Cargo hold structure

A cargo hold and hopper tank technology, applied in the field of cargo hold, can solve the problems of insufficient fatigue strength and increased arc stress, and achieve the effects of high strength, increased strength and increased effective support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

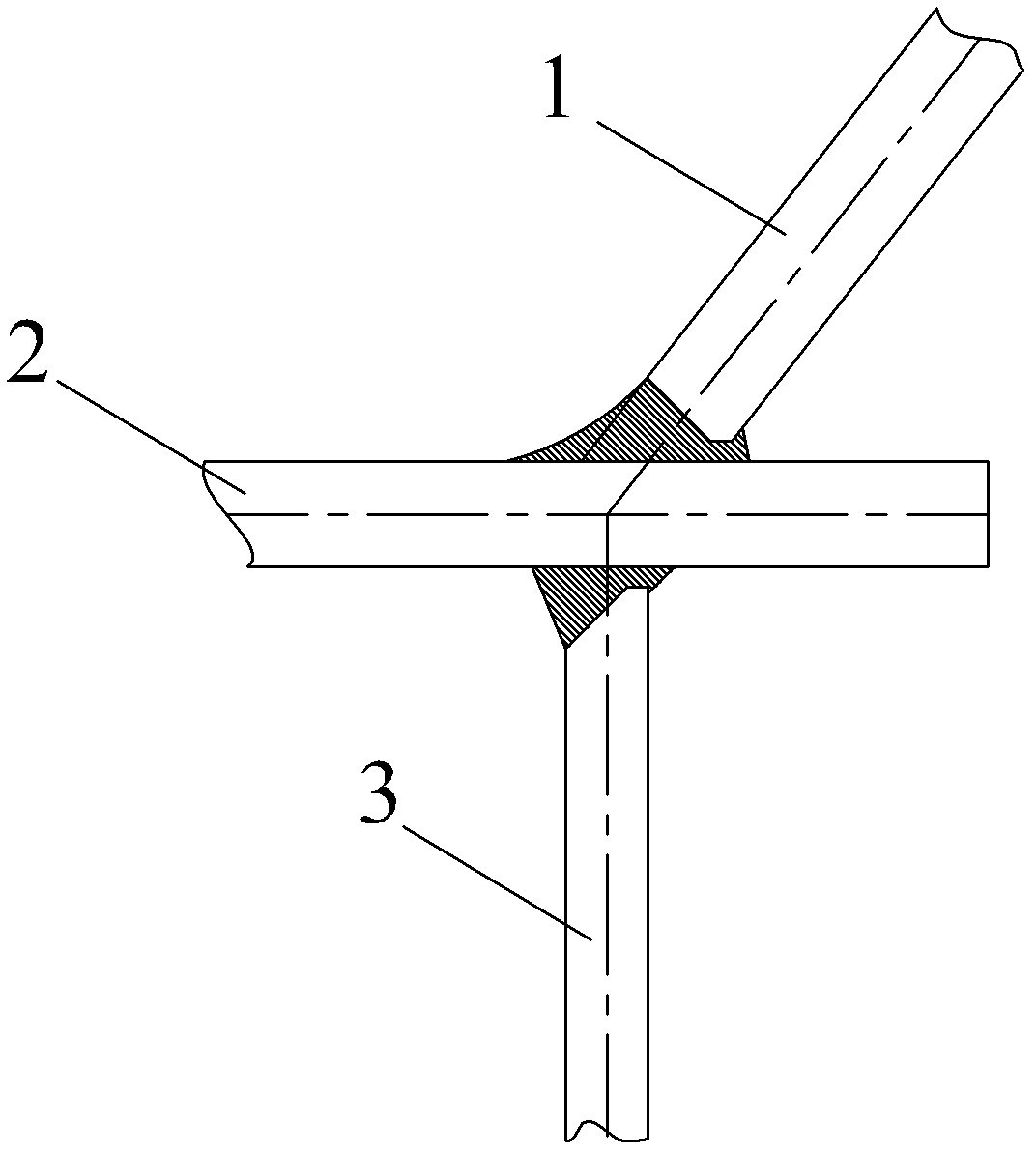

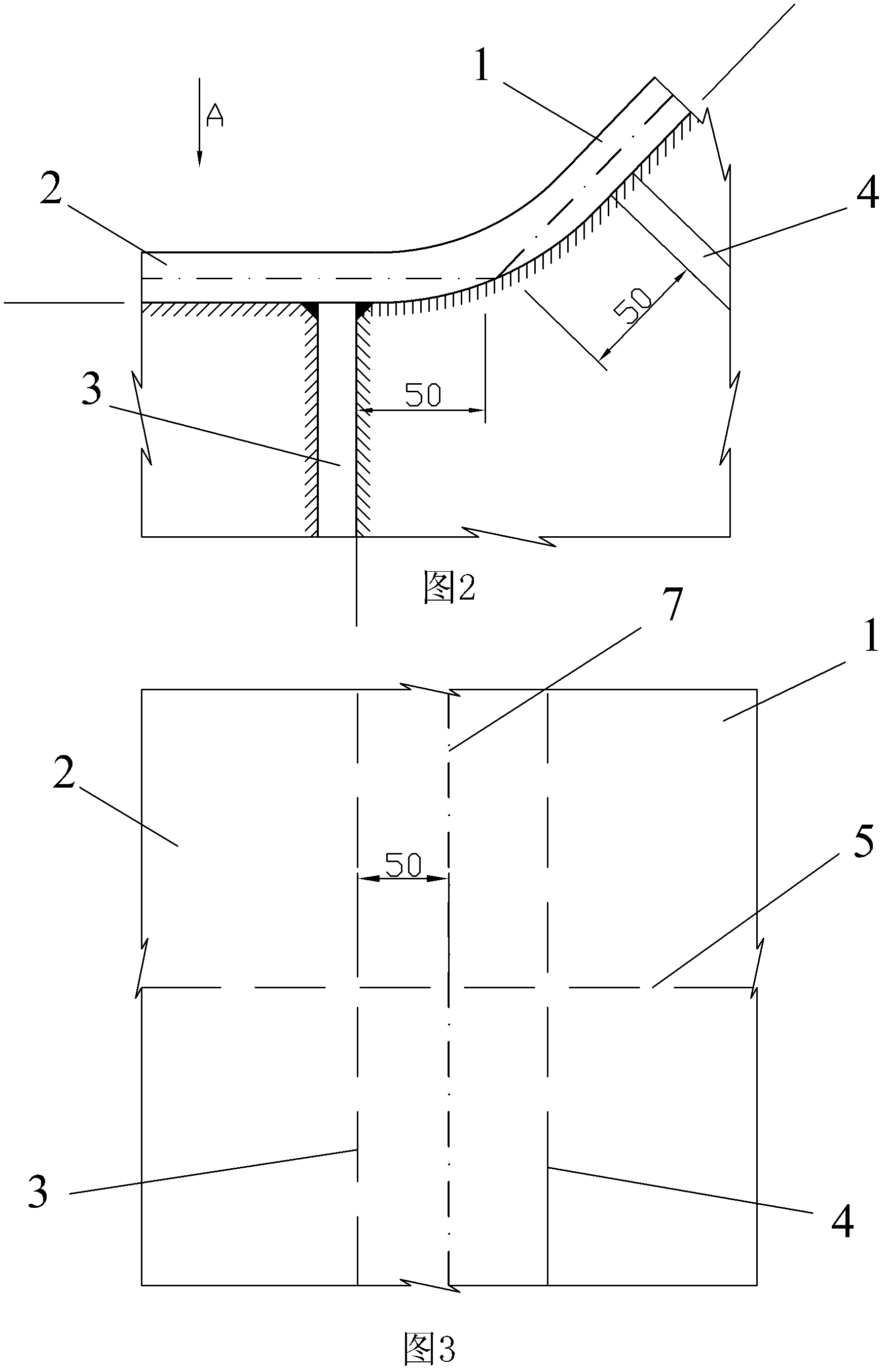

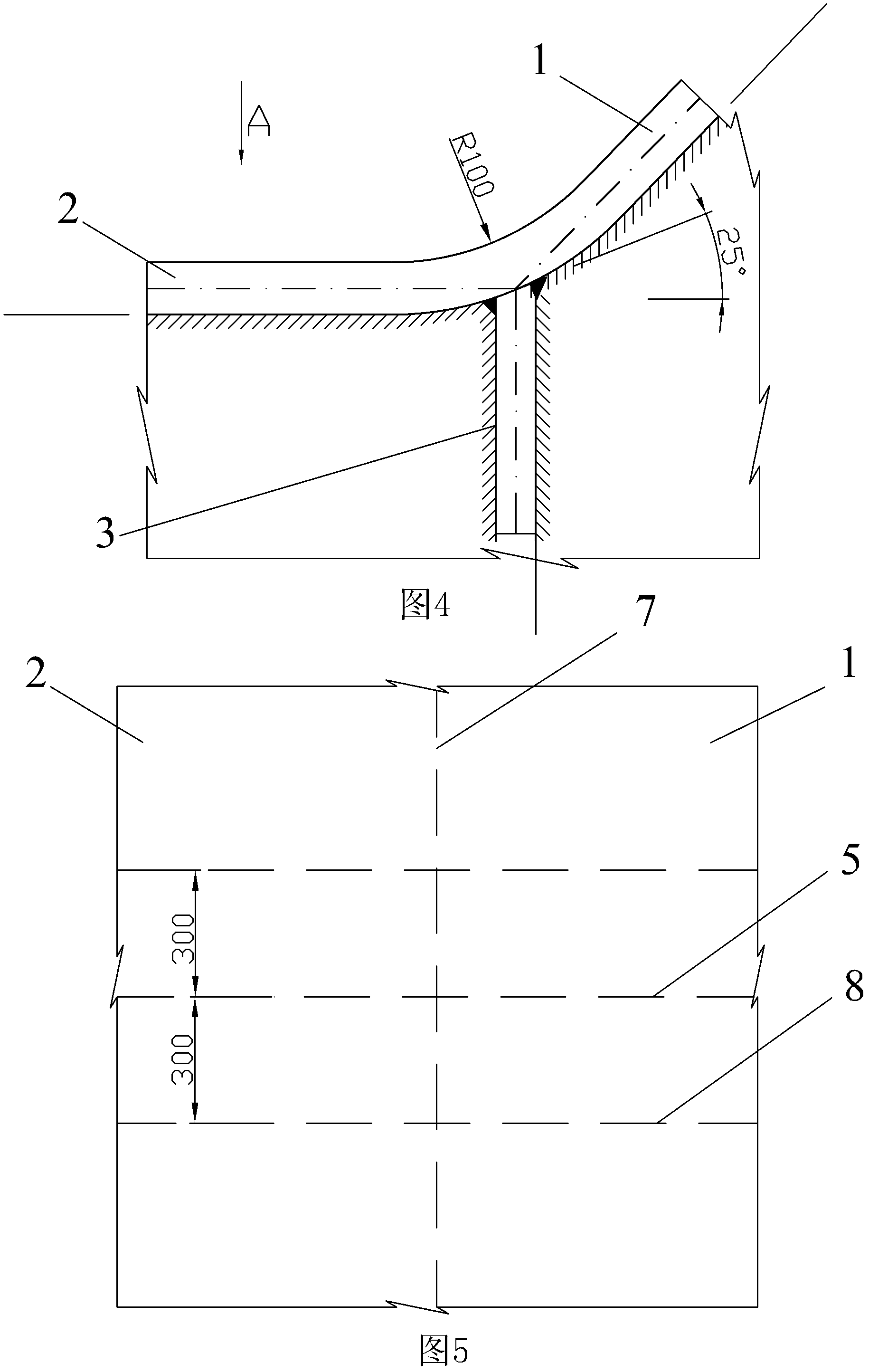

[0015] Such as Figure 4 with 5 The connecting structure design of the three-line centered arc transition type hopper cabin inclined bottom plate and inner bottom plate of the present invention mainly includes the connection of the longitudinal inclined bottom plate 1 and the inner bottom plate 2 in the form of a curved arc to make the inner bottom plate 2 and the inclined The intersection of the extension lines of the thickness center line of the bottom plate 1 is located on the arc surface. The inner bottom side longitudinal truss 3 is arranged at the intersection of the inclined bottom plate and the extension line of the inner bottom plate, that is, below the kink line 7 where the inclined bottom plate 1 and the extension surface of the inner bottom plate 2 intersect. And the center line of the inclined bottom plate 1, the inner bottom plate 2, and the inner bottom side stringer 3 are centered by three lines. In a preferred manner, the radius dimension of the arc connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com