Mechanical arm, wall surface treatment method, electronic equipment and storage medium

A processing method and a technology of a robotic arm, which are applied in the fields of electronic equipment and storage media, wall surface processing methods, and robotic arms, can solve problems such as large errors in wall surface processing methods, and achieve the effect of solving large grinding errors and effective grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The mechanical arm in this application is an operating device controlled by an operating robot at the end, which can be applied in the field of wall surface treatment, such as in the field of wall surface grinding, which can realize automatic grinding for complex walls, and in the field of wall surface spraying, can be According to the concave and convex changes of the wall to be treated, adjust in time to achieve smooth spraying, and the mechanical arm is not a workpiece on the fixed workbench, so its scope of use is not limited, and it can replace the existing mechanical arm, such as directly installed on the grinding Robots save costs.

[0071] For example, when grinding the wall surface to be treated, the grinding robot manually or automatically locates a suitable grinding position or location during use, and realizes the grinding of the wall surface to be treated by controlling the mechanical arm.

[0072] The mechanical arm is installed on the base of the grinding...

Embodiment 2

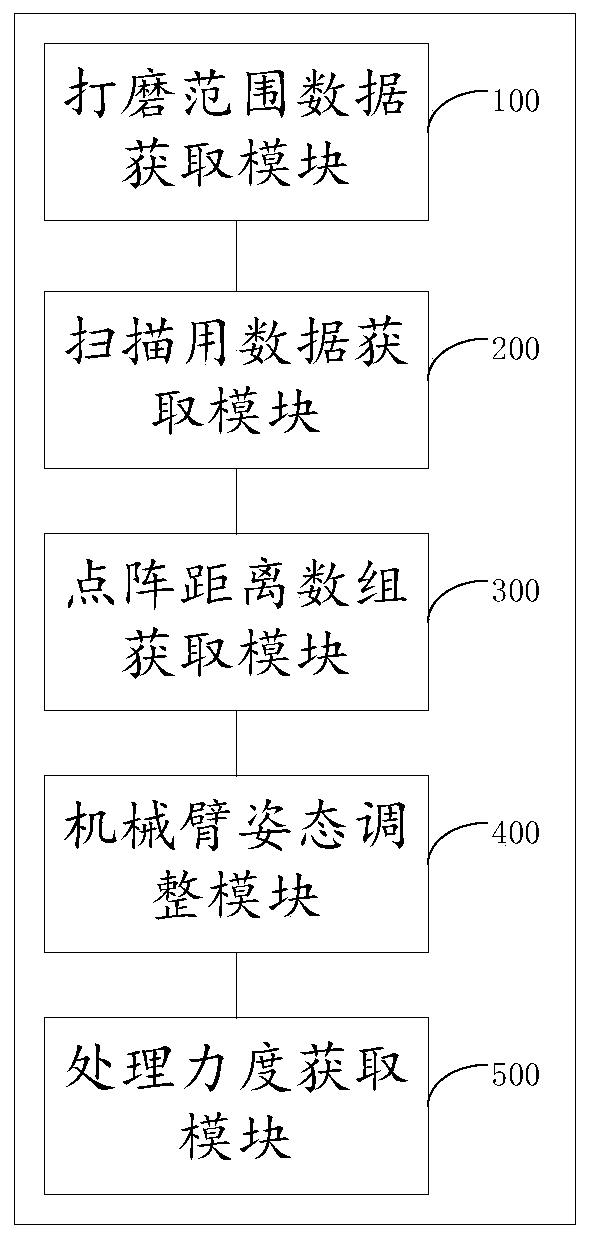

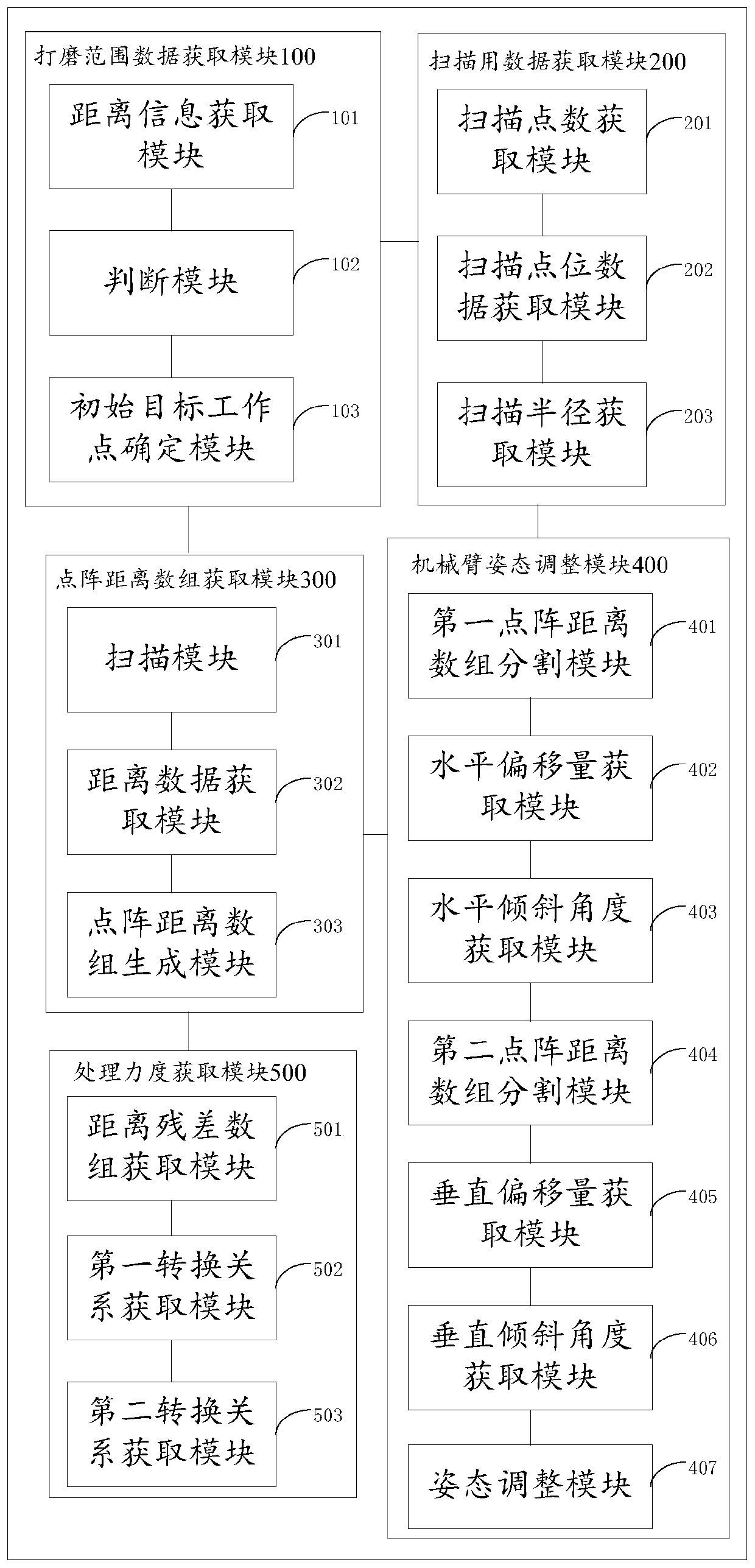

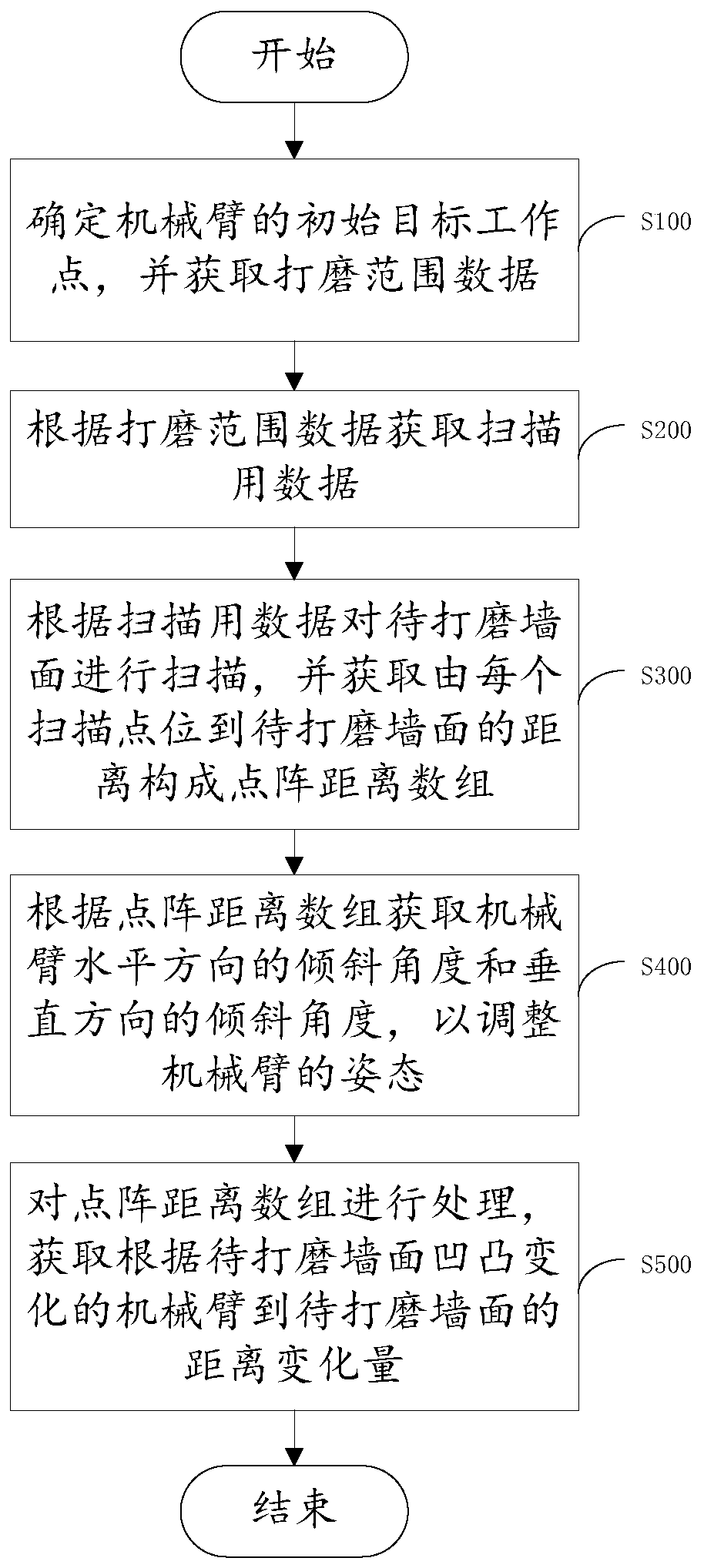

[0112] The embodiment of the present application provides a wall treatment method, specifically a grinding method, which is applied to the controller in embodiment 1, such as image 3 As shown, it is a flow chart of a polishing method provided in the embodiment of the present application. The method specifically may include the following steps:

[0113] Step S100: Determine the initial target working point of the mechanical arm, and obtain the grinding range data;

[0114] Before step S100, it is necessary to establish a three-dimensional coordinate system World(x, y, z) based on the wall to be polished, such as Figure 4 As shown, it is a schematic diagram of the spatial three-dimensional coordinate system established based on the wall to be polished. The center of the grinding robot arm is used as the origin of the three-dimensional coordinate system. After the posture adjustment of the following robot arm is completed, the grinding disc is parallel to the wall to be polished...

Embodiment 3

[0206] The embodiment of the present application also provides an electronic device, the electronic device includes a memory and a processor, the memory is used to store a computer program, and the processor runs the computer program so that the computer device executes the wall treatment method described in Embodiment 2.

[0207] The embodiment of the present application also provides a readable storage medium, where computer program instructions are stored in the readable storage medium, and when the computer program instructions are read and executed by a processor, the method described in Embodiment 2 is executed. The method of wall treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com