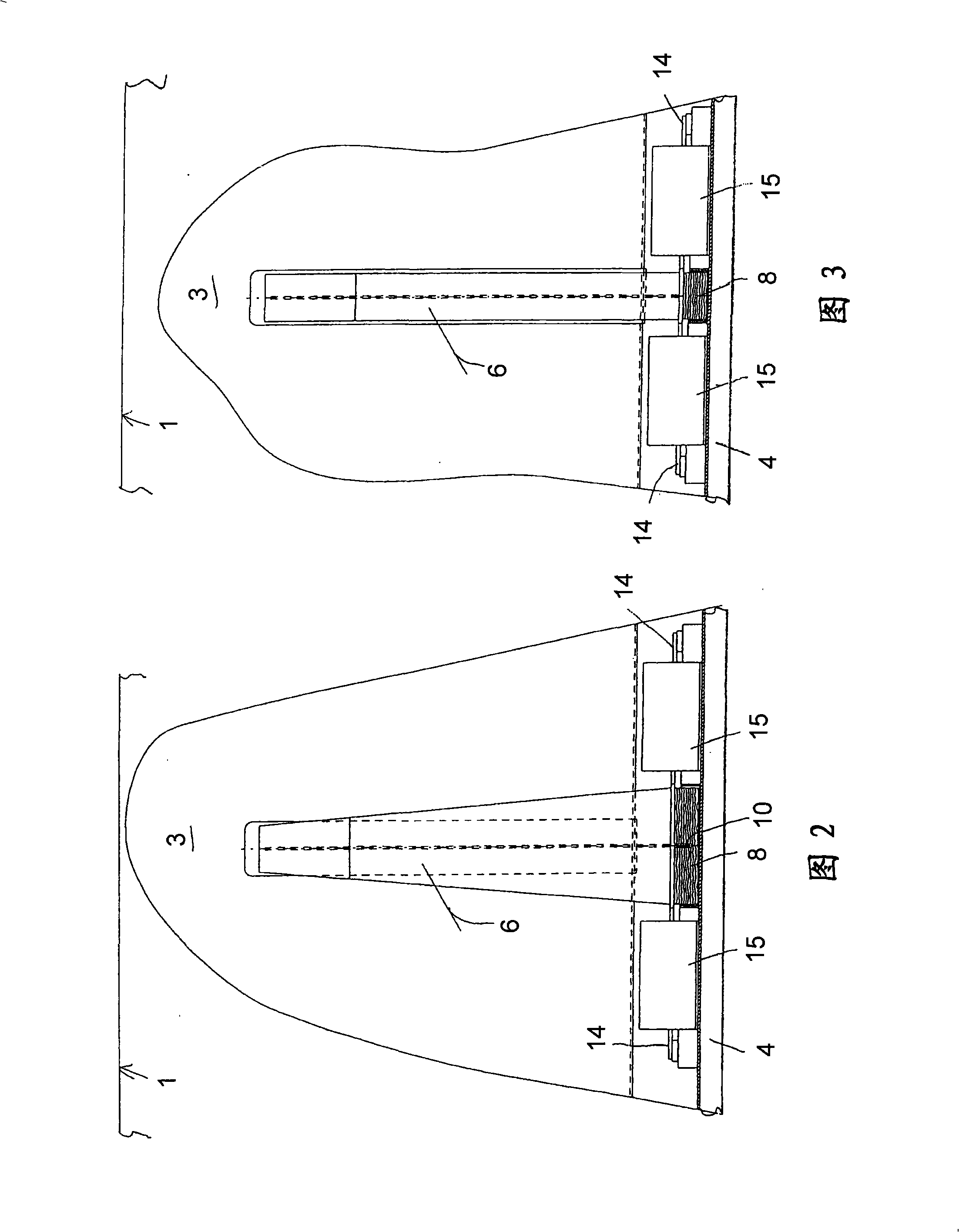

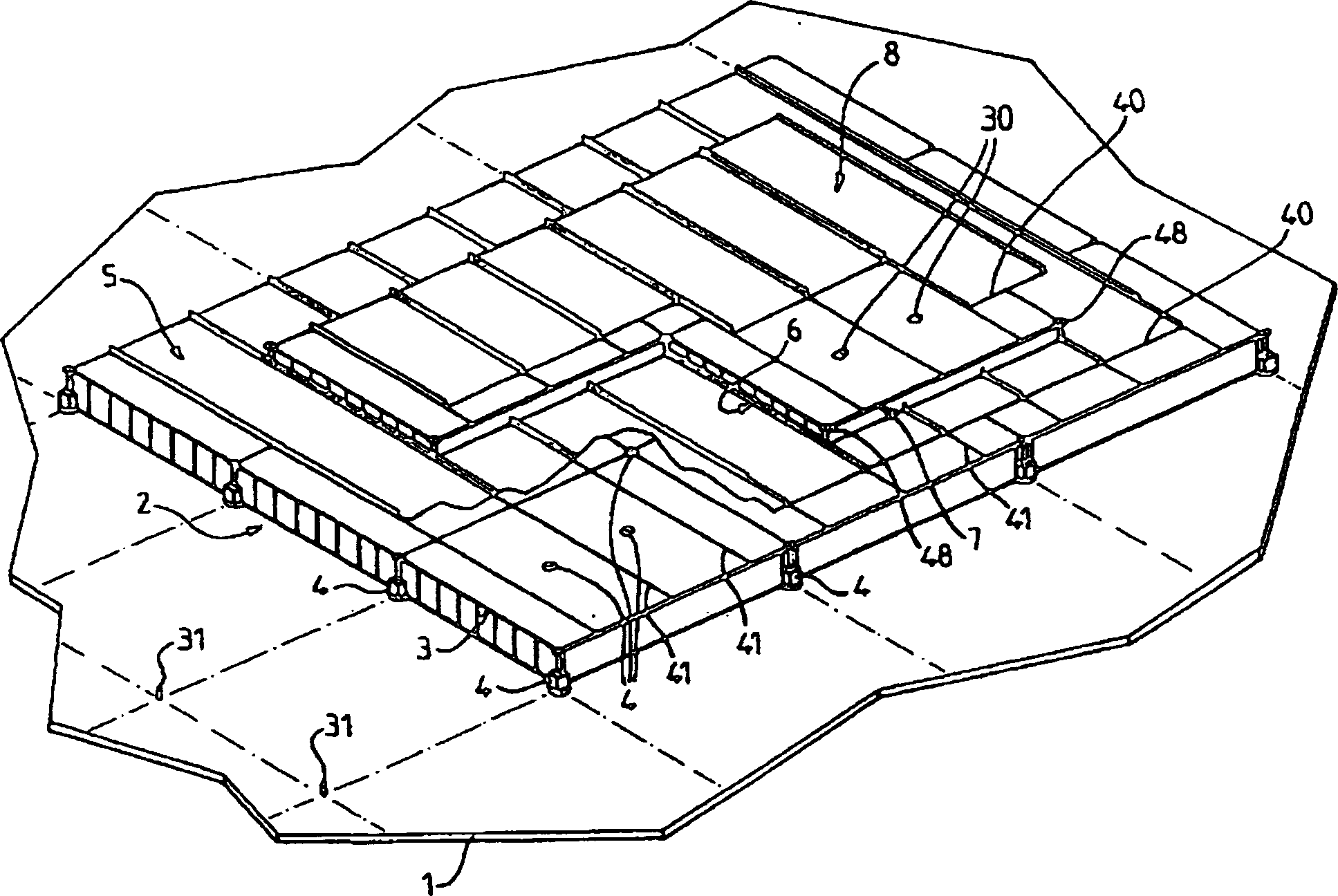

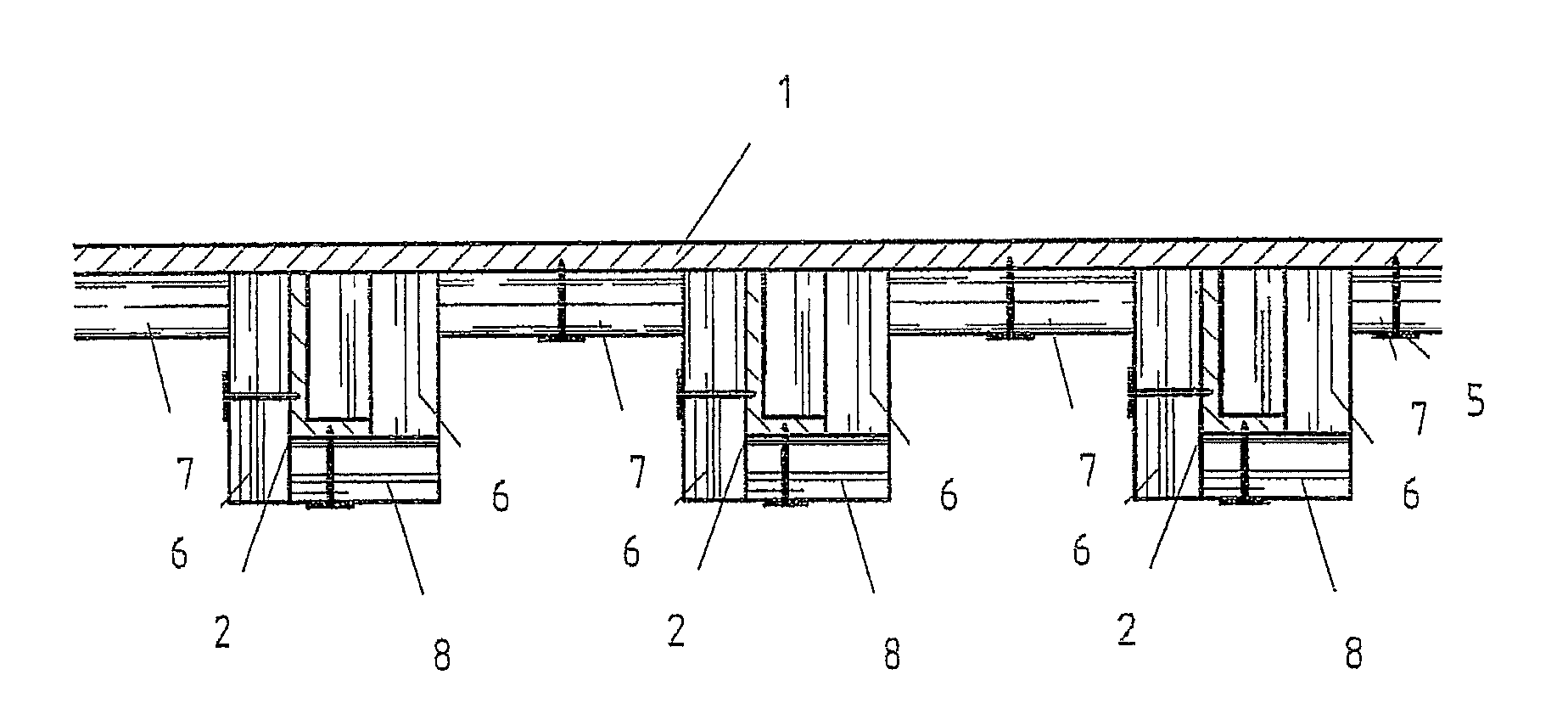

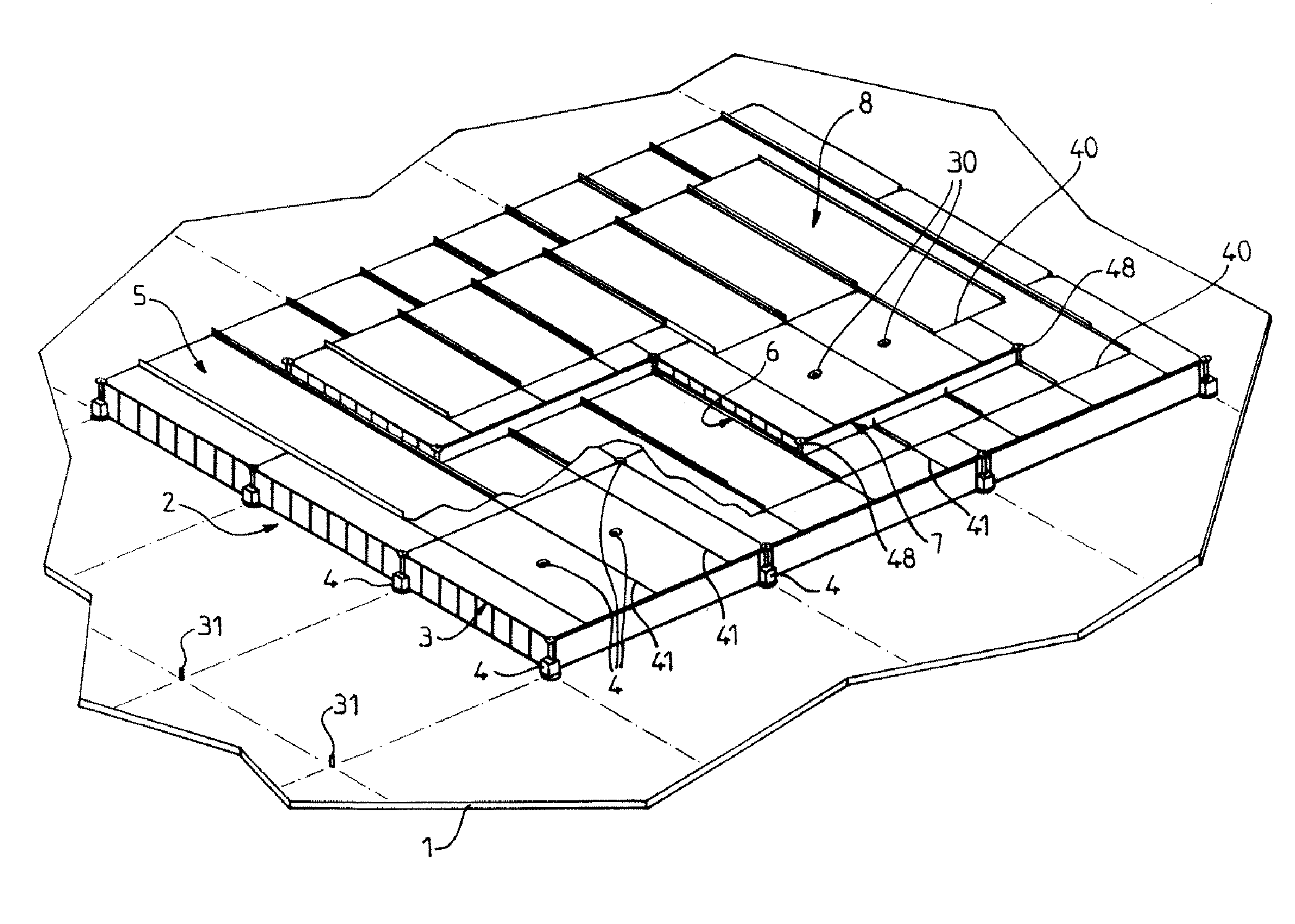

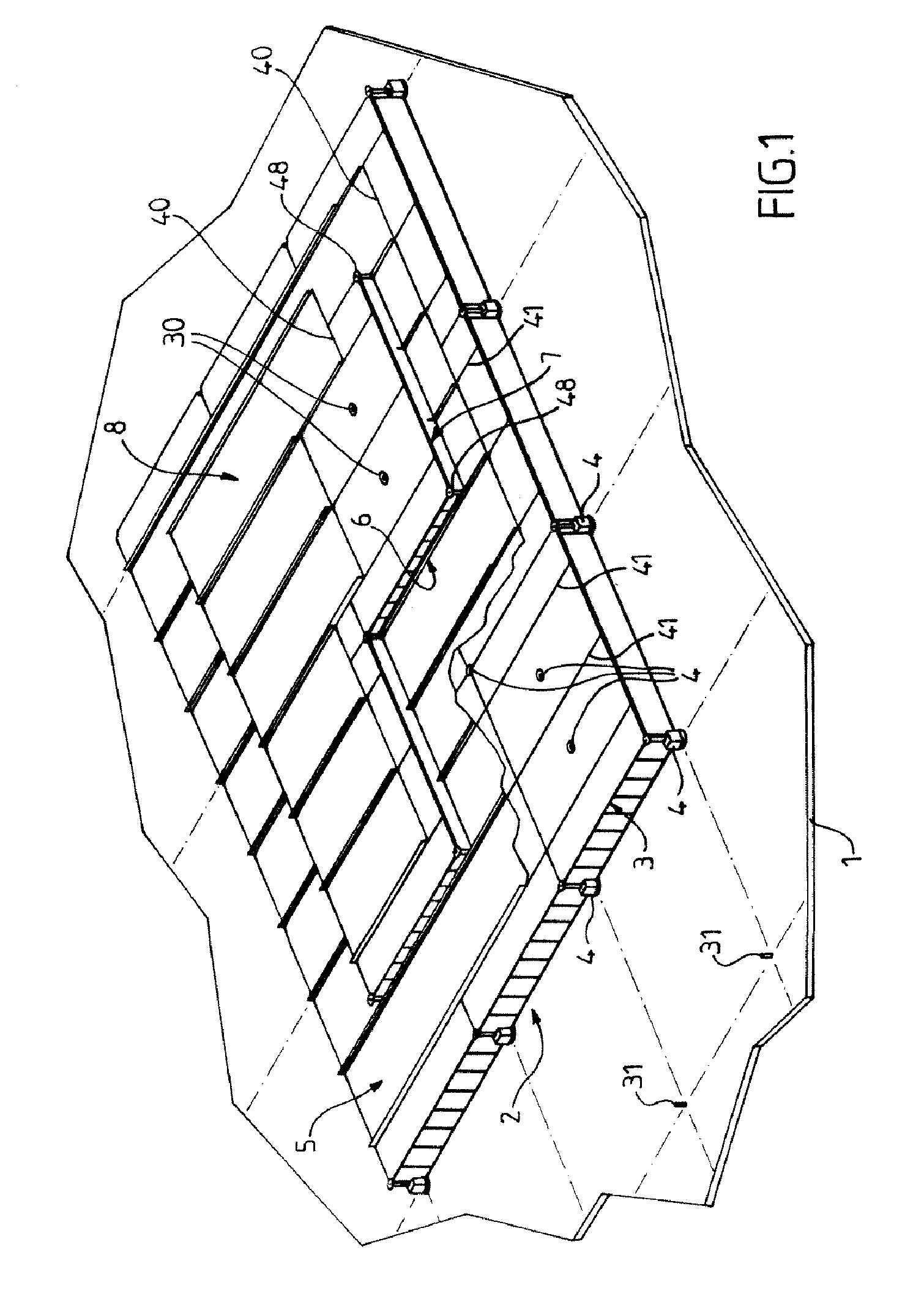

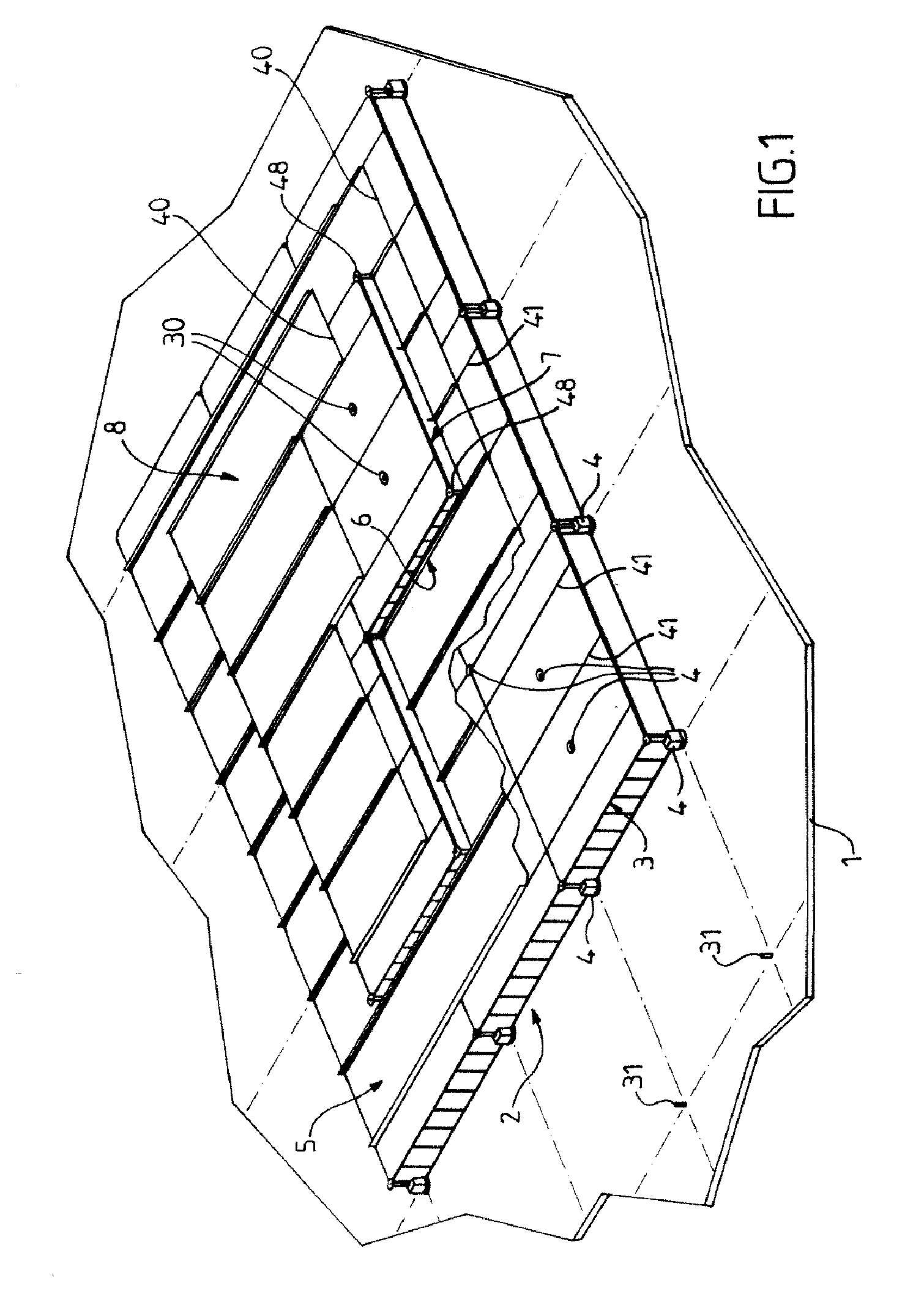

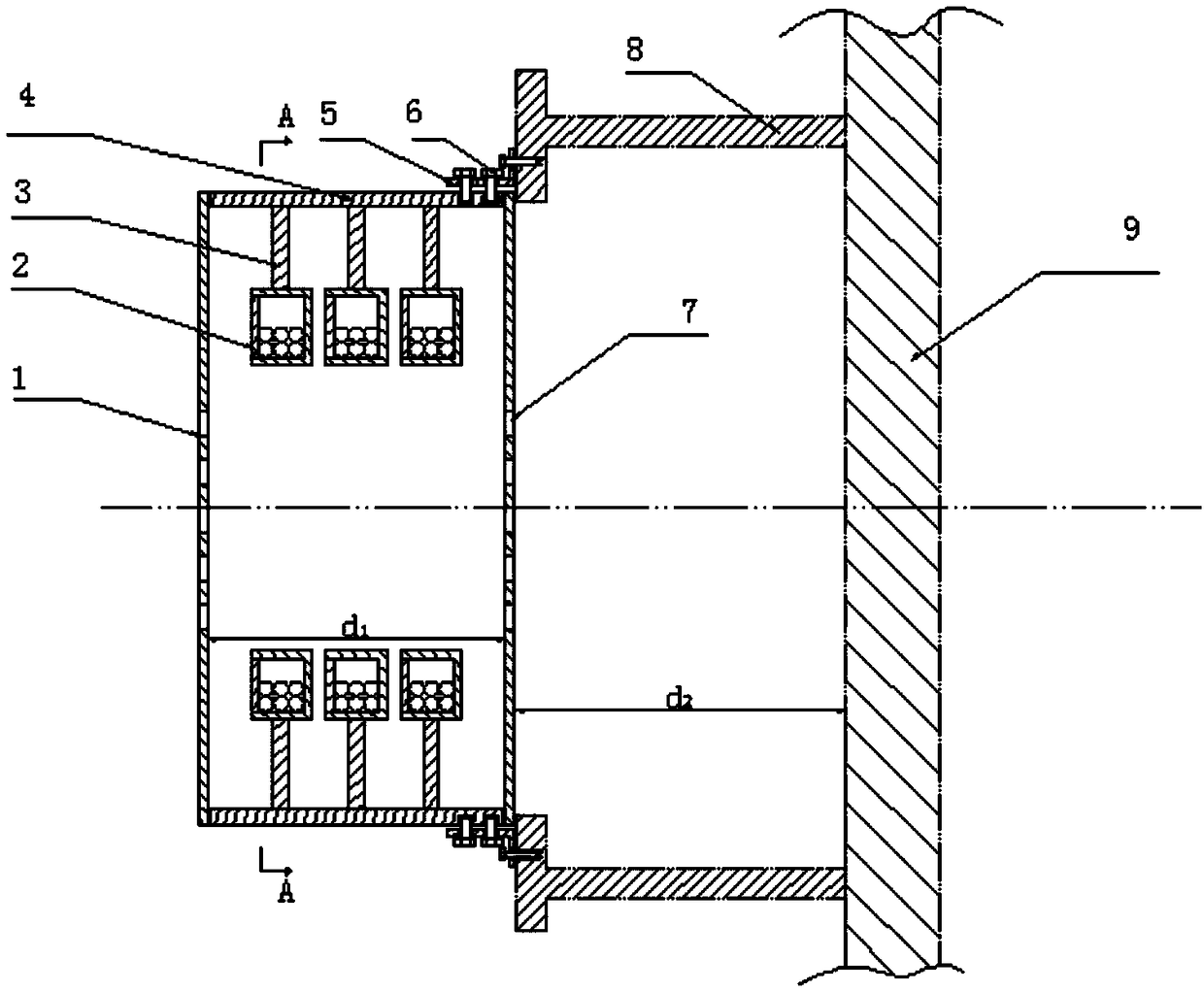

Device for mounting a tank in a ship

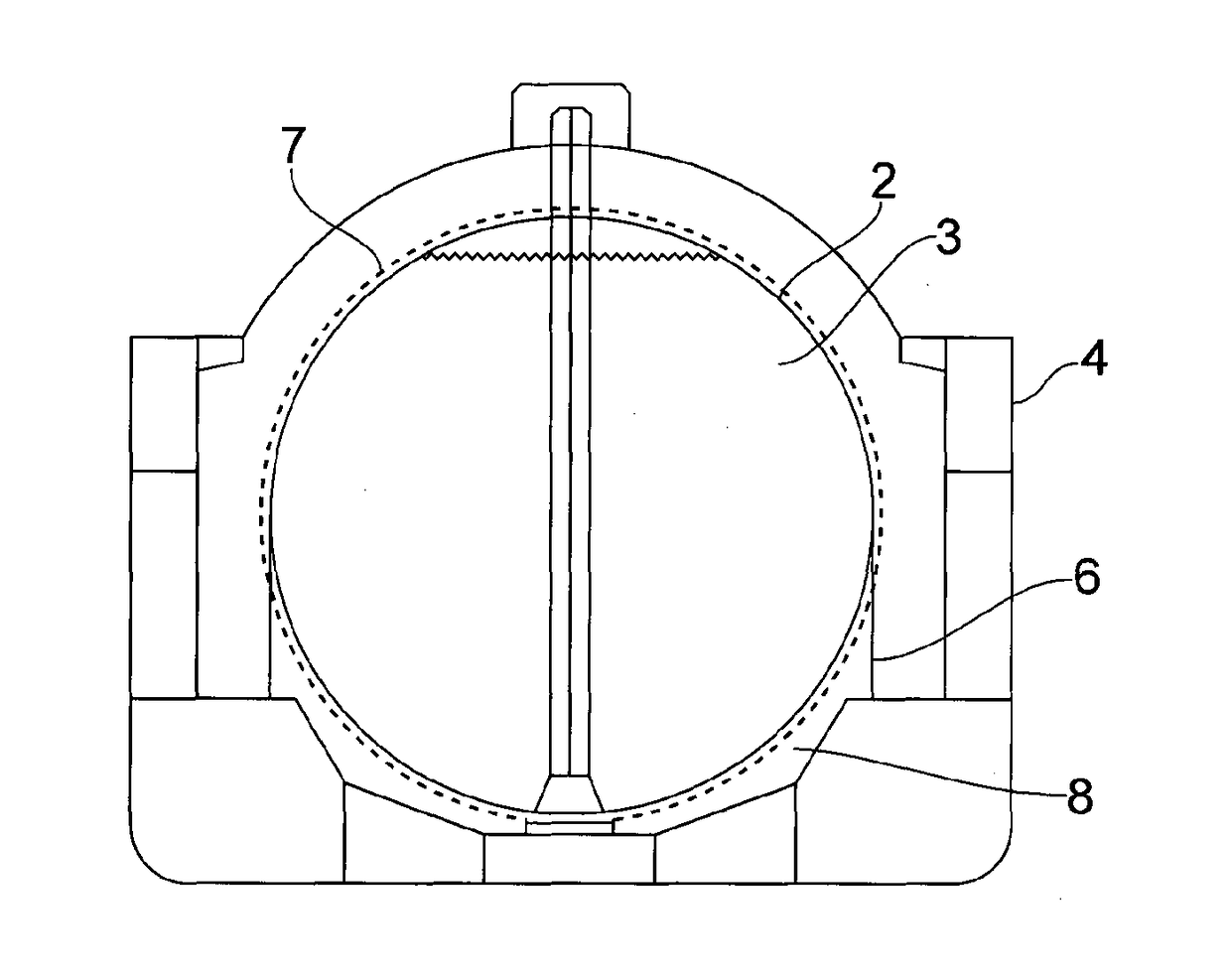

ActiveCN101321662APrevent longitudinal movementPrevent movementVessel mounting detailsVessel geometry/arrangement/sizeMarine engineeringThermal insulation

Disclosed is a device for mounting a tank in a ship (1). Said device comprises at least two foundations (4) which are fastened to the hull at a distance from each other in the longitudinal or transversal direction of the ship (1) and each of which supports one saddle (6) that is adapted to the shape of the tank (3) and is used for accommodating the tank (3). The inventive device further comprises an insulating layer (8) that is provided on each saddle (6) to thermally insulate the foundations (4) relative to the tank (3) as well as safety mechanisms (10; 12; 15) for mounting the tank (3) on the foundations (4), said safety mechanisms (10; 12; 15) allowing a relative movement between the tank (3) and at least one foundation (4) on the insulating layer (8) in the longitudinal direction of the tank. Each saddle (6) is fastened directly to the tank (3) and has a planar bottom face (7) while each foundation (4) has a planar top face (5), all bottom and top faces (7; 5) being parallel to one another. The insulating layer (8) is disposed between the bottom face (7) of the saddle (6) and the top face (5) of the associated foundation (4) while the safety mechanisms (10; 12; 15) allow a limited relative movement between each saddle (6) and the foundation (4) thereof on or in the insulating layer (8).

Owner:TGE MARINE GAS ENG GMBH

Laminated carbon foam sandwich for naval decking

A laminate sandwich structure useful for, inter alia, decking for naval vessels, which includes a core formed of carbon foam having a ratio of compressive strength to density of at least about 7000 psi / g / cc.

Owner:GRAFTECH INT HLDG INC

Composite steel structural plastic sandwich plate systems

InactiveUS6984452B2Solve the lack of ductilityReduce in quantityNon-magnetic metal hullsSynthetic resin layered productsStress concentrationComposite construction

Owner:INTELLIGENT ENG BAHAMAS

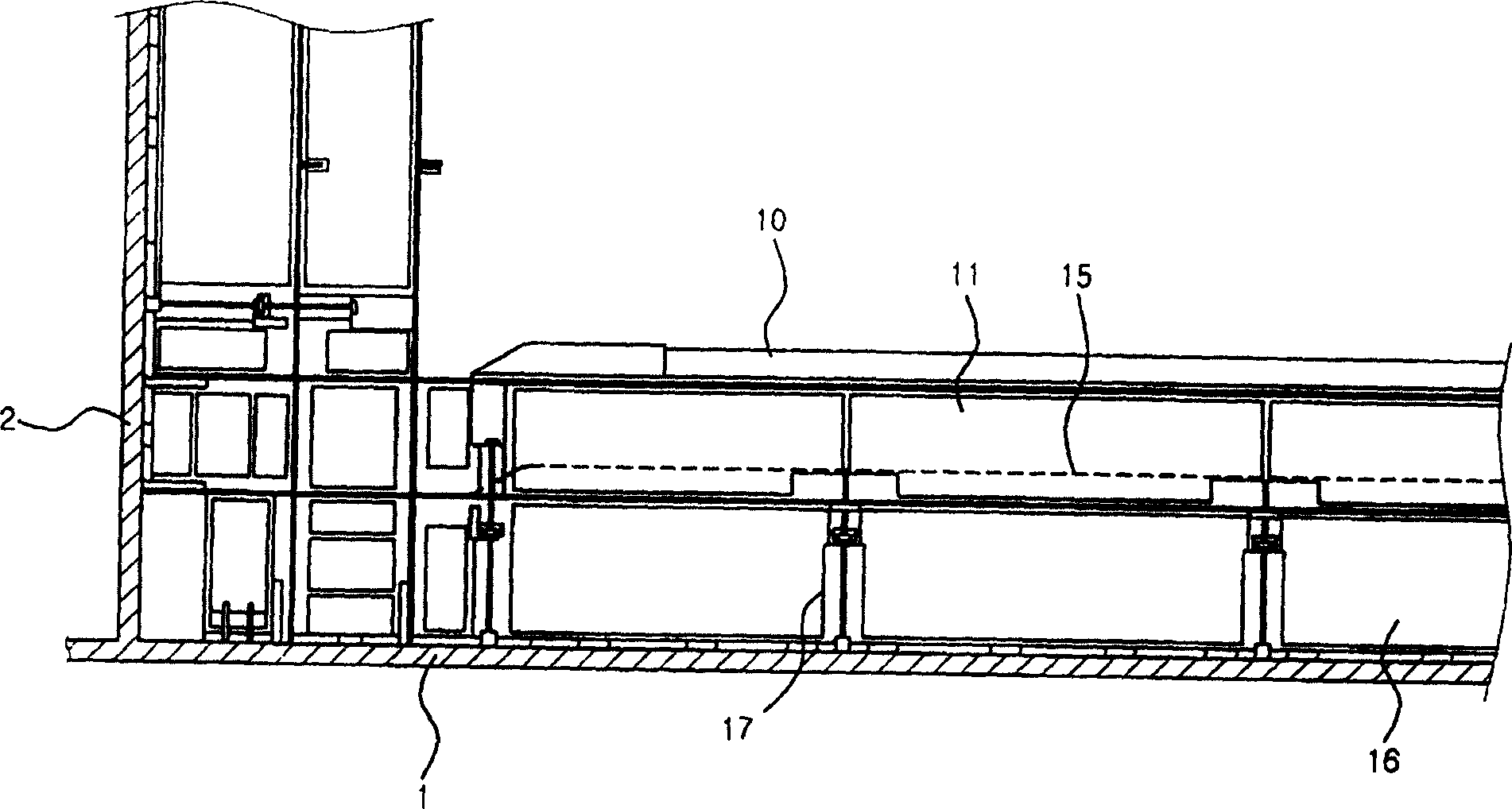

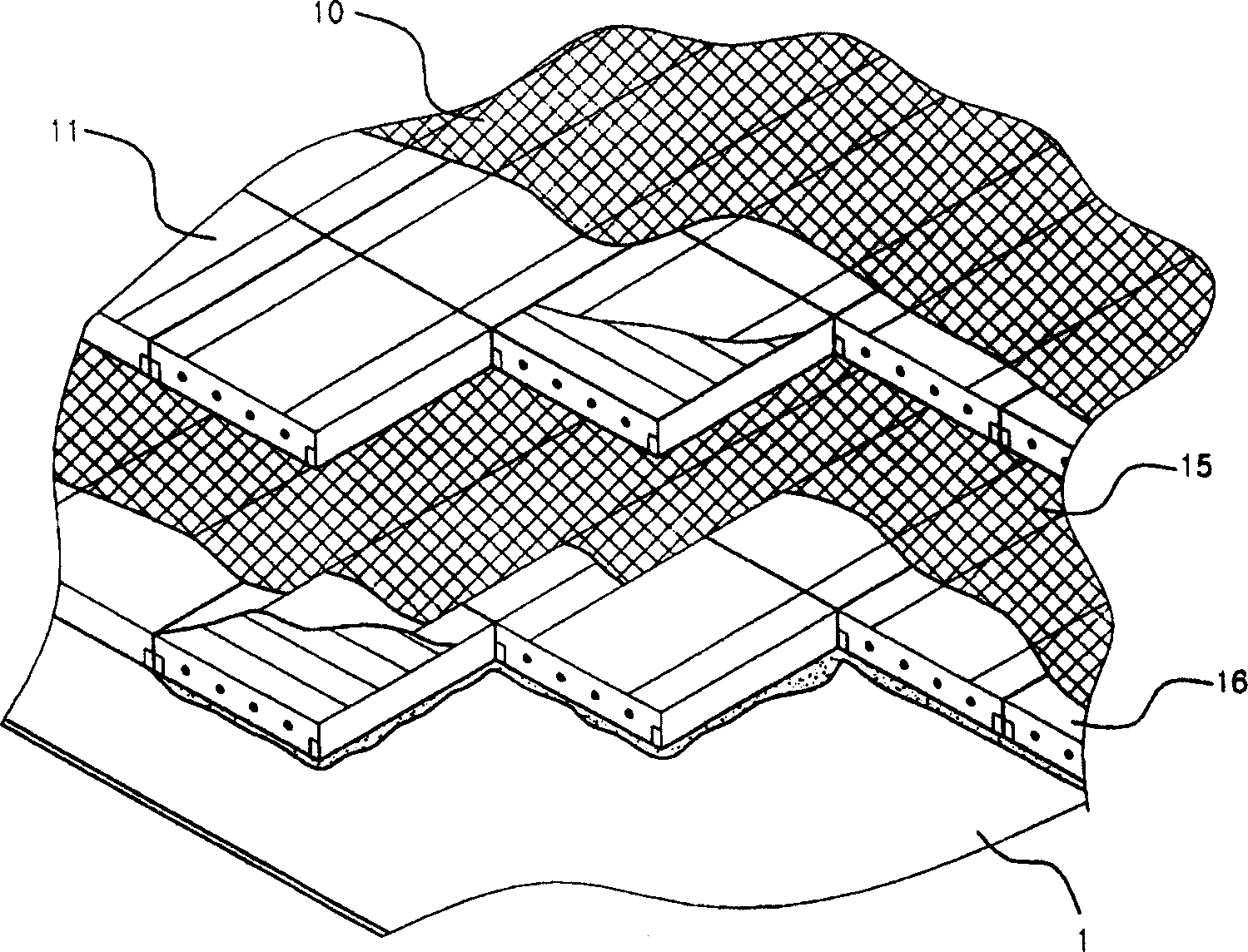

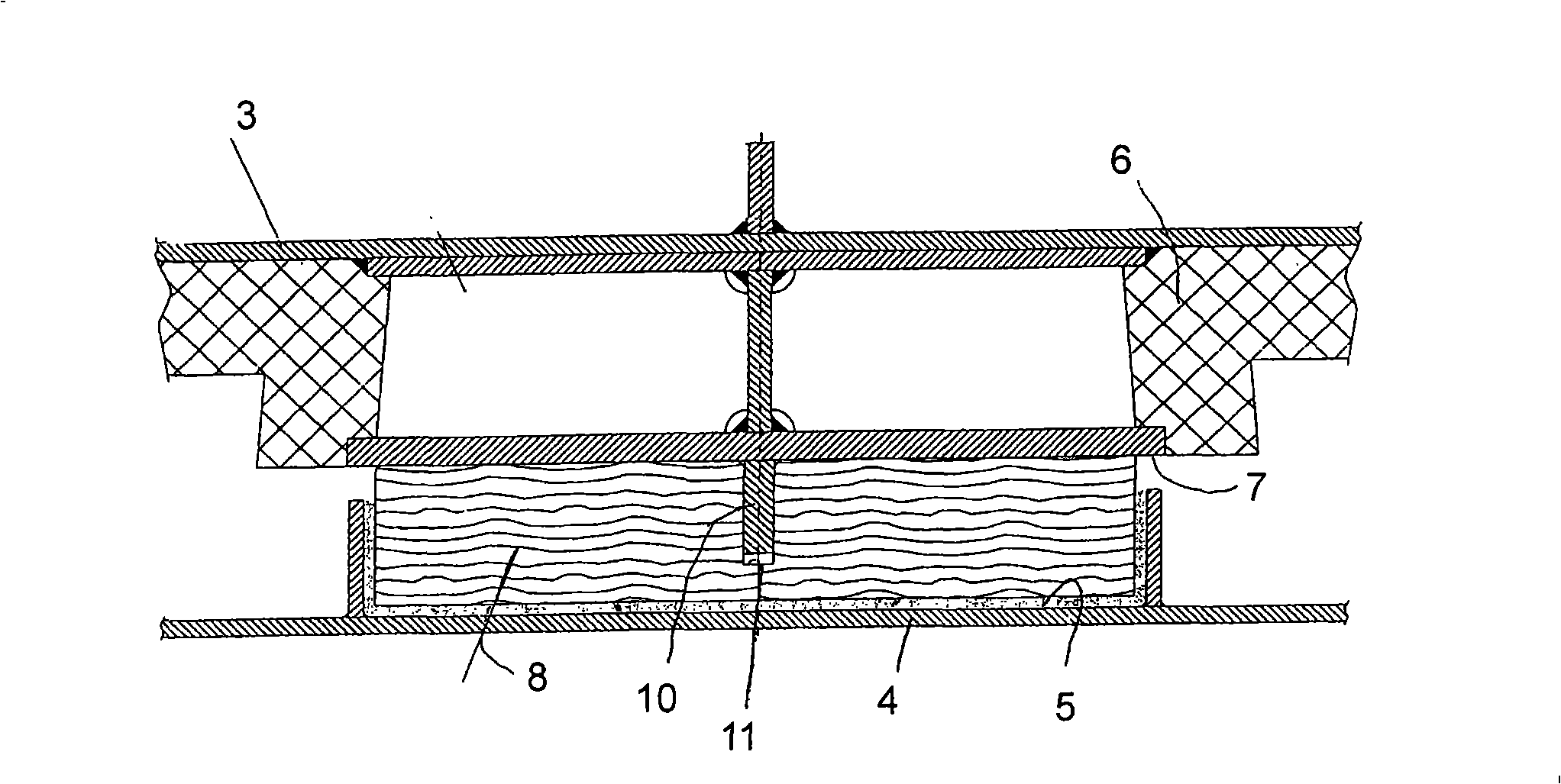

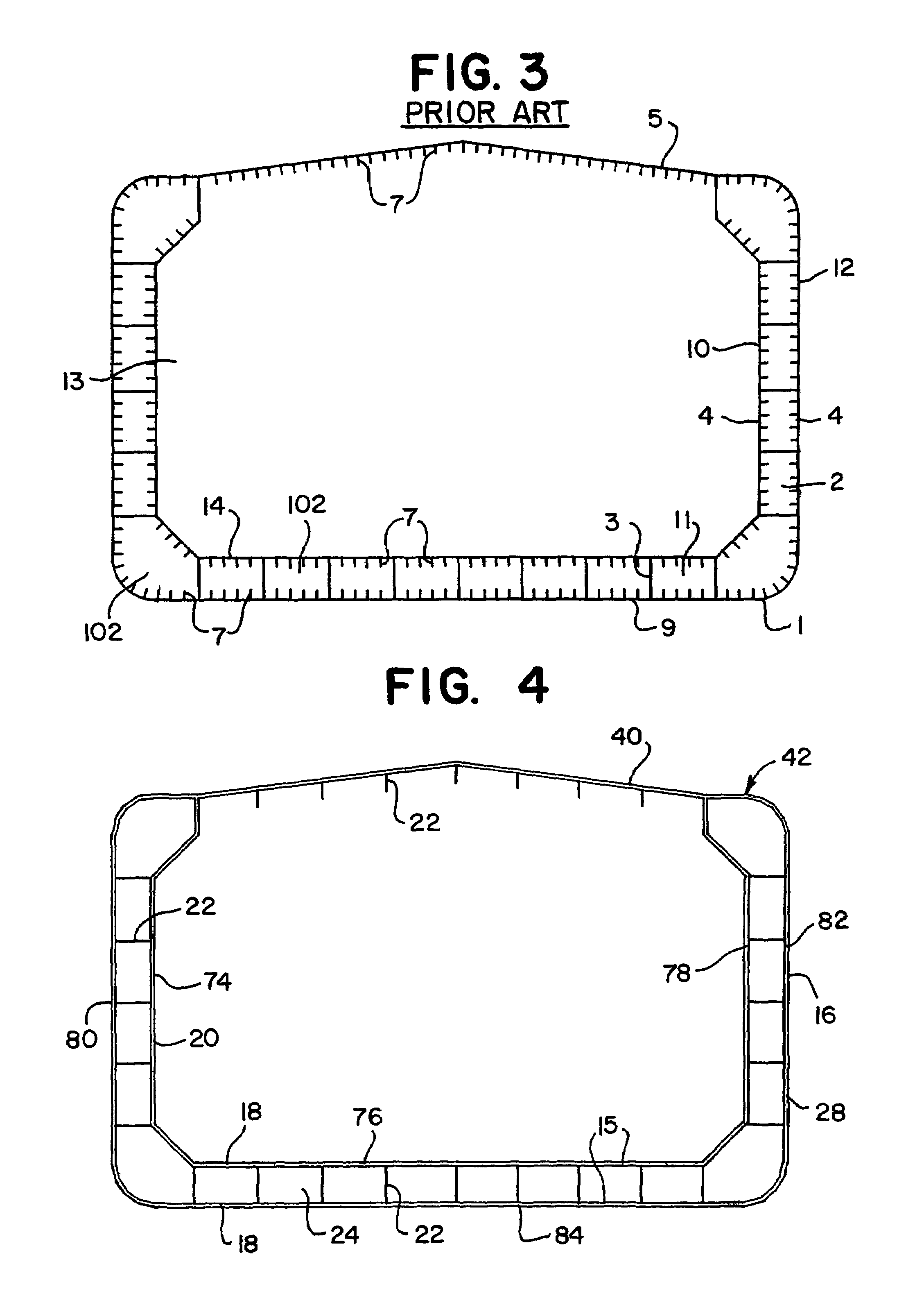

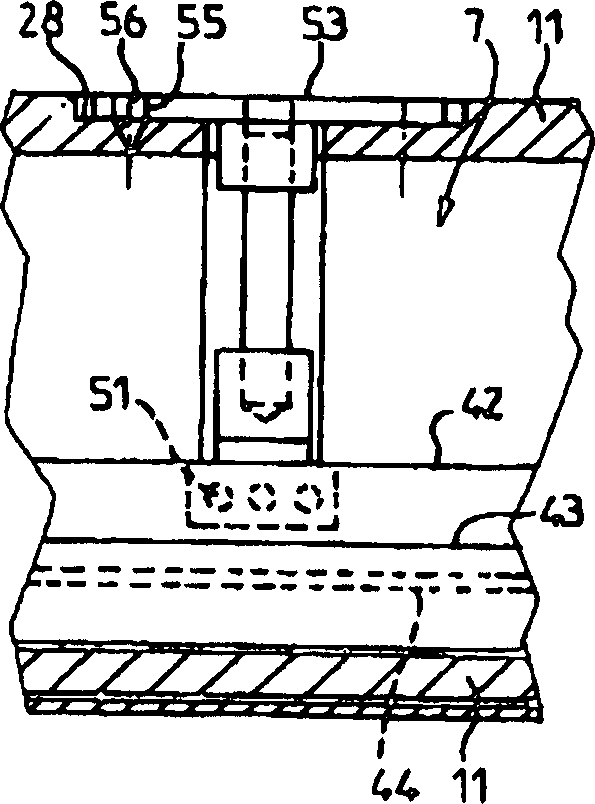

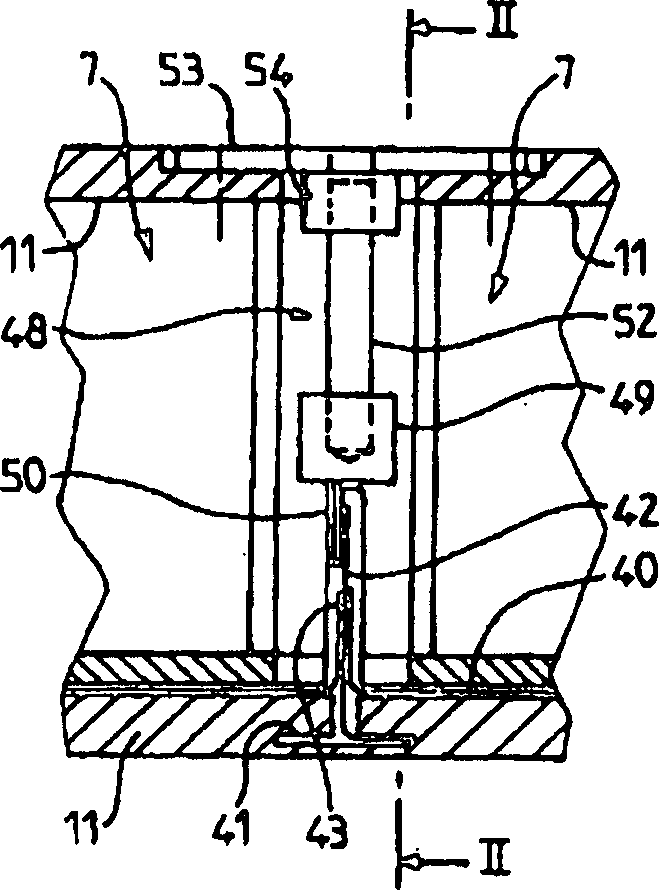

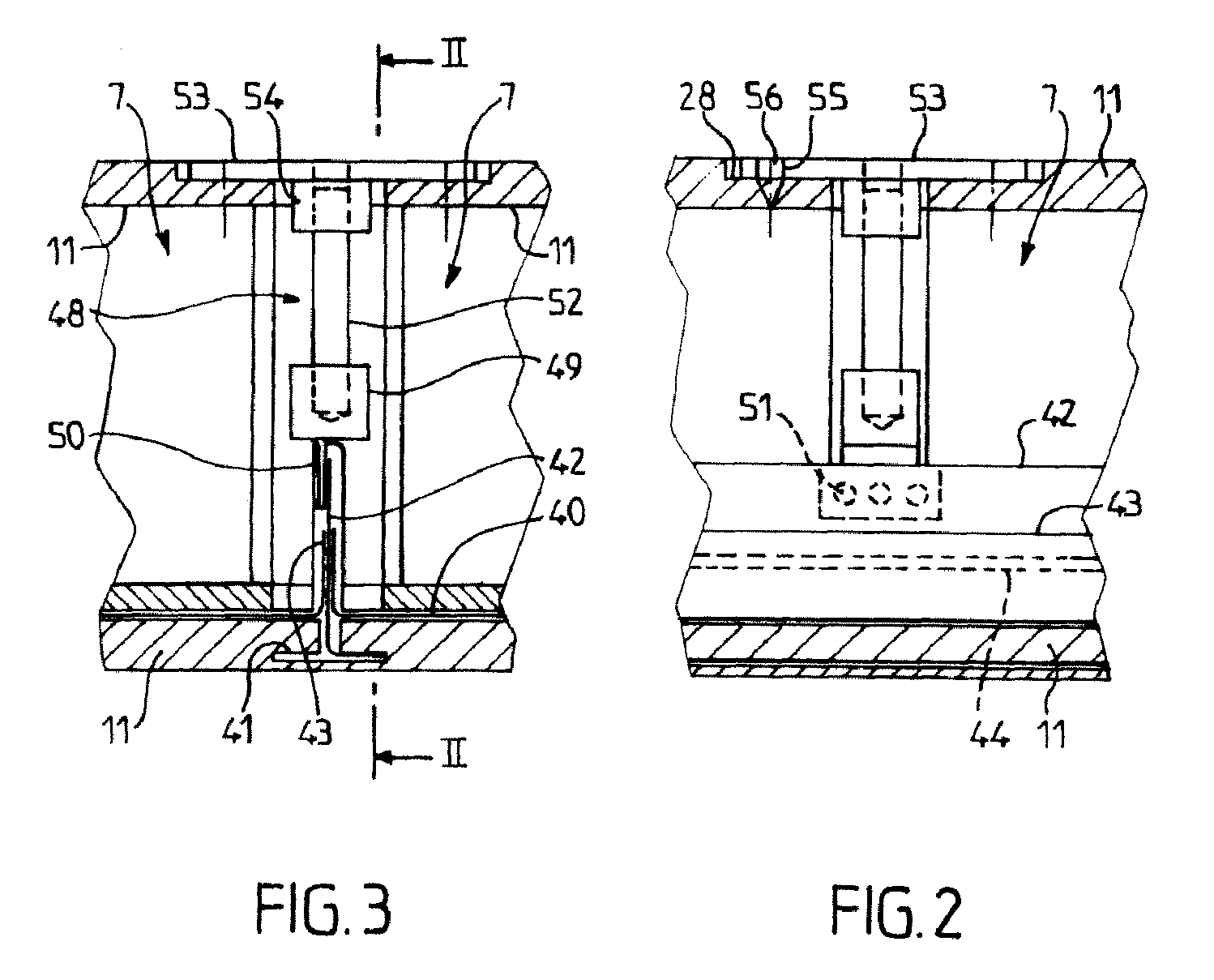

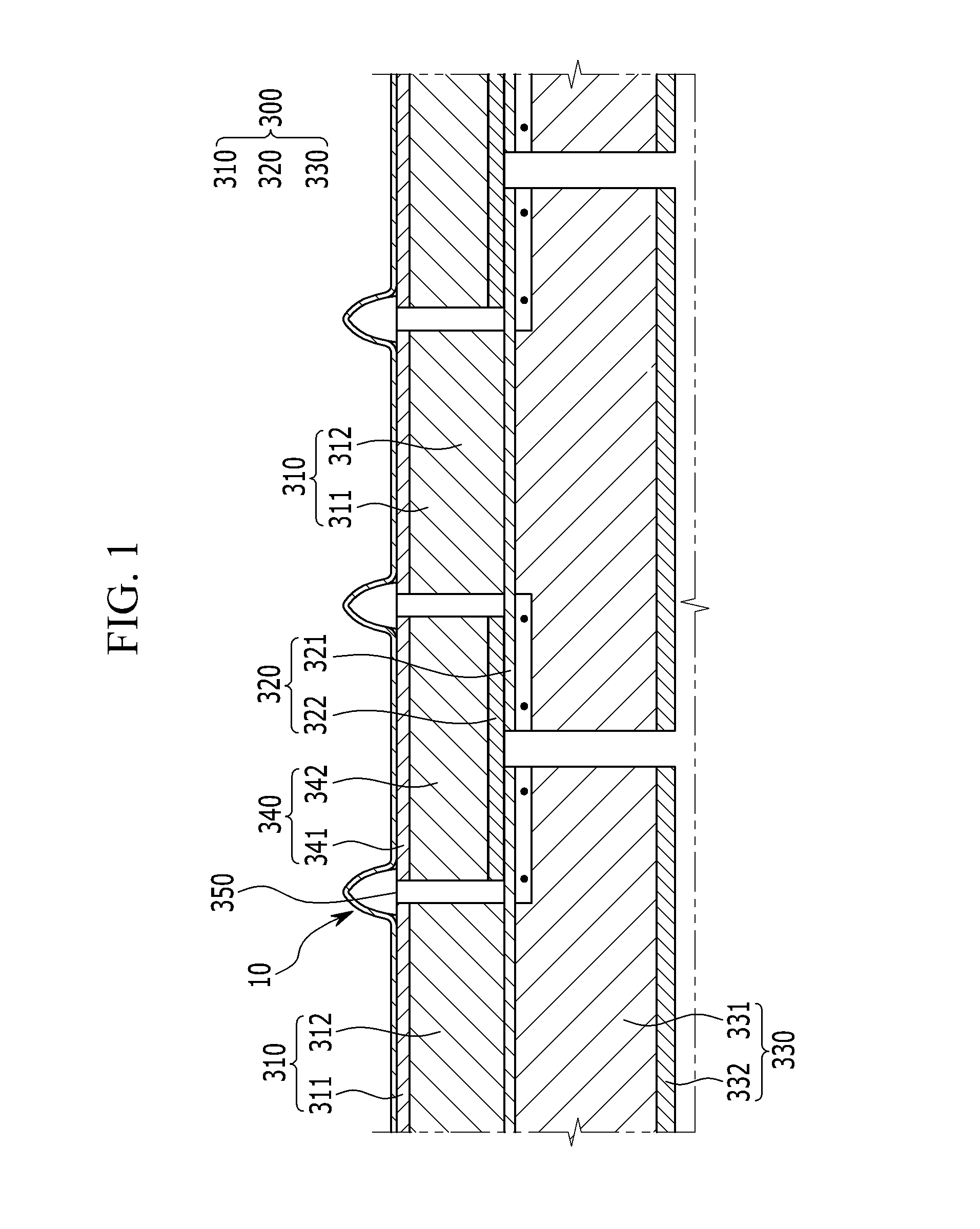

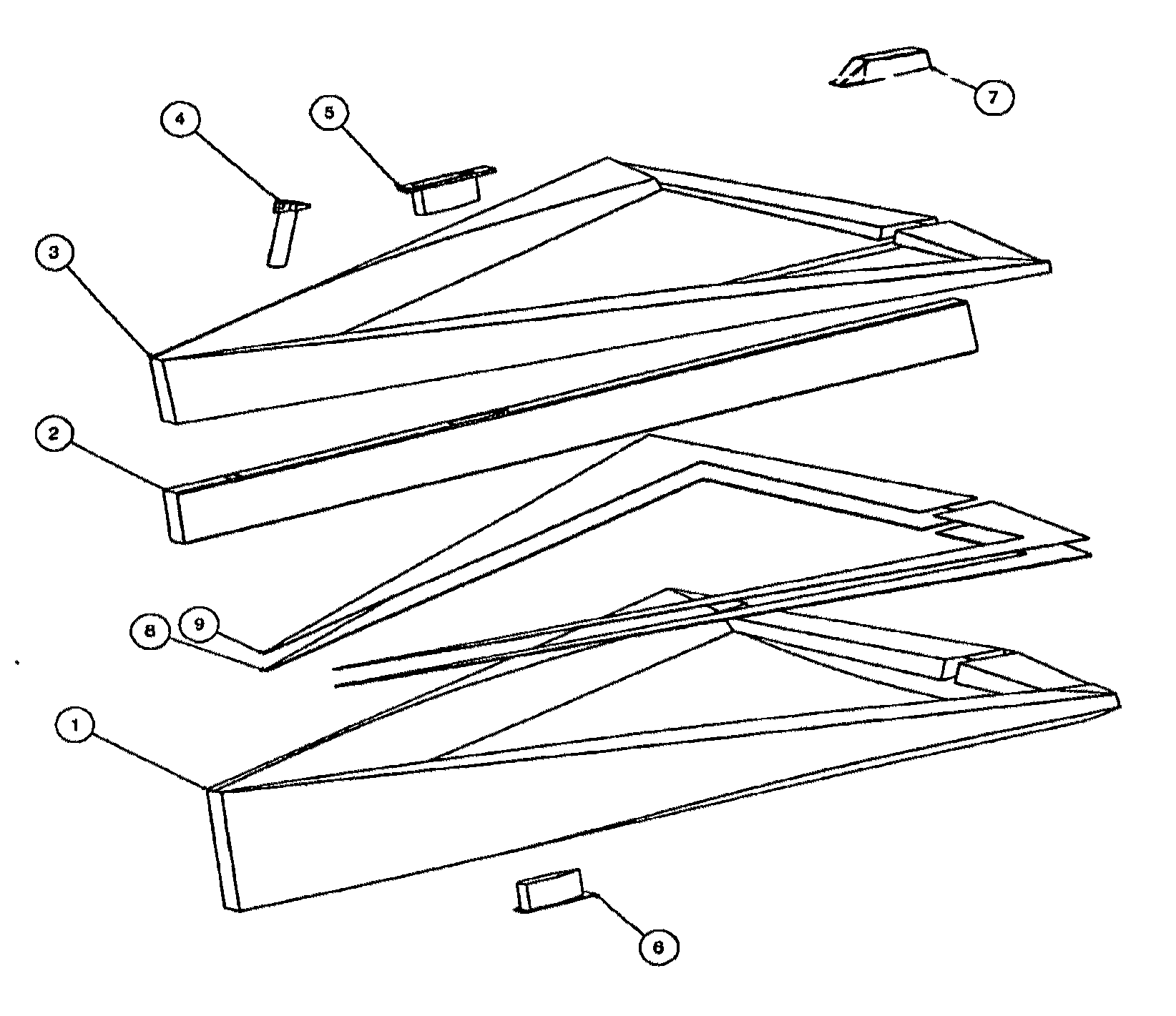

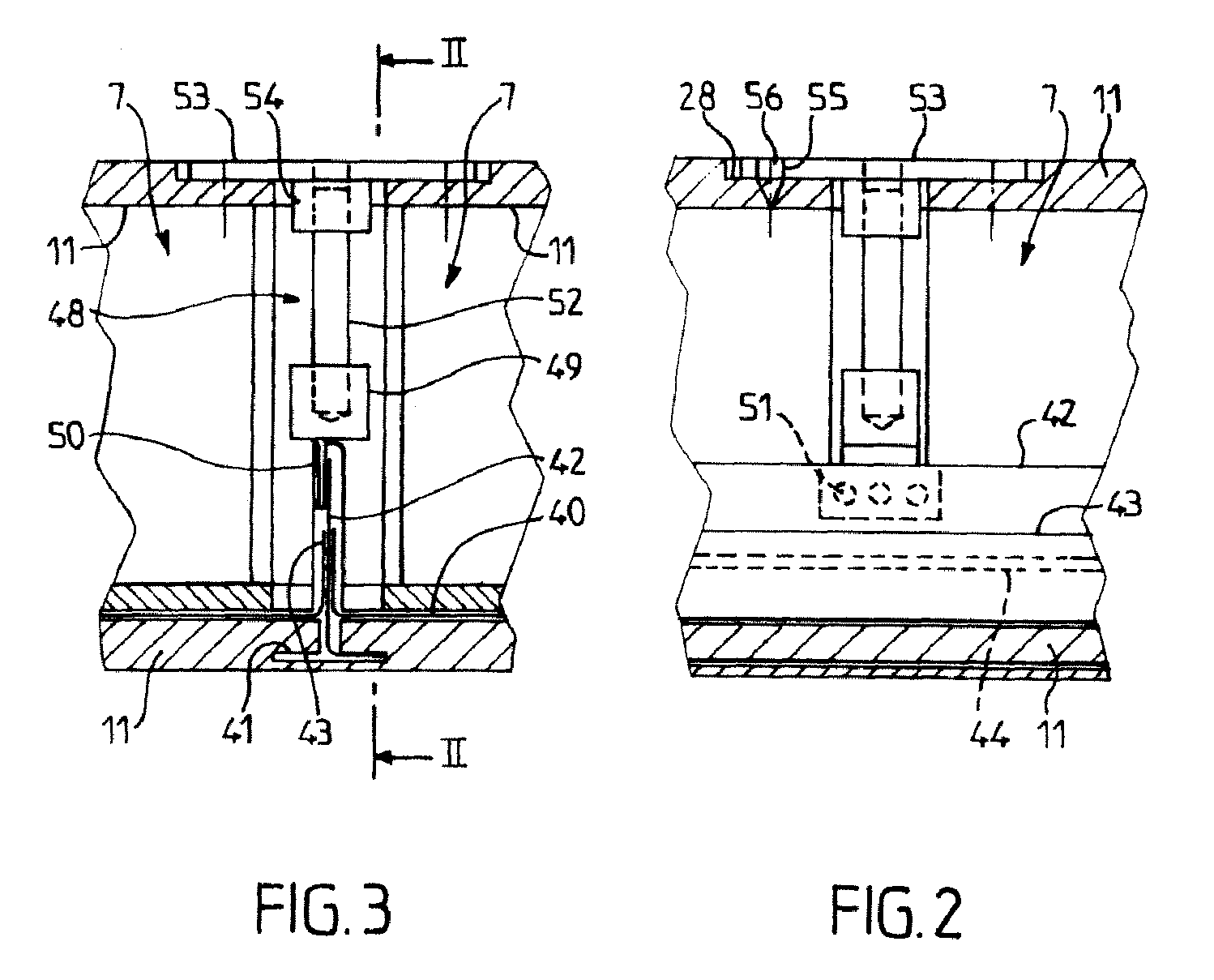

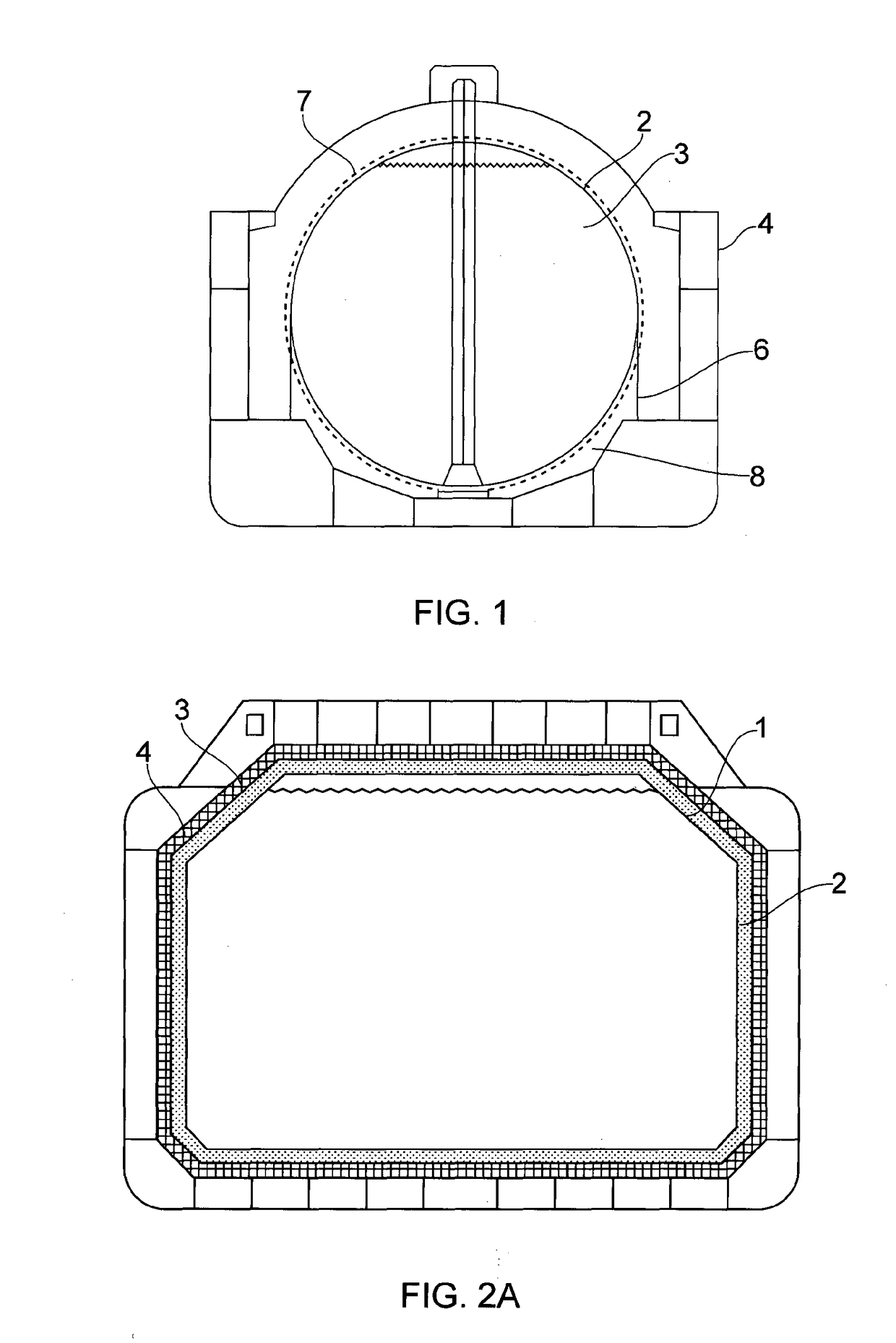

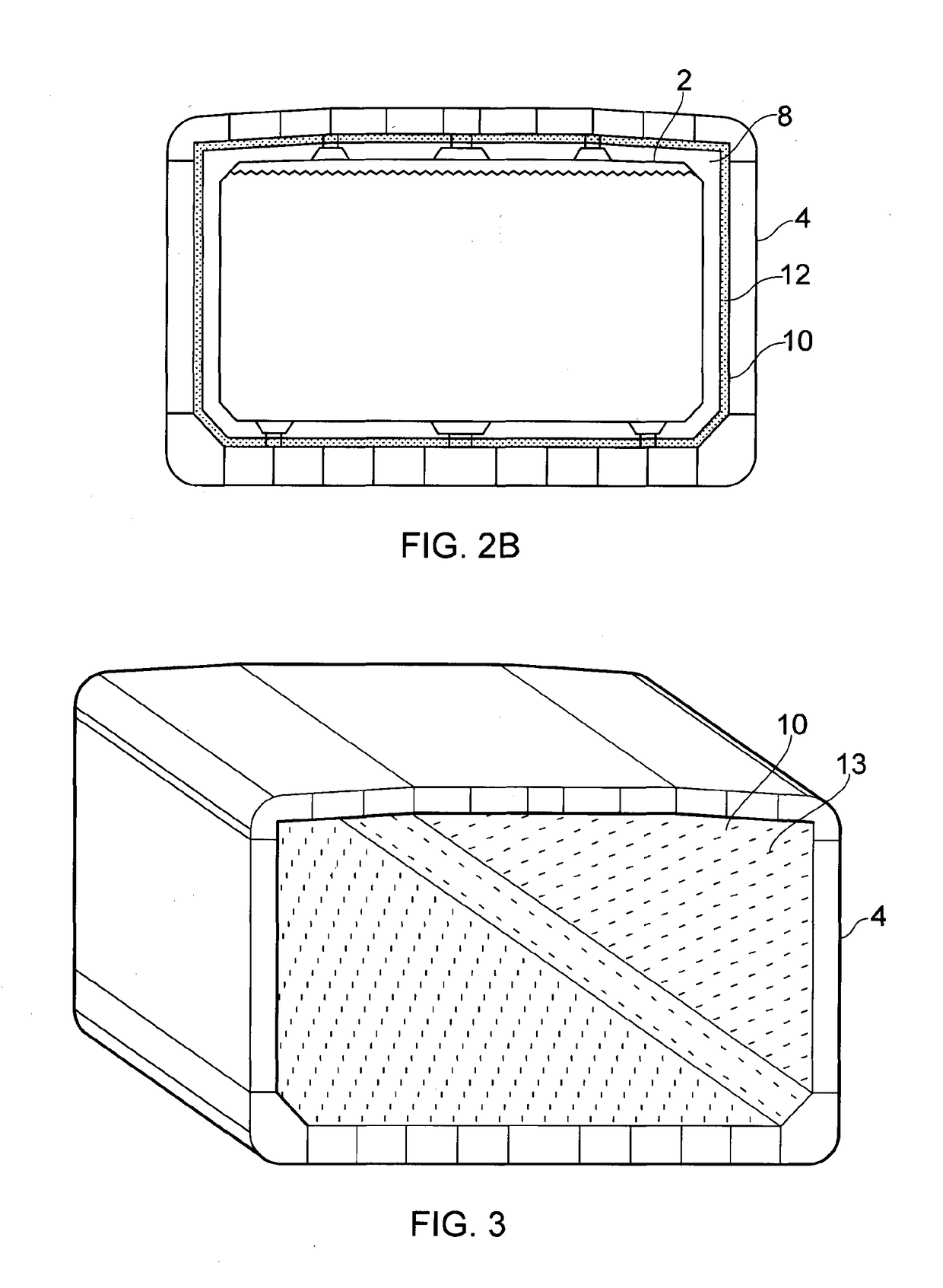

Sealed, thermally insulated tank with compression-resistant non-conducting-heat elements

A sealed and thermally insulated tank comprising at least one tank wall fixed to the hull (1) of a floating structure, said tank wall having main sealing compartments ( 8), the main heat-insulating space (6), the second sealing space (5) and the second heat-insulating space (2), at least one of the heat-insulating space is substantially composed of juxtaposed non-conductive components, each non-conductive The part comprises a heat-insulating liner (63) and a load-bearing part protruding through the thickness of said heat-insulating liner to bear the pressure, characterized in that the load-bearing part of the non-thermally conducting part comprises a post (65) parallel to said tank The cross-section in the plane of the wall is smaller than the dimensions of the thermally non-conductive part.

Owner:GAZTRANSPORT & TECHNIGAZ SA

Composite structural laminate plate construction

A composite structural laminate plate construction comprises two outer metal layers, a form between them and an elastomer layer bonded to the outer metal layers and filling the space between them other than that occupied by the form. The form may be foam and may be in partial contact with the metal layers.

Owner:INTELLIGENT ENG BAHAMAS

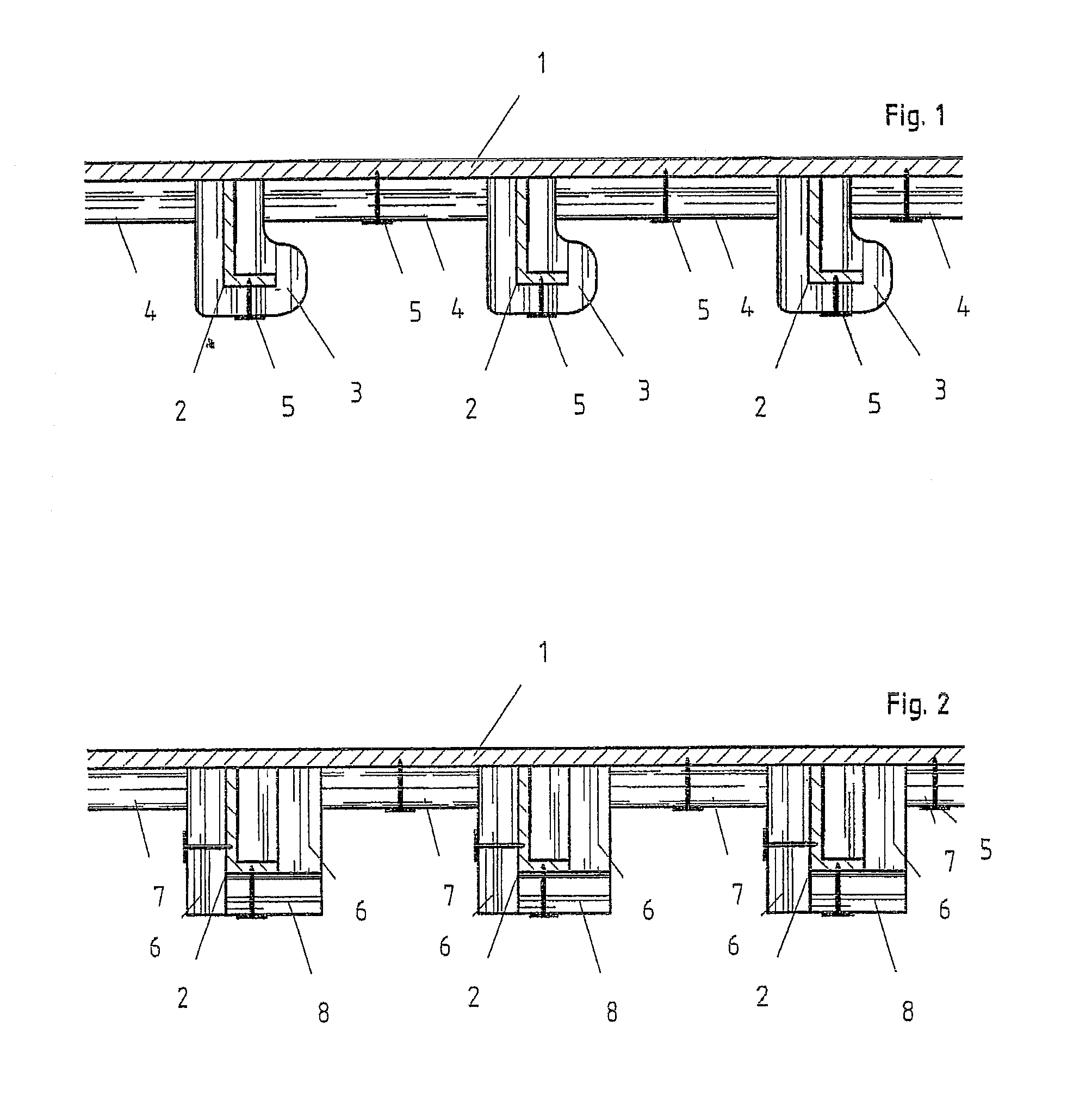

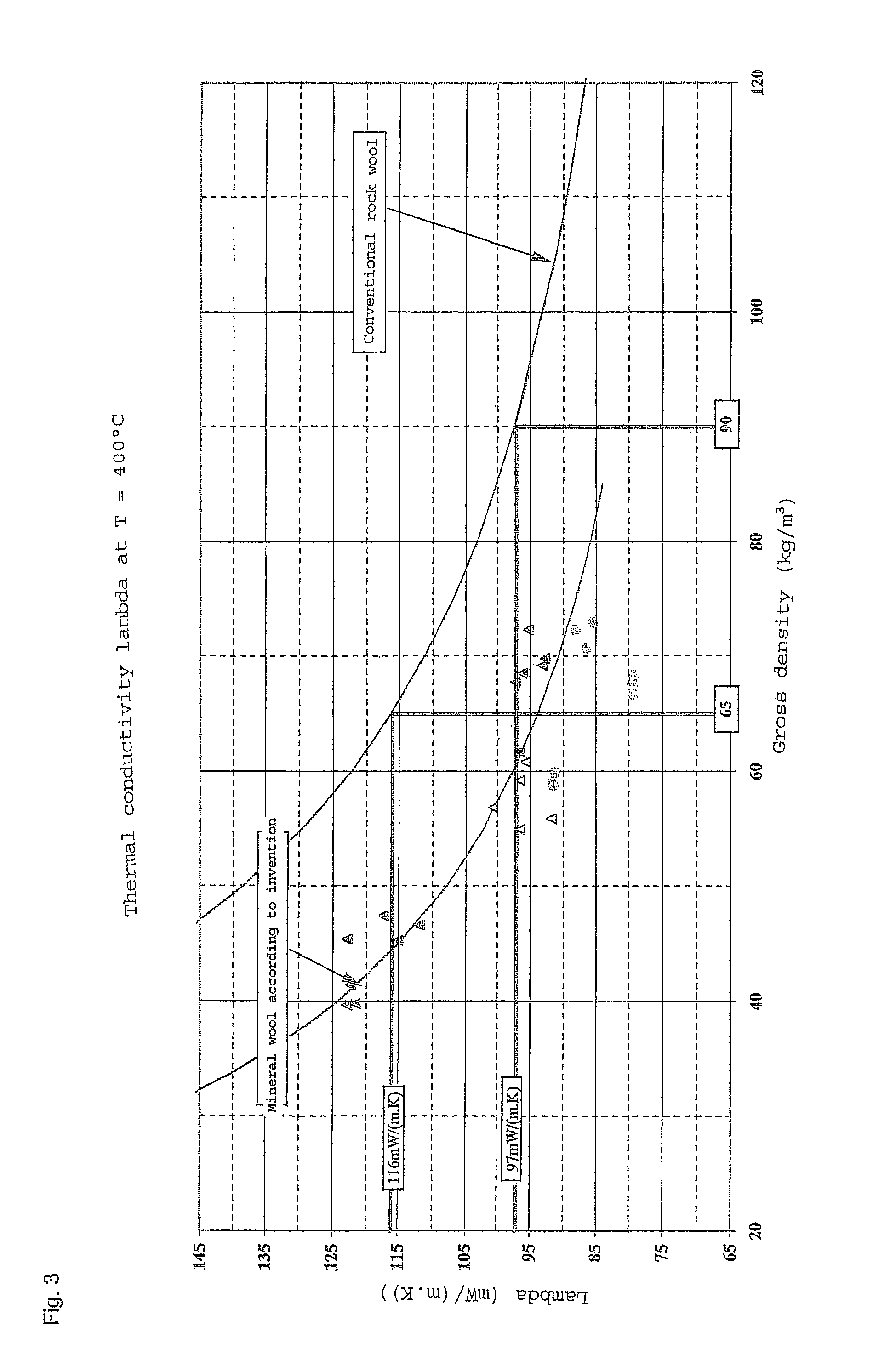

Insulating element from mineral fibers for shipbuilding

InactiveUS8026190B2Reduce weightNegatively affectedHull panellingsHeat proofingFiber diameterFiber structure

Insulating element from mineral fibers for shipbuilding with an insulating element in form of a plate or roll felt for shipbuilding the composition of the mineral fibers of the insulating element points an alkali / alkaline-earth mass ratio of the fiber structure of the insulating element is determined by an average geometrical fiber diameter of ≦4 μm and a surface weight of 0.8 through 4.3 kg / m2 and a binding agent portion above 0.5 until 4 weight %.

Owner:SAINT-GOBAIN GLASS FRANCE

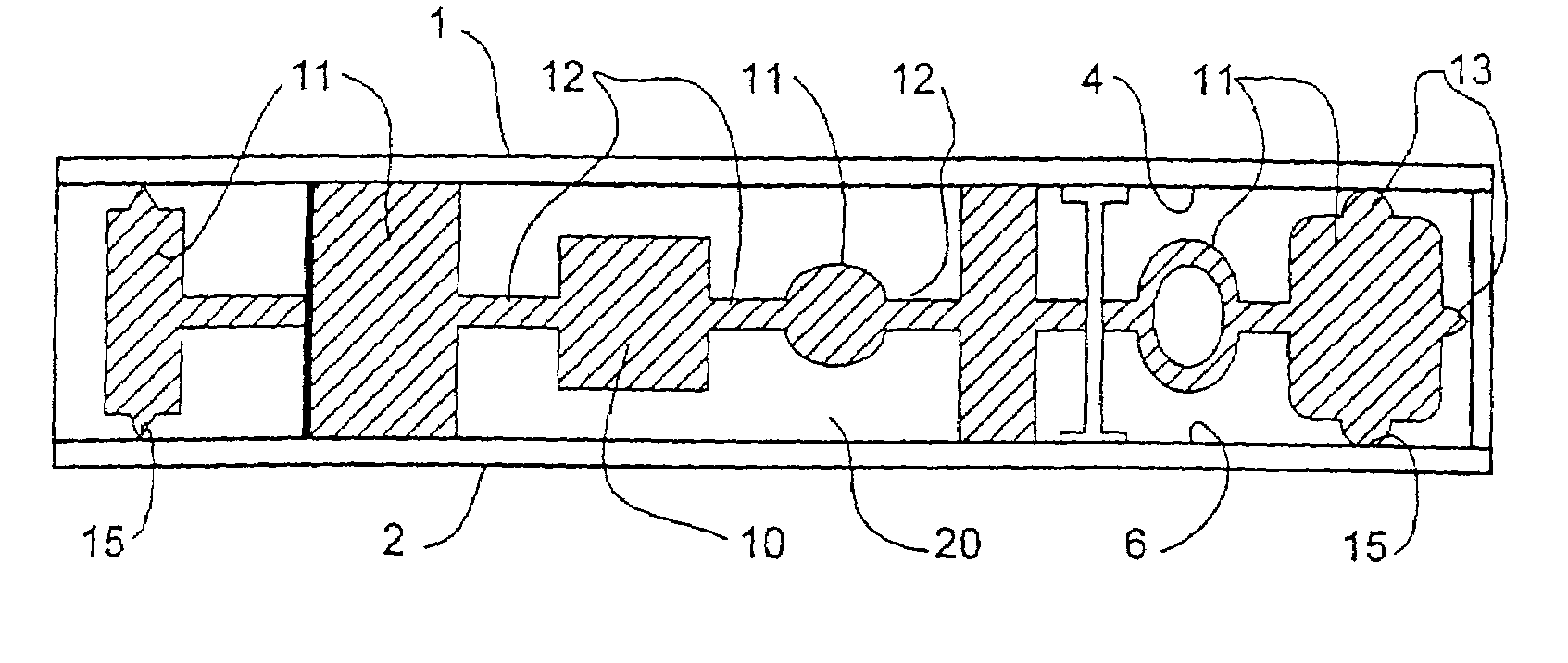

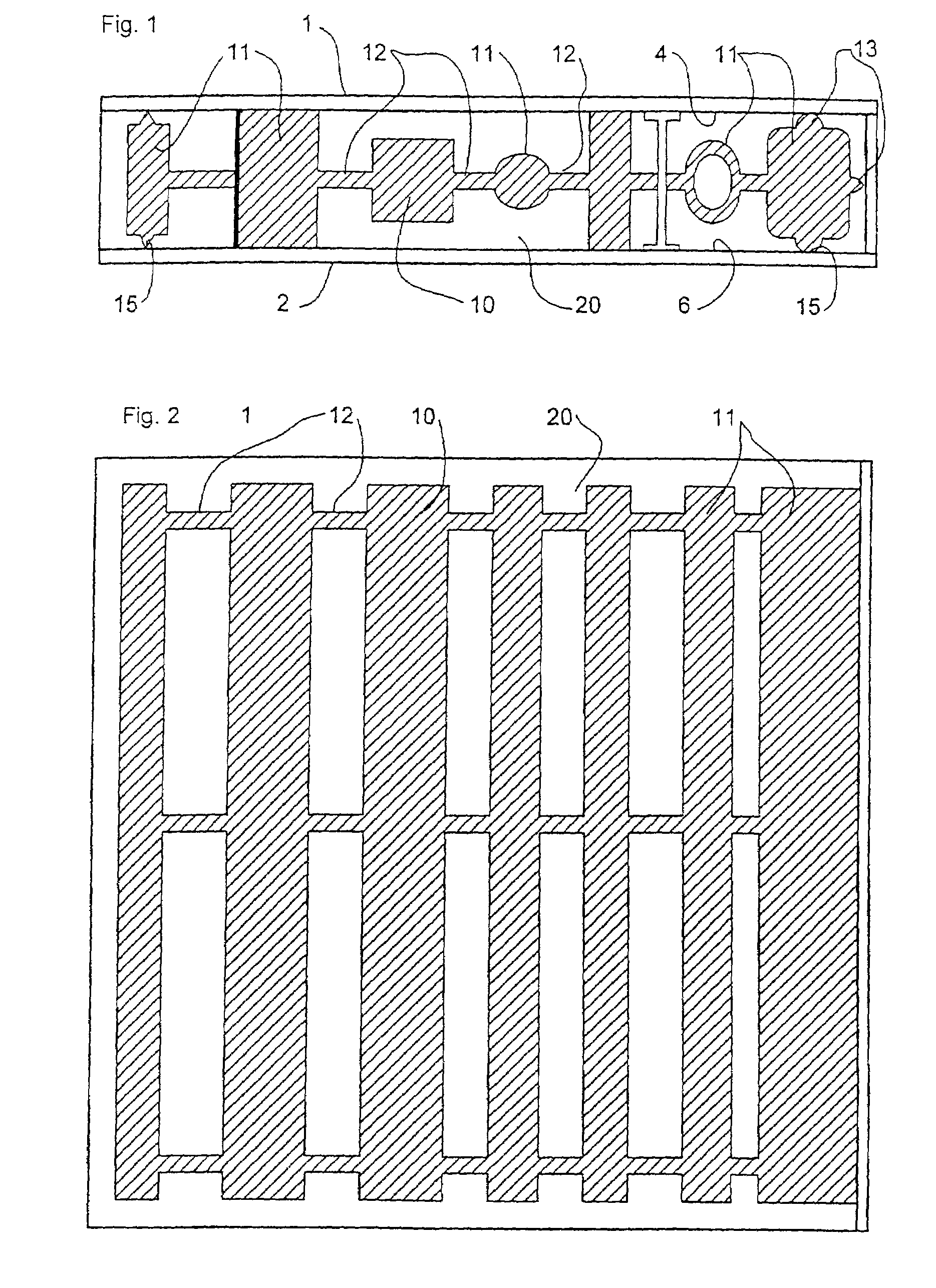

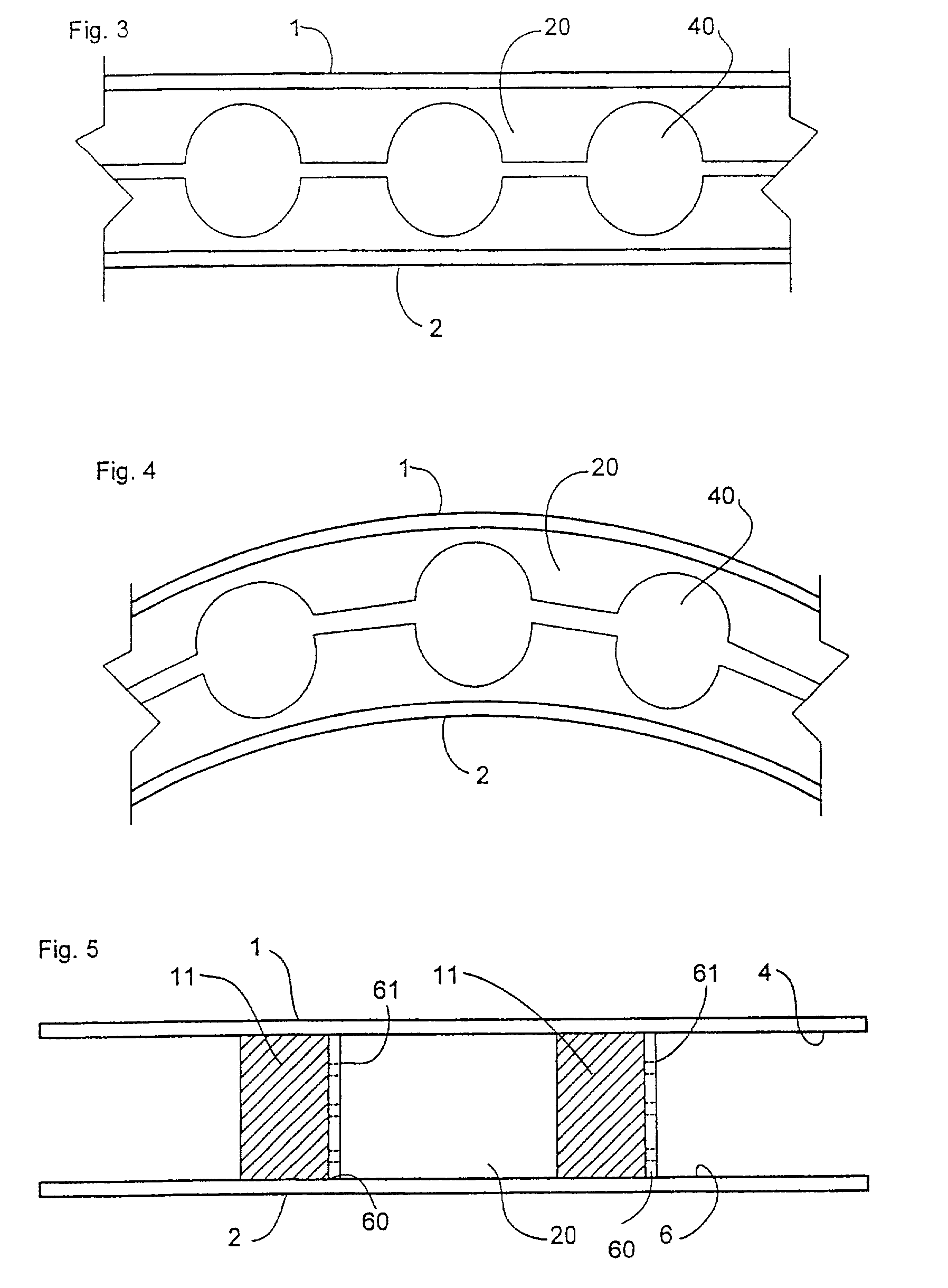

Sealed, thermally insulated tank with compression-resistant non-conducting elements

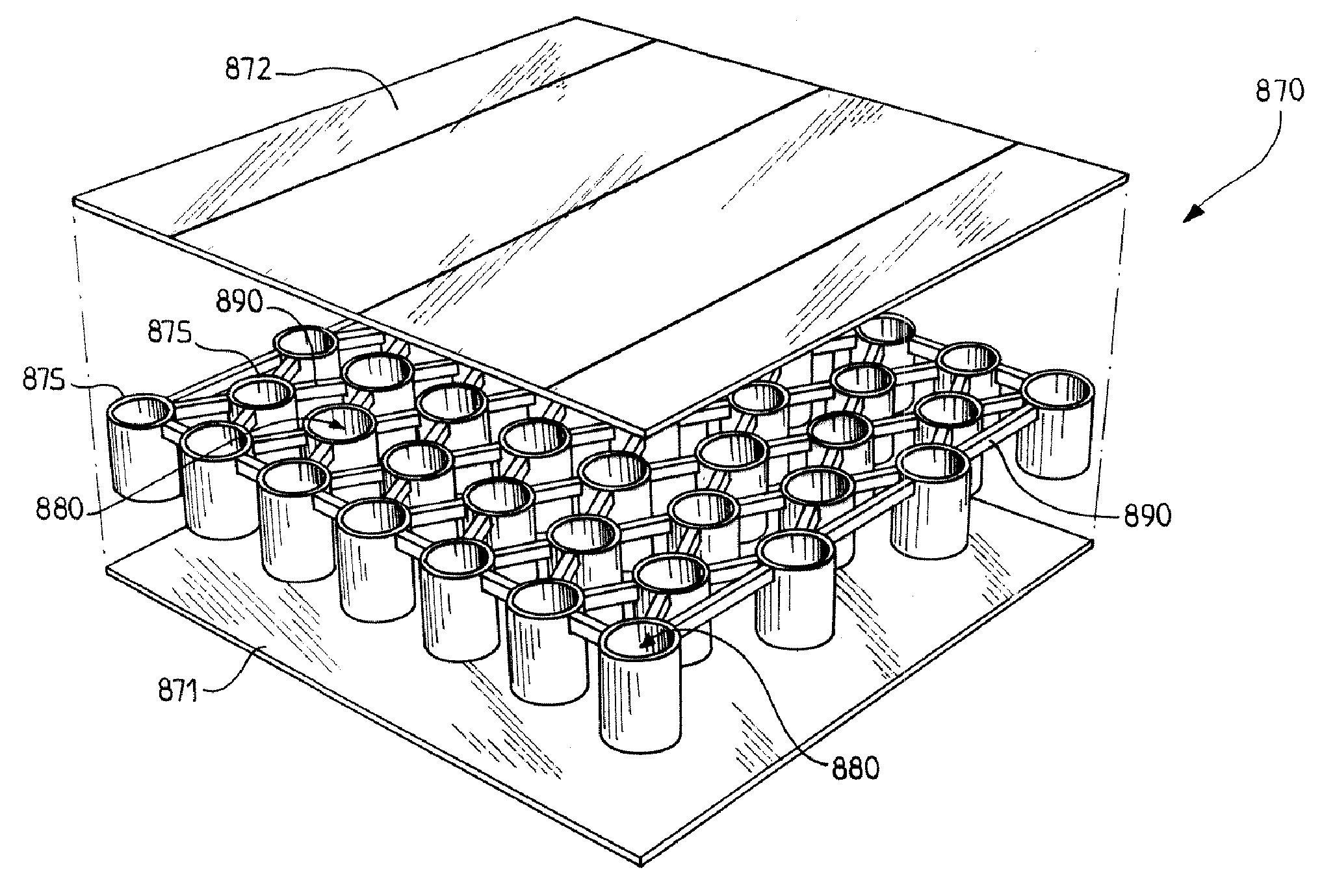

InactiveUS7900794B2Easy to adaptAvoid depressionDomestic cooling apparatusLighting and heating apparatusThermal insulationEngineering

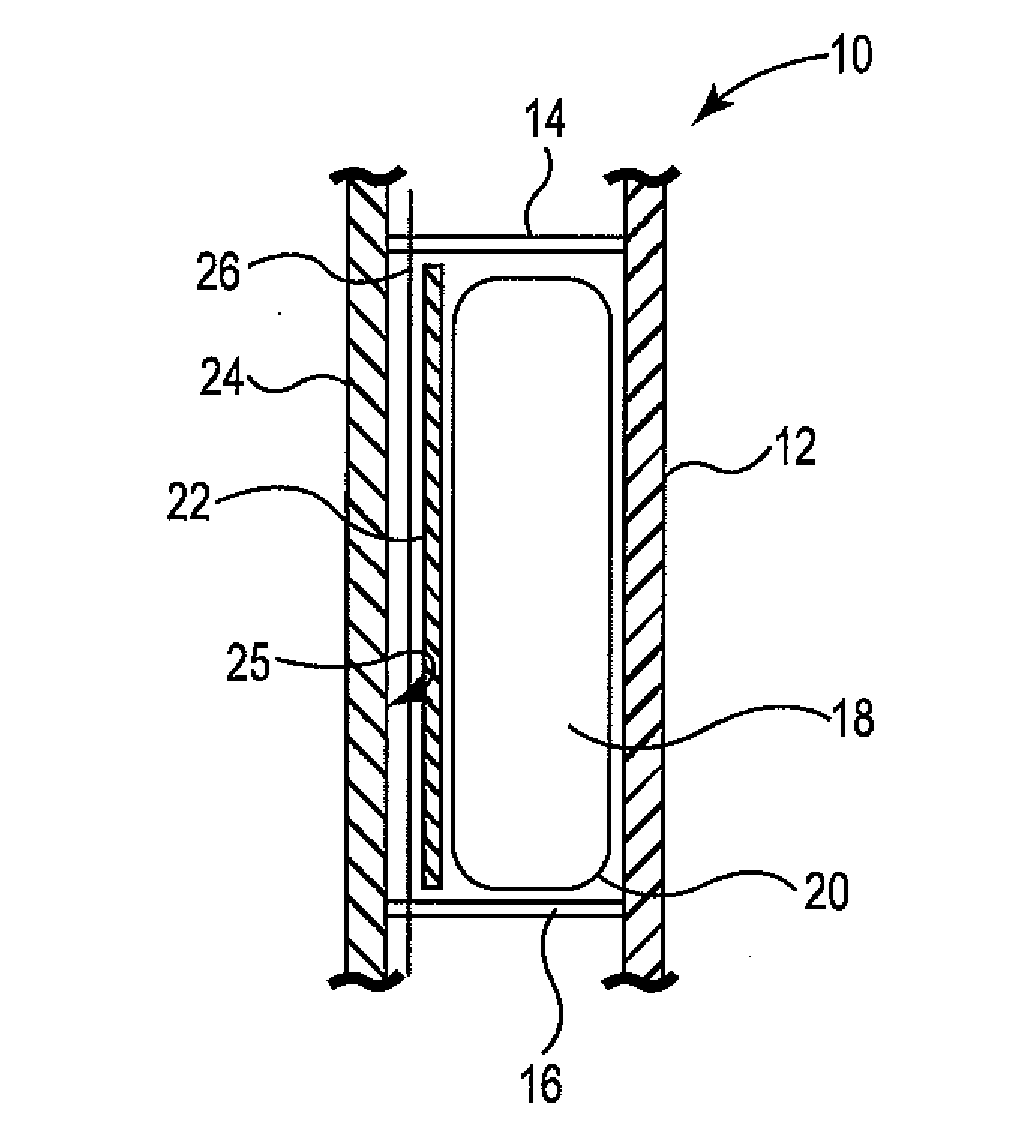

Sealed, thermally insulated tank has tank walls fixed to the load-bearing structure (1) of a floating structure, the tank walls having, in succession, in the direction of the thickness from the inside to the outside of the tank, a primary sealing barrier (8), a primary insulating barrier (6), a secondary sealing barrier (5) and a secondary insulating barrier (2), at least one of the insulating barriers includes juxtaposed non-conducting elements, each non-conducting element including a thermal insulation liner (63) and load-bearing elements that rise through the thickness of the thermal insulation liner in order to take up the compression forces, characterized in that the load-bearing elements of a non-conducting element include pillars (65) of small transverse section as compared to the dimensions of the non-conducting element in a plane parallel to the tank wall.

Owner:GAZTRANSPORT & TECHNIGAZ SA

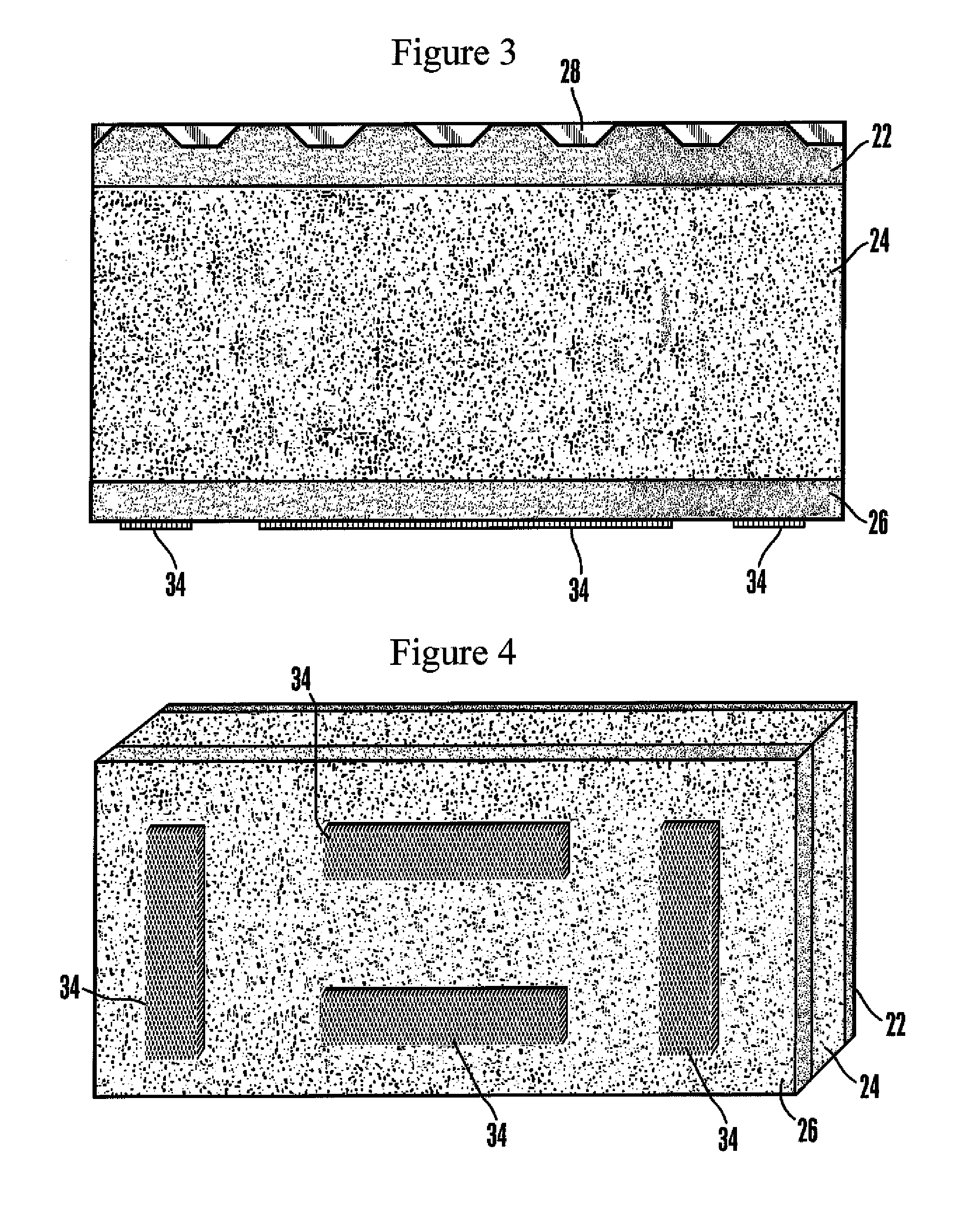

Multi-layer non-skid cushion pad for deck with easy removability

An assembly includes a top cushion layer made of first EVA material defining a flat top surface formed with a non-skid pattern and a bottom surface opposite to the top surface. Also included is a resilient middle cushion layer made of second EVA material softer than the first EVA material. The middle cushion layer defines a top surface supporting the bottom surface of the top cushion layer and a bottom surface opposite to the top surface of the middle cushion layer. The assembly includes a bottom cushion layer made of EVA material and defining a top surface supporting the bottom surface of the middle cushion layer and a bottom surface opposite to the top surface of the bottom cushion layer. The bottom surface of the bottom cushion layer includes at least one fastener configured to removably engage and disengage a complementarily configured fastener substrate on a deck by hand.

Owner:SOFT DECK

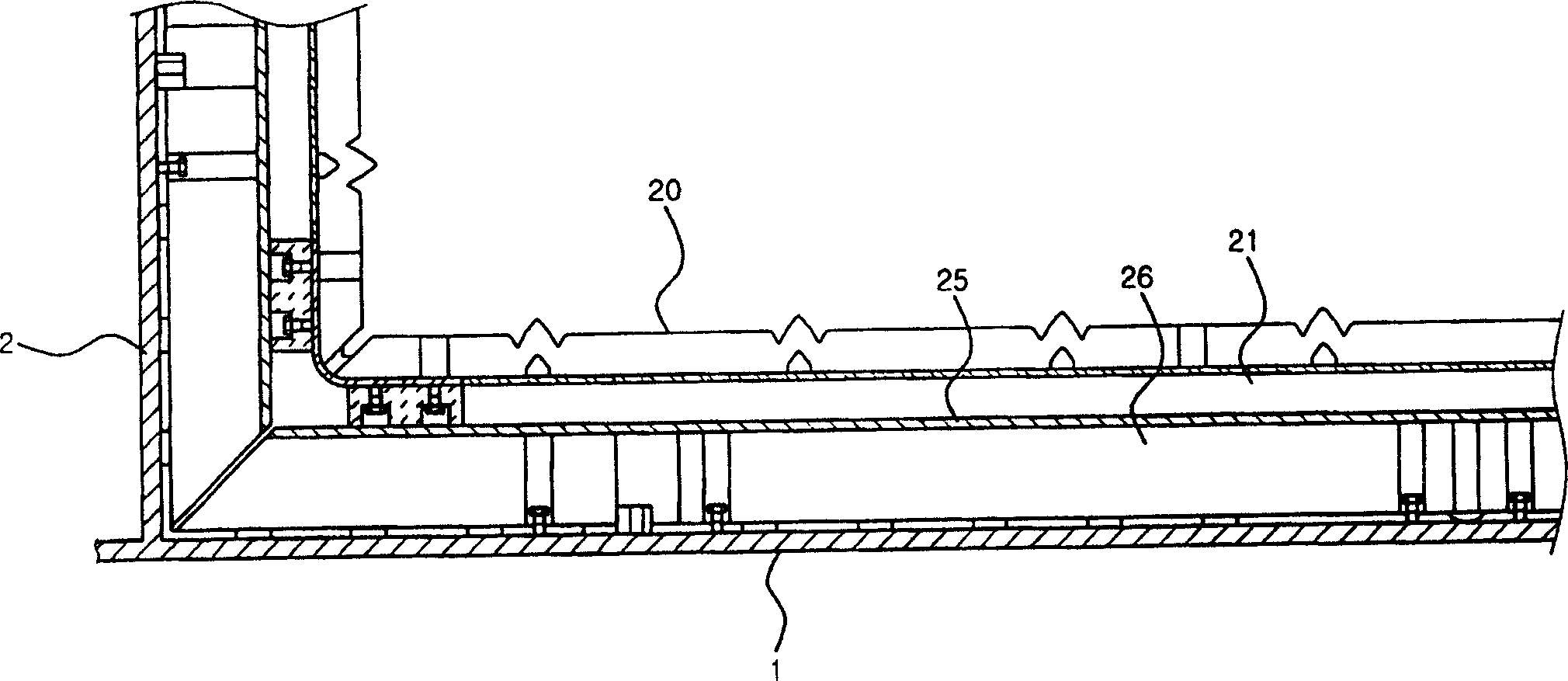

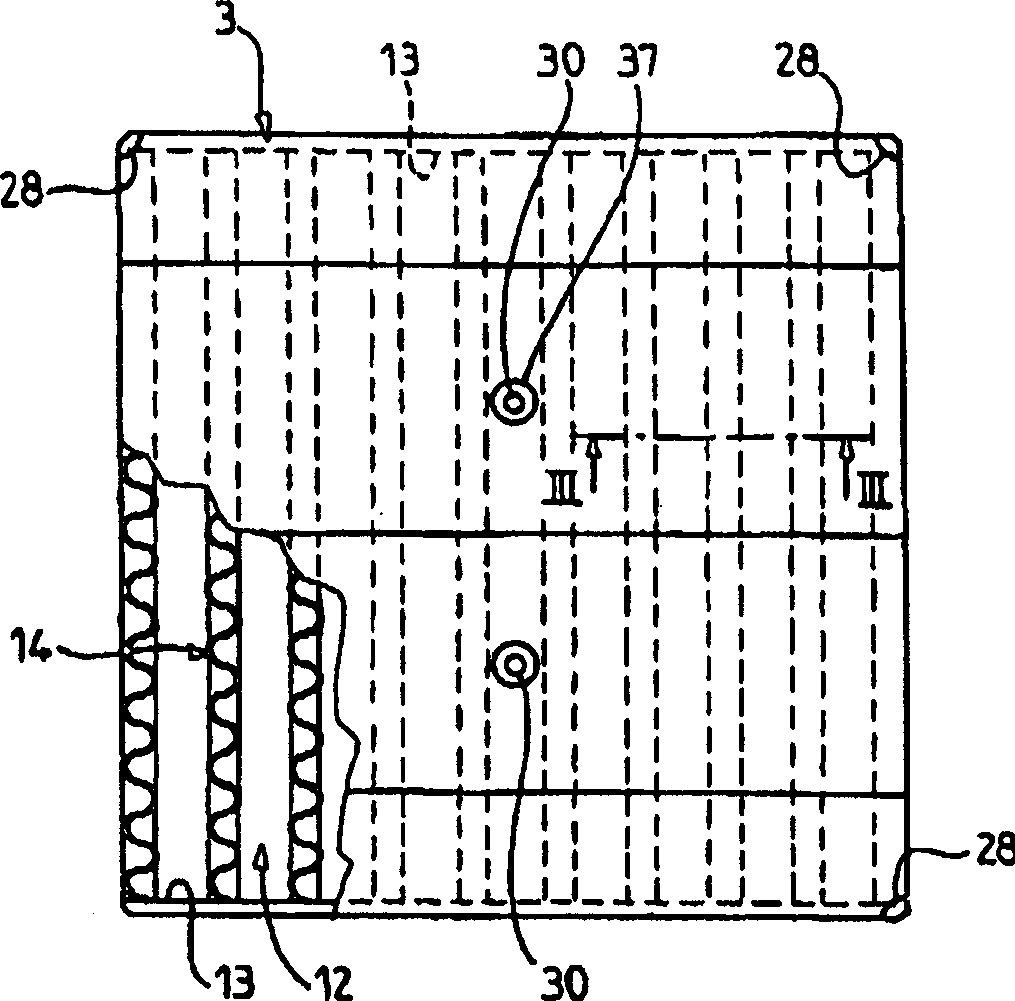

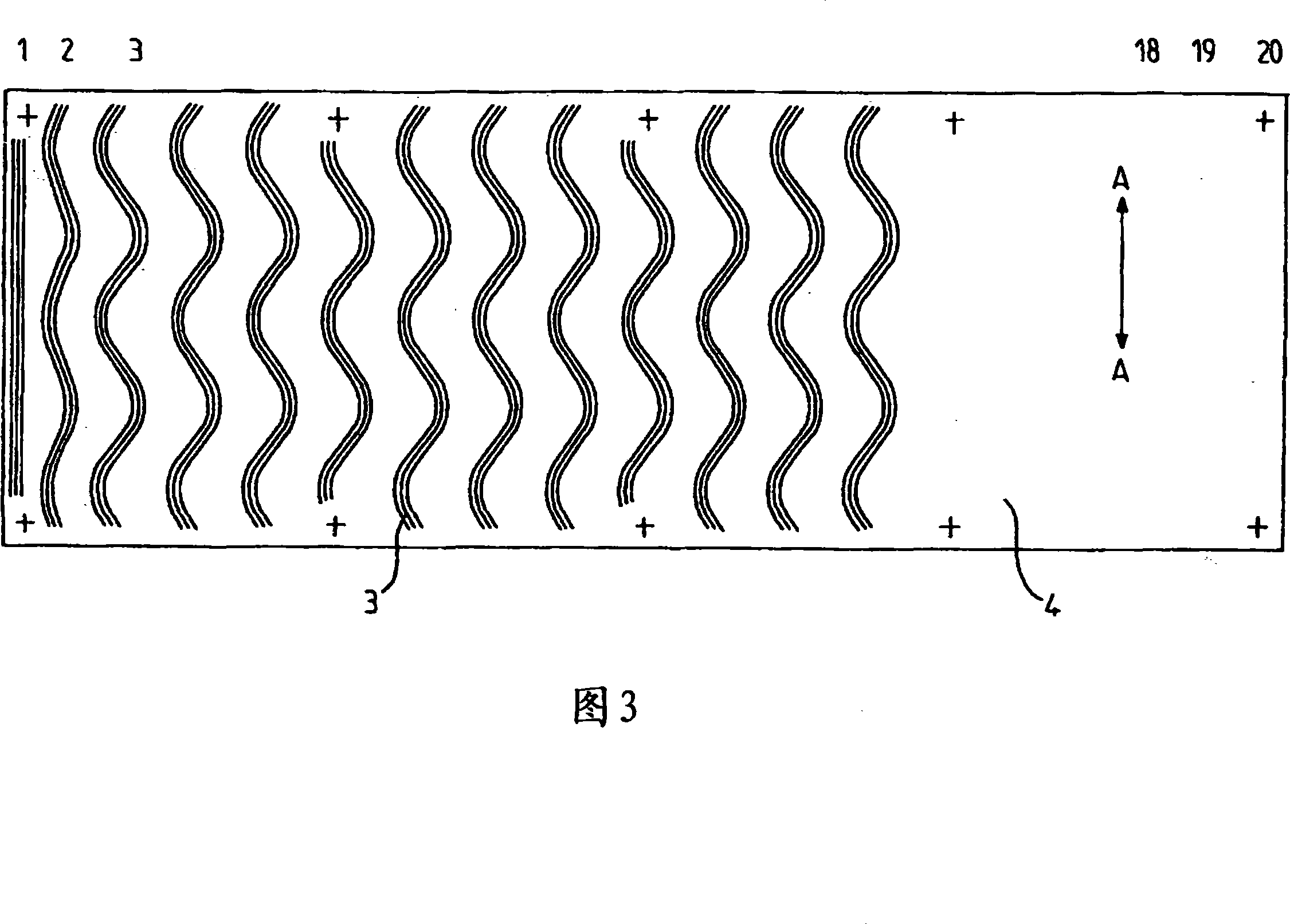

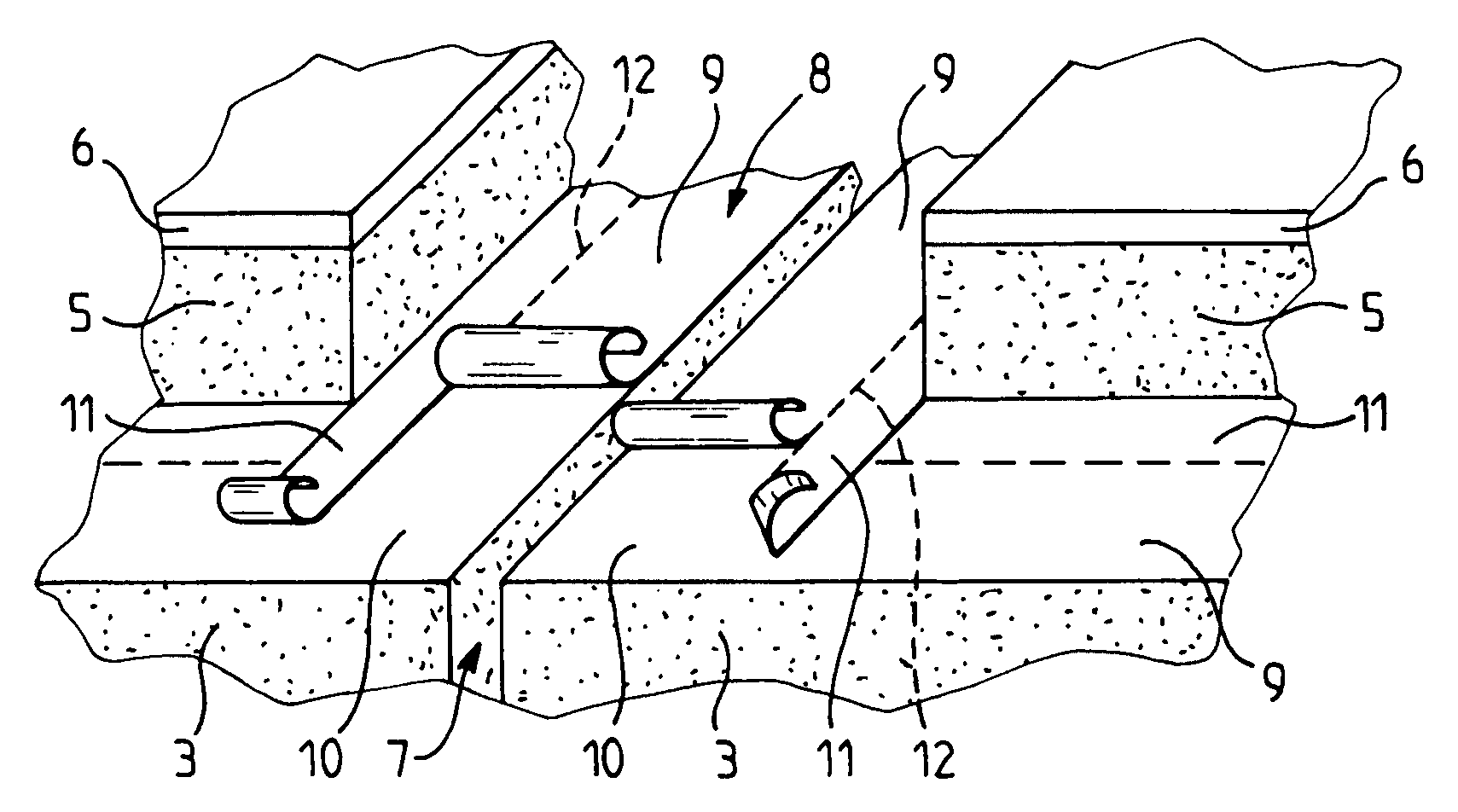

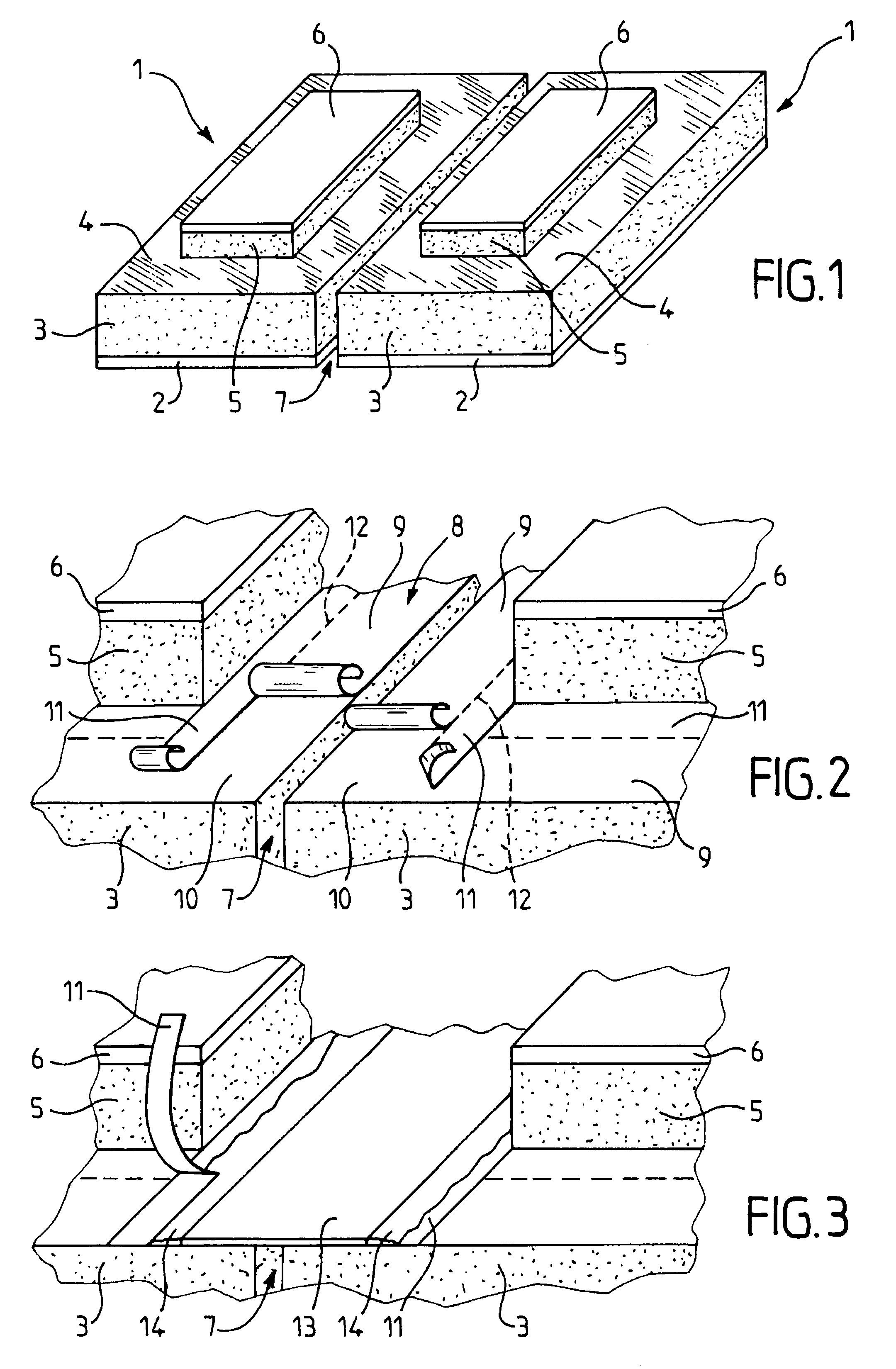

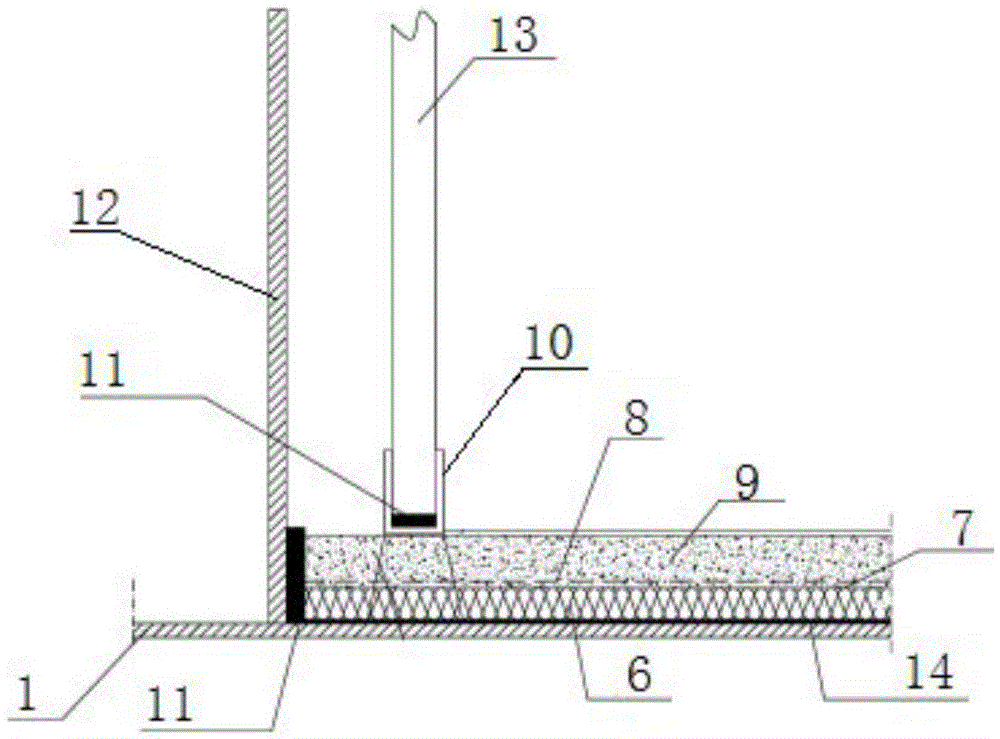

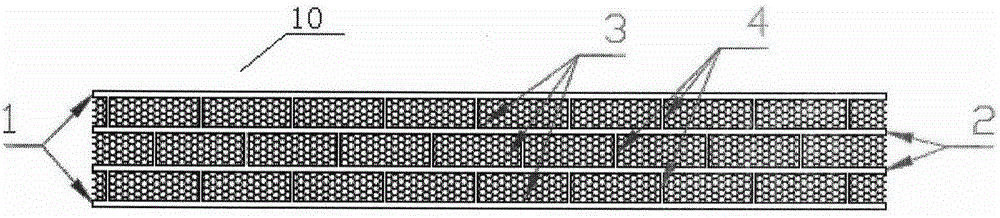

Method for adhesively fixing liquid gas adiabatic apparatus by undulance adhesive strip

The method involves arranging adhesive beads (3) on a lower side of a panel of an insulating block (4) along sinuous lines parallel to each other, and arranging the insulating block on an inner body (1) of a ship. The insulating block is pressed against the inner body until polymerization of an adhesive, and the adhesive beads are made of epoxy resin. The adhesive beads are applied on the lower side of the panel of the insulating block along the parallel sinuous lines, where a distance between the successive adhesive beads is equal or greater than 100 millimeter.

Owner:GAZTRANSPORT & TECHNIGAZ SA

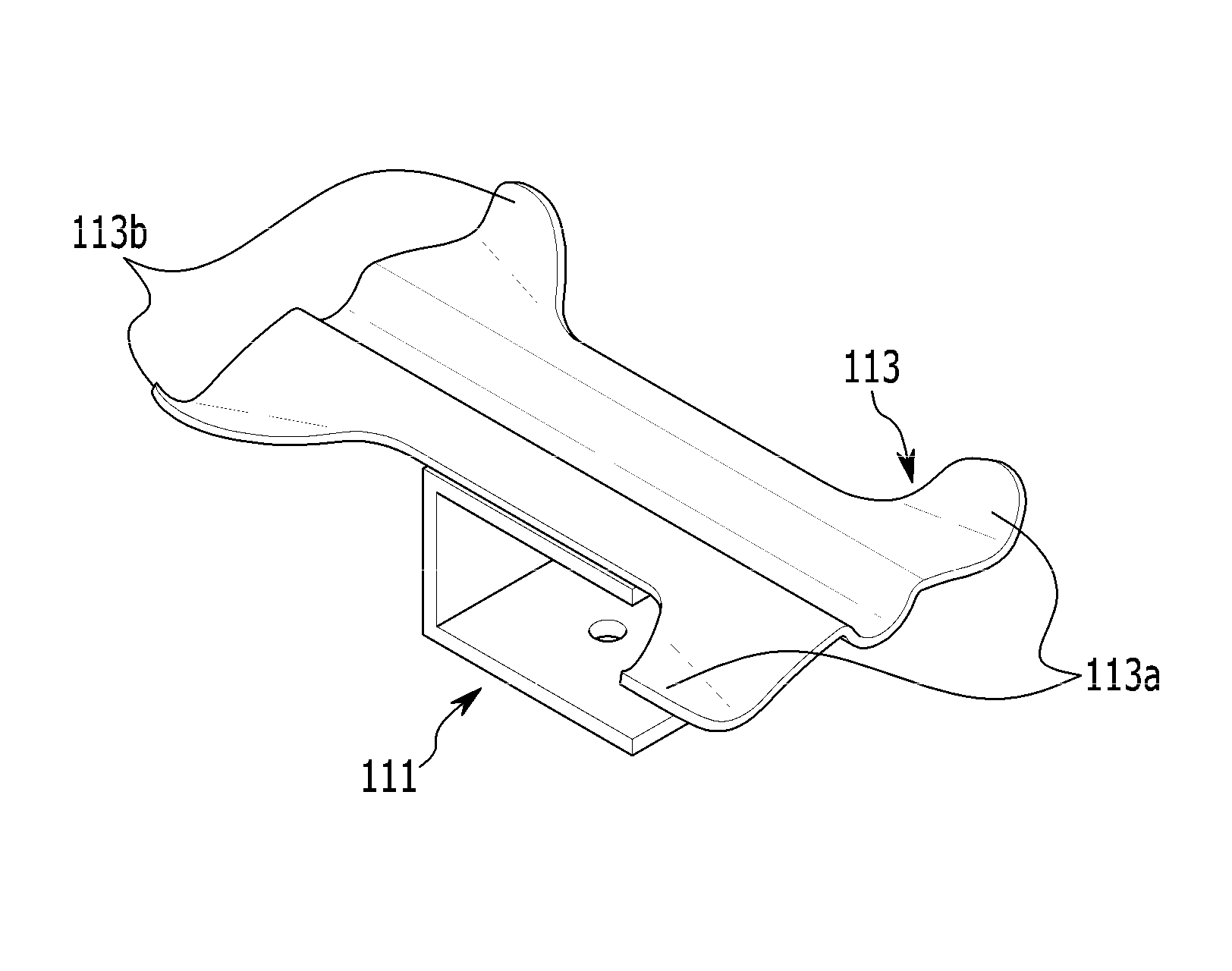

Reinforcing member fixing device for primary barrier of liquefied natural gas storage tank

A fixing device of a first barrier-reinforcing member is disclosed. An exemplary embodiment provides a fixing device of a first barrier-reinforcing member for supporting first and second corrugated portions that are formed in a first barrier to cross each other in a liquefied natural gas storage tank including a heat-insulating board and a first barrier positioned thereon and forming an inner wall, including: a fixing bracket including a coupling portion fixedly inserted in insertion grooves formed under lateral sides of a crossing portion where the first and second corrugated portions cross, and a body coupled to one side of the coupling portion; and a first fastening member for fastening an impact-absorbing plate between the heat-insulating board and the first barrier with the other side of the body. The reinforcing member is fixed to inner sides of the first and second corrugated portions by the impact-absorbing plate.

Owner:SAMSUNG HEAVY IND CO LTD

Prefabricated panel with protective film

InactiveUS7934353B2Improve securityImprove bonding qualityVessel wallsContainer filling methodsTectorial membraneEngineering

Owner:GAZTRANSPORT & TECHNIGAZ SA

Method for lowering noise of ship compartments

InactiveCN105644710AReduce noiseAvoiding a large amount of work for rectification of excessive noiseHull panellingsVibration attenuationEngineering

The invention relates to a method for lowering noise of ship compartments. The method for lowering the noise of the ship compartments is characterized in that in a ship design stage, the following steps are adopted, specifically, (1) an accommodation and a flue are separately arranged, and the compartments with high noise requirement are arranged by being far away from a noise source; (2) sound absorption materials are laid in the compartments, and the sound absorption treatment is performed by arranging sound absorption structures and coating the interior of the compartments with environment-friendly noise-reduction materials; (3) the sound insulation treatment is conducted, specifically, lining plates and independent wall plates with large noise-reduction values are adopted, ceilings are adopted so that vertical transmission of the noise can be cut off, and sound insulation windows and sound insulation doors are selected; and (4) the step of a vibration attenuation and vibration isolation measure is performed, specifically, decks adopt vibration attenuation and vibration isolation structures, the ceilings adopt high-damping materials with elastic connection and high internal friction force on steel plate. According to the method for lowering the noise of the ship compartments, as the noise-reduction treatment is already performed on the compartments in the design stage, a large quantity of workload of rectification when the noise exceeds standards after ship construction is completed is avoided, and the requirements of IMO A.468(XII) and MSC.337(91) are met.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

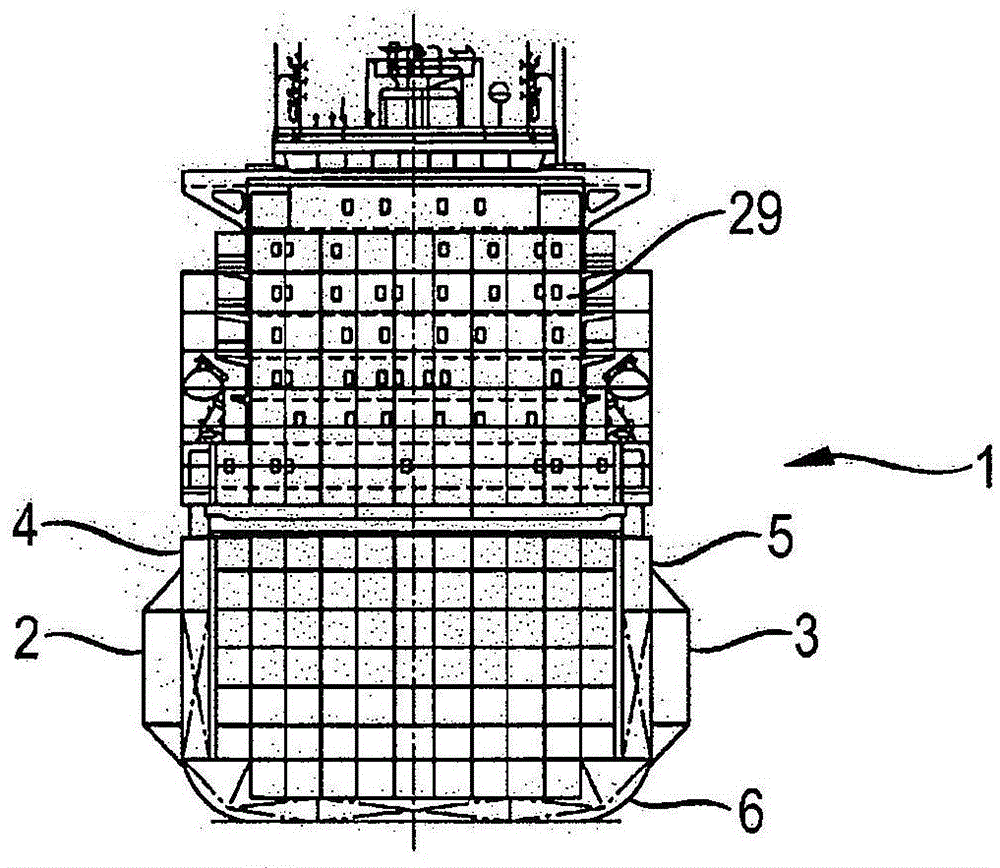

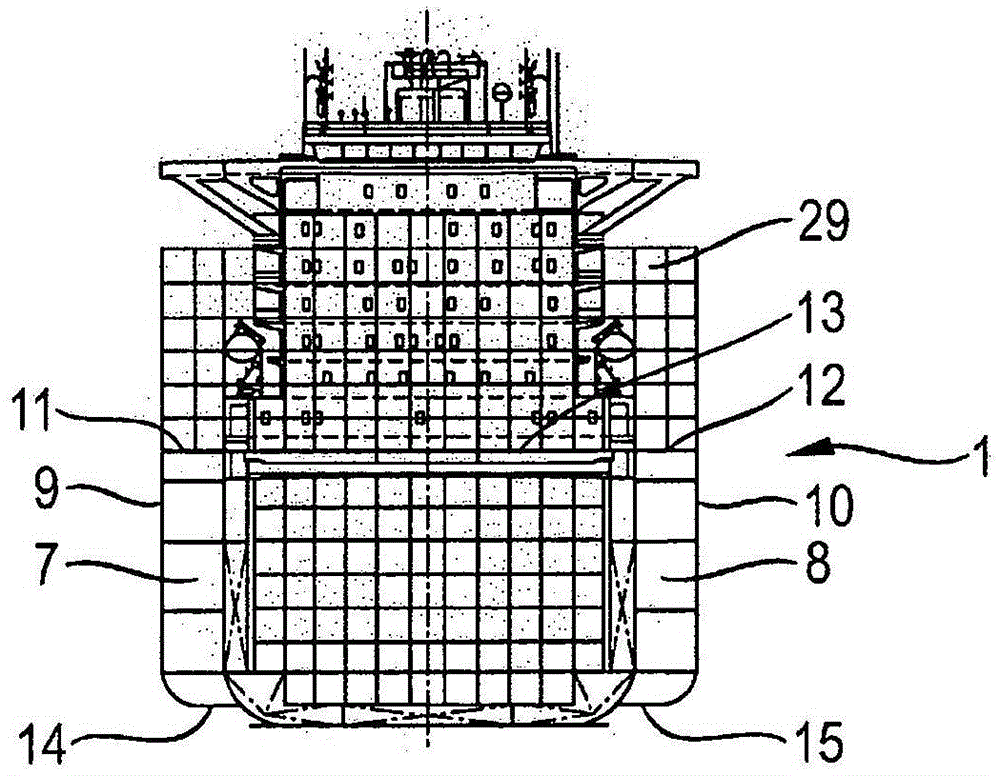

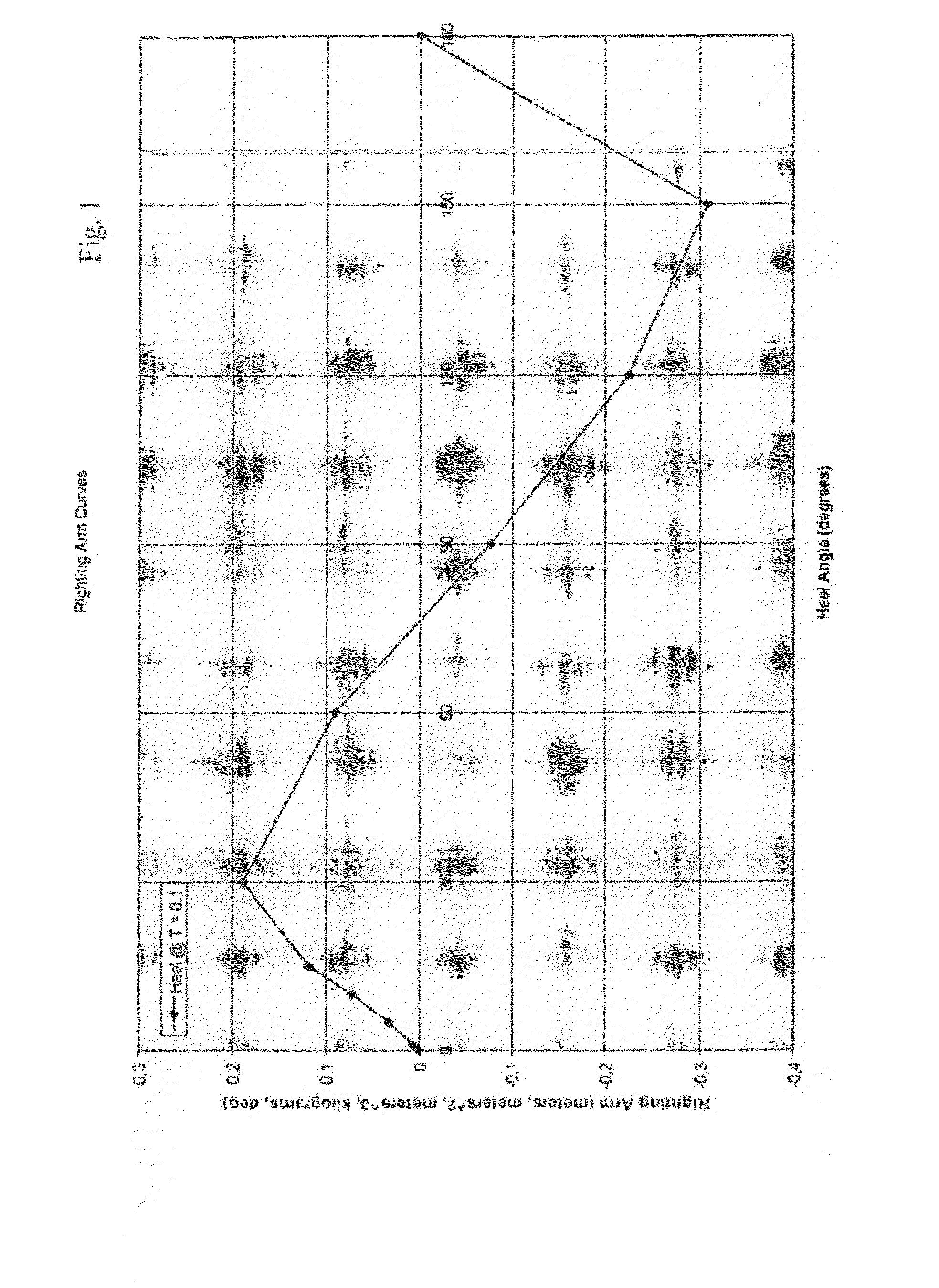

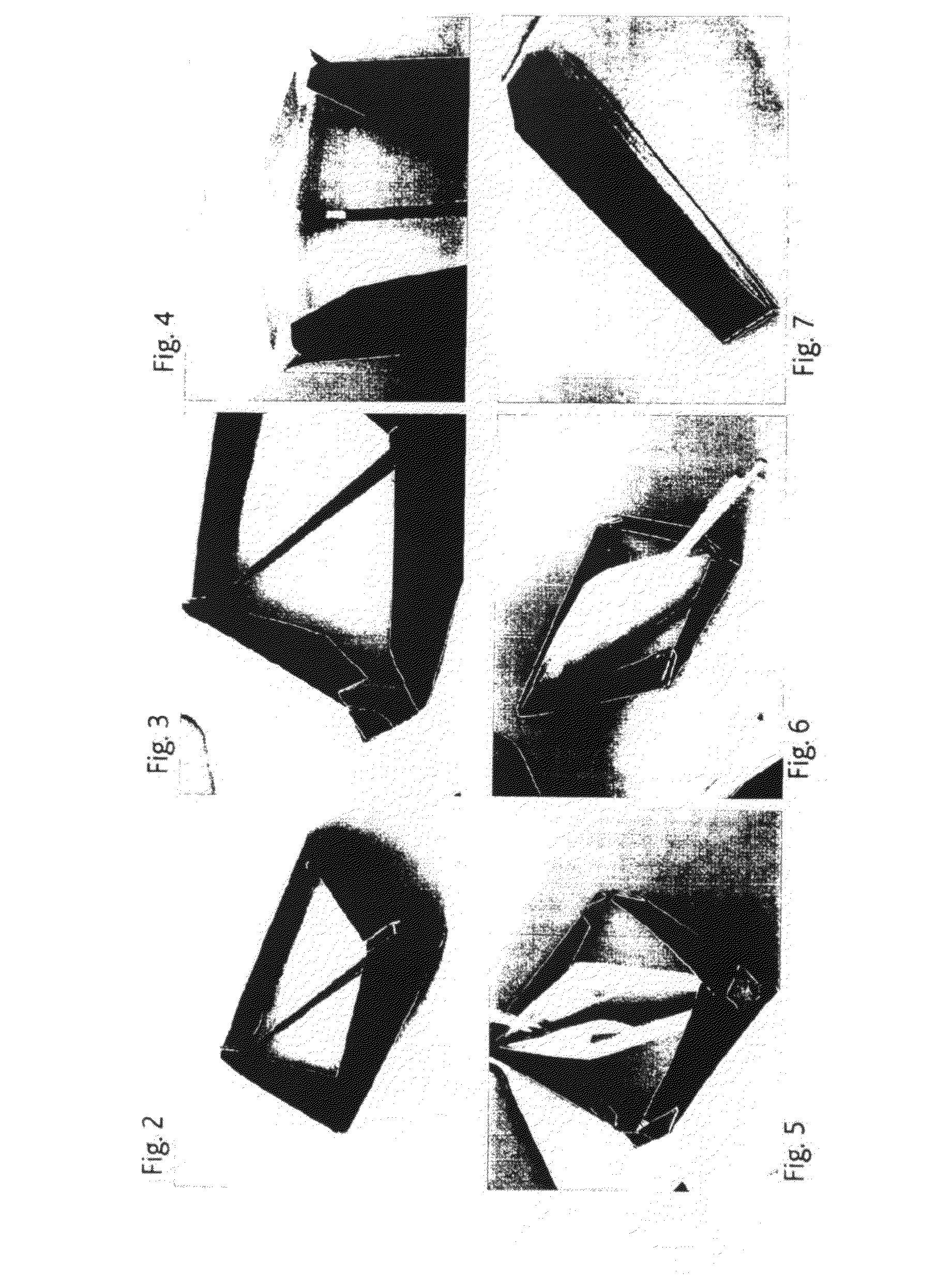

Method for enlarging a ship and enlarged ship

InactiveCN105658513AImprove lateral stabilityReduced steady ballast loadHull interior subdivisionHull decksStern

The invention relates to a method for enlarging a ship, in which method a container ship, conbulker, multi-purpose ship, LASH ship, or other ship having a high degree of deck opening is widened, wherein a front ship segment (23) comprising the bow (22) and a rear ship segment (25) comprising the stern (24) are separated from a middle ship segment (16) comprising at least part of the cargo hold, the middle ship segment (16) is divided into at least two middle ship parts (30, 31) in a longitudinal direction, the middle ship parts (30, 31) are moved apart in a transverse direction of the ship, an additional middle part (34) is installed between the middle ship parts (30, 31) that have been moved apart and thereby a widened middle ship segment is formed, a widened front ship segment (23) is attached to the front of the widened middle ship segment (16), and the rear ship segment (25) is attached directly to the rear of the widened middle ship segment (16).

Owner:NSB NIEDERELBE SCHIFFAHRTSGMBH

Collapsible boat formed from releasably connected laminar panels

InactiveUS20120073491A1Stable structureNon-magnetic metal hullsHull panellingsStructural engineeringEngineering

Owner:SIGNORINI MATTEO

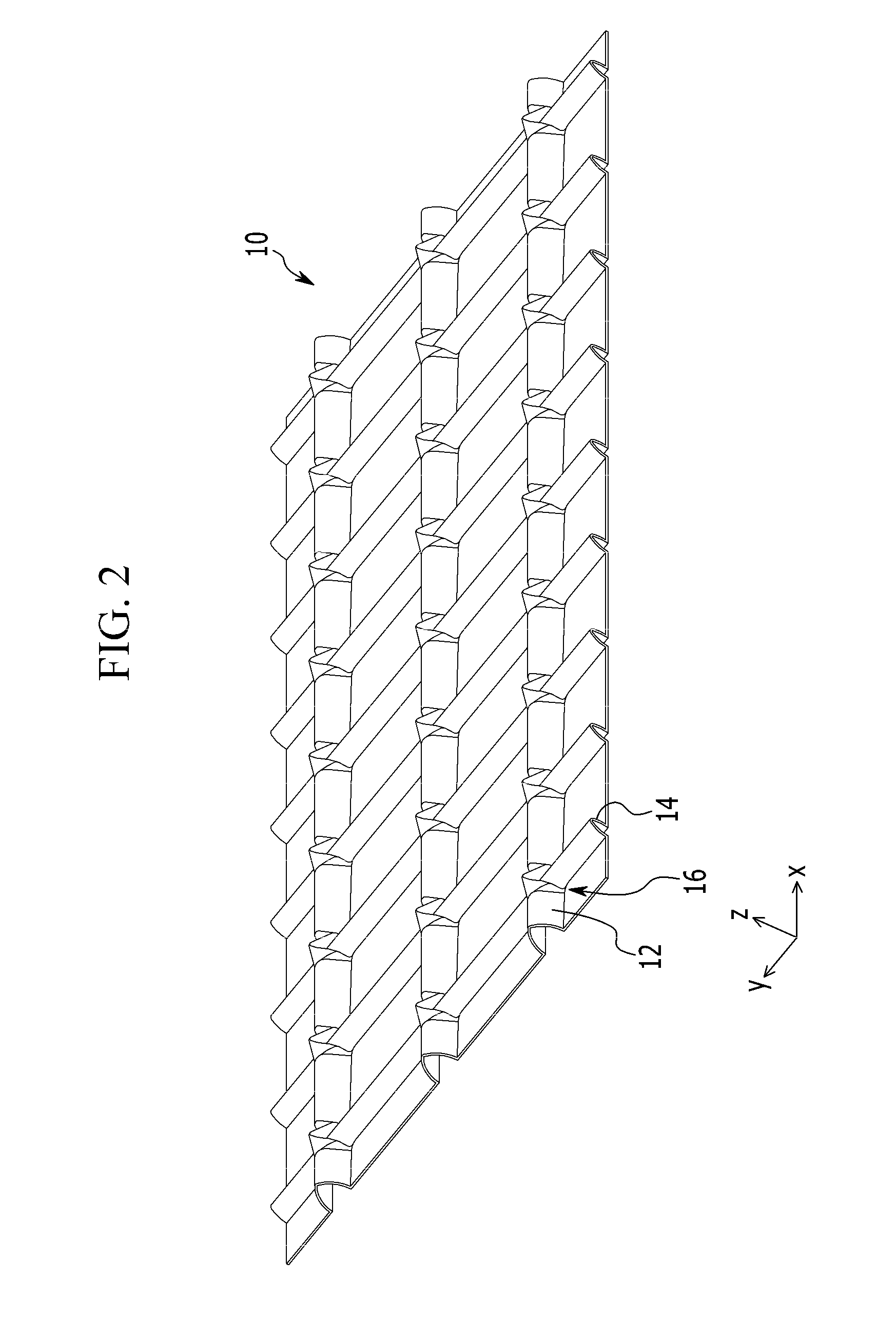

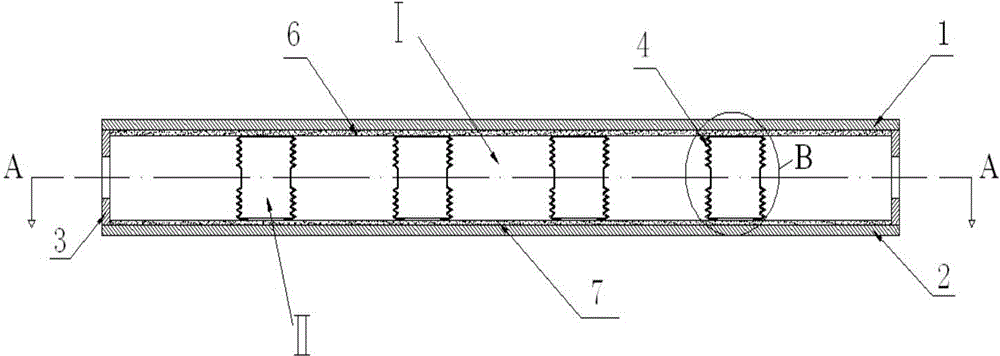

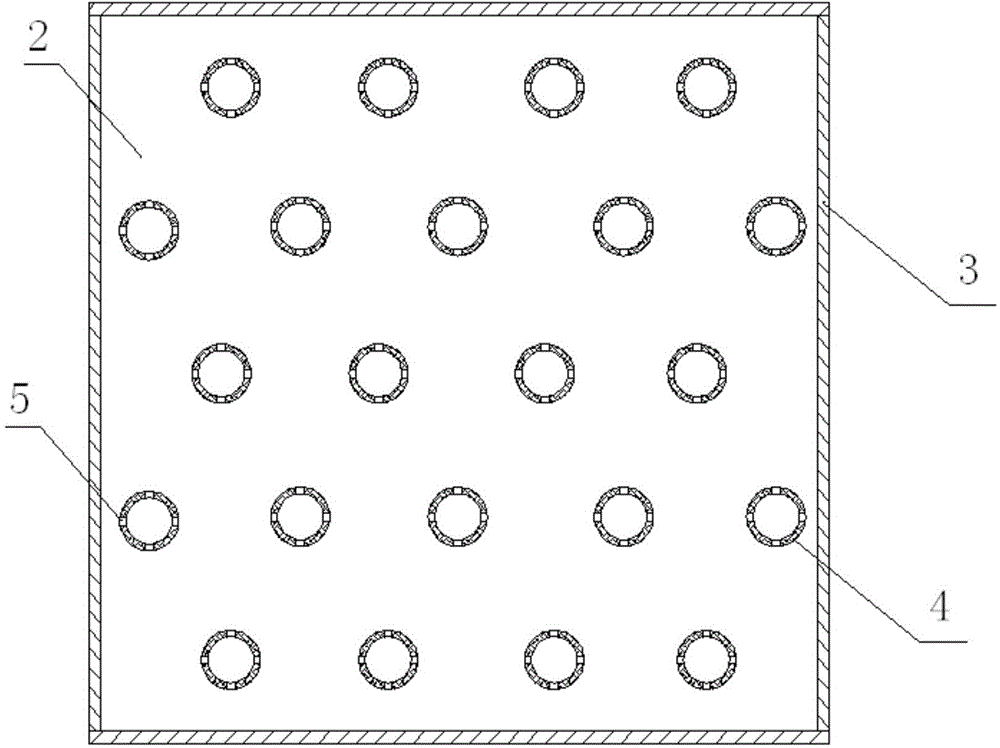

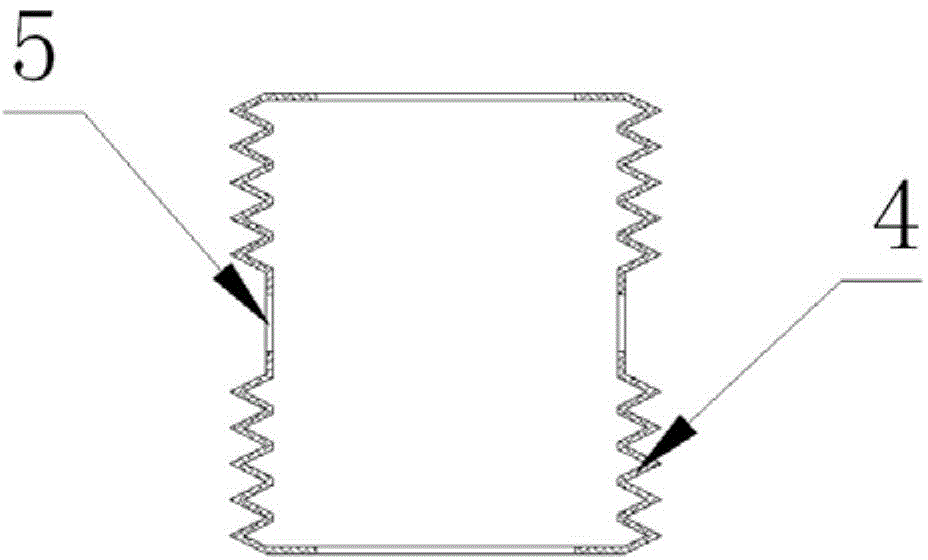

Vibration damping and noise reducing flexible sandwich plate for ship structure

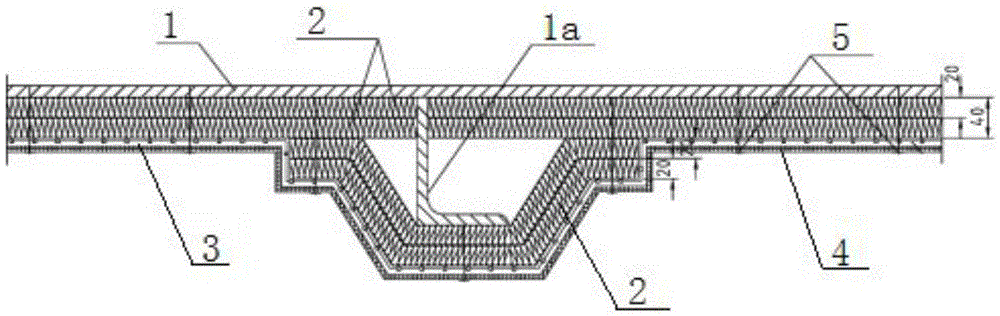

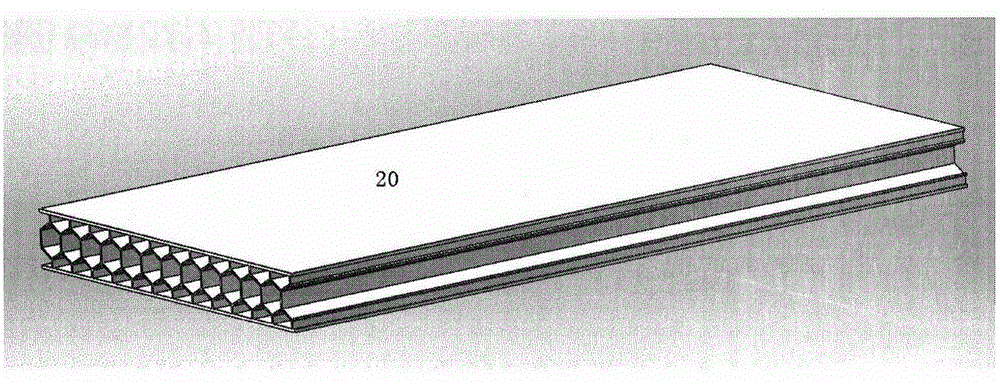

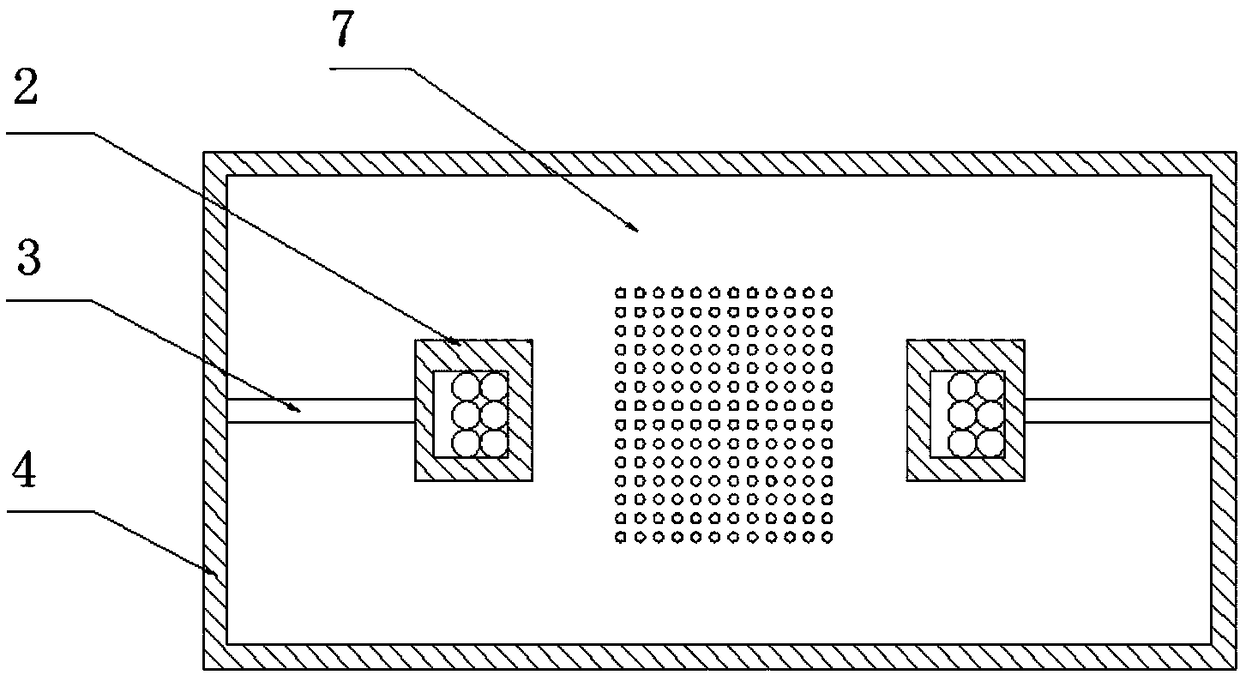

ActiveCN103600809AAchieve the purpose of silenceImprove sound insulation performanceHull panellingsThin shellsMarine engineering

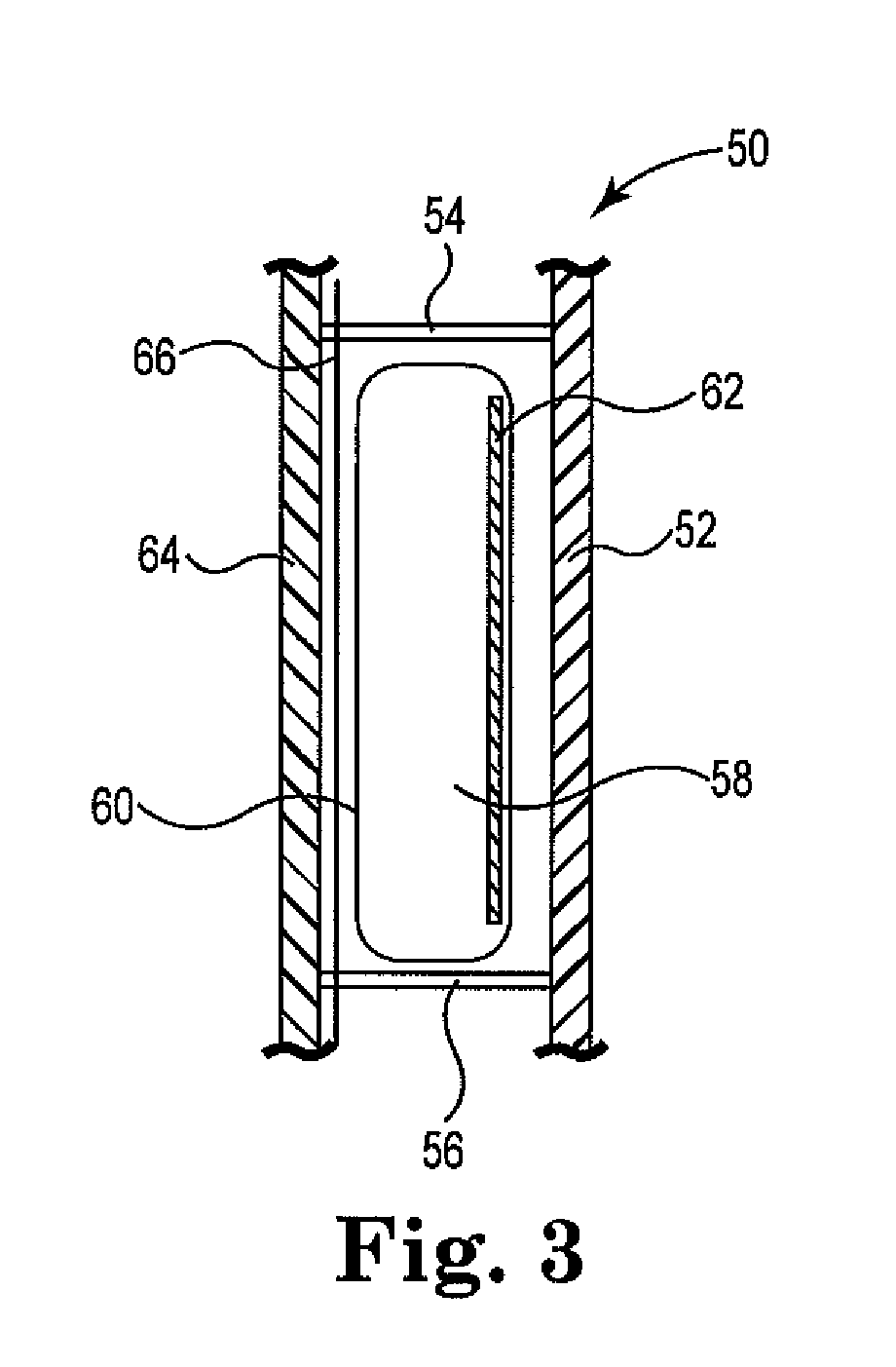

The invention discloses a vibration damping and noise reducing flexible sandwich plate for a ship structure. The vibration damping and noise reducing flexible sandwich plate for the ship structure comprises a framework, an inner face plate, an outer face plate and a flexible sandwich layer; the flexible sandwich layer is arranged between the inner face plate and the outer face plate; the inner face plate and the outer face plate which cover two openings of the framework are connected with the framework. The vibration damping and noise reducing flexible sandwich plate for the ship structure is characterized in that adhesive layers are arranged on opposite surfaces of the inner face plate and the outer face plate; the flexible sandwich layer is formed by cylindrical corrugated thin shell flexible structural bodies which are distributed in an equally spaced mode; two end surfaces of the cylindrical corrugated thin shell flexible structural bodies are connected with the inner face plate and the outer face plate through the adhesive layers respectively. The vibration damping and noise reducing flexible sandwich plate for the ship structure has the advantages of replacing a traditional ship outer casing rib structure, integrating a ship shell body structural function and a vibration damping and noise reducing function, improving the damping effect by more than 5 dB and improving the sound insulation effect by 10 dB compared with a traditional ship outer casing rib structure, maintaining the bearing capability of a ship casing structure and improving the hiding effect of the ship structure.

Owner:JIANGSU UNIV OF SCI & TECH

Sealed, thermally insulated tank with compression-resistant non-conducting elements

InactiveUS20100288778A1Easy to adaptImprove featuresDomestic cooling apparatusLighting and heating apparatusThermal insulationEngineering

Sealed, thermally insulated tank has tank walls fixed to the load-bearing structure (1) of a floating structure, the tank walls having, in succession, in the direction of the thickness from the inside to the outside of the tank, a primary sealing barrier (8), a primary insulating barrier (6), a secondary sealing barrier (5) and a secondary insulating barrier (2), at least one of the insulating barriers includes juxtaposed non-conducting elements, each non-conducting element including a thermal insulation liner (63) and load-bearing elements that rise through the thickness of the thermal insulation liner in order to take up the compression forces, characterized in that the load-bearing elements of a non-conducting element include pillars (65) of small transverse section as compared to the dimensions of the non-conducting element in a plane parallel to the tank wall.

Owner:GAZTRANSPORT & TECHNIGAZ

Multilayer composite grid sound barrier and application of multilayer composite grid sound barrier

InactiveCN105369923ALight in massImprove structural strengthHull panellingsFuselage insulationSound barrierIsolation layer

The invention provides a multilayer composite grid sound barrier. The multilayer composite grid sound barrier is of a multilayer composite three-dimensional structure, and comprises surface layers, a plurality of middle sound isolation layers and light-weight sandwich layers, wherein the surface layers are positioned on the surfaces of the two sides of the multilayer composite grid sound barrier; the middle sound isolation layers are positioned between the two surface layers; the light-weight sandwich layers are positioned between the surface layers and the middle sound isolation layers and between the middle sound isolation layers and fill gaps; the surface layers and the middle sound isolation layers are made of sound isolation materials or composite sound isolation materials; the light-weight sandwich layers are made of sound absorption material. The sound barrier also comprises keels; the keels are positioned between the surface layers and the middle sound isolation layers, connect the surface layers and the middle sound isolation layers and connect the middle sound isolation layers to form a three-dimensional grid structure; and the keels positioned at the two sides of the each middle sound isolation layer are not overlapped with the extension lines of the keels arranged at the other side of the middle sound isolation layer. The multilayer composite grid sound barrier has excellent sound isolation performance; meanwhile, good heat insulation performance is realized; the structure is firm, simple and reasonable; the weight is light; the thickness is small; the installation is convenient; the production and manufacturing process is simple; and the cost is low. The invention also provides application of the multilayer composite grid sound barrier.

Owner:北京谐声昊普声学技术有限公司

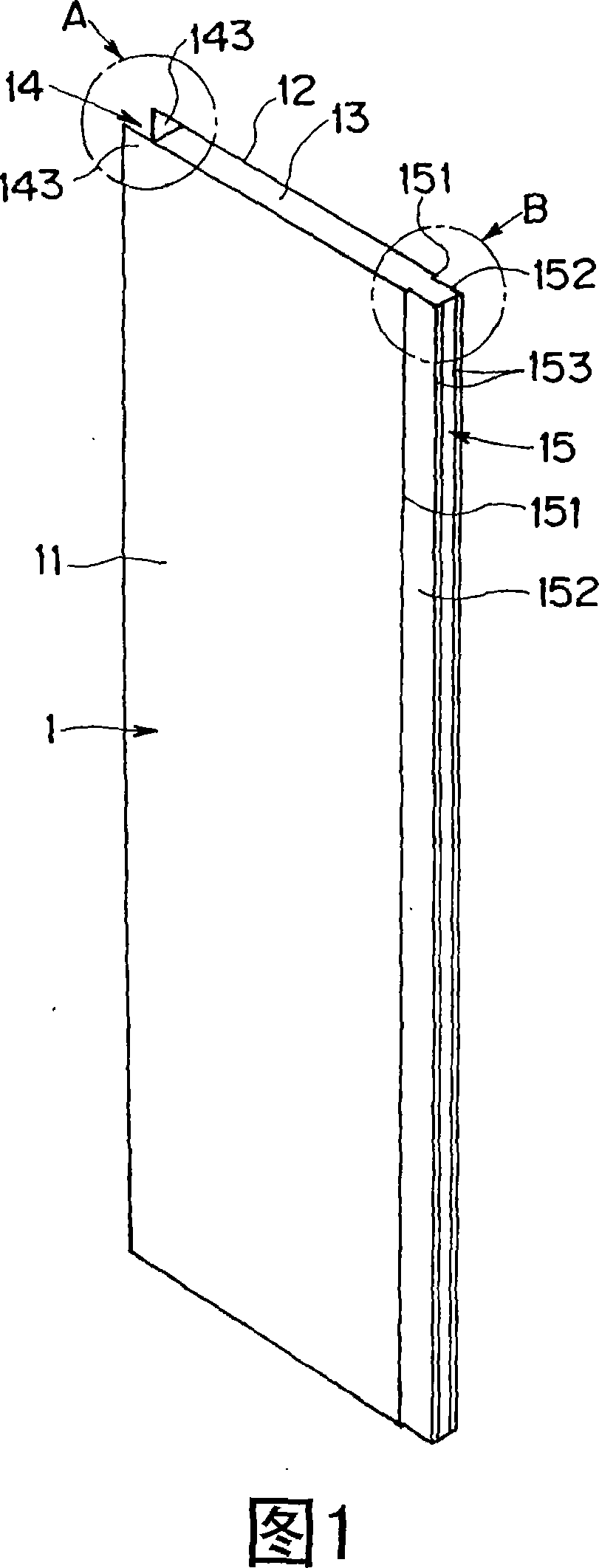

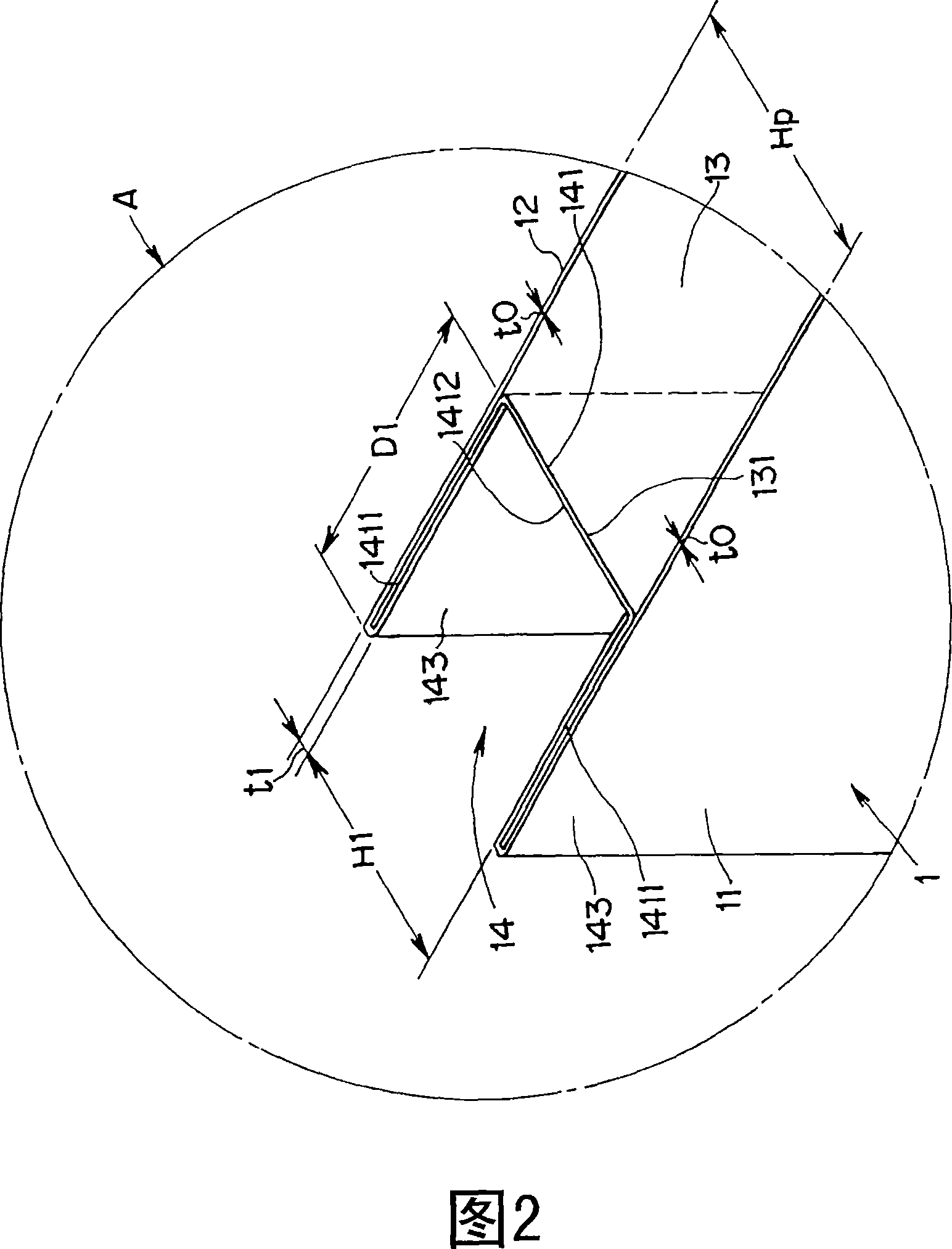

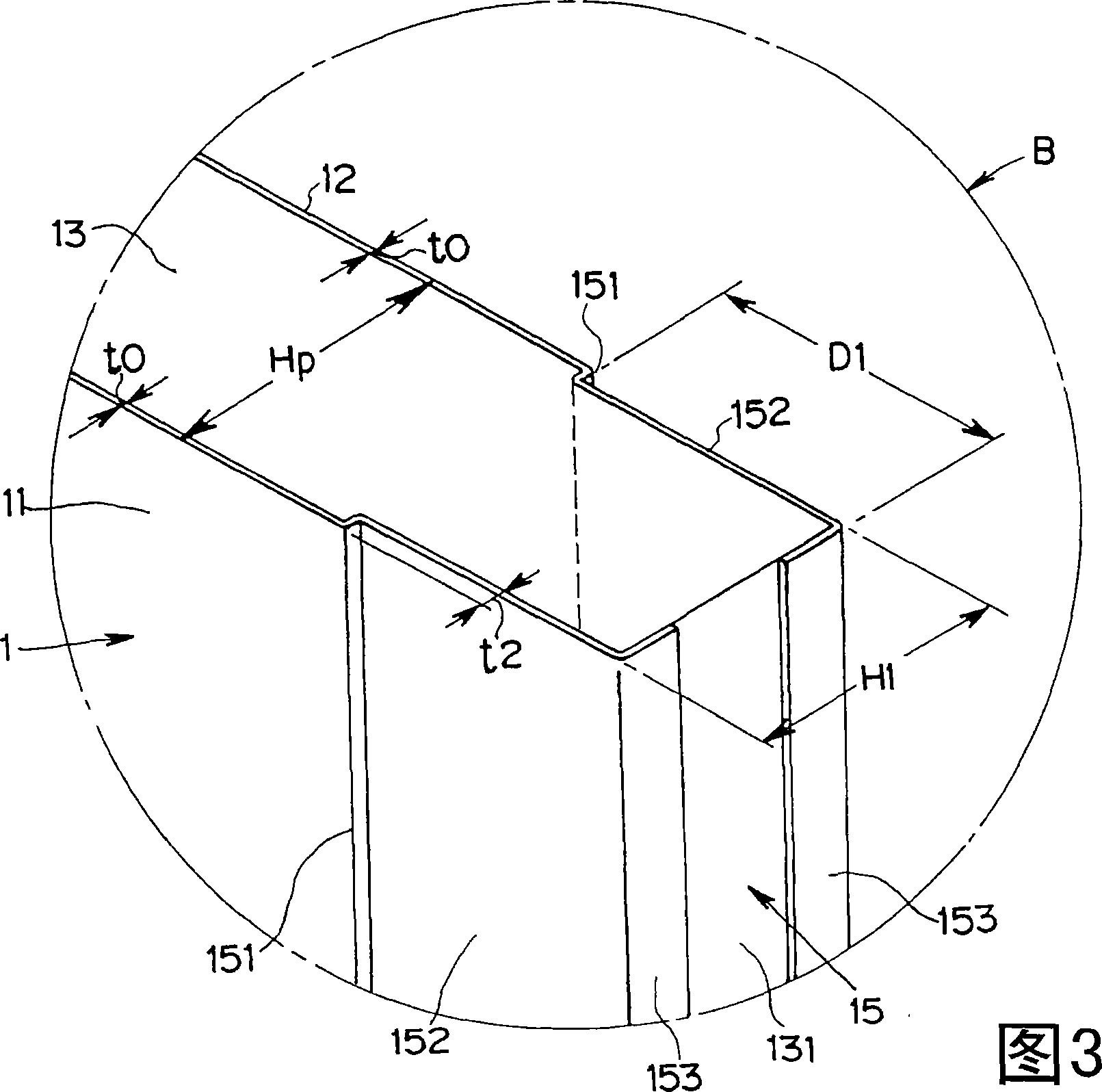

Fireproof panel for shipping

InactiveCN101045481AGuaranteed fire performanceImprove fire performanceLayered productsHull panellingsFire protectionEngineering

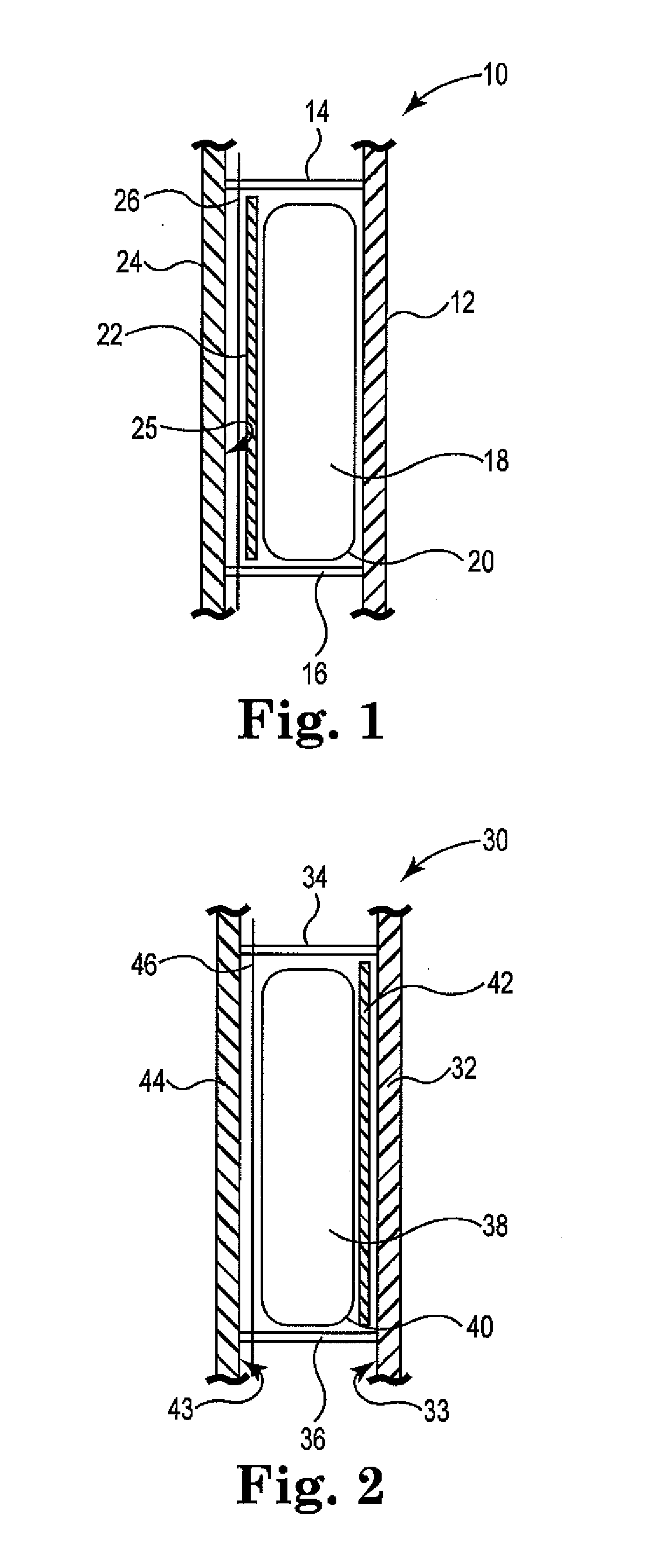

The invention provides a fireproof panel meeting the A-level fire-protection standard in the International Convention for the Safety of Life at Sea. The fireproof panel's structure is like this: the plate-type heat-insulating block (13) which will be formed as the panel's shape is clamped between the outside panel (11) and the inside panel (12) made of thin steel plates, and on the left and right edges of aforementioned outside panel (11) and inside panel (12) are formed the coupled convex part (15) and concave part (14) which form the scarfing structure; the scarfing width of the aforementioned convex part (15) and concave part (14) is set between 90% and 98% of the panel's thickness, and the scarfing depth is set between 60% and 100% of the panel's thickness.

Owner:株式会社圣美 +1

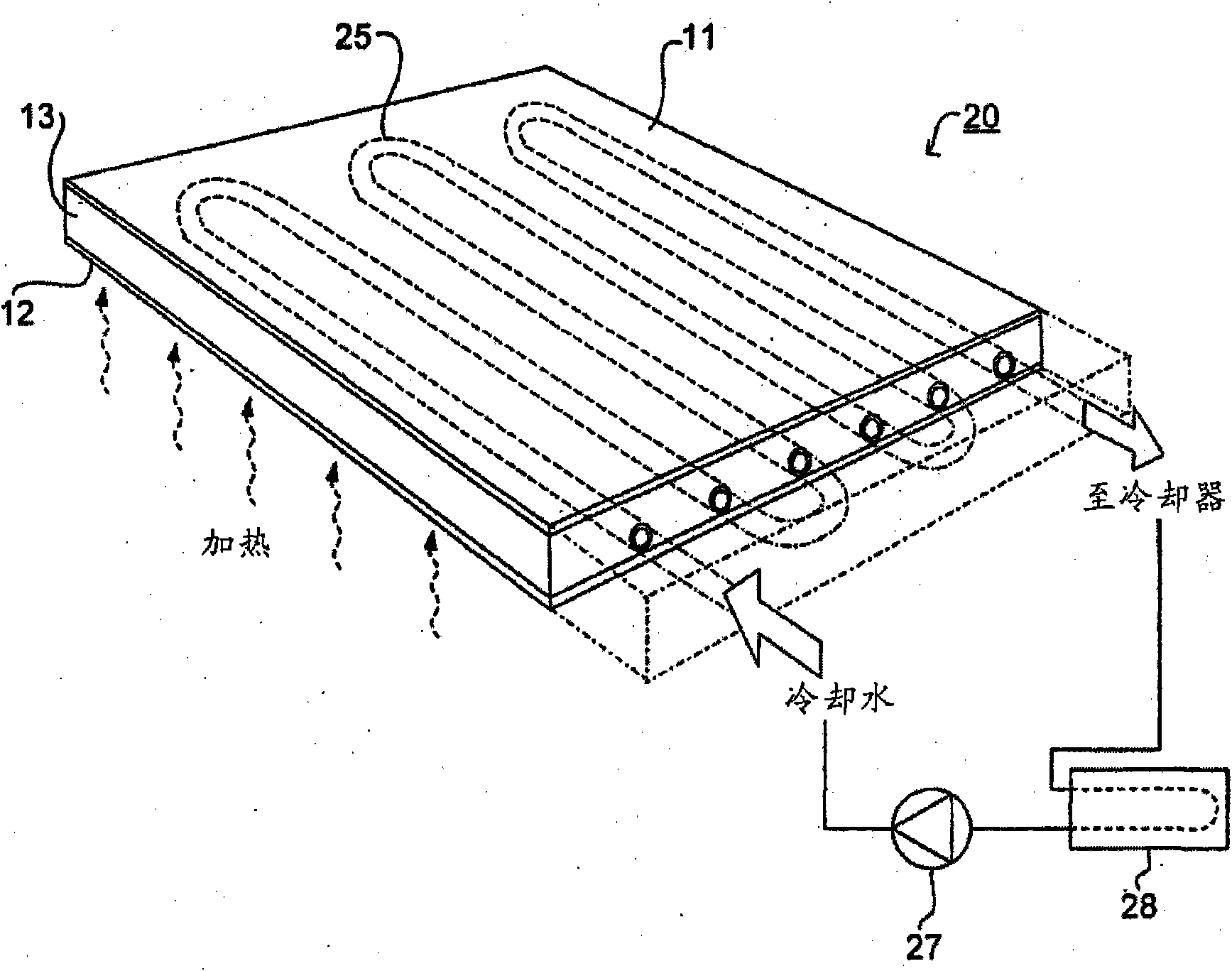

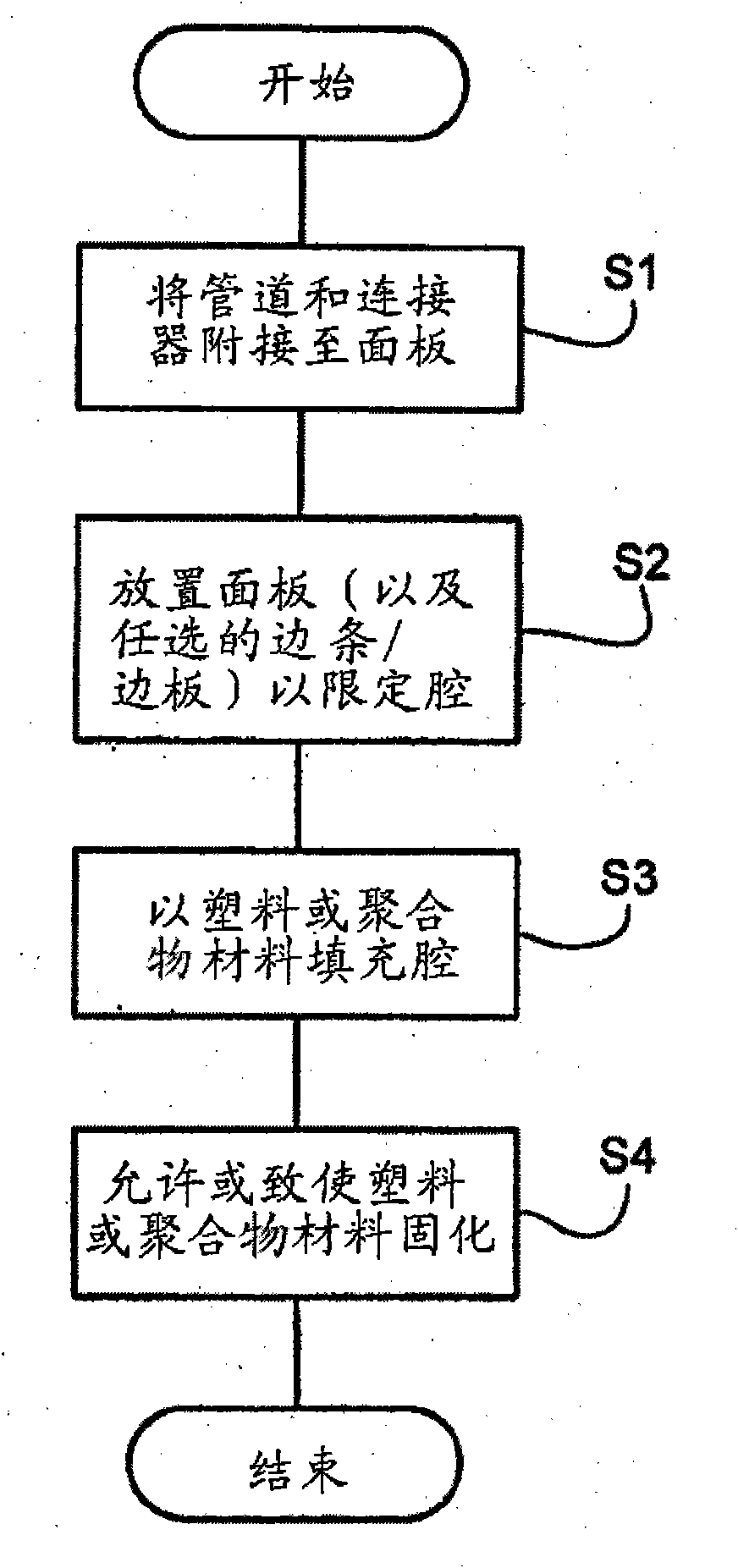

Improved structural sandwich plate panels and methods of making the same

The present application relates to a structural sandwich plate member comprising first and second outer metal plates and a core of plastics or polymer material bonded to the outer metal plates and arranged to transfer shear forces there between, wherein the member further comprises: a conduit for a temperature control medium, the conduit being embedded in the core and in thermal contact with at least one of the outer metal plates.

Owner:INTELLIGENT ENG BAHAMAS

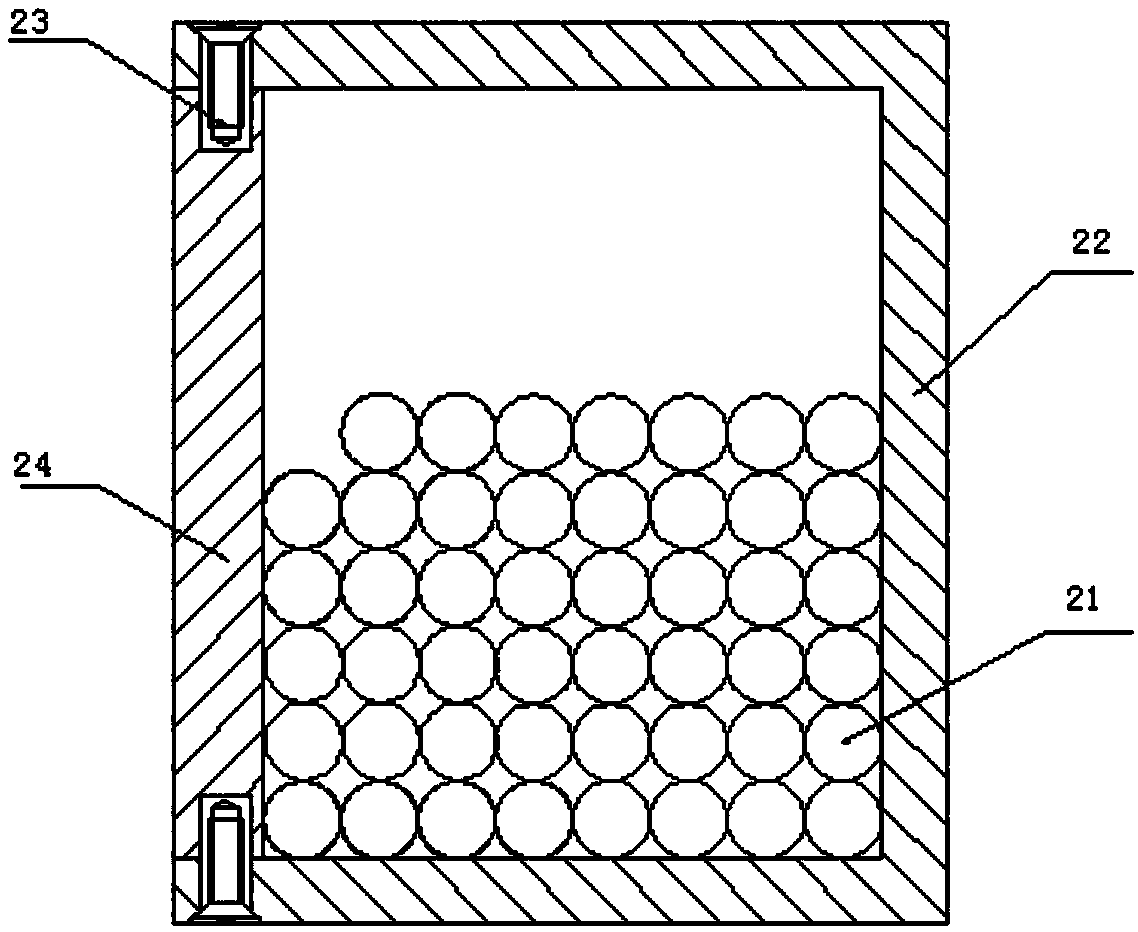

A composite structural member for reducing noise and vibration in a ship cabin

ActiveCN109018193AReduce vibrationEnhanced Damping ControlHull panellingsMicro perforated plateWorking environment

The invention discloses a composite structural member for reducing noise and vibration in a ship cabin., The member comprises a outer layer micro-perforated plate, a framework and an inner layer micro-perforated plate, all of which are connected through connecting parts and enclosing walls for a chamber. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedlyconnected and combined into a double-layer micro-perforated cavity through a frame, and a plurality of rows of multi-layer particle dampers are fixedly connected on two side walls corresponding to the frame in the cavity through elastic connecting rods. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedly connected to each other through a frame. The invention can optimize the sound absorption coefficient of the micro-perforated plate without changing the cabin structure, broaden the sound absorption frequency band, improve the sound absorption effect,reduce the vibration of the cabin structure, and create a good cabin working environment. Moreover, the invention has the advantages of compact structure and convenient installation. It has a good prospect of engineering application.

Owner:JIANGSU UNIV OF SCI & TECH

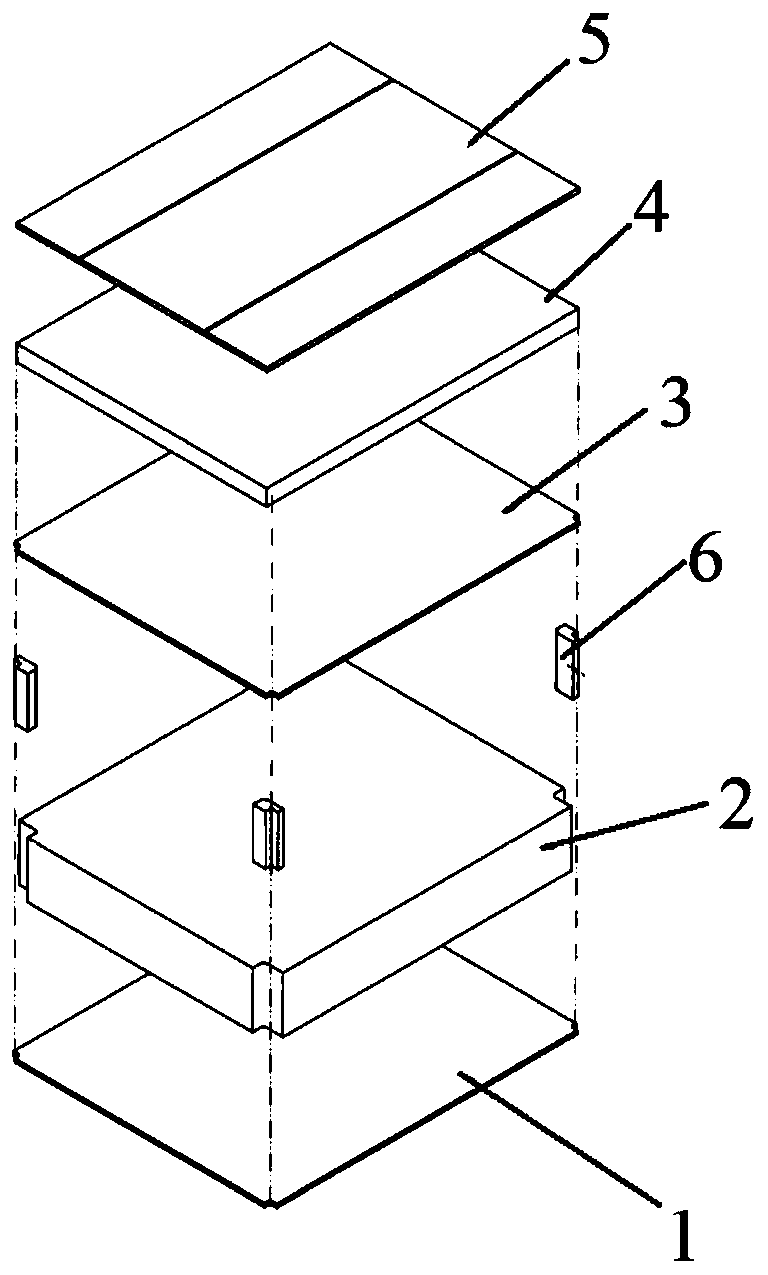

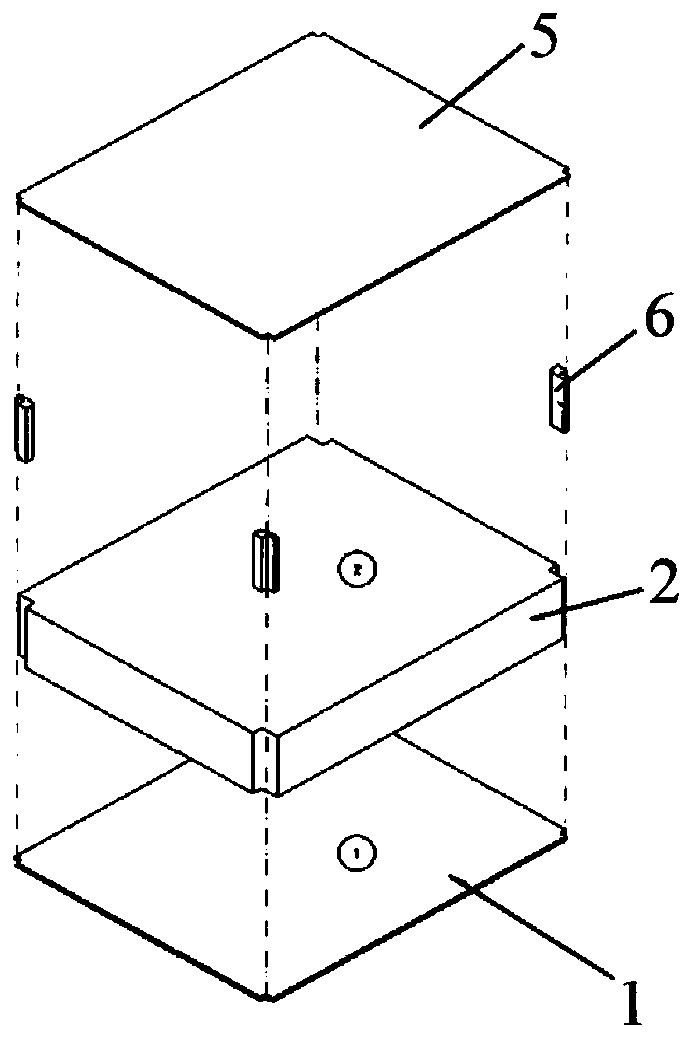

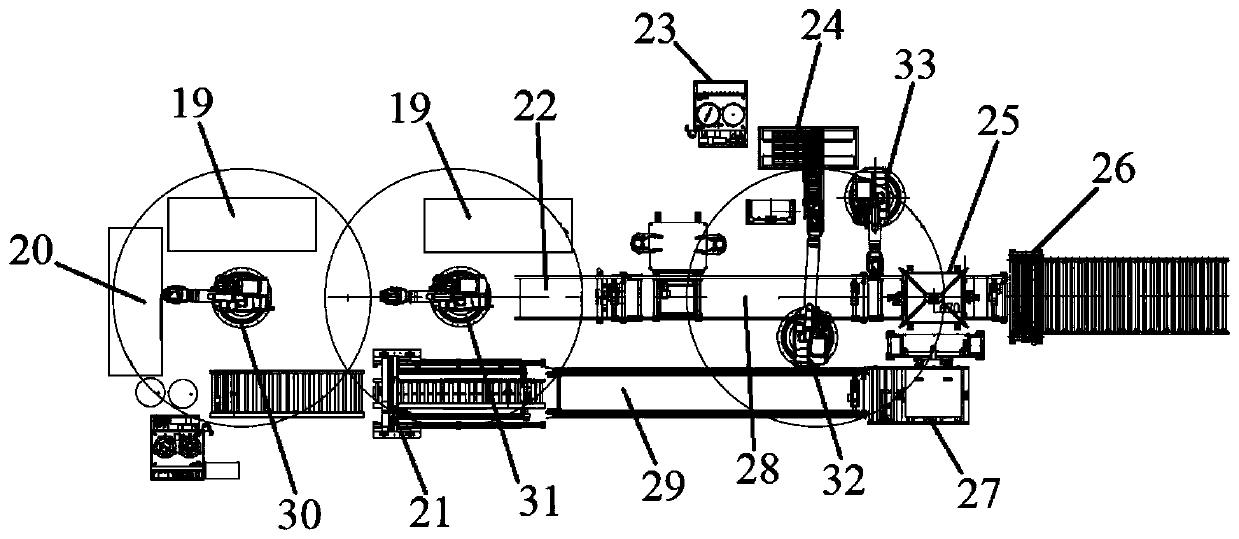

Split and current collecting interactive assembly manufacturing method for LNG marine polyurethane insulation box

ActiveCN110127367ASmall footprintBalance work timeLayered productsHull panellingsDevice failureFilm-coated tablet

The invention relates to a split and current collecting interactive assembly manufacturing method for LNG marine polyurethane insulation box; and the method comprises the following steps of: a code scanning process, a loading process, an automatic gluing process, a bottom component assembly process, a wood splint assembly gluing process, a wood plywood assembly process, an underlayer tensioner assembly process, an upper component assembly process, an upper tensioner assembly process, an overall calibration process, a plywood correction process, a top film coating process and a post-treatment process. Compared with the prior art, the invention makes full use of the existing automation equipment, adopts the split and current collecting interactive assembly manufacturing ideas, sets the parallel material transportation mode of the double conveying line, and the multi-station segment assembly method; the influence of the single linear arrangement on the production system due to equipment failure is greatly reduced; the manufacturing method not only reduces equipment investment and the occupied area of a production site, but also effectively balances the operation time of each process,improves production efficiency, and ensures high-precision quality requirement.

Owner:SHANGHAI JIAO TONG UNIV +1

Insulation system for floating marine structure

InactiveUS20160159438A1Reduce heat transferReduce probabilityAuxillariesVessel ventillation/heating/coolingInsulation systemBallast tank

Disclosed herein is a heat insulating system of a floating structure, and more particularly, a heat insulating system of a floating structure in which a heat insulating material is provided at at least one of a ballast tank, a trunk deck space, and a side passage way contacting the trunk deck to decrease a boil-off rate (BOR) occurring due to a heat transfer from an external region of a hull into an LNG storage tank.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Insulation apparatus and method

ActiveUS20170101163A1Easy to handleConvenient to accommodateVessel geometry/arrangement/sizeVessel wallsCouplingMarine engineering

The invention relates to a marine vessel cryogenic barrier which is formed of a plurality of individual panels, each panel being arranged to align with an adjacent panel on an inner surface of a hold space of a marine vessel and comprising a single coupling means at the centre of the panel and an impervious layer on a surface of the barrier facing the hold space.

Owner:LNT MARINE PTE LTD

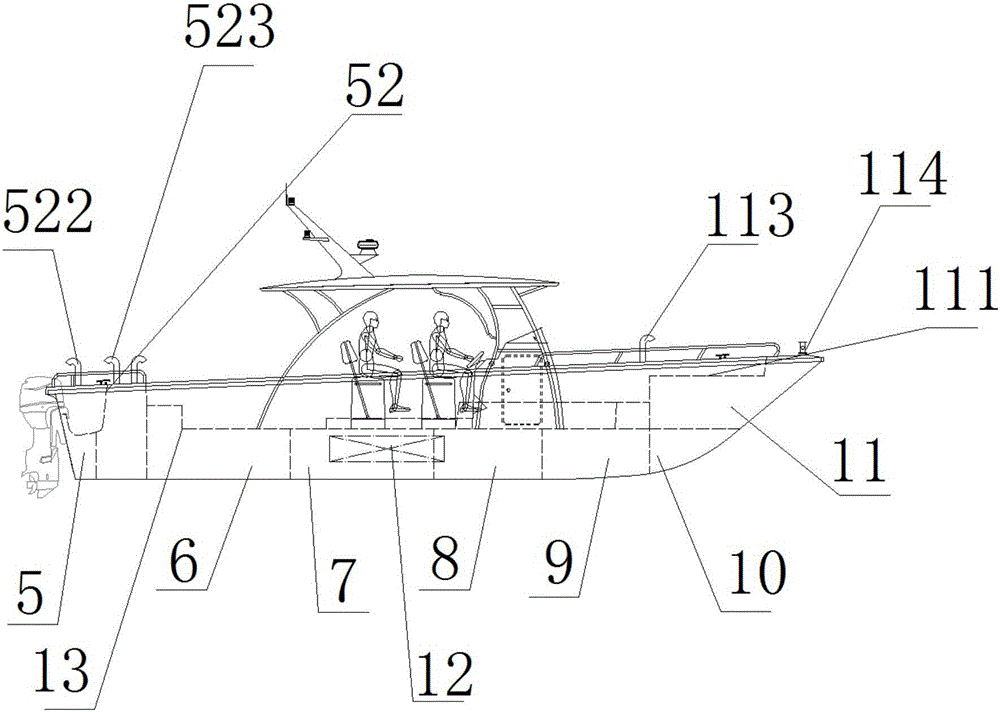

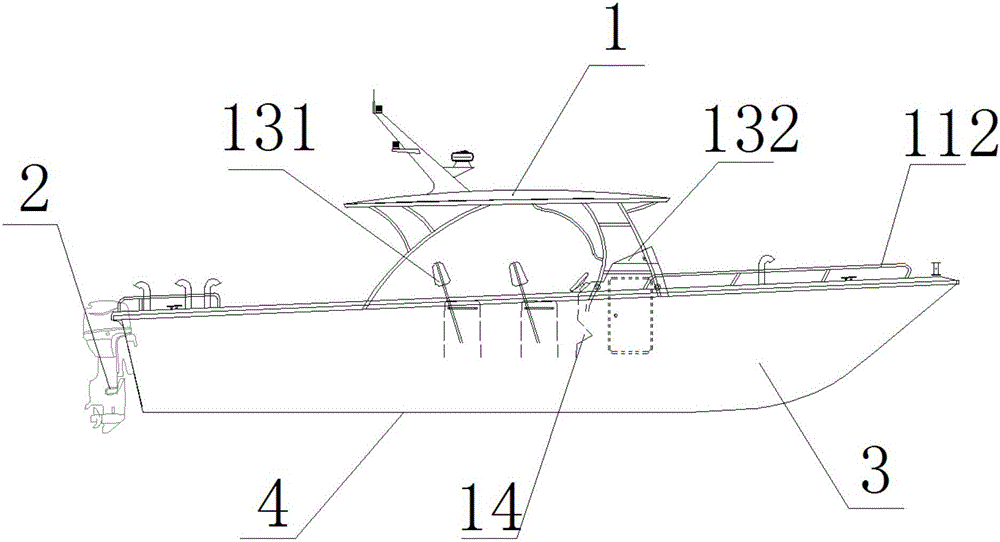

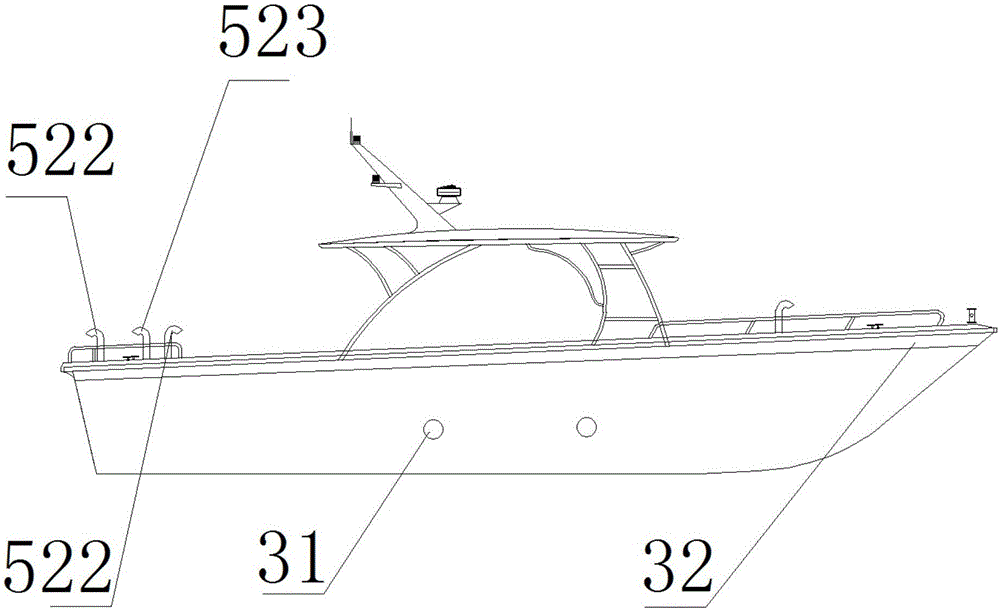

Novel anti-collision high-speed planing boat

ActiveCN106080969AGuaranteed stabilityImprove stabilityVessel cleaningHull interior subdivisionFuel tankStern

The present invention discloses a novel anti-collision high-speed planing boat, comprising a boat body composed of side plates and a bottom plate; the boat body is provided with a battery compartment, a first reserve buoyant compartment, a second reserve buoyant compartment, a third reserve buoyant compartment, a fourth reserve buoyant compartment and a fifth reserve buoyant compartment sequentially from tail to head, the fifth reserve buoyant compartment is provided with a head peak tank, an empty compartment is provided in the battery compartment, and a fuel tank compartment is arranged in each of the second reserve buoyant compartment and third reserve buoyant compartment; the bottom plate includes a stern bottom plate, a bow bottom plate and a middle bottom plate that connects the stern bottom plate and the bow bottom plate. By reasonably laying the boat body, boat stability is guaranteed; by designing the bottom plate into a big-front small-rear V-shaped bottom plate, sailing speed of the boat can be greatly increased and the demand for high-speed law enforcement is met.

Owner:CHONGQING JINGSUI CRUISE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com