Lithium battery recovery device

A recovery device and lithium battery technology, applied in battery recovery, recycling technology, waste collector recovery, etc., can solve the problems of not having the function of pressing materials and low crushing efficiency, so as to improve the crushing effect and facilitate the discharge of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

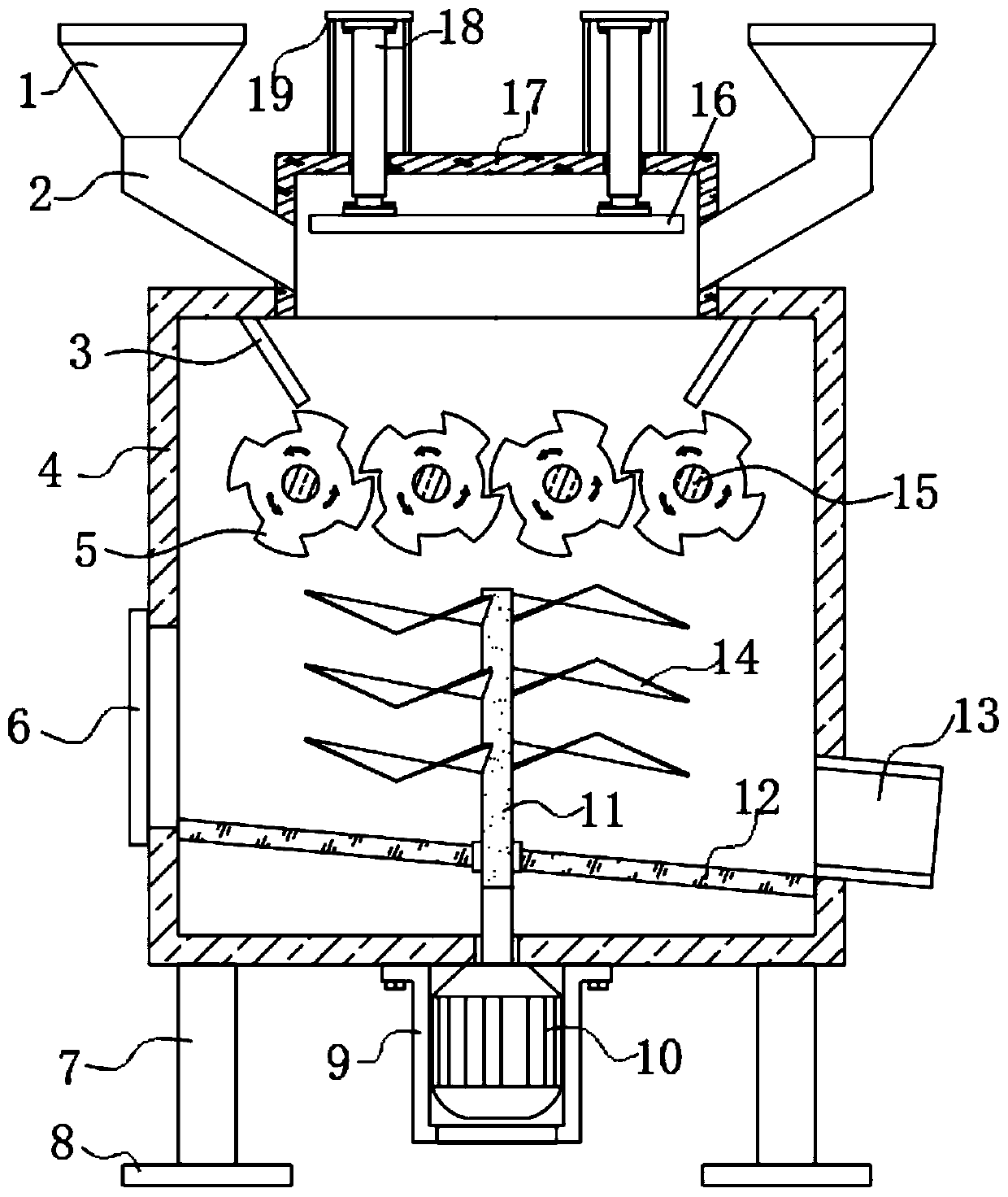

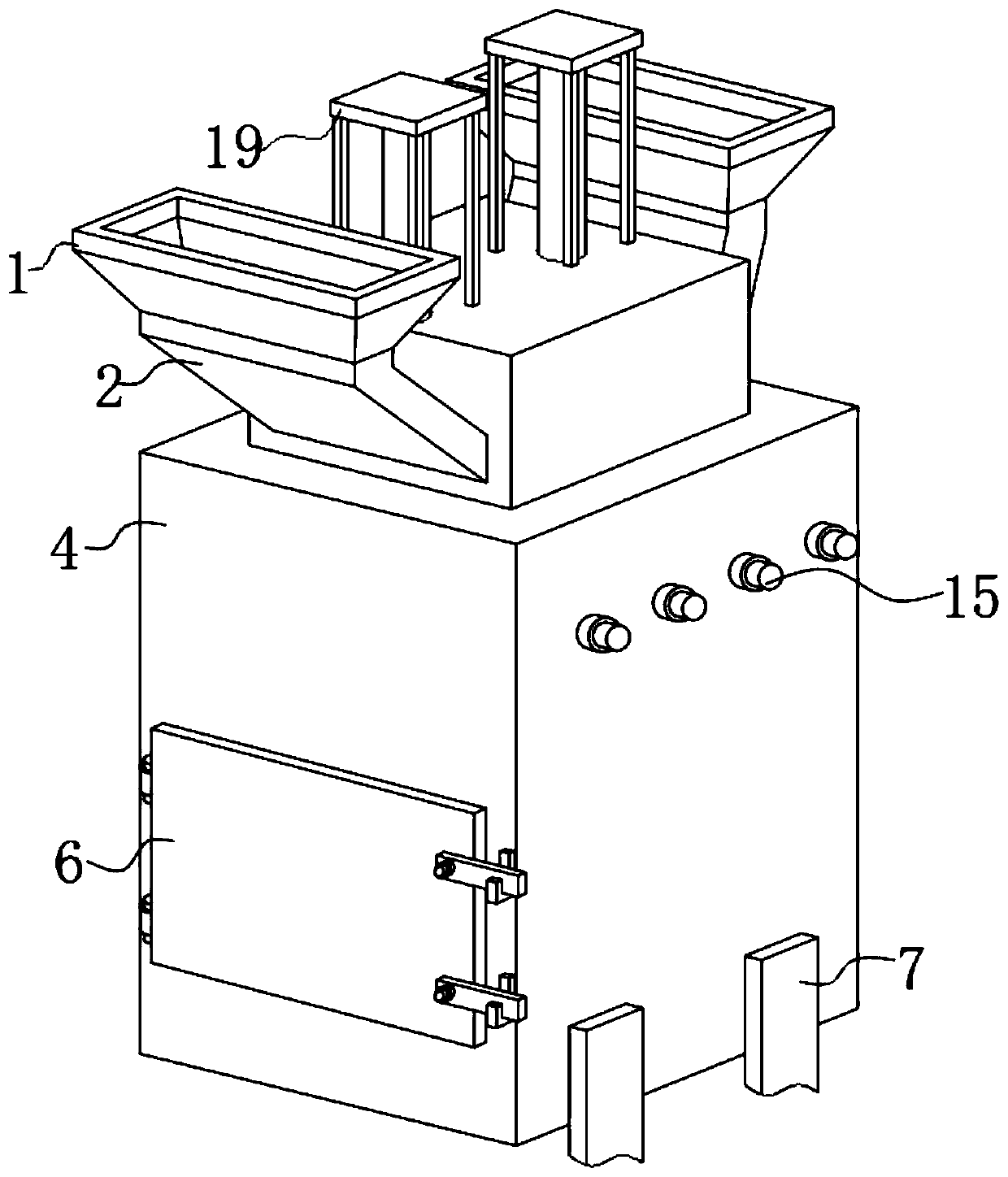

[0026] A lithium battery recycling device, such as Figure 1-2 As shown, it includes a casing 4, a pressing mechanism and a crushing mechanism. The top outer wall of the casing 4 has a feeding hole, and the pressing mechanism includes a bottomless casing 17, and the side wall of the casing 17 near the bottom is welded on the feeding hole. There are two through holes on the top of the casing 17, two mounting seats 19 are welded on the top of the casing 17, the bottom outer wall of the mounting seat 19 is fixed with electric telescopic rods 18 by bolts, and the two electric telescopic rods 18 The bottom ends of the two electric telescopic rods 18 are fixed with the same pressing plate 16 by bolts, and the electric telescopic rods 18, the first motor and the second motor 10 are started after the casting is completed. , the electric telescopic rod 18 drives the pressing plate 16 to move down, and then the lithium battery is pressed, so as to reduce the rolling of the lithium batte...

Embodiment 2

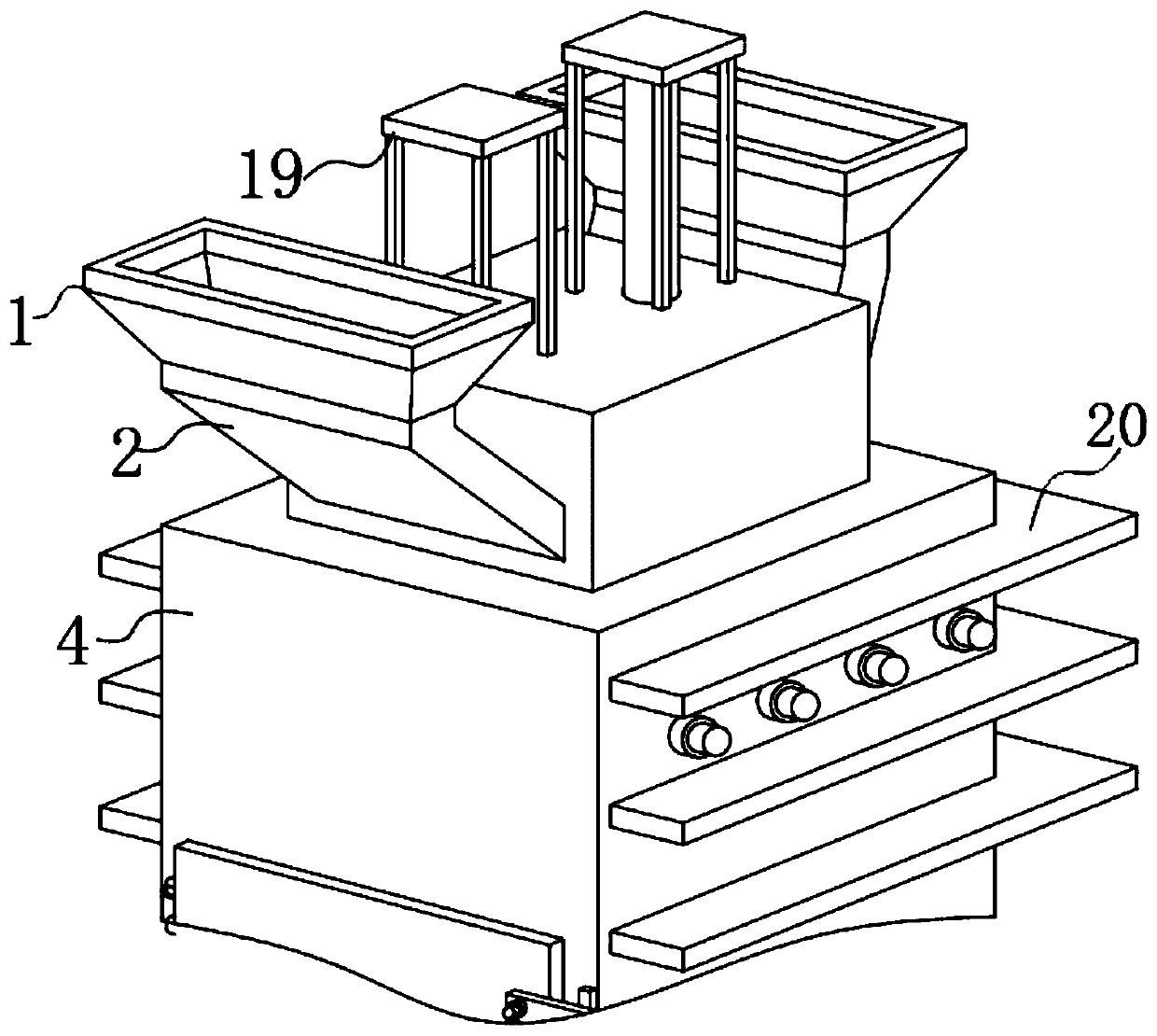

[0030] A lithium battery recycling device, such as image 3 As shown, in order to accelerate the problem of rapid heat dissipation of the box body 4; the present embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the box body 4 is provided with a plurality of U-shaped metal cooling fins 20, and the inner side of the metal cooling fins 20 The wall is welded to the three side outer walls of the casing 4.

[0031]When this embodiment is in use, because the inside of the box body 4 is crushed, there is more heat in the box body 4, and the heat is transferred to the side wall of the box body 4, and then radiates outward, while the specific heat of the metal cooling fins 20 is relatively high. Small, it absorbs heat quickly and dissipates heat quickly, so it can assist the radiation of heat on the side walls of the box body 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com