Patents

Literature

140results about How to "Convenient grinding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

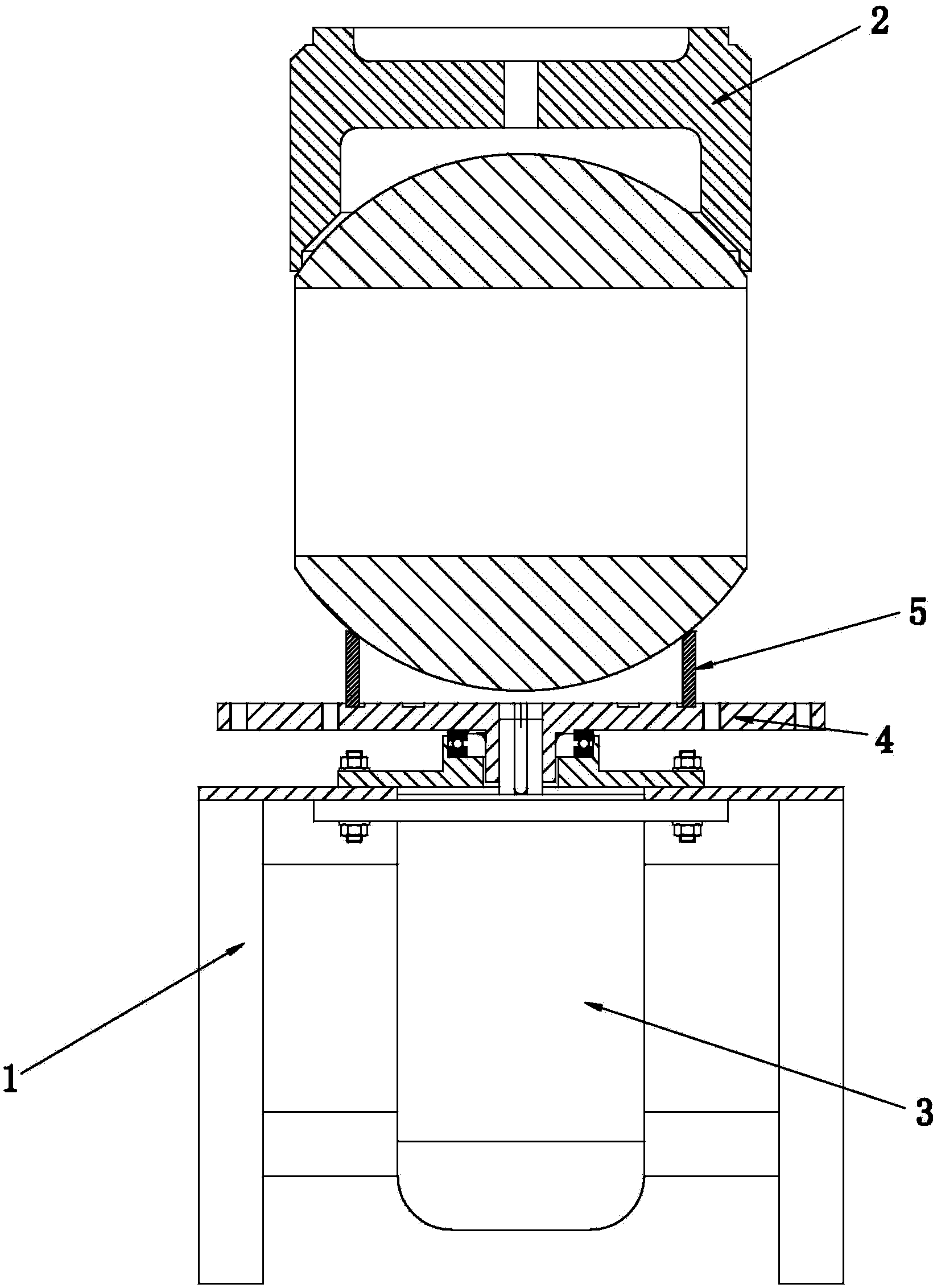

Grinding process of sealing surface of ball valve

The invention relates to a grinding process of a sealing surface of a ball valve. The grinding process comprises the steps of rough grinding, fine grinding, ultrafine grinding, and grinding and cleaning of a valve seat and a sphere, wherein a diamond paste and an engine oil mixture are adopted in the rough grinding, the particle size phi of the selected diamond paste ranges from 40mu m to 10mu m, so that the scratch removal and sphere rounding can be realized; in fine grinding, a diamond paste, kerosene and a microcrystal graphite mixture are adopted, the particle size phi of the selected diamond paste ranges from 7mu m to 5mu m, so that the primary mirror surface effect can be achieved; in the ultrafine grinding, a diamond paste and a microcrystal graphite and kerosene mixture are adopted, the particle size phi of the selected diamond paste is smaller than 5mu m, the rotating speed of the sphere is controlled to be below 5rpm to achieve the mirror surface effect, and finally the kerosene is coated on the sphere and grinding cleaning are performed to achieve a better mirror surface effect. The sphere ground and the sealing surface of the valve seat can achieve the mirror surface effect, the surface roughness can achieve Ra0.02-0.005, the operation torque is low, the service life is long, the valve seat can be adsorbed on the spherical surface of the sphere, and no leakage exists under the trial pressure of low-pressure nitrogen being 0.6Mpa.

Owner:WENZHOU ARTECH MACHINERY TECH CO LTD

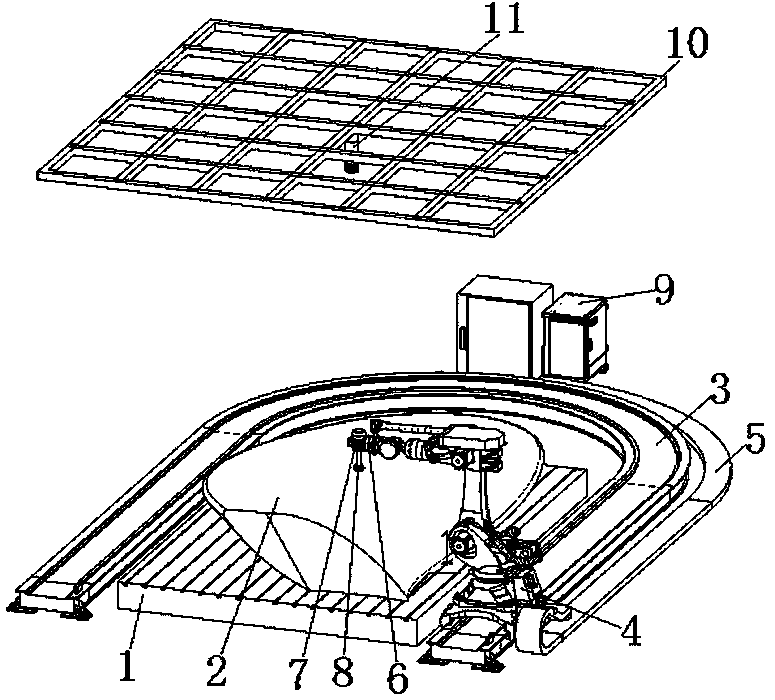

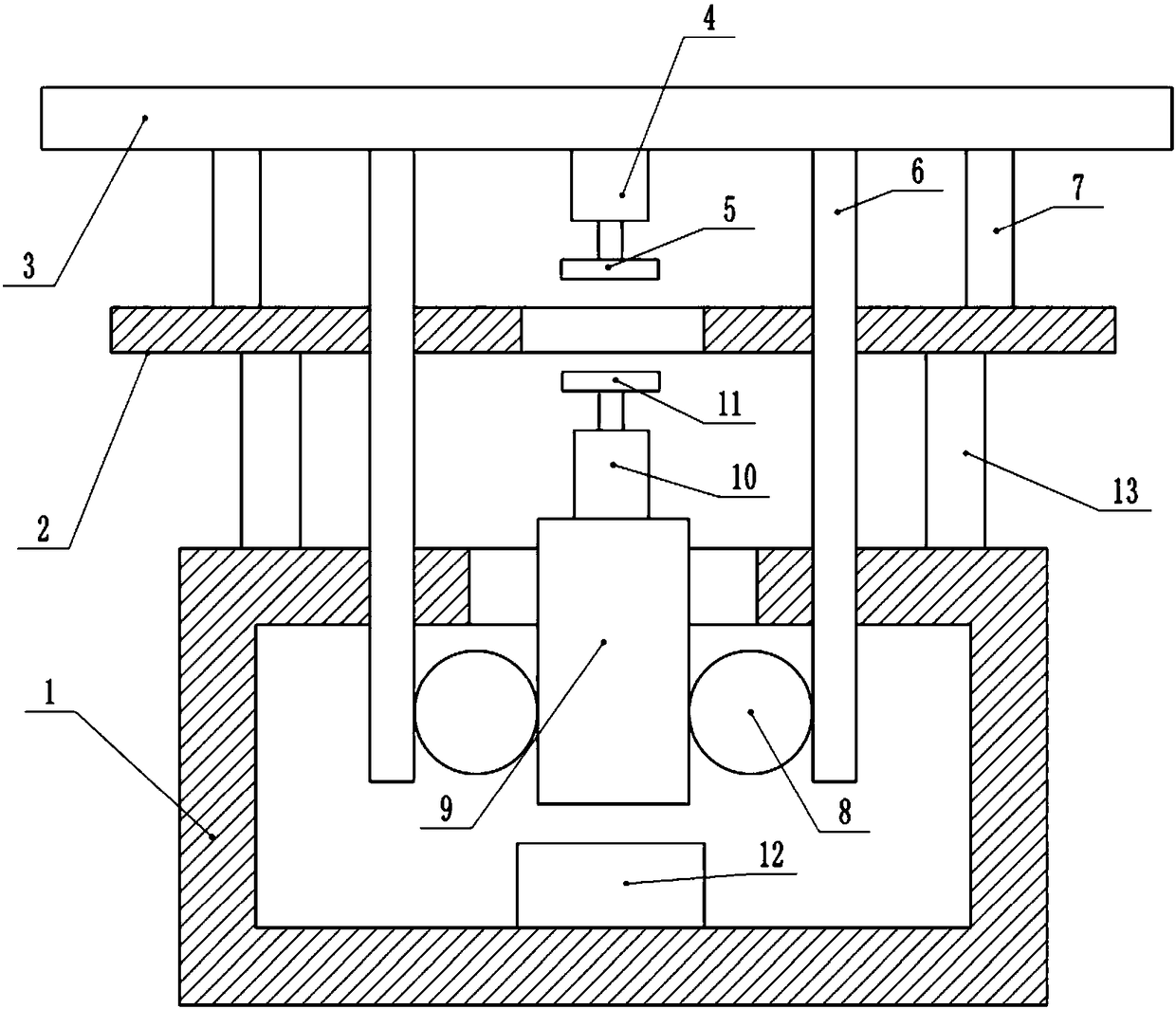

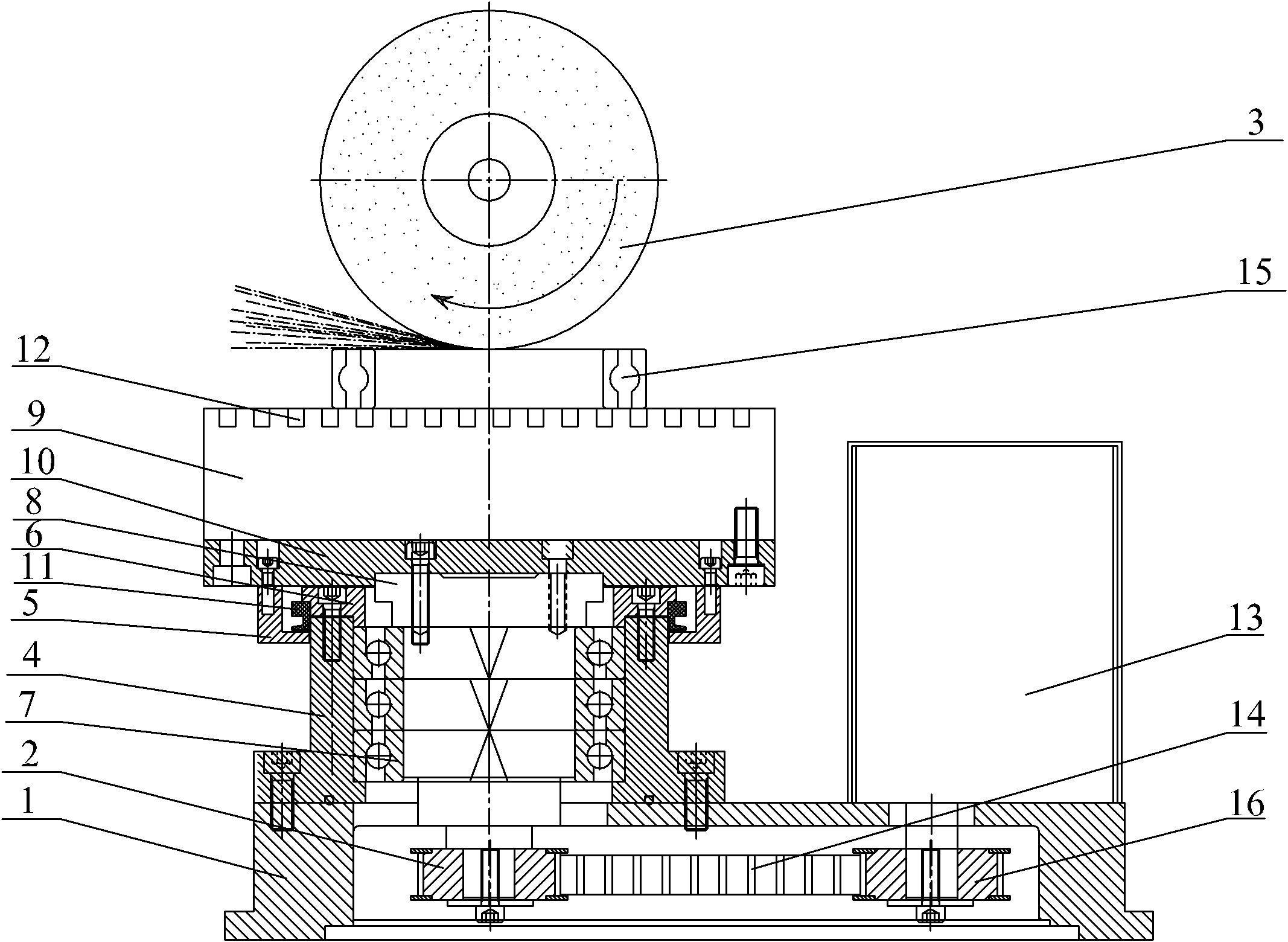

Automatic polishing system for water turbine blades

InactiveCN107866717AEffective sandingImprove sanding qualityAutomatic grinding controlGrinding machinesWater turbineControl system

The invention discloses an automatic polishing system for water turbine blades. The automatic polishing system for the water turbine blades comprises a clamping platform, an industrial robot, a polishing control system and a visual image system, and wherein the clamping platform is used for positioning and clamping the water turbine blade to be polished; the industrial robot is provided with a polishing mechanism, and the industrial robot is controlled by a polishing control system and is used for polishing the blade clamped on the clamping platform; and the polishing control system directs atthe current polishing surface of the blade to be polished and is used for planning a corresponding polishing path, then the planned polishing path is converted into a polishing action control programof the industrial robot and is conveyed to the industrial robot, and the visual image system is used for detecting the polishing quality and feeding back the polishing quality to the polishing control system. According to the automatic polishing system for the water turbine blades, the surface of the impact-type water turbine blade formed by precision casting can be provided with an automatic, intelligent and unified polishing treatment; and thus the polishing quality of the surface of the blade can be improved accurately and reliably.

Owner:SICHUAN ENG TECHN COLLEGE

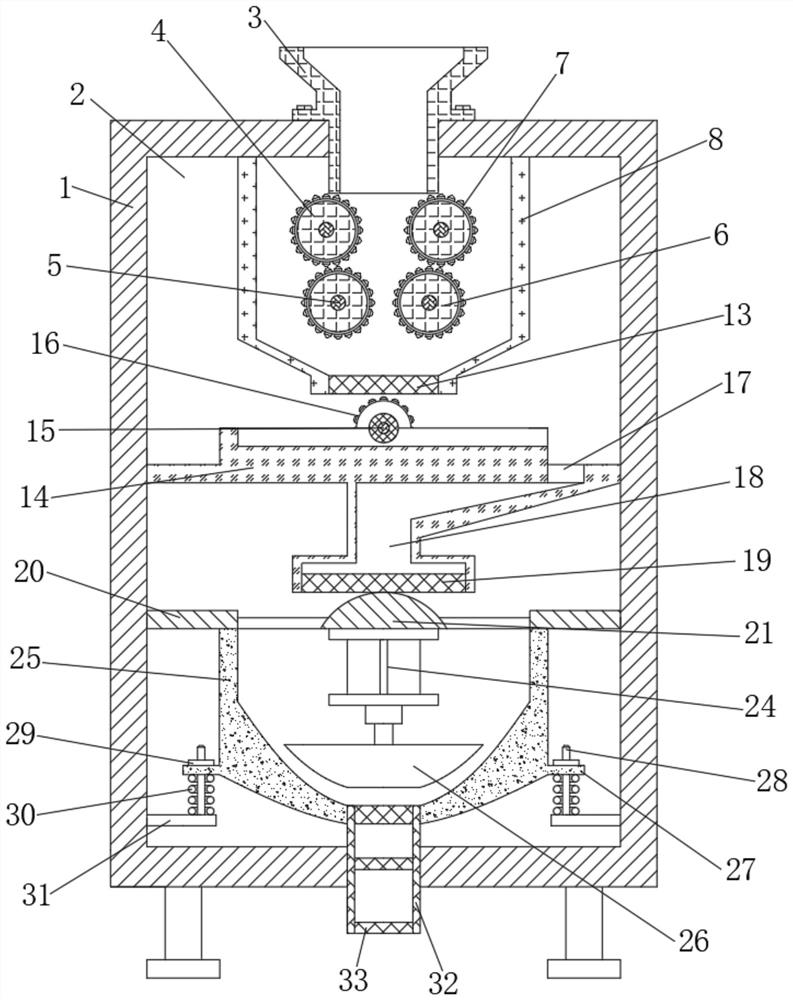

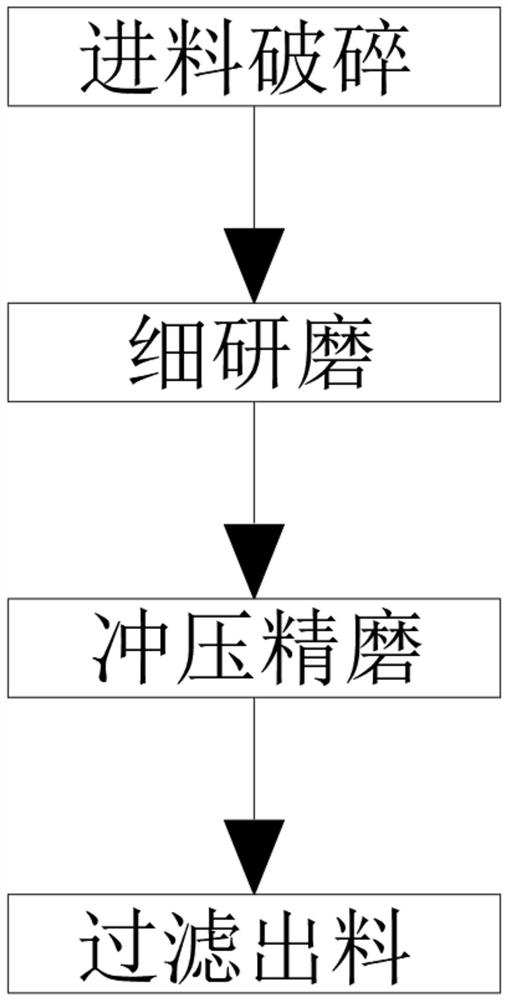

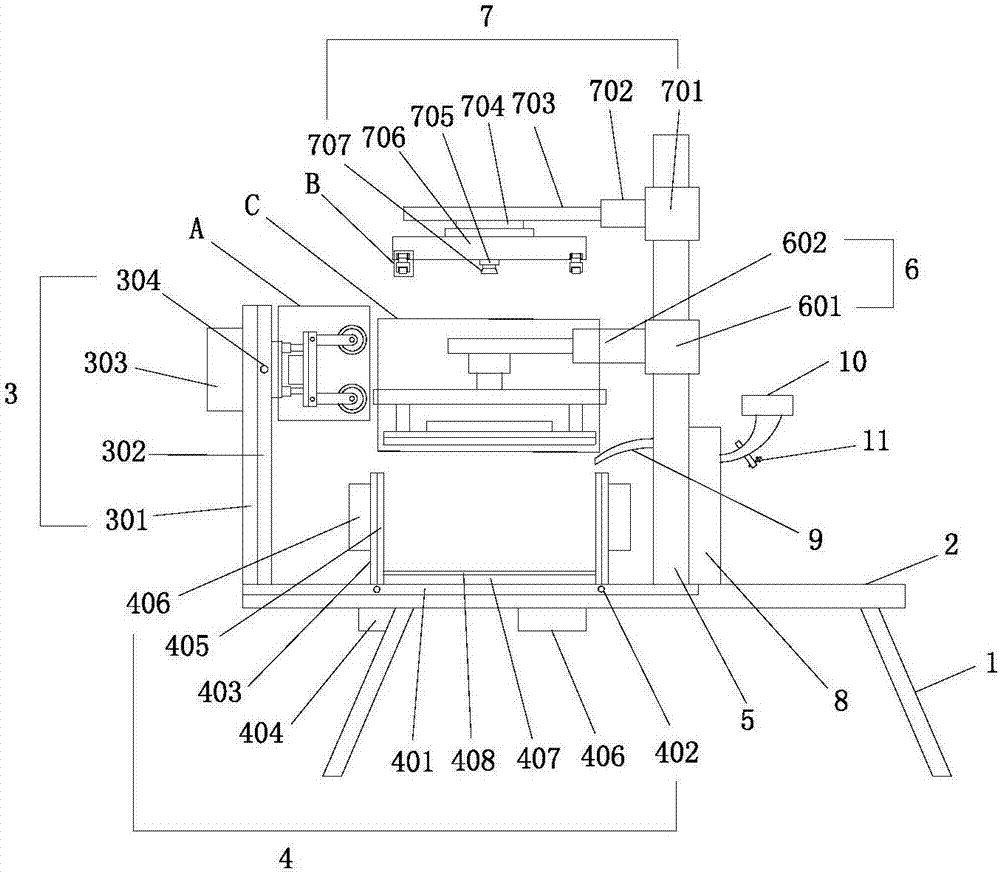

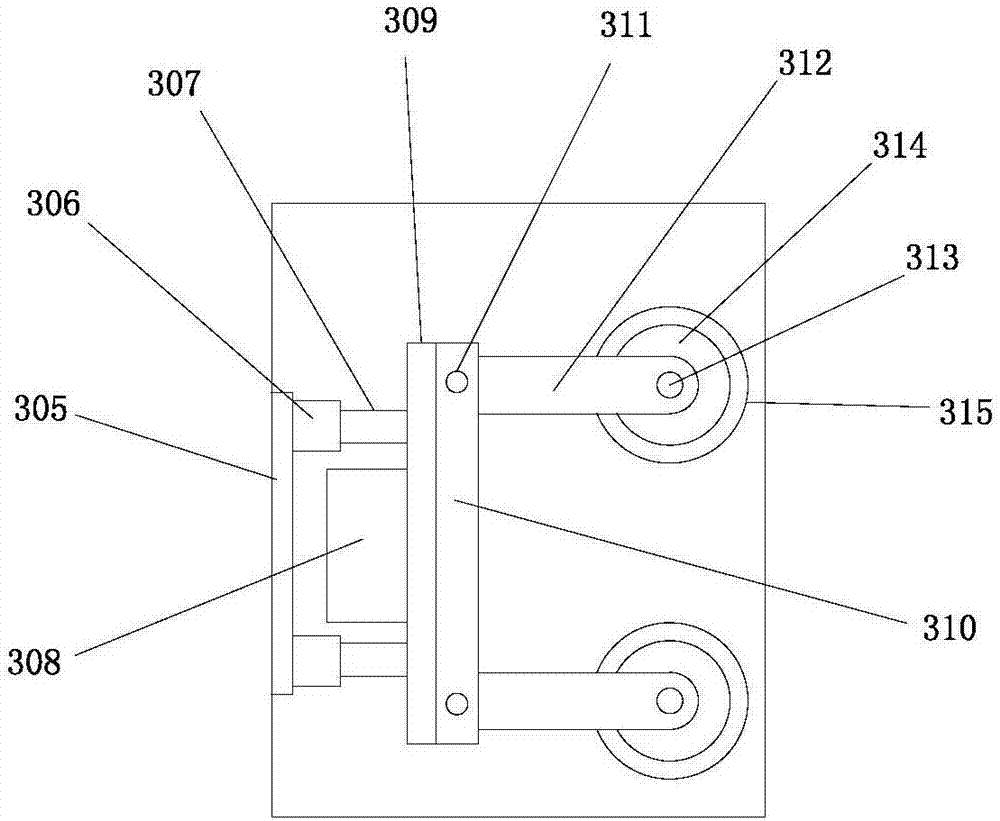

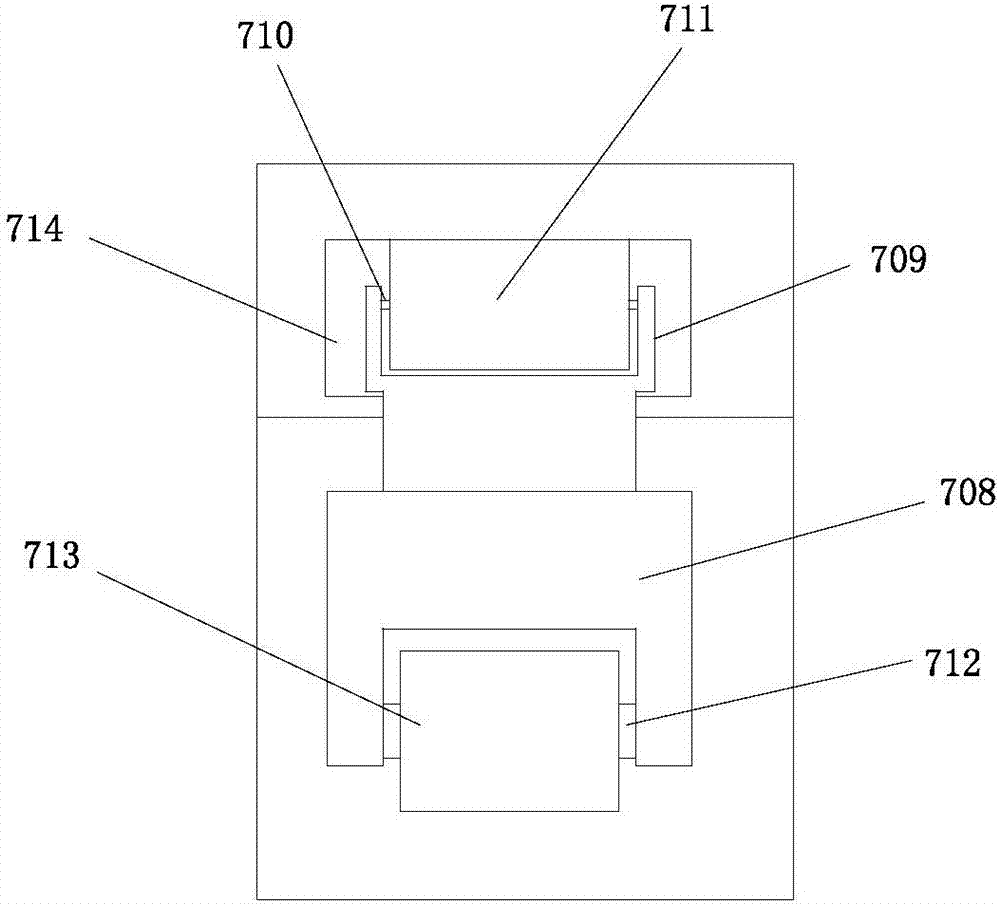

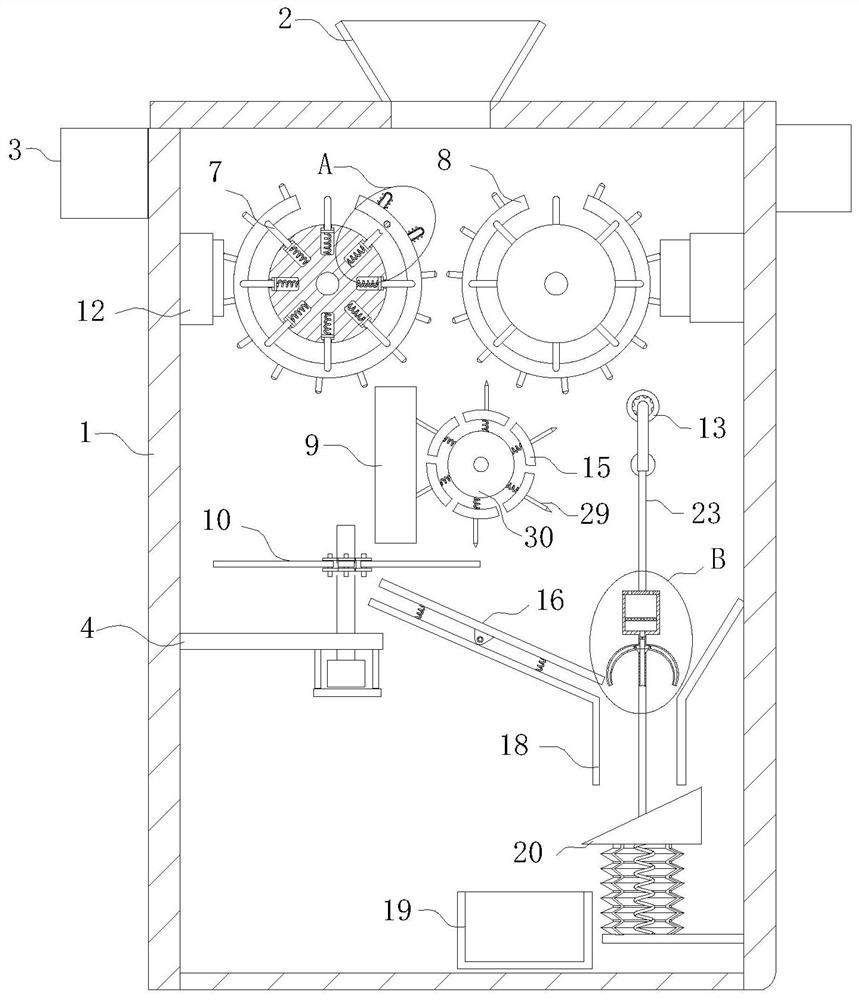

Superfine preparation method of nanoscale coating

InactiveCN111686911AGrind fullyQuality improvementGrain treatmentsHigh volume manufacturingMaterials science

The invention relates to the technical field of manufacturing of nanoscale coatings, in particular to a superfine preparation method of a nanoscale coating. The superfine preparation method comprisesthe steps of 1, crushing fed materials; 2, fine grinding; 3, stamping and accurate grinding; and 4, filtering and discharging. The superfine preparation method of the nanoscale coating has the beneficial effects that through arrangement of three-layer step-by-step crushing, sufficient grinding of the coating is achieved, so that the quality of the nanoscale coating is improved, meanwhile, the production cost is greatly reduced, the purpose of uninterrupted mass production is achieved, and the grinding efficiency is improved; and by arranging filter screens in the middle of step-by-step crushing, multi-stage quality detection is achieved, and the discharging qualification rate is greatly increased; and meanwhile by means of an automatic discharging mode, convenient grinding operation is achieved.

Owner:淄博金锐纳米材料科技有限公司

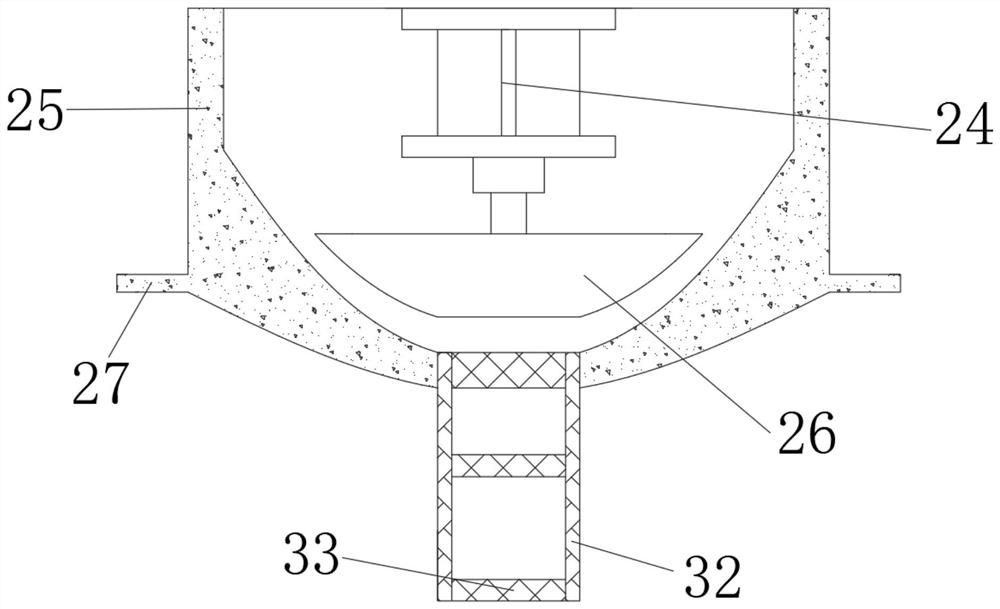

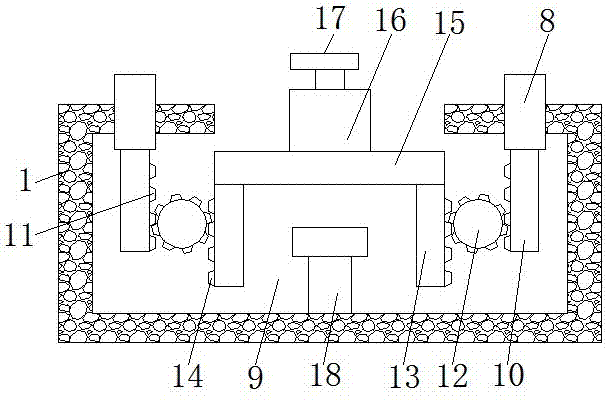

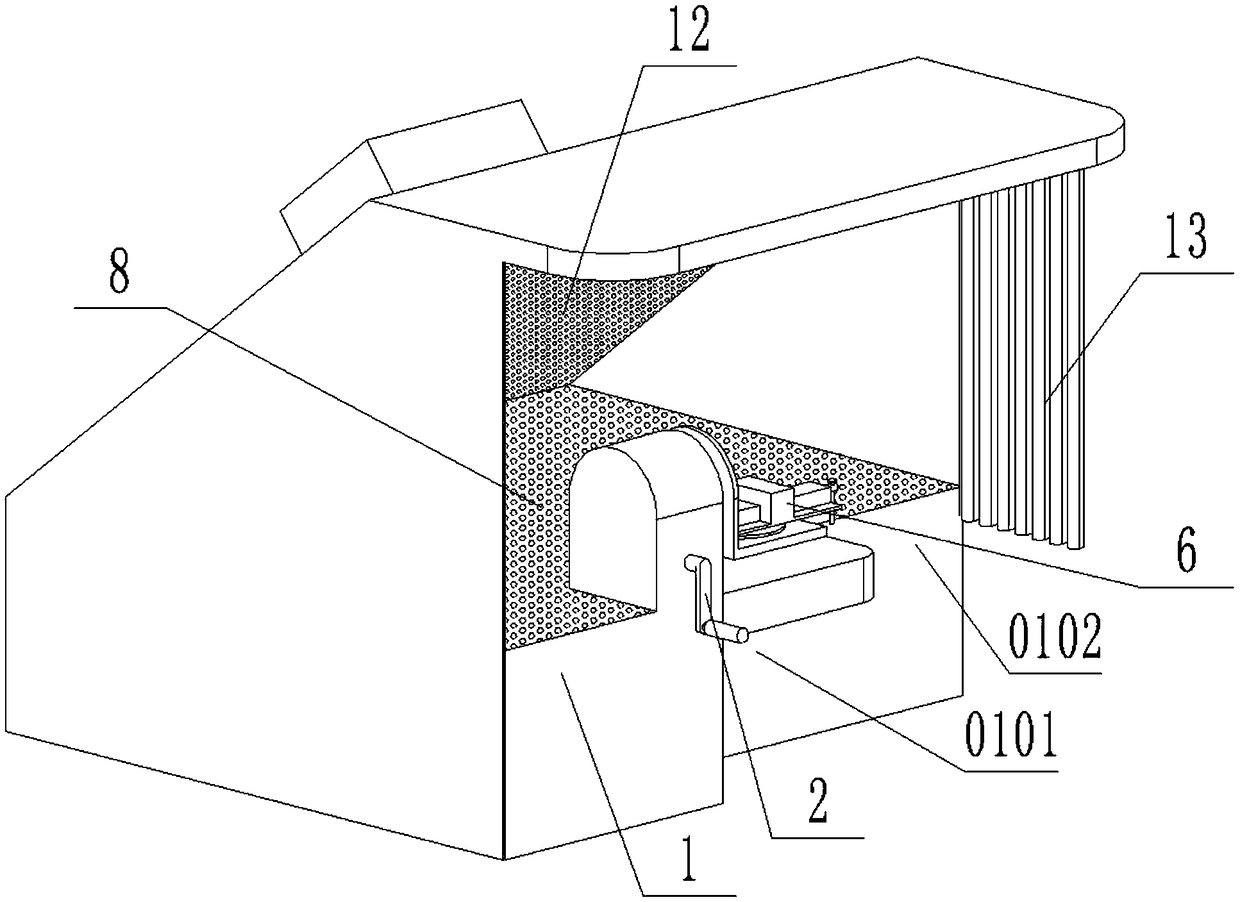

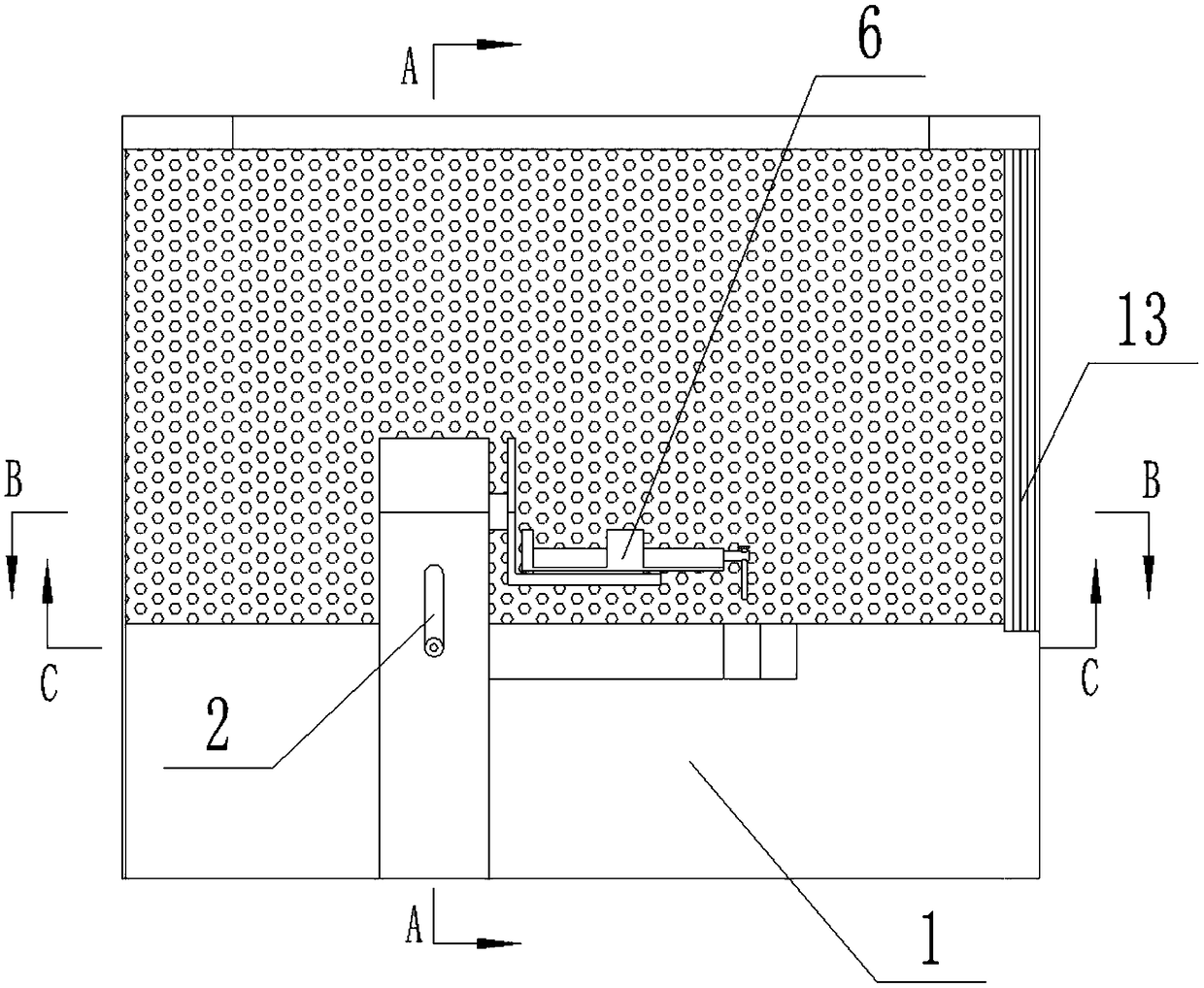

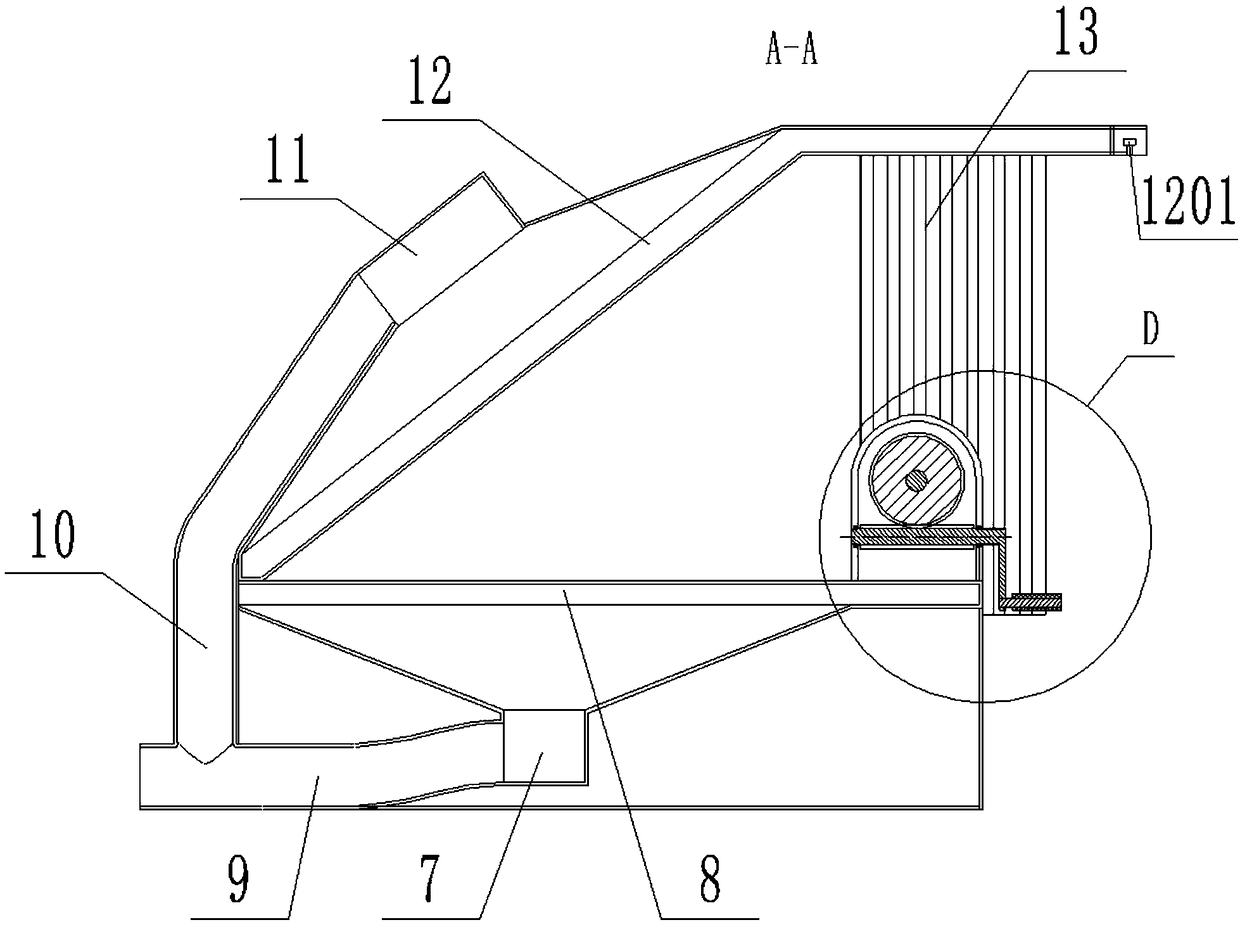

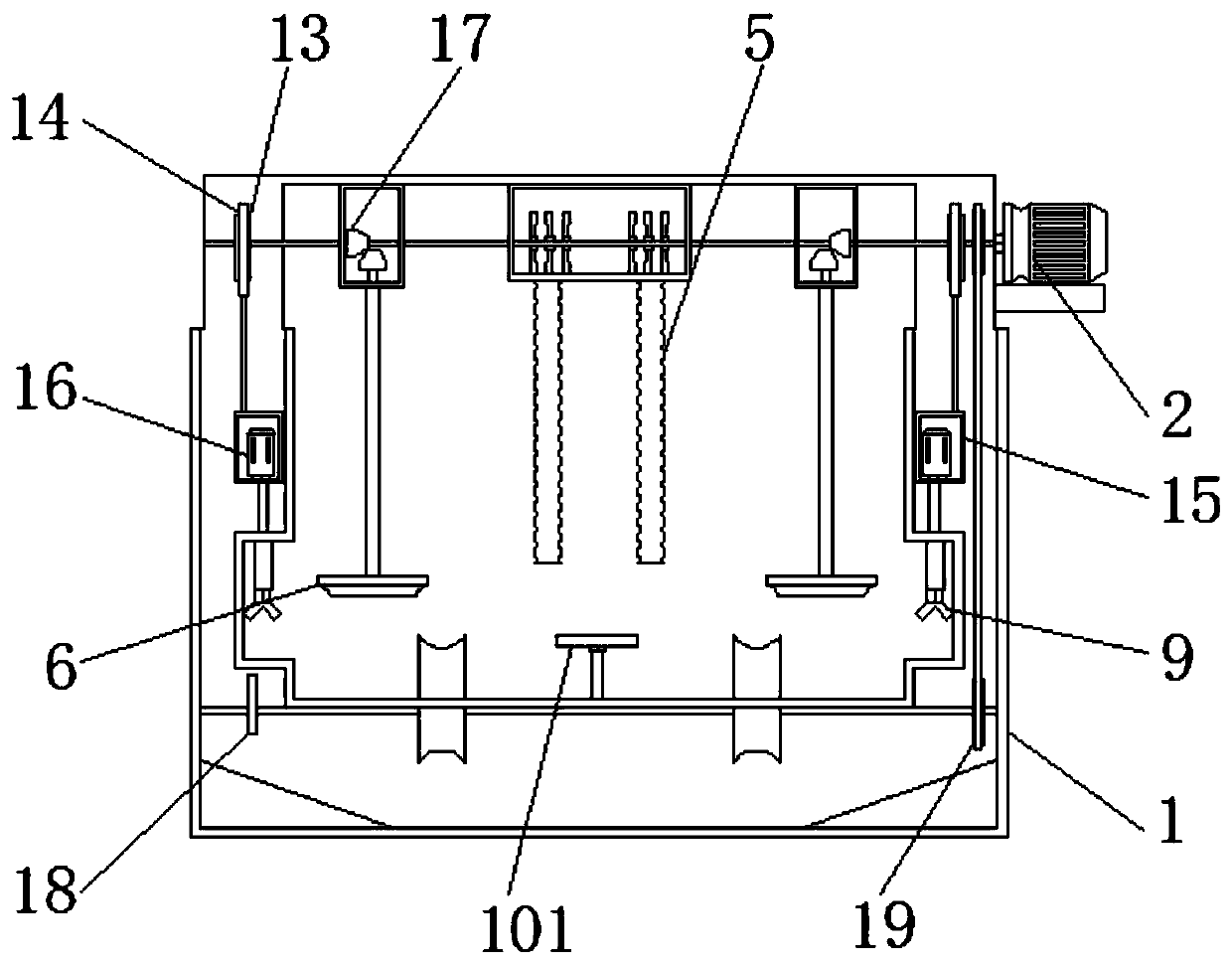

Casting and grinding machine for thermal insulation material molding

ActiveCN107962661AConvenient suction fixed limitConvenient limit operationEdge grinding machinesMouldsStopped workThermal insulation

The invention provides a casting and grinding machine for thermal insulation material molding. A first piston is rotated right above a molding mechanism through a first rotating shaft, and then a third heating box is opened, so that the third heating box heats a third heating plate and a material to be molded and grinded is solidified through the third heating plate. A fourth piston and a fourth piston shaft are matched to enable the third heating plate to compress the material to be molded and grinded, so that solidifying and compressing molding of the material to be molded and grinded is achieved; and then a second pulley is driven by a second motor to drive a second mounting plate to slide on a second sliding groove, the second motor is stopped working when the second mounting plate isadjusted to the position where grinding is suitable, and then the obtained material which is solidified and compressed to be molded is taken out and then is placed between grinding wheels which are used for grinding the peripheral edges of the material. The grinding quality of the edge of the material which is solidified and compressed to be molded is effectively improved, so that the corners of the periphery of the material which is solidified and compressed to be molded are smoother, and the material which is solidified and compressed to be molded is convenient to install.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

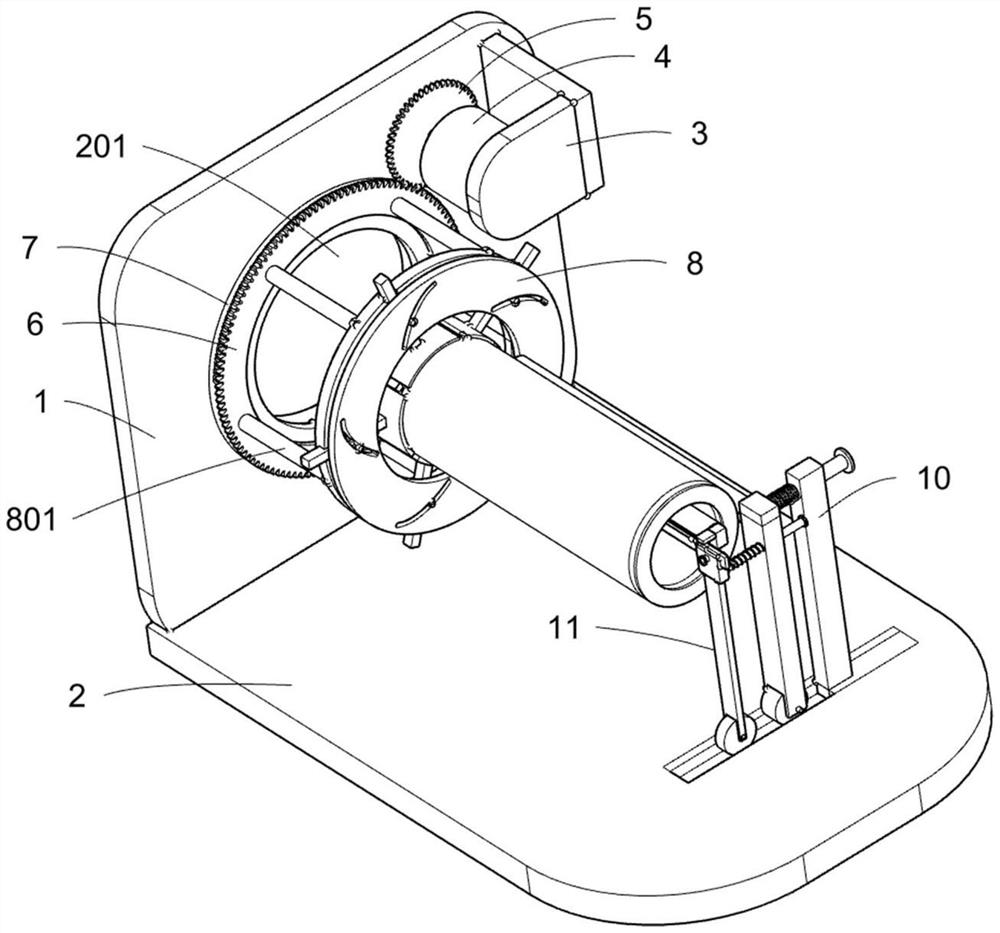

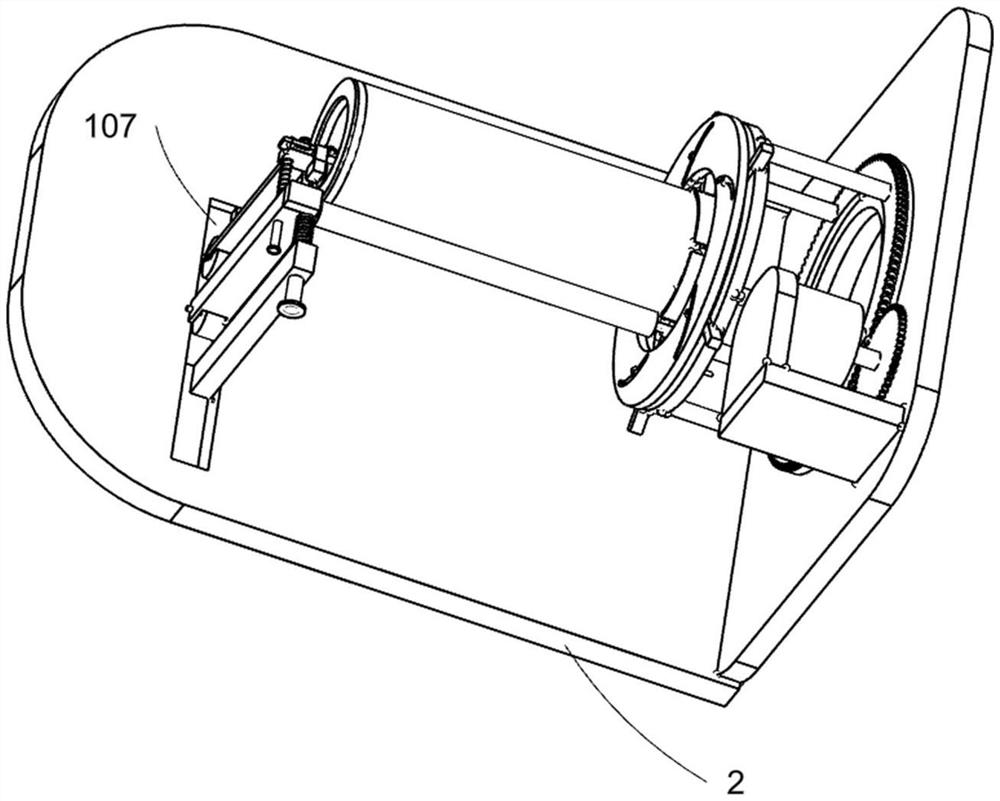

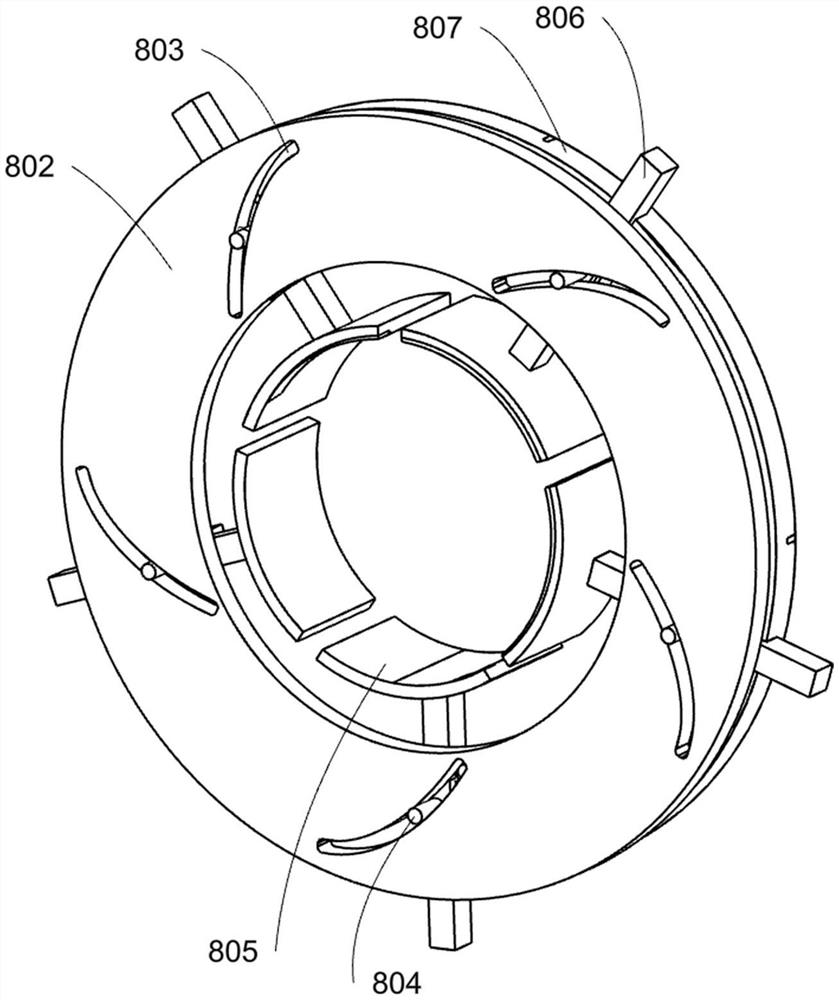

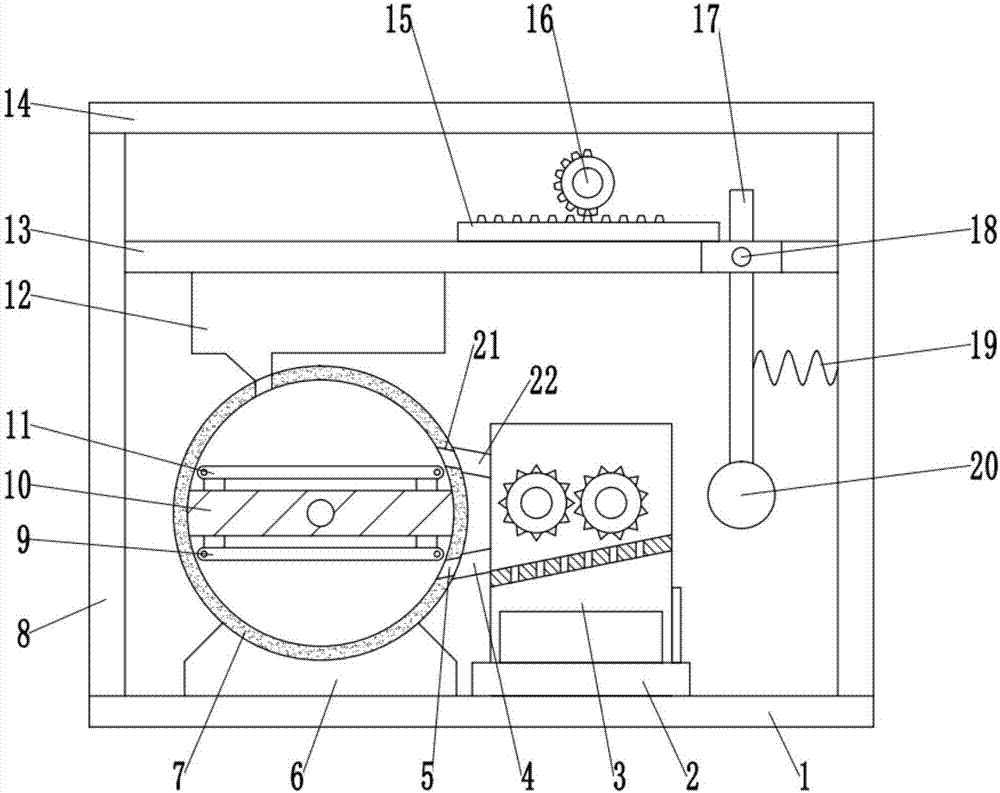

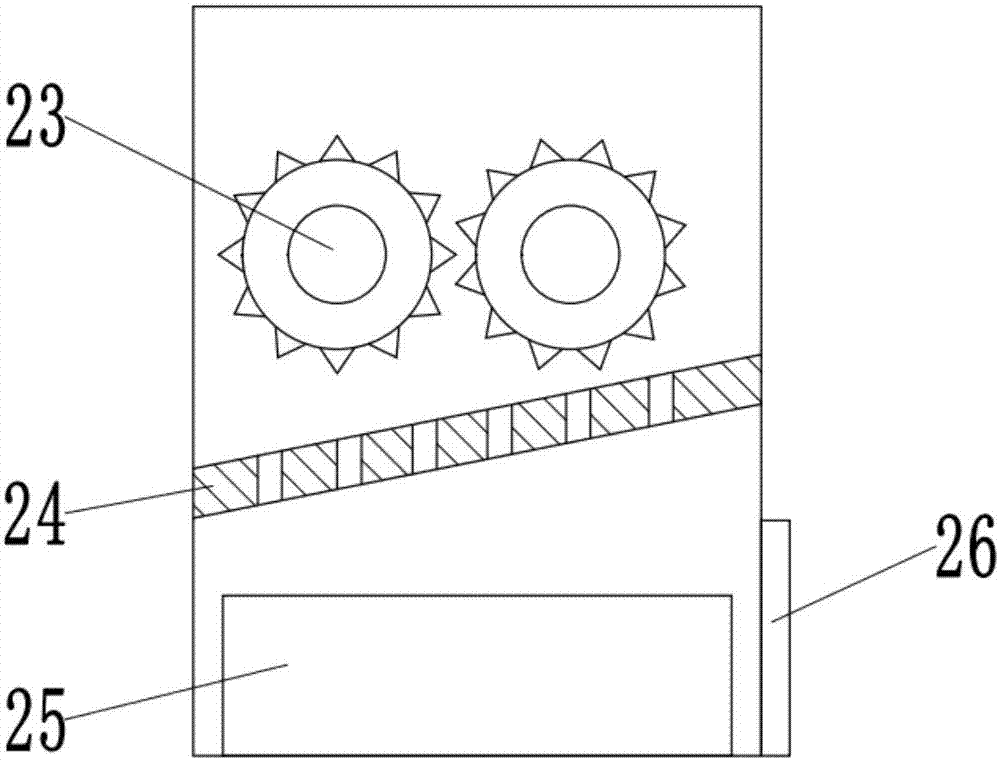

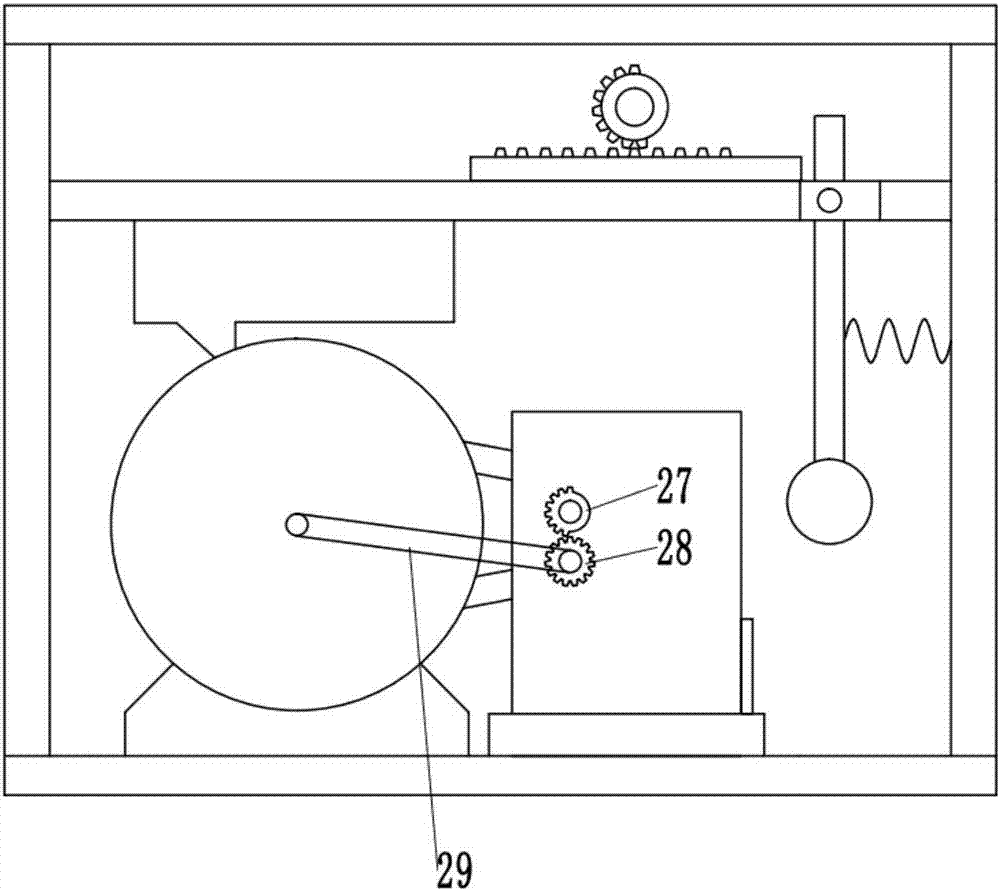

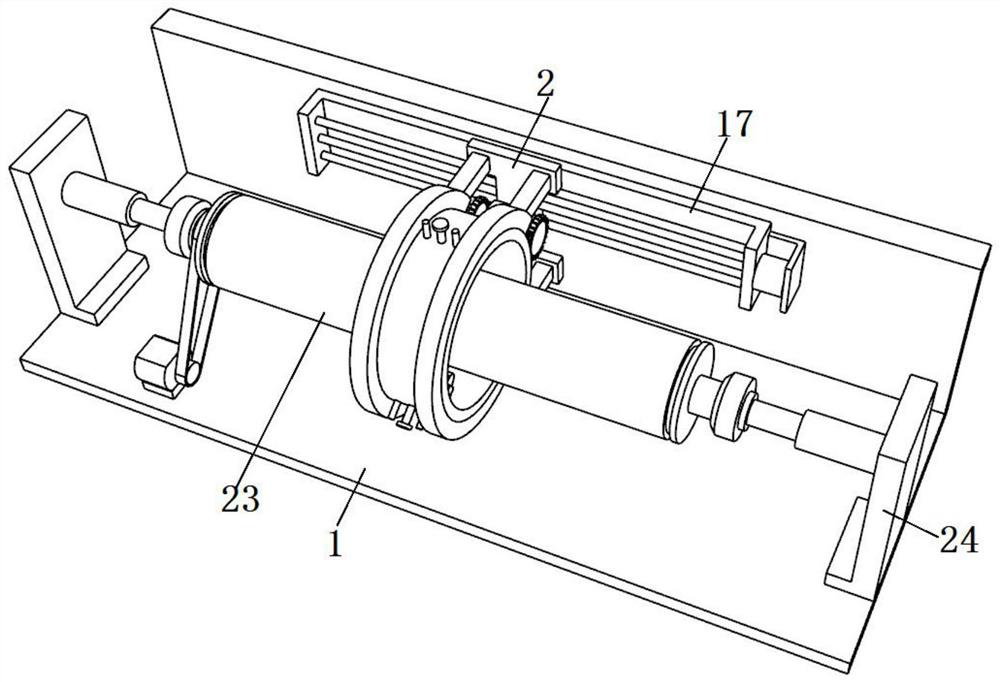

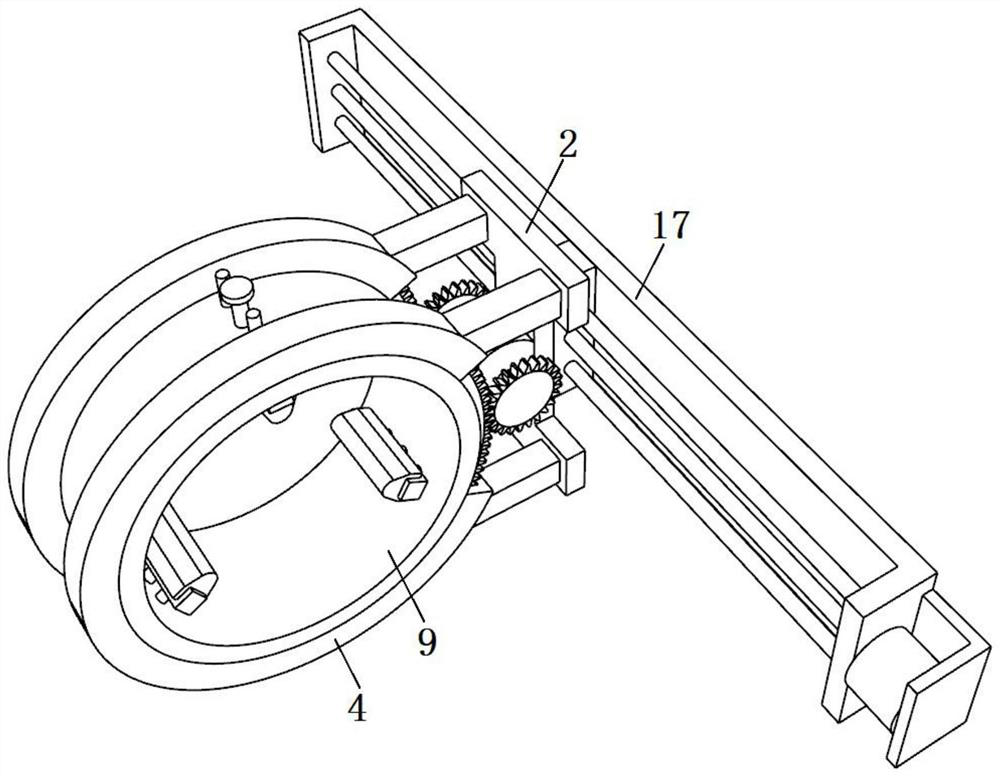

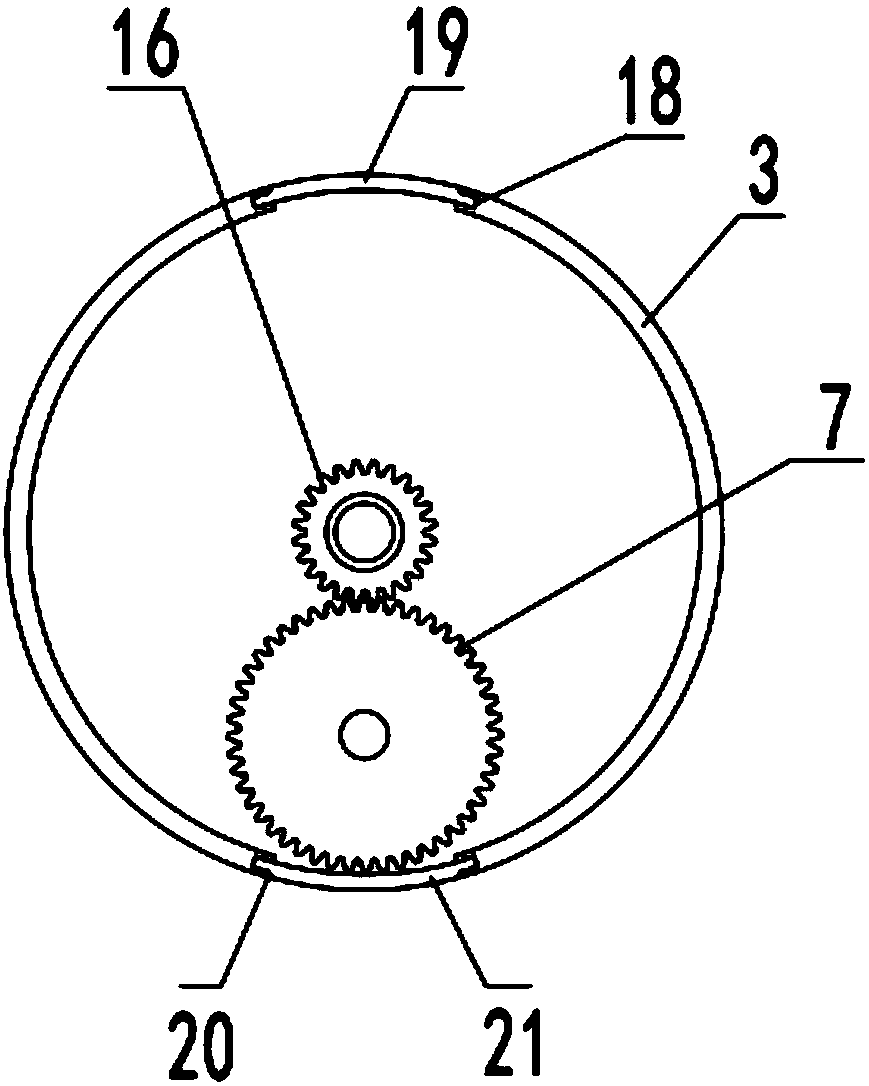

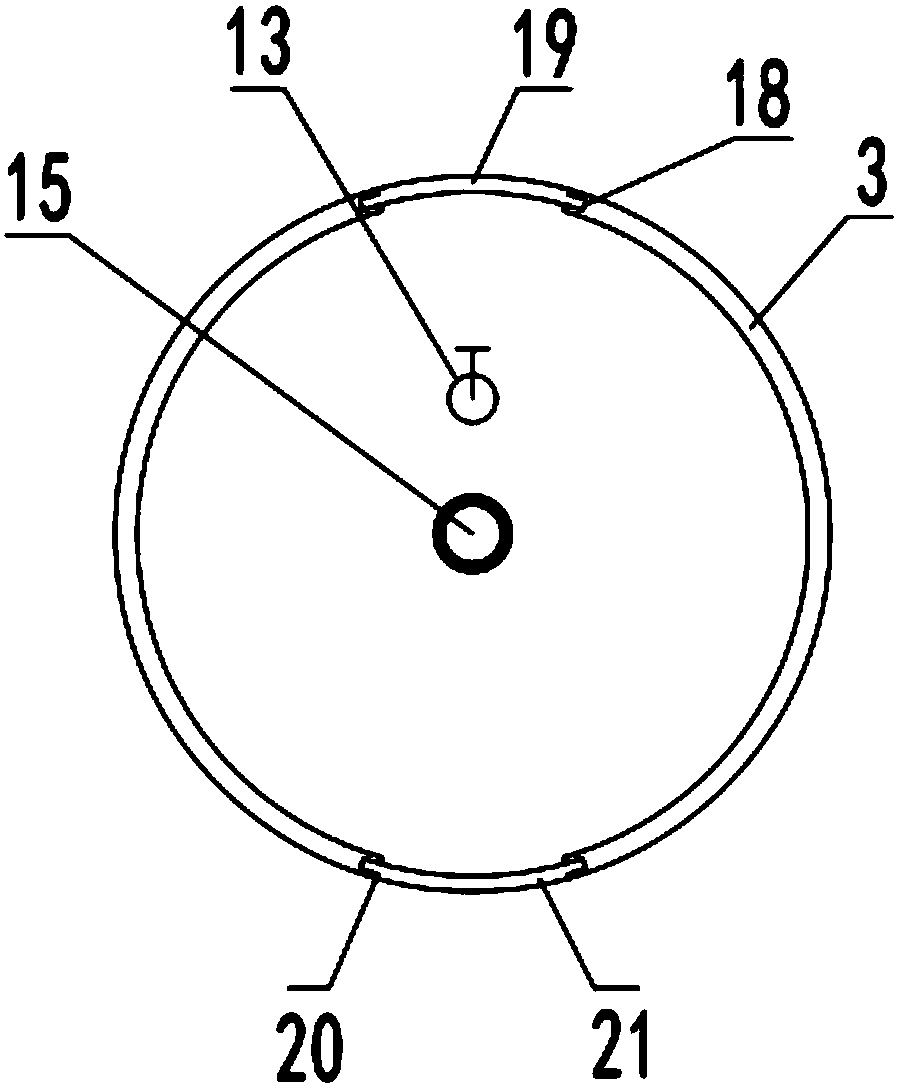

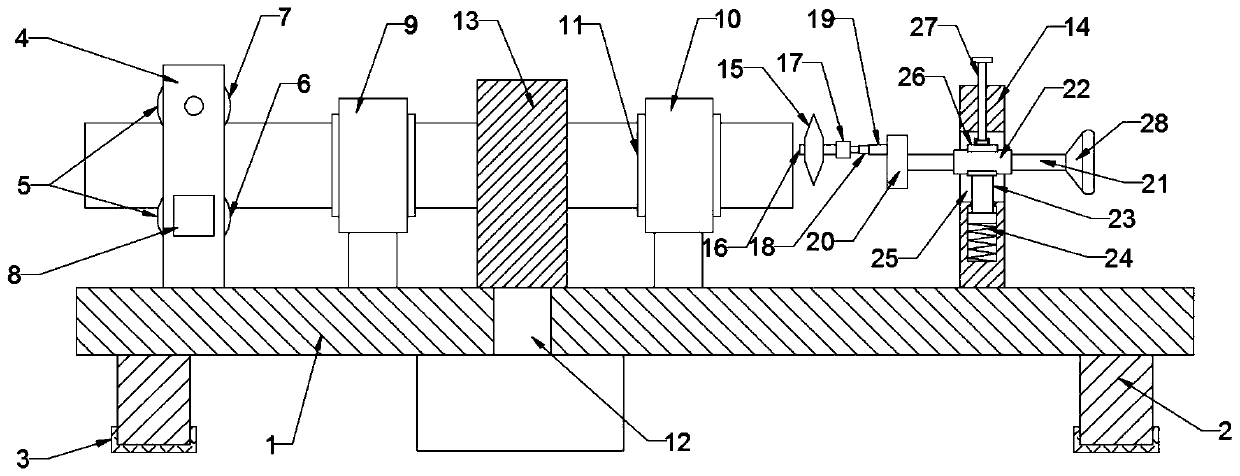

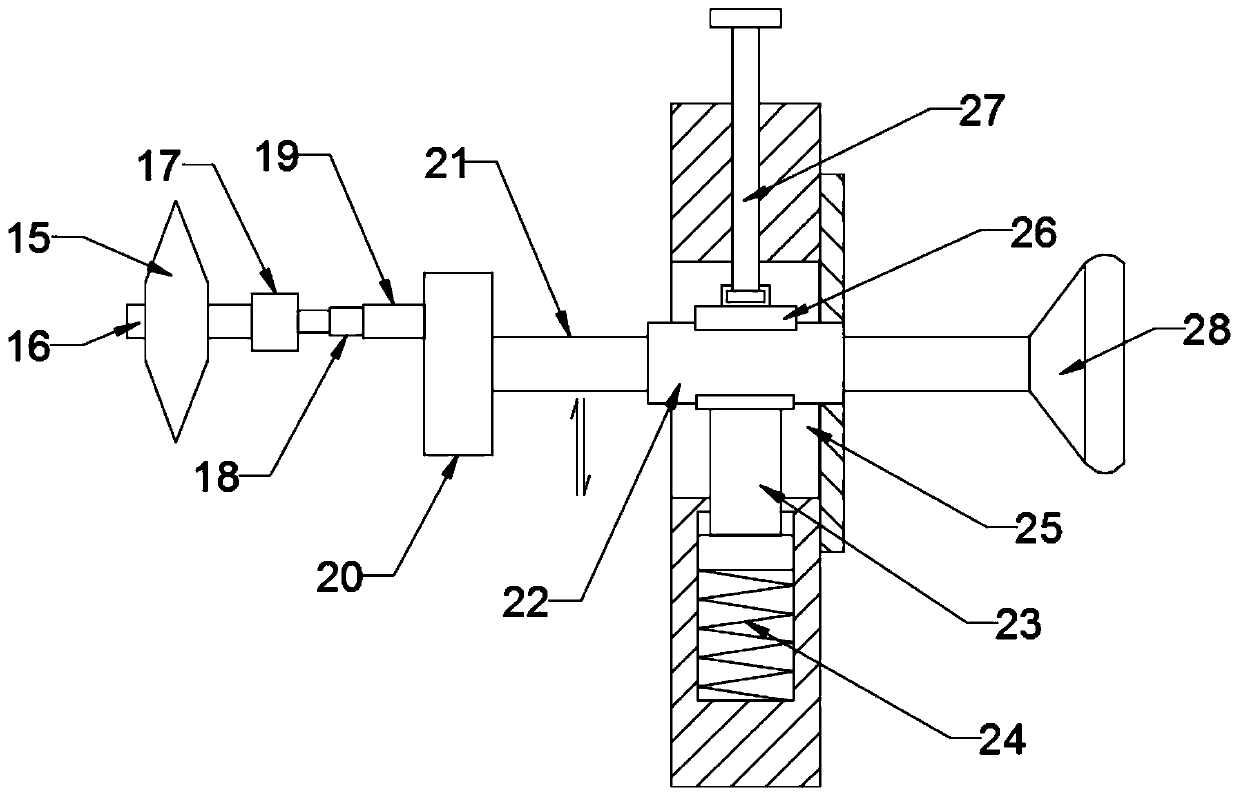

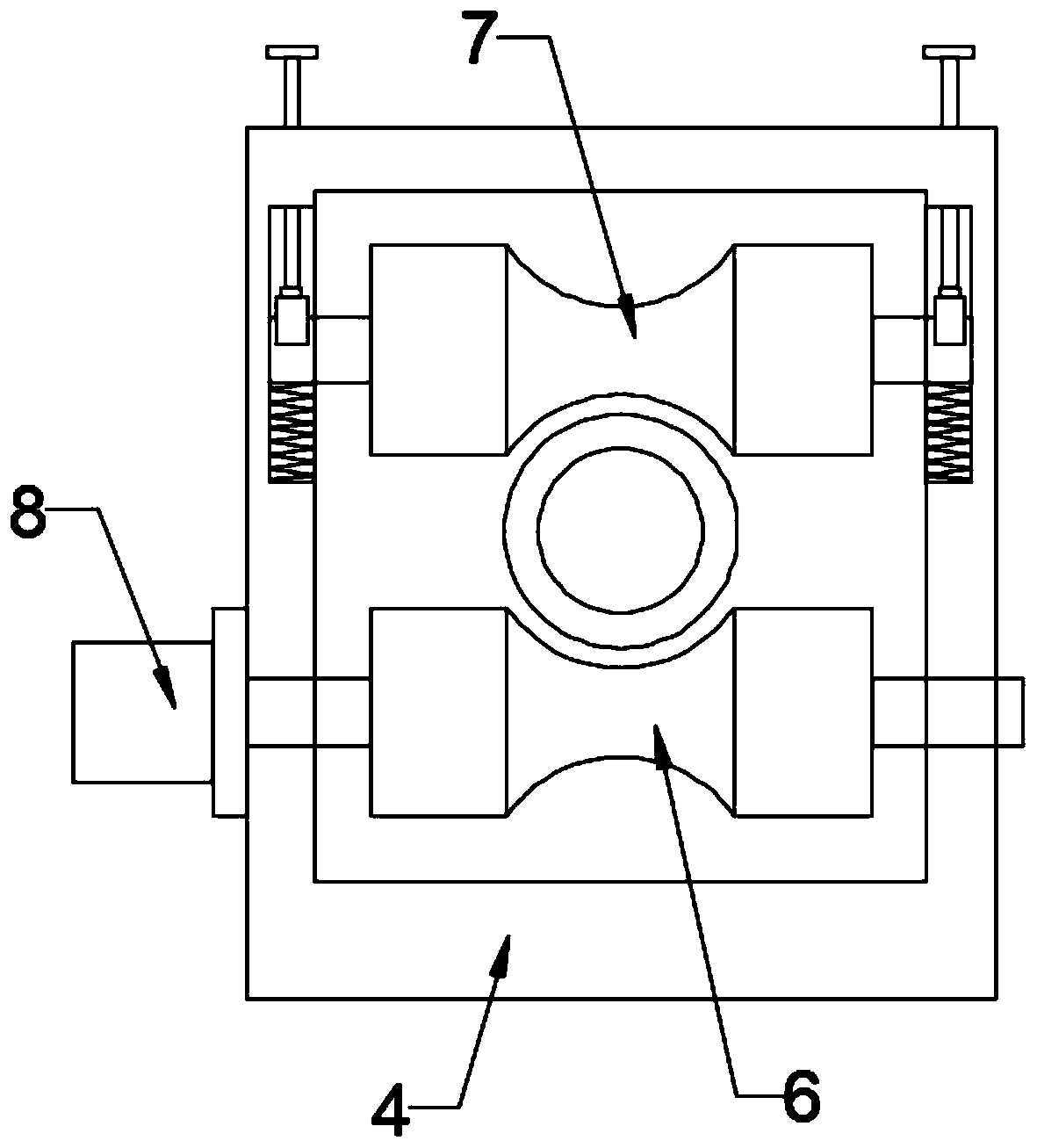

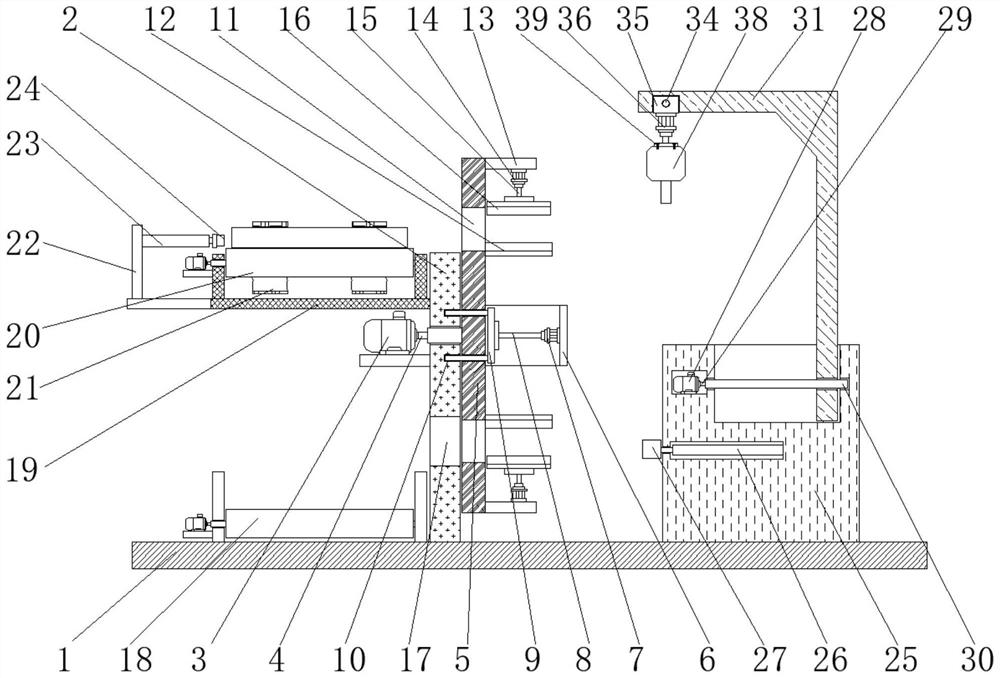

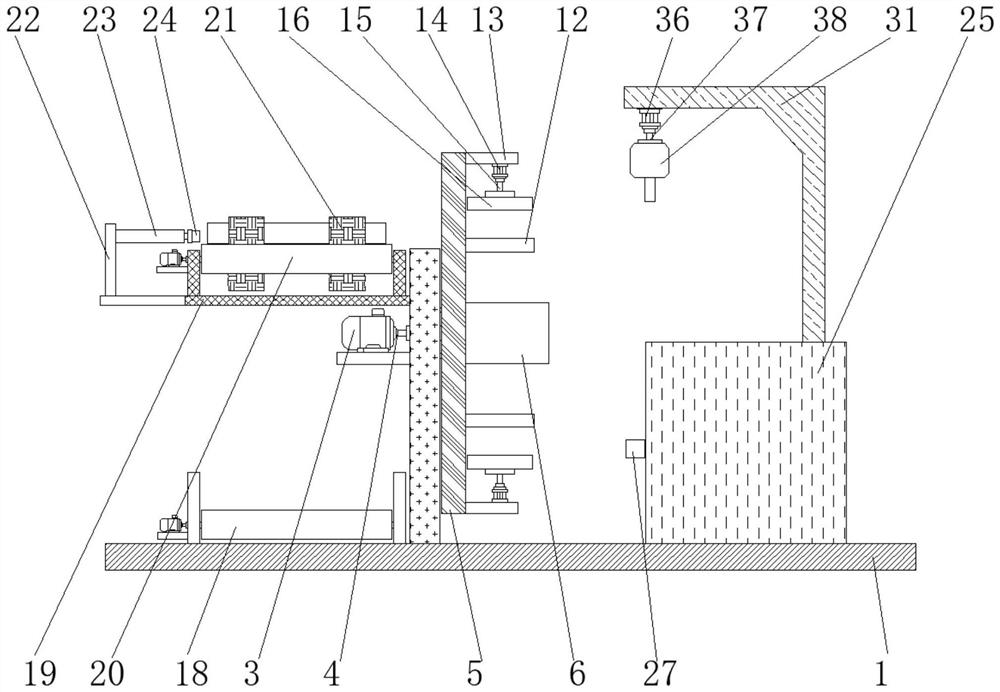

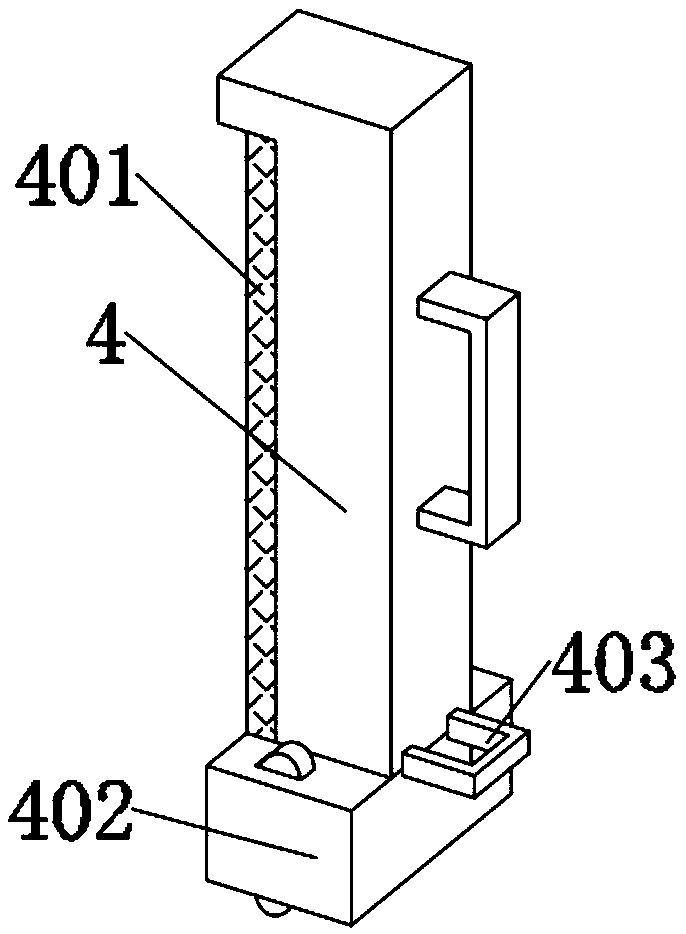

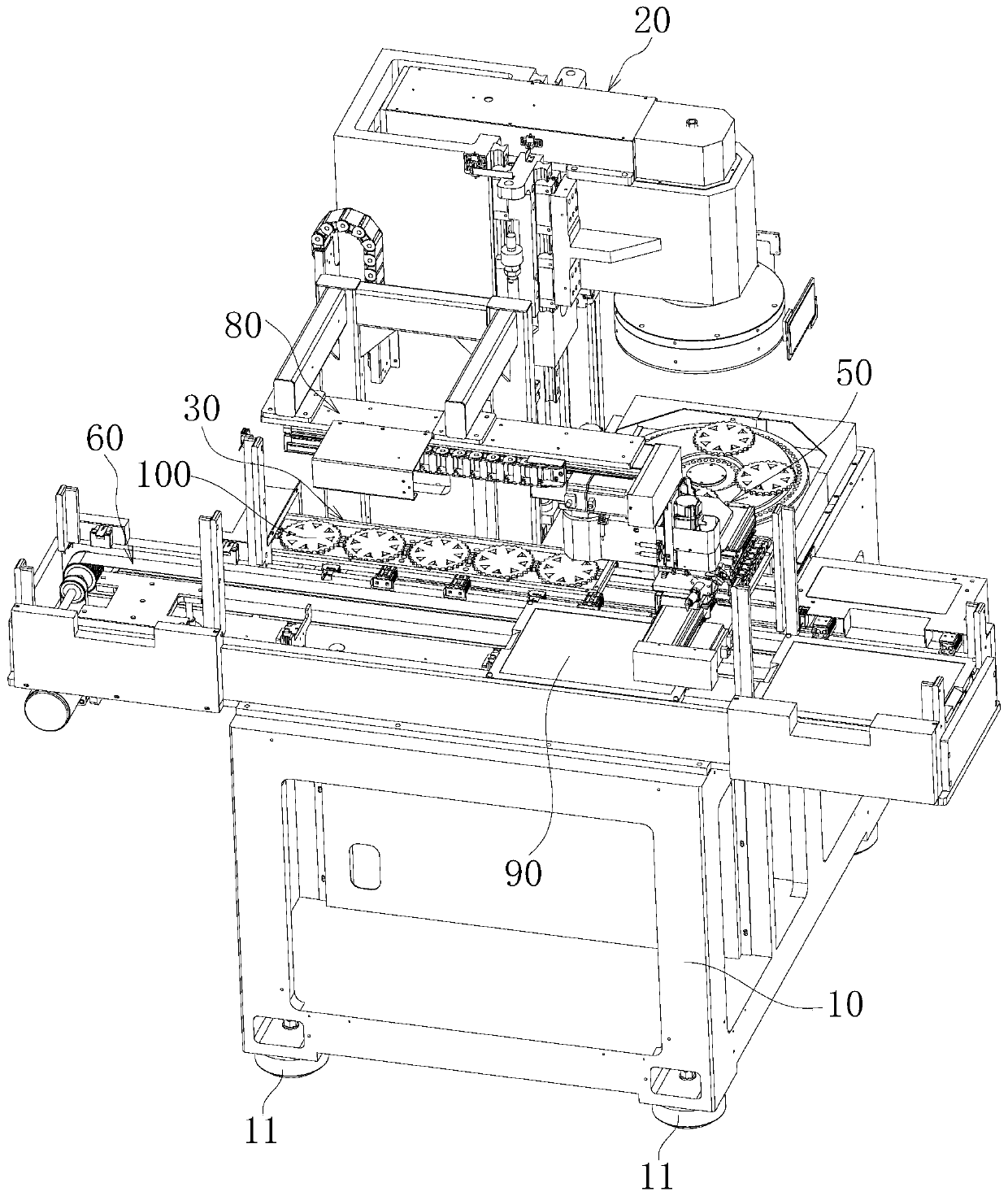

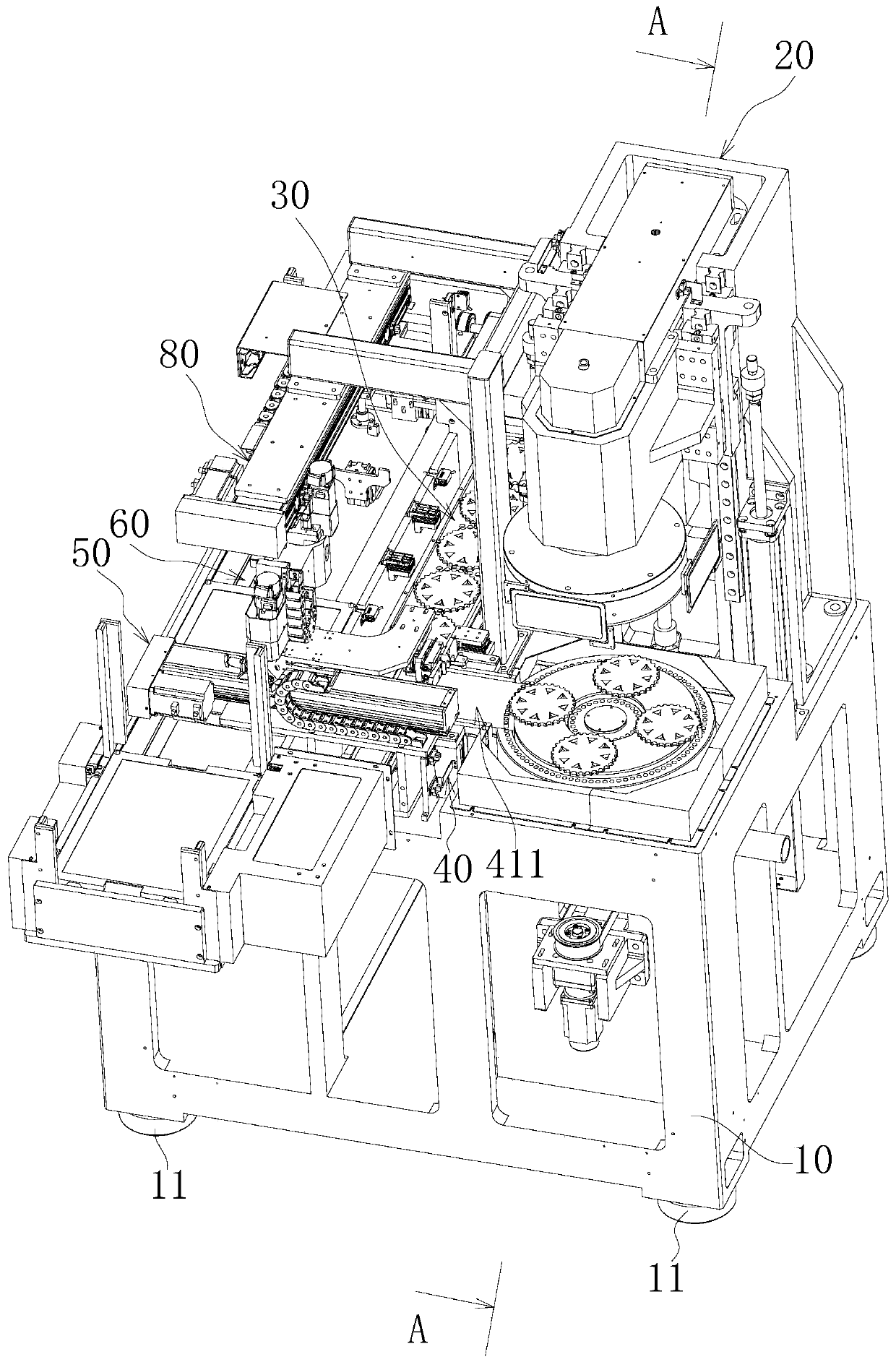

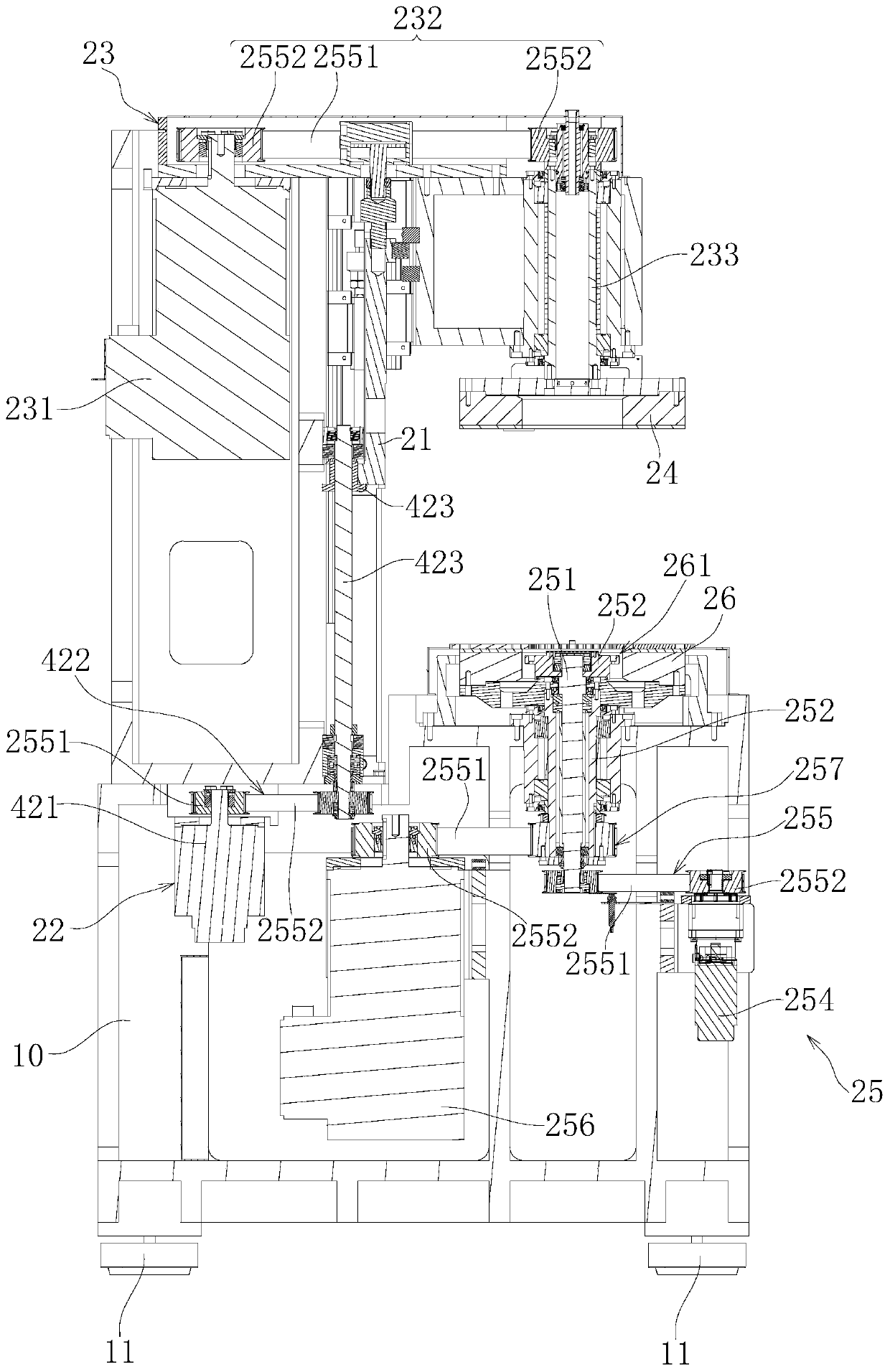

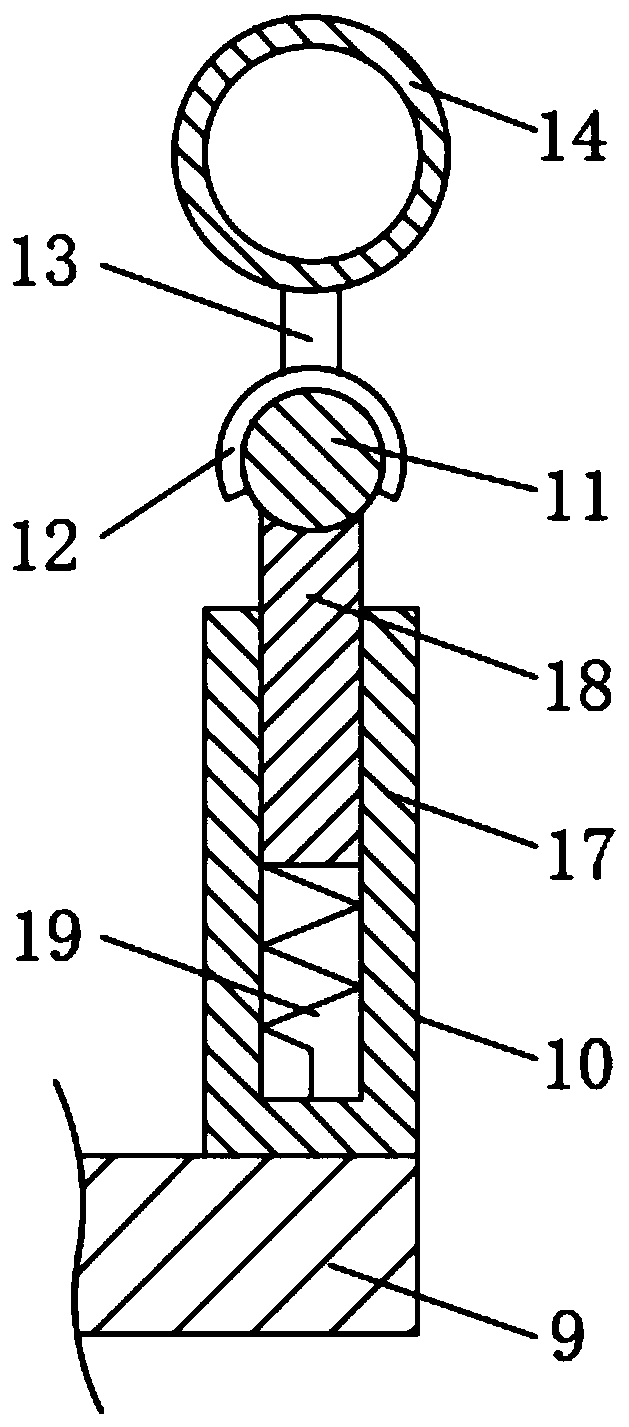

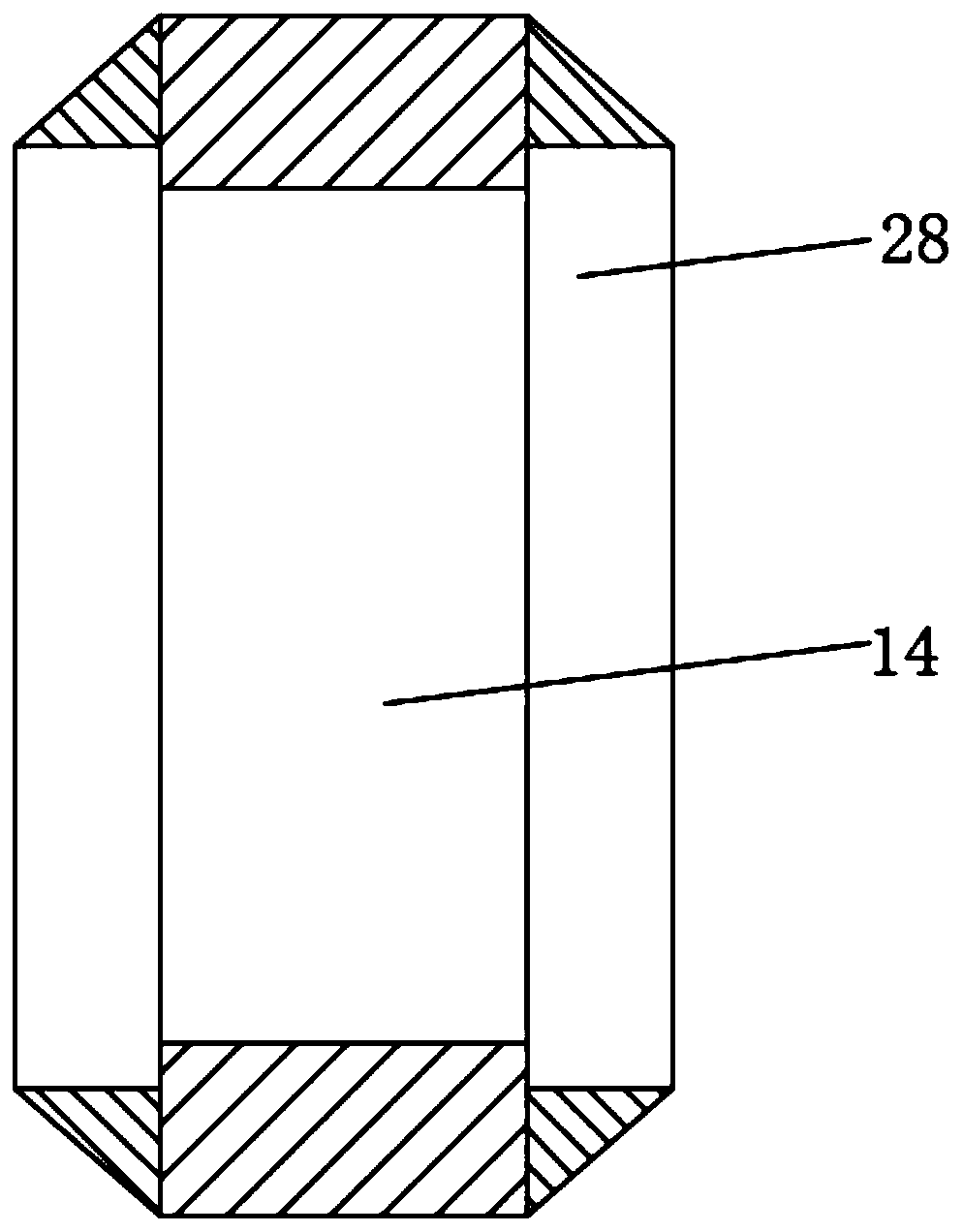

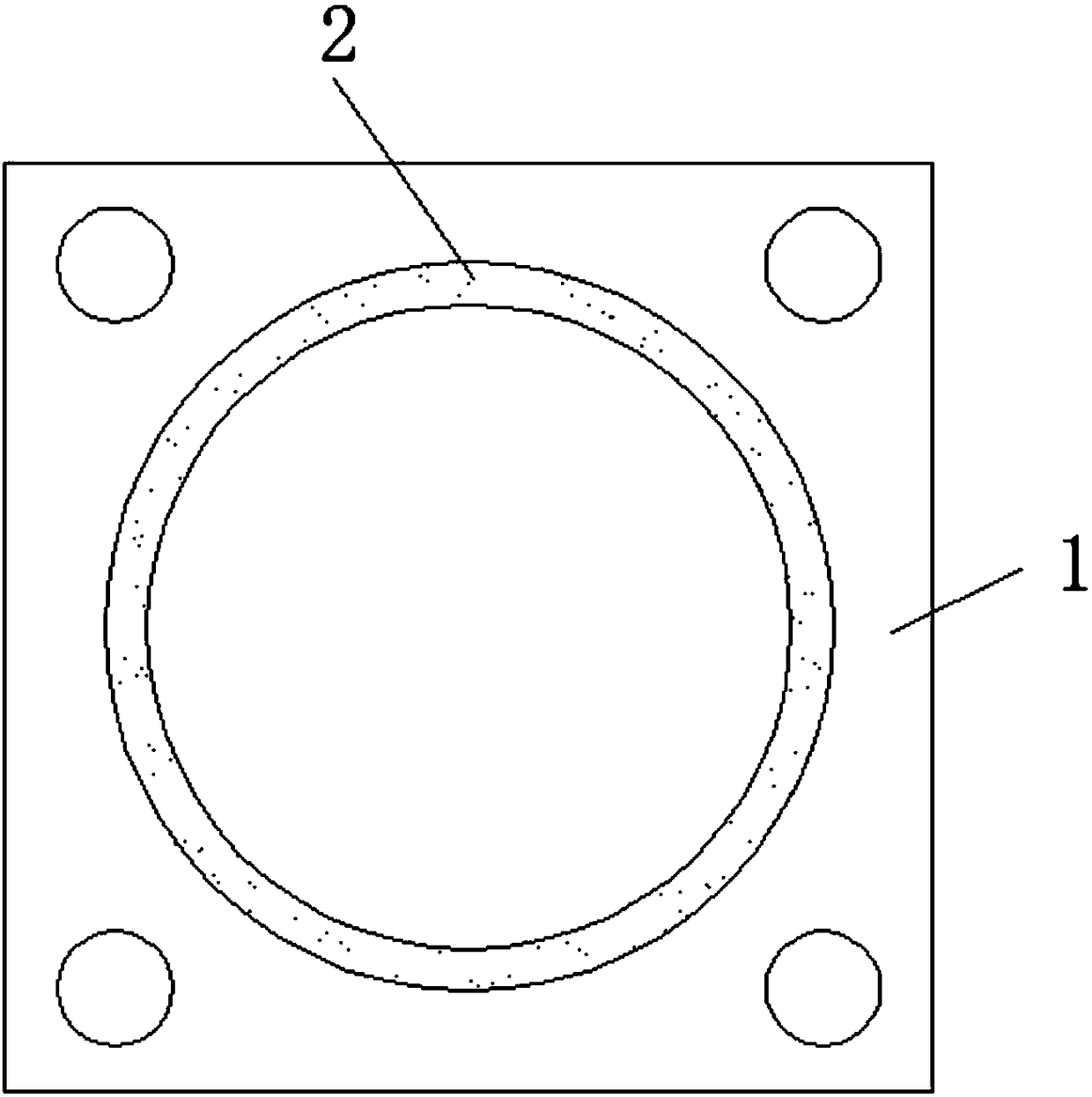

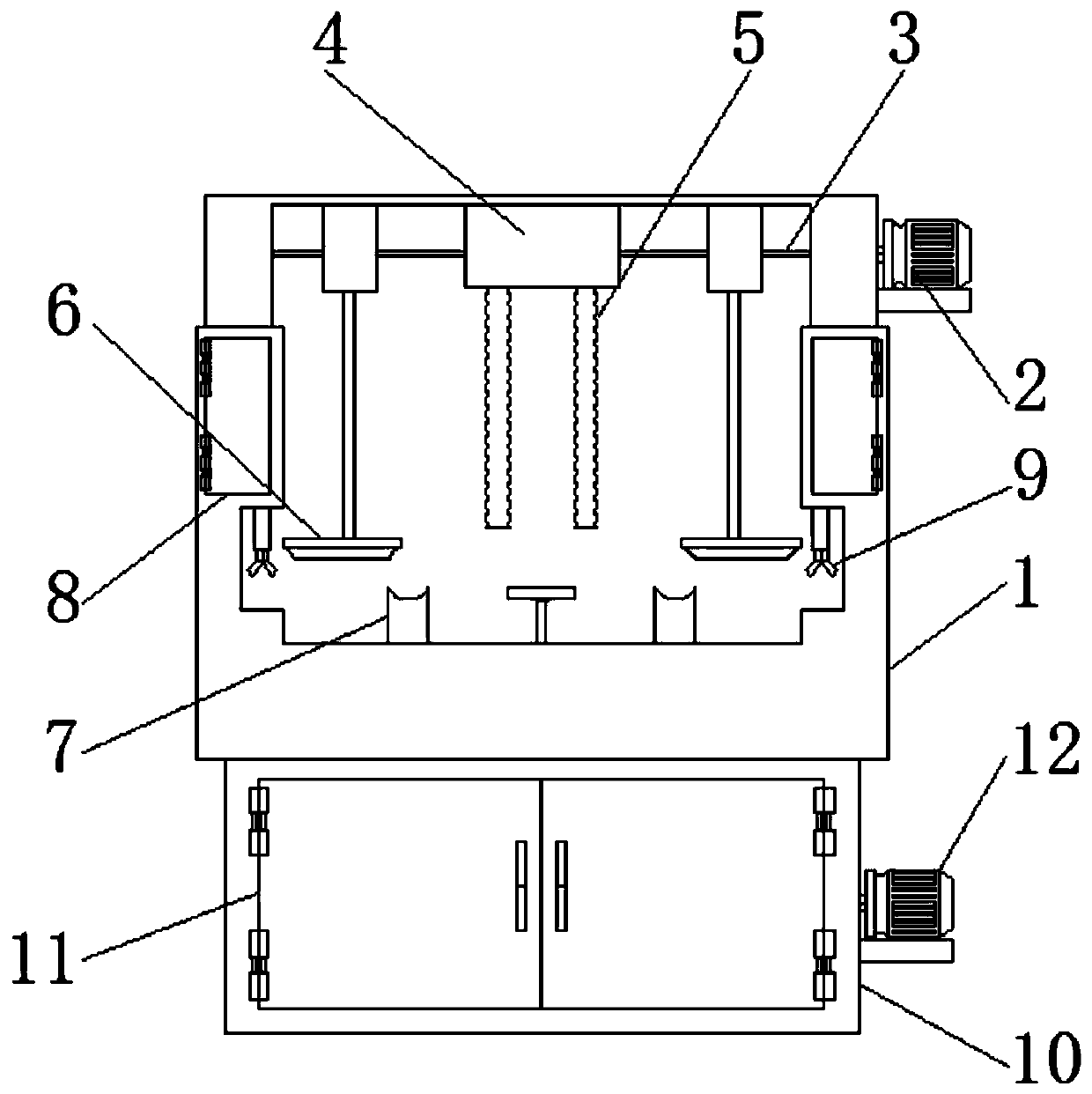

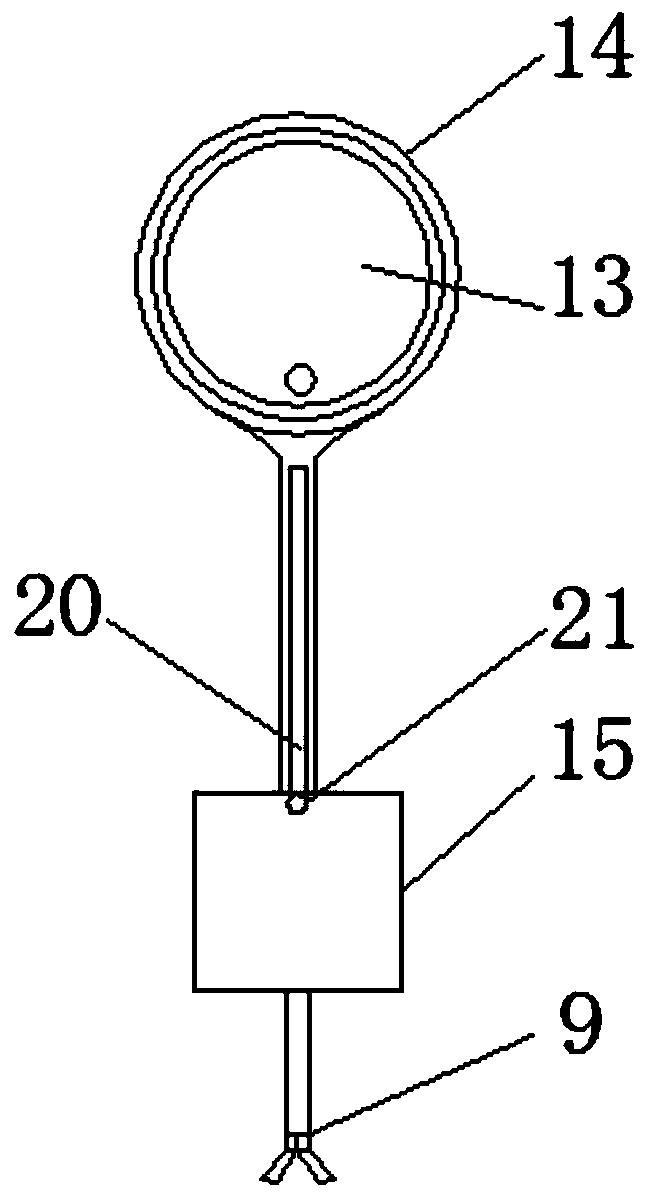

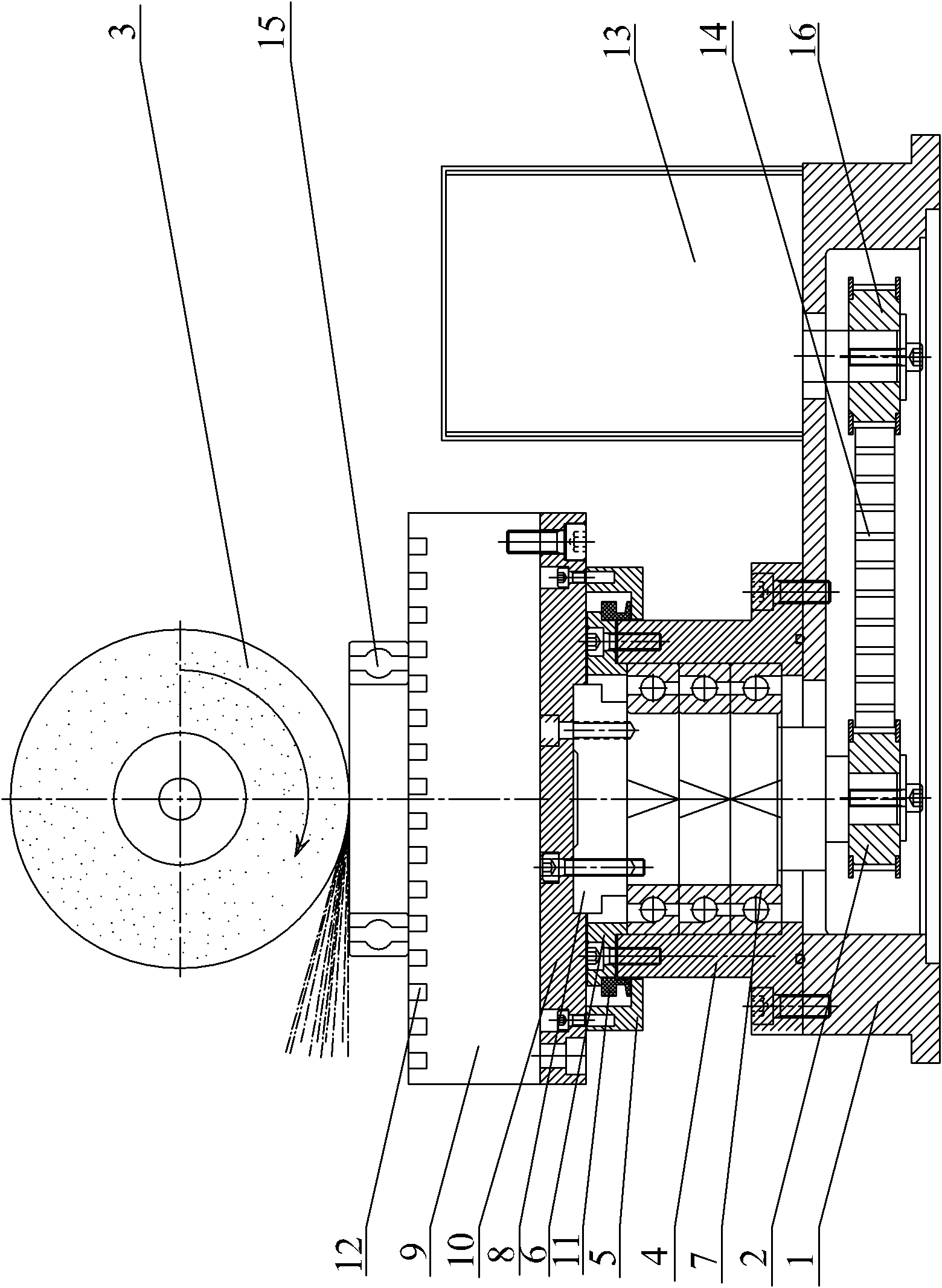

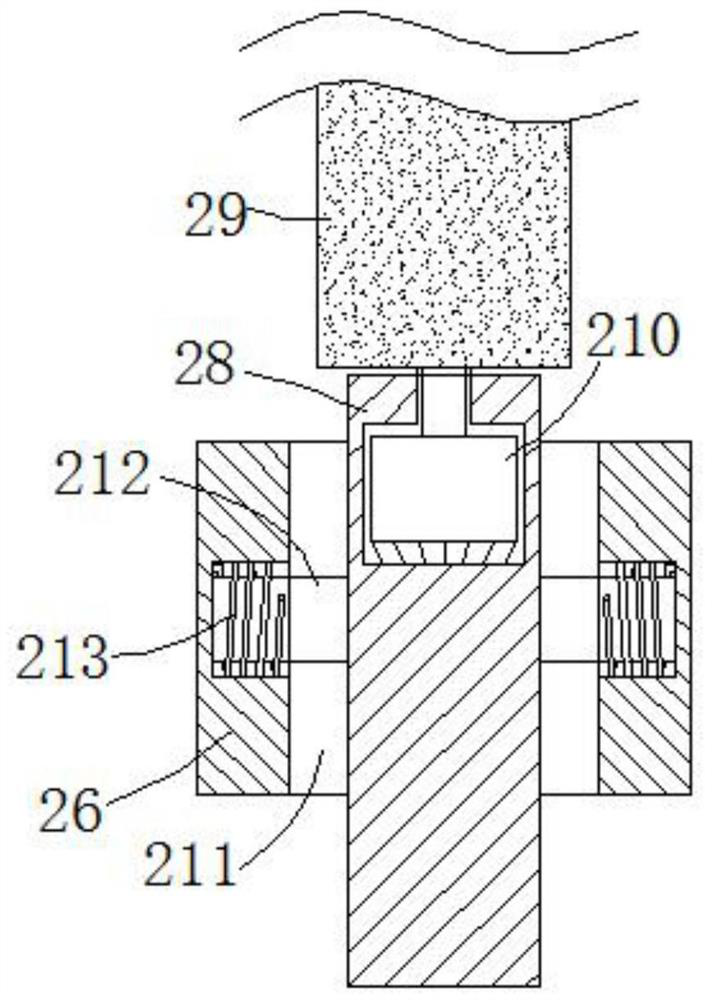

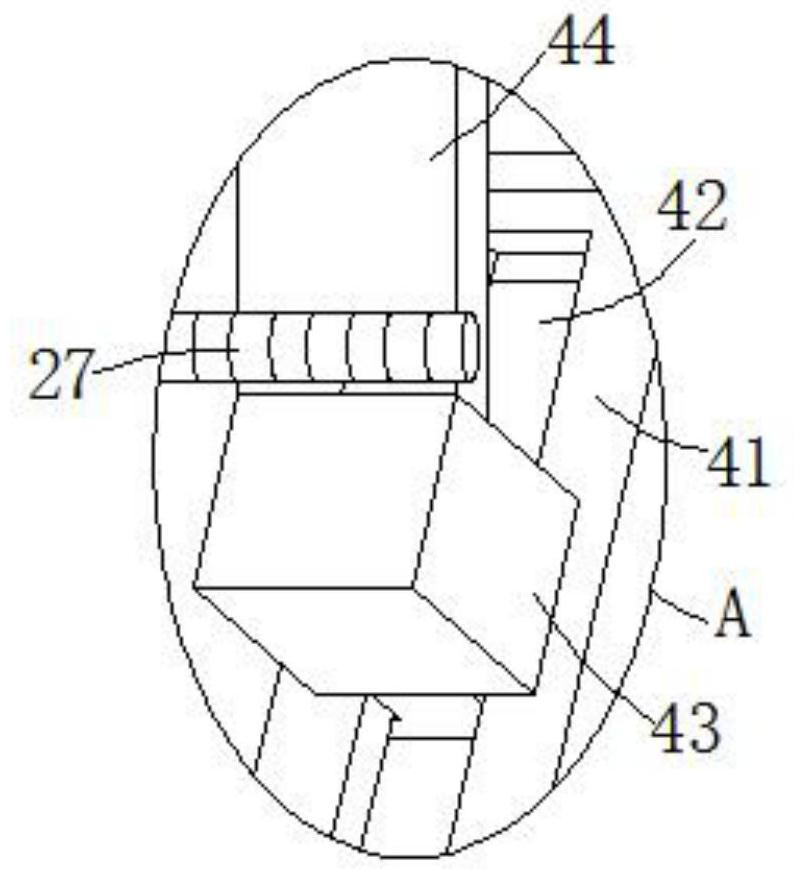

Cylindrical part inner and outer ring grinding equipment

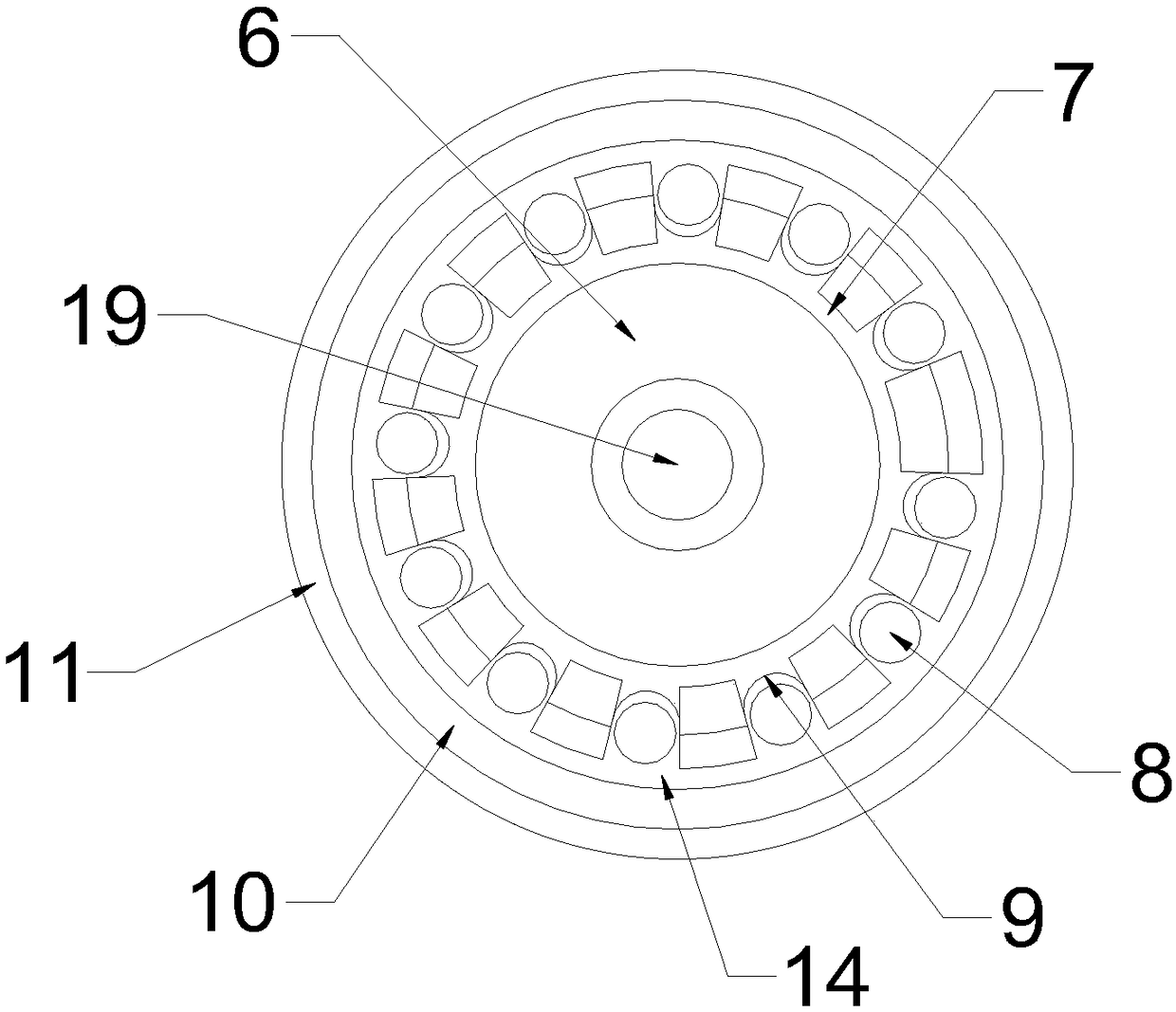

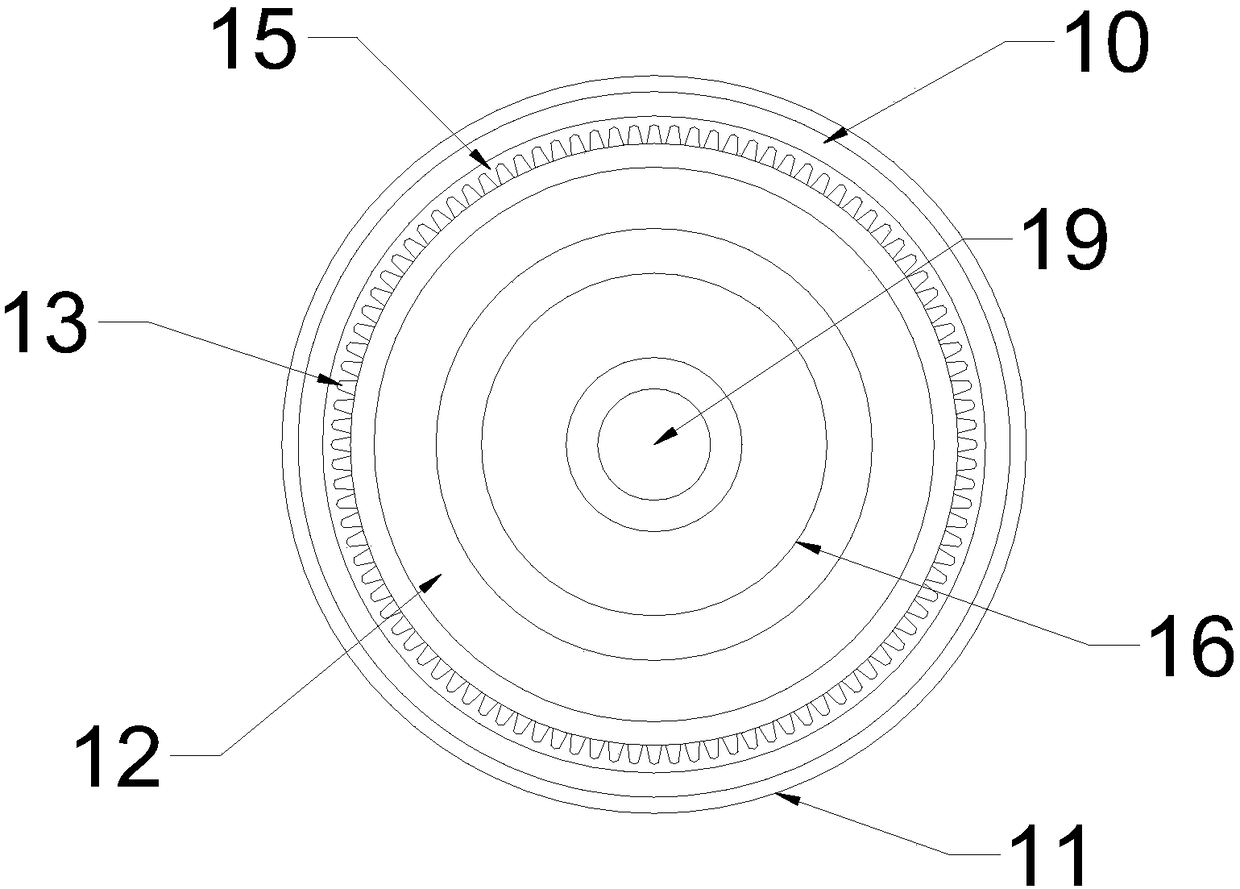

ActiveCN111941165AAutomatic grinding operationConvenient grinding operationGrinding carriagesRevolution surface grinding machinesElectric machineGear wheel

The invention discloses cylindrical part inner and outer ring grinding equipment, relates to the technical field of part machining, and solves the problems that existing cylindrical part grinding equipment can only conduct grinding operation on a single-specification cylindrical part and cannot conduct grinding operation on an inner ring and an outer ring at the same time. The cylindrical part inner and outer ring grinding equipment comprises a vertical plate, a horizontal plate, a machine plate, a rotating motor, a small gear, a large gear, a rotating disc, a fixing mechanism and the like. The horizontal plate is fixedly arranged at one end of the vertical plate, a large through hole is formed in the vertical plate, the machine plate is fixedly arranged on one side face of the vertical plate, and the rotating motor is fixedly arranged on the machine plate. By means of the grinding equipment, cylindrical parts with different inner diameters and different thicknesses can be ground, meanwhile, some special cylindrical parts with solid parts and hollow parts can be ground, the functionality is high, and the grinding requirements of more cylindrical parts can be met.

Owner:山东鑫力能机械制造股份有限公司

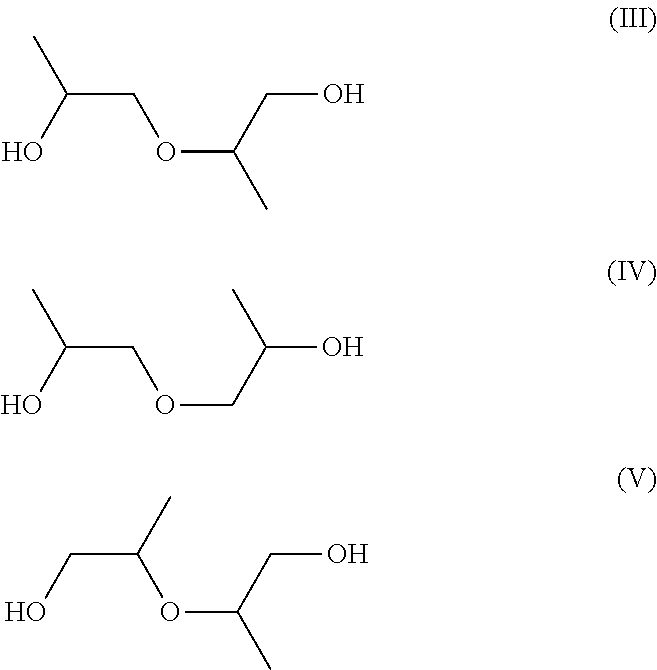

Additive for grinding on rolling mills

InactiveUS20170226011A1Boost grinding efficiencyIncrease productivityCement productionPolymer chemistryRolling mill

At least one glycol compound is used as a grinding aid when grinding at least one solid substance, in particular an inorganic and / or mineral solid substance, in a rolling mill, wherein the at least one glycol compound has a structure according to formula I: (formula 1) and wherein a) R1, R2, R3 each independently of one another stand for H or an alkyl, alkoxy or alkanol group with 1-8 carbon atoms, in particular with 2-4 carbon atoms; and b) X stands for a substituted or unsubstituted alkylene group with 1-8 carbon atoms, in particular 1-4 carbon atoms.

Owner:SIKA TECH AG

Rotating circulation type pseudo-ginseng prilling device

The invention discloses a rotating circulation type pseudo-ginseng prilling device. The rotating circulation type pseudo-ginseng prilling device comprises a base seat, a smashing box, a circulation device and a swing rod, the circulation device is of a circular disc structure, the right side wall of the circulation device is symmetrically provided with a raw material inlet and a circulation material outlet, the raw material inlet communicates with the upper portion of the smashing box through a material inlet pipe, the circulation material outlet communicates with the lower portion of the smashing box through a material outlet pipe, the circulation device is internally and rotatably provided with a rotating plate, the upper side of the rotating plate is fixedly provided with an upper conveyor belt, the bottom of the rotating plate is fixedly provided with a lower conveyor belt, the smashing box is internally and rotatably provided with two smashing rollers, and the position, located below the smashing rollers, of the inner portion of the smashing box is further slantly provided with a screening plate. According to the rotating circulation type pseudo-ginseng prilling device, by means of the arrangement of the circulation device, pseudo-ginseng materials are made to be in and out of the smashing box continuously, the pseudo-ginseng materials are made to be sufficiently smashed,the situation that smashed substance is in block shapes is avoided, subsequent powder grinding operation of the pseudo-ginseng is facilitated, and the production efficiency of enterprises is improved.

Owner:李小婷

Grinding device for mechanical parts

InactiveCN112846963AEffective sandingConvenient grinding operationRevolution surface grinding machinesGrinding drivesMechanical componentsGear drive

The invention discloses a grinding device for mechanical parts, and relates to the technical field of mechanical part machining. The grinding device for the mechanical parts comprises a supporting seat, wherein a group of clamping mechanisms is fixed on the supporting seat, a mechanical pipe fitting is fixed between the two clamping mechanisms, the two clamping mechanisms are symmetrically distributed about the mechanical pipe fitting, a grinding mechanism is fixed to one surface of the supporting seat, and connected outside the mechanical pipe fitting in a sleeved mode, and the grinding mechanism comprises a transmission assembly and a sleeve. According to the invention, a first single-shaft motor in the transmission assembly is controlled to run, so that the first single-shaft motor drives a threaded lead screw to rotate, a plurality of grinding blocks are driven to move along the mechanical pipe fitting to be ground in the mode of lead screw transmission, the plurality of grinding blocks can be driven by a double-shaft motor to rotate in the mode of gear transmission, then effective grinding treatment is carried out on the mechanical pipe fitting, and the grinding operation for the mechanical pipe fitting is simpler and more convenient, so that the grinding efficiency for the mechanical pipe fitting is increased, and manpower consumption in the grinding process for the mechanical pipe fitting is reduced.

Owner:广州市魅雅特贸易有限公司

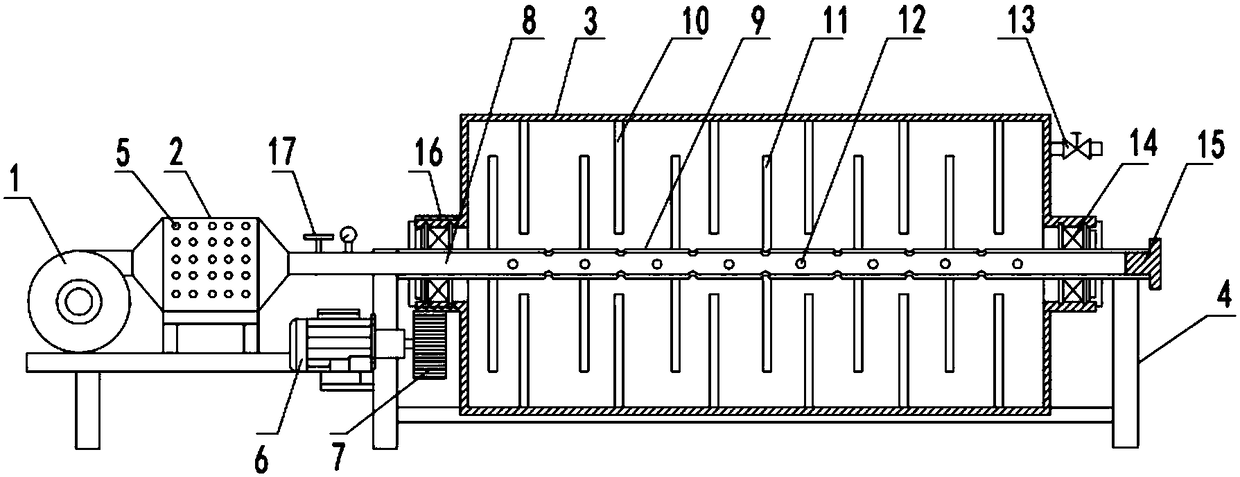

Improved bentonite crushing drum drying device

The invention discloses an improved bentonite crushing drum drying device. The improved bentonite crushing drum drying device comprises a fan, a heating device, a crushing barrel, a mounting rack anda spindle, wherein the spindle is mounted at the axis of the crushing barrel; the two ends of the spindle stretch out of the crushing barrel and are mounted on the mounting rack; the spindle and the crushing barrel independently rotate relatively; the spindle is of a hollow structure; a hot air pipe is mounted in the spindle; one end of the hot air pipe stretches out of the spindle and is connected with the heating device; a plurality of electric heating wires used for heating air are mounted in the heating device; and the fan is mounted on one side of the heating device. The improved bentonite crushing drum drying device has the beneficial effects that crushing and drying can be carried out at the same time, primary processing of bentonite coarse materials is achieved, follow-up powder grinding operation is facilitated, bentonite particles do not block air outlets, the service life of the device is long, the integral structure is simple, and operation and maintenance are quite convenient.

Owner:陈钦先

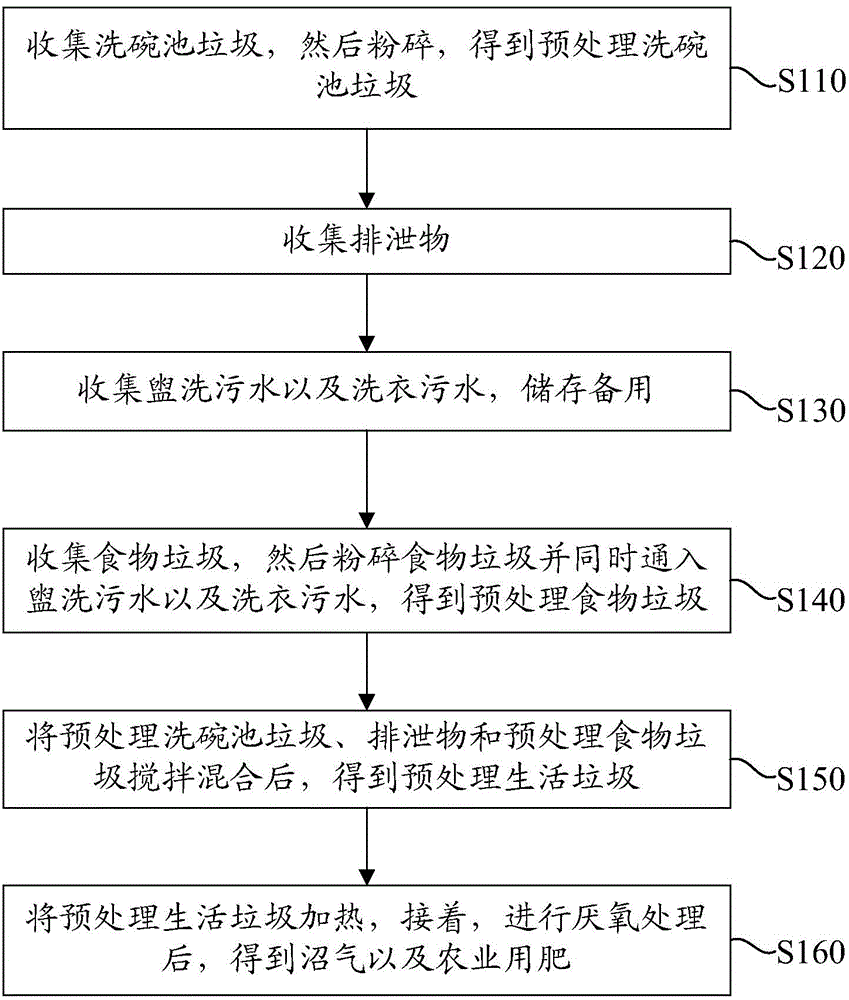

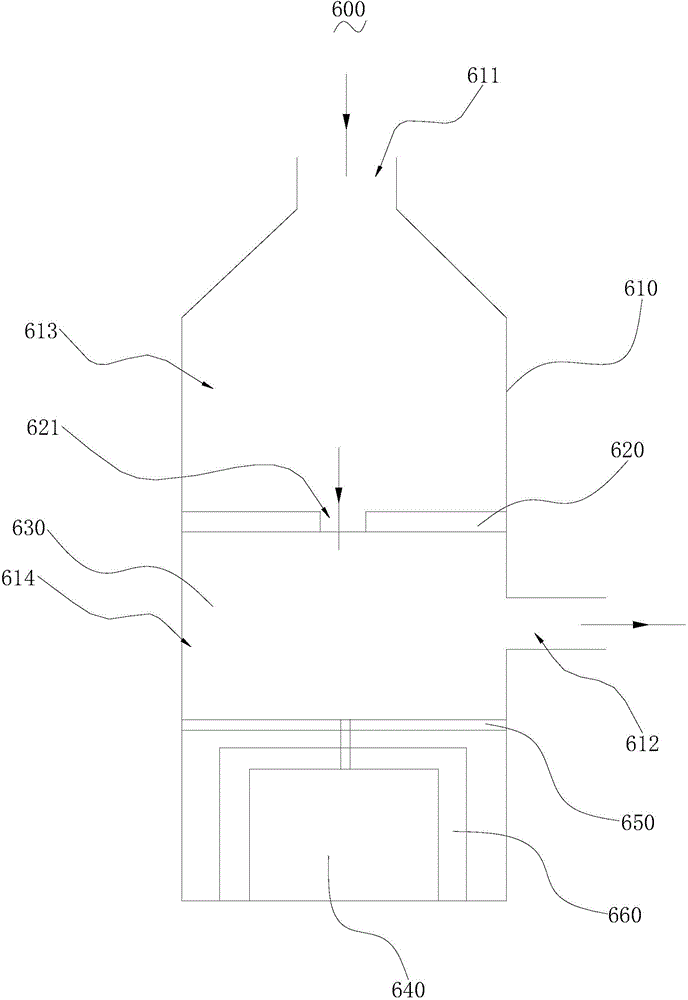

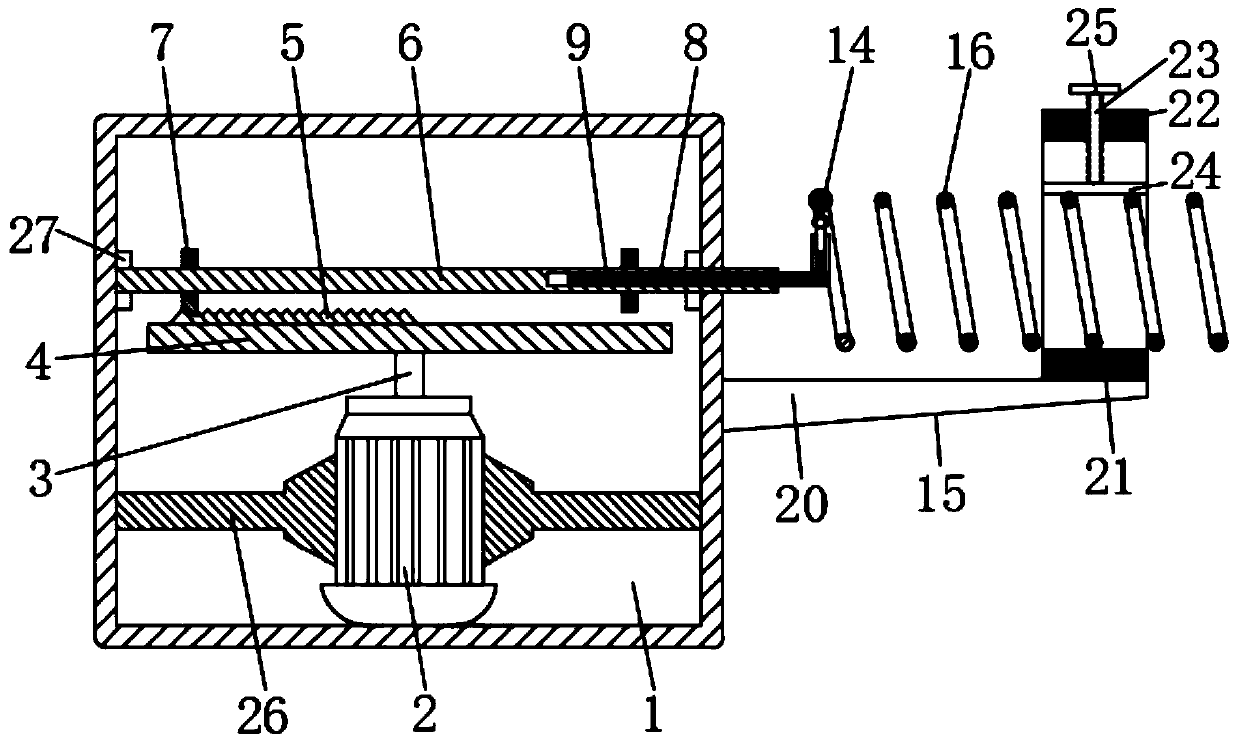

Mixing grinder

ActiveCN104399734AConvenient grinding operationImprove liquiditySolid waste disposalEngineeringSewage

The invention relates to a mixing grinder, which comprises a casing, a material separation plate, a stirring mechanism, a grinding mechanism and a grinding motor. A water inlet, a feeding port and a discharge hatch are arranged on the casing. The material separation plate is fixedly accommodated in the casing, the casing is separated to form a stirring chamber and a grinding chamber, the water inlet and the feeding port are communicated to the stirring chamber, the discharge hatch is communicated to the grinding chamber, a material passing hole is arranged on the material separation plate, and the stirring chamber and the grinding chamber are communicated through the material passing hole. The stirring mechanism is arranged on the casing, and is arranged by relative to the water inlet, the feeding port and the material passing hole. The grinding mechanism is arranged in the grinding chamber, and is respectively communicated to the material passing hole and the discharge hatch. According to the invention, the casing, the material separation plate, the stirring mechanism, the grinding mechanism and the grinding motor are arranged on the mixing grinder, so that the structure of the mixing grinder is simple and compact. In addition, the stirring mechanism is used for mixing and pretreating laundry sewage, washing sewage and food garbage, fluidity of food garbage is increased, transport can be better carried out, and the mixing grinder is in favor of grinding operation by the grinding mechanism.

Owner:韩翼

Building steel pipe cutting device

ActiveCN110076387ASuppress splashConvenient grinding operationTube shearing machinesShearing machine accessoriesMotor driveFurring

The invention discloses a building steel pipe cutting device, and belongs to the technical field of building cutting machinery. The building steel pipe cutting device aims to solve the problems that an existing steel pipe cutting machine usually cuts from the outside of the steel pipe, the operation requires that the thickness of a cutting sheet is larger than the diameter of the steel pipe or thesteel pipe is rotated for cutting, so that chippings are seriously splashed, and burrs are mostly located on the inner side surface and are not easy to polish. The technical key points of the building steel pipe cutting device are characterized by comprising a cutting machine tool, a feeding base, a first positioning base, a second positioning base, a mounting frame and the cutting sheet; the feeding base, the first positioning base, the second positioning base and the mounting frame are sequentially arranged on the cutting machine tool along the same axis, and the cutting sheet with the diameter smaller than that of the steel pipe is arranged on the mounting frame; and a cutting motor drives the cutting sheet to rotate at a high speed, the cutting sheet is also driven by an eccentric wheel to cut the steel pipe from inside to outside, so that splashing of the chippings is effectively inhibited, moreover, the burrs of the cut steel pipe are mostly located on the outer side surface, and therefore the later grinding operation of a steel pipe cut can be more easily carried out.

Owner:江苏冰溶重型机械有限公司

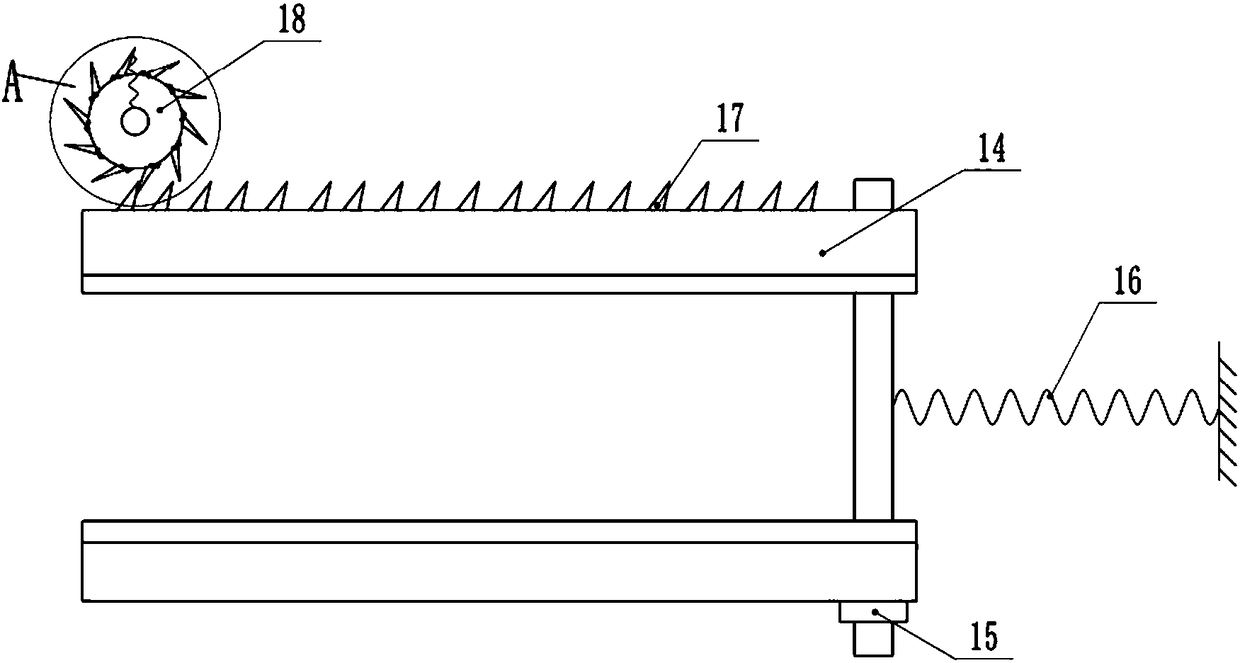

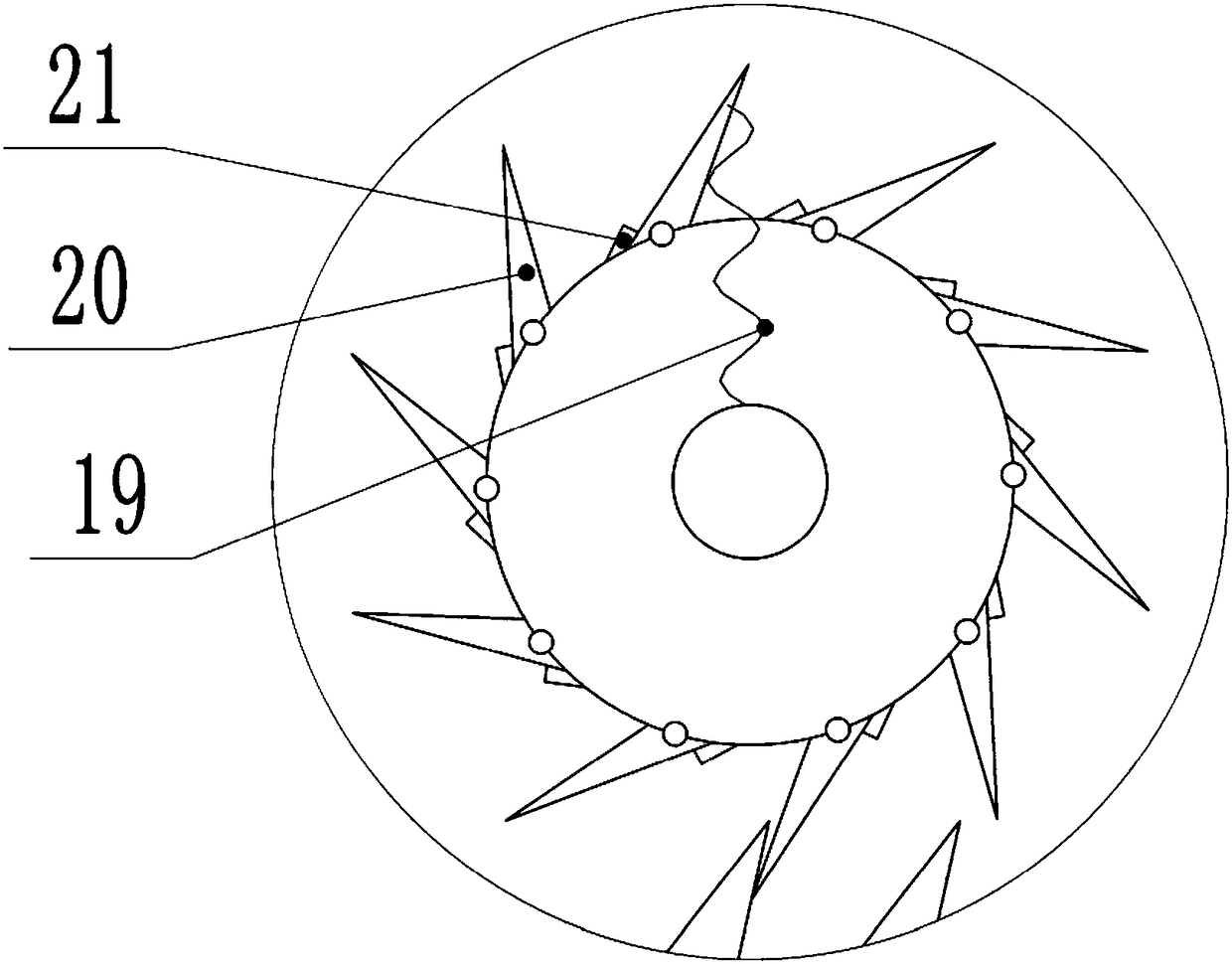

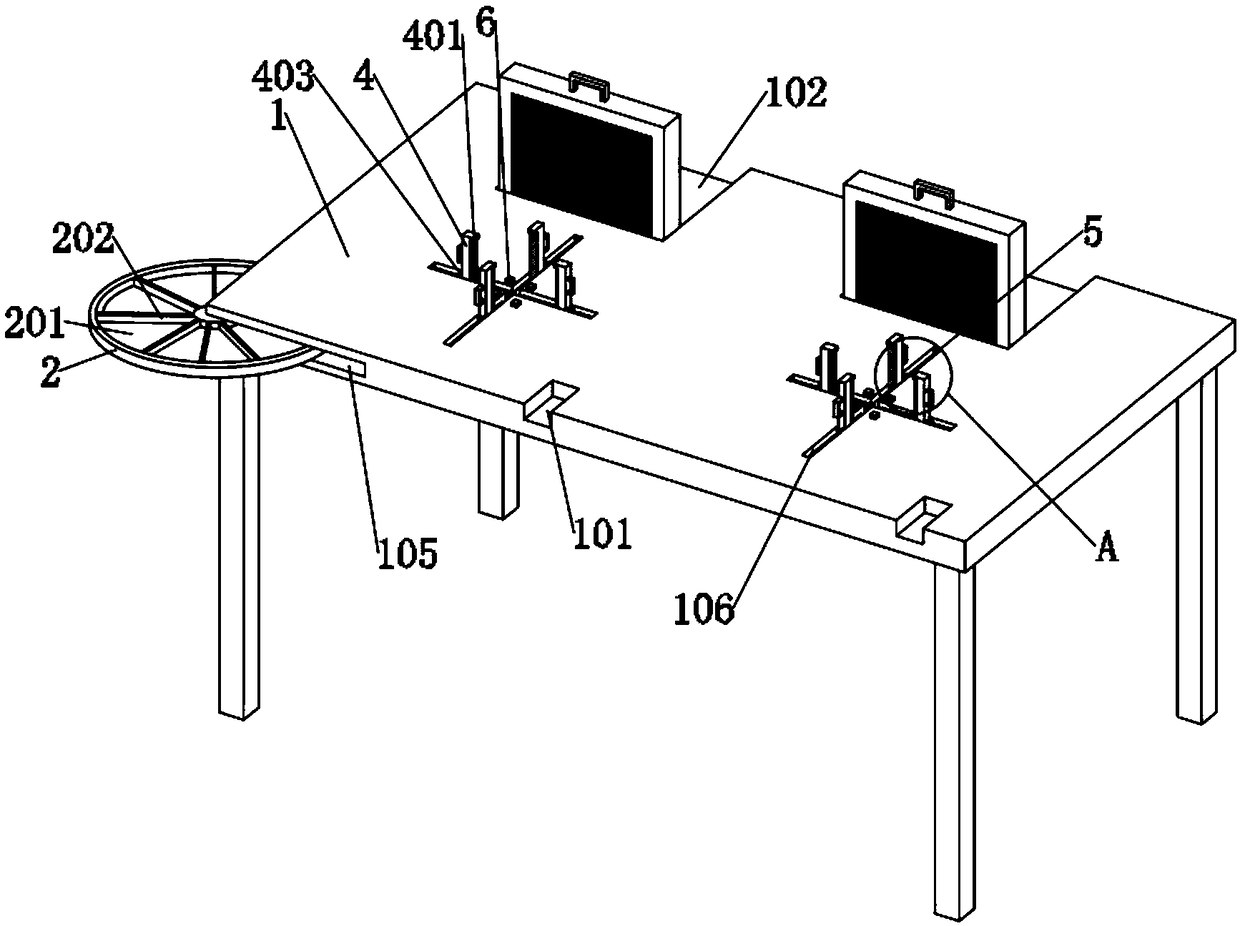

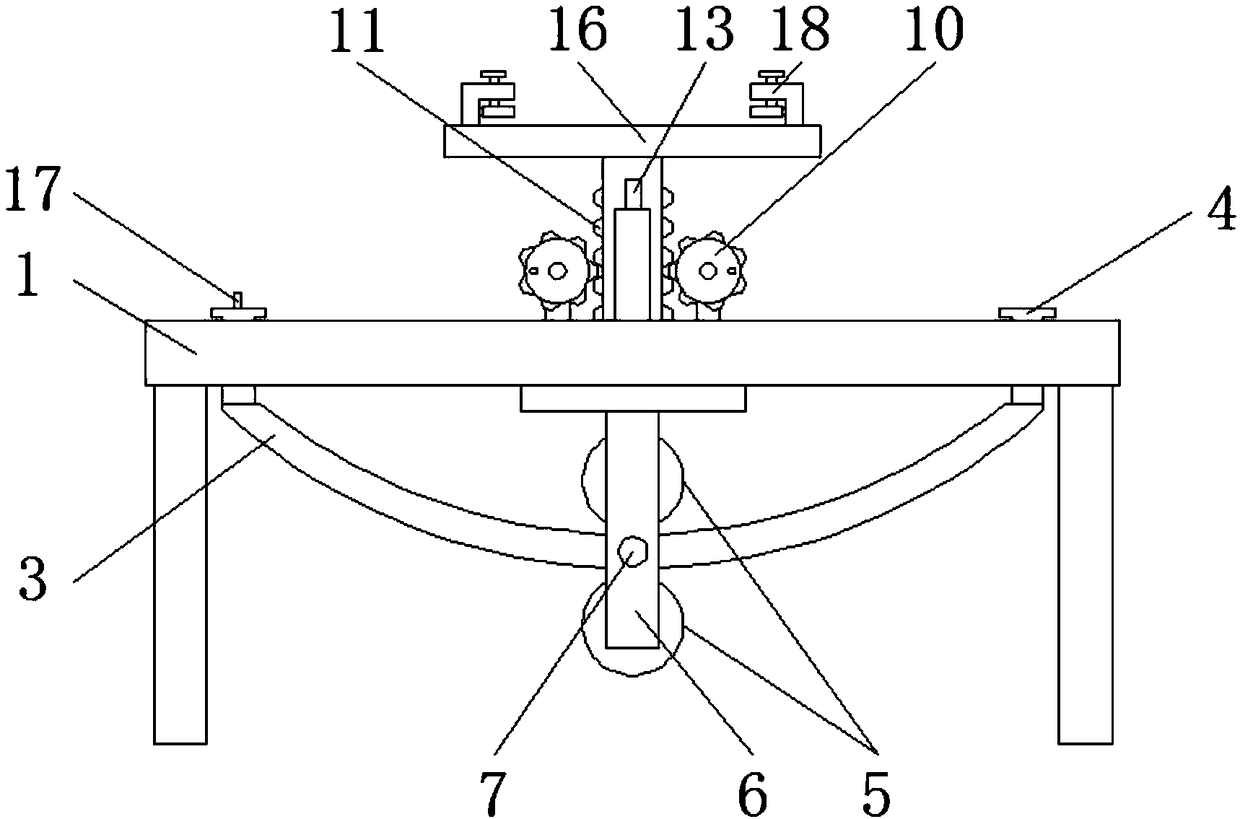

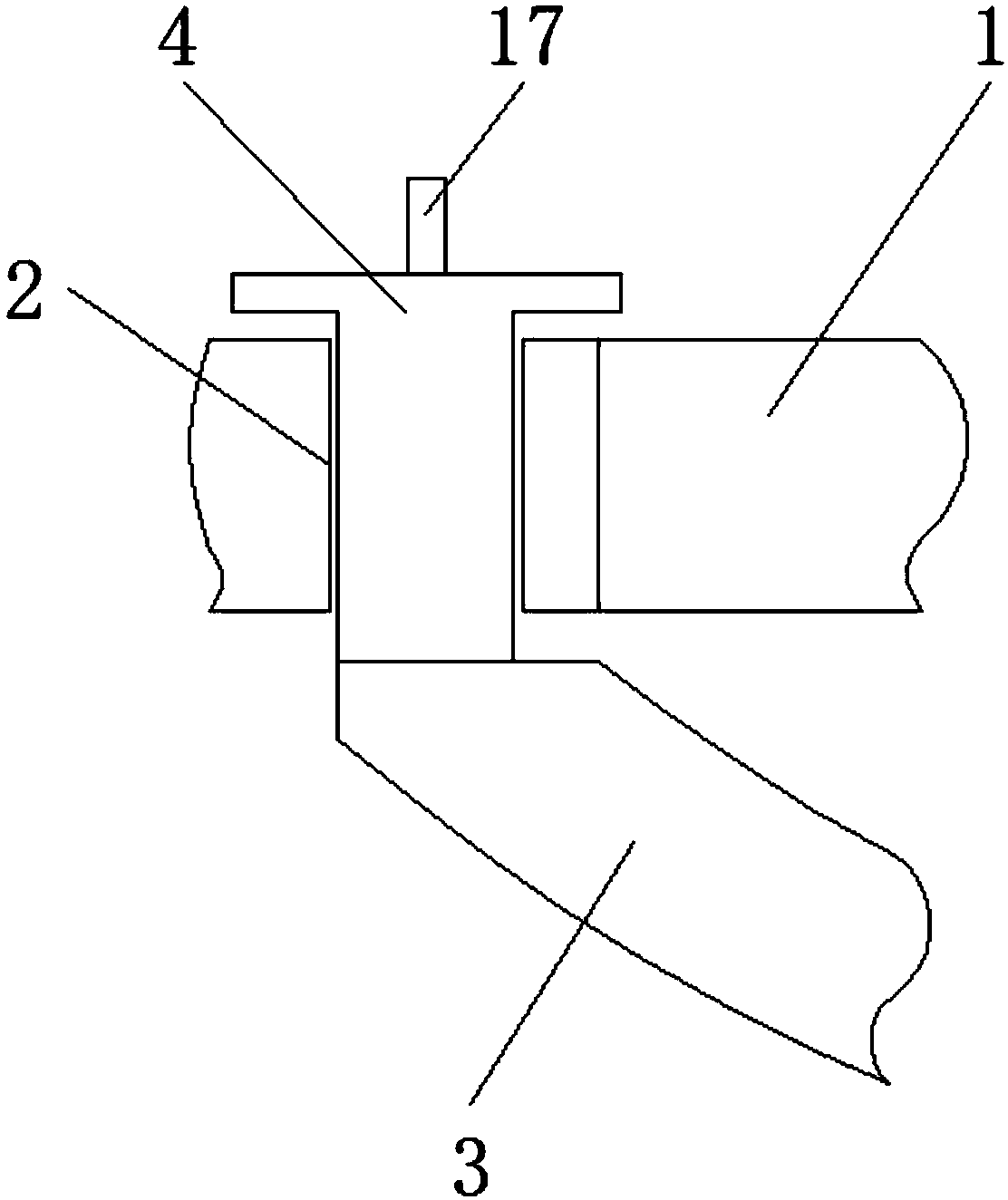

Strip-shaped plate grinding device

ActiveCN108296952AReduce laborReduce labor intensityGrinding carriagesGrinding work supportsEngineeringMechanical engineering

The invention belongs to the technical field of grinding equipment and particularly discloses a strip-shaped plate grinding device. The strip-shaped plate grinding device comprises a base and workingtables fixedly connected to the base. Telescopic rods are arranged on the working tables, and a fixed table is fixedly connected to the upper ends of the telescopic rods. Moving rods are arranged on the fixed table, and the lower ends of the moving rods are provided with gear teeth which are located in the base. Two gears engaged with the moving rods are arranged in the base, and a lifting table is engaged between the two gears. The lifting table and the fixed table are each provided with a grinding disc and a motor for driving the grinding disc to rotate. Material frames used for storing plates are arranged on the working tables, and through holes are formed in the middles of the working tables. First ratchets are arranged on one sides of the material frames, and rotary discs are arrangedon the working tables. Second ratchets are hinged to the rotary discs, and rotary shafts are fixedly connected to the rotary discs. Shaft sleeves are slidably connected to the rotary shafts, and springs are connected between the second ratchets and the shaft sleeves. Transmission mechanisms are arranged between the rotary shafts and output shafts of the motors, and the upper ends of the shaft sleeves are fixedly connected to the transmission mechanisms.

Owner:CHONGQING JIANAN IND & TRADE

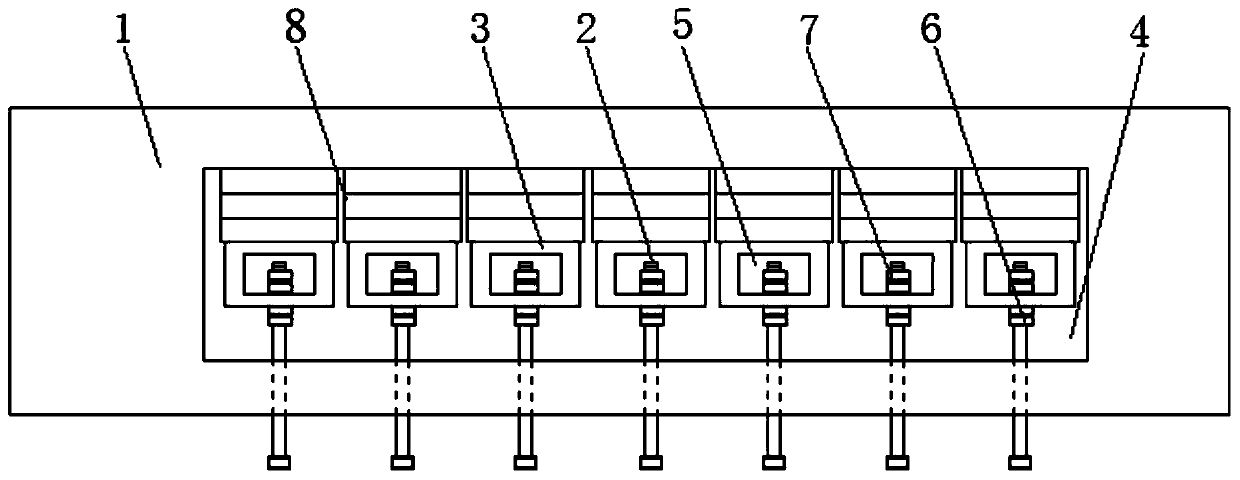

Hard alloy shaft sleeve batch plane grinding clamp

ActiveCN111730456AEasy to operateImprove stabilityGrinding drivesGrinding machinesHydraulic cylinderElectric machinery

The invention discloses a hard alloy shaft sleeve batch plane grinding clamp. The hard alloy shaft sleeve batch plane grinding clamp comprises a base and a second motor, supporting plates are fixed tothe upper side and the lower side of the right end face of a rotating plate correspondingly, a second opening is formed in a support, a first conveying belt device is rotationally connected to the left side of the upper end face of the base, a supporting frame is fixed to the left end face of the top of the support, a fixing frame is fixed to the left side of the supporting frame, a bearing seatis fixed to the right side of the upper end face of the base, a movable frame is slidably connected to the upper end face of the bearing seat, and a third hydraulic cylinder is fixed to the lower endface of the sliding block. According to the hard alloy shaft sleeve batch plane grinding clamp, when a hard alloy shaft sleeve moves to the right side of a first push block, a second conveying belt device stops rotating, the first push block moves rightwards and pushes the hard alloy shaft sleeve to the positions between a corresponding fixed clamping sleeve and a corresponding movable clamping sleeve, and then the corresponding movable clamping sleeve moves towards the inner side to clamp and fix the hard alloy shaft sleeve, so that the stability of the hard alloy shaft sleeve is convenientlyimproved.

Owner:JIANGSU YITONG FLUID TECH

Mould worktable special for mould manufacturing

ActiveCN109434690AEasy to useEasy to fixGrinding carriagesGrinding work supportsPulp and paper industryEmery paper

The invention provides a mould worktable special for mould manufacturing. The mould worktable comprises clamping components, supporting springs, stressed components and overturning plates; the rear part of each clamping component is provided with a pulling component of a rectangular structure through welding; the upper and lower inner positions of two ends of each embedded block are provided withpulleys through rotary shafts in an embedded mode; the outer sides of each embedded block are connected to the outer ends of a corresponding fixing groove through the corresponding springs; the top end of each clamping component is connected to the side of the tail end of the corresponding overturning plate through welding; the middle part of each overturning plate is connected to central positions of the two sides of the inner part of an assembly bin in a main body; moving components are used for fixing abrasive paper and driving the abrasive paper for polishing, so that a mould can be polished according to the own needs, and the abrasive paper can be conveniently used and fixed; and anti-slippery components are used for being in contact with the abrasive paper after the abrasive paper isfixed, so that the rear parts of the abrasive paper are prevented from sliding during use of the moving components and the abrasive paper.

Owner:苏州极普智能科技有限公司

Cutter grinding machine

ActiveCN111215990AIncrease productivityGood accuracyEdge grinding machinesGrinding carriagesPhysicsEngineering

The invention belongs to the technical field of cutter machining, and particularly relates to a cutter grinding machine. The cutter grinding machine comprises a rack and a grinding mechanism, a fixture bearing mechanism, a fixture channel and a fixture mechanical hand. The fixture bearing mechanism comprises a bearing plate and a linear motion assembly. The linear motion assembly is installed on the rack. The driving end of the linear motion assembly is connected with the bearing plate and used for driving the bearing plate to move in the length direction of the bearing plate. A plurality of positioning regions evenly arranged in the length direction of the bearing plate and used for bearing a fixture are arranged on the bearing plate. An opening for allowing the fixture to move in or moveout is formed in the side, close to the grinding mechanism, of each positioning region. The fixture channel is arranged between the grinding mechanism and the fixture bearing mechanism and used for communicating the opening with the grinding mechanism. The fixture mechanical hand drags the fixture so as to feed the fixture inside the fixture bearing mechanism into the grinding mechanism and feedthe fixture inside the grinding mechanism into the fixture bearing mechanism, and therefore automatic fixture feeding and discharging are achieved.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

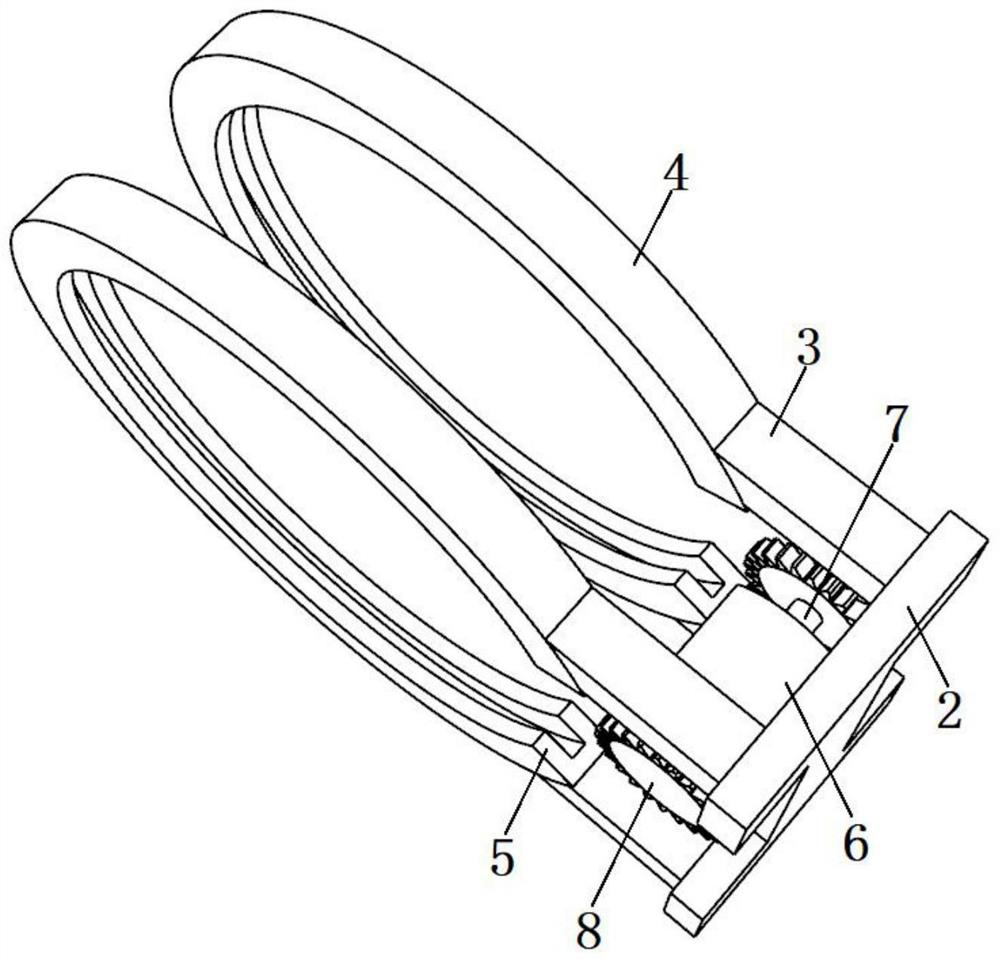

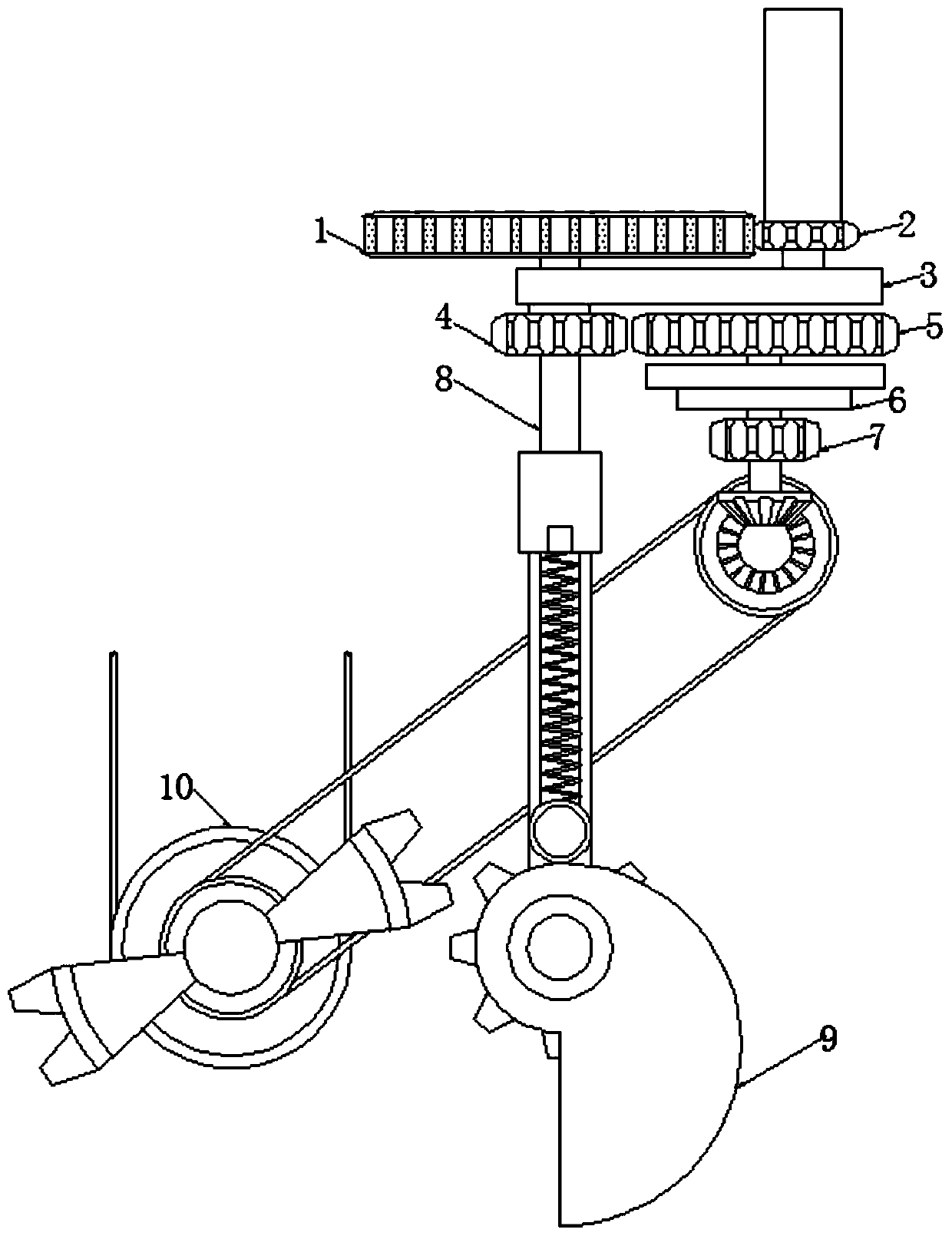

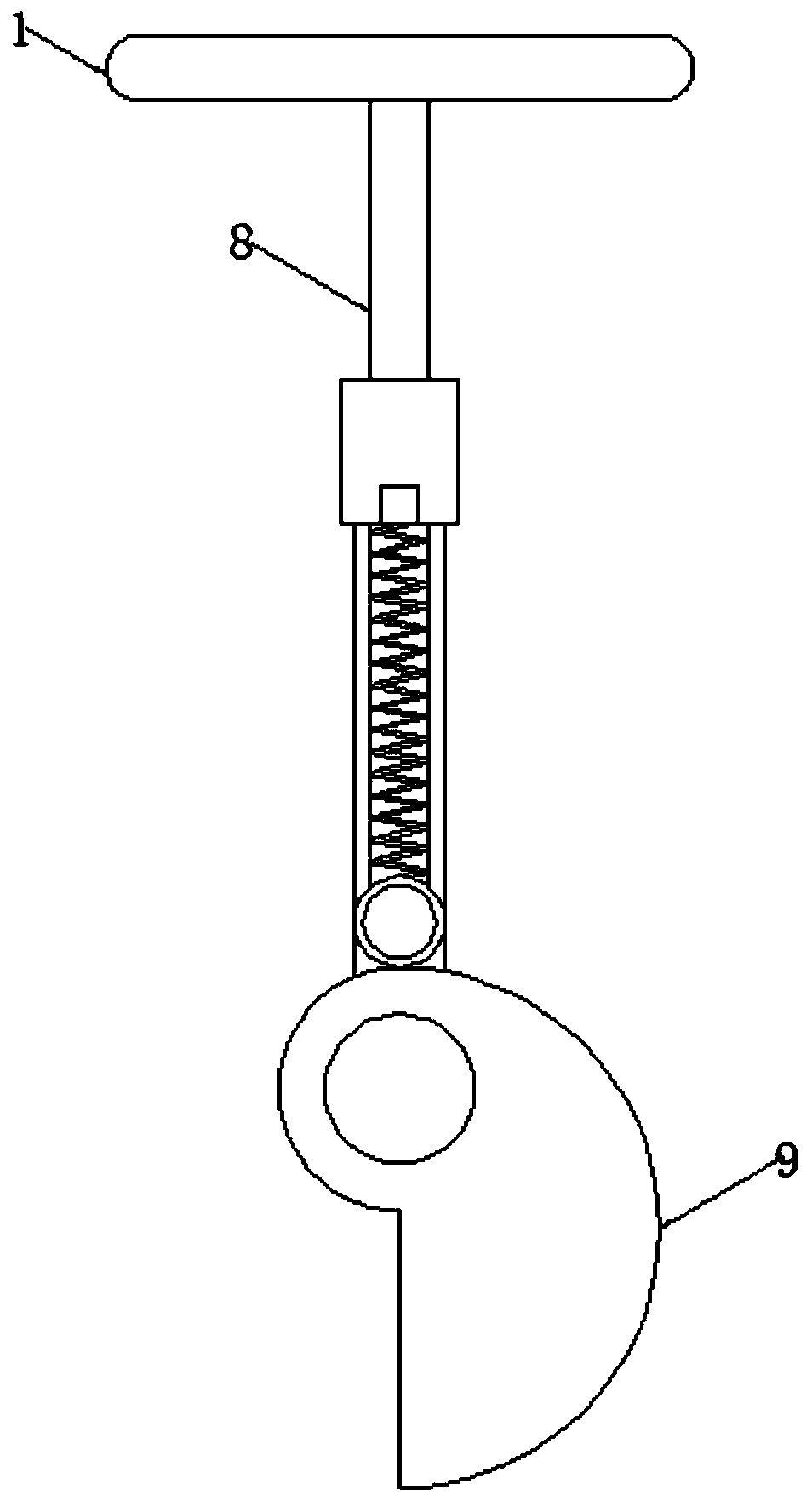

Mechanism for grinding spring

ActiveCN111136531AStable clampingConvenient grinding operationEdge grinding machinesGrinding carriagesAxis of symmetryGear wheel

The invention discloses a mechanism for grinding a spring. The mechanism comprises a shell, a motor is fixedly connected to the bottom of the inner wall of the shell, a first shaft is fixedly connected to the top of an output shaft of the motor, a rotating disc is fixedly connected to the top of the first shaft, the upper surface, close to the edge, of the rotating shaft is fixedly connected withan arc tooth plate, a second shaft is arranged over the rotating disc, the left end of the second shaft carries out limited rotation on the inner wall of the shell, two gears are fixedly connected tothe surface of the second shaft, the two gears are mounted in a manner of being symmetric with the vertical center line of the first shaft as the axis of symmetry, and the surface, close to the rightend, of the second shaft penetrates through the shell and carries out limited rotation on the shell. Through cooperative use of above structures, the problems that in the actual use process, due to the limited grinding area of a grinding disc, the spring cannot be sufficiently ground, for a rough spring, the actual grinding effect of the grinding disc is not ideal, inconvenience is brought to a user, and work efficiency is reduced can be solved.

Owner:杭州千岛湖赋溪实业有限公司

Working table for polishing auto parts

ActiveCN108555774AAngle of adjustment is stableGuaranteed adjustabilityGrinding work supportsEngineeringLarge range

The invention discloses a working table for polishing auto parts. The working table comprises a table body, limiting wheels, a toothed rail and a mounting plate, wherein an annular groove is formed inthe table body and is connected with a sliding ring; a circular arc pipe is fixed on the lower end face of the sliding ring; the limiting wheels are mounted on a movable rack; a gear rack is fixed onthe upper end face of an adjusting plate; the toothed rail is fixed on a lifting column; the lower end face of the mounting plate is connected with the top end of the lifting column; and a fixed clamp is fixed on the upper end face of the mounting plate. According to the working table, the annular groove, the sliding ring, the circular arc pipe, the limiting wheels and the movable rack form a structure, and the structure enables fixed auto parts to move within a circular arc plane at random along with movement of the structure, so that the situation that the polishing angle of the auto partscan be adjusted within a larger range is ensured, and a user can conveniently adopt a polishing tool to polish the auto parts through multiple angles.

Owner:芜湖牧羿自动化科技有限公司

a grinder

InactiveCN105945664BAchieve grindingReduce laborLapping machinesPlane surface grinding machinesArchitectural engineeringTreatment need

The invention discloses a high-efficiency polishing machine. The high-efficiency polishing machine comprises a base, and the top of the base is fixedly connected with first telescopic rods which are symmetrical. A fixed rod is arranged between the two first telescopic rods, and the two ends of the fixed rod are fixedly connected with the two first telescopic rods. The bottom of the fixed rod is fixedly connected with a second telescopic rod. The bottom of the second telescopic rod is fixedly connected with a first motor. A rotary shaft of the first motor is fixedly connected with a first polishing plate. A connecting rod is arranged under the first polishing plate. The bottom of the connecting rod is fixedly connected with third telescopic rods which are symmetrical. A cavity is reserved inside the base. The other ends of the two third telescopic rods both penetrate through the top of the base and extend into the base. According to the high-efficiency polishing machine, double-layer polishing can be carried out on accessories, and traditional polishing operation is simplified; when double layers are polished, polishing treatment need not be conducted repeatedly, so that time is saved, the manual labor amount is reduced, and the working efficiency is improved.

Owner:无锡梦舟实业有限公司

Brake disc grinding process

InactiveCN107695799AQuick clearEfficient removalEdge grinding machinesPolishing machinesAngle grinderEngineering

The invention discloses a brake disc grinding process. The brake disc grinding process comprises the following steps that (1) coarse grinding is conducted, specifically, an automobile brake disc is horizontally fixed, then an angle grinder is used for grinding the surface of the brake disc, and the effect that the included angle between a grinding wheel of the angle grinder and the surface of thebrake disc is 15-30 degrees during grinding is ensured; and (2) fine grinding is conducted, specifically, No. 400-600 dry abrasive paper is used for grinding the surface of the brake disc, and the positions, where cannot be ground by the angle grinder, of the surface of the brake disc is ground by the dry abrasive paper for 18-25 times. The angle grinder is used for coarsely grinding the surface of the brake disc, burrs and oxide layers on the surface of the brake disc can be ground off, and the flatness and smoothness of the surface of the brake disc can be further improved through coarse grinding, fine grinding and polishing, so that the brake disc has better usability, through a ball brush and waterproof abrasive paper, burrs and oxide layers on the inner walls of ventilation ports canbe removed, and the effect that the inner walls of the ventilation ports are smooth after grinding can be ensured.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

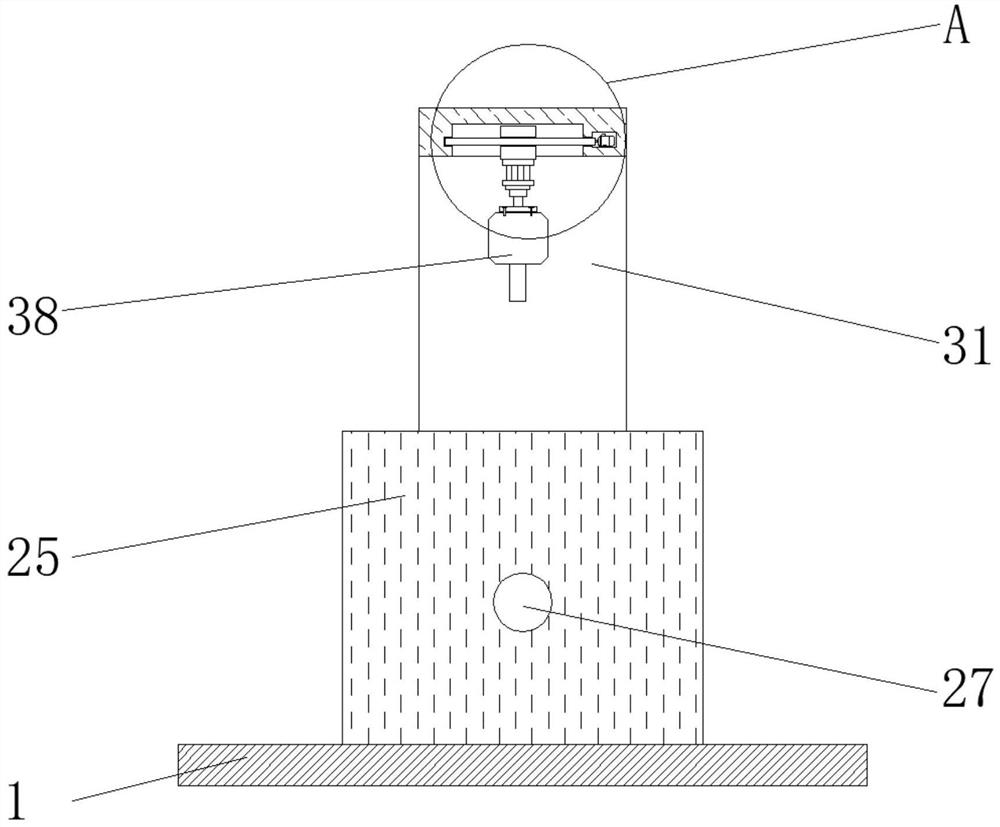

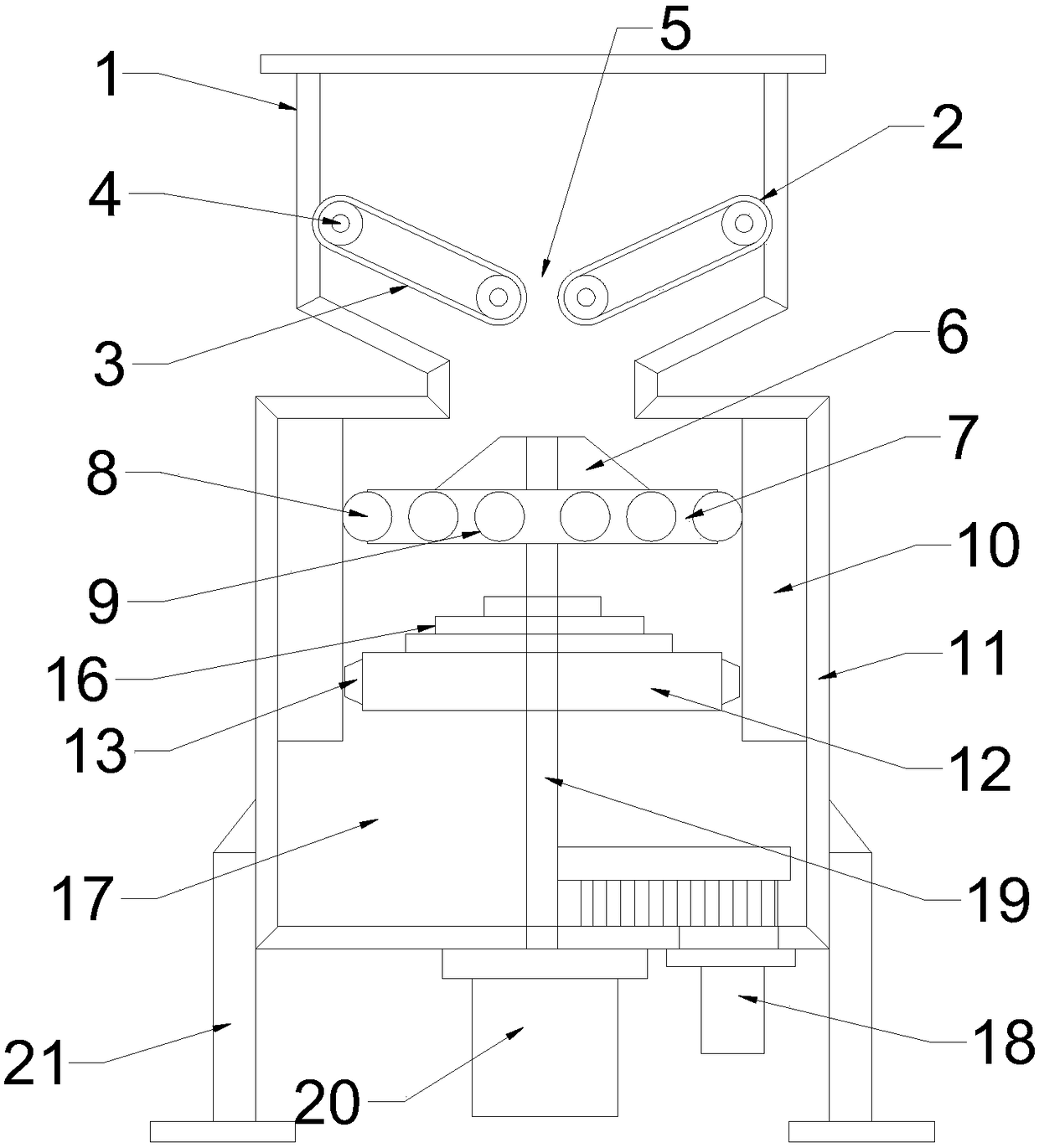

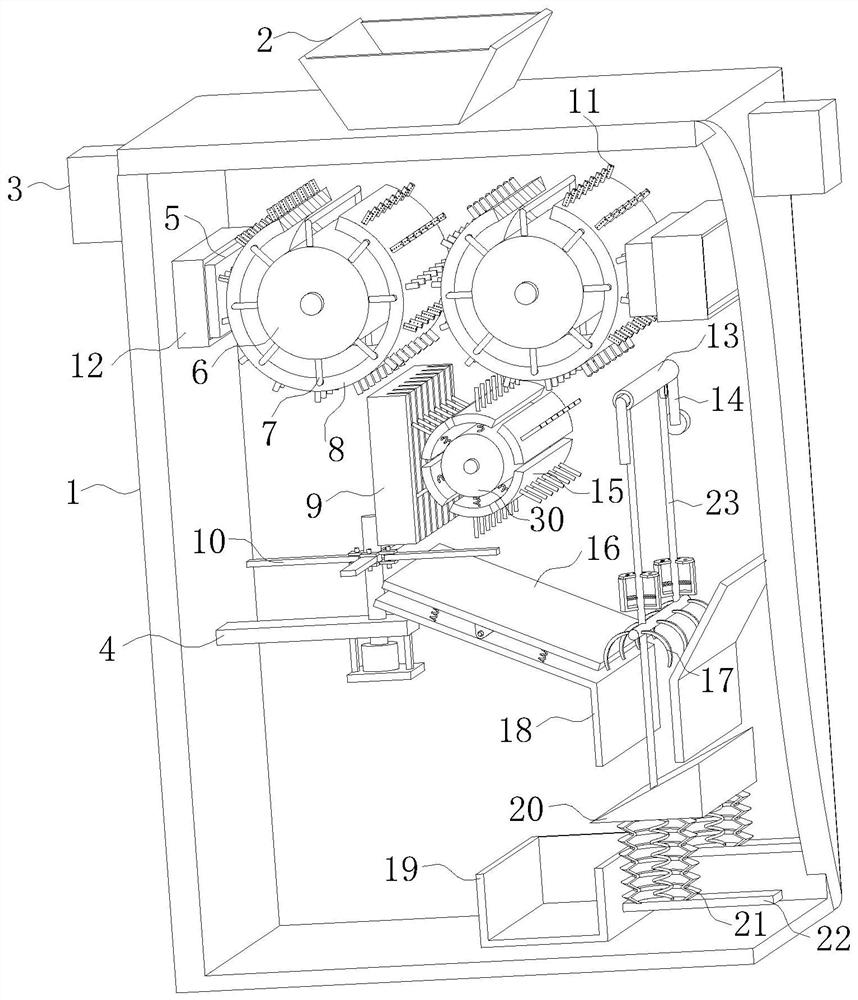

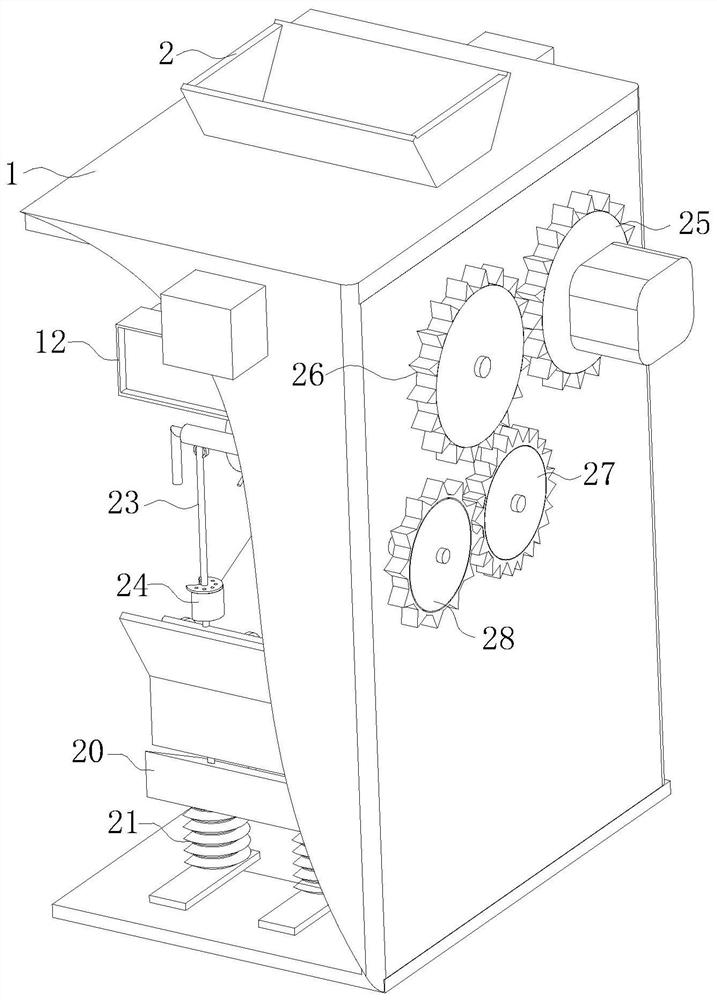

Ball type vertical efficient multistage grinding device

InactiveCN108405155AUniform particlesImprove the crushing and grinding effectGrain treatmentsElectric machineryBall type

The invention discloses a ball type vertical efficient multistage grinding device which comprises a feed hopper, a pre-crushing chain wheel set, a primary grinding wheel disc, a grinding barrel, a main case, a secondary grinding disc and a motor. The main case is fixed onto a framework, the grinding barrel is fixed onto the inner wall of the main case, a collecting cavity is arranged in the main case and is positioned below the grinding barrel, a discharge pipe is connected onto the main case and is positioned at the bottom of the collecting cavity, the feed hopper is connected with the top ofthe main case, the pre-crushing chain wheel set is mounted inside the bottom of the feed hopper, the primary grinding wheel disc and the secondary grinding disc are mounted in the grinding barrel andare fixed onto a rotary shaft, a plurality of ball grooves are formed in the outer side of the primary grinding wheel disc, grinding balls are embedded in the ball grooves, and a plurality of grinding teeth are arranged on the outer side of the secondary grinding disc. The ball type vertical efficient multistage grinding device has the advantages that material granules are uniform under the condition of pre-crushing and grinding treatment carried out by the pre-crushing chain wheel set, the grinding balls of the primary grinding wheel disc and the grinding teeth of the secondary grinding disc, good crushing and grinding effects can be realized, and the efficiency can be improved.

Owner:HUNAN KUANGCHU TECH CO LTD

Straw recycling system

The present invention belongs to the technical field of straw recycling and particularly relates to a straw recycling system. The straw recycling system comprises a recycling box, a discharge chute and filament splitting needles; a rear side wall of the recycling box is provided with two groups of squeezing rollers and besides the two groups of the squeezing rollers are symmetrically arranged about a bisector of the rear side wall of the recycling box; a rotating shaft of the squeezing roller positioned on a left side penetrates through the rear side wall of the recycling box and is in transmission connection with a driving motor; a driving circular gear is fixedly arranged on a rotating shaft of the driving motor; a rotating shaft of the other group of the squeezing roller penetrates through the rear side wall of the recycling box and is fixedly connected with a driven circular gear; and the driven circular gear and the driving circular gear are in meshed transmission, and a transmission ratio of the driving circular gear to the driven circular gear is one. Straws are subjected to extrusion, filament splitting, roughening, cutting and segmenting, thus the straws are treated into acoarse filament and segment structure which can be better dispersed when applied in cementing materials such as concrete, and besides, the treated straws have good blinding power to the cementing materials and can play functions of enhancing compression resistance and bending resistance of the cementing materials.

Owner:李绍

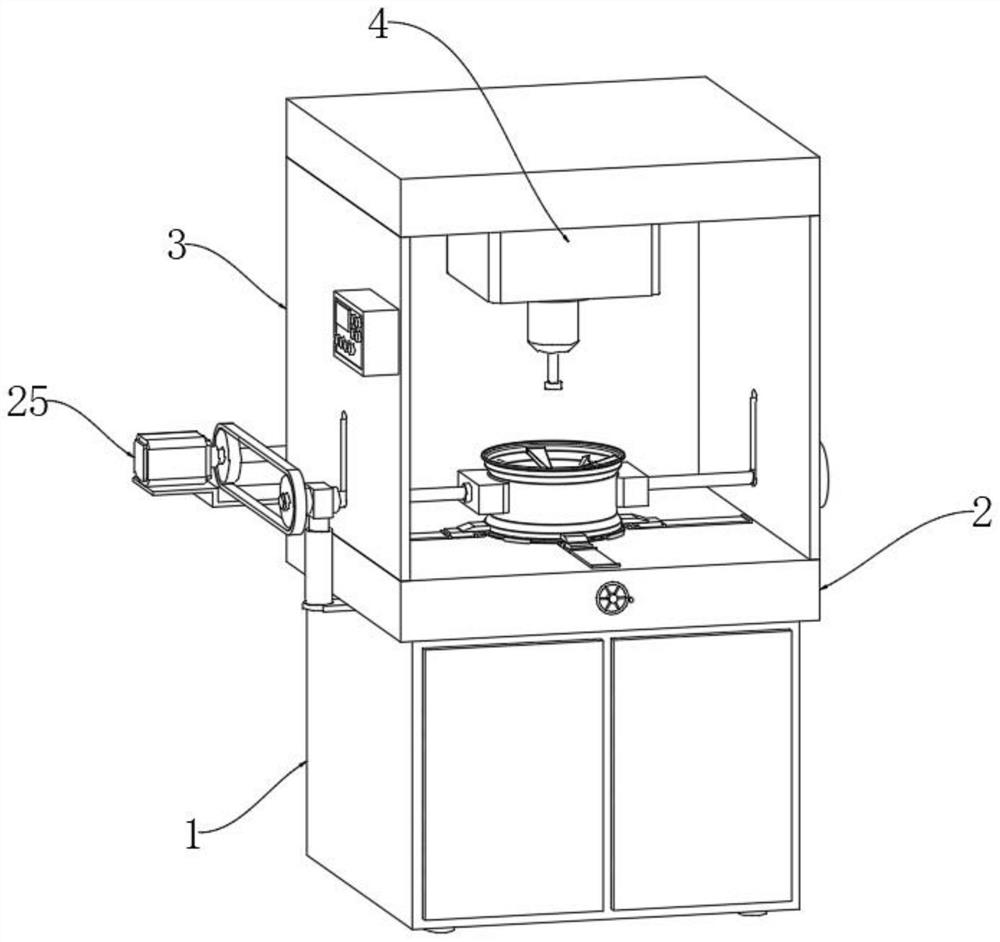

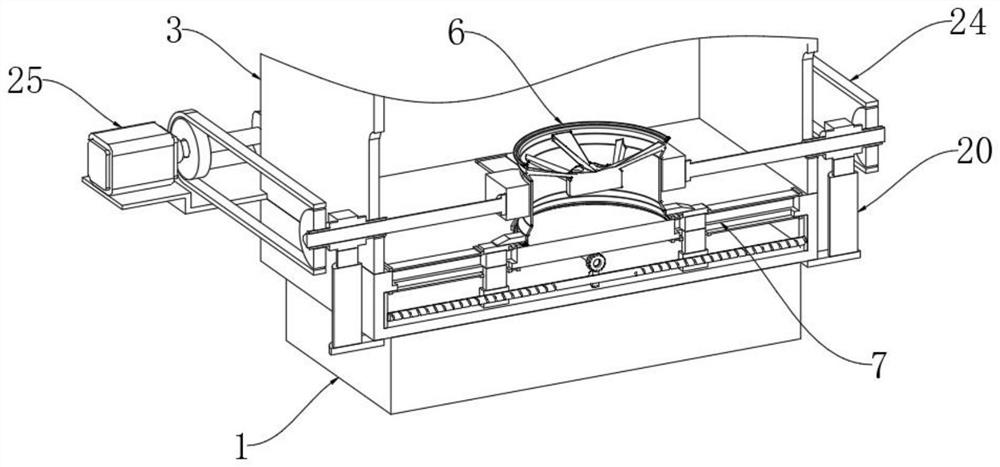

Surface machining equipment for aluminum alloy hub

PendingCN114290222AImprove work efficiencyProblems affecting work efficiencyPolishing machinesGrinding drivesCrankGear wheel

The invention relates to the technical field of hub surface machining, in particular to aluminum alloy hub surface machining equipment which comprises a cabinet. The operation table is mounted at the top of the cabinet; the upper machine body is mounted at the top of the operation table; the polishing equipment is mounted at the top end in the upper machine body; and the fixing assembly comprises sliding rails, sliding blocks are slidably connected into the sliding rails, bidirectional threaded lead screws are arranged in the operation table, bevel gears are installed in the middles of the outer sides of the bidirectional threaded lead screws, and one ends of one set of bidirectional threaded lead screws penetrate through the operation table and are provided with cranks. The problems that when the periphery of a hub is fixed, clamps need to be rotationally adjusted one by one, so that the hub is located in the center, and the working efficiency of operators is affected are effectively solved.

Owner:ZHENJIANG YUJIU INTELLIGENT EQUIP LTD BY SHARE LTD

Dedusting workbench for metal polishing

InactiveCN109202730AHigh activityEasy to grindGrinding/polishing safety devicesEngineeringHigh kinetic energy

The invention provides a dedusting workbench for metal polishing. The workbench comprises a workbench pedestal, a bottom movement space and pulleys; the back end surface of a handle is coaxially and fixedly connected with a worm, the upper portion of the workbench pedestal is axially connected with a turning bench, a bench clamp is fixedly connected onto the turning bench, and a bottom blower fanis fixedly connected to the inner bottom of the workbench pedestal. The bottom of the front end surface of a top dust absorbing plate is in sliding connection with a shielding curtain via the pulleys.The foots of a user can move conveniently via the bottom movement space, convenience is provided for polishing, and the working efficiency is improved; and the back of the top dust absorbing plate isof an inclined structure, dust with high kinetic energy and not absorbed by the top dust absorbing plate can be reflected to a dust-absorbing plate in the surface of the workbench during polishing, and dust is avoided from escaping after rebounding or returning to a worker and causing damage.

Owner:新昌县奔力机械有限公司

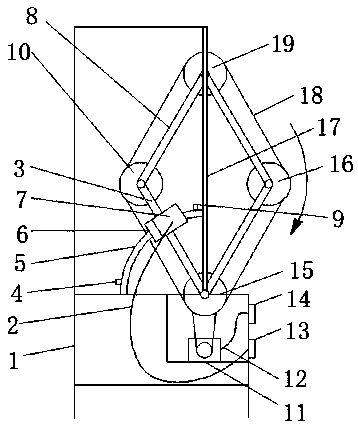

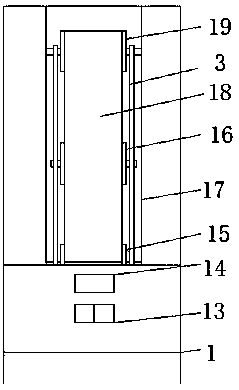

Door machining tenoning machine

PendingCN110948634AGuaranteed stabilityAvoid labor-intensiveTongue/grooves making apparatusTenon making apparatusGear wheelElectric machinery

The invention discloses a door machining tenoning machine. The door machining tenoning machine comprises a machining box body, grinding blocks and a second driving motor; a first driving motor is fixed to a bearing on one side of the machining box body, and the output end of the first driving motor is connected with a rotating rod; an air bellow is connected to the outer side of the rotating rod in a penetrating mode, and a dust removing pipeline is connected to the bottom of the air bellow in a penetrating mode; the grinding blocks are installed on the left side and the right side of the airbellow, and an auxiliary pulley is arranged right below the air bellow; and an equipment box door is hinged to the outer side of the machining box body, a tenon is connected to the outer side of the machining box body in a penetrating mode, a recycling base is welded to the bottom of the machining box body, and a discharging box door is hinged to the outer side of the recycling base. The door machining tenoning machine is provided with a plane gear and a driving electric cylinder, and in the machining process, the plane gear is conveniently used for driving the auxiliary pulley to rotate, so that the situation that a wooden door needs to be pushed by personnel in the machining process to consume a large amount of labor intensity is avoided.

Owner:HANGZHOU HAODI DECORATES FURNITURE

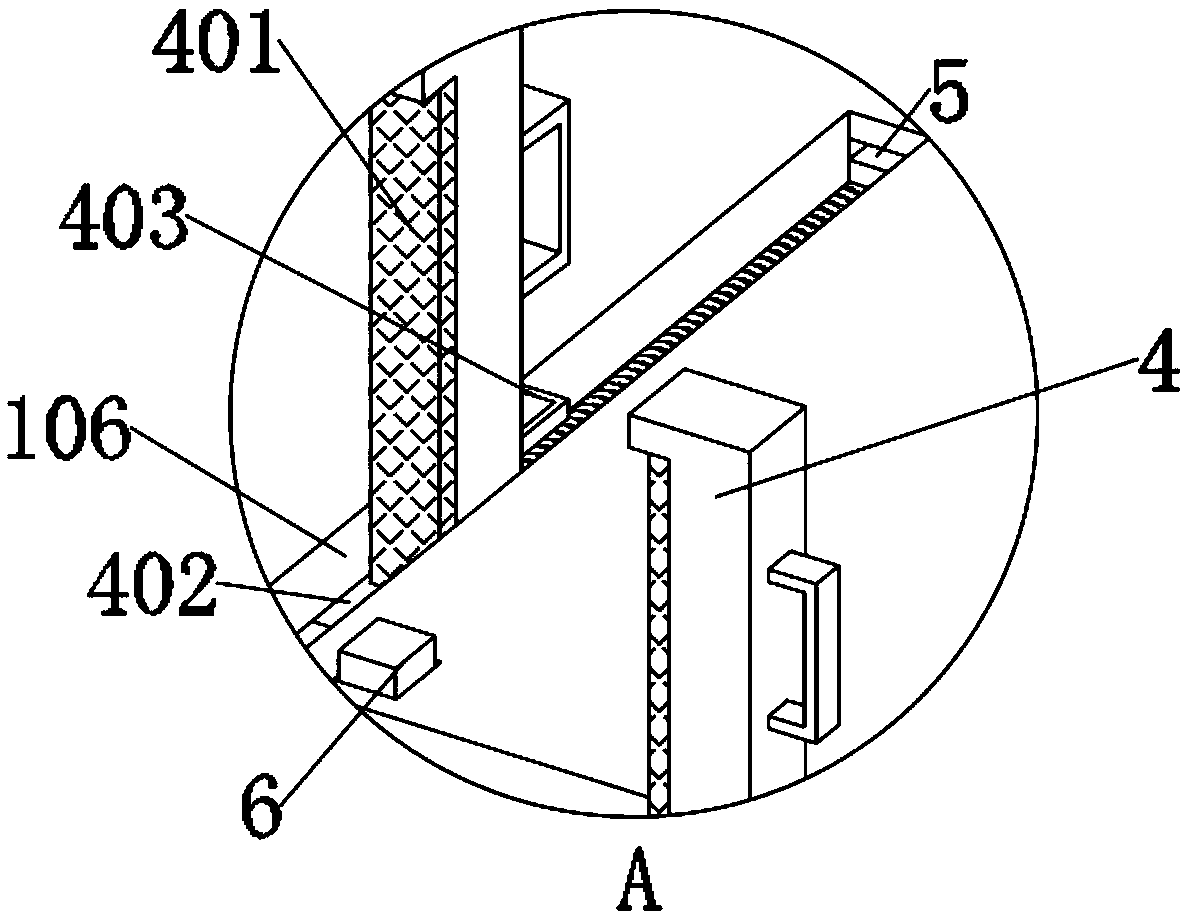

Building high-efficiency tile edge grinding equipment achieving automatic locating and fixing

InactiveCN111360629AFacilitate subsequent grinding operationsConvenient grinding operationEdge grinding machinesGrinding drivesGear wheelBar pressing

The invention relates to the architectural technological field, and discloses building high-efficiency tile edge grinding equipment achieving automatic locating and fixing. The equipment comprises a supporting plate, and the outer side of the supporting plate is movably connected with a first gear. A first rotating disc rotates so that the supporting plate can intermittently move up and down, andtiles move therewith; a second rotating disc rotates so that a press rod can intermittently move up and down; when the press rod moves up, vertical rods of a clamping rod get close to each other, andthe positions of the bottom tiles are adjusted; when the press rod moves down, the vertical rods of the clamping rod get away from the tiles, and subsequent grinding operation can be achieved conveniently; the bottom of the press rod is attached to the tiles, the function of fixing positions is achieved on the tiles, the tiles are prevented from deviating when ground, and grinding operation can becarried out smoothly; and a connecting plate rotates so that the first gear can achieve autorotation while turning over, a grinding tool at the top of the first gear synchronously moves, the edges ofthe tiles are effectively ground, and the situation that the surfaces of the tiles are uneven, and use of the ties is influenced is avoided.

Owner:日照金慧科技信息咨询有限公司

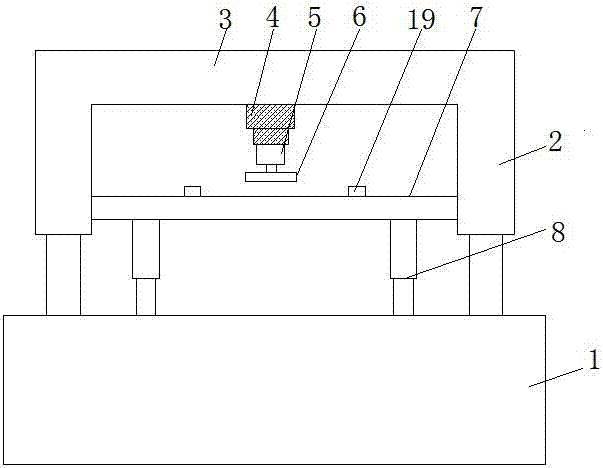

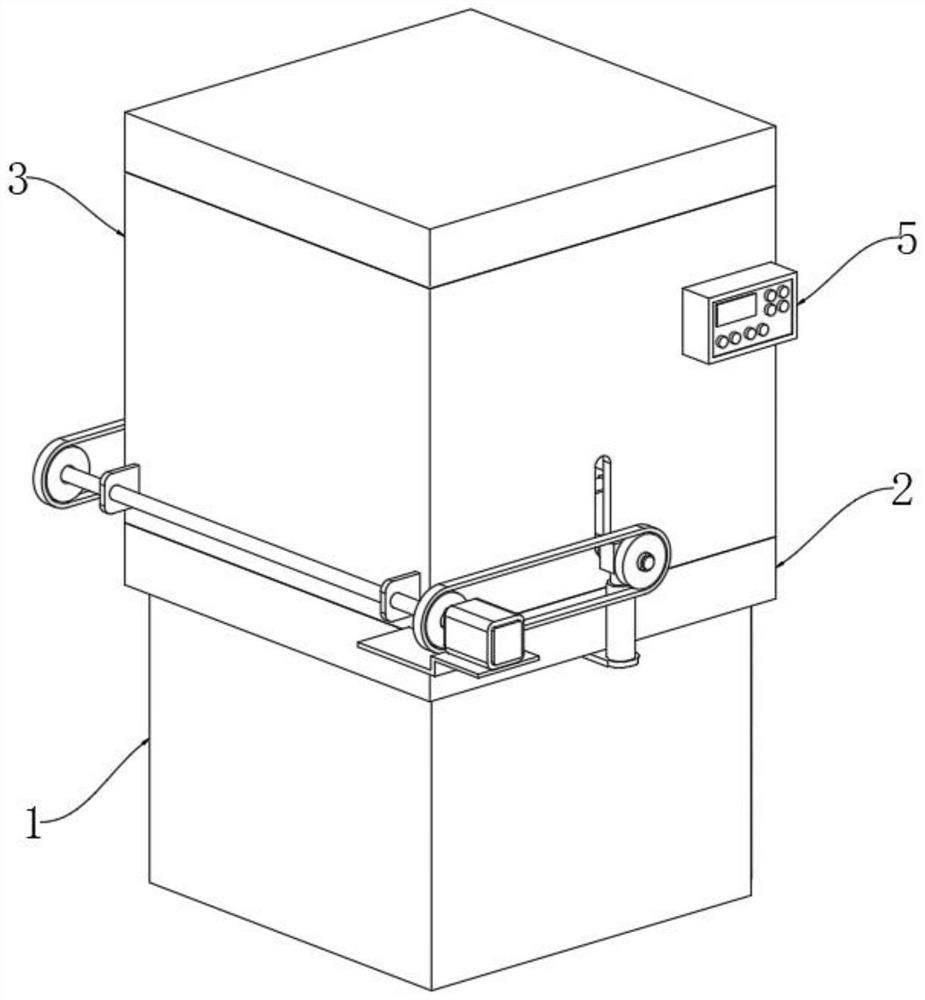

Bearing ring grinding equal-high rotary table

InactiveCN102126170AConvenient grinding operationControllable sizePlane surface grinding machinesDrive motorEngineering

The invention relates to a bearing ring grinding equal-high rotary table, which comprises a driving motor fixed on one side of the top end face of a chassis of the table, wherein the output shaft of the driving motor is fixed with a driving wheel; a bearing block is fixed on the other side of the top end face of the chassis of the table; the top end part of the bearing block is fixed with a bearing end cover; a bearing is arranged in the bearing block; a rotating spindle is arranged in the bearing block rotationally through the bearing; the bottom end part of the rotating spindle is fixed with a driven wheel; a synchronous belt is arranged on the driving wheel and the driven wheel; the top end part of the rotating spindle is fixed with a sucker connecting bottom plate; a distance is spaced between the bottom end face of the sucker connecting bottom plate and the top end face of the bearing end cover; and a permanent magnet sucker is fixed on the sucker connecting bottom plate. The bearing ring grinding equal-high rotary table can realize equal-high inner and outer rings of the bearing, and achieve the effects of coping the protrusion of the bearing and realizing equal height; and the coping operation is simple and the dimension is easy to control.

Owner:WUXI NO 2 BEARING

Plate edge burr grinding device

InactiveCN112658871AEasy to achieve real-time clampingIncrease productivityEdge grinding machinesGrinding carriagesStructural engineeringMechanical engineering

The invention discloses a plate edge burr grinding device, and relates to the related technical field of plate processing. The plate edge burr grinding device comprises a supporting mechanism and a grinding mechanism, wherein the supporting mechanism comprises a transverse supporting beam and a longitudinal supporting beam, and the transverse supporting beam and the longitudinal supporting beam are distributed in a T-shaped structure and are fixedly welded to each other; a buffering barrel is vertically welded to the middle section of the upper end of the longitudinal supporting beam, an inverted-T-shaped clamping groove is formed in the top end of the buffering barrel, and an inverted-T-shaped buffering rod is inserted into the inverted-T-shaped clamping groove in a sliding mode; and the grinding mechanism comprises a connecting seat, the connecting seat is fixedly welded at the upper end of the inverted-T-shaped buffering rod, and adjusting mechanisms used for adjusting the grinding position of the grinding mechanism are arranged on the two sides of the upper end of the longitudinal supporting beam. According to the plate edge burr grinding device, plates of different sizes and thicknesses can be conveniently clamped in real time, grinding operation is convenient, the grinding operation efficiency is improved, and finally the production efficiency of finished plates is improved.

Owner:周西丽

Guitar grinding device capable of adjusting grinding face

InactiveCN107671653AConvenient grinding operationReduce workloadGrinding drivesBelt grinding machinesPulp and paper industrySurface grinding

The invention discloses a guitar grinding device capable of adjusting the grinding surface. It includes a frame, the frame is fixedly connected with the first roller, one side of the first roller is connected with the first motor, the two sides of the first roller are connected with the second roller through the first movable connecting rod, and the two sides of the first roller are connected with the second roller. The movable connecting rod is connected with the third roller, the two sides of the second roller and the third roller are respectively connected with the fourth roller through the second sliding connecting rod, and the both sides of the fourth roller are connected with vertical sliding rods through the chute; Abrasive belts are wound on the first cylinder, the second cylinder, the third cylinder and the fourth cylinder. The invention has the beneficial effects that the angle of the grinding surface can be adjusted according to the grinding parts during the grinding process, the guitar and components of the grinding radian or groove are simple, the grinding operation is simple, the workload is small, and the working efficiency is high.

Owner:贵州金韵乐器有限公司

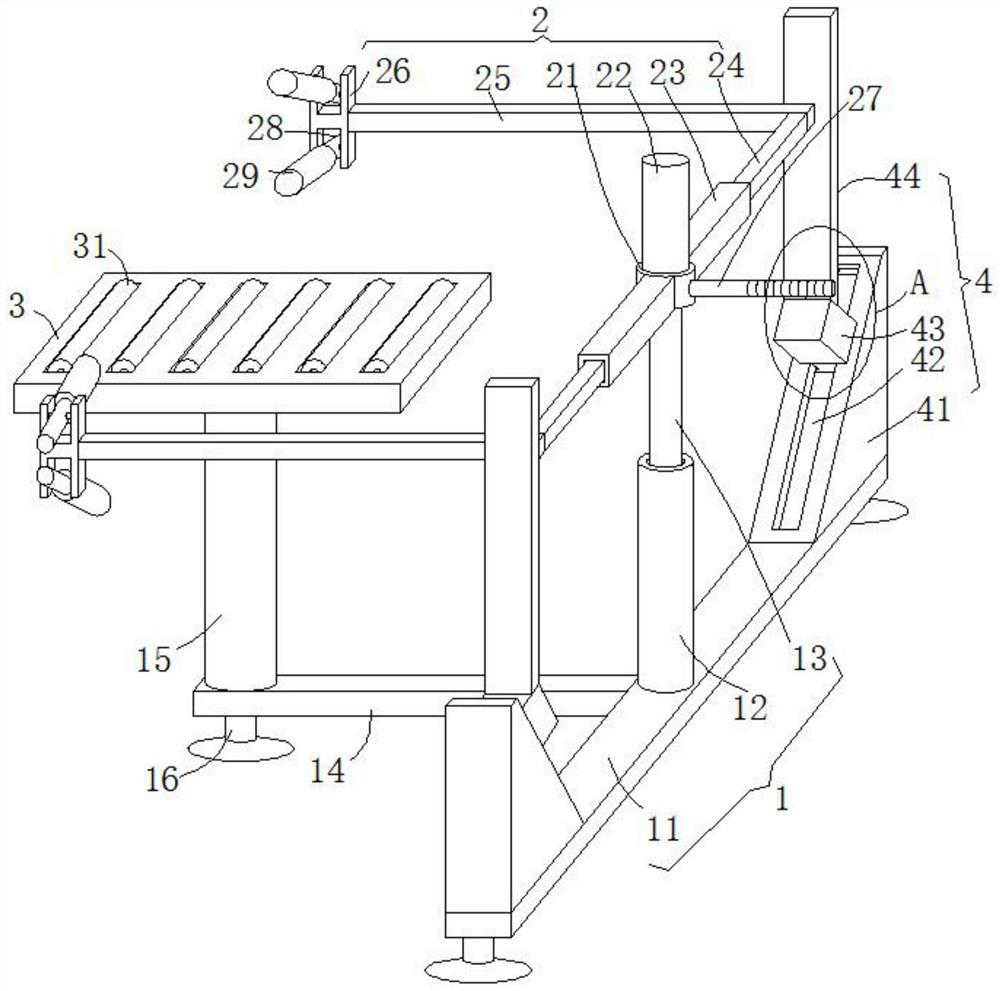

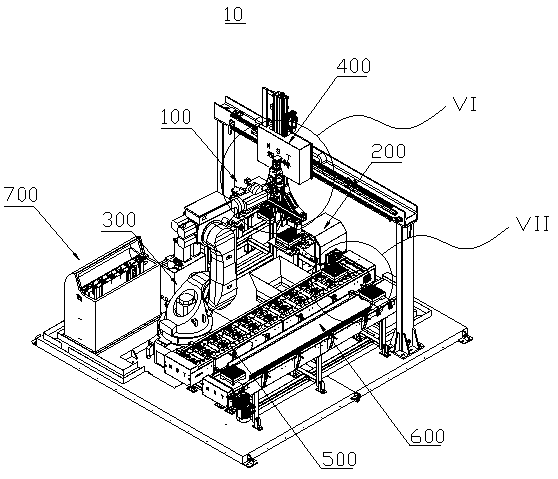

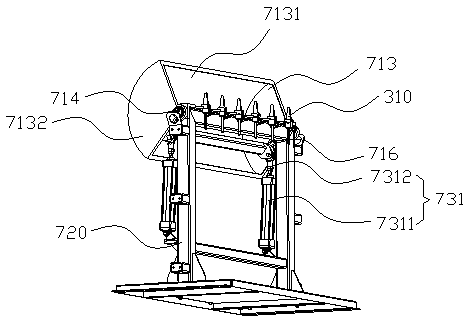

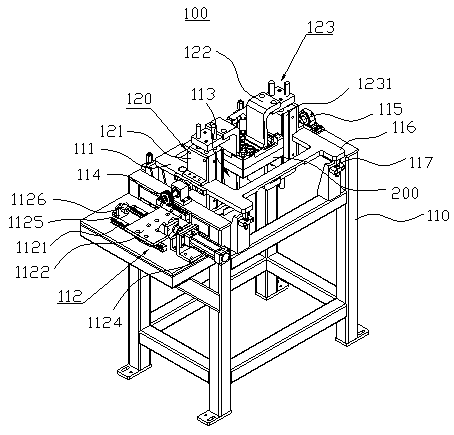

Robot grinding machining production line

PendingCN111590433ASimple structureReasonable designAutomatic grinding controlGrinding machinesProduction lineRobot machining

The invention discloses a robot grinding machining production line, and relates to the technical field of robot machining. The robot grinding machining production line comprises a grinding machine arm, a grinding fixing device, an overturning transposition device, a component transferring device, a feeding conveying belt and a discharging conveying belt. During machining, a component moves to theposition below the component transferring device along the feeding conveying belt, the component transferring device grabs and places the component to the grinding fixing device, the grinding fixing device fixes the component, and the grinding machine arm conveniently conducts grinding operation. After one face is ground, the component transferring device grabs and places the component to the overturning transposition device, and after the overturning transposition device conducts face overturning on the component, the component transferring device is used for grabbing and placing the component to the grinding fixing device for grinding of the other face, and finally the component transferring device is used for placing the component to the discharging conveying belt. The whole robot grinding machining production line is simple in structure, reasonable in design and convenient to use, the full-automatic operation of component feeding, grinding and discharging can be achieved, and highmachining efficiency and machining precision are achieved.

Owner:四川纽赛特工业机器人制造有限公司

Non-magnetic steel impact specimen grinding clamp and grinding method

InactiveCN110814935AReduce sample size failure rateImprove grinding efficiencyGrinding machinesGrinding work supportsGrindingEngineering

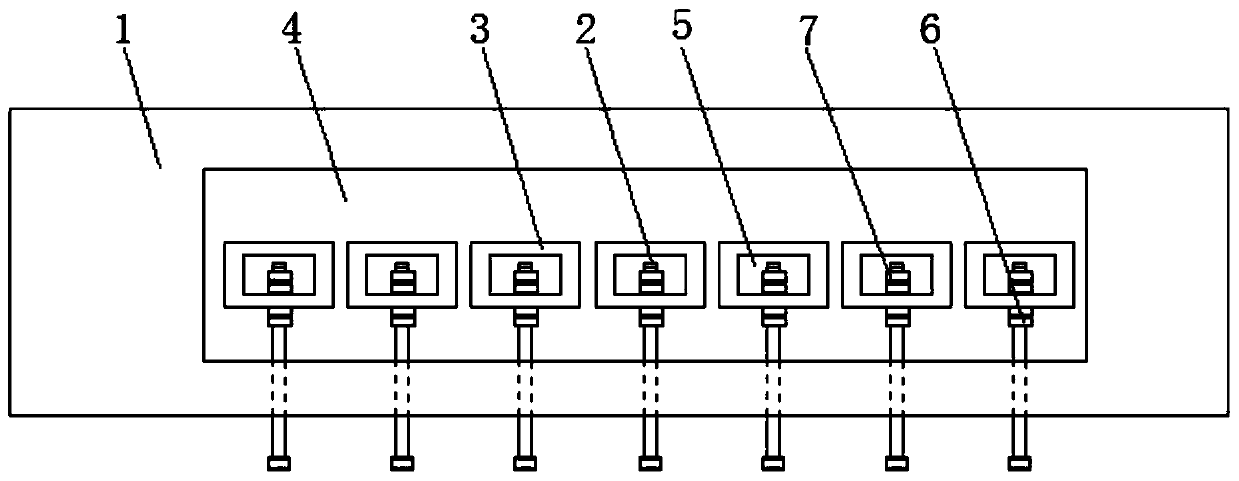

The invention discloses a non-magnetic steel impact specimen grinding clamp and grinding method. The grinding clamp comprises a base body, more than one adjusting rod and jacking blocks with the samenumber as the adjusting rods; the whole base body is concentric-square-shaped; a specimen clamping area used for clamping impact specimens is arranged in the base body; the adjusting rods are installed in the base body at intervals in the length direction of the base body; the adjusting rods extend into the specimen clamping area; the lengths of the rod sections, located in the specimen clamping area, of the adjusting rods are adjustable; the jacking blocks are located in the specimen clamping area and are connected with the adjusting rods; the base body is made of magnetic steel; the height of the base body and the heights of the jacking blocks are all smaller than the heights of the impact specimens; and the impact specimens are clamped and fixed with the jacking blocks through the basebody. According to the non-magnetic steel impact specimen grinding clamp and grinding method, the grinding clamp capable of being sucked by a grinding machine is designed by utilizing the characteristics that the impact specimens are regular in shape and are same in size, the multiple impact specimens can be clamped at one time, and the grinding efficiency is greatly improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com