Very large crude carrier with no swash bulkheads and no cross braces

A technology of washing bulkhead and super-large, applied in the direction of hull bulkhead, hull, ship parts, etc., can solve the problems of increasing the complexity of structural design, increasing the process workload of shipyards, etc., to achieve convenient stowage, good safety performance, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

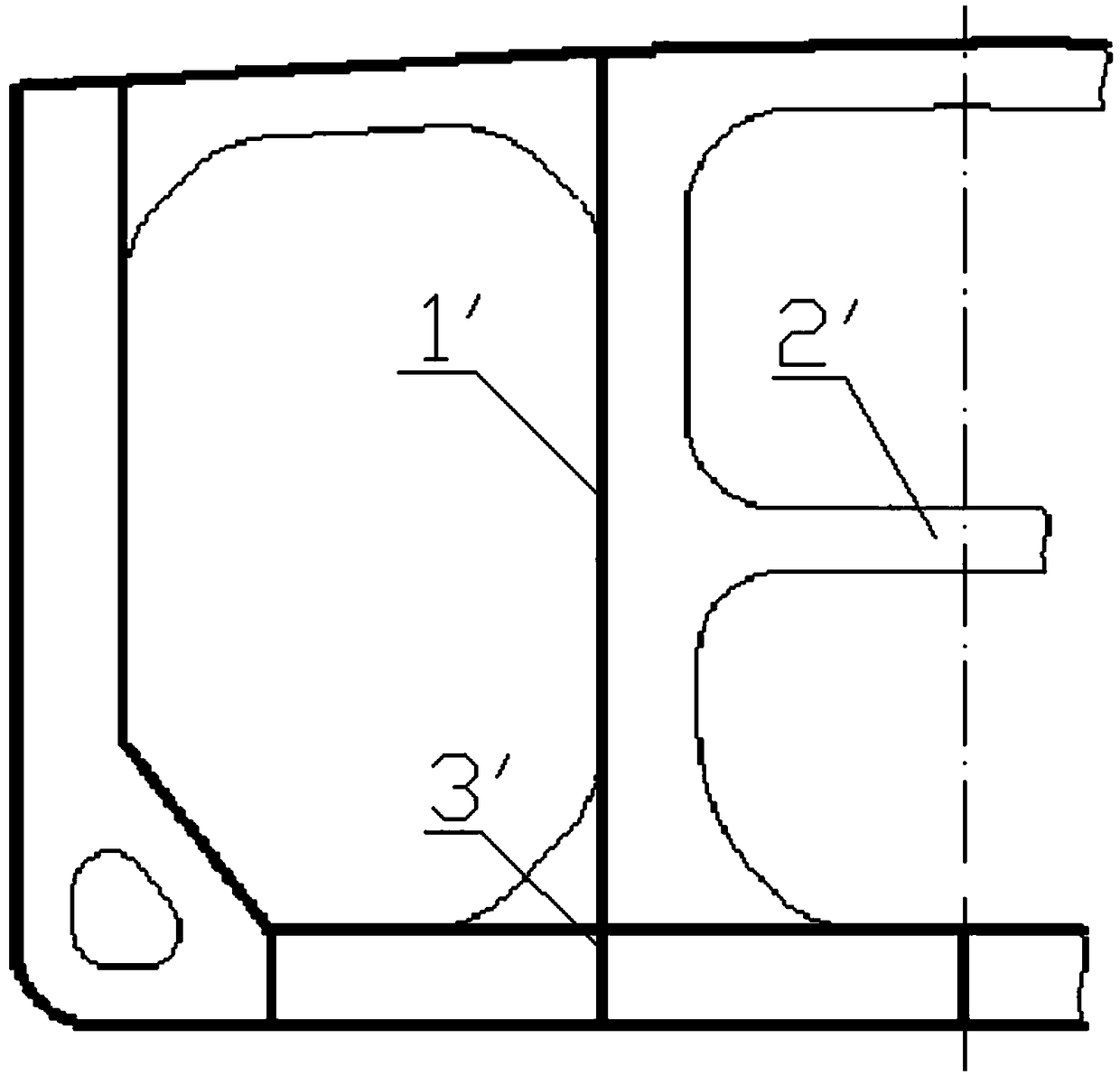

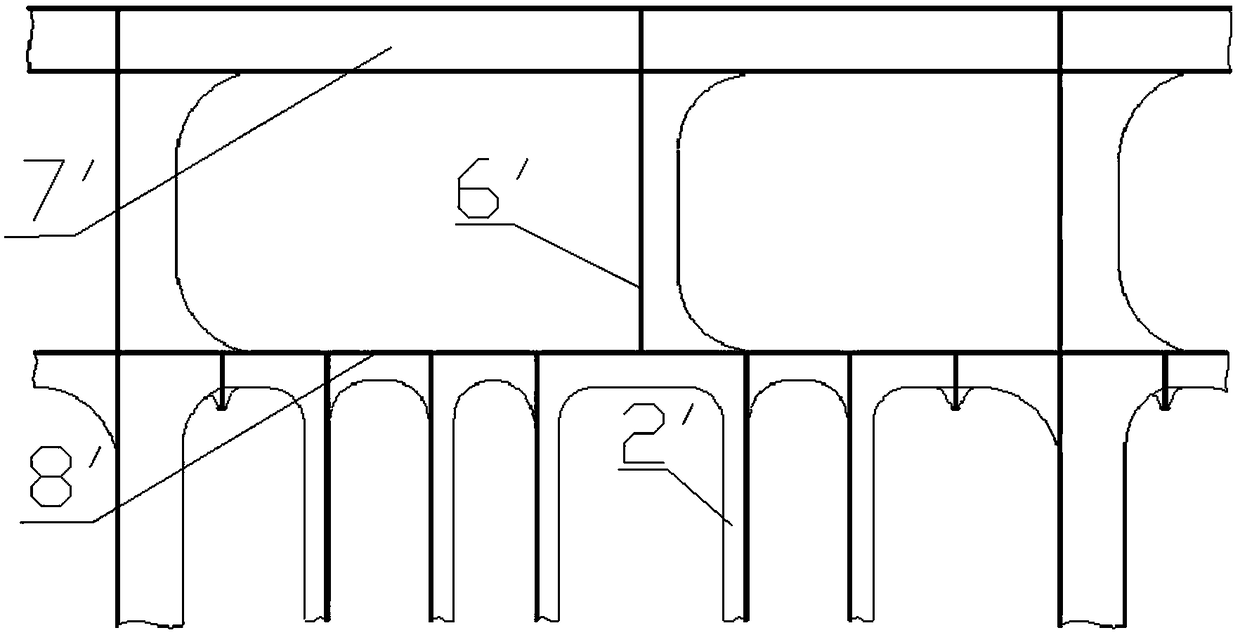

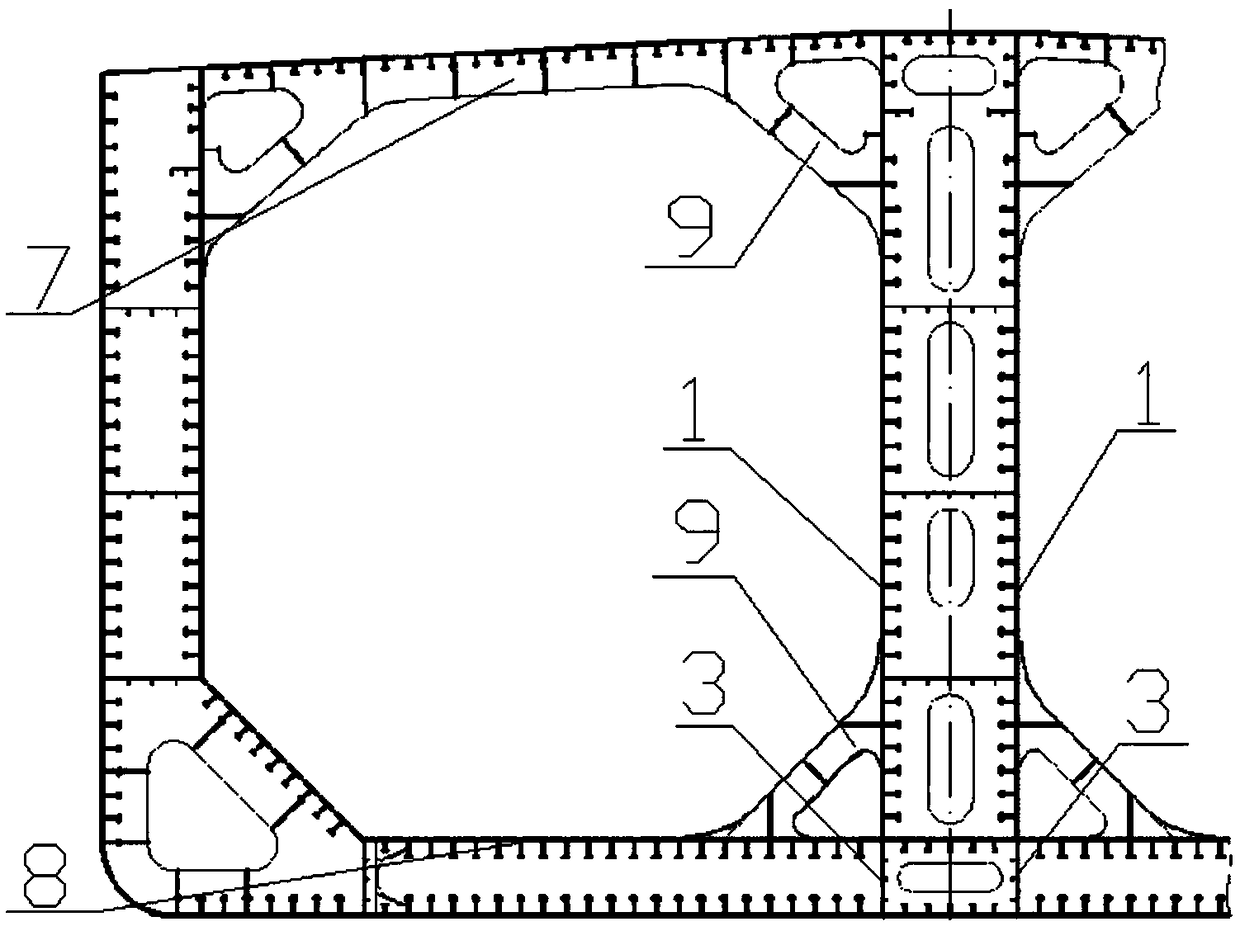

[0030] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Figure 5 A very large crude oil carrier without swash bulkheads and no cross braces provided by the present invention will be described in detail.

[0031] image 3 It is a schematic diagram of the structure at the strong frame of an embodiment of an ultra-large crude oil carrier without swash bulkheads and no cross-bracing of the present invention; Figure 5 It is a schematic diagram of cargo oil tank layout of an embodiment of a very large crude oil carrier without swash bulkheads and no cross braces according to the present invention. In this embodiment, the VLCC without swash bulkheads and no cross braces mainly includes longitudinal Bulkhead 1, watertight girder 3, middle cargo hold 4, side cargo hold 5, deck 7, inner bottom plate 8, bracing bracket 9.

[0032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com