Variable-position shearing and breaking device of compound stratum pipe pushing machine

A technology of composite strata and crushing devices, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems affecting crushing efficiency and slag discharge efficiency, improve the crushing effect, reduce invalid rolling, and improve muddy water slag discharge efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

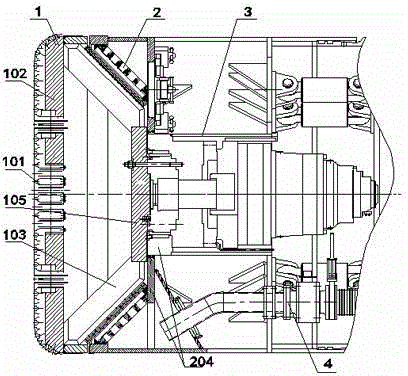

[0017] Embodiment one: see figure 1 , figure 2 and image 3 A displacement, shearing and crushing device of a pipe jacking machine for composite formations includes a cutter head 1, a front shield cone ring 2 and a main drive device 3 located at the front end of the pipe jacking machine. The flange 105 of the cutter head 1 is fixedly connected to the main On the output end of the driving device 3, then the main driving device 3 is fixedly connected to the pressure chamber partition 204 of the front shield cone ring 2, and the slag discharge device 4 is located at the lower part of the main driving device 3, such as figure 1 shown.

[0018] The cutter head includes a cutter 101, a cutter head panel 102, a twist leg 103, an active crushing plate 104 and a flange 105. The flange 105 is connected with six twist legs 103 that are radially distributed relative to the central axis of rotation. The ends of the twist legs 103 are Connected to the cutterhead panel 10, the cutterhea...

Embodiment 2

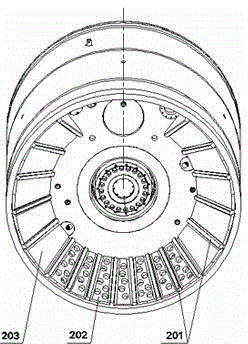

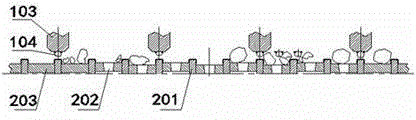

[0023] Embodiment two: see figure 1 and Figure 4 In this embodiment, the structure of a displacement shear crushing device for a pipe jacking machine in a composite formation is basically the same as in Embodiment 1, and the similarities will not be repeated. The difference lies in: Figure 4 As shown in the expanded view, the passive baffle 201 in the longitudinal section of the front shield cone ring 4 is trapezoidal, and when the main drive device 3 drives the cutter head 1 to rotate along the central axis of rotation, as Figure 4 As shown in the expanded diagram, each active crushing plate 104 of the cutter head 1 advances (rotates) along with the running direction of the twisted leg 103 and creates alternately changing shear spaces relative to the front shield cone ring 2, so that the large-sized rocks move forward (rotating) with the active crushing plate. When 104 rotates, it is stuck by the trapezoidal passive baffle 201, and the large-sized rock is crushed into mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com