Supertanker

A technology for super-large oil tankers, applied to hull bulkheads, hull parts, hulls, etc., can solve problems such as complicated process and complex structure, and achieve the effect of low process technology and light structure weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

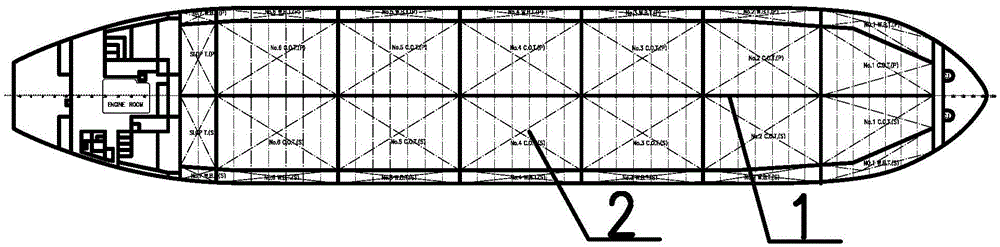

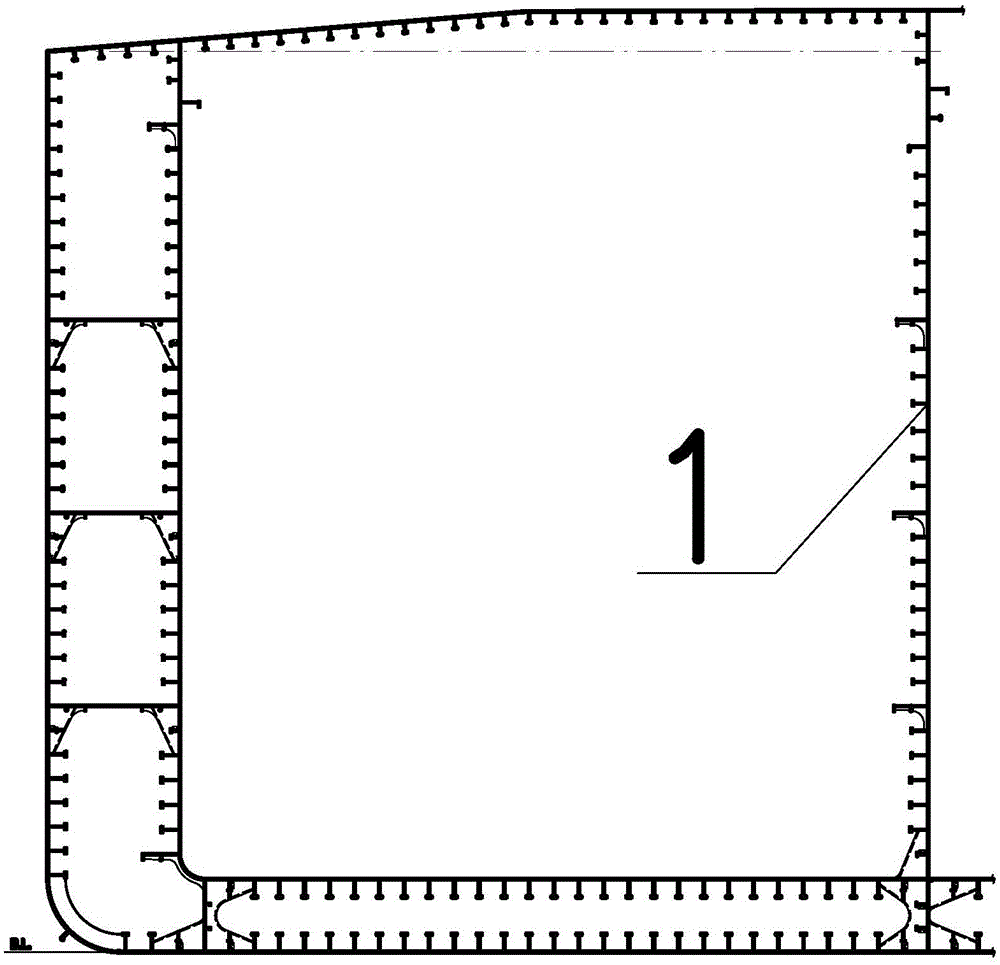

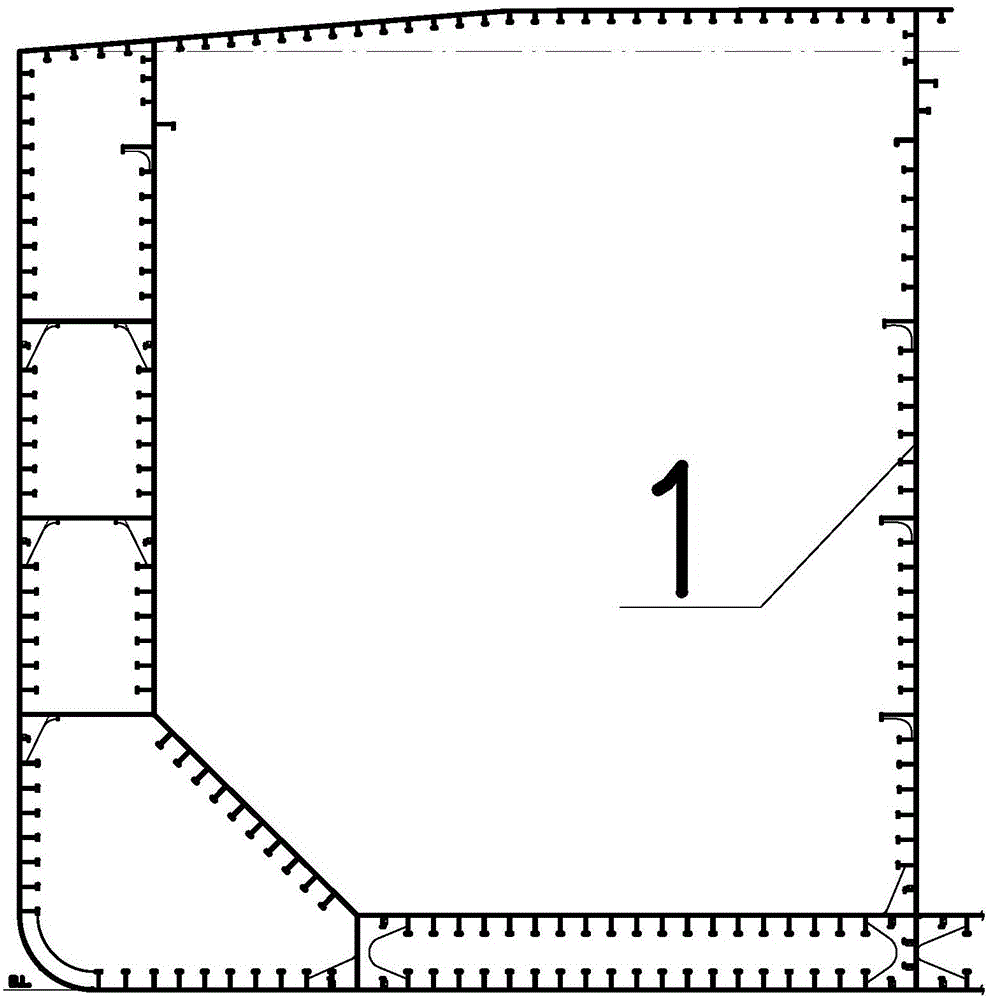

[0028] Such as Figure 1 to Figure 8 As shown, the present invention provides a VLCC, including the VLCC cargo hold area, which also includes:

[0029] One longitudinal bulkhead 1, only one longitudinal bulkhead 1 is arranged in the cargo tank area of the VLCC, and it is preferably arranged on the central axis of the oil tanker;

[0030] The main support members 2, the main support members have obvious truss-like characteristics21, including: while increasing the end connection area and section modulus of the vertical girders of the longitudinal bulkhead, the deck webs and the horizontal girders of the transverse bulkhead, all the main support members Large and small openings 22 are provided in the lower stress area of the member. In addition, the lower stress area of the web of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com