Stainless steel chemical tanker cabin wall structure

A technology of chemicals and stainless steel, applied to hull bulkheads, hull compartments, hulls, etc., can solve problems such as high construction costs, achieve the effects of total weight reduction, cost reduction, and high degree of subdivision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

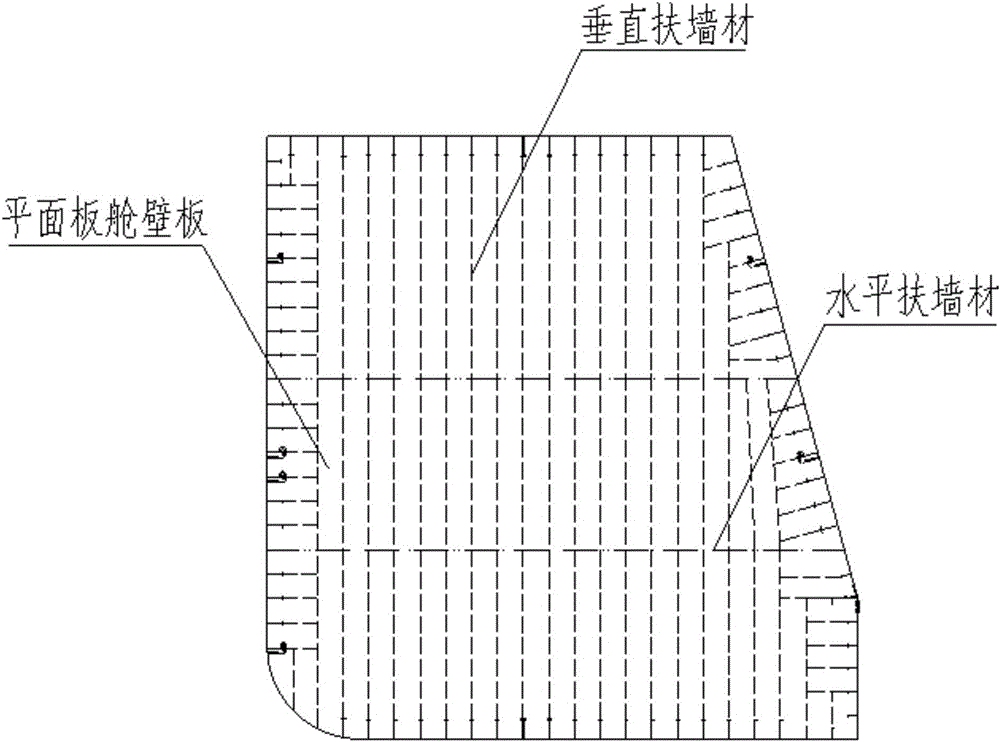

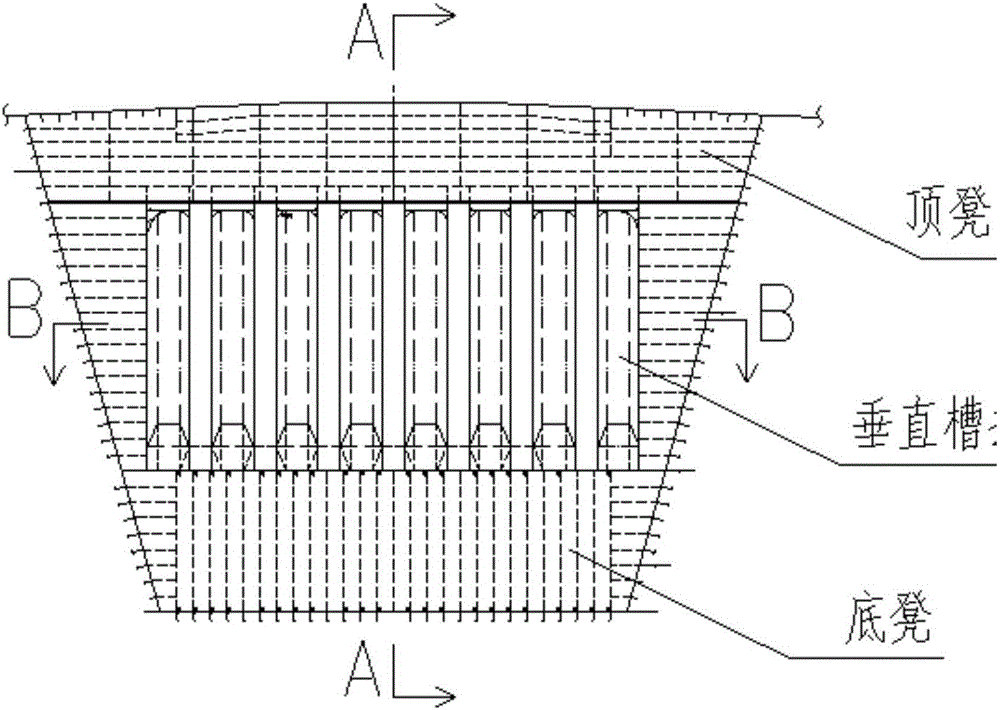

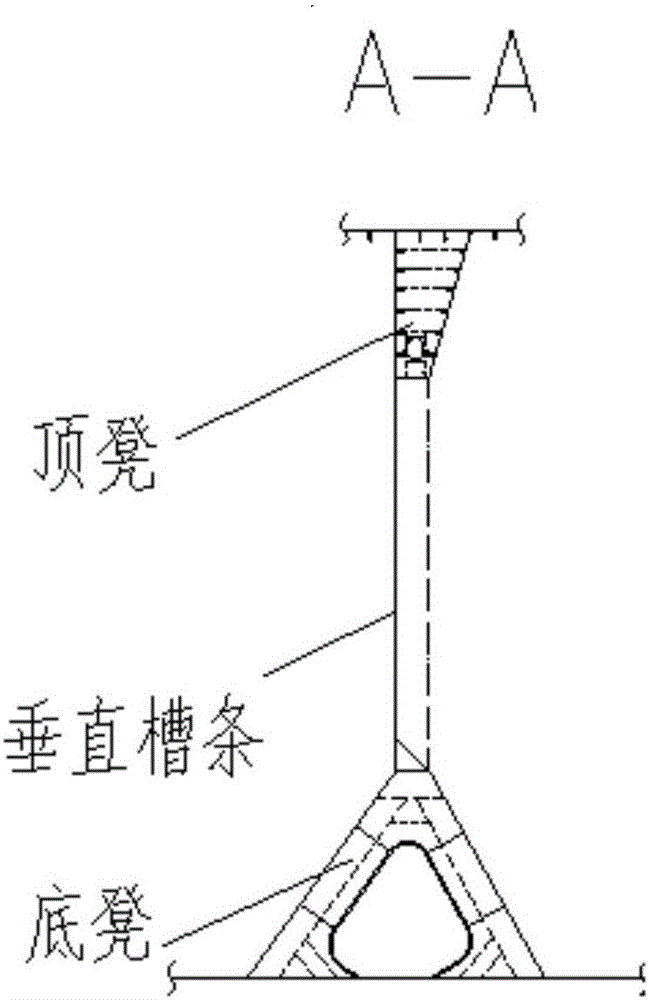

[0032] see figure 1 , a stainless steel chemical tanker bulkhead, including a longitudinal bulkhead part and a transverse bulkhead part, which divide the chemical cargo tank into several compartments; the longitudinal bulkhead part is a double-plate planar longitudinal bulkhead, and the Reinforced by transverse bulkheads, longitudinal horizontal girders and longitudinal weak members; the transverse bulkhead part is a horizontal trough-type transverse bulkhead, and the horizontal trough-type transverse bulkhead consists of several pieces whose thickness decreases step by step from bottom to top The welds between the panels are horizontal and straight; the horizontal groove-type transverse bulkhead is made of stainless steel, and the plane longitudinal bulkhead inside the compartment that is in direct contact with chemicals is made of stainless steel; the transverse bulkhead is made of stainless steel. Plates, longitudinal horizontal girders and longitudinal weak members are mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com