Fuel-saving accelerator

A speed booster and diaphragm technology, which is applied in the direction of machines/engines, secondary air defueling, engine components, etc., can solve problems such as poor sealing effect and poor air intake, so as to reduce fuel consumption, reduce exhaust emissions, and increase torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

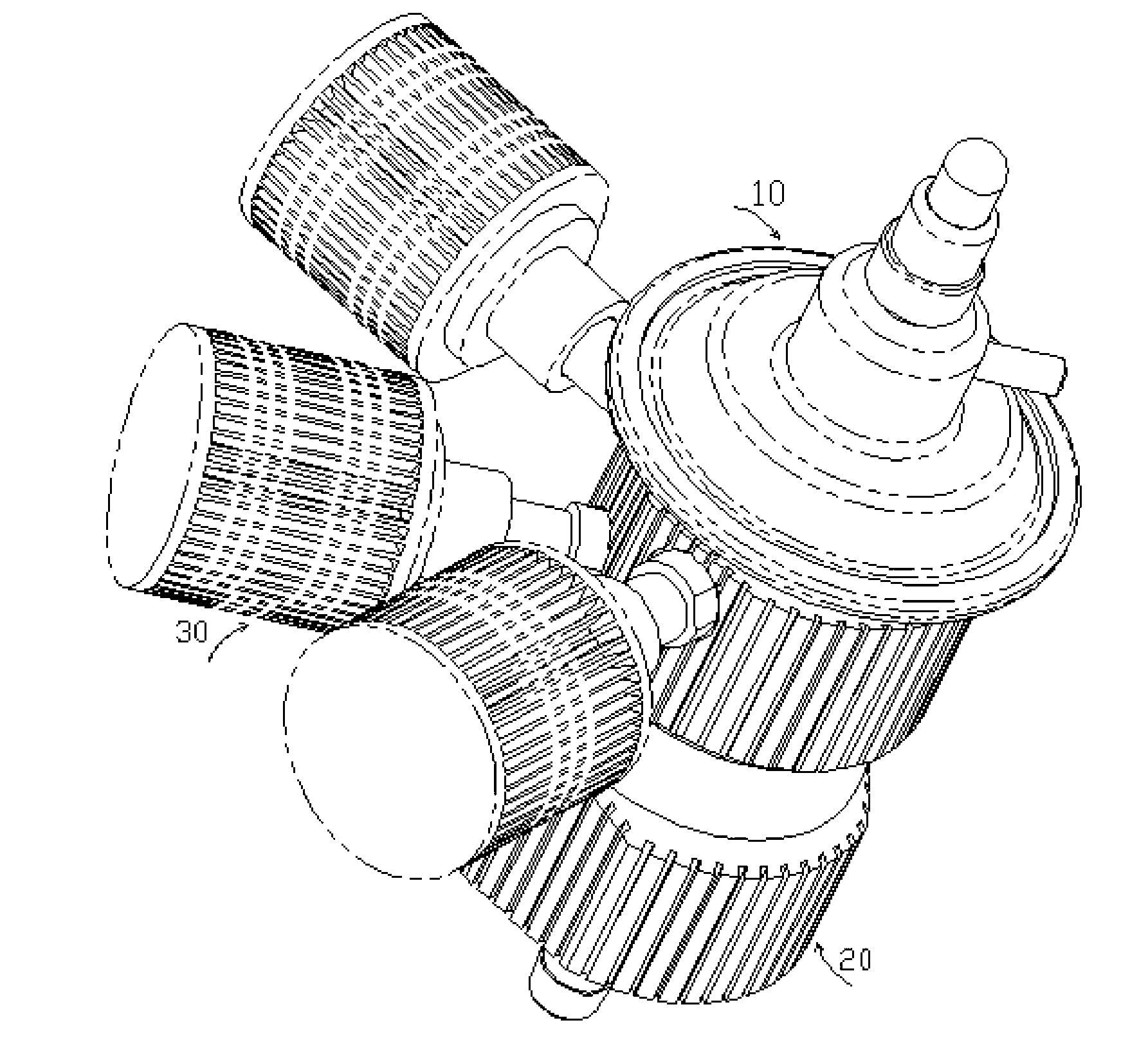

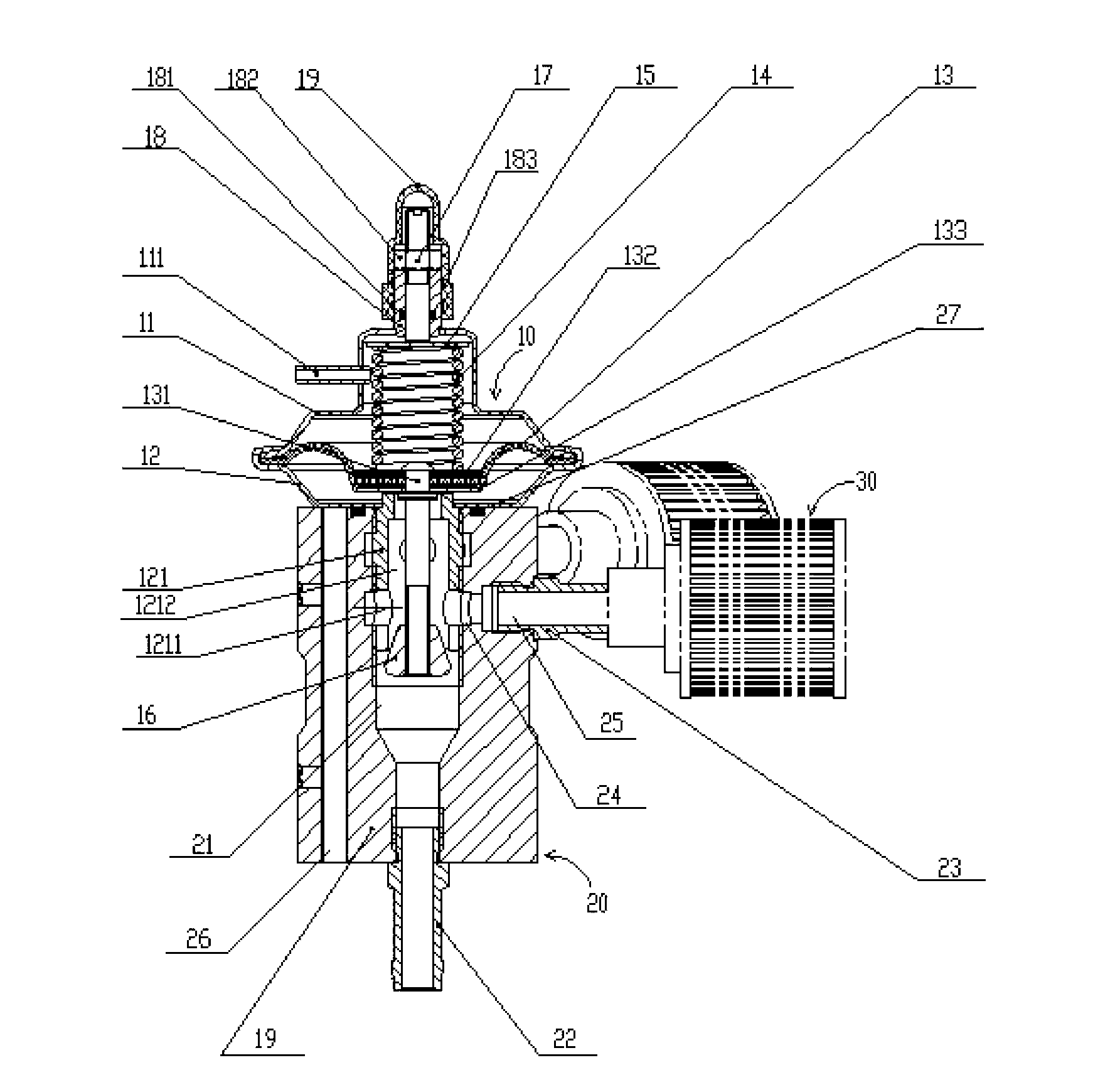

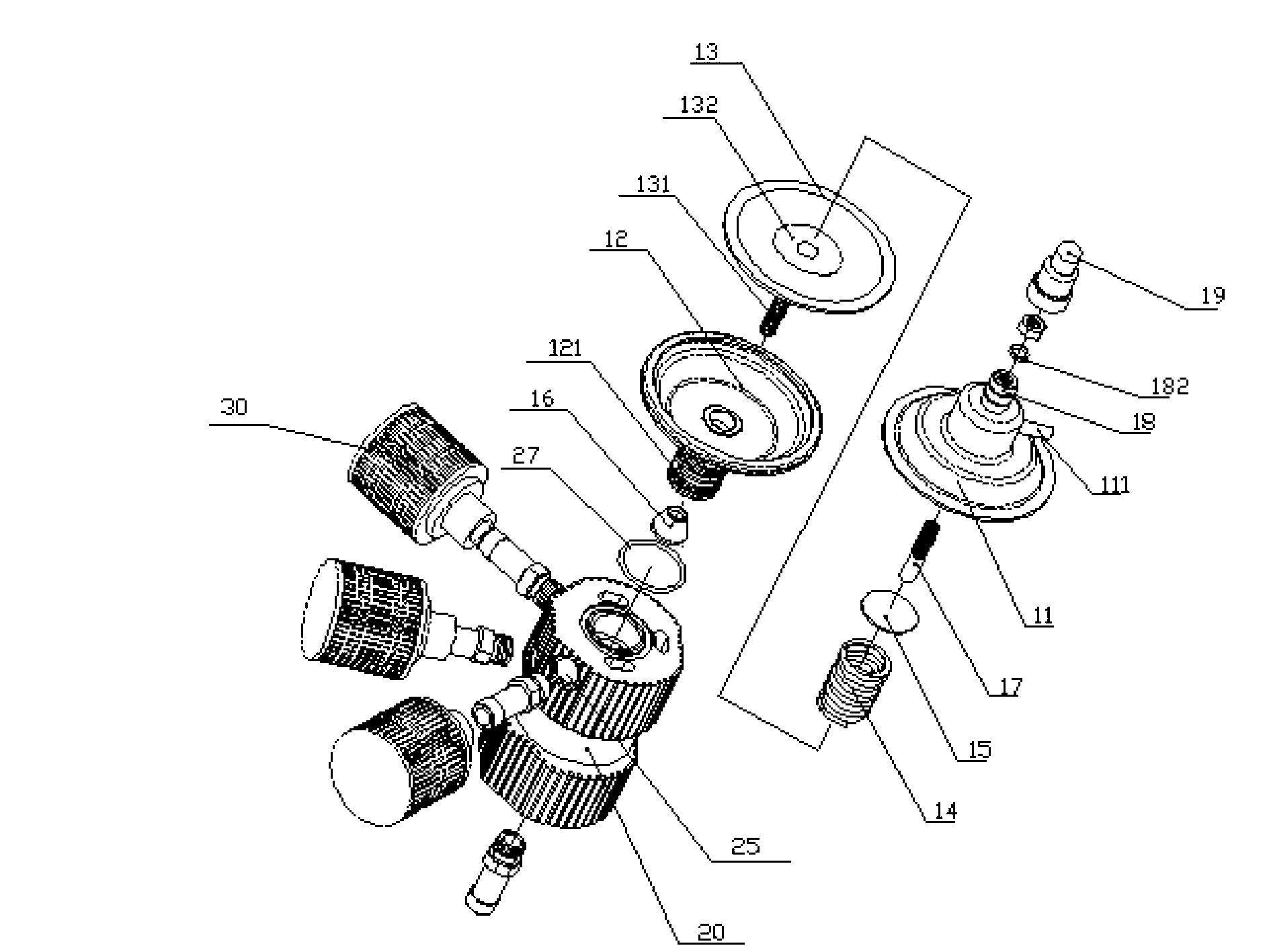

[0036] Refer to attached picture

[0037] The fuel-saving speed booster of the present invention is characterized in that it comprises:

[0038] A vacuum diaphragm seat, including the first diaphragm seat 11, the second diaphragm seat 12 that are sealed together, and the diaphragm 13 clamped between the first diaphragm seat 11 and the second diaphragm seat 12;

[0039] The first diaphragm seat 11 has a first screw rod 17 at one end away from the second diaphragm seat 12, and the part of the screw hole in the first screw rod 17 adjacent to the first diaphragm seat 11 is a straight hole portion with a smooth inner wall; A control pipe 111 on a diaphragm seat 11 connects the inner cavity of the first diaphragm seat to the exhaust gas circuit of the engine;

[0040] One end of the second diaphragm seat 12 away from the first diaphragm seat 11 is provided with a second screw rod 121, the second screw rod 121 has an external thread, and its center is provided with a passage 1212 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com