Rock breaker with transversely retractable vehicle body

A technology of horizontal expansion and rock breaker, applied in the field of rock breakers, can solve the problem that the ripper cannot make full use of the shear force of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

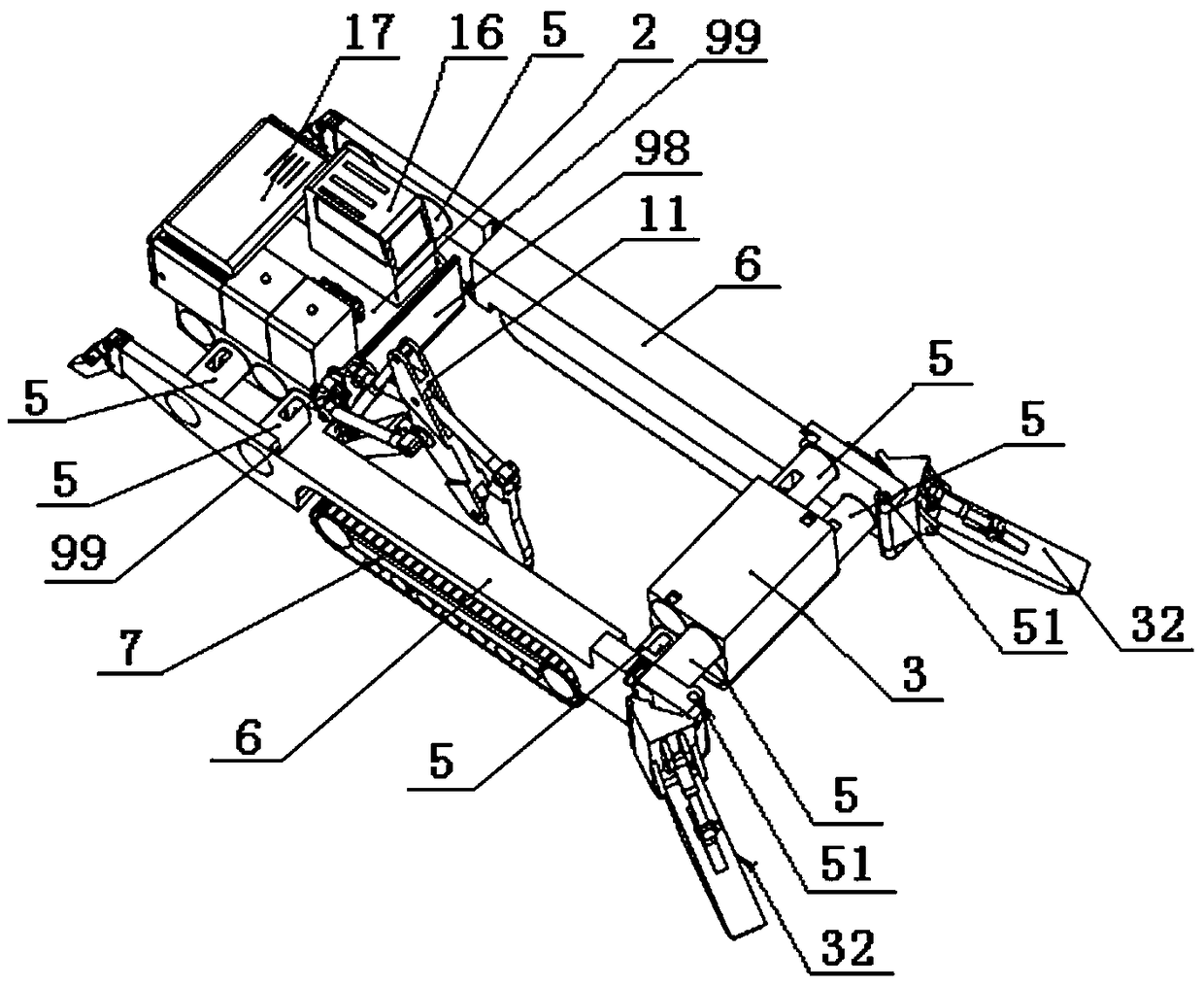

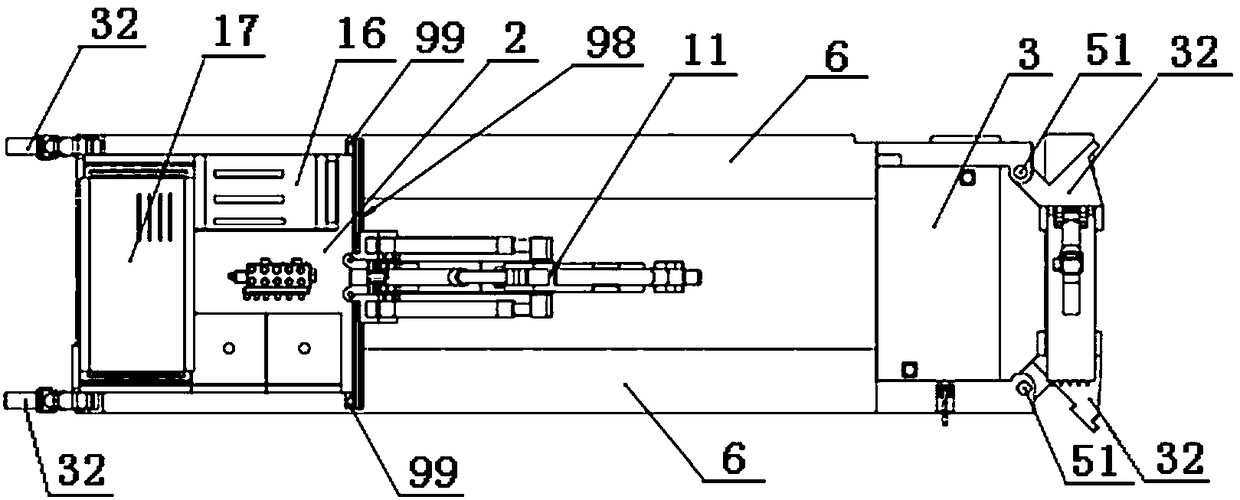

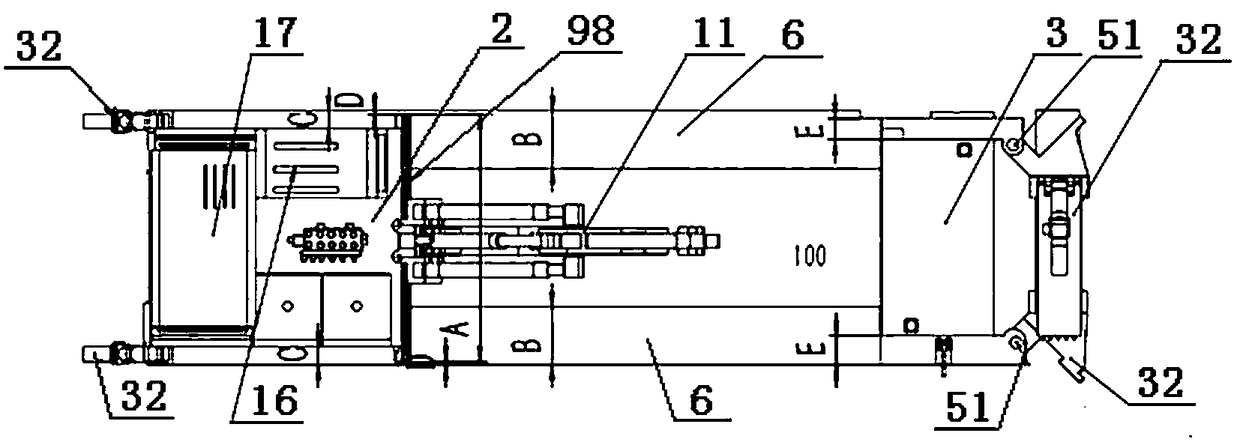

[0032] The rock breaker has a power of 263 kilowatts and a total weight of 55 tons. The car body has a telescopic function. The width of the car body during transportation is 3.5 meters. The maximum width of the rock breaking operation is 5.5 meters when it is opened. The total length of the rock breaker is 13.5 meters , where the length occupied by the support is 2 meters.

[0033] The rock breaking machine whose car body can be stretched horizontally, the front and rear ends of the symmetrical right and left beams 6 are respectively connected with the front connecting beam 3 and the rear connecting beam 2 through the telescopic tube 5 to form an up and down hollow car body, and the rear connecting beam 2 has a control Chamber 16. Power chamber 17, the front end plate 98 of the rear connecting beam 2 is connected with the rock arm 11, and the rock arm 11 is equipped with a ripper with bucket teeth, and the ripper is driven by an oil cylinder. The minimum distance F between th...

Embodiment 2

[0047] The rock breaker has a power of 263 kilowatts and a total weight of 55 tons. The car body has a telescopic function. The width of the car body during transportation is 3.5 meters. The maximum width of the rock breaking operation is 5.5 meters when it is opened. The total length of the rock breaker is 13.5 meters , where the length occupied by the support is 2 meters.

[0048] It includes a power part 17, a control room 16, a car body with a hollow area in the up and down direction, and a rock arm 11 located in the hollow area. Walking 7 is arranged on both sides of the car body, and the rock arm 11 can carry a ripper using a bucket tooth For rock breaking operations, the ripper is driven by an oil cylinder, the side beams 6 on both sides of the car body are slidingly connected with the front connecting beam 3 and the rear connecting beam 2 through the telescopic tube 5, the two side beams 6 are provided with walking 7, and the front end plate 98 is welded and fixed on th...

Embodiment 3

[0059] The rock breaking machine has a power of 263 kilowatts and a total weight of 55 tons. The car body has a telescopic function. The width of the car body during transportation is 3.5 meters. The maximum width of the rock breaking operation is 5.5 meters when it is opened. .

[0060] It includes a power part 17, a control room 16, a car body with a hollow area in the up and down direction, and a rock arm 11 located in the hollow area. Walking 7 is arranged on both sides of the car body, and the rock arm 11 can carry a ripper using a bucket tooth Carrying out rock-breaking operations, the side beams 6 on both sides of the car body are slidingly connected with the front connecting beam 3 and the rear connecting beam 2 through the telescopic tube 5, the two side beams 6 are provided with walking 7, and the front end plate 98 is fixed to the rear connecting beam 2 with bolts, and the control The chamber 16 and the power part 17 are arranged on the rear connecting beam 2, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com