Patents

Literature

281results about How to "Effective sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

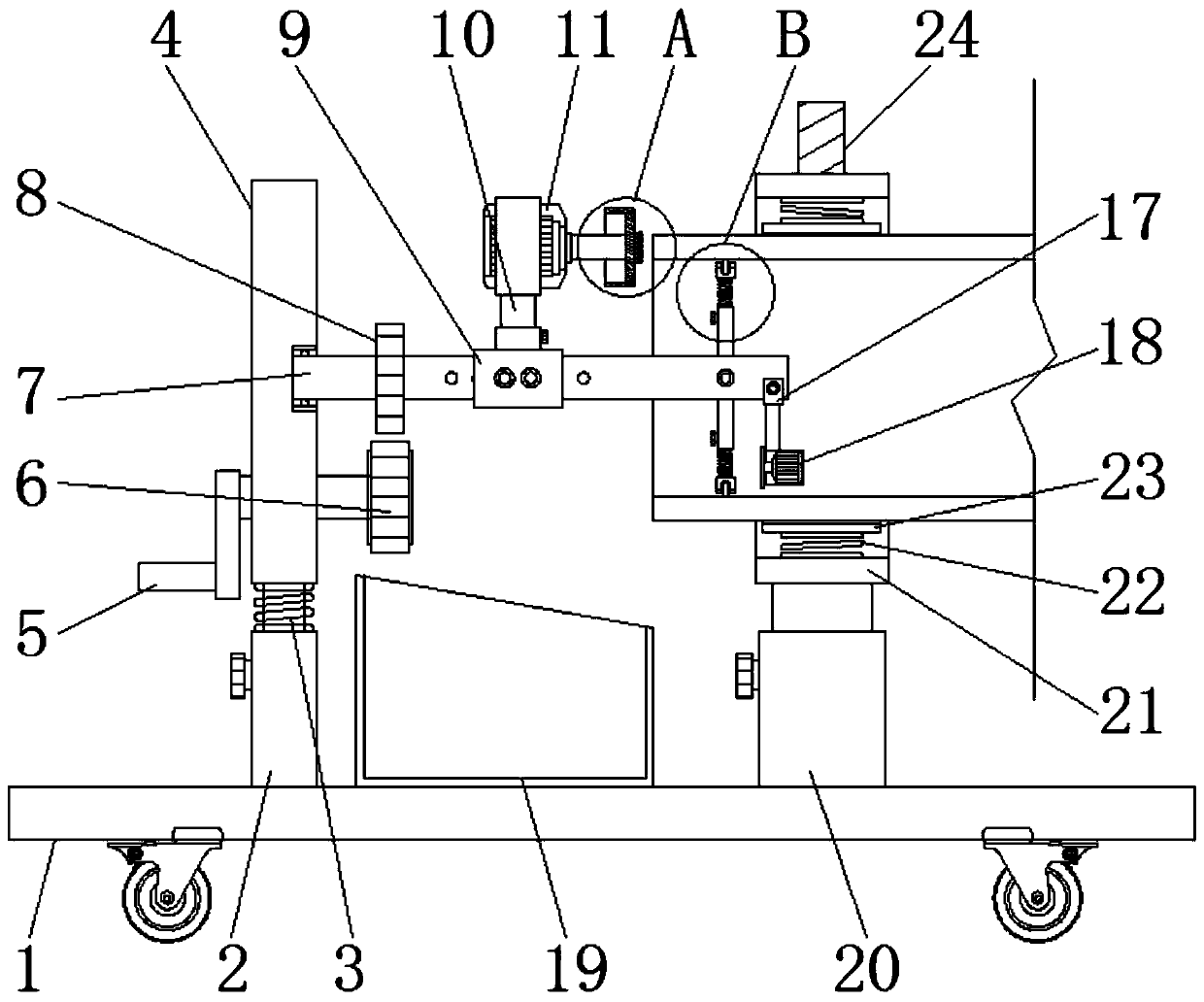

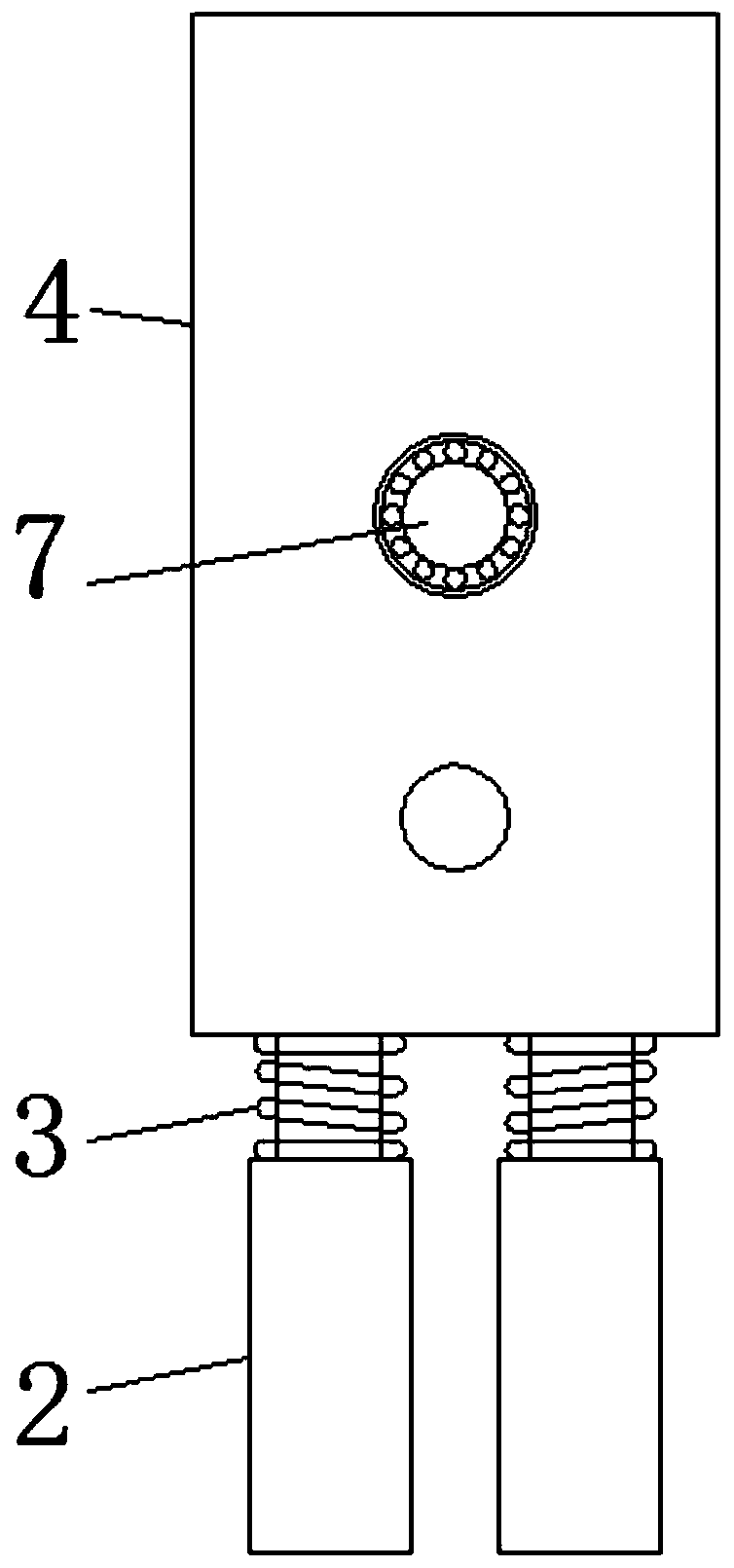

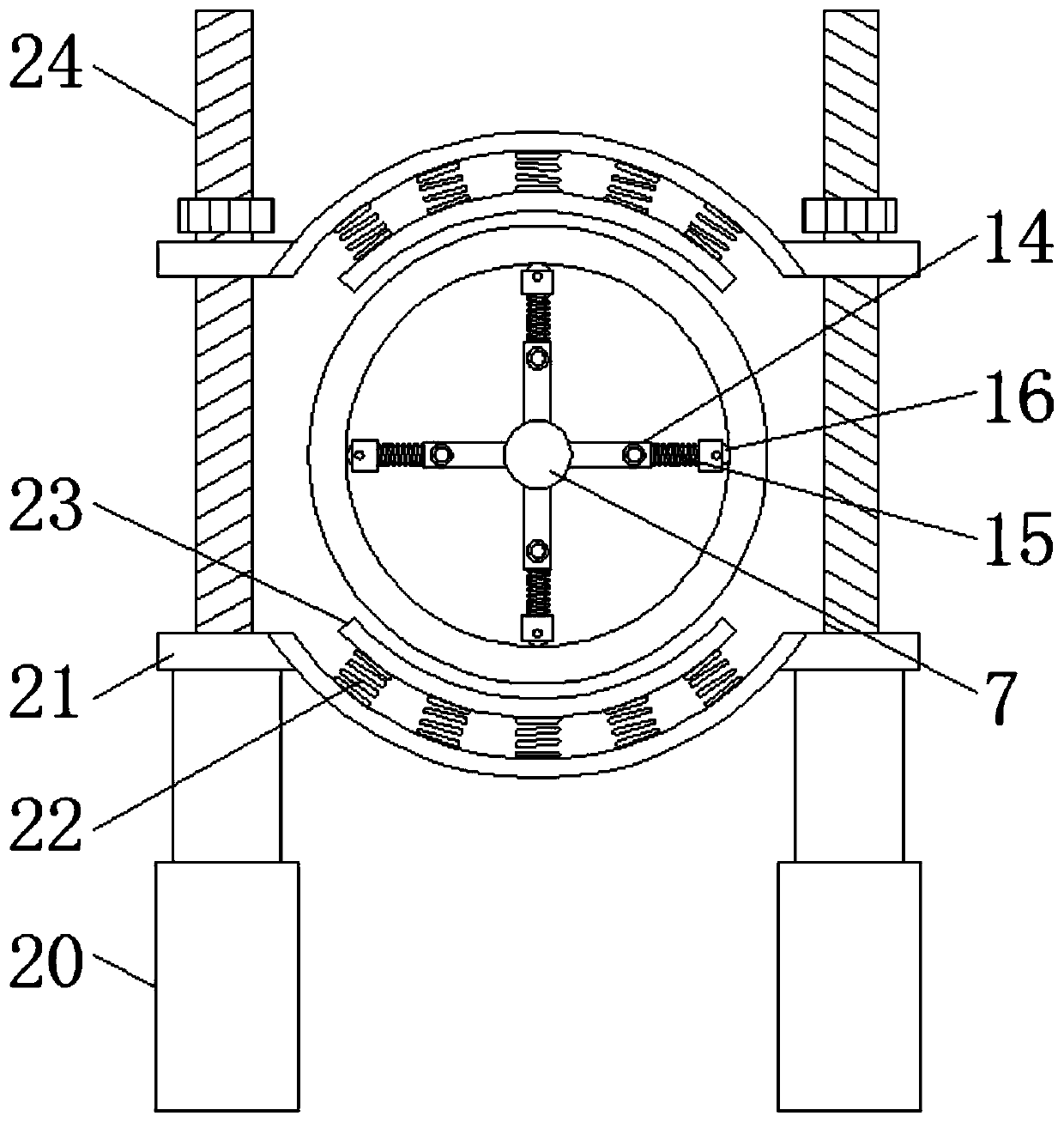

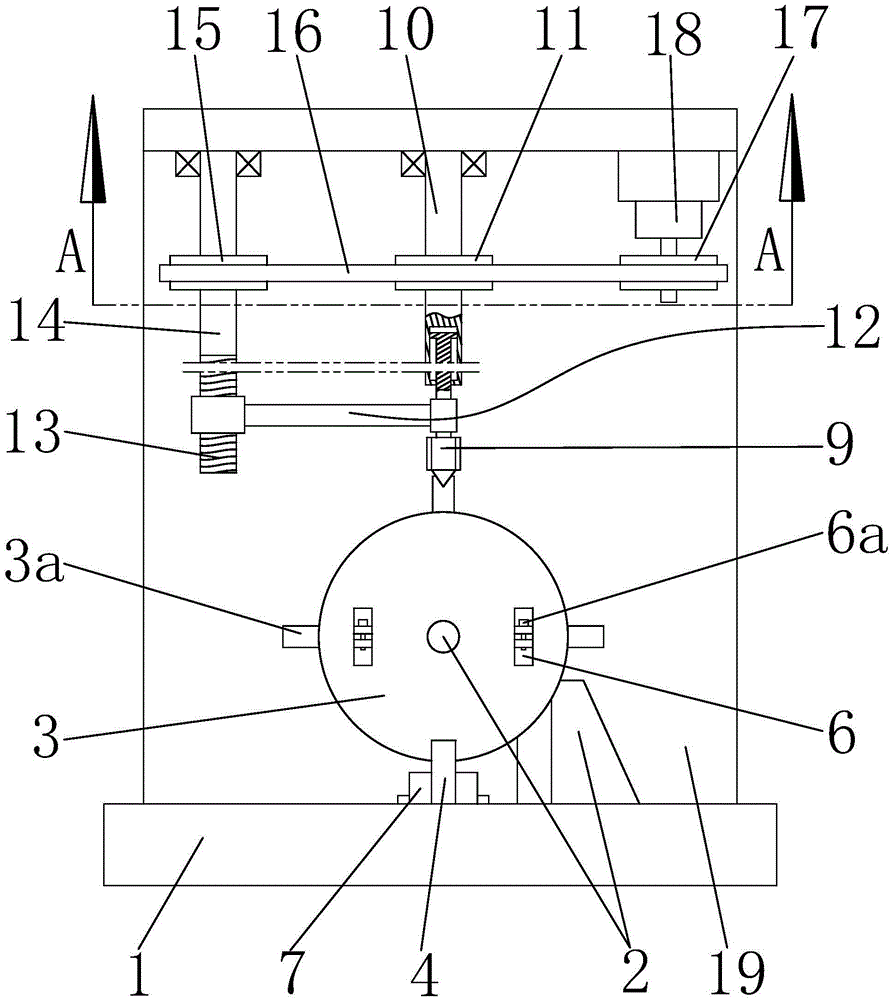

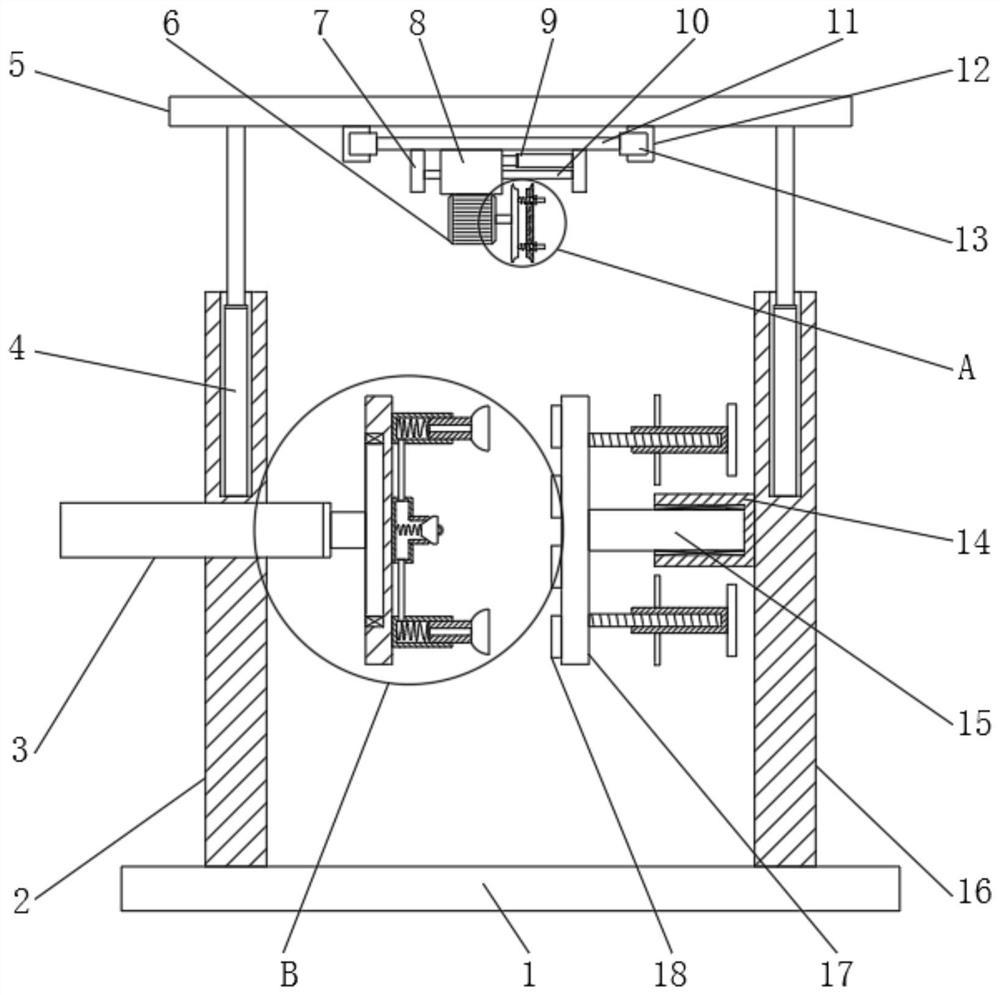

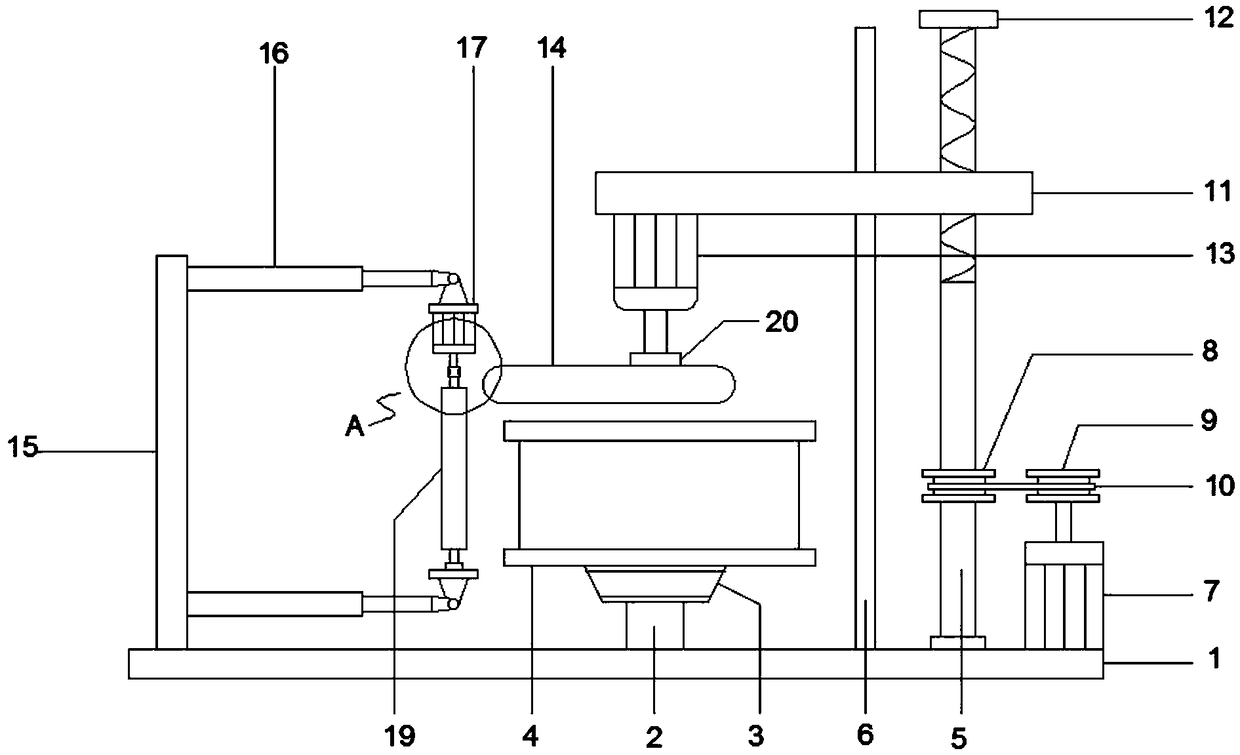

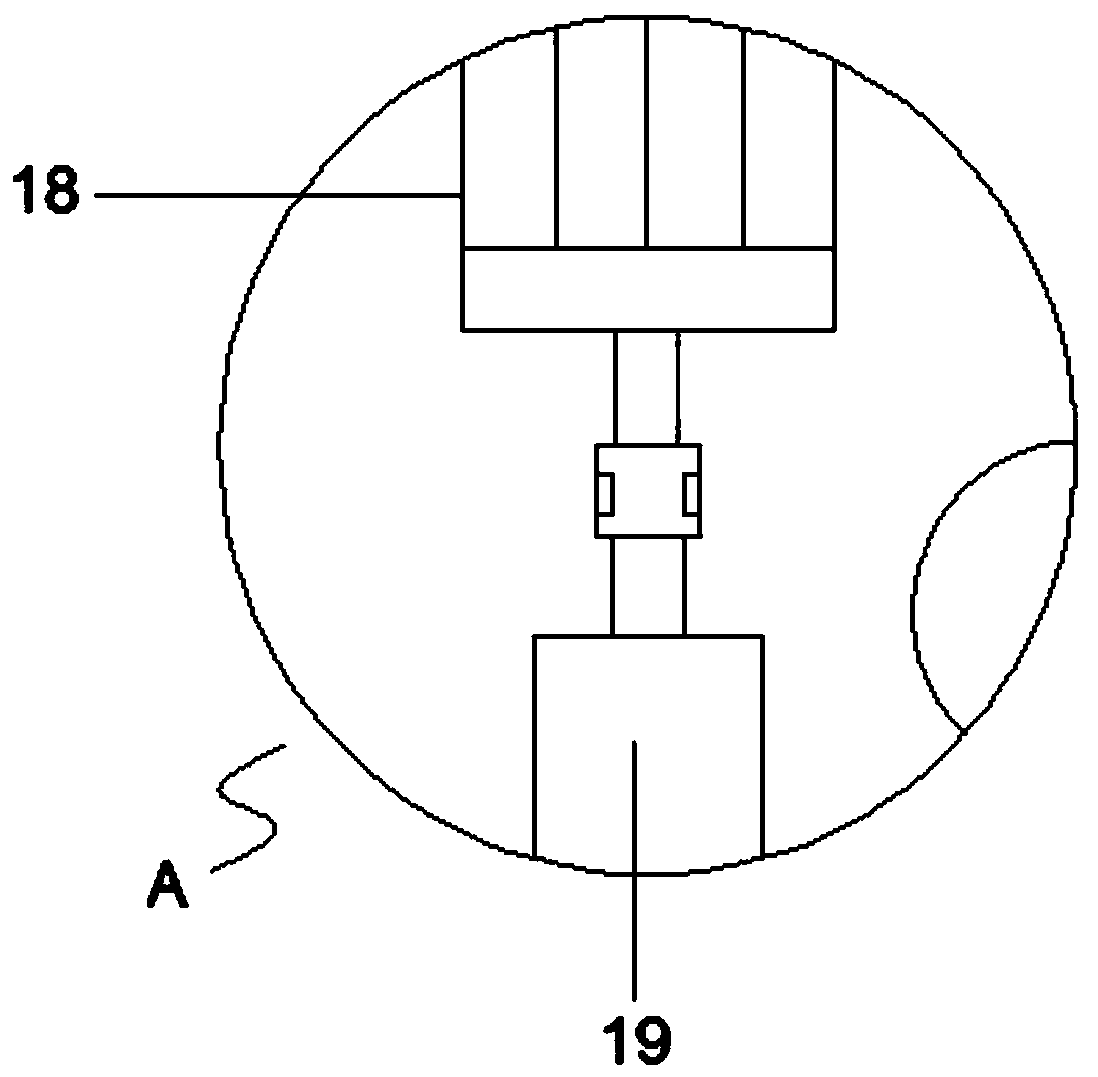

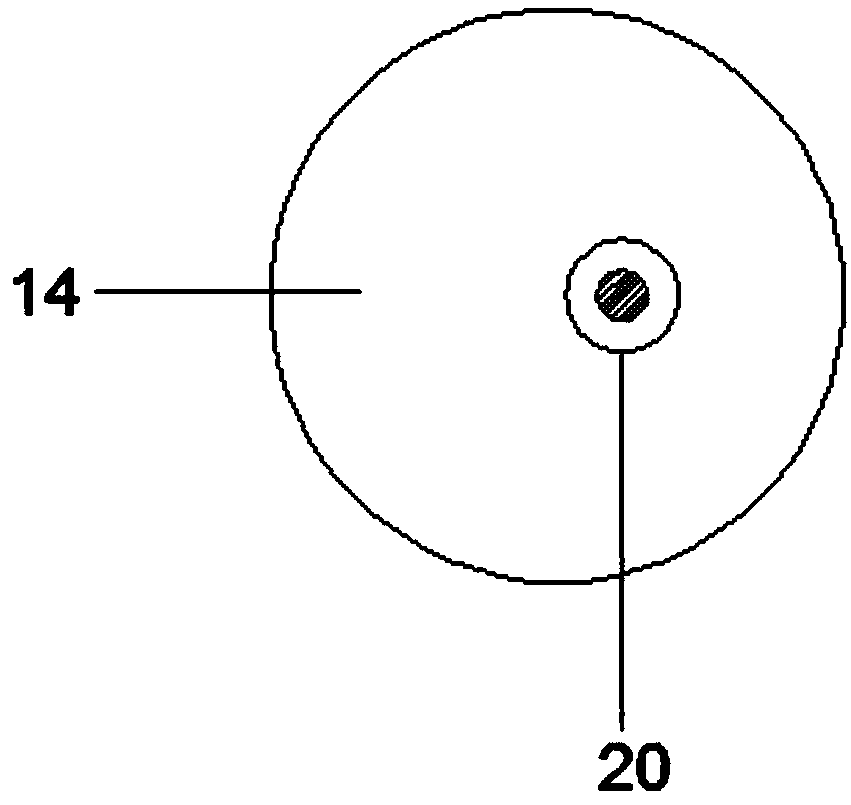

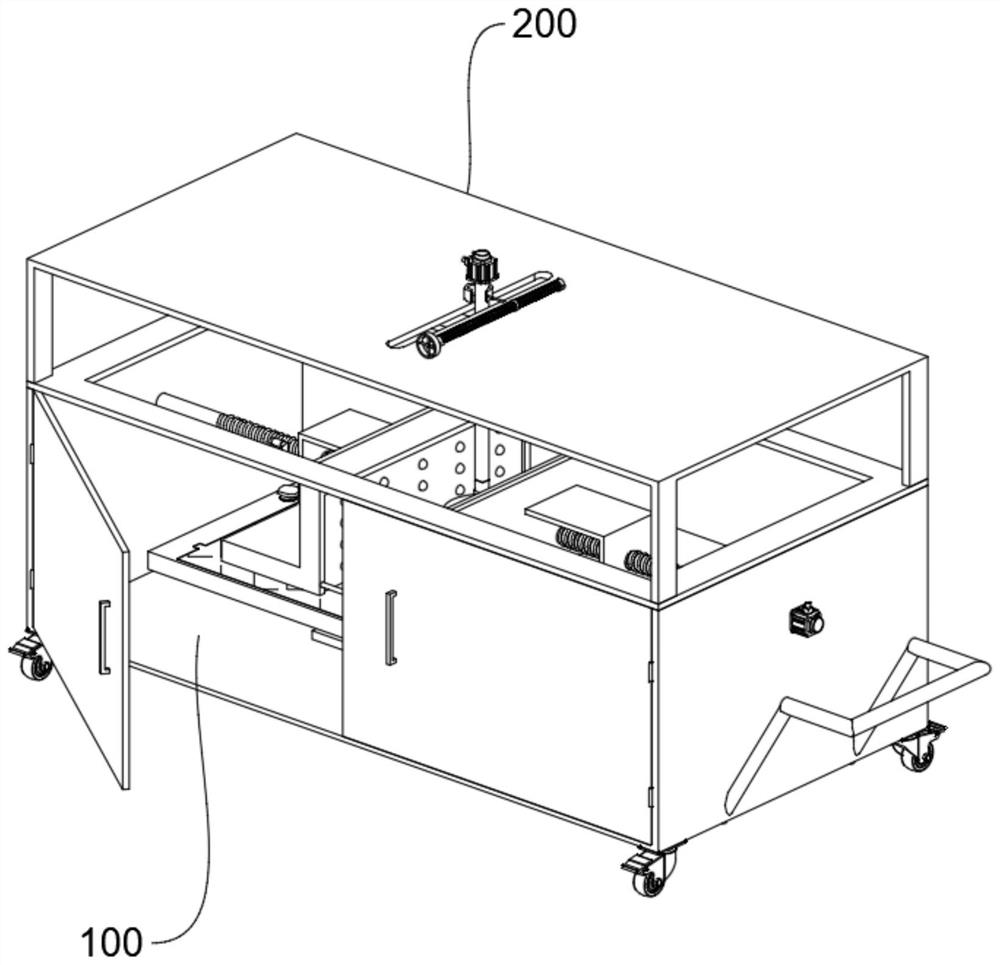

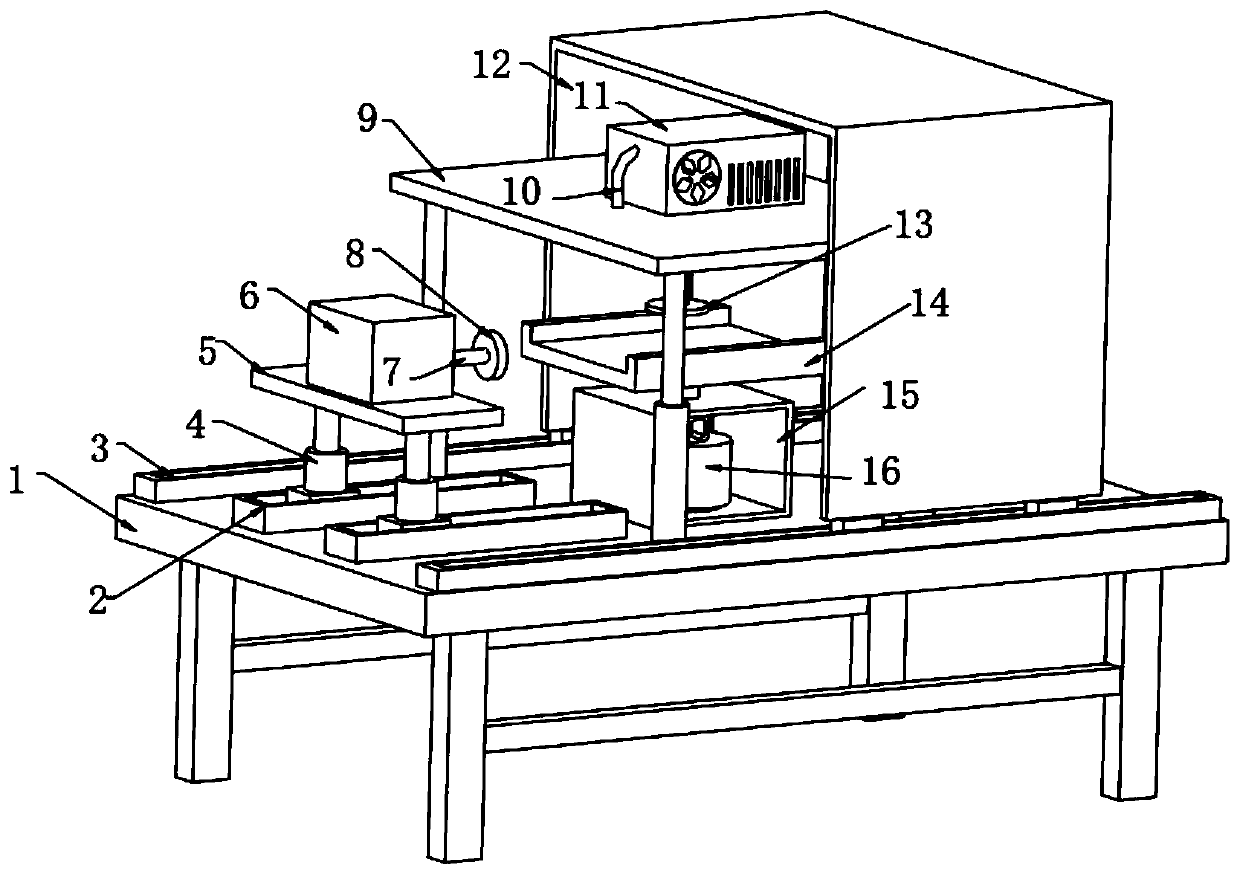

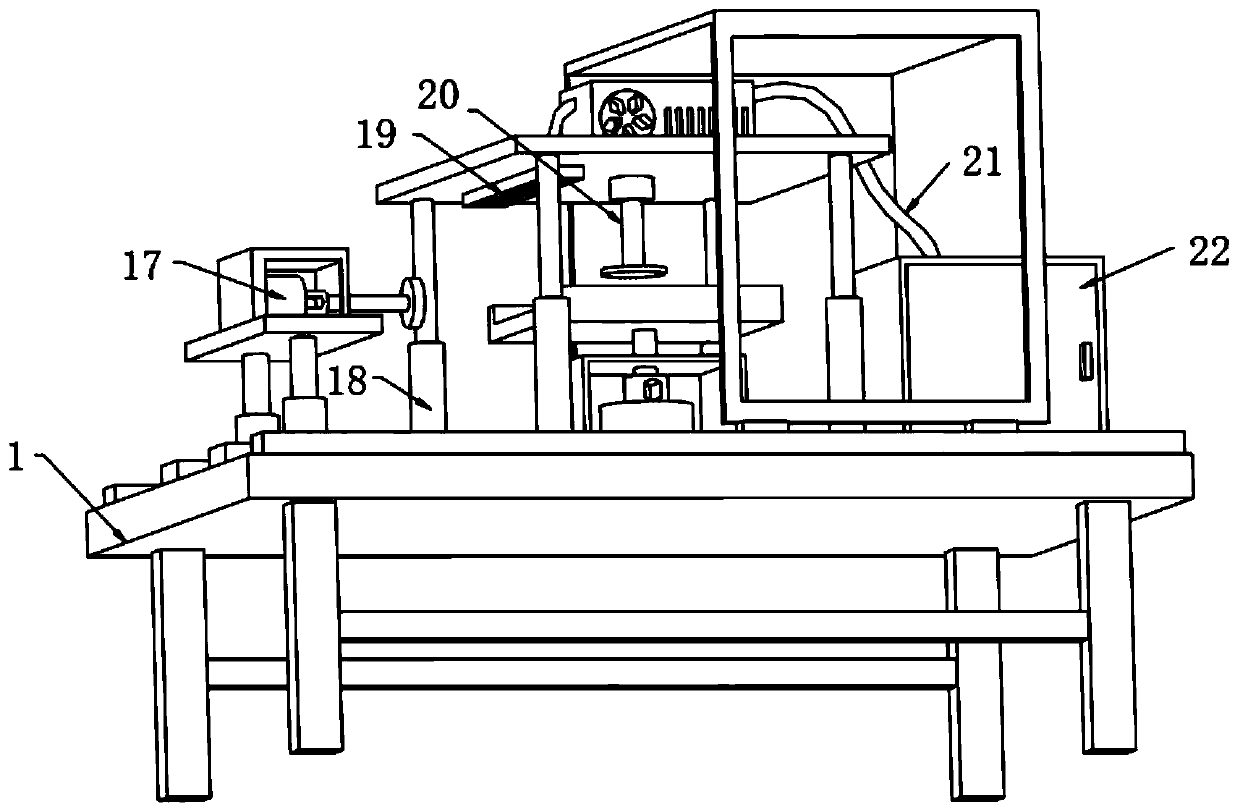

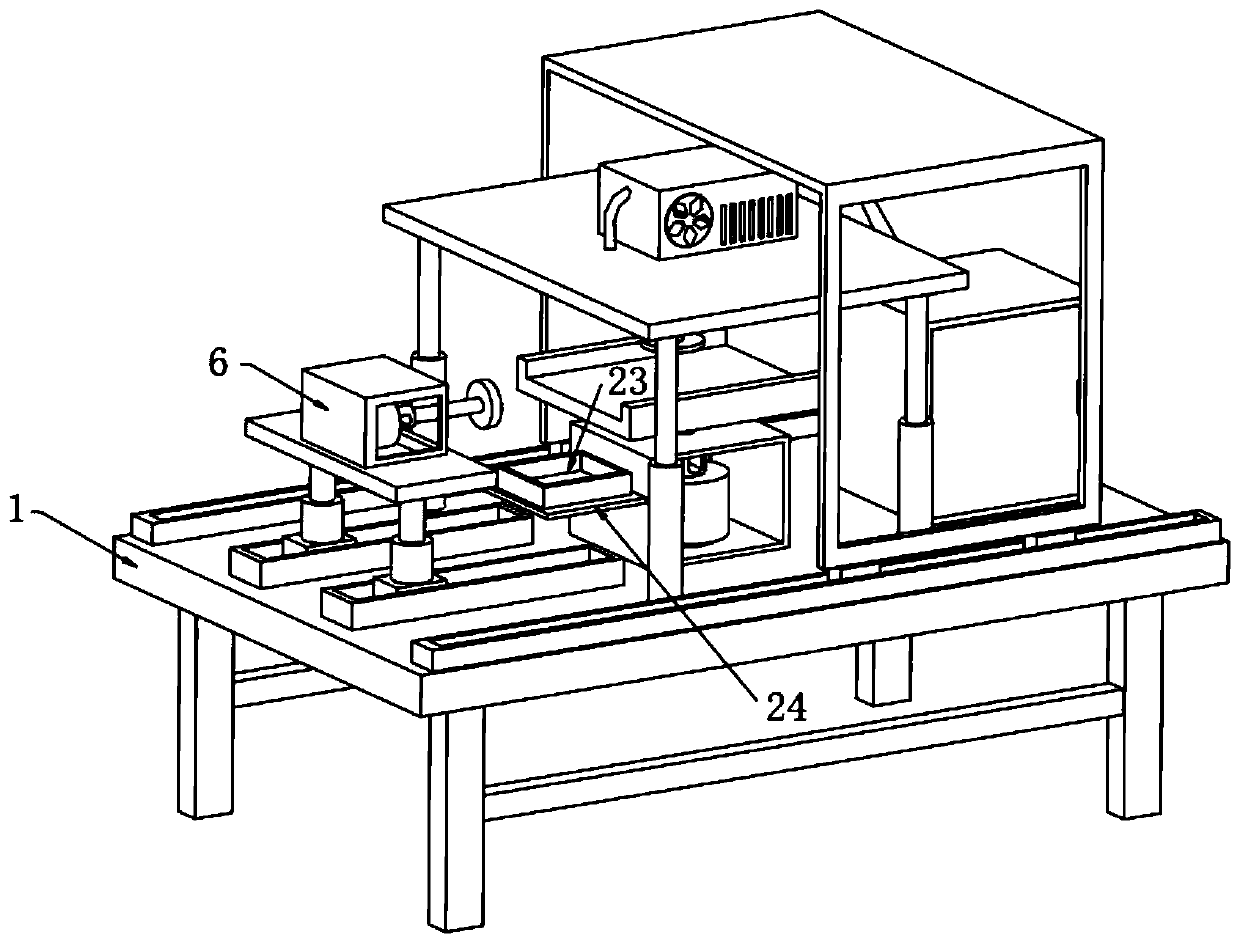

Building construction pipeline end surface processing device capable of conveniently fixing different sizes

ActiveCN109702578AImprove stabilityAdjustable grinding rangeEdge grinding machinesGrinding carriagesArchitectural engineeringSurface processing

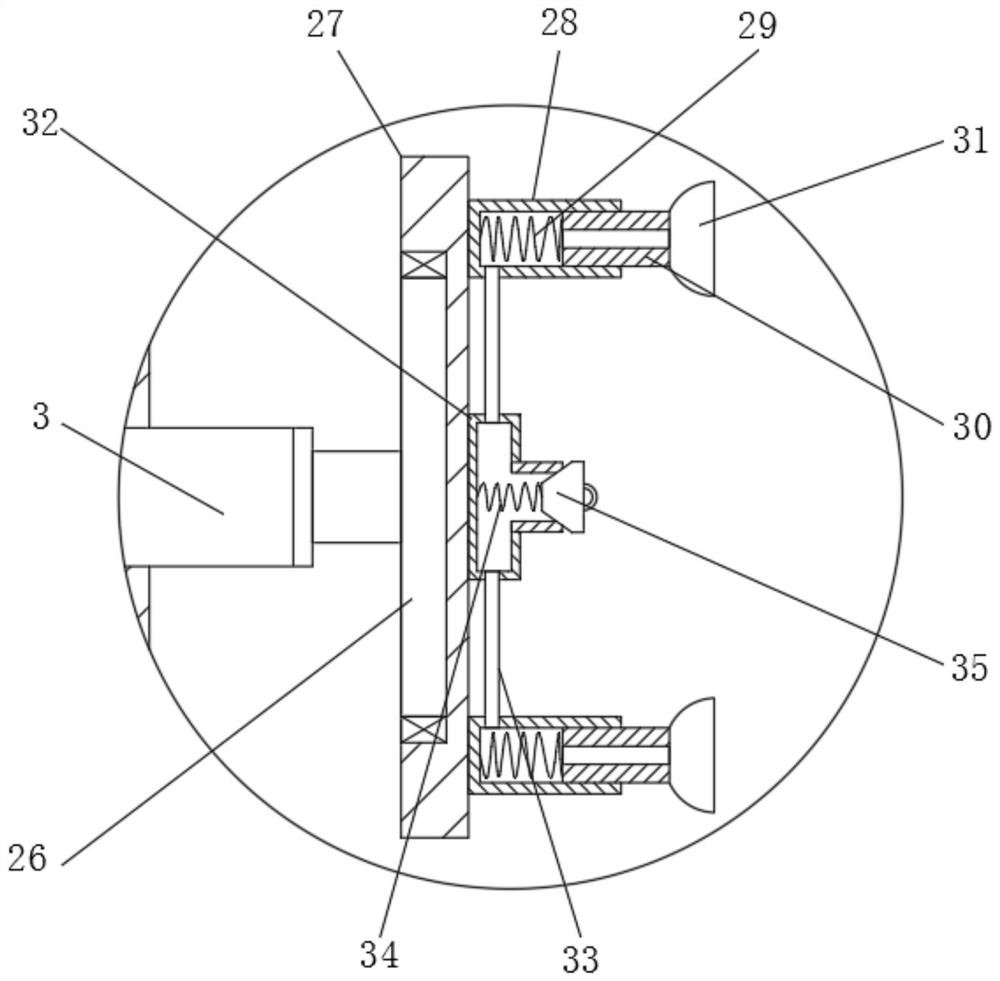

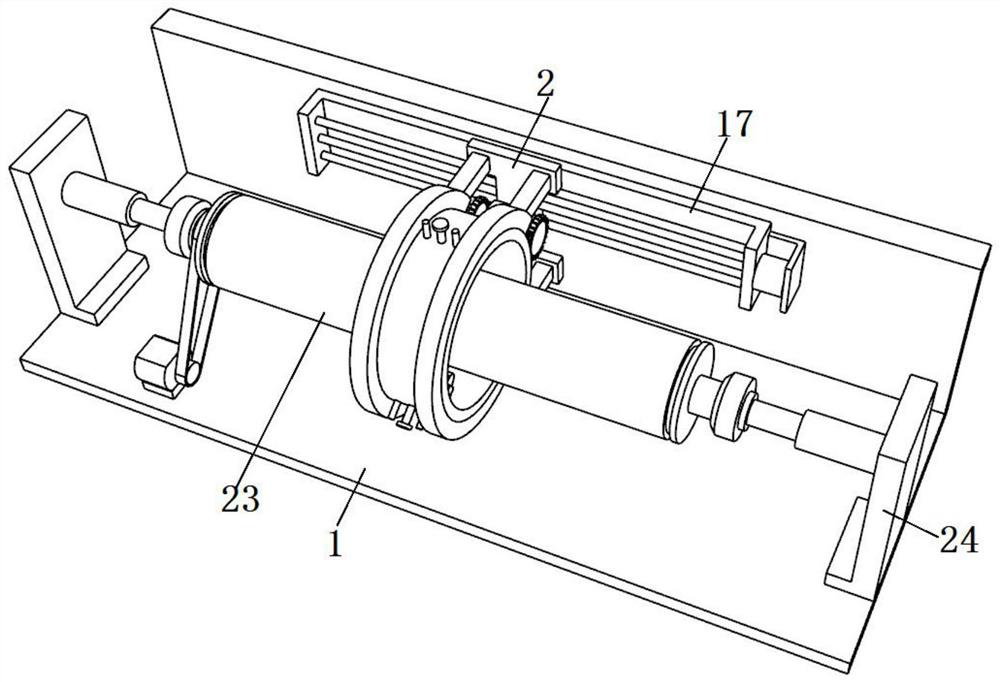

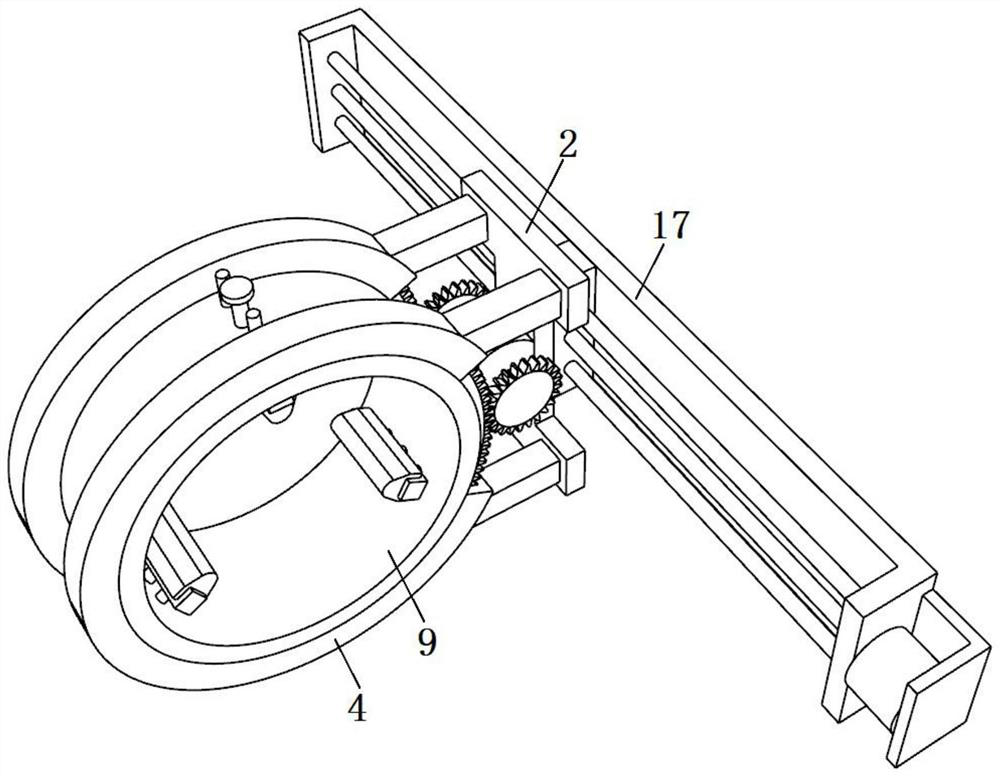

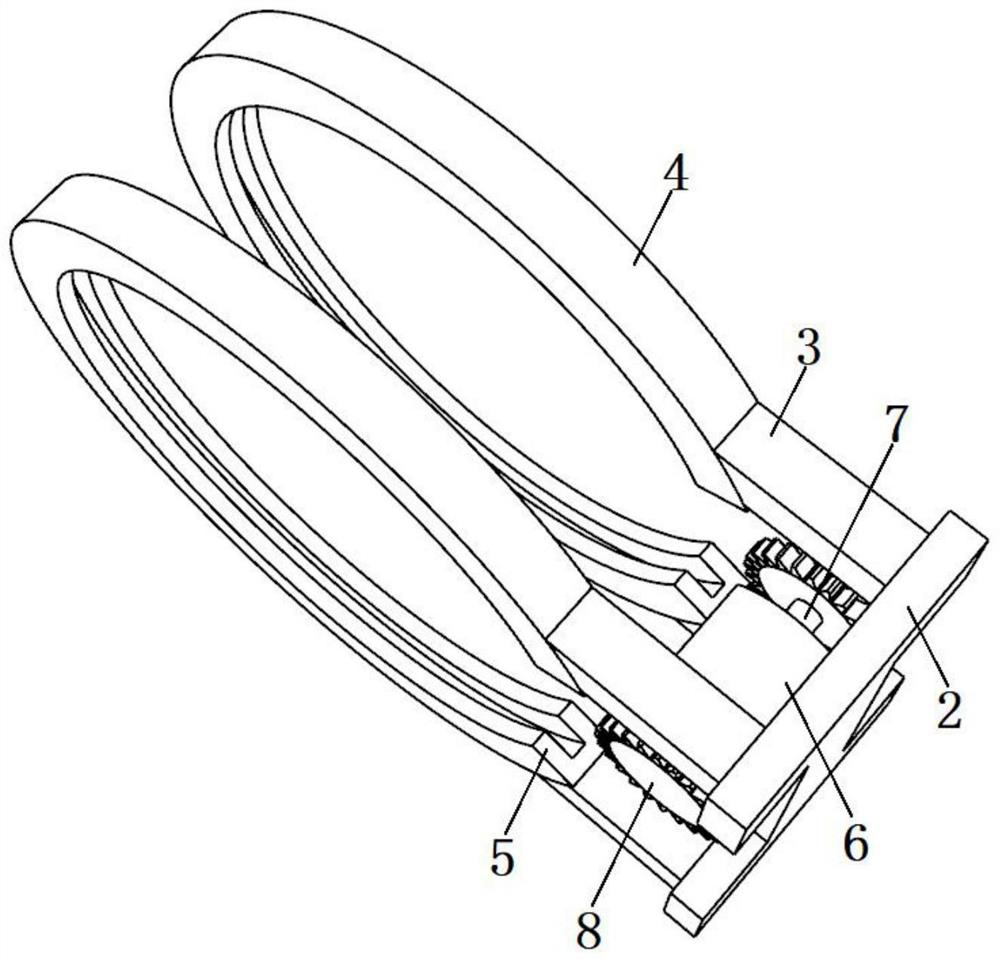

The invention discloses a building construction pipeline end surface processing device capable of conveniently fixing different sizes. The building construction pipeline end surface processing devicecapable of conveniently fixing the different sizes comprises a bottom plate, a first telescopic rod is fixedly mounted on the upper surface of the left end of the bottom plate, a supporting plate is fixedly connected to the top end of the first telescopic rod, a first toothed disc is fixedly mounted at the right end of a handle, a rotary rod is movably connected into the upper end of the supporting plate, a movable barrel is connected to the middle of the rotary rod through bolts, a motor is fixedly connected to the upper end of a second telescopic rod, a second polishing block is fixedly mounted on the outer surface of a first polishing block, and third telescopic rods are connected to the outer surface of the right end of the rotary rod in an equal angle mode. According to the building construction pipeline end surface processing device capable of conveniently fixing the different sizes, polishing is comprehensive and uniform, the polishing degree and effect of an annular end surfacecan be controlled manually, a round supporting structure is arranged in a pipeline, the height and a clamping range of a pipeline clamping structure are convenient to adjust, and a device for integrally connecting sweeps is arranged.

Owner:RIZHAO POLYTECHNIC

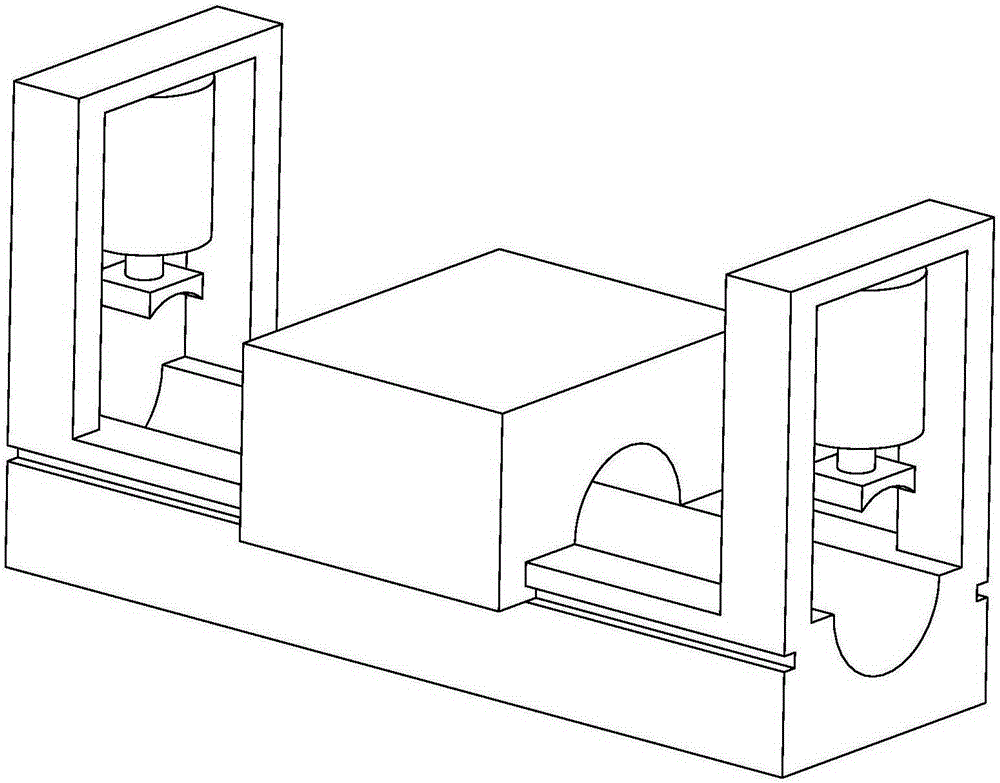

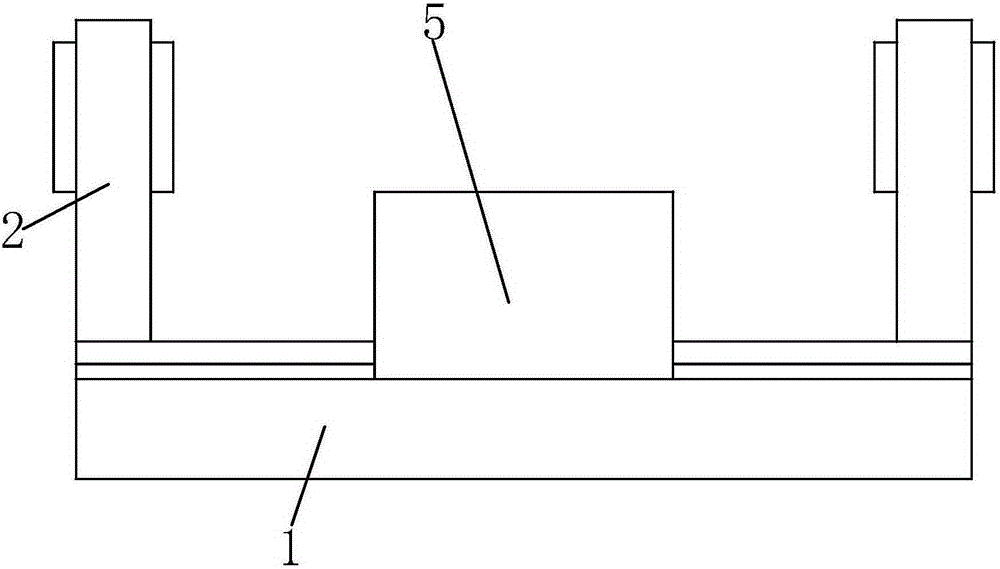

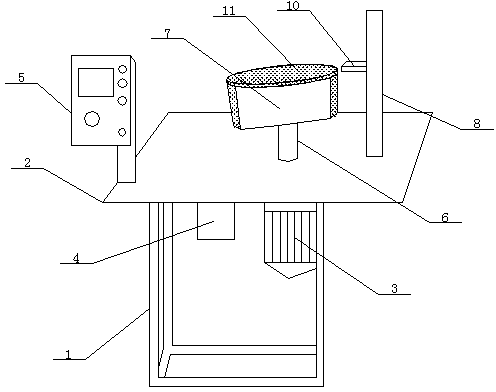

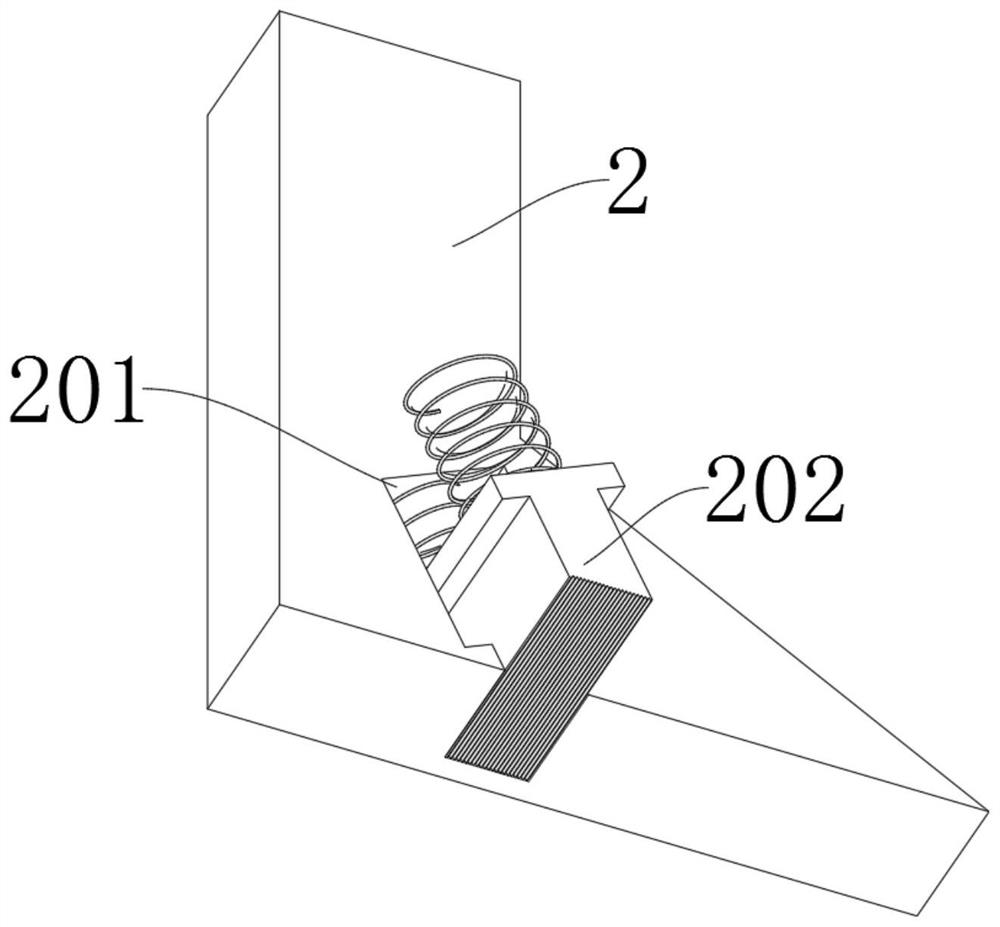

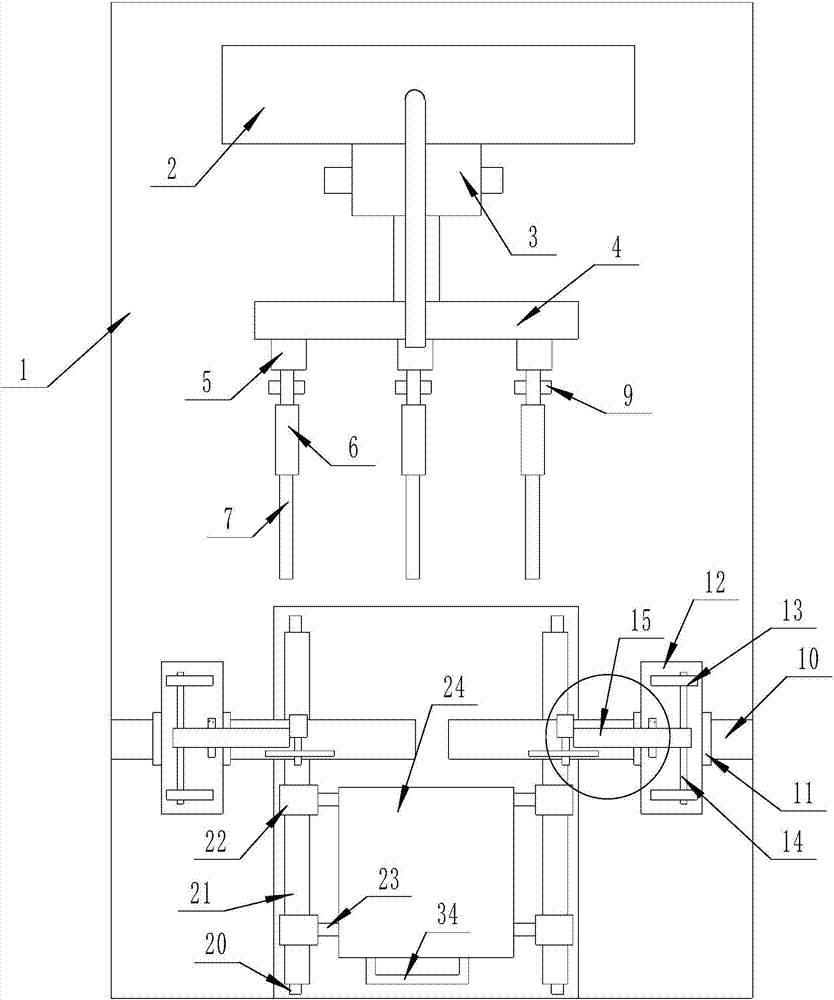

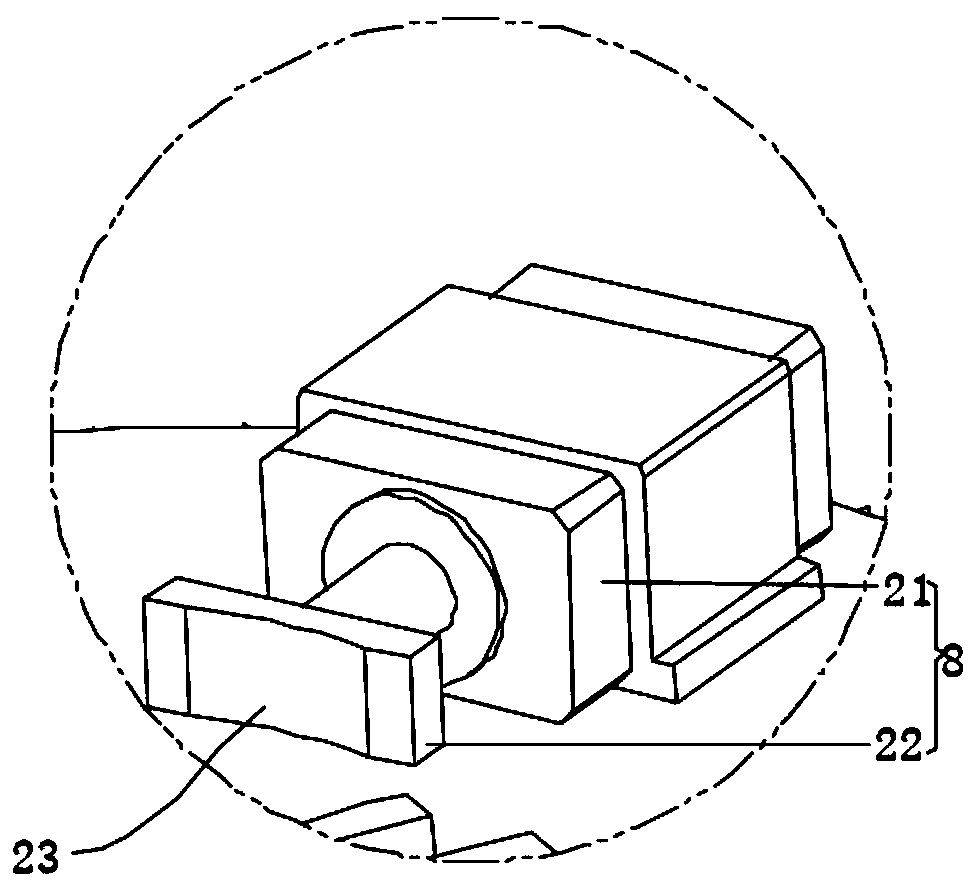

Device for circular tube polishing

InactiveCN105313009AFast automatic clampingEffective sandingRevolution surface grinding machinesGrinding work supportsEngineering

The invention relates to a device for circular tube polishing. The device for circular tube polishing mainly comprises a base plate seat and a curved groove in the base plate seat. Elevated platforms are arranged at both the left end and the right end on the base plate seat. Air cylinders are installed on the lower portions of the elevated platforms respectively. The air cylinders are connected with curved press blocks. A polishing block is arranged on the curved groove and fit with the curved groove in shape. In addition, the polishing block is installed on the base plate seat horizontally in a slide mode. The device for circular tube polishing is simple to use. A circular tube can be fixedly clamped fast and automatically, and it is convenient for an operator to polish effectively. Labor is saved during using relatively.

Owner:WUHU HENGHAO MACHINERY MFG

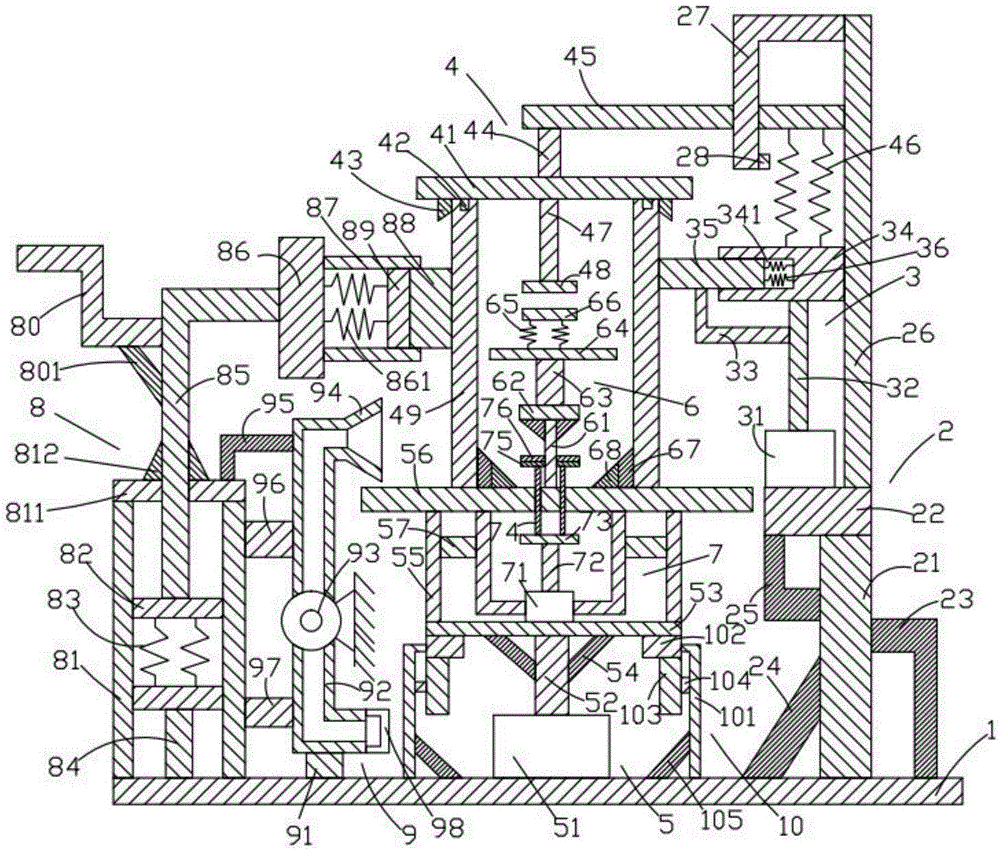

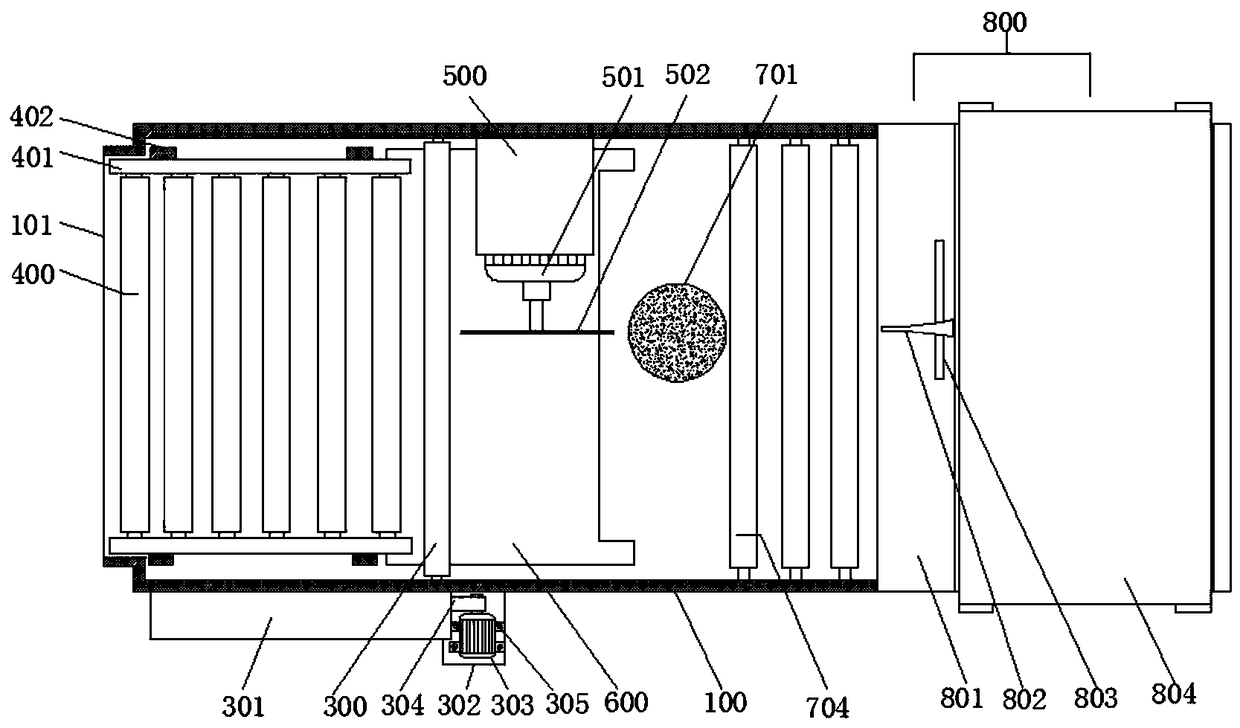

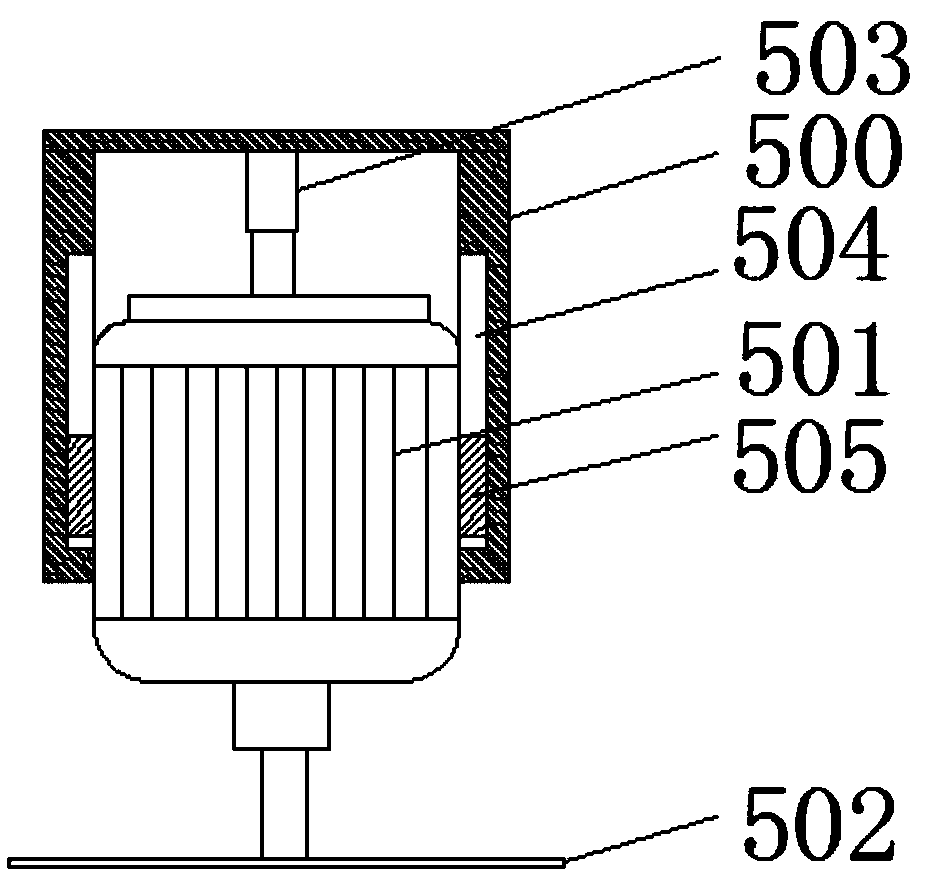

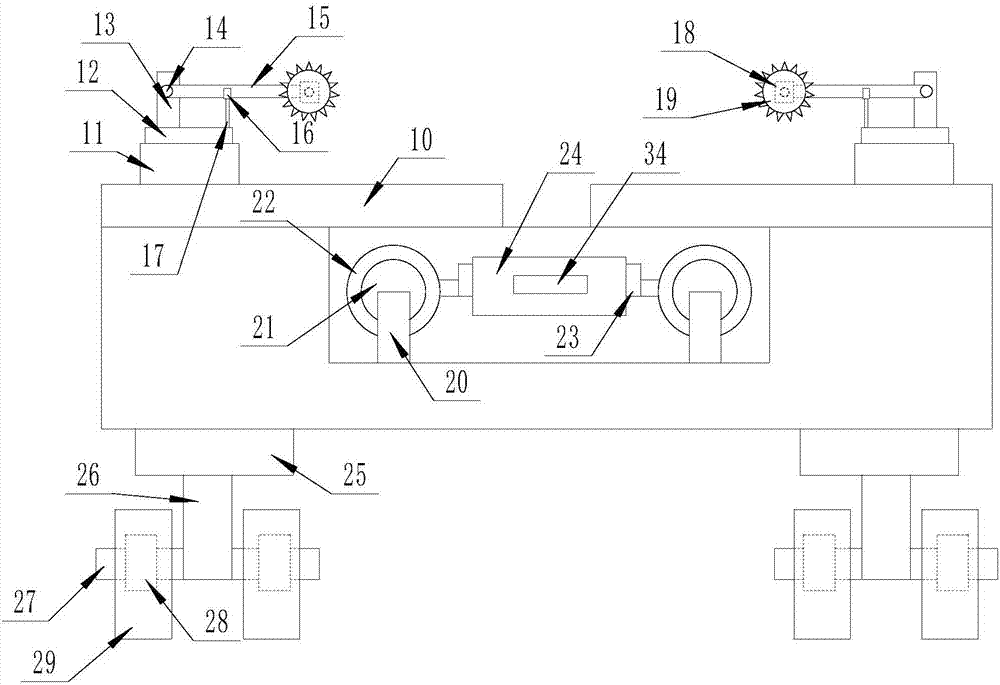

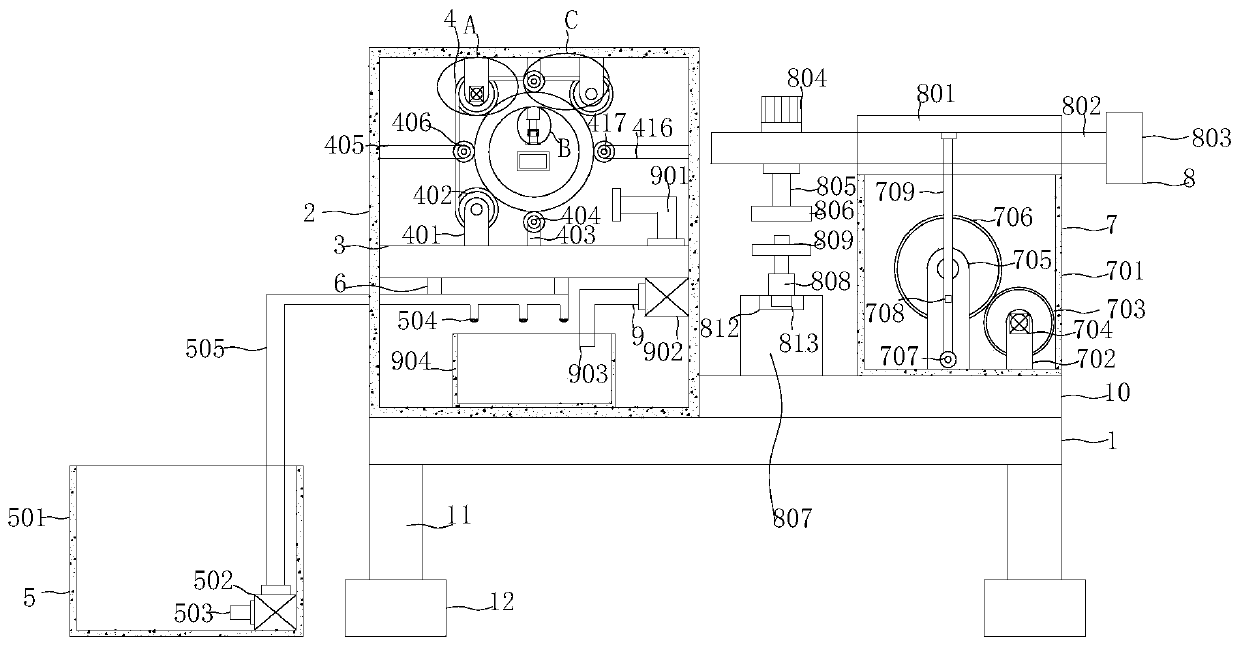

Oil sieve tube outer wall polishing device with dust removing function

InactiveCN105290894AEffective sandingIncrease productivityGrinding carriagesRevolution surface grinding machinesMagnetPetroleum engineering

The invention relates to an oil sieve tube outer wall polishing device with the dust removing function. The polishing device is used for polishing the outer surface of an oil sieve tube. The oil sieve tube outer wall polishing device with the dust removing function comprises a bottom plate, a bracket device, a polishing device body, a fixing device, a motor device, a suction device, an air cylinder device, a cleaning device, a dust suction device and a support device. The bracket device comprises a first support rod, a first cross rod, a first bracket, a first oblique rod, a second bracket, a second support rod, a third bracket and a first positioning block. The polishing device body comprises a first air cylinder, a first push rod, a third bracket, a first fixing block, a polishing block and a first spring. The fixing device comprises a first cover plate, a second fixing block, a first fixing ring, a first vertical rod, a second cross rod, a second spring, a second vertical rod and a first magnet. The motor device comprises a motor, a revolving shaft, a first rotary plate, a first connecting rod, a third support rod, a second rotary plate and a second fixing ring. According to the oil sieve tube outer wall polishing device with the dust removing function, the oil sieve tube can be polished rapidly and effectively, the polishing efficiency is high, and the polishing effect is good.

Owner:张萍

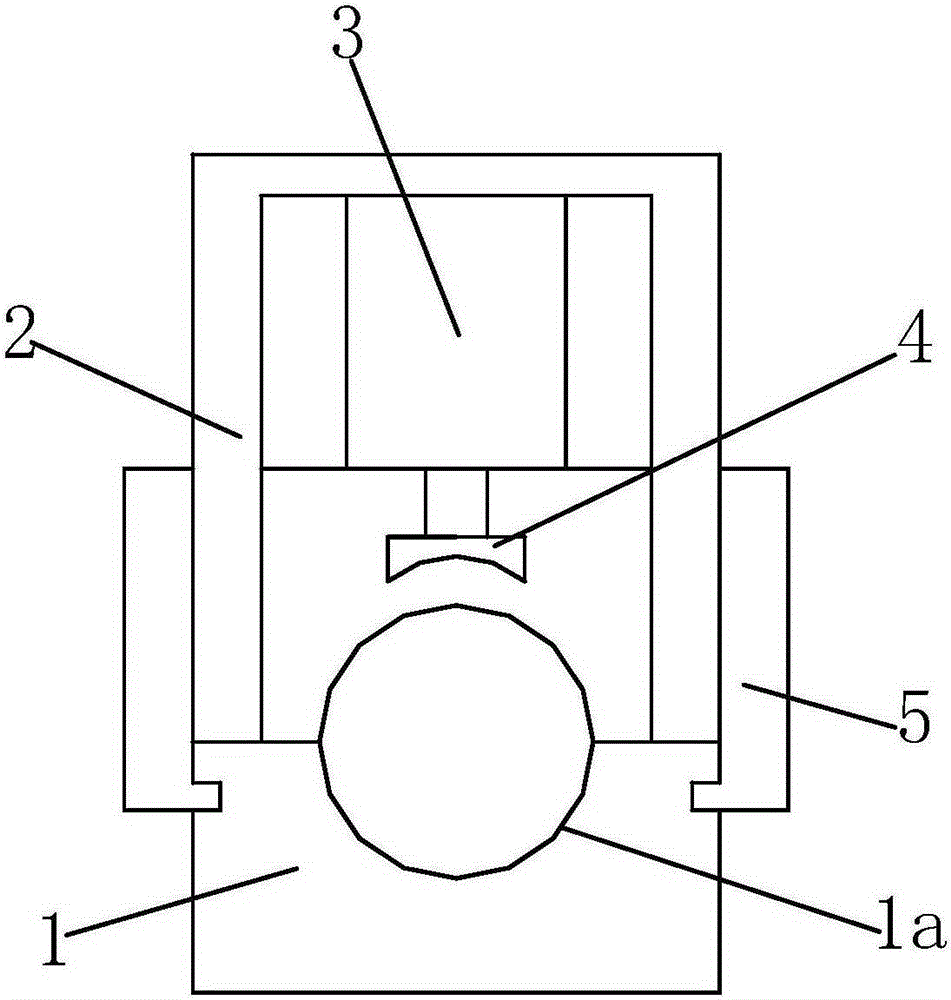

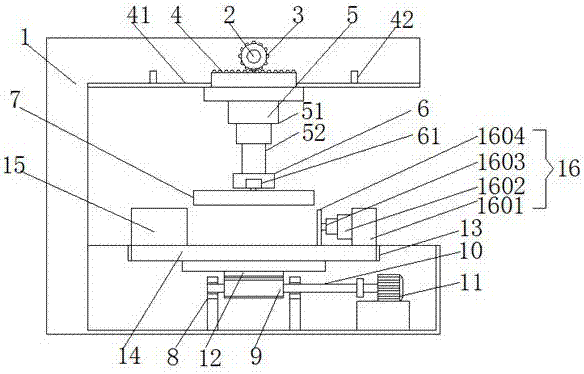

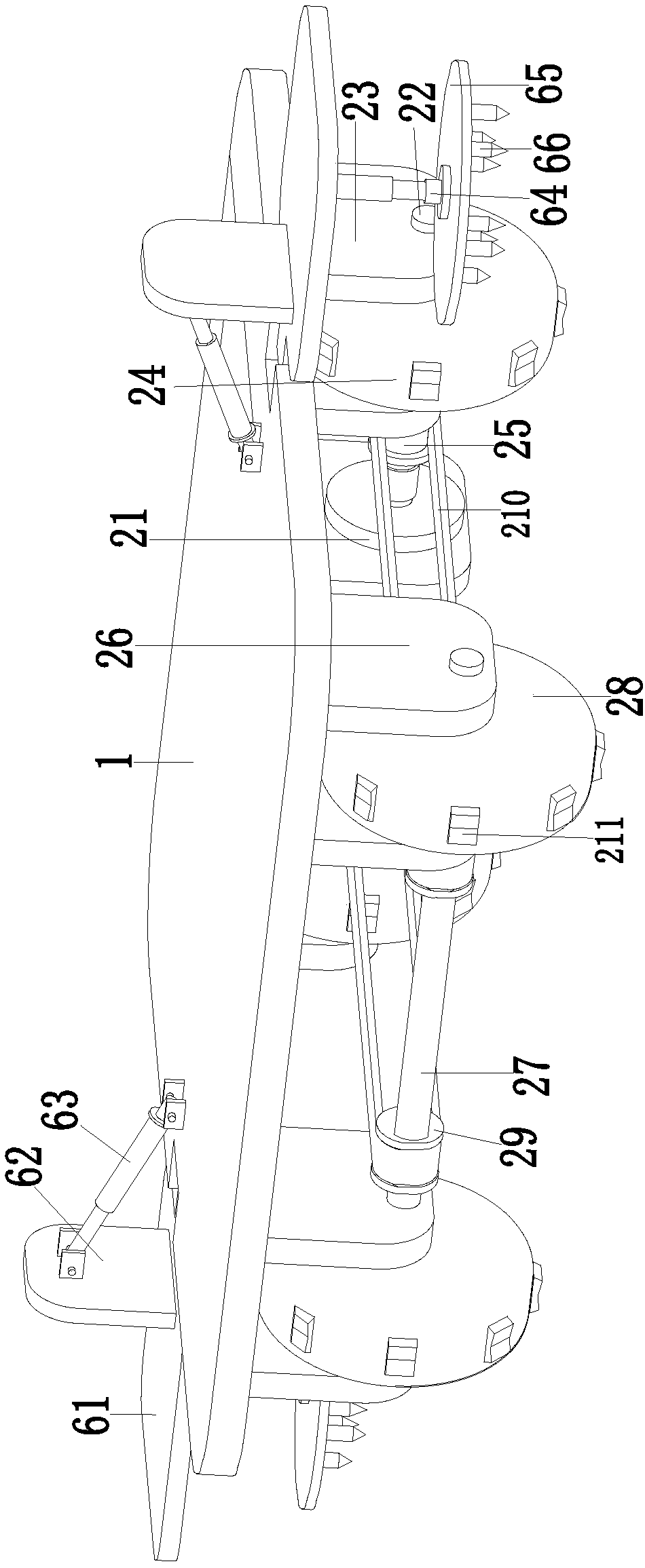

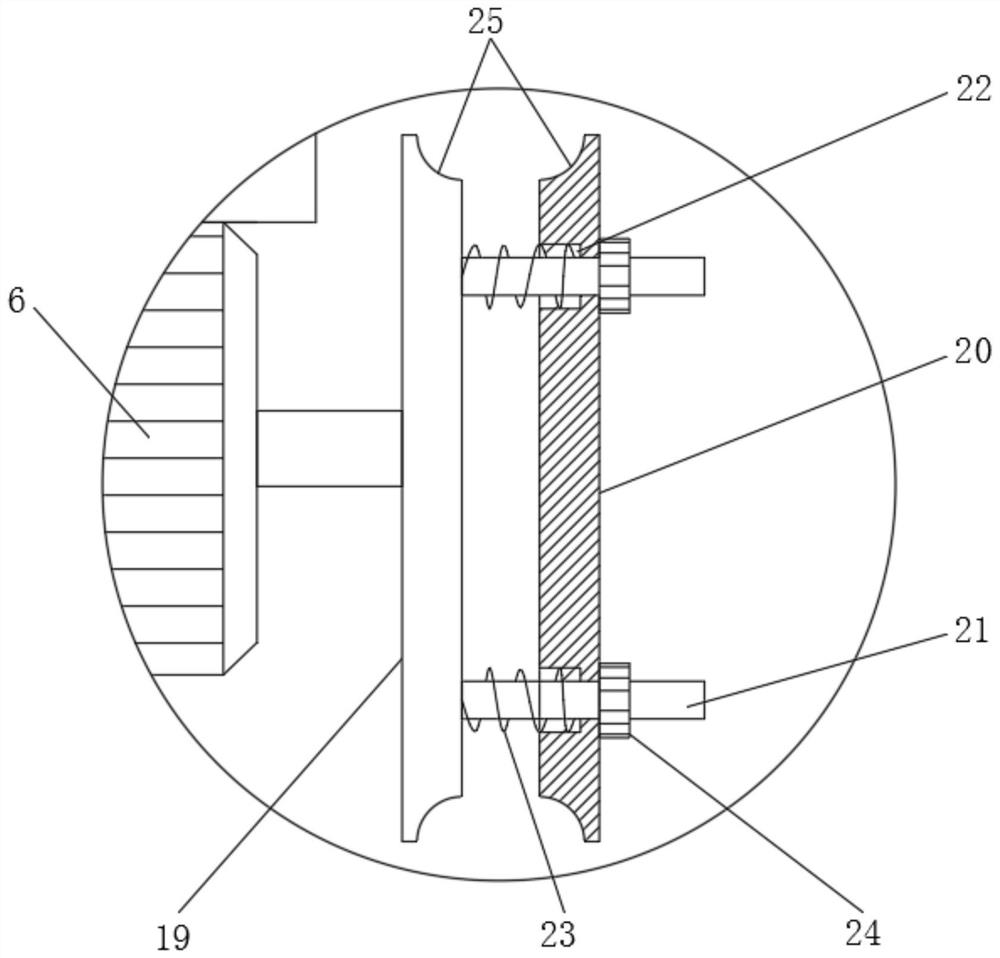

Cross joint pipe inner side wall polishing device

ActiveCN105563253AEffective sandingEasy to grindRevolution surface grinding machinesGrinding drivesMechanical engineering

The invention relates to a cross joint pipe inner side wall polishing device. The cross joint pipe inner side wall polishing device comprises a base and a mounting frame. A rotary plate is slidably mounted on the mounting frame, a positioning pin is disposed on the lower portion in front of the rotary plate, and the positioning pin is connected with an air cylinder; two C-shaped clamping openings are formed in the front end face of the rotary plate, and fastening bolts are mounted at the front ends of the clamping openings; four outwards extending plates are uniformly distributed on the circular arc end face of the rotary plate, a clamping seat is slidably mounted on the base, and the clamping seat is connected with a spring; a polishing driving assembly is disposed above the rotary plate and comprises a polisher, the position of the polisher is matched with that of the positioning pin, and a back frame for fixedly mounting the polishing driving assembly is disposed in rear of the polishing driving assembly. By means of the cross joint pipe inner side wall polishing device, the polisher can be controlled to automatically polish the single inner side pipe wall of a cross joint pipe, positioning shifting can be achieved by controlling the rotary plate to rotate by 90 degrees, and the polishing efficiency is improved.

Owner:临沂罗开投资有限公司

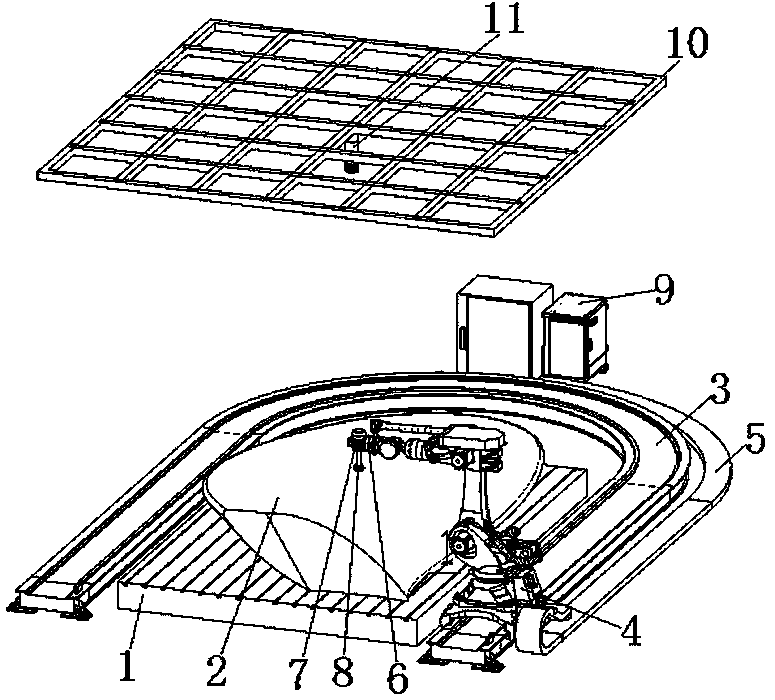

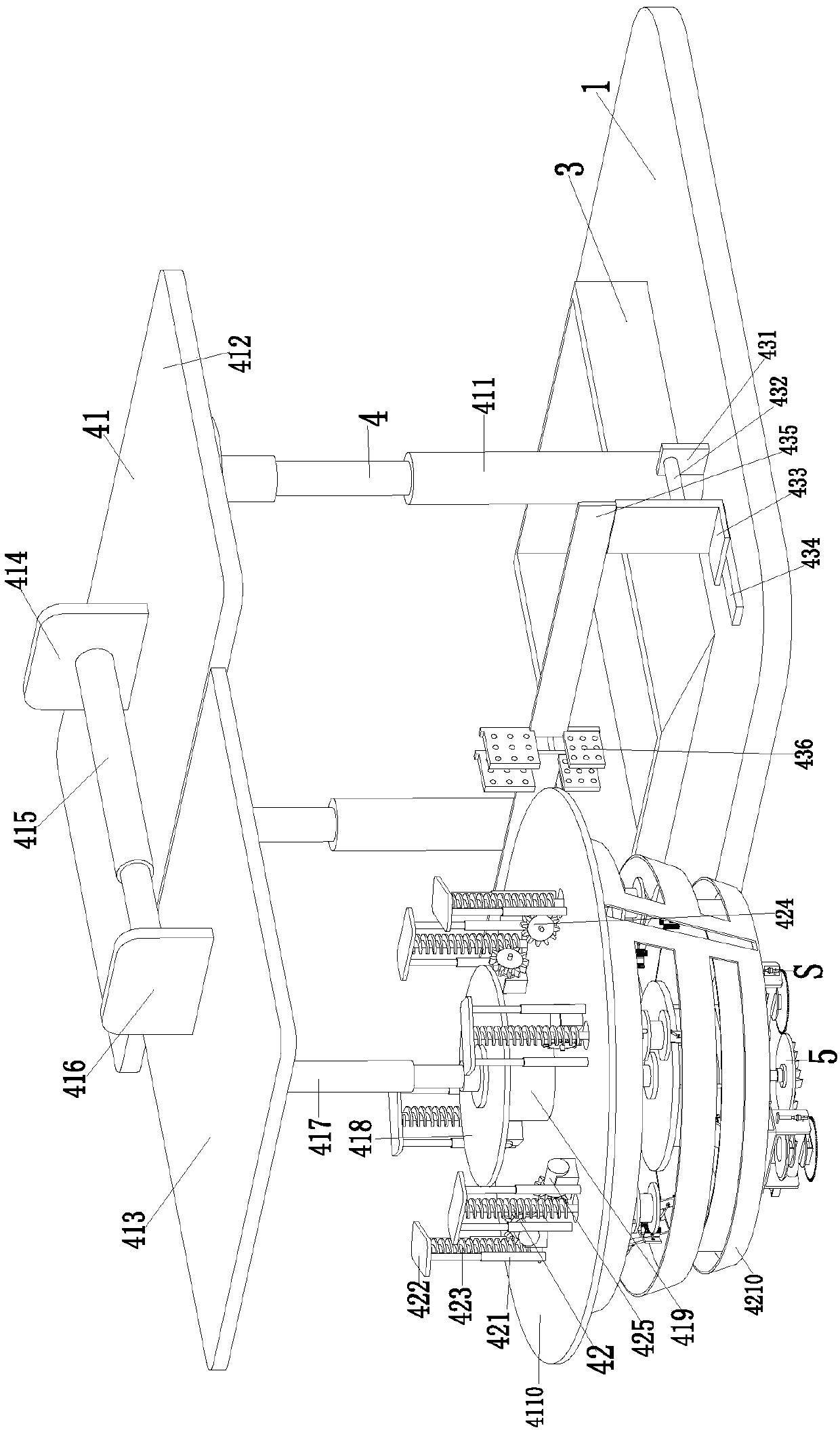

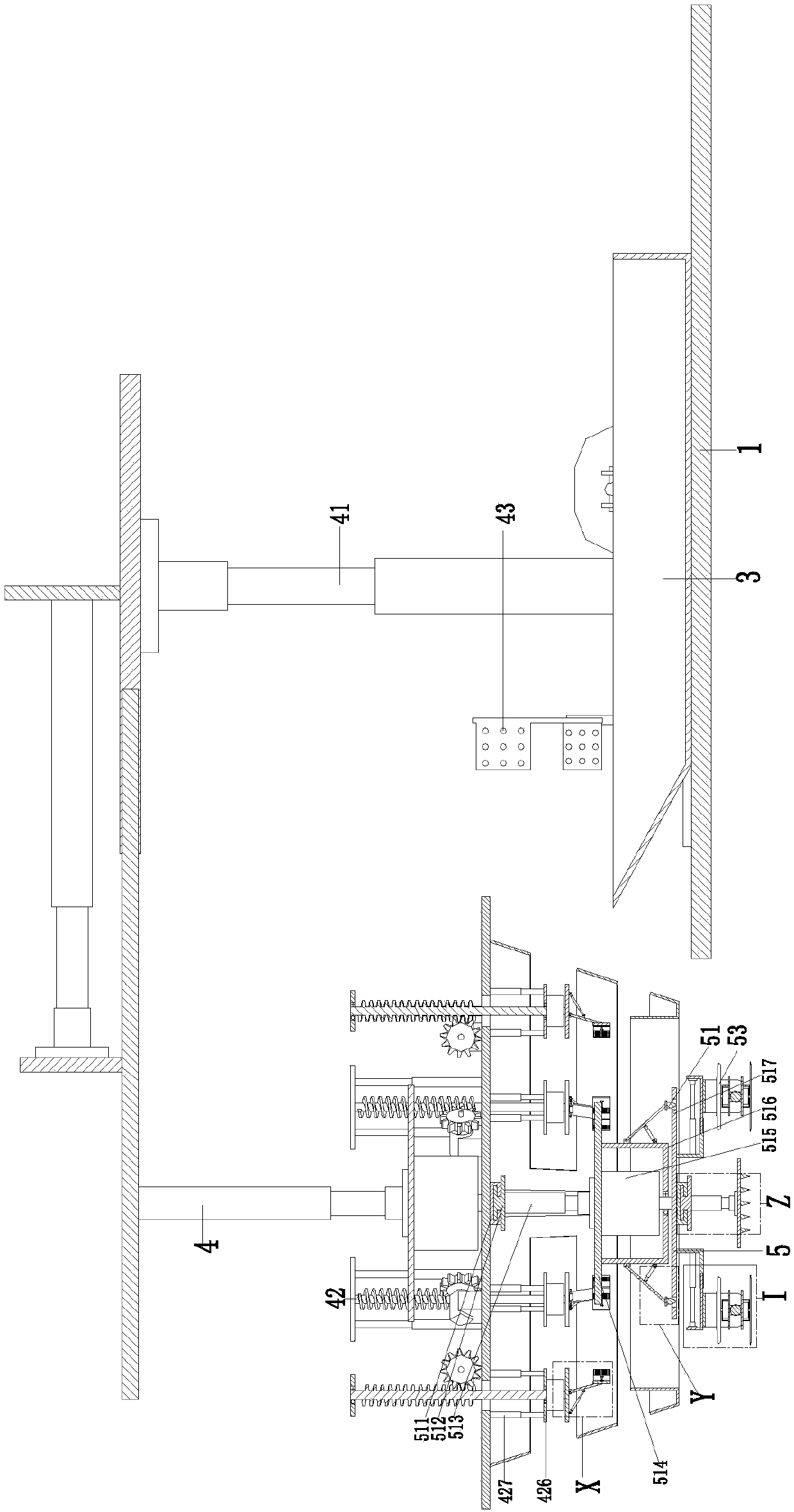

Automatic polishing system for water turbine blades

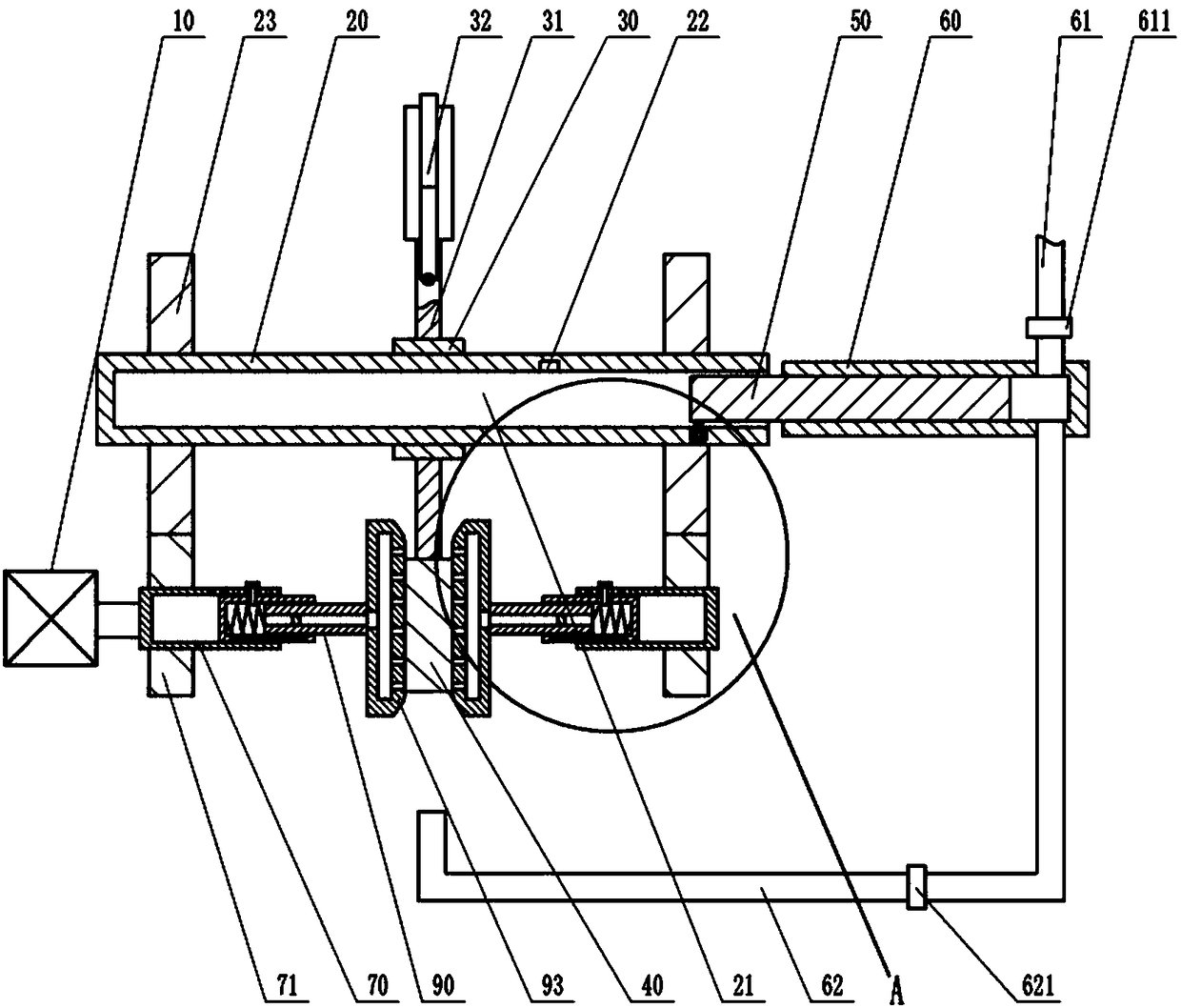

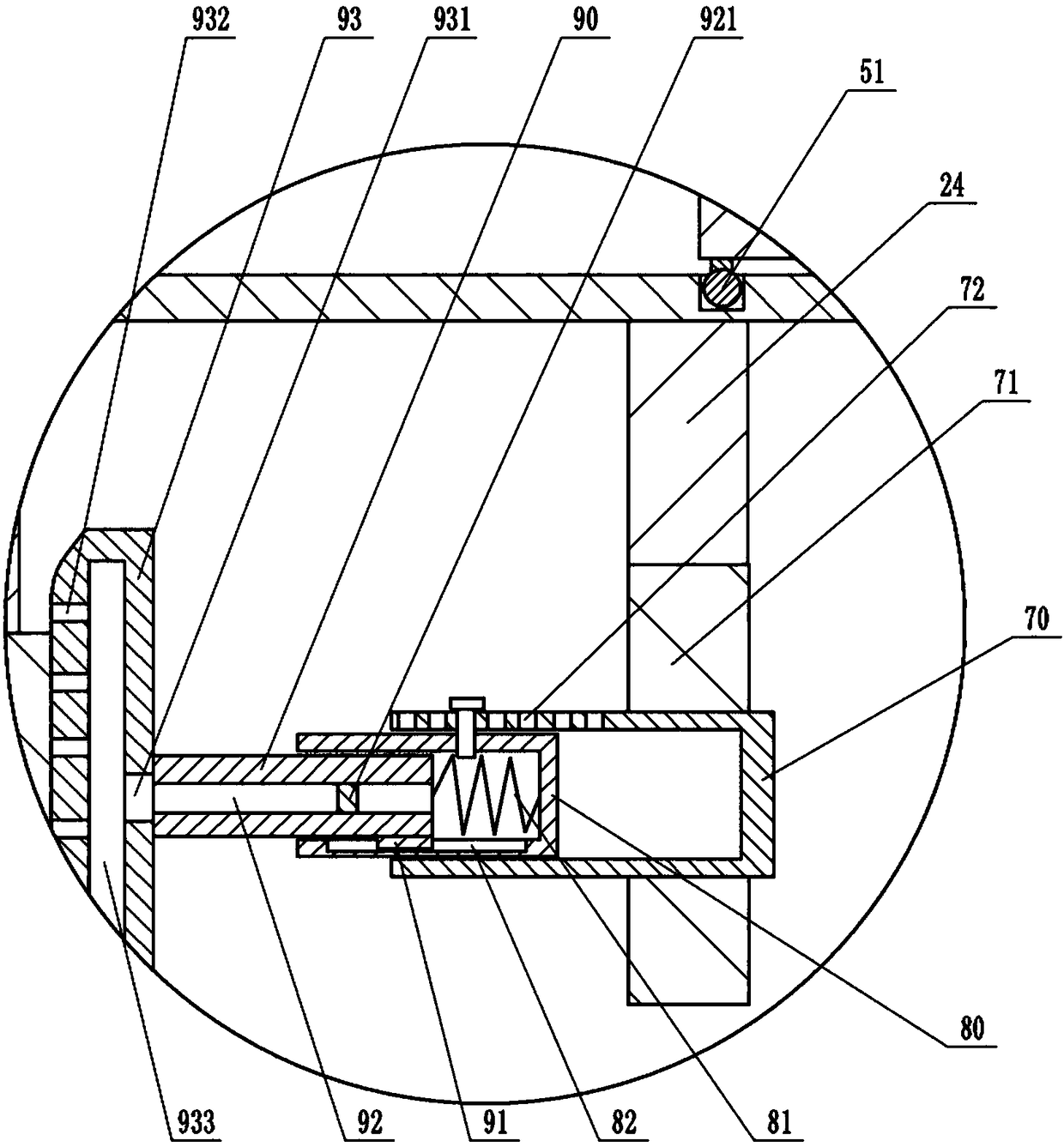

InactiveCN107866717AEffective sandingImprove sanding qualityAutomatic grinding controlGrinding machinesWater turbineControl system

The invention discloses an automatic polishing system for water turbine blades. The automatic polishing system for the water turbine blades comprises a clamping platform, an industrial robot, a polishing control system and a visual image system, and wherein the clamping platform is used for positioning and clamping the water turbine blade to be polished; the industrial robot is provided with a polishing mechanism, and the industrial robot is controlled by a polishing control system and is used for polishing the blade clamped on the clamping platform; and the polishing control system directs atthe current polishing surface of the blade to be polished and is used for planning a corresponding polishing path, then the planned polishing path is converted into a polishing action control programof the industrial robot and is conveyed to the industrial robot, and the visual image system is used for detecting the polishing quality and feeding back the polishing quality to the polishing control system. According to the automatic polishing system for the water turbine blades, the surface of the impact-type water turbine blade formed by precision casting can be provided with an automatic, intelligent and unified polishing treatment; and thus the polishing quality of the surface of the blade can be improved accurately and reliably.

Owner:SICHUAN ENG TECHN COLLEGE

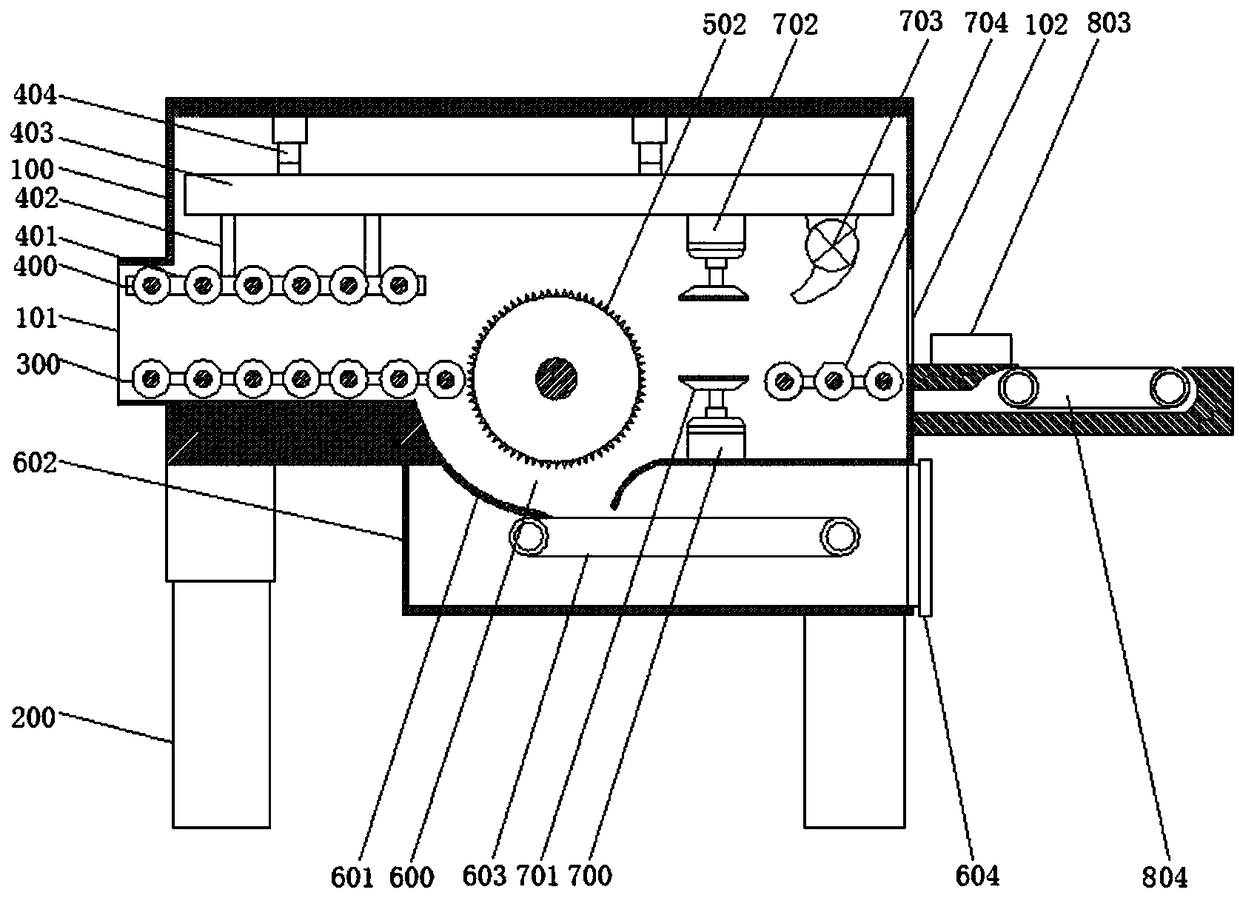

Cutting and polishing machine for solid wood floor

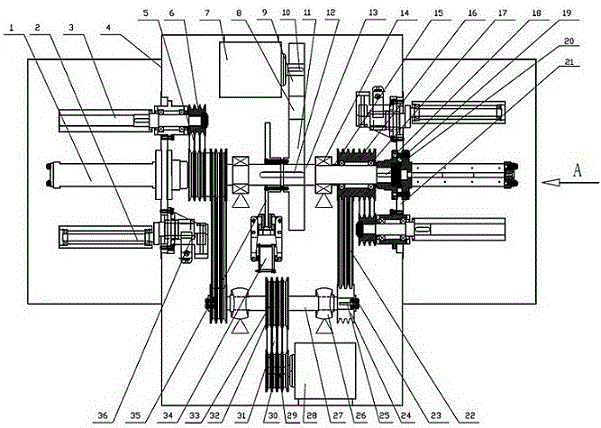

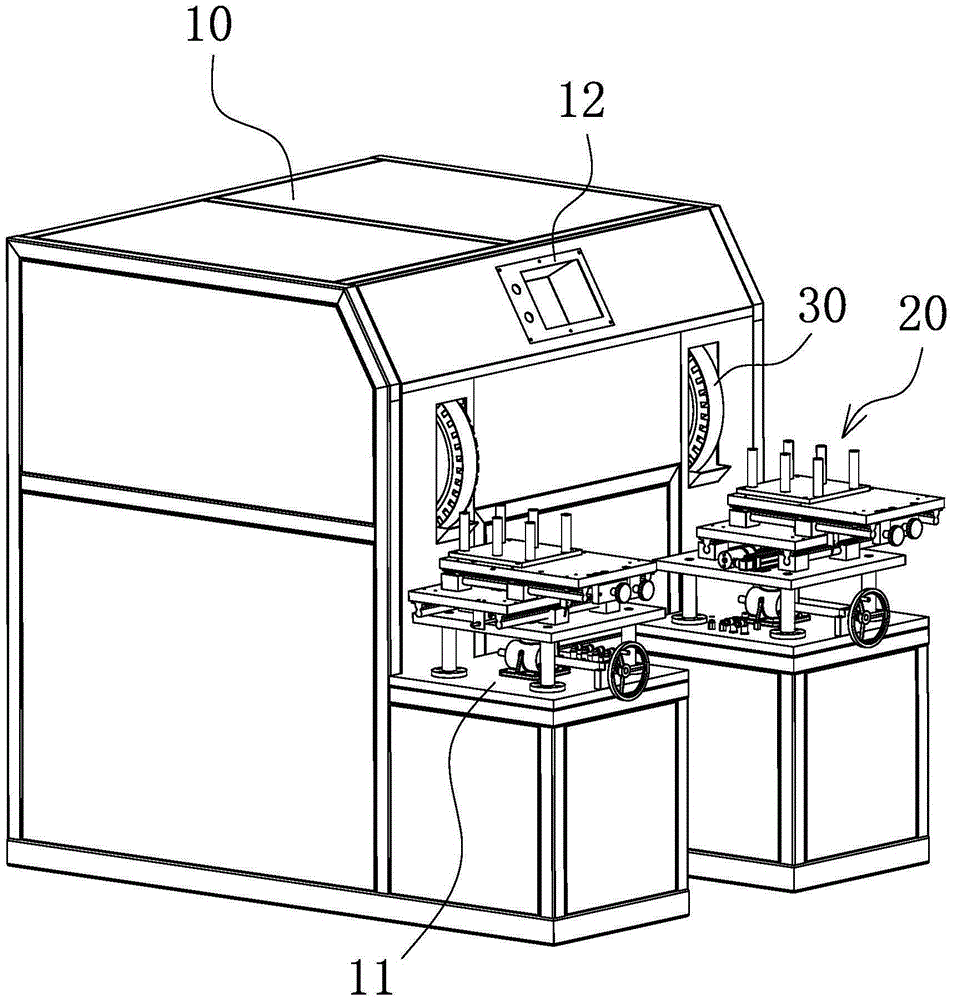

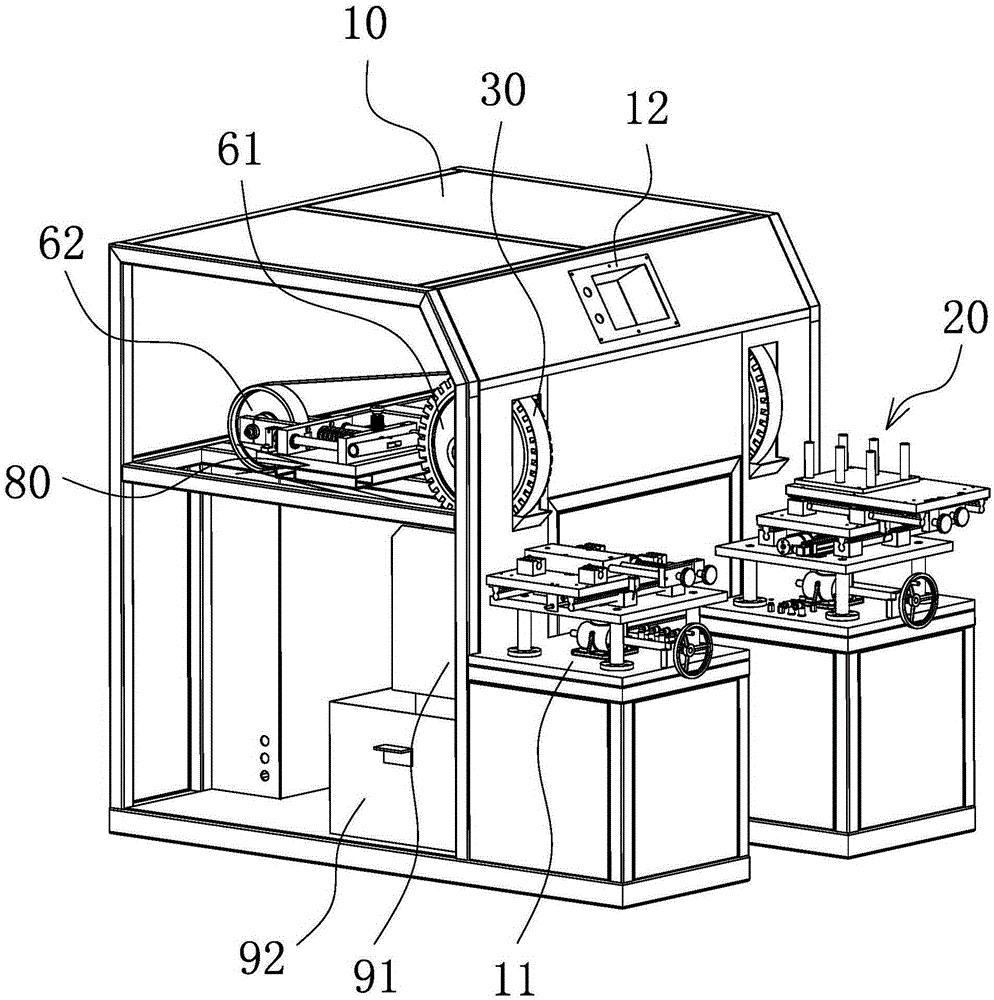

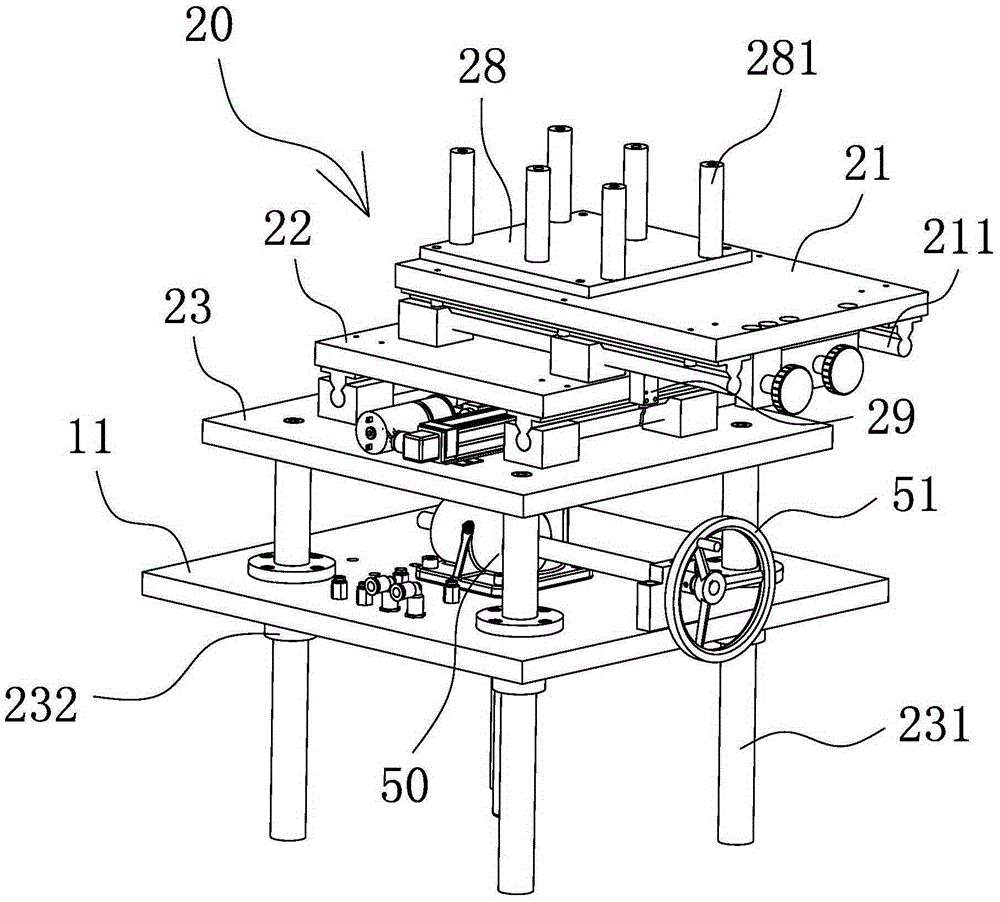

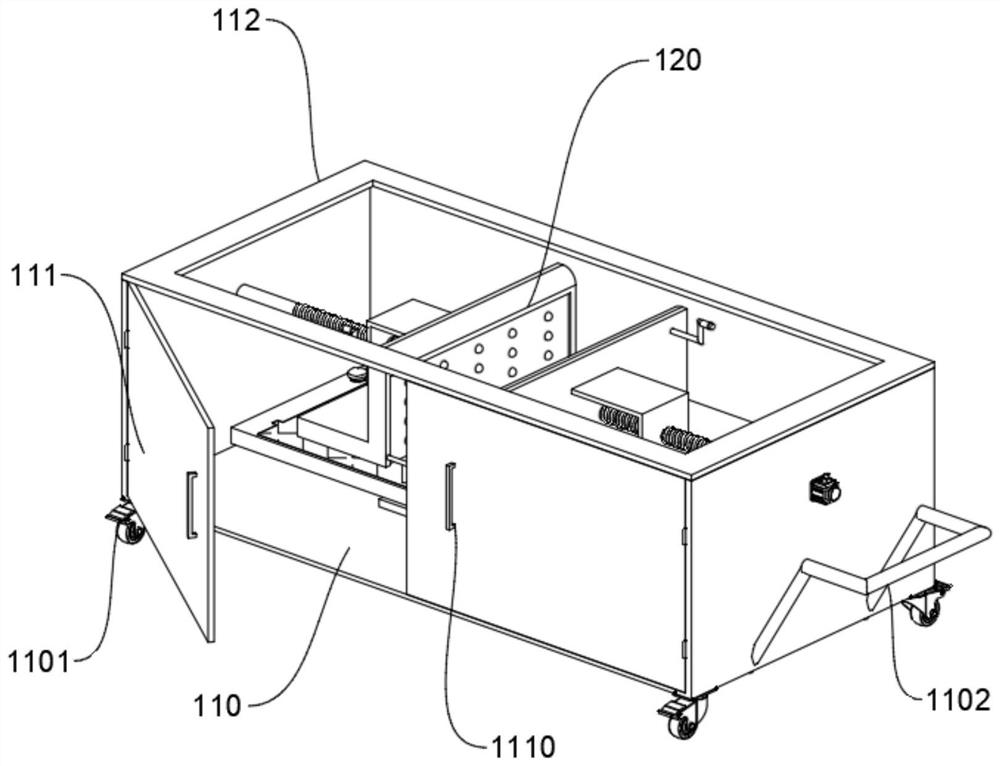

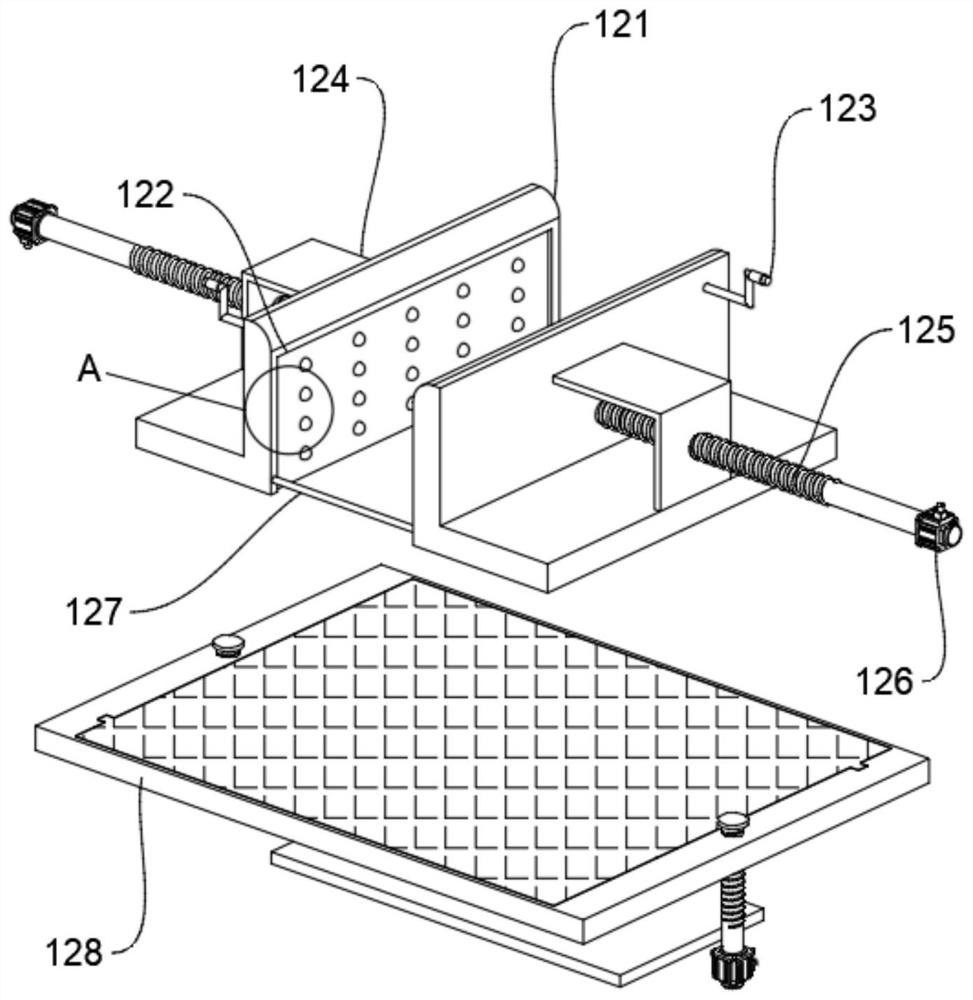

ActiveCN109366620AStable structure deliveryEffective sandingPolishing machinesCircular sawsSolid woodEngineering

The invention discloses a cutting and polishing machine for a solid wood floor. The cutting and polishing machine comprises a box body; a feeding opening is formed in the right side surface of the boxbody; a driving roller set is arranged on the right side of the lower end of the feeding opening; one end of the driving roller set is rotationally connected with a bearing on the inner side wall ofthe box body; the other end of the driving roller set penetrates through the outer side wall of the box body to be inserted in a driving box; a motor fixing plate is arranged on the right side of thedriving box; a driving motor is fixed to the motor fixing plate; power is transmitted to the driving roller set through a belt by an output shaft of an output shaft of the driving motor; a compressionroller set is arranged right above the driving roller set; cross slabs are arranged at the front end and the rear end of the compression roller set; and compression rollers on the compression rollerset are rotationally connected with bearings arranged on the cross slabs. The cutting and polishing machine is simple in structure, realizes the integration of automatic cutting and polishing, can effectively recover wood chips in the processes of cutting and polishing, improves the entire environment, and is higher in practicability.

Owner:安徽可尔海思新材料科技有限公司

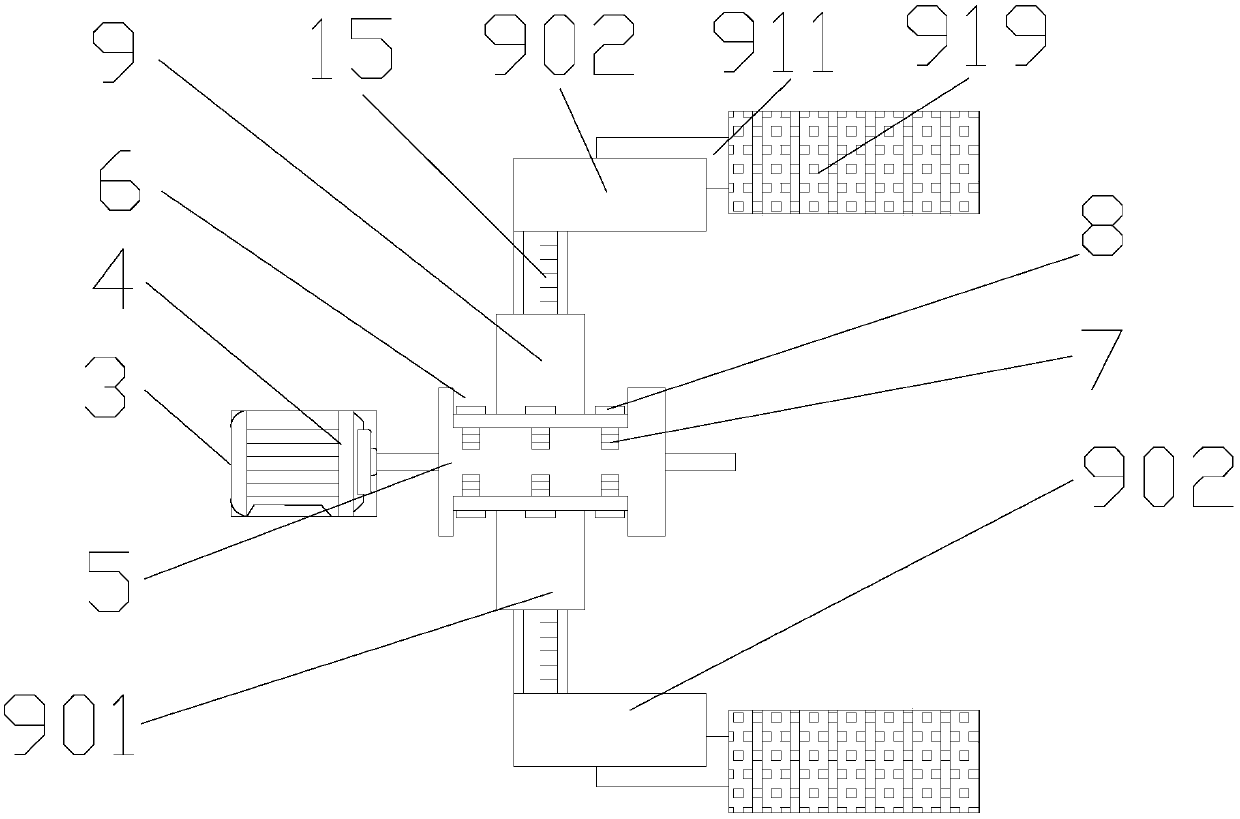

Wire surface rust removal polisher

ActiveCN104907907AAvoid dust pollutionReduce manufacturing costGrinding drivesBelt grinding machinesBelt grindingEngineering

The invention relates to a wire surface rust removal polisher. Rust removal polishing is performed on the surface of a wire in the mode that an abrasive belt moves to grind the wire and rotates around the circumference of the wire, the abrasive belt conducts helical motion on the surface of the wire due to linear movement of the wire, and therefore grinding dust removal can be performed on the whole surface of the wire. In addition, removed iron rust can be recycled, and therefore the production cost is lowered; a physical abrasive belt grinding method replaces a traditional chemical electrolysis pickling method, and therefore air pollution is reduced.

Owner:HANGZHOU XINGGUAN MACHINERY

Polishing and machining device for automobile parts

InactiveCN107186624AEffective lateral movementAdjust grinding heightGrinding carriagesGrinding drivesCouplingEngineering

The invention discloses a grinding and processing device for automobile parts, which includes a machine body, and is characterized in that: a first motor is arranged on the inner side of the storage box above the machine body, the output shaft of the first motor is fixedly connected with a first gear, and the bottom of the first gear meshes with the There is a first tooth plate, and the bottom of the inner cavity of the storage box above the body is provided with a first chute, the bottom of the first tooth plate is slidably connected in the first chute, and the bottom surface of the first tooth plate is fixedly connected with a telescopic device through a fixing plate , the bottom end of the expansion device is fixedly connected with a grinding device, the bottom inner cavity of the body is fixed by a bearing through a support frame, a rotating shaft is movably connected between the two bearings, the right end of the rotating shaft is connected with a second motor through a coupling, and the upper end of the rotating shaft is covered Connected with the second gear. The present invention has the advantage of clamping the auto parts for multiple times by setting the first motor and the second motor to cooperate with each other, and solves the problem of low grinding efficiency of the existing auto parts grinding processing device.

Owner:于法周

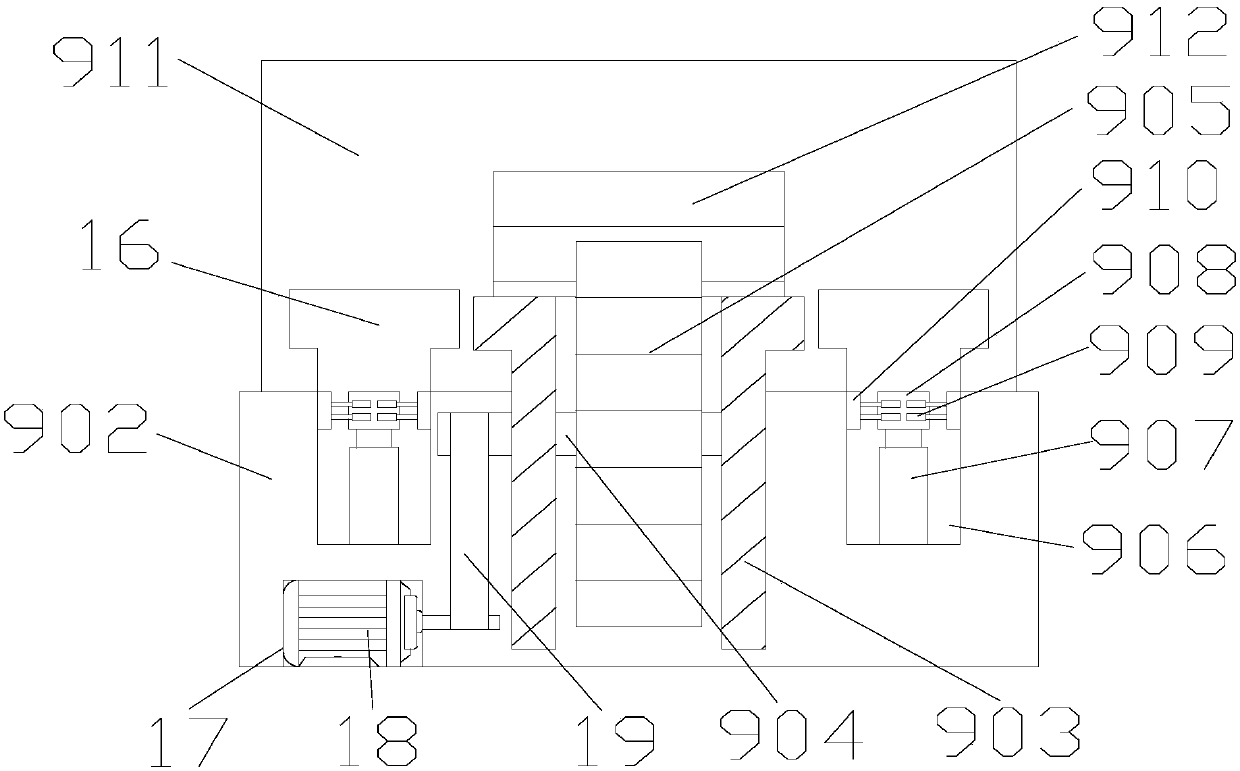

Magnetic ring grinding device

ActiveCN107891323AEffective sandingEffectively fixedGrinding carriagesRevolution surface grinding machinesWorking environmentArchitectural engineering

The invention discloses a magnetic ring grinding device. The device comprises a base, one side of the top of the base is fixedly connected with a first motor box through a T-shaped supporting frame, the bottom of the inner wall of the first motor box is fixedly connected with a first motor, and the output end of the first motor is sleeved with a first fixing part; the top and the bottom of the first fixing part are both provided with a first groove; a threaded groove is formed in the side, close to the center of the first fixing part, of the inner wall of each first groove; a second fixing part is fixedly connected to the side, away from the T-shaped supporting frame, of the top of the base. The invention relates to the technical field of magnetic ring equipment. The magnetic ring grindingdevice can be used for grinding magnetic rings more effectively, the magnetic rings can be effectively fixed, a magnetic ring fixing device can be adjusted according to the height of the magnetic rings to be suitable for fixing the magnetic rings in different specifications, dust generated in the magnetic ring grinding process can be effectively absorbed, and a good grinding working environment can be guaranteed.

Owner:南通德元机械制造有限公司

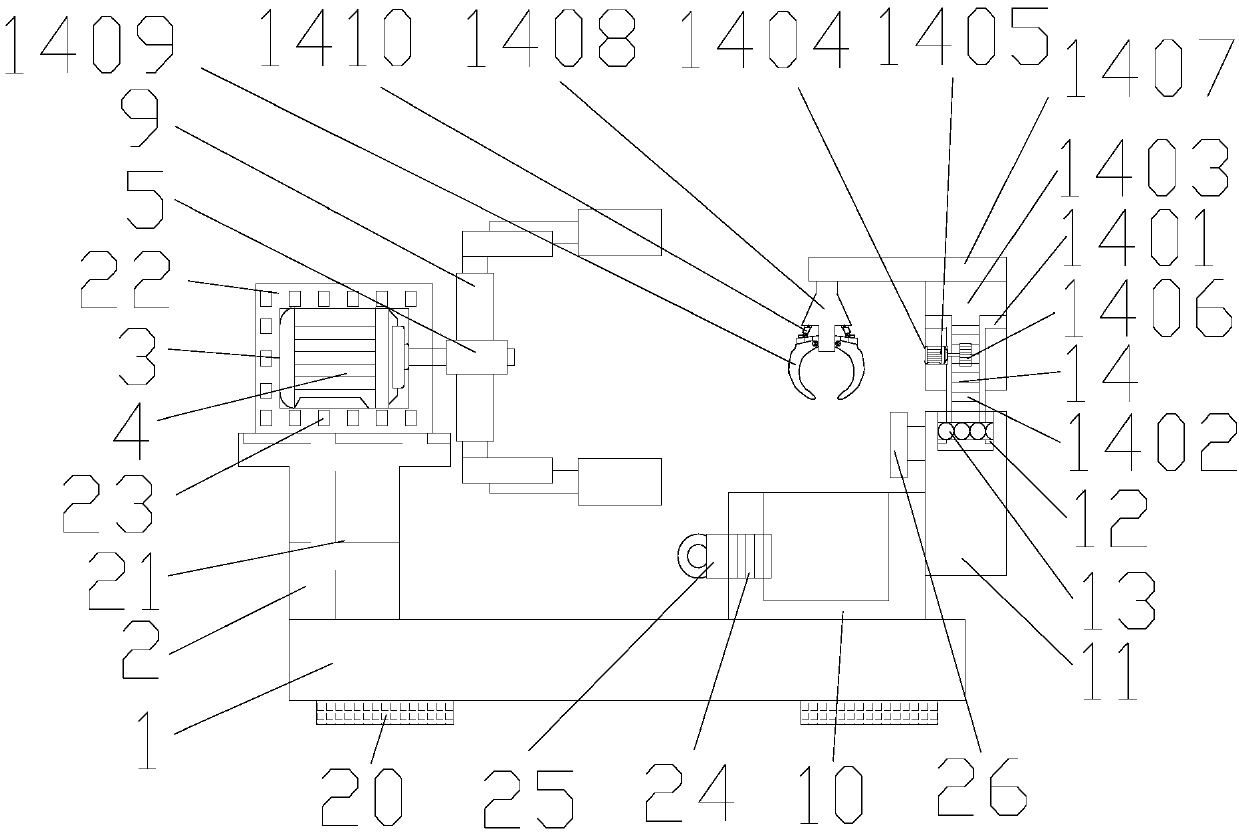

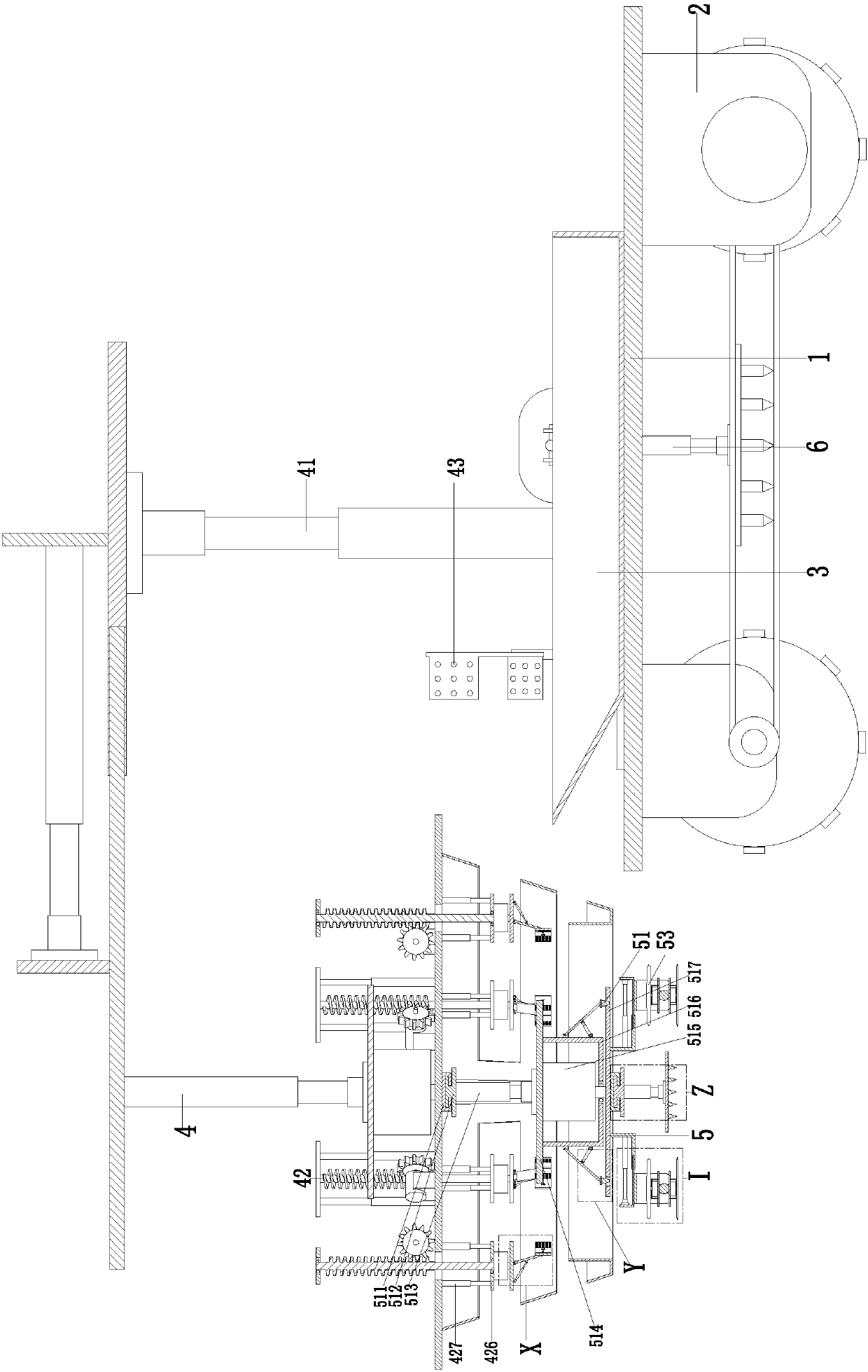

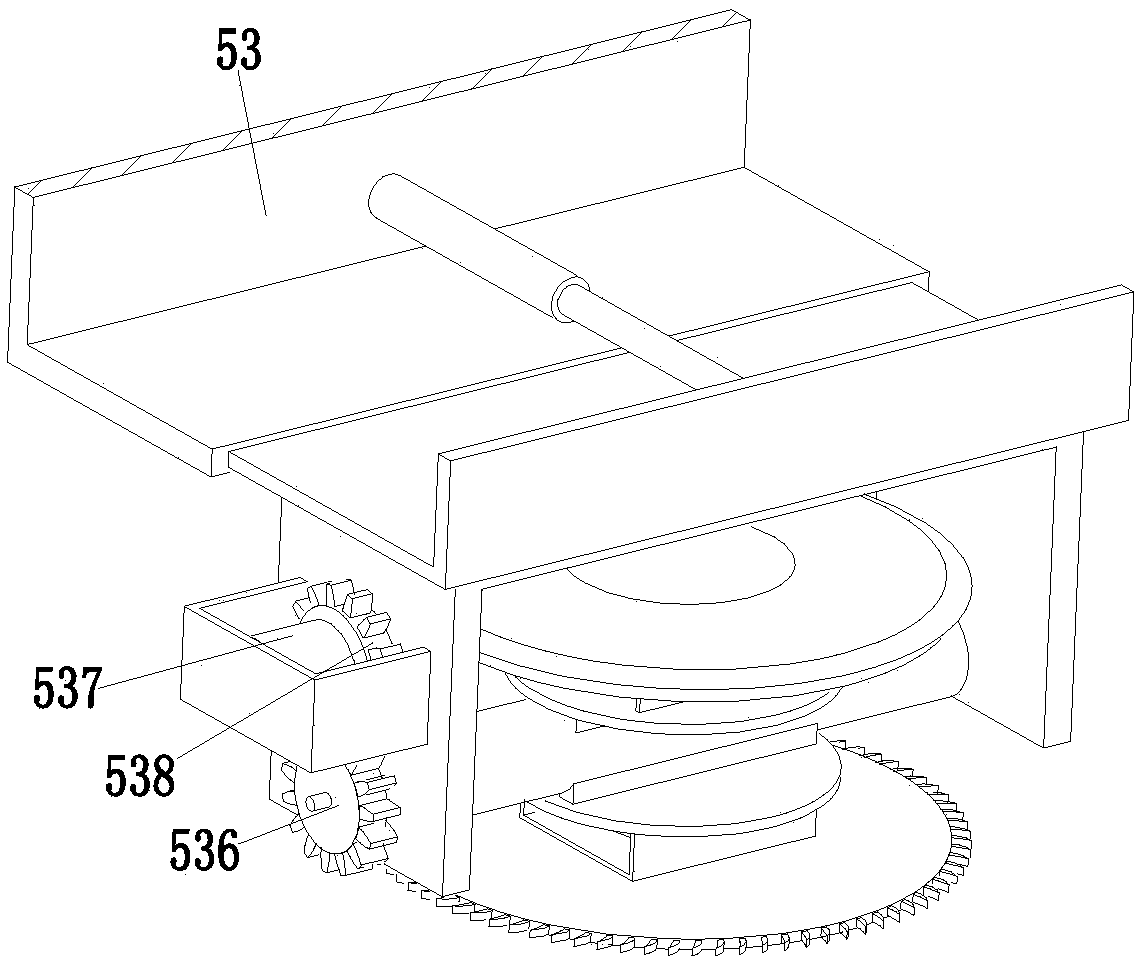

Automatic treatment equipment for bridge construction pile foundation steel bar for high-speed railway track

InactiveCN107626859ARealize safety hazardNo safety hazardEdge grinding machinesGrinding machine componentsRebarUltimate tensile strength

The invention relates to automatic treatment equipment for a bridge construction pile foundation steel bar for a high-speed railway track. The automatic treatment equipment comprises a bottom plate; awalking device is installed at the lower end of the bottom plate; a collection tank is installed on the bottom plate; a collection device is installed at the front end of the bottom plate; and a cutting and polishing device is installed at the lower end of the collection device. The automatic treatment equipment provided by the invention can solve the problems that redundant pile foundation steelbars need to be manually cut in the pile foundation steel bar treatment process, manual assistance is needed in the pile foundation steel bar cutting process, the top ends of the pile foundation steel bars after cutting need to be manually polished, the pile foundation steel bars after cutting need to be manually collected, the labor intensity of manually cutting the pile foundation steel bars islarge, and particles in the pile foundation steel bar cutting process is liable to cause damage to a worker, so that safety hidden dangers exist, the cutting technology and the polishing technology cannot be performed at the same time, the time is wasted, the operation of manually conveying the pile foundation steel bars is complex, the labor intensity is large, the working efficiency is low andthe like at an existing building site and can realize the function of automatic treatment of the pile foundation steel bars.

Owner:储小燕

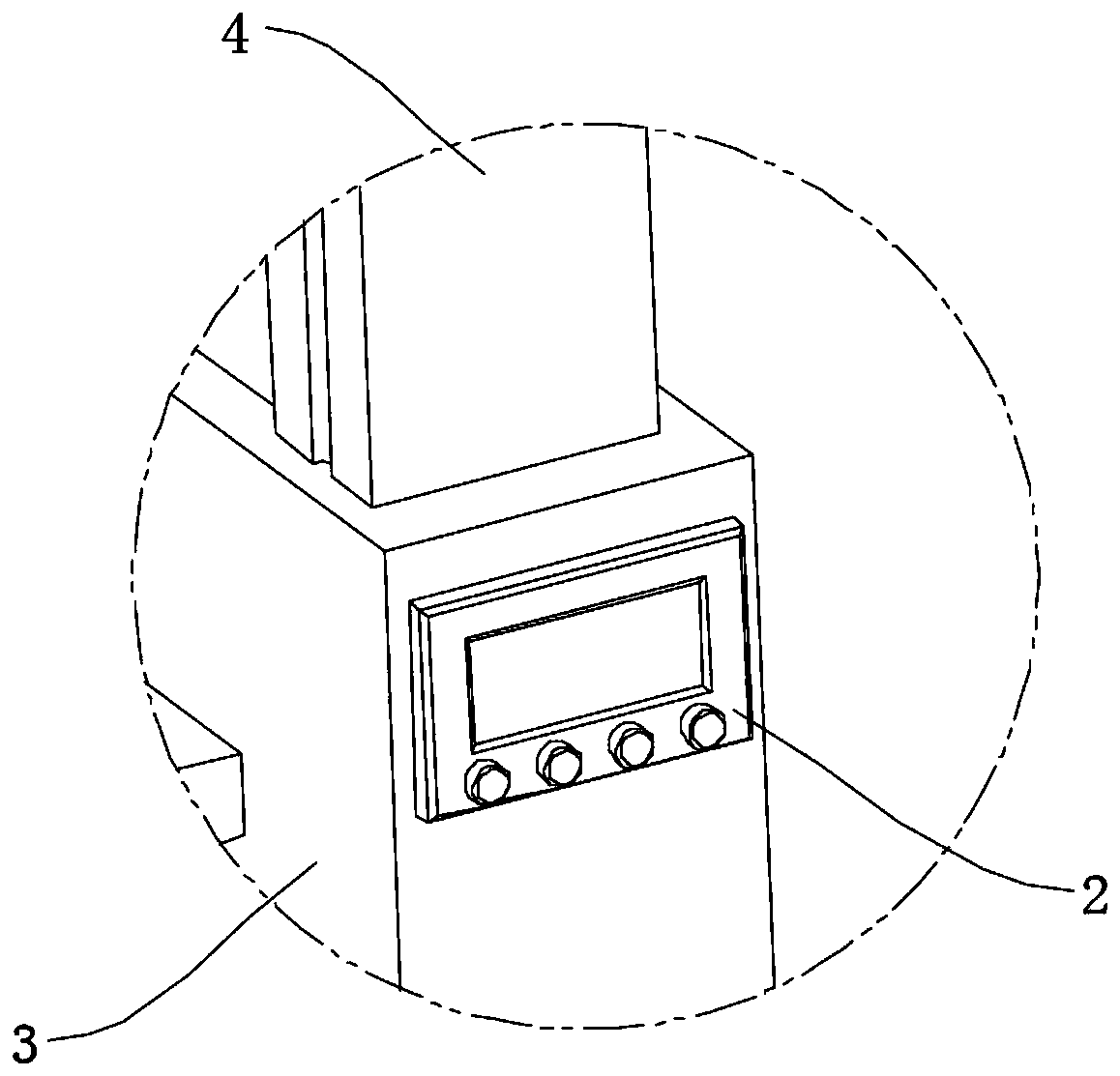

Polishing machine

InactiveCN103962916AHandheld gauze solutionResolve frictionGrinding machinesGrinding work supportsSemi automaticElectric machinery

A polishing machine relates to the field of production equipment of carbon pans. A working platform is arranged on a rack, a motor is arranged below the working platform, a speed regulating device is arranged on one side of the motor, a control panel is arranged above the working platform, the upper end of the motor is connected with a rotary disc through a rotating shaft, an upright is arranged on one side of the rotary disc, a sliding chute is formed in one side of the upright corresponding to the rotary disc, and a fixing rod is movably arranged in the sliding chute. The rotary disc is a cylinder, and polishing material layers are arranged on the side surface and at the upper end of the rotary disc respectively. The polishing material layers are made of a steel SK4. The polishing machine is simple in structure, effectively solves the problem that a worker needs to take gauze or a polishing block to polish beside a machine through the relative friction, is good in polishing effect, saves time and labor, and achieves semi-automatic polishing in the true sense.

Owner:KUNSHAN SHANGDAZHI MACHINERY

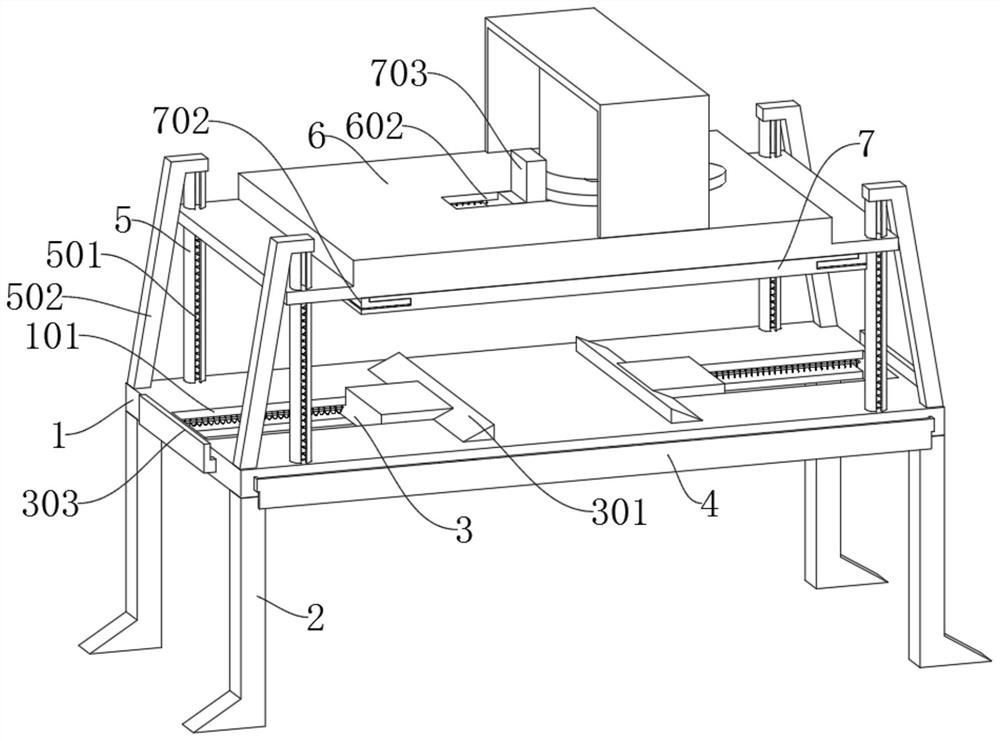

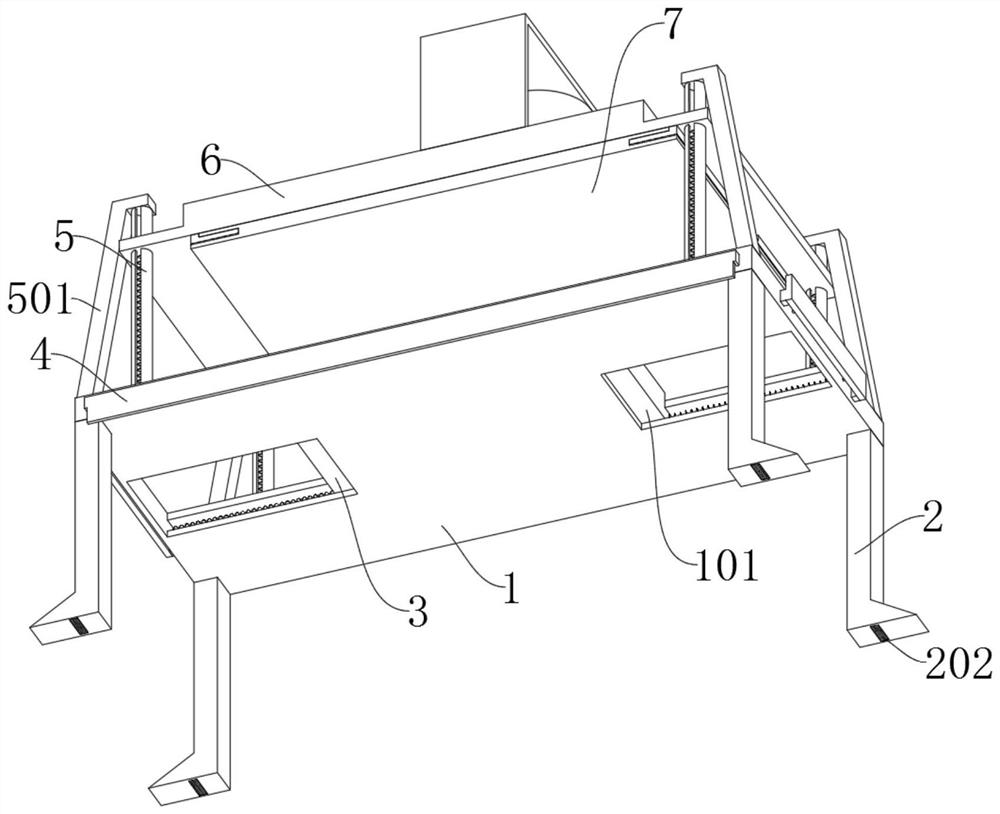

Joinery board grinding device for furniture production and processing

ActiveCN111843680AEasy to fixEffective clampingGrinding work supportsPlane surface grinding machinesManufacturing engineeringMechanical engineering

The invention provides a joinery board grinding device for furniture production and processing, and relates to the technical field of grinding devices. The device aims to solve the problems that whenan existing joinery board grinding device is used, an adjusting and fixing structure of the device is inconvenient to operate and joinery boards in different sizes always need to be adjusted and fixedwith great efforts. The device comprises a main body and supporting pieces, wherein the main body is of a rectangular plate-shaped structure and is subjected to dull polishing; the supporting piecesare located at the bottom corners of the main body, and the top ends of the supporting pieces are fixedly connected with the bottom corners of the main body; side pieces are located at the front end of the main body, and clamping plates of the side pieces are installed in side grooves. Stress parts are used for being installed in guide grooves in the two ends of the main body, so that when a joinery board is placed on the main body and needs to be fixed, springs can directly push the stress parts to move, the stress parts can directly drive ejecting parts to eject and fix the joinery board, and then the joinery board is more convenient to fix.

Owner:广东中泰家具集团有限公司

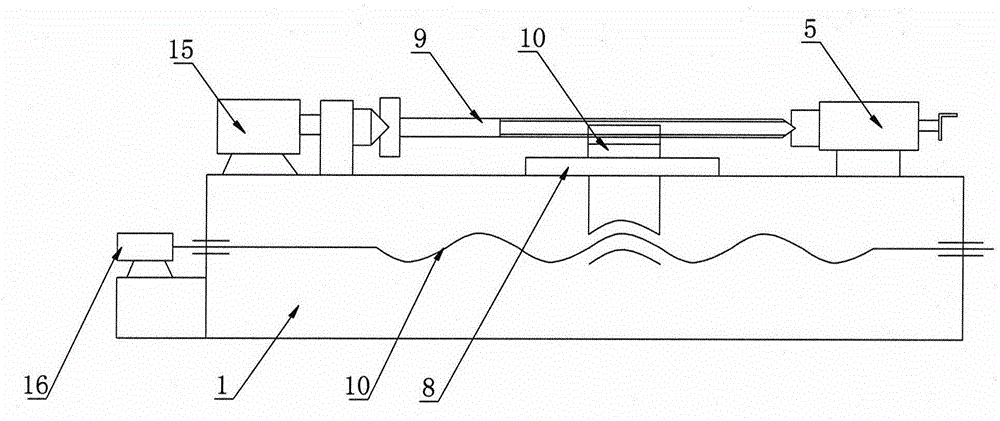

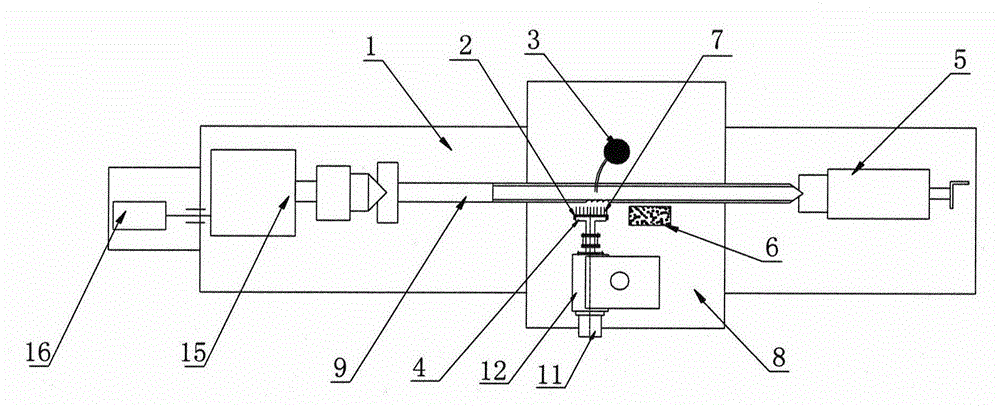

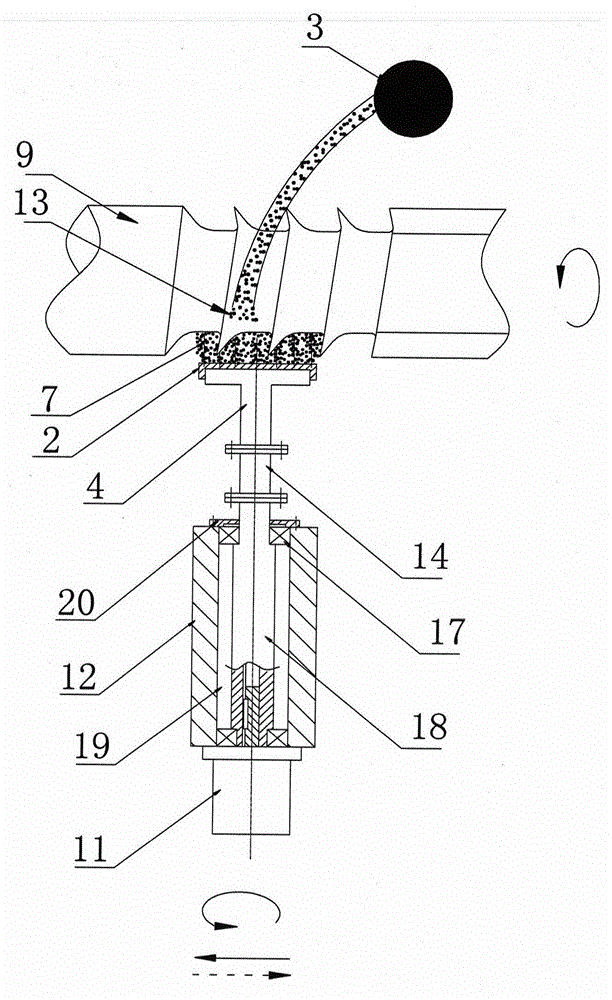

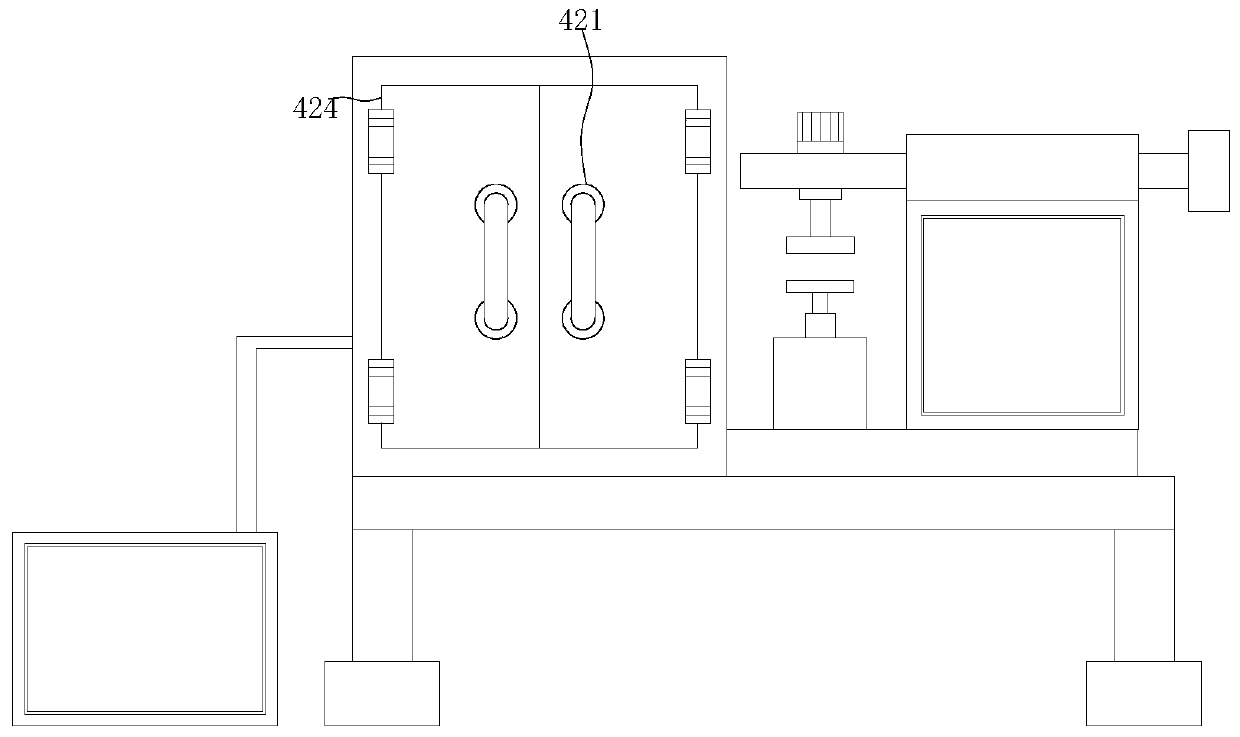

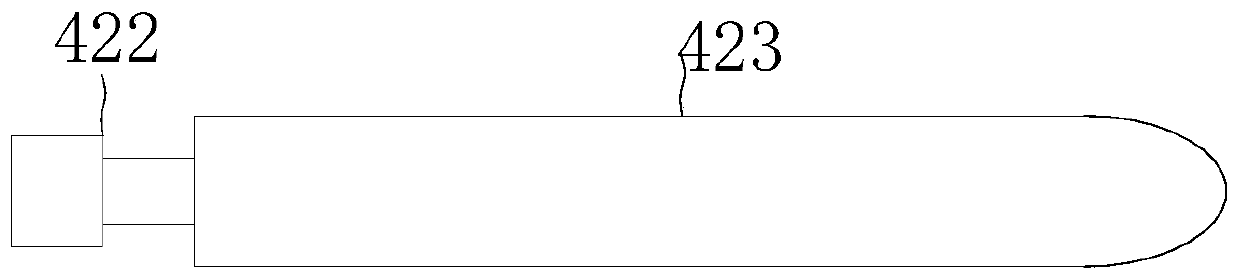

Ultrasonic vibration magneto-rheological brush polishing machine for non-magnetic screws

The invention discloses an ultrasonic vibration magneto-rheological brush polishing machine for non-magnetic screws. The polishing machine comprises a lathe body, polishing fluid with magneto-rheological fluid, an ultrasonic magnetic polishing assembly and a pump body for spraying the polishing fluid. The ultrasonic magnetic polishing assembly comprises a clamping handle, a first connecting shaft arranged in the clamping handle in a rotating mode, a motor for driving the first connecting shaft to rotate, an ultrasonic vibrator fixedly connected to the first connecting shaft, and a brush plate fixedly connected to the ultrasonic vibrator. Magnetic conduction brushes are arranged on the brush plate. A magnetic field generator is fixed to the brush plate. The ultrasonic magnetic polishing assembly can also adopt an ultrasonic vibrator fixed to the clamping handle, a wheel brush rack connected with the ultrasonic vibrator, a second connecting shaft arranged on the wheel brush rack, a magnetic field generator arranged on the second connecting shaft in a sleeving mode, and a brush plate arranged on the outer wall of the magnetic field generator. The polishing machine has the advantages that by means of an ultrasonic generator and a magnetic conduction brush plate, extremely-high surface roughness can be obtained, and elements can be ground in all directions without dead corners.

Owner:ZHEJIANG NORMAL UNIVERSITY

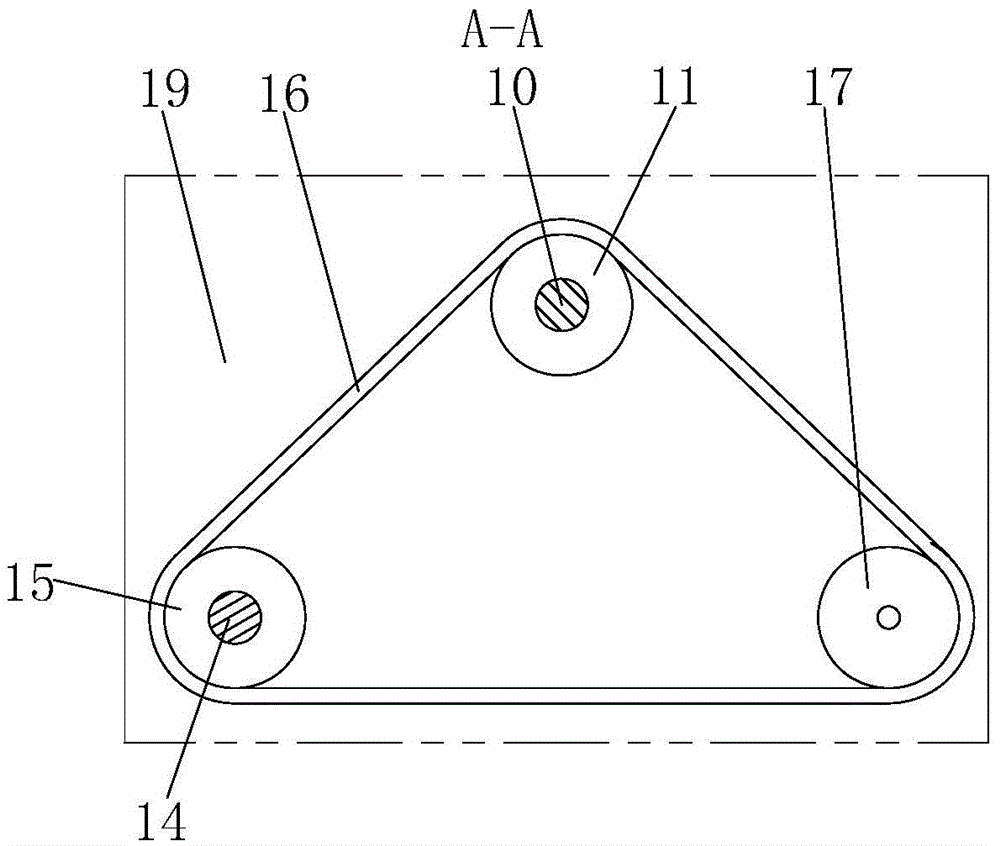

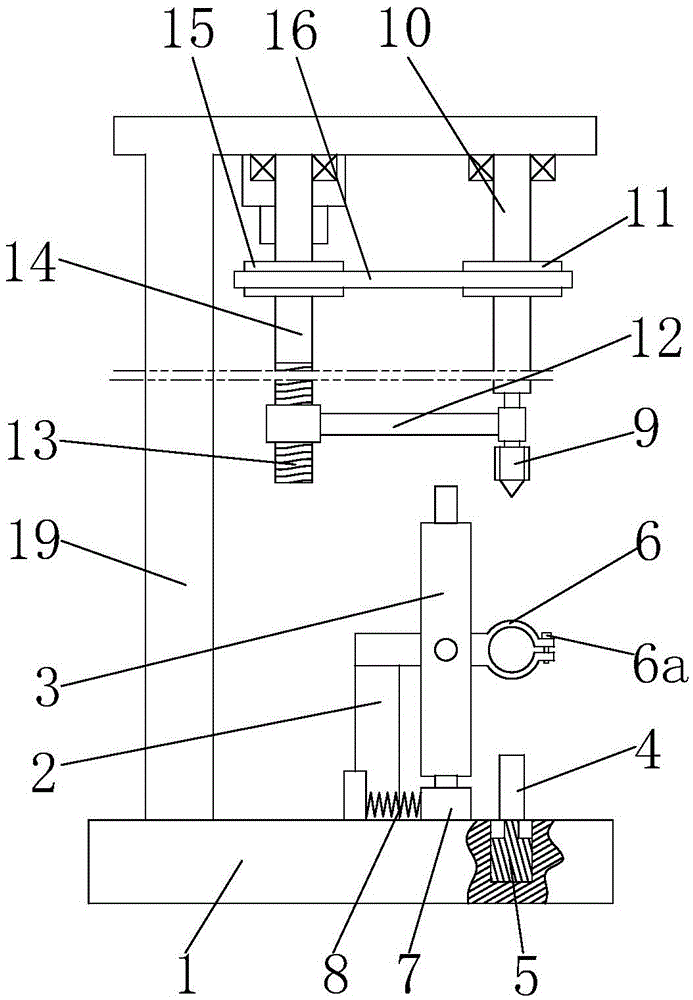

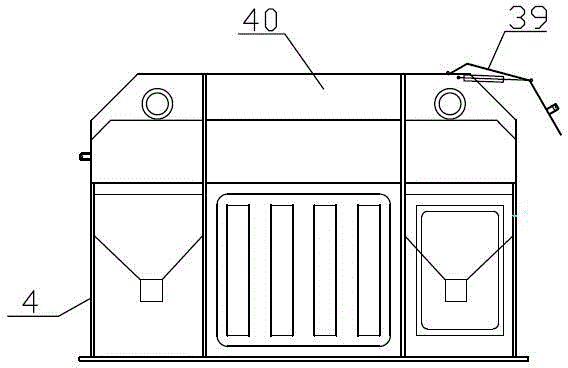

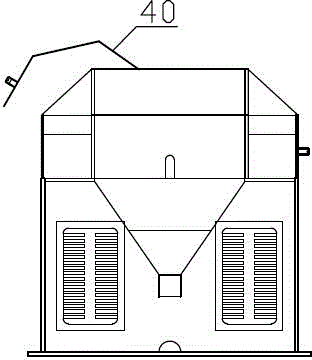

Automatic grinding machine

The invention provides an automatic grinding machine and belongs to the technical field of machines. The problem that the grinding position of an existing grinding machine cannot be adjusted is solved through the automatic grinding machine. The automatic grinding machine comprises a machine frame, a workbench, an abrasive belt and a drive motor, wherein the workbench is arranged on one side of the machine frame and used for containing a workpiece, and an adjusting assembly used for adjusting the horizontal position of the workpiece is installed on the workbench; the abrasive belt is arranged in the machine frame and partially extends out of the machine frame to make contact with the workpiece; and the drive motor is arranged in the machine frame, connected with the abrasive belt and used for driving the abrasive belt to grind the workpiece. The automatic grinding machine has the advantages that the grinding position is adjustable and the service life is long.

Owner:宁波创二代机械科技有限公司

Steel tube filling cutting equipment

ActiveCN107263109AEasy to operateGuaranteed not to deformOther manufacturing equipments/toolsMechanical engineeringSteel tube

The invention discloses steel tube filling cutting equipment. The steel tube filling cutting equipment comprises a strip-shaped bearing pedestal, wherein a steel tube inner filling structure is arranged at one end of the upper surface of the strip-shaped bearing pedestal; a cutting mechanism is arranged at the other end of the upper surface of the strip-shaped bearing pedestal; a waste residue collecting mechanism is arranged on the center of the upper surface of the strip-shaped bearing pedestal; and a moving mechanism is arranged on the lower surface of the strip-shaped bearing pedestal. The steel tube filling cutting equipment has the beneficial effects that operation is relatively simple, manual holding is only required, labor intensity is relieved, cutting efficiency is improved, and the cut end surface is guaranteed to be not deformed during cutting; and meanwhile, the cut end surface also can be effectively grinded, so that cutting of steel tubes of different diameter sizes can be adapted.

Owner:湖北国通领驭建设集团有限公司

Glass processing equipment

InactiveCN112388434ANot easy to dropGood processing effectEdge grinding machinesGrinding carriagesPhysicsPiston

The invention discloses glass processing equipment which comprises a bottom plate. A left vertical plate is fixedly connected to the outer wall of the top of the bottom plate; a mounting opening is formed in the outer wall of one side of the left vertical plate; a first hydraulic cylinder is arranged on the inner wall of the mounting opening; a disc is arranged at one end of a piston of the firsthydraulic cylinder; a rotating disc is rotatably connected to the outer wall of the disc through a bearing; a clamping mechanism is arranged on the outer wall of one side of the rotating disc; a rightvertical plate is fixedly connected to the outer wall of the top of the bottom plate; a fixing cylinder is fixedly connected to the outer wall of one side of the right vertical plate; a rotating shaft is rotatably connected to the inner wall of the fixing cylinder through a bearing; a clamping plate is fixedly connected to one end of the rotating shaft; a limiting mechanism is arranged on the outer wall of one side of the clamping plate; and mounting grooves are formed in the outer walls of the tops of the left vertical plate and the right vertical plate. According to the glass polishing equipment provided by the invention, glass is not prone to falling off during polishing, a machining effect is better, and the rotating direction of the glass can be adjusted without the need for taking down the glass.

Owner:临泉县蓝天钢化玻璃有限公司

Grinding device for mechanical parts

InactiveCN112846963AEffective sandingConvenient grinding operationRevolution surface grinding machinesGrinding drivesMechanical componentsGear drive

The invention discloses a grinding device for mechanical parts, and relates to the technical field of mechanical part machining. The grinding device for the mechanical parts comprises a supporting seat, wherein a group of clamping mechanisms is fixed on the supporting seat, a mechanical pipe fitting is fixed between the two clamping mechanisms, the two clamping mechanisms are symmetrically distributed about the mechanical pipe fitting, a grinding mechanism is fixed to one surface of the supporting seat, and connected outside the mechanical pipe fitting in a sleeved mode, and the grinding mechanism comprises a transmission assembly and a sleeve. According to the invention, a first single-shaft motor in the transmission assembly is controlled to run, so that the first single-shaft motor drives a threaded lead screw to rotate, a plurality of grinding blocks are driven to move along the mechanical pipe fitting to be ground in the mode of lead screw transmission, the plurality of grinding blocks can be driven by a double-shaft motor to rotate in the mode of gear transmission, then effective grinding treatment is carried out on the mechanical pipe fitting, and the grinding operation for the mechanical pipe fitting is simpler and more convenient, so that the grinding efficiency for the mechanical pipe fitting is increased, and manpower consumption in the grinding process for the mechanical pipe fitting is reduced.

Owner:广州市魅雅特贸易有限公司

Multifunctional automobile hub grinding device

InactiveCN109333289AEffective sandingFast and effective sanding of hubs for fasteningGrinding carriagesGrinding drivesEngineeringOperating time

The invention discloses a multifunctional automobile hub grinding device in the technical field of automobile hubs. The multifunctional automobile hub grinding device comprises a bottom plate. A baseplatform is fixedly connected to the center of the top of the bottom plate. An electromagnetic suction plate is fixedly connected to the top of the base platform. A hub to be ground is placed on the top of the electromagnetic suction plate. An external threaded rotary rod is movably connected to the right side of the top of the bottom plate through a bearing. A limiting slide bar is fixedly connected to the right side of the top of the bottom plate. A rotating motor I is mounted on the top of the right end of the bottom plate. The multifunctional automobile hub grinding device can conduct fixing on the hub to be ground quickly and effectively, and the pre-fixing time before grinding is shortened to a great extent. Meanwhile, the multifunctional automobile hub grinding device can conduct effective grinding on the top and the side face of the hub simultaneously. A user does not need to grind the top and the side face of the hub respectively. The operating time is shortened. The multifunctional automobile hub grinding device can adjust the grinding angle of the side face, so that the hub has more selectable angles. Meanwhile, the multifunctional automobile hub grinding device is suitable for different sizes and thicknesses of hubs and can conduct effective grinding on various types of sizes of hubs.

Owner:含山县天宇机械铸造厂

Hardware plate double-face grinding device based on clamping turnover mechanism

PendingCN112720115AImprove practicalityEffective sandingGrinding carriagesGrinding drivesElectric machineryScrew thread

The invention relates to the technical field of grinding equipment, in particular to a hardware plate double-face grinding device based on a clamping turnover mechanism. The device comprises a clamping turnover structure, wherein the clamping turnover structure comprises a working bin; a middle frame is hinged to the upper end of the working bin; a clamping turnover plate is installed in the working bin; clamping frames are installed at the side ends of clamping plates; clamping lead screws are arranged in clamping frames; the clamping lead screws are in threaded connection with the clamping frames; clamping motors are arranged at one side ends of the clamping lead screws correspondingly; the clamping motors are located on the outer side of the working bin; the bottoms of the side ends, opposite to the clamping plates, of the clamping motors are movably connected through connecting rods; and rotating rods are symmetrically arranged on the surfaces of the side ends of the clamping plates. By means of the clamping turnover structure, the clamping turnover structure can enable a hardware plate to be clamped in multiple sizes, overturning is conducted after one side of the hardware plate is ground, the other side of the hardware plate can be synchronously ground, and the grinding efficiency is improved.

Owner:魏琦

Grinder for part machining

InactiveCN108515396AImprove processing efficiencySimple structureGrinding drivesLapping machinesInlet valveMachine tool

The invention belongs to the technical field of machine tools or devices suitable for grinding part planes, and particularly discloses a grinder for part machining. The grinder comprises a rack, a transmission unit, a motor and two grinding units; the grinding units comprise telescopic rods and grinding discs, and first gears are arranged on the telescopic rods; the transmission unit comprises a rotating shaft and a piston cylinder; a plunger is slidably connected into the piston cylinder; a closed curved groove is formed in the inner wall of the rotating shaft, and a push rod is arranged on the plunger; a water inlet pipe and a water drainage pipe are connected to the piston cylinder, a one-way water inlet valve is arranged on the water inlet pipe, and a one-way water drainage valve is arranged on the water drainage pipe; a second gear and a fixing ring are arranged on the rotating shaft; and a plurality of clamping mechanisms are arranged on the fixing ring and located between the two grinding units, and comprise cross rods fixed to the fixing ring and clamps arranged on the cross rods and used for clamping parts. By using the grinder for part machining, the two opposite side faces of the parts can be ground simultaneously, the multiple parts can be ground simultaneously, and the efficiency is improved.

Owner:重庆市耀植机械有限责任公司

Edge polishing device for office furniture production

PendingCN110842757AImprove dust removal effectHarm reductionEdge grinding machinesGrinding carriagesPolishingEngineering

The invention discloses an edge polishing device for office furniture production. The edge polishing device for office furniture production comprises a worktable. Second hydraulic rods which are distributed in an equally spaced manner are fixed to the outer wall of the top of the worktable, a same transverse plate is arranged on the outer walls of the tops of the second hydraulic rods, a dust suction disc is arranged on the outer wall of the bottom of the transverse plate, a fan is fixed to the outer wall of the top of the transverse plate, a same dust suction pipe is arranged at the input endof a fan and on the inner wall of one side of the dust suction disc, a dust suction box is arranged on the outer wall of the top of the worktable, a same dust guide pipe is arranged on the inner wallof the top of the dust suction box and at the output end of the fan, and a protecting mechanism and a polishing mechanism are arranged on the outer wall of the top of the worktable. By arranging thedust suction disc, the dust suction pipe, the fan and the dust suction box, when a panel is polished, the fan is started, and the dust suction disc imports dust and relatively small chips into the dust suction box through the dust suction pipe and the dust guide pipe, so that the dust collecting effect of the device is improved and the damage of dust to the environment and staff is reduced.

Owner:湖北天瑞木业股份有限公司

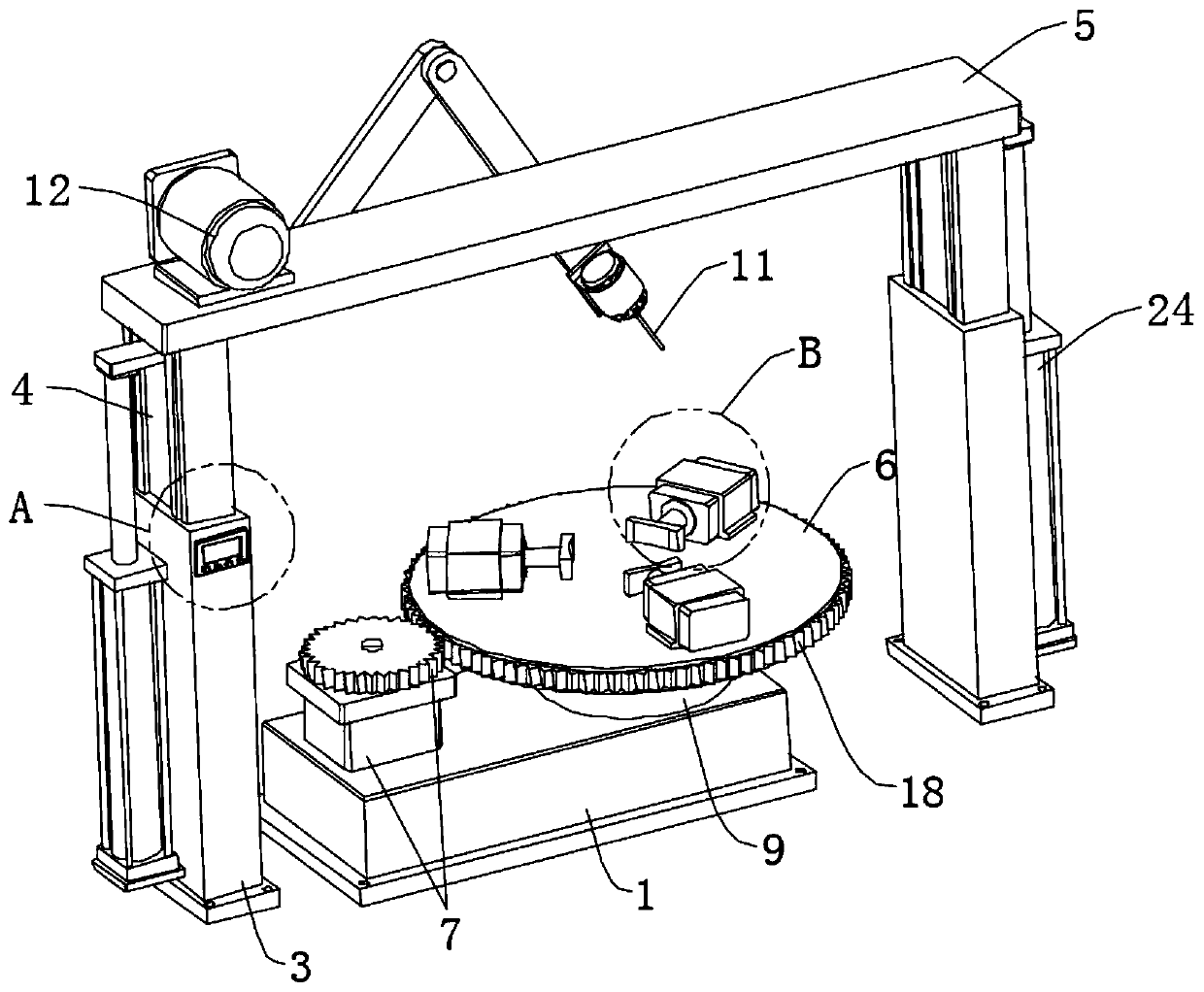

Grinding equipment for plastic product processing

InactiveCN111113197AStable clampingEasy to polishEdge grinding machinesGrinding drivesElectric machineryIndustrial engineering

The invention relates to the technical field of plastic product processing, in particular to grinding equipment for plastic product processing. A base is included. A controller, a supporting frame, arotation mechanism and a grinding mechanism are further included. The top of the supporting frame is provided with a lifting plate through sliding strips in a sliding manner. The rotation mechanism comprises a machining table, a drive assembly and three clamping assemblies. The grinding mechanism comprises a grinding bar, a stepping motor and a connecting rod assembly. The stepping motor, the drive assembly and the three clamping assemblies are electrically connected with the controller. Compared with existing grinding equipment, the grinding equipment for plastic product processing can rapidly adjust the grinding angle, meanwhile, plastic products different in modeling and shape or the local uneven positions of the surfaces of the plastic products can be effectively ground, the grinding speed is high, the grinding efficiency is higher, meanwhile, the grinding cost is reduced, and the practicability of the equipment is further improved.

Owner:嘉善金嘉塑业有限公司

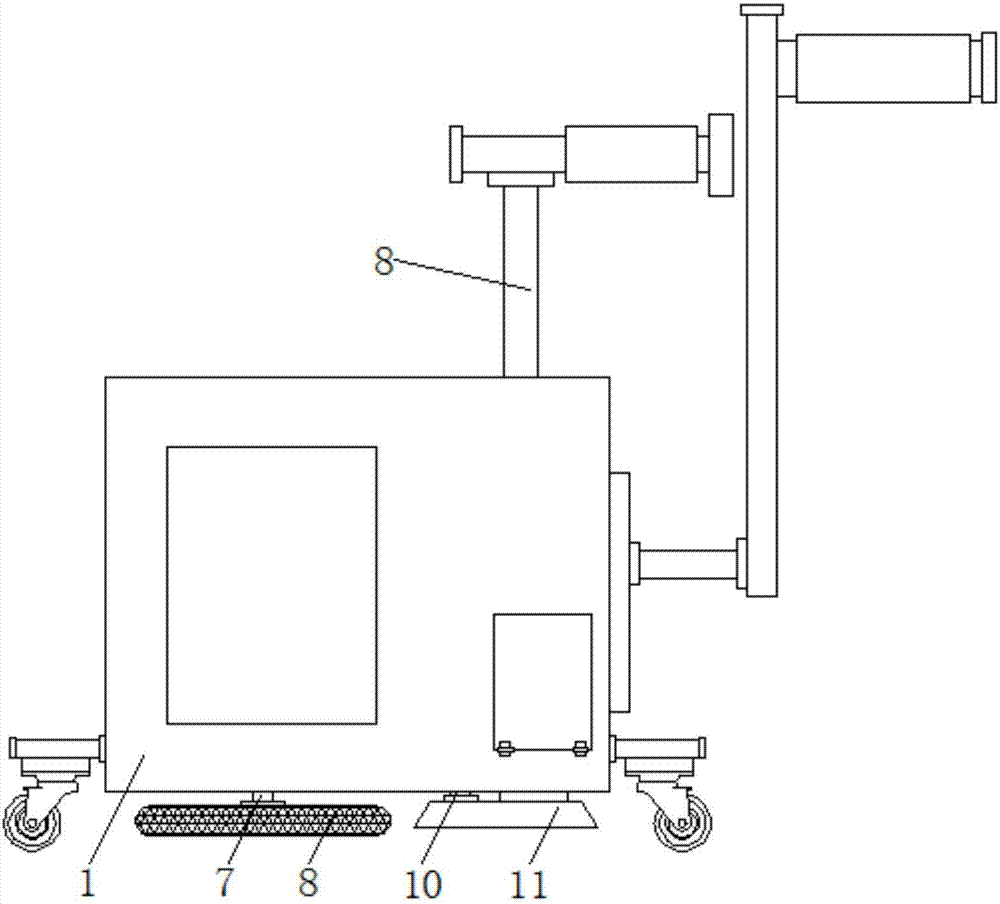

Conveniently used floor grinder

PendingCN107457636AEasy to useReduce the burden onPlane surface grinding machinesGrinding/polishing safety devicesArchitectural engineeringGrinding wheel

The invention relates to the technical field of floor grinders, and discloses a conveniently used floor grinder which comprises a box. A top plate is fixedly connected between two sides of the inner wall of the box, a bottom box is fixedly connected between the right side of the bottom of the top plate and the right side of the bottom of the inner wall of the box, a bottom plate is slidably connected between the left side of the bottom box and the left side of the inner wall of the box, the bottom of the bottom plate is fixedly connected with a motor box, the bottom of the inner wall of the motor box is fixedly connected with a motor, an output shaft of the motor is fixedly connected with a central shaft through a coupler, one end, far away from the output shaft of the motor, of the central shaft sequentially penetrates the motor box and the box and extends to the bottom of the box, and one end of the central shaft extending to the bottom of the box is fixedly connected with a grinding wheel. The conveniently used floor grinder prevents damage in grinding, decreases unnecessary waste and is quite convenient to use and move, simple in structure and high in practicability.

Owner:安吉晶圣光伏发电有限公司

Jeans multi-pattern hole breaking device for garment processing

InactiveCN110924031AEffective Hole TreatmentEfficient replacementPattern makingUsing liquid separation agentEngineeringGrinding wheel

The invention discloses a jeans multi-pattern hole breaking device for garment processing, and relates to the technical field of jeans multi-pattern hole breaking. The jeans multi-pattern hole breaking device for garment processing comprises a supporting platform, wherein a hole breaking box is arranged on the outer surface of the top of the supporting platform; a partition plate is mounted on theinner wall of the hole breaking box in a welding mode; a hole breaking mechanism is arranged on the outer surface of the top of the partition plate; two sets of second connecting blocks which are symmetrically designed are mounted on the outer surface of the bottom of the partition plate in the welding mode; a dust collection mechanism is arranged on the outer surface of the bottom of the partition plate; and a mounting plate is mounted on the outer surface of the top of the supporting platform in the welding mode. According to the jeans multi-pattern hole breaking device for garment processing, hole breaking treatment can be carried out on jeans more effectively, hole breaking grinding wheels can be replaced more effectively, multi-pattern hole breaking treatment can be carried out on the jeans, the working efficiency is improved, the environment is further protected against dust pollution, and the cleanness of air in an operation space is protected.

Owner:湖州拉姆蕾姆服饰有限公司

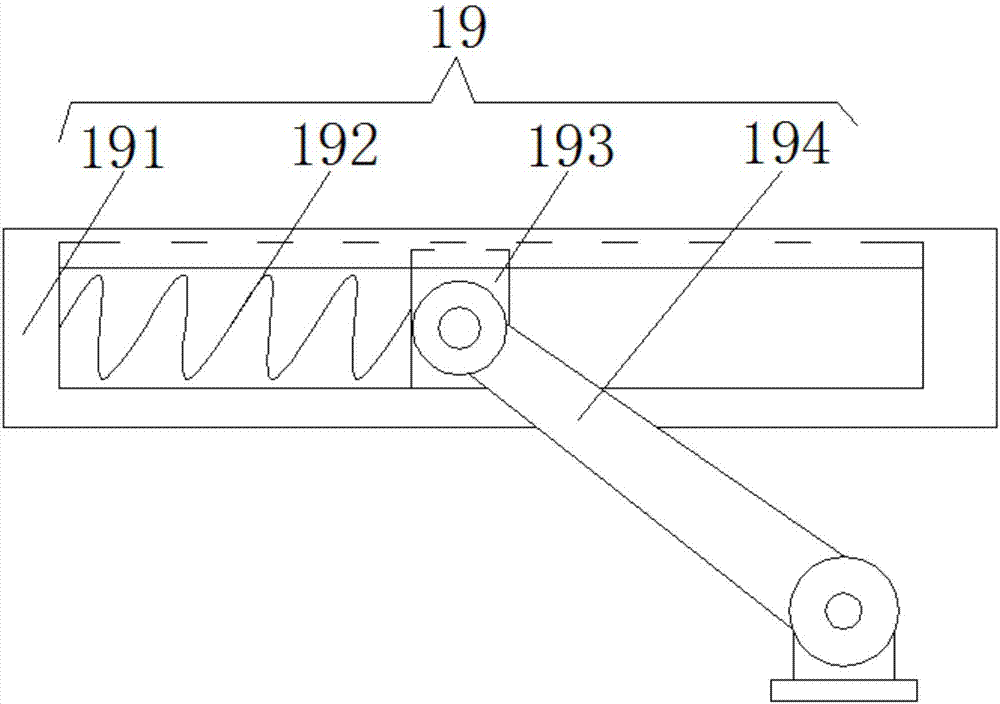

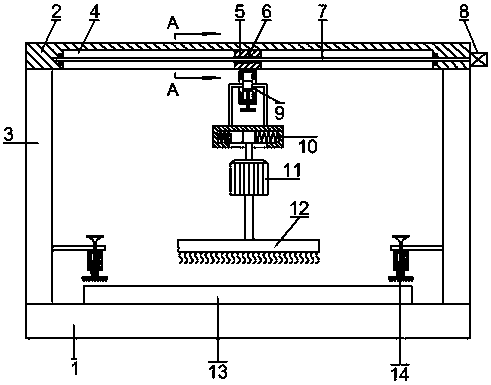

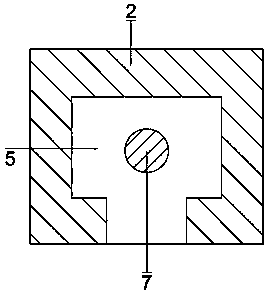

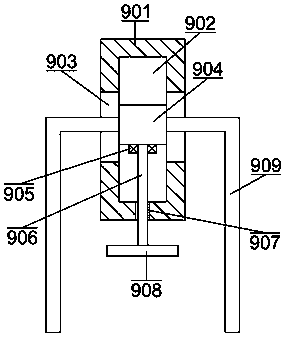

Woodwork processing and manufacturing equipment having partial reciprocating sanding function

PendingCN109290891AReduce widthChange sanding heightEdge grinding machinesGrinding carriagesReciprocating motionEngineering

The invention discloses woodwork processing and manufacturing equipment having a partial reciprocating sanding function. The equipment comprises a bottom plate and a top plate; two ends of the bottomplate are symmetrically and fixedly connected with two vertical plates; the top plate is fixedly connected with the top ends of the two vertical plates; a moving slot of which the opening faces down is formed in the top plate; a moving block is arranged in the moving slot; a horizontal threaded through hole is formed in the moving block; the interior of the horizontal threaded through hole is in threaded connection with a horizontal threaded rod; two ends of the horizontal threaded rod are rotatably connected with two ends of the moving slot correspondingly; and the right end of the horizontalthreaded rod is fixedly connected with an output shaft of a motor. The equipment disclosed by the invention has the beneficial effects that horizontal reciprocating motion of a reciprocating slidingblock is realized by utilizing matching of an electromagnet into which pulse current is switched and a spring to drive a sanding plate to do the horizontal reciprocating motion, so that the sanding effect is effectively improved; bigger burrs located somewhere are sanded for multiple times, so that flatness of woodwork is effectively guaranteed.

Owner:浙江花景木业有限公司

Wood door production process

InactiveCN104589453AQuality assuranceGuaranteed aestheticsWood working apparatusMicrocomputerMicrocontroller

The invention discloses a wood door production process, which comprises the following concrete steps that raw material plates with knags and cracks are removed, in addition, qualified raw material plates are loaded into a drying kiln to be subjected to spray steaming and heating drying; a thicknesser is used for carrying out thickness pressing on the plates, and a single chip microcomputer is used for edge straightening; a plate splicing machine is used for splicing the plates; a sanding machine is used for sanding the surfaces of the plates; a cold milling machine is used for tightly pressing the plates; a precise plate cutting saw is used for processing the plates into door edges and door core plates in specific dimensions; a groover is used for grooving the door core plates and forming mortise holes in the door edges; the door edges and the door core plates are combined together on a door installing work frame; a saw machine is used for regularly cutting the door edges; the sanding machine is used for carrying out sandblasting on the surfaces of the door edges and the surfaces of the door core plates; the precise sanding machine is used for sanding the surfaces of the door core plates and the surfaces of the door edges; sanding belts are manually used for further sanding the surfaces of the door core plates and the surfaces of the door edges which are processed by the precise sanding machine; a paint spraying device is used for spraying paint on the surfaces of the door core plates and the surfaces of the door edges; packaging and forming are carried out. The wood door production process has the advantages that the quality of the produced wood doors is high, and the appearance of the produced wood doors is attractive, and the like.

Owner:ANHUI ROYAL JOHNNIE WOODEN PROD

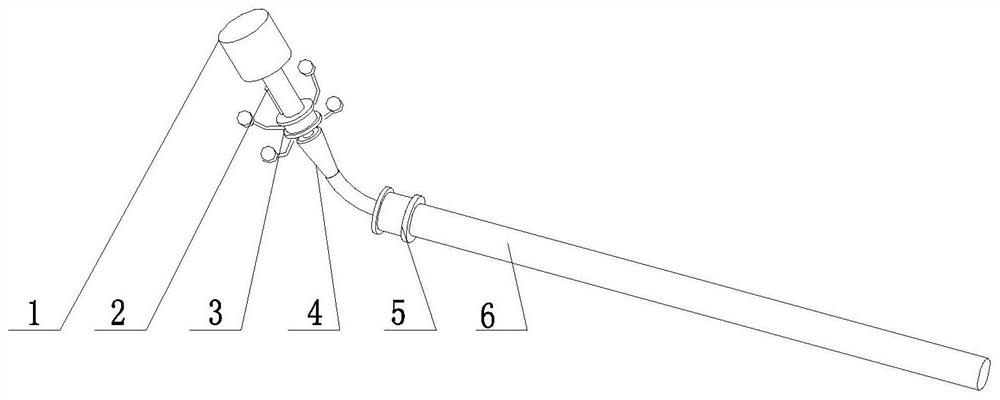

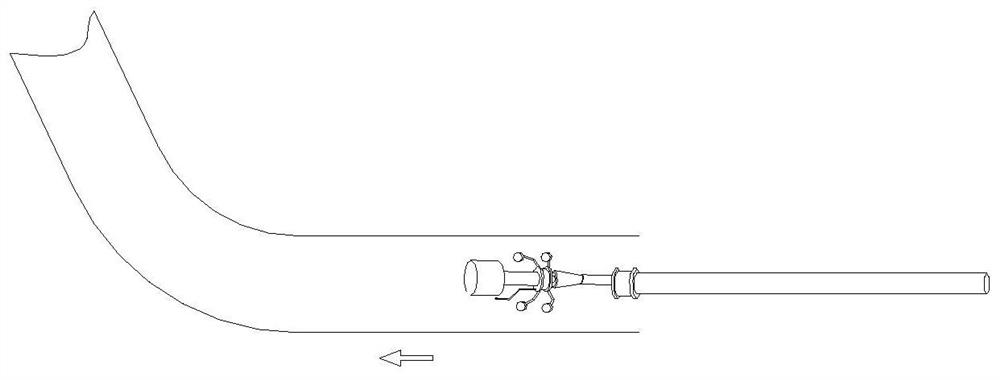

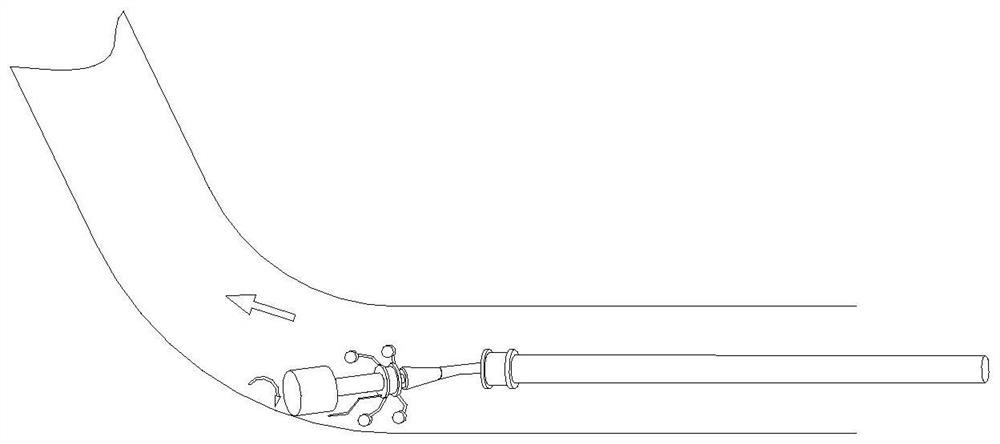

Carrier rocket guide pipe inner wall scratch detecting and polishing device and method

InactiveCN112059765AAchieve grindingRealize detectionRevolution surface grinding machinesGrinding feed controlUniversal jointElectric machinery

The invention provides a carrier rocket guide pipe inner wall scratch detecting and grinding device and method. The carrier rocket guide pipe inner wall scratch detecting and grinding device comprisesa grinding wheel, an endoscope probe, a planet wheel, a driving motor and a universal joint, wherein the grinding wheel is connected with the planet wheel through a connecting column; the endoscope probe is arranged on the connecting column; the planet wheel is connected with the driving motor; the driving motor is connected with the universal joint; and the universal joint is connected with a main pipe to realize movement turning at a pipe elbow. A grinding device and a detection device are integrated into an internal structure, a grinding head and endoscope detection are combined into a whole, linkage work is achieved, detection and grinding of a pipeline product with a bent pipe in a carrier rocket pressurization conveying system can be achieved, scrapping of the whole pipe caused by scratches generated in the machining process of the interior of the pipe and redundant objects is avoided, the machining cost of guide pipe parts is saved, and the material utilization rate is increased.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

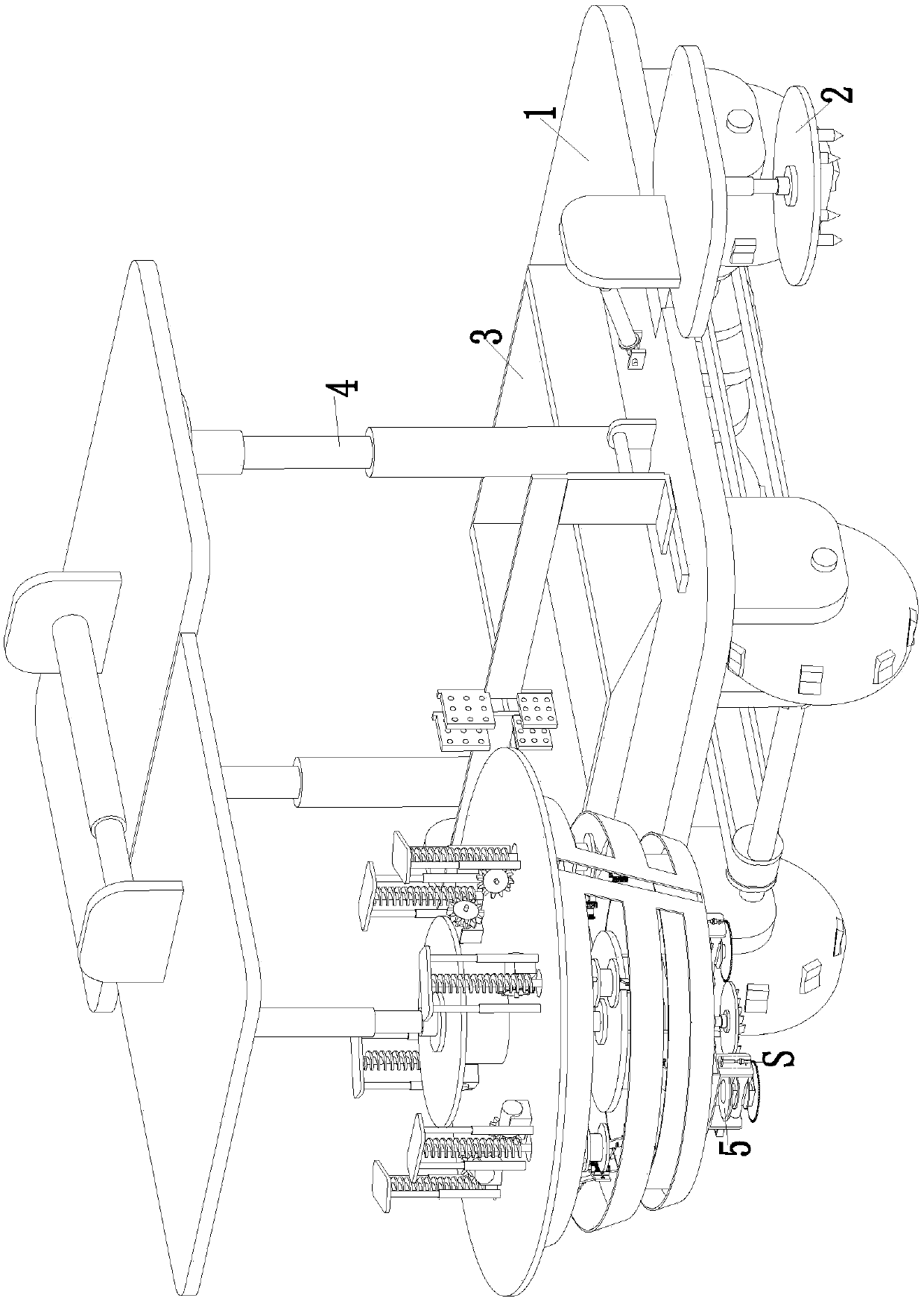

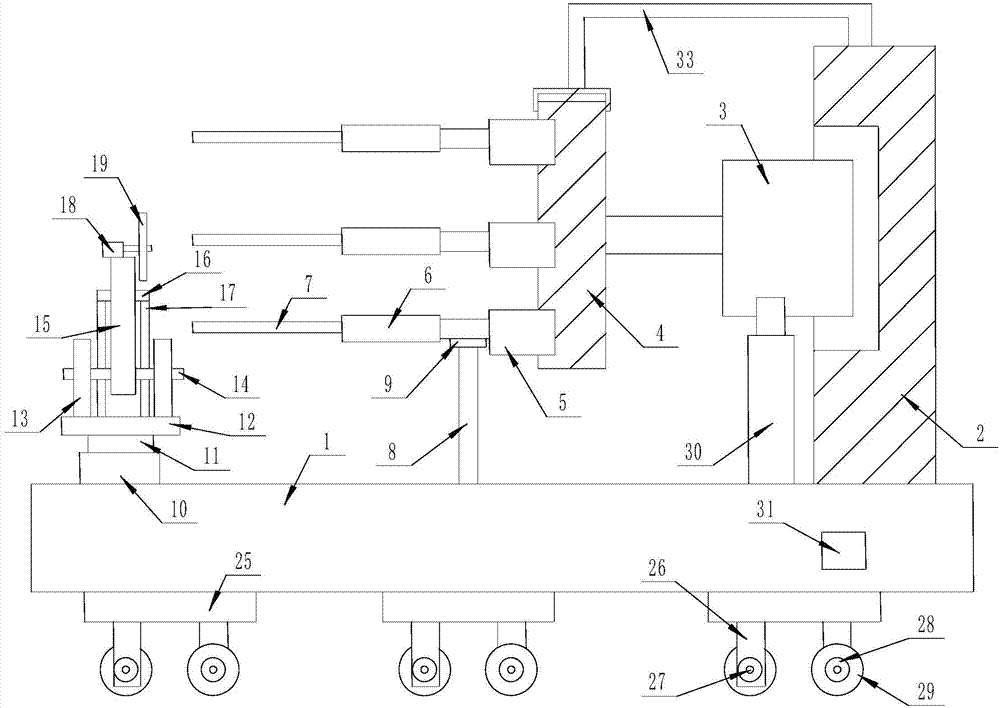

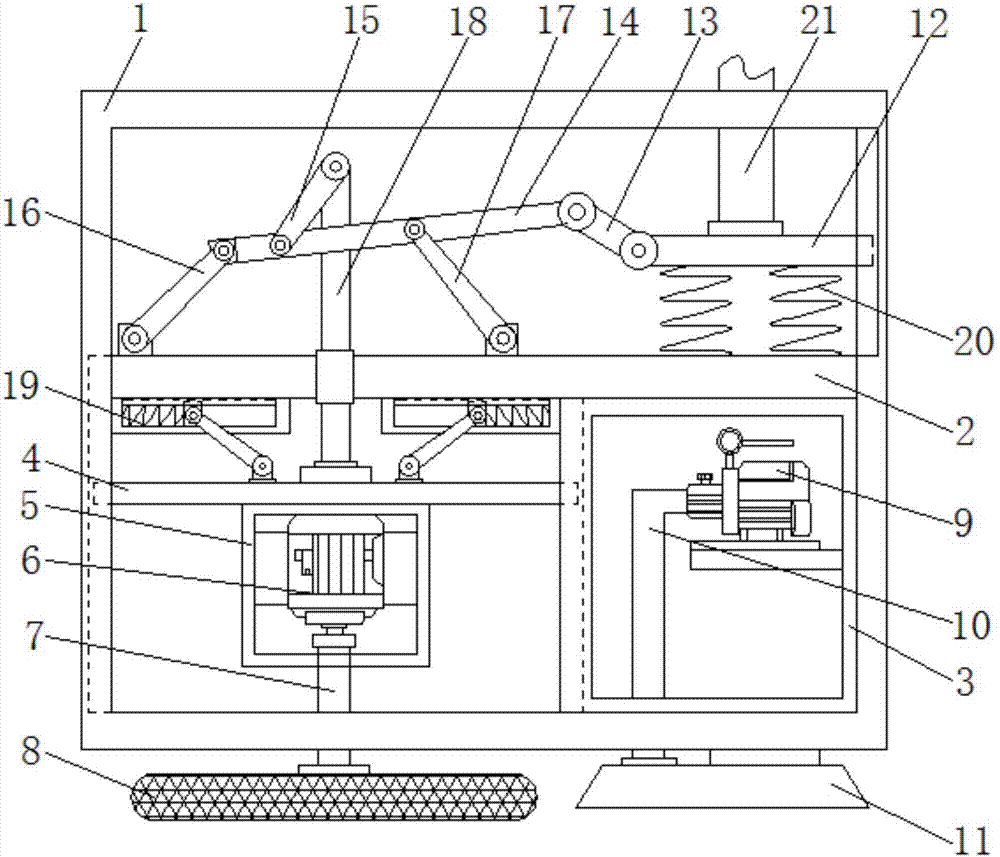

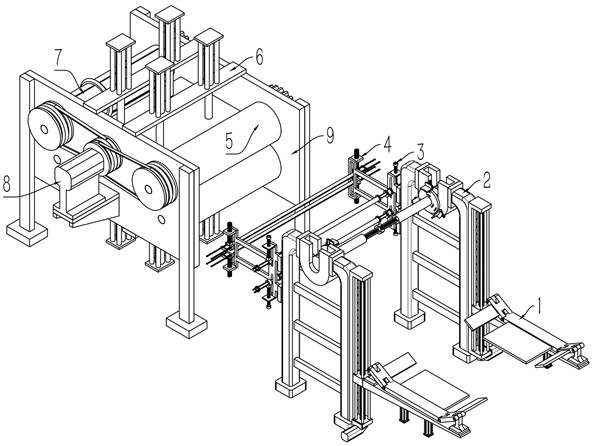

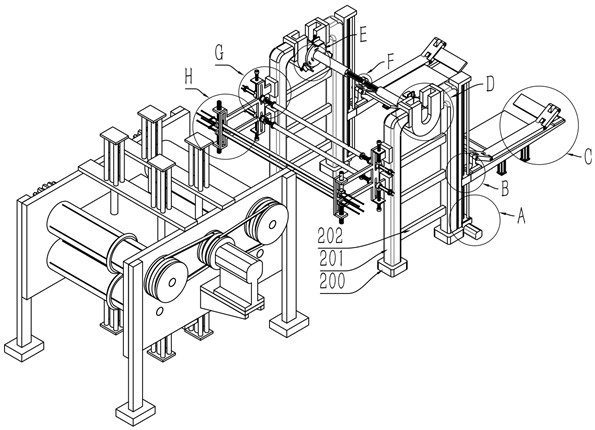

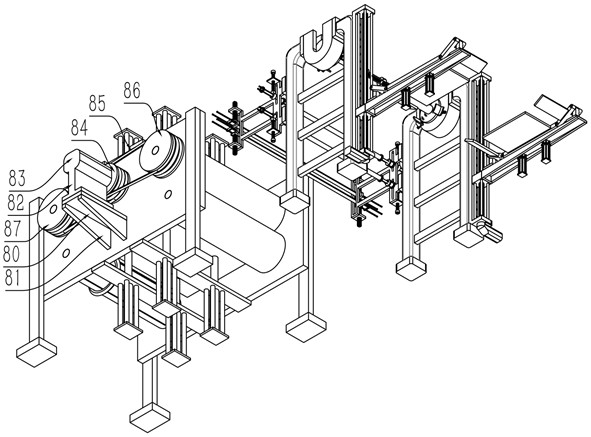

Mechanized treatment equipment for reinforcement building materials for construction of bridge pile foundation

InactiveCN107639183AImprove cutting efficiencyReduce labor intensityPlane surface grinding machinesRebarUltimate tensile strength

The invention relates to mechanized treatment equipment for reinforcement building materials for construction of a bridge pile foundation. The mechanized treatment equipment for reinforcement buildingmaterials for construction of the bridge pile foundation comprises a bottom plate, wherein a collecting box is mounted on the bottom plate; a collecting device is mounted at the front end of the bottom plate; and a cutting and polishing device are mounted at the lower end of the collecting device. The problems that in a pile foundation reinforcement treatment process on an existing construction site, top ends of cut pile foundation reinforcements require to be polished manually, the labor intensity of manual cutting on the pile foundation reinforcements is large, particles generated in the cutting process of the pile foundation reinforcements easily damage workers, potential safety hazards exist, a cutting process and a polishing process cannot be carried out simultaneously, time is wasted, manual pile foundation reinforcement conveying operation is complicated, the labor intensity is large, the working efficiency is low and the like are solved, and a function of mechanized treatmenton the pile foundation reinforcements can be fulfilled.

Owner:储小燕

Sand blasting method for aluminum alloy wheel hub

The invention discloses a sand blasting method for an aluminum alloy wheel hub. The sand blasting method comprises the steps that the prototype of the aluminum alloy wheel hub passes through a first sand blasting section, a second sand blasting section and a third sand blasting section sequentially; the sand blasting of the first sand blasting section is conducted with quartz sand of the mesh number being 10-50; the sand blasting of the second sand blasting section is conducted with quartz sand of the mesh number being 50-100; and the sand blasting of the third sand blasting section is conducted with quartz sand of the mesh number being 100-300. According to the design, the prototype of the aluminum alloy wheel hub is made to pass through the first sand blasting section, the second sand blasting section and the third sand blasting section sequentially, so that the surface of the prototype of the aluminum alloy wheel hub is not just subjected to a one-step polishing process simply and accordingly the surface smoothness of the aluminum alloy wheel hub is greatly improved. Due to the fact that the gradient sand blasting is set sequentially, the surface of the aluminum alloy wheel hub can be polished effectively, and can be adjusted step by step according to the roughness of the surface, and the effect of the smoother surface is achieved.

Owner:WUHU HUANGYAN IND

Plate flattening and cutting device for lamp post production line

ActiveCN111872702AEasy to transportImprove the flattening effectGrinding drivesShearing machinesSteel beltStructural engineering

The invention discloses a plate flattening and cutting device for a lamp post production line. The device comprises a transferring unit, a coil placing unit, a limiting unit, a surface treatment unit,a flattening unit, pressing units, a cutting unit and a driving unit; the surface treatment unit comprises a pair of fixing assemblies, two pairs of adjusting assemblies are arranged at each of the upper end and the lower end of each fixing assembly, and a treatment assembly is arranged between each pair of adjusting assemblies; the flattening unit is used for preliminarily flattening a coiled material; the pressing units are used for flattening the coiled material again; the cutting unit is used for cutting a plate; and the driving unit is used for driving the flattening unit and the cuttingunit. According to the device, steel strip coils can be conveniently transferred and conveyed, the steel strip coils can be effectively limited in the conveying process, the surfaces of the steel strip coils can be treated, and steel strips can be flattened twice, so that the flattening effect of the steel strips is improved, preset-length cutting of the steel strip coils is conveniently conducted, and the practicability is high.

Owner:SICHUAN HUATI LIGHTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com