Automatic compacting device of sand box

A technology of automatic compaction and sand box, applied in casting and molding equipment, metal processing equipment, molding machines, etc., can solve the problems of unsatisfactory use effect, high labor intensity of workers, shortened service life, etc., and achieve reasonable structural design, The effect of reducing the labor intensity of workers and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

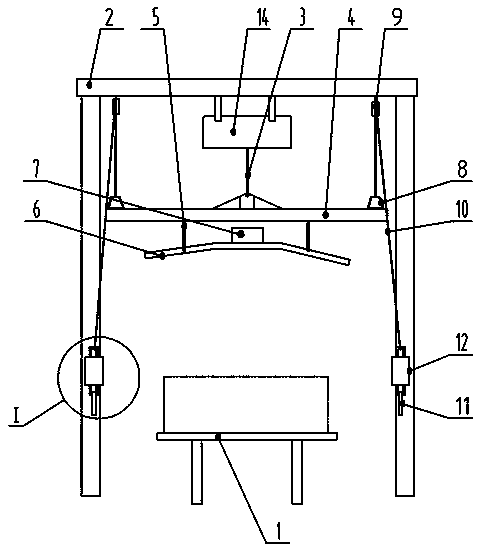

[0023] see Figure 1-Figure 3 , in the figure, the sand box automatic compacting device of the present invention comprises a workbench 1 for placing the sandbox, a gantry 2 is straddled on both sides of the workbench, a lifting mechanism is installed on the horizontal beam of the gantry, and the lifting mechanism passes through a steel wire rope 3 Connected with horizontal suspension beam 4, horizontal suspension beam below is suspended with flat sand board 6 by rope 5, is fixedly installed with vibrating motor 7 at the top of flat sand board, and the width of flat sand board matches with sand box width.

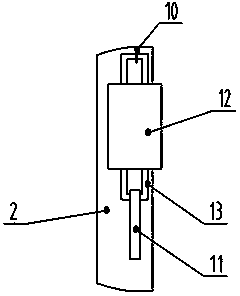

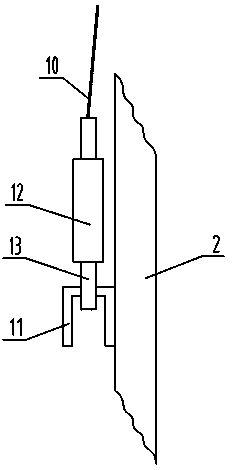

[0024] It also includes a safety mechanism, which includes auxiliary suspension rings 8 arranged on both sides of the horizontal suspension beam, pulleys 9 are correspondingly arranged on both sides of the horizontal beam with respect to the auxiliary suspension rings, one end of the safety rope 10 is fixed on the auxiliary suspension ring, and the other end is wound around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com