Patents

Literature

89results about How to "Reduce sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

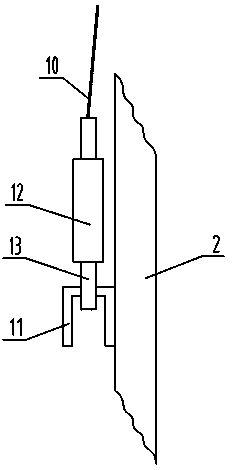

Resin mixture and glass reinforced plastic section bar prepared thereby

InactiveCN101157795ALightweight and high strengthThermal insulationPolymer scienceLow temperature curing

The invention relates to a resin mixture used for producing FRP (fiberglass-reinforced plastics) profile, the FRP profile made from the mixture and a preparation method thereof. The resin mixture comprises the following materials according to weight proportion: 10 of resin, 0.4 to 3 of low shrinkage agent, 2 to 15 of fillers, 0.05 to 0.2 of low temperature curing agent, 0.05 to 0.2 of high temperature curing agent, 0.05 to 0.2 of parting agent, 0.02 to 0.5 of pigment and appropriate amount of coupling agent and ultraviolet absorbent. The preparation method of the FRP profile by using the mixture is that: a reinforcing material is immersed into the resin mixture. The obtained material is extruded to get forming under high temperature and high pressure through a die; during the extrusion forming, the die is heated after being separated into three segments, and the temperature of the three segments is respectively 60 DEG C to 100 DEG C of a first segment, 100 DEG C to 150 DEG C of a second segment, 100 DEG C to 148 DEG C of a third segment; the haulage speed is 320 mm / min.

Owner:潘锦荣

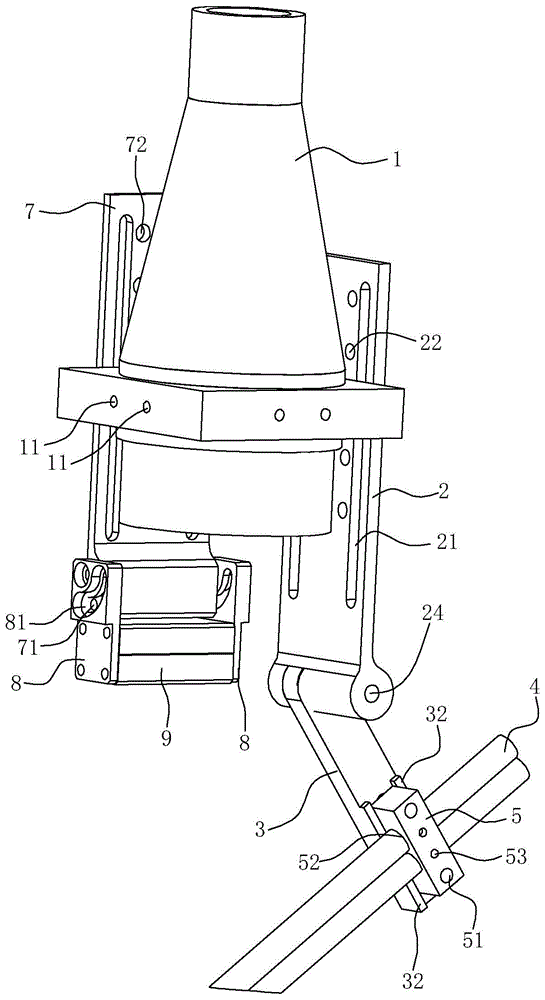

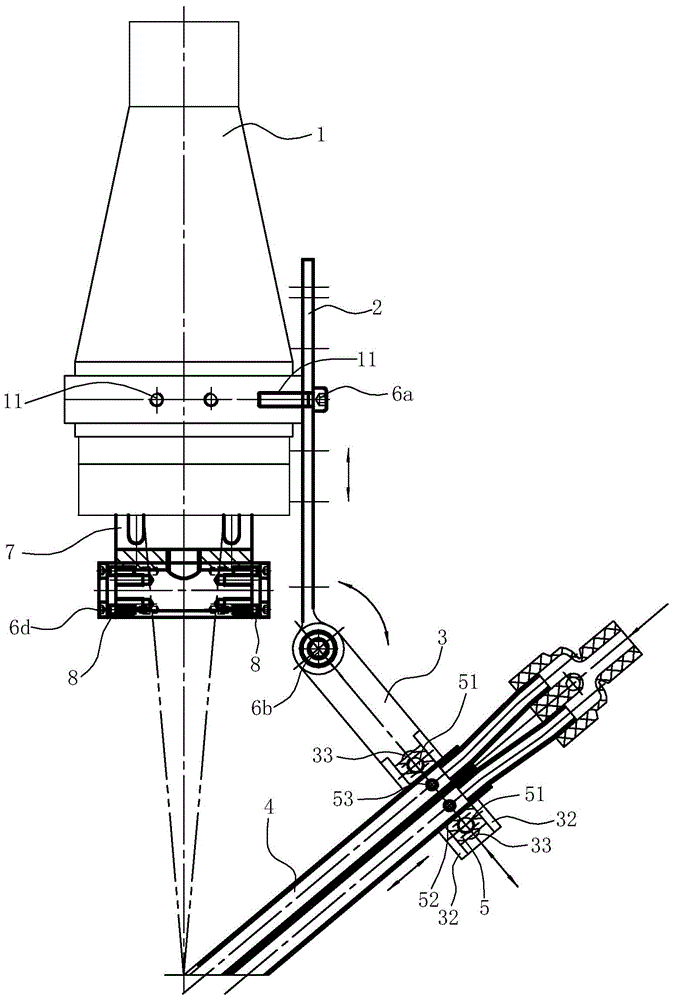

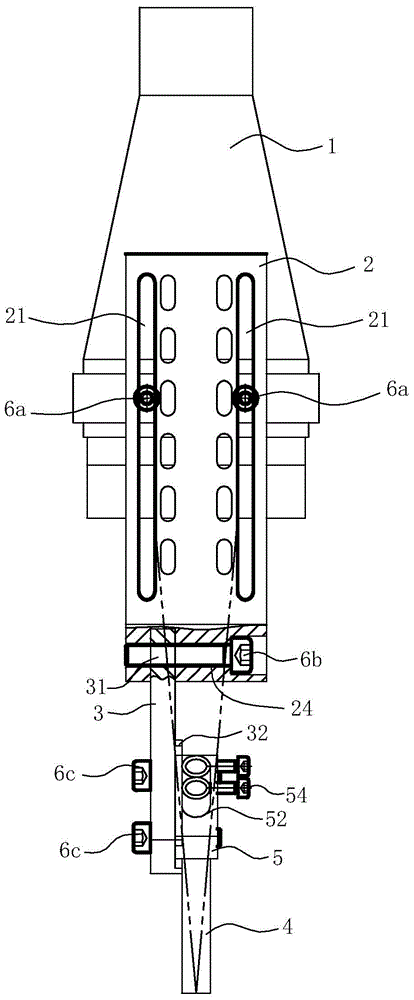

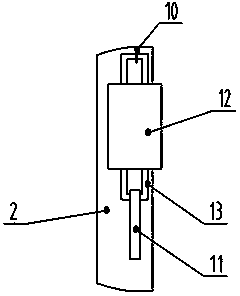

Gas blowing protective device used during stainless steel sheet pulse laser welding and welding process

ActiveCN105149777AInhibition of shieldingPlay the role of "repression"Welding/soldering/cutting articlesMetal working apparatusEngineeringLaser

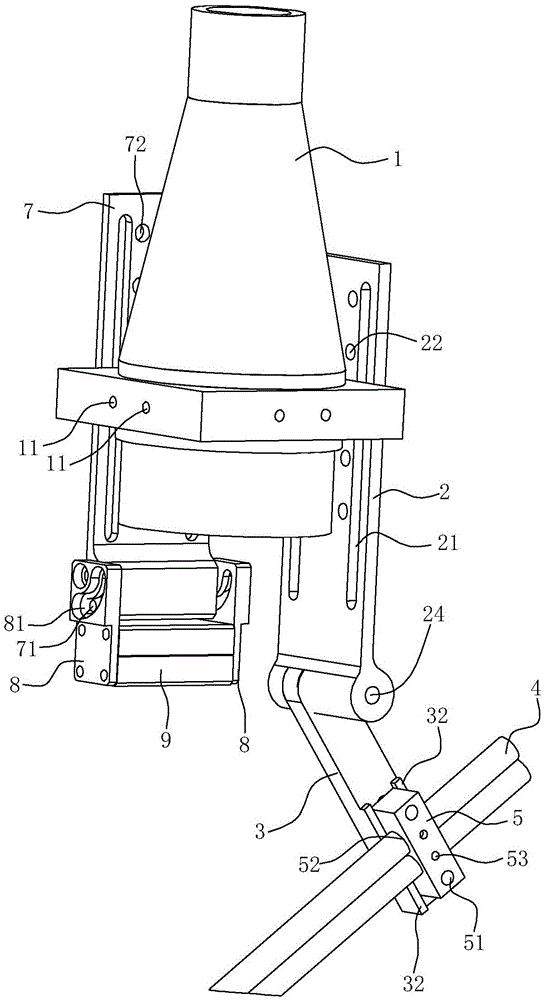

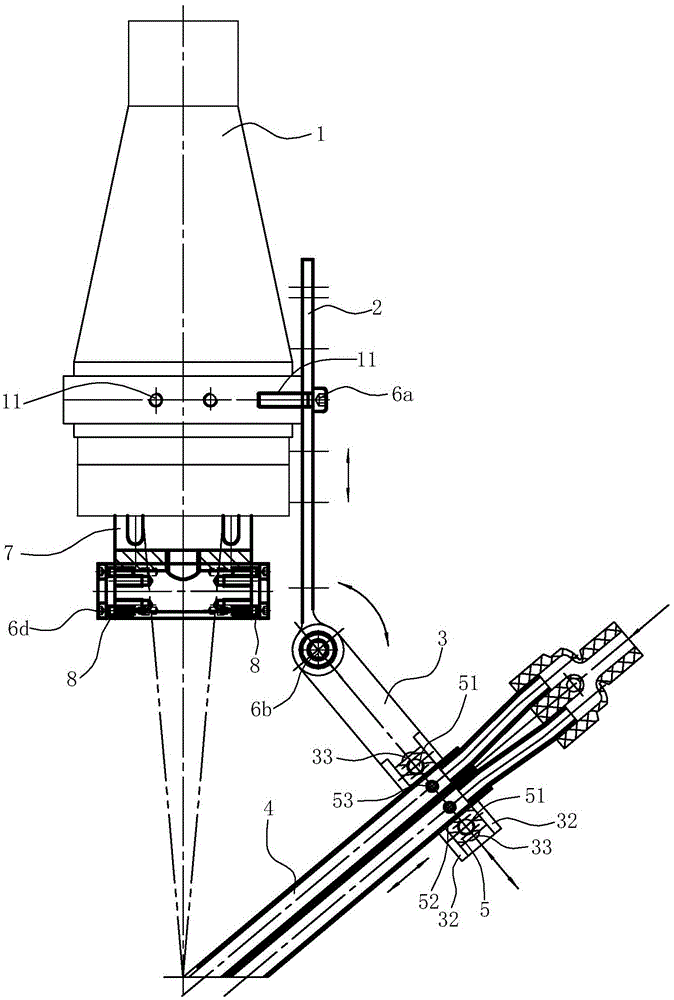

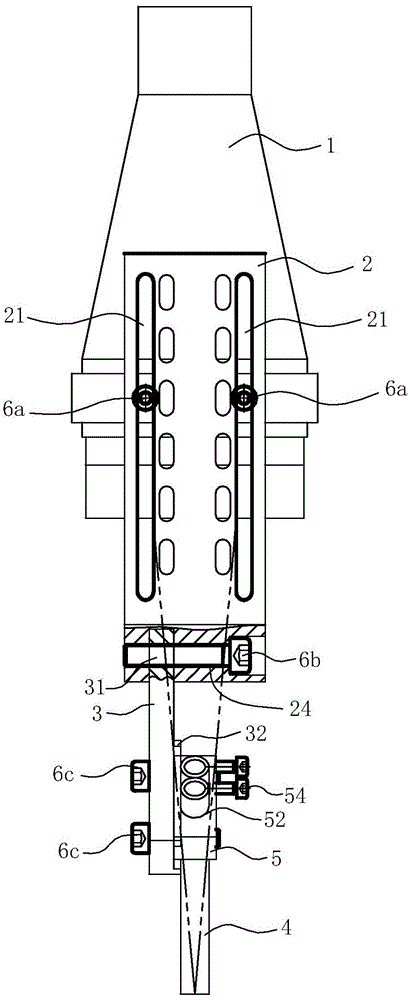

The invention relates to a gas blowing protective device used during stainless steel sheet pulse laser welding. The device comprises a side gas blowing protection part installed on a collimating focusing head and is characterized in that the side gas blowing protection part comprises a first adjusting plate, a rotary rod, a slider and a side gas blowing pipe; the first adjusting plate is fixed on the side wall of the collimating focusing head and can be adjusted up and down; the rotary rod is arranged at the lower end of the first adjusting plate in a rotary manner and the angle of swing relative to the first adjusting plate can be adjusted; the slider is fixed on the outer side wall of the rotary rod and the axial position of the slider along the length direction relative to the rotary rod can be adjusted; the side gas blowing pipe is fixed on the slider in a penetrating manner and can be adjusted along the thickness direction relative to the slider. The gas blowing protective device used during stainless steel sheet pulse laser welding is convenient in adjustment of height and angular positions. After the protective device is adopted, side gas blowing can be adjusted to an optimum position, so that welded product weld surfaces are oxidation-free and have good gloss. The invention also relates to a welding process.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

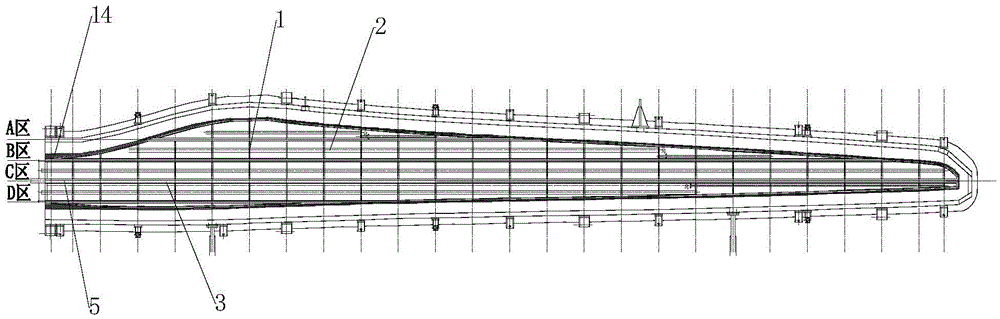

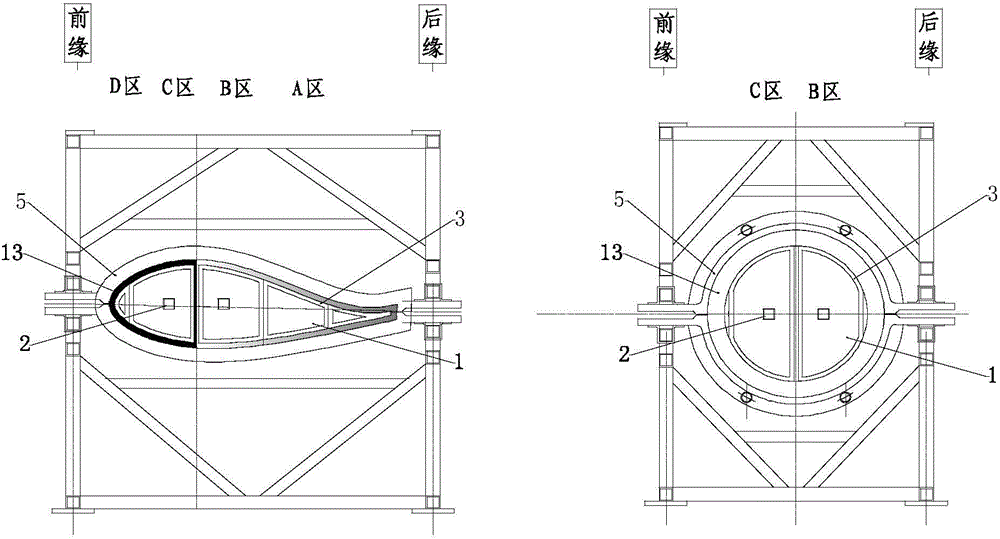

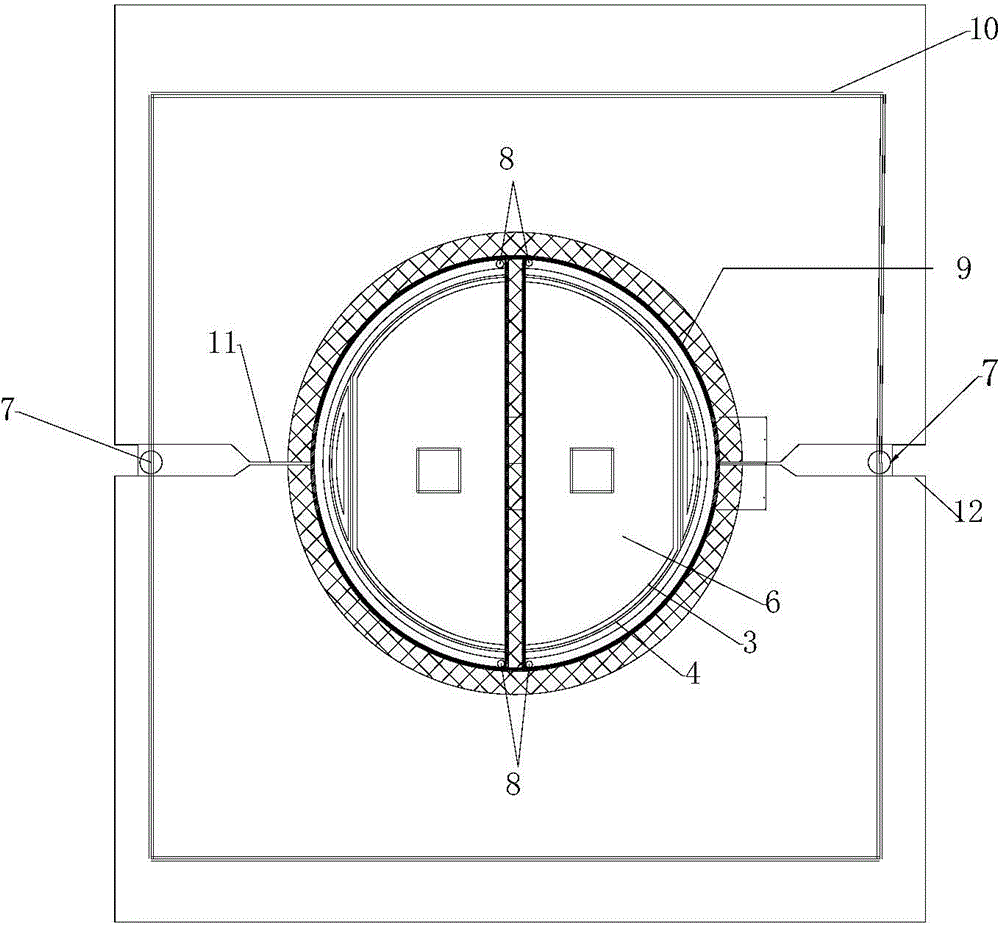

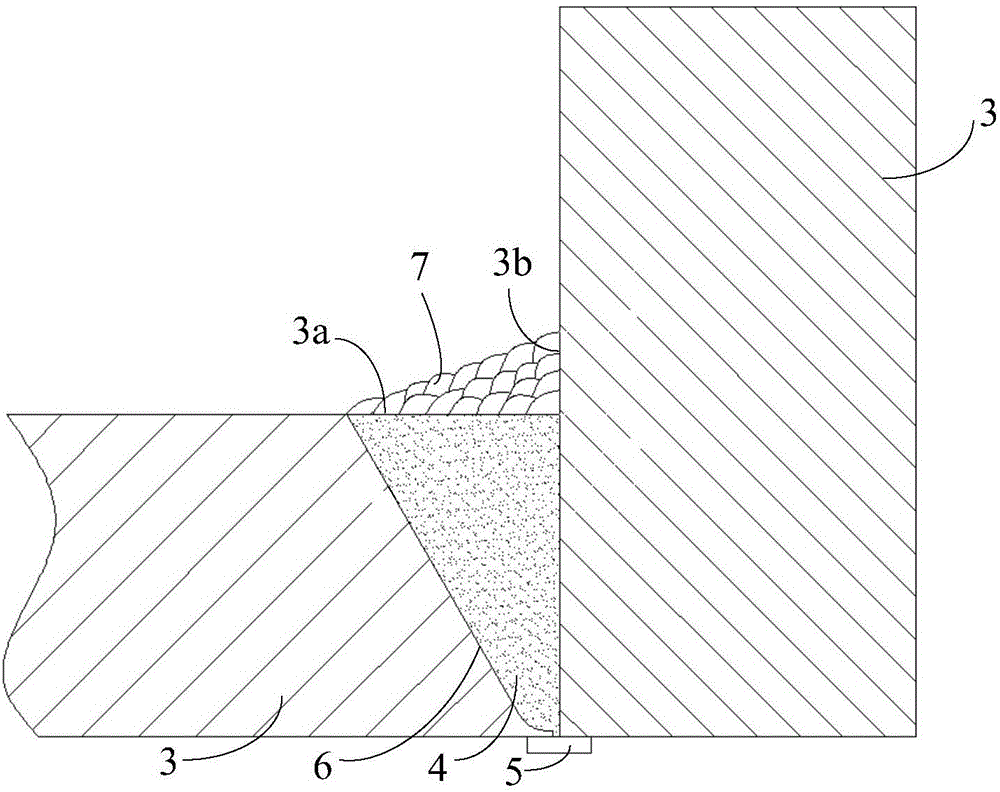

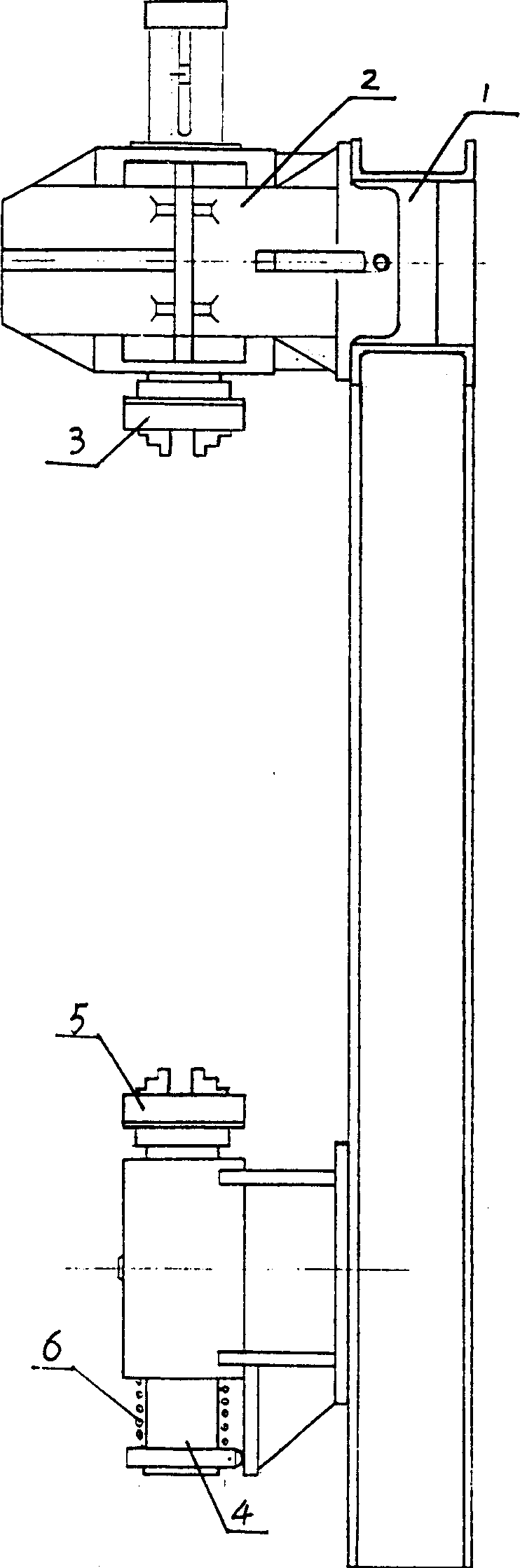

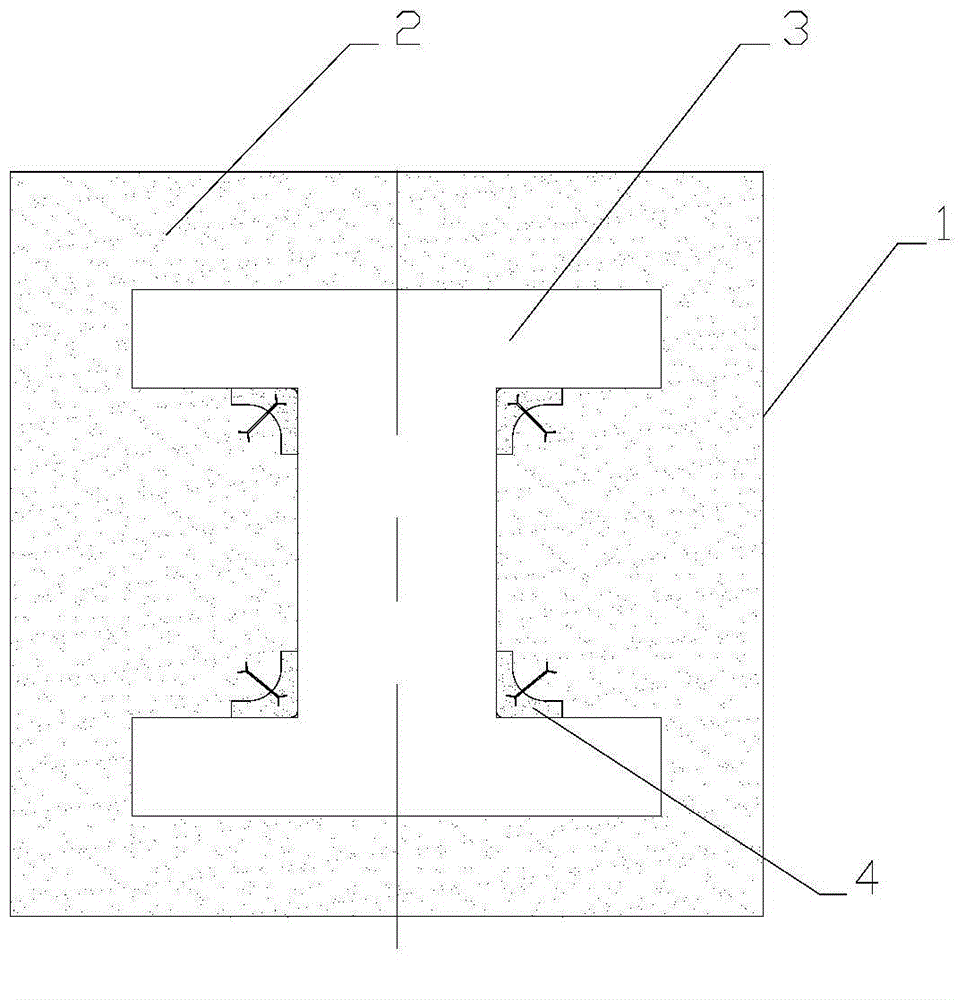

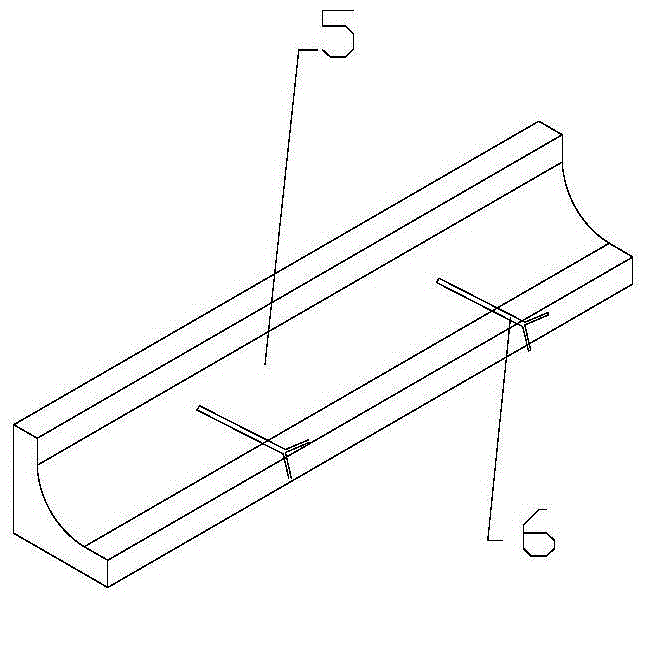

Integral molding method of composite material blade for wind power generation, and apparatus thereof

The invention relates to an integral molding method of a composite material blade for wind power generation, and an apparatus thereof. The apparatus comprises an upper die, a mandrel, a lower die and an electric heating device, the lower surface of the upper die forms a groove matching with the shape of one side of a blade, the upper surface of the lower die forms a groove matching with the shape of the other side of the blade, a glass steel web is arranged between the upper die and the lower die, the mandrel comprises four partition mandrels, the four partition mandrels are respectively arranged above and below the glass steel web, and the surfaces of the four partition mandrels and the glass steel web are respectively wrapped with elastic sponges capable of shrinking in the vacuum pumping process; the upper die and the lower die are respectively provided with exhaust openings, and the exhaust openings are connected with a vacuum pumping device; and the vacuum pumping device vacuumizes after die closing, the elastic sponges on the upper die, the lower die and the glass steel web shrink, epoxy resin is poured, and molding is carried out to form the windward side, leeside and middle reinforcement integrally molded blade. Compared with methods and apparatuses in the prior art, the method and the apparatus have the advantages of effective solving of the cracking problem of blades, and improvement of performances of the blades.

Owner:JIANGSU YUEKE NEW MATERIAL

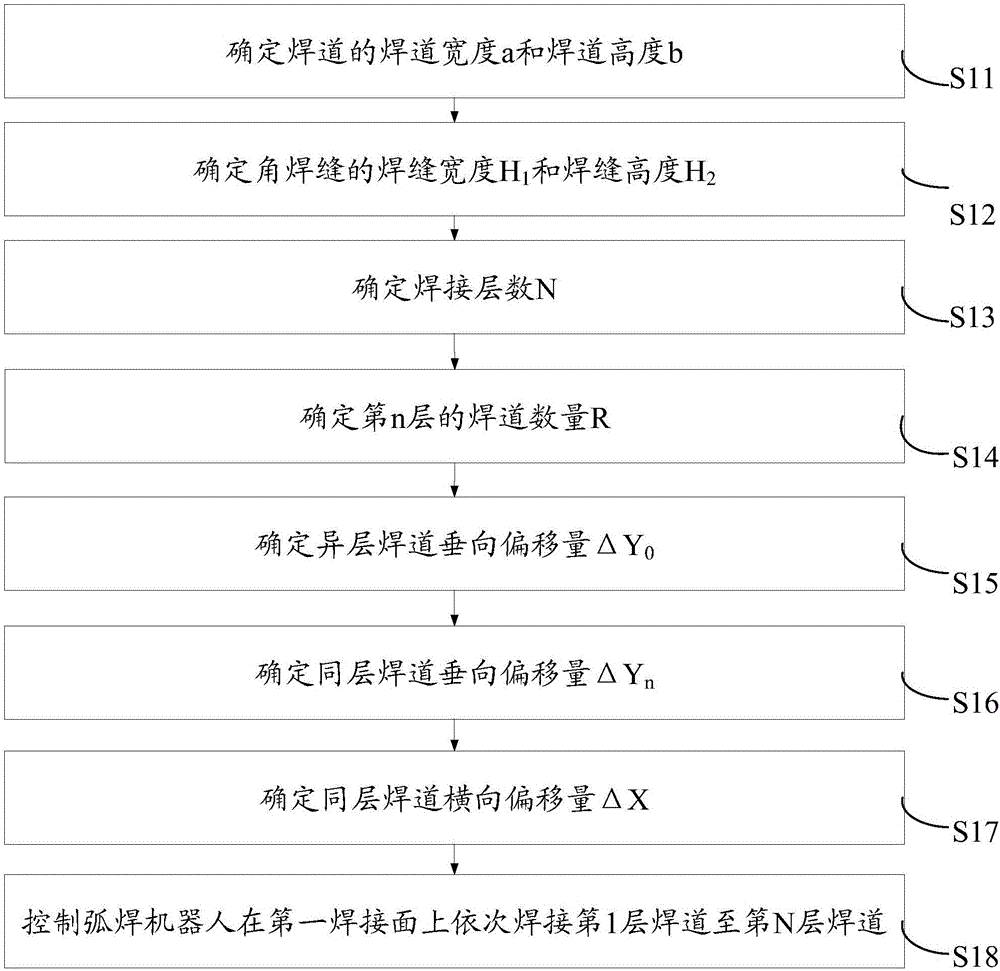

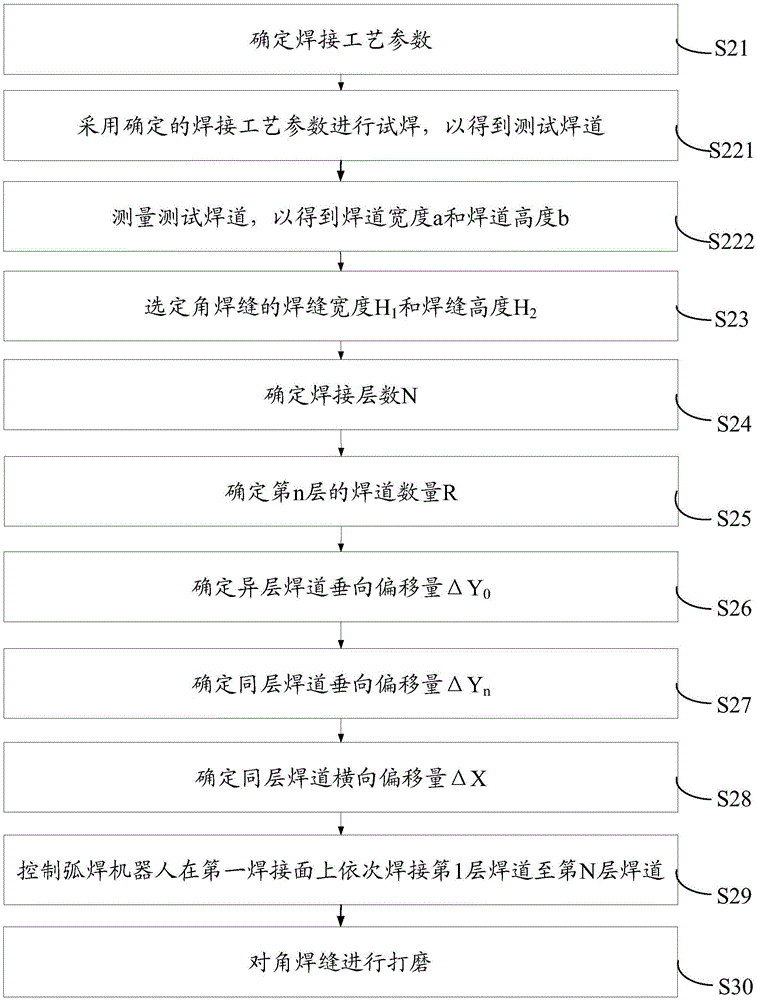

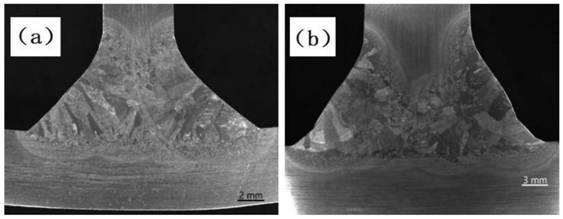

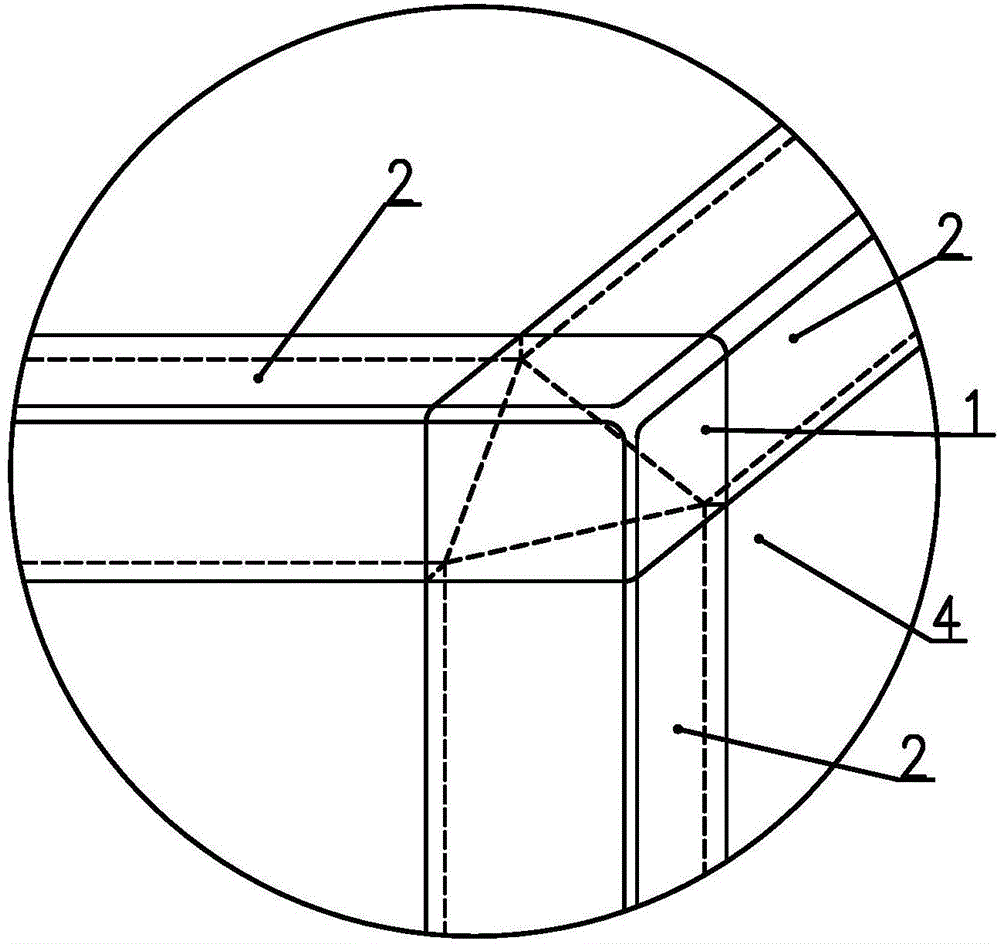

Fillet welding method based on arc welding robot

ActiveCN106238864AQuality improvementReduce sandingArc welding apparatusWorkpiece edge portionsStress concentrationFillet weld

The invention discloses afillet welding method based on an arc welding robot, belongs to the technical field of welding. The method comprises the steps of determining the width and height of the weld pass; determining the width and height of the fillet weld; determining a welding layer number; determining a weld pass number in the nth layer; determining a vertical offset of the weld passes on different layers; determining a vertical offset of the weld passes on the same layer; and determining a transverse offset of the weld passes on the same layer. Through determination of the width a and the height b of the weld pass, determination of the width and the height of the fillet weld, and determination of the welding layer number, the weld pass number on each layer, the vertical offset of the weld passes on the different layers, the vertical offset of the weld passes on the same layer and the transverse offset of the weld passes on the same layer according to the width and the height of the weld pass and the width and the height of the fillet weld, the quality of finally formed fillet weld is improved, the material stress concentration is reduced, and the fillet weld polishing is reduced.

Owner:WUHAN MARINE MACHINERY PLANT

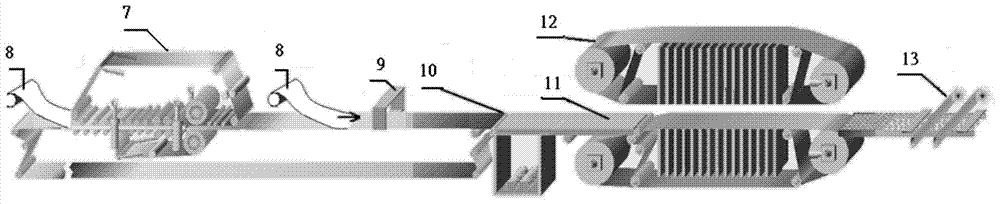

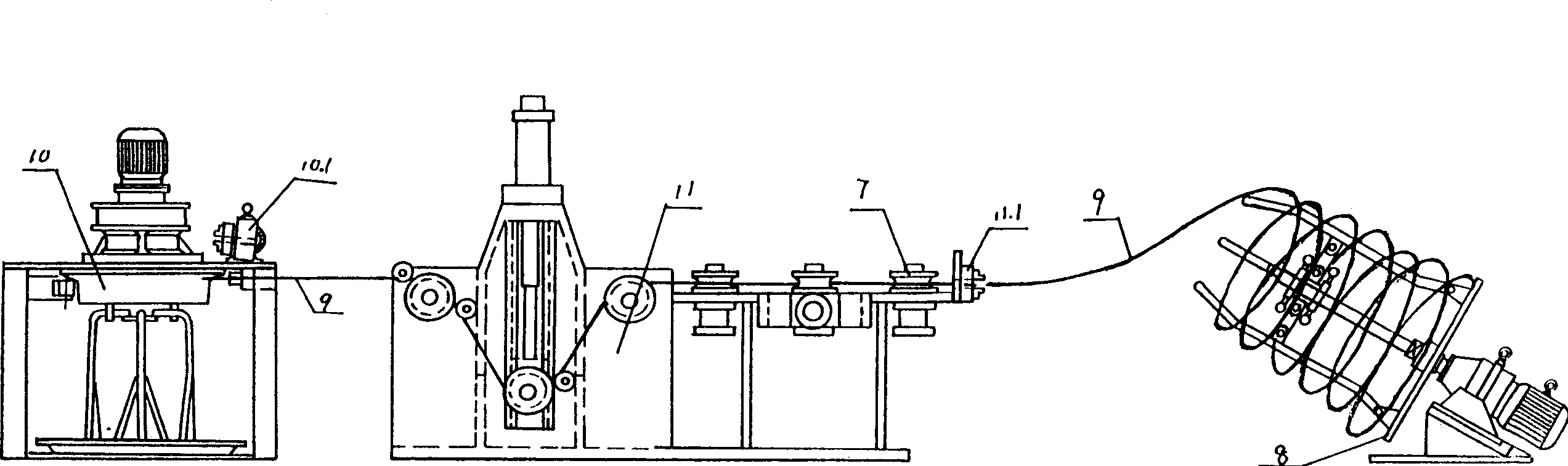

Production process of continuous artificial board production line

ActiveCN103786408ASolve problems such as material dropGood effectLaminationLamination apparatusProduction linePlastic film

The invention relates to a continuous artificial board production process belonging to the field of manufacturing of artificial boards. The production process of a continuous artificial board production line is characterized by comprising the steps of pre-spreading a base support layer which is equal to a plate blank in width or is slightly wider than the plate blank on a spreading belt of the artificial plate production line, wherein the base support layer adopts a layer of thin paper, or a layer of hot melt adhesive film or a layer of special plastic thin film or tree bark, is integrally formed or is formed by splicing a plurality of pieces of paper or films, and is subjected to gum dipping or release agent spraying; spreading by a spreading section of the belt of the production line, and prepressing by a prepressing machine, wherein the base support layer and the plate blank have certain binding strength; then carrying out hot pressing by a pressing machine to complete the production of the artificial plate finally. According to the production process, the problems of material dropping and steel belt sticking in the production process can be solved, the production cost is lowered greatly, the product quality is stable, one-time forming of the plate can be realized, and finished plates such as laminated boards, veneers and floors can be laminated once.

Owner:GLOBE ENVIRONMENTAL SHANGHAI

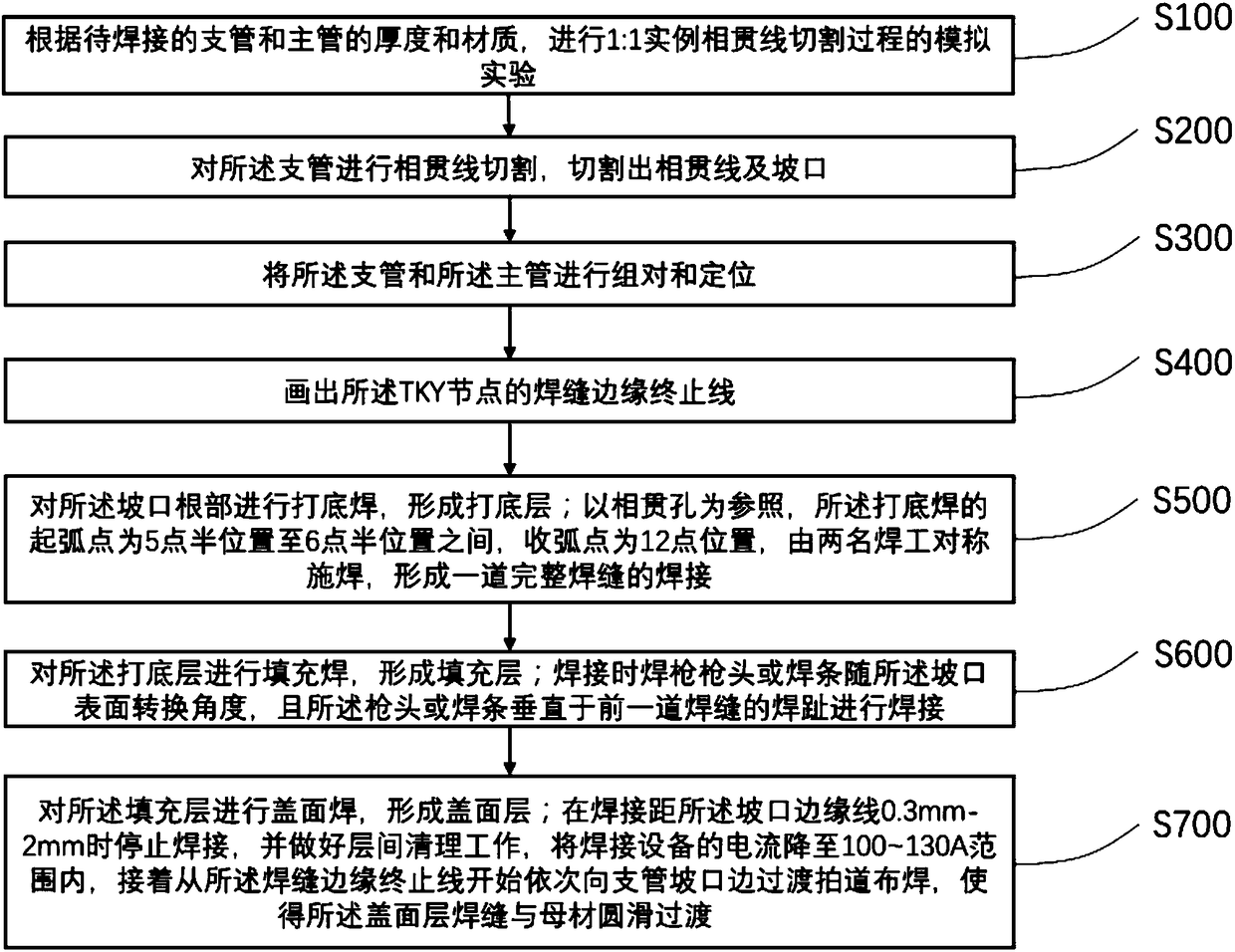

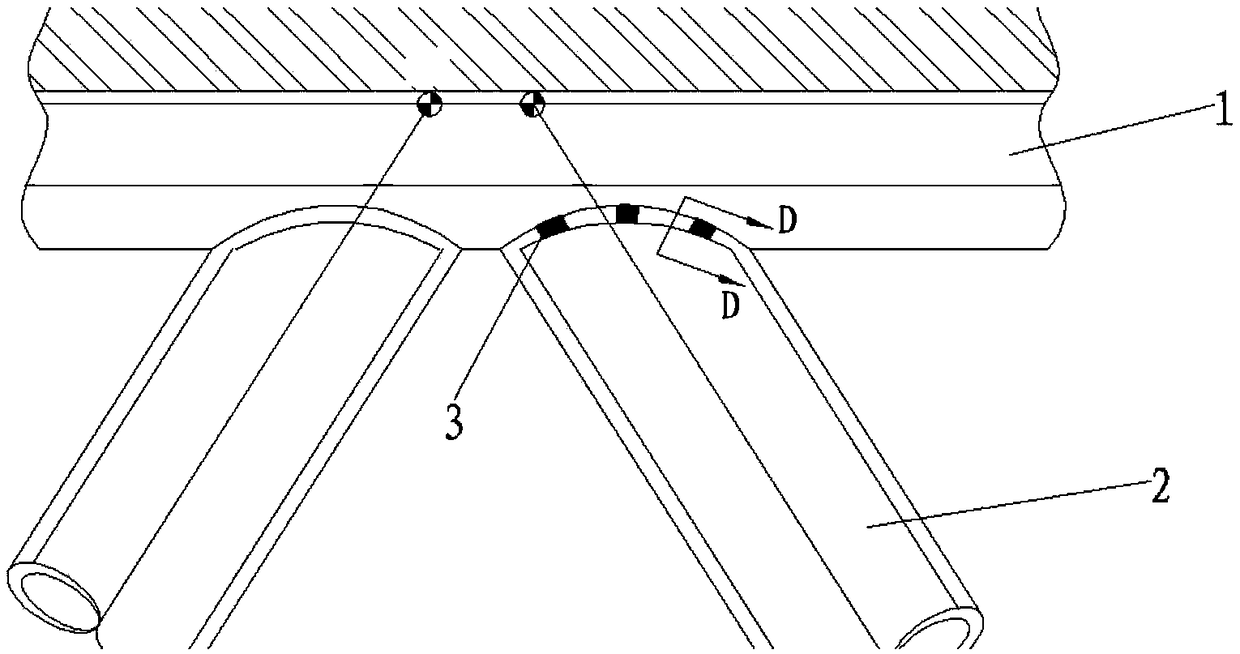

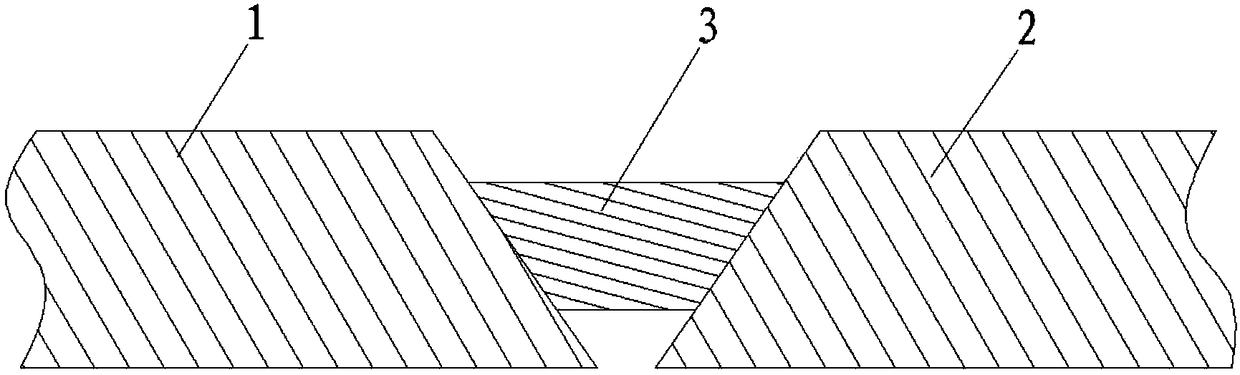

Welding method for TKY joints of steel structure

ActiveCN108453340AGuaranteed fatigue strengthReduce sandingGas flame welding apparatusPower flowEngineering

The invention discloses a welding method for TKY joints of a steel structure. The welding method includes the following steps that firstly, a 1: 1 example intersecting line cutting simulation test isperformed; secondly, intersecting line cutting is performed; thirdly, fitting up and positioning are performed; fourthly, weld joint edge terminated lines of the TKY joints are drawn; fifthly, backingwelding is performed to form a bottoming layer; sixthly, filling welding is performed to form a filling layer; and seventhly, surface covering welding is performed to form a surface covering layer, current of a welding device is decreased into the range of 100-130 A, welding stops when the distance from welding to a groove edge line is 0.3 mm to 2 mm, then from the weld joint edge terminated lines, arranging and welding are sequentially in transition to the groove edge of a branch pipe, and a surface covering layer weld joint and parent metal are made to be in smooth transition. The welding method guarantees that the fatigue strength and other mechanical performance of the TKY joints reach standards, one-time welding forming is performed, root portion defects are not likely to be caused,weld joint grinding is reduced, the labor intensity of workers and the production cost are lowered, and the production efficiency is improved.

Owner:上海拓直数字科技有限公司

Derust method and device of metallic material

InactiveCN1830589ASimple structureReliable performanceWork treatment devicesExtrusion cleaning devicesMetallic materialsDiiron Trioxide

Owner:肖金安

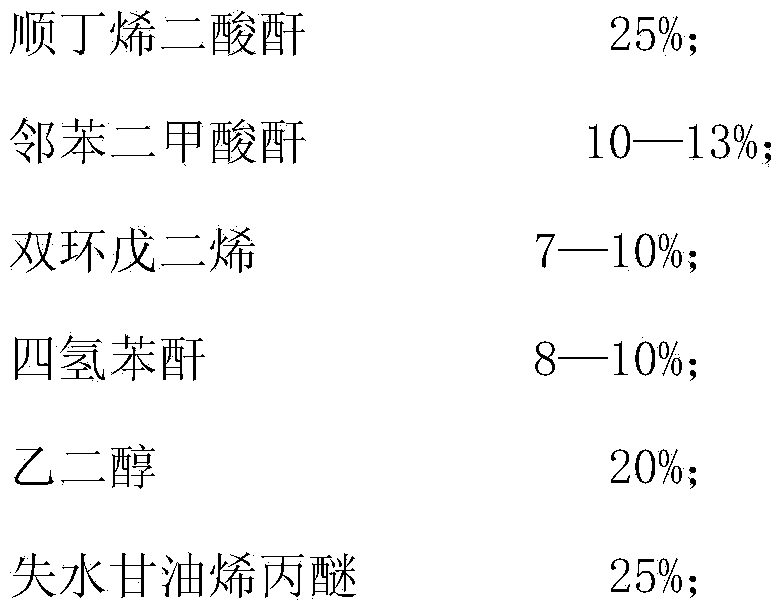

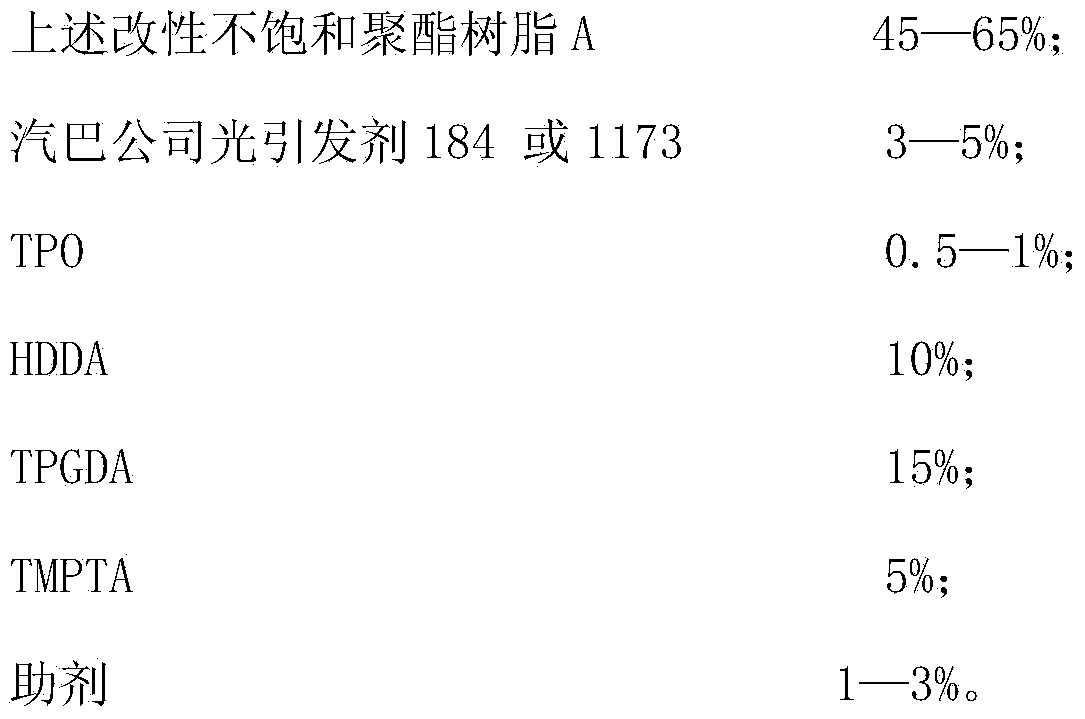

Polishing-free highlight coating resin

The invention relates to modified unsaturated polyester resin and in particular relates to polishing-free highlight coating resin. The polishing-free highlight coating resin is characterized in that at least one air-dried monomer is introduced into unsaturated polyester and at least two photoinitiators, namely surface layer initiator photo-curing resin and deep layer initiator photo-curing resin respectively, are adopted. According to the polishing-free highlight coating resin, the air-dried monomer is introduced into the unsaturated polyester, multiple photoinitiators are adopted for playing a synergistic effect, and an ingenious formulation design is adopted, so as to obtain a polishing-free highlight coating, so that a polishing process is eliminated, the production efficiency is improved, the usage amount of resin is reduced, and the production cost is saved; furthermore emission of VOC (volatile organic compounds) is reduced while a photocuring process is adopted, thereby being consistent with the policy of building a resource-saving and environmentally-friendly society advocated in China.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

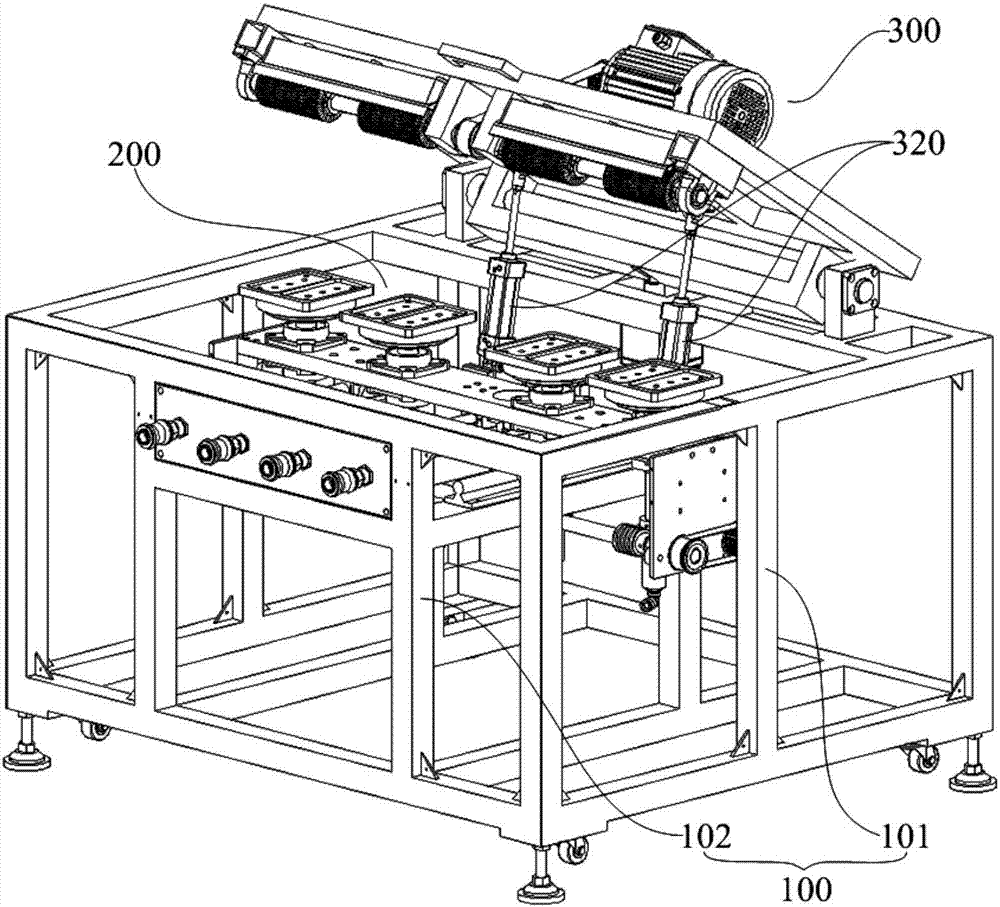

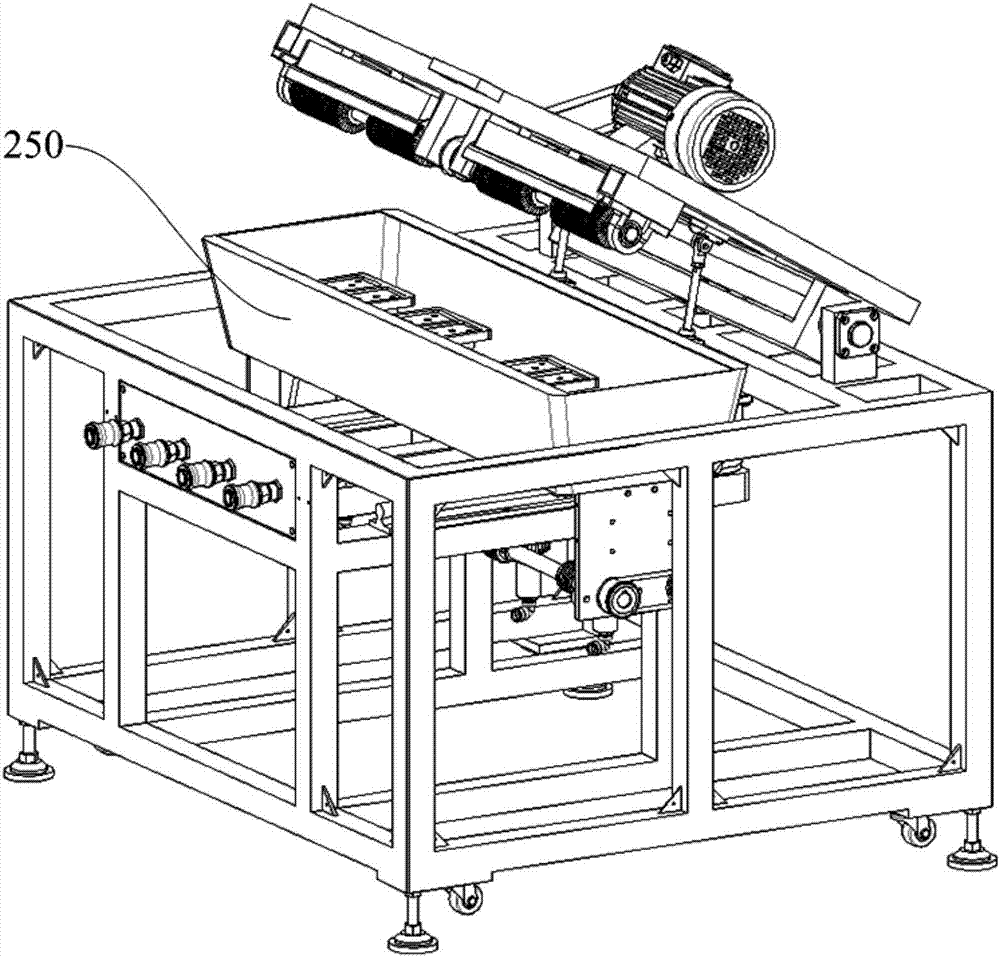

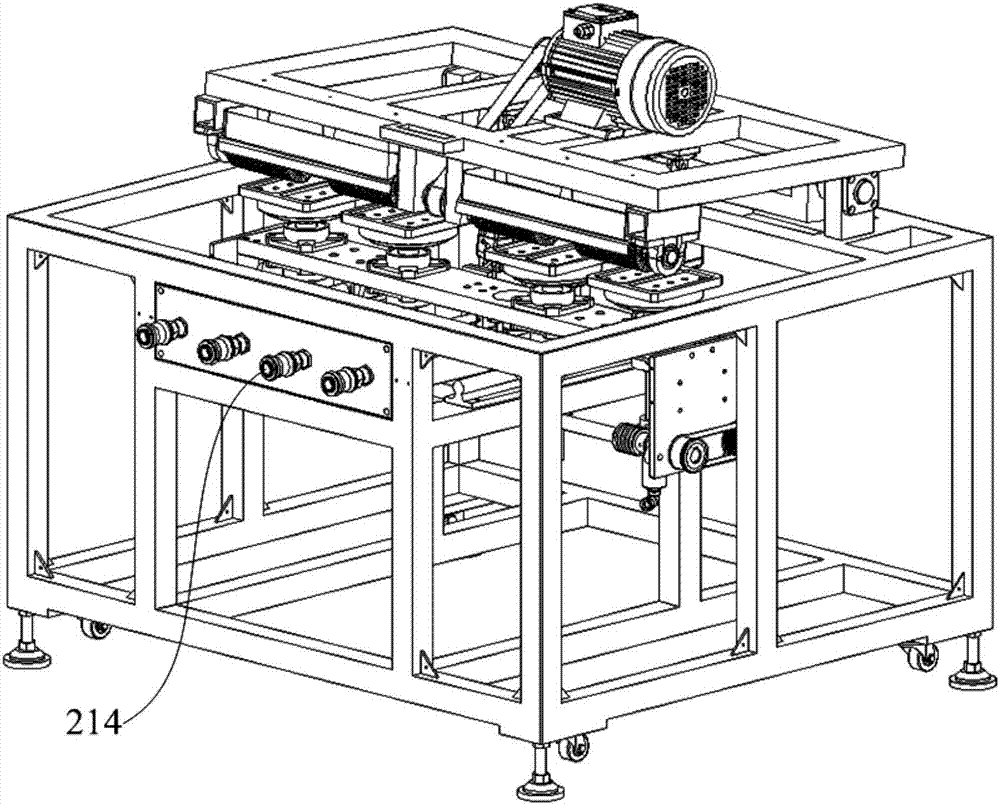

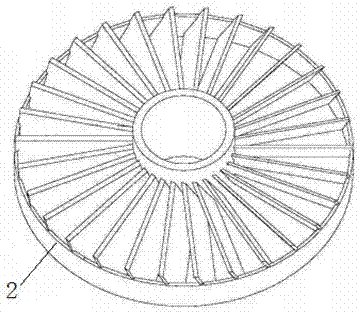

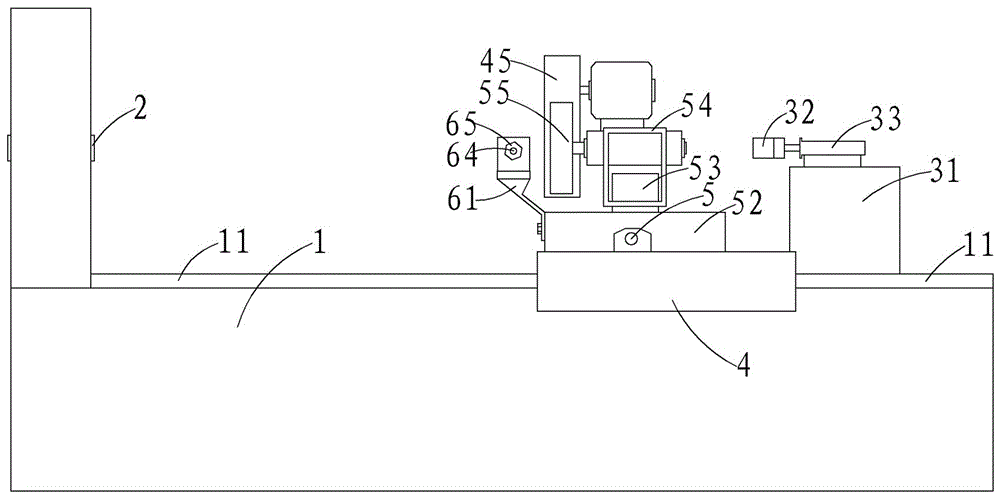

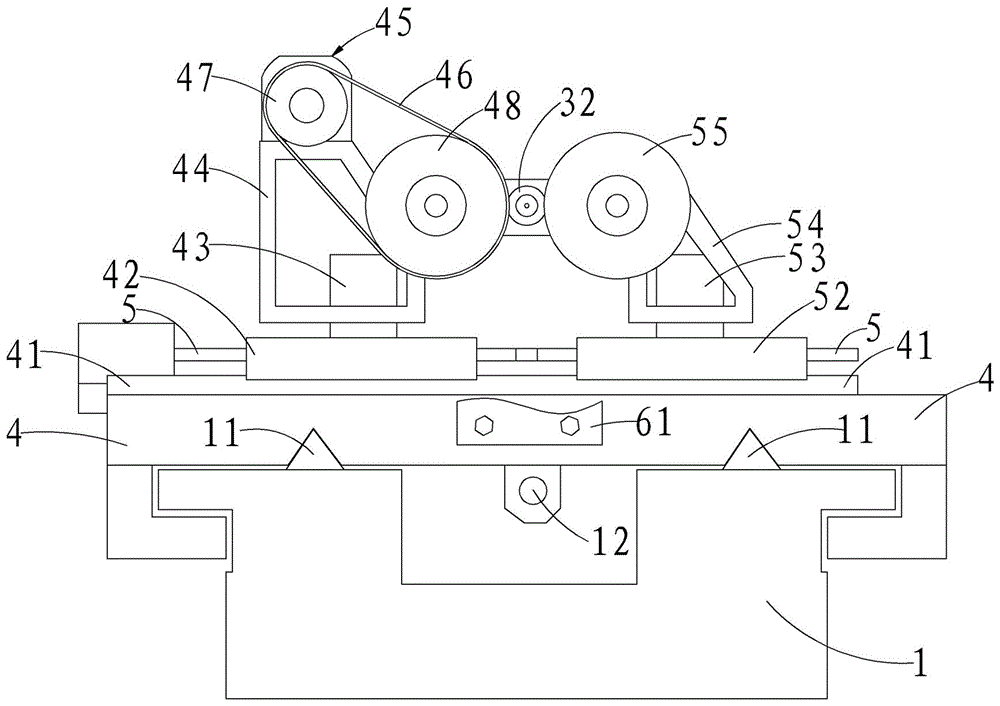

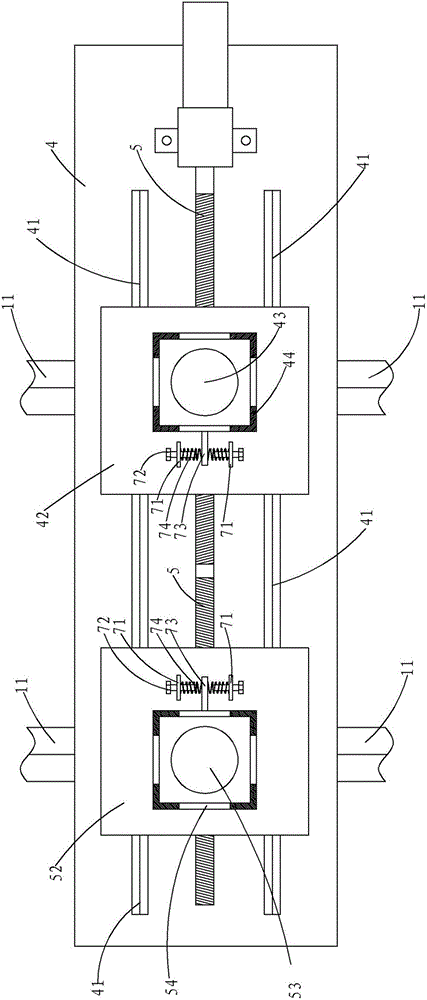

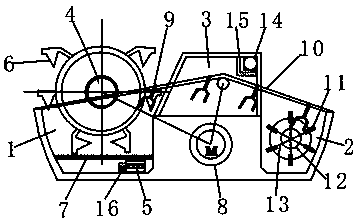

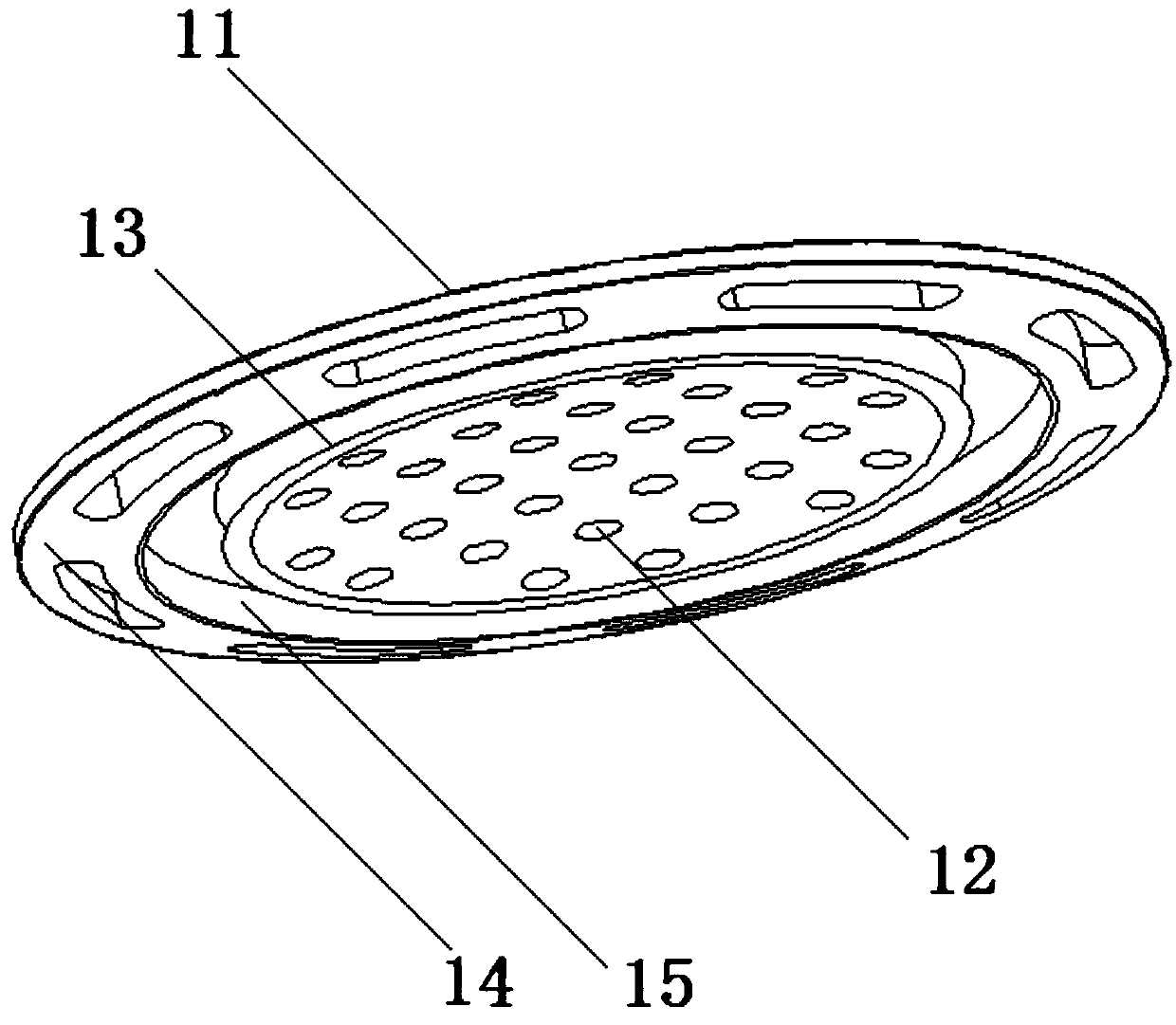

Polishing machine with 3D hook face

ActiveCN107081670AReduce sandingReduce wearGrinding carriagesPolishing machinesReciprocating motionPolishing

The invention discloses a polishing machine with a 3D hook face. The polishing machine comprises a rack, a jig assembly and a polishing wheel assembly. The rack comprises an inner frame and an outer frame. The jig assembly is fixed on the inner frame, and comprises a plurality of workpiece disks and a first driving mechanism used for driving the workpiece disks to move in a reciprocating mode. Containing tanks used for containing workpieces are formed in the workpiece disks. The polishing wheel assembly is rotatably matched with the outer frame, and comprises a mounting rack matched with the outer frame in a rotating mode, and a plurality of polishing wheels used for polishing the workpieces are arranged on the mounting rack. According to the polishing machine with the 3D hook face, the workpieces move in a reciprocating mode relative to the polishing wheels, so that multi-degree abrasion of the polishing wheels to the edges of the concave surfaces of the workpieces is reduced, and the multi-degree abrasion suffered by the edges of the concave surfaces of the workpieces is avoided through the height difference between tank ports and tank bottoms of the containing tanks.

Owner:东莞市精伟达科技有限公司

Pure-natural pollution-free dry-mixed floor mortar

The invention relates to a pure-natural pollution-free dry-mixed floor mortar, which is prepared from the following raw materials in parts by weight: 200 to 250 parts of cement, 710 to 750 parts of yellow sand, 40 to 70 parts of pulverized fuel ash, 0.5 to 2 parts of additive, and 20 to 30 parts of natural thickening agent, wherein the additive is hydroxypropyl methyl cellulose; the natural thickening agent is a mixture prepared from the raw materials in parts by weight: 20 to 30 parts of glutinous rice flour, 15 to 35 parts of egg white powder, 25 to 30 parts of clay soil powder and 15 to 30 parts of straw meal. The pure-natural pollution-free dry-mixed floor mortar has the advantages that the natural thickening agent is adopted, so that on one hand, the overall viscosity of the mortar added with water can be improved, and a series of problems of shrinkage crack, water seepage, sand strip, peeling deformation, low strength level and the like of a surface layer of a floor at the later stage are prevented; on the other hand, the mortar is pollution-free to a human body, and the problem that straw stalks cannot be utilized can be effectively solved; the materials can be effectively smashed through a rotary cutter disc, and a filter effect of a filter box is effectively improved through horizontally swinging the filter box in a reciprocating way.

Owner:江苏中鼎建材集团有限公司

Painted flexible wood veneer processing method and painted flexible wood veneer product

InactiveCN102615688AExtended service lifeReduce the probability of defective productsLiquid surface applicatorsWood treatment detailsWood veneerPulp and paper industry

The invention discloses a painted flexible wood veneer processing method, which comprises the steps of conducting softening treatment to a wood veneer by using a wood veneer softening material and then coating a layer of paint on the surface of the wood veneer. The product can replace the wood veneer with a non-woven fabric or back lining paper stuck on the back surface of the wood veneer in the traditional method and the wood veneer with a paint surface in the common wood veneer veneering technology. The painted flexible wood veneer can be used for the surface decoration of curved surface and flat surface parts of various wooden products, doors, windows and plates, the problems that the existing veneer is stripped off from the non-woven fabric and the wood veneer is stripped off from the back lining paper during processing and use are improved, the situation that the wood veneer is cracked when the wood veneer is stuck on a processed piece is avoided, the service life of the product is improved, the complex processes such as painting, drying, sanding and polishing, especially curved surface sanding and polishing in the transitional technology are reduced, the production efficiency is greatly improved, the production cost is saved and the use prospect is very promising.

Owner:应晨霞

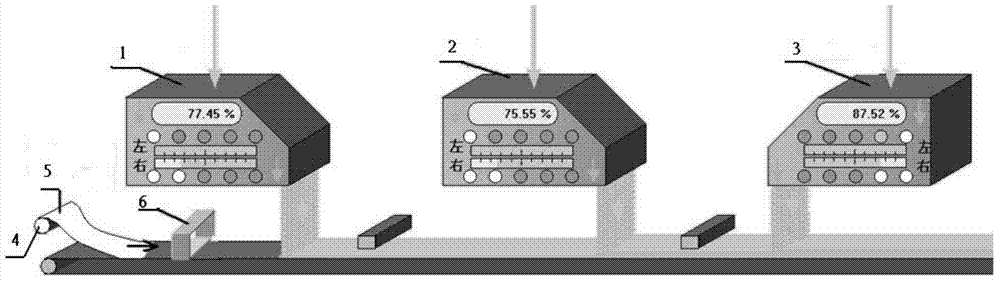

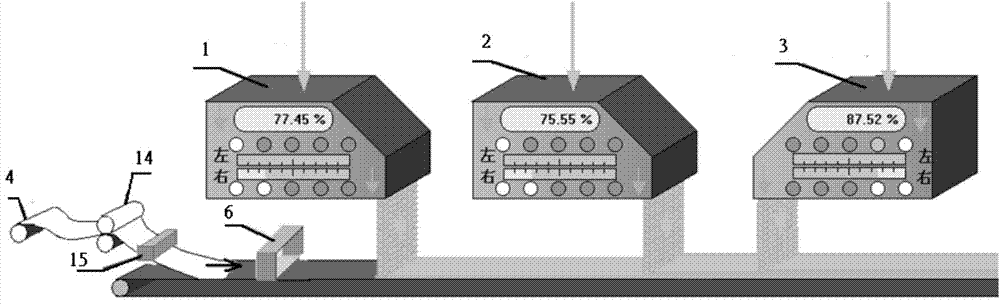

Polycrystalline silicon ingot slicing device and method

The invention discloses a polycrystalline silicon ingot slicing device and method. The polycrystalline silicon ingot slicing device comprises a plurality of cutting lines which are parallel to one another, wherein an edge cutting line positioned on an outermost side is used for cutting out an edge; the outer side of the edge cutting line is further provided with at least one additional cutting line for subdividing the edge to separate an edge close to a crucible surface and an edge close to a central silicon ingot out. According to the polycrystalline silicon ingot slicing device and method provided by the invention, an edge material is partitioned into two parts; the edge close to the crucible surface is high in impurity content, and is molten down for purification and cast; the edge close to the central silicon ingot can be recycled directly after being cleaned, so that wear to the edge close to the crucible surface can be reduced, the impurities in a silicon material are reduced, the cast ingot quality is enhanced, and the problems of incomplete impurity removal and loss of a dusty silicon material are solved.

Owner:JINKO SOLAR CO LTD +1

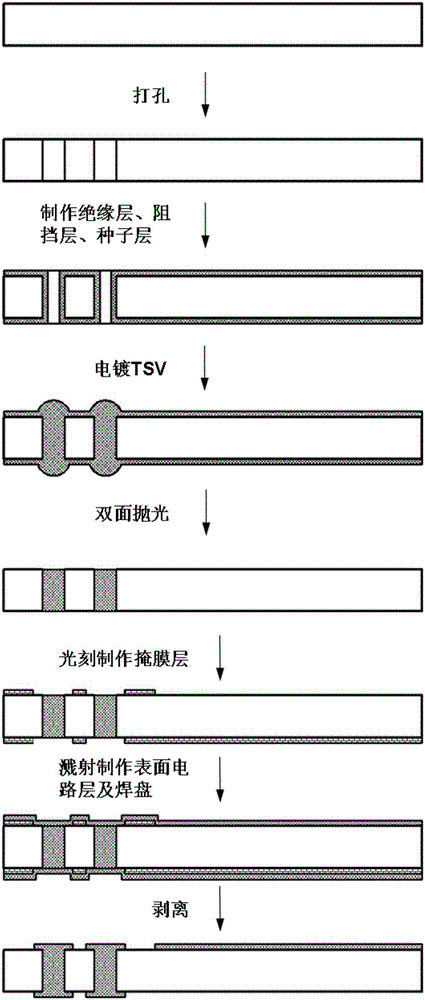

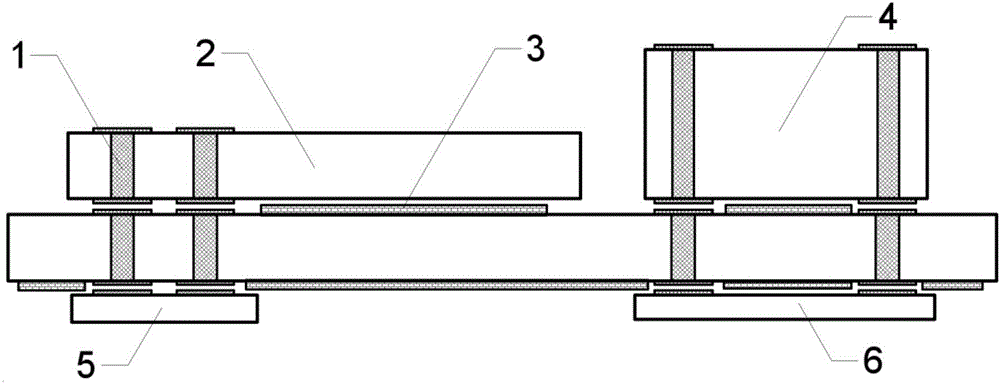

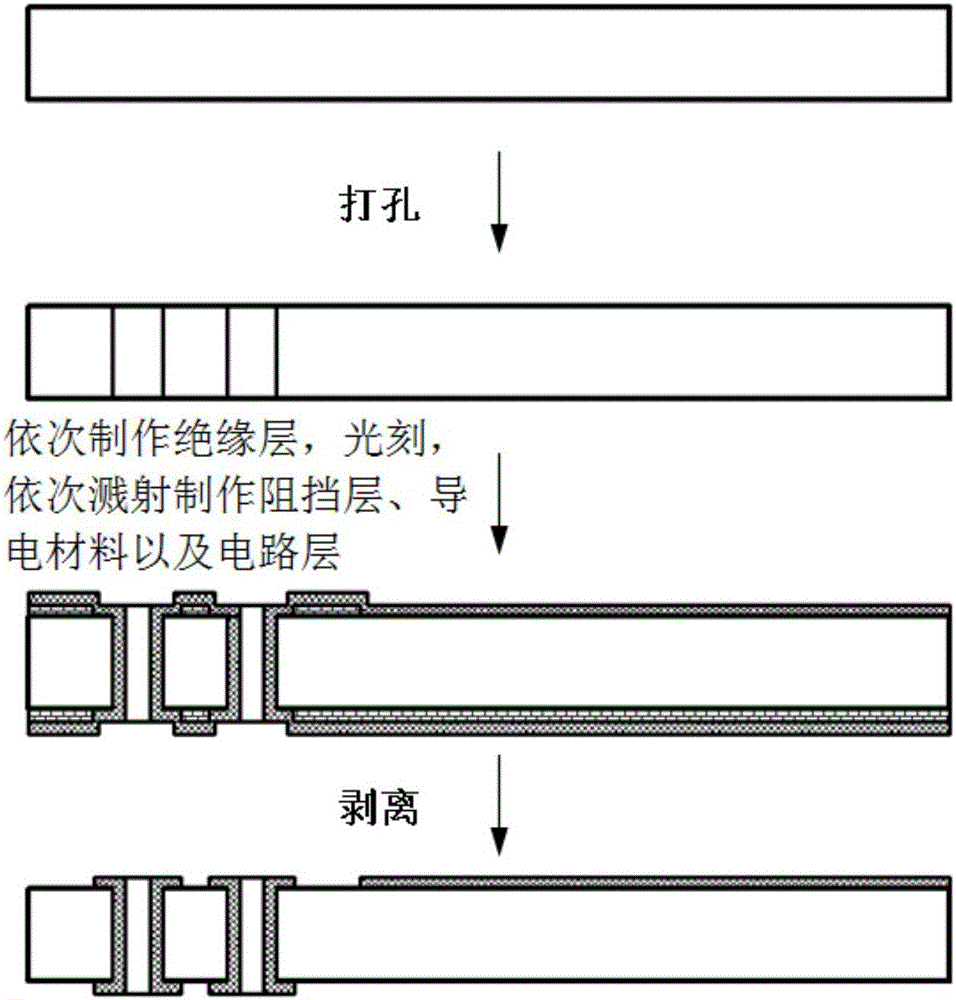

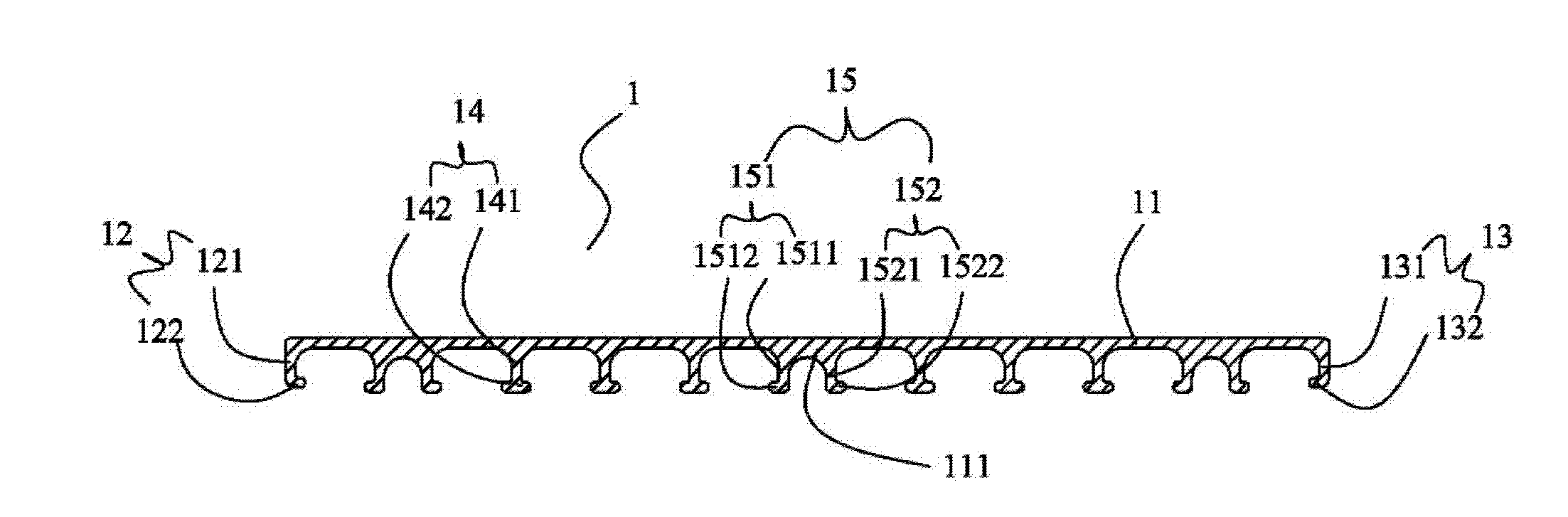

Semiconductor substrate, three-dimensional package chip and through-silicon via packaging method

InactiveCN106711095AAvoid deformationExtend your lifeSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

The invention discloses a semiconductor substrate, a three-dimensional package chip and a through-silicon via packaging method. The semiconductor substrate has a through-silicon via running through the semiconductor substrate; the internal surface of the through-silicon via is circumferentially deposited by a conductive material, the thickness of which is smaller than 2 mum; the volume fraction of the conductive material in the through-silicon via is 5 vol.%-95 vol.%; and the center of the through-silicon via has a gap running through the through-silicon via. Only the internal surface of the through-silicon via is circumferentially deposited by the conductive material, and the center of the through-silicon via in the semiconductor substrate still has a certain gap, so that the prepared three-dimensional package chip does not deform easily under hot and cold environment, yield is improved, and the service life of the three-dimensional package chip is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

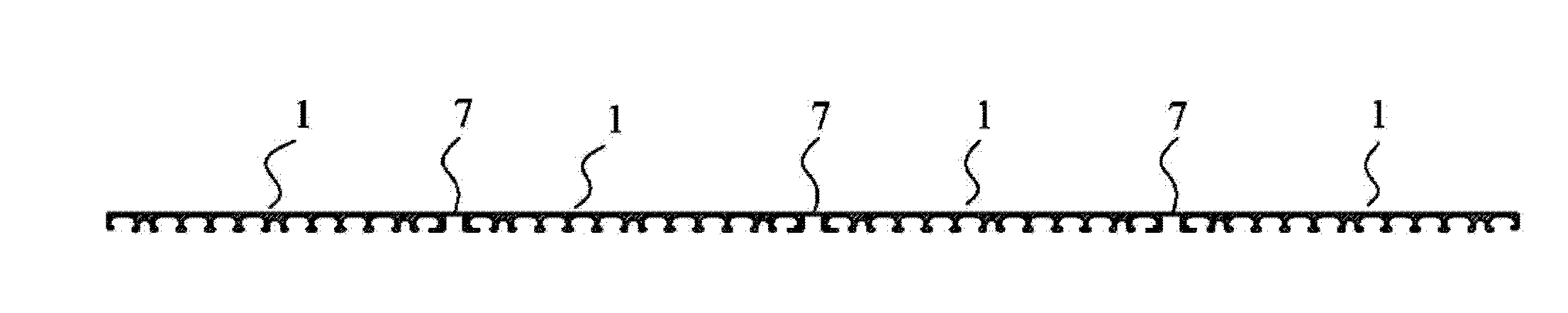

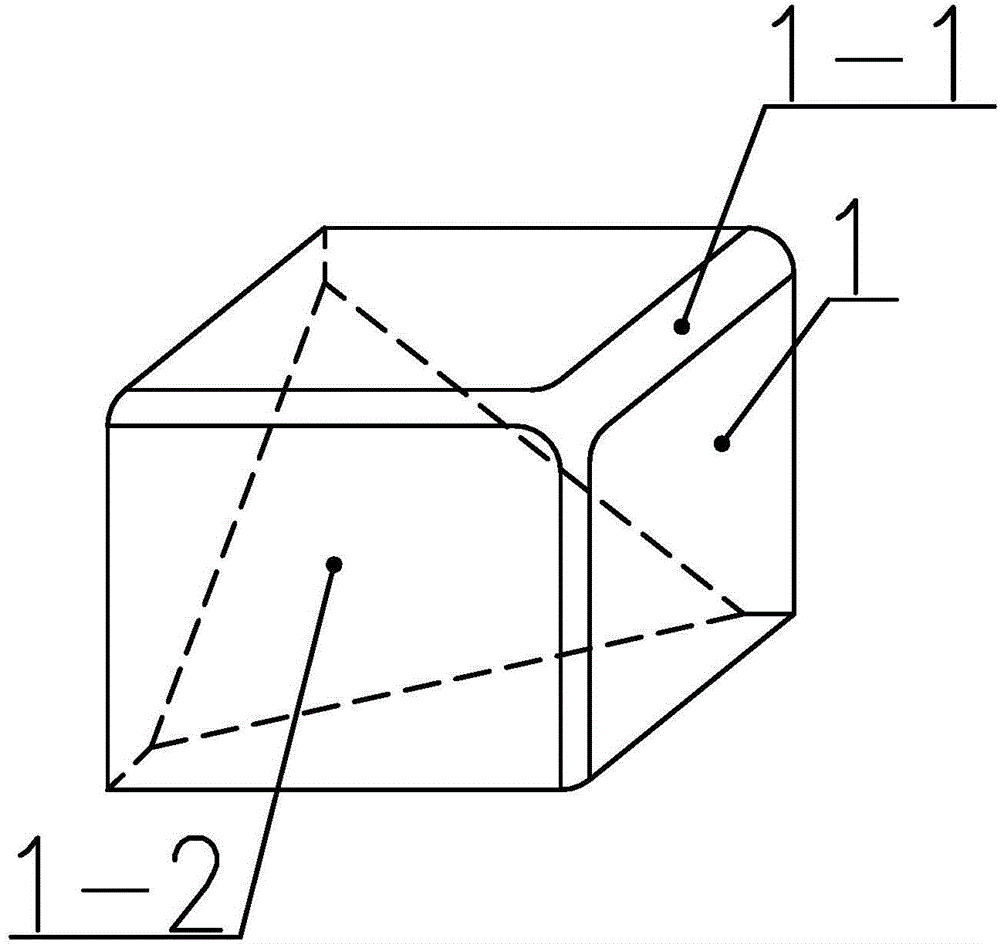

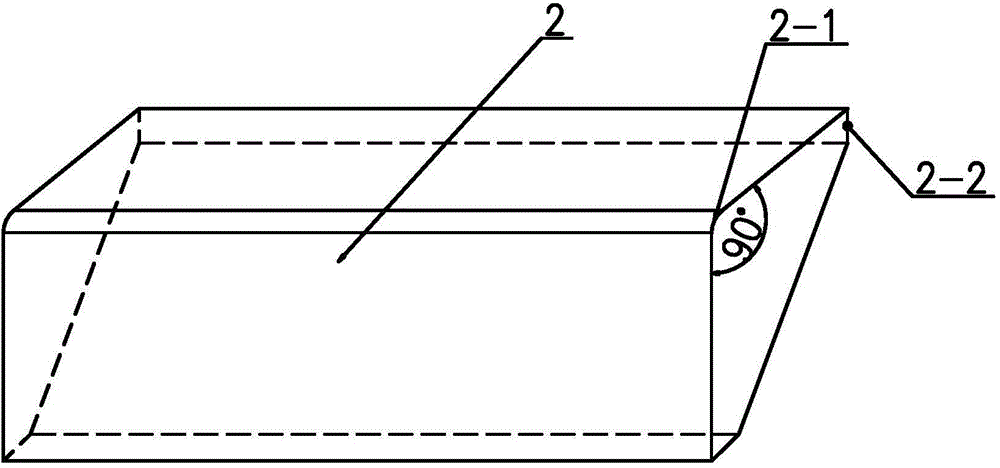

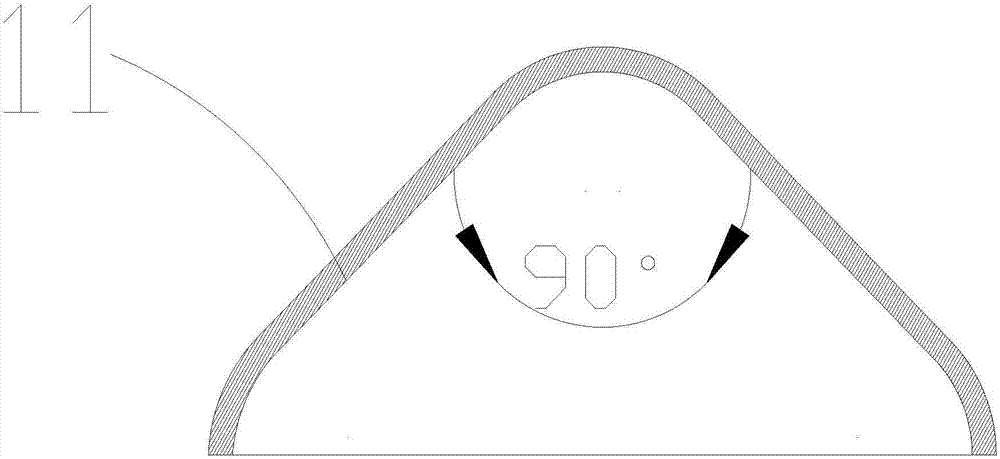

Container bottom plate and container bottom plate unit made of novel composite material for container bottom plate

The invention relates to a container bottom plate unit made of a novel composite material. The novel container bottom plate unit is made of the fiber strengthening polymer matrix composite material and comprises a panel and a plurality of webs, the bottom of the panel downwards extends to form the webs, the webs comprise two end webs located at two ends of the panel and a middle web located in the middle of the panel, and the heights of the two end webs are equal to or lower than the height of the middle web. Container bottom plate units can be in lap joint along transverse inner fasteners or / and are spliced with 'Omega'-shaped container steel center sills in a matched manner to form an total container bottom plate. The container bottom plate unit is made of the fiber strengthening polymer matrix composite material, a bottom plate unit structure and a splicing mode thereof, which correspond to the material, are adopted, and accordingly the container bottom plate unit has an excellent environmental protection performance, an excellent lightweight performance and an excellent installation performance.

Owner:NANTONG CIMC ECO NEW MATERIAL DEV CO LTD +1

Blow protection device for pulse laser welding of thin plate stainless steel

ActiveCN105149777BInhibition of shieldingPlay the role of "repression"Welding/soldering/cutting articlesMetal working apparatusEngineeringLaser

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

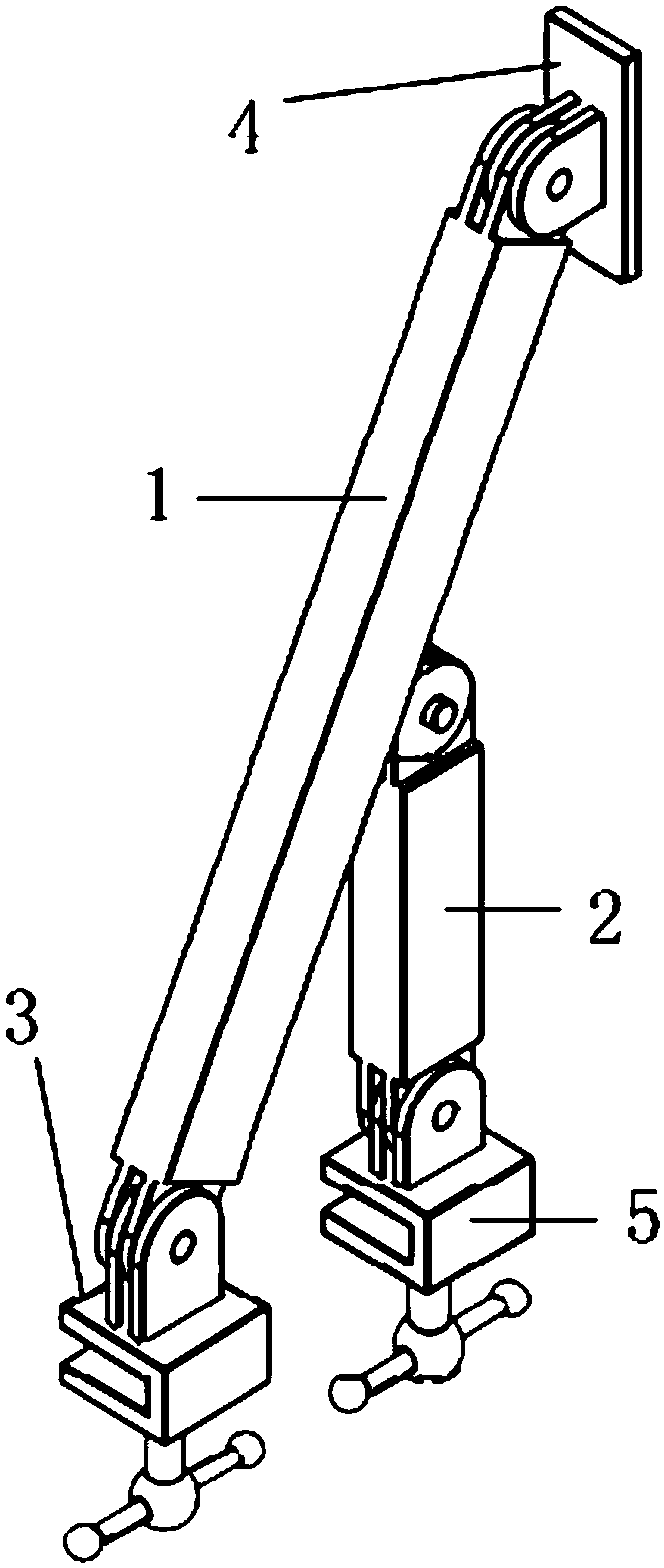

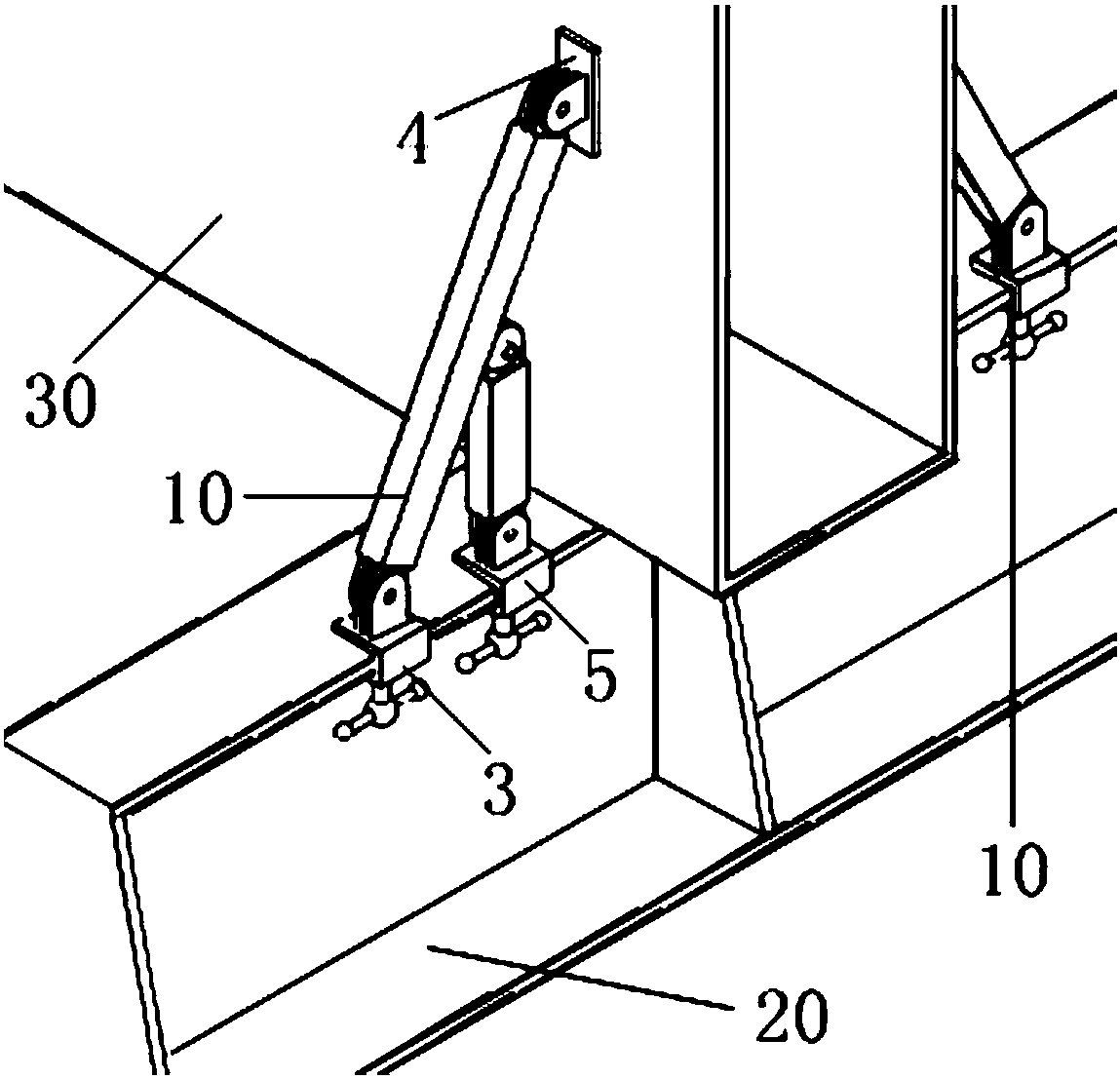

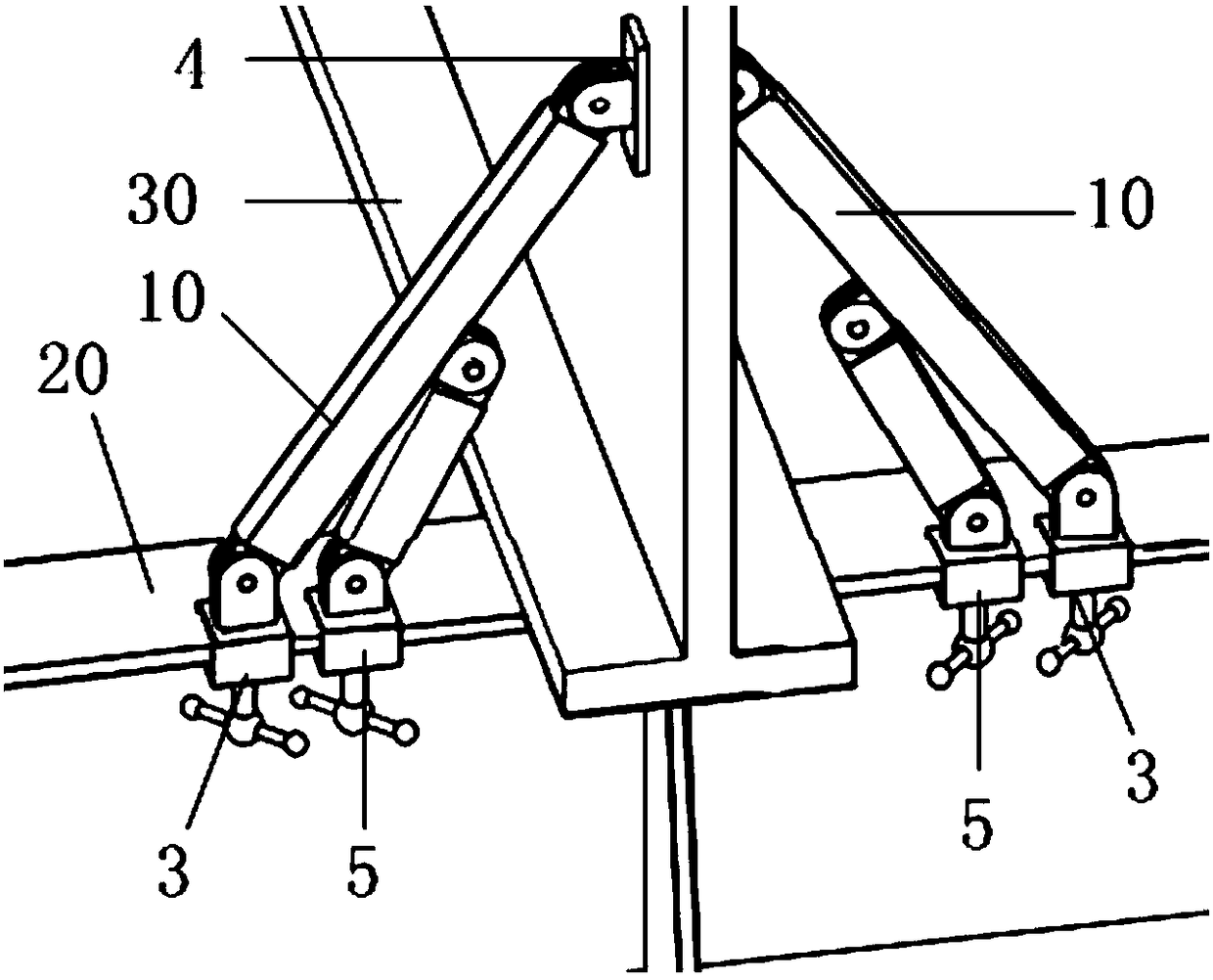

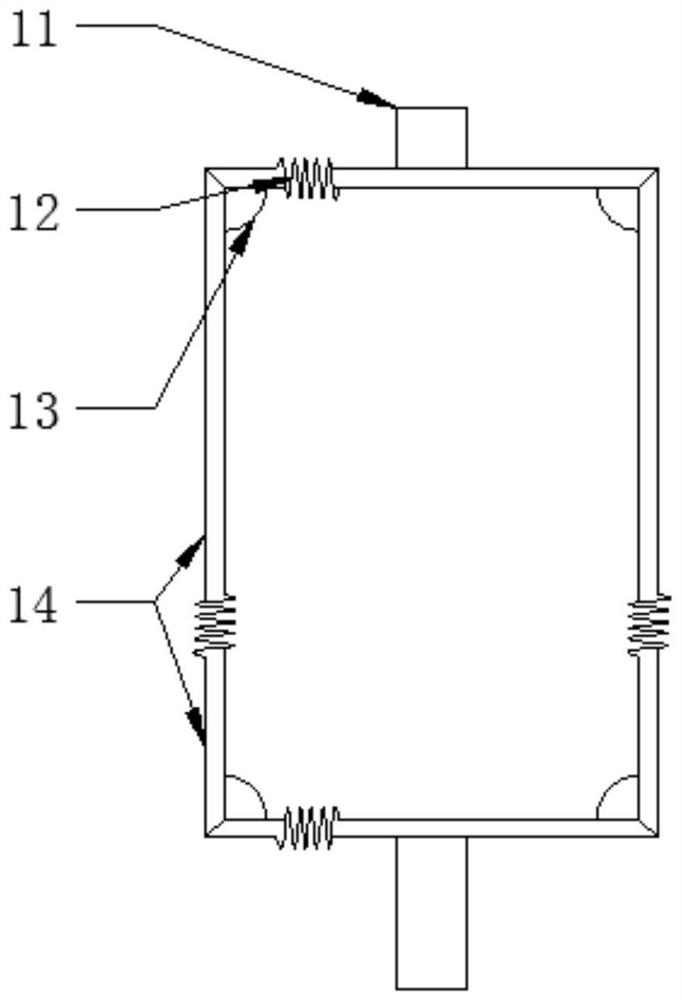

Supporting device

The invention provides a supporting device, and relates to the technical field of steel structure auxiliary equipment. The supporting device comprises a long supporting rod, a short supporting rod, asupporting plate, a first clamping-fixing piece and a second clamping-fixing piece; one end of the long supporting rod is rotatably connected with the first clamping-fixing piece, the other end of thelong supporting rod is rotatably connected with the supporting plate, one end of the short supporting rod is rotatably connected with the second clamping-fixing piece, and the other end of the shortsupporting rod is rotatably connected with a rod body of the long supporting rod; and the first clamping-fixing piece and the second clamping-fixing piece are fixed to a first to-be-supported part, the plate face of the supporting plate is attached to a second to-be-supported part so as to support the second to-be-supported part, wherein the second to-be-supported part is located above the first to-be-supported part, and the second to-be-supported part makes contact with the first to-be-supported part mutually. According to the supporting device, operation is convenient, the working efficiencyis improved, the repeated utilization rate is high, and the cost is reduced.

Owner:中建钢构四川有限公司

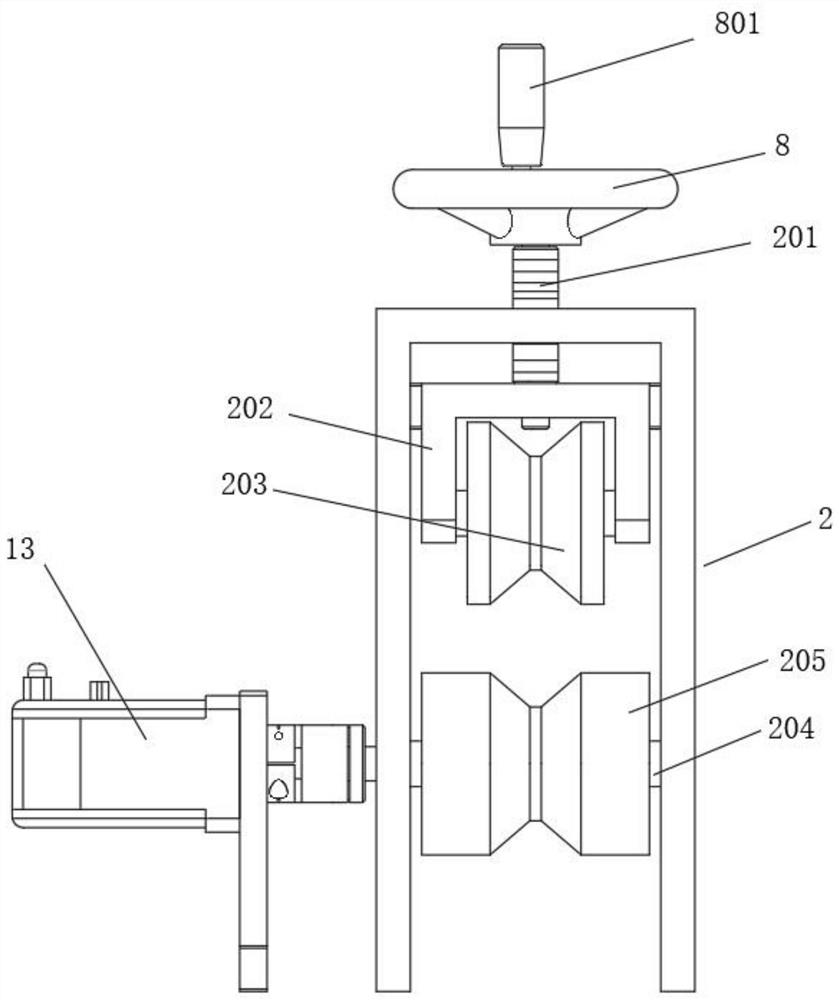

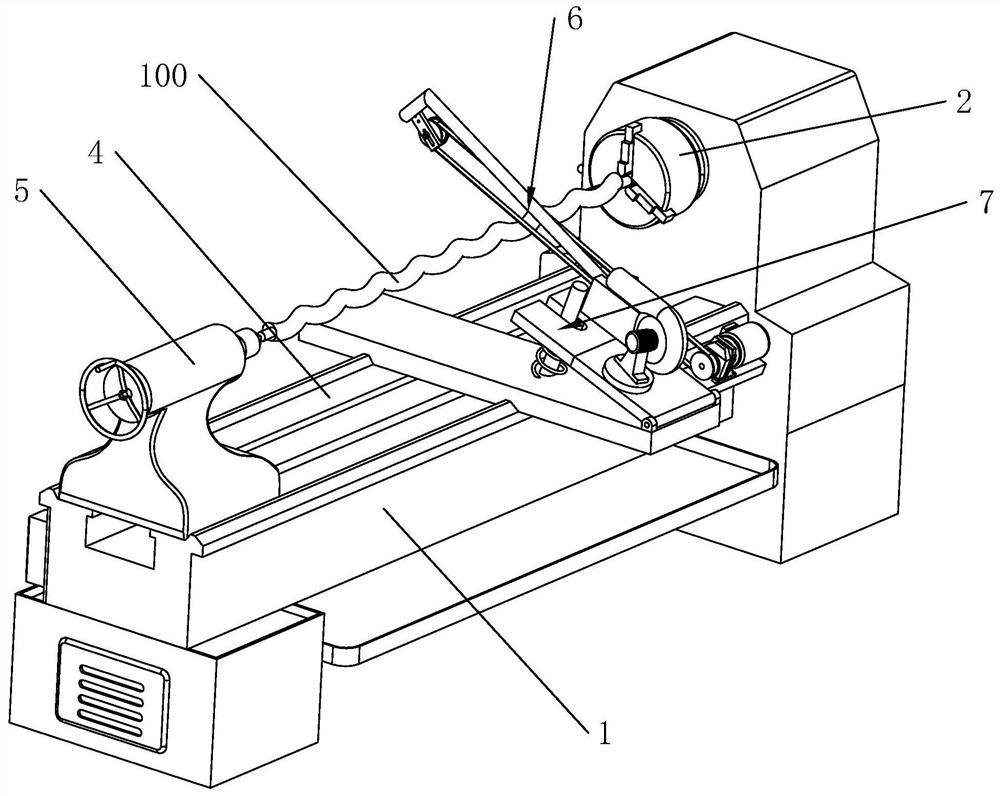

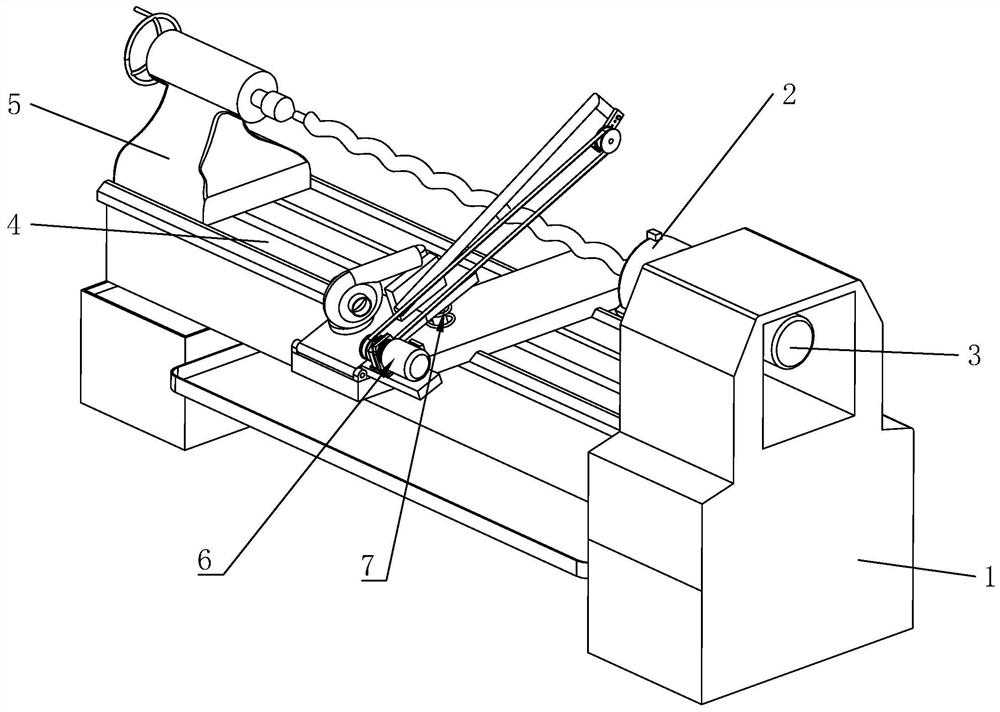

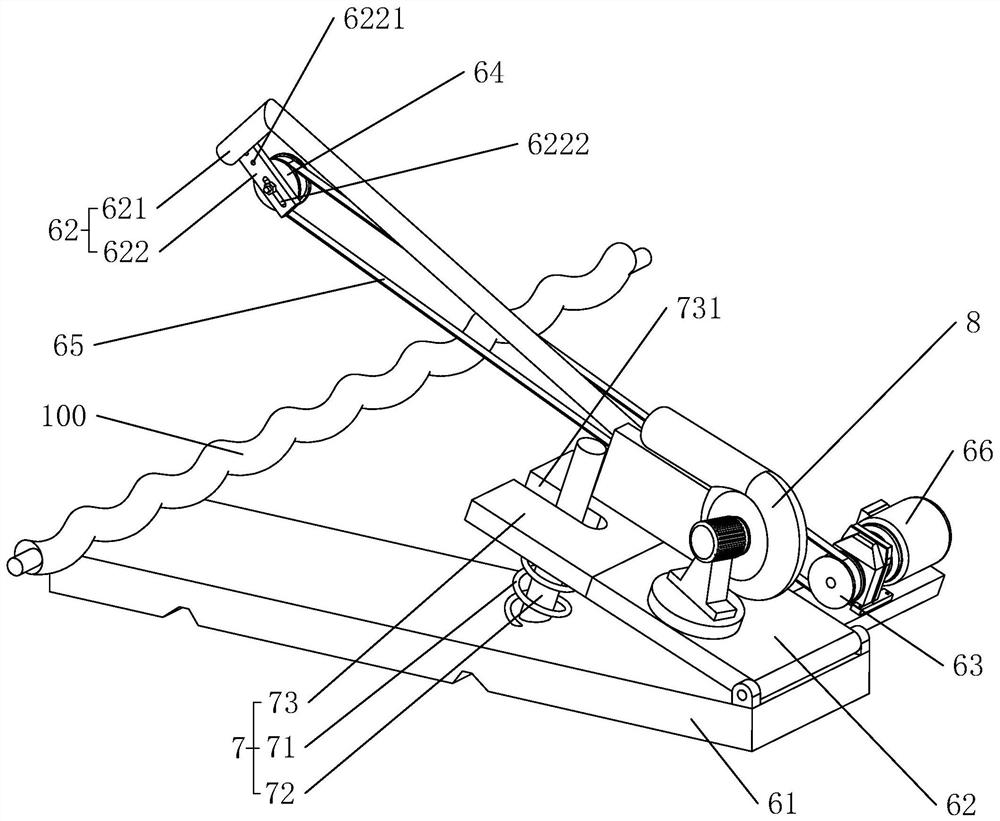

Javelin grinding machine tool

ActiveCN105751038AComplete quickly and efficientlyAvoid bouncingGrinding carriagesBelt grinding machinesRotational axisReciprocating motion

The invention belongs to a javelin grinding machine tool which comprises a tool body, a rotating shaft, an abutting mechanism and a grinding mechanism. The rotating shaft is arranged at one end of the tool body, the abutting mechanism is arranged at one end of the tool body and corresponds to the rotating shaft, the grinding mechanism is arranged on the tool body through a sliding rail and positioned between the rotating shaft and the abutting mechanism, a locking mechanism is arranged between the abutting mechanism and the tool body, and an adjusting screw pushing the grinding mechanism to be in reciprocating motion is arranged between the grinding mechanism and the tool body. Two ends of a javelin blank are supported, the javelin blank is rotated by the rotating shaft, and at the same time, an abrasive belt machine matched with an abutting wheel grinds a javelin; radian of the surface which is ground is controlled jointly by an auxiliary adjusting screw and the adjusting screw, so that grinding of the surface of the javelin blank can be completed accurately, quickly and efficiently to meet standards, mechanization level is high, and the grinding process of the javelin blank can be completed quickly, efficiently and accurately; the whole javelin grinding machine tool automatically controls a running track of the abrasive belt machine in the whole process through a control system, and strict standardization can be realized.

Owner:HEBEI SILVER ARROW SPORTING GOODS CO LTD

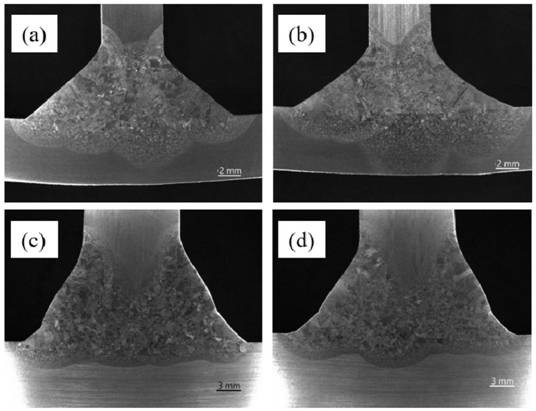

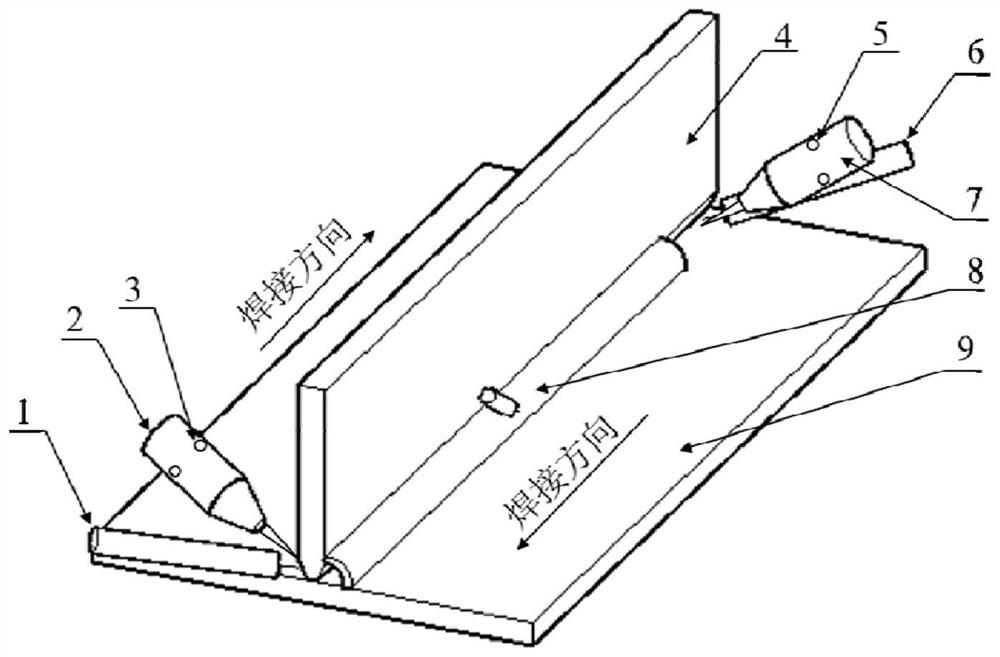

Welding method for heterogeneous titanium alloy T-shaped joint

ActiveCN113814535AImprove consistencyImprove welding strengthArc welding apparatusIncreasing energy efficiencyShielding gasStructural engineering

The invention discloses a welding method of a heterogeneous titanium alloy T-shaped joint, which comprises the following steps of: 1, processing a to-be-welded part of a rib plate into a K-shaped groove, and fixing the K-shaped groove on a welding tool clamp; 2, adopting coaxial powder feeding type laser cladding, wherein lasers act on the to-be-welded area on the two sides of the T-shaped connector correspondingly, an MIG welding gun swinging periodically is arranged on the rear side of a laser beam, and the included angle between the MIG welding gun and the rib plate and the included angle between the laser beam and the rib plate are adjusted to be located on the same plane; 3, setting welding process parameters; and 4, introducing shielding gas in advance, conducting double-face laser cladding composite electric arc welding of the T-shaped connector, conducting synchronous different-direction welding on welding heat sources on the two sides, wherein electric arcs swing periodically, single-pass welding forming of the workpiece is achieved, and the shielding gas is continuously introduced for cooling after welding. The laser cladding powder is used for regulating and controlling configuration, the internal consistency of the welding seam is enhanced, the welding seam strength is improved, and cracks are restrained through components of the welding wire before solidification of a molten pool.

Owner:JIANGSU UNIV OF SCI & TECH +1

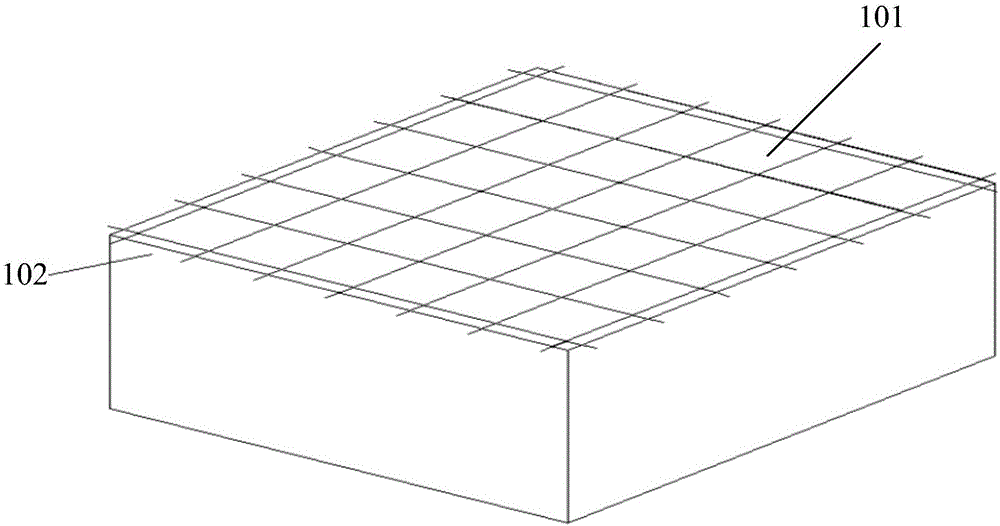

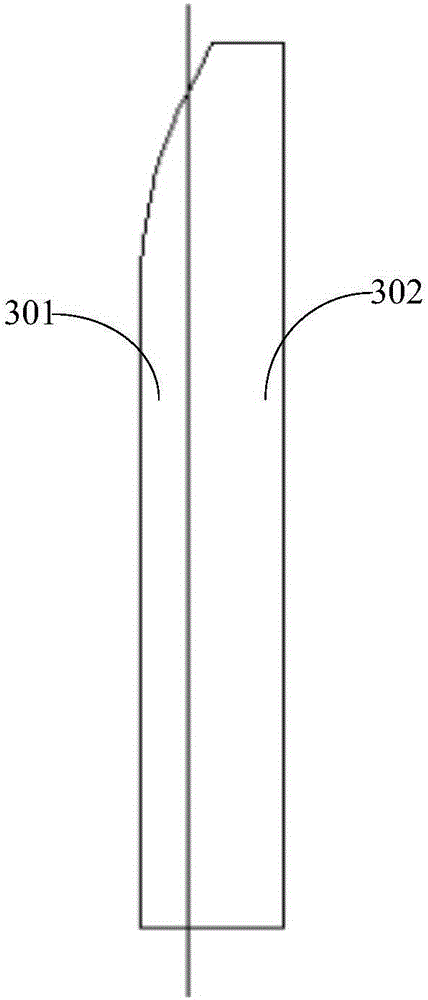

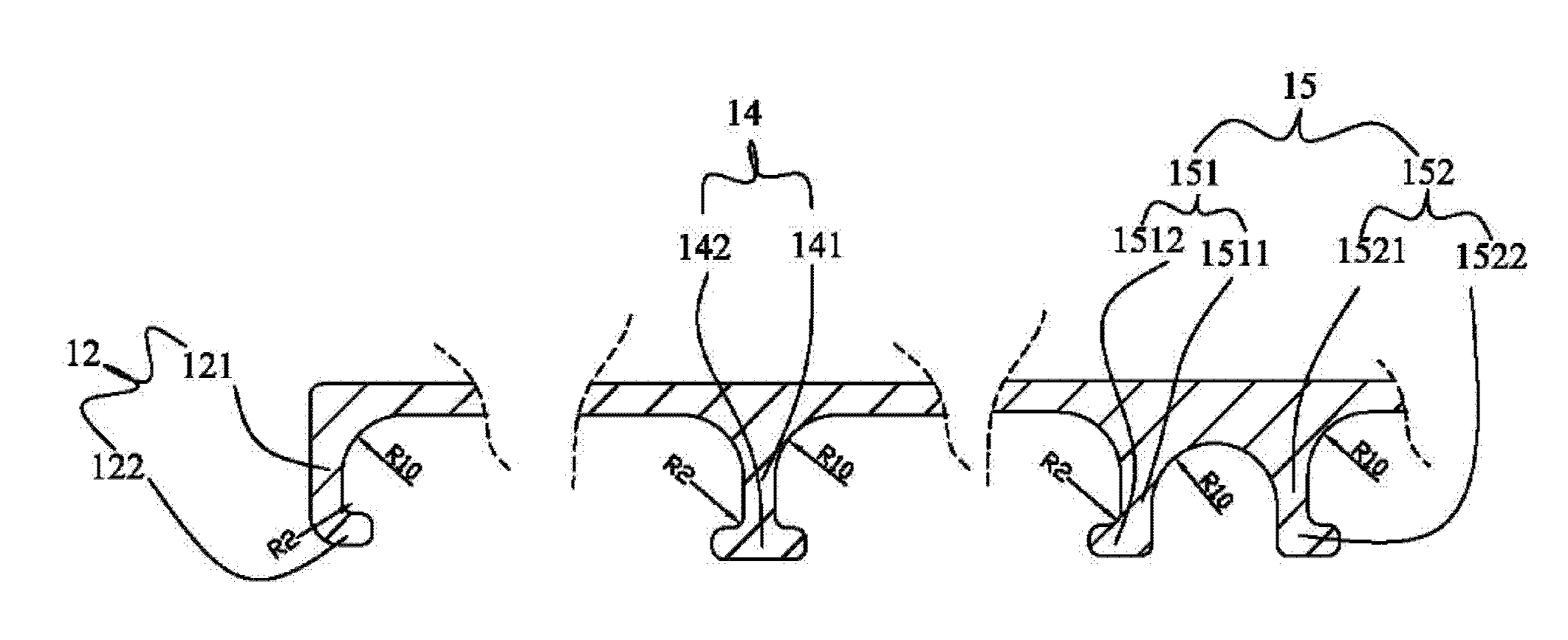

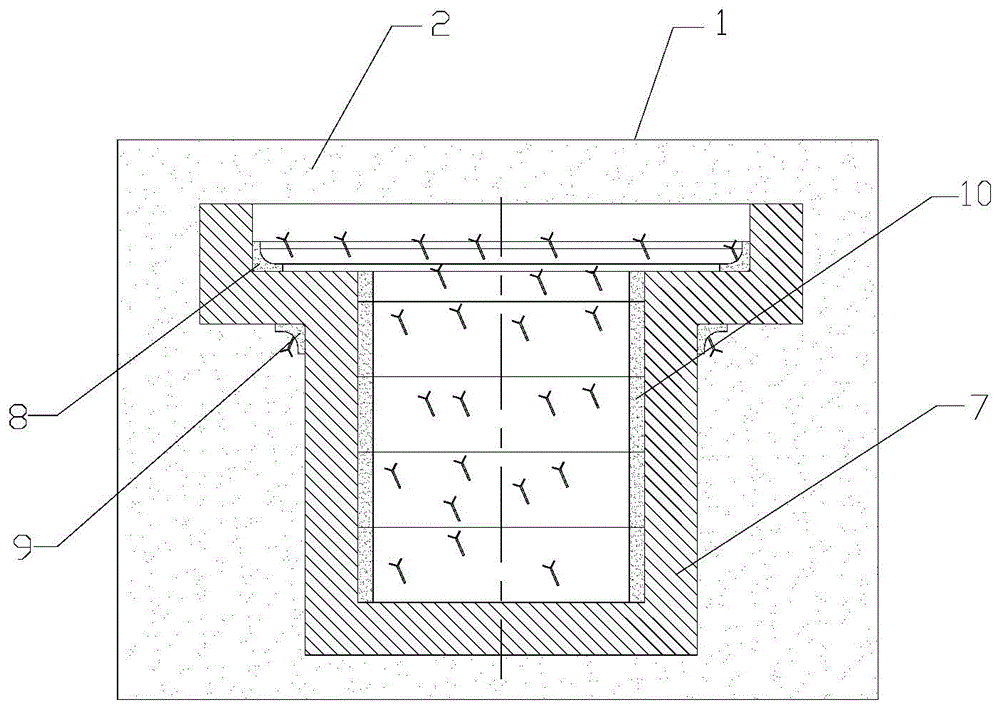

Method used for preventing sand adhesion of sand mould castings, and sand mould prefabricated components

InactiveCN104826986AReduce sticky sandReduce sandingFoundry mouldsFoundry coresMaterials sciencePrefabrication

The invention relates to a method used for preventing sand adhesion of sand mould castings, and sand mould prefabricated components. Each of the sand mould prefabricated components comprises a prefabricated block and connecting claws; the connecting claws are embedded in the prefabricated block, and are firmly connected with the prefabricated block; and the two ends of each connecting claw are provided with Y-shaped support legs. According to the method, prefabrication of the sand mould prefabricated components corresponding to certain parts in sand mould modeling is carried out; in modeling processes, the sand mould prefabricated components are placed at corresponding parts, filling of moulding sand and pressing are carried out, and the connecting claws on the sand mould prefabricated components are mixed with the moulding sand so as to realize integration of the sand mould prefabricated components with the moulding sand. The special-type prefabricated components are fixedly arranged at the preset parts of sand moulding, so that casting sand adhesion and sand filling are avoided, local deformability and collapsibility are improved, local temperature is controlled, casting quality is increased, production cost is reduced, and operation is convenient. The sand mould prefabricated components are provided with universal R angles; plane standardization can be realized; and cutting and splicing can be carried out.

Owner:鞍山千钢机械制造有限公司

Novel wheel electroplating spraying equipment

The invention discloses novel wheel electroplating spraying equipment. The equipment comprises an electroplating pool and a painting chamber; the electroplating pool and the painting chamber are connected through a drying channel; a rotating frame is mounted at the top of the electroplating pool; the electroplating pool comprises a plating layer metal box, a clip to be plated, and a barrier net; the plating layer metal box and the clip to be plated are arranged on two sides of the barrier net; the rotating frame is driven through a motor; an unloading frame is arranged in the rotating direction of the rotating frame, and is connected with the motor through a conveying belt; the conveying belt is arranged in the drying channel; the painting chamber comprises a painting head, a paint storagebox and a conducting pipe; the painting head is connected with the paint storage box through the conducting pipe; an air blower is mounted in the drying channel; and a high-heat heating wire is mounted in an air outlet of the air blower. The equipment can perform the electroplating and painting treatment on a production line, reduces the labor intensity and the workload, simplifies the process flow, improves the production efficiency, and reduces the comprehensive production cost.

Owner:赵斌

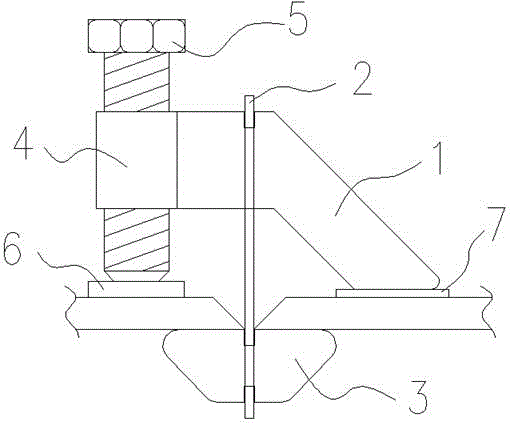

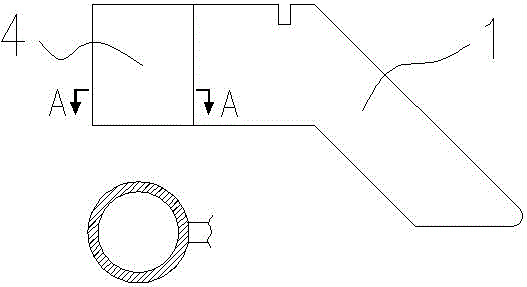

Movable horse board

InactiveCN104476069ASave materialSave welding consumablesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMotherboard

The invention relates to a movable horse board. The movable horse board comprises a main board, a plug board, a base plate, a nut and a bolt, wherein the main board is composed of a horizontal component and an oblique component; the upper end of the plug board is arranged on the main board, and plug board is vertical to the horizontal component on the main board; the lower end of the plug board is arranged on the base plate; one end of the horizontal component of the main board is connected with the nut while the other end is connected with the oblique component; the bolt is arranged in the nut. The movable horse board has advantages that the movable horse board can be used repeatedly, a lot of horse board material, welding material, manpower and the like are saved; the subsequent horse board cutting, grinding and paint repairing workload is reduced; the movable horse board is beautiful and does not have horse legs.

Owner:WISON NANTONG HEAVY IND

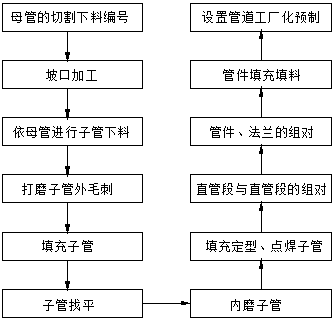

Construction process of high-pressure stainless steel acetylene filled tube

The invention discloses a construction process of a high-pressure stainless steel acetylene filled tube. The process comprises following steps of firstly, cutting, discharging and numbering of a mother tube; secondly, groove preparation; thirdly, sub tube discharging according to the mother tube; fourthly, sub tube outer burr grinding; fifthly, sub tube filling; sixthly, sub tube leveling; seventhly, sub tube inner grinding; eighthly, filling, shaping and sub tube spot welding; ninthly, assembling of straight tube segments; ninthly, pipe fitting and flange assembling; eleventhly, pipe fittingpadding filling; twelvethly, pipefitting industrialization prefabrication. According to the process, the straight pipe segments are wholly filled, a filling platform is developed, a whole filling method is adopted for construction, and the problems that due to one-by-one sub tube filling, the efficiency is low, and the quality is poor are solved; sub tube whole filling is carried out, after filling, sub tube arranging interval quality is good, staggered collapsing is avoided, the schedule is greatly improved, and the traditional straight pipe segment filling construction process is thoroughlychanged.

Owner:SHANXI INSTALLATION GRP CO LTD

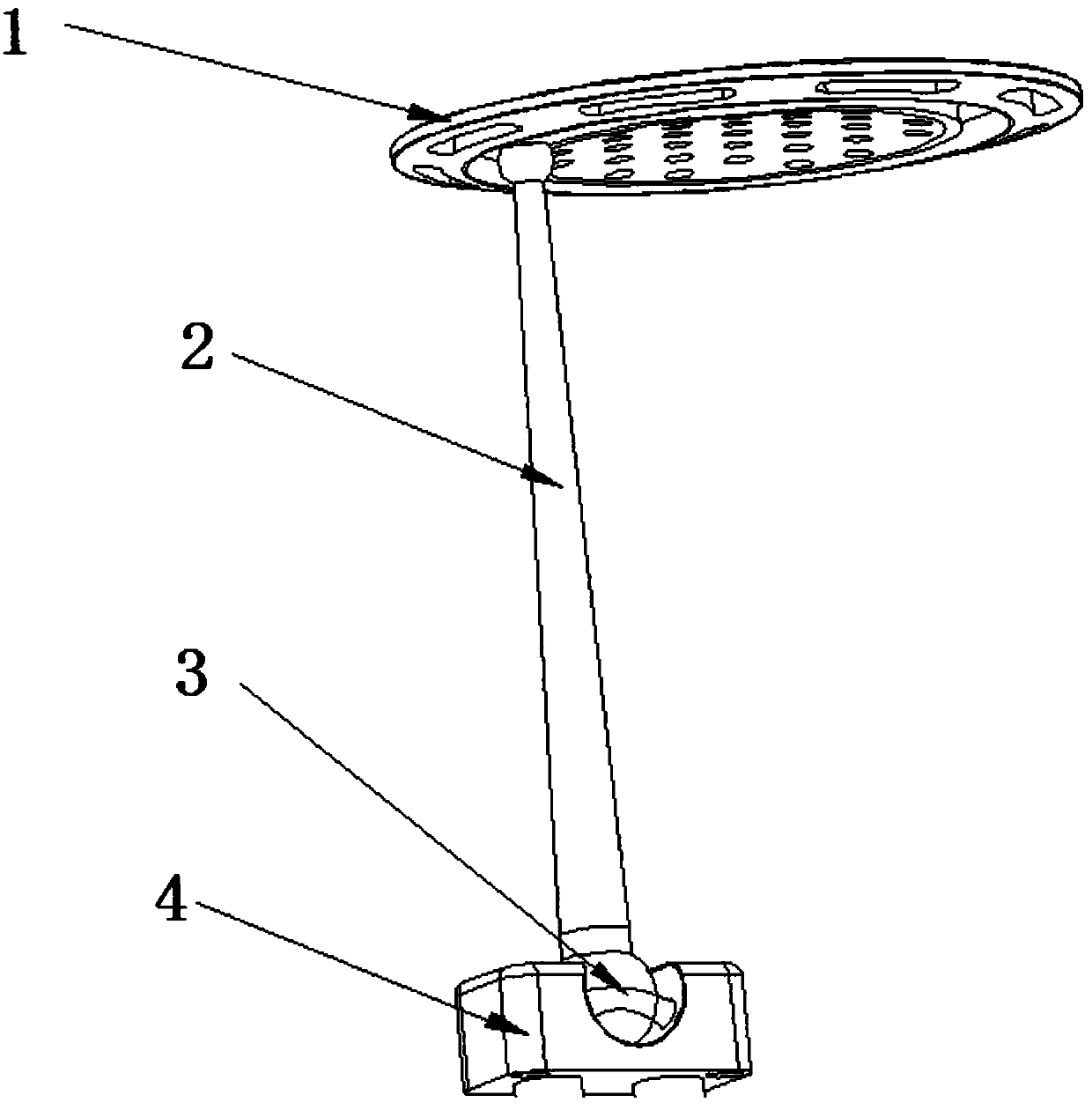

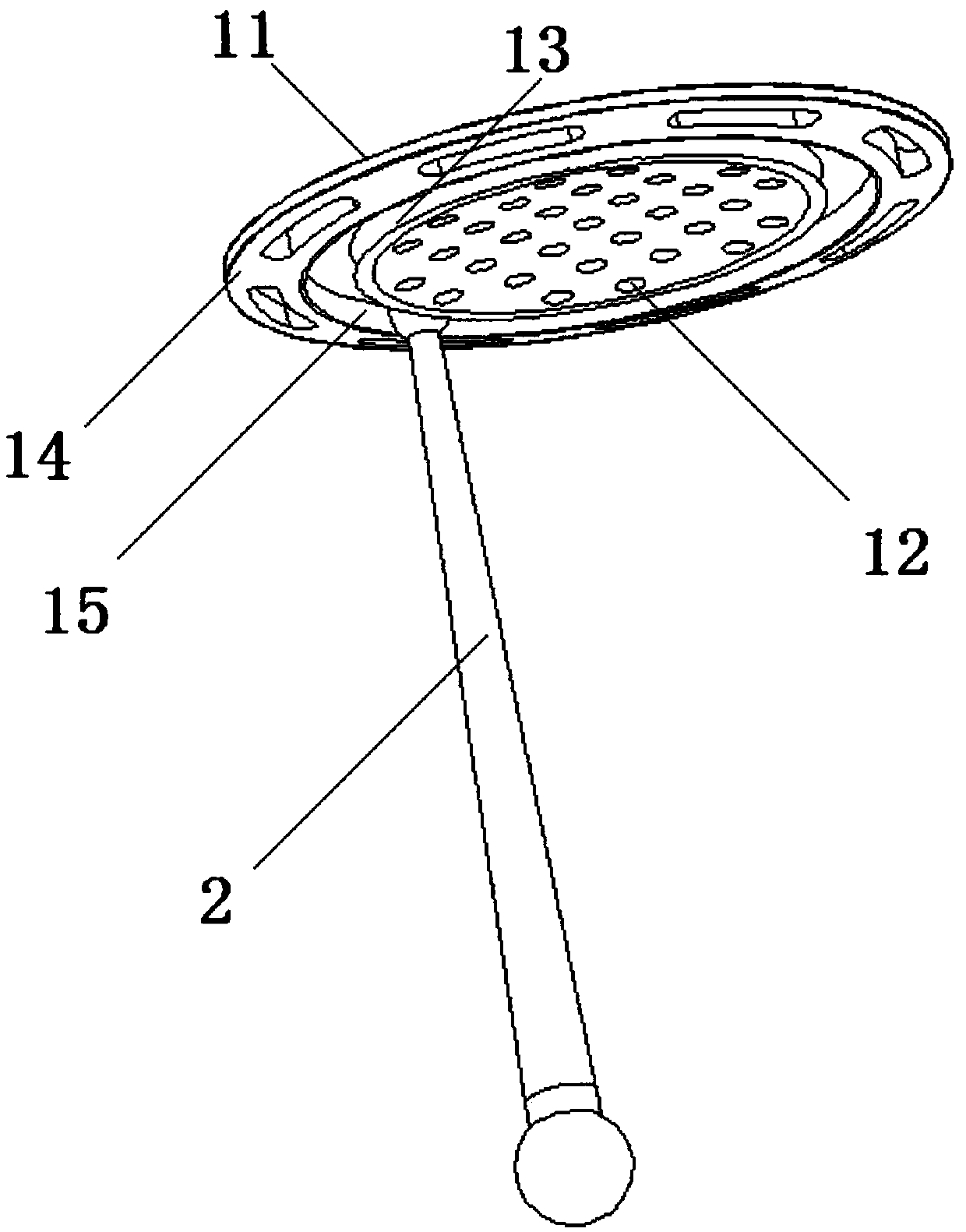

Replaceable artificial auditory ossicle prosthesis device

The invention discloses a replaceable artificial auditory ossicle prosthesis device. The device comprises an elastic ear membrane affinity sheet, a crank, an elastic fixing pin and a base, wherein theelastic ear membrane affinity sheet is slidably connected with the top of the crank, and the bottom of the crank is fixedly connected with the base through the elastic fixing pin; the elastic ear membrane affinity sheet fits the ear membrane, and the base is fixed into the podalic plate. The device aims at solving the problem of hearing loss caused by prolapse, breakage, displacement and the likeof existing artificial auditory ossicle prosthesis devices after operations; a spring fixing pin is pulled out, a main body part is inserted, and then the spring fixing pin is inserted to complete the whole use process, so that the time of doctors during the operations is greatly saved, and the workload of the doctors during the operations is greatly reduced; through the operation of a sphericalstructure at the lower end of the crank and the position of the base, automatic adjustment is achieved according to the heights of the auditory ossicles of different human bodies, time for the doctorsto conduct cutting, grinding and the like is shortened, and the workload of cutting, grinding and the like is reduced for the doctors. The angle of the replaceable artificial auditory ossicle prosthesis device can be adjusted according to different ear membranes of each person.

Owner:苏州真懿医疗有限公司

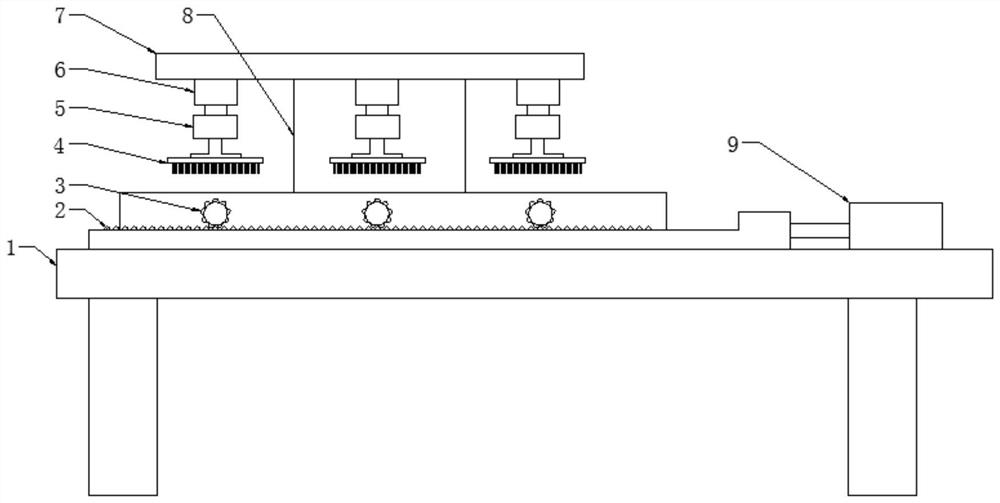

Iron rod surface rust removal and paint spraying integrated device for hardware machining

The invention relates to the technical field of rust removal and paint spraying, and particularly relates to an iron rod surface rust removal and paint spraying integrated device for hardware machining. The iron rod surface rust removal and paint spraying integrated device comprises a base table, a transmission assembly, a paint spraying frame and a moving assembly. A paint air pump sprays paint outwards through a spraying pipe from a spraying head. After an iron rod is ground, the iron rod immediately passes through the position below the paint spraying frame, and the paint is sprayed to thesurface of the iron rod through the spraying head. A grinding assembly of the iron rod surface rust removal and paint spraying integrated device for hardware machining is tightly connected with the paint spraying frame, so that the device achieves integration, accordingly, the occupied area of the device is reduced, and the using convenience is improved; and meanwhile, grinding rust removal and paint spraying are connected more tightly, the iron rod is prevented from being oxidized again after being ground and subjected to rust removal, and the rust removal and maintenance effect of the iron rod surface rust removal and paint spraying integrated device for hardware machining on the iron rod is improved.

Owner:张旭东

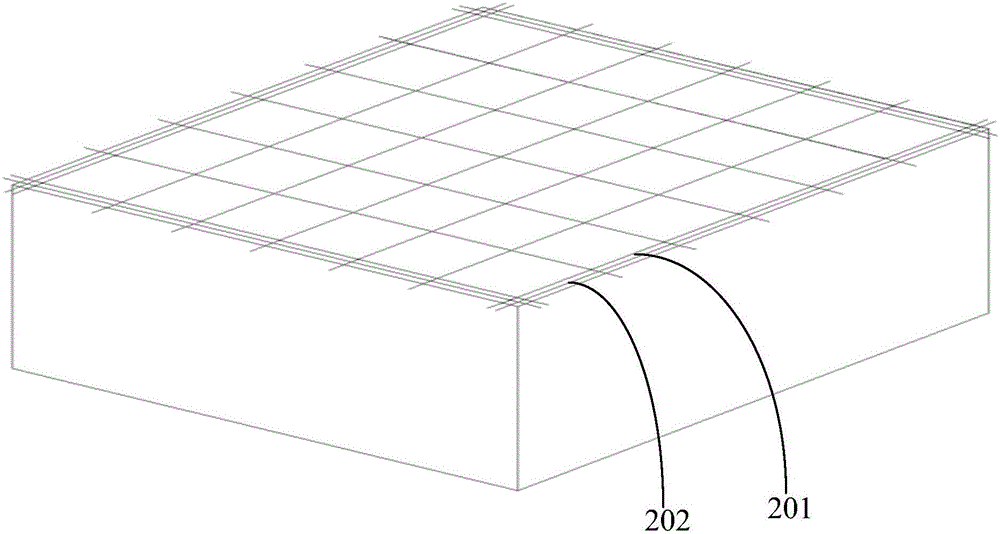

No-mold casting method for preventing sand bonding and prefabricated part

InactiveCN104815953AReduce sticky sandReduce sandingFoundry mouldsFoundry coresTemperature controlCasting mold

The invention discloses a no-mold casting method for preventing sand bonding and a prefabricated part. The method comprises the following steps: (1) the prefabricated part is manufactured; (2) a no-mold sand mold is formed; and when the sand mold is processed, the mounting position of the prefabricated part is left in the easy sand bonding place in a molding cavity of a casting sand box of the no-mold sand mold and in the plane place having specific requirement on the casting quality through judging according to the casting structure; and (3) the prefabricated part is fixed in the left position of the sand mold through bonding; and the sand mold is prefabricated and molded. Compared with the prior art, the method has the following beneficial effects: the special prefabricated part is manufactured beforehand, and is fixed in the left position of the casting mold for realizing such special process targets as reduction of casting sand bonding and wrapping, improvement of local deformability, improvement of local collapsibility and local temperature control. The method can improve the casting quality and reduce the production cost. The method is convenient and simple in operation, and can manufacture the prefabricated parts to standard prefabricated parts with unified specification for cutting and splicing.

Owner:鞍山千钢机械制造有限公司

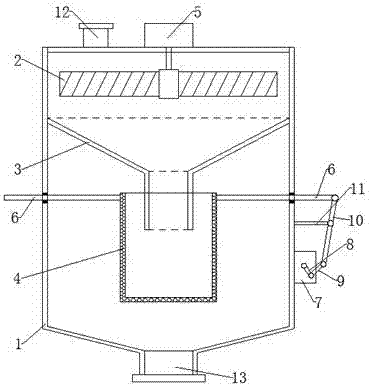

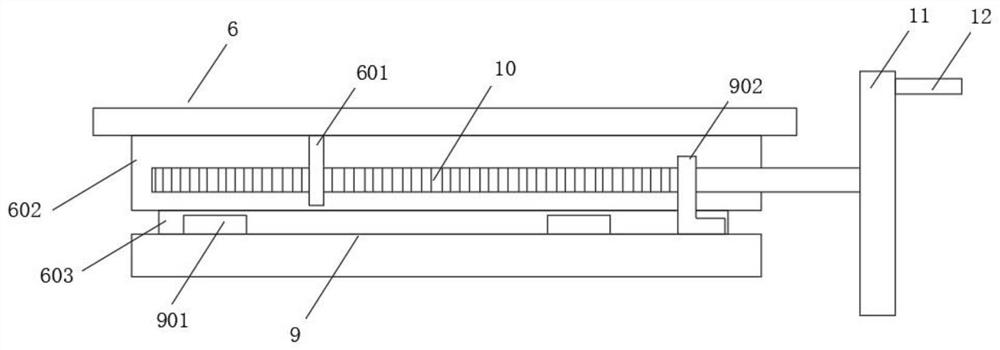

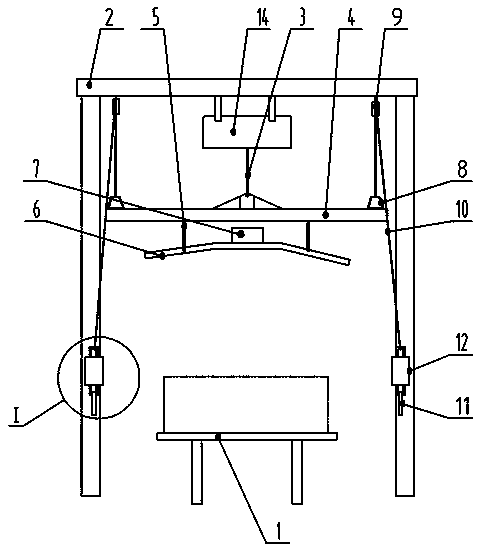

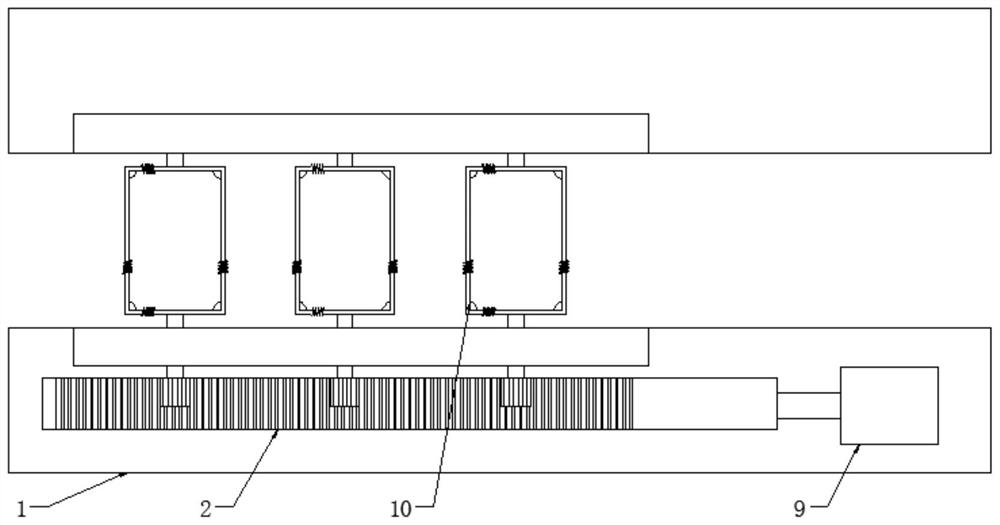

Automatic compacting device of sand box

The invention belongs to the technical field of foundry casting, and particularly relates to an automatic compacting device of a sand box. The automatic compacting device comprises a working platform for placing the sand box, wherein a portal frame is arranged at two sides of the working platform in a spanning manner, a lifting mechanism is arranged on a horizontal cross beam of the portal frame, and is connected with a horizontal suspending beam by virtue of a steel rope, a sand flattening plate is suspended below the horizontal suspending beam by virtue of a rope, a vibration motor is fixedly arranged at the top of the sand flattening plate, and the width of the sand flattening plate is matched with the width of the sand box. The automatic compacting device of the sand box, disclosed by the invention, is reasonable in structural design, high in strength, safe and efficient in working process, convenient to operate and use, and very suitable for popularization and implementation; the compactness of sand is high, and the labor intensity of workers is remarkably reduced.

Owner:ZHEJIANG SHENGHAO CASTING

Production technology of metal ice particles

ActiveCN107283135AImprove the cooling effectHigh production process efficiencyMetallurgyCooling effect

The invention discloses a production technology of metal ice particles. The production technology comprises the steps of (1) cutting a metal sheet; (2) manufacturing metal components; (3) forming through holes in the side walls of a part of metal outer shells; (4) welding one metal component with through holes and another metal component without through holes, and manufacturing one hollow metal outer shell with an airtight cavity inside which communicates with the exterior through the through holes; (5) injecting a coolant through the through holes; (6) sealing the through holes through welding; and (7) carrying out grinding and polishing. Through the adoption of the technical scheme, the metal ice particles can be produced, reutilization is facilitated, and beverages are not diluted and do not go bad; the coolant is sealed in the metal outer shells, and the cooling effect of the metal ice particles is greatly improved; and production efficiency is high, manufacturing is facilitated, and grinding and polishing treatment intensity is low.

Owner:中山市品派生活日用制品有限公司

Refrigerator bottom plate polishing equipment

PendingCN114012530AReduce sandingTurn fasterEdge grinding machinesGrinding work supportsIceboxStructural engineering

The invention discloses refrigerator bottom plate polishing equipment in the technical field of refrigerator production equipment. The refrigerator bottom plate polishing equipment comprises an upper rack and a lower rack, wherein the upper rack is connected with a polishing mechanism through a longitudinally telescopic first air cylinder. The refrigerator bottom plate polishing equipment further comprises a clamping mechanism used for fixing a refrigerator bottom plate, and the two sides of the clamping mechanism are fixedly connected with rotating shafts; the lower rack comprises two supporting frames which are arranged in parallel, and the clamping mechanism is rotationally connected between the two supporting frames through the two rotating shafts; and the polishing mechanism is located over the clamping mechanism. According to the scheme, the refrigerator bottom plate does not need to be directly picked up to be turned over, the refrigerator bottom plate can be quickly turned over by rotating the clamping mechanism, and compared with the prior art, the labor intensity is reduced, and the efficiency is greatly improved.

Owner:SUIYANG HUAFENG ELECTRICAL APPLIANCE

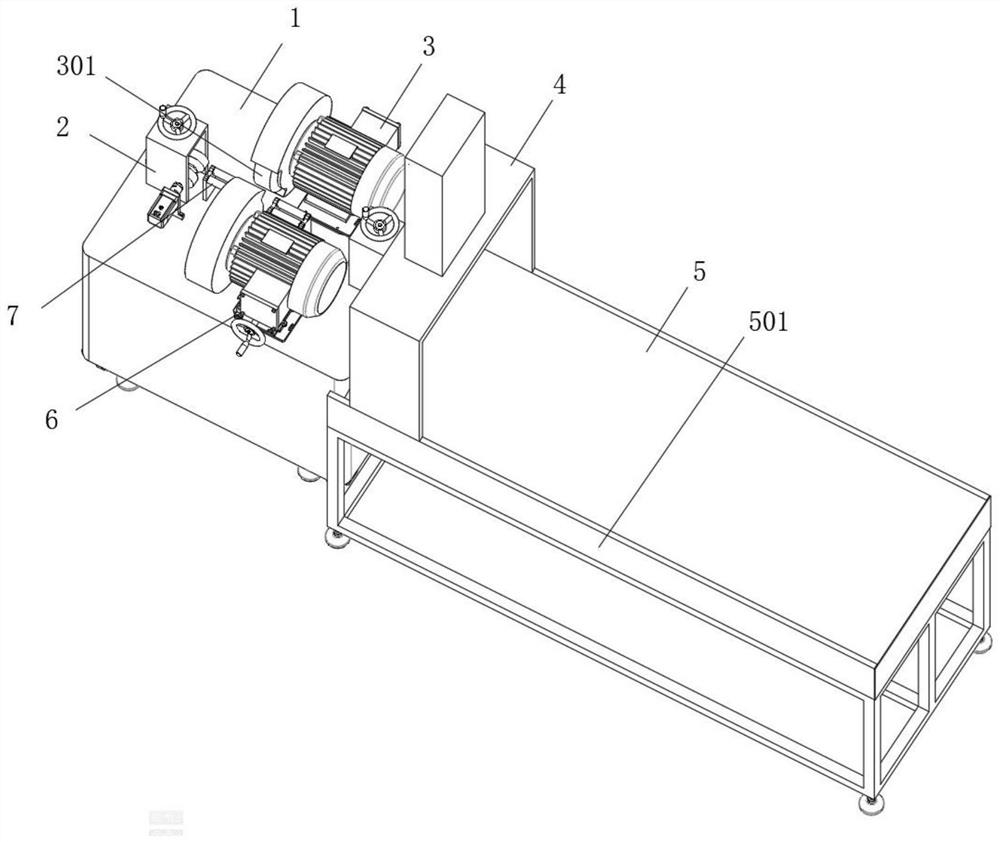

Lathe for screw machining of screw rod pump

InactiveCN111890190AReduce labor intensityReduce forceGrinding carriagesBelt grinding machinesClassical mechanicsTailstock

The invention relates to a lathe for screw machining of a screw rod pump, and relates to the field of screw processing of screw rod pumps. The lathe comprises a lathe body, a three-jaw chuck, a firstdrive component, a guide rail, a tailstock and a grinding device. The three-jaw chuck is arranged on the lathe body and used for clamping a screw. The first drive component is arranged on the lathe body and used for driving the three-jaw chuck to rotate. The guide rail is arranged on the lathe body. The tail bracket is arranged on the guide rail and used for jacking the screw. The grinding deviceis arranged on the lathe body. The grinding device comprises a base arranged on the lathe body, a bracket hinged on the base, a driving pulley rotationally connected with the bracket, a driven pulleyrotationally connected with the bracket, a grinding belt wound on the driving pulley and the driven pulley for grinding the screw, and a second driving component arranged on the bracket to drive the driving pulley to rotate. The grinding belt is pressed on the top of the screw. The lathe reduces the strength when the screw of the screw rod pump is manually ground.

Owner:CHANGSHA HUHANG METALLURGICAL EQUIP FACTORY

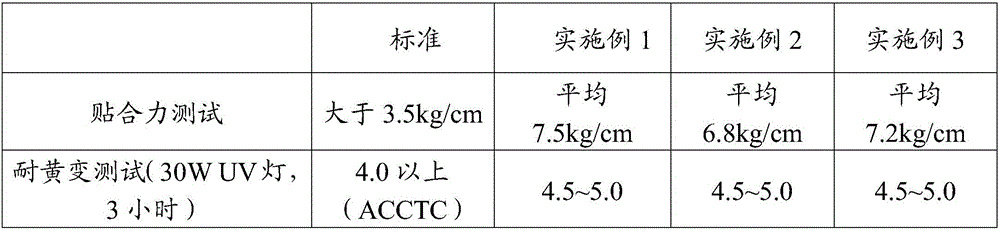

Outsole, method for attaching outsole to mid-sole and made shoe sole

ActiveCN106235513AAvoid deformationGuaranteed aestheticsSolesDomestic footwearBiochemical engineeringStock solution

The invention provides an outsole. The outsole sequentially comprises an outsole substrate, a rubber stock solution film layer attached on the outsole substrate and a release film layer attached on the rubber stock solution film layer. The outsole surface is smooth and clean, and the cumbersome surface treatment processes such as polishing and treating agent adding are omitted. The invention further discloses a method for attaching the outsole to a mid-sole. In the attaching process, a hardening glue type thin film is added, cohesiveness is good, when the outsole is attached to the mid-sole, cohesiveness-increasing post treatment processes such as gluing, glue spraying and pressing are not needed, mold and time cost is reduced, and the production efficiency is greatly improved. Meanwhile, the invention discloses a shoe sole made through the method for attaching the outsole to the mid-sole. The outsole and the mid-sole of the shoe sole are closely attached, and the shoe sole is attractive and durable.

Owner:刘银实

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com