Refrigerator bottom plate polishing equipment

A refrigerator bottom plate and equipment technology, which is applied to grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low production efficiency and achieve the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

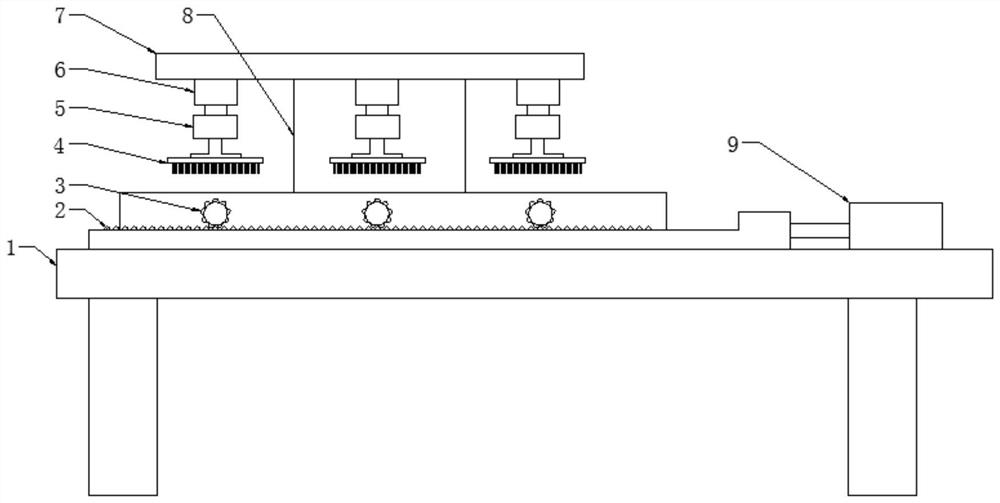

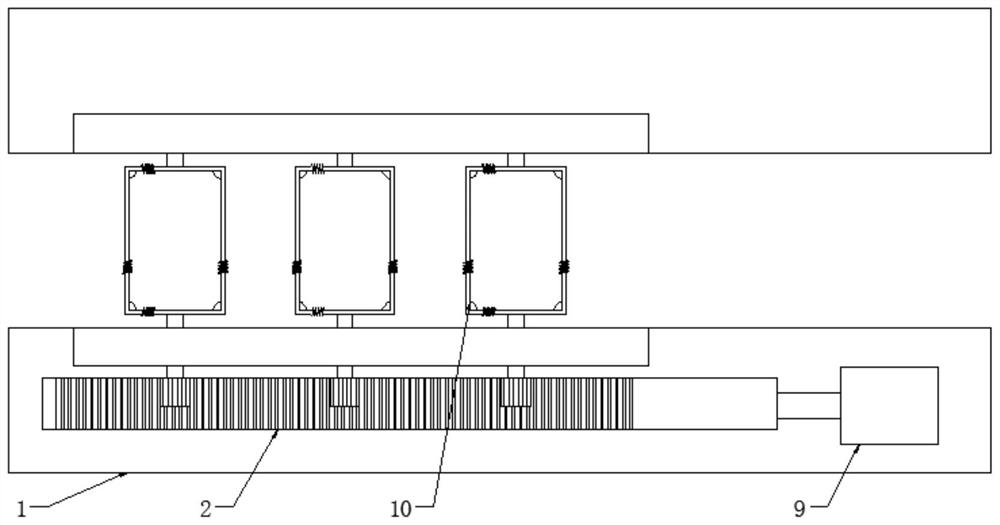

[0020] Embodiment 1, basically as attached figure 1 Shown: a refrigerator bottom plate grinding equipment, including an upper frame 7, a lower frame and three clamping mechanisms 10 arranged at intervals and used to fix the refrigerator bottom plate, the upper frame 7 is connected to the bottom frame of the lower frame through a support plate 8 Directly above. The lower frame includes two parallel support frames 1, and the upper frame 7 is connected with three grinding mechanisms through the longitudinally telescopic first cylinder 6. The grinding mechanism includes a motor 5 and a grinding head 4 positioned below the motor 5, and the motor 5 Connected with the telescopic end of the first air cylinder 6, the grinding head 4 is fixedly connected with the output shaft of the motor 5.

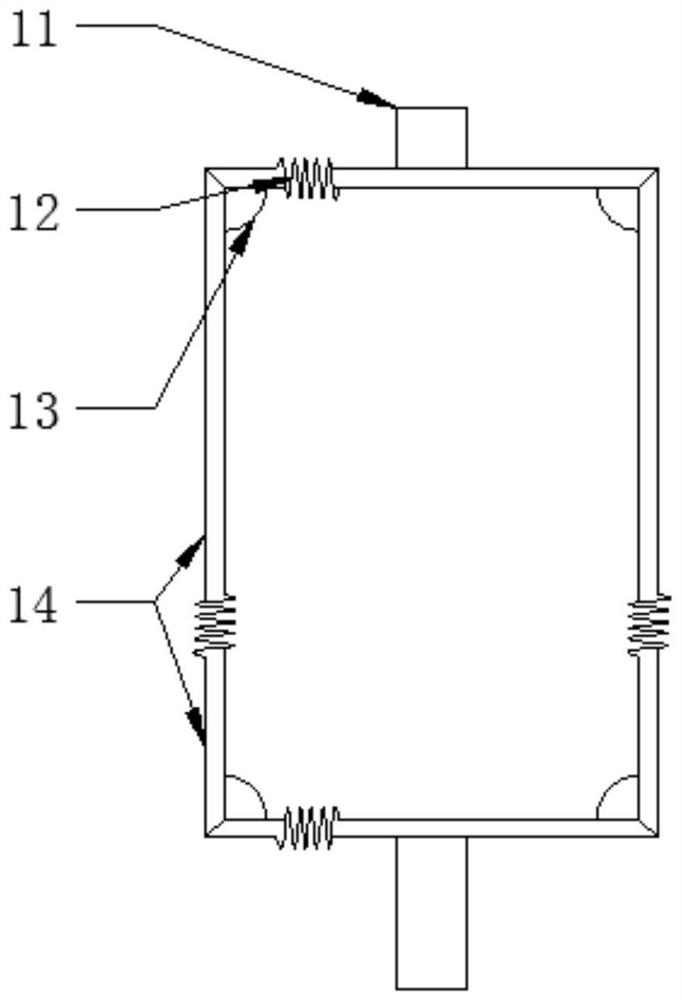

[0021] The grinding mechanism is located directly above the clamping mechanism 10 . combine figure 2 , image 3 As shown, the clamping mechanism 10 is formed by connecting end to end of four ...

Embodiment 2

[0022] Embodiment 2, the difference with embodiment 1 is as Figure 4 As shown: in the clamping mechanism 10 of this program, the two ends of the spring 12 are connected with screw rods 15, and the ends of the fixed-length rod 14 are provided with threaded holes, and the screw rod 15 is connected with the fixed-length rod 14 through the threaded holes.

Embodiment 3

[0023] The difference between Embodiment 3 and Embodiment 2 is that the power mechanism in this solution adopts another motor, and the output shaft of the motor is fixedly connected with the rotating shaft 11 .

[0024] Taking Embodiment 2 as an example, the specific implementation process is as follows: use the clamping mechanism 10 to clamp and fix the bottom plate of the refrigerator, and the grinding mechanism is located directly above the clamping mechanism 10, so the grinding mechanism can grind the surface of the refrigerator bottom plate when it is running. Because the clamping mechanism 10 is rotatably connected to the two support frames 1 through the rotating shaft 11, after finishing one side of grinding, the first cylinder 6 drives the grinding mechanism to move up, and the second cylinder 9 is activated to make the rack 2 slide, thereby driving the gear 3. Rotate, so that the clamping mechanism 10 turns over and the other side of the bottom plate of the refrigerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com