Derust method and device of metallic material

A technology for metal materials and metal bars, applied in metal extrusion, metal rolling, metal rolling, etc., can solve the problems of noise and dust pollution, poor working environment for workers, incomplete cleaning and cleaning of material surfaces, etc. Reliable and stable performance, large residual value recovery value, easy management and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

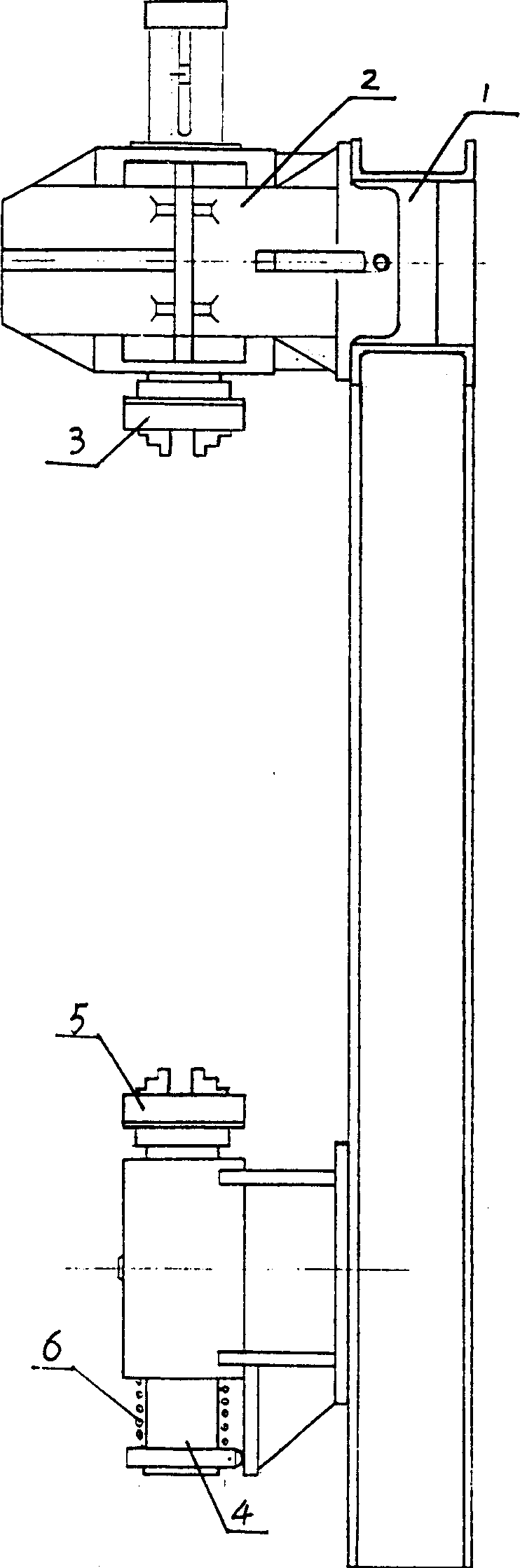

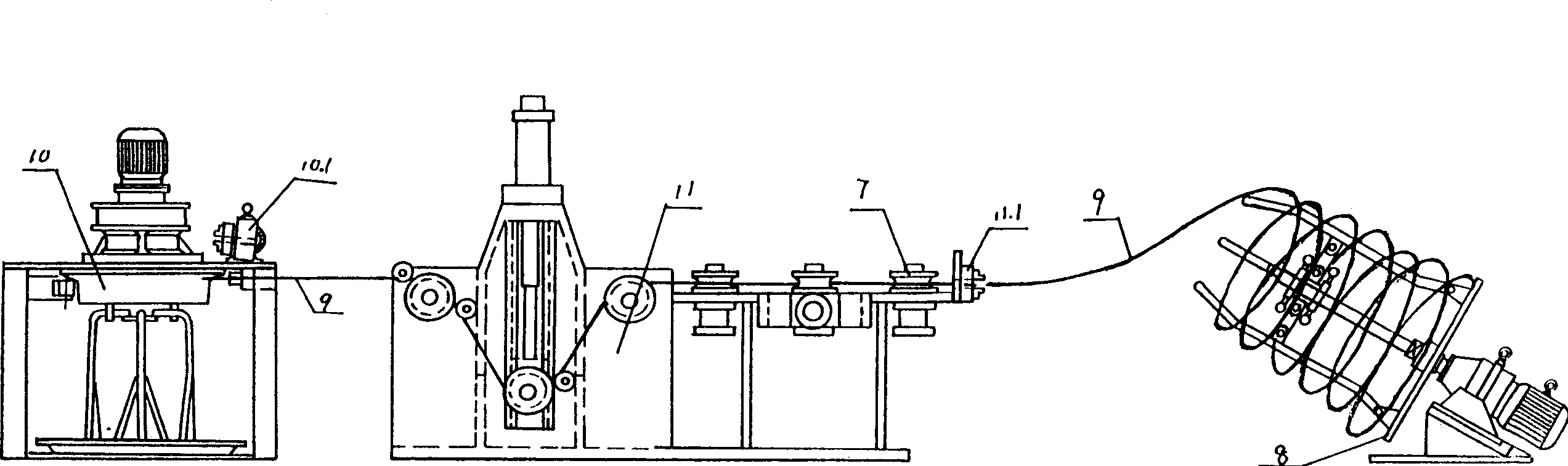

[0019] The present invention metal bar, metal pipe rust removal device such as figure 1 As shown, it includes an organic base 1, a reduction box 2 is installed on the upper side of the base, and a motor that drives the reducer to rotate. A clamping bar or other geometric type is installed on the output shaft of the reducer near the center of the base. The rotatable chuck 3 of shape material, the other side of support is equipped with slide shaft 4, non-rotating chuck 5, spring 6.

[0020] The working principle of the metal rod and metal pipe rust removal device of the present invention is: a metal material to be twisted and rust removed, when the reducer rotates, the clamped metal material is twisted accordingly, and after the twisted to the rated number of turns, reverse twist To the corresponding number of turns, the internal structure of the metal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com