Large-volume cement paste mixing device and mixing method thereof

A mixing and mud technology, which is applied in the direction of cement mixing device, liquid ingredient supply device, mixing operation control device, etc., can solve the problems of low mixing uniformity and low mixing efficiency, and meet the requirements of large displacement cementing Construction conditions, compact structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

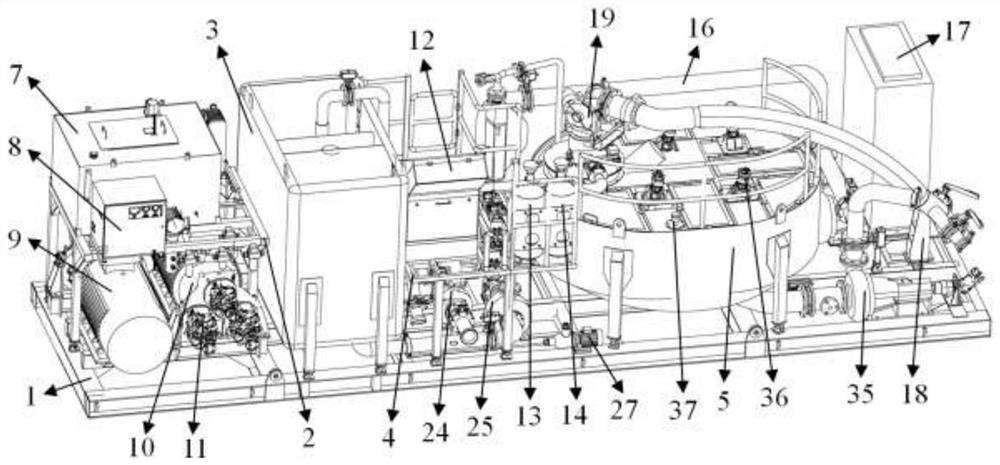

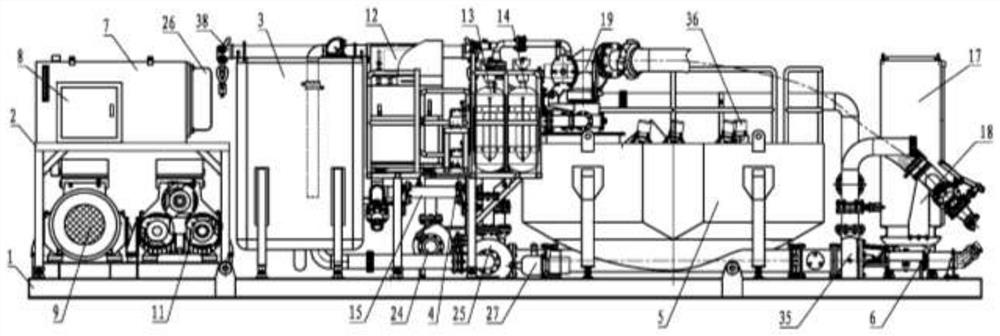

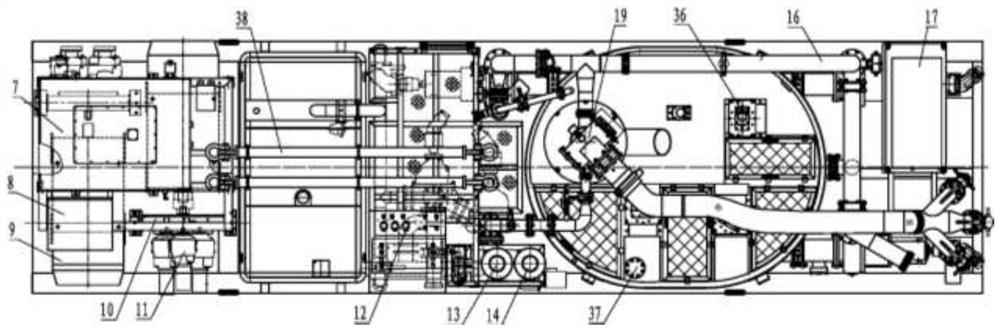

[0042] A large-volume cement slurry mixing device and a mixing method thereof according to the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] Such as figure 1 , figure 2 and image 3 As shown, a large-volume cement slurry mixing device includes a skid body 1, on which a power bracket 2, a water tank 3, an operating platform 4, a mixing tank 5, a starter cabinet bracket 6, and a power bracket 2 are sequentially arranged. Including a hydraulic oil tank 7 and an air control cabinet 8, two motors 9 are installed on the lower part of the power bracket 2, each motor 9 is connected to a transfer case 10 through a coupling, and a hydraulic pump group 11 is installed on the transfer case 10;

[0044] An electric control console 12, an oil injection tank 13 and a defoaming tank 14 are installed on the operation platform 4, and a clear water manifold 15 is installed on the lower part of the operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com