Patents

Literature

87results about How to "Reduce scrolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

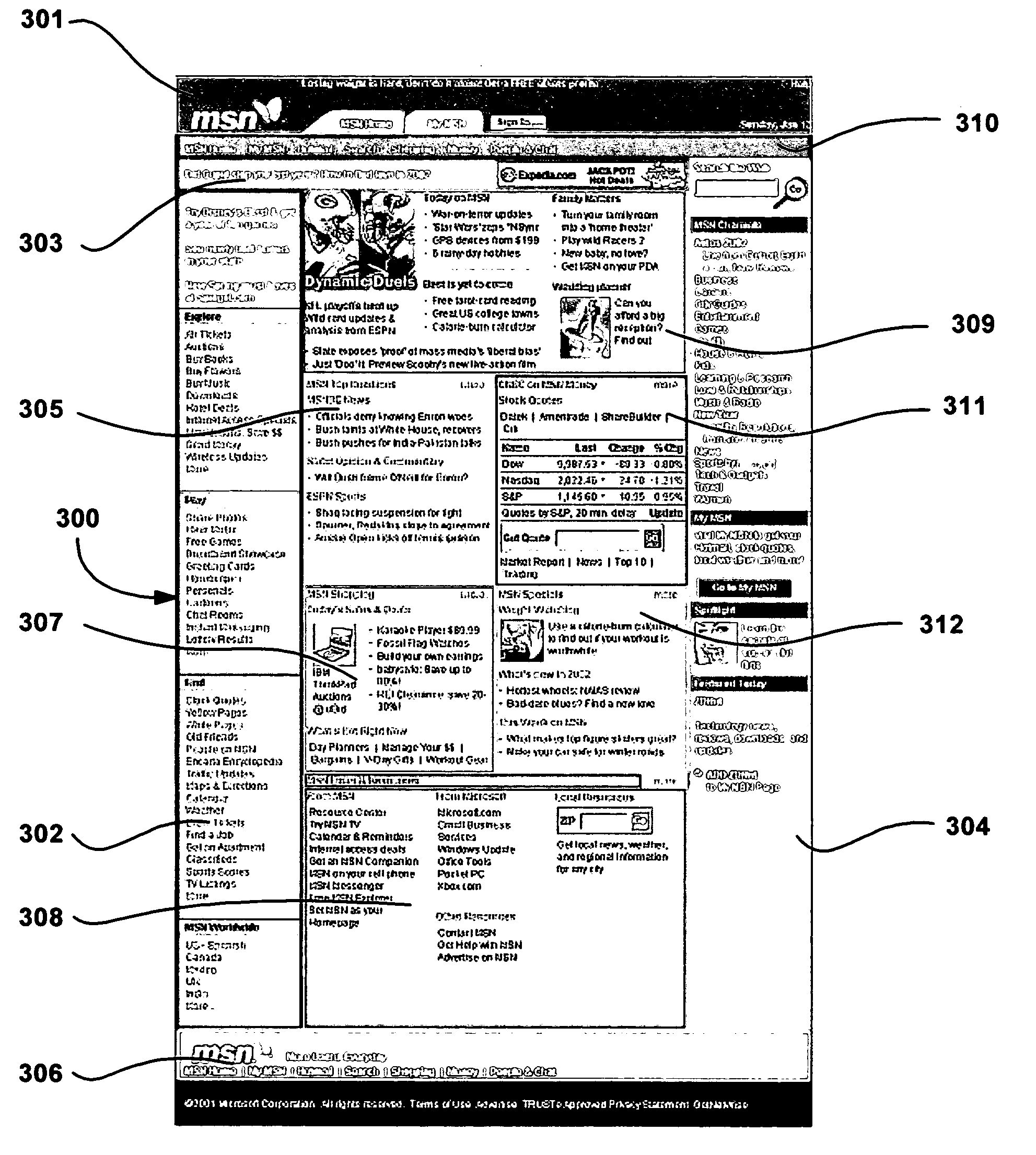

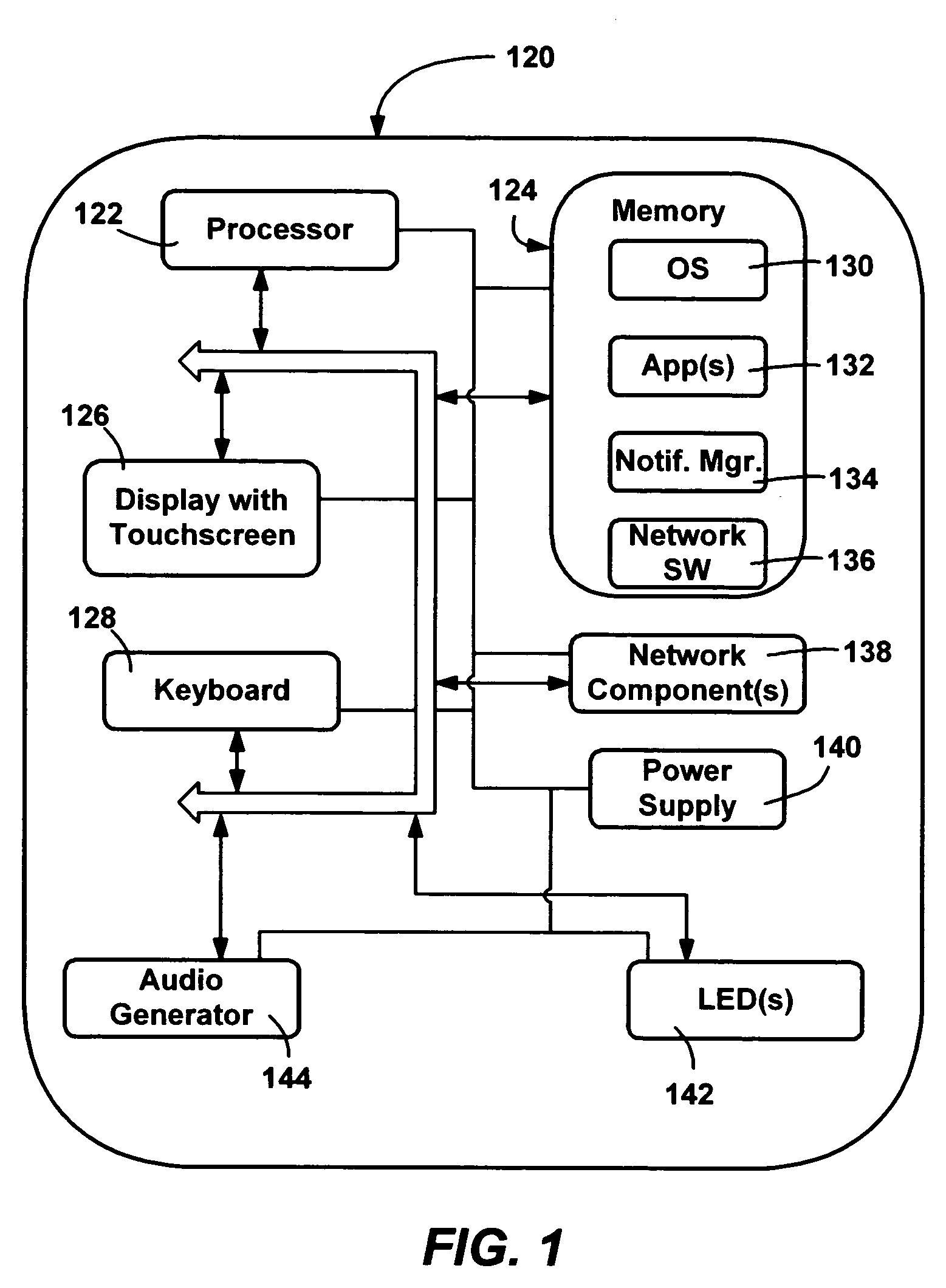

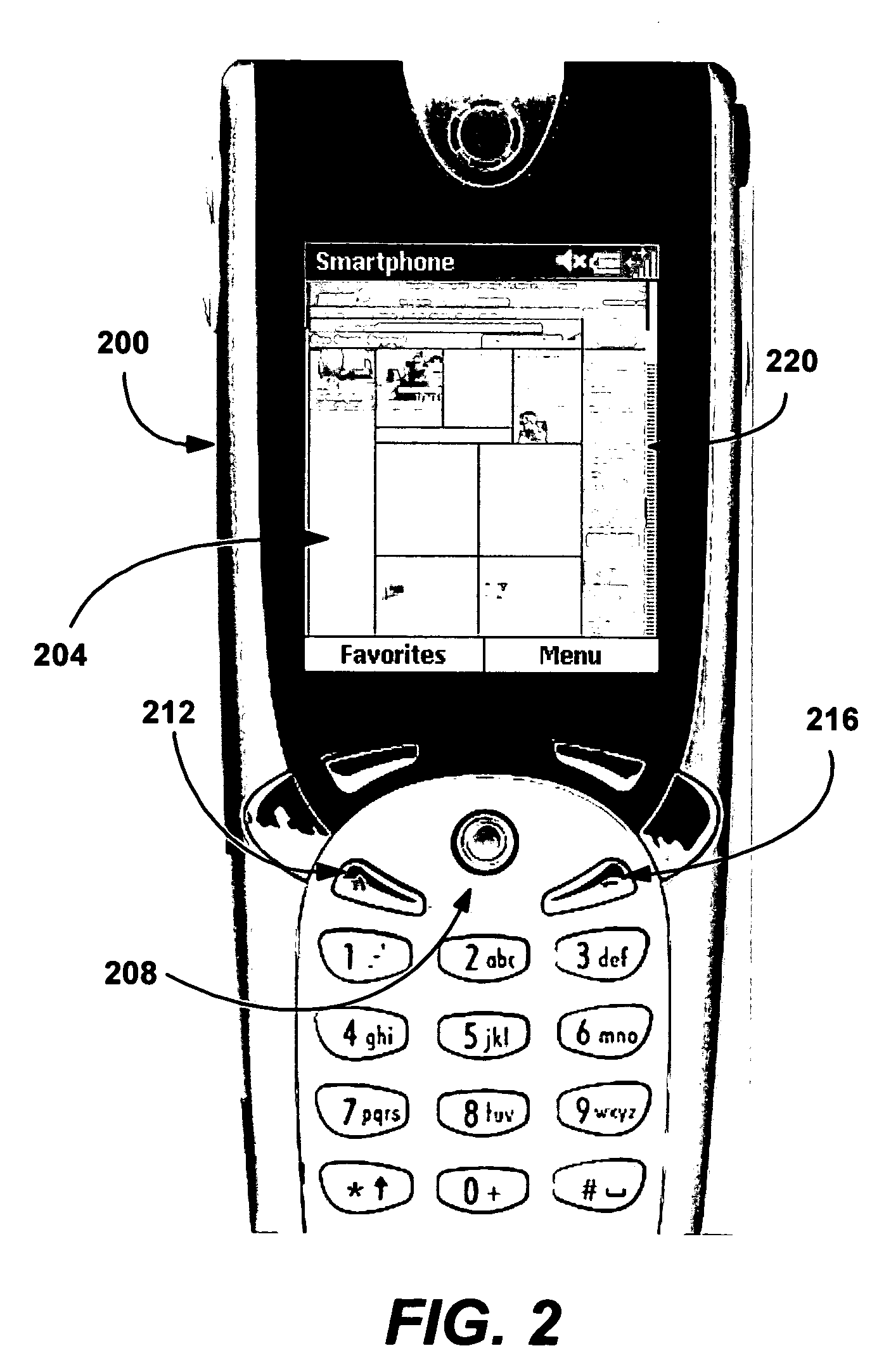

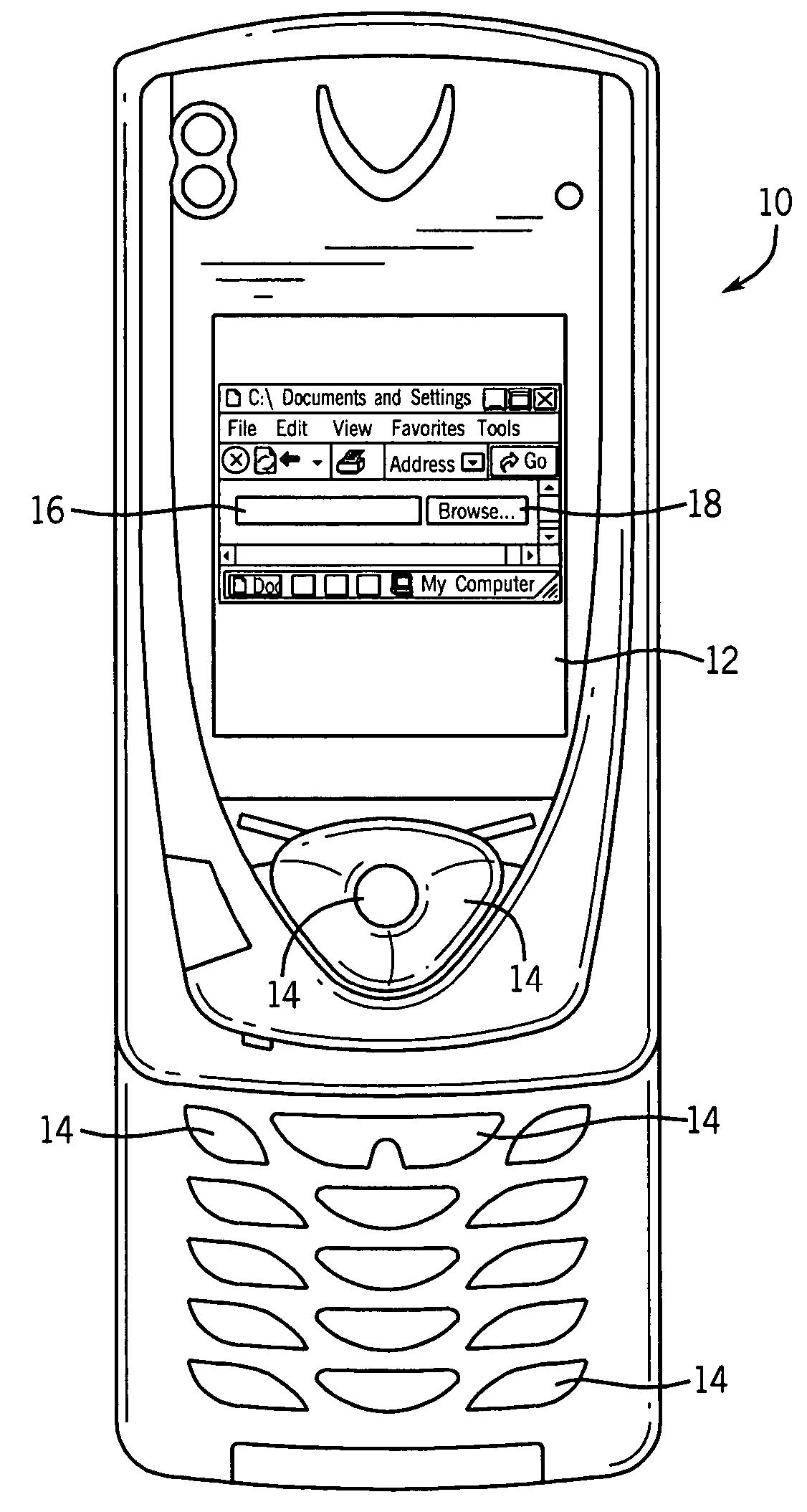

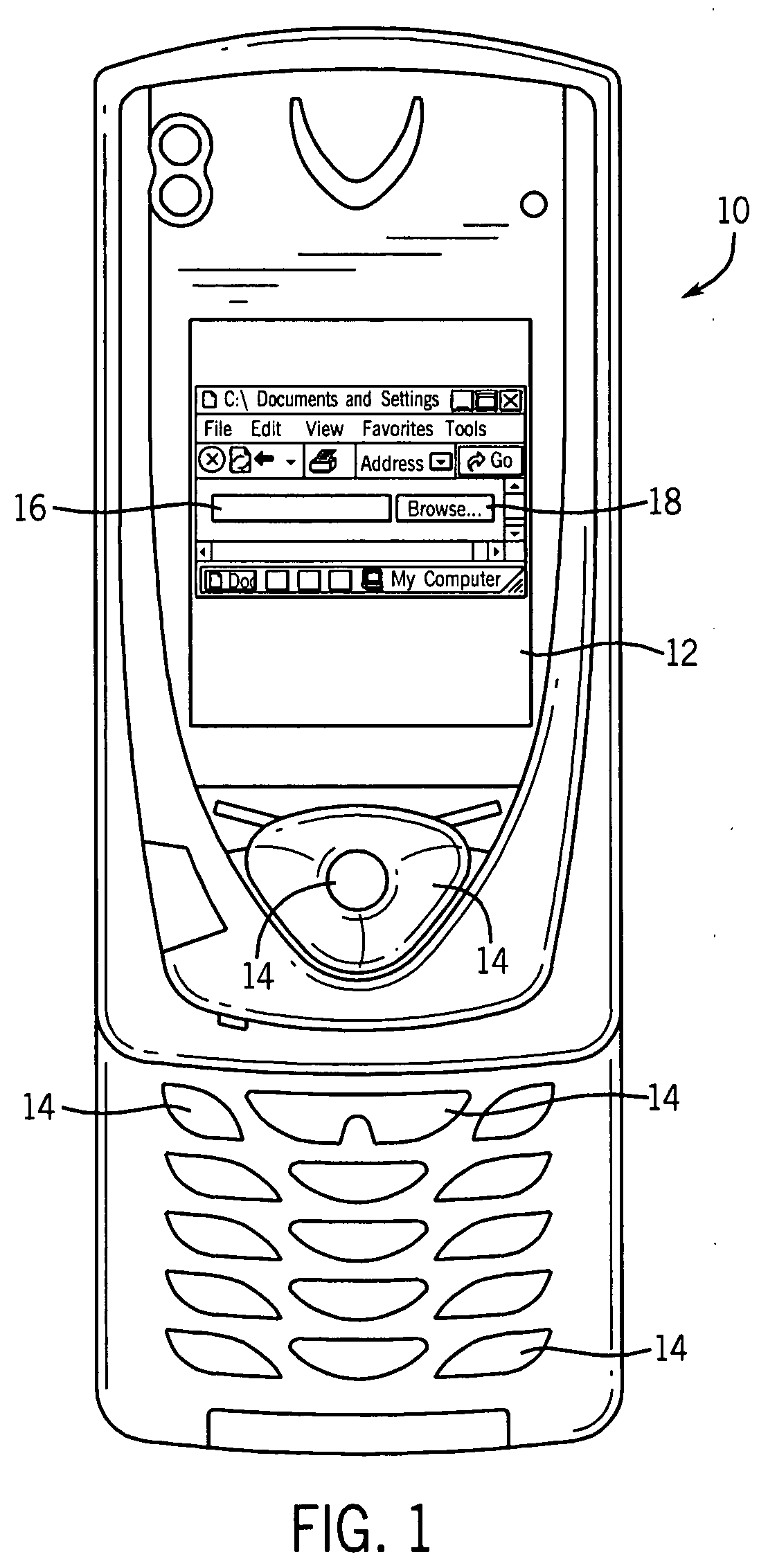

Method and system for improved viewing and navigation of content

InactiveUS7441207B2Reduce scrollingEasy to understandDigital data information retrievalSpecial data processing applicationsUser needsThumbnail Image

A system and method for small computing devices that present a thumbnail image of content such as a web page, allows a viewer to select a region, and zooms in on the selected region in a way that reduces scrolling and helps users to understand the content they are reading. The page is scaled such that a user need only scroll in one dimension to see the content, and is divided into regions. Regions may be arranged as cells of a grid, or arranged by logically-related content. A user navigates among the regions as desired, selects a region from the thumbnail view, and obtains an expanded version of that region. In the expanded view, the region is ordinarily scaled so that the user scrolls in only one dimension to view the content of the region. Browser “Back” commands are supported, as are frames.

Owner:MICROSOFT TECH LICENSING LLC

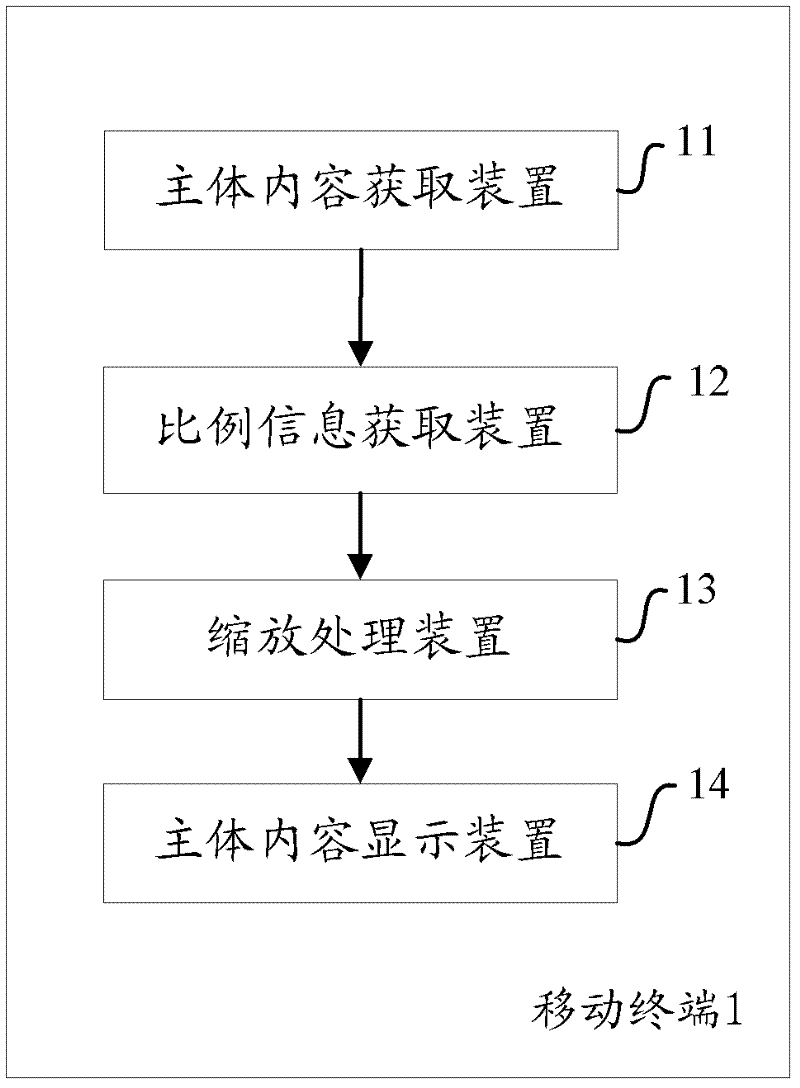

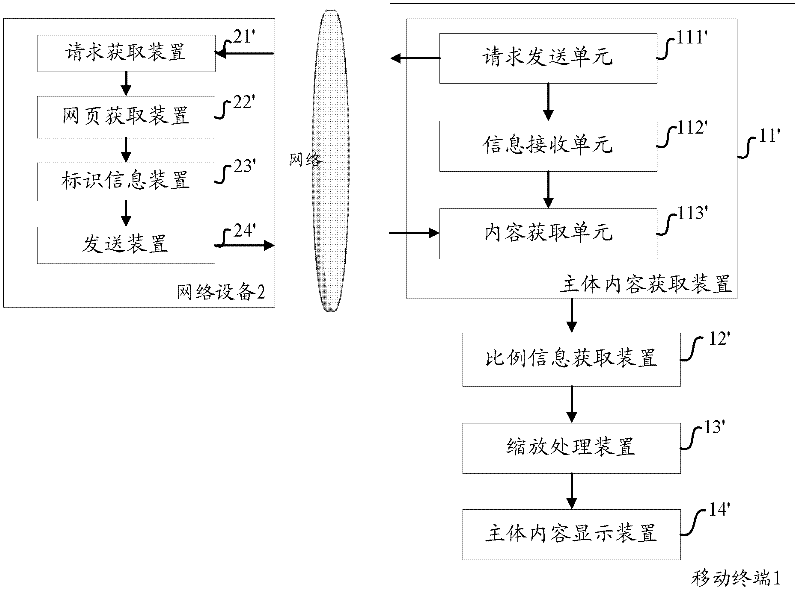

Method and equipment for displaying webpage main content on mobile terminal

ActiveCN102314502AReduce scrollingEasy to operateSpecial data processing applicationsImage resolutionComputer graphics (images)

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

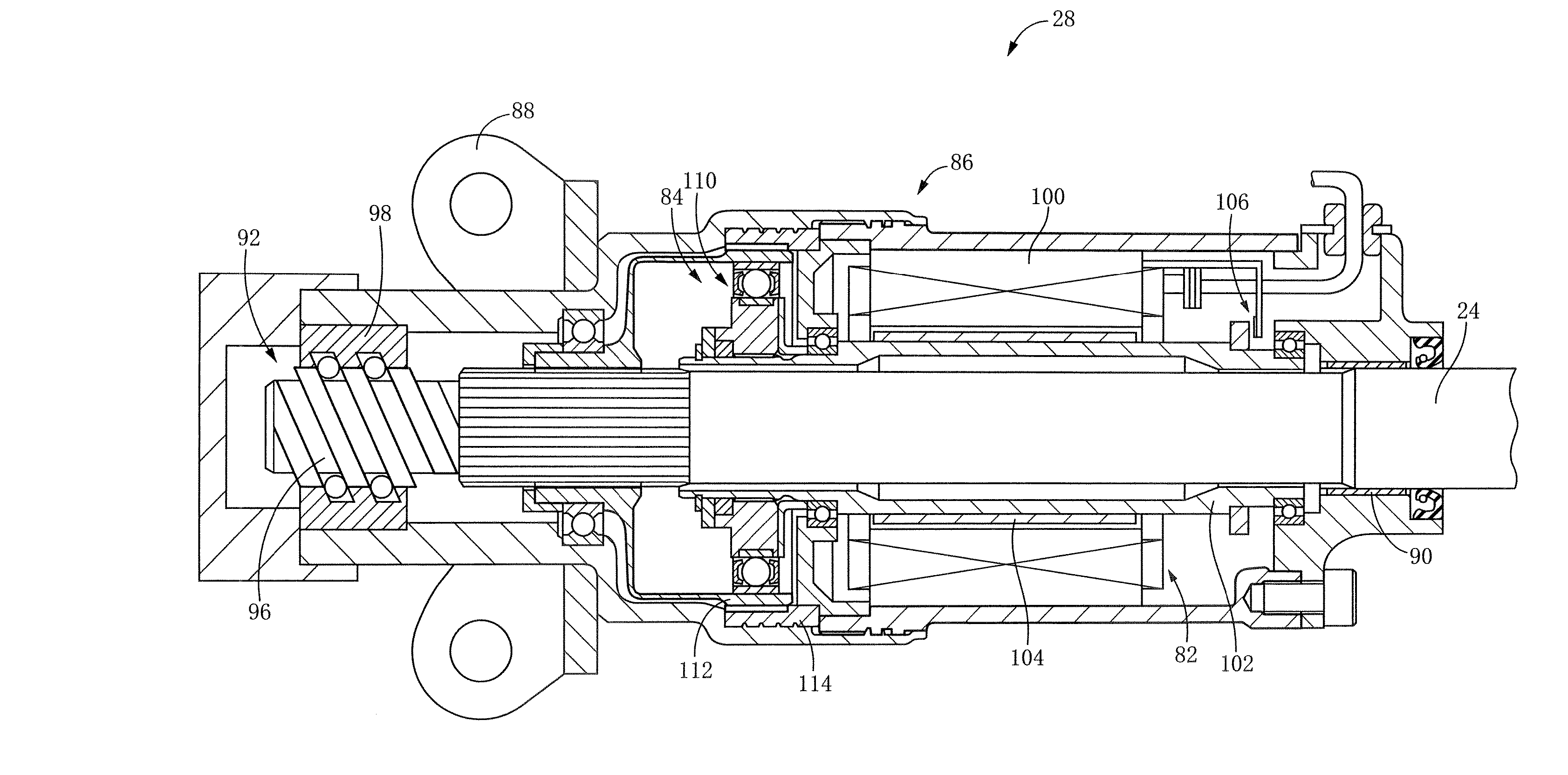

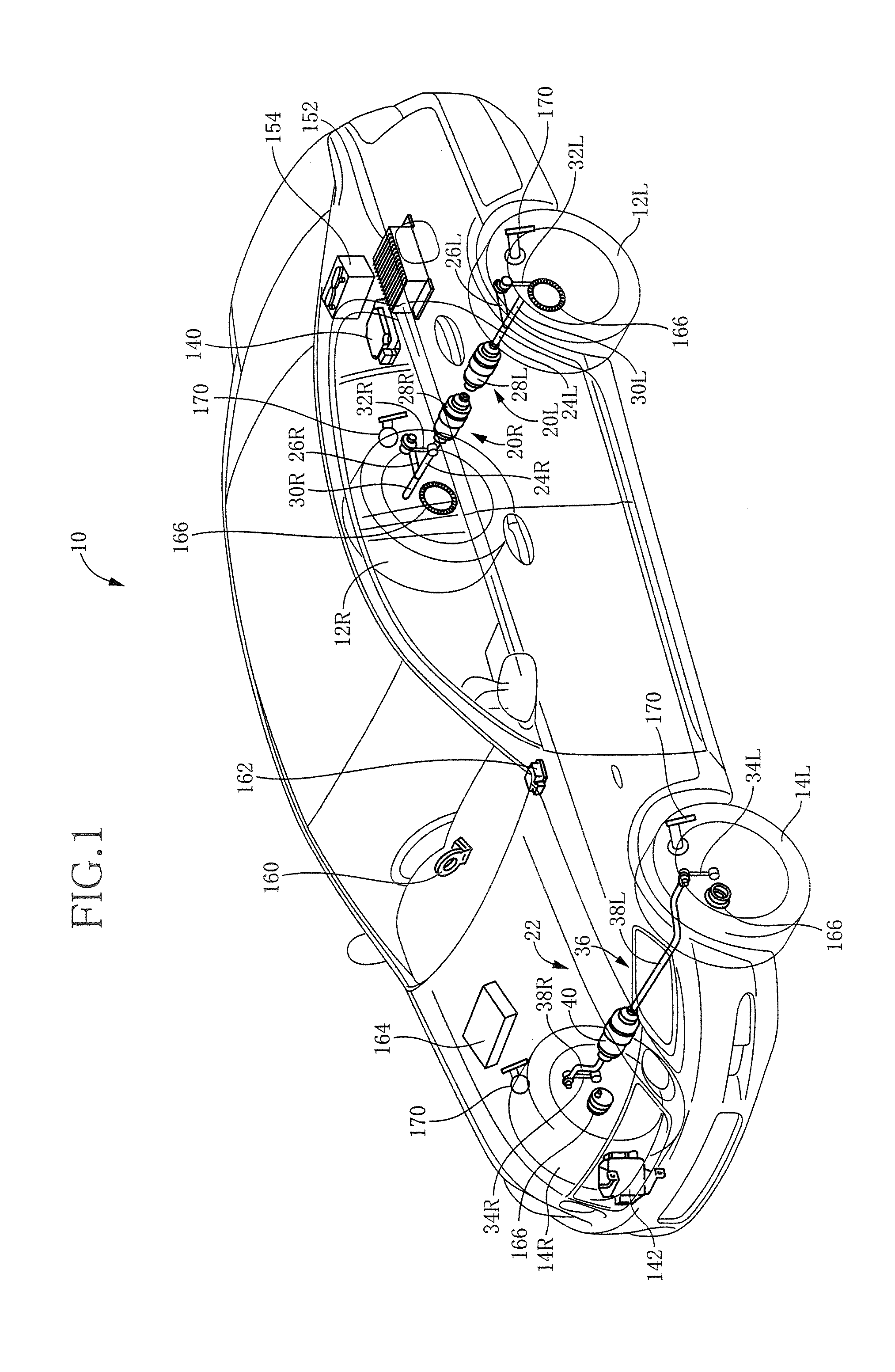

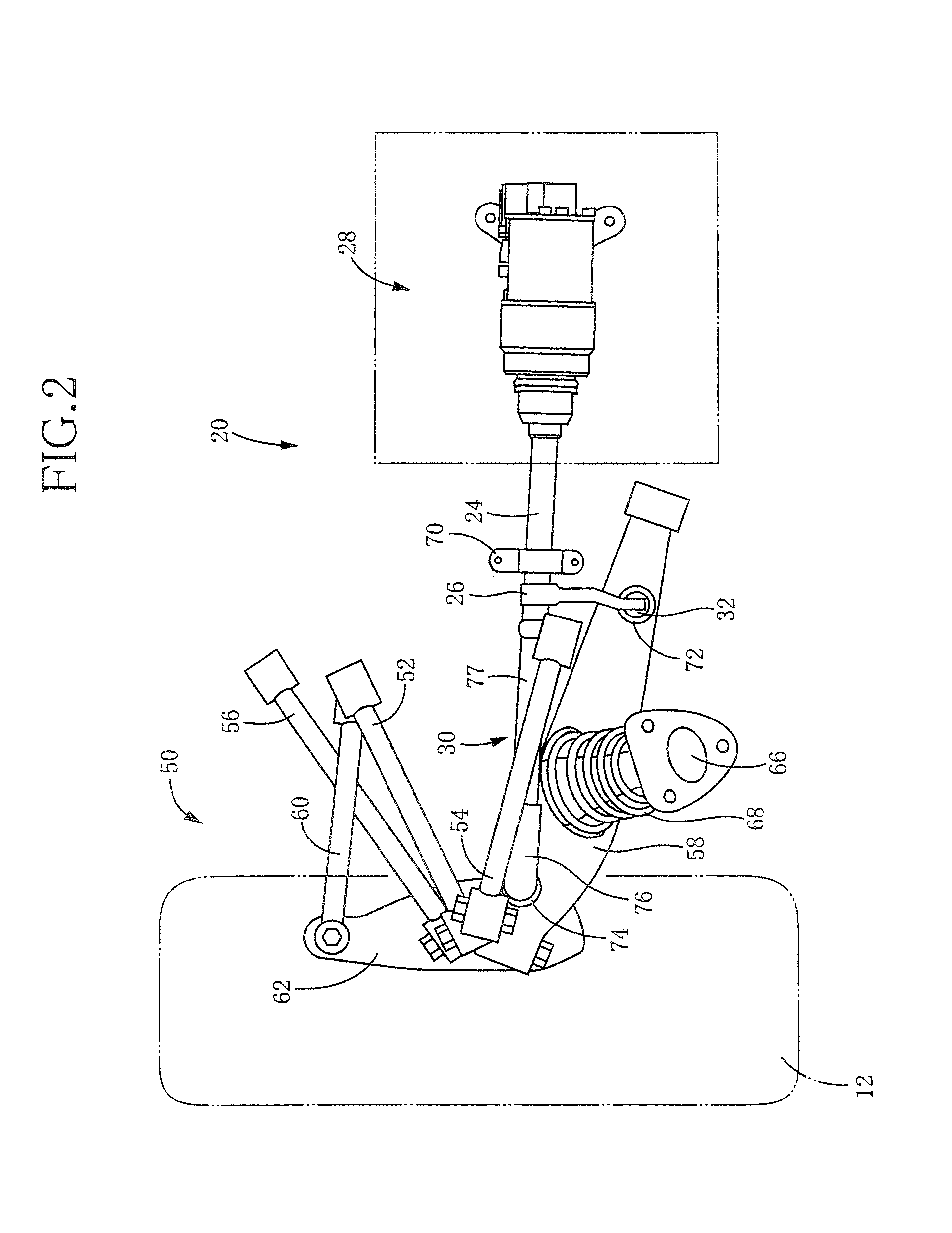

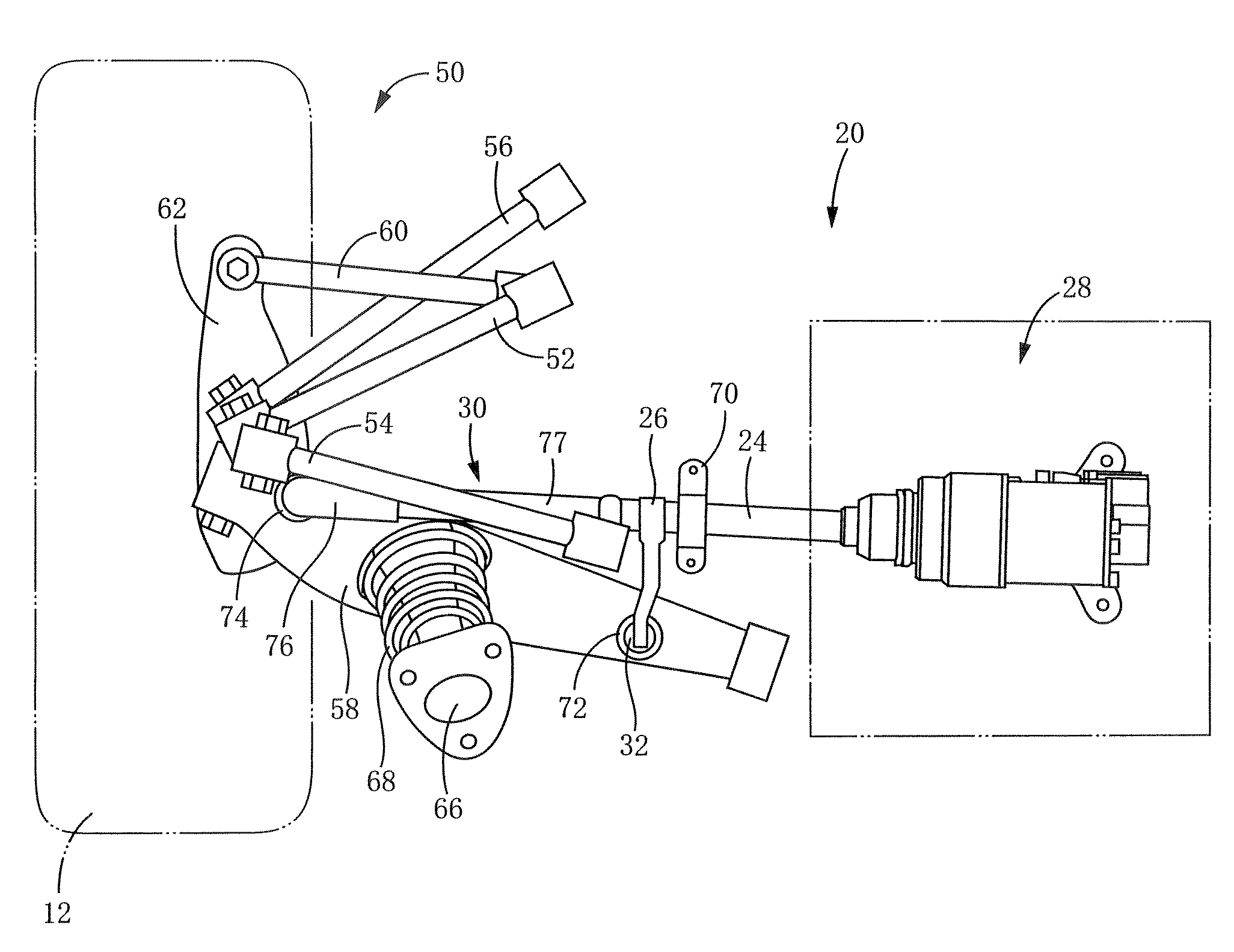

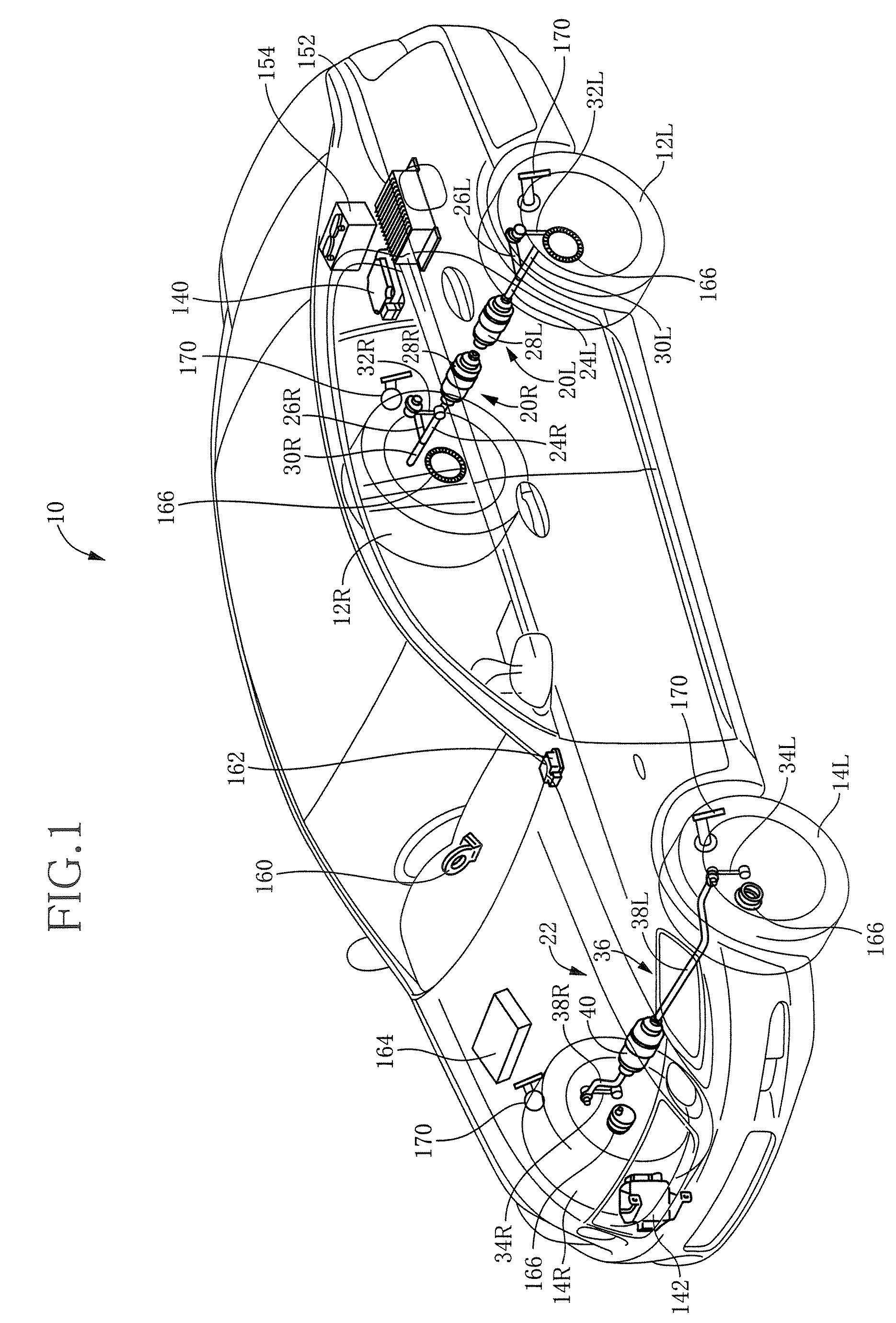

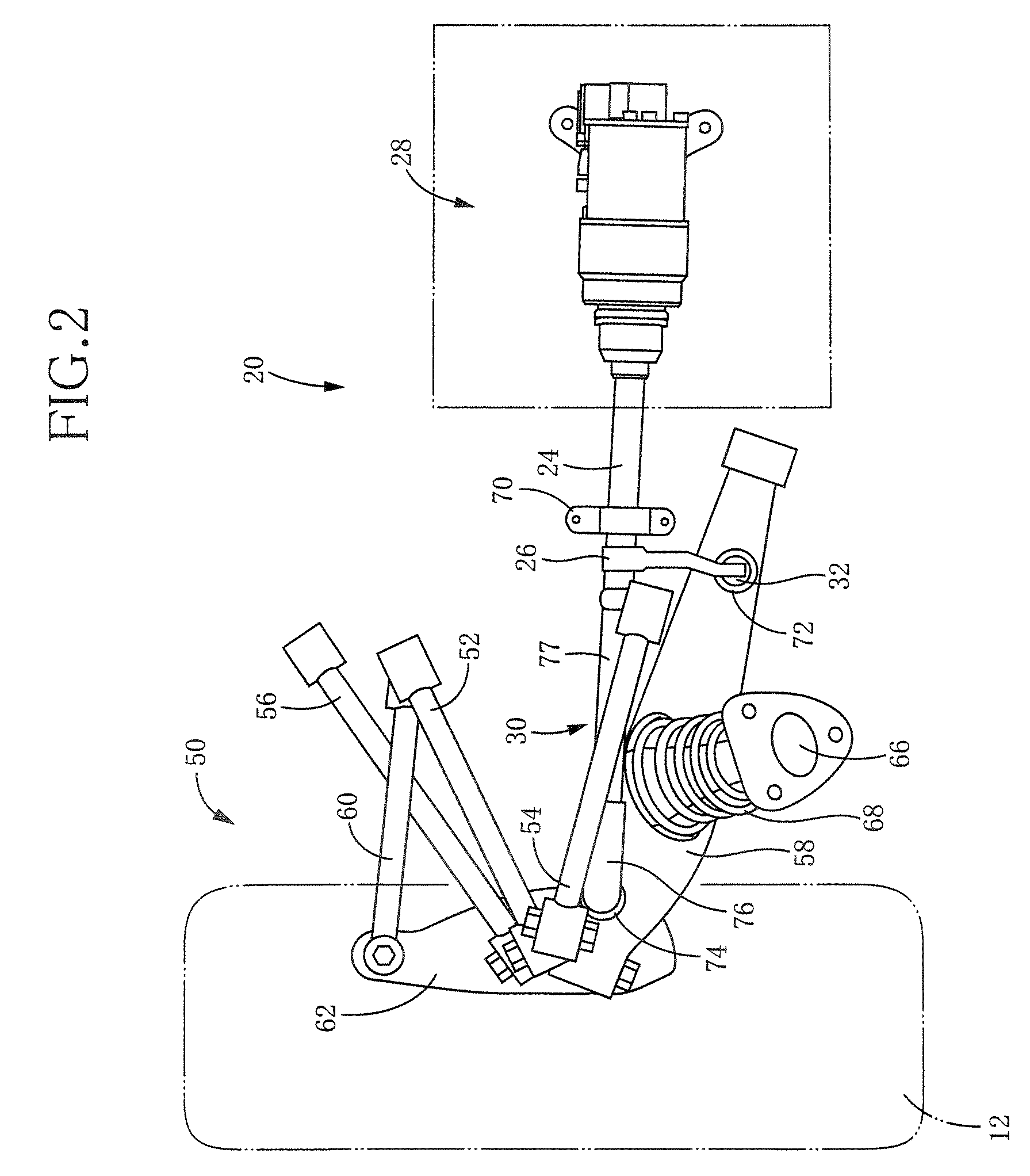

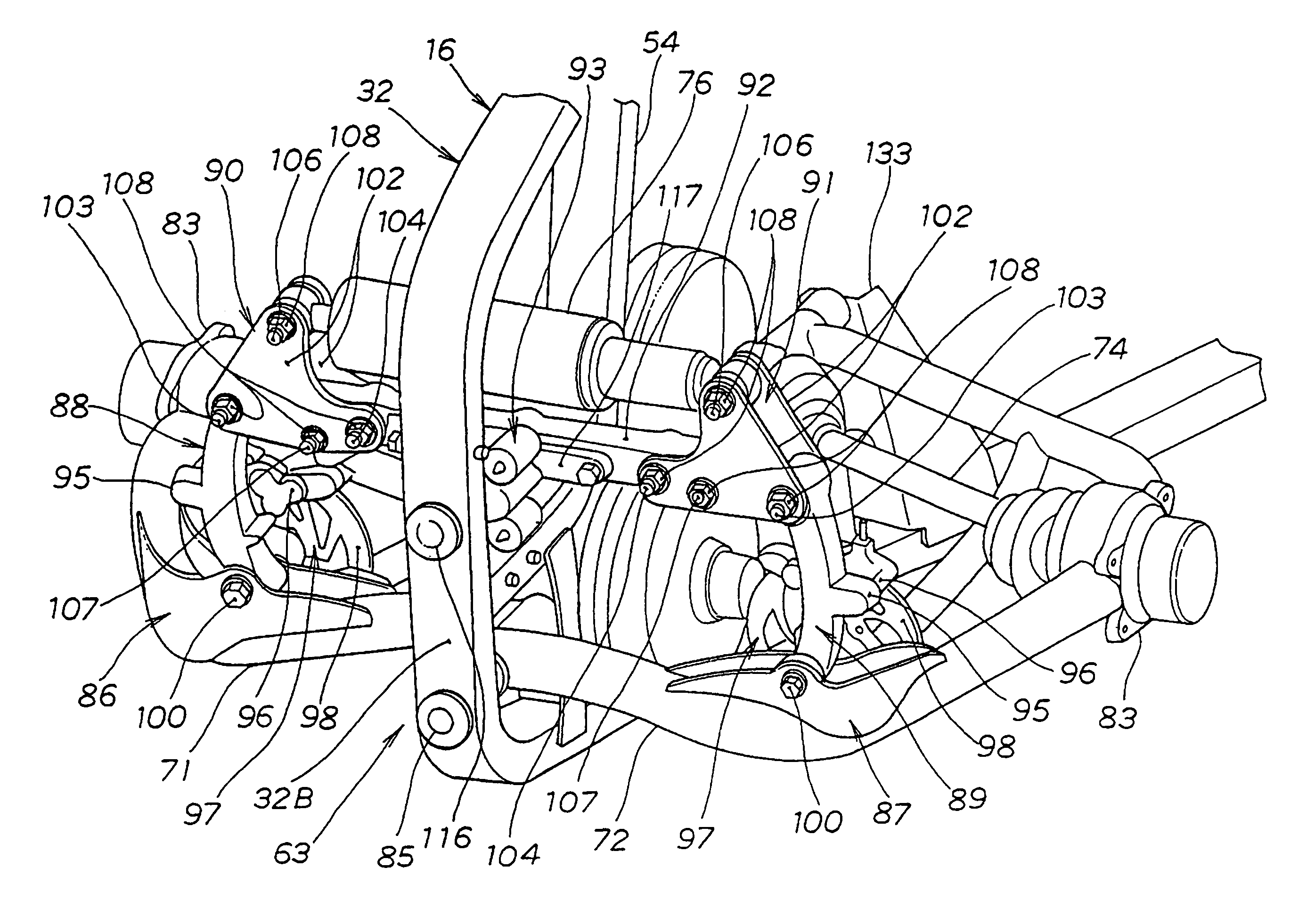

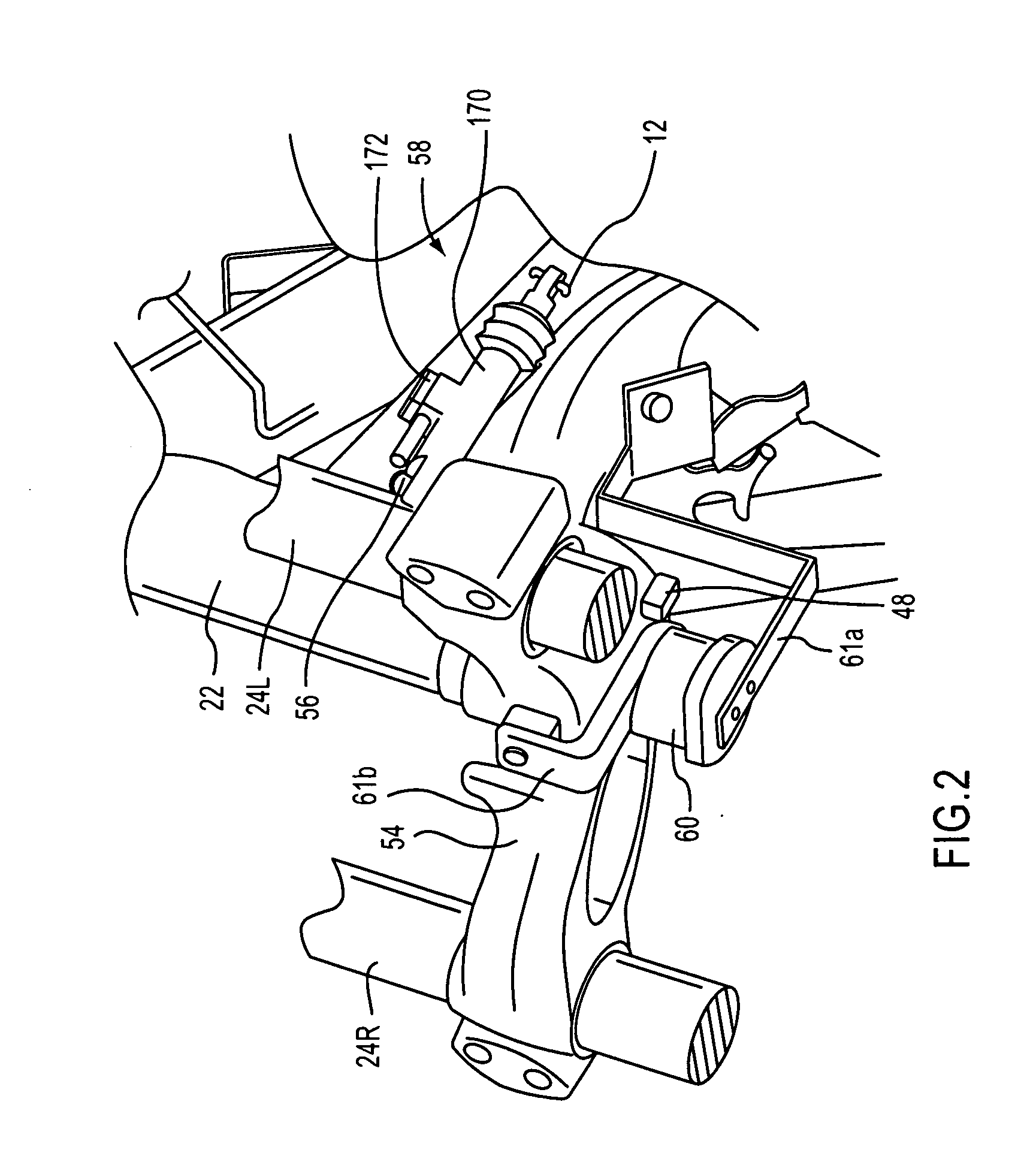

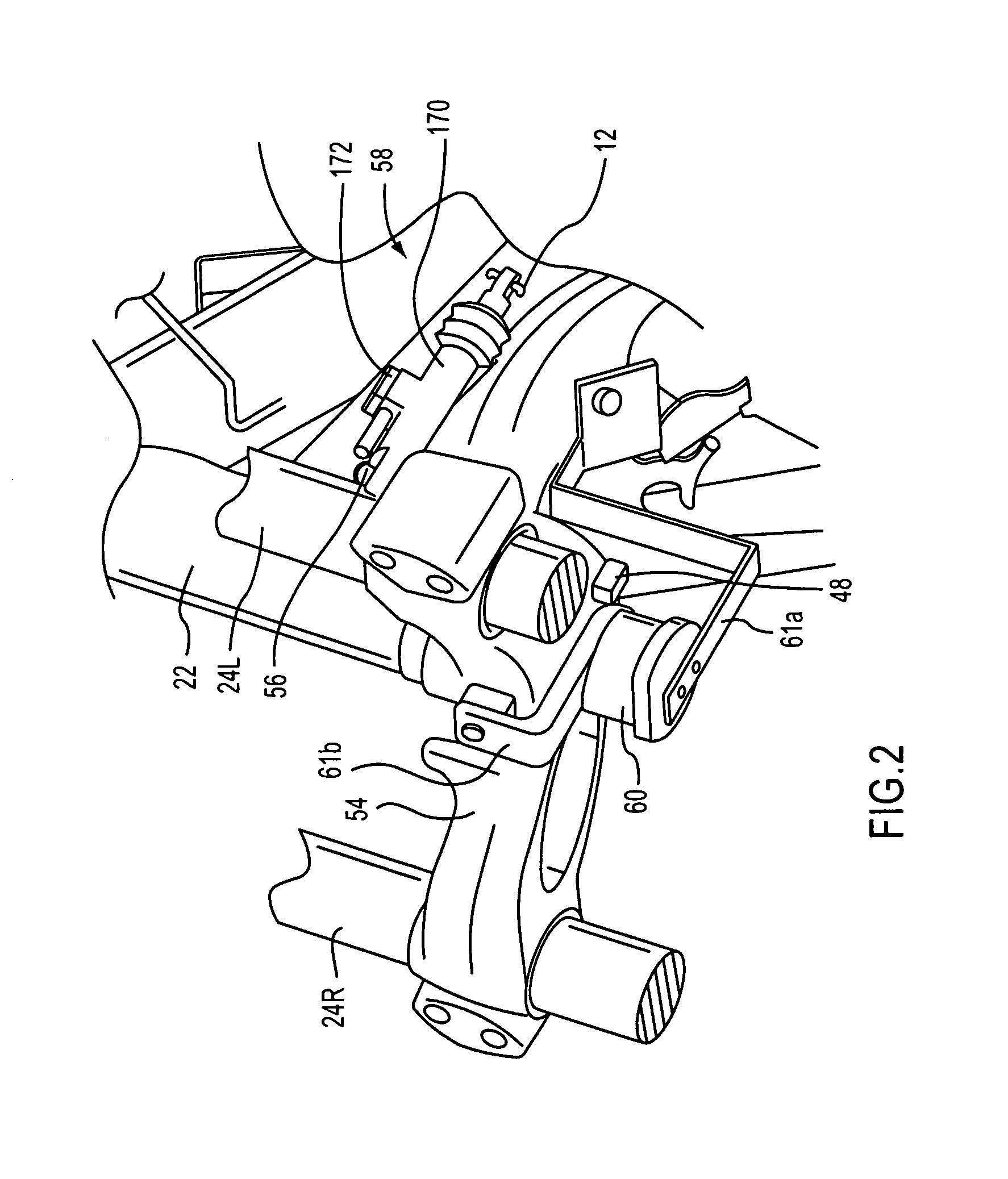

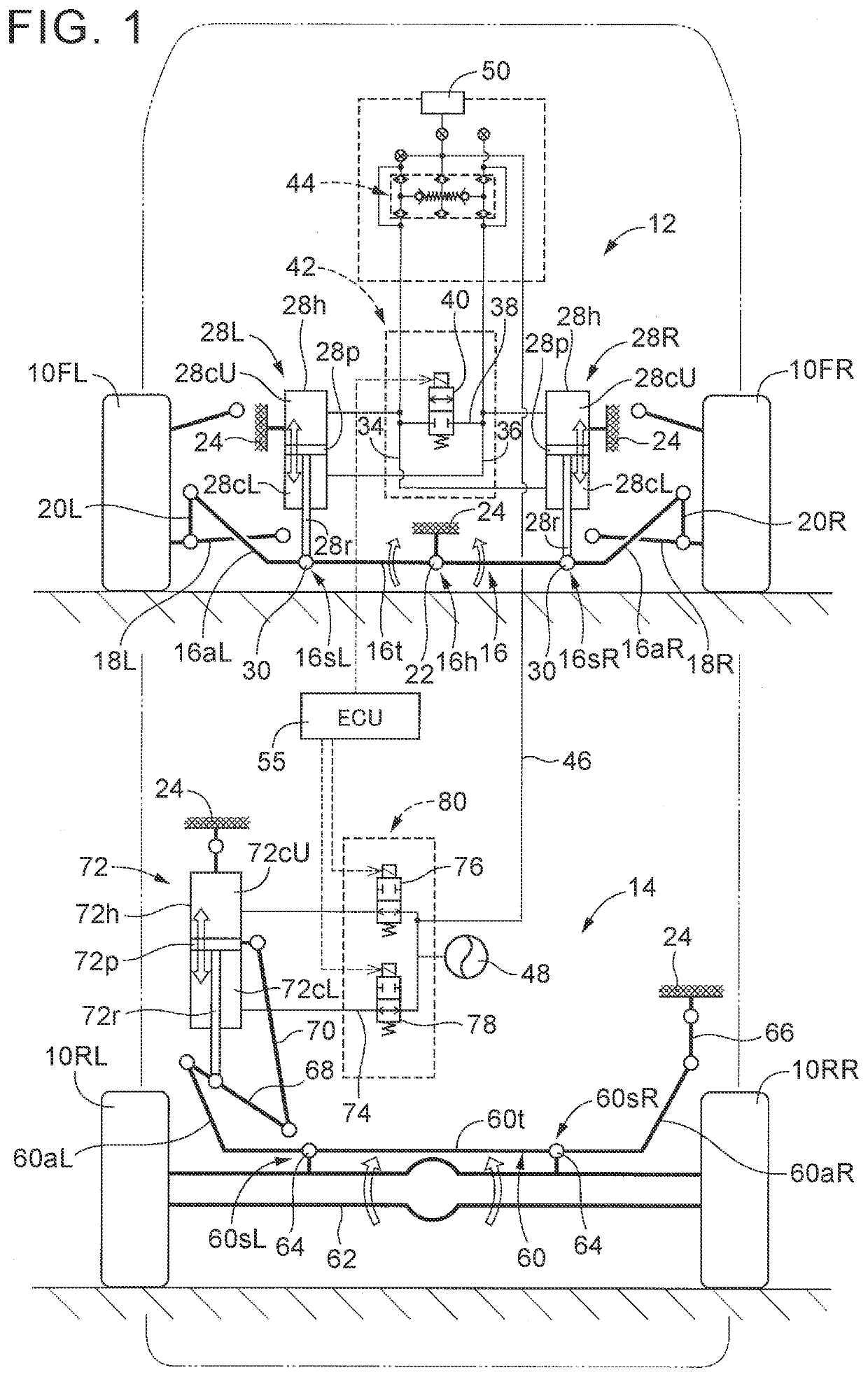

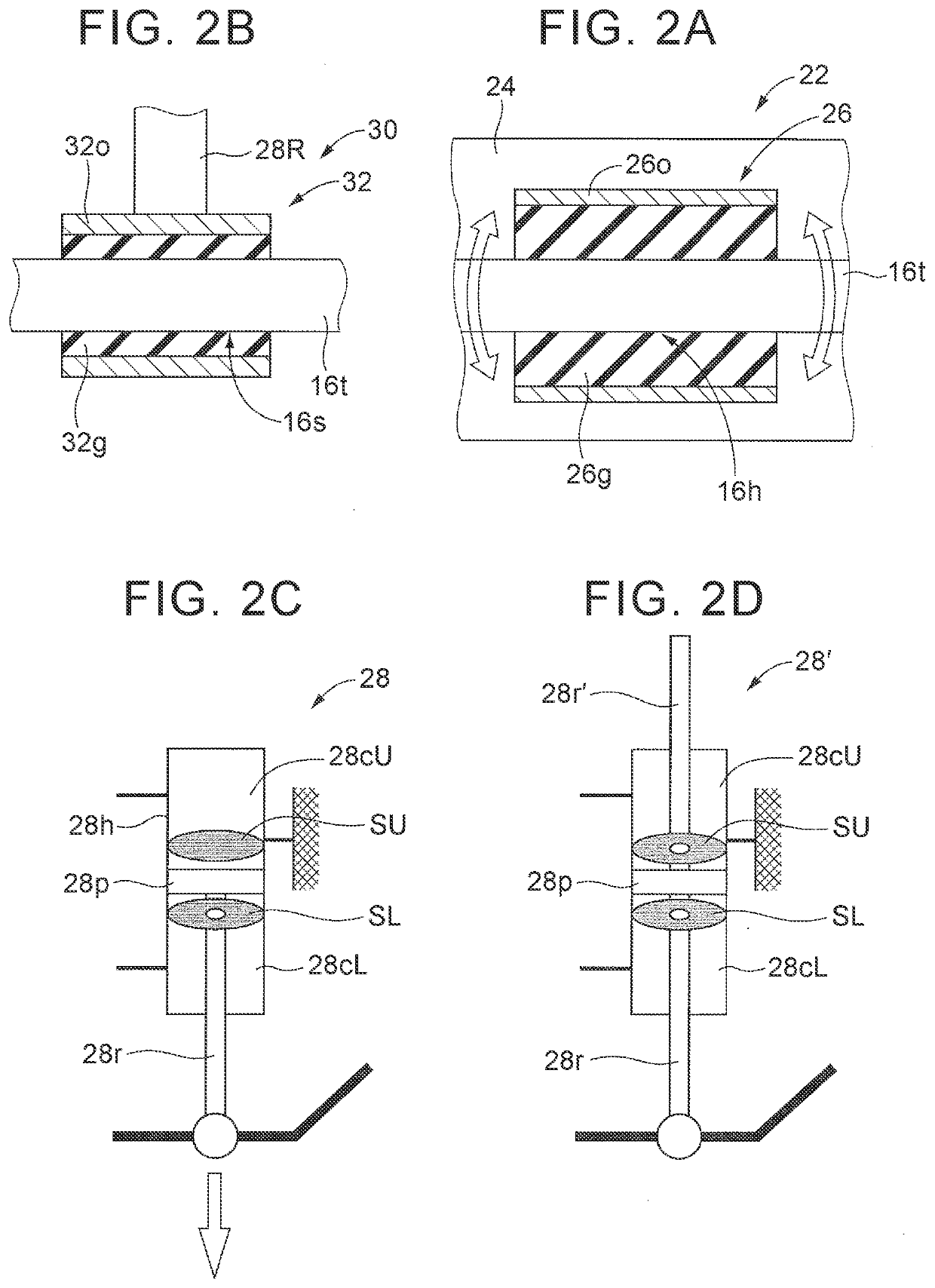

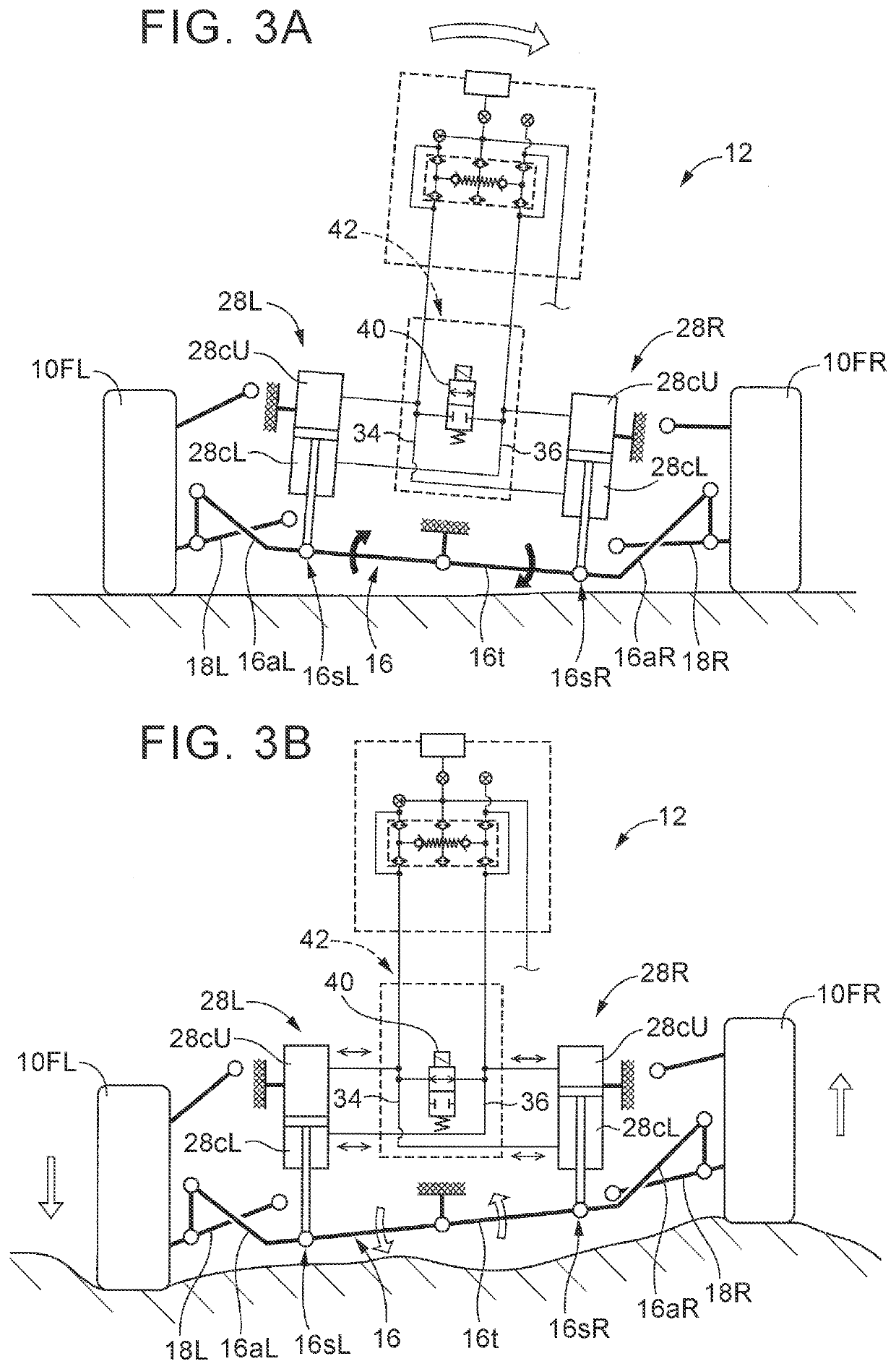

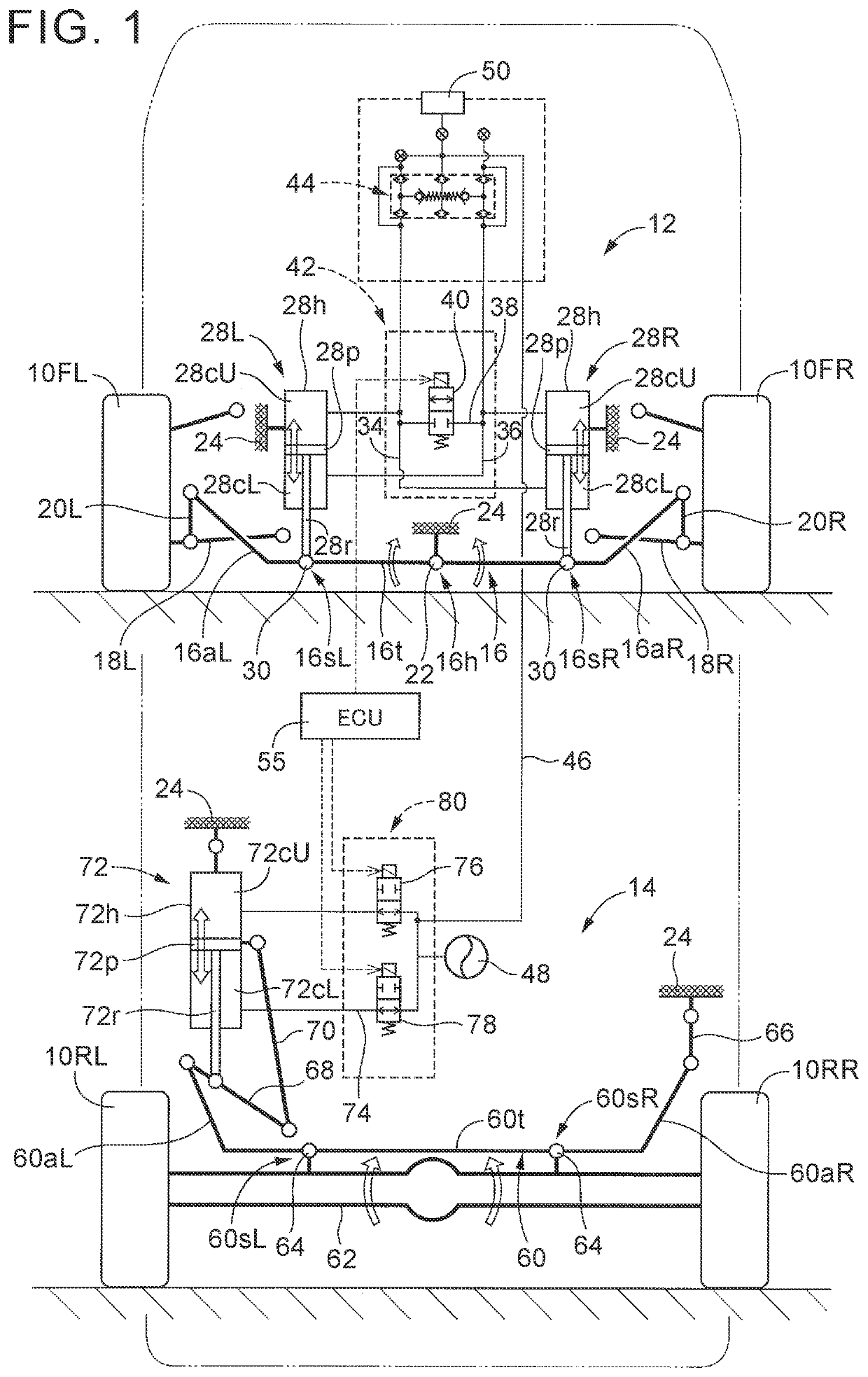

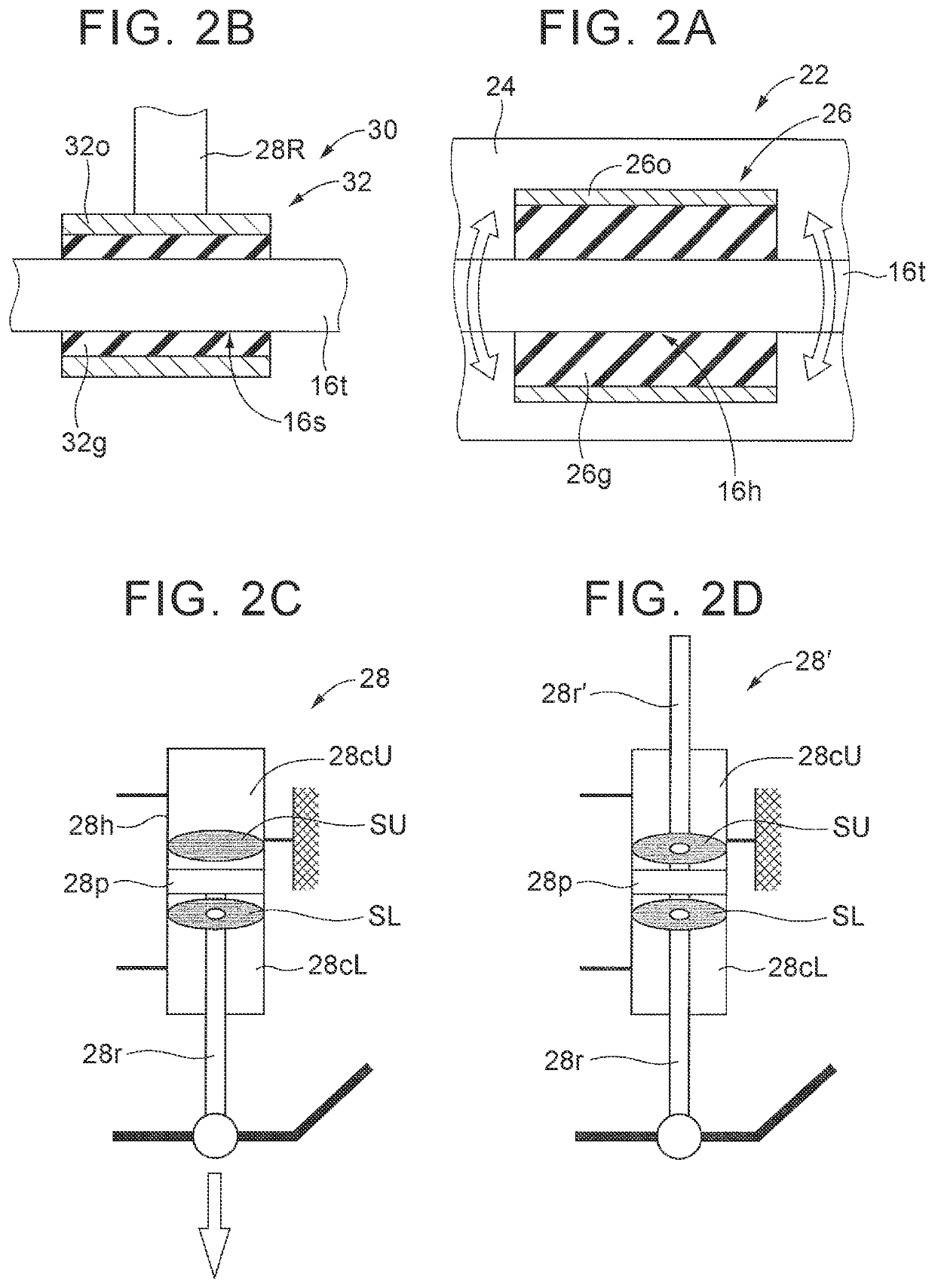

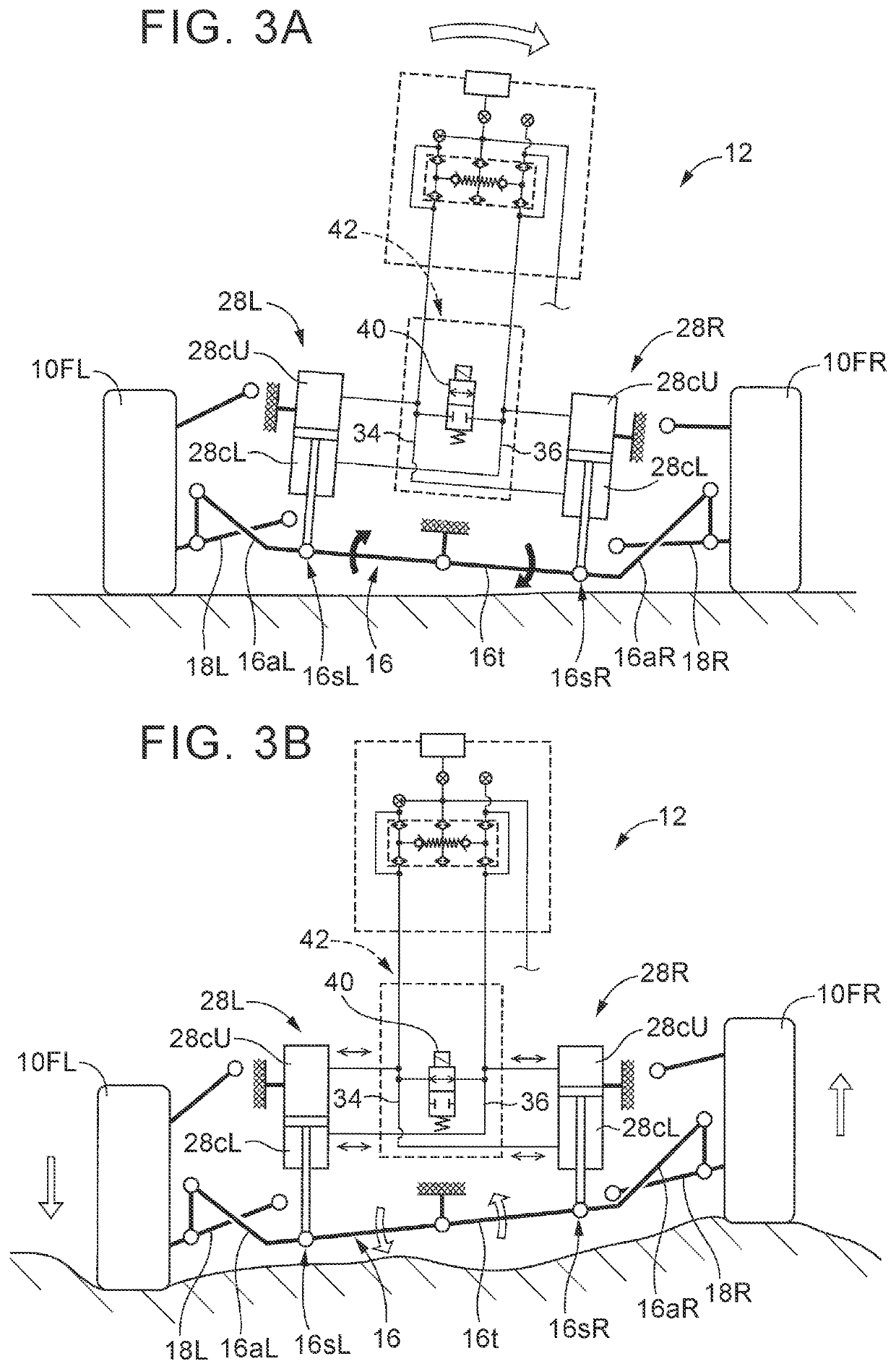

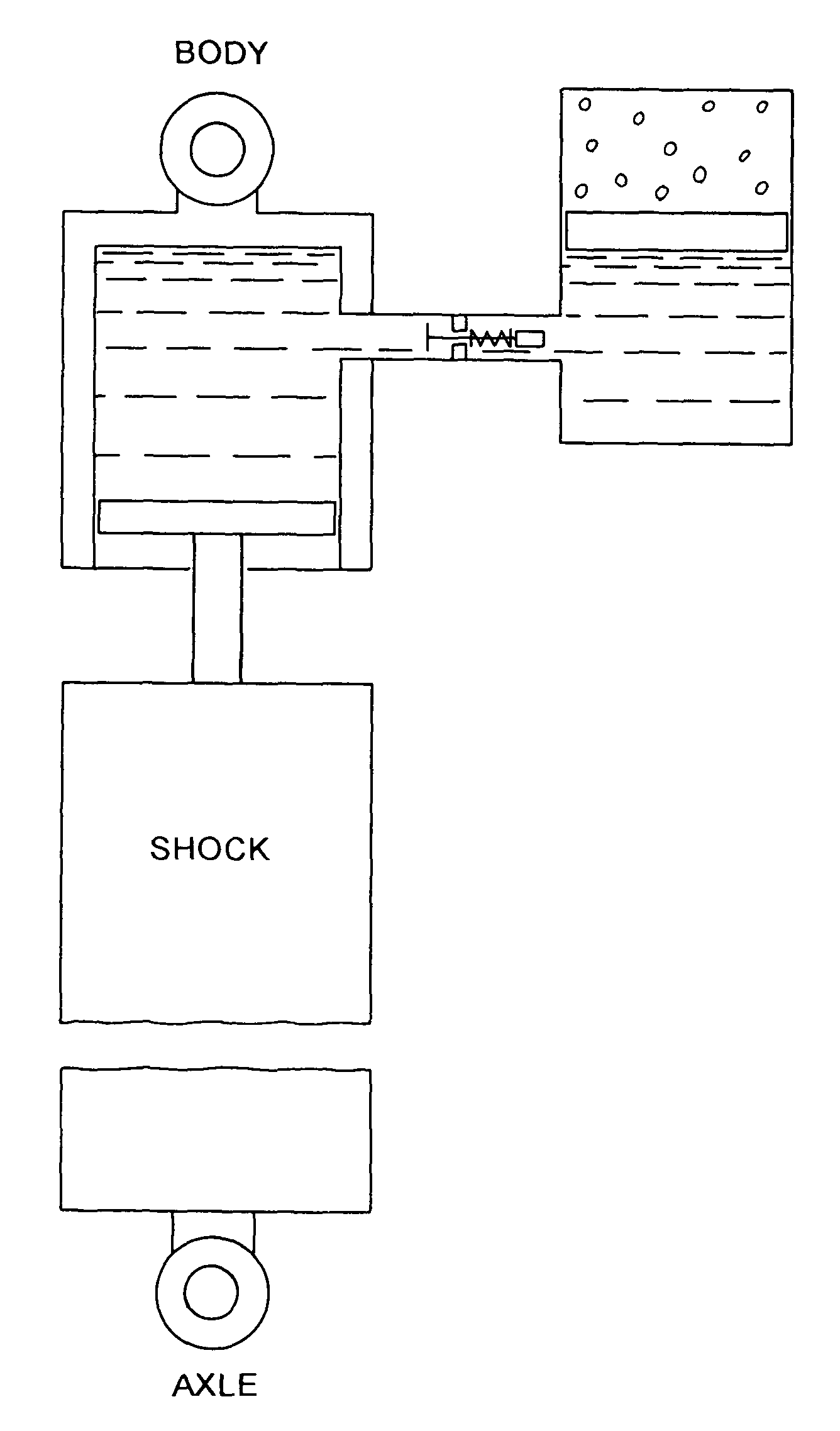

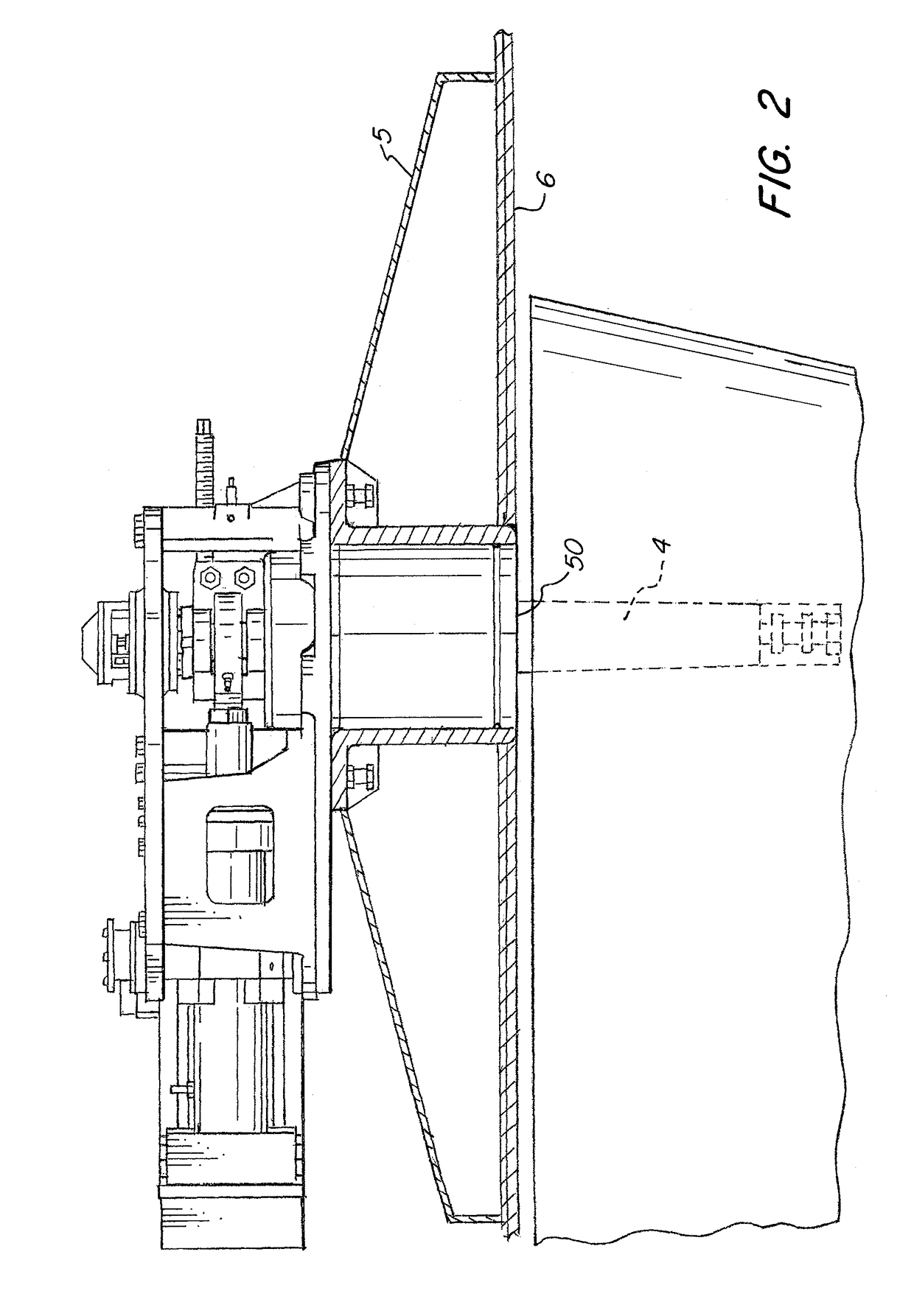

Device for changing distance between wheel and vehicle body, and system including the device

InactiveUS20070290473A1Reduce spacingAdjustable distanceVehicle cleaning apparatusLoading/unloading vehicle arrangmentEngineeringActuator

An adjuster device includes (a) a shaft held by a vehicle body; (b) an arm extending from the shaft in a direction intersecting an axial direction of the shaft; (c) an actuator causing one of rotation of the shaft and axial movement of the shaft in the axial direction; and (d) a motion converter converting the one of the rotation of the shaft and the axial movement of the shaft, into the other of the rotation of the shaft and the axial movement of the shaft. The arm is connected at a distal end portion thereof to one of at least one suspension arm, so as to enable the rotation of the shaft to cause change in a vertical distance between a wheel and the vehicle body. The shaft is connected to one of the at least one suspension arm and / or to an axle carrier, so as to enable the axial movement of the shaft to cause change in an alignment of the wheel. Also disclosed is an adjusting system including the adjuster device.

Owner:TOYOTA JIDOSHA KK

Device for changing distance between wheel and vehicle body, and system including the device

InactiveUS7766344B2Adjust running characteristicReduce spacingInterconnection systemsResilient suspensionsEngineeringSuspension (vehicle)

An adjuster device includes (a) a shaft held by a vehicle body; (b) an arm extending from the shaft in a direction intersecting an axial direction of the shaft; (c) an actuator causing one of rotation of the shaft and axial movement of the shaft in the axial direction; and (d) a motion converter converting the one of the rotation of the shaft and the axial movement of the shaft, into the other of the rotation of the shaft and the axial movement of the shaft. The arm is connected at a distal end portion thereof to one of at least one suspension arm, so as to enable the rotation of the shaft to cause change in a vertical distance between a wheel and the vehicle body. The shaft is connected to one of the at least one suspension arm or to an axle carrier, so as to enable the axial movement of the shaft to cause change in an alignment of the wheel. Also disclosed is an adjusting system including the adjuster device.

Owner:TOYOTA JIDOSHA KK

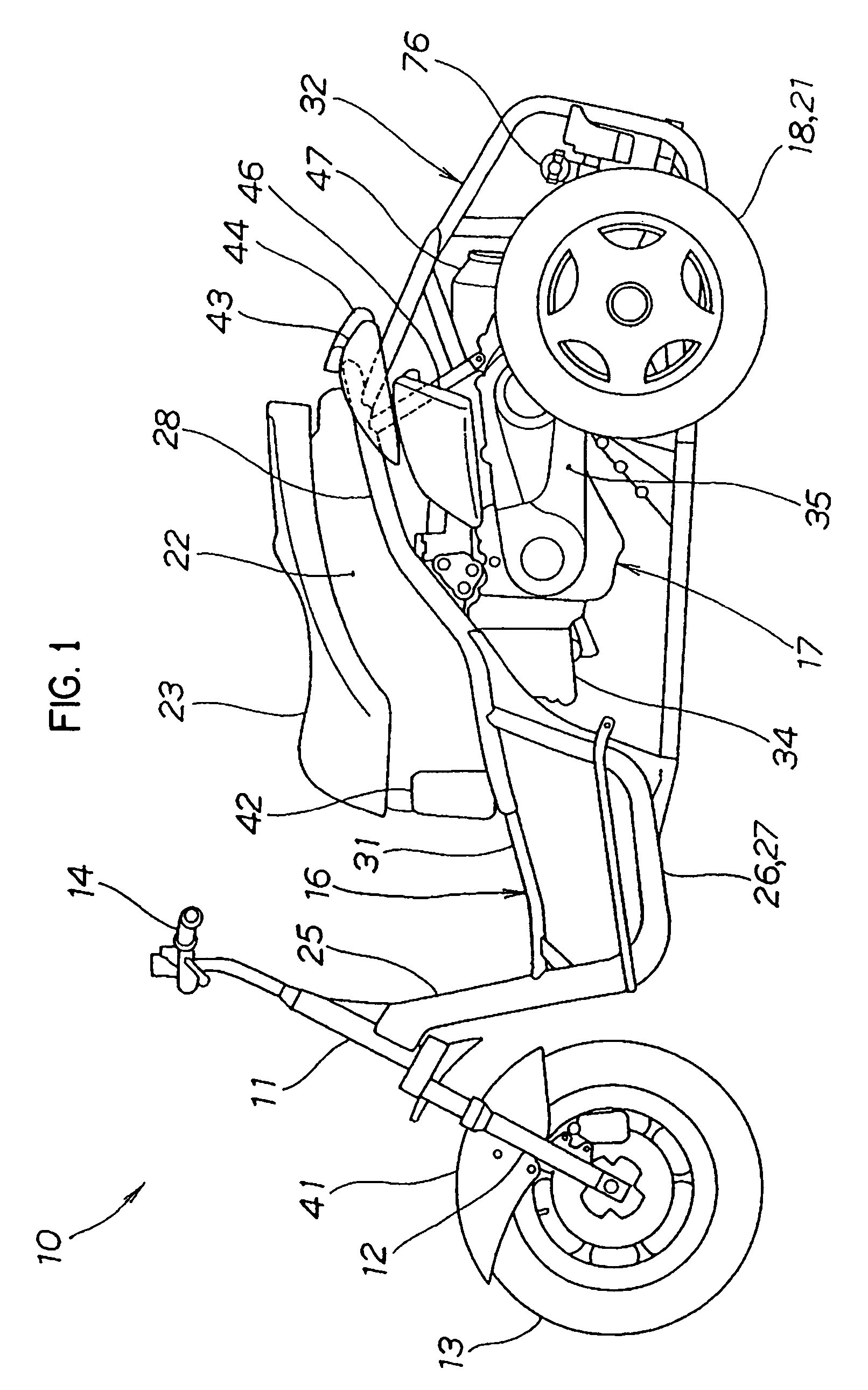

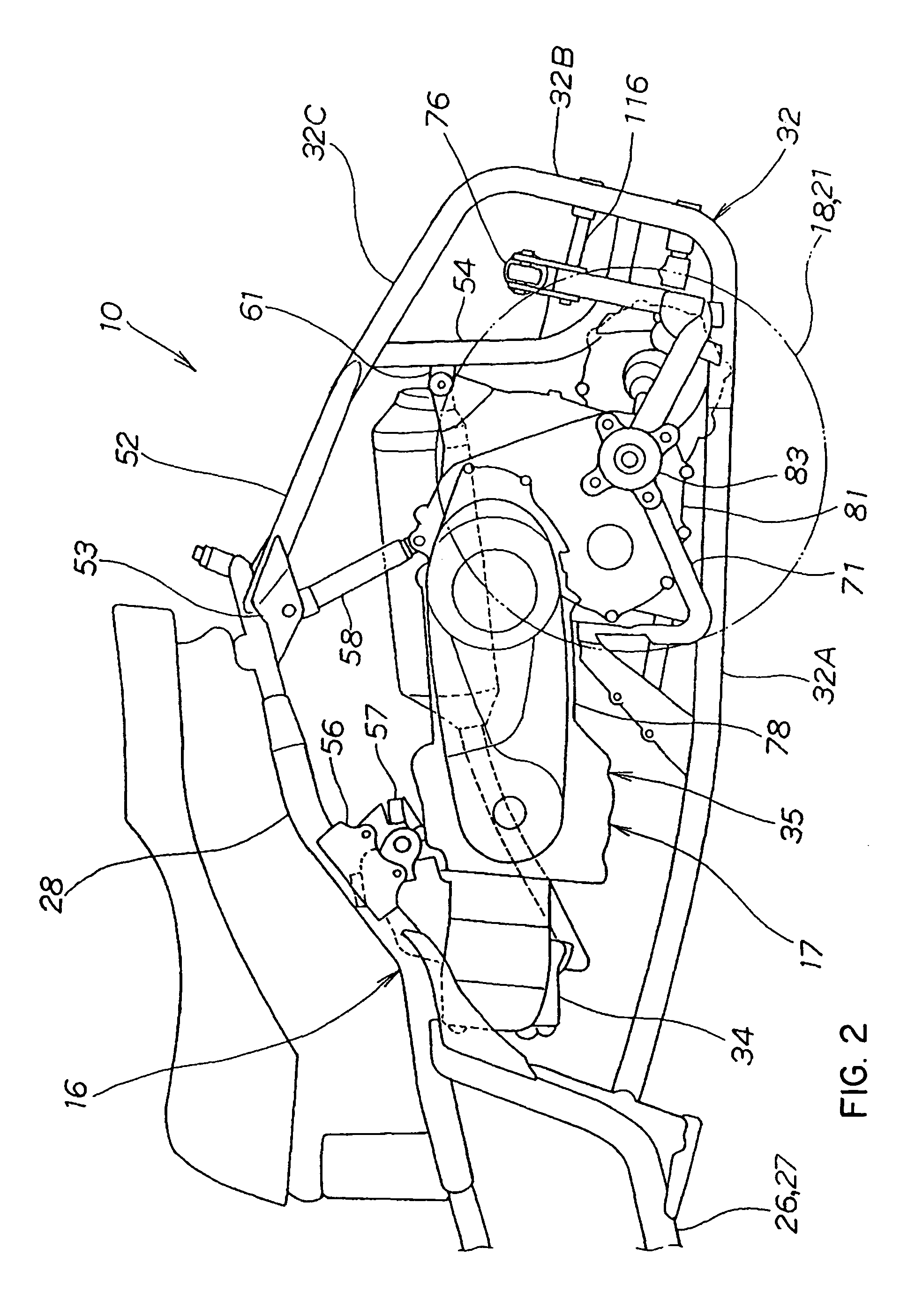

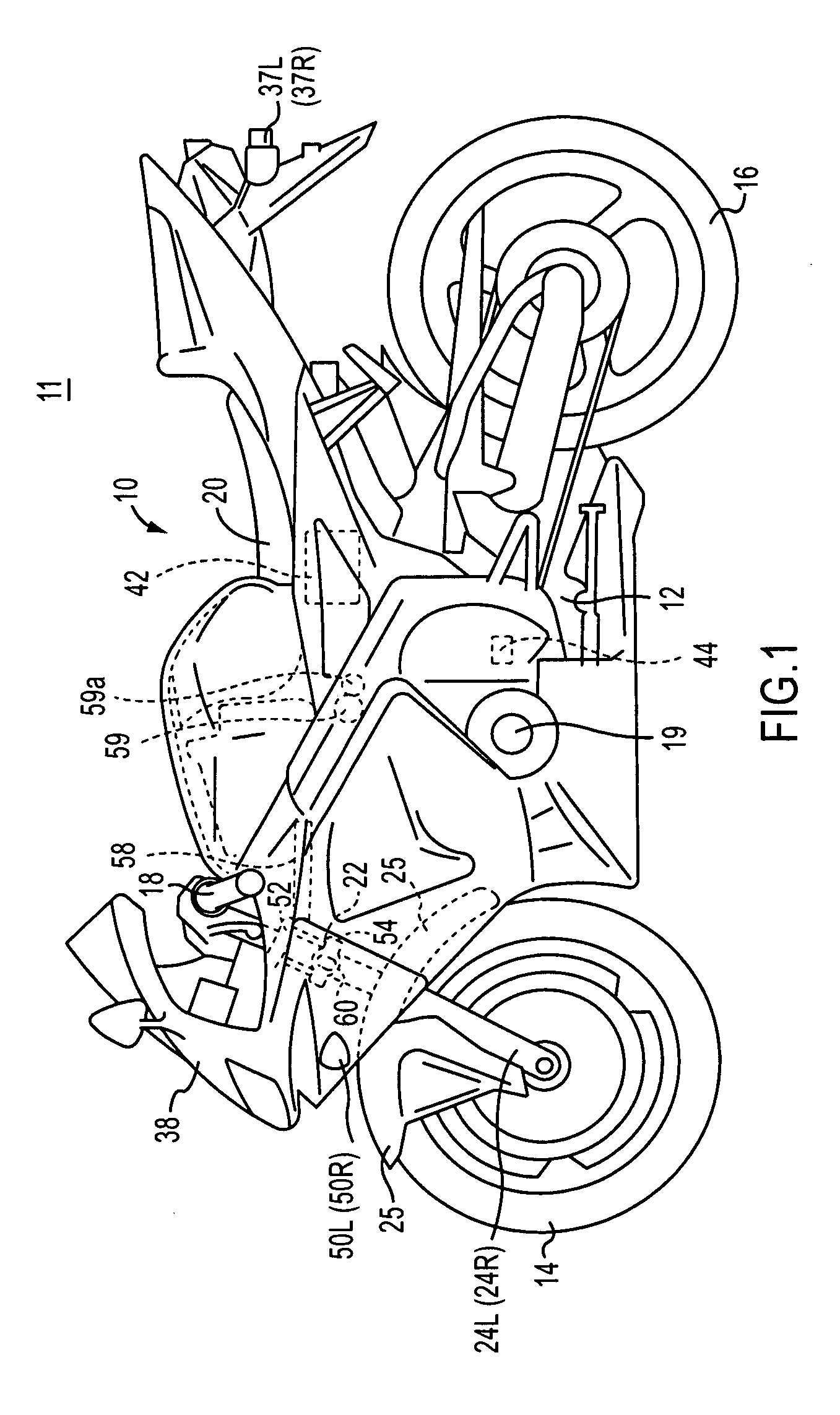

Three-wheel vehicle with swinging mechanism

In a three-wheel vehicle, right and left suspension arms are independently attached to a front swinging shaft and a rear swinging shaft so that the suspension arms can swing vertically, and the front swinging shaft and the rear swinging shaft function as a swinging shaft for swinging the body frame. A swinging mechanism is provided to restrict lateral rotation of the body frame.

Owner:HONDA MOTOR CO LTD

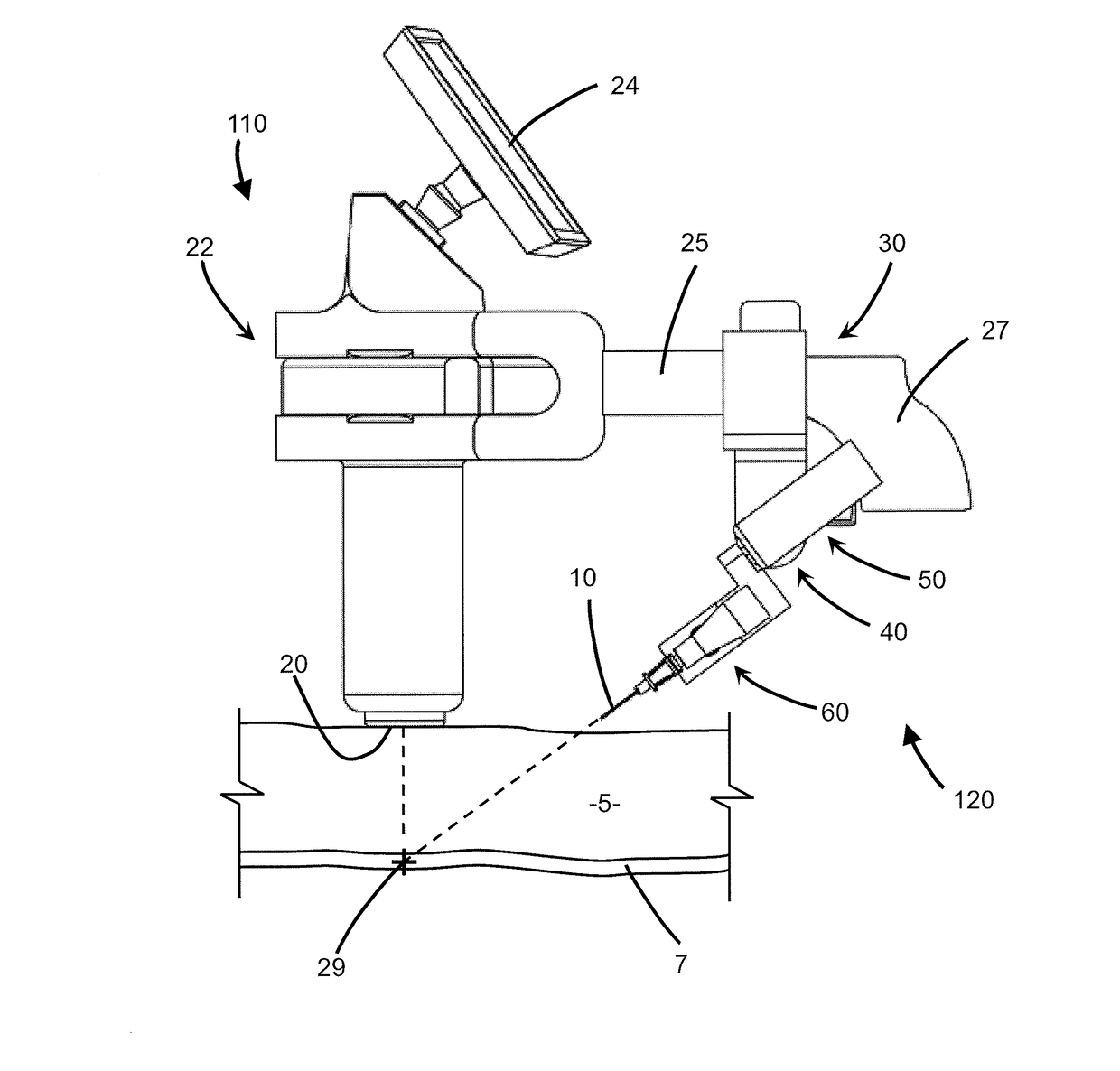

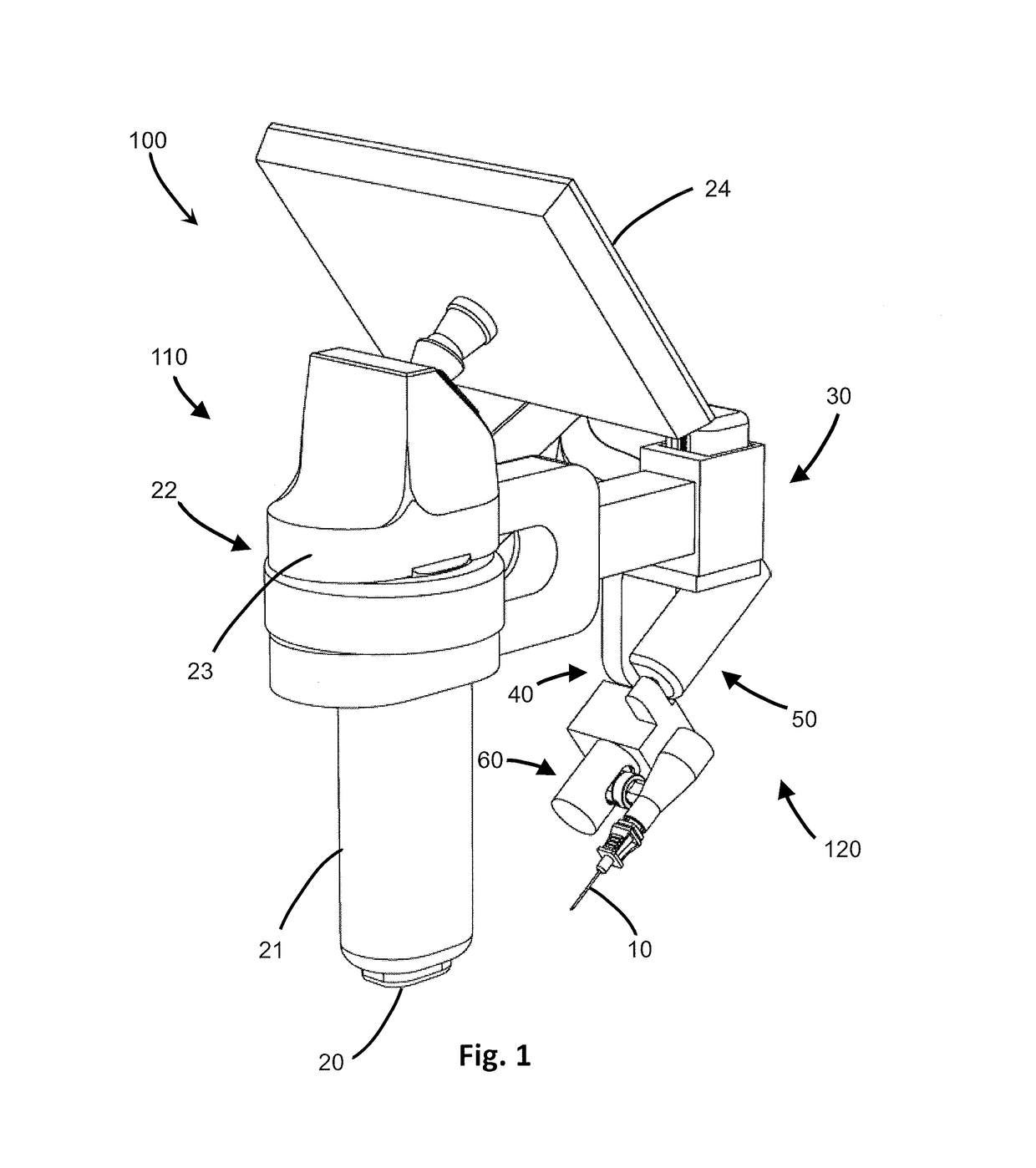

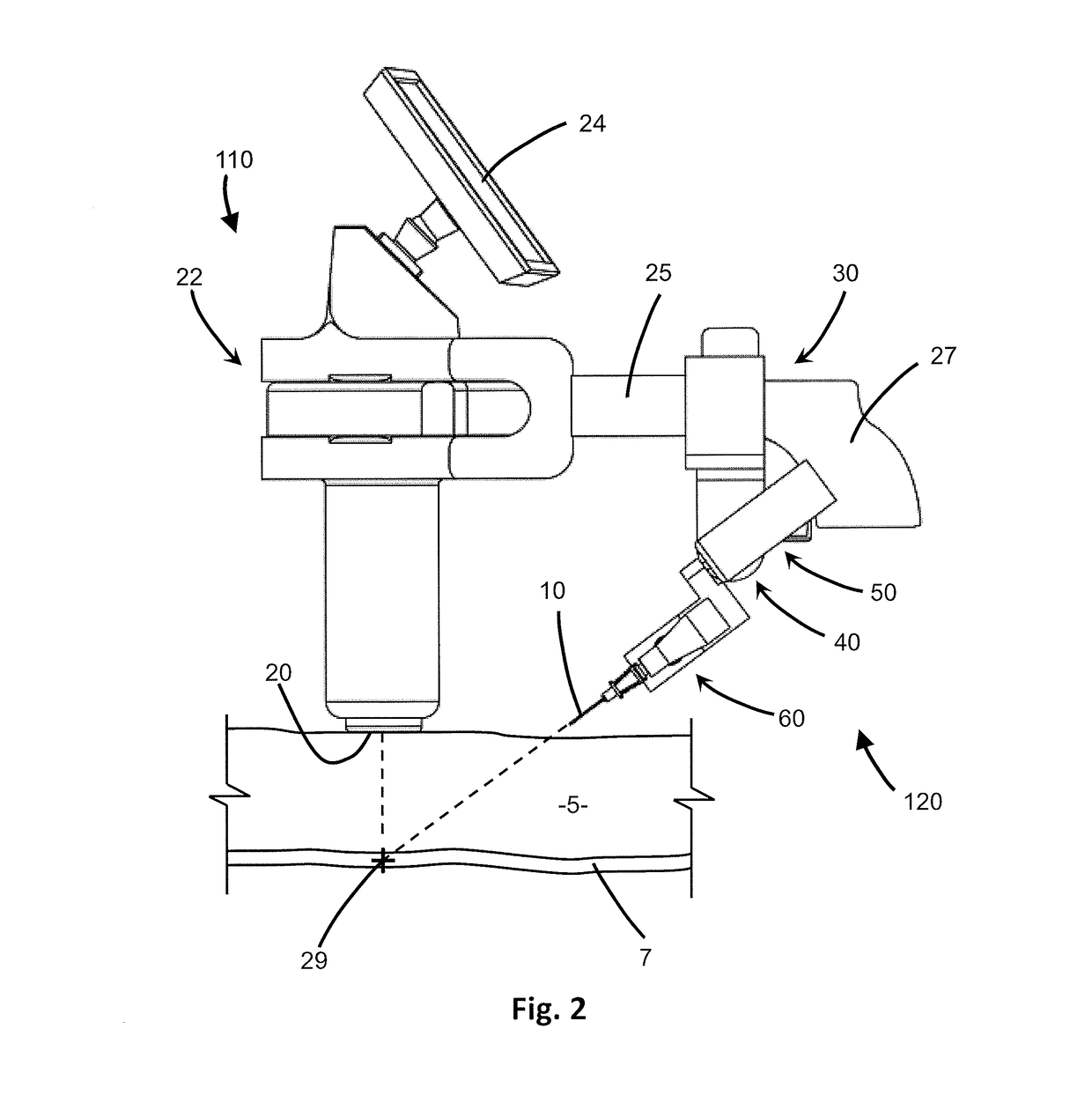

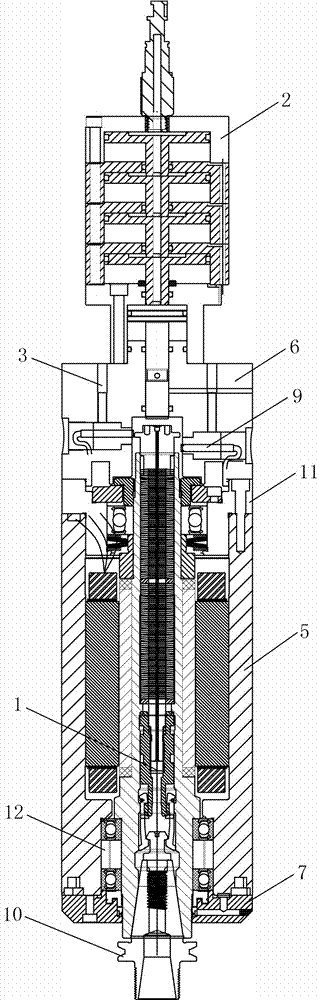

Device and System for Insertion of Penetrating Member

A system, device and method for insertion of a penetrating member into tissue is disclosed, which may be handheld and automated. A detector obtains data regarding subdermal locations of tissue structures, including cavities such as blood vessels. A processor calculates the distance between a preselected target point below the tissue surface, such as within a blood vessel, and the tissue surface, and adjustment data for vertical, angular and extension adjustment of the penetrating member. Vertical, angular and extension actuators carry out the adjustments in real-time as calculated and directed by the processor. Changes in the location of the target point result in automatic recalculation and adjustment by the processor and various actuators. A vibrational actuator induces vibration to the penetrating member during insertion, overcome tissue deformation and vein rolling. A guidewire may be inserted through or by the device, for dilator and catheter insertion once the penetrating member is removed.

Owner:BAYLOR COLLEGE OF MEDICINE +1

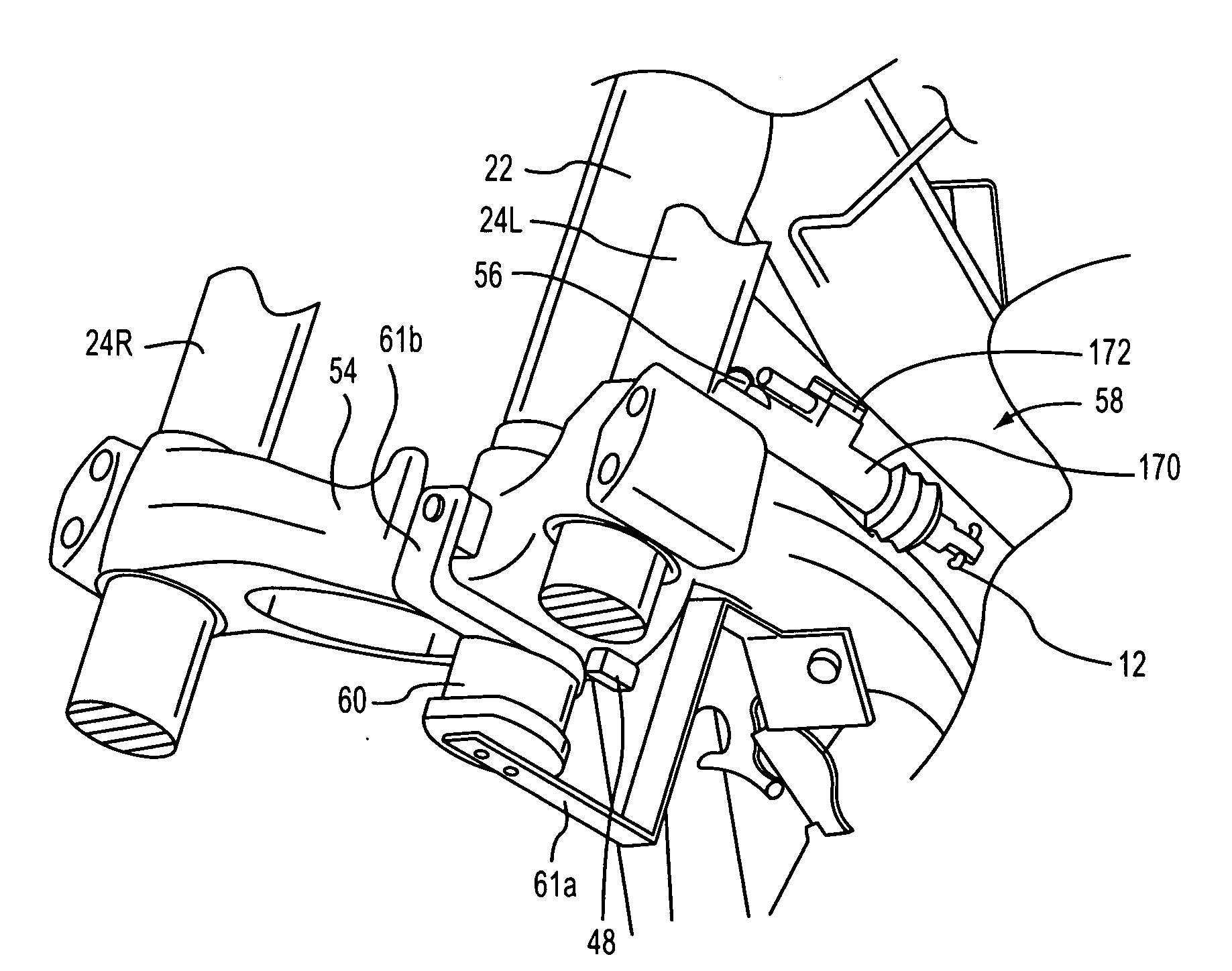

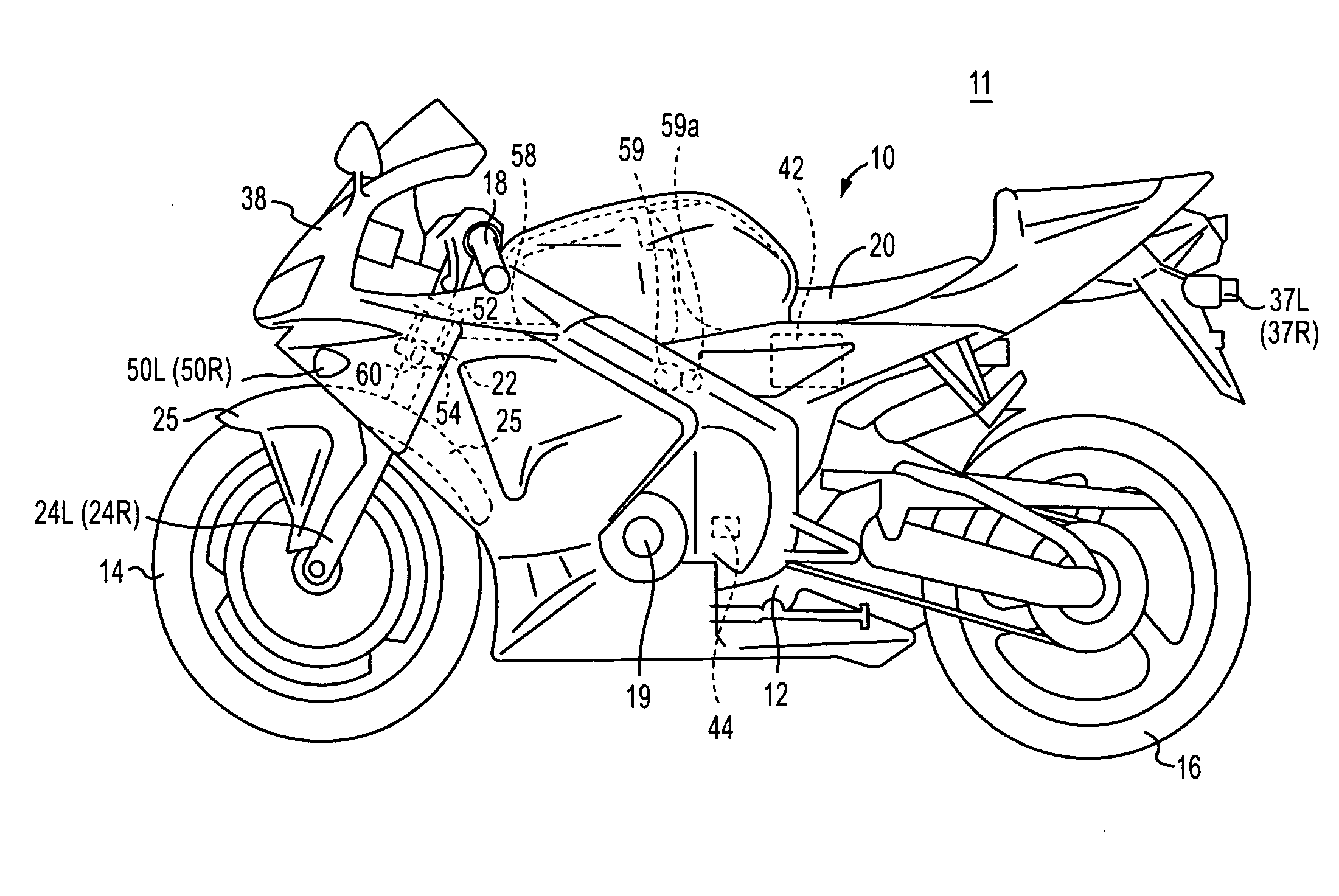

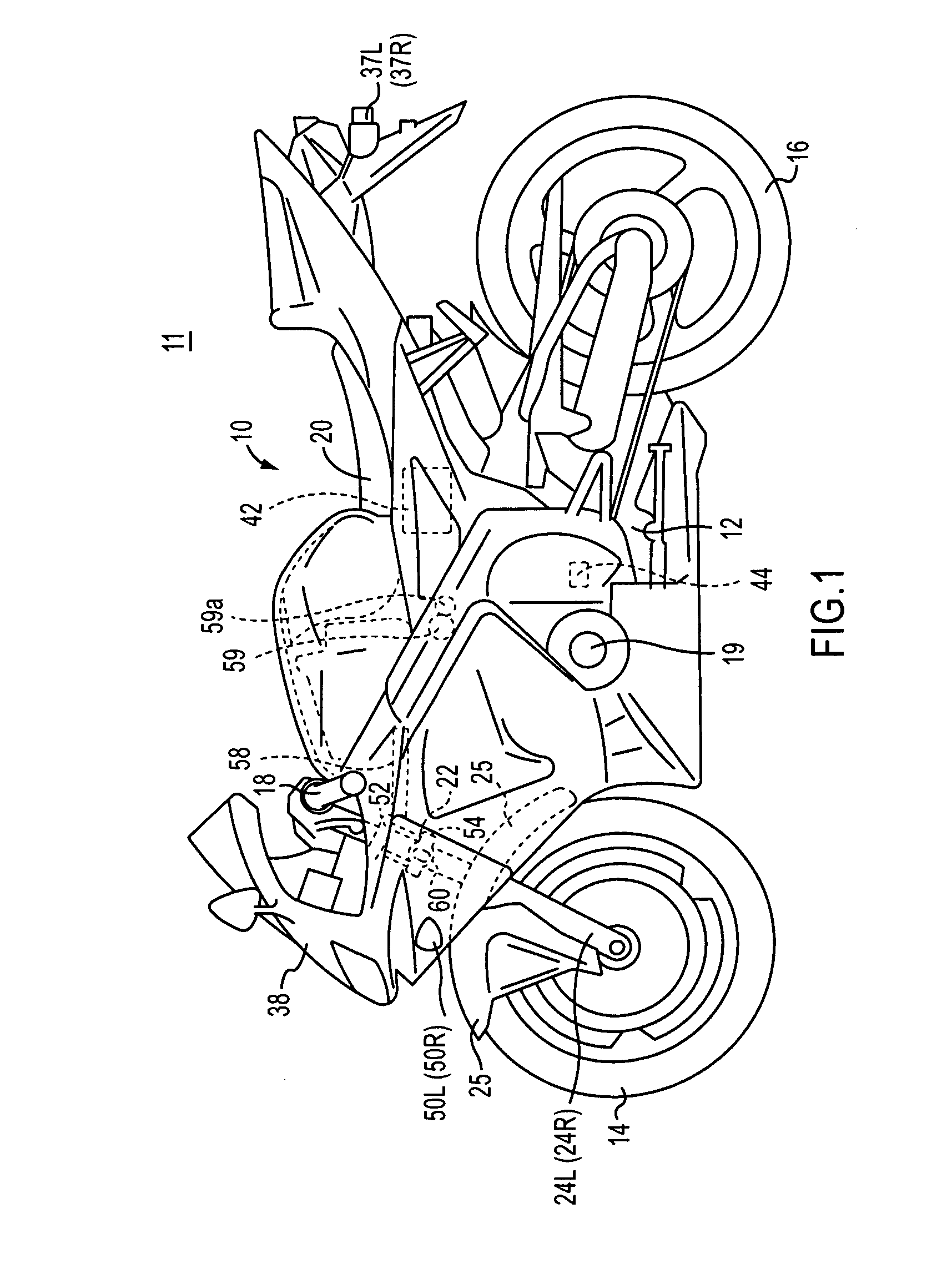

Steering assist system for motorcycle

ActiveUS20090139793A1Reduce scrollingSteering initiationsDigital data processing detailsActuatorControl theory

A steering assist system for a motorcycle includes an actuator configured to provide a steering torque to steering of a motorcycle. A target-torque calculation unit is configured to obtain a target-torque for the steering, on a basis of a state of the motorcycle. A torque detecting unit is configured to detect a steering torque. A torque control unit is configured to drive an actuator on a basis of a deviation between the target torque obtained from the target-torque calculation unit and the steering torque obtained from the torque detecting unit.

Owner:HONDA MOTOR CO LTD

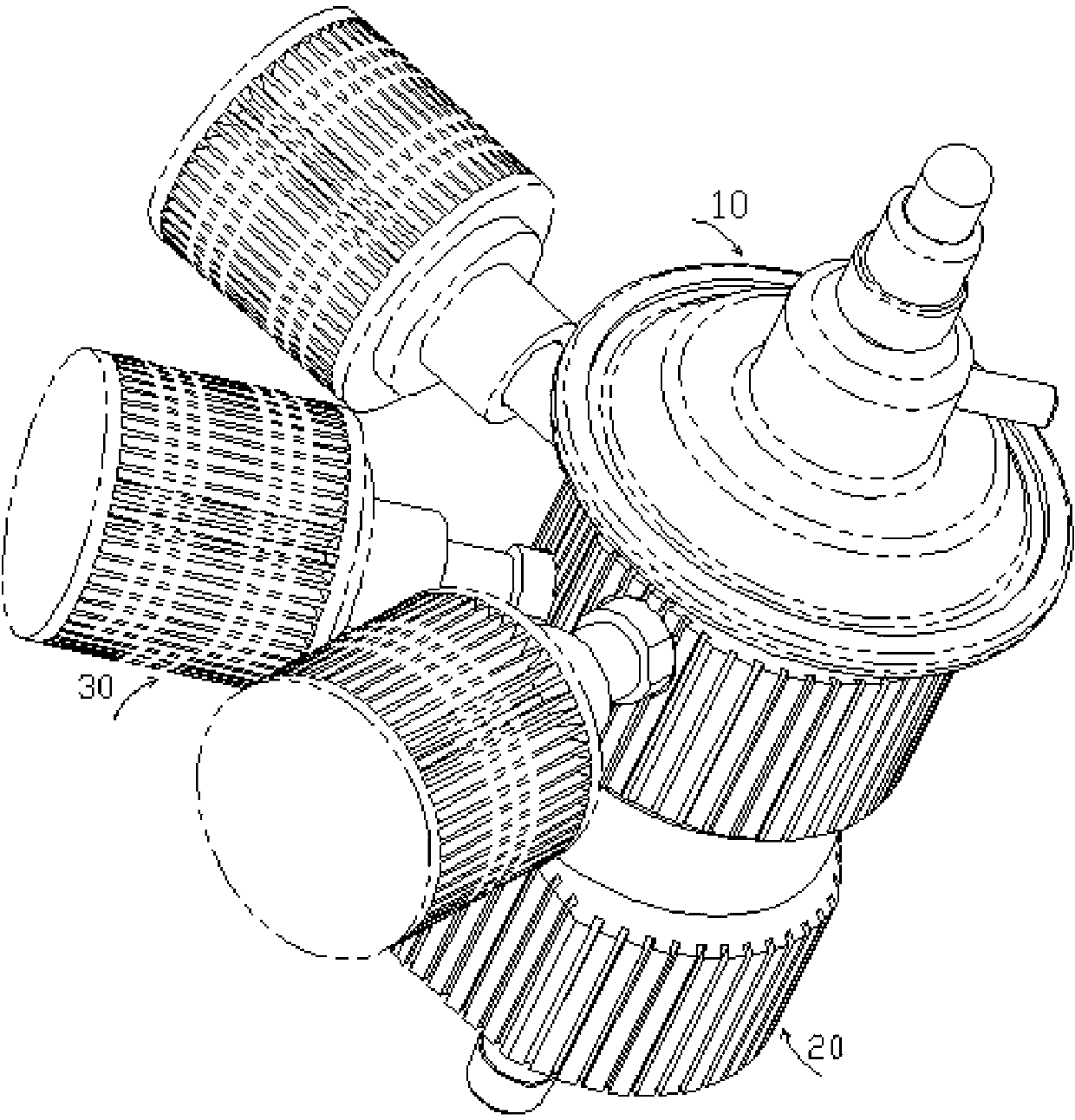

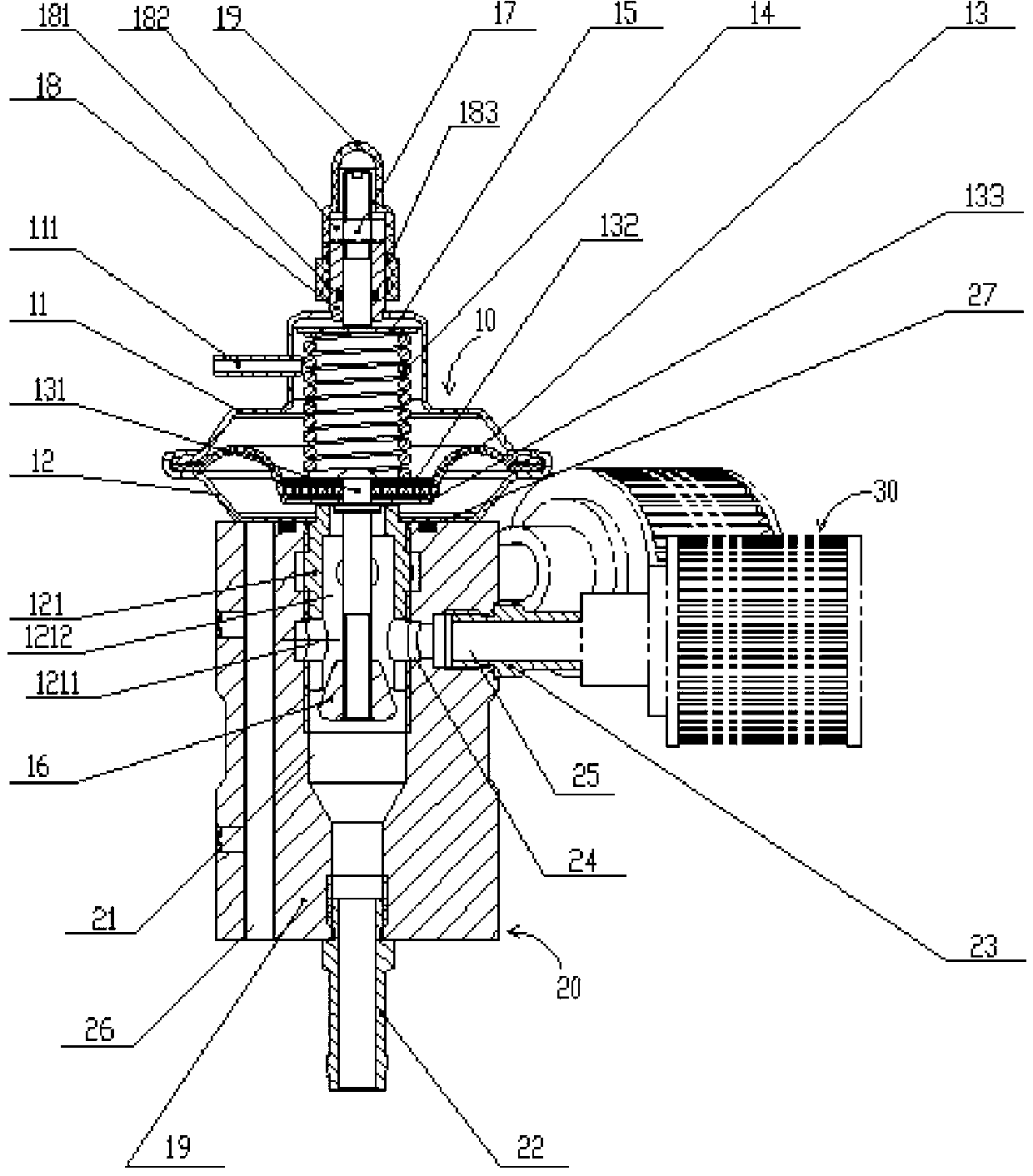

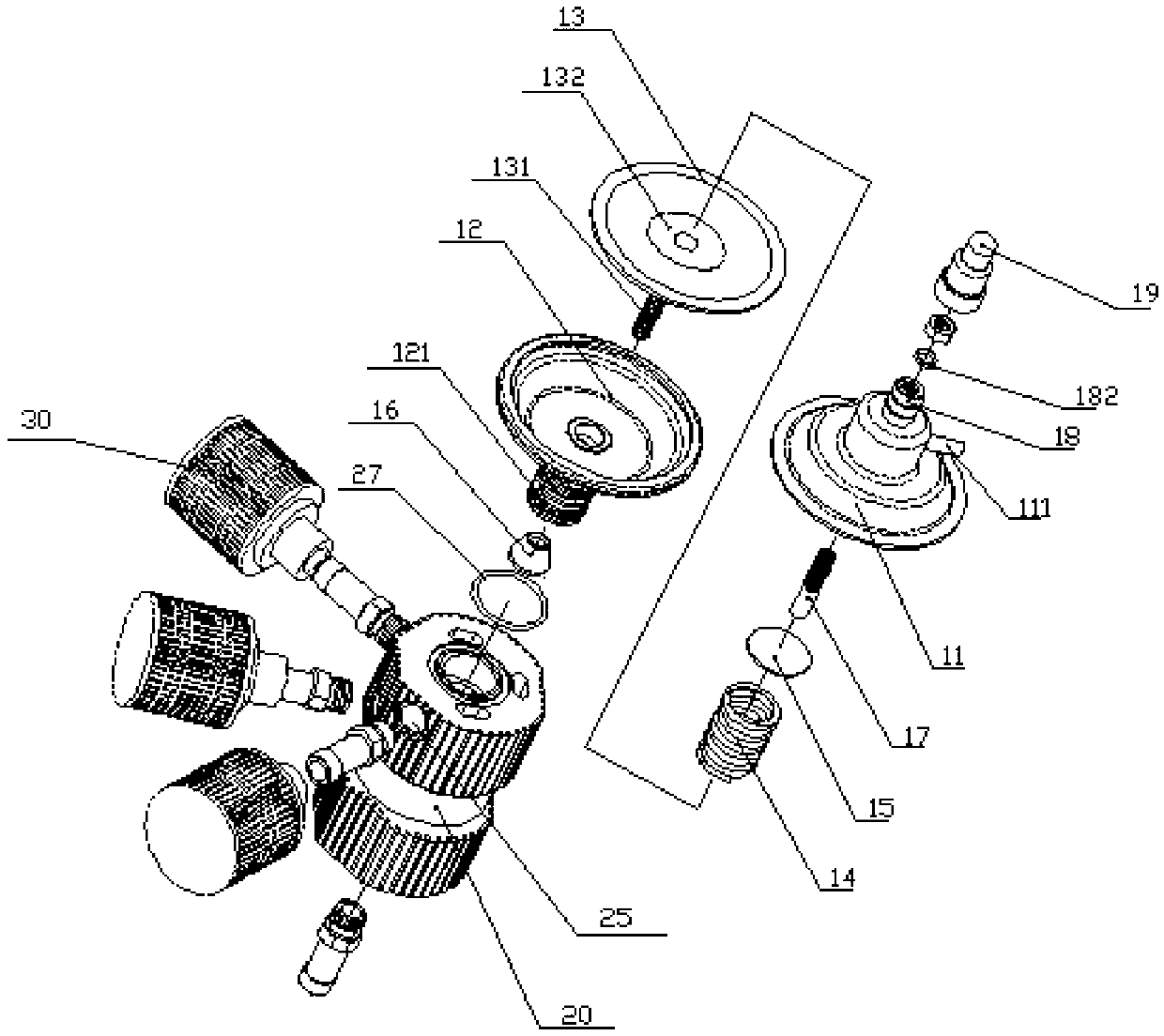

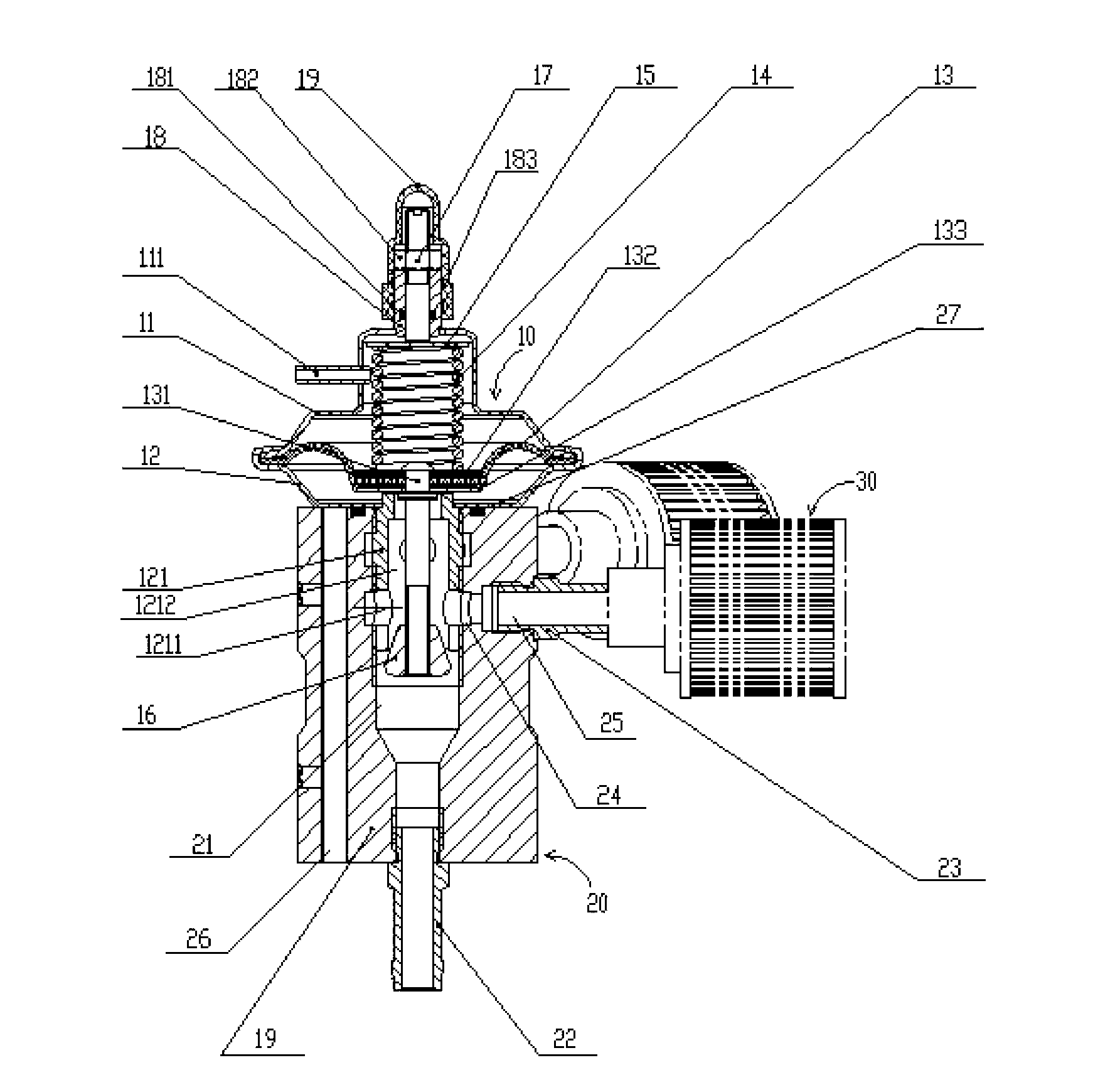

Oil saving accelerator

InactiveCN102996287AAvoid smallDischarge in timeMachines/enginesSecondary air addition to fuelEngineeringAir cleaners

The invention discloses an oil saving accelerator. The oil saving accelerator comprises a vacuum diaphragm seat and a fixed seat with two ends, wherein the vacuum diaphragm seat comprises a first diaphragm seat and a second diaphragm seat which are sealed in a butt jointing way as well as a diaphragm clamped between the first diaphragm seat and the second diaphragm seat; the center of the fixed seat is provided with a first through hole running through the two ends of the fixed seat, one end of the first through hole is in screw connection with a first screw rod of the second diaphragm seat, while the other end of the first through hole is connected with a pipe joint; the wall surface of the fixed seat, adjacent to a second screw rod, is provided with a plurality of air vents for connecting an air cleaner; the inner wall surface of the first through hole is provided with an annular groove; the inner end openings of the air vents are positioned inside the annular groove; and a second through hole is communicated with the annular groove.

Owner:浙江宇嘉新能源科技股份有限公司

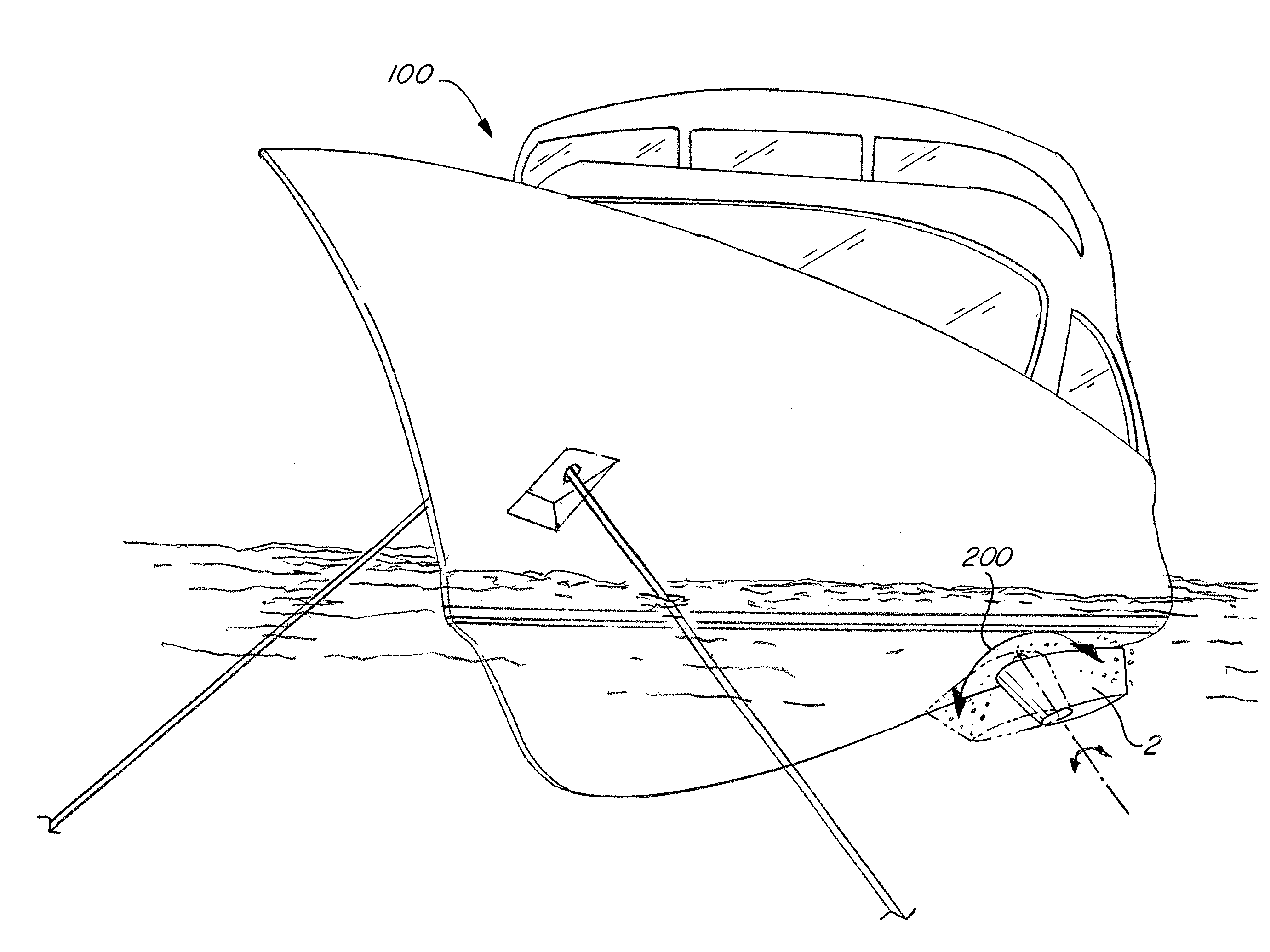

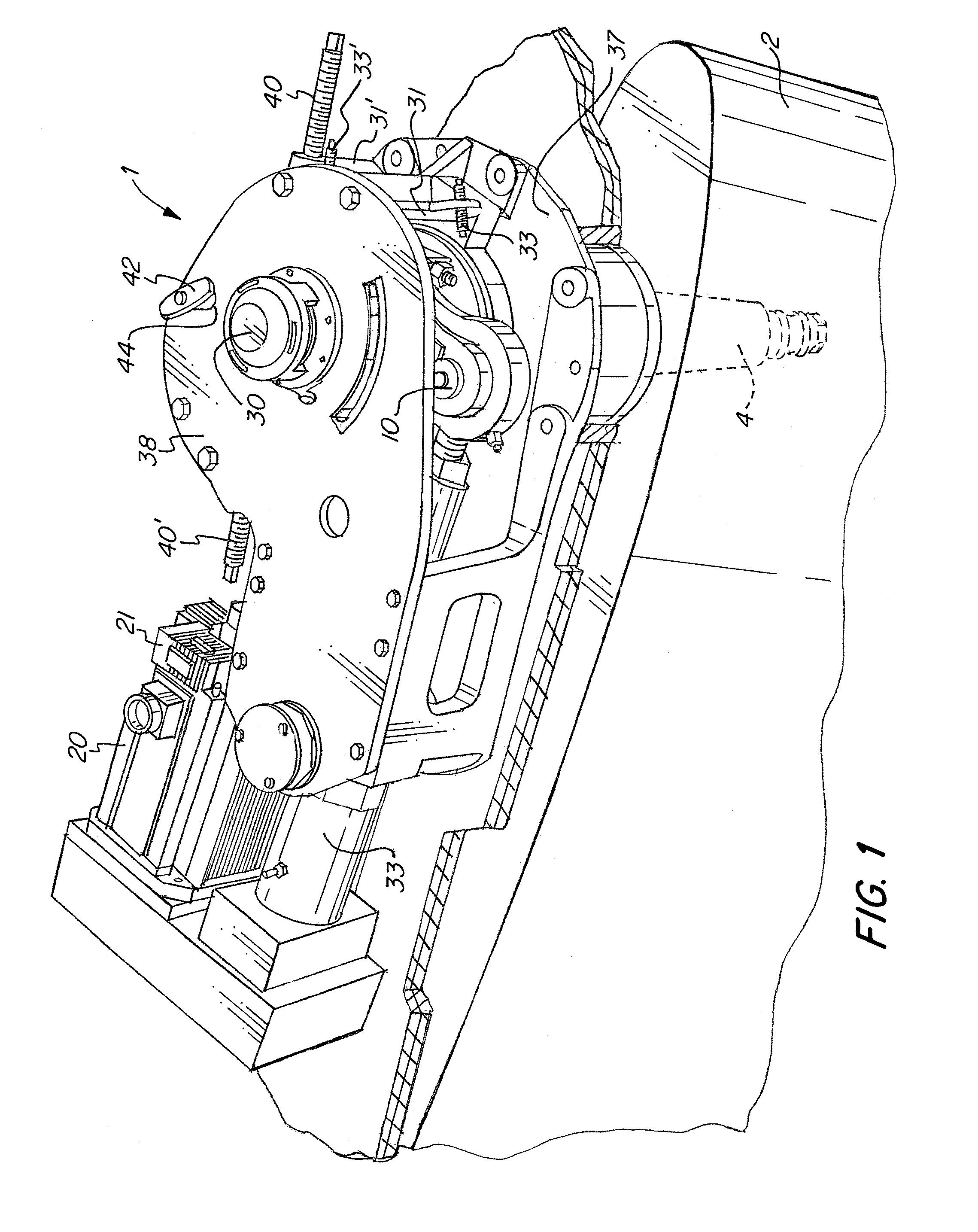

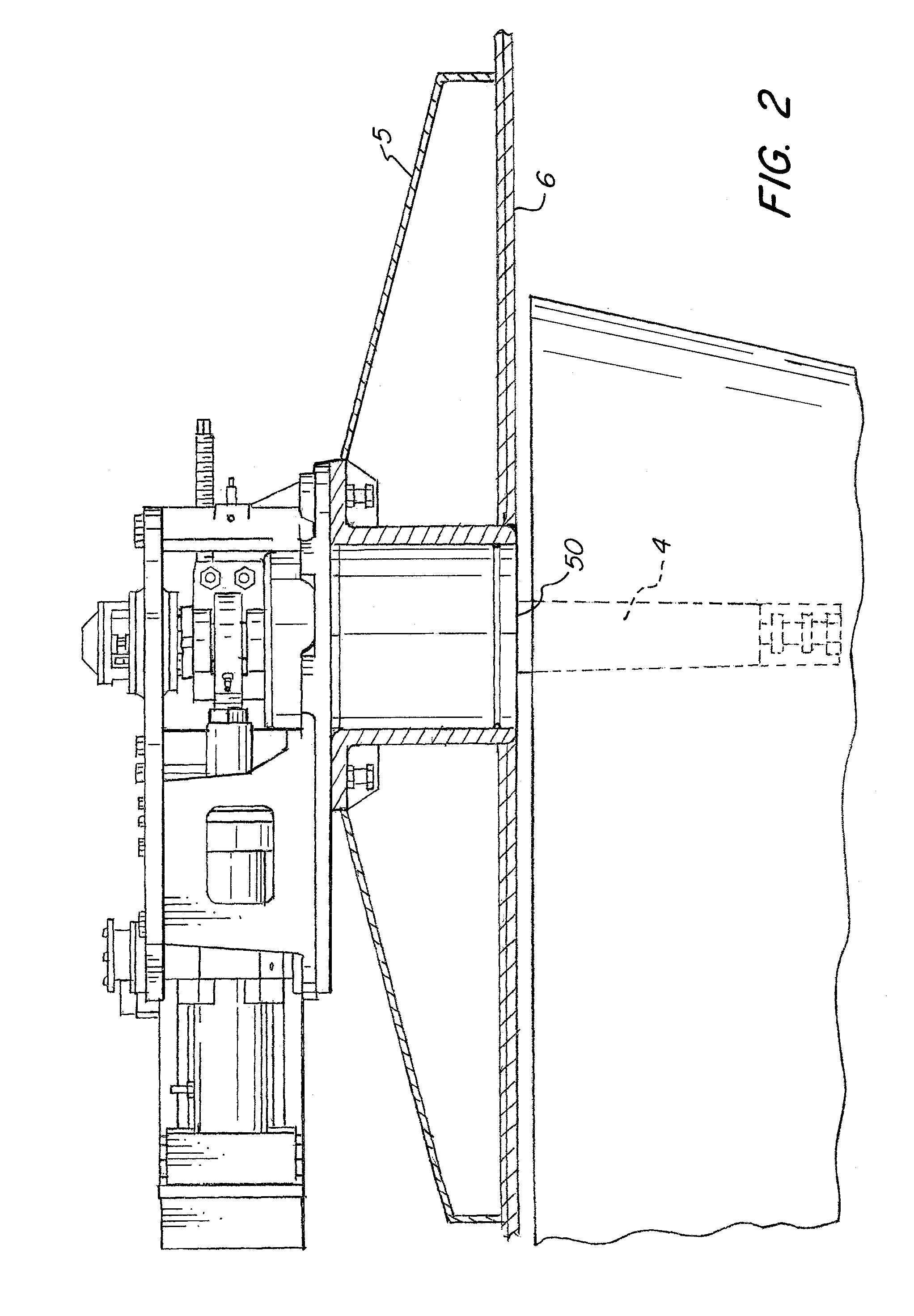

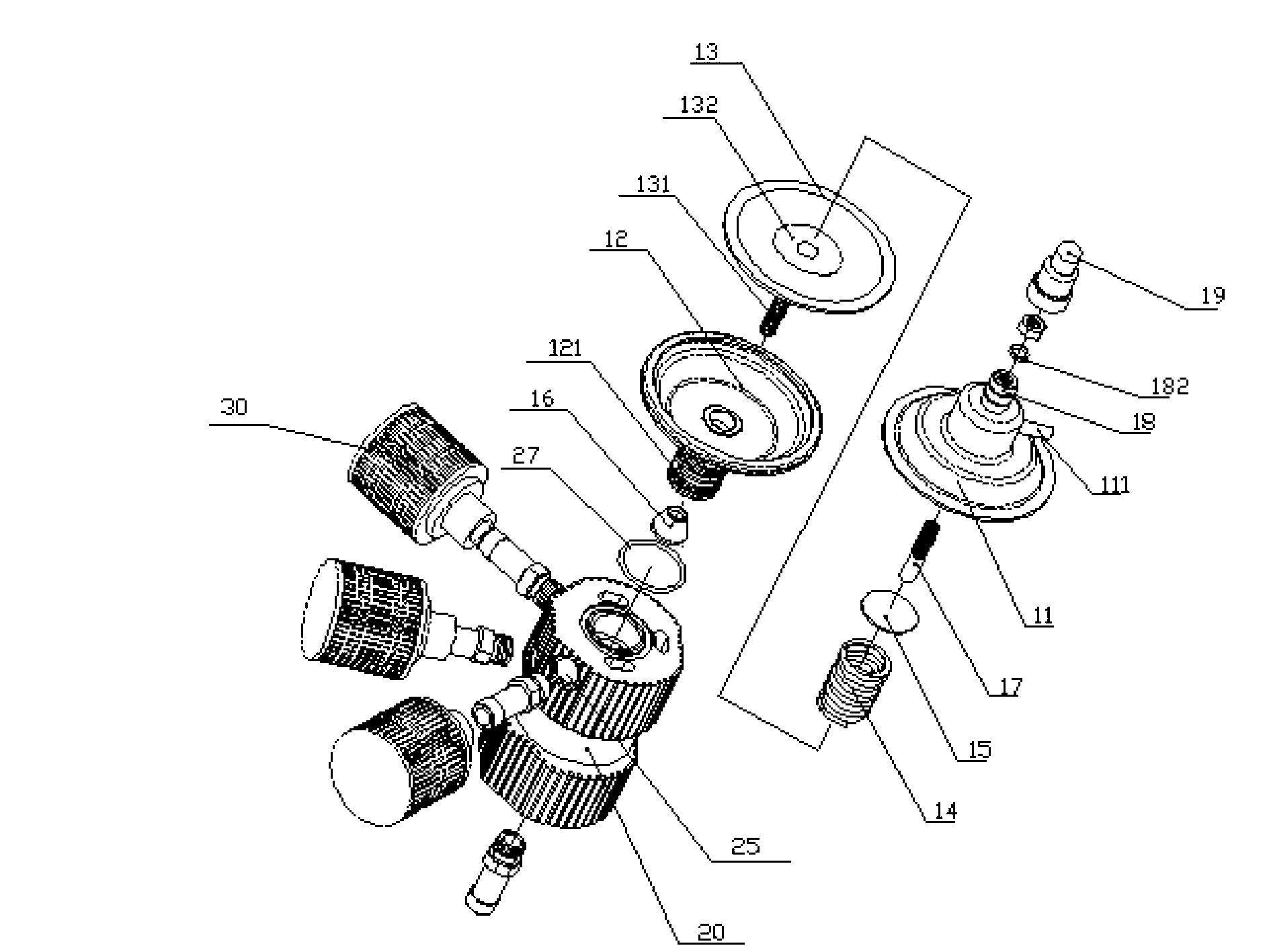

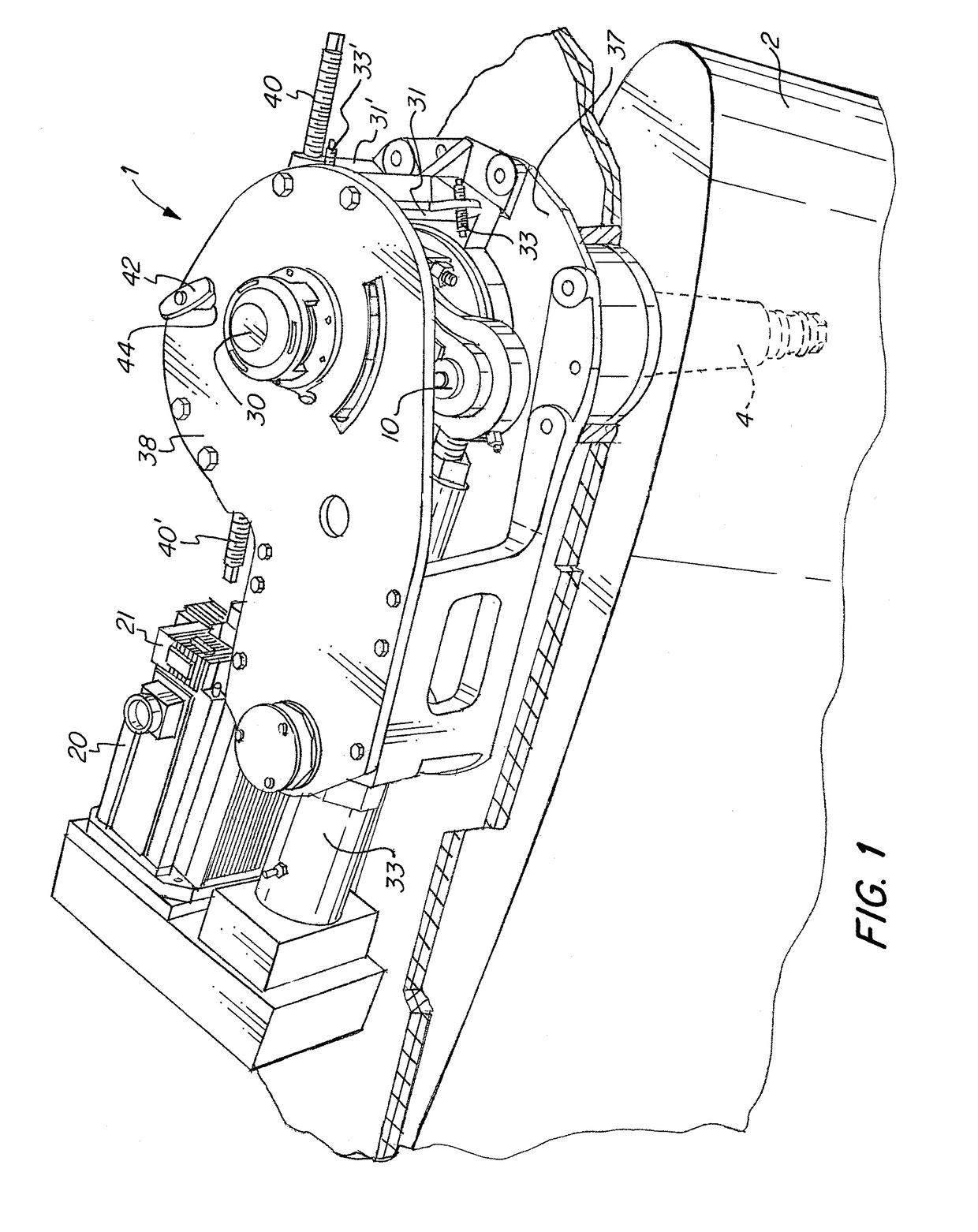

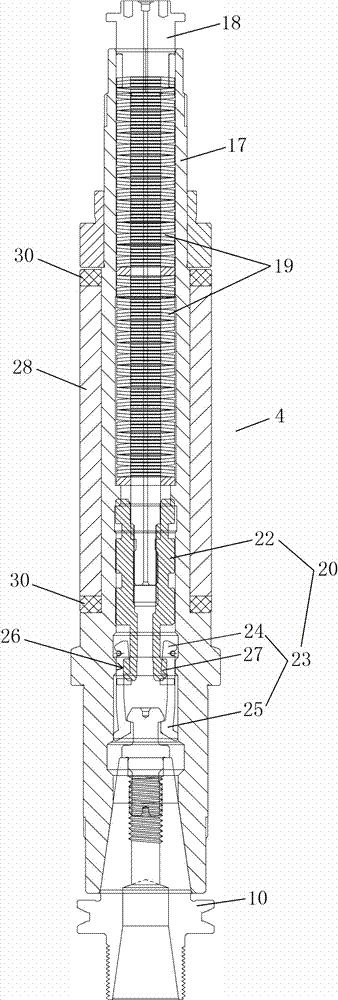

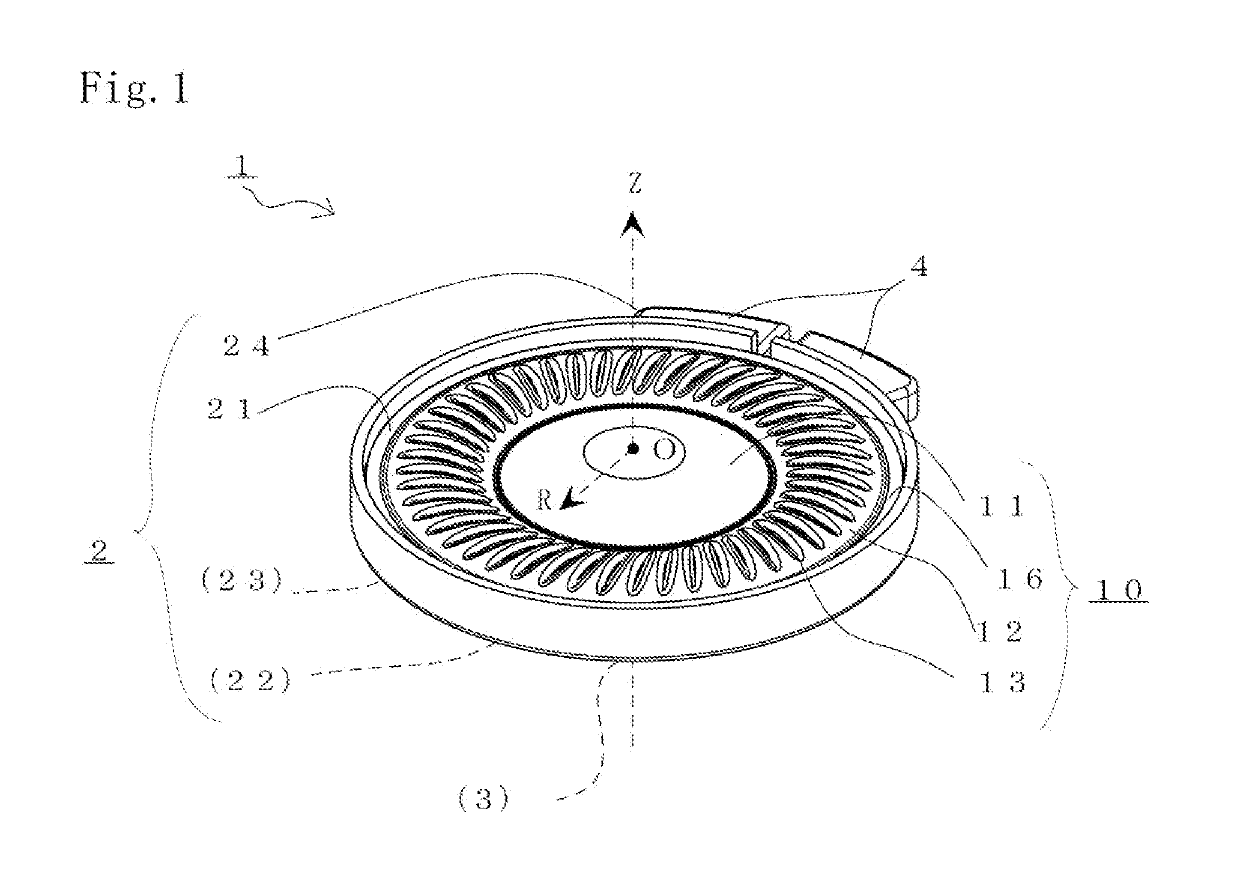

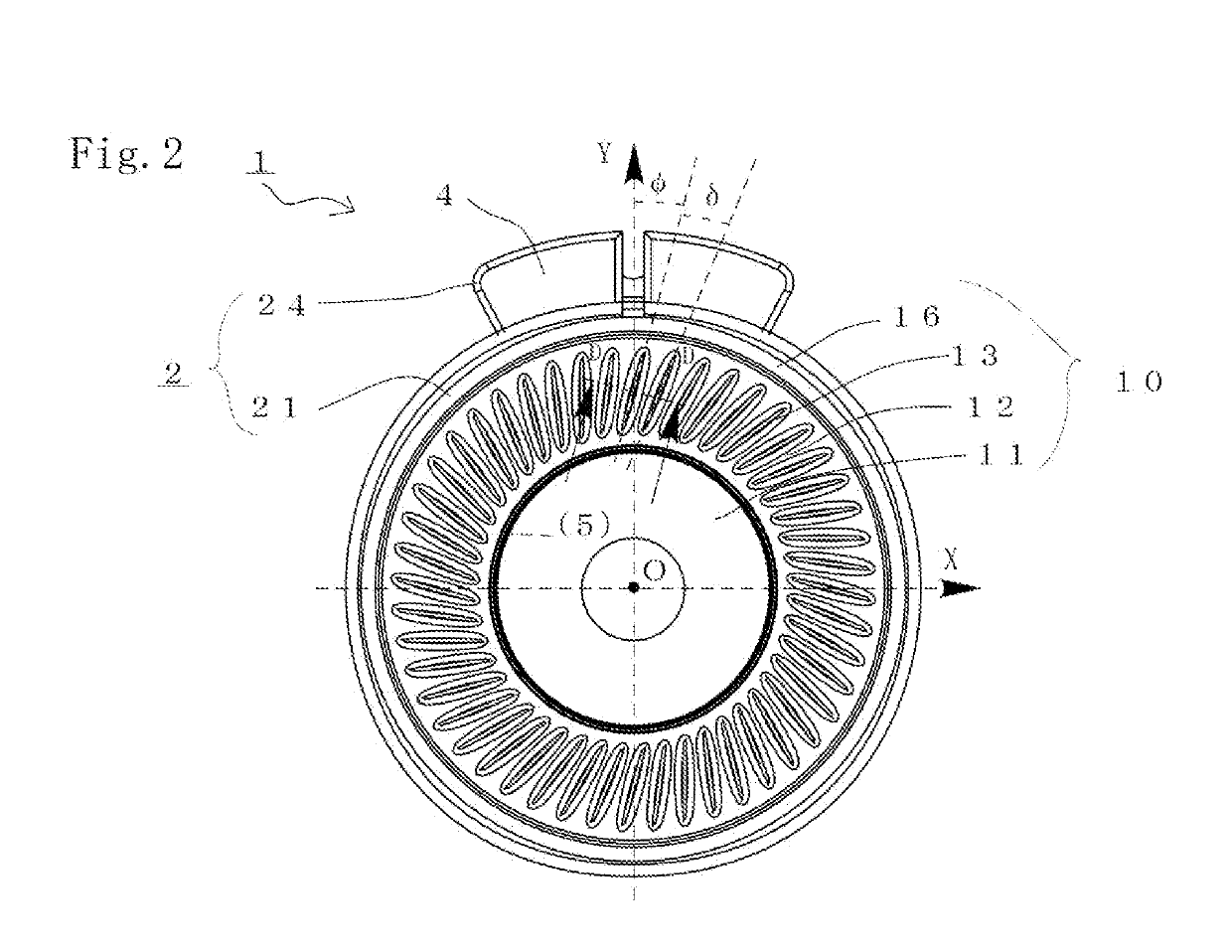

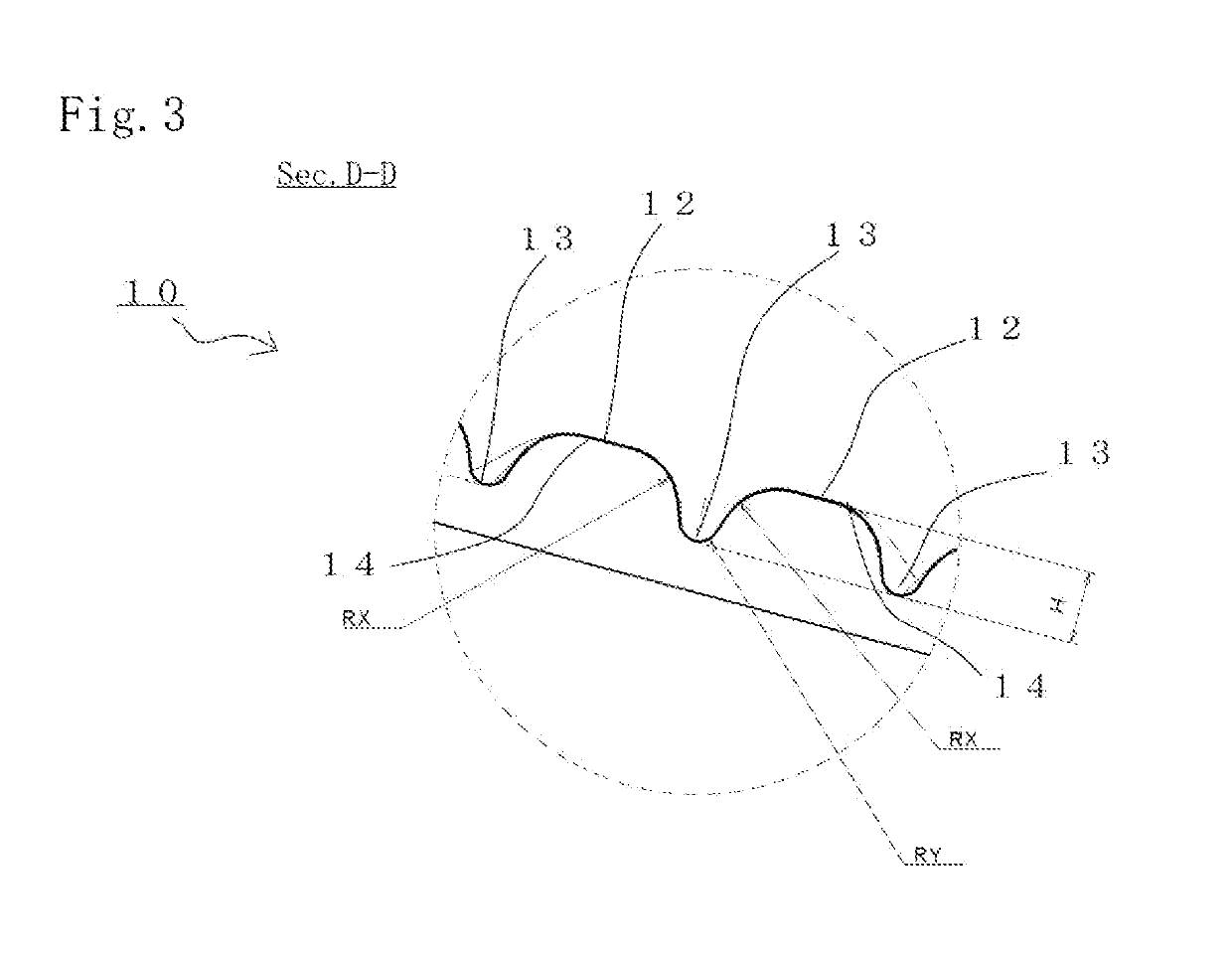

Electric Fin Stabilizer

ActiveUS20160121978A1Reduce usageEasy to installSpeed controllerElectric devicesMarine engineeringControl signal

A marine vessel stabilizer and control including a fin having a stem extending into the hull. An arm is connected to the stem and extends towards a connector which is connected to a rod. A housing is connected to another end of the rod and a screw passes through the housing. A motor is connected to the screw and configured to rotate to rotate the fin. A controller is connected to the motor, a speed sensor, a roll sensor and a fin position sensor such that a control signal can be calculated and the position of the fin can be determined to reduce roll of the vessel both when making headway and when at rest (zero speed). When the vessel is at rest, the fin is be configured to rotate through maximum angles greater than 15 degrees from either side of a neutral position.

Owner:NAIAD MARITIME GRP

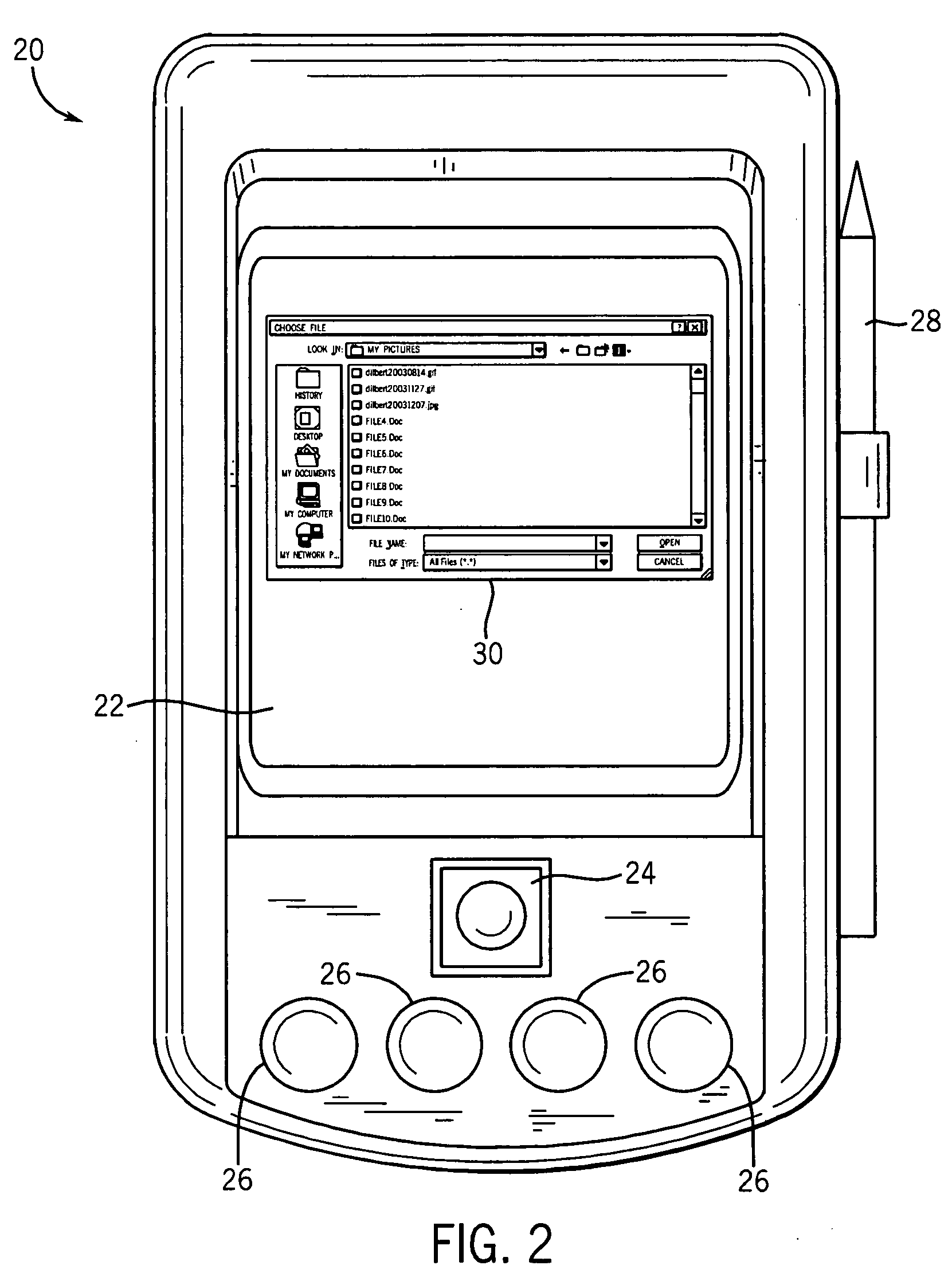

User input system and method for selecting a file

InactiveUS20050166161A1Efficient and easy and less burdensome selection functionEasier, and less burdensome file selection functionDigital computer detailsSubstation equipmentUser inputComputer program

A present invention relates to methods, devices, systems, and a computer program products for selecting files from a file list. The methods, devices, systems and computer program products are configured to provide more efficient ways for selecting a file from a file list in various usage scenarios.

Owner:NOKIA CORP

Non-heat treated wire or bar steel for springs

InactiveUS6206984B1Reduce scrollingHigh tensile strengthFurnace typesHeat treatment furnacesBreakage rateRebar

A non-heat treated wire or bar steel for springs which is characterized by having in its as-rolled state a tensile strength of 120-150 kgf / mm2 and a bending breakage rate no higher than 15% when tested according to JIS Z-2248 under the condition of r / d=2.8 where r (mm) denotes the inside radius of the bending curvature and d (mm) denotes the diameter of the as-rolled stock.

Owner:KOBE STEEL LTD

Steering assist system for motorcycle

ActiveUS8606464B2Reduce scrollingDigital data processing detailsSteering initiationsActuatorControl theory

Owner:HONDA MOTOR CO LTD

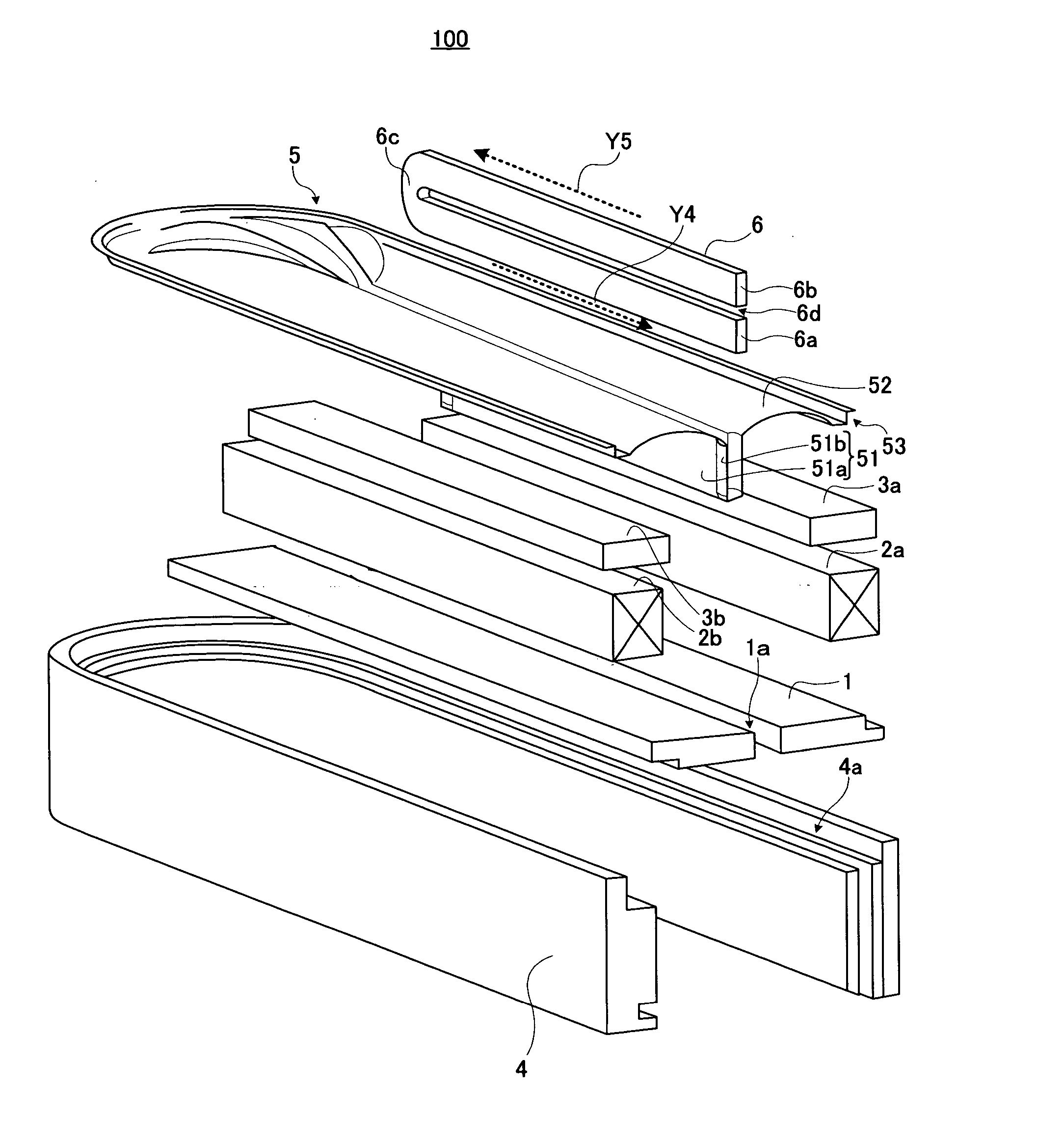

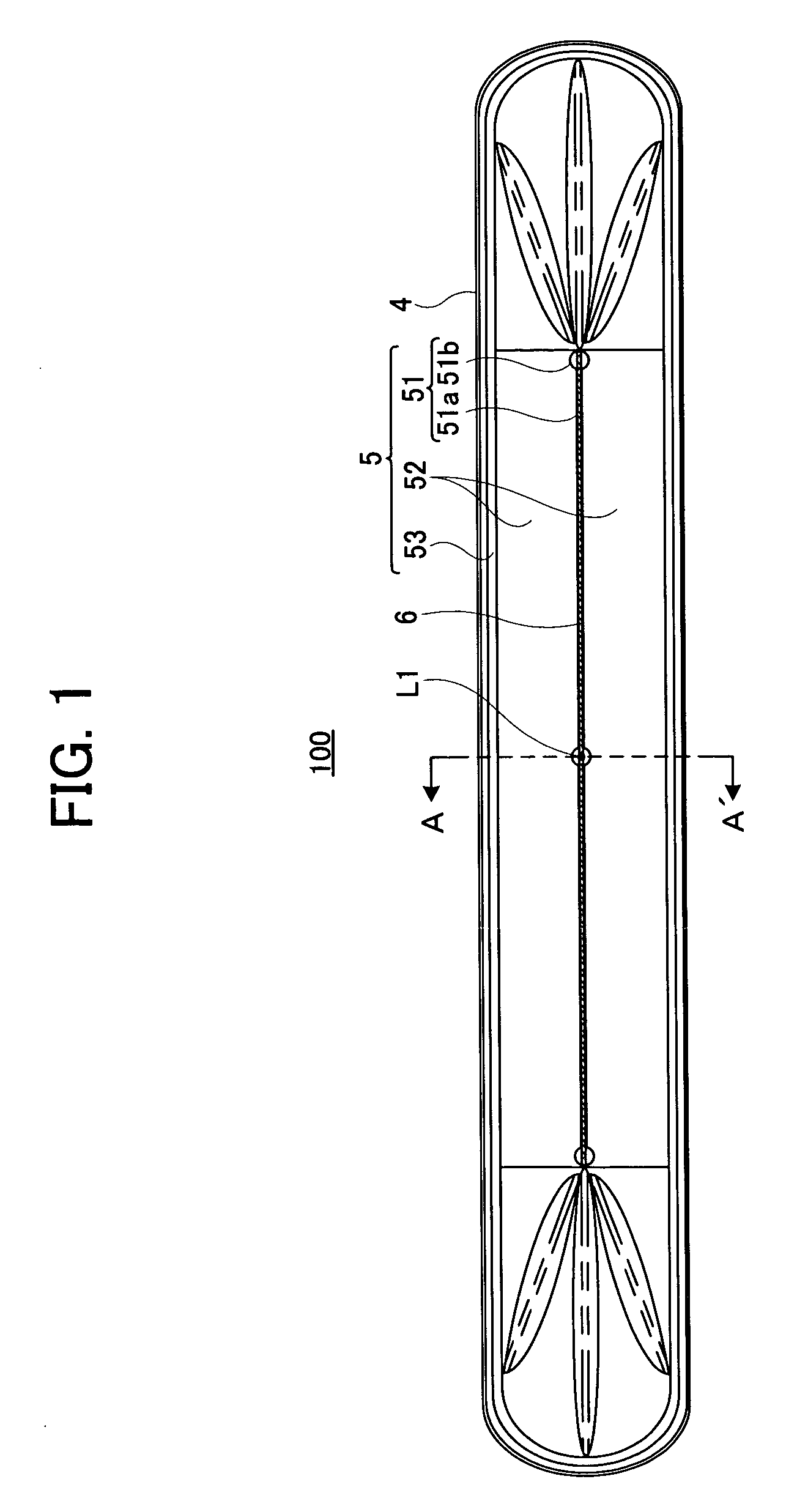

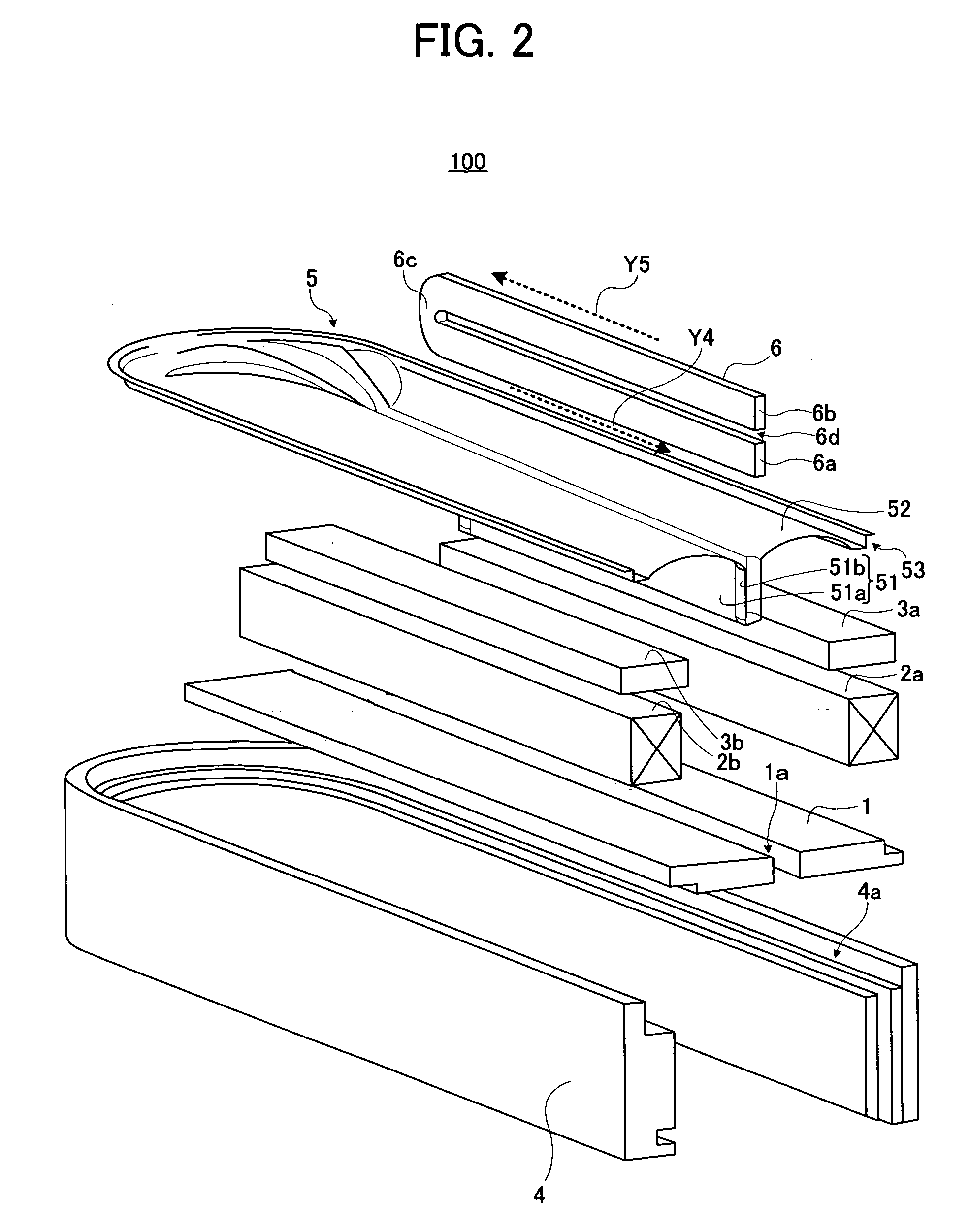

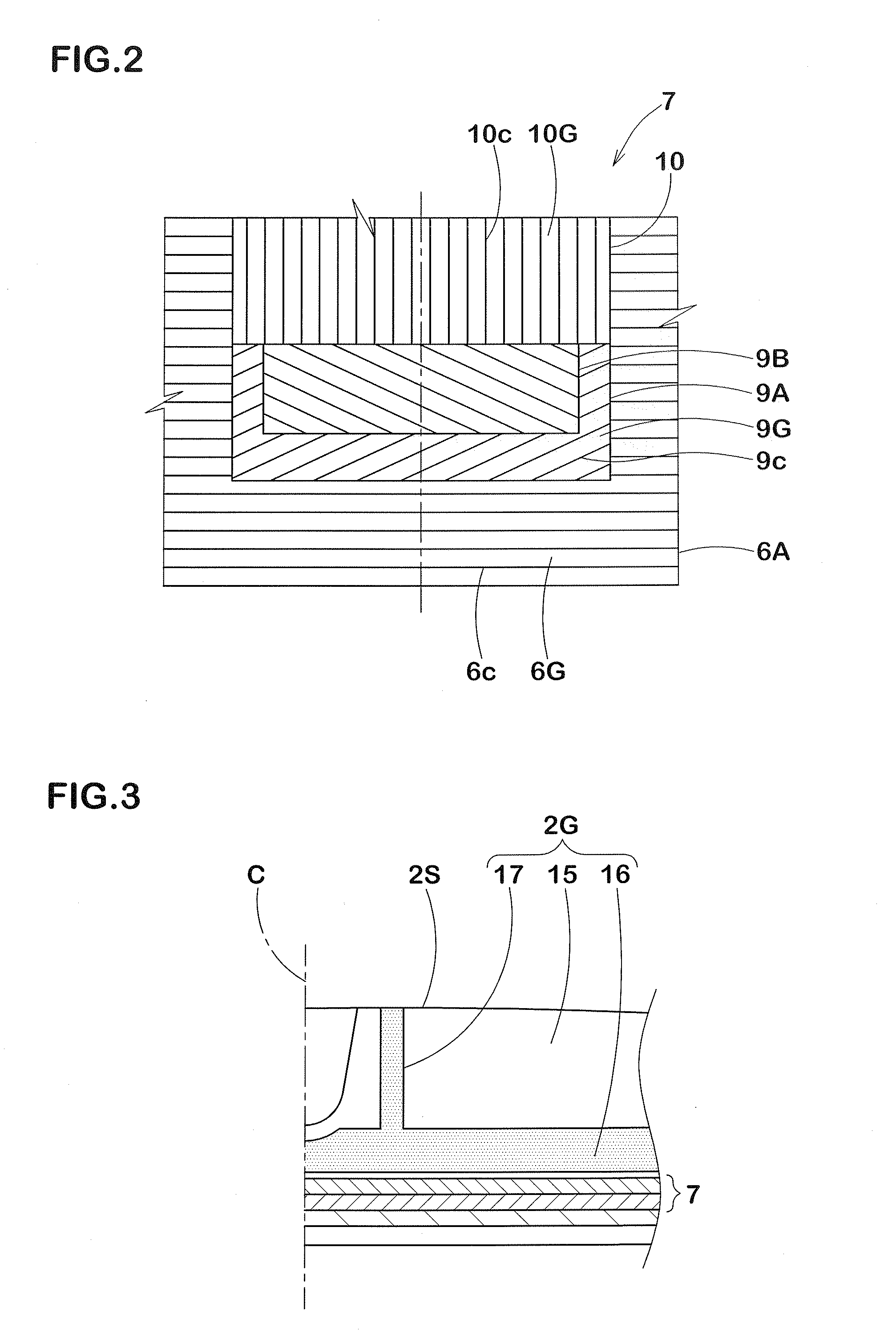

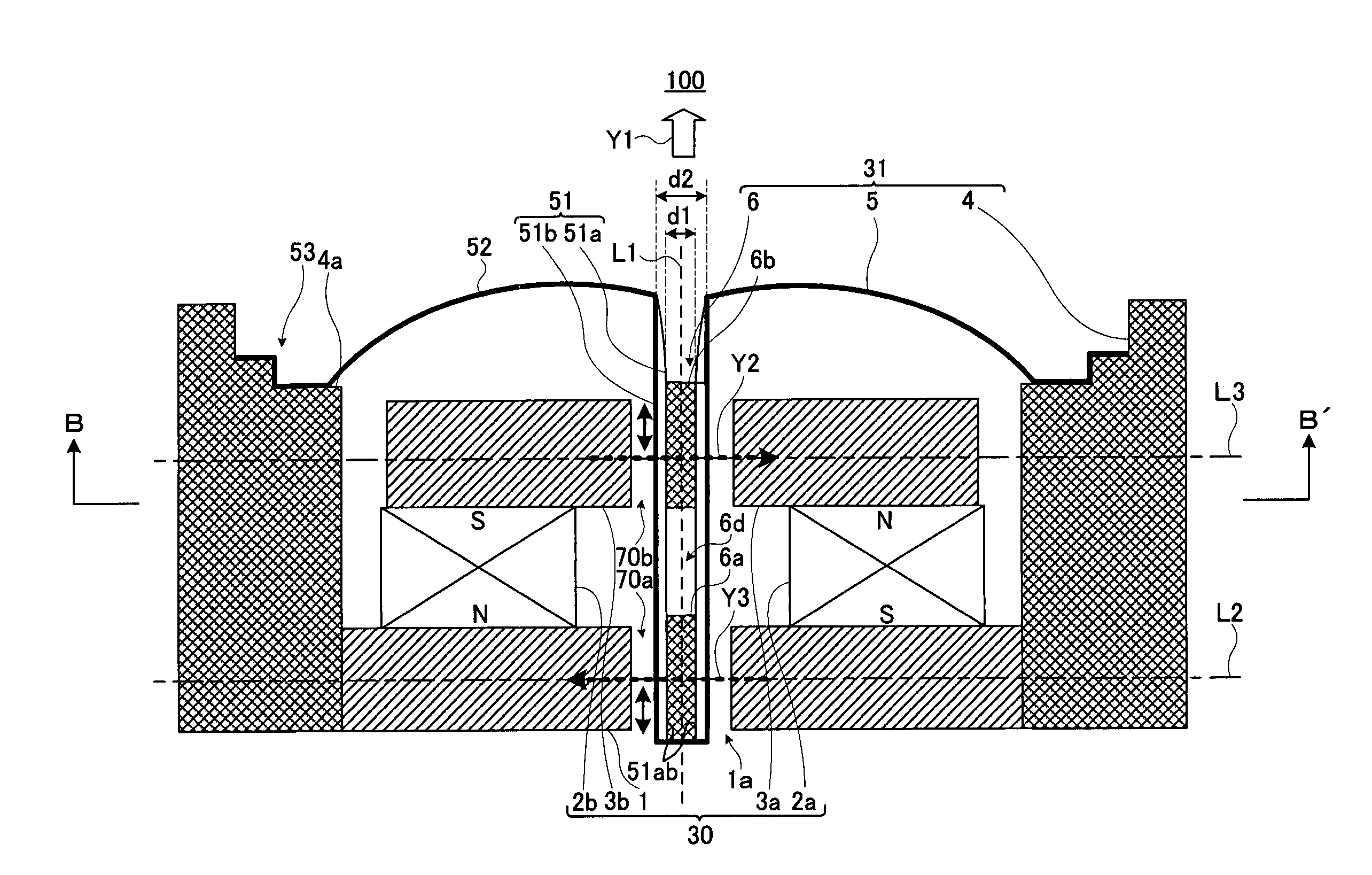

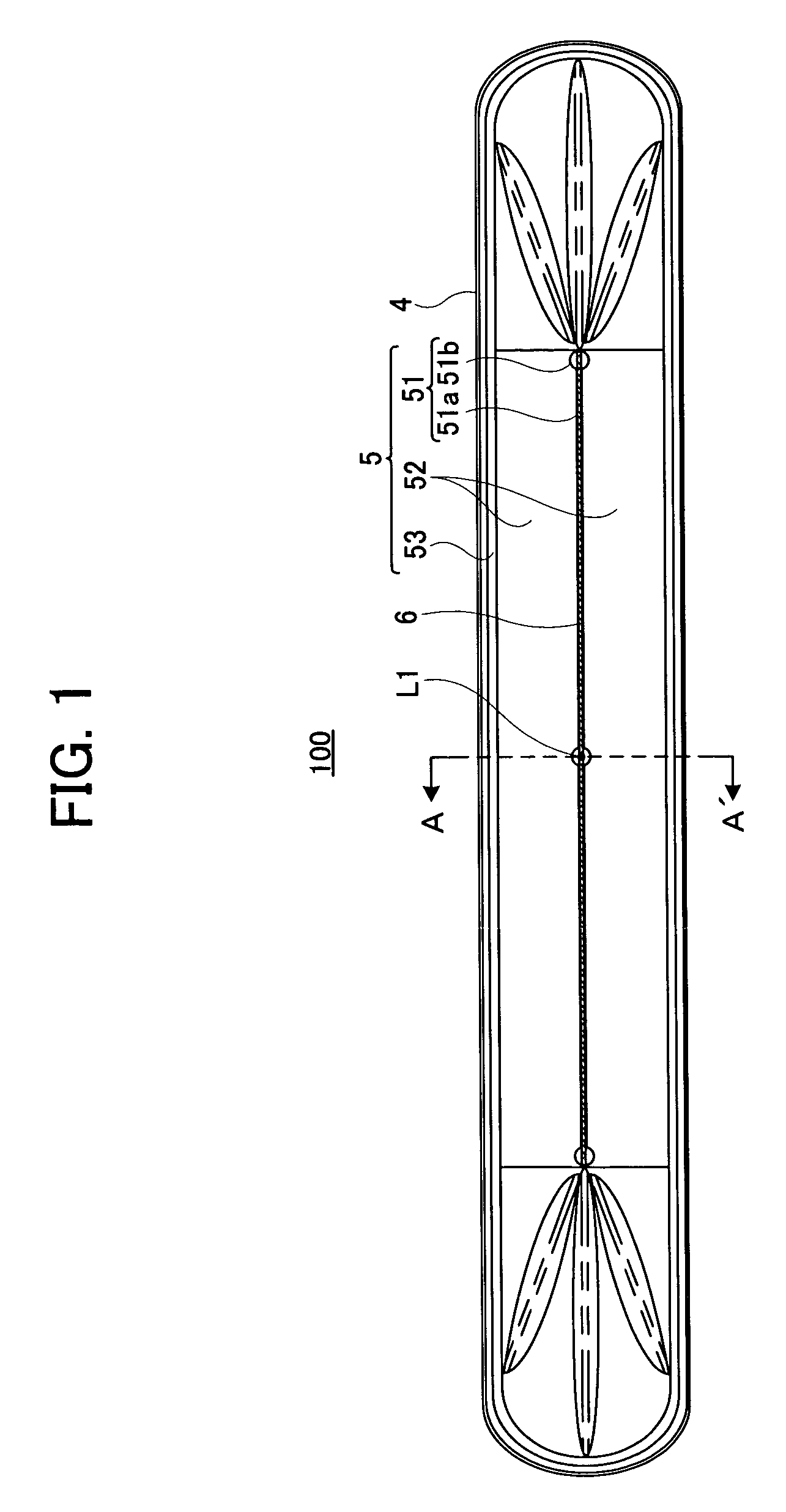

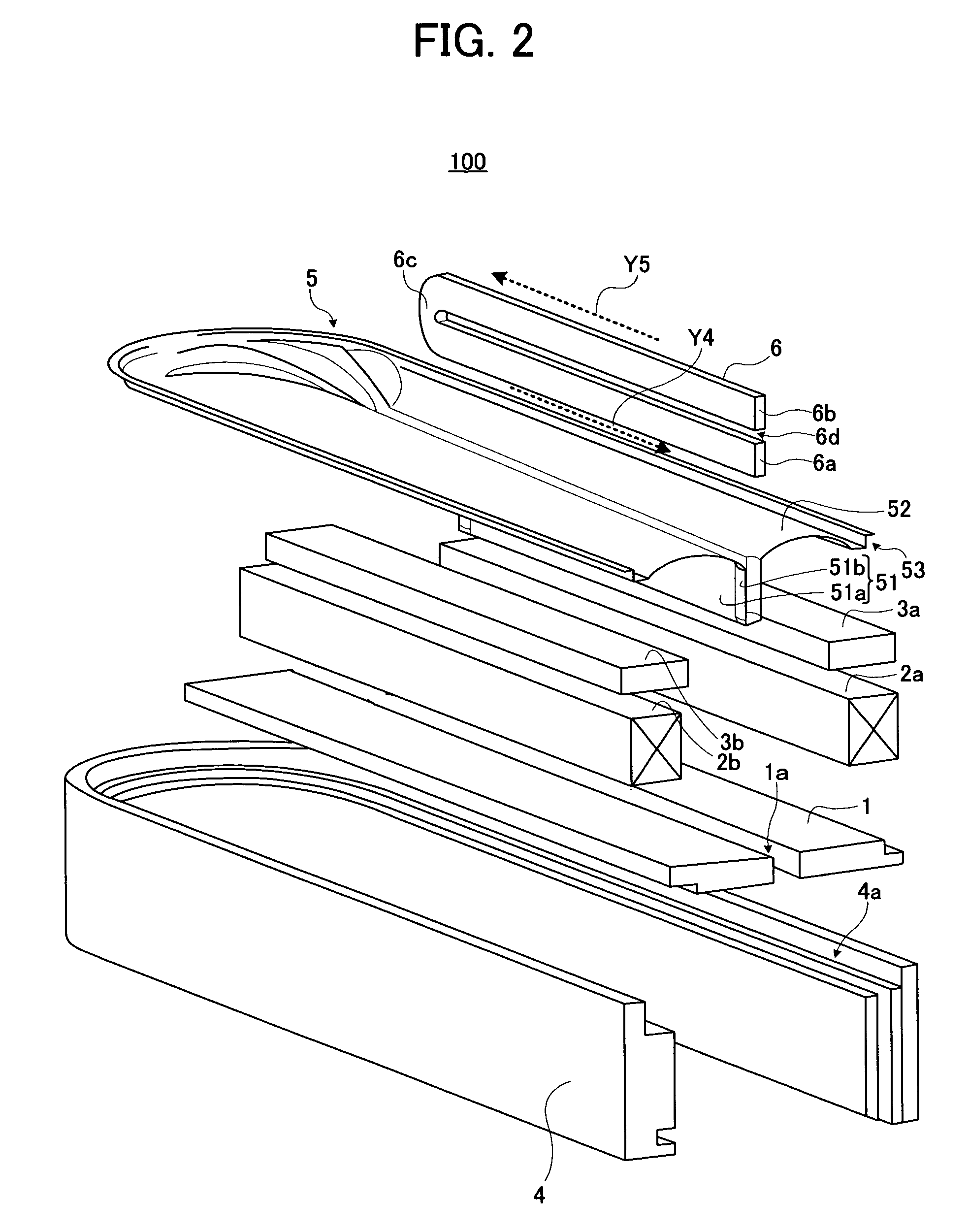

Diaphragm for speaker device, speaker device and mobile phone

InactiveUS20070140520A1Reduce rollingReduce scrollingTransducer detailsSound producing devicesLoudspeakerEngineering

A diaphragm of a speaker device, formed into an elongated configuration, has a recessed shape and includes a voice coil arrangement part extending in its longitude direction. The voice coil arrangement part has a gap with a constant width in its lateral direction and includes a voice coil supporting part for supporting a voice coil and an expanded part provided at a position along it.

Owner:PIONEER CORP +1

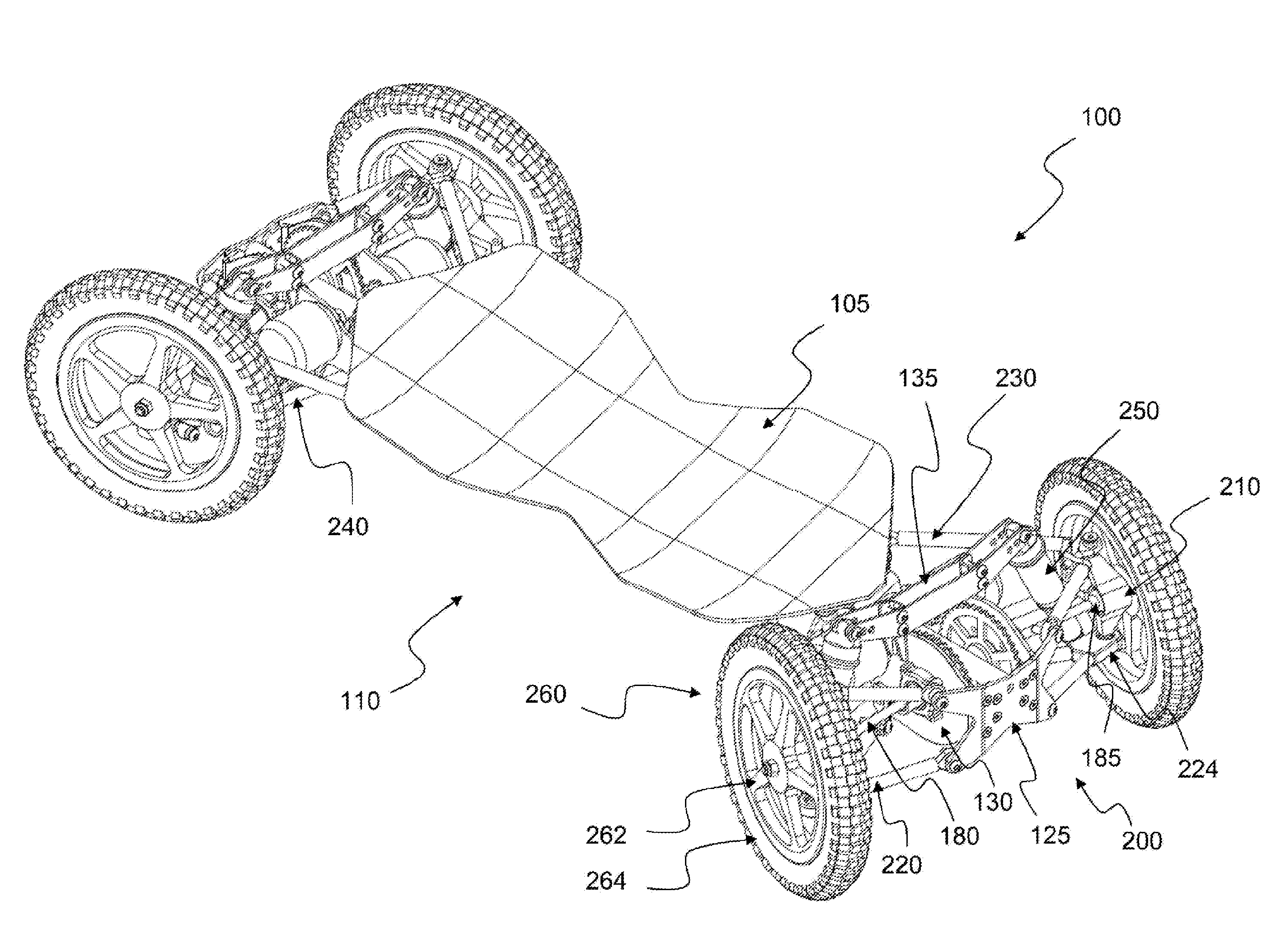

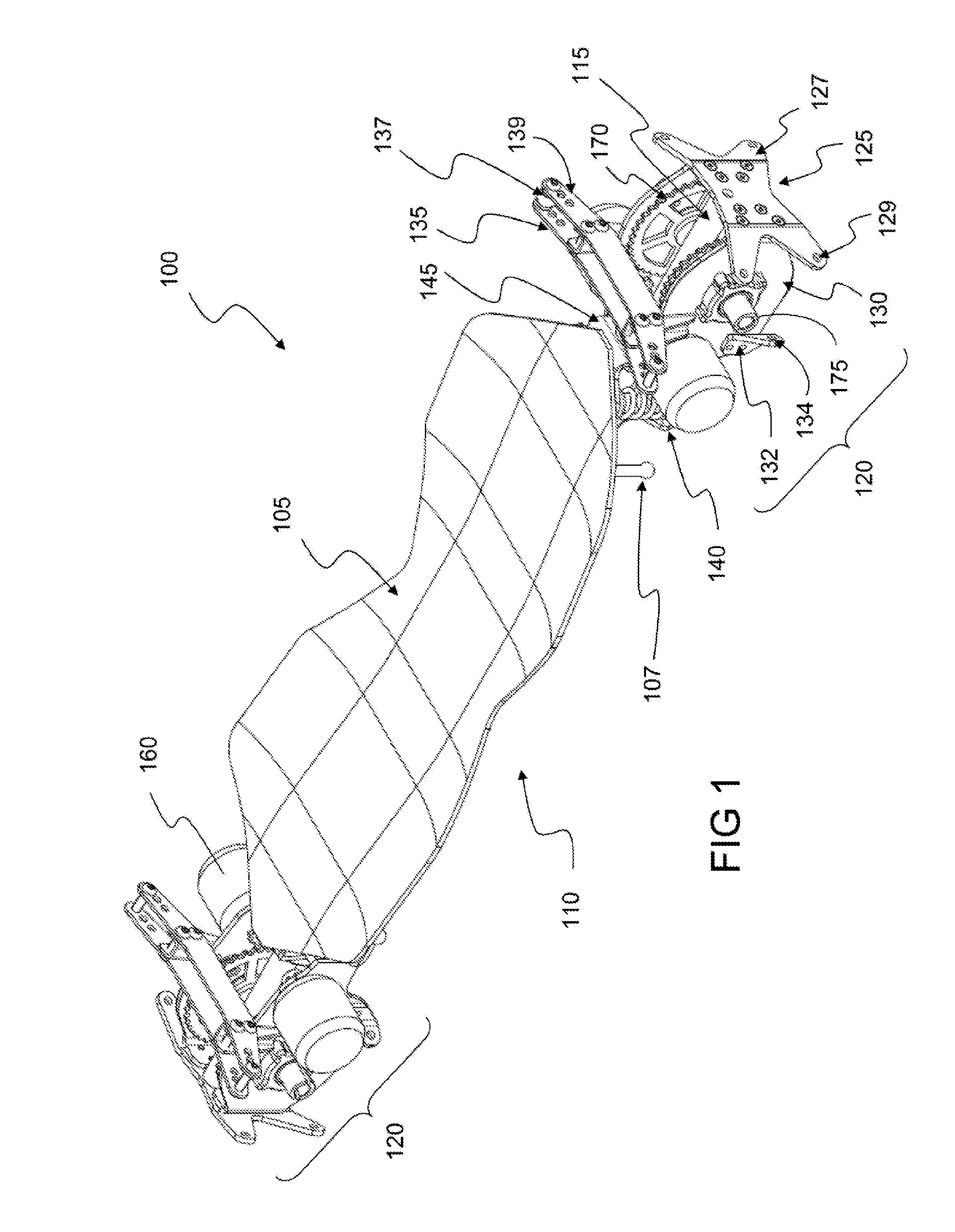

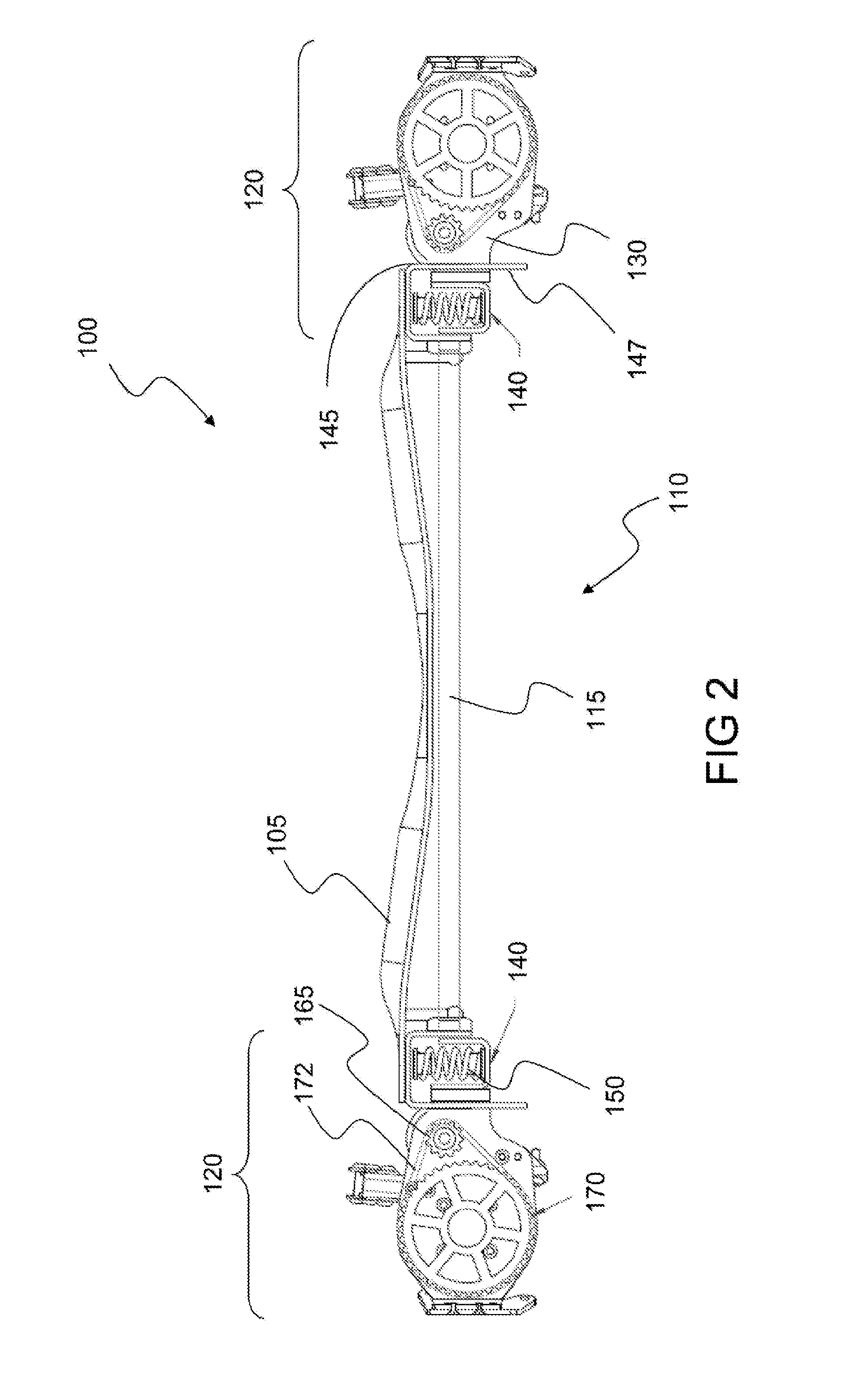

Apparatus for board sports

InactiveUS20160206949A1Reduce scrollingImproved and adjustable steering and handlingElectric propulsion mountingSkate-boardsEngineeringCaster

A wheeled apparatus for board sports is provided. The wheeled apparatus includes a board, a plurality of wheels supported by a plurality of steering knuckles, and at least one linkage between the board and the steering knuckles. The at least one linkage enables a camber and / or a caster and / or a toe angle of the wheels to be adjusted by pivoting the board.

Owner:BAJABOARD INT

Stabilizer device and stabilizer system

ActiveUS20200180386A1Robust structureRoll of the vehicle body is thus effectively reducedInterconnection systemsResilient suspensionsVertical motionElectrical and Electronics engineering

Owner:TOYOTA JIDOSHA KK

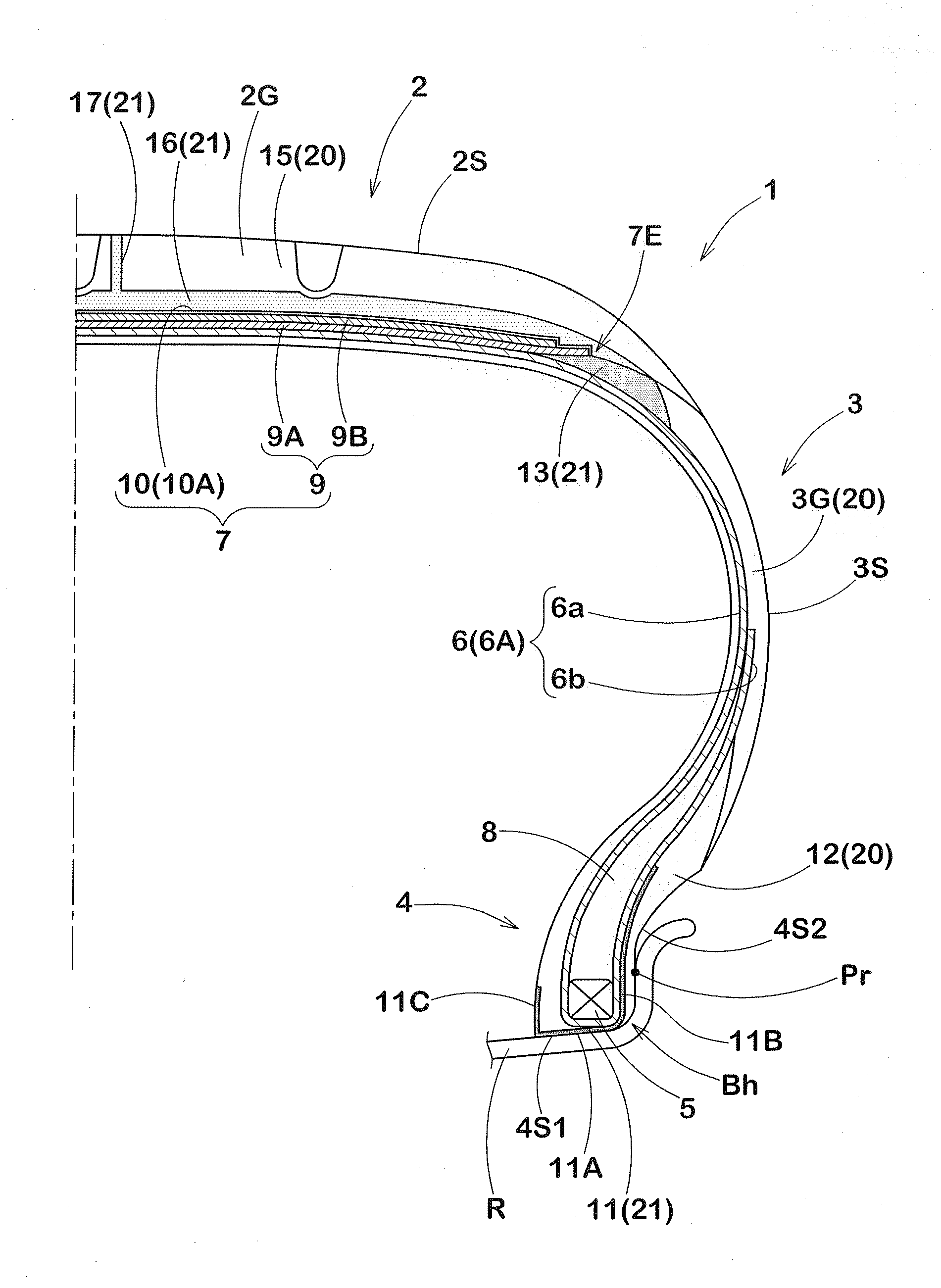

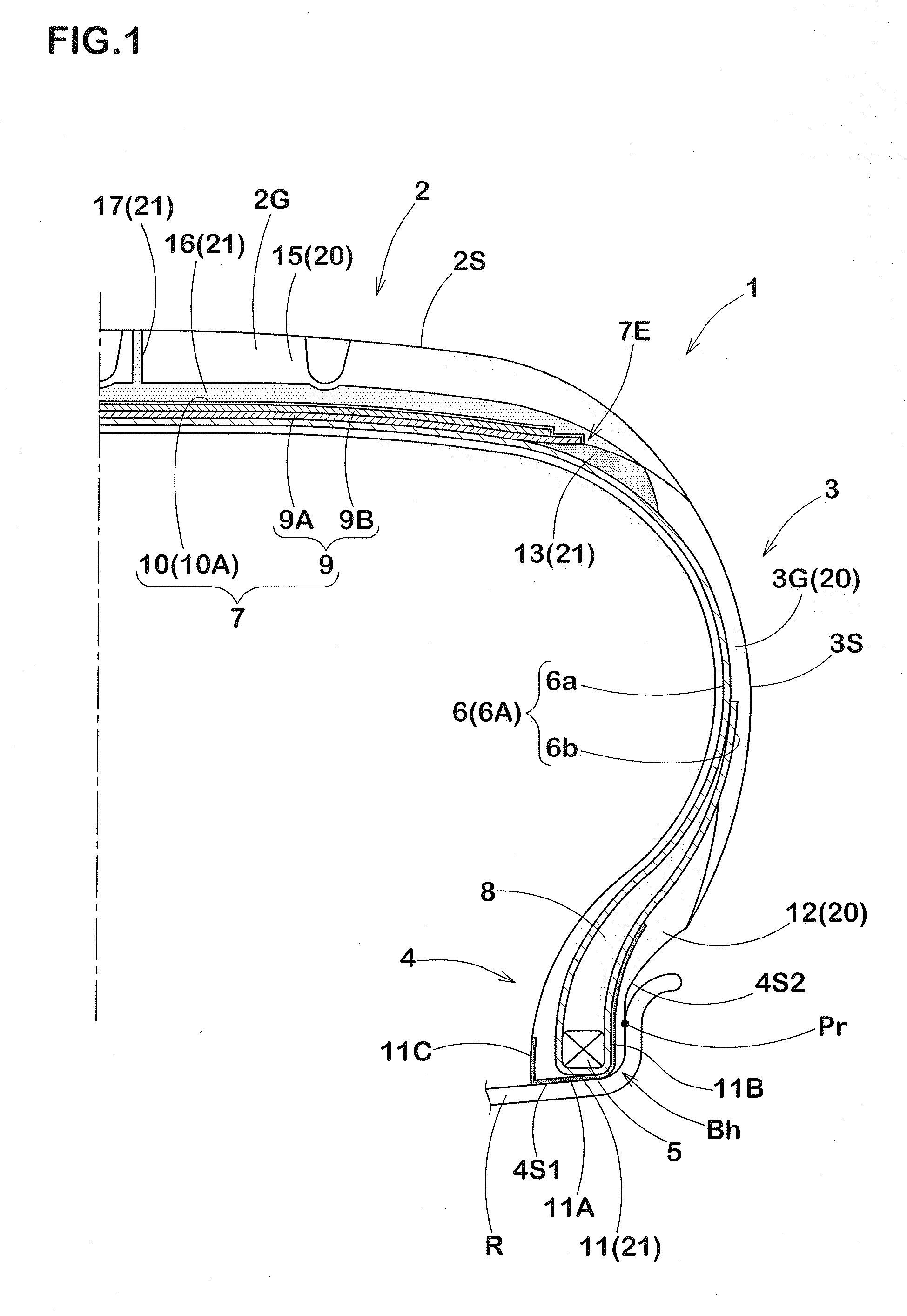

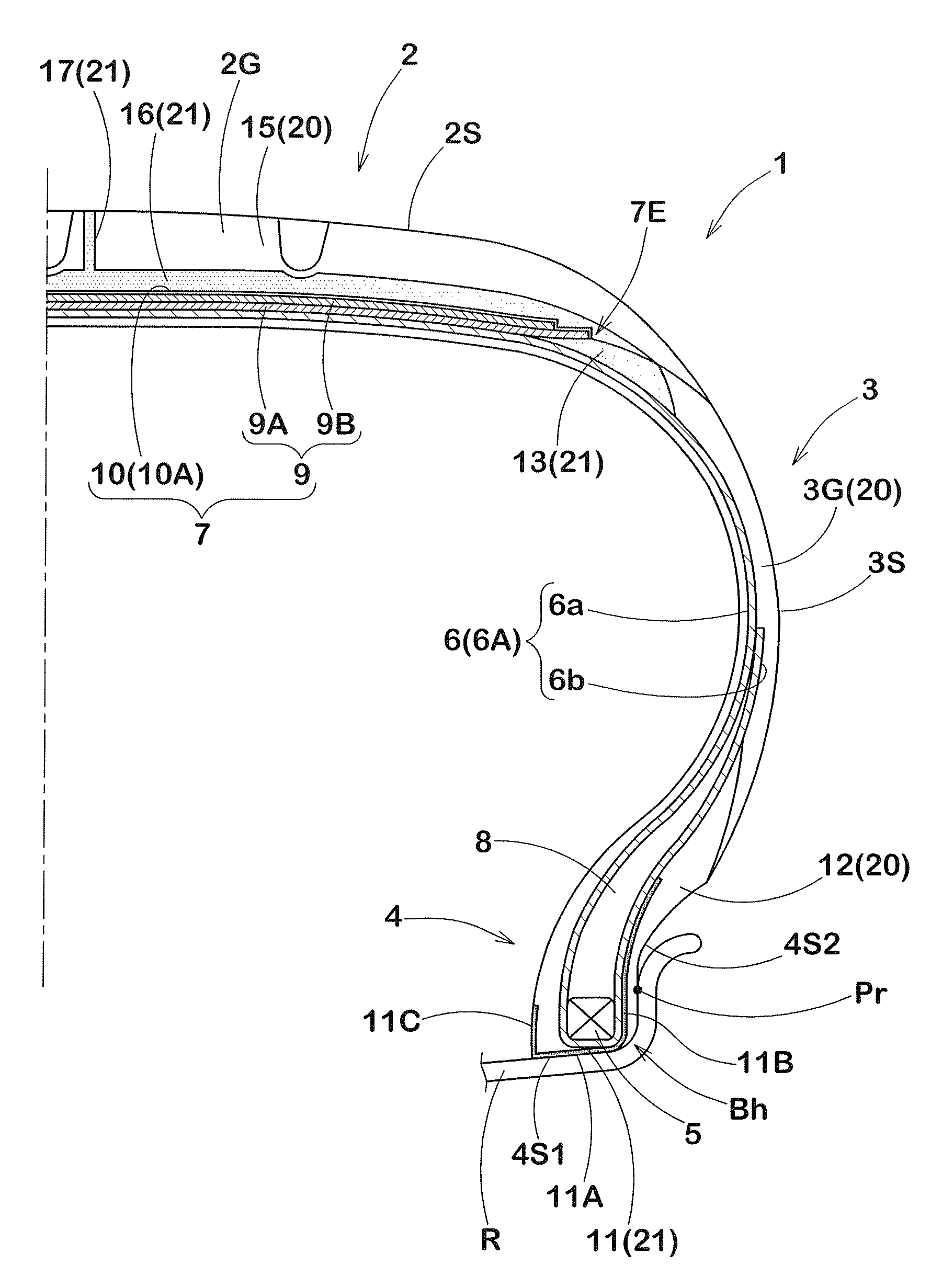

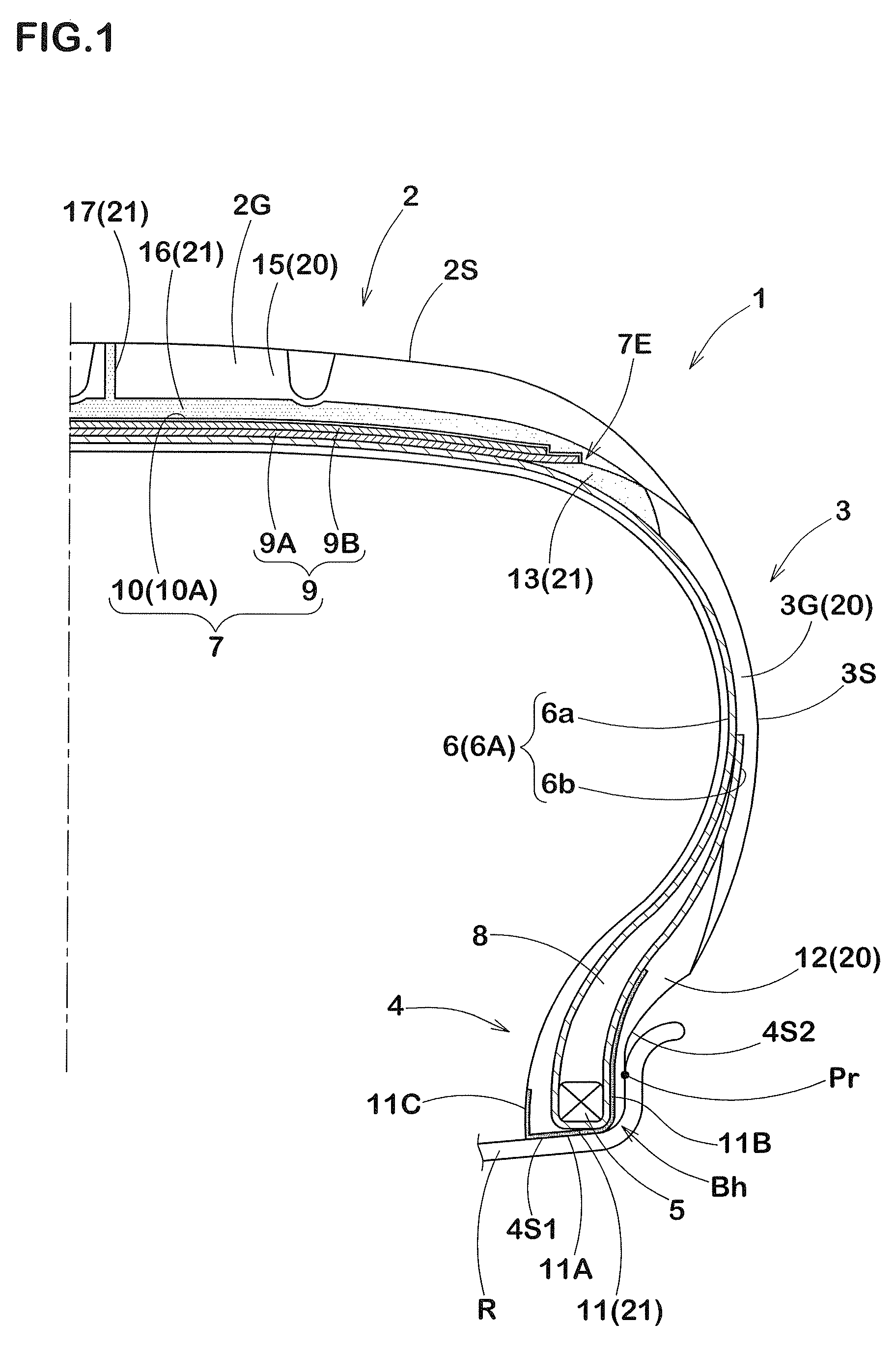

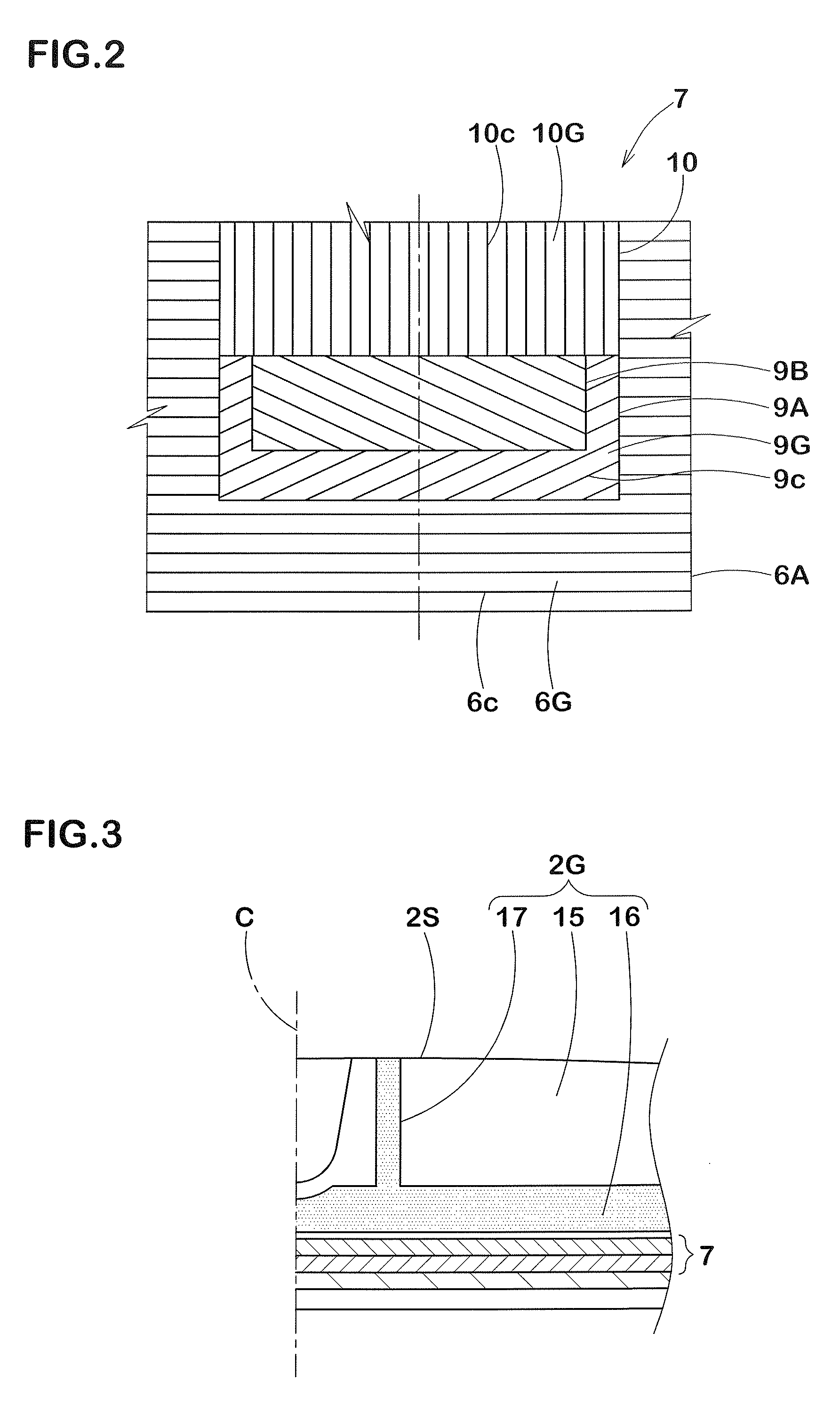

Pneumatic tire

InactiveUS20100243115A1Excellent low rolling resistanceReduce scrollingSpecial tyresPneumatic tyre reinforcementsGround contactRubber material

Accumulation of static electricity is prevented while enhancing rolling resistance performance of tire. Tread rubber 2G has tread rubber body 15 forming tread ground contact surface 2S, under tread 16 disposed radially inward of the tread rubber body, and terminal portion 17 penetrating the tread rubber body in the radial direction, the under tread 16 being in contact with cushion rubbers 13 each having cushion main portion 13A interposed between edge portion 7E of tread-reinforcing layer 7 and carcass 6 over an overlap width W1 of 1 mm or more. Tread rubber body 15, topping rubber 7G of tread-reinforcing layer 7 and sidewall rubbers 3G are made of an insulating rubber material 20 having a volume resistivity of at least 1×108 Ω·cm, and under tread 16, terminal portion 17, cushion rubber 13, topping rubber 6G of carcass 6 and chafer rubber 11 are made of a conductive rubber material having a volume resistivity of less than 1×108 Ω·cm.

Owner:SUMITOMO RUBBER IND LTD

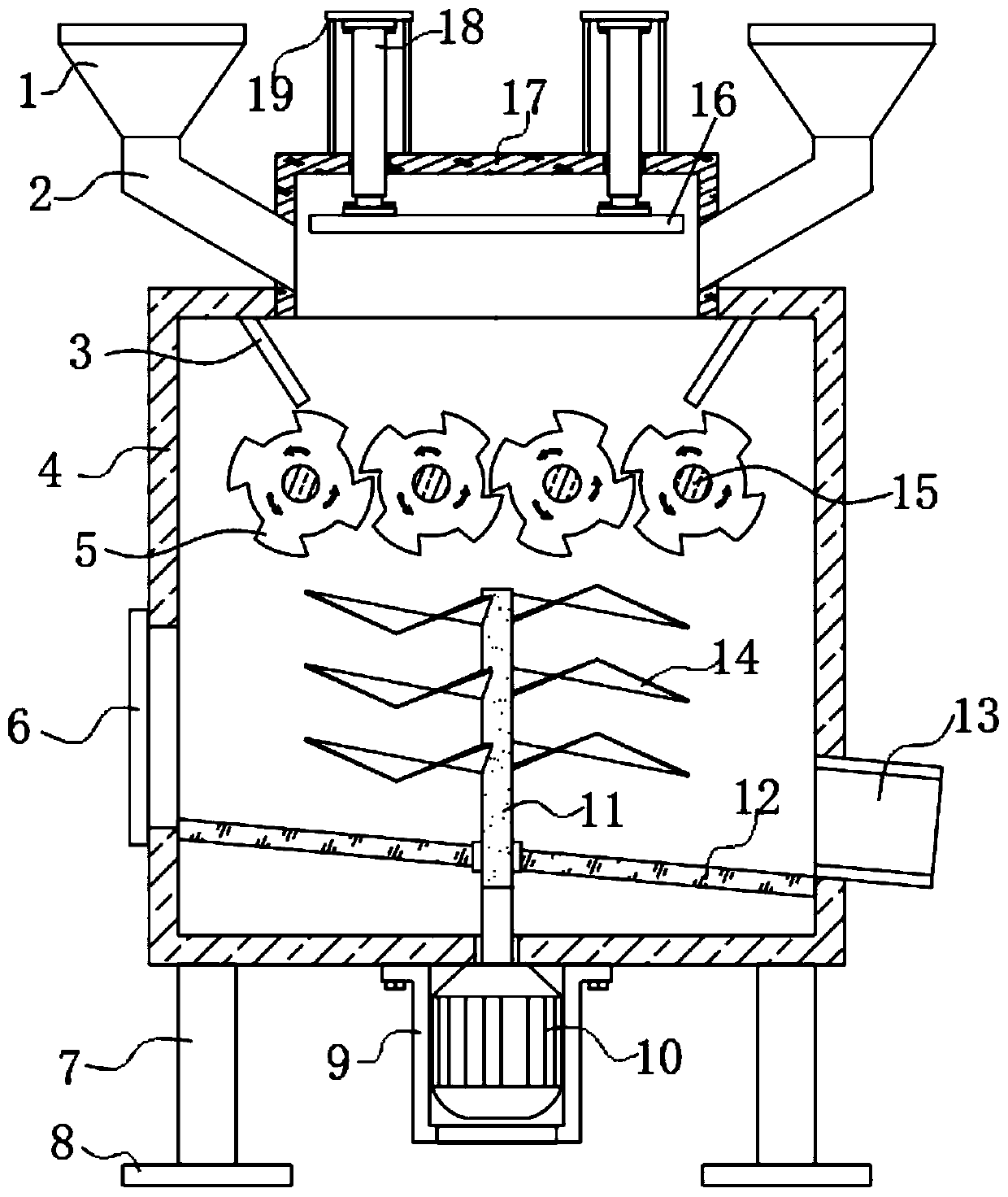

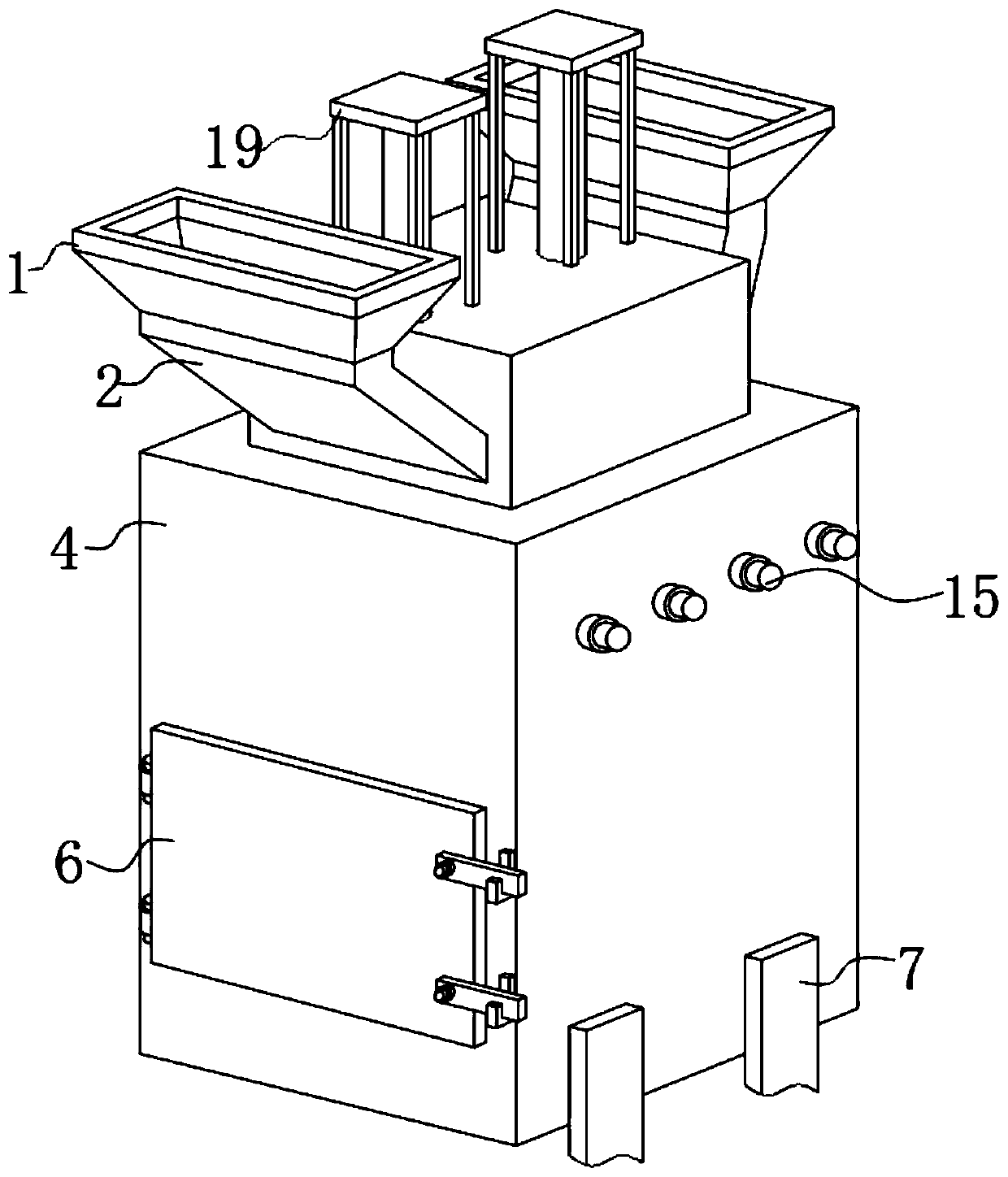

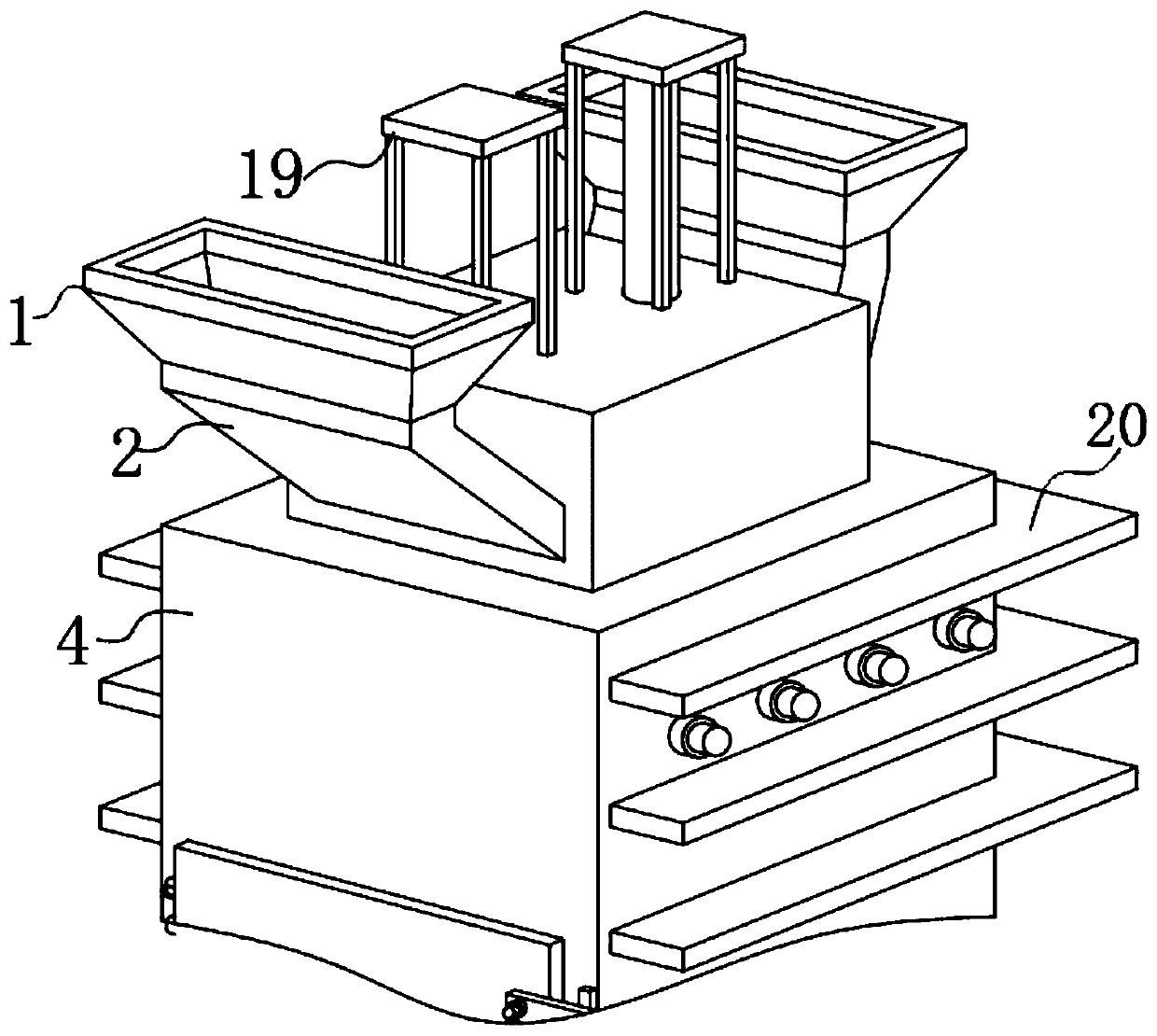

Lithium battery recovery device

InactiveCN110681474AReduce scrollingCrushing accelerationWaste accumulators reclaimingGrain treatmentsStructural engineeringMechanical engineering

The invention discloses a lithium battery recovery device, relates to the technical field of lithium battery recovery, and solves the problem that a traditional lithium battery recovery device cannotpress fed materials. The lithium battery recovery device specifically comprises a box body, a pressing mechanism and a pulverizing mechanism; a feed hole is formed in the outer wall of the top of thebox body; the pressing mechanism comprises a bottomless cover shell; the side wall, near the bottom end, of the cover shell is fixedly connected to the inner wall of the feed hole; two through holes are formed in the top of the cover shell; two mounting bases are fixedly connected to the top of the cover shell; electric extension rods are fixed on the outer walls of the bottoms of the mounting bases through bolts; the bottom ends of the two electric extension rods are positioned in the cover shell after penetrating through the through holes; and the same pressing plate is fixed at the bottom ends of the two electric extension rods through bolts. The lithium battery recovery device can press the fed materials, and assists a tooth-shaped pulverizing wheel to achieve better and quicker pulverization.

Owner:湖南金凯循环科技股份有限公司

Diaphragm for speaker device, speaker device and mobile phone

A diaphragm of a speaker device, formed into an elongated configuration, has a recessed shape and includes a voice coil arrangement part extending in its longitude direction. The voice coil arrangement part has a gap with a constant width in its lateral direction and includes a voice coil supporting part for supporting a voice coil and an expanded part provided at a position along it.

Owner:PIONEER CORP +1

Fuel-saving accelerator

InactiveCN103016211AAvoid smallDischarge in timeMachines/enginesSecondary air addition to fuelAir filterBiomedical engineering

A fuel-saving accelerator comprises a vacuum membrane seat and a fixing seat, wherein the vacuum membrane seat comprises a first membrane seat, a second membrane seat, and a membrane clamped between the first membrane seat and the second membrane seat; the first membrane seat and the second membrane seat are buckled in a sealed manner; the fixing seat comprises two ends; a first through hole penetrating two ends of the fixing seat is formed in the center of the fixing seat; one end of the through hole is in screwed connection with a first screw of the second membrane seat; a pipe joint is connected with the other end of the through hole; a plurality of breathing holes used for connecting an air filter are formed in the fixing seat in positions near a wall of a second screw; a circular groove is formed in the inner wall of the first through hole; the inner end openings of the breathing holes are formed in the circular groove; and a second through hole is communicated with the circular groove.

Owner:浙江宇嘉新能源科技股份有限公司

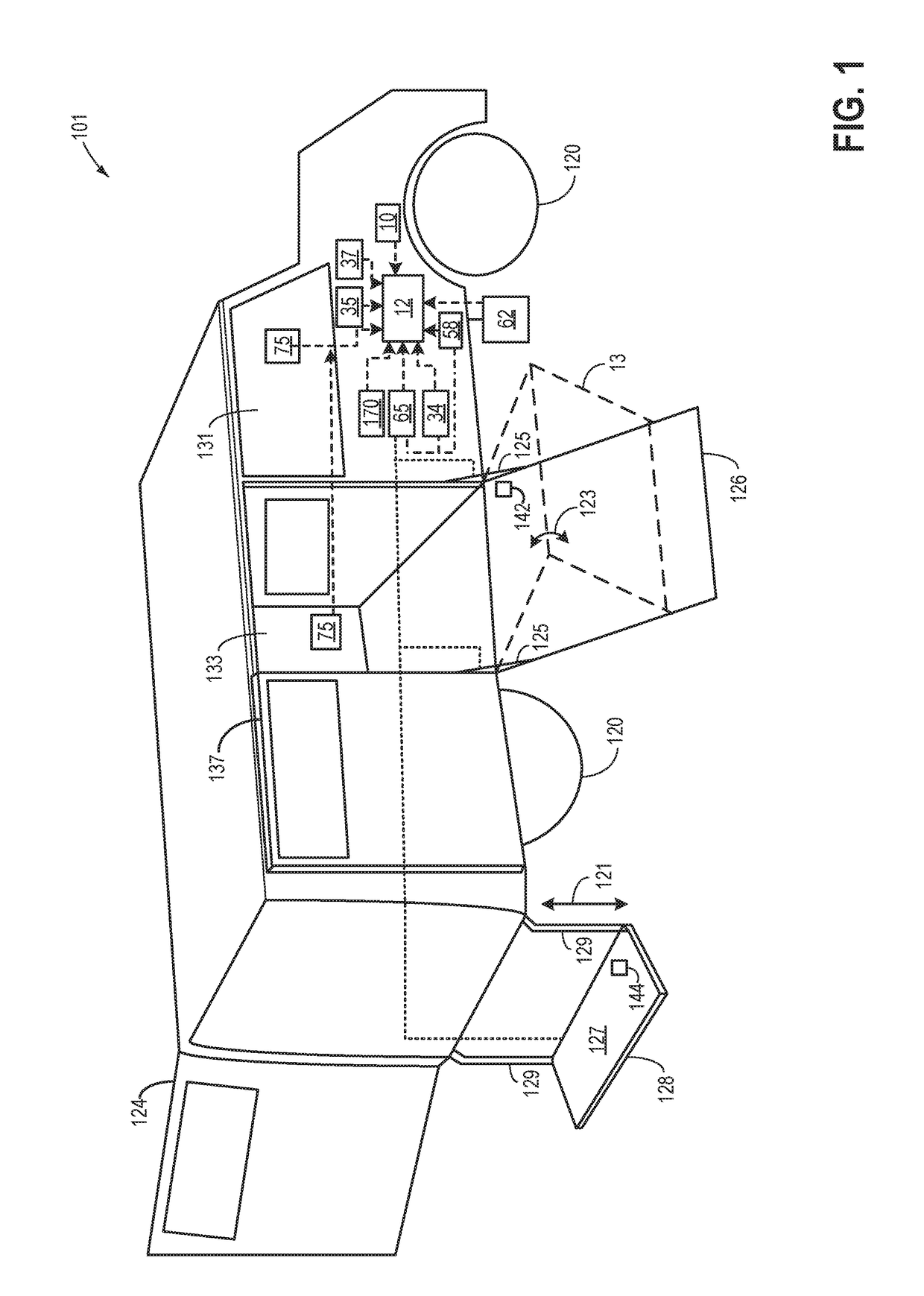

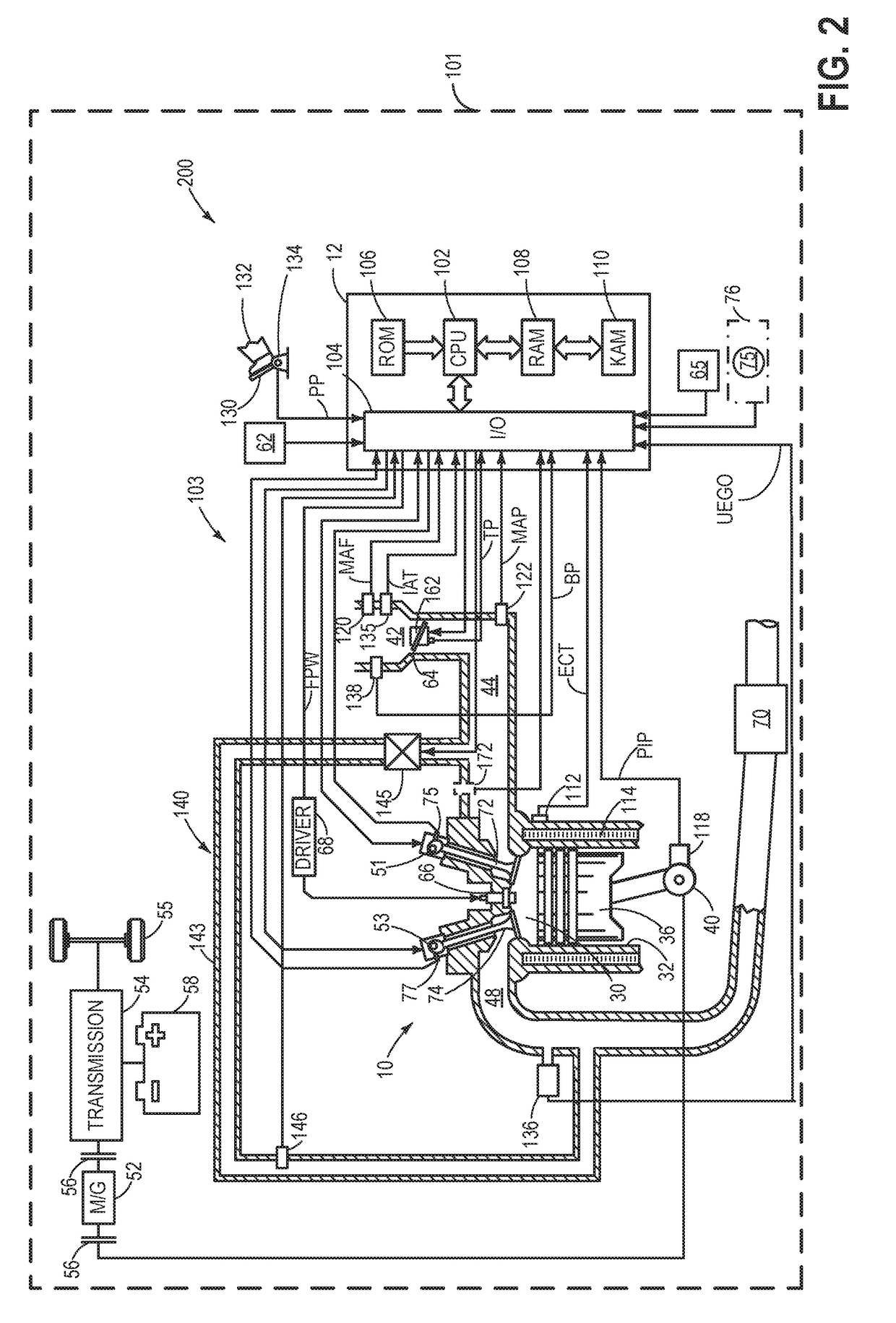

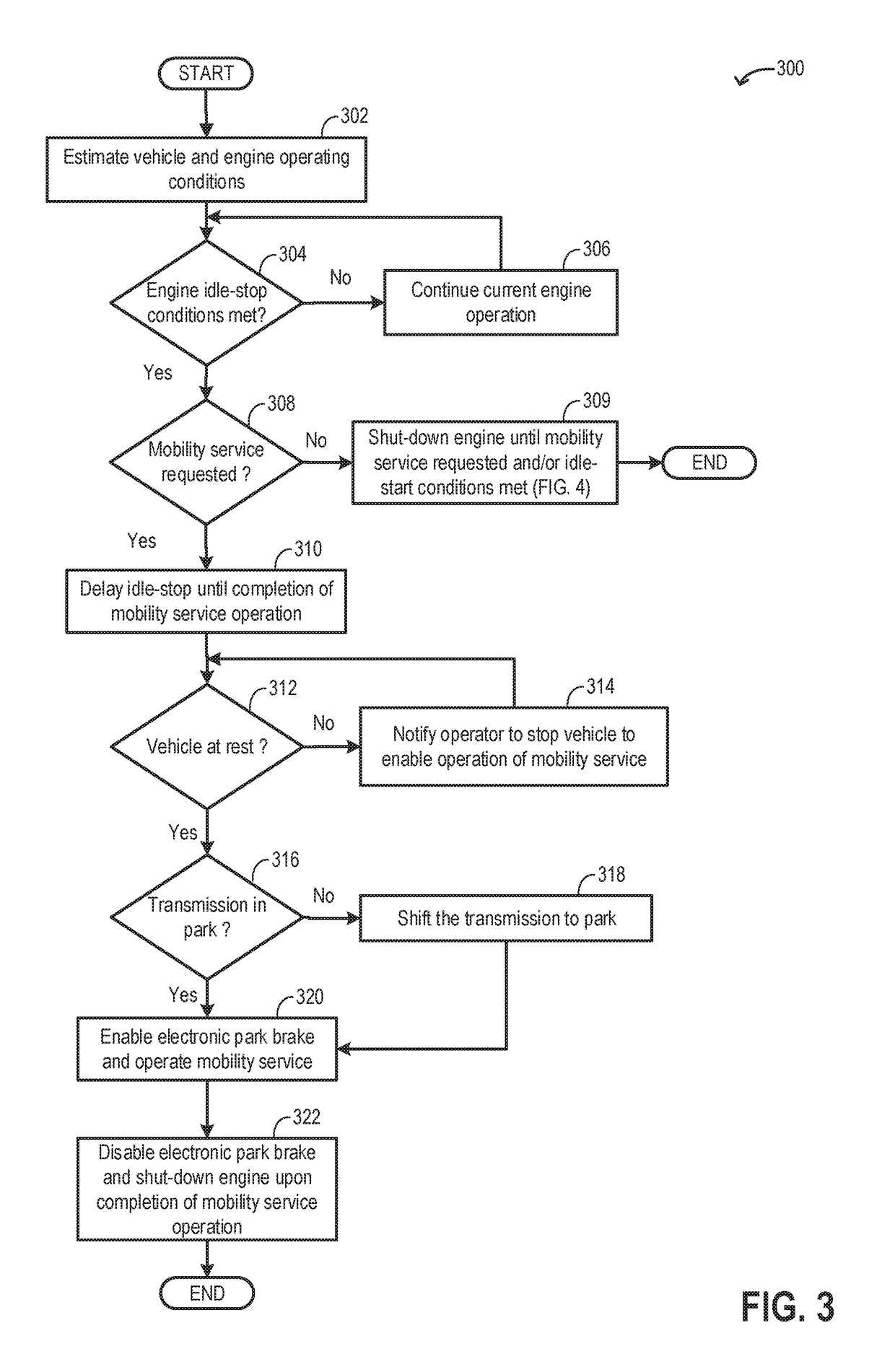

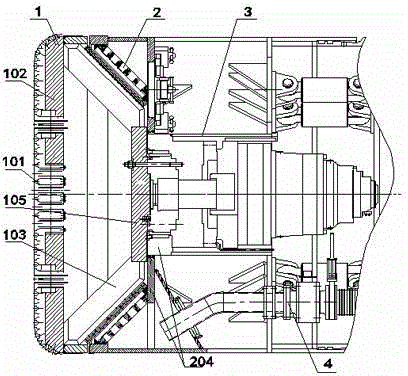

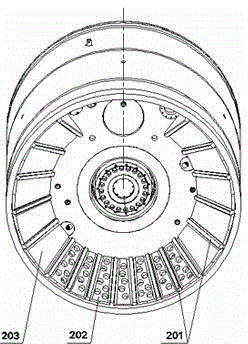

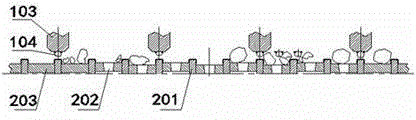

Methods and systems for operating a mobility service vehicle

ActiveUS20180344545A1Improve coordinationEasy to operateVehicle with raised loading platformVehicle fittings for lifting and manoeuvringMobile serviceBraking system

Methods and systems are provided for operation of a lifting mechanism coupled to a mobility service vehicle. In one example, a method may include, during an engine idle-stop, in response to a request for operation of a lifting mechanism used by mobility devices to access the vehicle, the transmission may be shifted to park, an electronic braking system may be enabled, and the engine may be restarted to provide power for operation of the lifting mechanism.

Owner:FORD GLOBAL TECH LLC

Variable-position shearing and breaking device of compound stratum pipe pushing machine

The invention discloses a variable-position shearing and breaking device of a compound stratum pipe pushing machine and relates to the technical field of tunneling. A tool disc is arranged at the front end of the pipe pushing machine, the output end of a main driving device is fixedly connected with a flange of the tool disc, and the main driving device is fixedly connected with a pressure cabin partition of an anterior shield cone ring. When the main driving device drives the tool disc to rotate along a rotary central shaft, an active breaking plate of the tool disc rotates along a bracket and generate alternative shear space relative to the anterior shield cone ring, large rock can be passively stopped by a baffle when rotating along with the active breaking plate and can be broken into many small rocks by shearing force as the principal and extrusion force as the auxiliary, and the small broken rocks can be discharged to a discharge device via slag holes in a trapezoidal slag discharge plate, and a bus of the conical surface formed spatially is parallel to the bus of the spatial conical surface formed by the anterior shield cone ring when the bracket rotates. Accordingly, large rocks can be broken by the variable-position shear space, and invalid rolling is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

Stabilizer device and stabilizer system

ActiveUS11192424B2Roll of the vehicle body is thus effectively reducedReduce scrollingInterconnection systemsResilient suspensionsEngineeringControl theory

Owner:TOYOTA JIDOSHA KK

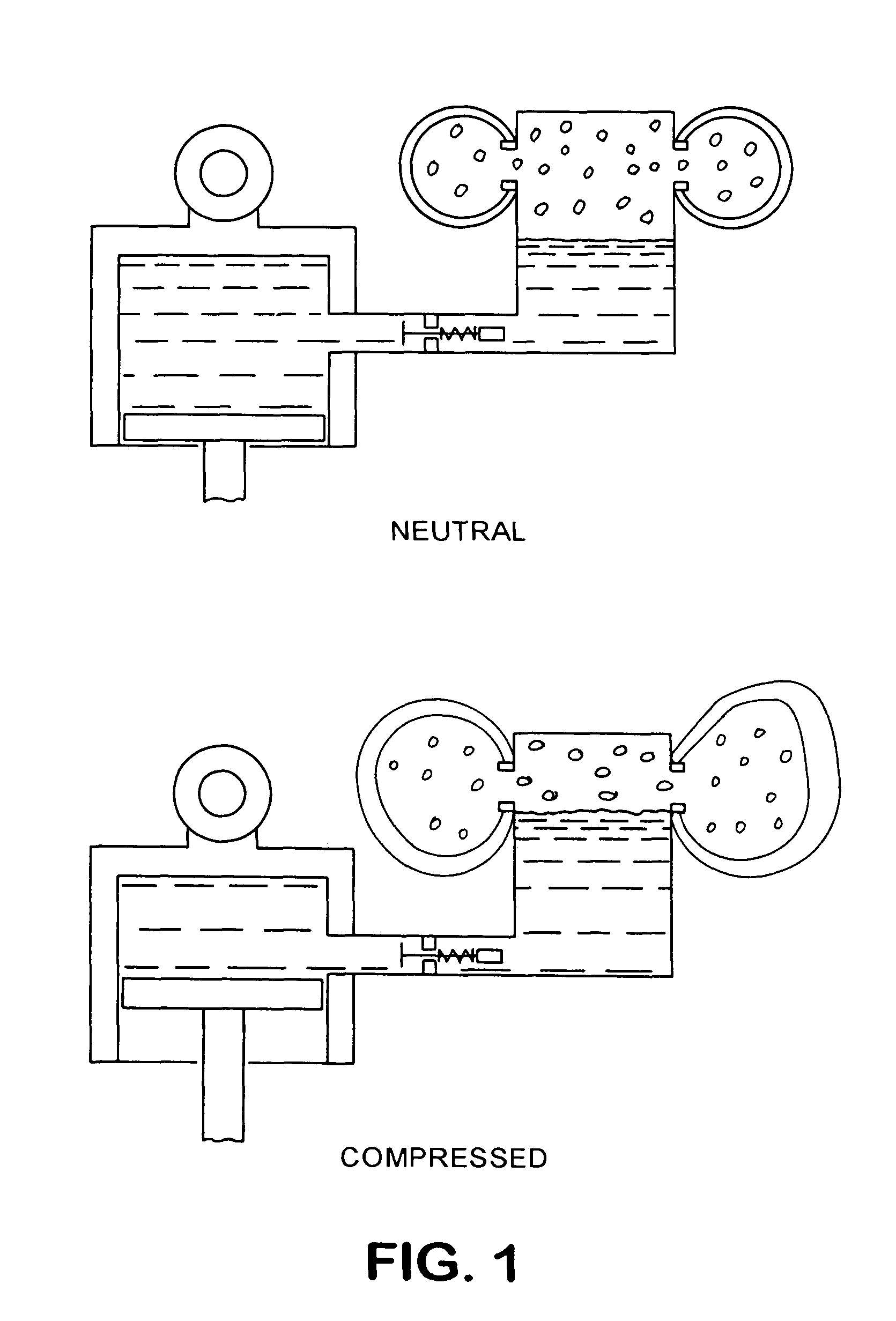

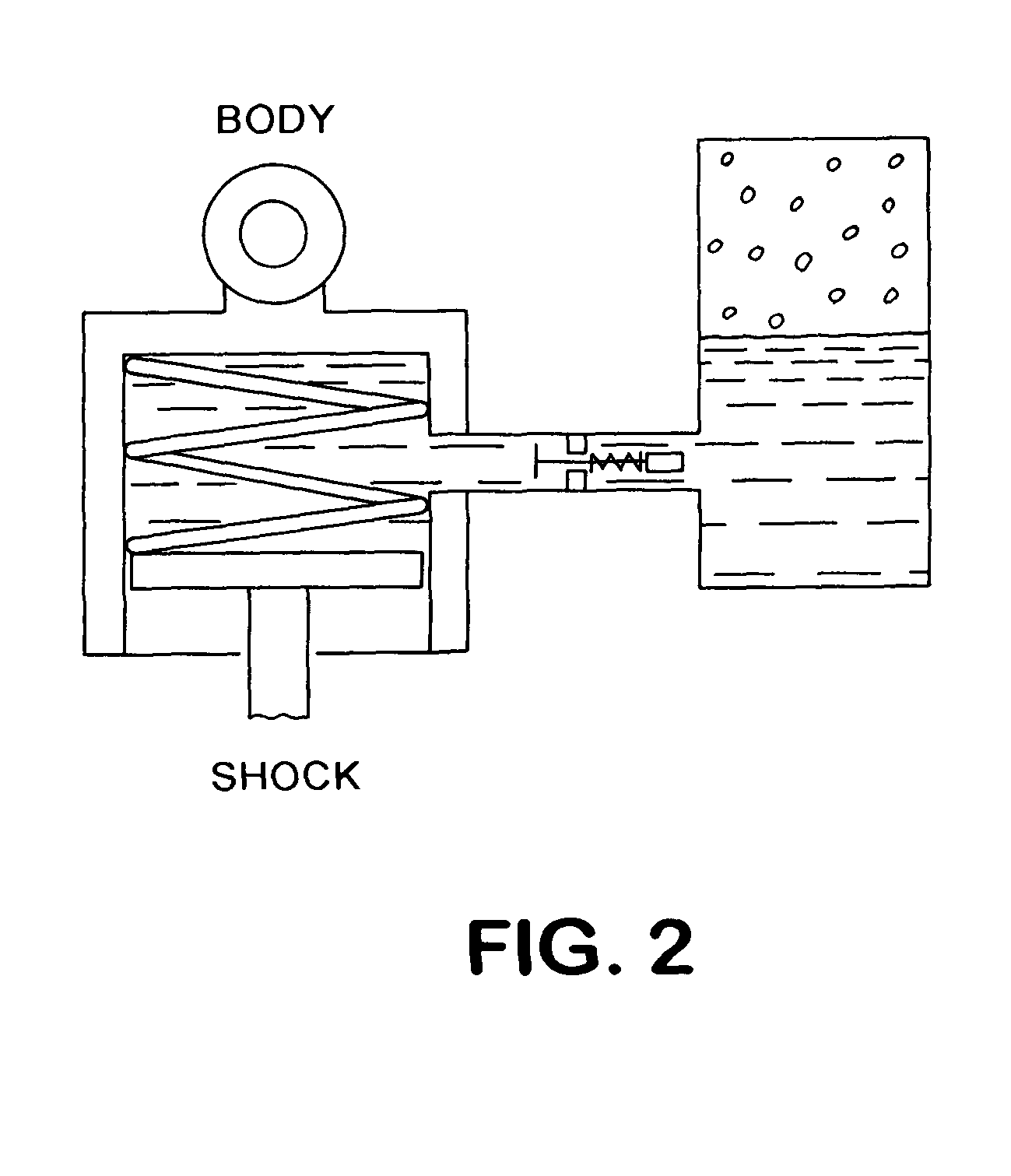

Variable response bushing

InactiveUS8627930B2Reducing and eliminating compressionReduce and eliminate rollSpringsFluid steeringEngineeringHardness

Owner:OMEGAD LLC

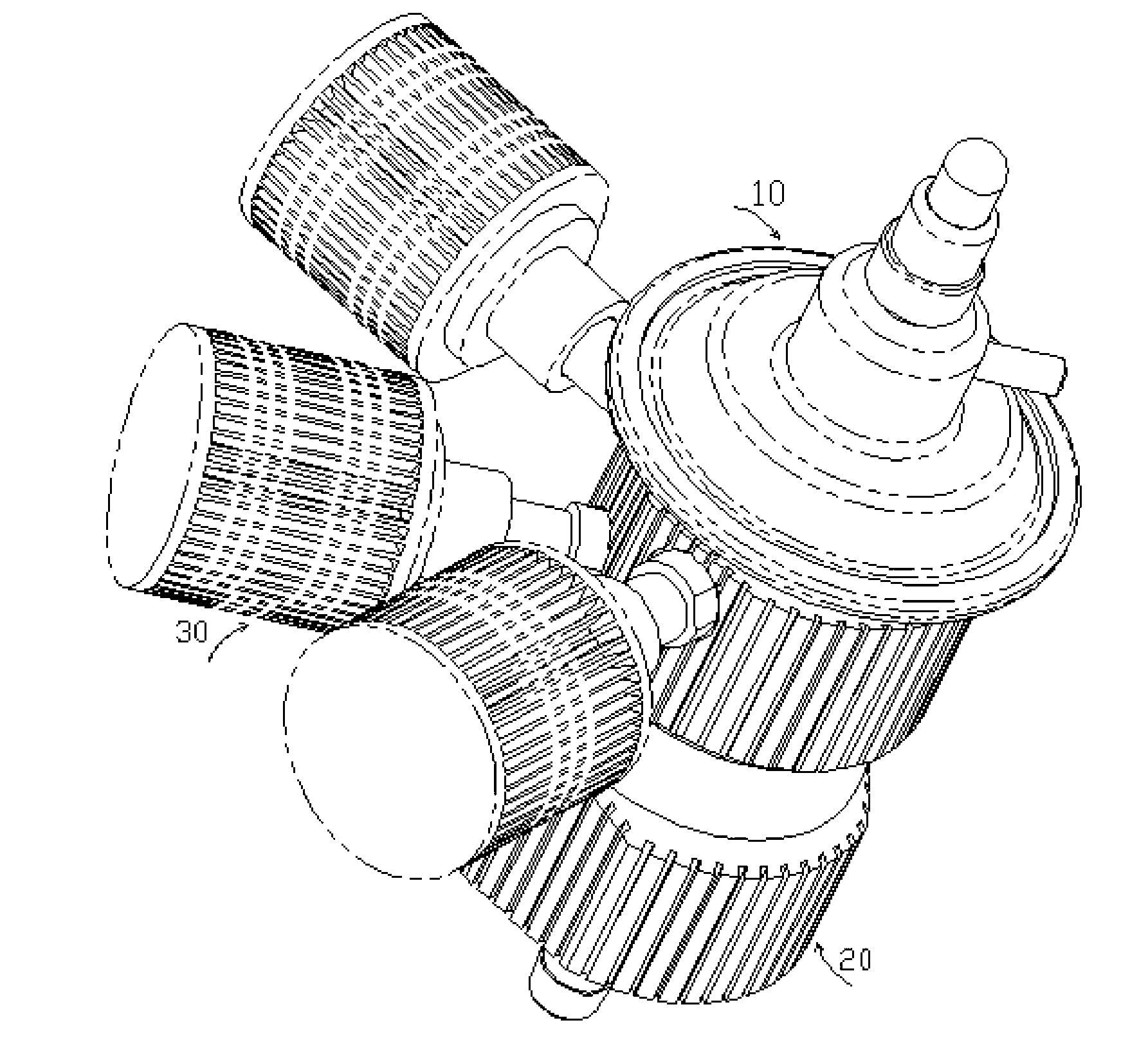

Electric fin stabilizer

ActiveUS9944363B2Reduce usageEasy to installVessel movement reduction by foilsAttitude controlMarine engineeringControl signal

A marine vessel stabilizer and control including a fin having a stem extending into the hull. An arm is connected to the stem and extends towards a connector which is connected to a rod. A housing is connected to another end of the rod and a screw passes through the housing. A motor is connected to the screw and configured to rotate to rotate the fin. A controller is connected to the motor, a speed sensor, a roll sensor and a fin position sensor such that a control signal can be calculated and the position of the fin can be determined to reduce roll of the vessel both when making headway and when at rest (zero speed). When the vessel is at rest, the fin is be configured to rotate through maximum angles greater than 15 degrees from either side of a neutral position.

Owner:NAIAD MARITIME GRP

Apocynum venetum fiber blending antibiosis, cool and comfortable yarn and preparing method thereof

The invention discloses apocynum venetum fiber blended antibiosis, cool and comfortable yarn and a preparing method thereof. The apocynum venetum fiber blended antibiosis, cool and comfortable yarn comprises, by weight, 15-30 percent of apocynum venetum fiber, 35-50 percent of aloe viscose and 35-45 percent of milk fiber. The performance indexes of the blended yarn comprise the single-yarn breaking strength ranging from 11.5 cN / tex to 21.2 cN / tex, the single-yarn breaking strength variable coefficient Cv value ranging from 7.9 percent to 17.0 percent, and the yarn evenness variable coefficient Cv value ranging from 13.5 percent to 19.6 percent. The apocynum venetum fiber blended antibiosis, cool and comfortable yarn has the advantages that the fabric made of the blended yarn has the healthcare functions of antibiosis, antiphlogosis, skin protection, body building, face beautifying, skin moistening and the like, the fabric is high in strength, good in wet absorbing and breathable performance and dyeing performance, soft in hand feeling, good in moistening performance and mold-proof and moth repellency and wide in product usage range, and the fabric can be used for manufacturing various clothes, bedclothes, underwear, sportswear, fitness clothes and other various knitted or woven healthcare textiles.

Owner:ZHONGYUAN ENGINEERING COLLEGE

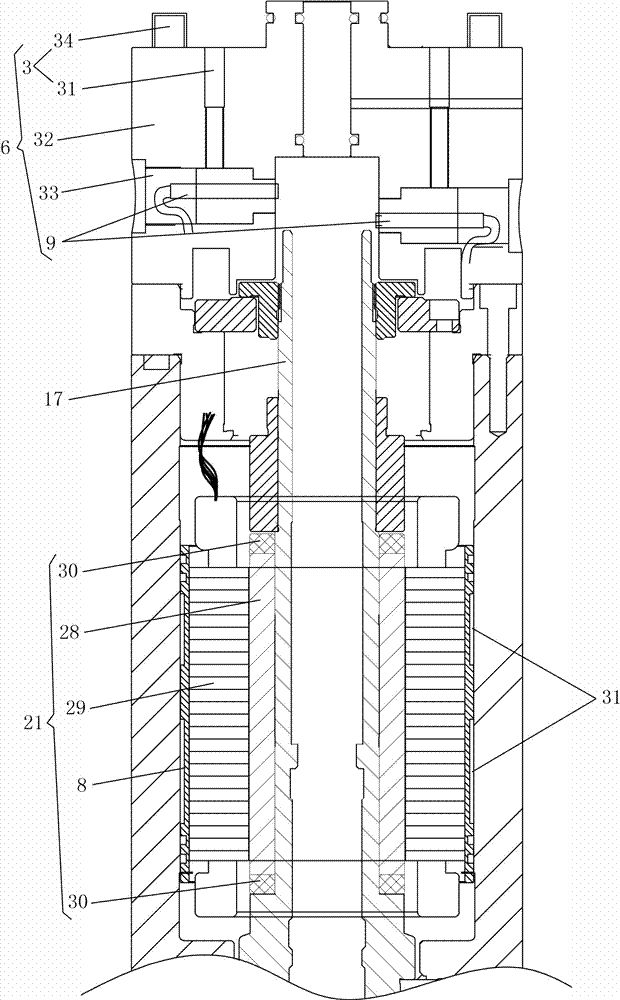

Electric spindle capable of realizing automatic tool changing and provided with build-in shank

PendingCN107042420AImprove structural strengthRealize automatic tool changeFeeding apparatusMaintainance and safety accessoriesBall bearingStator coil

The invention relates to an electric spindle capable of realizing automatic tool changing and provided with a build-in shank. A spindle body is provided with a cooling mechanism and comprises a spindle box, a back seat and a dust cover; spindle assemblies are press-fitted in the spindle box; the back seat and the dust cover are arranged at two ends of the spindle box; the spindle assemblies are fixedly mounted in the spindle box through cooling copper sleeves; a detection device and a control device are arranged on the back seat; one end of each spindle assembly is in transmission connection with a driving device; and the other end of each spindle assembly is detachably connected with an external device. The electric spindle has the beneficial effects as follows: a stator coil outer sleeve is changed from a steel piece into a brass casting, a circulating water-cooling channel is added in the casting outer sleeve, the temperature is prevented from increasing too fast, the operation precision of the spindle is kept, a clamping jaw and the shank are organically combined, meanwhile, a built-in encoder connected with a control center is configured, functions of automatic tool changing, instant accurate stop and the like are realized, a rotor magnetic piece is in short-circuited connection through an end copper ring, the consumption is reduced, a steel angular contact ball bearing is replaced with a ceramic ball bearing, the friction and the heat are reduced, and the life is prolonged.

Owner:岳阳市显隆电机有限公司

Diaphragm, speaker unit using same, headphone and earphone, and diaphragm manufacturing method

ActiveUS20190289401A1Improve displacement symmetryExcellent reproduce sound qualityEarpiece/earphone attachmentsNon-planar diaphragms/conesLoudspeakerEngineering

An edge portion of a diaphragm is configured such that multiple recessed ribs formed by recessing of a raised surface are provided in an inclination direction inclined with respect to a radial line passing through a center point and are arranged rotationally symmetrically, and among the recessed ribs and a fixing portion defined on the outermost peripheral side of the diaphragm, defines an outer peripheral edge portion at which no recessed ribs are formed. A voice coil is coupled to a voice coil attachment portion. A lead line is fixed with a first adhesive forming a first adhesive layer along a valley portion defined between a certain recessed rib and an adjacent recessed rib thereof on a back side of the edge portion, and is further fixed with a second adhesive forming a second adhesive layer with the lead line being curved along the outer peripheral edge portion.

Owner:ONKYO KK

Pneumatic tire with electrically conductive rubber material

InactiveUS8336589B2Reduce scrollingIncrease heightSpecial tyresPneumatic tyre reinforcementsRubber materialGround contact

Accumulation of static electricity is prevented while enhancing rolling resistance performance of tire. Tread rubber 2G has tread rubber body 15 forming tread ground contact surface 2S, under tread 16 disposed radially inward of the tread rubber body, and terminal portion 17 penetrating the tread rubber body in the radial direction, the under tread 16 being in contact with cushion rubbers 13 each having cushion main portion 13A interposed between edge portion 7E of tread-reinforcing layer 7 and carcass 6 over an overlap width W1 of 1 mm or more. Tread rubber body 15, topping rubber 7G of tread-reinforcing layer 7 and sidewall rubbers 3G are made of an insulating rubber material 20 having a volume resistivity of at least 1×108 Ω·cm, and under tread 16, terminal portion 17, cushion rubber 13, topping rubber 6G of carcass 6 and chafer rubber 11 are made of a conductive rubber material having a volume resistivity of less than 1×108 Ω·cm.

Owner:SUMITOMO RUBBER IND LTD

Charging material for blast-furnace smelting and blast-furnace smelting method

InactiveCN107586903AHigh degree of reductionReduce return rateBlast furnace detailsAlkalinityIron powder

The invention discloses a charging material for blast-furnace smelting and a blast-furnace smelting method. The charging material for blast-furnace smelting comprises components in parts by weight asfollows: 60-85 parts of alkaline sintered ore, 10-20 parts of acid pellets and 0-5 parts of geological minerals, wherein alkalinity of the alkaline sintered ore is 2.2-2.3, and alkalinity of the acidpellets is 0.2-0.4; the alkaline sintered ore is prepared from 40-50 parts by weight of vanadium bearing titanomagnetite, 5-10 parts by weight of common fine iron powder, 5-15 parts by weight of boron-bearing iron ore powder, 1-5 parts by weight of SiC powder and 6-10 parts by weight of CaO as raw materials through sintering; the acid pellets are prepared from 50-60 parts by weight of the vanadiumbearing titanomagnetite, 5-10 parts by weight of common fine iron powder, 1-2 parts by weight of magnesite, 3-5 parts by weight of dolomite and 1-2 parts by weight of bentonite as raw materials through sintering. According to the blast-furnace smelting method adopting the charging material for blast-furnace smelting, liquidity of iron slag can be guaranteed, a slag charge structure is changed, slag basicity is reduced, effective availability of the charging material for blast-furnace smelting is improved, blast-furnace smelting efficiency is improved, and smelting cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

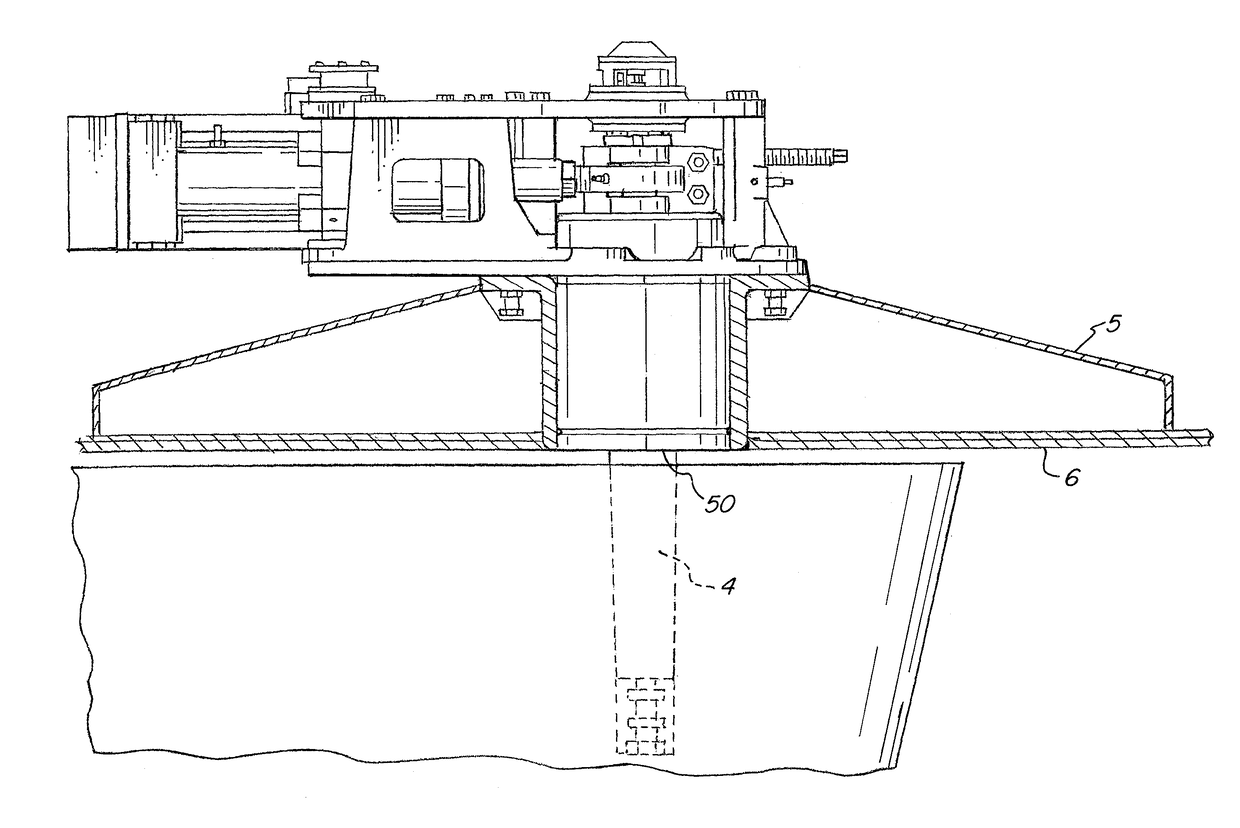

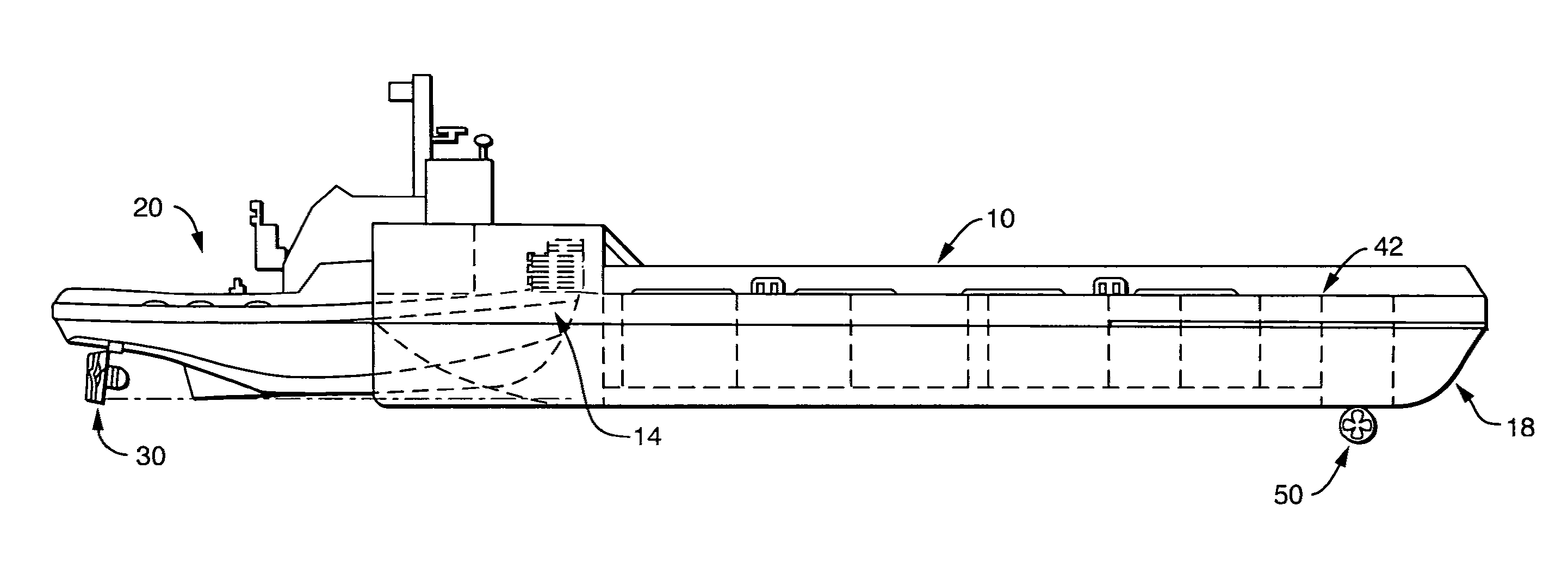

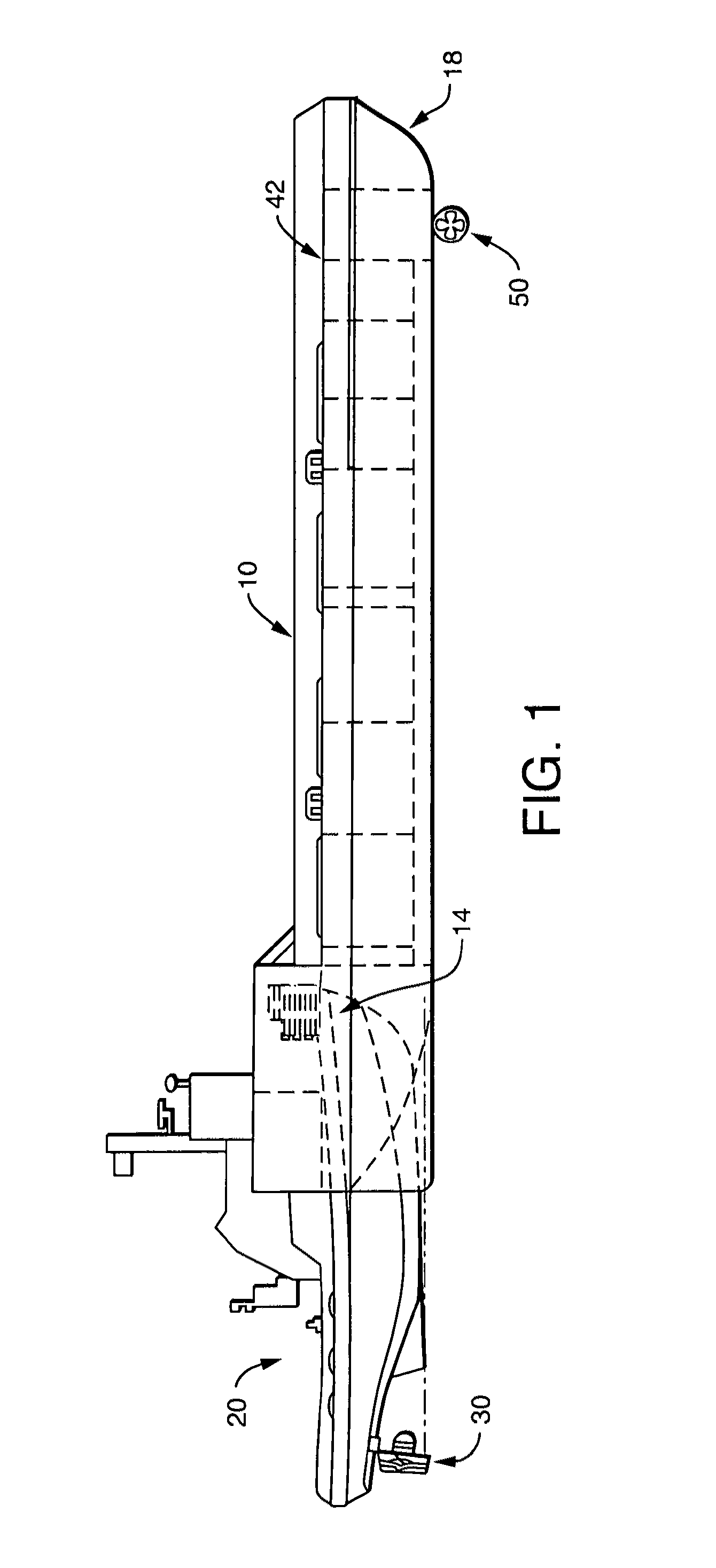

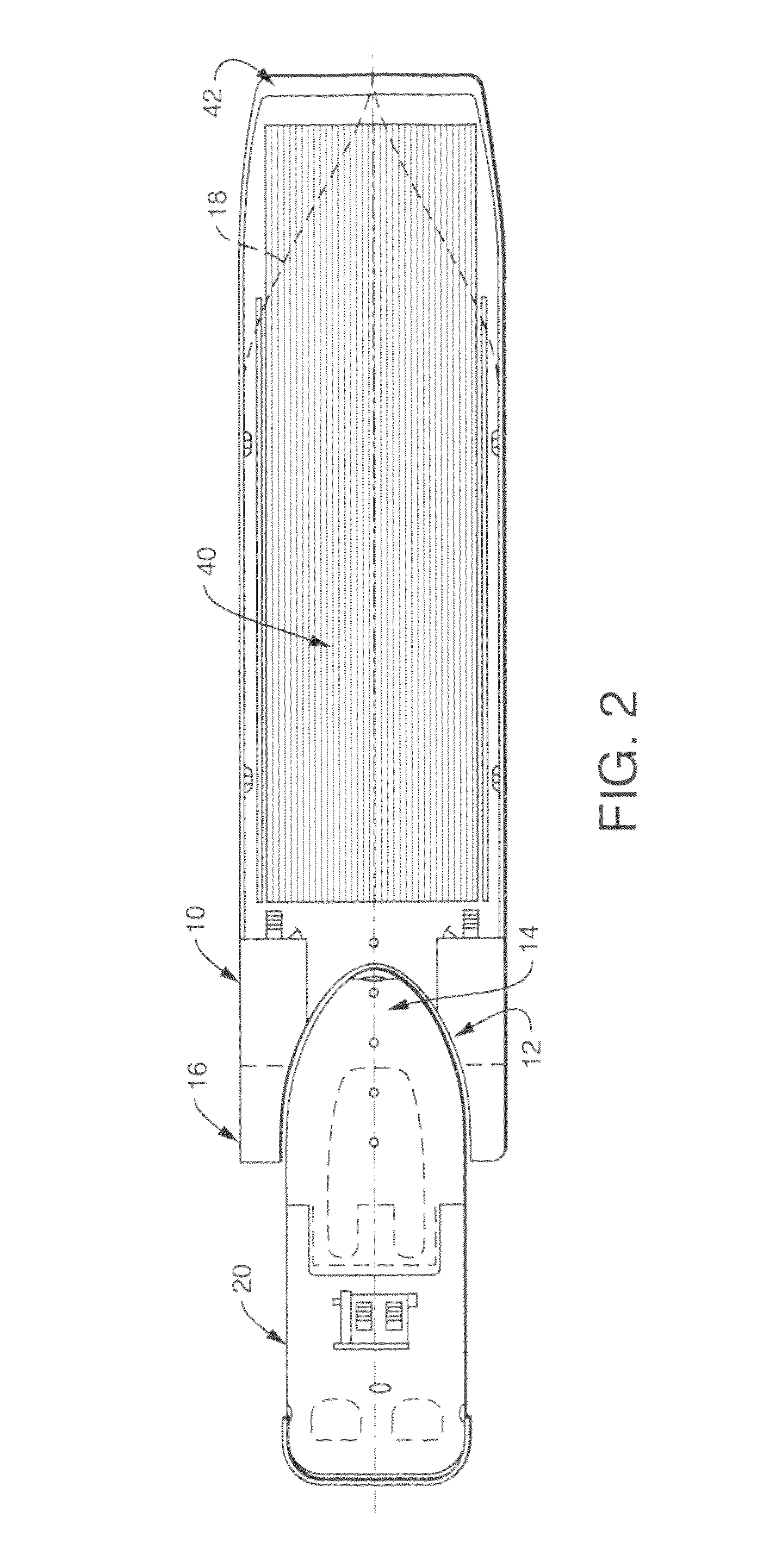

Tug-barge offshore cargo transport

InactiveUS8844459B2Efficiently and safely supplyReduce scrollingTowing/pushing equipmentData processing applicationsSternBARGE

Disclosed is a tug-barge offshore cargo transport device and method, comprised of two separate elements which are removably attached: a barge and a tug boat. The barge includes a bow shaped to cut through and deflect waves, a rectangular cargo deck protected by a bulwark, compartments below the cargo deck, means for maneuvering the barge, and means at the stern of the barge for removably attaching the barge to a tug boat. The tug boat includes means at the bow to removably attach to the barge, and means to control the means for maneuvering the barge from the tug boat.

Owner:PEREZ ROBERT H

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com