Damping type oscillation prevention cabin wall for independent C-type cargo hold of LNG injection ship

A sloshing bulkhead and damping technology, applied to hull bulkheads, hulls, hull parts, etc., can solve the problems of high strength requirements for diaphragms and poor sloshing effects, and achieve good manufacturability and simple structure , the effect of suppressing sloshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

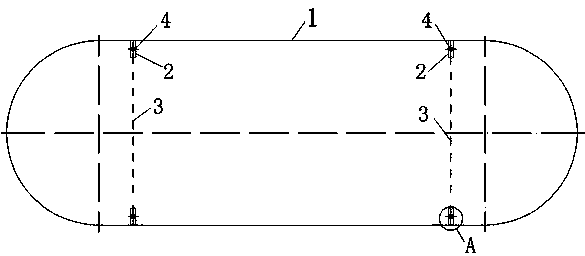

[0028] The structure of the present invention will be further described below with reference to the accompanying drawings.

[0029] figure 1 It shows the layout of the damped surge bulkhead for the independent C-type cargo tank of the LNG bunkering ship. In the figure, this damping type bulkhead includes a transverse groove-shaped reinforcement ring 2 connected to an independent C-type cargo hold 1 , and a perforated diaphragm 3 connected to the transverse reinforcement ring 2 via No. 1 spring 4 . The transverse groove-shaped reinforcing ring 2 is fixed along the lateral circumference of the independent C-type cargo hold 1, and is arranged on both ends of the independent C-type cargo hold 1, and is in the same plane as the saddle of the independent C-type cargo hold 1.

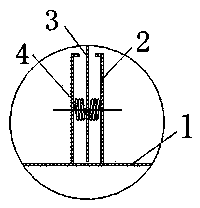

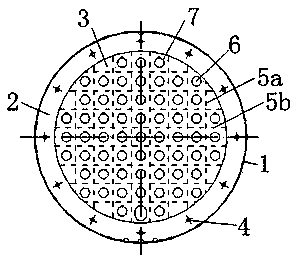

[0030] figure 2 An enlarged view of the connection mechanism between the transverse grooved reinforcement ring 2 and the perforated diaphragm 3 is shown. The perforated diaphragm 3 is arranged in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com