Patents

Literature

333results about "Hull bulkheads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

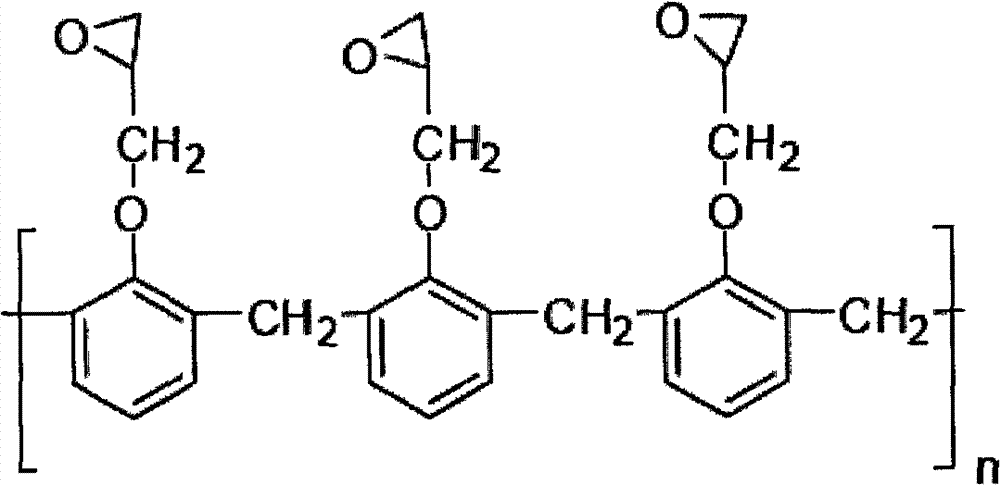

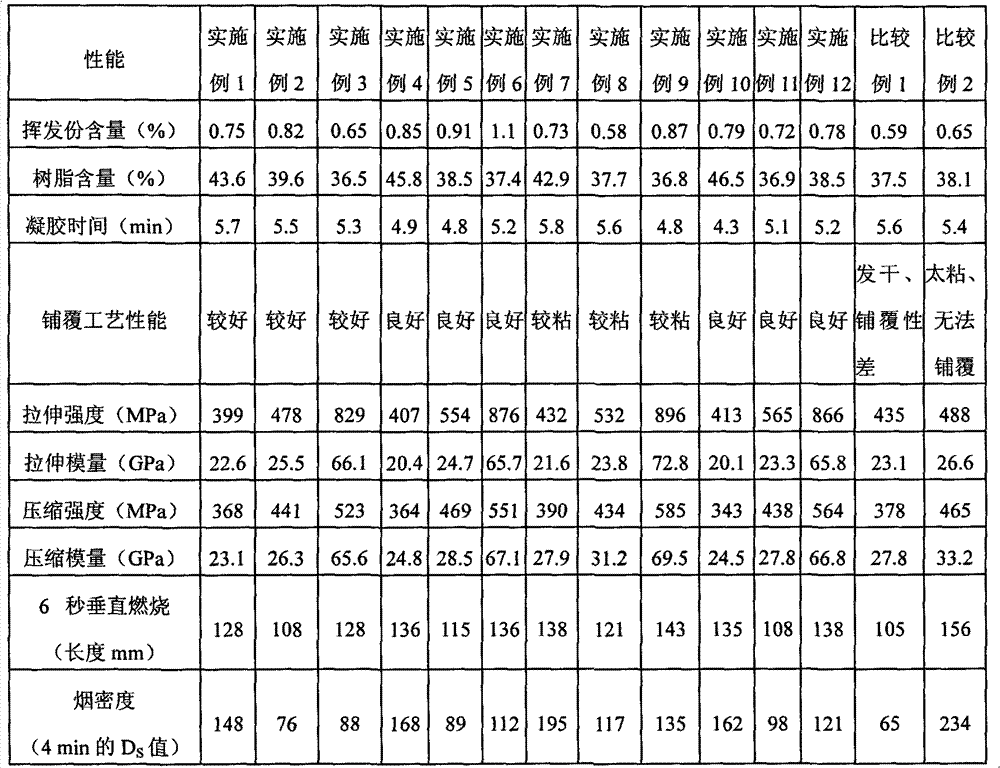

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

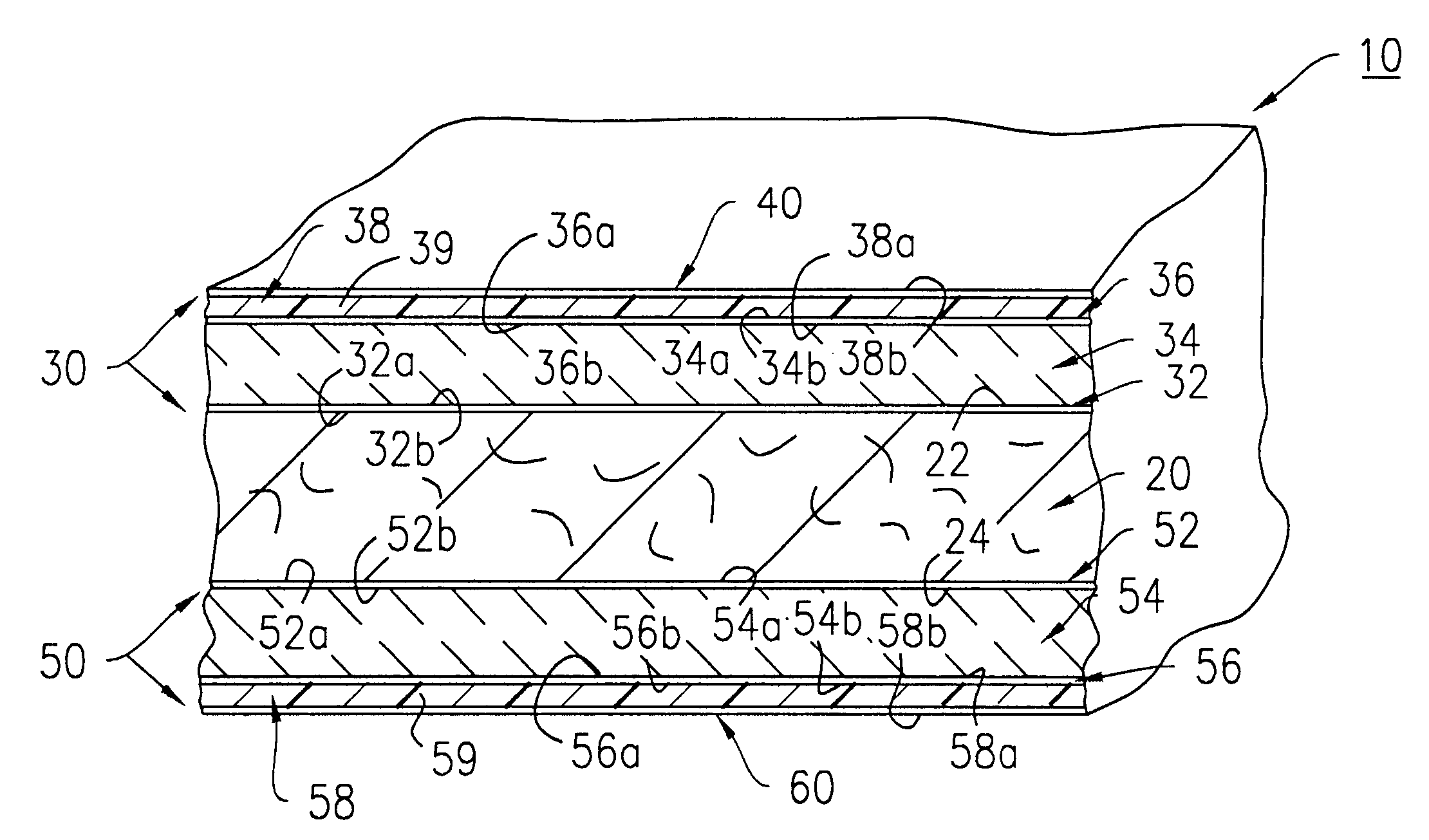

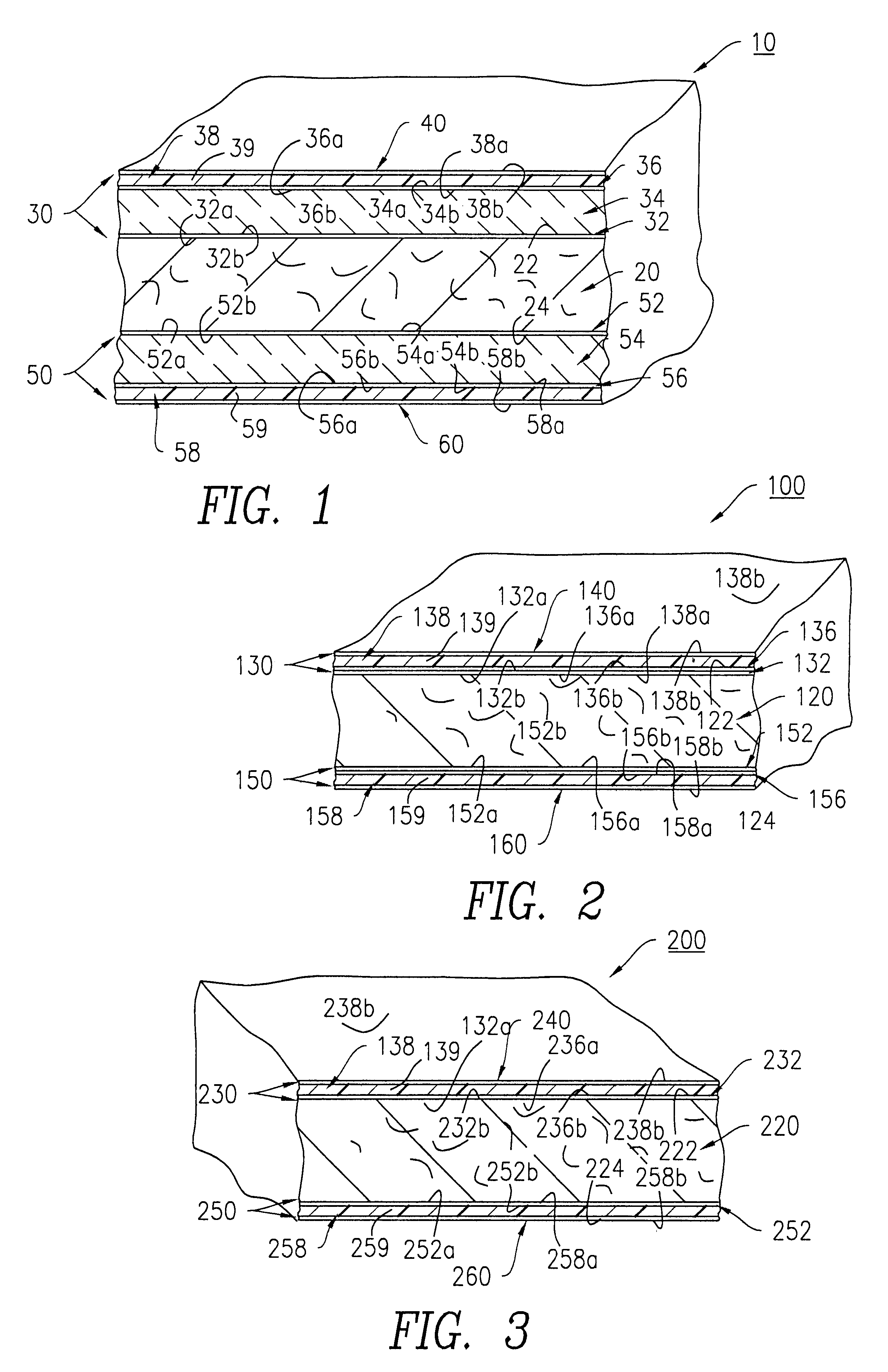

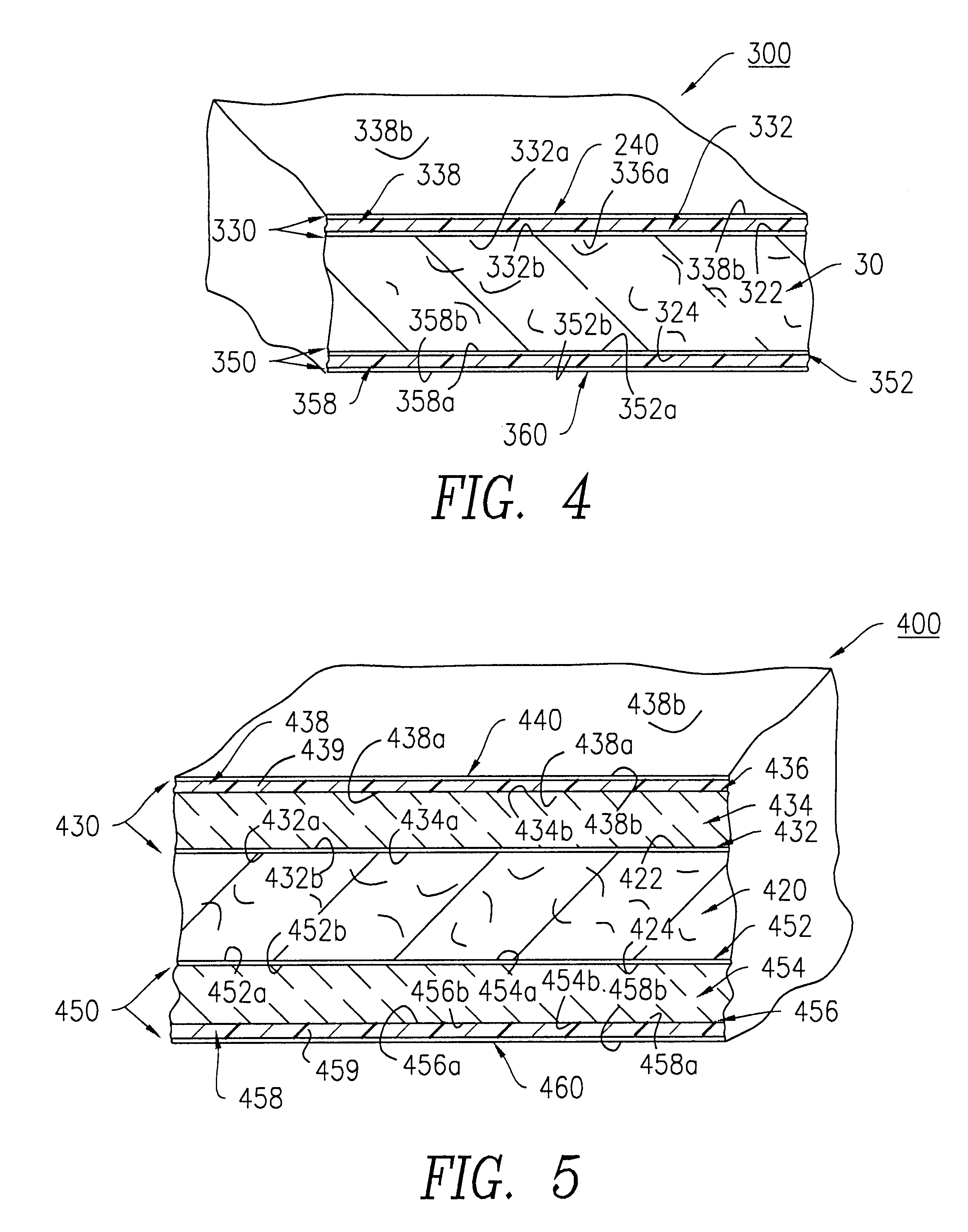

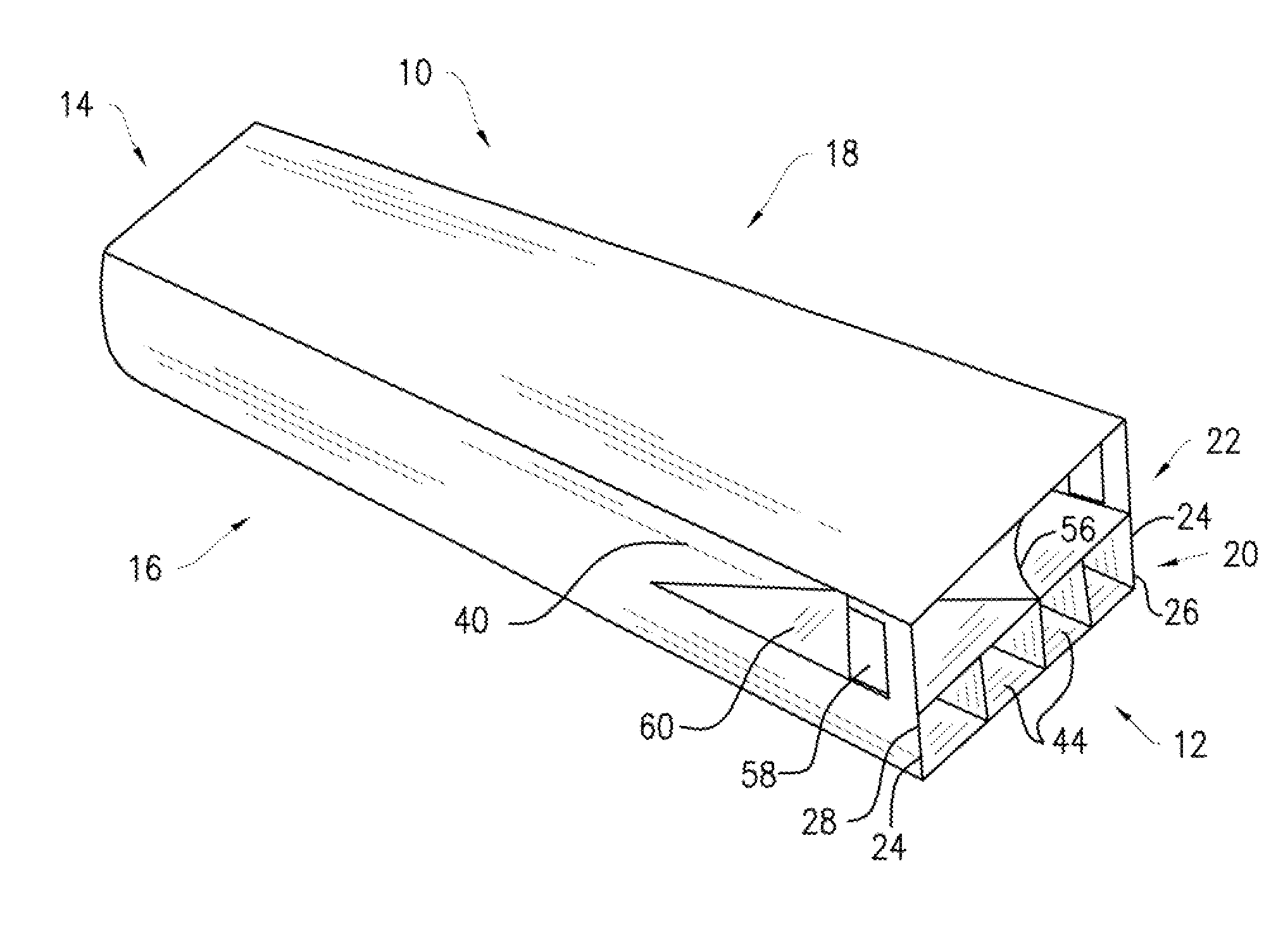

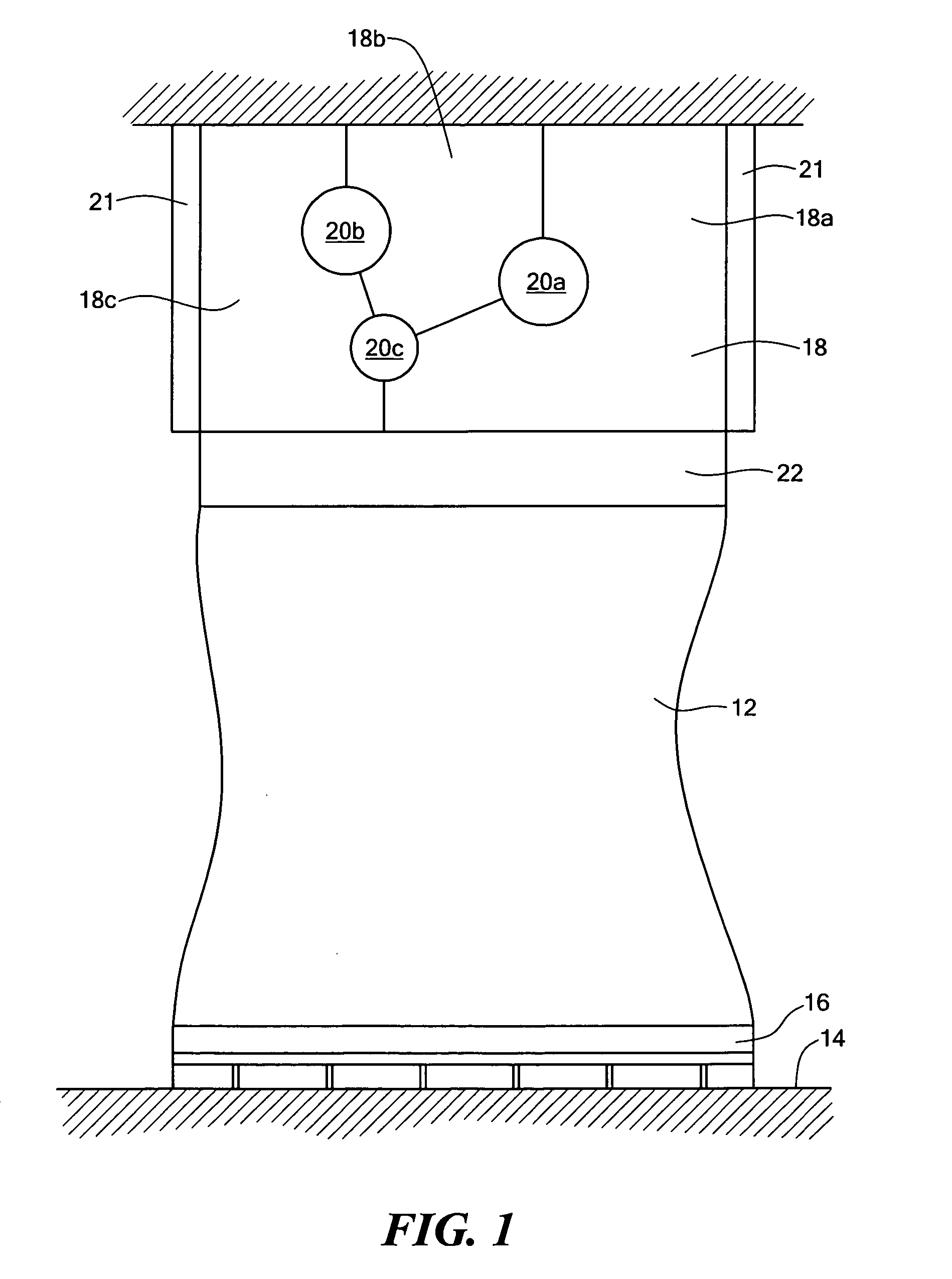

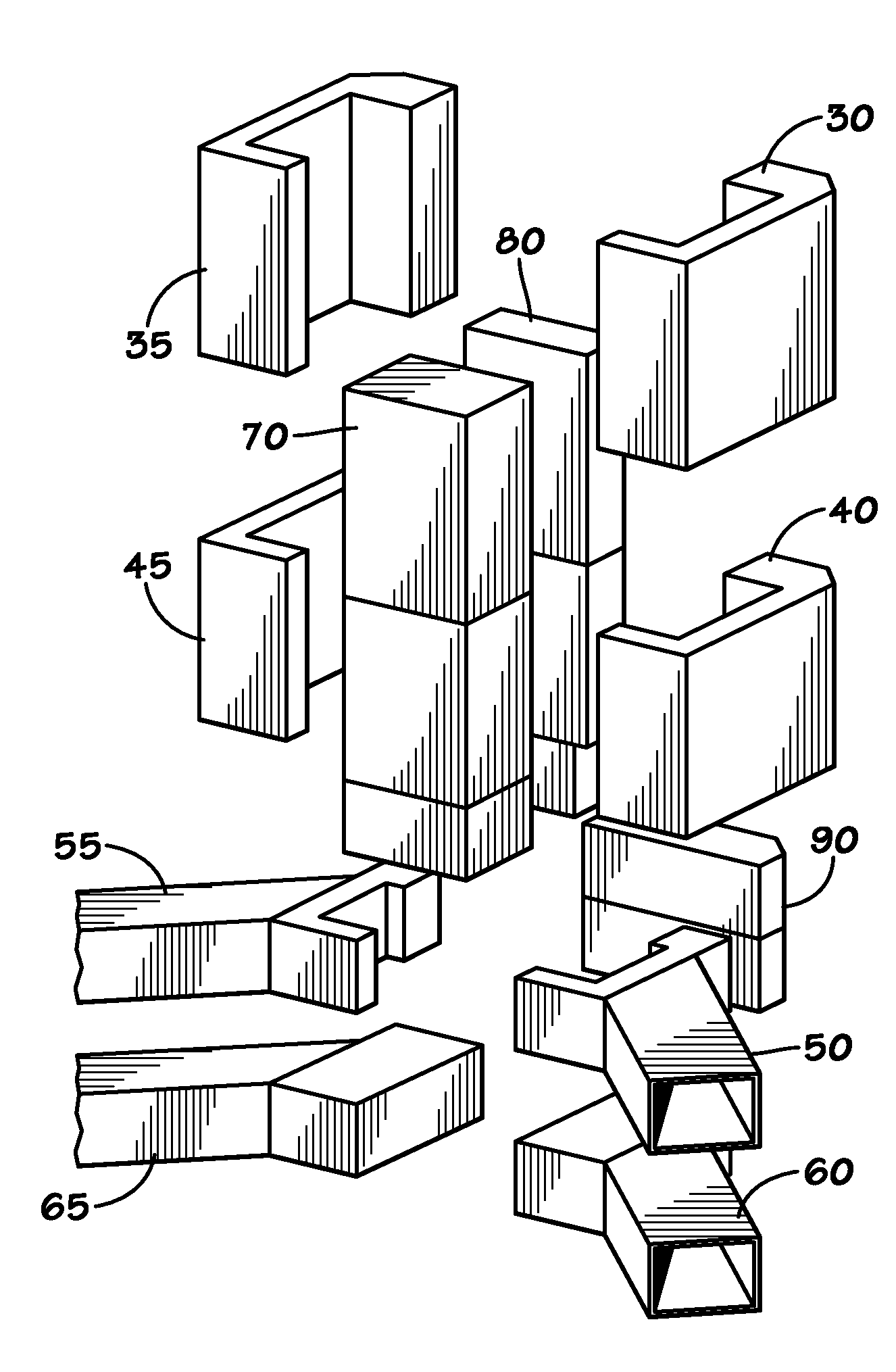

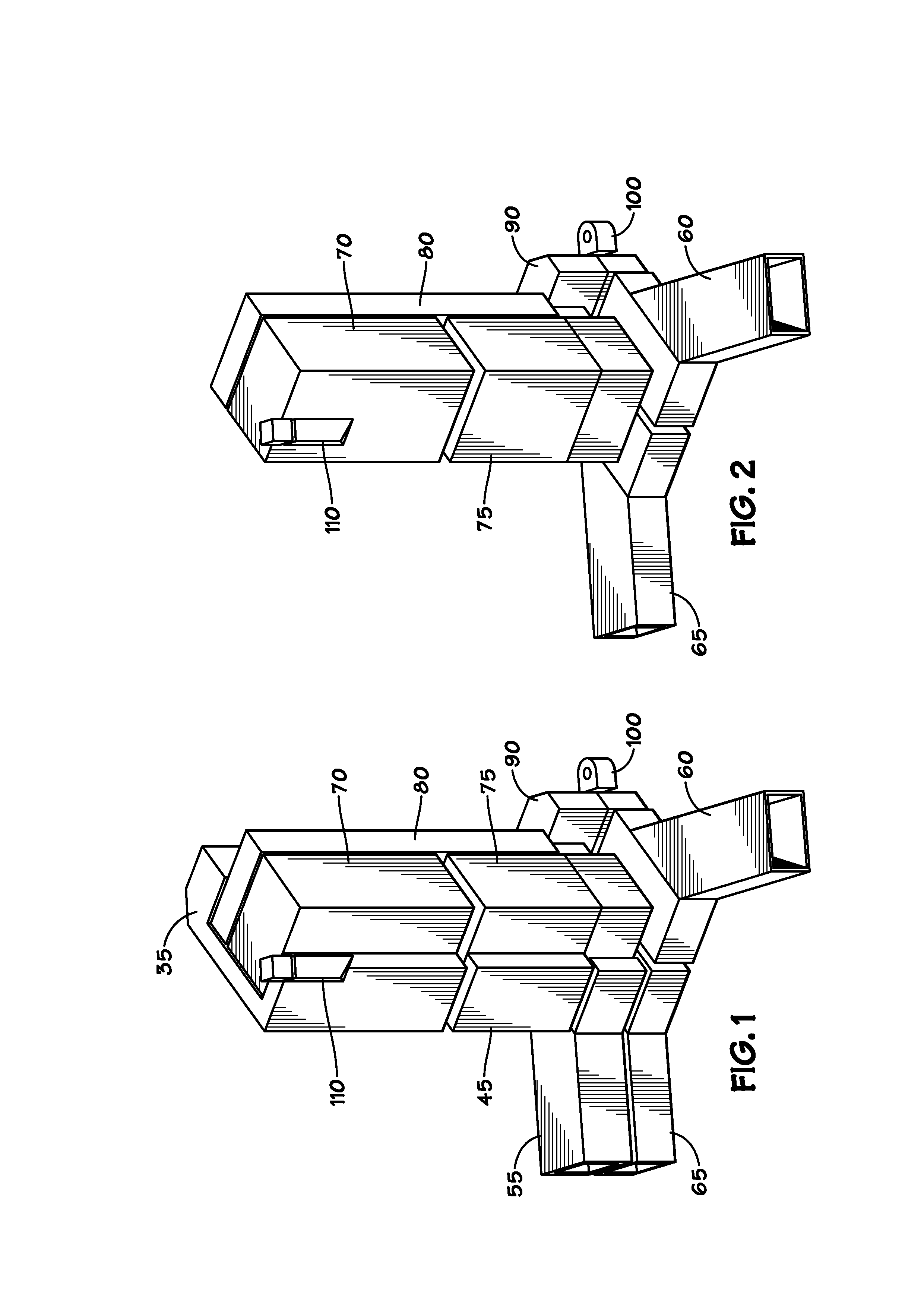

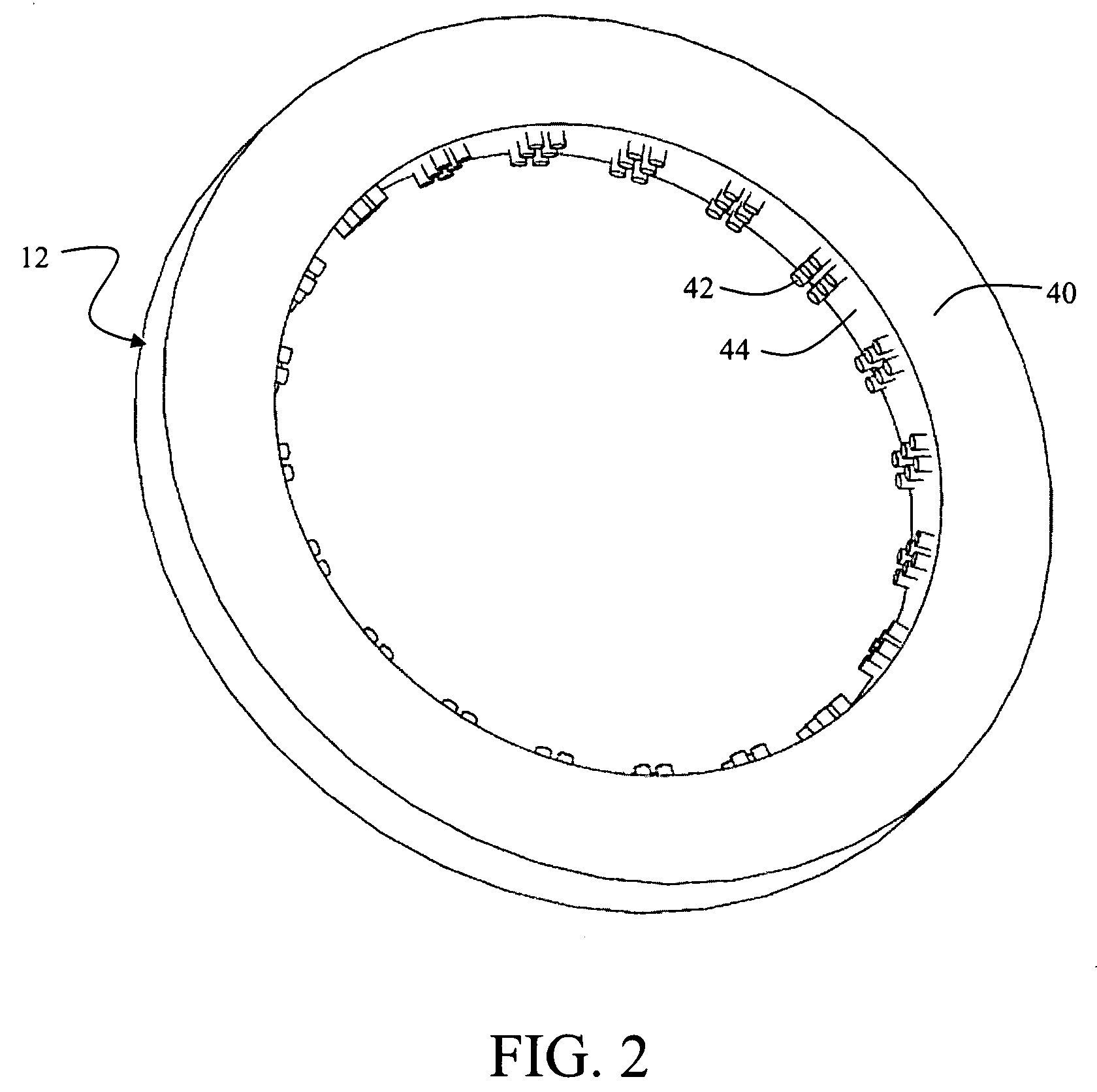

Pre-fabricated fireproof bulkhead with special interlocking joints for a ship

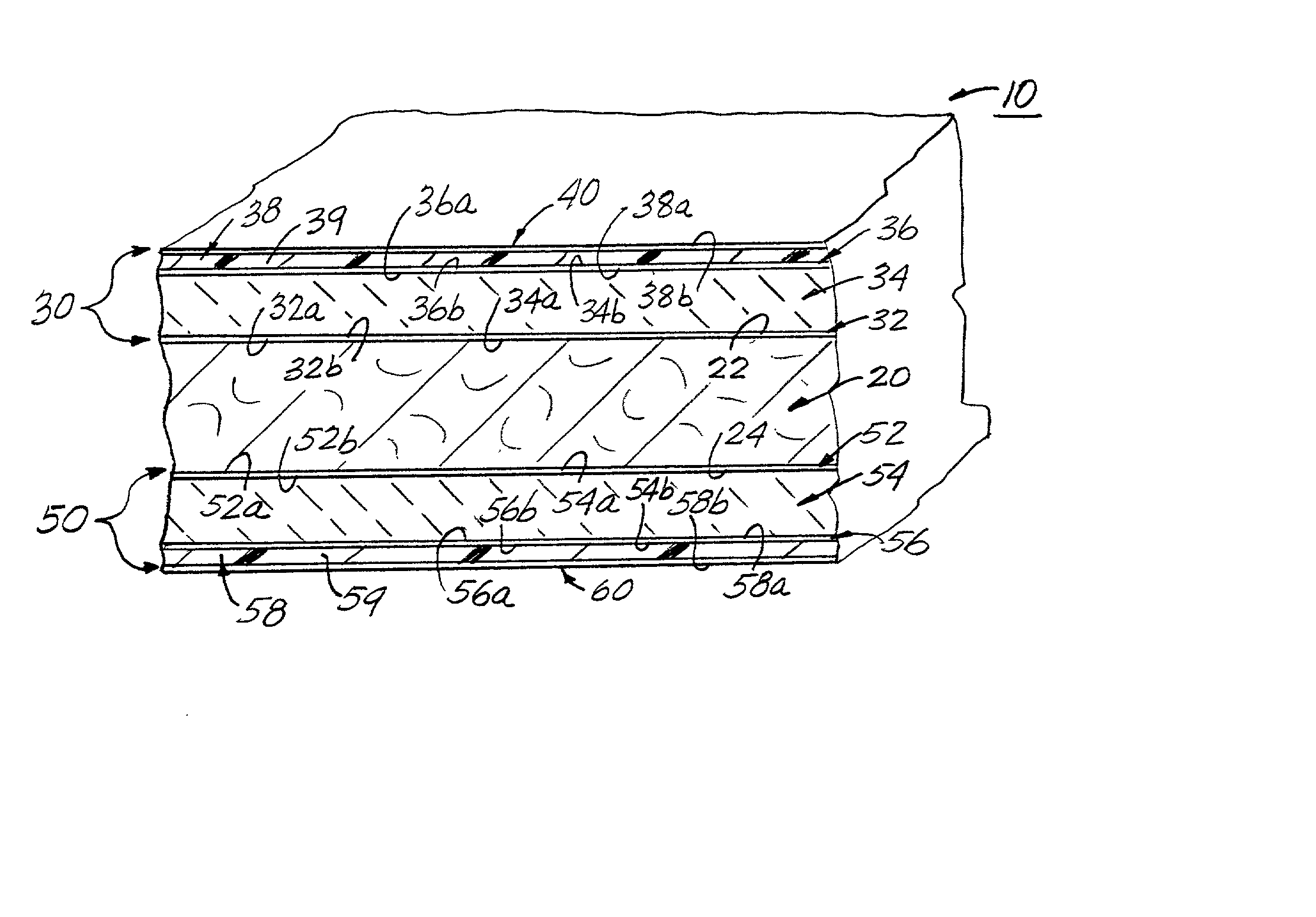

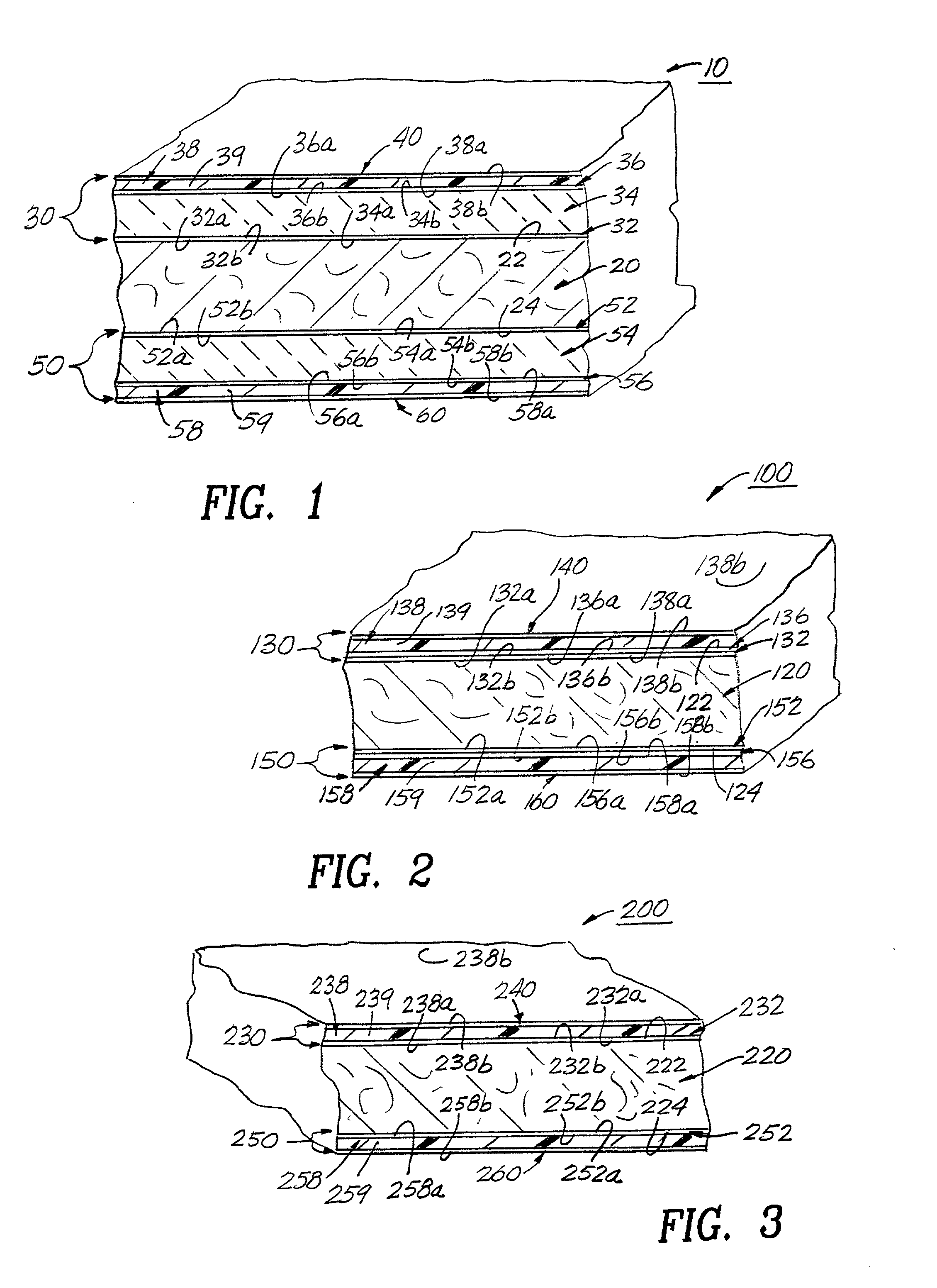

A prefabricated fireproof bulkhead section for a ship. The fireproof bulkhead section includes an inner core layer made of an incombustible fiber material and having a first side for receiving a first composite and a second side for receiving a second composite for forming a fireproof bulkhead section. The first composite includes a first metal layer formed of a metal sheet, a first ceramic layer formed of ceramic fibers, a first foil layer formed of a metal foil sheet and a first outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet; and the second composite includes a second metal layer formed of a metal sheet, a second ceramic layer formed of ceramic fibers, a second foil layer formed of a metal foil sheet and a second outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet. The fireproof bulkhead section further includes connecting means in the form of section locking joints for connecting and interlocking two or more of fireproof bulkhead sections together. The fireproof bulkhead section provides protection for at least 60 minutes at a temperature of up to 1700° F.; and has a weight of less than 4.5 lbs per square foot. An interlocking fireproof bulkhead paneling system for supporting a plurality of fireproof bulkhead sections for a ship's bulkhead. The interlocking fireproof paneling bulkhead system includes a plurality of fireproof bulkhead sections each having an upper edge and a lower edge; a plurality of connected ceiling track members for slidably receiving the upper edges of the plurality of fireproof bulkhead sections; and a plurality of connected floor track members for slidably receiving the lower edges of the plurality of fireproof bulkhead sections. Each of the fireproof sections includes connecting means in the form of section locking joints for connecting and interlocking two or more of the fireproof bulkhead sections together. Each of the fireproof bulkhead sections includes an inner core layer made of an incombustible fiber material and having a first side for receiving a first composite and a second side for receiving a second composite for forming said fireproof bulkhead section. The first composite includes a first metal layer formed of a metal sheet, a first ceramic layer formed of ceramic fibers, a first foil layer formed of a metal foil sheet and a first outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet; and the second composite includes a second metal layer formed of a metal sheet, a second ceramic layer formed of ceramic fibers, a second foil layer formed of a metal foil sheet and a second outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet. The interlocking fireproof bulkhead paneling system provides protection for at least 60 minutes at a temperature of up to 1700° F; and has a weight of less than 4.5 lbs per square foot.

Owner:NO FIRE ENG

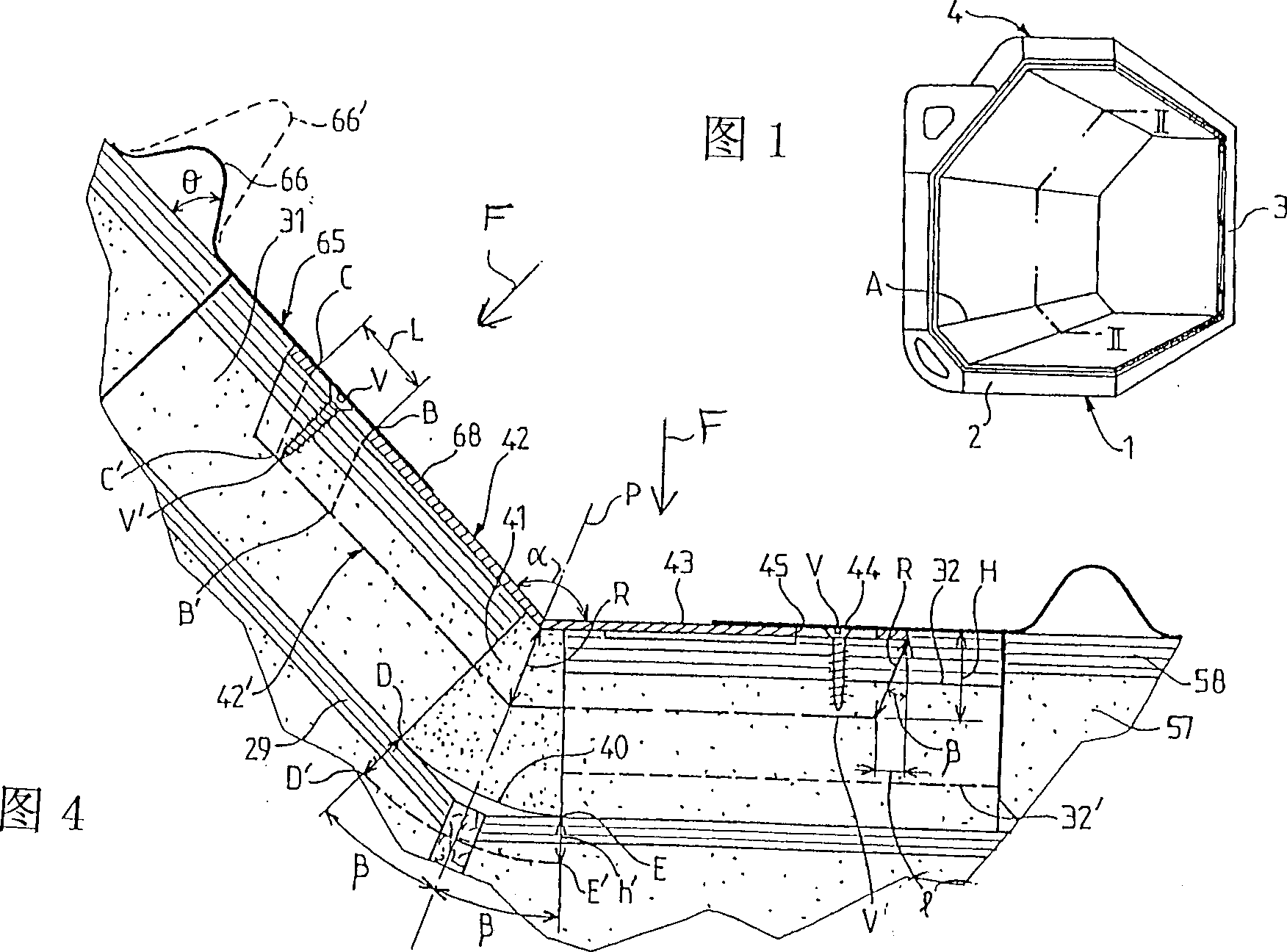

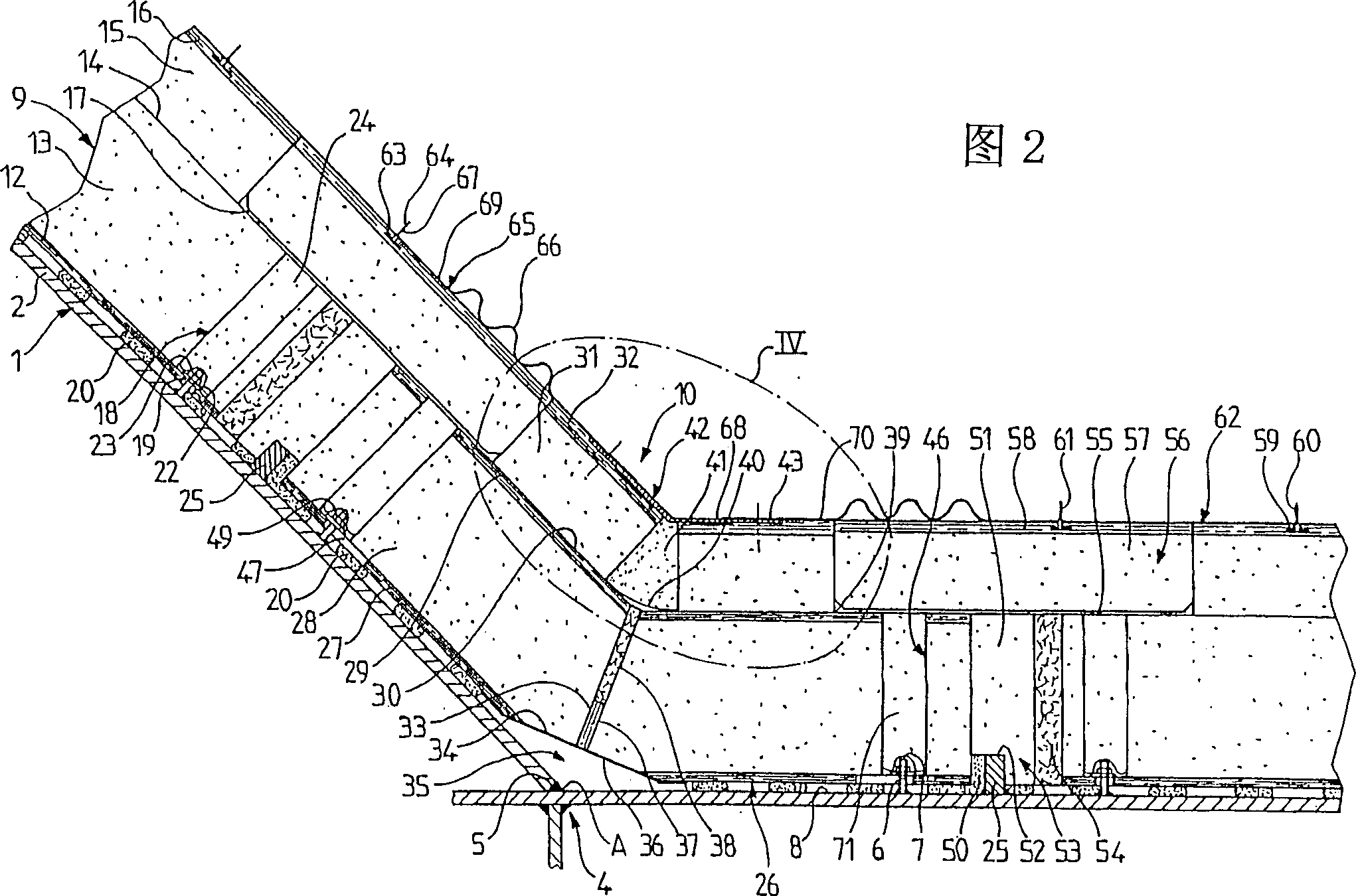

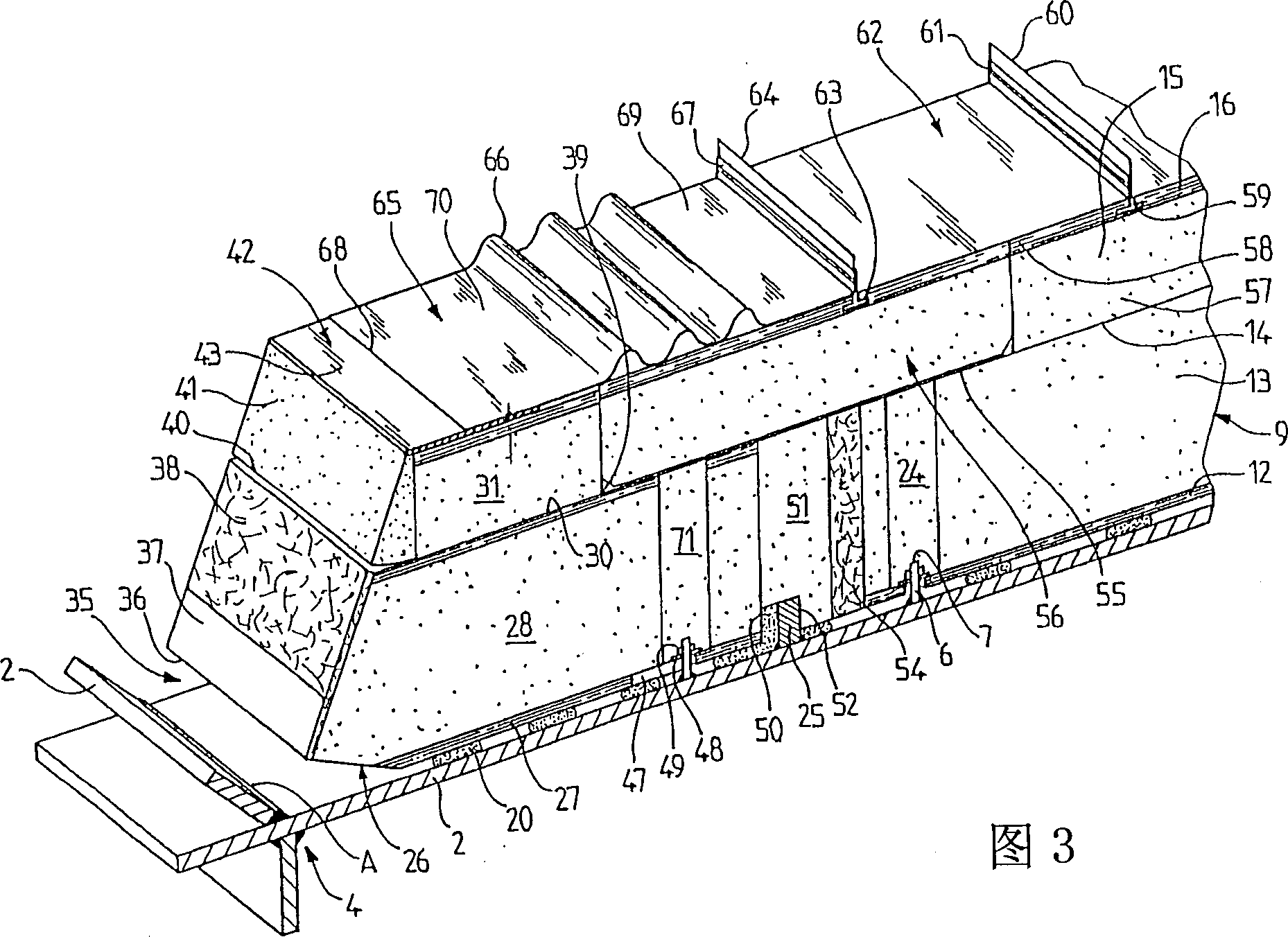

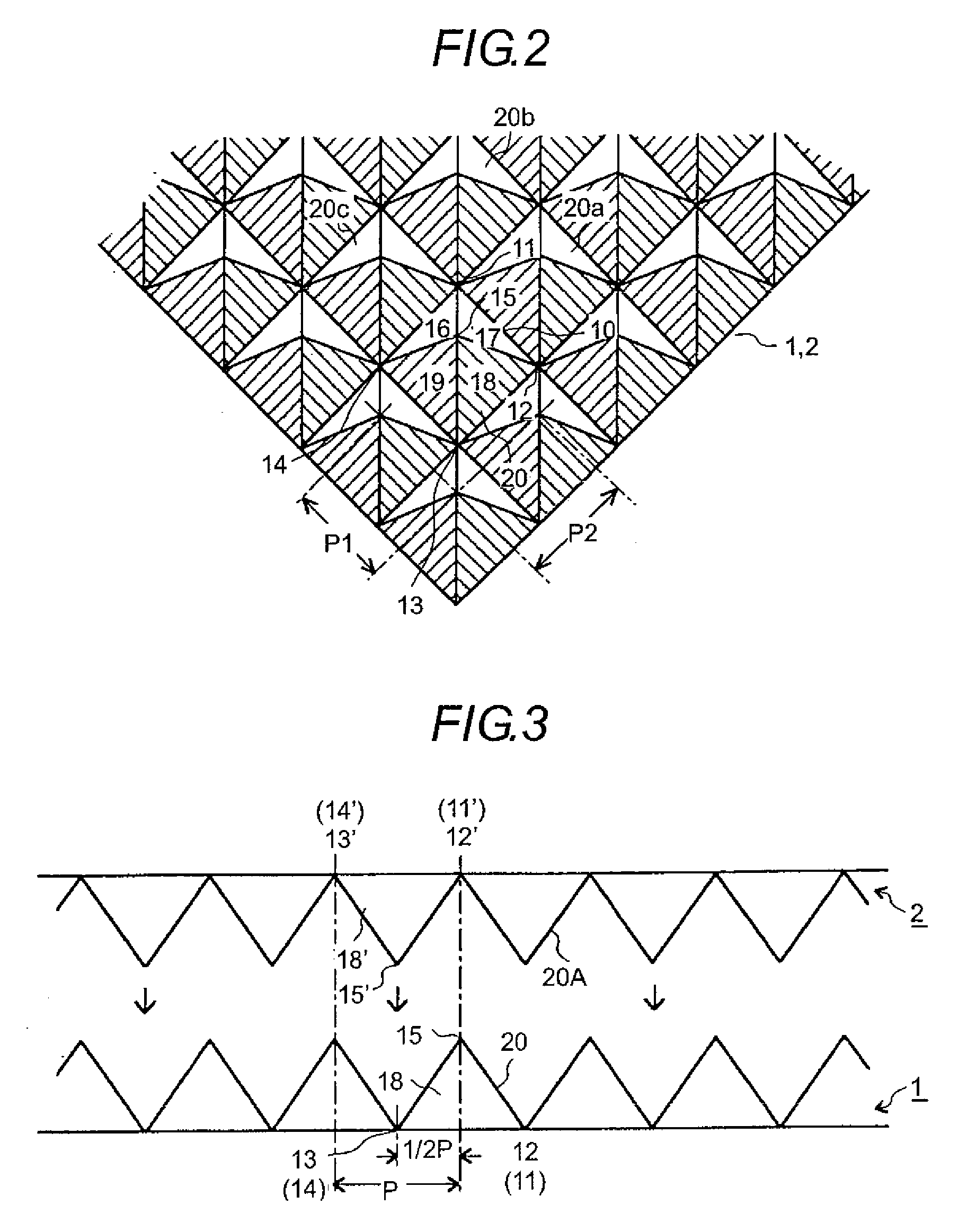

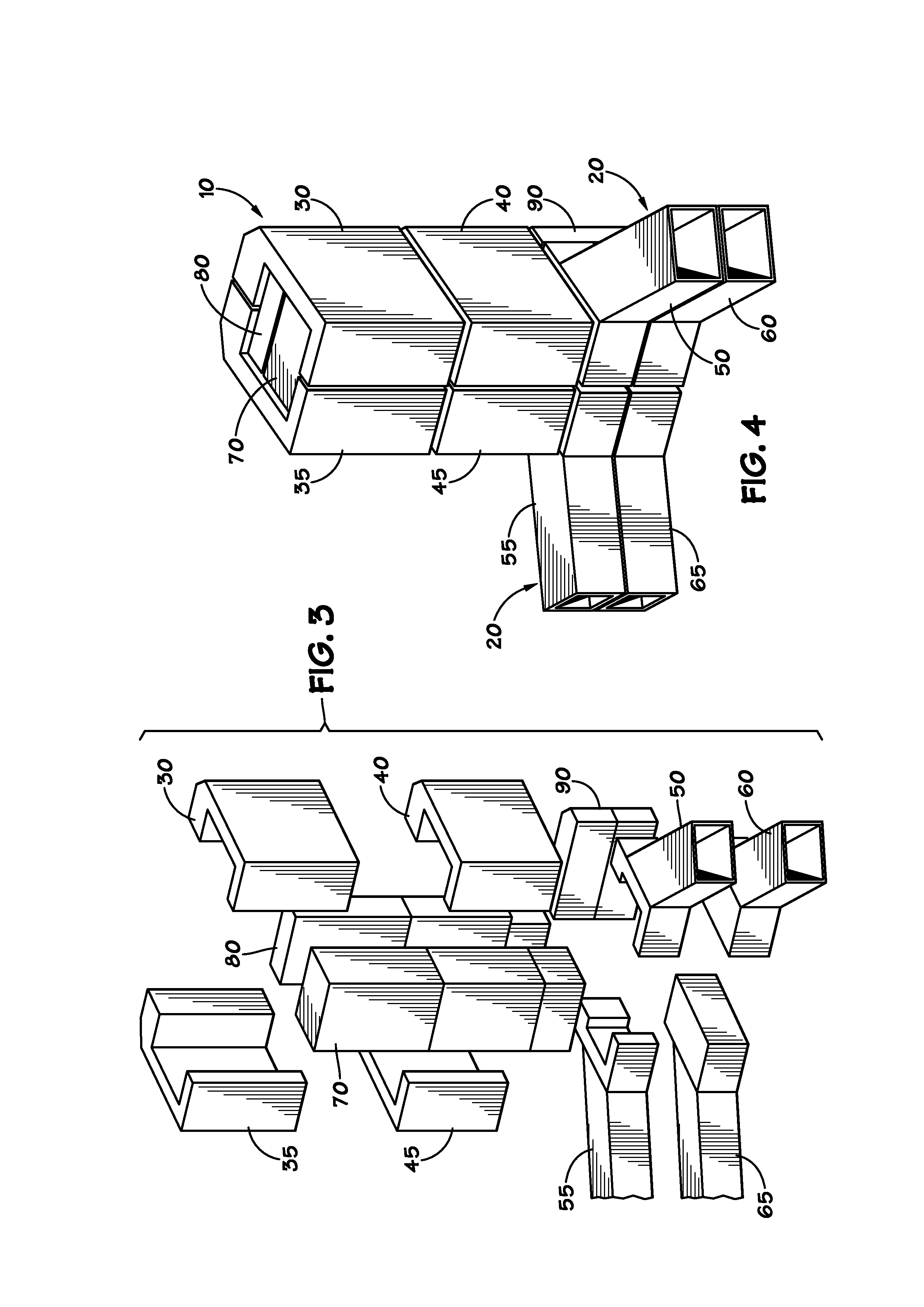

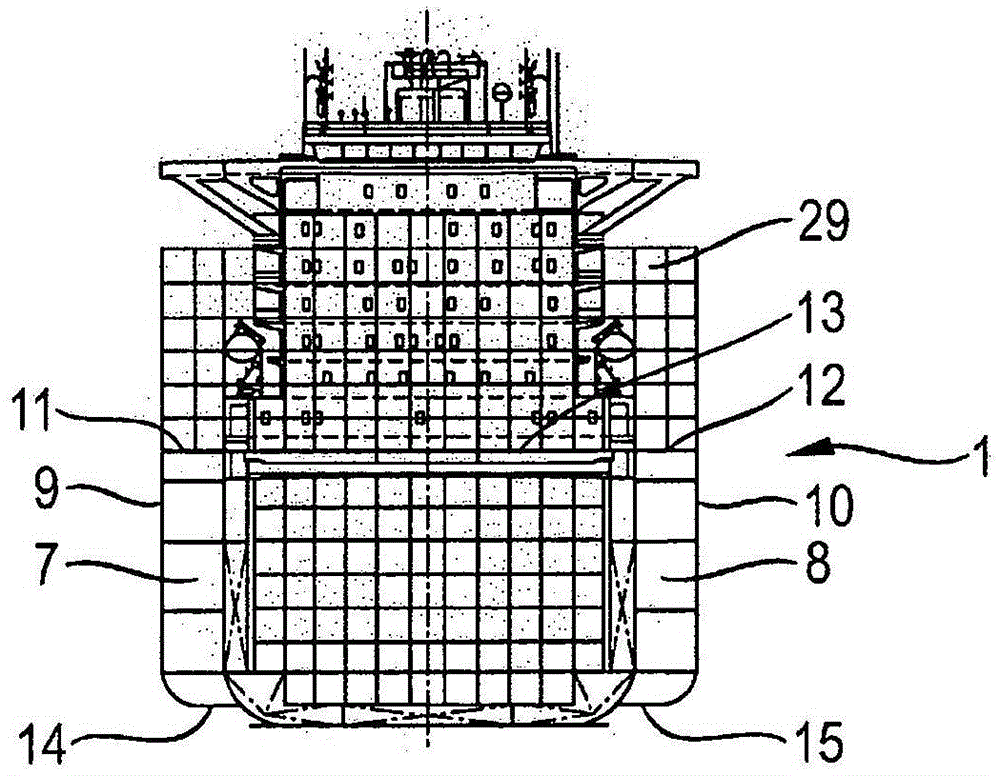

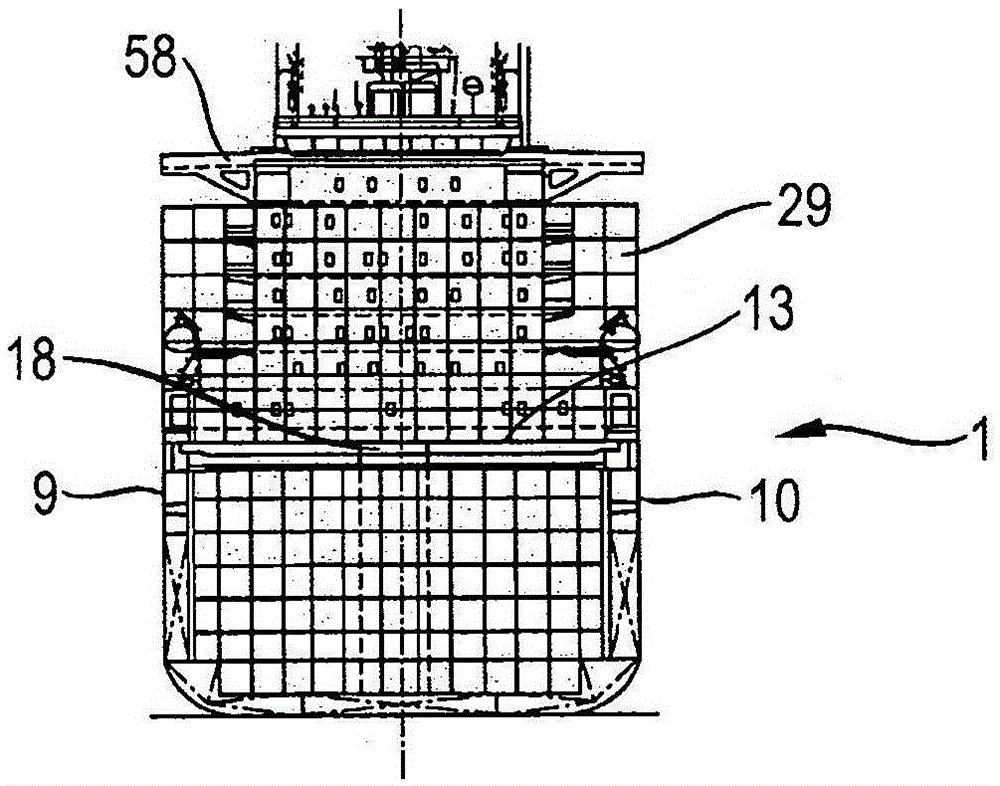

Watertight heat insualtion container with improved longitudinal stereo cross angle

Watertight and thermally insulating tank intended for the transportation of liquefied gases by sea, said tank being built into a bearing structure (1) comprising longitudinally adjacent faces (2) forming a dihedron (4); said tank comprising two successive watertightness barriers, one of them a primary watertightness barrier in contact with the product contained in the tank and the other a secondary watertightness barrier (14,55,30,40) arranged between said primary watertightness barrier and the bearing structure, a primary thermally insulating barrier (12,13,24,27,28,29,37,38,51,54,71) being arranged between these two watertightness barriers and a secondary thermally insulating barrier (15,16,57,58,31,32,41) being arranged between said secondary watertightness barrier and the bearing structure; said primary watertightness barrier comprising substantially flat running metal strakes (62) and, on each side of the longitudinal solid angle of intersection (A) of at least one of said dihedra, a longitudinal row of corner strakes (65) which are corrugated so that they can deform transversely.

Owner:GAZTRANSPORT & TECHNIGAZ SA

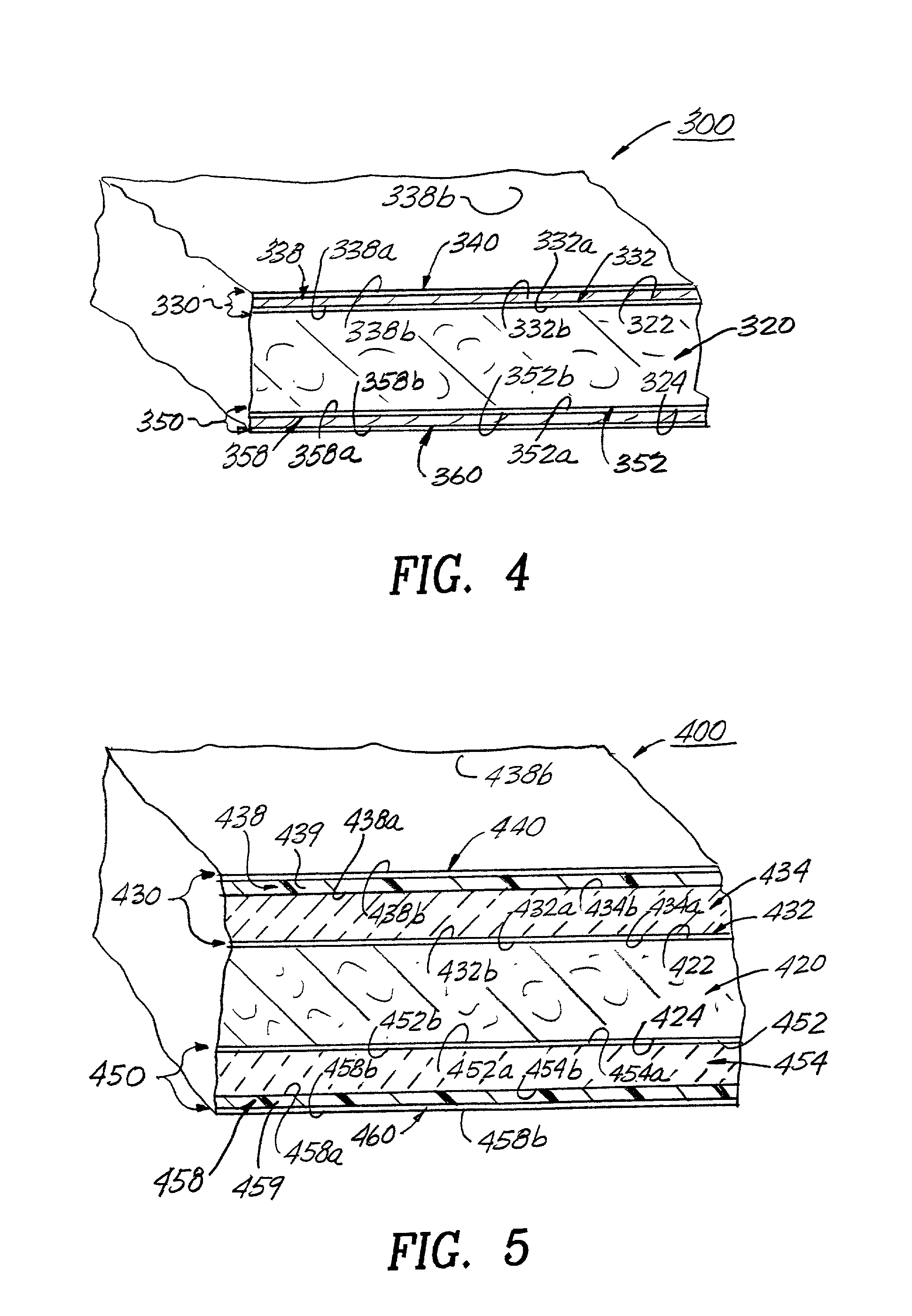

Pre-fabricated fireproof bulkhead with special interlocking joints for a ship

A prefabricated fireproof bulkhead section for a ship. The fireproof bulkhead section includes an inner core layer made of an incombustible fiber material and having a first side for receiving a first composite and a second side for receiving a second composite for forming a fireproof bulkhead section. The first composite includes a first metal layer formed of a metal sheet, a first ceramic layer formed of ceramic fibers, a first foil layer formed of a metal foil sheet and a first outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet; and the second composite includes a second metal layer formed of a metal sheet, a second ceramic layer formed of ceramic fibers, a second foil layer formed of a metal foil sheet and a second outer layer formed of an intumescent, fire-retardant coating on a fiberglass sheet. The fireproof bulkhead section further includes connecting means in the form of section locking joints for connecting and interlocking two or more of fireproof bulkhead sections together. The fireproof bulkhead section provides protection for at least 60 minutes at a temperature of up to 1700° F.; and has a weight of less than 4.5 lbs per square foot.

Owner:NO FIRE ENG

Ship with a special lower level

InactiveUS20100071607A1Reduce pressureImproves ship 's performanceNon-magnetic metal hullsSteering ruddersMarine engineeringFront and back ends

Owner:KONSTANTINOVSKIY ALEXANDR

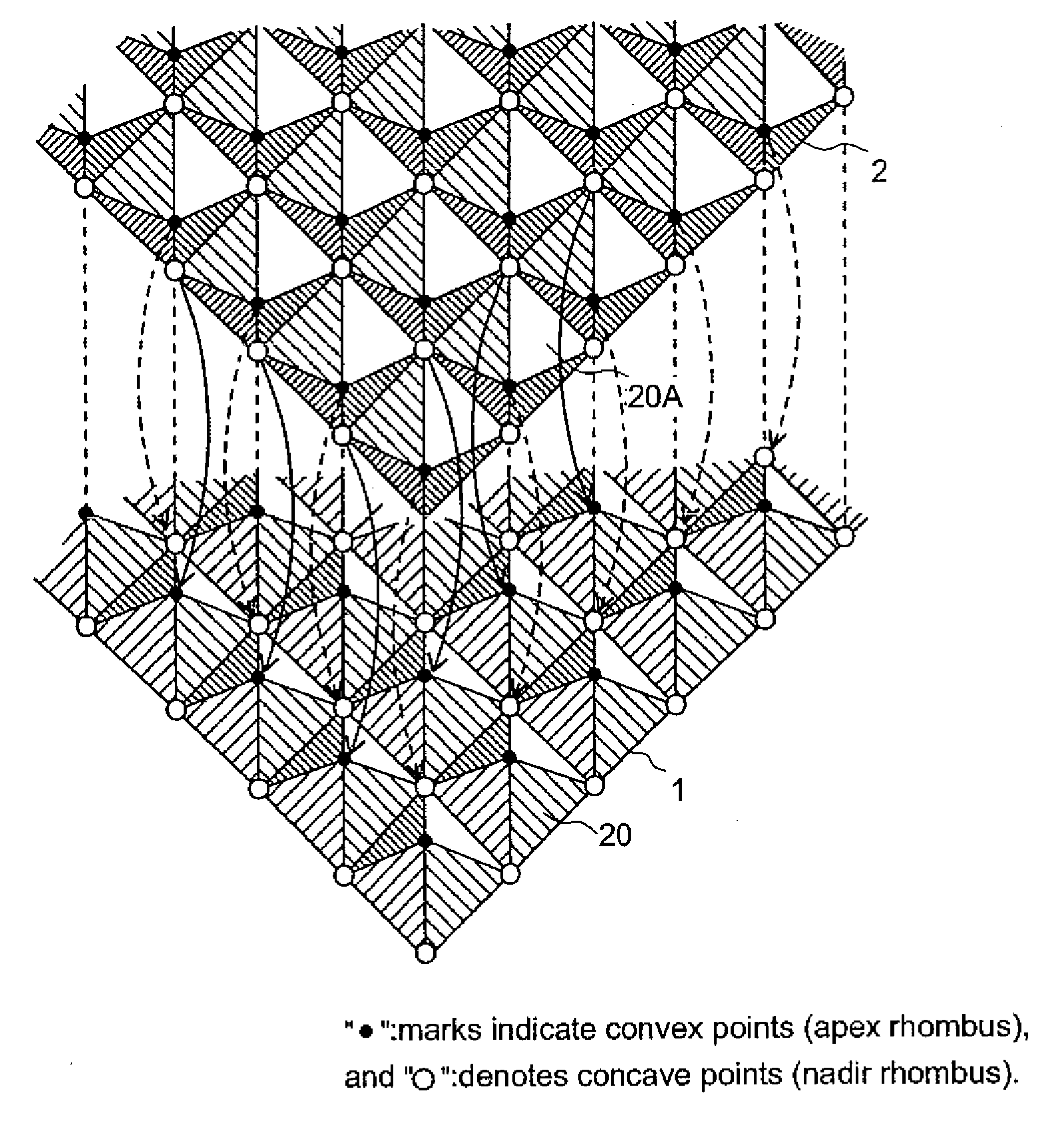

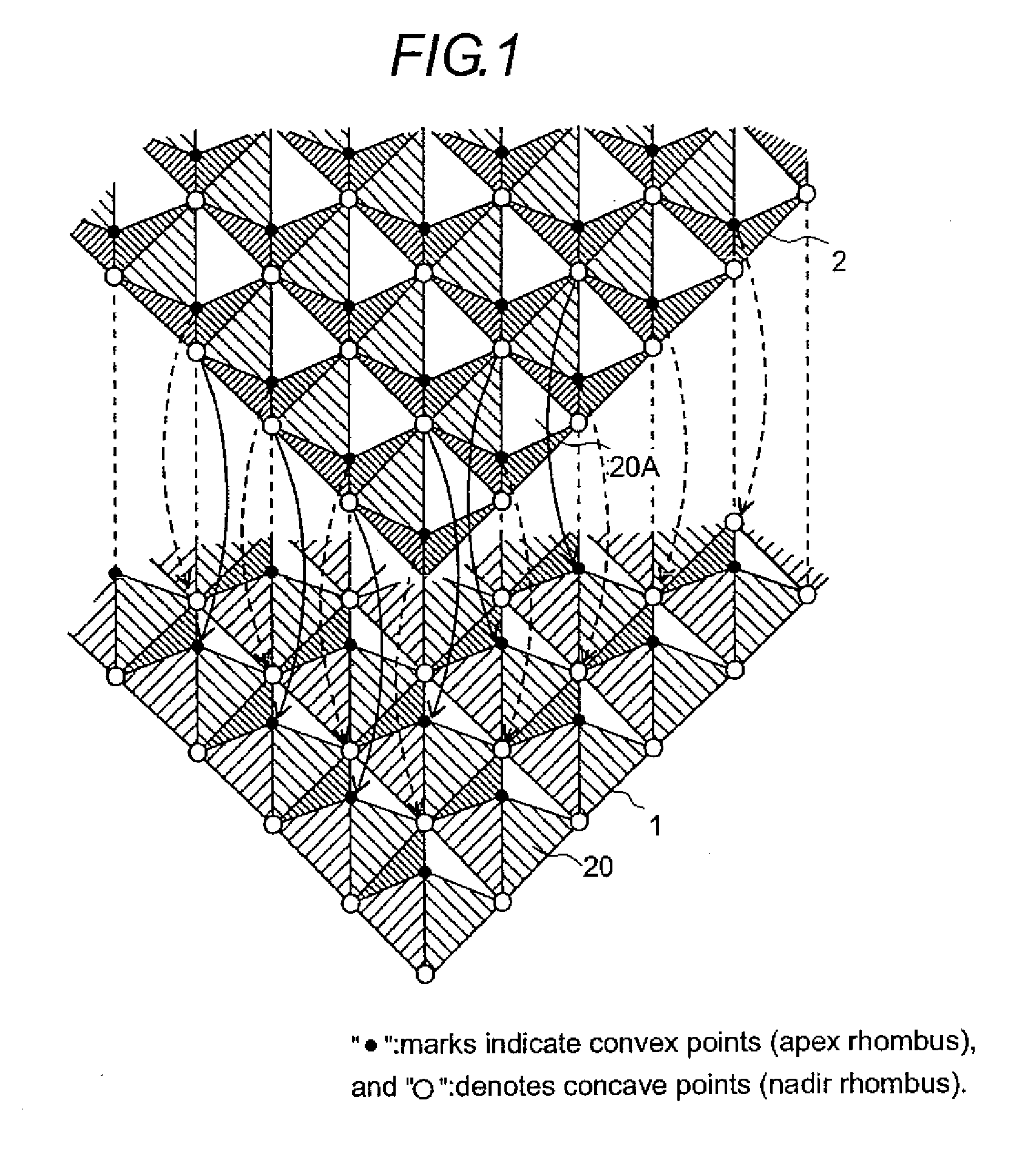

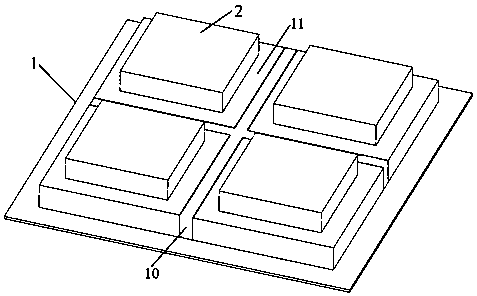

Space truss structure surface slab assembly

An apex rhombus is delimited over the center point of a square, which is delimited by plotting four nadir rhombuses on the same plane, and each of the nadir rhombuses and the apex rhombus are jointed to form a group of pyramidal surfaces equipped with four planar slopes having substantially the same height in a pyramidal form. Two pyramidal surface slabs are assembled, each composed of pyramidal surfaces around one pyramidal surface, each sharing one nadir rhombus, adjacent each other, and arranged in a grid pattern at an equal pitch in plural directions. The pyramidal surfaces arranged in a grid pattern are each displaced by one-half pitch in a specific direction, such that the apex rhombus of one of the pyramidal surface comes in contact with the nadir rhombus of the other pyramidal surface, whereby the two pyramidal surfaces are placed one on the other.

Owner:SHOJI BUNICHI

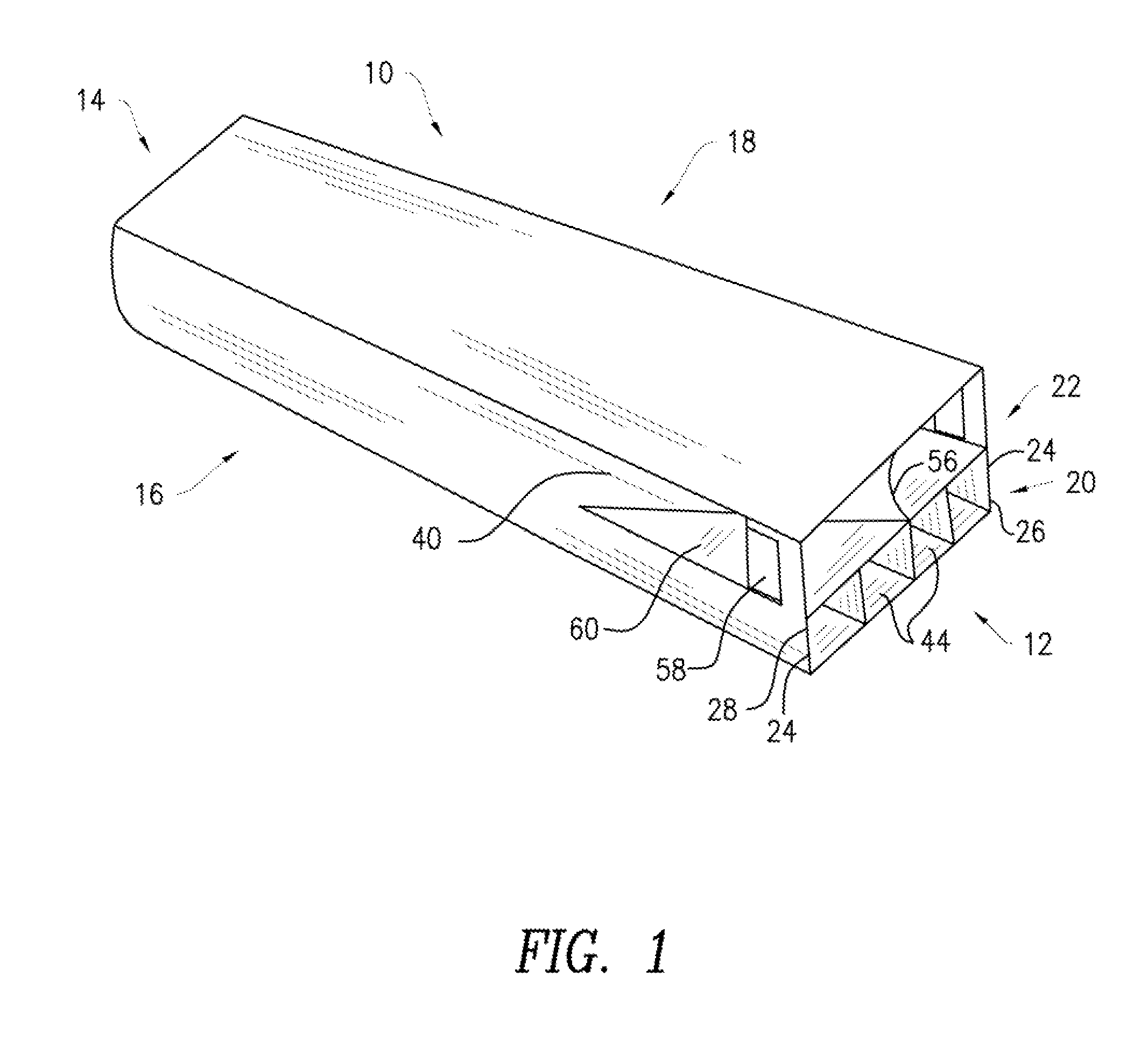

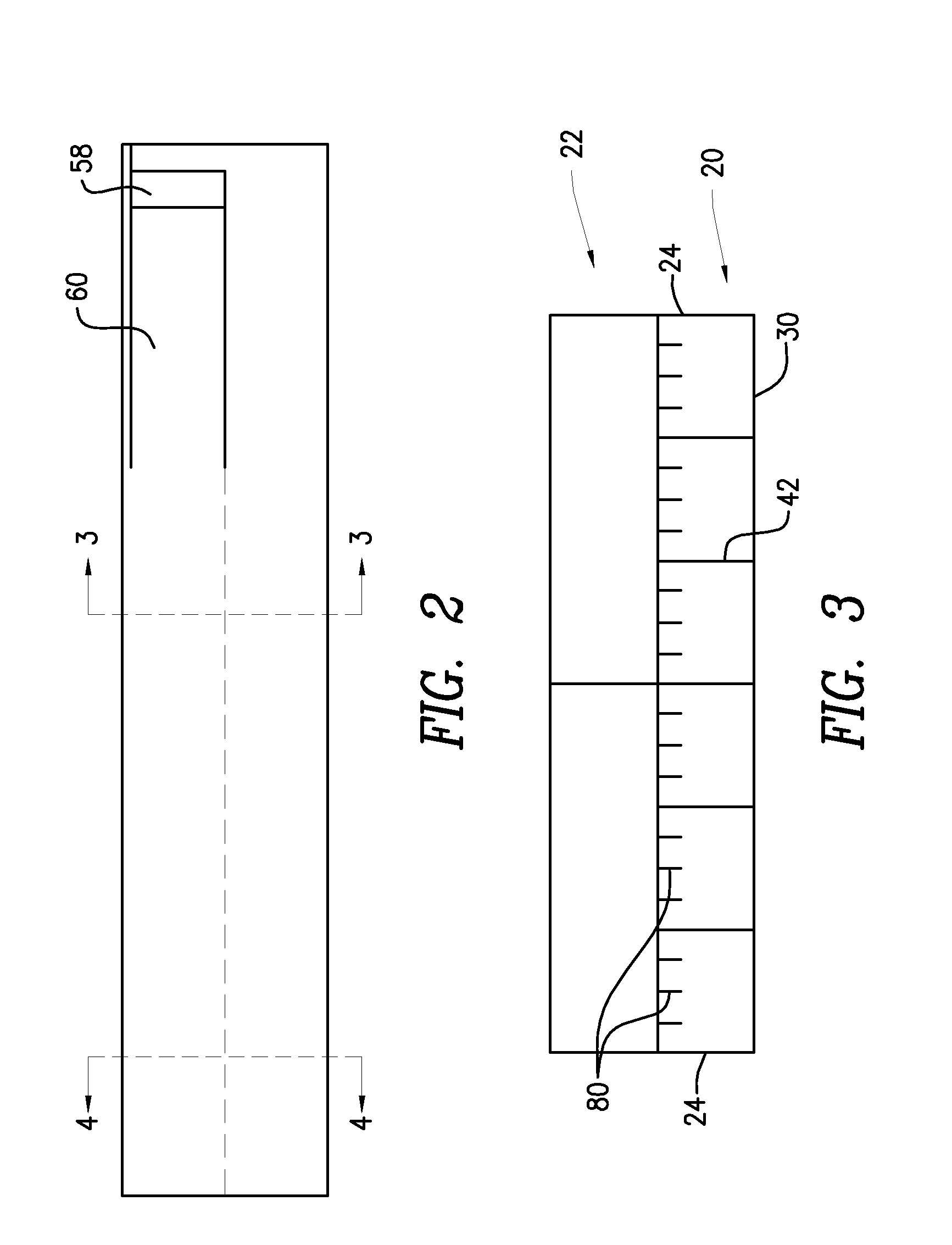

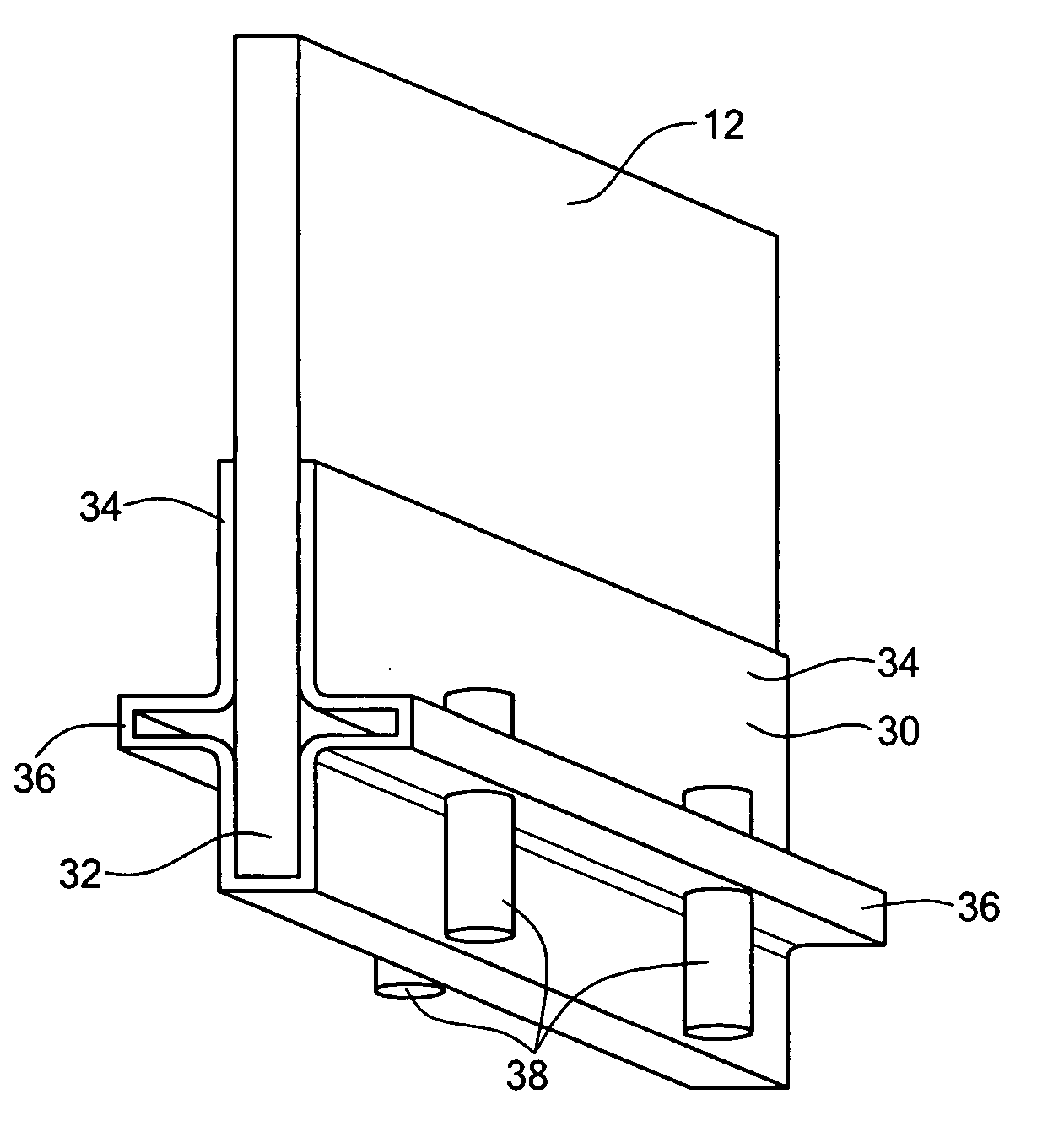

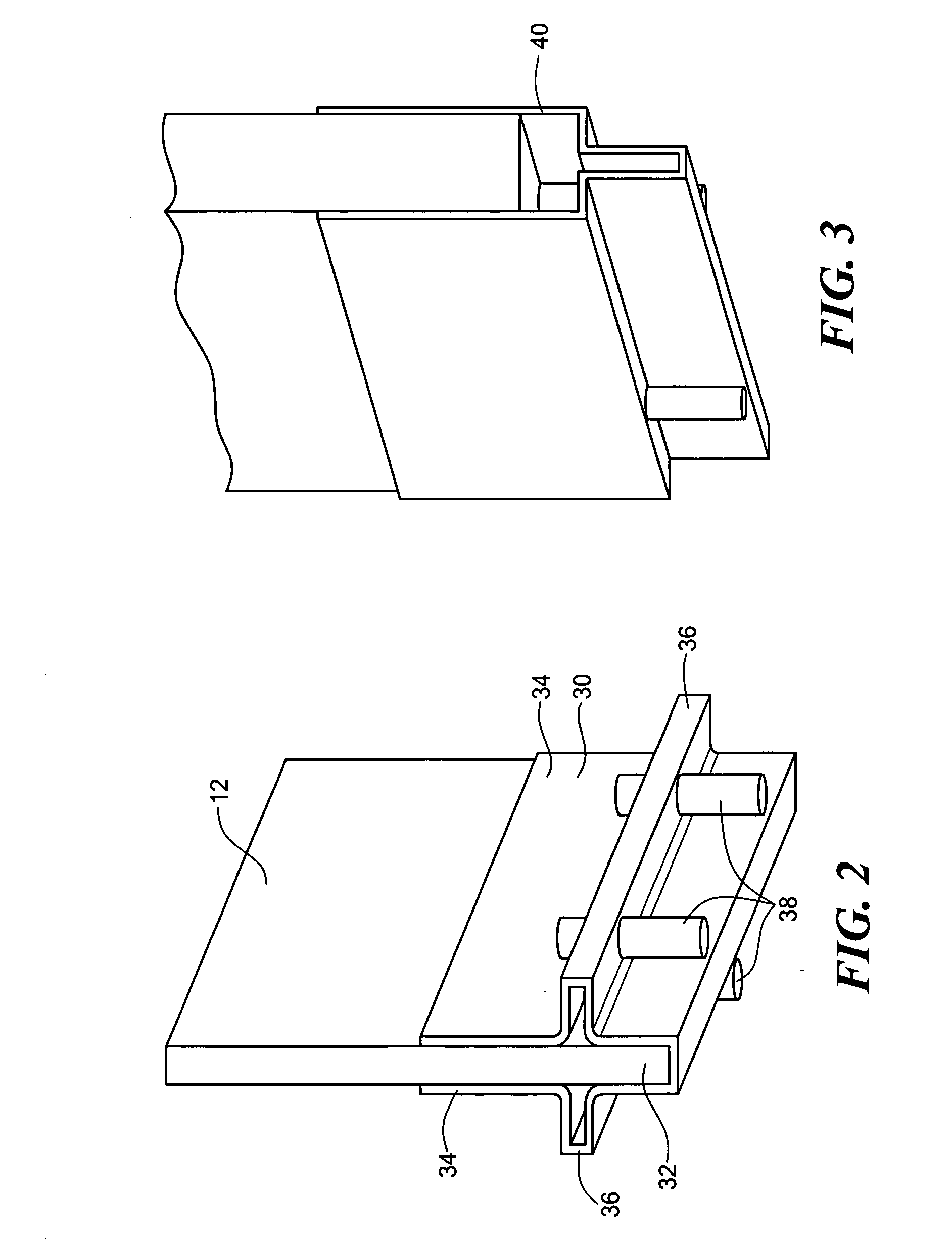

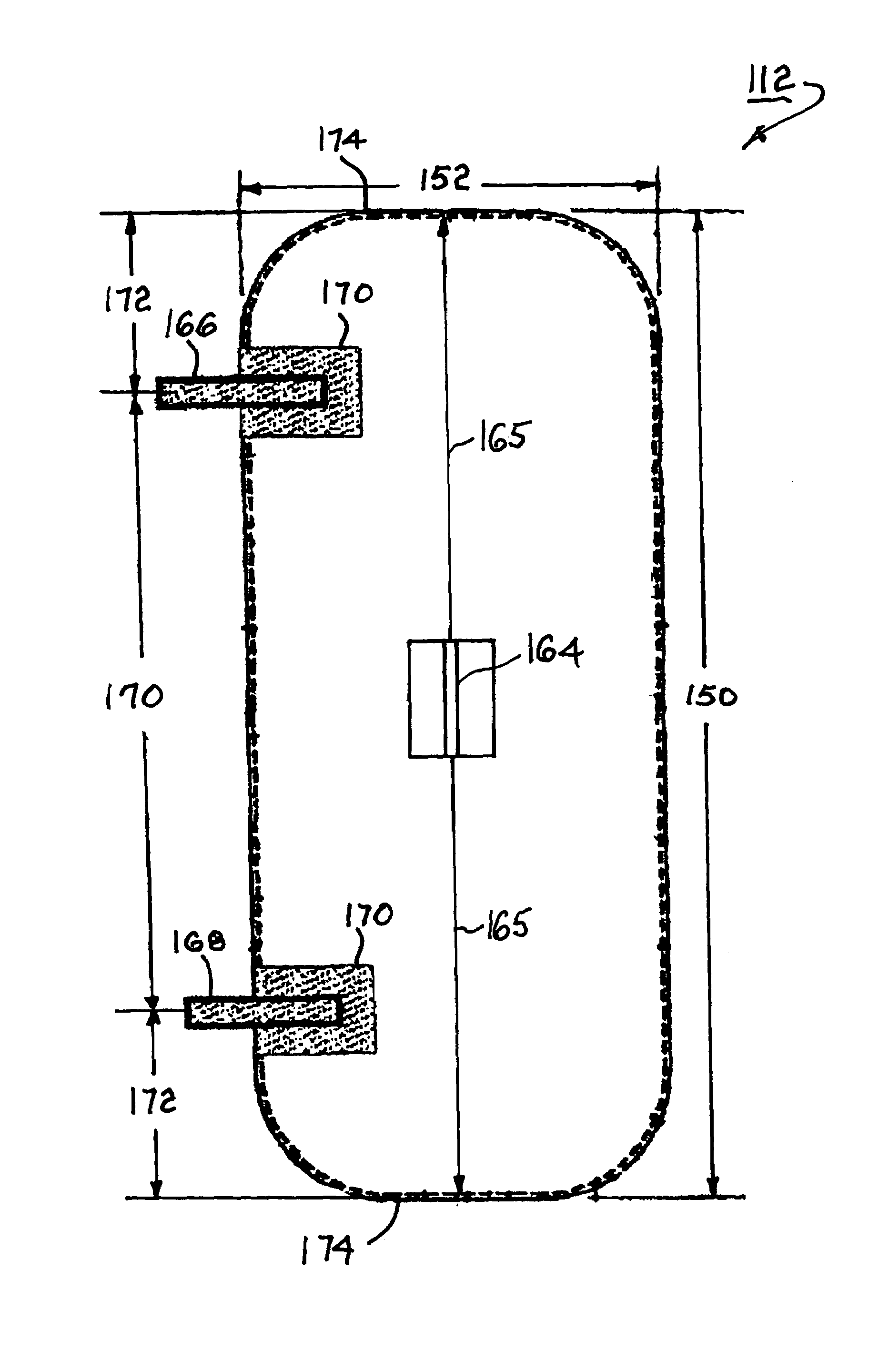

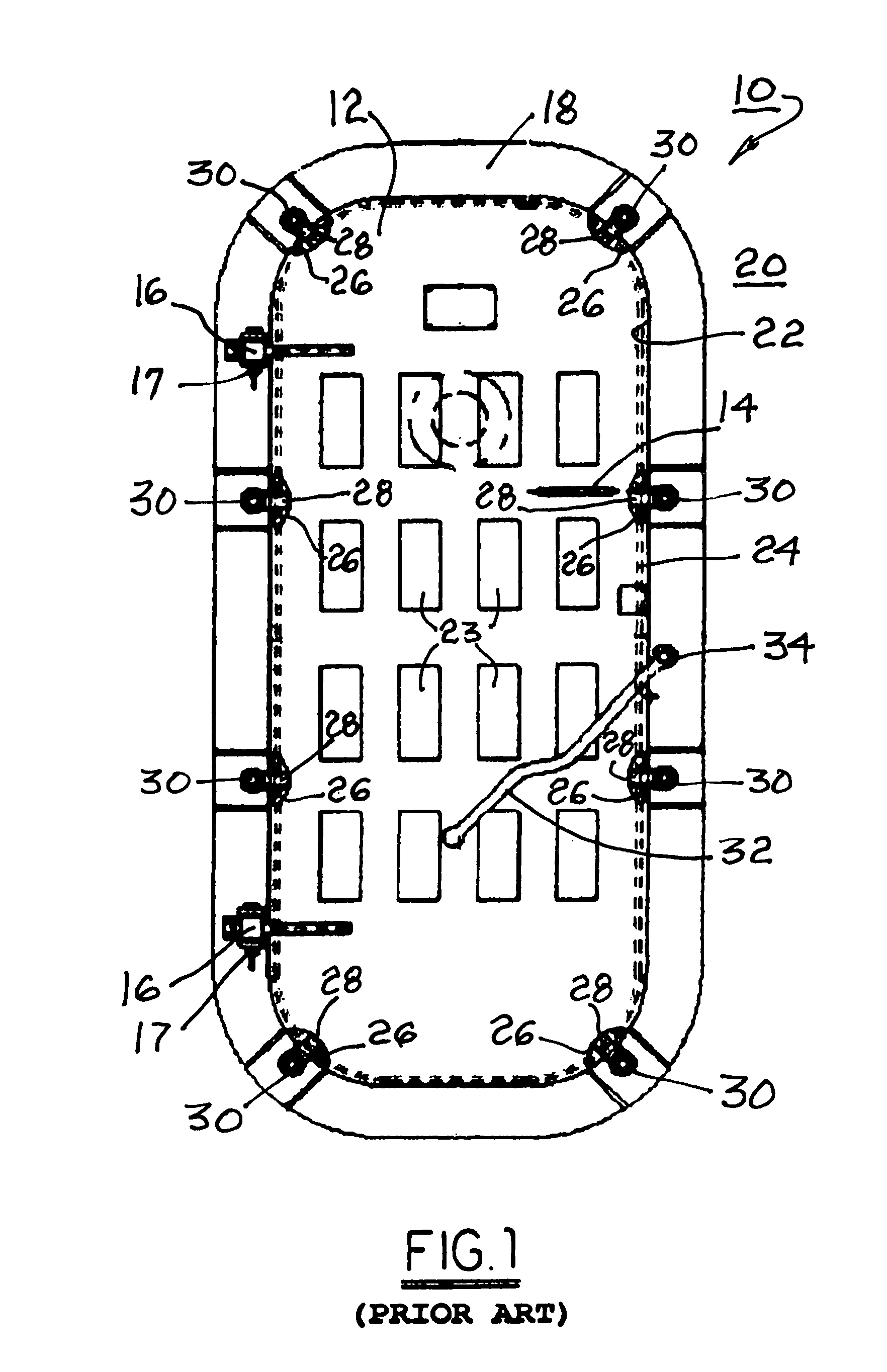

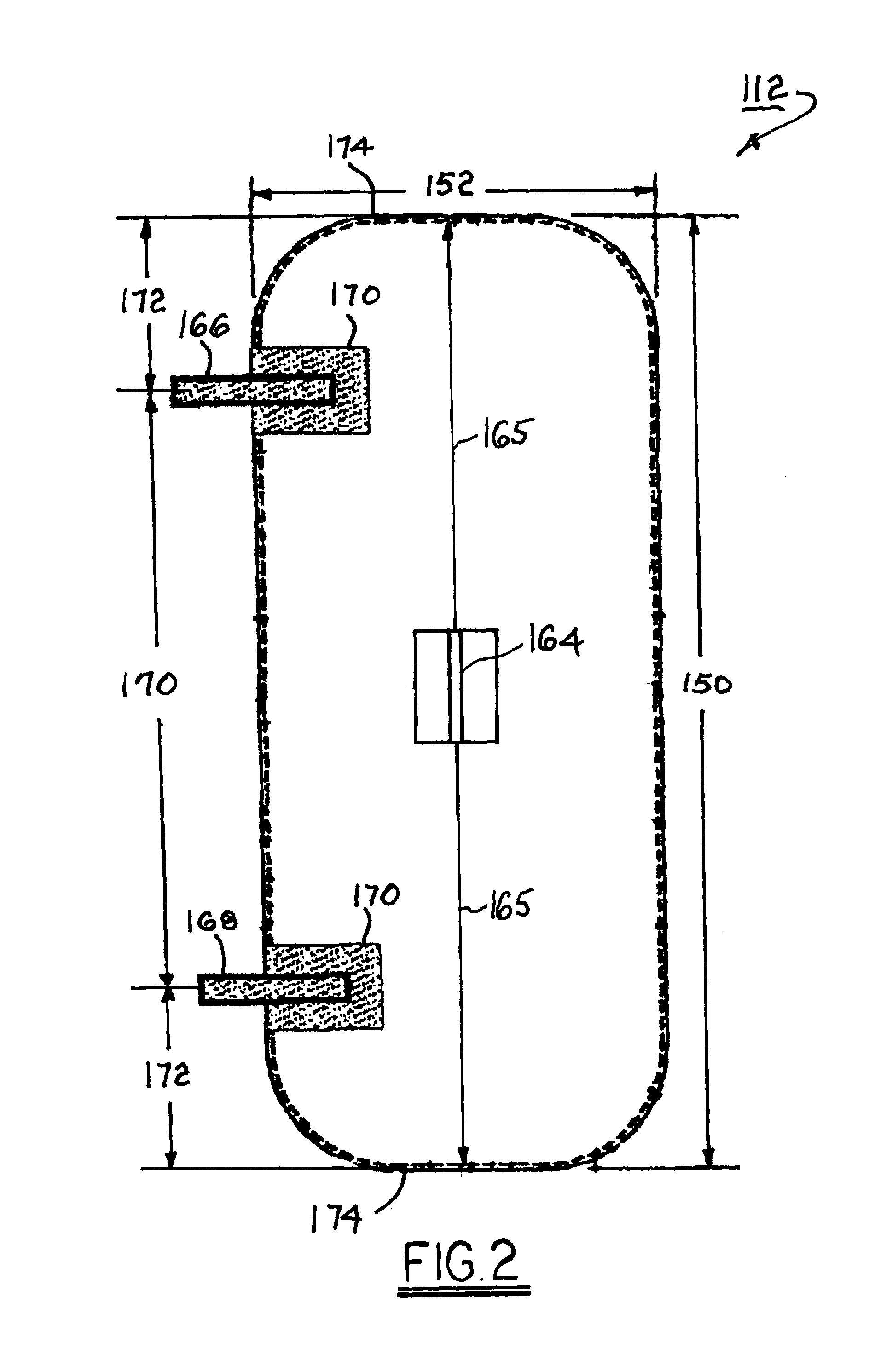

Joiner panel system

InactiveUS20050072087A1Easy to installReduce the time required for installationRoof covering using tiles/slatesLaminationFiberMicrosphere

A joiner panel system is formed from a composite material and includes a panel attached to a deck by a coaming or shoe and attached at its upper edge by a curtain plate that fits around obstructions at the ceiling area. The shoe can be readily installed to an uneven steel deck by stud welding to reduce installation time or attached to a composite material deck. A curtain plate fabrication method uses a laser scan or close range photogrammetry of the overhead area to optimize and automate the cutting of curtain plate sections. The curtain plate sections can then be readily installed in the overhead area. A composite material panel to provide good flame, smoke and toxicity properties and good mechanical properties is formed from a phenolic resin foam material, micro-balloons to reduce the weight and density, and reinforcing fibers and powder material to improve the mechanical properties. The panel can be formed by a method in which the core and face skins are co-cured to provide a good bond.

Owner:KAZAK COMPOSITES

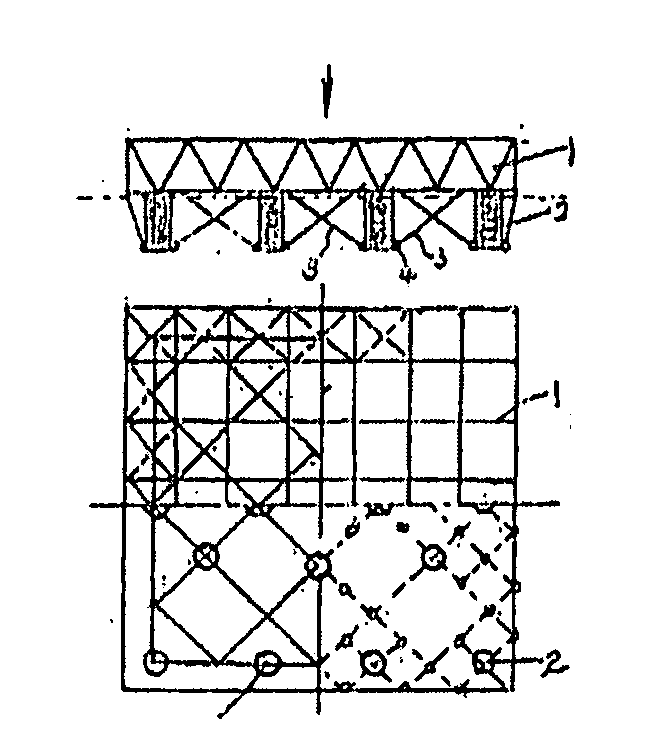

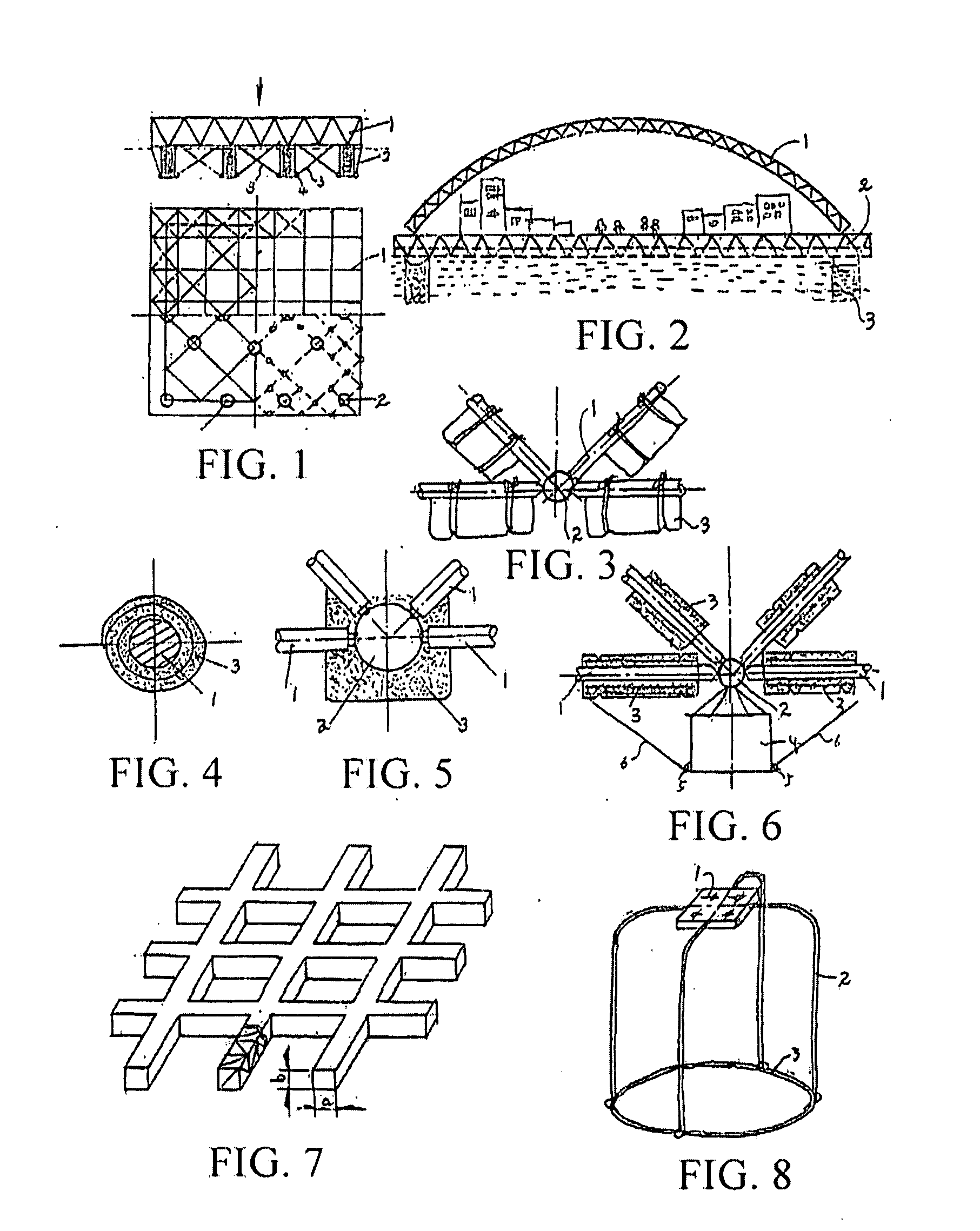

Floating Latticework

InactiveUS20100218712A1Improve rigidityHigh strengthBascule bridgesHull bulkheadsMarine engineeringSpatial structure

A floating latticework is suitable for a latticework, a truss-frame structure and a net-shell structure over water. The floating latticework is the combination of a latticework (1) and a floating structure (2), or members of the latticework (1) in themselves are able to float. The floating structure (2) makes the latticework (1) floated over water, the surface of upper chords of which is in form of a platy structure or covered and fixed with a platy structure, as a plane used for loading. There is an advantage that the space-structure floating body is less influenced by wind and wave, which go through its space. A ship structure and a cofferdam structure are parallel solutions with the above solution. Their skeletons are net-shell structure, wherein they are provided with high structural strength.

Owner:YAN JIANJUN

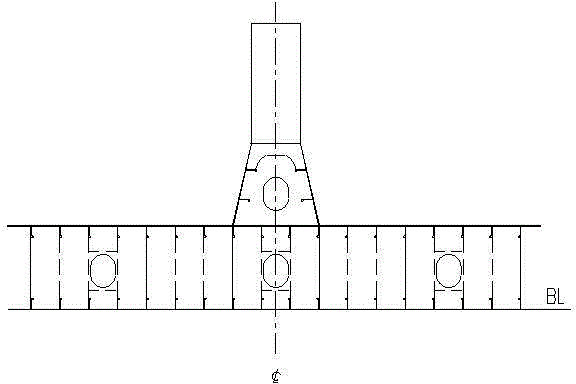

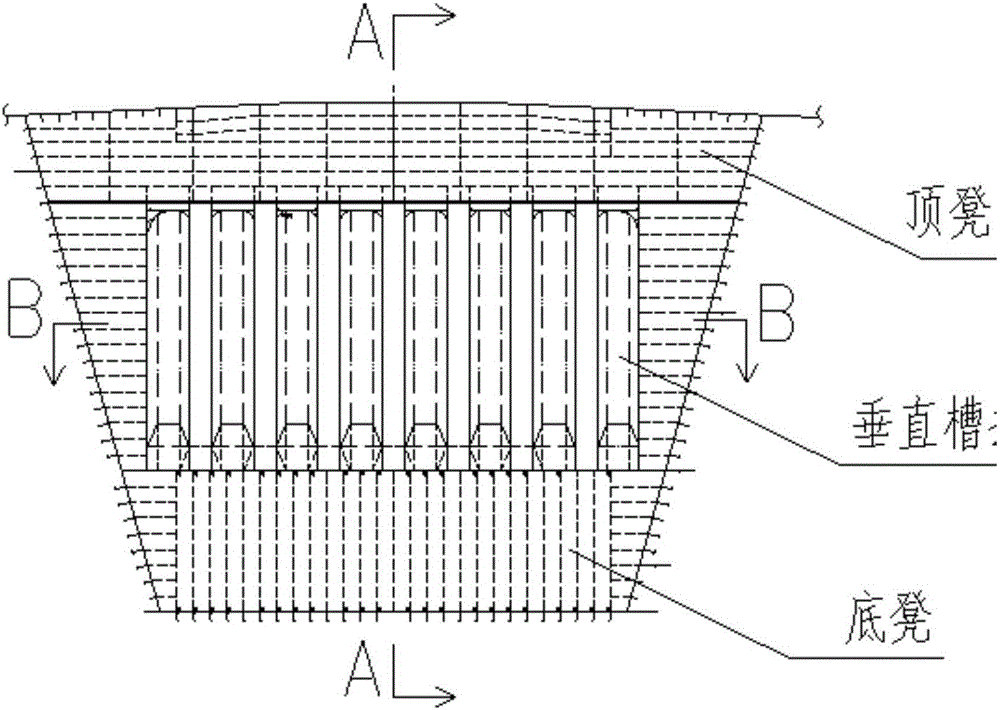

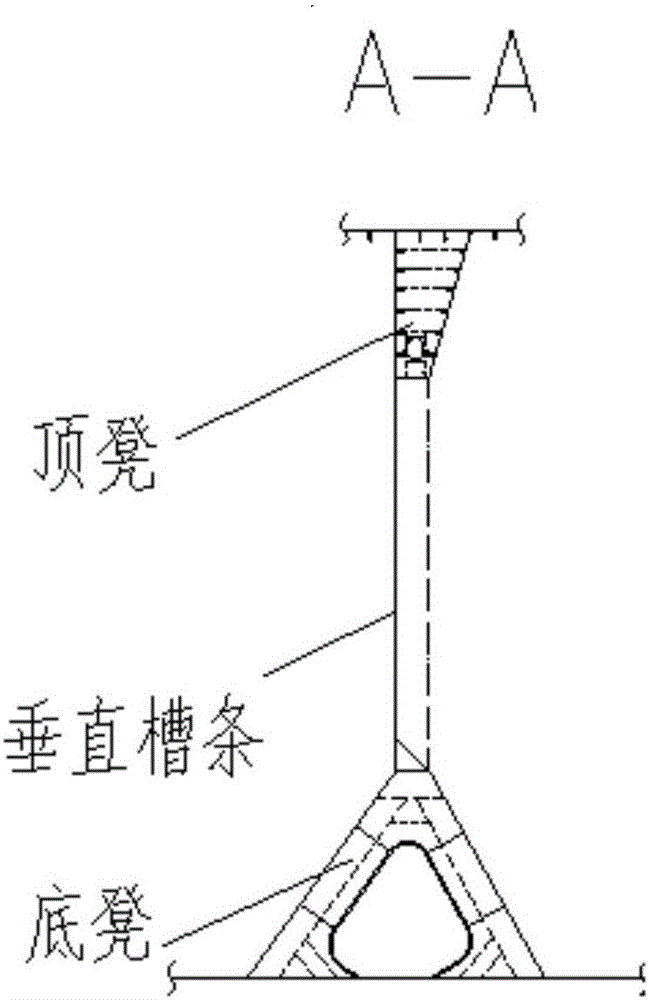

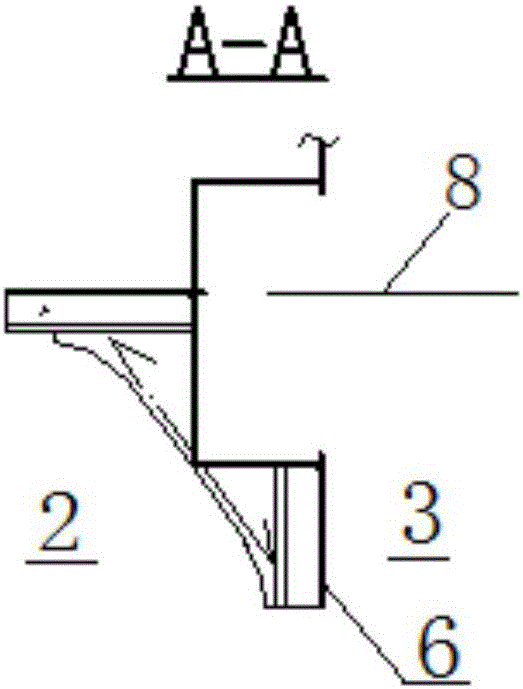

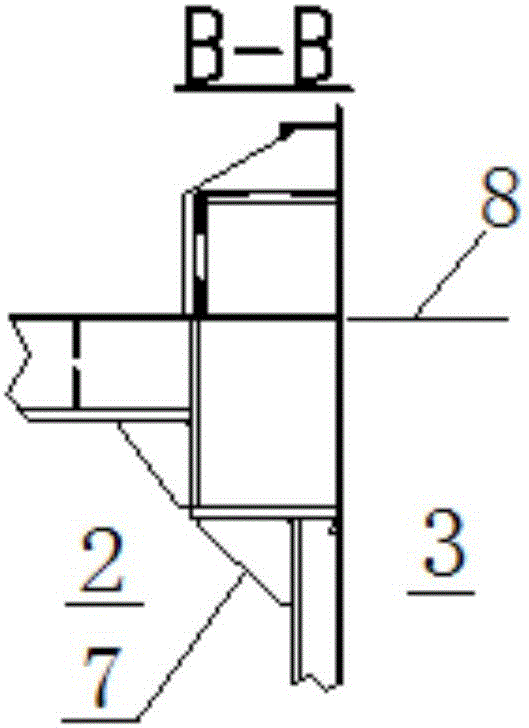

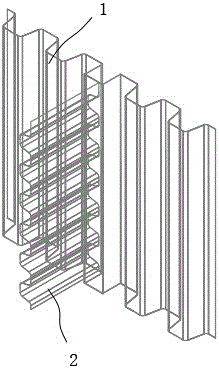

Bottom structure of vertical corrugated bulkhead of ship

InactiveCN103910027ALarge capacityIncrease loading capacityHull double bottomsHull bulkheadsStress concentrationMarine engineering

A bottom structure of a vertical corrugated bulkhead of a ship is characterized in that corrugated rib plates identical to the section of the corrugated bulkhead in shape are mounted and welded between a ship bottom plate and an inner bottom plate and at corresponding rib positions of the corrugated bulkhead to replace traditional planar solid rib plates, transitional reinforcement U-shaped toggle plates are mounted and welded at openings of notches at the upper ends of the corrugated rib plates and the lower end of the vertical corrugated bulkhead, U-shaped sides of the U-shaped toggle plates above the inner bottom plate are welded to a corrugated seal plate which functions in sealing the U-shaped toggle plates and facilitating cabin cleaning and serves as a discharging plate on a bulk freighter, U-shaped sides of the U-shaped toggle plates below the inner bottom plates are free sides, and horizontal reinforcement rib plates are welded close to the U-shaped sides of the U-shaped toggle plates. By mounting and welding the U-shaped toggle plates at the upper ends of the corrugated rib plates and the lower end of the vertical corrugated bulkhead, stress at the welding joint of the vertical corrugation bulkhead and the inner bottom plate is reduced while stress concentration is eliminated, and the corrugated rib plates can be thinned properly as compared with the corrugated bulkhead.

Owner:谢合清

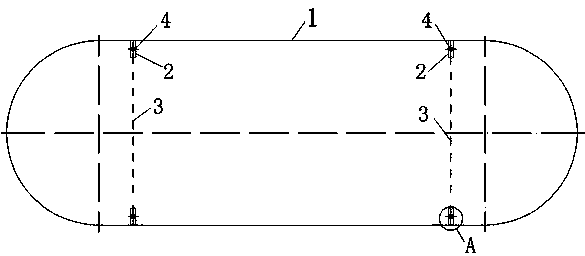

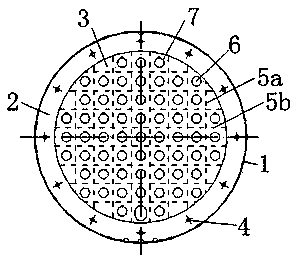

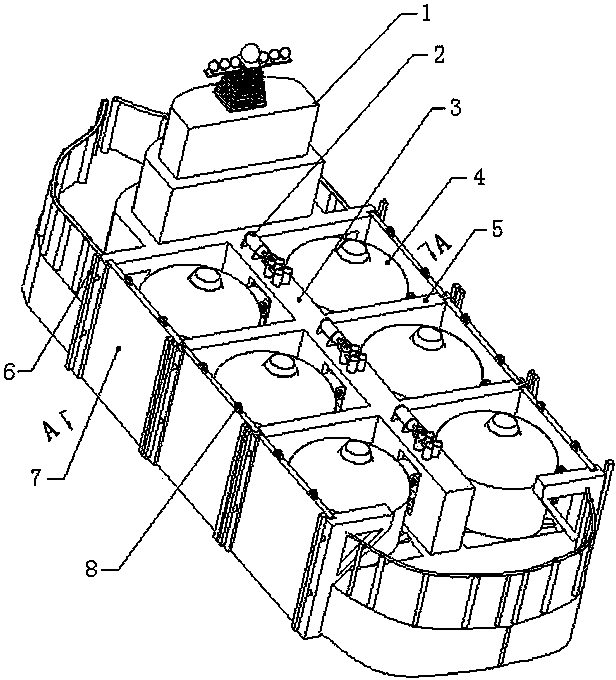

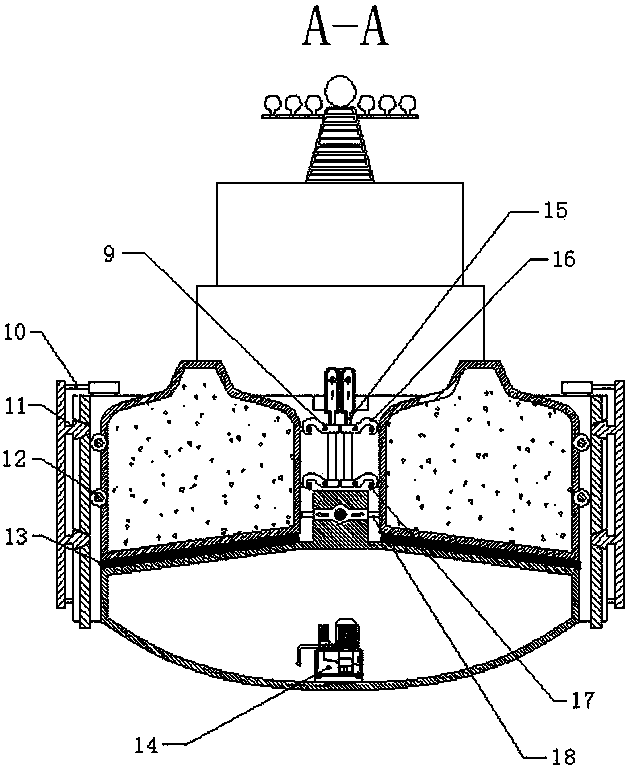

Damping type oscillation prevention cabin wall for independent C-type cargo hold of LNG injection ship

The invention discloses a damping type oscillation prevention cabin wall for an independent C-type cargo hold of an LNG injection ship and belongs to the technical field of liquid cargo oscillation resistance of the independent C-type cargo hold of the LNG injection ship. The oscillation prevention cabin wall has the function that oscillation of liquid cargos in the independent C-type cargo hold can be reduced and is composed of transverse groove-shaped reinforcing rings connected with the independent C-type cargo hold, transverse hole separating boards connected with the transverse groove-shaped reinforcing rings through springs, reinforcing ribs connected to the hole separating boards and common-hinged type spring hole drilling covers connected to the hole separating boards. Each end of the independent C-type cargo hold is provided with one damping type oscillation prevention cabin wall. The damping type oscillation prevention cabin wall has the advantages of being simple in structure, capable of conducting elastic damping type limiting, good in manufacturability, convenient to install, low in manufacturing cost, capable of effectively restraining oscillation of the liquid cargoes and suitable for the independent C-type cargo hold of the LNG injection ship for oscillation reduction and a liquefied gas storage tank for oscillation reduction.

Owner:DALIAN UNIV OF TECH

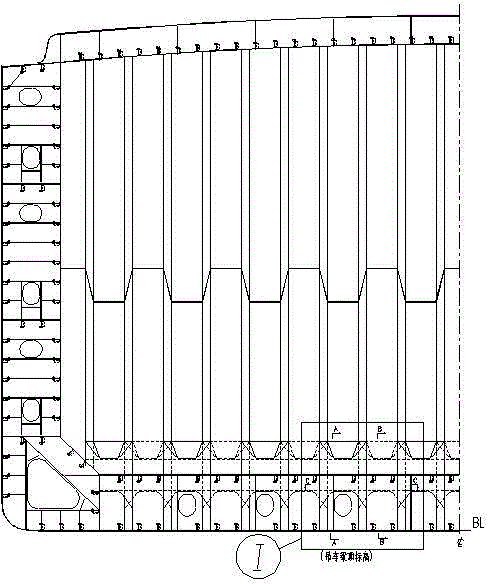

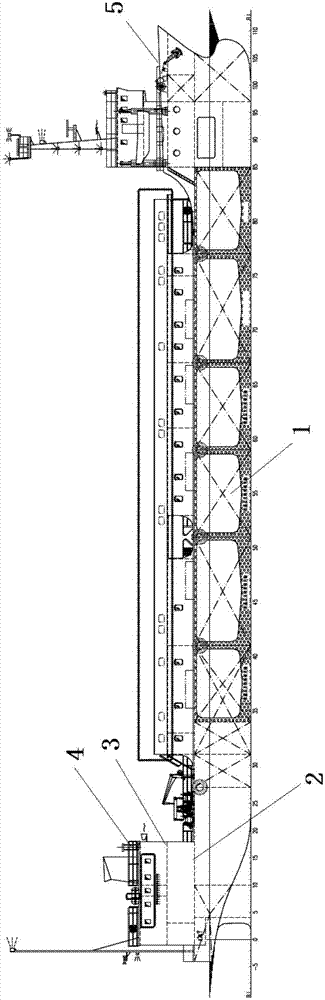

Cold water mass culture work boat

The invention discloses a cold water mass culture work boat which comprises a hull and an upper deck arranged on the hull. A fire protection deck and a ceiling deck are arranged above the position, located on a stern, of the upper deck. A forecastle deck is arranged above the position, located on a bow, of the upper deck. Multiple watertight transverse bulkheads are arranged below a main deck anddivide the bottom of the hull into multiple tanks including water ballast tanks, an engine room, fuel oil tanks, collection tanks, fish culture water tanks, sundry tanks, fresh water tanks, a standbyfish culture water tank and an empty tank. The fish culture water tanks and the standby fish culture water tank are formed in the middle portion of the bottom of the hull. The three collection tanks arranged side by side are formed in the tail portion of the fish culture water tanks and the standby fish culture water tank. The three fuel oil tanks arranged side by side are formed behind the collection tanks. The fish culture water tanks and the standby fish culture water tank are provided with insulating layers. The cold water mass culture work boat has the three-month non-supply production capacity on the sea, and the requirement for cold water fish culture in four seasons of a year is met.

Owner:RIZHAO GANGDA SHIPBUILDING HEAVY IND

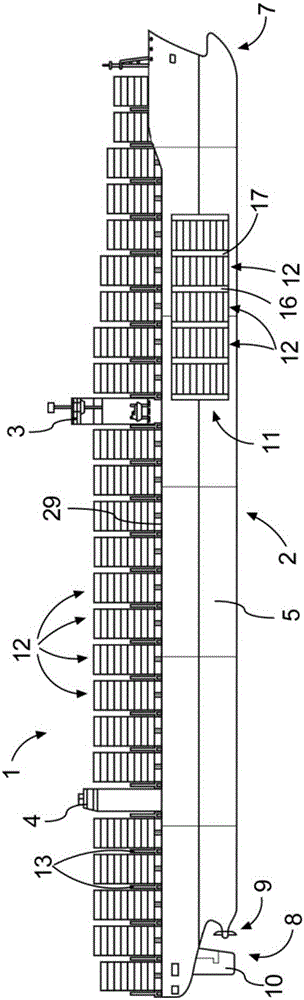

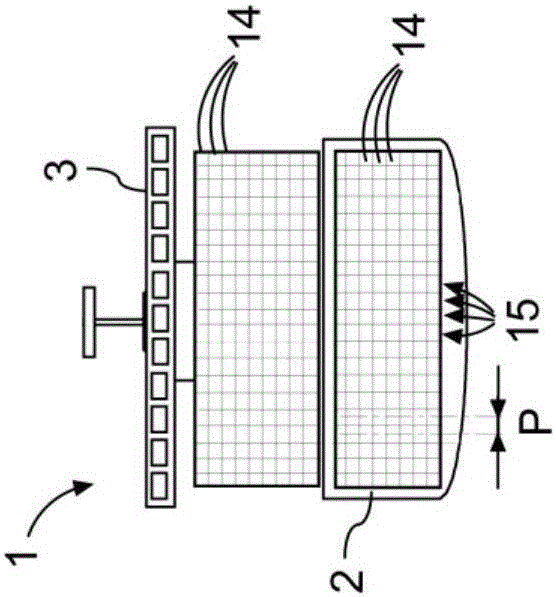

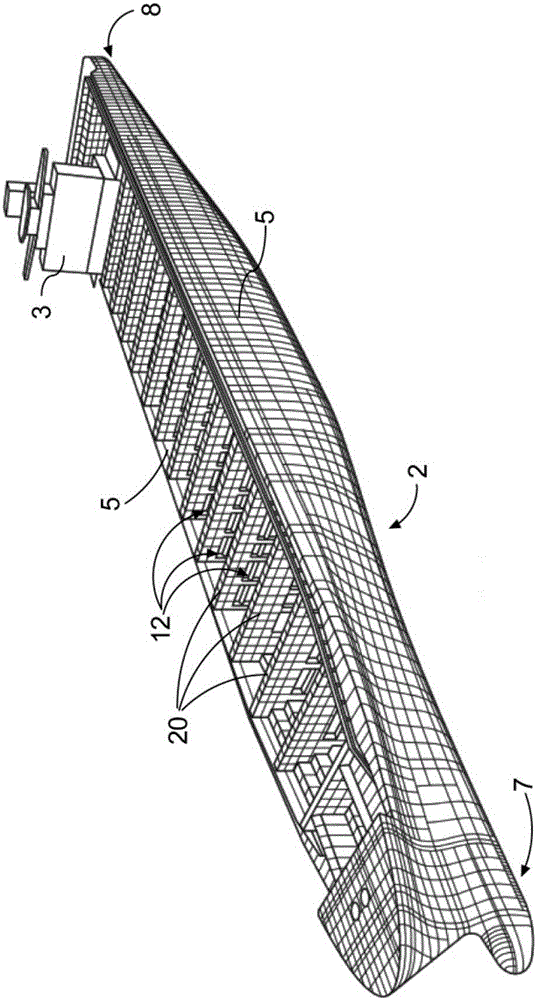

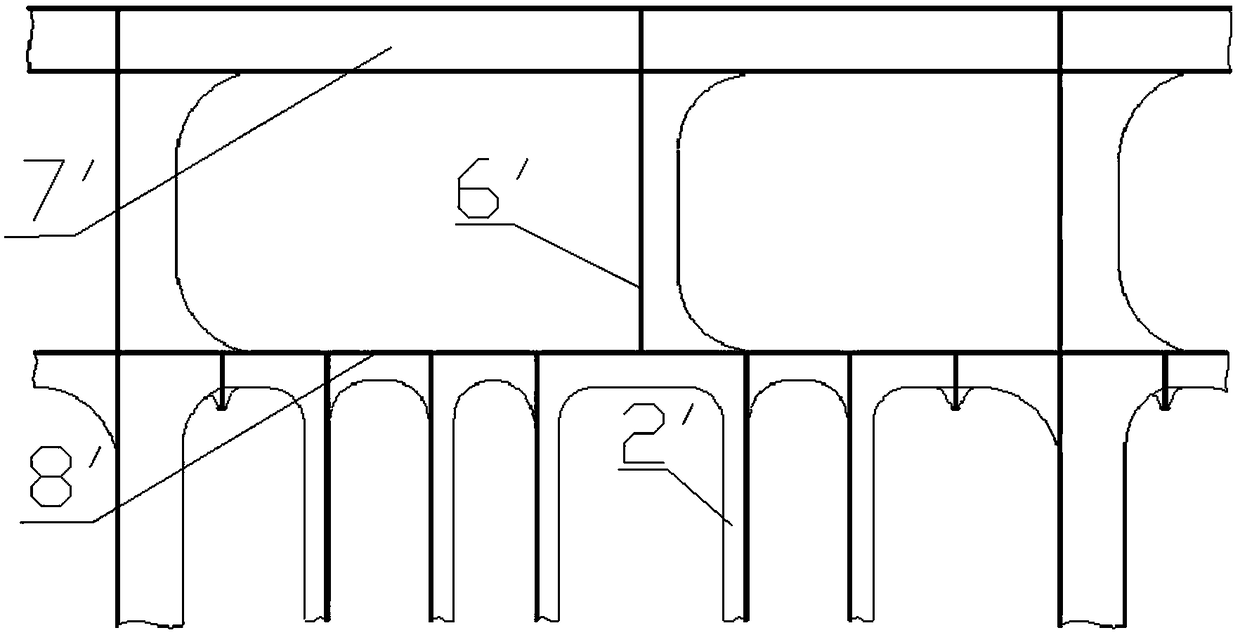

Container vessel for cabinet freezer and having increased capacity

The invention provides a hull of a container vessel. The hull includes a cargo hold for holding non-freezing combined transport containers and freezing combined transport containers. Each freezing container is provided with a freezing unit at the longitudinal end thereof. The hull is provided with a plurality of transverse bulkheads which longitudinally divides the cargo hold into a plurality of container compartments. Beams are associated with all the transverse bulkheads and each beam crosses the whole width of the hull and is connected to side surfaces of the hull at upper edges or nearby positions of the hull. The width of the container compartments is divided into a plurality of container lines, and a separation distance P among the container lines slightly exceeds the width of a single combined transport container. Each beam includes a hollow rectangular section having four side surfaces, at least one of the four side surfaces of at least one container compartment facing the beam is provided with a line of maintenance openings, adjacent maintenance openings of the line of maintenance openings are spaced in the separation distance P, and the shape and the size of the maintenance openings are designed to allow freezing combined transport containers facing the maintenance openings to enter and be maintained through the relevant maintenance openings.

Owner:MAERSK LINE AS

Supertanker

InactiveCN105059470AThe overall structure is light in weightReduce processHull bulkheadsEngineeringMechanical engineering

Owner:708TH RES INST OF CSSC

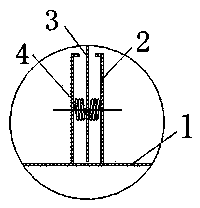

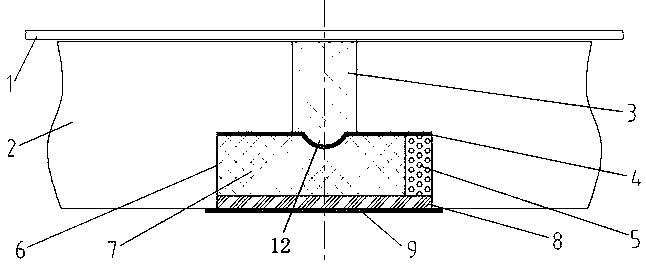

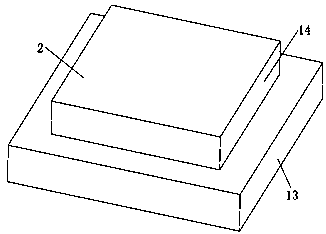

Sealing structure of joint of insulating blocks of B type enclosure system

ActiveCN109606564AAvoid squeezingPrevent extrusion and ensure that the tightness of the joint is not damagedEngine sealsThermal insulationThermal insulationThermal expansion

The invention discloses a sealing structure of a joint of insulating blocks of a B type enclosure system. The sealing structure comprises a plurality of first insulating blocks fixed on the wall of acargo hold; a first gap filled with a first thermal-insulation buffer material is formed between the lower sides of every two adjacent first insulating blocks; and a second gap for arranging a first aluminum foil, a second insulating block, a second thermal-insulation buffer material, and a sealing elastic material is formed between the upper sides of every two adjacent first insulating blocks; the first aluminum foils are arranged on the first thermal-insulation buffer materials; the second insulating blocks are arranged on the first aluminum foils; the space between the second insulating blocks and the first insulating blocks is filled with second thermal-insulation buffer materials; the sealing elastic materials are arranged on the surfaces of the second insulating blocks; and second aluminum foils are arranged on the surfaces of the sealing elastic materials. Therefore, a problem of the sealing failure of the insulating block joint due to the thermal expansion and cold contractionat the independent cabin wall is solved effectively; and the extrusion between the insulating blocks is prevented and the sealing performance of the joint is not damaged.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Bulkhead door for a vessel

InactiveUS7213528B1Good chemical resistanceEasy to disassembleHull bulkheadsWatertight door arrangementsAdhesiveStandard distance

A bulkhead door for watertight closing of a bulkhead opening of a naval vessel, comprising a composite outer shell and inner shell, a chamber therebetween, and a channel along the door margin for retaining a gasket without adhesive. The chamber may be filled with a material such as a rigid foam to increase door strength and rigidity. The outer shell includes hinge blades spaced apart by a standard distance and spaced equally from ends of the door, so that each door may be used for either a right-hand or left-hand bulkhead hinge pin orientation. Metal strikers are bonded to the outer surface of the door for engaging closure dogs in use. A door may be provided without any strikers, and the strikers then bonded to the door at appropriate locations during installation of a door to a specific bulkhead opening location.

Owner:PERFORMANCE BY DESIGN INT

Method and Apparatus for Corrosion Allowance Mitigation

InactiveUS20130180445A1Reduce the amount requiredHull interior subdivisionNon-magnetic metal hullsMarine engineeringBallast tank

A design and construction method reduces the amount of structural material (e.g., steel) required when applying the corrosion allowance to the design of floating offshore structures. The (hull) structural elements involved are typically flat or curved panels where at least one side is wet, e.g.; inside a ballast tank or exposed to seawater. The method minimizes the area to which the largest corrosion allowance is applied. One principle of this method is to have a maximum of one wet side for each hull watertight plating element. The stiffening of this hull structural element is applied to the dry side, i.e., the side that requires the lesser amount of corrosion allowance. Practice of the method typically results in a hull design wherein ballast tanks do not share a common structural element with either another ballast tank or the hull external shell.

Owner:SEAHORSE EQUIP

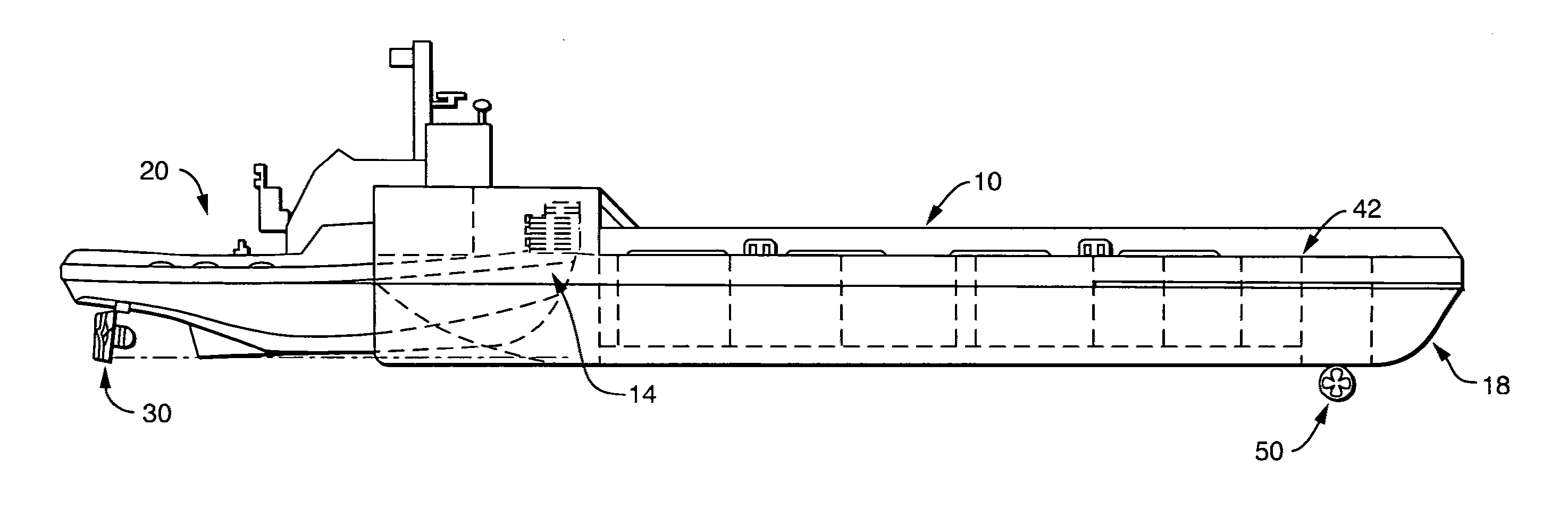

Tug-barge offshore cargo transport

InactiveUS20120226636A1Efficiently and safely supplyReduce scrollingHull interior subdivisionHull decksSternBARGE

Disclosed is a tug-barge offshore cargo transport device and method, comprised of two separate elements which are removably attached: a barge and a tug boat. The barge includes a bow shaped to cut through and deflect waves, a rectangular cargo deck protected by a bulwark, compartments below the cargo deck, means for maneuvering the barge, and means at the stern of the barge for removably attaching the barge to a tug boat. The tug boat includes means at the bow to removably attach to the barge, and means to control the means for maneuvering the barge from the tug boat.

Owner:PEREZ ROBERT H

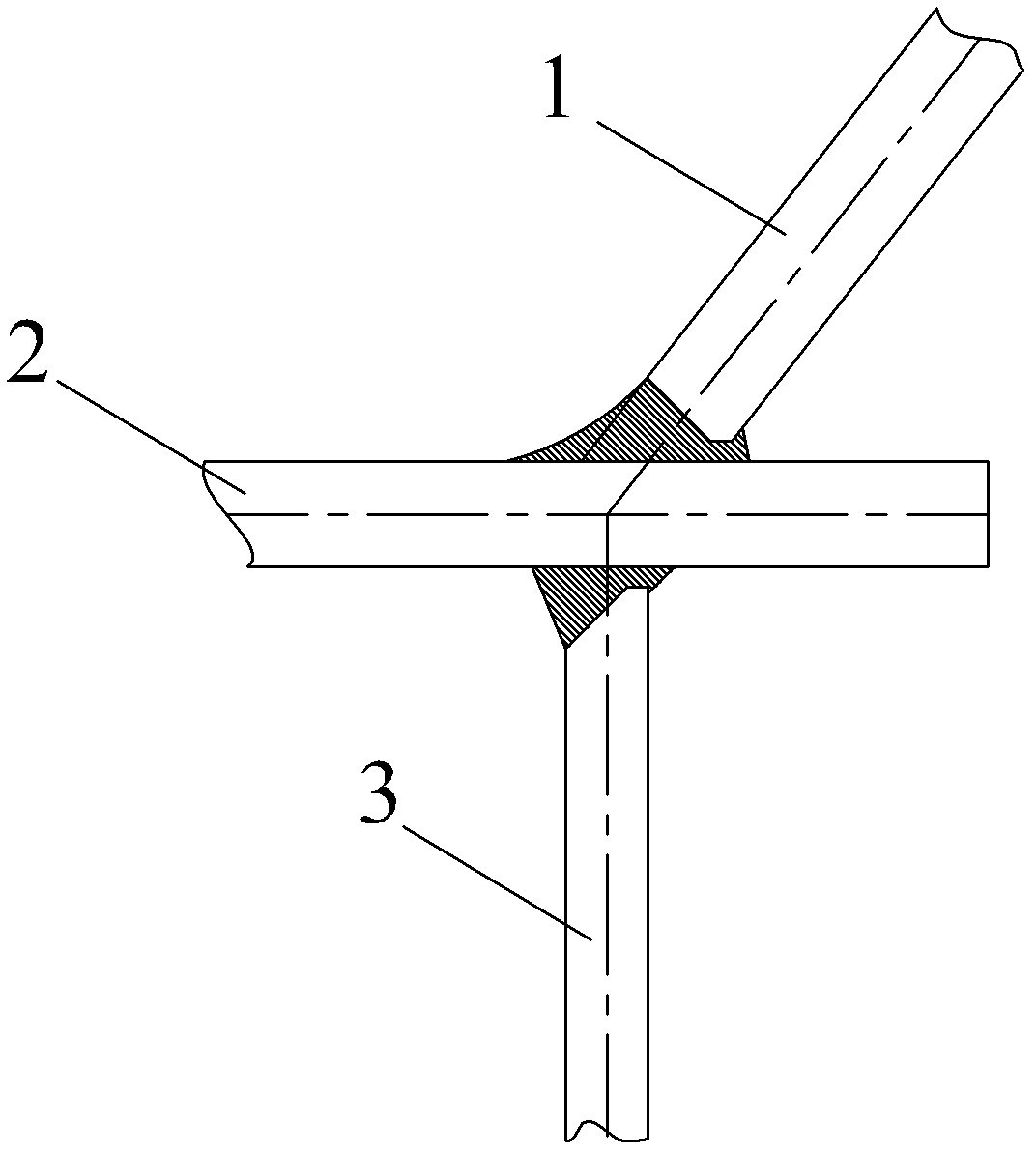

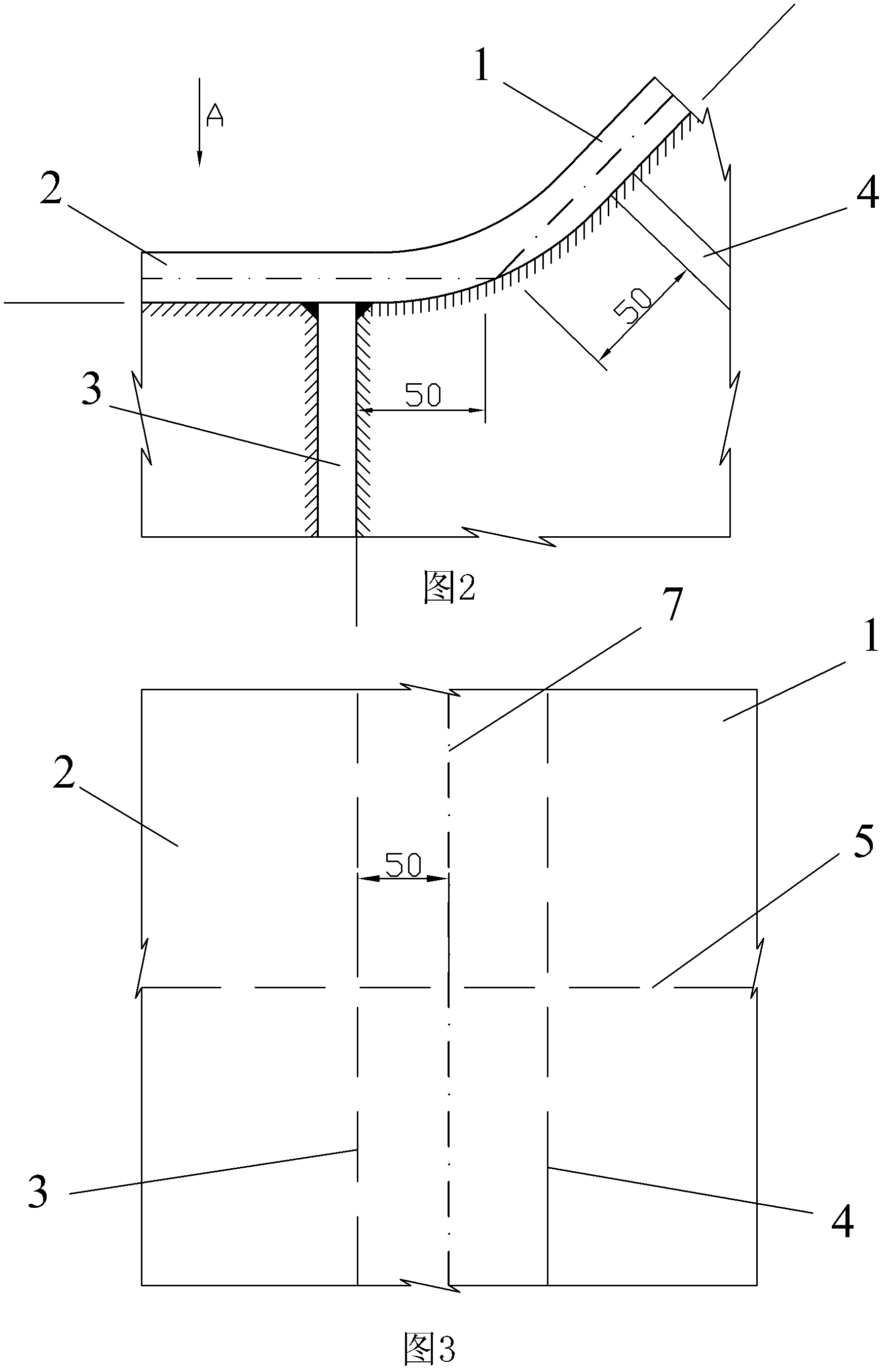

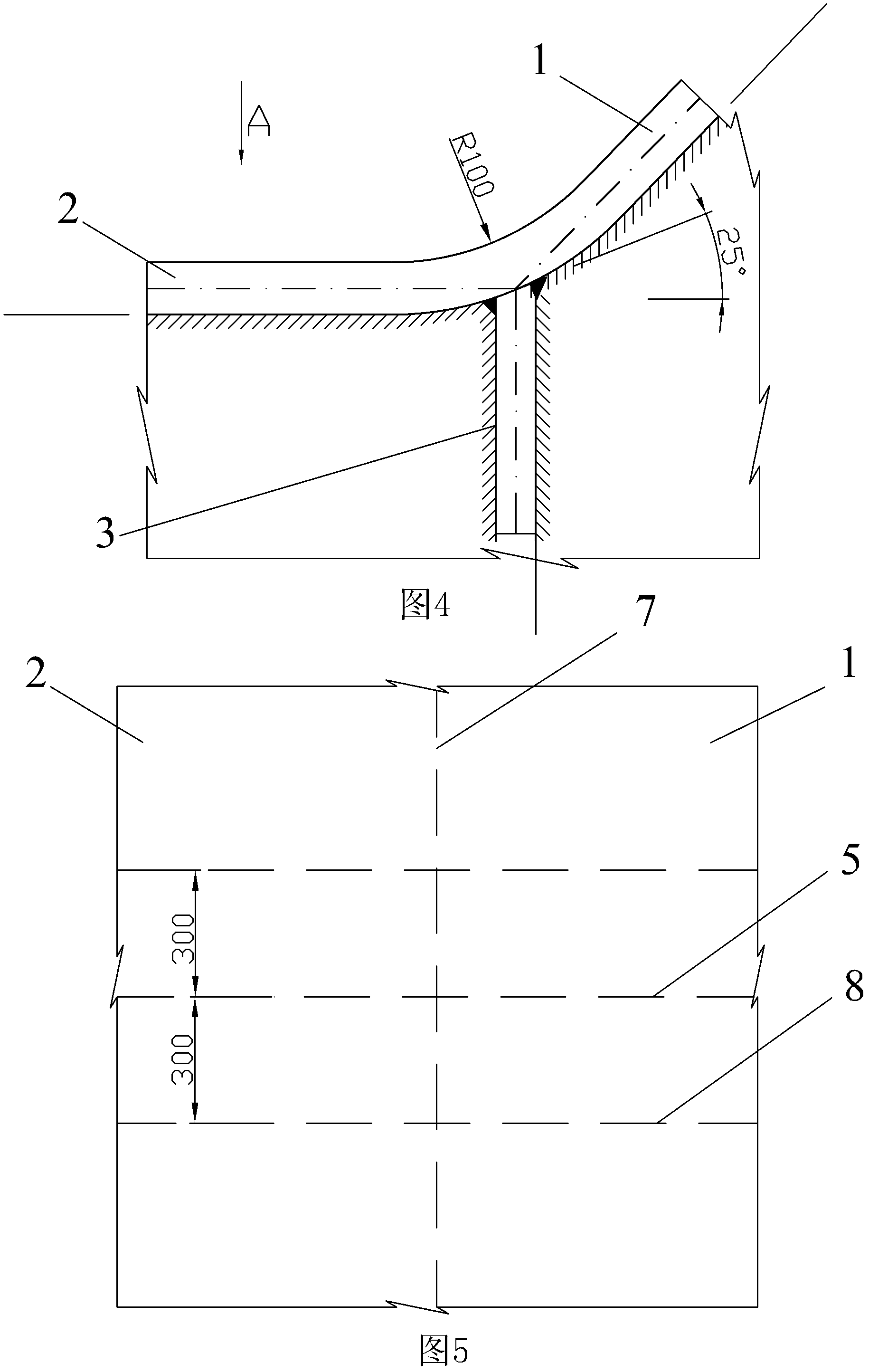

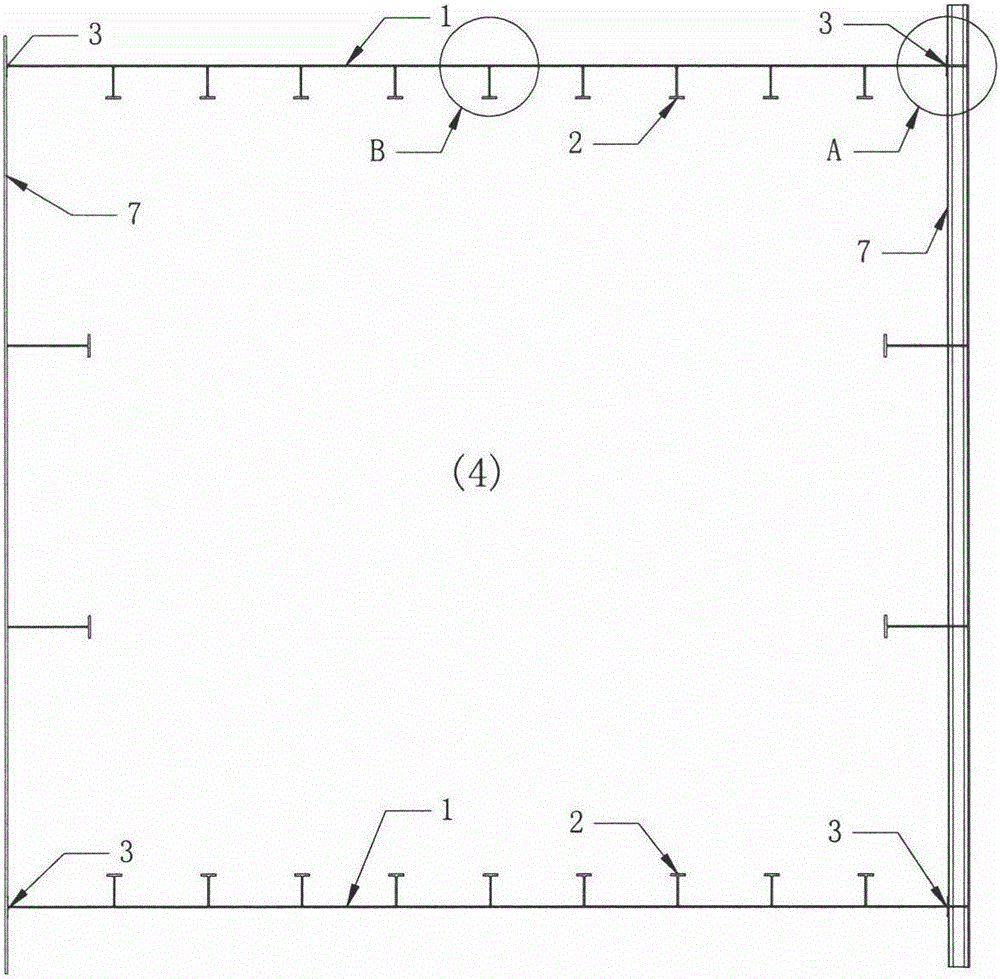

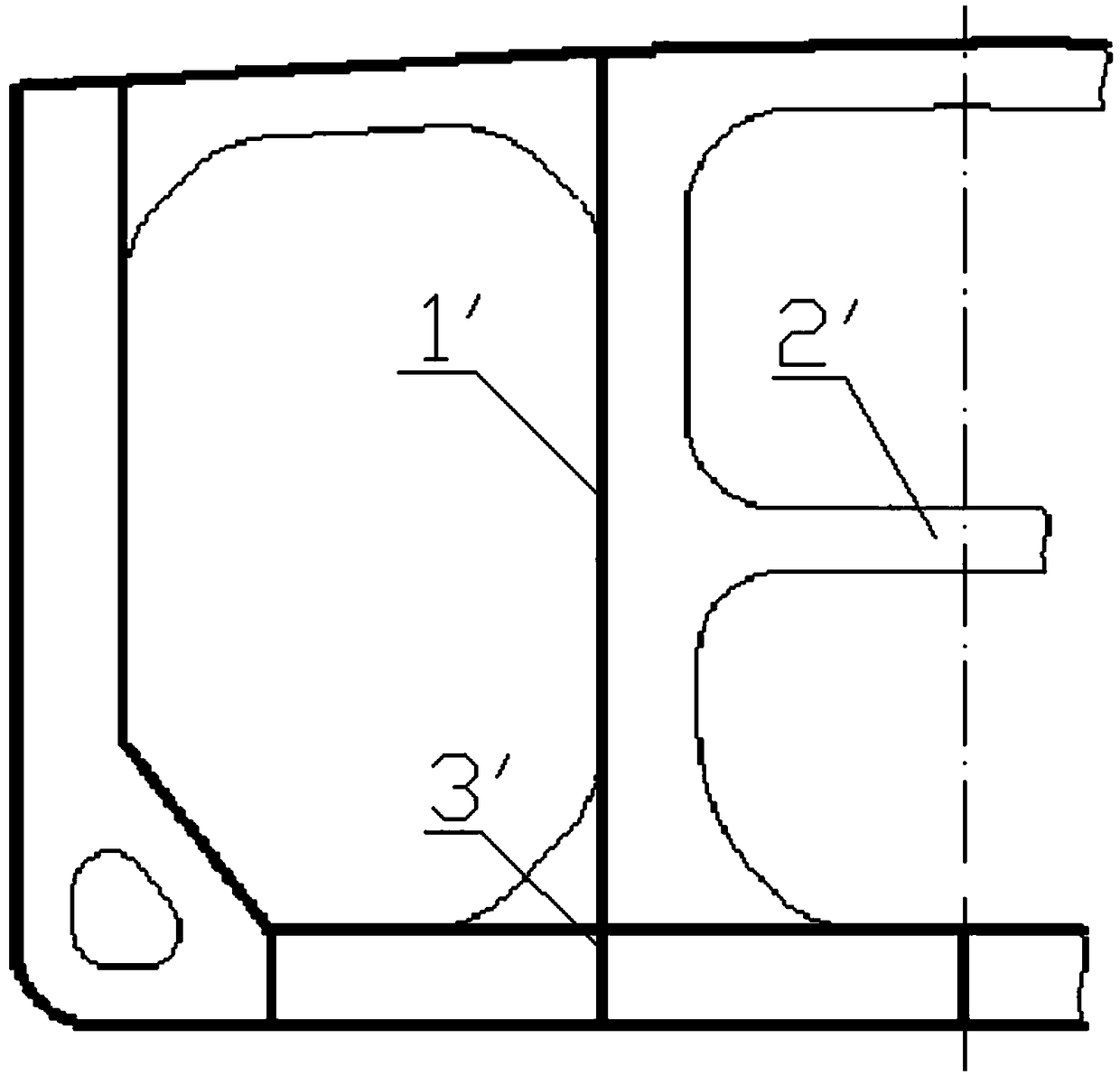

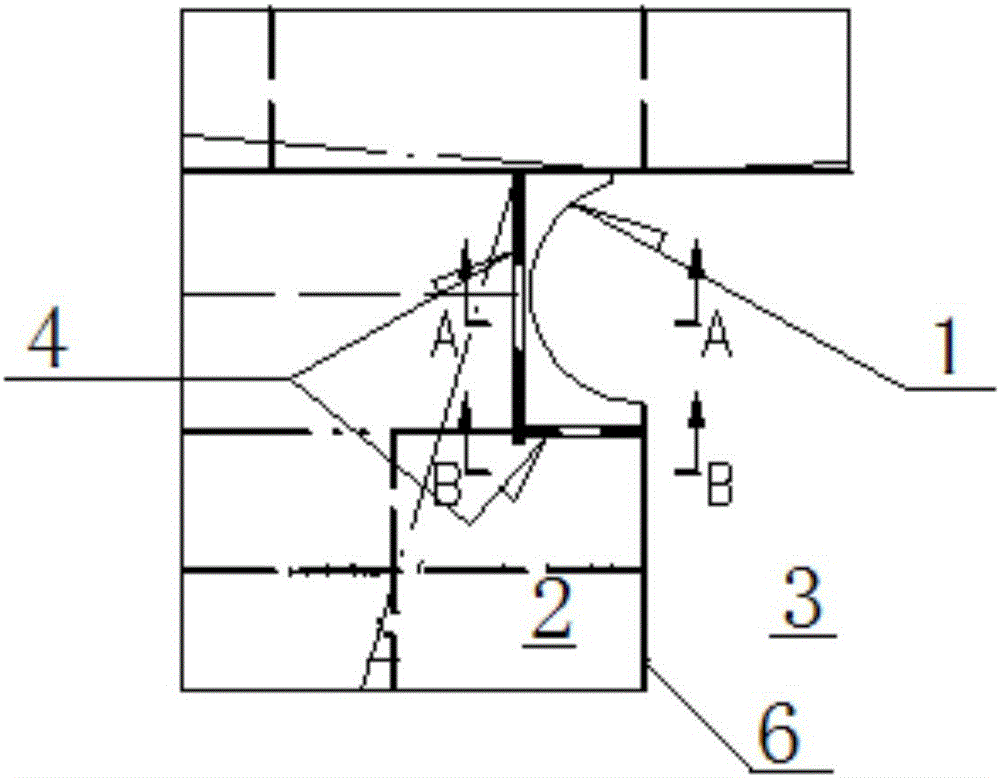

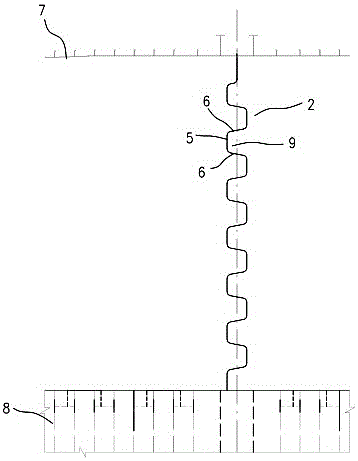

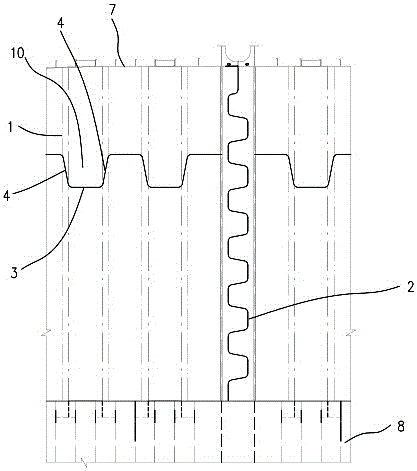

Cargo hold structure

ActiveCN103129699AImprove stress concentrationReduce welding workloadHull bulkheadsMachining processOil tanker

The invention discloses a cargo hold structure which comprises a bottom side tank inclined bottom plate (1), an inner bottom plate (2) and an inner bottom side stringer (3), wherein the lower portion of the inner bottom side stringer (3) is vertically supported. The inclined bottom plate (1) and the inner bottom plate (2) are connected through a board and by utilizing of a bent arc transition mode. The inner bottom side stringer (3) is supported below a knuckle line (7) formed by intersecting of extension planes of the inclined bottom plate (1) and the inner bottom plate (2). The cargo hold structure is especially suitable for an oil tanker cargo hold. A three-line centering and arc transition type connection structure of the bottom side tank inclined bottom plate and the inner bottom plate is mainly designed. According to the cargo hold structure, welding and polishing work load is effectively reduced. Fatigue resistance is effectively improved, at the same time, constructing and machining processes are simplified, work efficiency is improved, and the cargo hold structure has the advantages of being low in cost and high in strength.

Owner:DALIAN SHIPBUILDING IND

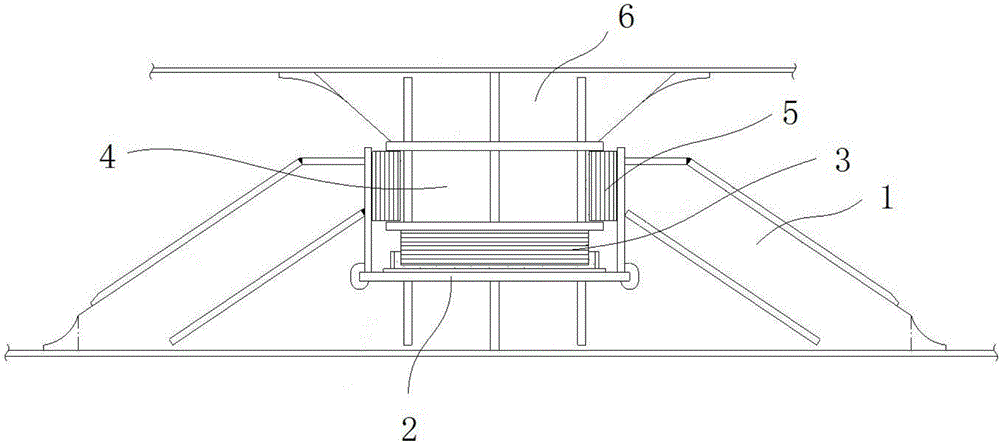

Impact resistant platform for ship

InactiveCN107554685AReduced dynamic responseGood effectVessel cleaningHull bulkheadsBinding energyEngineering

The invention relates to the technical field of local anti-shock of ships, in particular to a ship anti-shock platform, which includes a front bulkhead and a rear bulkhead, multiple sets of elastic sliding devices are arranged between the front bulkhead and the rear bulkhead, and two adjacent An energy-absorbing buffer device is arranged between the groups of elastic sliding devices. The present invention adopts such a structural arrangement, by providing multiple sets of elastic sliding devices between the front bulkhead and the rear bulkhead, and an energy-absorbing buffer device is provided between two adjacent sets of elastic sliding devices, under the impact force, Through the organic combination of the elastic sliding device and the energy-absorbing buffer device, the impact energy is converted into the internal energy of the energy-absorbing buffer device and the elastic potential energy of the elastic sliding device, thereby reducing the dynamic response of the impact force to the hull and effectively achieving the effect of protecting the hull. The structure is simple and the effect is remarkable.

Owner:WUHAN UNIV OF TECH

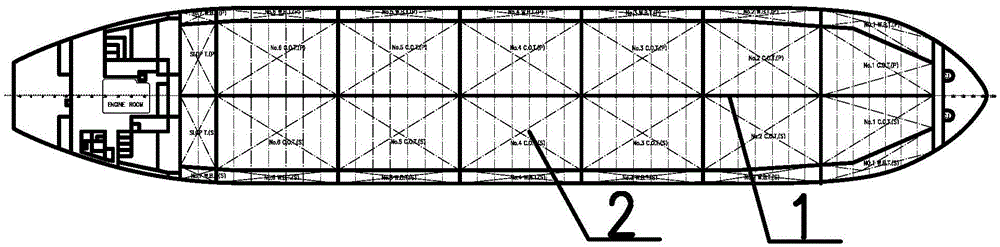

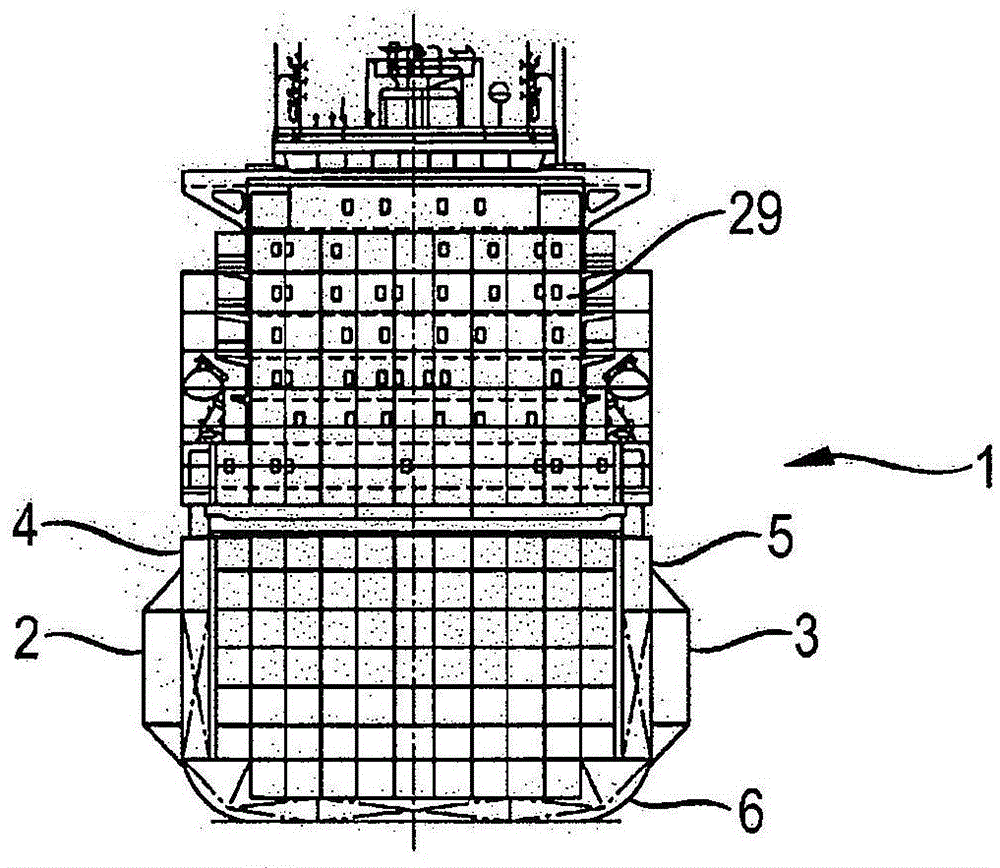

Method for enlarging a ship and enlarged ship

InactiveCN105658513AImprove lateral stabilityReduced steady ballast loadHull interior subdivisionHull decksStern

The invention relates to a method for enlarging a ship, in which method a container ship, conbulker, multi-purpose ship, LASH ship, or other ship having a high degree of deck opening is widened, wherein a front ship segment (23) comprising the bow (22) and a rear ship segment (25) comprising the stern (24) are separated from a middle ship segment (16) comprising at least part of the cargo hold, the middle ship segment (16) is divided into at least two middle ship parts (30, 31) in a longitudinal direction, the middle ship parts (30, 31) are moved apart in a transverse direction of the ship, an additional middle part (34) is installed between the middle ship parts (30, 31) that have been moved apart and thereby a widened middle ship segment is formed, a widened front ship segment (23) is attached to the front of the widened middle ship segment (16), and the rear ship segment (25) is attached directly to the rear of the widened middle ship segment (16).

Owner:NSB NIEDERELBE SCHIFFAHRTSGMBH

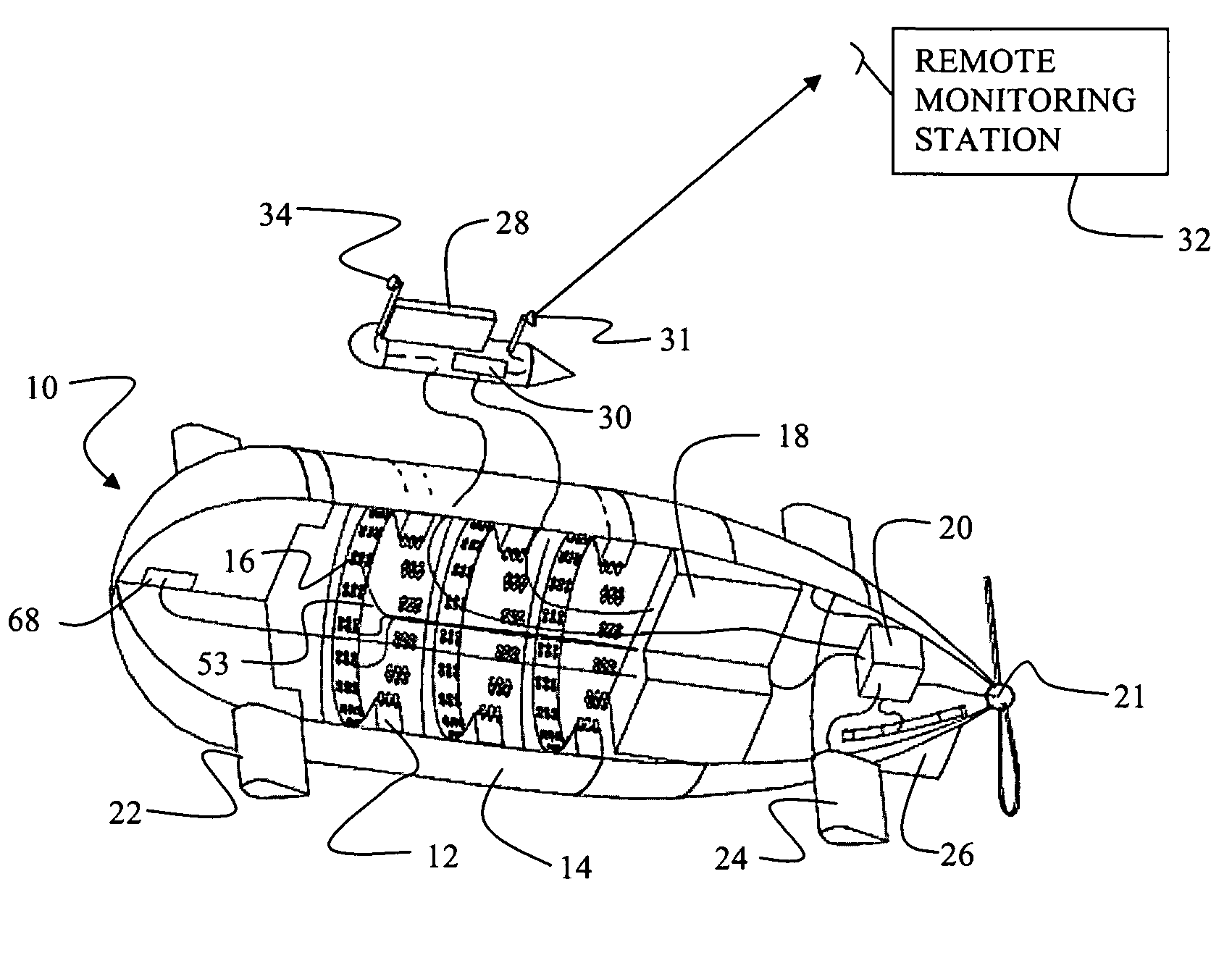

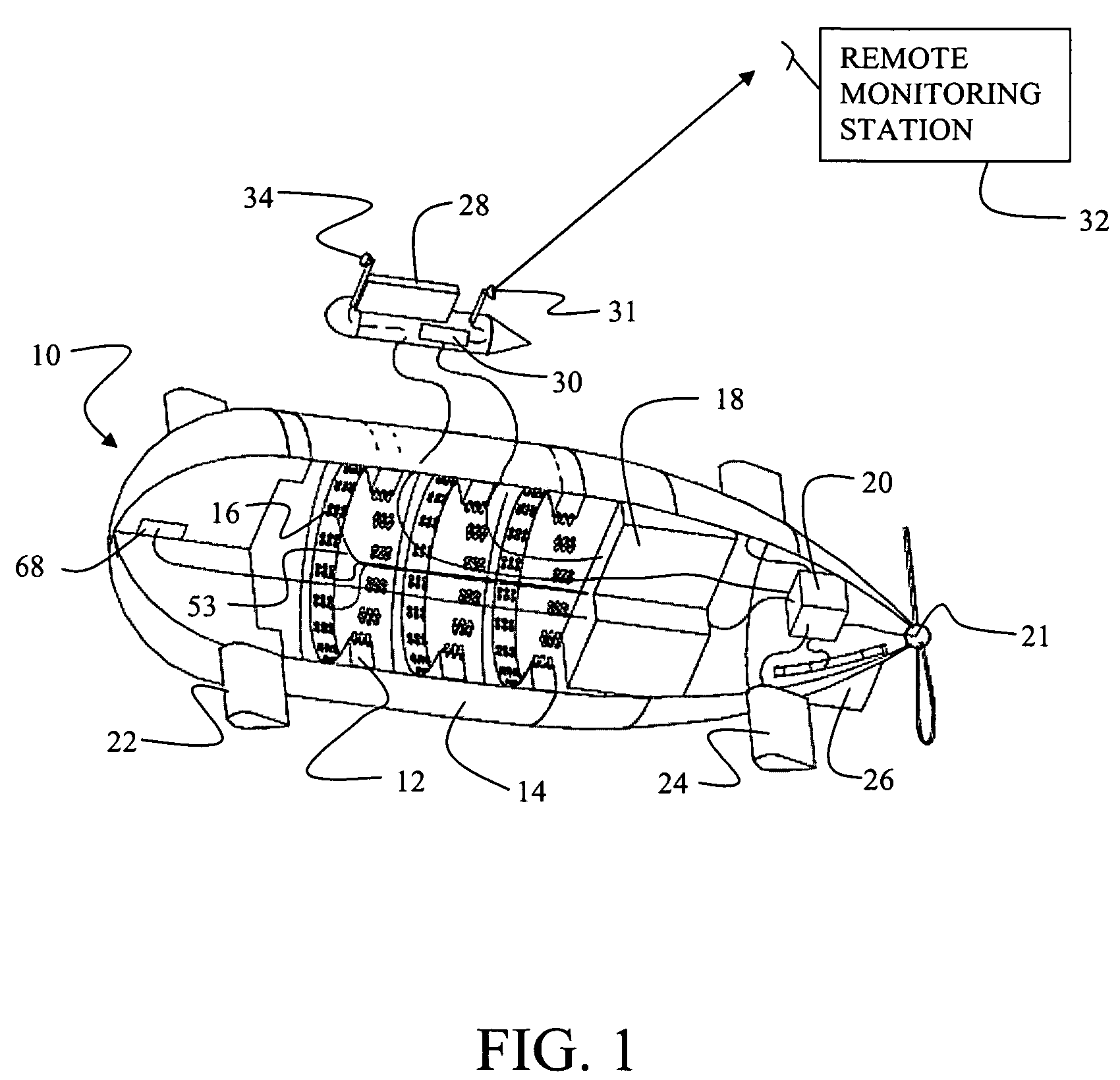

Unmanned underwater vehicle integrated radiation detection system

ActiveUS8352105B2Digital data processing detailsRoad vehicles traffic controlCommunications systemControl system

An unmanned underwater vehicle incorporates a structure having an integral scintillating material for a radiation detector and detection electronics connected to the radiation detector for measurement of the scintillation. A communication system is employed for transmission of scintillation measurement to a remote facility and a navigation control system provides for autonomous operation of the unmanned underwater vehicle or remote operation through the communications system.

Owner:THE BOEING CO

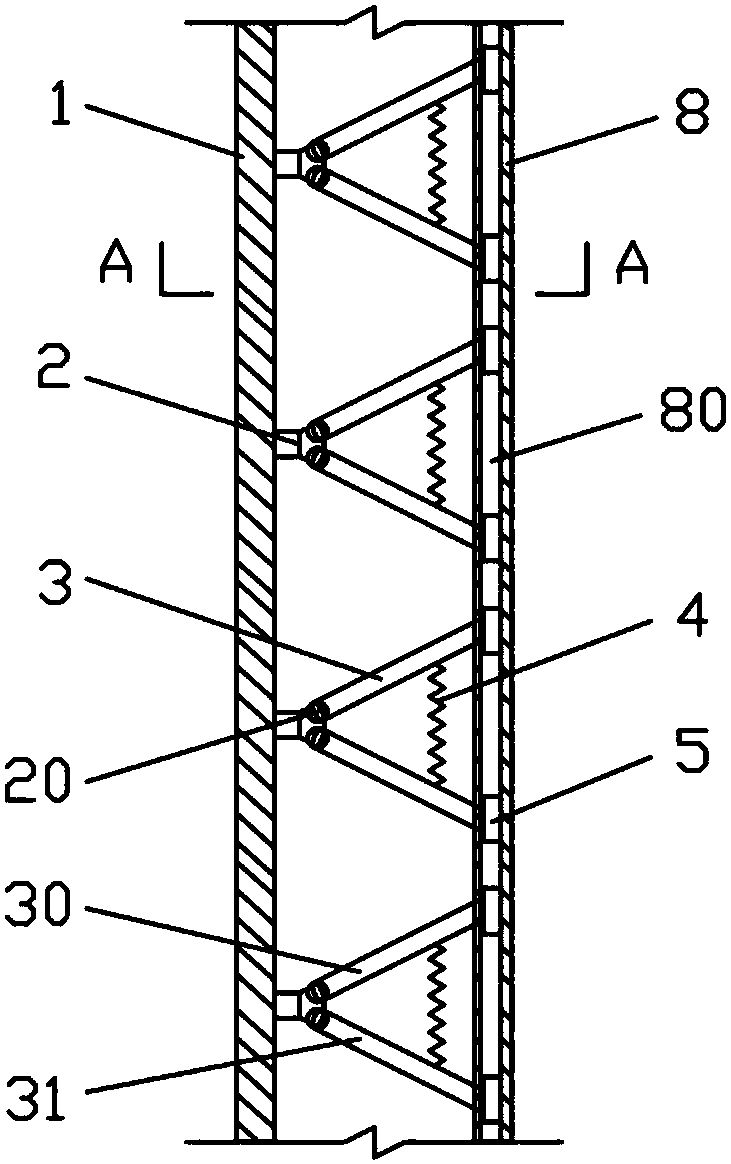

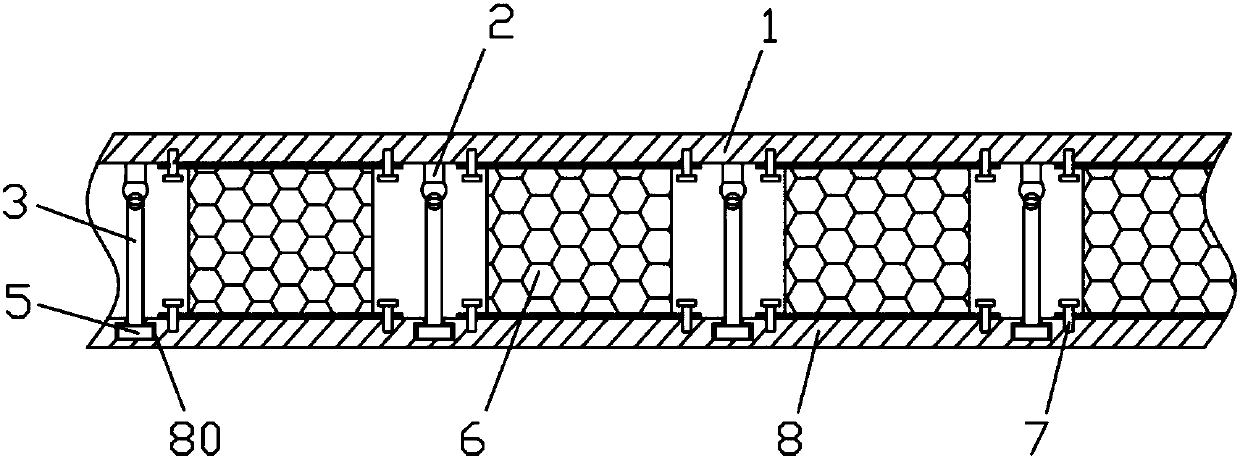

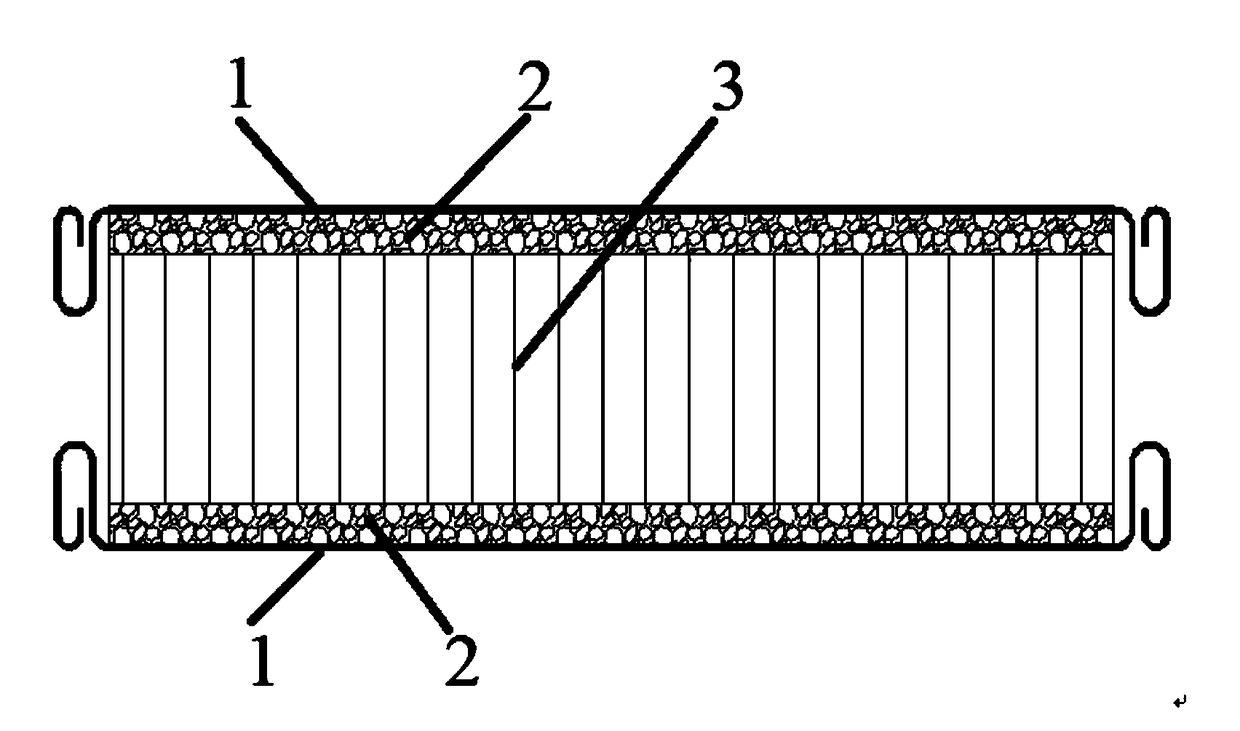

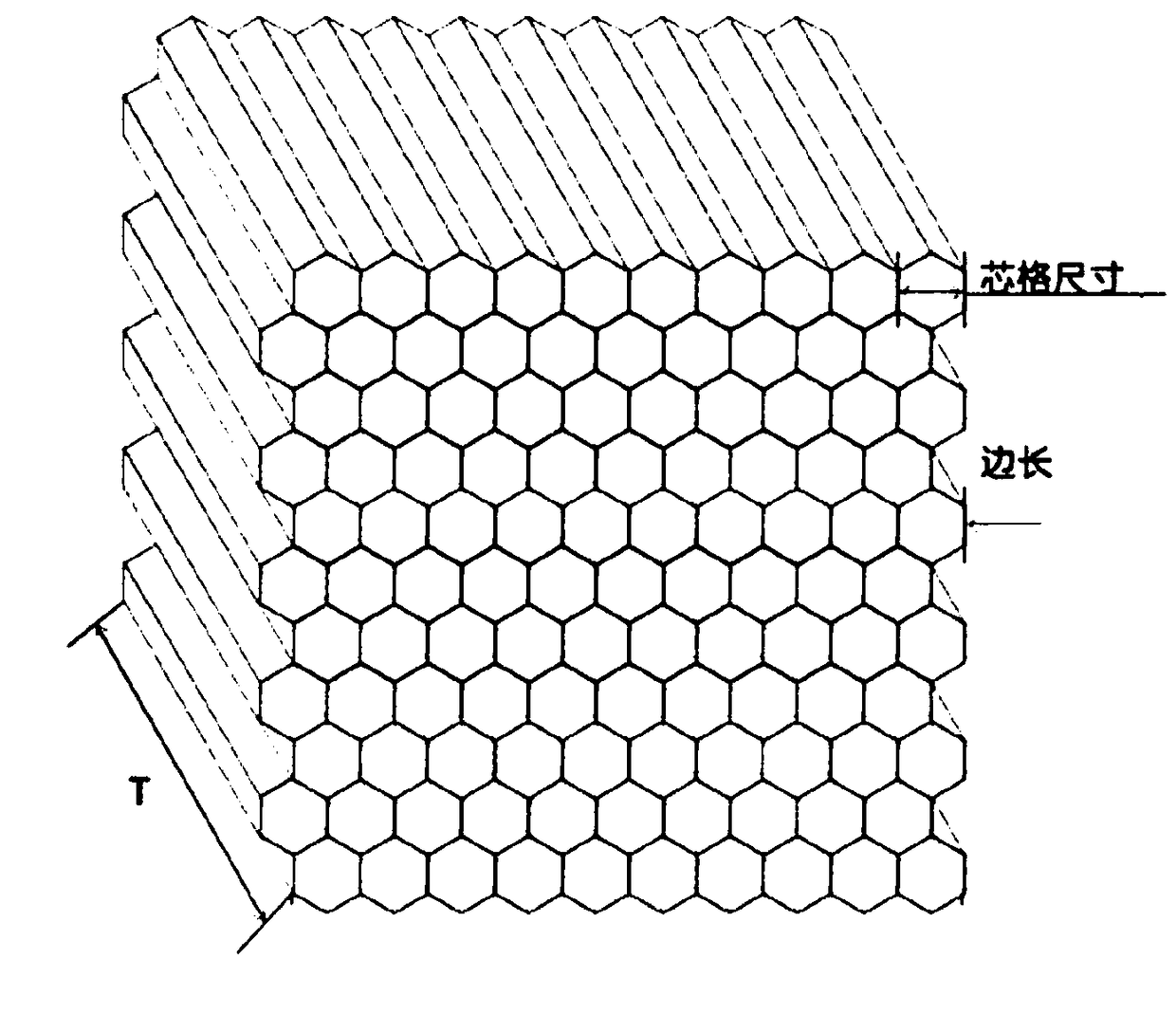

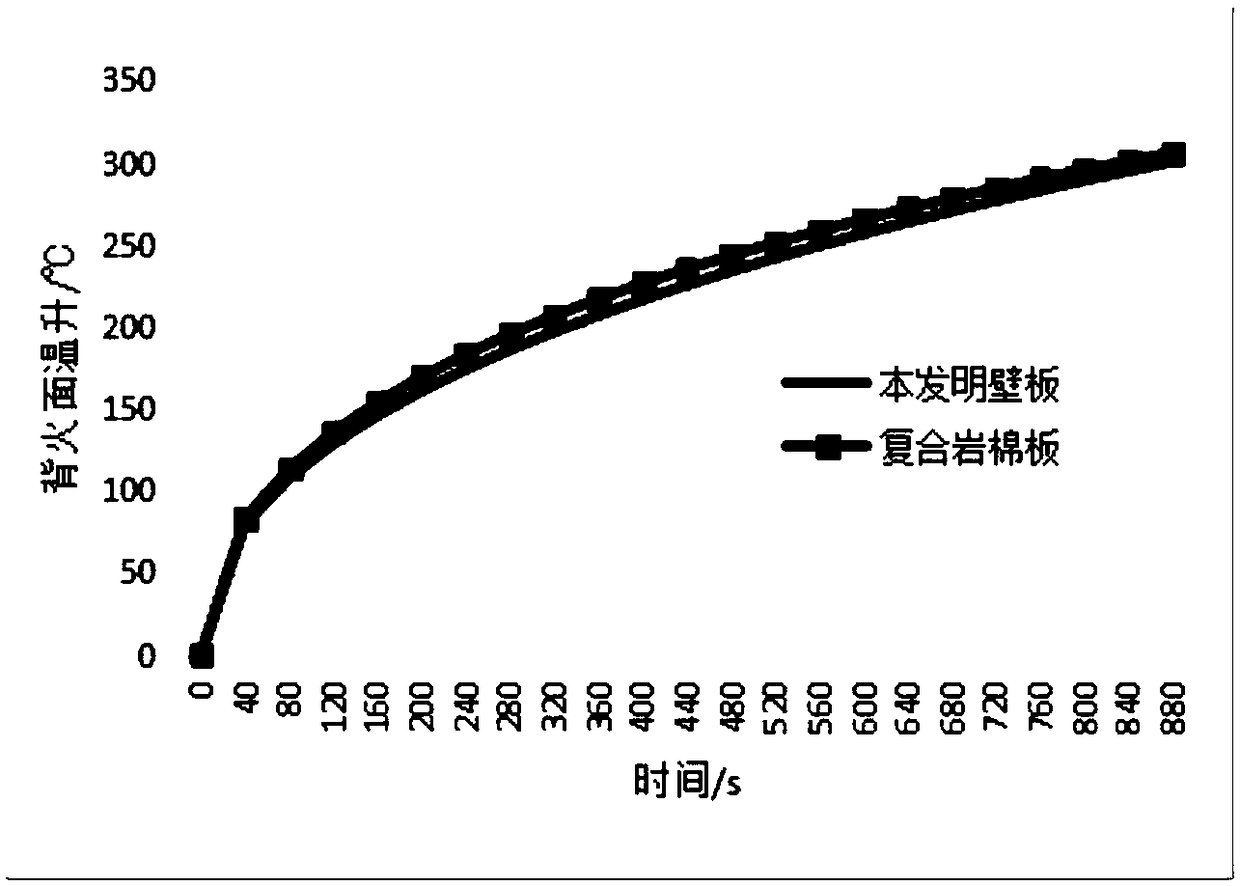

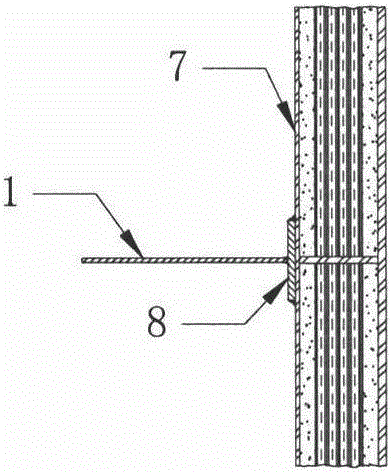

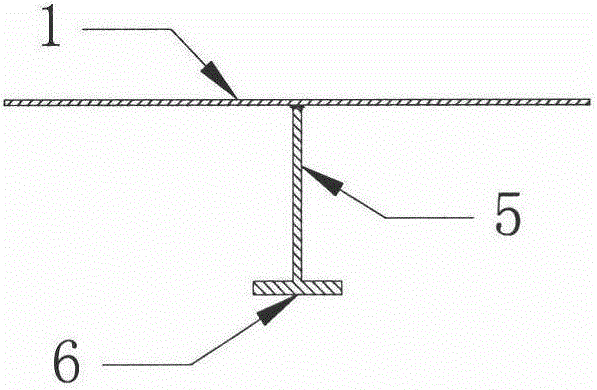

Lightweight acoustic insulation and fire resistant ship compartment wallboard and production method thereof

InactiveCN108819381AMeet the mechanical performance requirementsReduce weightLayered product treatmentSynthetic resin layered productsMarine engineeringThermal insulation

The invention discloses a lightweight acoustic insulation and fire resistant ship compartment wallboard and a production method thereof. A connecting structure is arranged on the side of the ship compartment wallboard; the ship compartment wallboard comprises a five-layer structure, namely a panel (1), an interlayer thermal insulation material layer (2), a supporting core material layer (3), another interlayer thermal insulation material layer (2) and another panel (1) in sequence; thermal insulation materials of the interlayer thermal insulation material layers (2) are aerogel. Compared witha composite rockwool panel, the ship compartment wallboard disclosed by the invention has light weight; compared with an aluminum honeycomb panel, the ship compartment wallboard has the advantages that fire-resisting separating performance and acoustic insulation performance are greatly improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

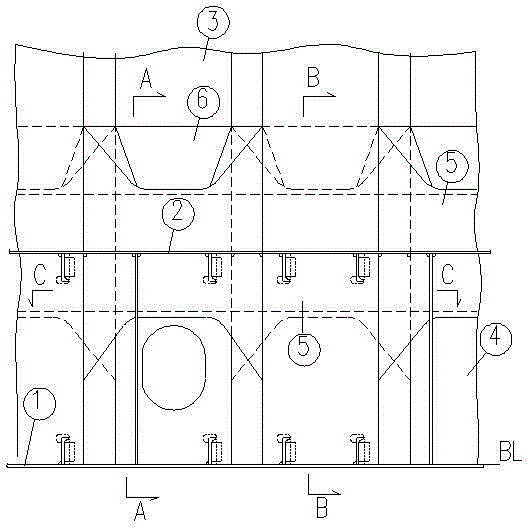

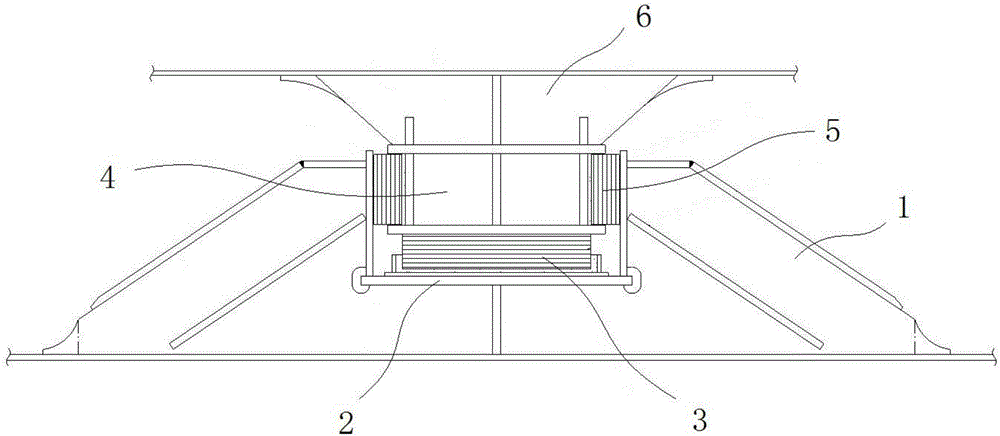

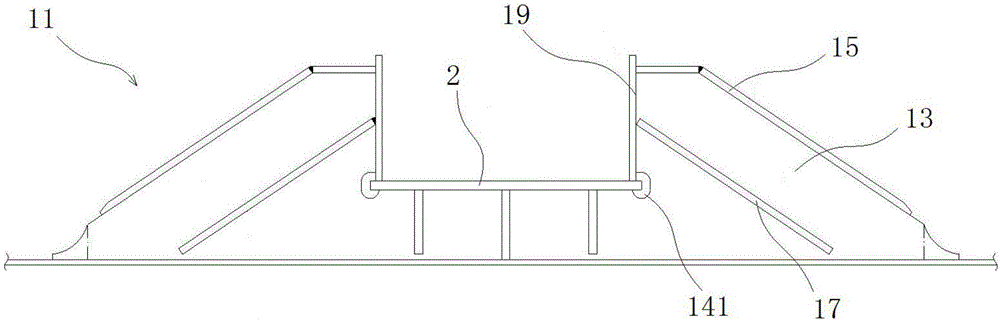

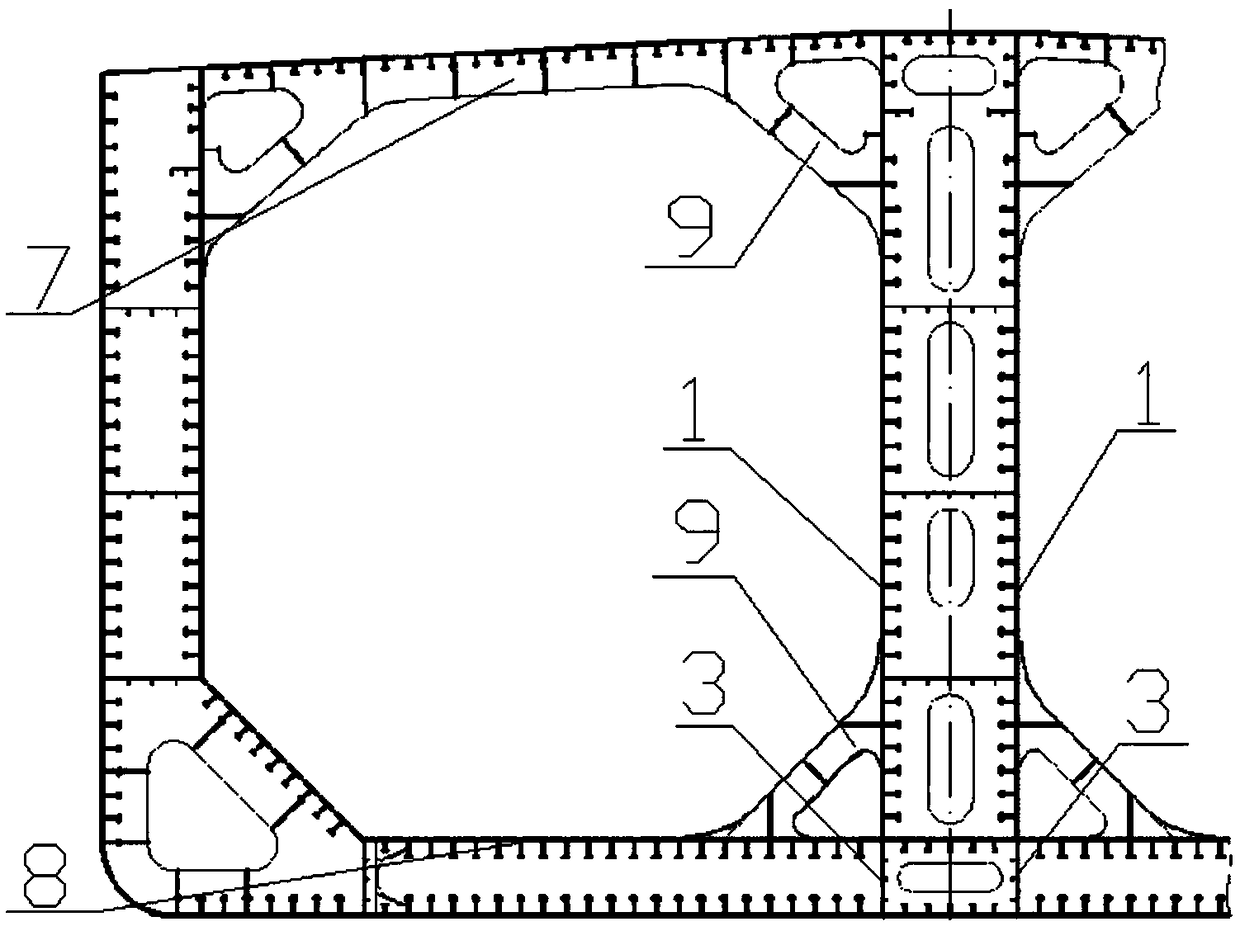

Three-way limiting device of independent liquefied gas ship liquid cargo tank

ActiveCN106741612AAvoid additional forceEligible for useHull interior subdivisionHull bulkheadsThree degrees of freedomMarine engineering

The invention provides a three-way limiting device of an independent liquefied gas ship liquid cargo tank and belongs to the technical field of ship liquid cargo tank limiting. The three-way limiting device of the independent liquefied gas ship liquid cargo tank comprises an integrated supporting assembly, a horizontal supporting plate, a horizontal laminated wood assembly, first toggle plates, a supporting assembly and vertical laminated wood assemblies, wherein the integrated supporting assembly, the horizontal supporting plate and the horizontal laminated wood assembly are arranged on one side of a main ship body; and the first toggle plates, the supporting assembly and the vertical laminated wood assemblies are located on one side of the liquid cargo tank. The integrated supporting assembly is arranged perpendicular to the plane of the main ship body, the horizontal supporting plate is arranged on the supporting assembly, the side, away from the integrated supporting assembly, of the horizontal supporting plate is provided with the horizontal laminated wood assembly, and limitation of the main ship body in the vertical direction is achieved; the side, away from the horizontal supporting plate, of the horizontal laminated wood assembly is provided with the supporting assembly, the vertical laminated wood assemblies are arranged between the four sides of the supporting assembly and the integrated supporting assembly, the effect that the supporting assembly is limited in the transverse direction and in the longitudinal direction is guaranteed, and limitation of the liquid cargo tank in the other two directions is achieved; and a three-degree-of-freedom limiting device is arranged, limitation is achieved in a limited space, and the space utilization rate is high.

Owner:708TH RES INST OF CSSC

Explosion venting bulkhead structure with unequal intensity of naval vessel cabin

InactiveCN106043594AAvoid destructionImprove residual strengthHull bulkheadsUltrasound attenuationResidual strength

The invention relates to an explosion venting bulkhead structure with unequal intensity of a naval vessel cabin. The explosion venting bulkhead structure consists of an explosion venting plate, reinforcing ribs and corner connecting structures with unequal intensity, wherein the explosion venting plate is used for being damaged rapidly when an explosion occurs in the cabin to release pressure in the cabin; the reinforcing ribs are arranged on the inner side of the cabin, and are used for supporting the explosion venting plate and guaranteeing the residual intensity of a vessel body after the explosion venting plate is damaged; and the corner connecting structures with unequal intensity are arranged between the explosion venting plate and a strong bulkhead structure of the cabin, and are used for connecting the explosion venting plate and the strong bulkhead structure of the cabin, and guaranteeing that damage occurs on one side of the explosion venting plate when the explosion occurs in the cabin. Under the load of the explosion in the cabin of the naval vessel, the structure can be rapidly damaged to relieve pressure, so that the intensity and the energy of explosion products are dissipated through spatial distance and volume attenuation, the pressure of quasi-static air pressure is dispersed and reduced, the situation that the strong bulkhead structure of the cabin is integrally destroyed is avoided, and the residual intensity of the naval vessel structure is greatly improved.

Owner:NAVAL UNIV OF ENG PLA

Stainless steel chemical tanker cabin wall structure

InactiveCN105730610AGuaranteed structural strengthIncrease capacityHull interior subdivisionHull bulkheadsMaterials scienceStainless steel material

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

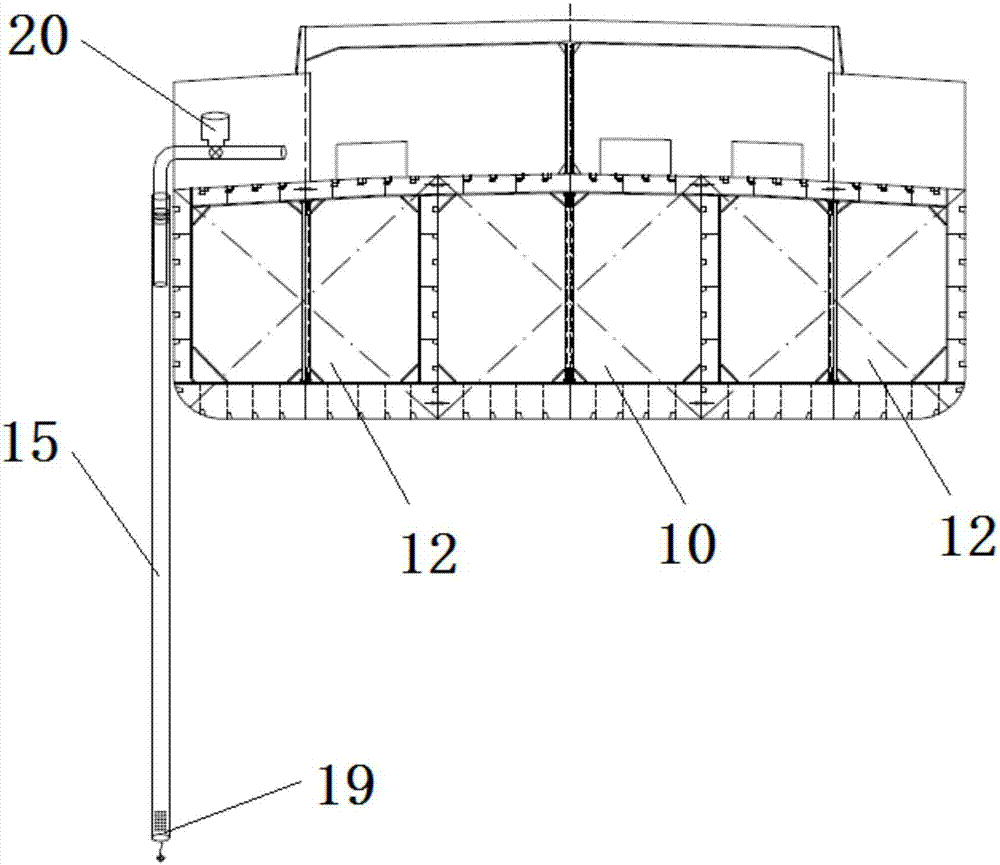

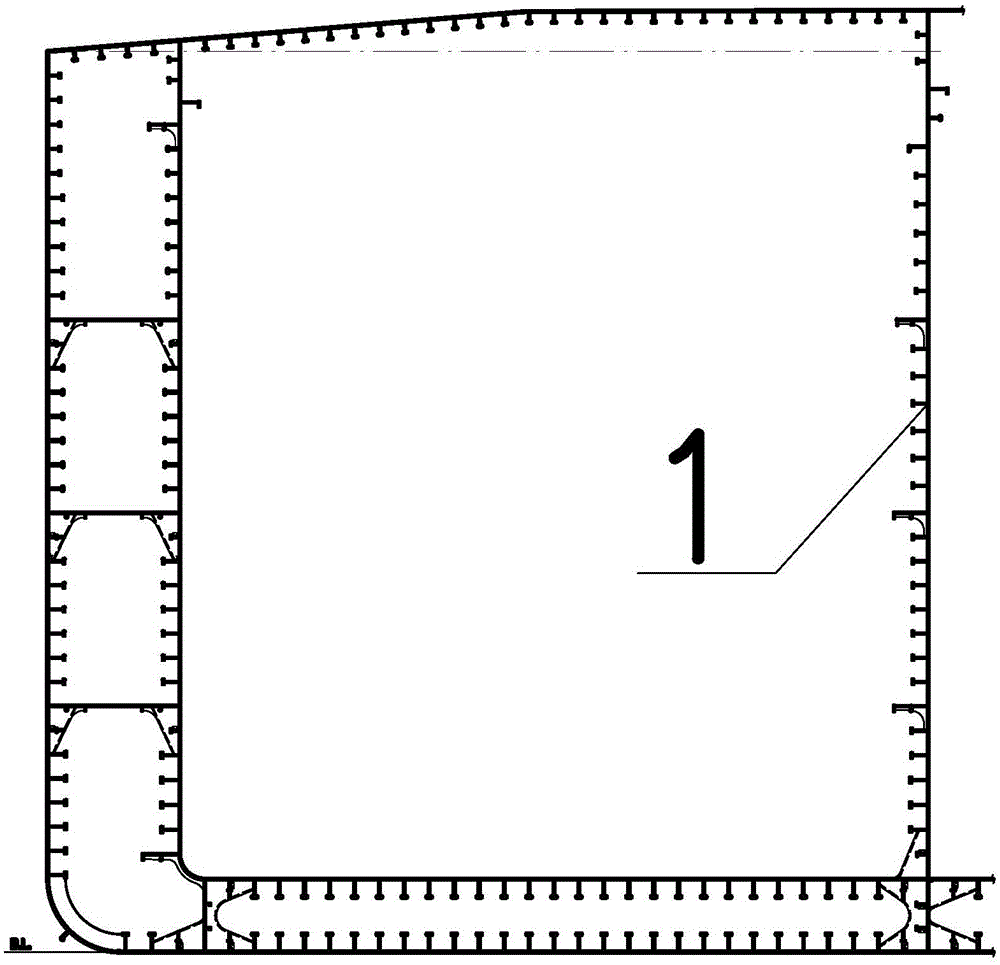

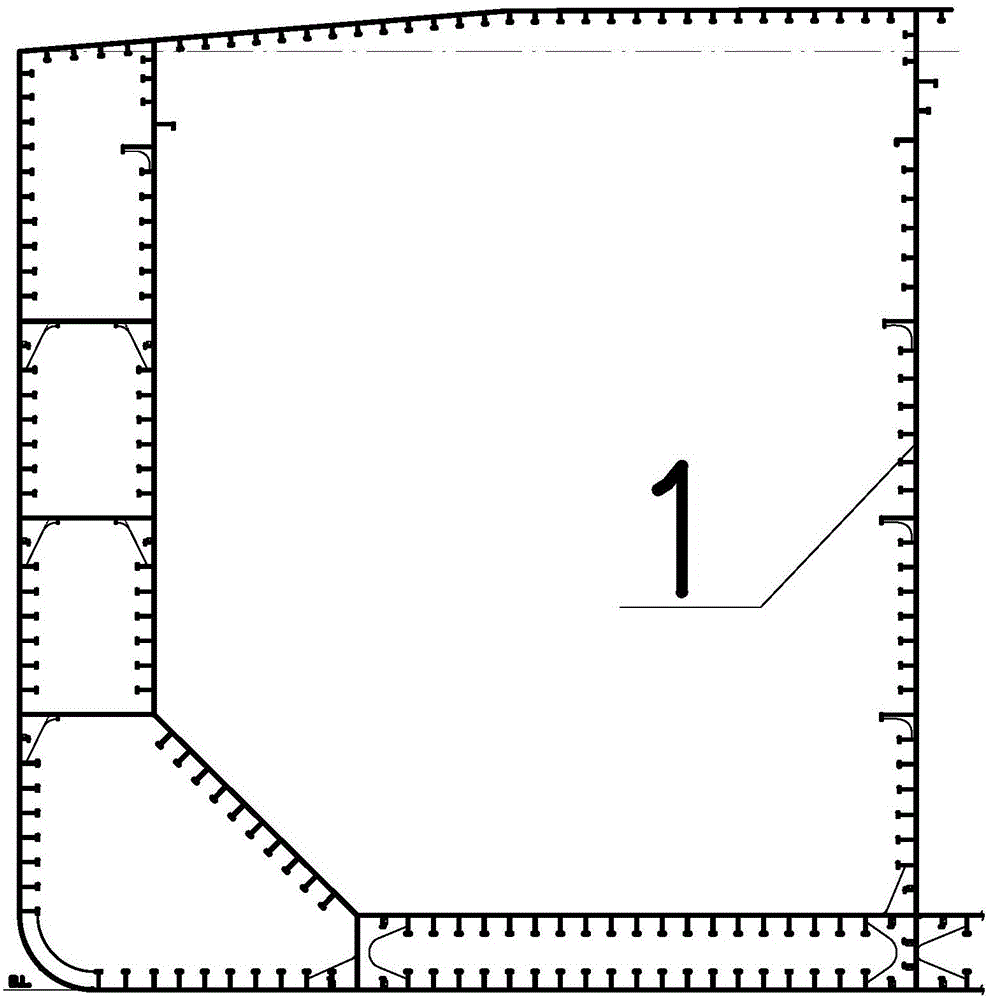

Very large crude carrier with no swash bulkheads and no cross braces

ActiveCN108945287AIncrease stiffnessImprove securityVessel partsHull bulkheadsMarine engineeringDouble bottom

The invention discloses a very large crude carrier (VLCC) with no swash bulkheads and no cross braces, and belongs to the technical field of shipbuilding. The VLCC comprises a double-bottom structureand cargo oil tanks, wherein an inner bottom plate is arranged above a ship bottom plate; a deck is arranged above the inner bottom plate; a plurality of longitudinal bulkheads and a plurality of transverse bulkheads are arranged between the inner bottom plate and the deck; each of the longitudinal bulkheads is provided with a corresponding watertight longitudinal girder at the lower part; the plurality of cargo oil tanks comprise a plurality of middle cargo tanks and a plurality of side cargo tanks; the middle cargo tanks are arranged at the middle of the upper end surface of the inner bottomplate along the longitudinal direction of a hull; the length of the middle cargo tanks is much greater than the width of the middle cargo tanks; a part of the middle cargo tanks and a part of the side cargo tanks are provided with reinforcing frameworks; the longitudinal bulkheads are provided with transverse perforated plates at the position of the reinforcing frameworks; the plurality of side cargo tanks are arranged in two rows and separately arranged on two sides of the middle cargo tanks; and the ratio of the length of each of the side cargo tanks to the length of the VLCC is less than 0.13. Through the rearrangement of the cargo oil tanks, the VLCC with no swash bulkheads and no cross braces provided by the invention simplifies the structural design and saves a part of manufacturingtechniques.

Owner:708TH RES INST OF CSSC

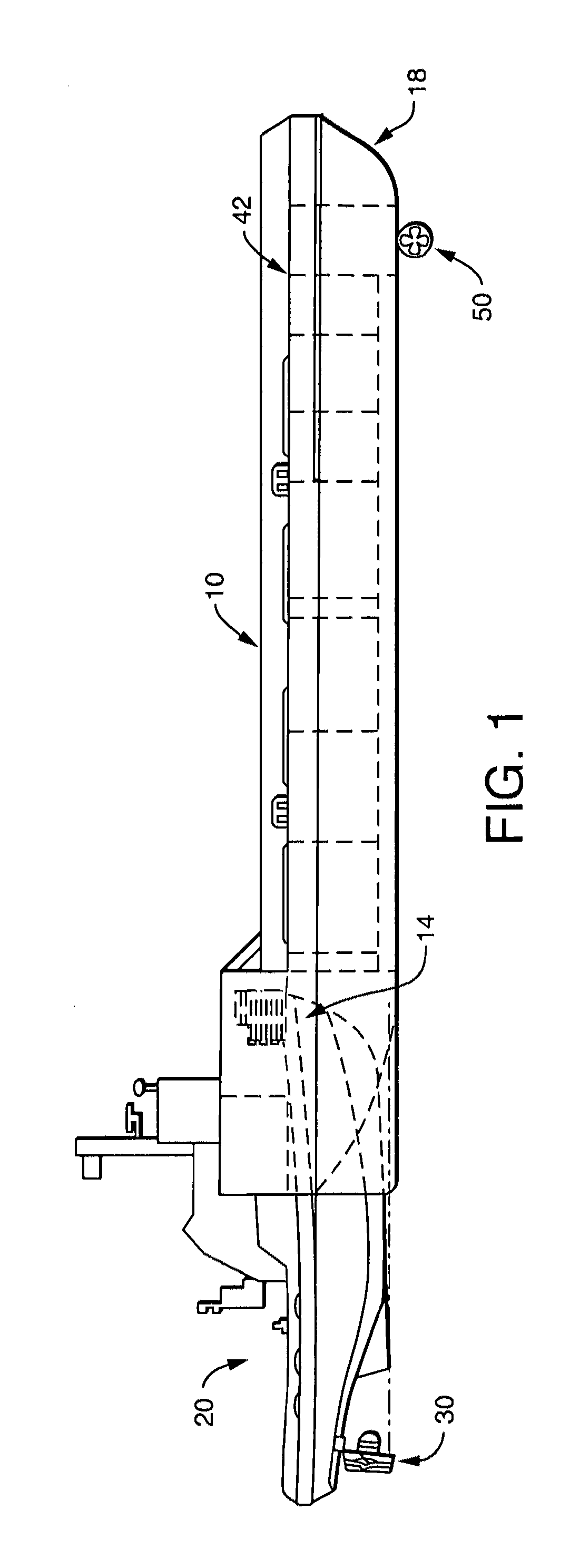

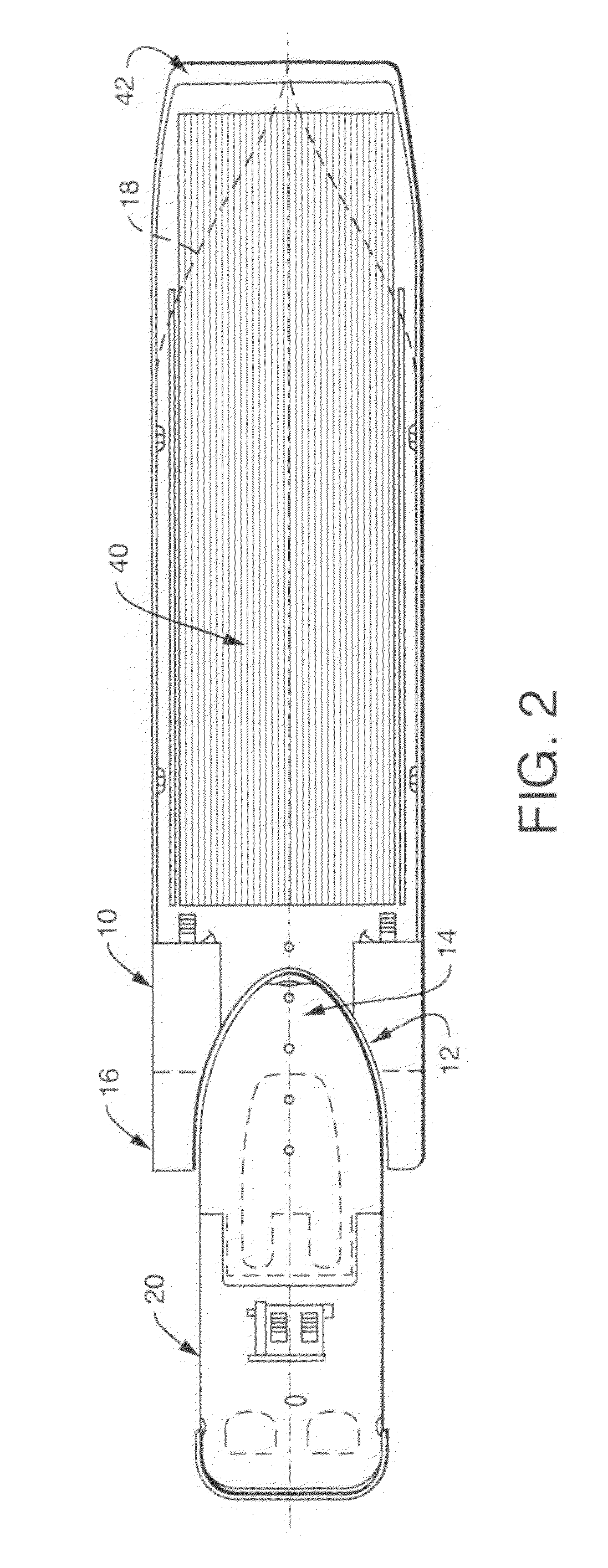

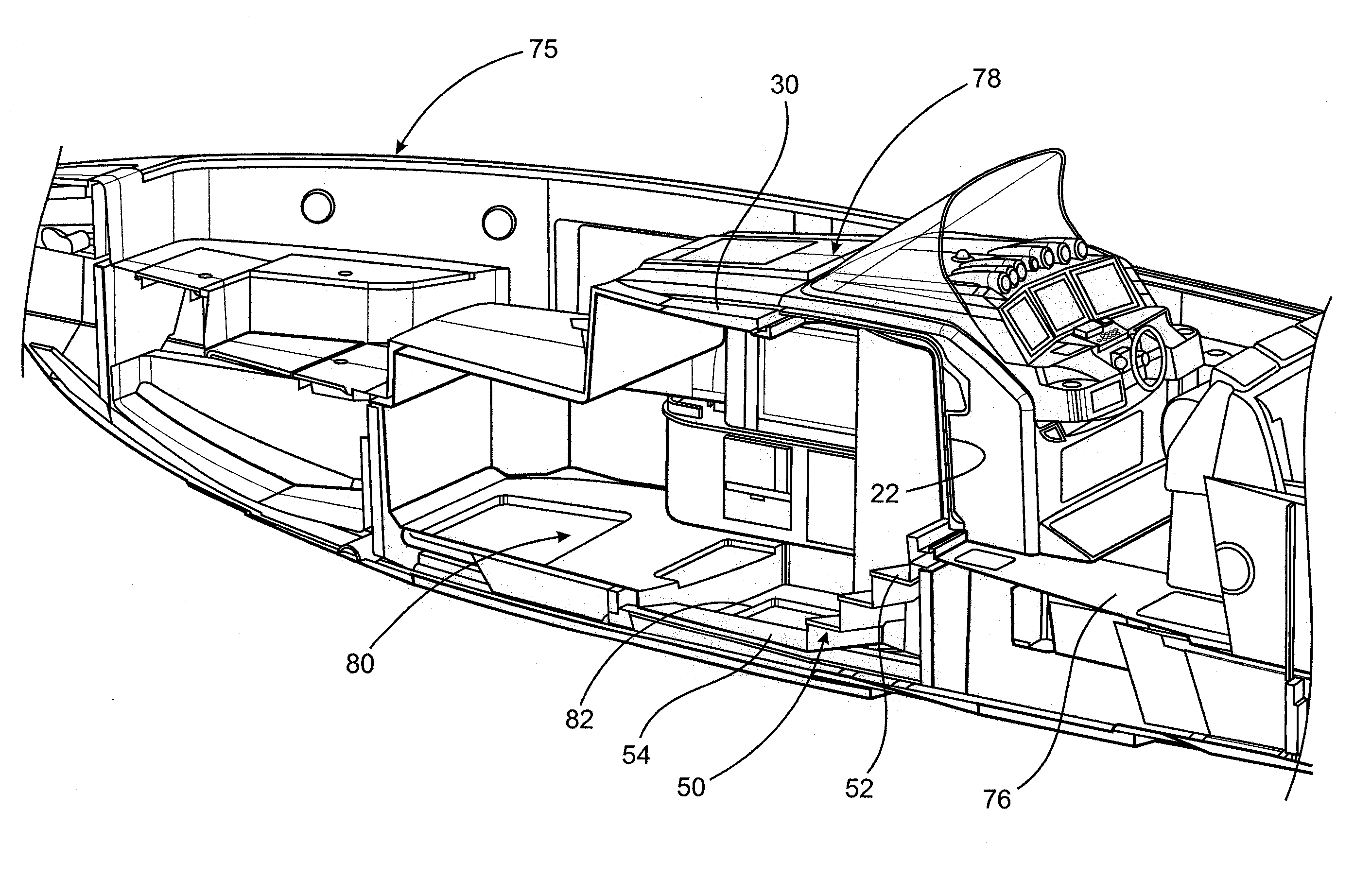

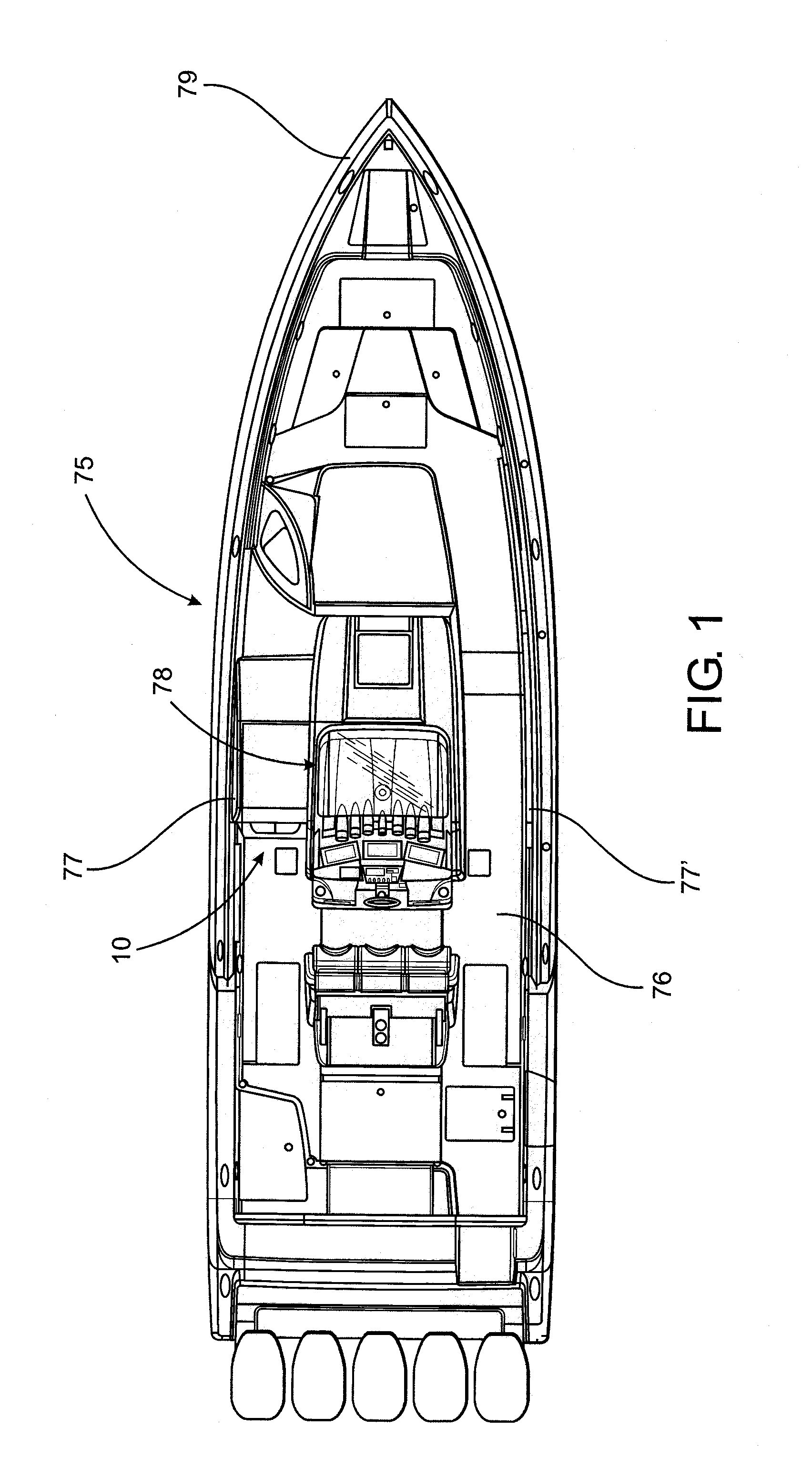

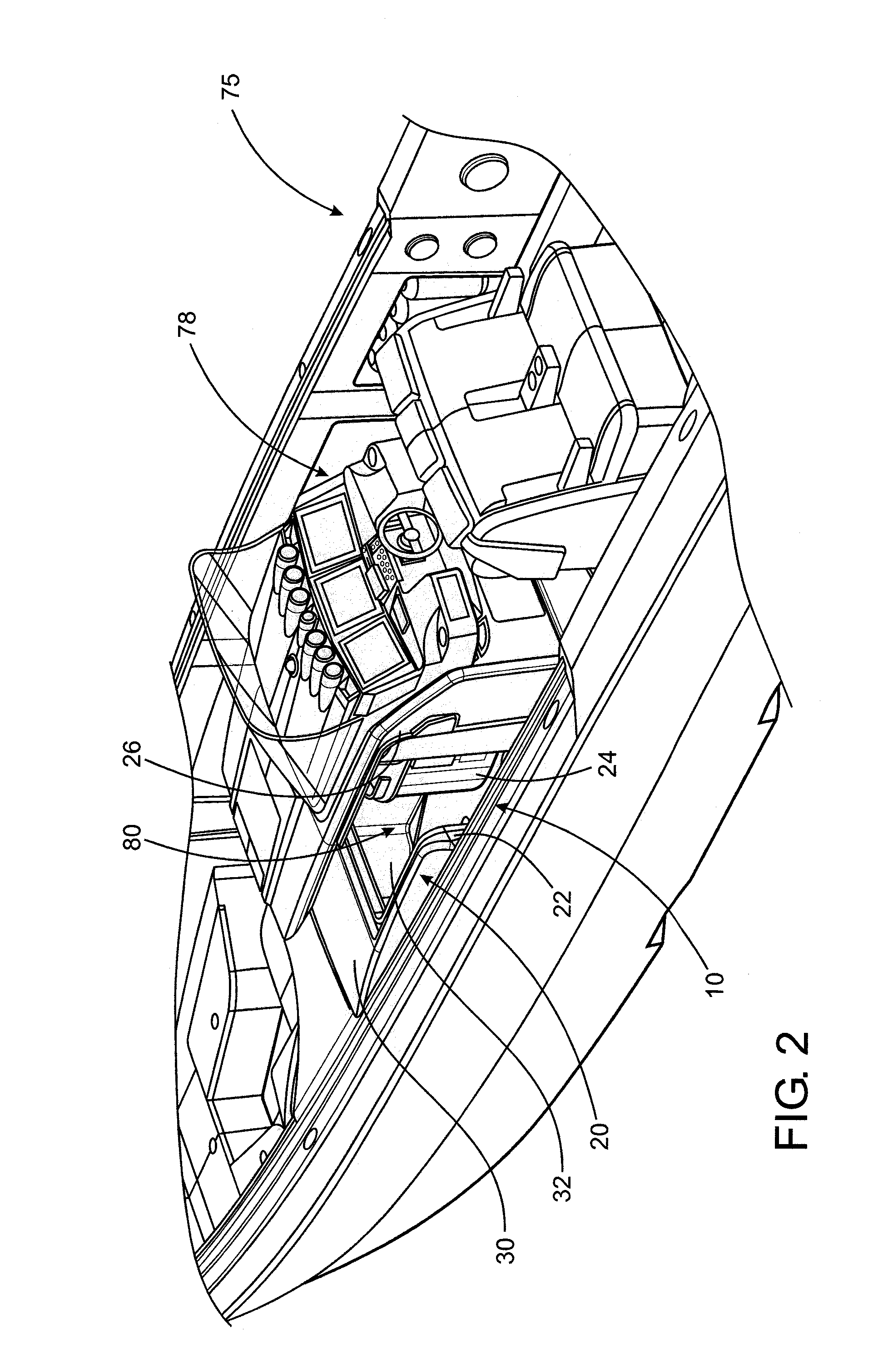

Underdeck mid-cabin entry system for mono hull boat

ActiveUS9021972B1Avoid impeding movementHeight canNon-magnetic metal hullsVessel partsEngineeringPoint of entry

An under deck mid cabin entry system for a mono hull boat including an entry console and exposed top and front surfaces. Front and top openings extend to the top edge of the front surface and collectively define a generally L shaped entryway. The entry console is disposed to the side of a center console and provides access to steps extending beneath the main deck. A top step is within the entry console proximate to the front surface and the steps curve towards a central beam of the boat and descend into the mid cabin such that a bottom step proximate to a floor of the mid cabin directs a user into a central area of the mid cabin and terminates to avoid obstructing movement in the central area.

Owner:CIGARETTE IP HLDG LLC

Ship hatch negative corner packaging structure

InactiveCN106364626AReduce lossesNot easy to produce stockHull bulkheadsCapacity lossMarine engineering

The invention relates to a ship hatch negative corner packaging structure. The ship hatch negative corner packaging structure comprises a negative corner (1) fixedly arranged at a position of a hatch, wherein the negative corner is used for dividing a liquid tank (2) from a cargo compartment (3); the negative corner is packaged by adopting a bevel (5); the bevel extends from the top of the liquid tank to the lower part of the cargo compartment; an included angle formed between the bevel and a vertical direction is 30 degrees to 60 degrees; and a reinforcing bar (7) is fixedly arranged at a connection position of the liquid tank (2) and the cargo compartment (3), and the trend of the reinforcing bar is parallel to the bevel. According to the ship hatch negative corner packaging structure disclosed by the invention, a design of a bevel structure is adopted, the negative corner is packaged in a beveled packaging form instead of a conventional rectangular sealing form, and the tank capacity loss of the liquid tank is reduced. Stock is not easy to be produced in the bevel structure, and the consumption of plates is less than that of a conventional form, so that the mounting of the reinforcing bar at the back is facilitated, and a triangular beveled bracing form is firmer than a conventional rectangular packaging form in local strength, and is more beautiful.

Owner:上海斯达瑞船舶海洋工程服务有限公司

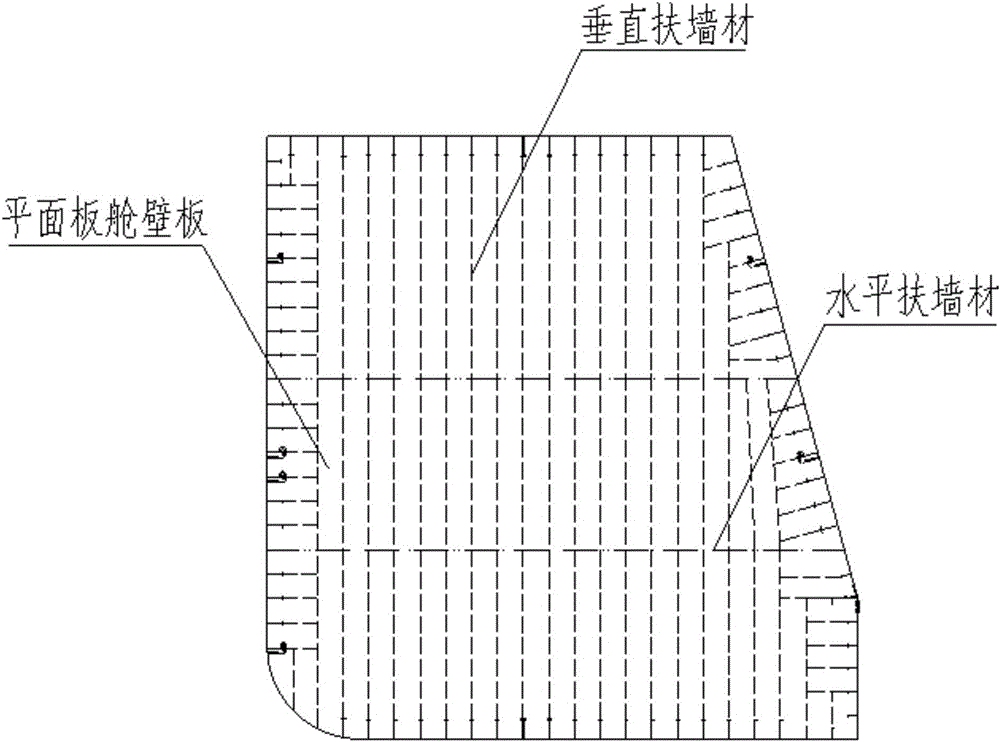

Groove-shaped wall structure of ship oil cabin

A groove-shaped wall structure of a ship cabin comprises a cabin front wall and a cabin longitudinal oil tight wall which is perpendicular to the cabin front wall, wherein the cabin front wall is a perpendicular groove-shaped wall; the cabin longitudinal oil tight wall is a horizontal groove-shaped wall; the perpendicular groove-shaped wall comprises a plurality of vertical panels which are perpendicular to the bottom surface of the cabin; the adjacent vertical panels are arranged in a front and back staggered mode and are integrally connected by first connecting web plates to form the perpendicular groove-shaped wall with a wave structure; the horizontal groove-shaped wall comprises a plurality of horizontal panels which are perpendicular to the bottom surface of the cabin and are arranged from top to bottom; the adjacent horizontal panels are arranged in a left and right staggered mode and are integrally connected by second connecting web plates to form the horizontal groove-shaped wall with a wave structure; the side of the horizontal groove-shaped wall is fixedly connected with the vertical panel, at the corresponding end, of the perpendicular groove-shaped wall; the upper side and the lower side of the horizontal groove-shaped wall are fixedly connected with an upper deck and the bottom surface of the cabin correspondingly. The groove-shaped wall structure has the advantages of simple structure, high bearing strength, light weight and high cabin capacity.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

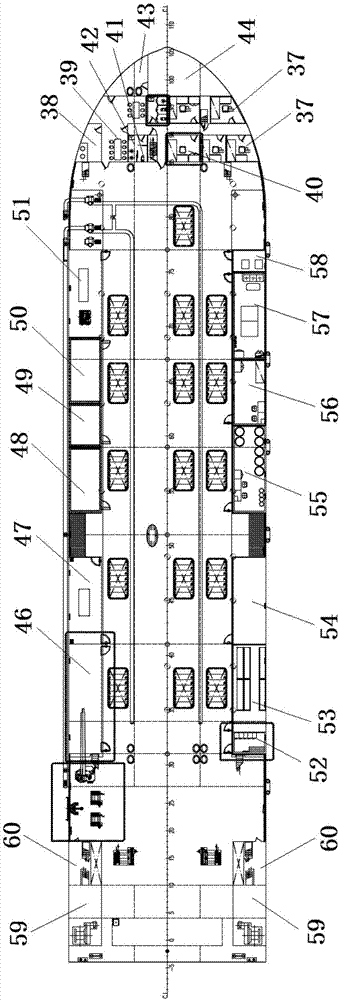

Independent liquefied gas ship

ActiveCN103879516ASuccessfully discardedReduce pollutionAccommodation for deck loadsHull bulkheadsCantilevered beamHydraulic pump

The invention discloses an independent liquefied gas ship, and belongs to the field of liquid cargo ships. The liquefied gas ship comprises a ship, hydraulic pumps, a cantilever beam, storage tanks, separation cabins, connecting rods, release doors, release ejector rods, release pins, hydraulic pump stations, hydraulic ejector rods, trippers and push rods. The storage tanks on a main deck of the ship are separately arranged on the left side and the right side of the cantilever beam, are separated from one another by the separation cabins and are bound on the cantilever beam by the aid of the trippers, the hydraulic pumps are arranged at input ends of the hydraulic ejector rods, the corresponding independent release doors are arranged on a left chord and a right chord of each storage tank and are fixed onto the ship by the aid of the corresponding release pins, the corresponding release pins in each release door are connected with one another by the two corresponding connecting rods, the corresponding release ejector rods are fixed to the upper end and the lower end of each connecting rod, the hydraulic pump stations are arranged at input ends of the release ejector rods, and each telescopic push rod is arranged at an output end of the corresponding hydraulic pump station and is fixed onto the cantilever beam. The liquefied gas ship has the advantage that problems of tremendous loss and excessively large polluted sea areas due to a ship abandonment escape mode adopted when a firefighting system on an existing ship cannot handle sudden events related to shipped liquefied gas can be solved.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com