Method for enlarging a ship and enlarged ship

A technology for ships and cargo ships, which is applied to the enlarged ship field, can solve the problems of high dead weight, increase fuel consumption, emission of harmful substances, and emission of harmful substances at renovation costs, so as to reduce fuel consumption and emission of harmful substances, and reduce stable pressure. The effect of the cabin load and the improvement of the cargo carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

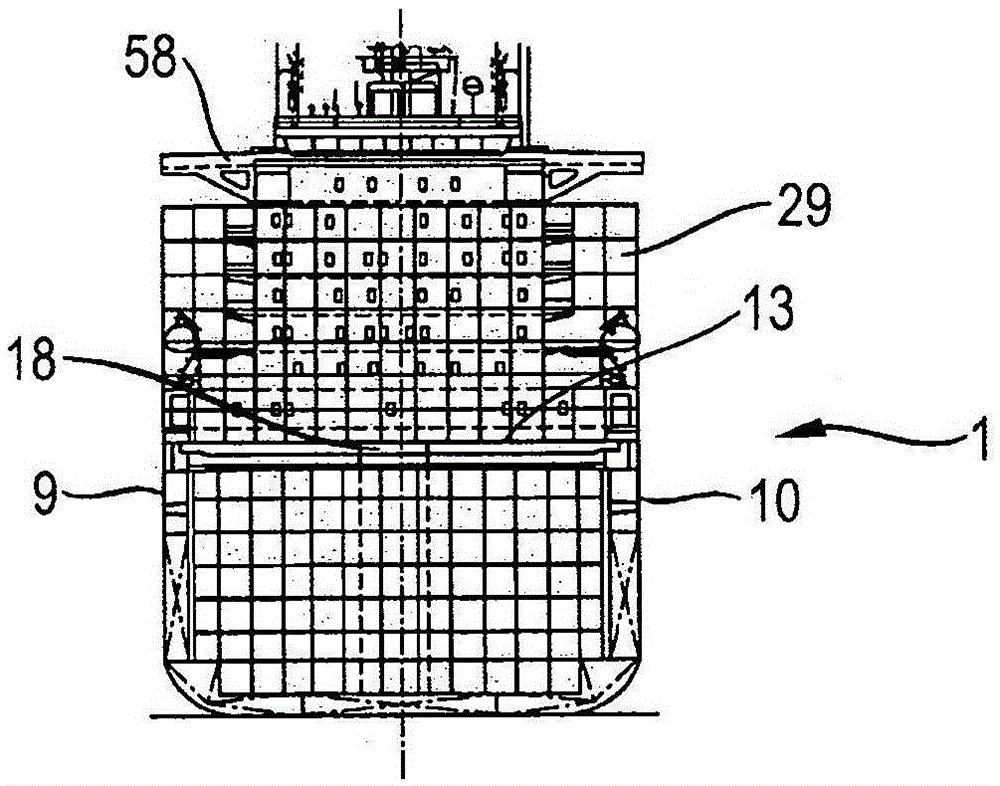

[0089] In the following descriptions of different ships, identical components are provided with the same reference numerals.

[0090] In addition, the area of the ship changed by the transformation is darkened.

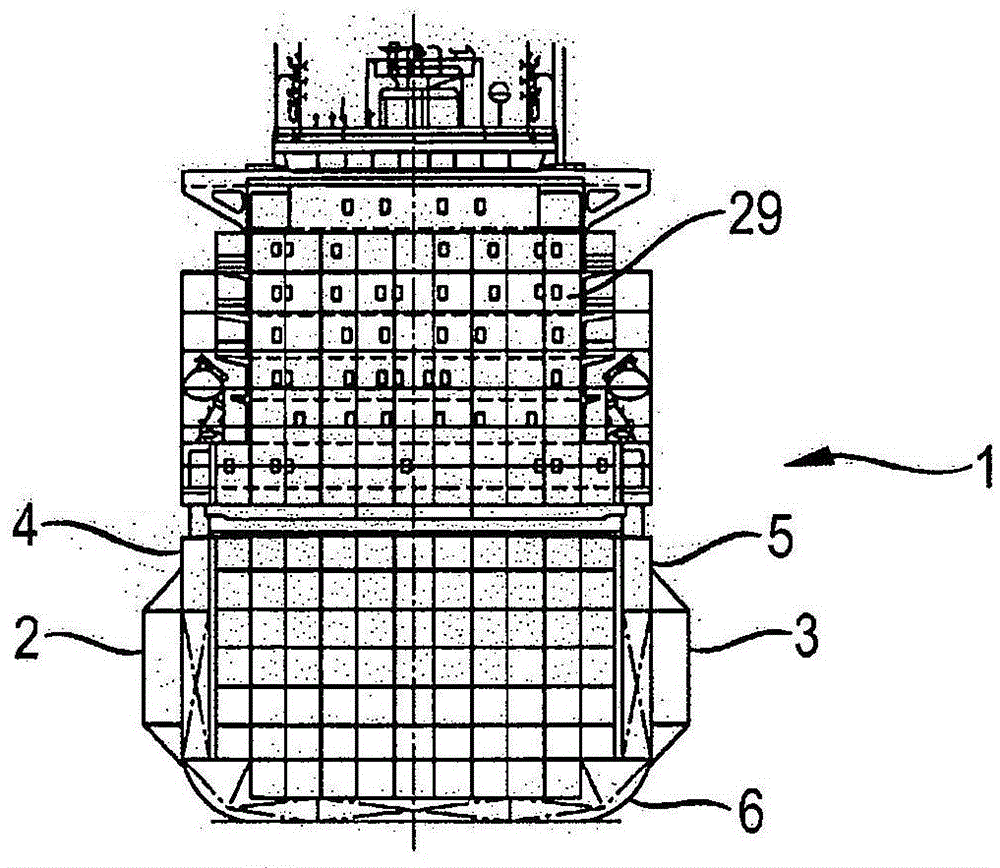

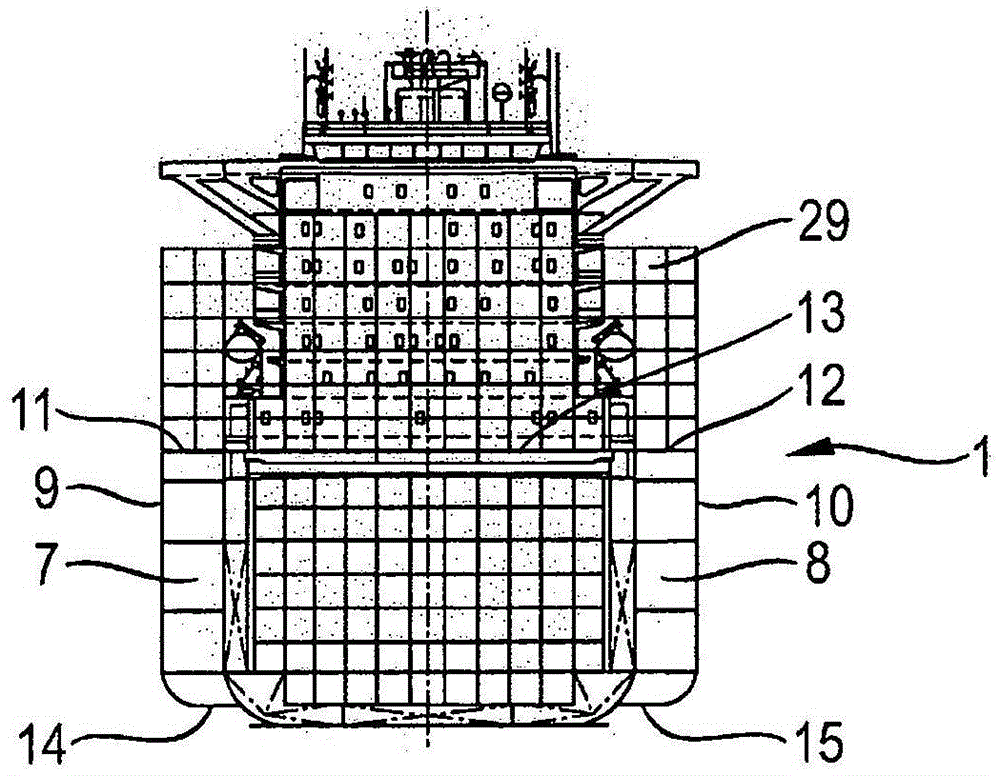

[0091] exist Figures 1 to 3 A Panamax container ship is shown in respectively, which has an initial cargo capacity of 4300 standard containers (20-foot equivalent units TEU).

[0092] according to figure 1 , the vessel 1 is widened by mounting side lugs 2 , 3 onto the outer sides of the side walls 4 , 5 of the hull 6 . The broadsides extend above and below the waterline. This widening increases the lateral stability of the vessel 1 and reduces the ballast water requirement. No additional cargo capacity is thus provided.

[0093] figure 2 Another widening solution for the same vessel 1 is shown. On the outside of the side walls 4 , 5 of the hull 6 there are attached structural parts 7 , 8 which are provided with additional side walls 9 , 10 on the outside. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com