Groove-shaped wall structure of ship oil cabin

A wall structure and groove type technology, applied in the direction of hull bulkhead, hull, ship construction, etc., can solve the difficulty of increasing the installation process of the vertical groove wall, increase the thickness of the vertical groove wall steel plate, and increase the vertical groove shape Problems such as wall weight can be avoided to achieve the effect of avoiding centering, reducing weight and reducing welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

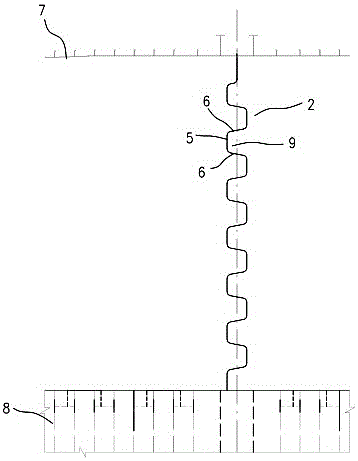

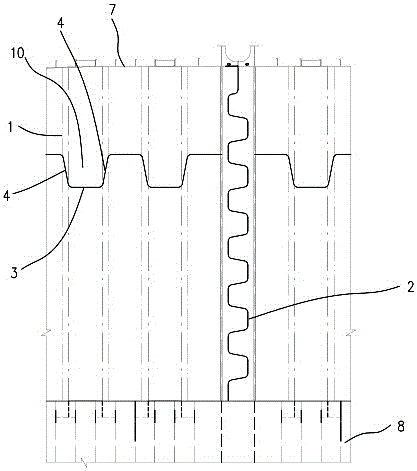

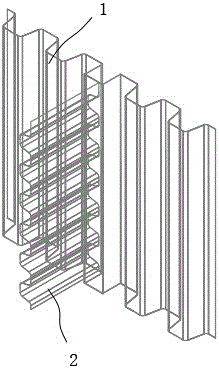

[0009] A channeled wall structure for a ship's cabin, such as Figure 1 to Figure 3 As shown, it includes the front wall of the cabin and the longitudinal oil-tight wall of the cabin perpendicular to the front wall of the cabin. The front wall of the cabin is a vertical grooved wall 1, and the longitudinal oil-tight wall of the cabin is a horizontal grooved wall 2. The trough wall 1 includes a plurality of vertical panels 3 perpendicular to the bottom surface of the cabin, and the adjacent vertical panels 3 are arranged in a front-to-rear staggered position, and the adjacent vertical panels 3 are connected by the first connecting web 4 to form a vertical panel with a wave structure. The grooved wall 1; the horizontal grooved wall 2 includes a plurality of horizontal panels 5 arranged from top to bottom vertically on the bottom surface of the cabin, and the adjacent horizontal panels 5 are arranged in a left and right misalignment, and the adjacent horizontal panels 5 pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com