Skirt and frame of tank container

A tank container and skirt technology, which is applied in the frame field of tank containers, can solve the problems of large longitudinal impact force and rowing system, and achieve the ability of improving the ability to withstand and transmit longitudinal impact, good stability, and reasonable force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be further described below through specific embodiments in conjunction with the accompanying drawings, and any modifications or changes made to the present invention will fall within the scope of protection of the present invention.

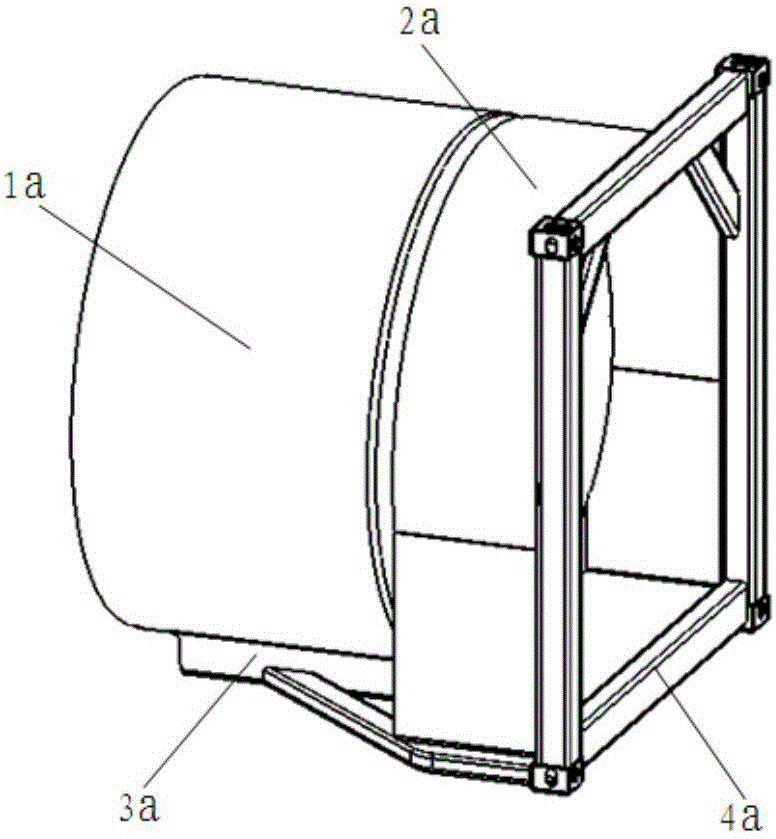

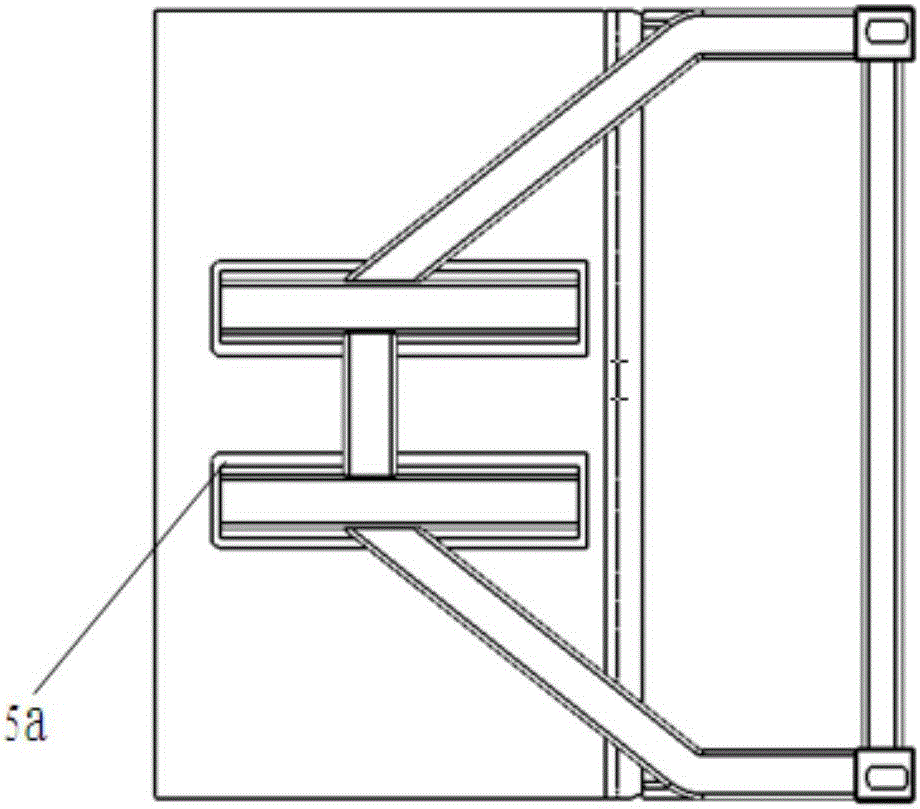

[0042] see Figure 11 to Figure 14 , is an embodiment of the invention. The frame structure of the tank container mainly includes a tank body 1c, a skirt 2c, a longitudinal beam assembly 3c, an end frame 4c, and a longitudinal beam backing plate 5c. One end of the skirt 2c is welded to the tank body 1c, and the other end is welded to the end frame 4c, so that the tank body 1c and the end frame 4c are integrated.

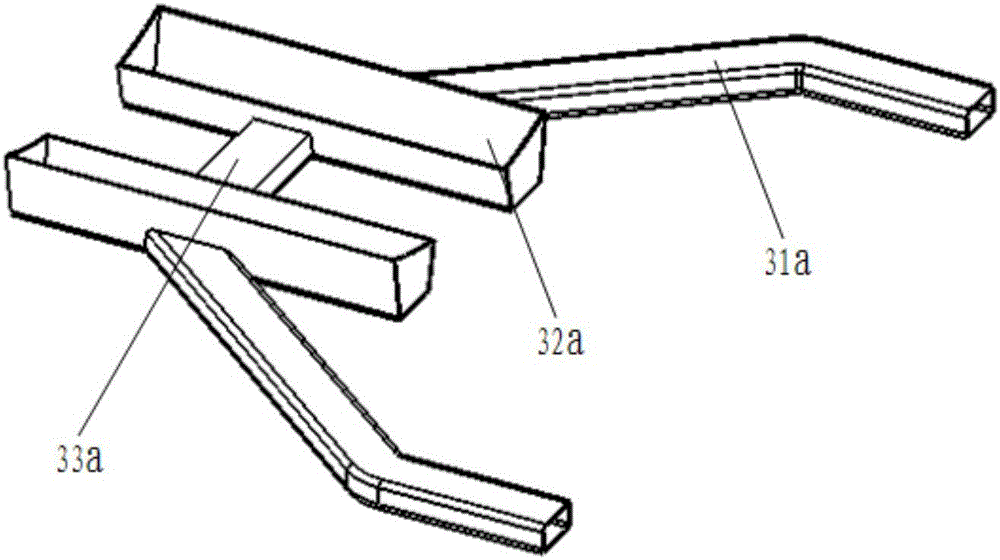

[0043] The skirt 2c is composed of a box body 21c and a rear sealing plate 22c. The upper part of the box body 21c is a semi-straight cylinder structure, and the outer diameter of the cylinder is the same as the outer diameter of the tank; A section of circular arc straight c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com