Patents

Literature

55 results about "Treatment intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

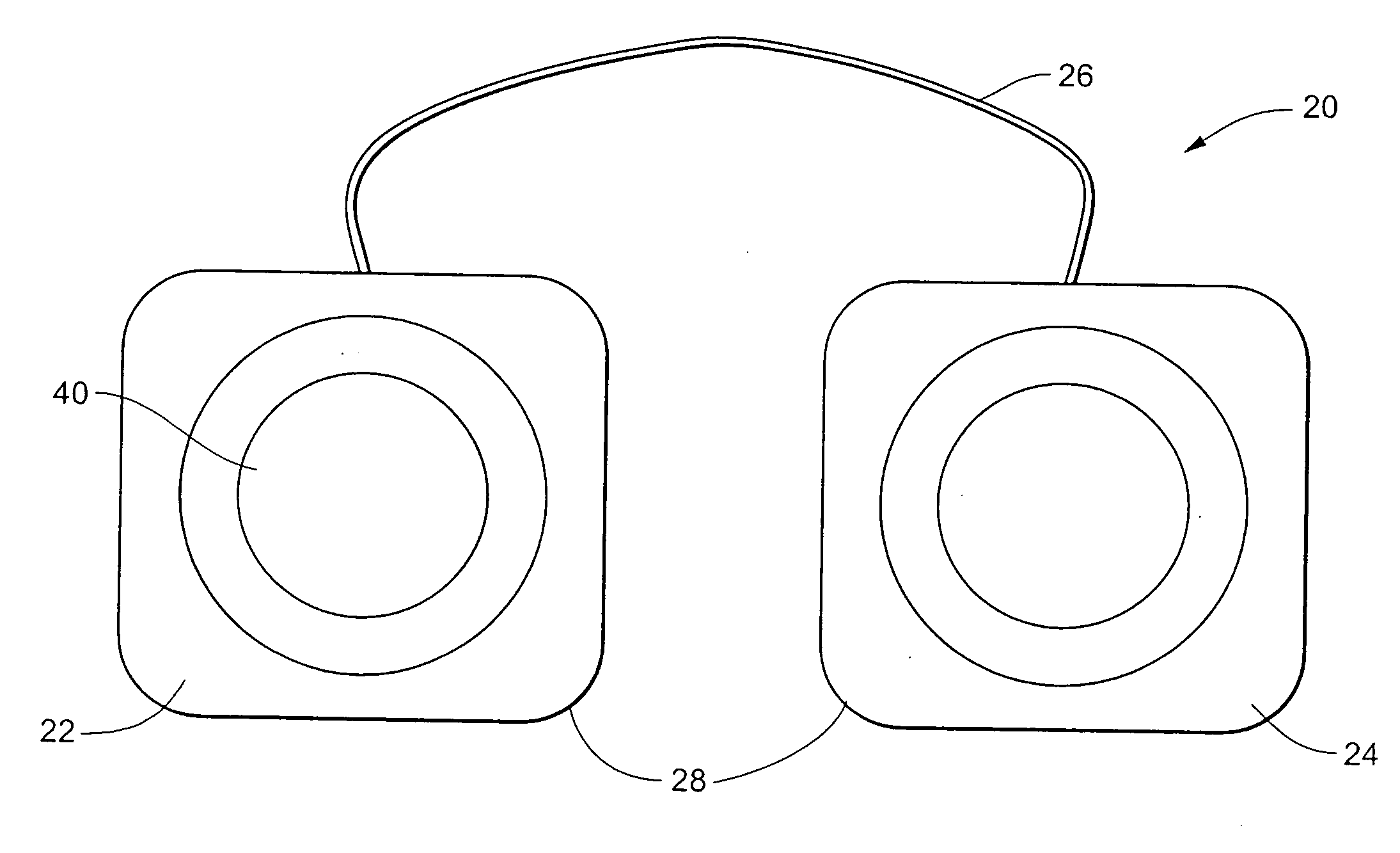

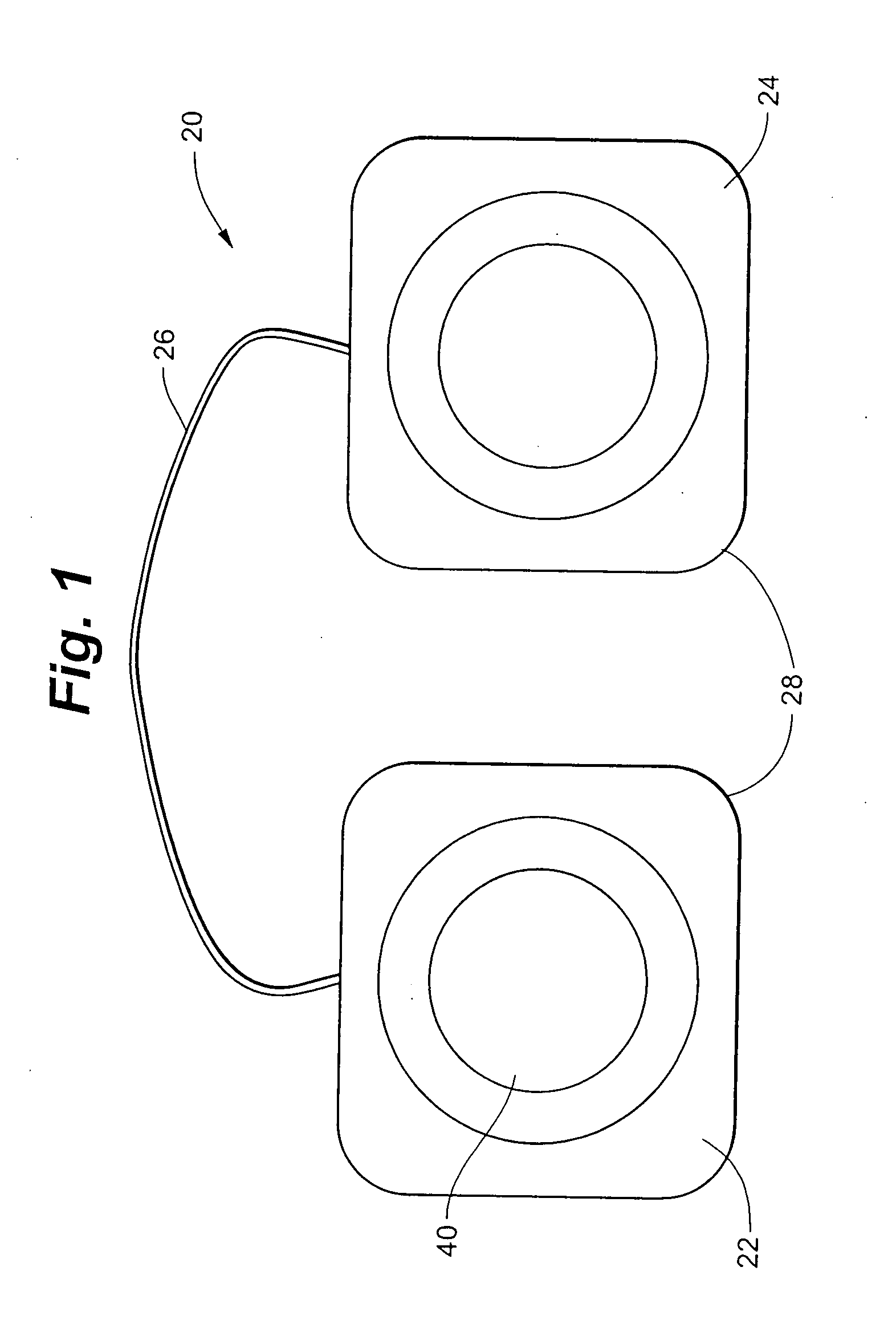

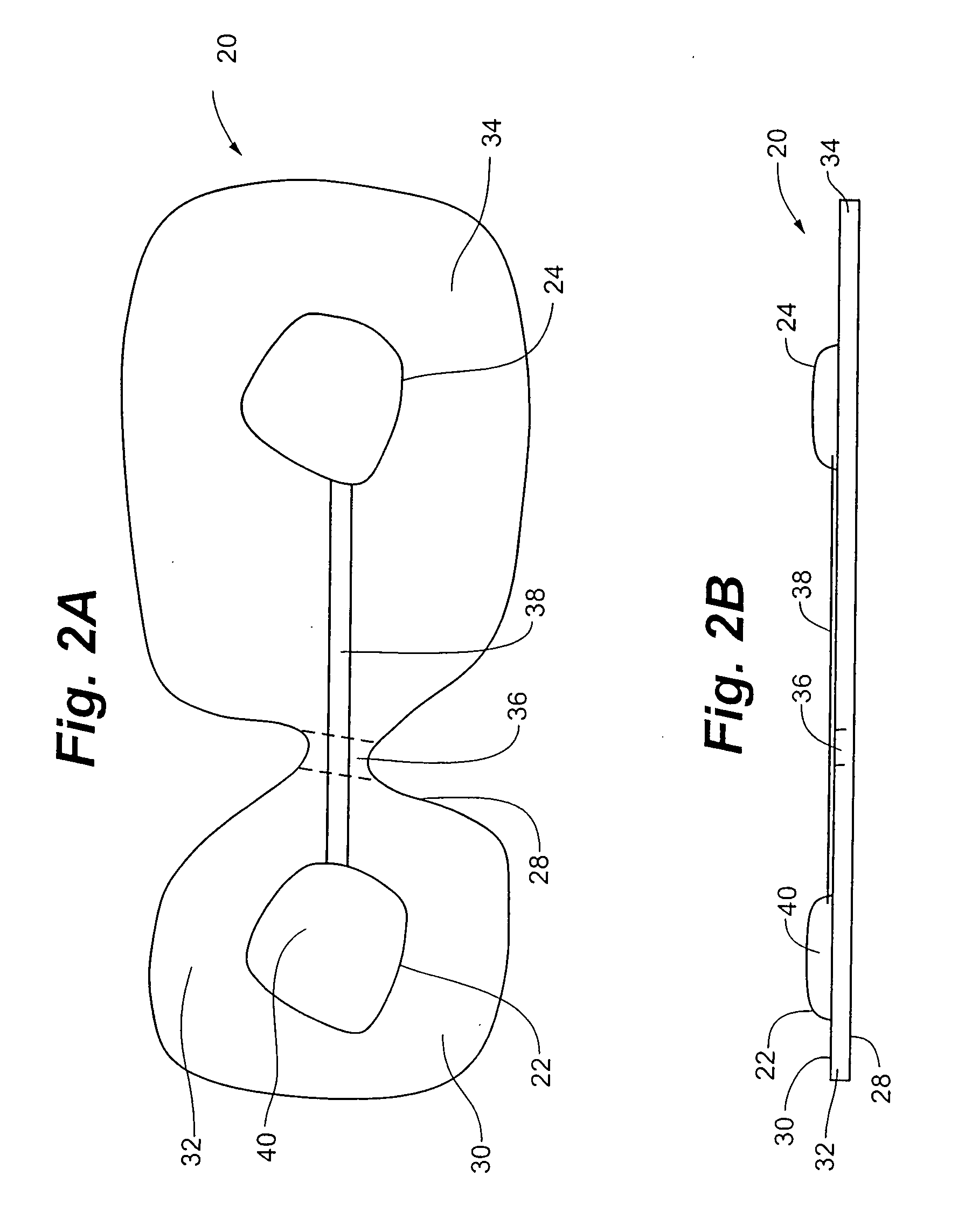

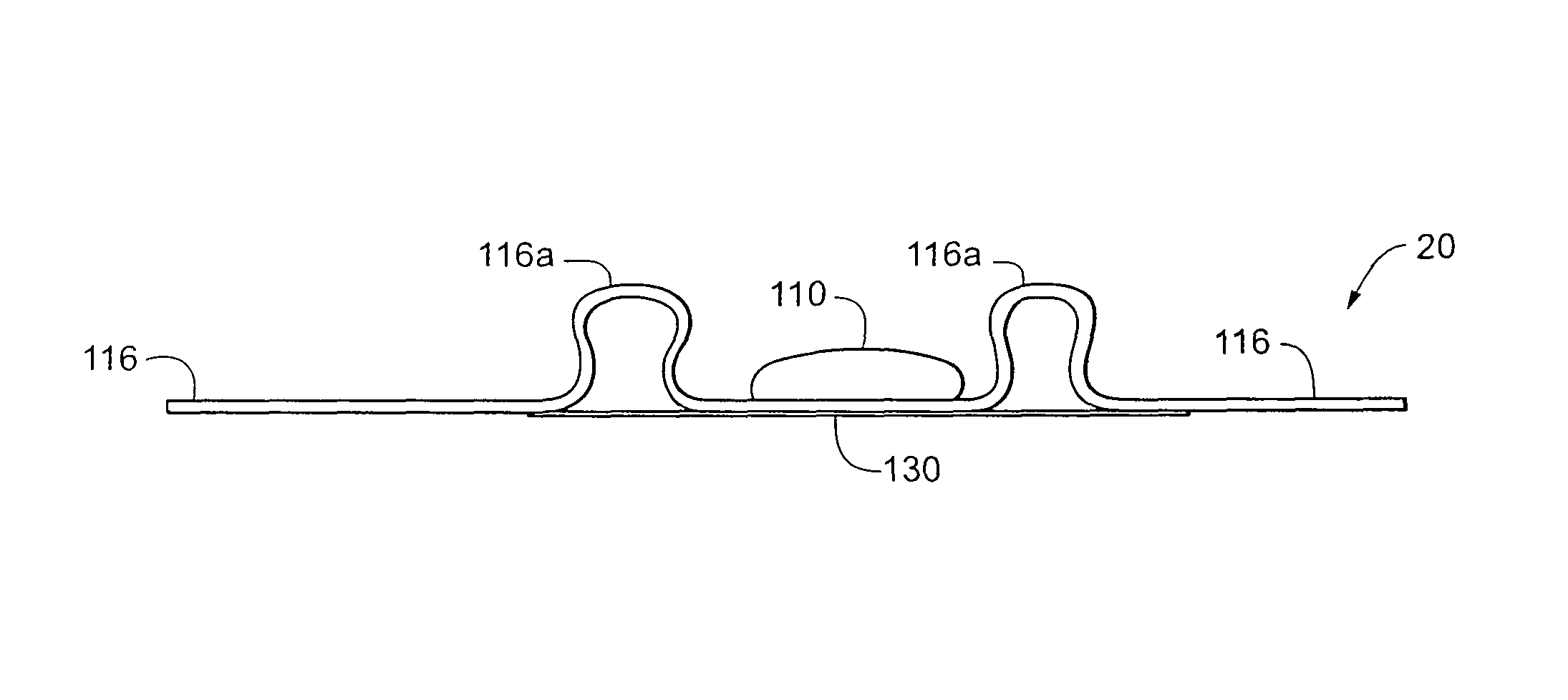

Electrical stimulation device and method for therapeutic treatment and pain management

ActiveUS20100042180A1Easily and tactilely differentiateAvoid accidental activationExternal electrodesElectricityManaged pain

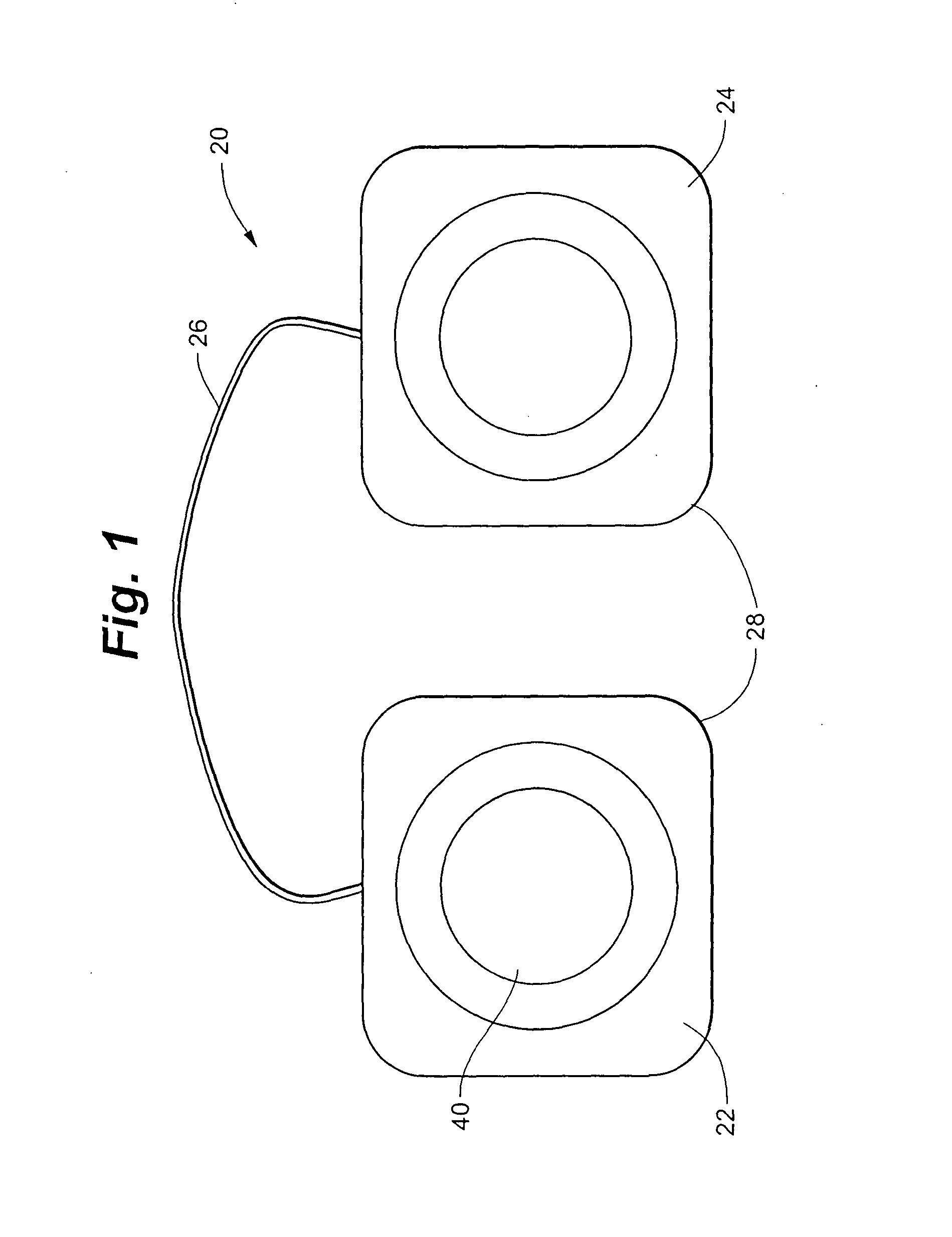

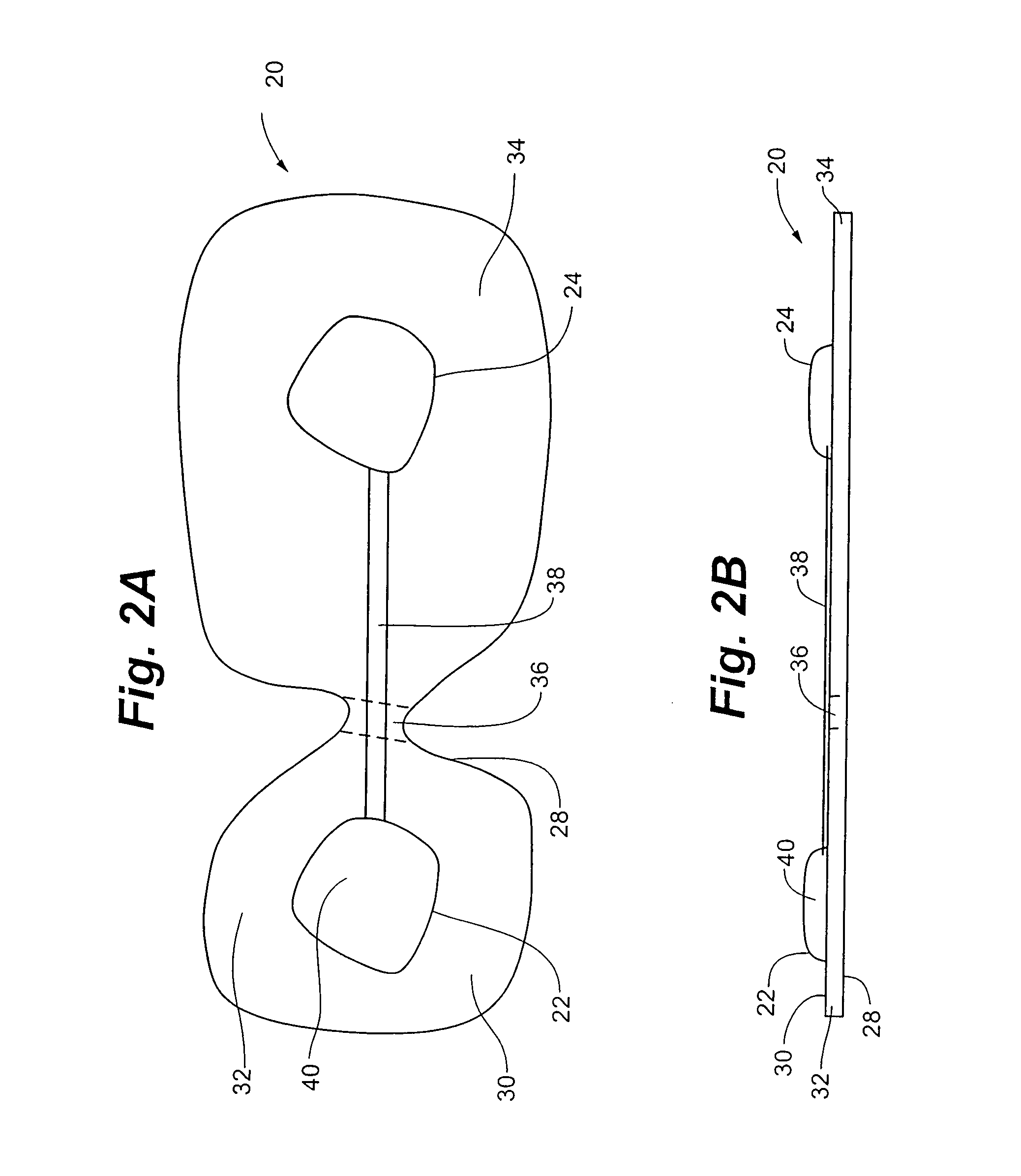

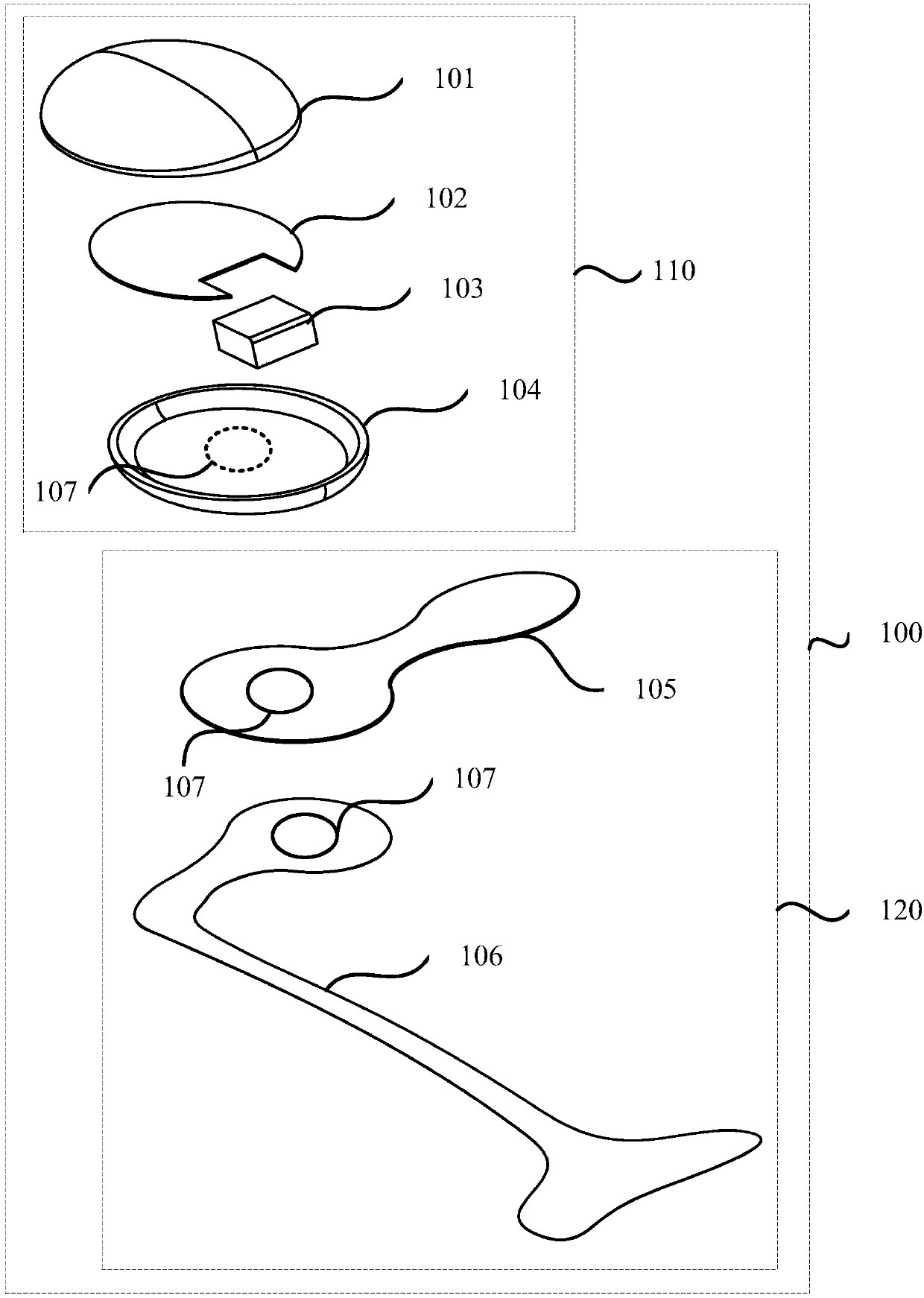

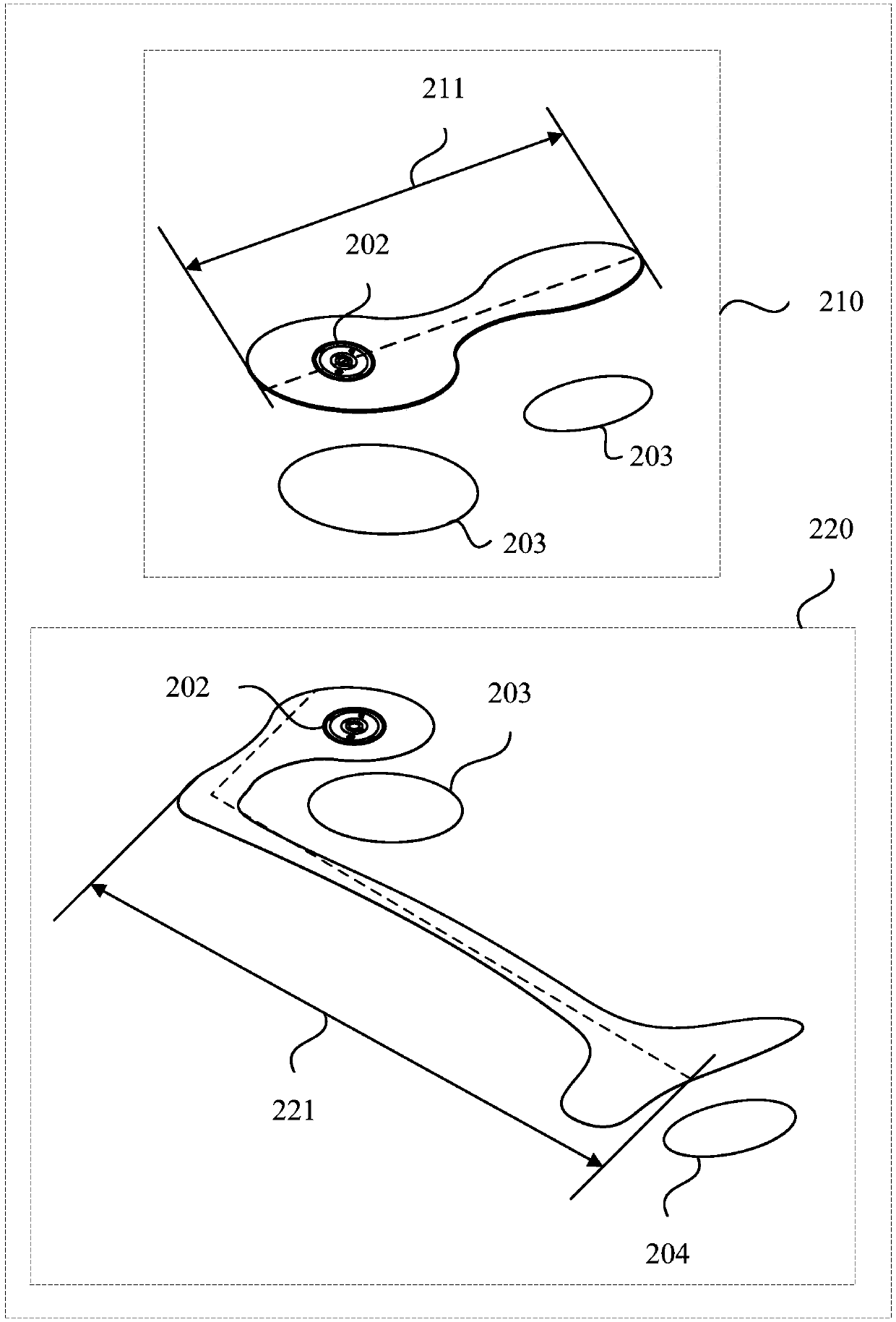

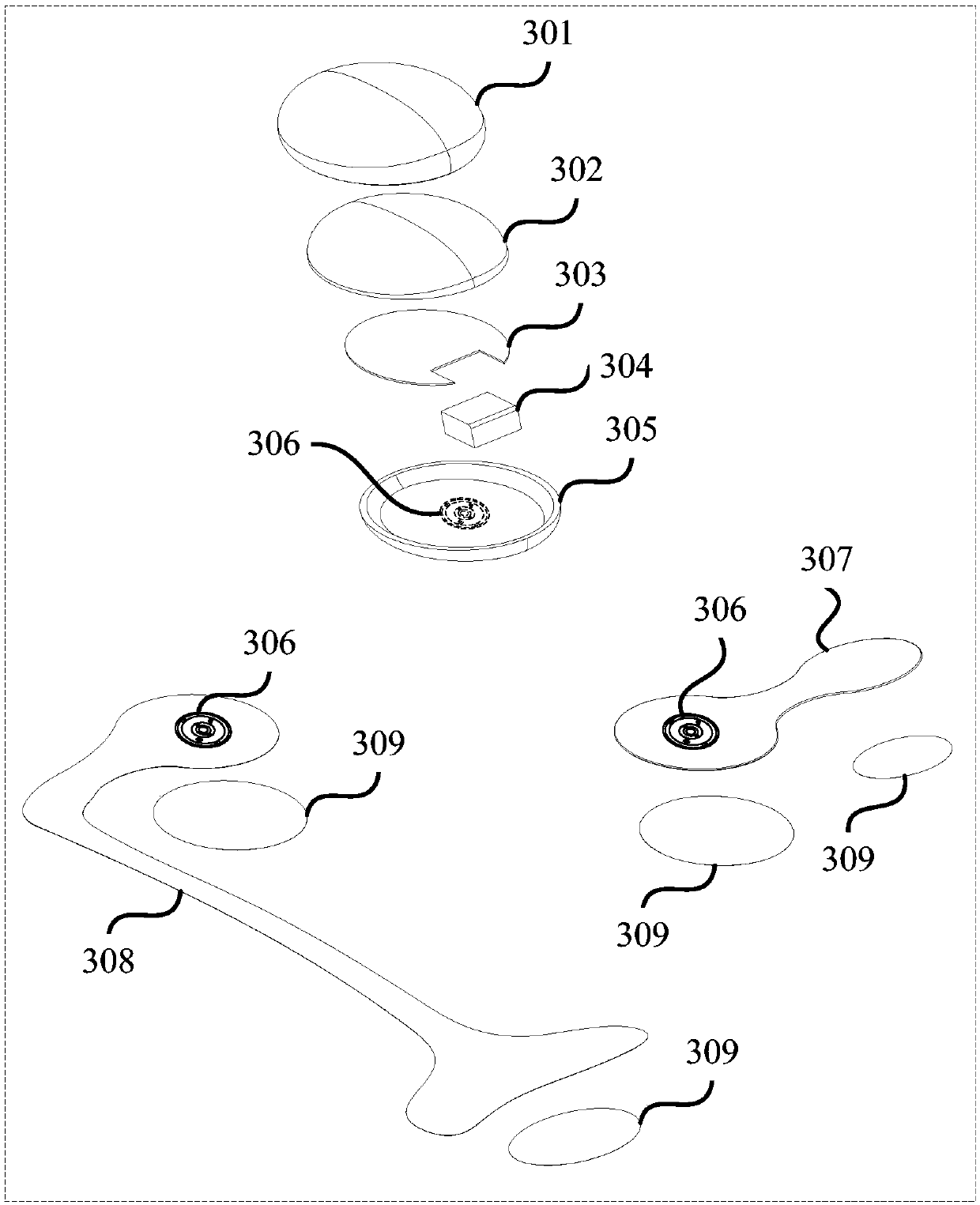

A disposable electrical stimulation device and method for providing therapeutic treatment and pain management in a convenient, compact configuration. Electrode size and shape and relative configuration can be varied according to an intended application and use, or a universal configuration can be provided for use on almost any area of the body. The common structure of communicatively coupled dual electrodes including control circuitry and a power source accommodates a range of different sizes, configurations, stimulation treatment intensities, and other physical and electrical characteristics that can be pre-customized and packaged for specific, limited time use. The device can therefore be used in methods of providing therapy, managing pain, and achieving other treatment goals by electrical stimulation.

Owner:ENCORE MEDICAL ASSET CORP +1

Light foamed soil for abutment back backfilling and construction method

InactiveCN105000845AImprove liquiditySelf-reliantSolid waste managementCeramicwareFoaming agentTreatment duration

The invention discloses a light foamed soil for abutment back backfilling. The light foamed soil comprises cement, a mixed material, water, a conditioning agent, a foaming agent, a micro-foam agent, and a waterproof agent. The invention also provides a preparation method of light foamed soil for abutment back backfilling. The micro-foam agent is prepared into foams by a plunger pump and an air compressor, the materials are mixed and stirred by a stirrer, and the slurry extraction speed is controlled by a frequency converter so as to control the volume weight of the finished product. The invention also provides an on-site construction method of light foamed soil applied to abutment back backfilling. The light foamed soil provided by the invention belongs to light materials, has small foundation load after filling, greatly reduces the foundation treatment intensity, and saves the foundation treatment duration. After pouring and before initial setting, light foamed soil has very good fluidity and fill self-compaction, avoids the defect of non-full filling of conventional fillers, has strong constructability, and can effectively solve the phenomenon of bumping at bridge head.

Owner:河南华泰新材科技股份有限公司

Electrical stimulation device and method for therapeutic treatment and pain management

ActiveUS8958883B2Easily and tactilely differentiateAvoid accidental activationExternal electrodesArtificial respirationElectricityManaged pain

A disposable electrical stimulation device and method for providing therapeutic treatment and pain management in a convenient, compact configuration. Electrode size and shape and relative configuration can be varied according to an intended application and use, or a universal configuration can be provided for use on almost any area of the body. The common structure of communicatively coupled dual electrodes including control circuitry and a power source accommodates a range of different sizes, configurations, stimulation treatment intensities, and other physical and electrical characteristics that can be pre-customized and packaged for specific, limited time use. The device can therefore be used in methods of providing therapy, managing pain, and achieving other treatment goals by electrical stimulation.

Owner:ENCORE MEDICAL ASSET CORP +1

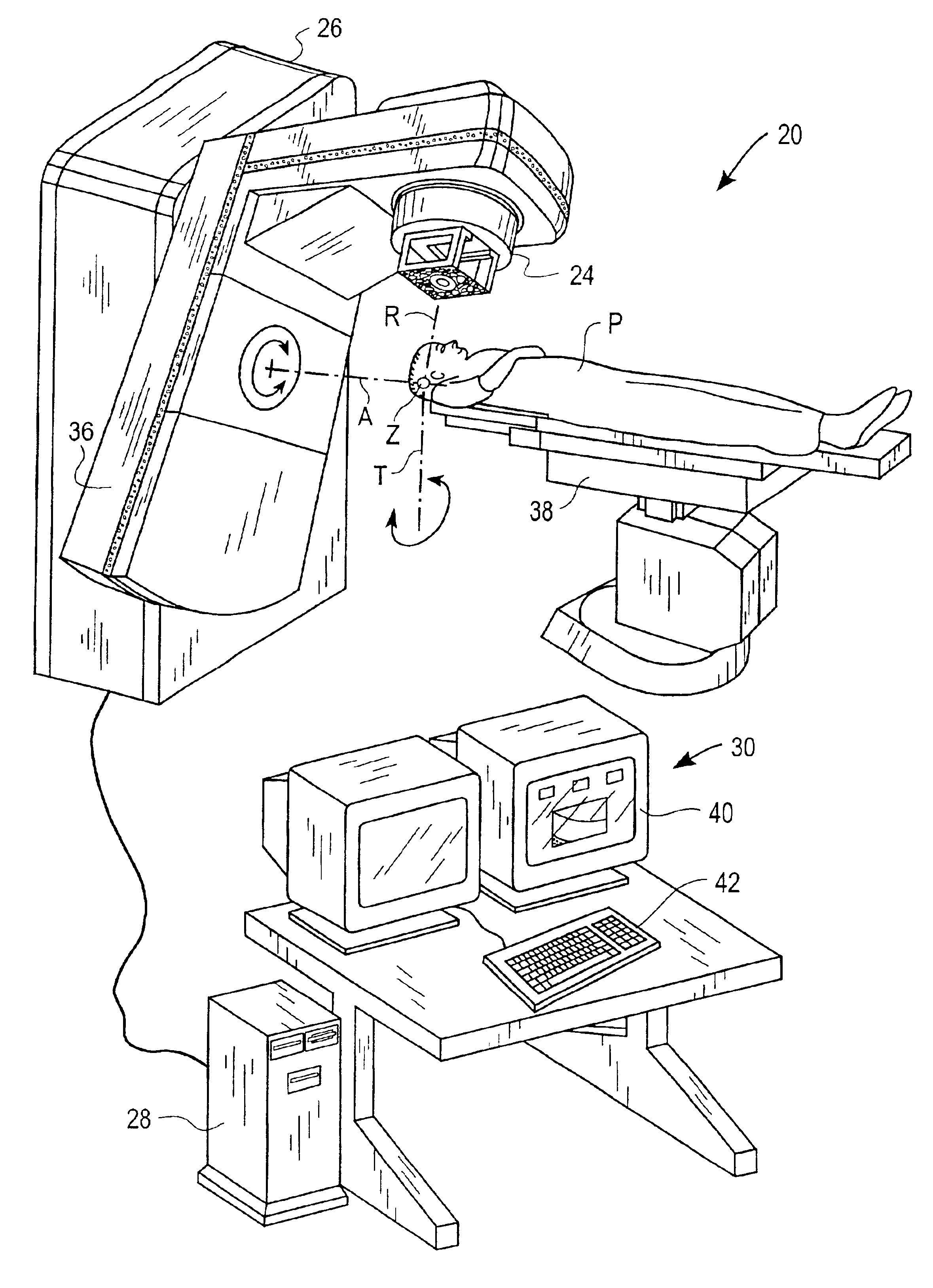

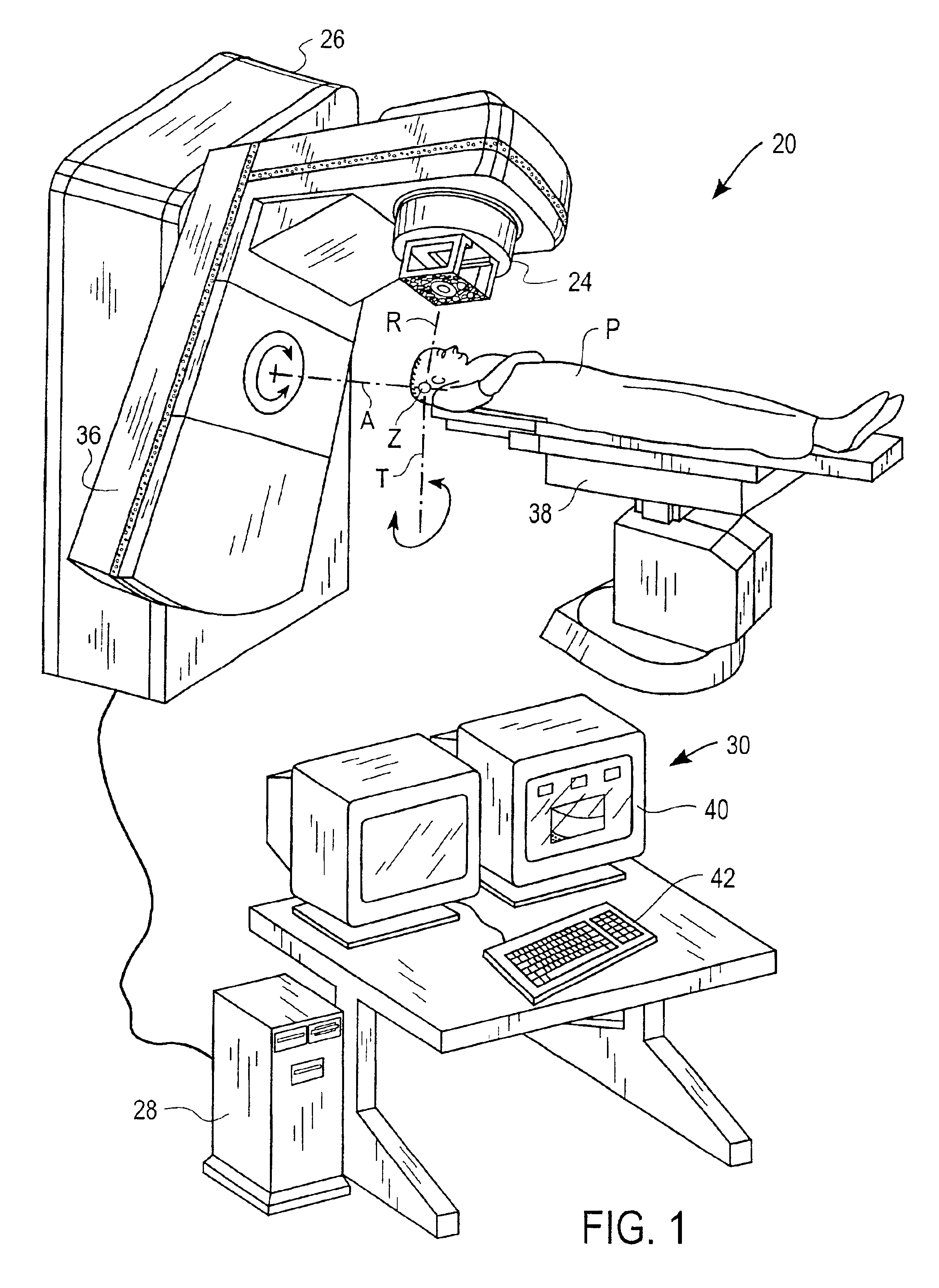

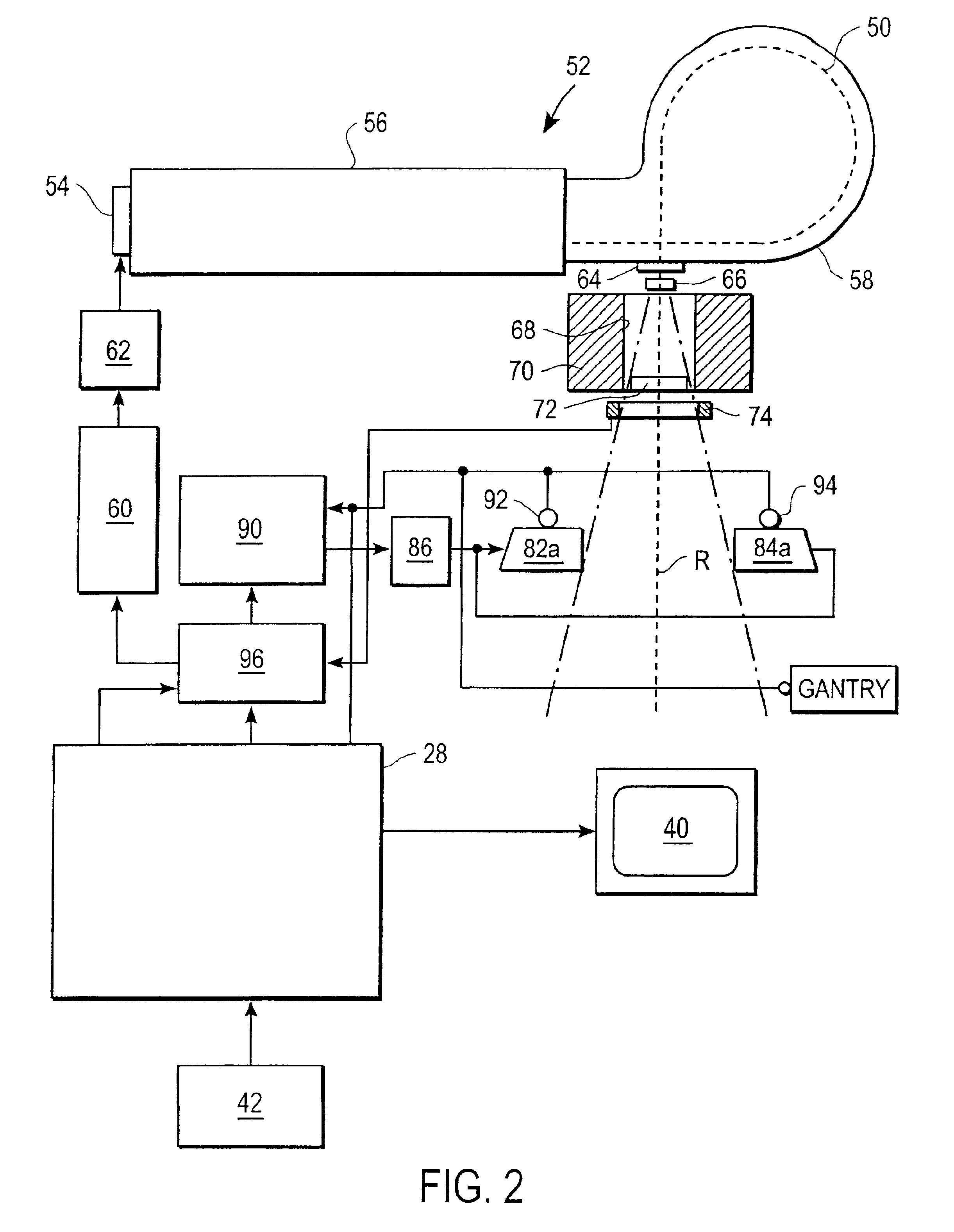

Intensity map resampling for multi-leaf collimator compatibility

InactiveUS6907282B2Ultrasonic/sonic/infrasonic diagnosticsSurgeryMulti leaf collimatorTreatment intensity

A method for converting a source intensity map into a target intensity map having a geometry compatible with a desired multi-leaf collimator configuration. The source intensity map and the target intensity map each have a geometry defining sampling points of cells within the maps. The method includes defining a field on an object for radiation delivery. The field includes a plurality of cells defining the source intensity map, each of the cells having a treatment intensity level. An intermediate intensity map geometry is created such that the intermediate map contains sampling points of the source intensity map and the target intensity map. The method further includes defining treatment intensity levels for cells of the intermediate map and calculating treatment intensity levels for cells of the target intensity map based on the intensity level of the intermediate map cells.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

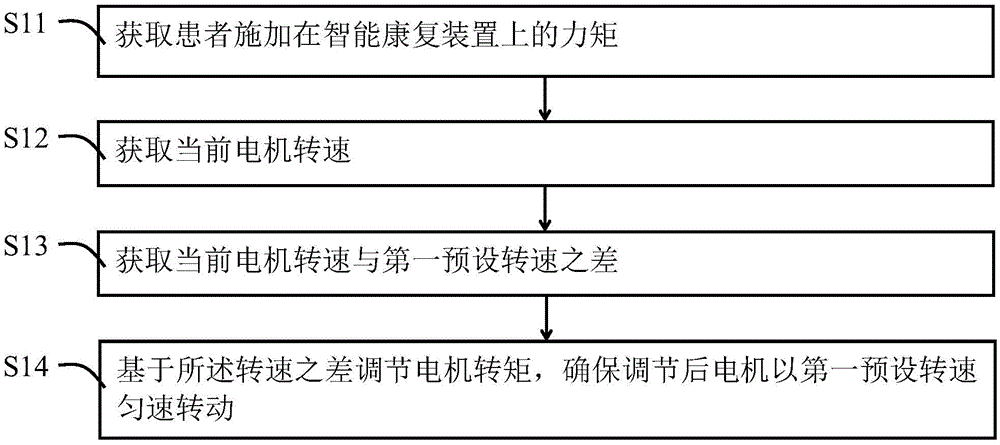

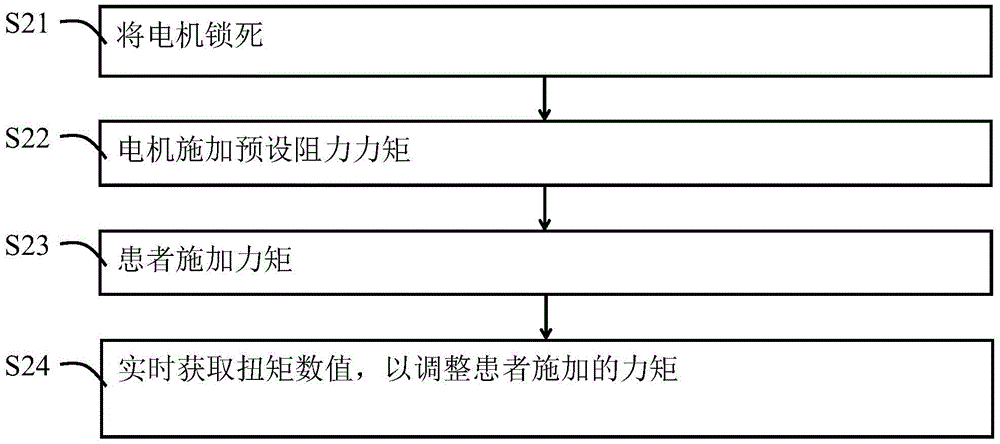

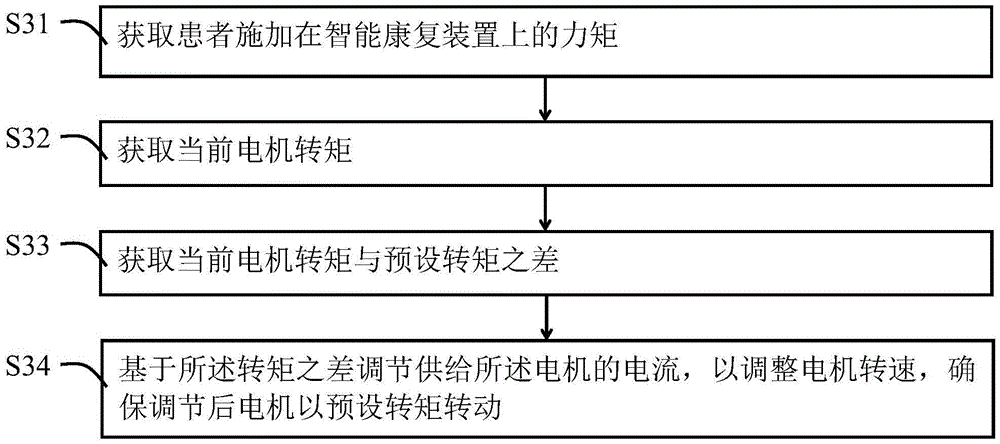

Intelligent rehabilitation method and system

InactiveCN105640740AShorten rehab training timeChiropractic devicesMuscle exercising devicesControl theoryTreatment intensity

The invention provides an intelligent rehabilitation method and system, and belongs to the medical technical field. The intelligent rehabilitation method comprises the steps that a patient executes one or more of following motion modes for training: a constant-speed mode, wherein torque of a motor is adjusted in real time based on torque applied by the patient, so as to guarantee that the motor rotates constantly at a preset rotation speed; an equal-length mode, wherein, the torque applied by the patient is adjusted based on preset resistance torque applied by the motor; an isotonic mode, wherein, the rotation speed of the motor is adjusted in real time based on the torque applied by the patient, so as to guarantee that the torque of the motor is not changed; a passive mode, wherein, the voltage for being supplied to the motor is adjusted based on the rotation speed of the motor after the patient applies the torque, so as to guarantee that the rotation speed of the motor is consistent with the preset rotation speed. Thus, the patient can set by himself corresponding treatment intensity, treatment time, and the like based on his own conditions; besides, active movements of the patient and passive stretching are combined, so that the rehabilitation training time is greatly shortened for the patient.

Owner:CHANGZHOU JIANBEN MEDICAL REHABILITATION EQUIP

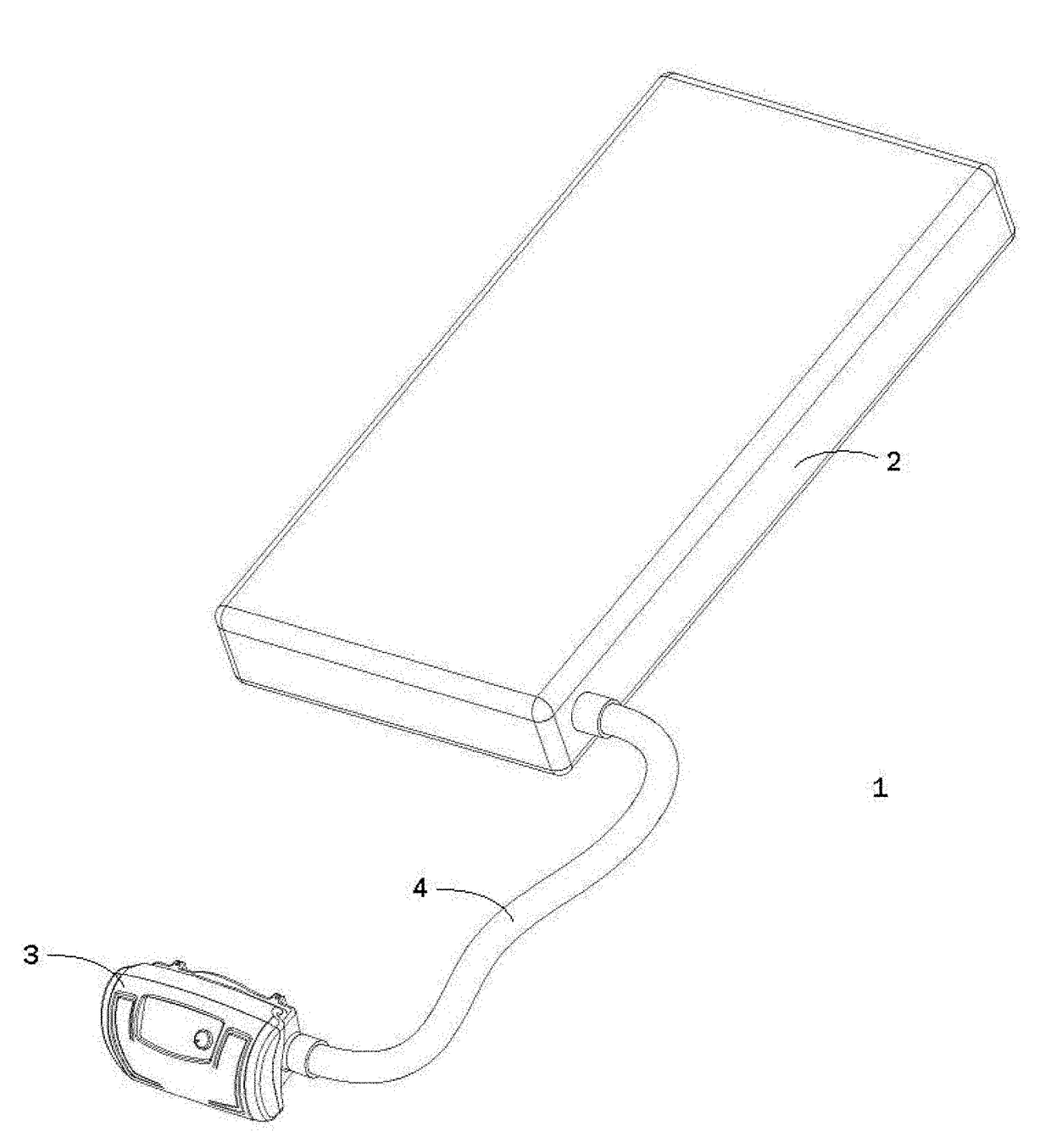

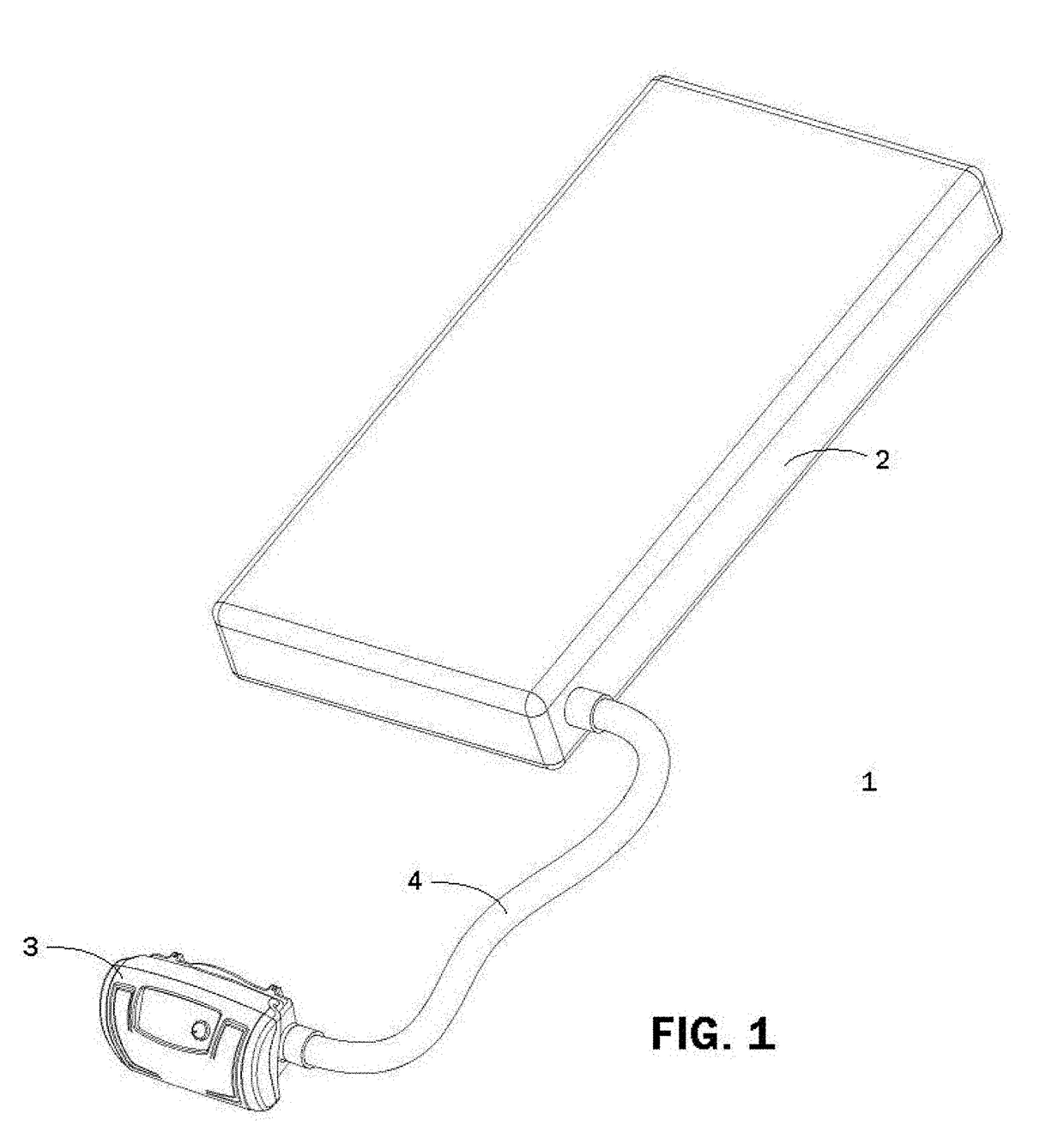

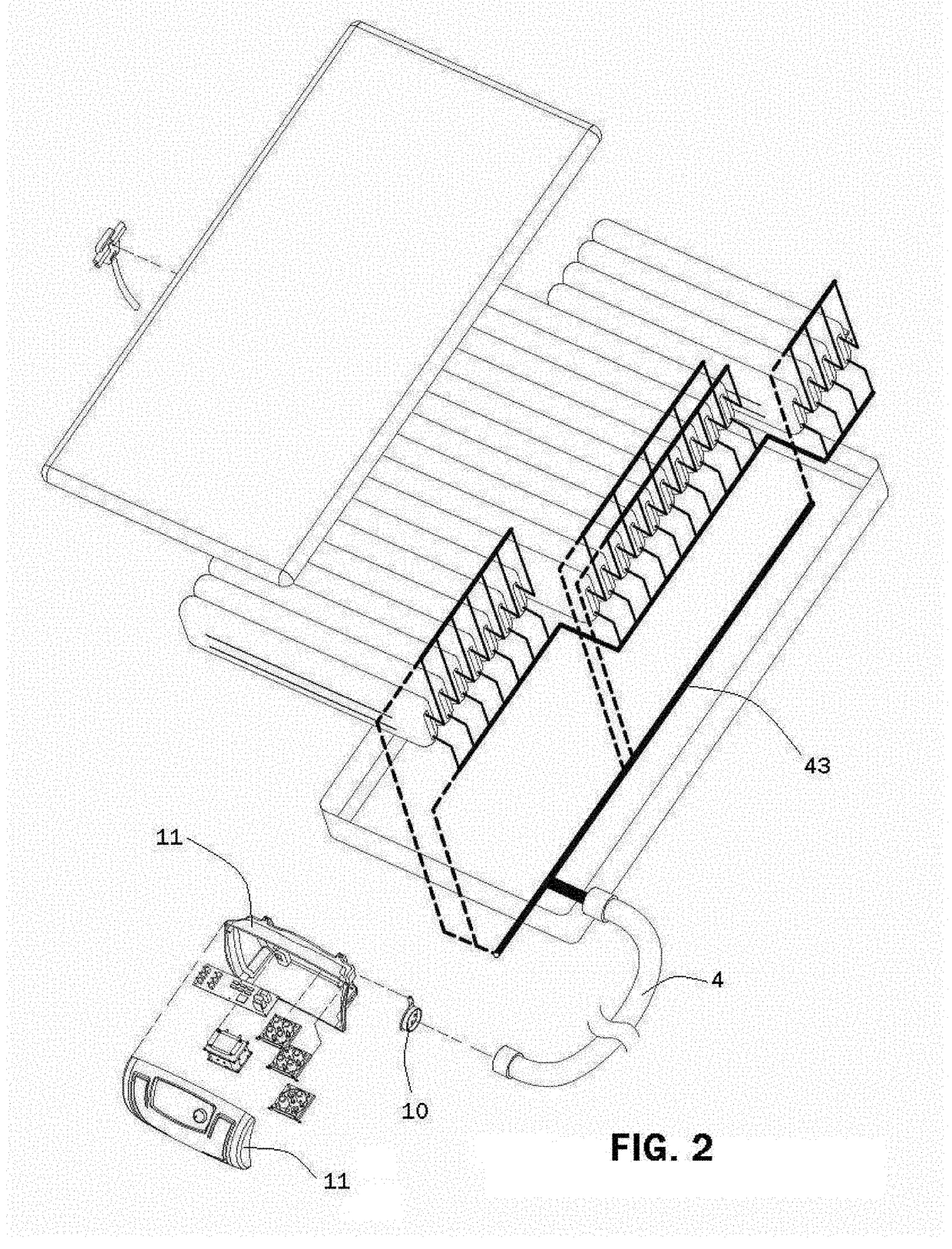

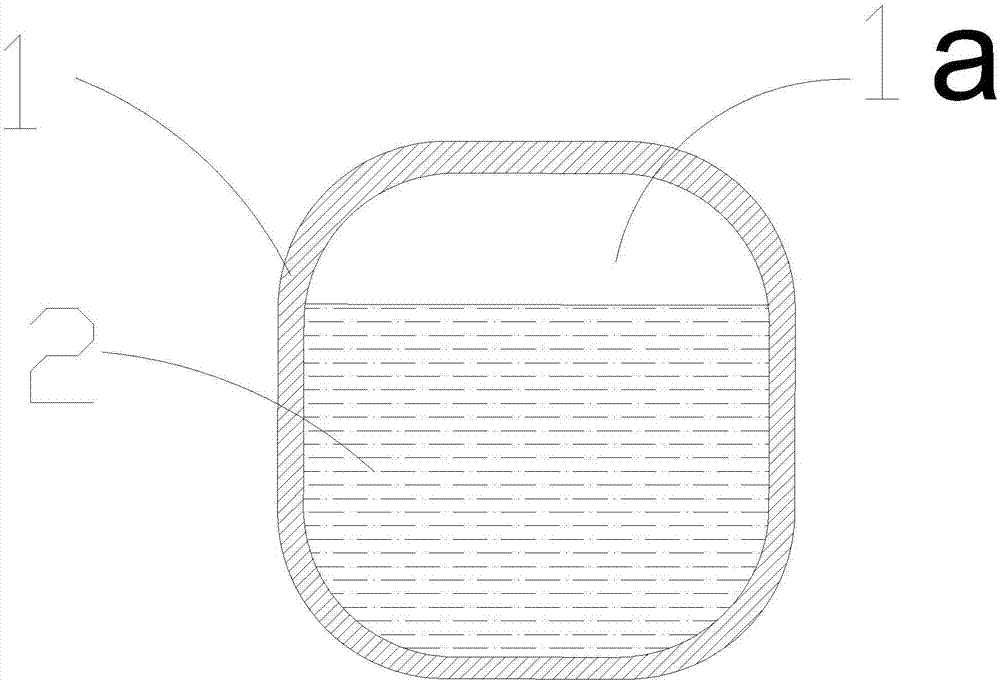

Mattress System

ActiveUS20180153766A1Simple structureEffective pressure rangeElectrotherapyNursing bedsTherapeutic effectEngineering

The present invention provides a mattress system (1) devised to achieve a function of automatic detection, mainly comprising: a mattress (2) having a simple structure; a control unit (3) equipped with a unique user interface (31) for caregivers to simultaneously adjust three major functions, namely, therapy mode, therapy intensity and comfort level; and a connection pipe (4) for supplying air and power. The system (1) is further provided with a built-in auto-setting function to sense the body characteristics of the patient (39) lying on the mattress (2) and determine an effective supporting pressure range for the patient (39). By detecting a pressure difference representing the body characteristics of the patient (39) lying on the mattress (2) and comparing with the data stored in a built-in database, the system (1) can always provide the patient (39) with not only a well-proved therapeutic effect through the auto-setting function, but also an adjustable comfort level on the patient's request through the user interface (31).

Owner:SHL HEALTHCARE AB

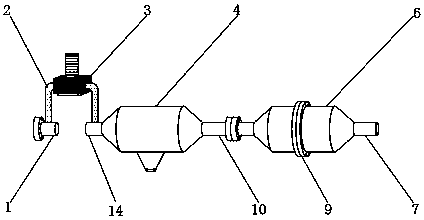

Process for treating oily sludge through hot steam

InactiveCN106219940AOptionalLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisOil sludgeMicroparticle

The invention relates to a process for treating oily sludge through hot steam. The process comprises the following steps that an oily sludge stock solution is pumped into a pre-treatment system through a pipeline, and the dehydration rate of sludge reaches 93% to 98% under the process conditions that the sound intensity ranges from 0.5 W / cm<2> to 0.8 W / cm<2>, the frequency ranges from 5 kHz to 25 kHz, the action time ranges from 3 min to 8 min, the demulsifier dosage ranges from 0.2% to 0.7%, the temperature ranges from 60 DEG C to 80 DEG C, and sedimentation is conducted for 1 h to 2 h; then the oily sludge stock solution is sent into a smashing unit, and large particles are ground into microparticles; the pretreated dehydrated sludge is conveyed to a heat treatment system through a closed conveyor belt, the pretreated dehydrated sludge meets with a hot steam jet flow vertically in a treatment trough of the heat treatment system, the oily sludge is directly decomposed into individual components, and organic matter such as heavy oil and asphaltene in the oily sludge is subjected to pyrolysis under the action of a mesoporous pyrolysis catalyst. According to the process, water of oily sludge is efficiently removed, the treatment intensity of the subsequent process is reduced, most of crude oil in the oily sludge can be recycled, the organic matter such as the heavy oil and the asphaltene can be subjected to pyrolysis due to high temperature heating, and the efficiency and quality of recycled oil can be improved.

Owner:XIAN HUANUO ENVIRONMENTAL PROTECTION CO LTD

Technology for producing han-hemp knitted home fabric

InactiveCN105696177AGood moisture absorptionImprove dehumidification effectWeft knittingWarp knittingYarnWax

The invention discloses a technology for producing a han-hemp knitted home fabric. The technology includes the following steps: spinning, yarn steaming, waxing, humidifying, weaving, dyeing, sanding, and finishing. The produced han-hemp home fabric by adoption of the technology is excellent in moisture absorption performance, moisture-removing performance and wear-ability. Compound tea saponin or caustic soda and hydrogen peroxide is used to perform dyeing pretreatment on the han-hemp knitted home fabric, and then fiber damage can be reduced; a sanding technology is adopted to treat han-hemp short fiber, and then the treatment intensity of cellulose can be weakened; and a hydrophilic amino silicon oil softening agent is used, and then the moisture absorption performance of the fabric can be improved.

Owner:江阴市长泾花园毛纺织有限公司

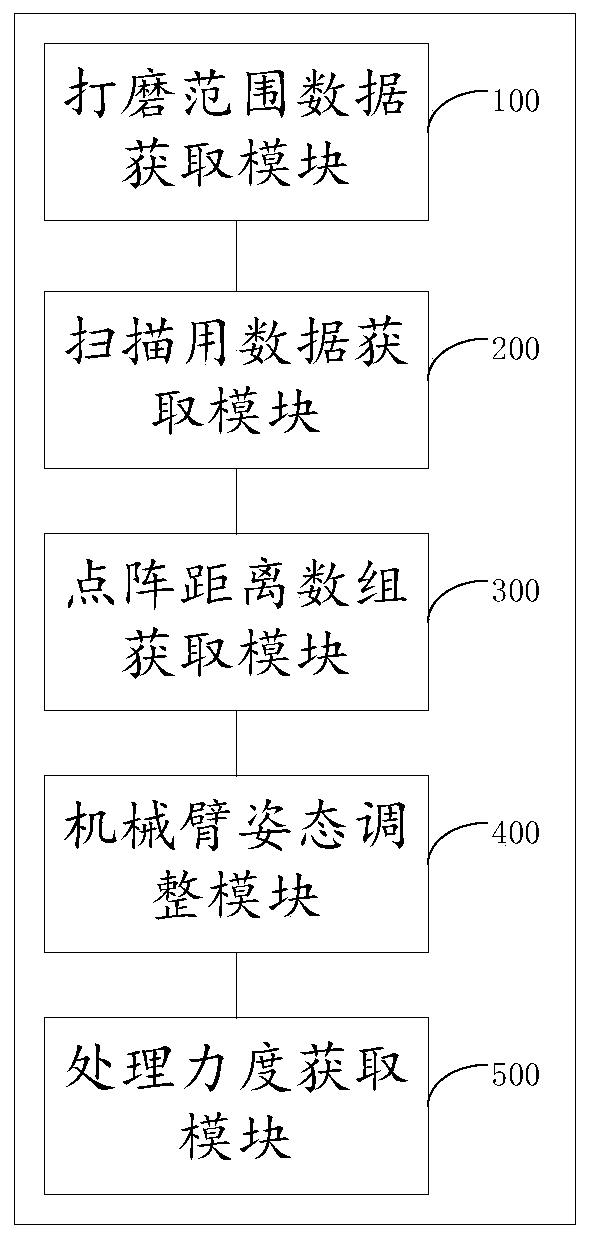

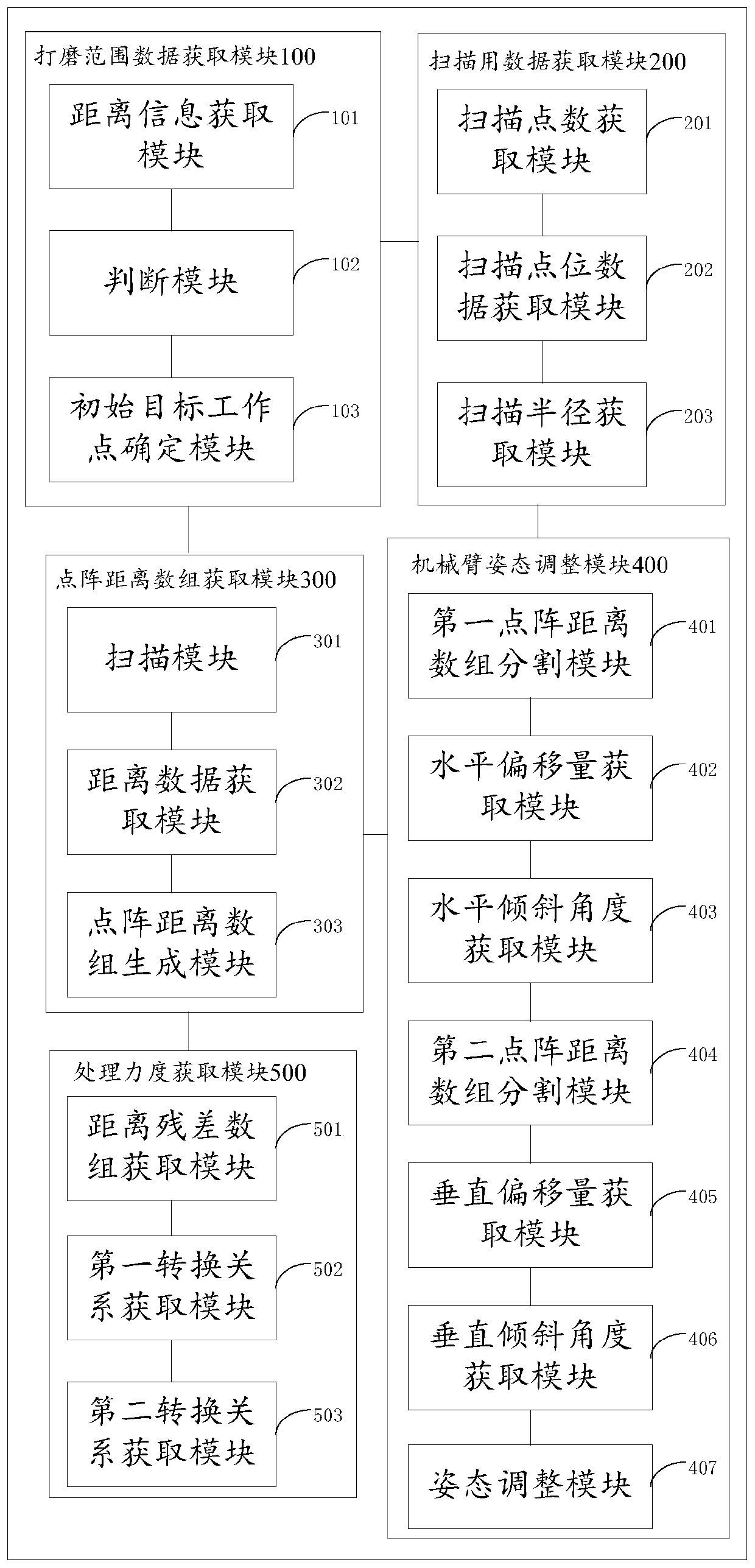

Mechanical arm, wall surface treatment method, electronic equipment and storage medium

ActiveCN111496579ARealize automatic attitude correctionGrind evenly and flatProgramme-controlled manipulatorGrinding feed controlEngineeringMechanical engineering

An embodiment of the invention provides a mechanical arm, a polishing method, electronic equipment and a storage medium, and relates to the technical field of polishing equipment operation. Accordingto the method, an initial target working point of the mechanical arm is determined, and polishing range data are obtained; data for scanning are obtained according to the polishing range data; a to-be-treated wall surface is scanned according to the data for scanning, and the distance between each scanning point location and the to-be-treated wall surface is obtained to form a lattice distance array; an inclination angle in the horizontal direction and an inclination angle in the vertical direction of the mechanical arm are obtained according to the lattice distance array to adjust a posture of the mechanical arm; and the lattice distance array is processed, the distances changing amount from the mechanical arm to the to-be-treated wall surface based on concave-convex change of the to-be-treated wall surface is obtained, the treatment intensity is planned according to the concave-convex change of the to-be-treated wall surface, the treatment accuracy and the treatment efficiency are improved, and the problem of big errors of an existing wall surface treatment method is solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

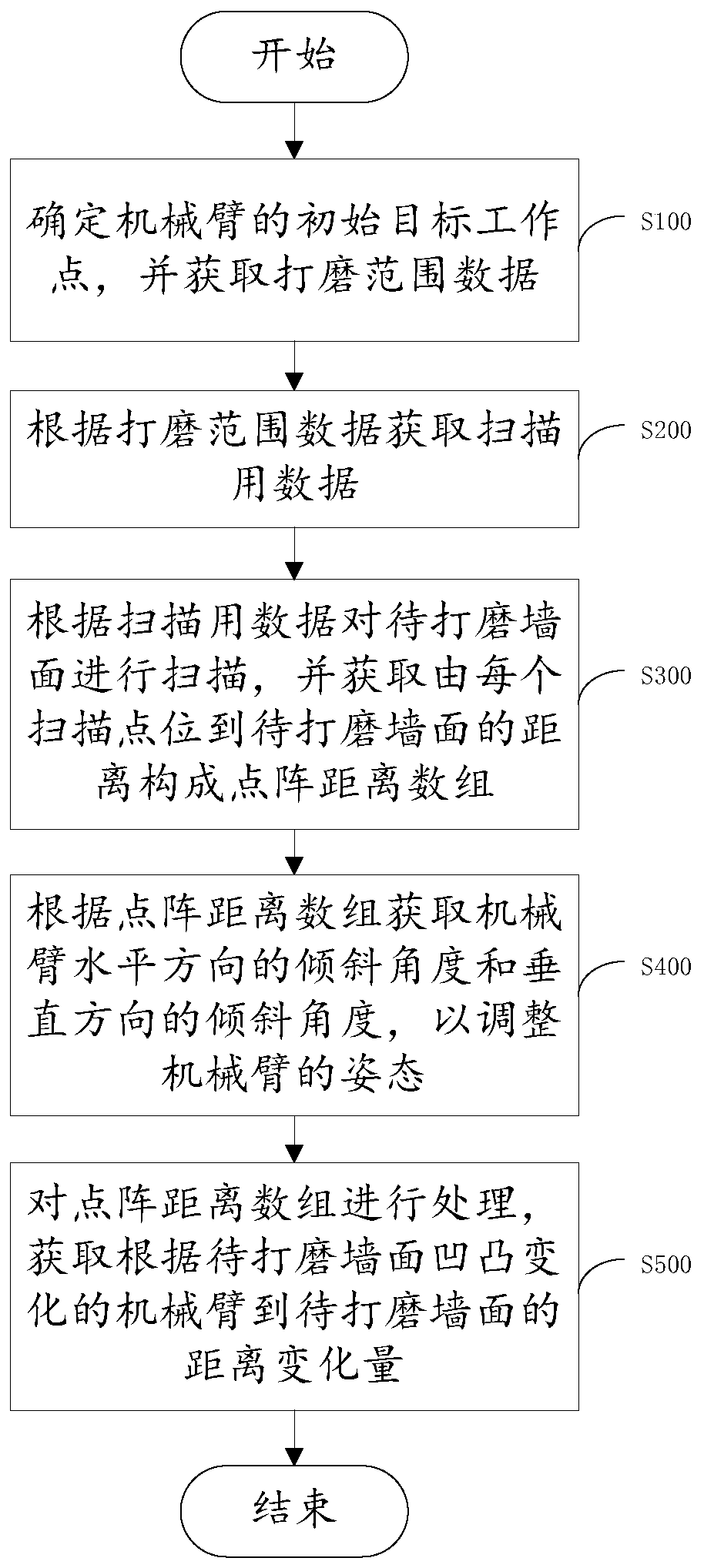

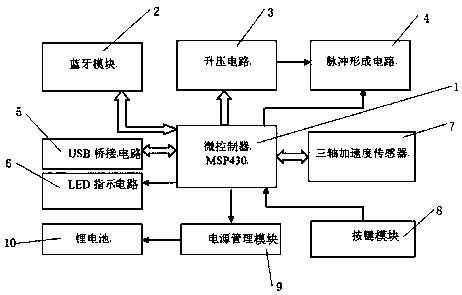

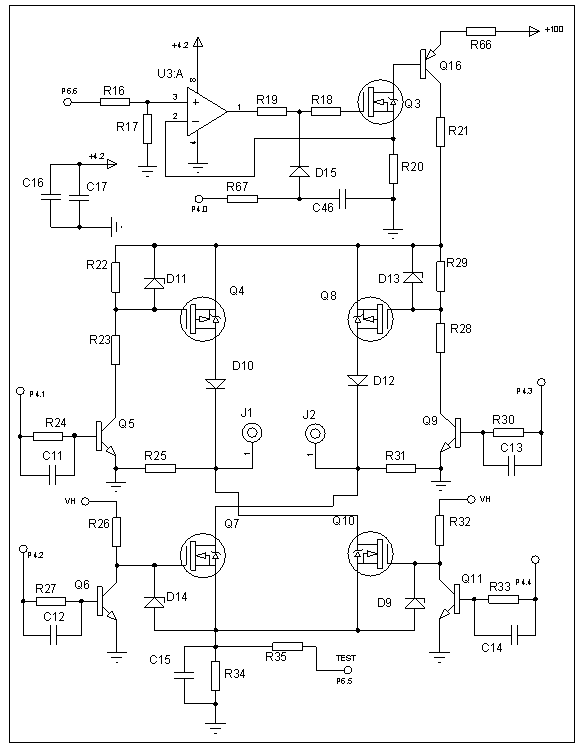

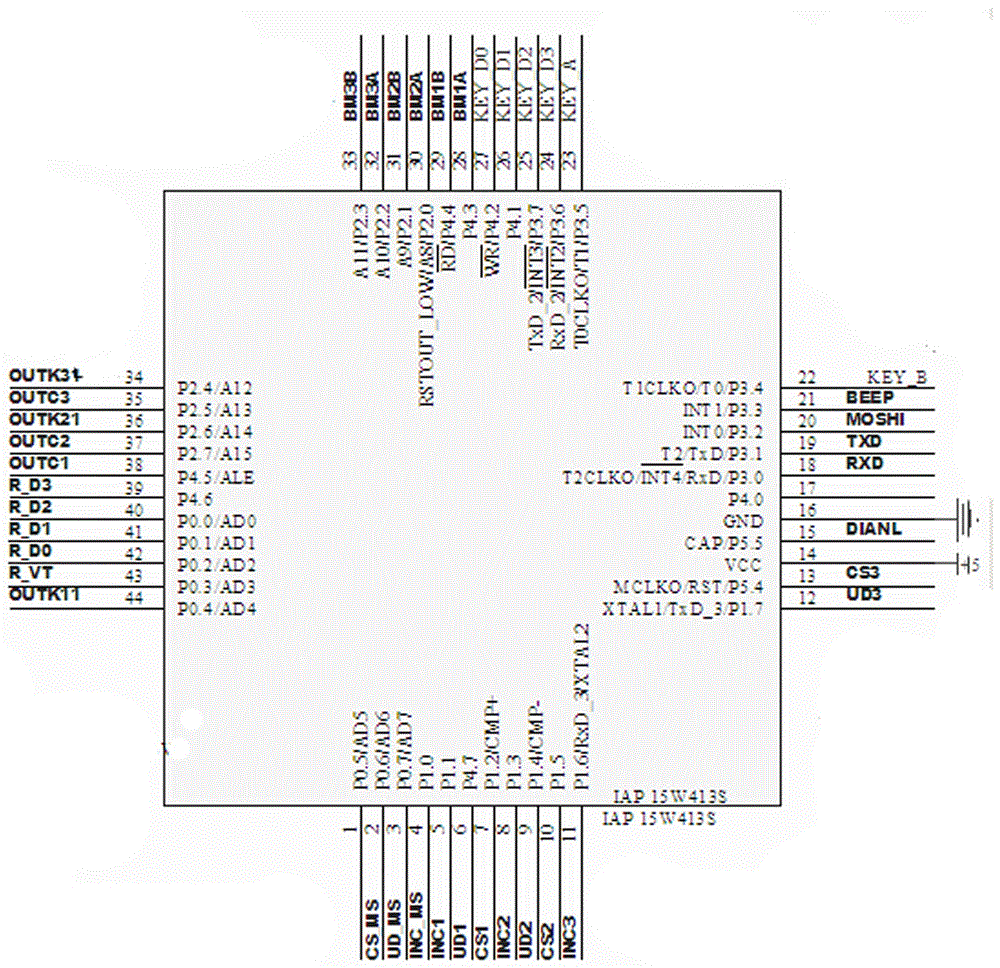

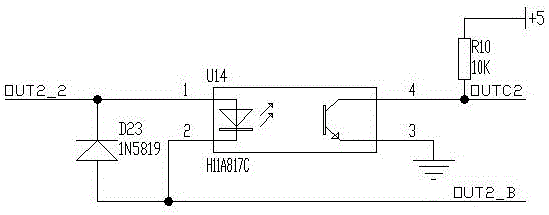

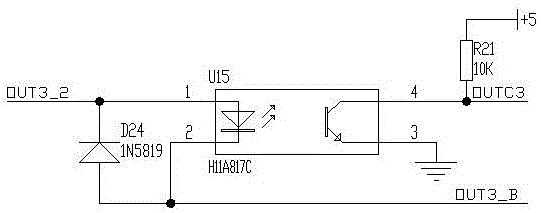

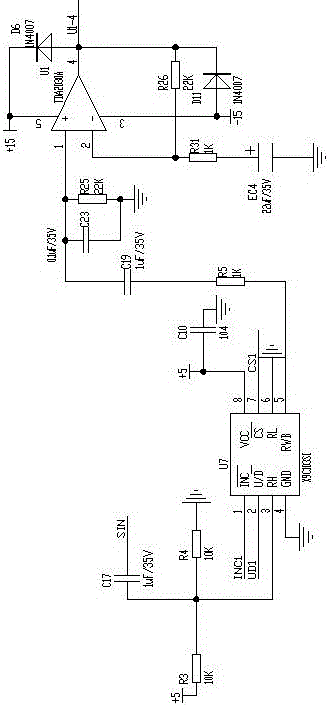

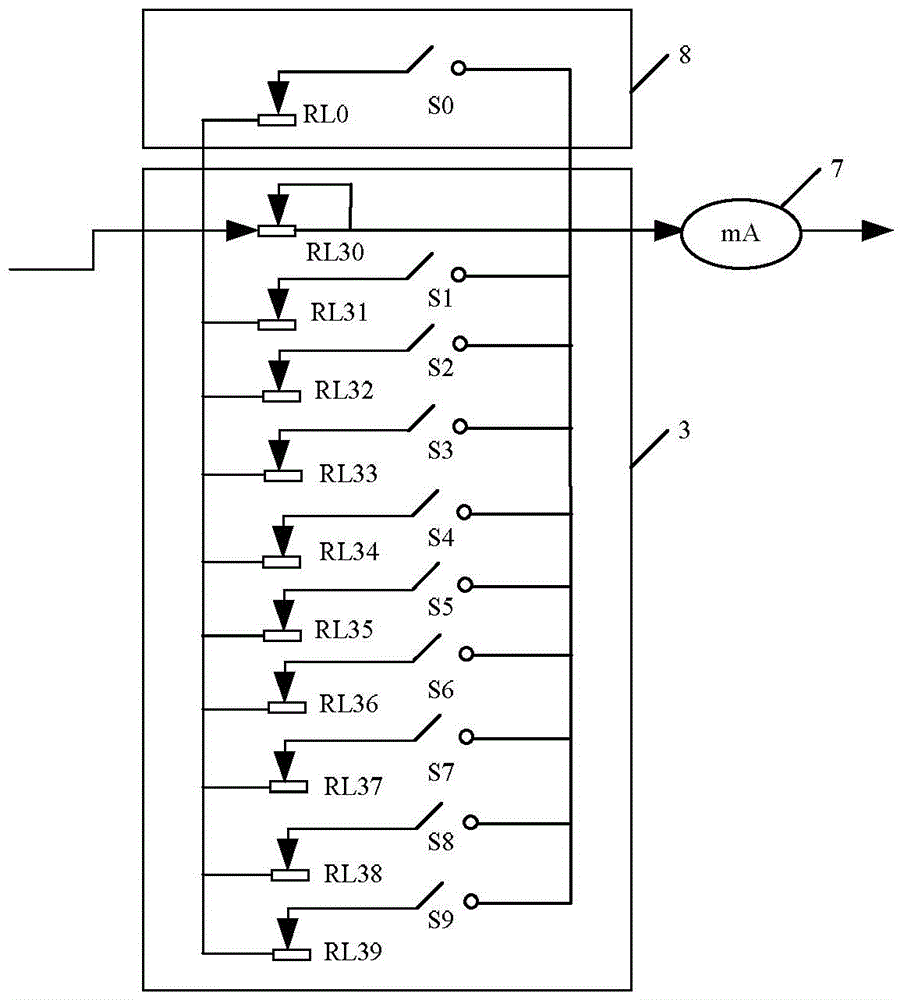

Hardware circuit of pain electric pulse therapy instrument

ActiveCN108578891AFacilitated releaseAnalgesic effectElectrotherapyArtificial respirationMicrocontrollerElectrical impulse

The invention relates to a hardware circuit of a pain electric pulse therapy instrument. The hardware circuit comprises a microcontroller, a Bluetooth module, a boosted circuit, a pulse forming circuit, a USB bridge circuit, an LED indicating circuit, a power management module, a button module, a three-axis acceleration sensor and a lithium battery, wherein an output pin of the microcontroller isconnected to input ends of the Bluetooth module, boosted circuit, pulse forming circuit, USB bridge circuit, LED indicating circuit, power management module, button module and three-axis accelerationsensor separately, an output end of the boosted circuit is connected to the input end of pulse forming circuit, and an output end of the power management module is connected to the input end of the lithium battery. The hardware circuit of the pain electric pulse therapy instrument has the advantages that the used electric pulse frequency and pulse width are different from those of existing products, and a user can select the treatment intensity according to his / her own symptoms and use effects.

Owner:汉中秦航精密机电有限公司

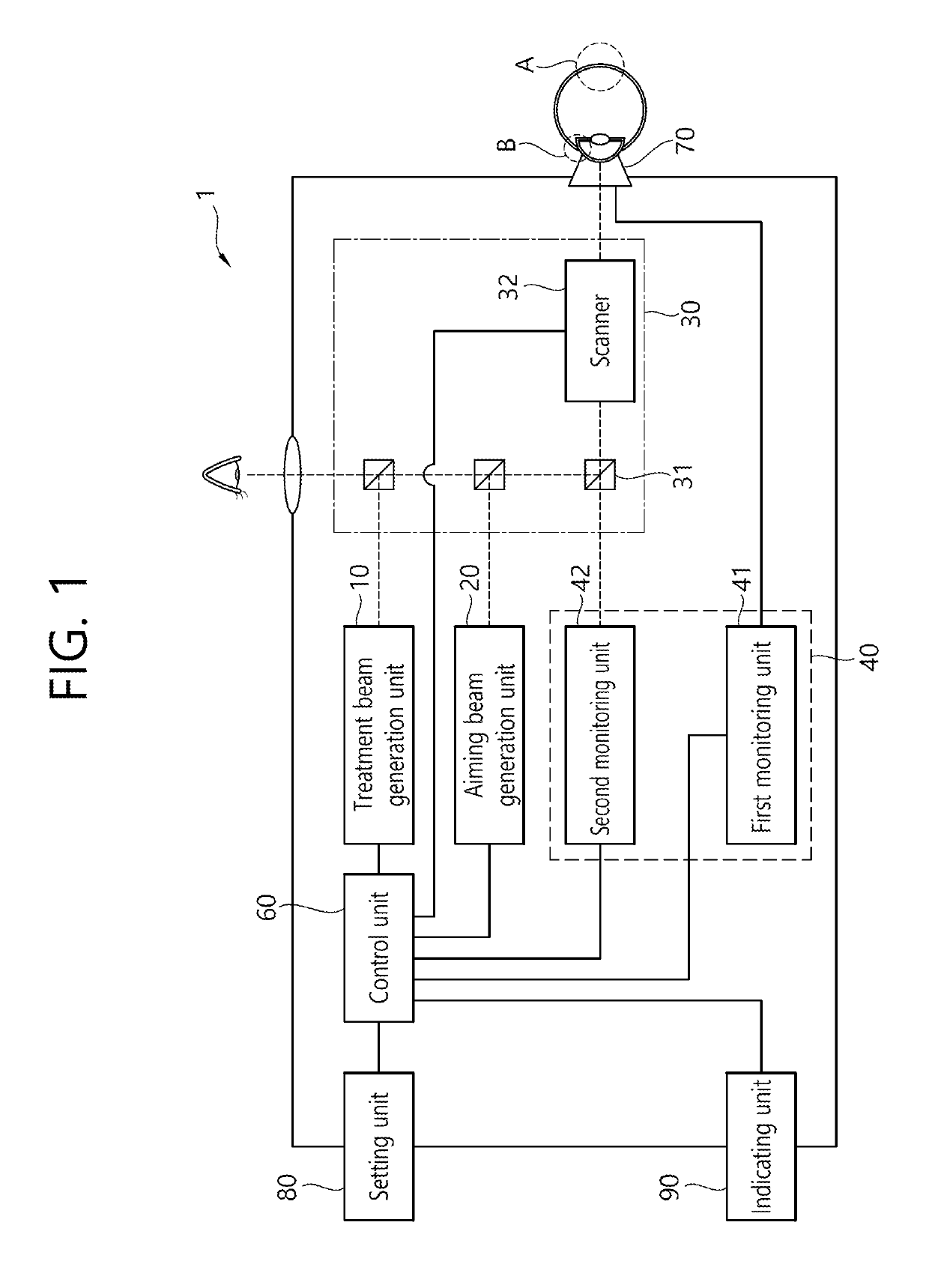

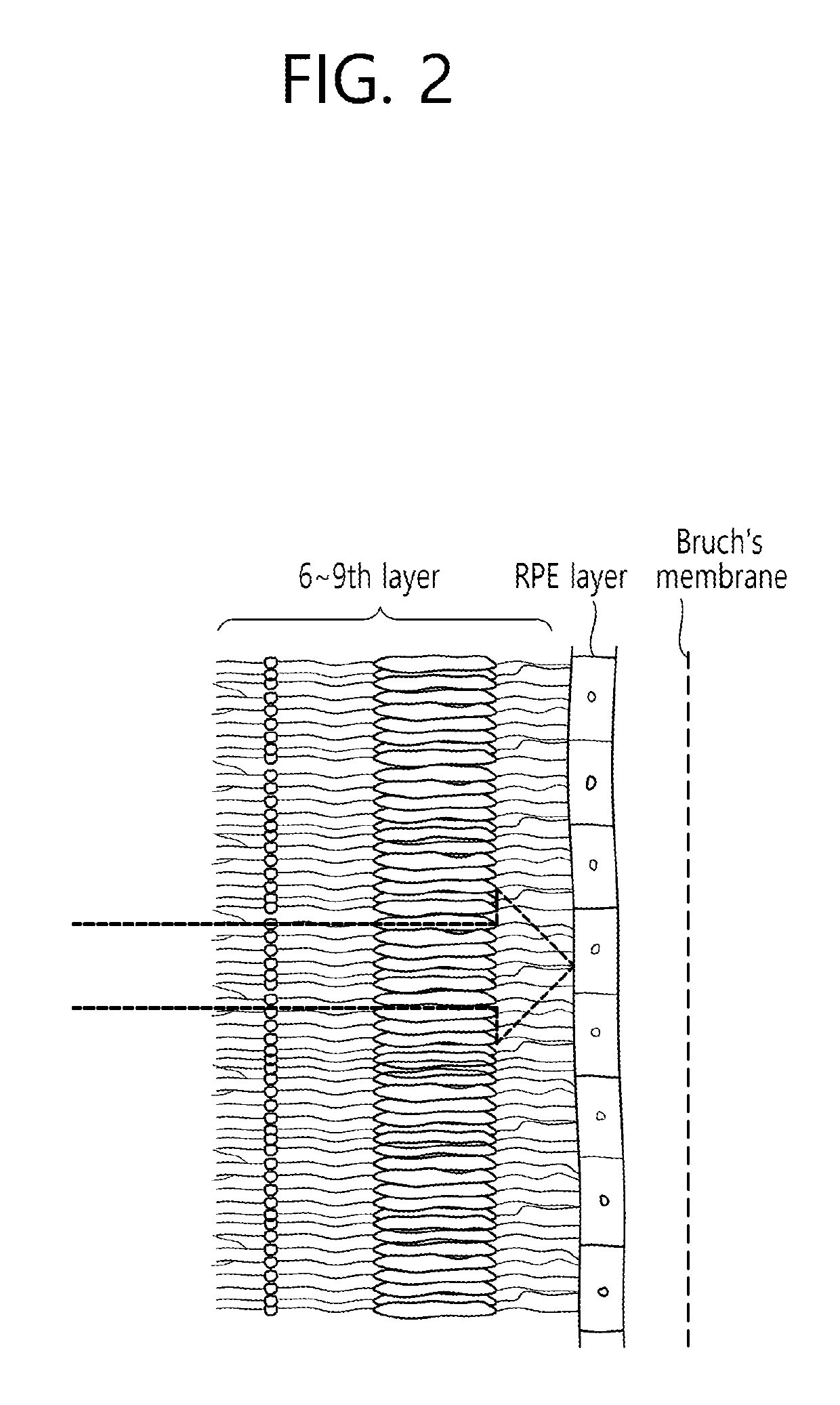

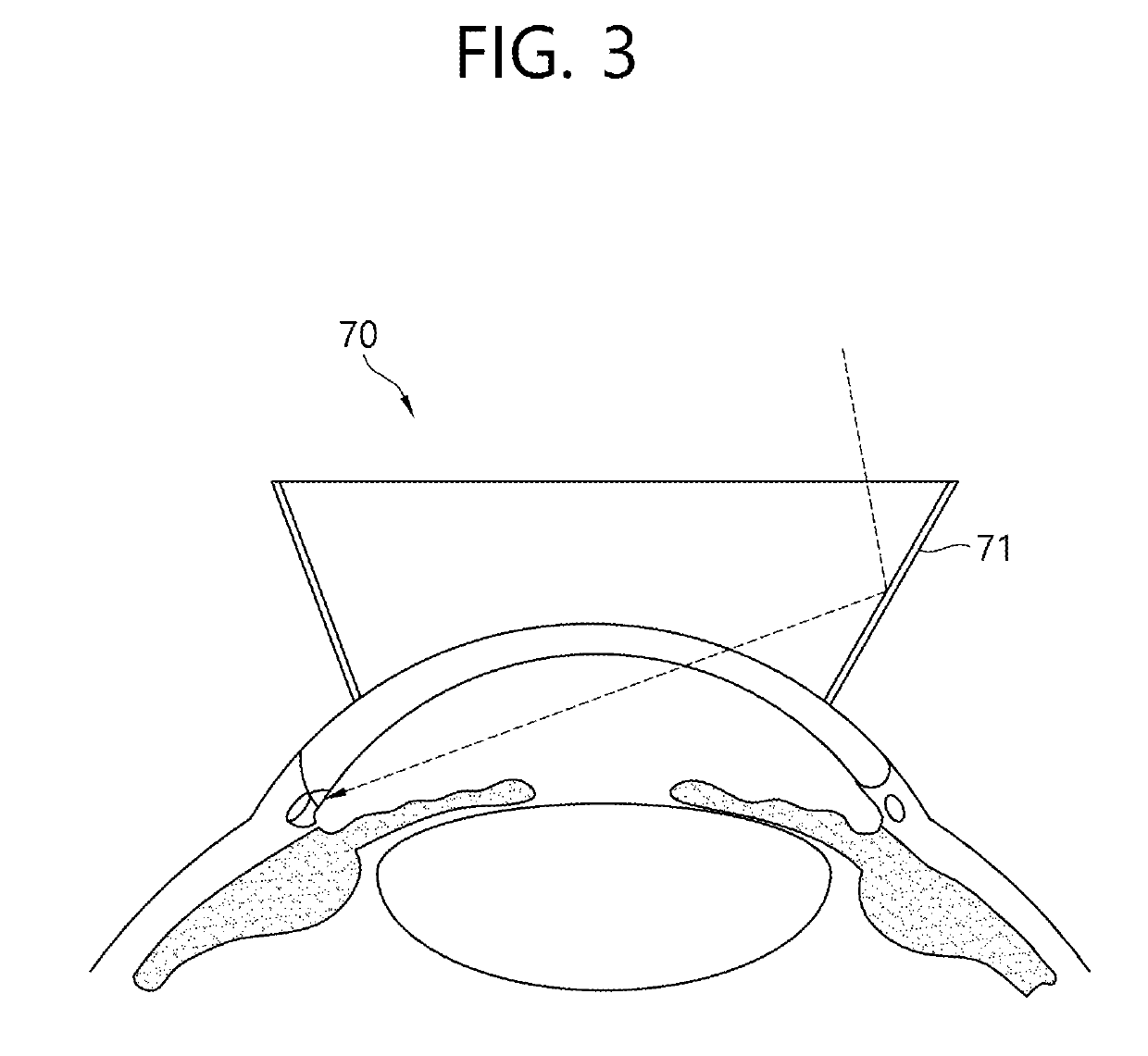

Ophthalmic treatment device and control method therefor

ActiveUS20190151146A1Convenient treatmentEffective monitoringLaser surgeryLight therapyOphthalmologyUltimate tensile strength

The present invention relates to an ophthalmic treatment apparatus and a control method therefor, and provides an ophthalmic treatment apparatus and a control method therefor, the ophthalmic treatment apparatus comprising: a setting unit formed so as to set a treatment mode; a therapeutic light emission unit emitting therapeutic light at a target position of an eyeground multiple times so as to perform treatment; a monitoring unit for monitoring information on the state of the target position by the therapeutic light during the emission of the therapeutic light; and a control unit for determining whether a treatment intensity according to the treatment mode has been reached, by using the information monitored by the monitoring unit, and for controlling an operation of the therapeutic light emission unit on the basis of the determination.

Owner:LUTRONIC

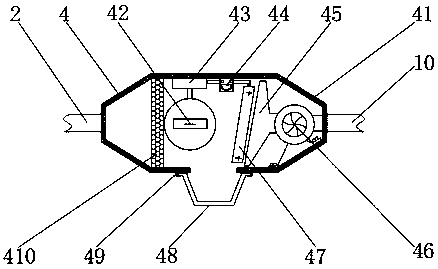

Wearable electrical stimulator

PendingCN108042914AEasy to useSolve the problem that treatment cannot be carried out according to individual needsImplantable neurostimulatorsArtificial respirationElectricityPower flow

The embodiment of the invention discloses a wearable electrical stimulator. The wearable electrical stimulator comprises an upper cover, a lower cover, a power supply device, a control device, a calming electrode tab and an exciting electrode tab; the upper cover is connected with the lower cover to encapsulate the power supply device and the control device which are electrically connected; the control device is used for selecting signals and outputting current shift signals according to the mode, and generating calming impulse signals or exciting impulse signals; the calming electrode tab isused for applying the calming impulse signals to a human body through the cervical nerve; and the exciting electrode tab is used for applying the exciting impulse signals to the human body through thetemporal branch of the facial nerve and the right trigeminal nerve. According to the wearable electrical stimulator, for the first time, two different working modes of calm nerves and excitatory nerves are integrated into a wearable device, so that a user can configure the corresponding electrode tab, treatment mode and treatment intensity according to his / her own condition, so that the needs ofpersonalized treatment for the user is met, both calming function and enhancing nerve excitability function are achieved.

Owner:深圳华瑞技术有限公司

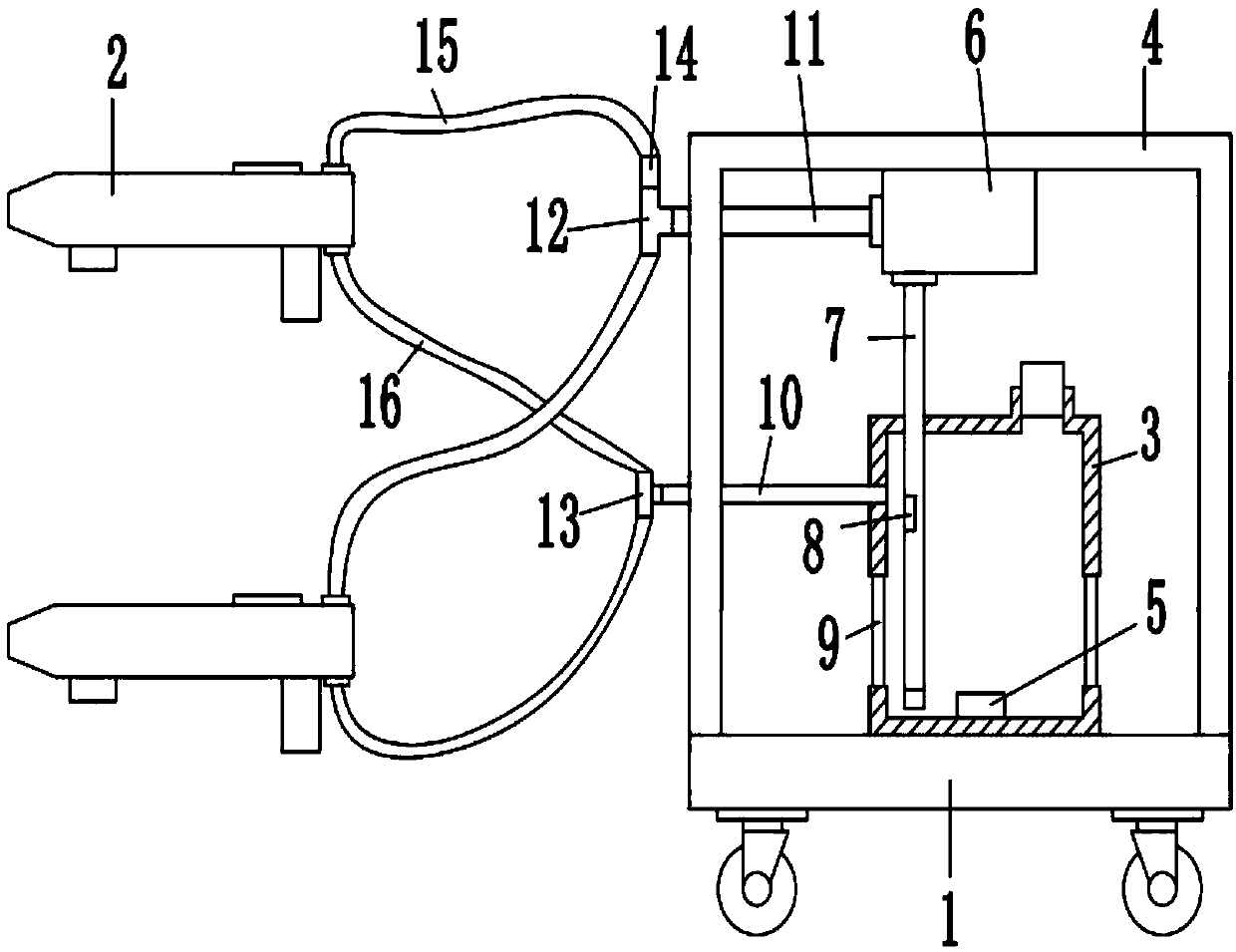

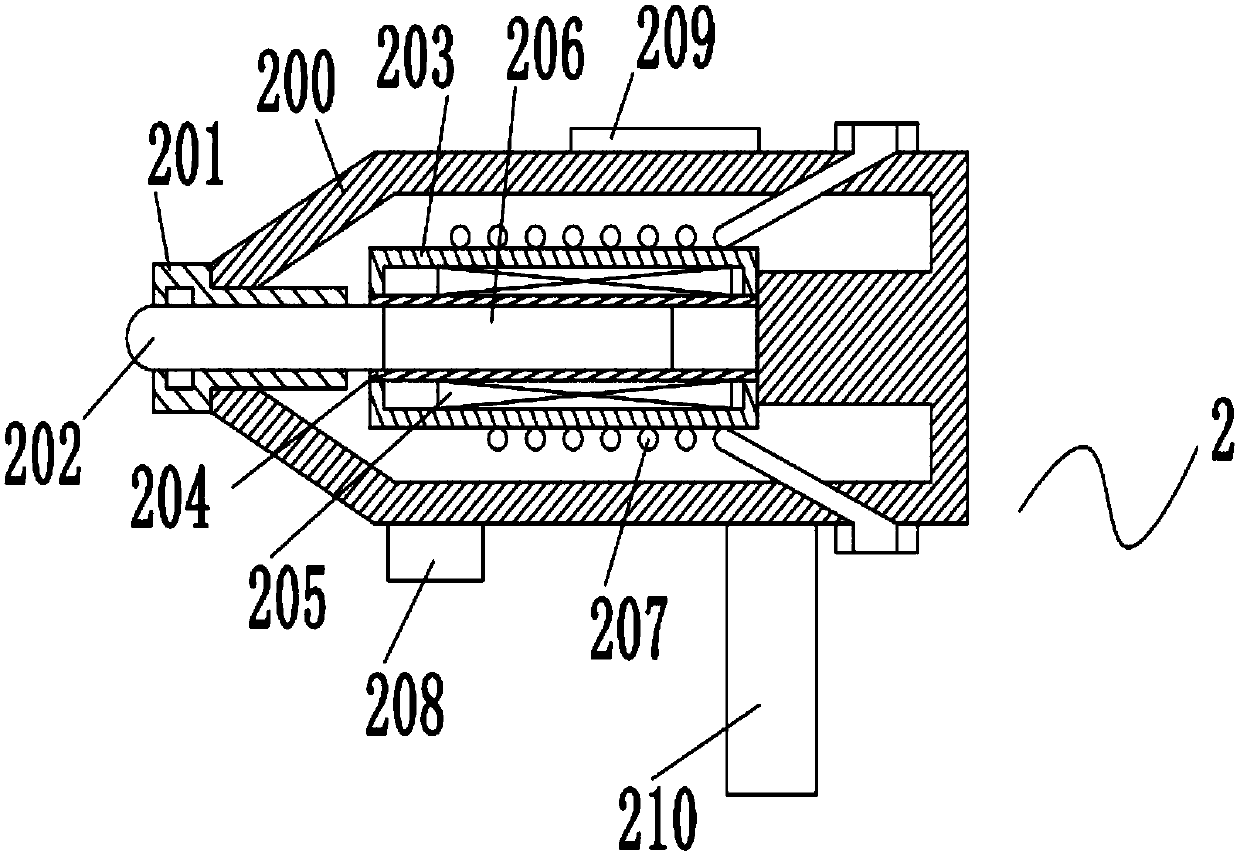

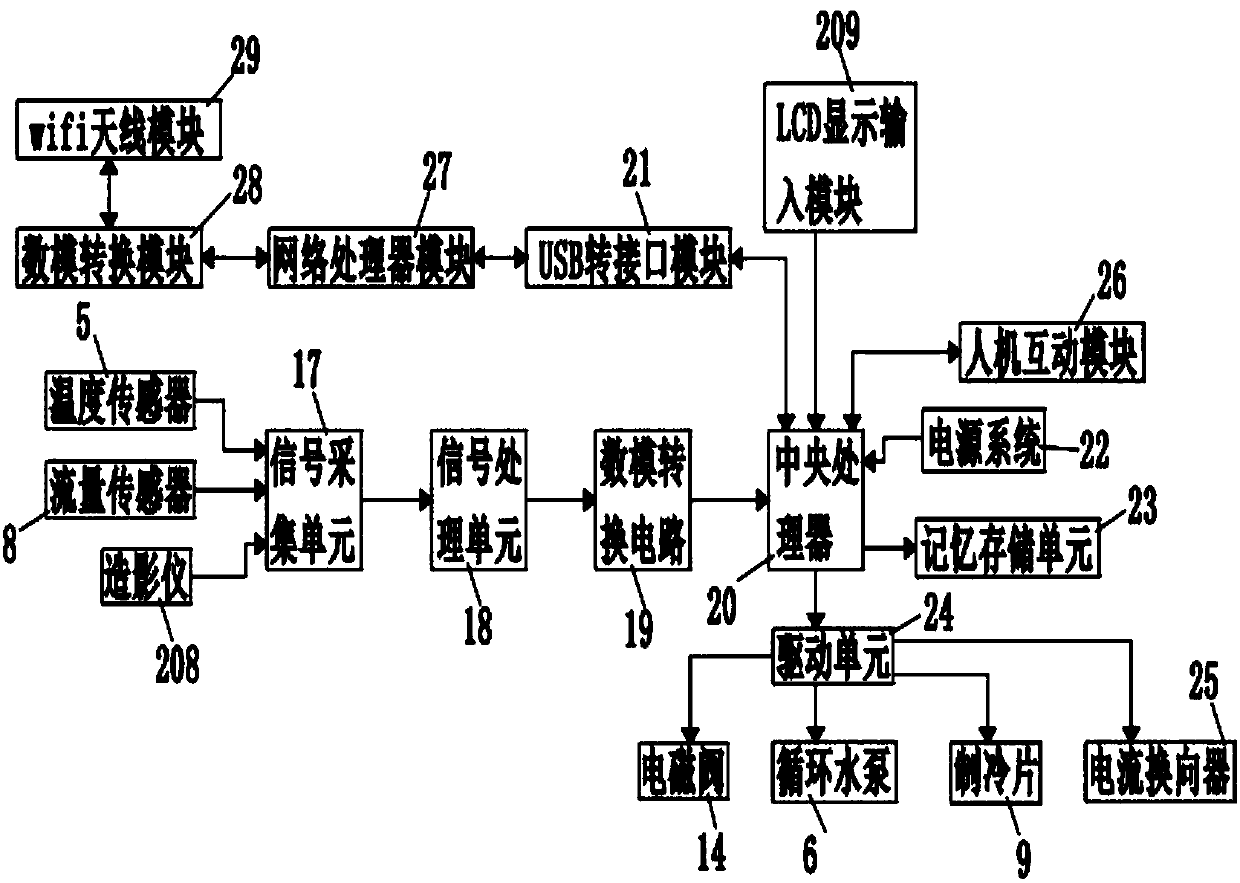

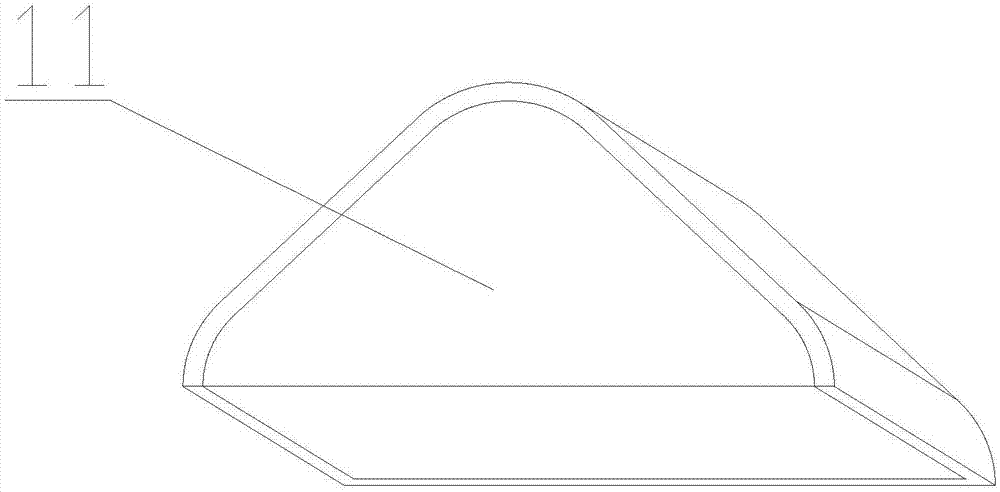

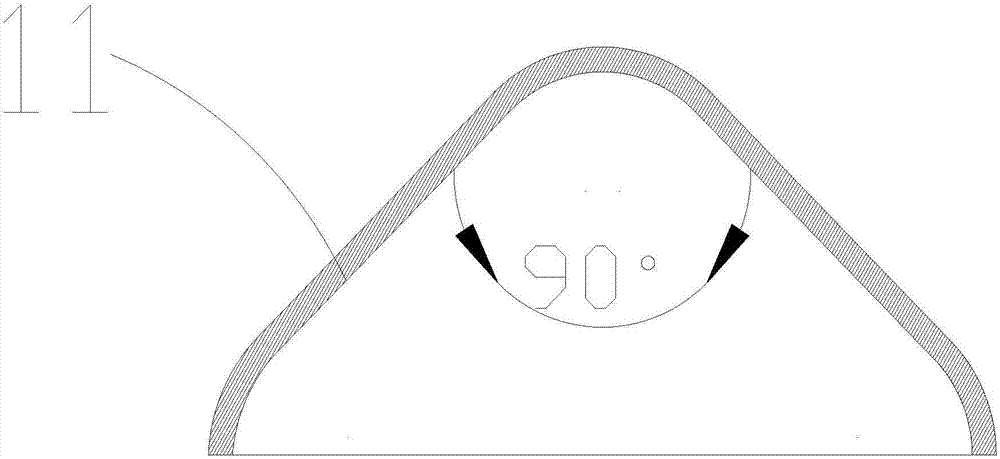

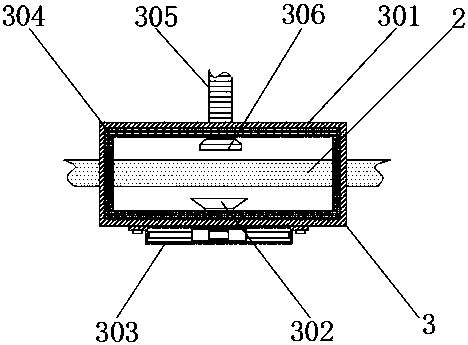

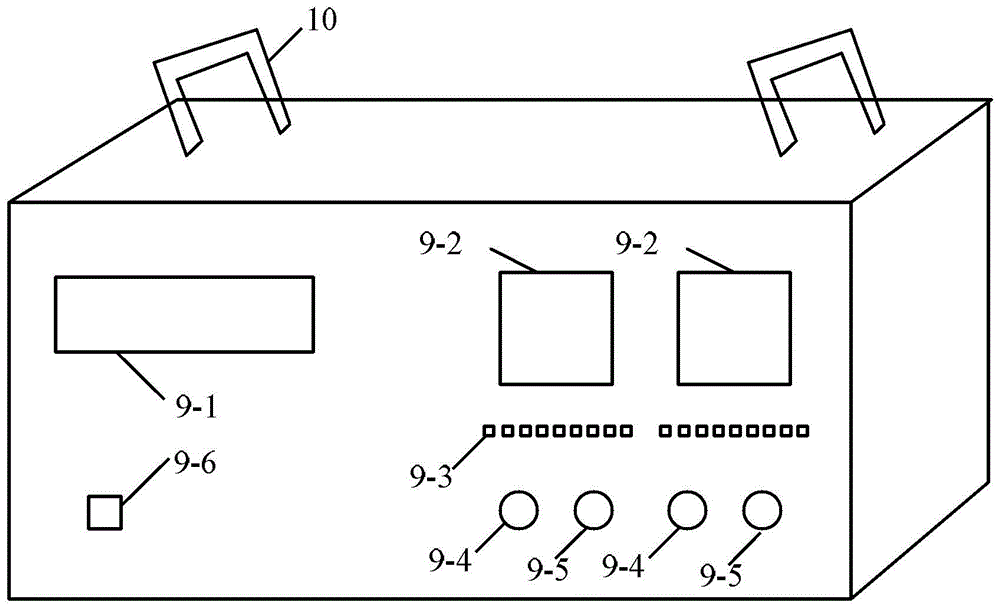

Intelligent impact wave therapeutic apparatus with water-cooling heat dissipation function

ActiveCN107550706AImprove experienceImprove work efficiencyVibration massageData acquisitionTreatment intensity

The invention discloses an intelligent impact wave therapeutic apparatus with the water-cooling heat dissipation function. The intelligent impact wave therapeutic apparatus comprises a movable base and two therapeutic heads; a water tank and a gantry frame are arranged on the top of the movable base, the water tank is located in an inner cavity of the gantry frame, a temperature sensor is arrangedat the bottom in an inner cavity of the water tank, the number of times of impact wave therapy in one therapy process of a patient, therapy intensity of each time and the wounded part image collectedby a radiography instrument are wirelessly transmitted to a mobile terminal through a USB adapter interface module, a network processor module, a digital-to-analogue conversion module and a wifi antenna module, data is recorded by a memory storage unit, so that the therapy condition is detected in real time, data collection, data backup and network data communication conduction in the whole therapy process are completed, and the patient is helped to learn the own therapy stage at any time. The intelligent impact wave therapeutic apparatus is excellent in heat dissipation effect and convenientto use, improves working efficiency and can be networked wirelessly.

Owner:SHENZHEN DJ INNOVATION IND CO LTD

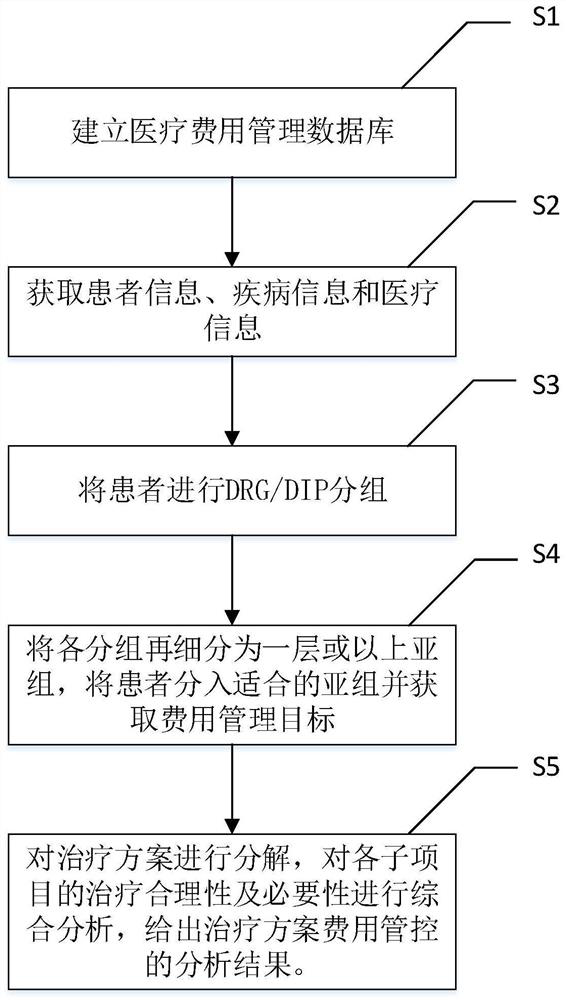

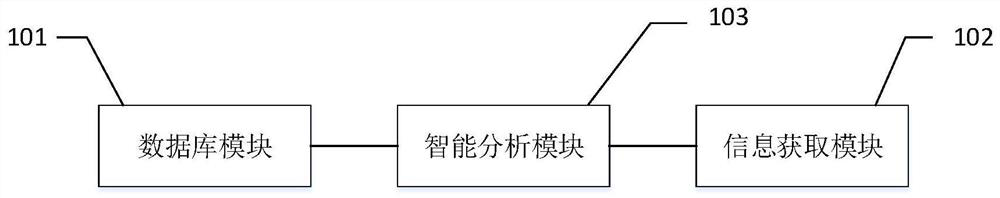

Medical expense management method and system

PendingCN113921124AReduce financial burdenStandardize diagnosis and treatment behaviorHealthcare resources and facilitiesPatient-specific dataDiseaseTreatment intensity

The invention discloses a medical expense management method and system. The medical expense management method comprises the following steps: establishing a medical expense management database; acquiring patient information, disease information and medical information; carrying out DRG / DIP grouping on the patients; subdividing each group into one or more layers of subgroups, dividing the patients into proper subgroups, and obtaining an expense management target; and decomposing the treatment scheme, comprehensively analyzing the treatment rationality and necessity of each sub-project, and giving an analysis result of cost management and control of the treatment scheme. The medical expense management system comprises a database module, an information acquisition module and an intelligent analysis module. According to the medical expense management method and system, medical expense management is carried out based on the DRG / DIP, each item of the treatment scheme or the treatment intensity of each item is adjusted, the medical expense can be precisely managed and controlled, medical resources are reasonably distributed, diagnosis and treatment behaviors are standardized, excessive treatment is avoided, and the economic burden of a patient is relieved.

Owner:曹庆恒

Production technology of metal ice particles

ActiveCN107283135AImprove the cooling effectHigh production process efficiencyMetallurgyCooling effect

The invention discloses a production technology of metal ice particles. The production technology comprises the steps of (1) cutting a metal sheet; (2) manufacturing metal components; (3) forming through holes in the side walls of a part of metal outer shells; (4) welding one metal component with through holes and another metal component without through holes, and manufacturing one hollow metal outer shell with an airtight cavity inside which communicates with the exterior through the through holes; (5) injecting a coolant through the through holes; (6) sealing the through holes through welding; and (7) carrying out grinding and polishing. Through the adoption of the technical scheme, the metal ice particles can be produced, reutilization is facilitated, and beverages are not diluted and do not go bad; the coolant is sealed in the metal outer shells, and the cooling effect of the metal ice particles is greatly improved; and production efficiency is high, manufacturing is facilitated, and grinding and polishing treatment intensity is low.

Owner:中山市品派生活日用制品有限公司

Novel environment-friendly tail gas treatment device

InactiveCN108691622AQuick clearSimple structureCombination devicesInternal combustion piston enginesTreatment effectWater vapor

Owner:叶彩英

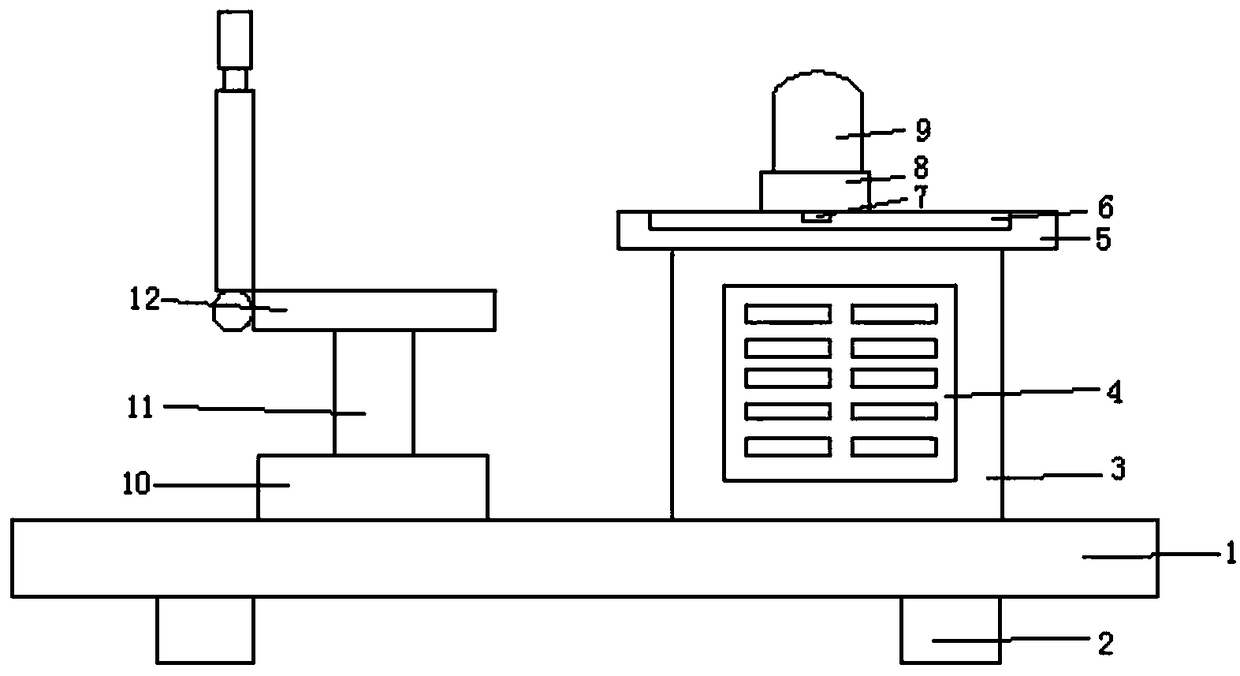

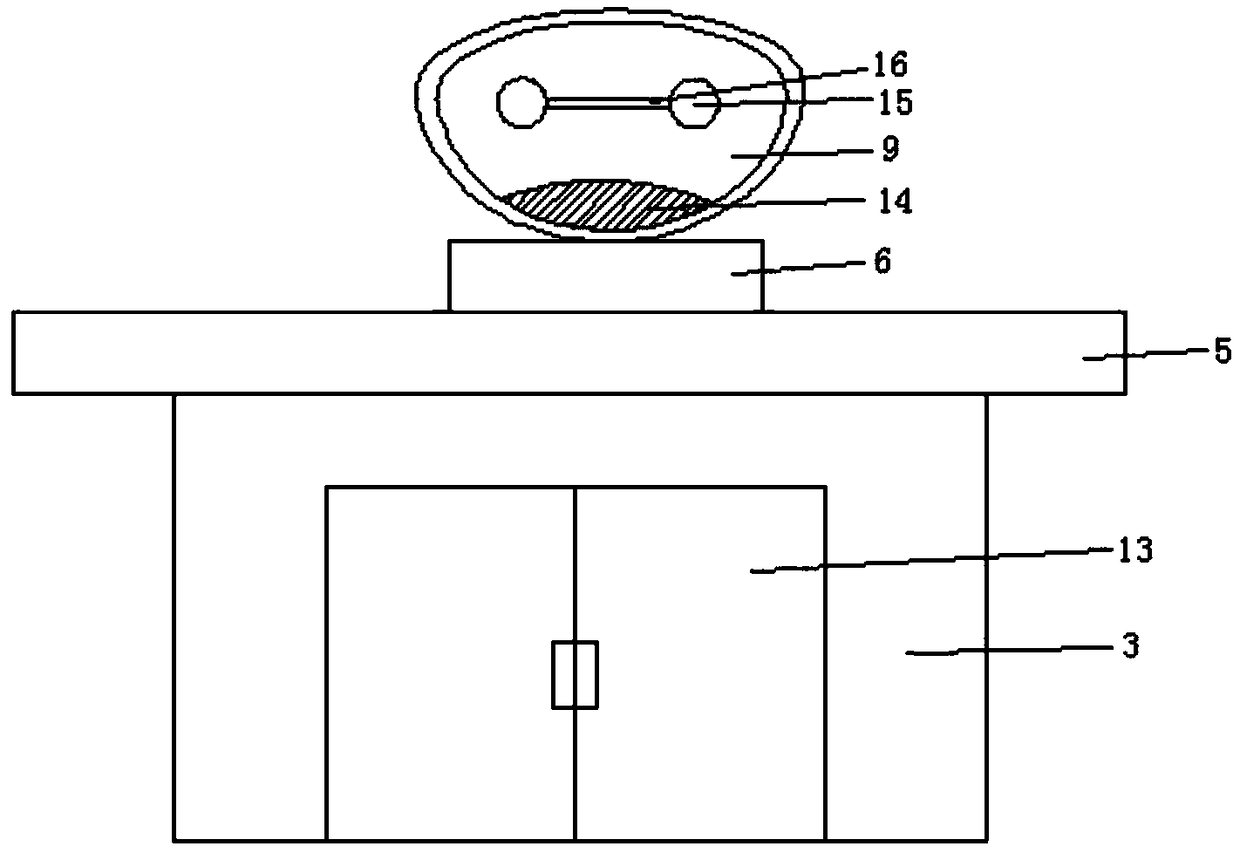

A laser therapeutic device for ophthalmology

A laser therapeutic device for ophthalmology includes a base, a case, a laser generator and a pulse generator. The case is arranged on the upper part of the base, the upper part of the case is provided with an operation table, the upper part of the operation table is provided with a fixing seat, a slide block is arranged at the bottom of the fixing seat, a slide groove is arranged inside the operation table, a laser emitting head is arrange inside that shell, the laser emitting head is provide with an adjusting rod, a laser generator is arranged on that upper part of the power supply, the leftside of the laser generator is provided with a pulse generator, the laser generator and an upper part of that pulse generator are provided with a convert, a laser treatment device for ophthalmology by converting the transducer to a treatment intensity suitable for the eye, the laser generator and a pulse generator are arranged to prevent that light emit by the laser generator and the pulse generator from being too strong from causing harm to the eye, and an adjusting rod is arranged between the laser emitting heads, so that the distance of the laser emitting heads can be adjusted according tothe distance between the eyes of the patient.

Owner:于翠杰

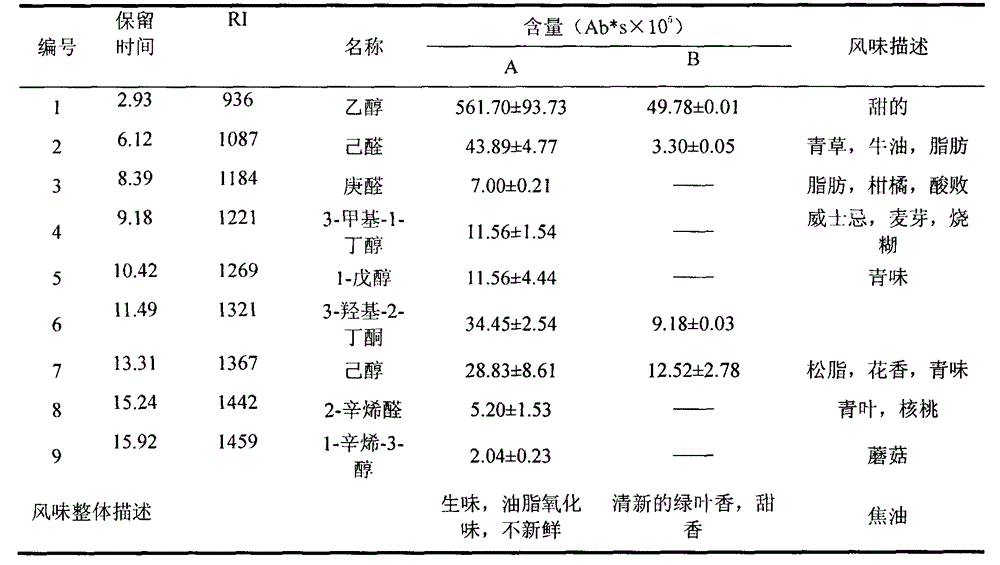

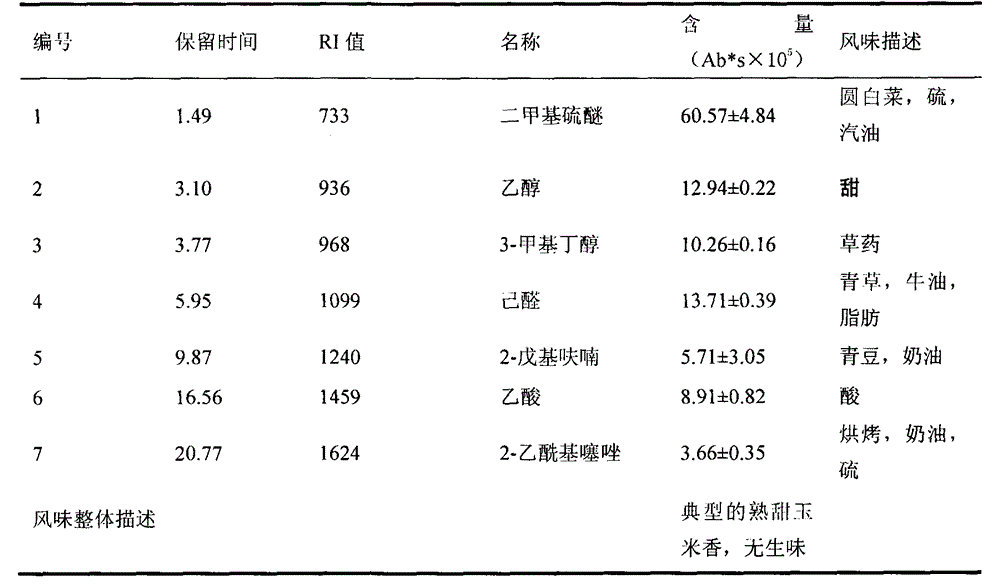

Method for fabricating sweet corn juice other than thermal pretreatment

The invention provides a method for fabricating sweet corn juice other than thermal pretreatment. The method comprises the following steps: 1, immersing sweet corn kernels which are harvested freshly into 0.1 moL / L of Na<2>HPO<4>, so that a pH9.0 buffered solution is obtained, and adopting a colloid mill for conducting the homogenate; 2, centrifugally removing substances which are prone to sediment corn juice; 3, utilizing citric acid for adjusting the pH to 6.5-7.0; 4, conducting high-temperature steam sterilization for 20 minutes at the temperature of 121 DEG C. By mean of the method, the heat treatment intensity in the corn juice processing process is reduced, and compared with a sample which is subjected to blanching pretreatment, the fresh and tender flavor of a sweet corn can be better presented.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

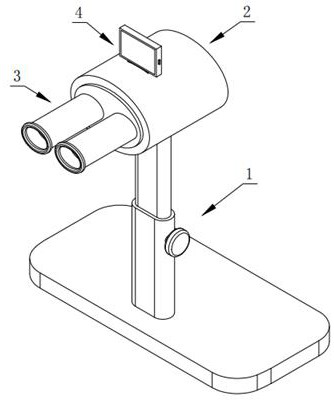

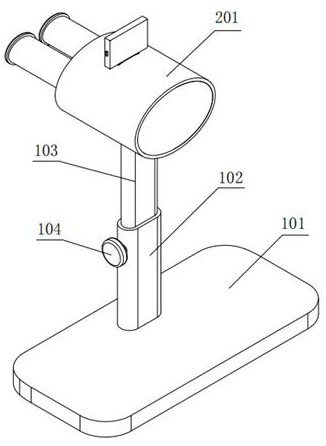

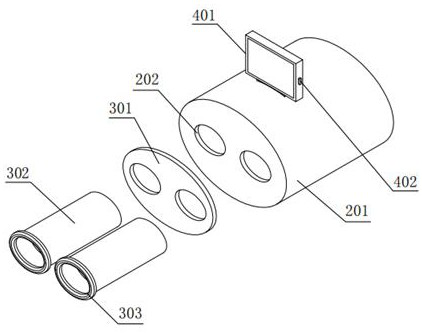

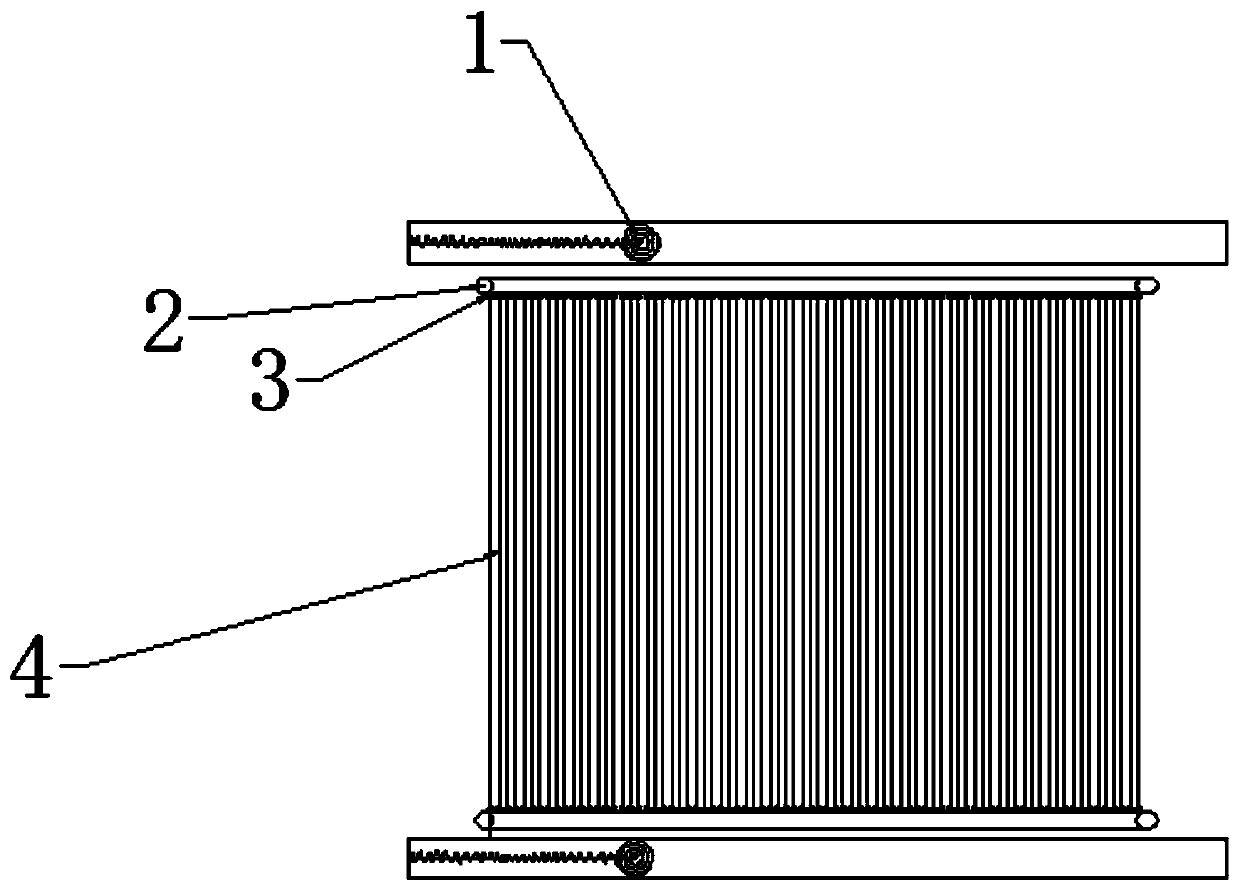

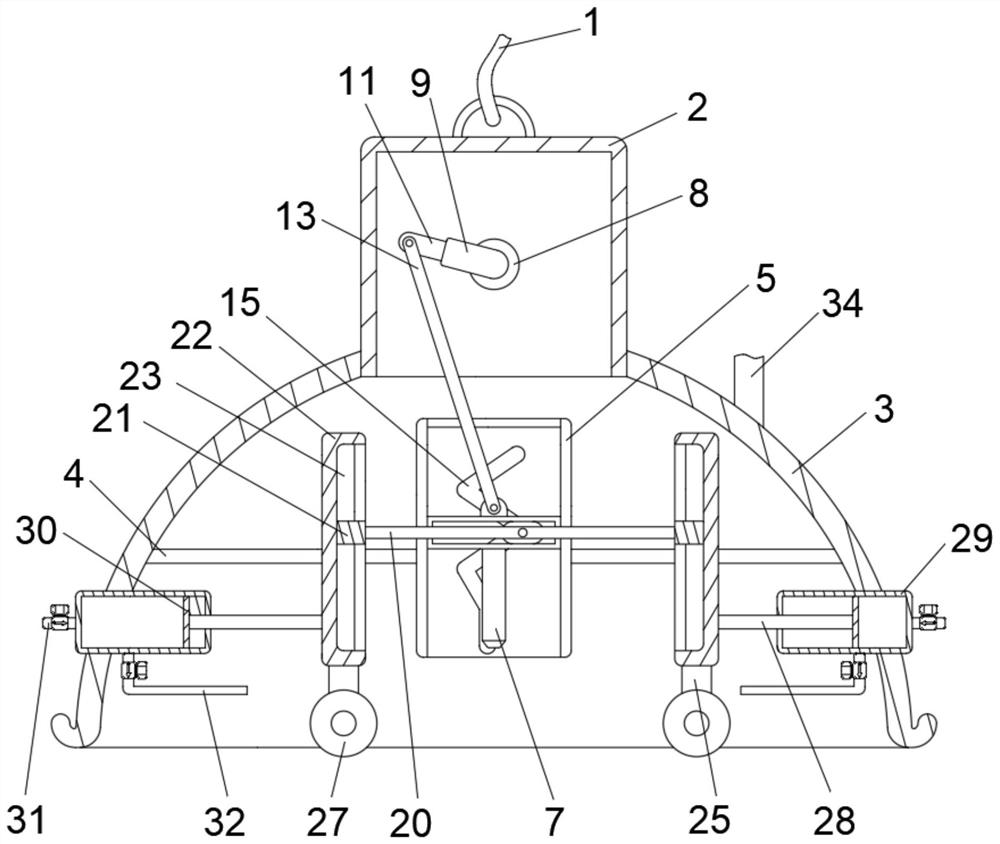

Light feeding instrument with adjustable treatment intensity

PendingCN114177537AAdjustable treatment intensityEliminate usage limitationsLight therapyOphthalmologyControl cell

The invention belongs to the technical field of light feeding instruments, and discloses a light feeding instrument with adjustable treatment intensity, which comprises a bottom support assembly, a red light generation assembly, a lens cone assembly and a control unit. The bottom supporting assembly is used for forming an installation foundation of the treatment-intensity-adjustable nursing light instrument, the bottom supporting assembly comprises a base, a hollow supporting column and a supporting rod, the base is horizontally arranged, the hollow supporting column is vertically and fixedly installed on the upper portion of the base, and the supporting rod is installed in the upper end of the hollow supporting column through an adjusting bolt; the red light generating assembly is used for generating red light. According to the light feeding instrument with the adjustable treatment intensity, the intensity of the generated treatment red light is adjustable, the requirement for myopia treatment of myopia patients with different myopia degrees can be met, the treatment effect is good, and the use limitation is effectively eliminated; more importantly, the risk of fundus lesion, maculopathy and other potential side effects caused by overhigh red light intensity or long-time use can be reduced.

Owner:西安市第九医院

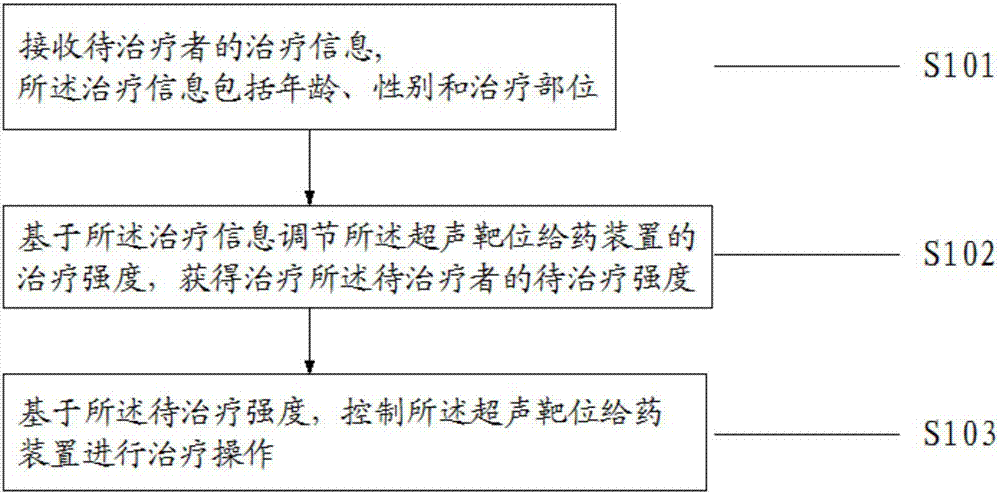

Control method of ultrasonic target administration apparatus

InactiveCN107403070AFix technical inefficienciesMaster usageUltrasound therapyMedical devicesPhysical therapyUltimate tensile strength

The invention relates to the technical field of electronics, and especially relates to a control method of an ultrasonic target administration apparatus. The method comprises receiving treatment information of a person to be treated, wherein the treatment information comprises the age, sex and treatment position; adjusting treatment intensity of the ultrasonic target administration apparatus based on the treatment information, and obtaining to-be-treated intensity of treating the person to be treated; and controlling the ultrasonic target administration apparatus to perform treatment operation based on the to-be-treated intensity. According to the embodiments, after the treatment information of the person to be treated is obtained, the treatment intensity of the ultrasonic target administration apparatus can be automatically adjusted based on the treatment information to obtain the to-be-treated intensity, the ultrasonic target administration apparatus is controlled to perform the treatment operation according to the to-be-treated intensity, and the technical problems that in the prior art, the treatment intensity of the ultrasonic target administration apparatus can only be manually adjusted, and efficiency is low are solved.

Owner:成都德而塔生物科技有限公司

Electronic meridian therapeutic instrument

InactiveCN106730326AHigh strengthGood treatment effectElectrotherapyArtificial respirationDiseaseMicrocontroller

The invention discloses an electronic meridian therapeutic instrument, which comprises a single-chip microcomputer unit, an operation amplifier power supply unit, a single-chip microcomputer power supply unit, a communication unit, three paths of adjustment treatment intensity output units, three paths of booster units, three paths of cup drop units, three paths of relay control units, a current detection unit, a waveform generation unit, a waveform output control unit, a current setting adjustment unit, a key unit, a remote controller unit, an overvoltage and over-current protection unit and a warning tone unit. The advantages are that the electronic meridian therapeutic instrument is good in treatment effect, can reach a meridian dredging effect, is high in disease cure rate, is low in cost and is safe and reliable.

Owner:潍坊大地医疗器械有限公司

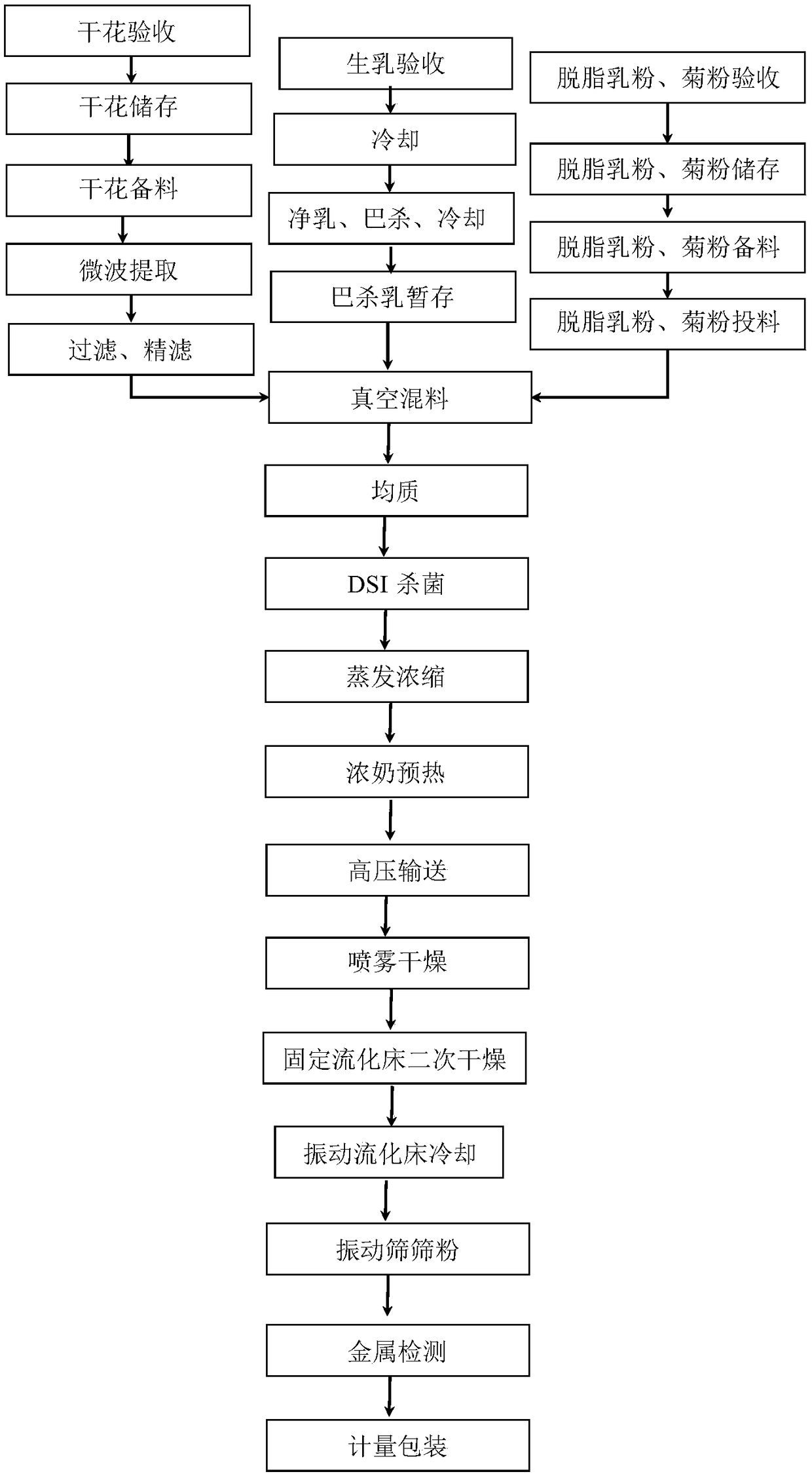

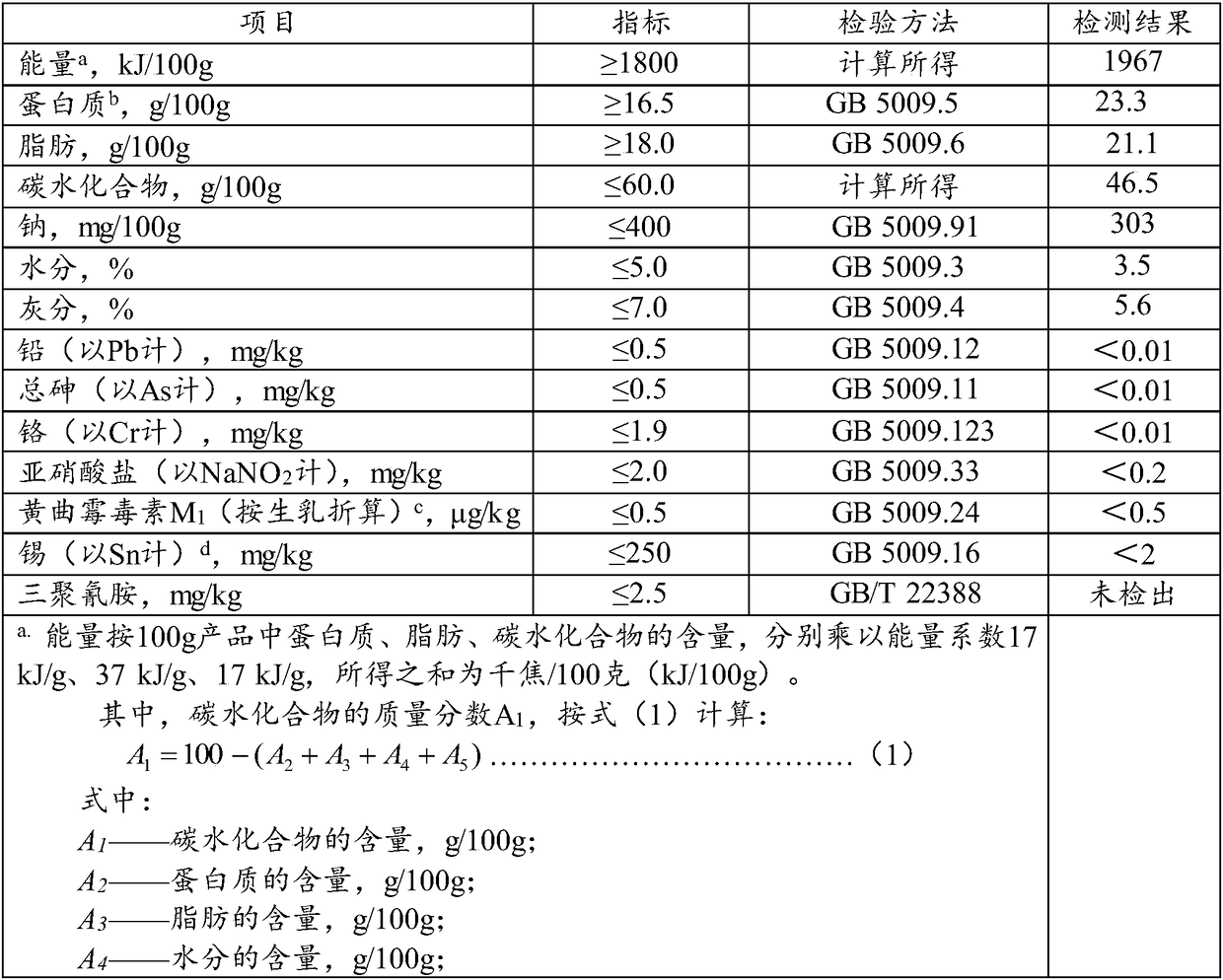

Flower tea milk powder and preparation method thereof

InactiveCN109007173AReduce heat treatment intensityReduce processing lossMilk preparationTea substituesFluidized bed dryingLiquid milk

The present invention provides a preparation method of flower tea milk powder. The preparation method comprises the following steps: A) roses, Hangzhou white chrysanthemum, honeysuckle and jasmine flowers are mixed; water is added; the materials are subjected to microwave heating extraction; and the extract is filtered to obtain a flower tea extract; and B) the flower tea extract and liquid milk are mixed; and homogenization, sterilization, concentration, spray-drying, fluidized bed drying, powder sieving and metal detecting are conducted successively to obtain the flower tea milk powder. Theprovided flower tea extract directly participates in production accessory materials for modified milk powder. The preparation method lowers the heat treatment intensities of the sterilization, concentration, etc. required for the processing of the extract, reduces processing losses of plant polyphenols, improves the distribution uniformity of the finished product and expands an industrial application field of edible flowers. From the continuous production technology of the flowers to the finished product, the prepared flower tea milk powder product is uniform and stable, and mellow in flower fragrance, has anti-oxidation and anti-aging effects, and is more conducive to increasing the added value of the product.

Owner:贝因美(杭州)食品研究院有限公司

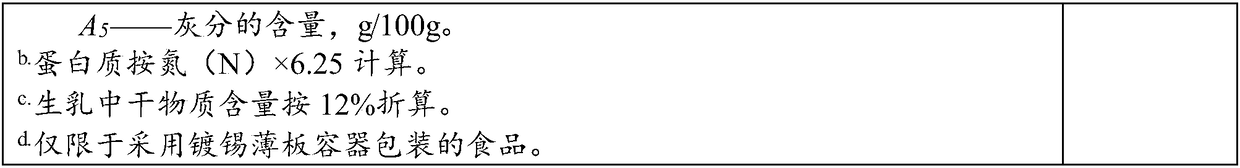

Micro-current stimulation instrument with adjustable treatment intensity

The invention discloses a micro-current stimulation instrument with adjustable treatment intensity. The micro-current stimulation instrument comprises a host and a pair of ear-clip electrodes and further comprises a pulse generator and a pulse current adjustment circuit, wherein the pulse generator and the pulse current adjustment circuit are arranged in the host, the pulse generator can generate bipolar asymmetric rectangular waves; the pulse current adjustment circuit is connected with the pulse generator and is used for adjusting strength of pulse current; the host is provided with six treatment intensity adjustment gears including a 0 [mu]A treatment intensity adjustment gear, a 100 [mu]A treatment intensity adjustment gear, a 200 [mu]A treatment intensity adjustment gear, a 300 [mu]A treatment intensity adjustment gear, a 400 [mu]A treatment intensity adjustment gear and a 500 [mu]A treatment intensity adjustment gear, and the gears are connected with a master controller. The micro-current stimulation instrument with adjustable treatment intensity is provided with 1-5 gears of treatment intensity, each number represents 100 microamperes, a patent can select the most suitable intensity during treatment, and the micro-current stimulation instrument has advantages of rich functions and use convenience.

Owner:JIANGMEN BAMAY MEDICAL DEVICES

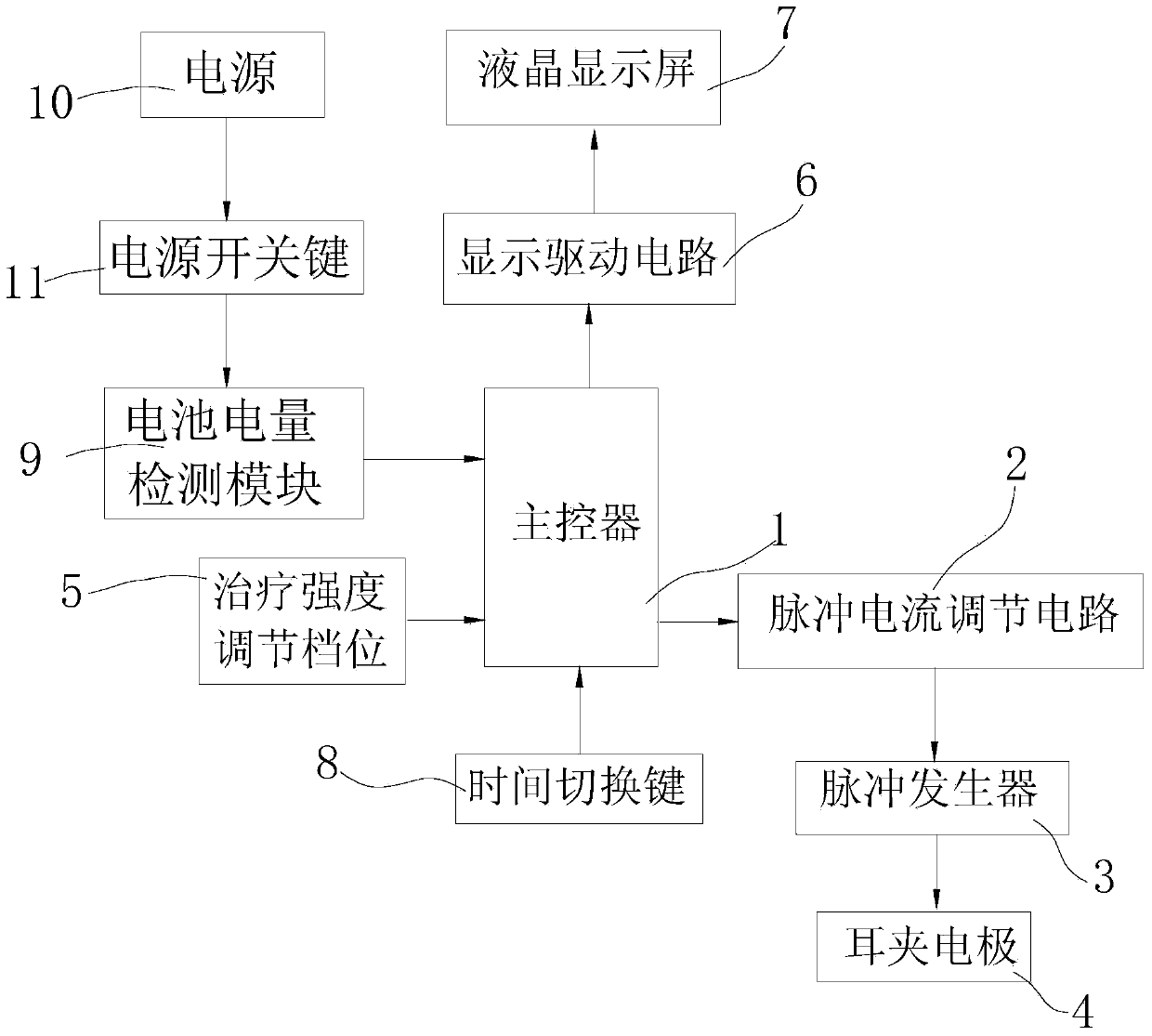

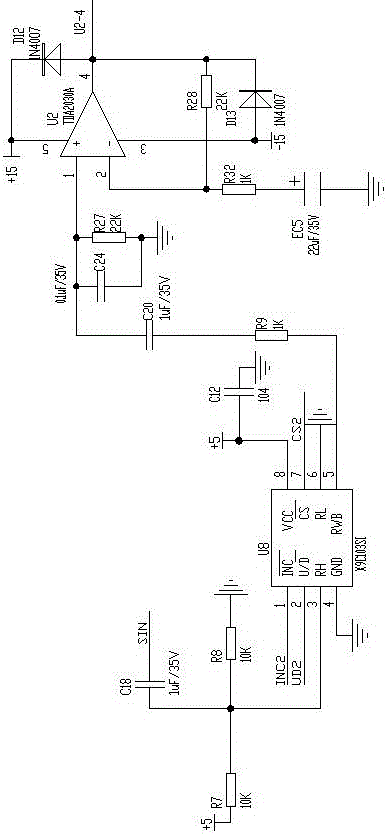

High-reliability electronic meridian treatment instrument

InactiveCN106580675AImprove anti-interference abilityControl output currentDevices using electric currentsMicrocontrollerEngineering

The invention discloses a high-reliability electronic meridian treatment instrument. The high-reliability electronic meridian treatment instrument comprises an operational amplifier power supply unit, a single chip microcomputer power supply unit, and a three-way treatment intensity adjustment output unit, wherein the three-way treatment intensity adjustment output unit comprises an A-way treatment intensity adjustment output unit, a B-way treatment intensity adjustment output unit and a C-way treatment intensity adjustment output unit; the operational amplifier power supply unit comprises a diode D1 and a diode D2; the single chip microcomputer power supply unit comprises a power supply voltage-stabilizing chip U5; the A-way treatment intensity adjustment output unit comprises an integrated circuit U7; the B-way treatment intensity adjustment output unit comprises an integrated circuit U8; and the C-way treatment intensity adjustment output unit comprises an integrated circuit U9. The high-reliability electronic meridian treatment instrument has the following advantages of high reliability, high anti-interference performance, capability of effectively controlling output current, stable voltage output, high signal output stability, low error, good curative effect and low manufacturing cost.

Owner:潍坊大地医疗器械有限公司

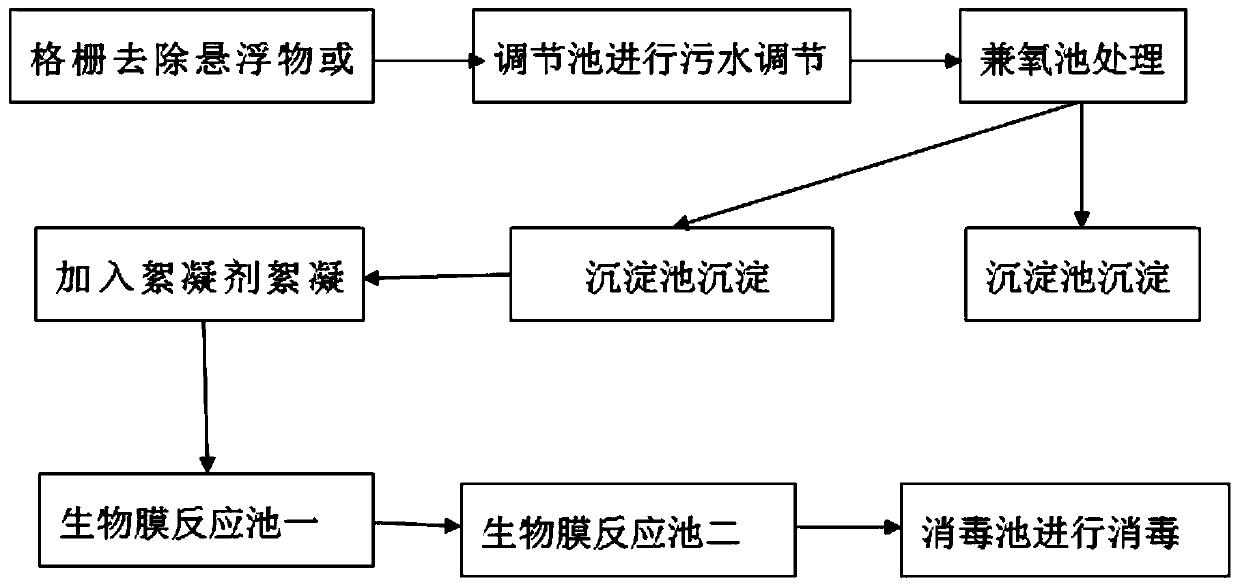

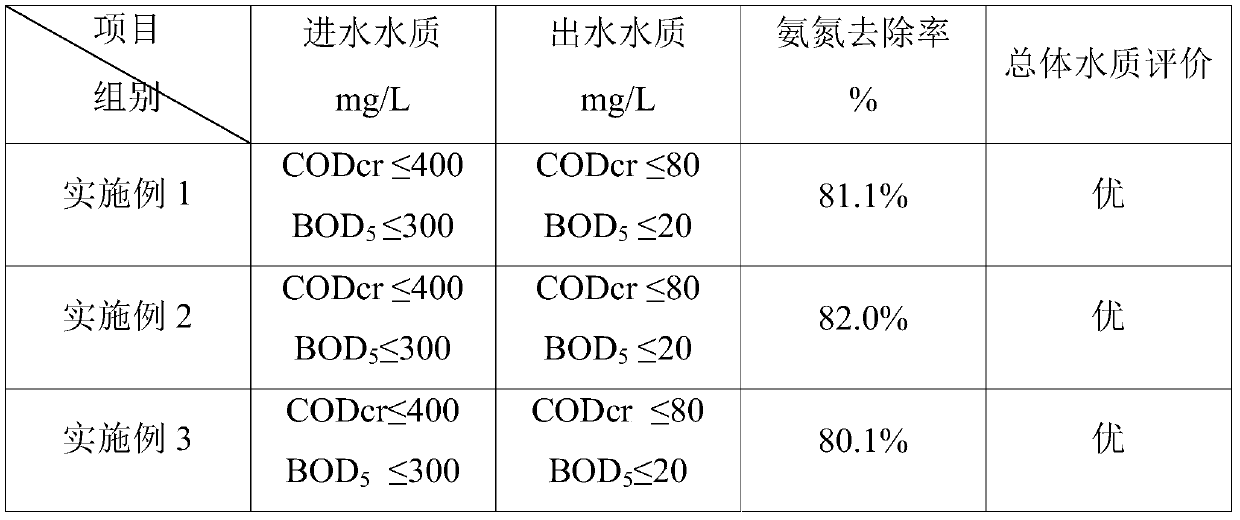

MBR biological film backwashing decontamination method

InactiveCN110183030AReduce odorExcellent decontaminationTreatment using aerobic processesSpecific water treatment objectivesSludgeWater quality

The invention provides a MBR biological film backwashing decontamination method, which comprises: removal of large suspended matters or floating matters, sewage regulation, treatment with a facultative pool, precipitation, flocculation, biological film treatment, and disinfection. According to the present invention, impurities with different particle sizes are filtered out through a stepwise method so as to achieve the excellent decontamination effect, and part of organic matters are decomposed in the facultative pool so as to effectively reduce the odor in the sewage and achieve the short treatment time; by using the MBR biological film backwashing method, the sludge content in the sewage is effectively reduced, the sludge treatment intensity is increased, the detergency is more than 95%,the water quality after the treatment is good, and the biological film decontamination has high safety; by using the nylon ring mud-scraping device, the biological film can have strong adaptability to water quality change, and the raw material cost is low; and the method has advantages of high organic load, low cost, simple steps, easy construction management and significant decontamination effect.

Owner:TIANHE COLLEGE GUANGDONG POLYTECHNIC NORMAL UNIV

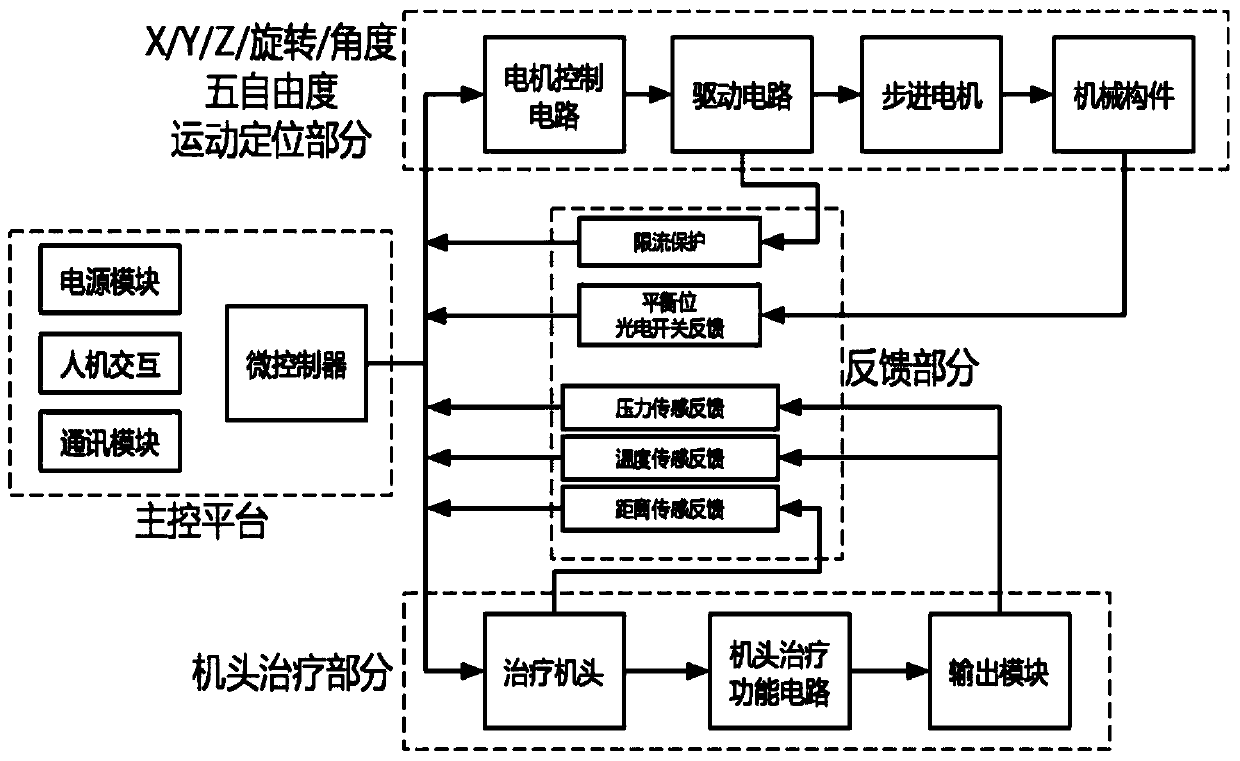

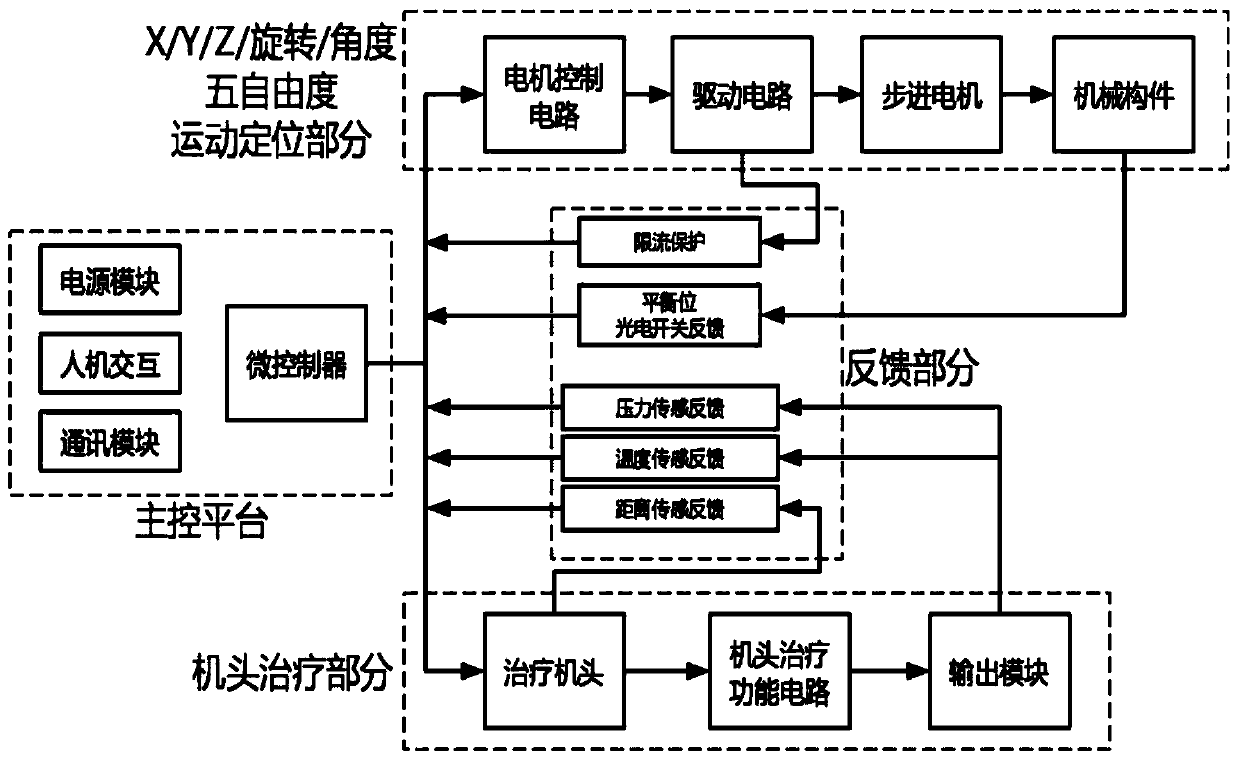

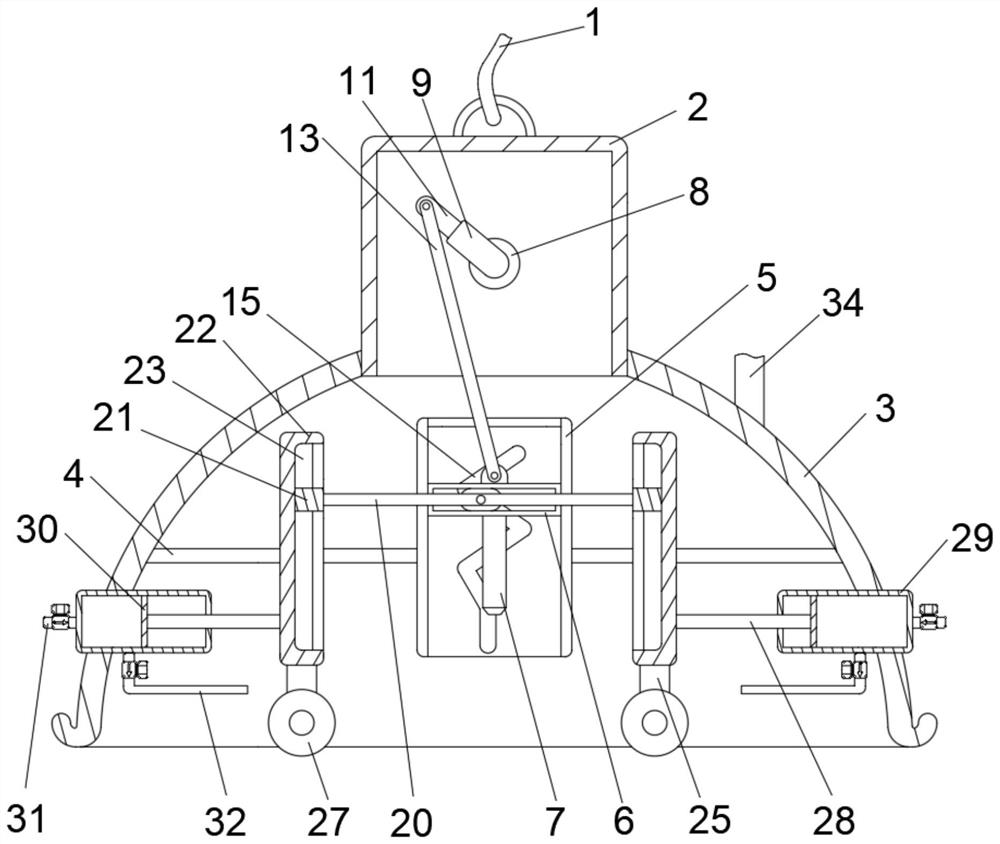

Clinical intelligent auxiliary control system

PendingCN109966134AHealing Power FalloffReduced Healing StrengthVibration massageMechanical componentsControl system

The invention discloses a clinical intelligent auxiliary control system which comprises a main control platform, a head treatment portion, a feedback portion and a five-degree-of-freedom movement positioning portion. The main control platform is connected with the head treatment portion, the feedback portion and the five-degree-of-freedom movement positioning portion, and the five-degree-of-freedom movement positioning portion comprises a motor control circuit, a driving circuit, a stepping motor and a mechanical component. Compared with existing manual therapy, the system is positive and obvious in effect. High-precision movement control and accuracy and stability beyond manpower can be realized. Therefore, sufficient endurance can be kept, labor efficiency is improved, treatment intensity cannot be 'attenuated', treatment is executed under an objectively 'set' standard, and the system has great significance and social values for reducing the labor intensity of medical staff in the treatment (operation) process and liberating medical workers from heavy medical instrument related operation.

Owner:HUADONG HOSPITAL

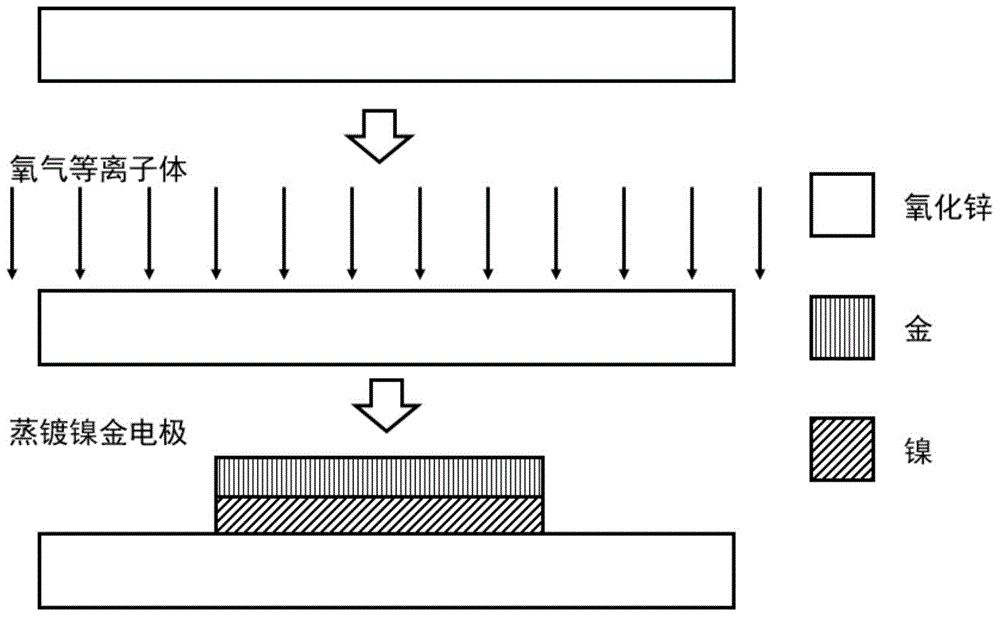

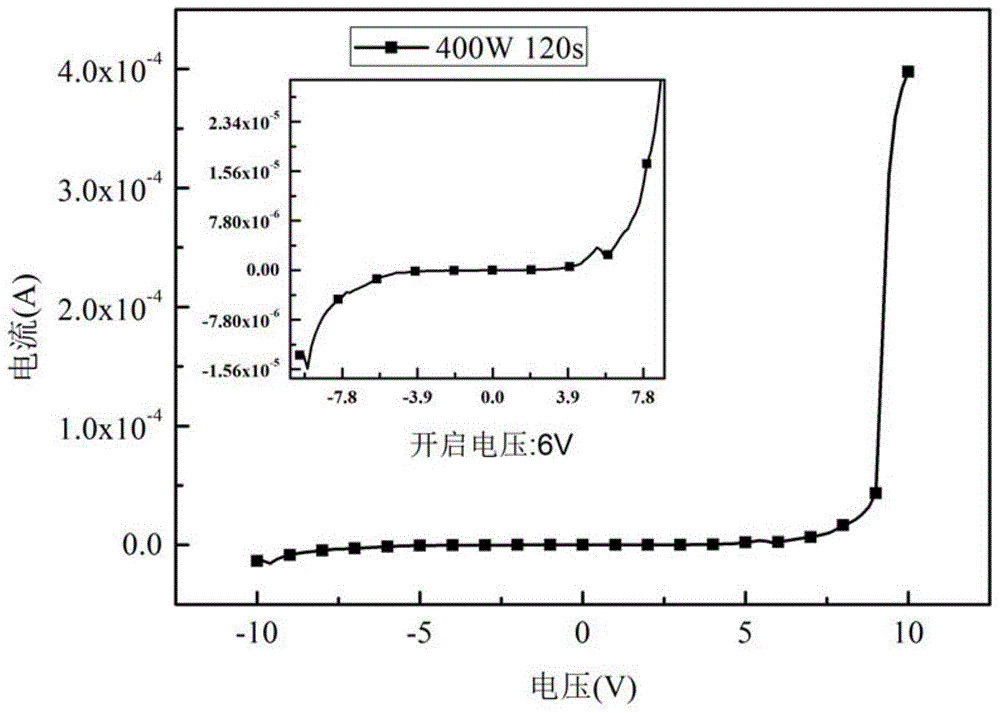

Method for forming Schottky contact on surface of zinc oxide and regulating Schottky contact

InactiveCN104638065AAdjust surface propertiesAdjust contact characteristicsFinal product manufactureSemiconductor devicesOperabilityOxygen

The invention discloses a method for forming Schottky contact on the surface of zinc oxide and regulating the Schottky contact. The method mainly comprises the following steps: (1) putting a cleaned zinc oxide sample into a plasma treatment cavity, and vacuumizing the cavity until high vacuum degree is reached; (2) feeding oxygen to regulate the pressure intensity of the cavity to appointed pressure intensity; (3) switching on a radio frequency power supply to build up the oxygen in the cavity by certain power; (4) when enough treatment time is achieved, taking out the sample, and evaporating a nickel-gold electrode to obtain a Schottky contact electrode. The method is high in operability, stable and reliable, and a novel method for treating the surface of the zinc oxide is developed; the difficulty in preparing the Schottky contact on the zinc oxide is solved; furthermore, the contact performance can be regulated by regulating the treatment intensity. The method is novel, reliable, very short in time consumption, easy to operate and suitable for large-scale semiconductor industrial application.

Owner:SUN YAT SEN UNIV

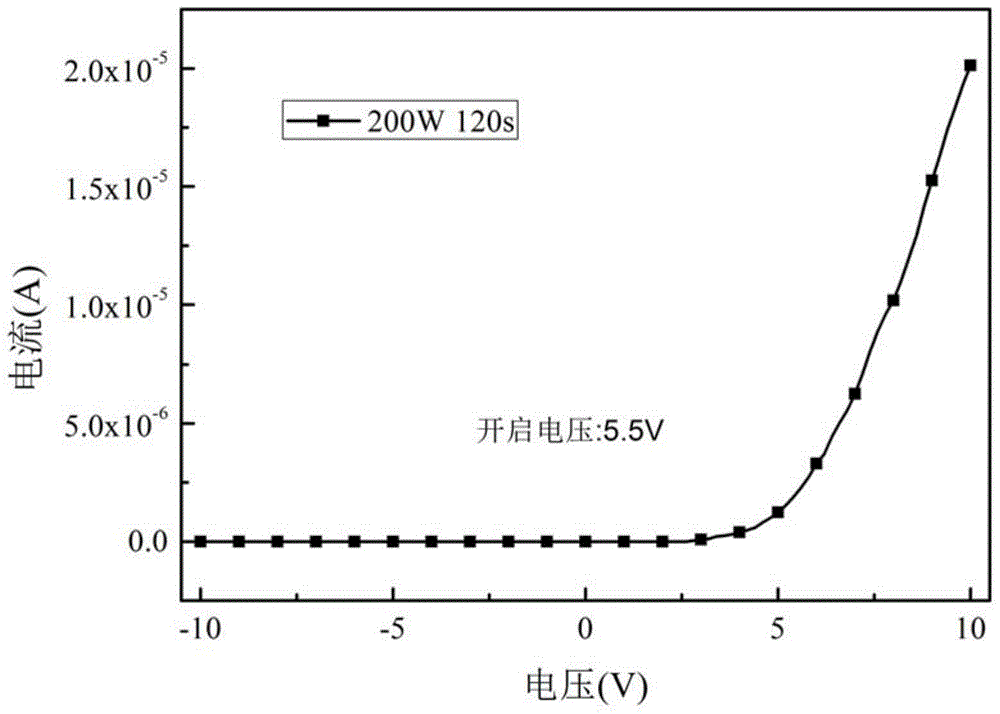

High-moisture tobacco material drying method and drying tower

The invention provides a tobacco material drying method and drying tower capable of realizing drying of high-moisture tobacco materials and high utilization rate. The drying tower comprises a material-feeding steam lock, a material-absorbing venturi tube, an inner drying drum and an outer drying drum, wherein the material-absorbing venturi tube is vertical to the ground; the inner drying drum and the outer drying drum are coaxial; tobacco materials are sucked into the inner drying pipe by the negative pressure generated by dry air flow in passing through the venturi tube; the diameters of an upper section and a lower section of the inner drying pipe are approximately equal in the height direction, and the diameter of the upper section is larger than that of the lower section; and correspondingly, the diameter of the upper section of the outer drying drum is larger than that of the lower section of the outer drying drum, therefore, the drying air speed becomes fast from slow in the inner drying drum, and becomes slow from fast when the tobacco materials reach the top end and are sprayed to the outer drying drum, so that the heat exchange time of the dried tobacco materials is longer, the drying is more sufficient and further the requirement for drying the high-moisture tobacco materials is met. The drying method and drying tower provided by the invention have the characteristics of energy conservation, low drying temperature, high drying efficiency and difficult crushing of the tobacco materials and the like, and can meet the process requirements of treatment intensity and drying uniformity and the like of the high-moisture tobacco materials.

Owner:ZHISI HLDG GRP

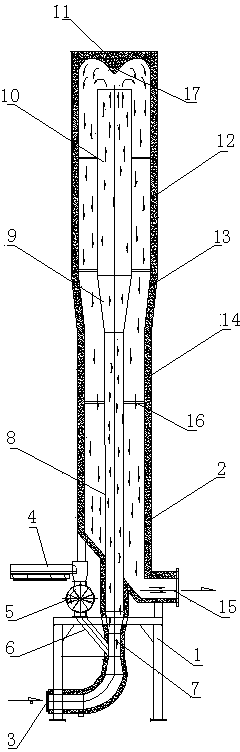

Lesheng Electric Energy Fourteen Meridian Therapeutic Apparatus

The invention discloses a musical sound electric energy fourteen channel therapeutic instrument, and relates to the technical field of a medical apparatus, for solving the problems of narrow effect scope, unstable effects and incapability of timely adjustment of a treatment intensity according to conditions of patients by use of a conventional therapeutic instrument. Music is played through a cassette recorder, music signals are converted into electric signals, i.e., voltages, the voltages generate different amplitude along with the vibration frequencies of the music so as to enable output voltage values to be different, the voltage values are converted into corresponding voltages through conversion of a power supply transformer, corresponding voltage values are output after adjustment of the voltages through an adjustment circuit, the voltage values are expressed in the form of currents and then are input to a medical electrode, and the medical electrode receives different current values and then acts on the fourteen channels of a human body or acupuncture points or affected parts of human skin to enable the human body to generate pricking of different intensities so as to achieve a disease prevention and treatment effect. The musical sound electric energy fourteen channel therapeutic instrument is applied to disease treatment.

Owner:HARBIN HUAYU MEDICAL ELECTRONICS INSTR

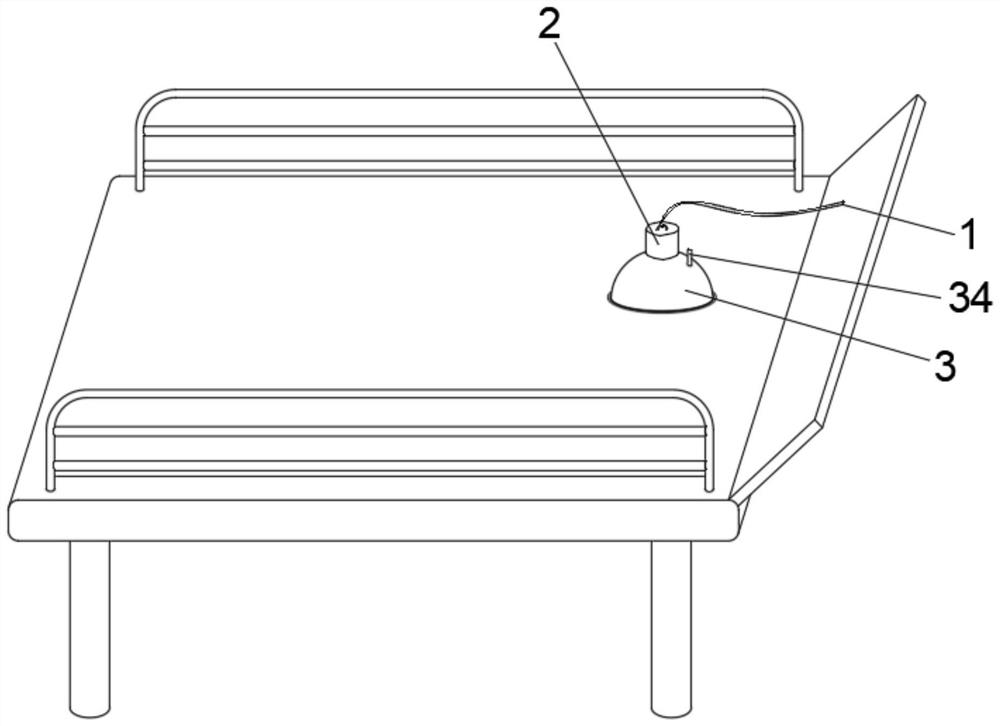

Electric acupuncture apparatus for treating cerebral hemorrhage secondary nerve injury

InactiveCN114470518APrevent looseningReasonable treatment intensityElectrotherapyRoller massageHuman bodyMassage

The invention discloses an electric acupuncture apparatus for treating cerebral hemorrhage secondary nerve injury, and relates to the technical field of nerve injury treatment device.The electric acupuncture apparatus comprises a rope body fixedly connected to the surface of a bed body, a barrel is fixedly connected to the end of the rope body, a cover is fixedly connected to the bottom end of the barrel, and a limiting rod is fixedly connected to the inner wall of the barrel; a limiting plate is fixedly connected to the end of the limiting rod, a sliding plate is slidably connected to the inner wall of the limiting plate, an electric needle is fixedly connected to the bottom face of the sliding plate, the top of the electric needle is electrically connected with an external power source through a wire, and the driving part drives the electric needle to vertically move so as to intermittently stimulate acupuncture points of the human body. Through mutual cooperation of the structures, intermittent electrical stimulation is performed on a patient, reasonable treatment intensity is guaranteed, electrical stimulation treatment and massage stimulation treatment are combined, treatment strength is improved, electrical stimulation treatment and massage stimulation treatment are alternately performed, and the treatment effect is greatly improved.

Owner:HEILONGJIANG UNIV OF CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com