Production technology of metal ice particles

A production process and ice granule technology, which is applied to the production process field of metal ice granules, can solve the problems of detrimental beverage flavor, imperceptibility, and beverage discoloration, etc., and achieves high production efficiency, easy repeated use, and improved refrigeration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

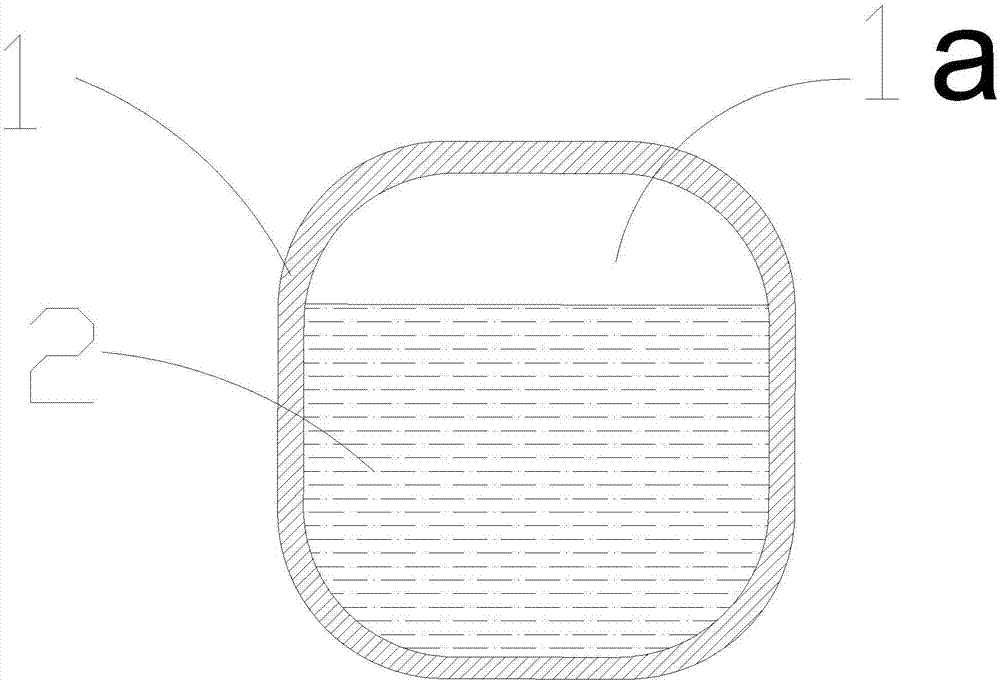

[0029] Figure 1 to Figure 5 A metallic ice particle according to one embodiment of the present invention is schematically shown. As shown in the figure, the device includes a stainless steel shell 1 and a saturated saline solution 2 sealed inside the stainless steel shell 1 .

[0030] Wherein, the saturated salt water 2 accounts for 70%-100% of the internal volume of the stainless steel shell 1 .

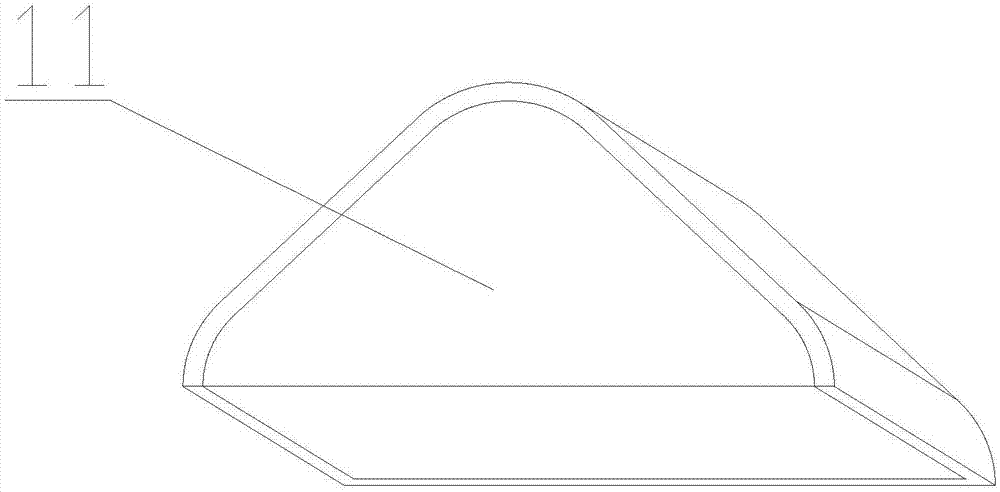

[0031] The stainless steel shell 1 is a hollow cube, and is welded by two stainless steel components 11 by arc welding or spot welding.

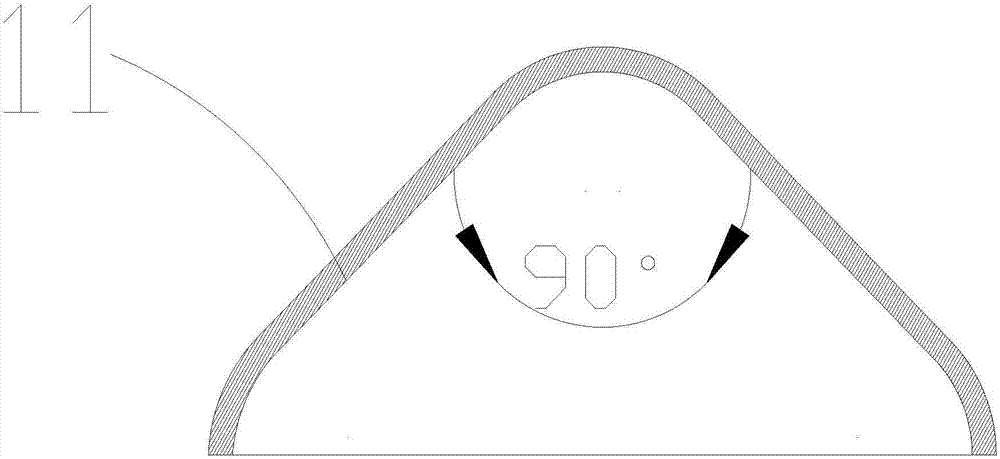

[0032] Four welding lines 12 are formed at the joints of the two stainless steel components 11 .

[0033] The stainless steel member 11 has a rectangular opening and its bottom is a rectangular groove.

[0034] The welding line 12 forms a closed rectangle.

[0035] Such as Figure 4 As shown, in this embodiment, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com