Patents

Literature

59results about How to "Improve the crushing and grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

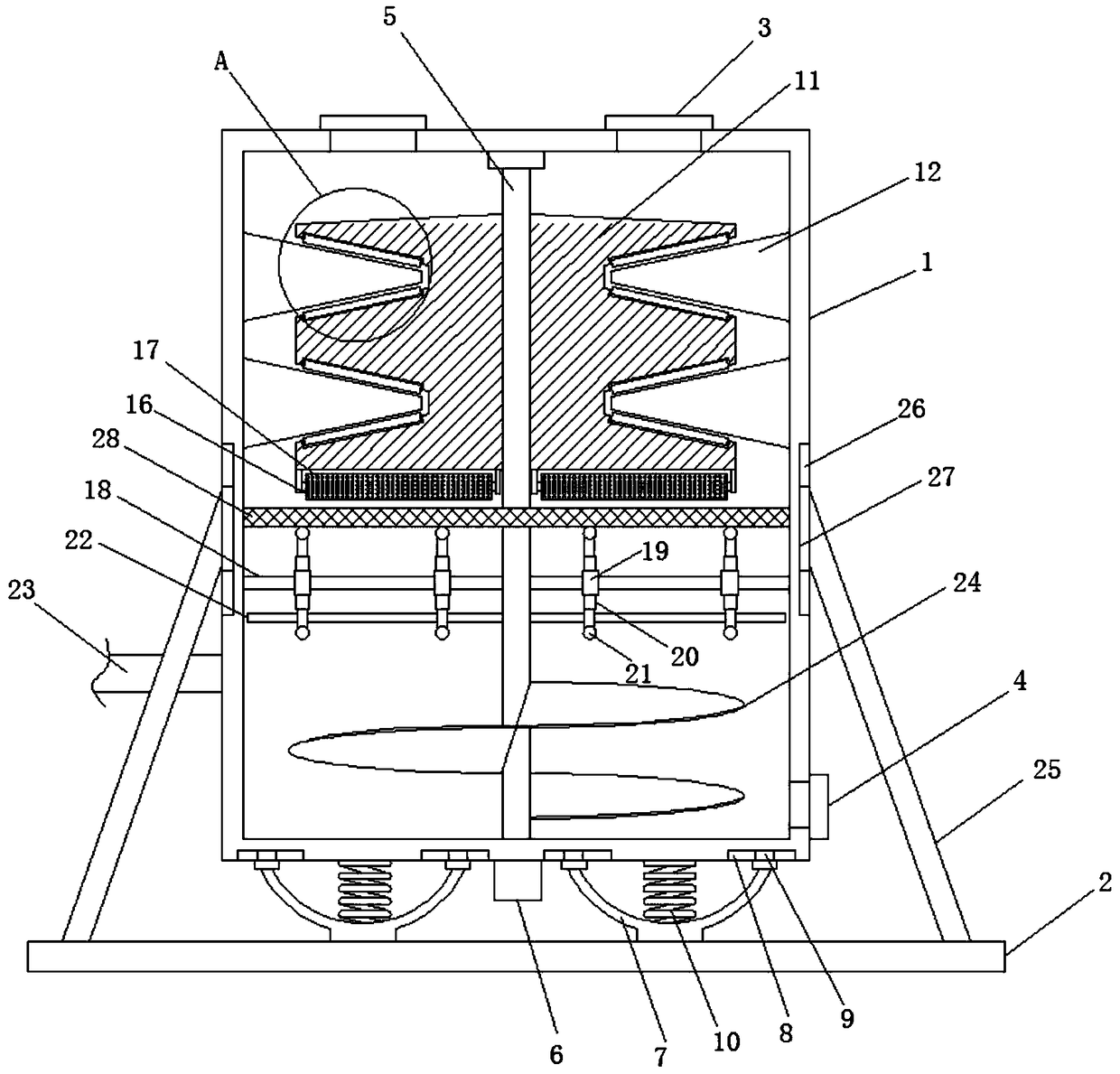

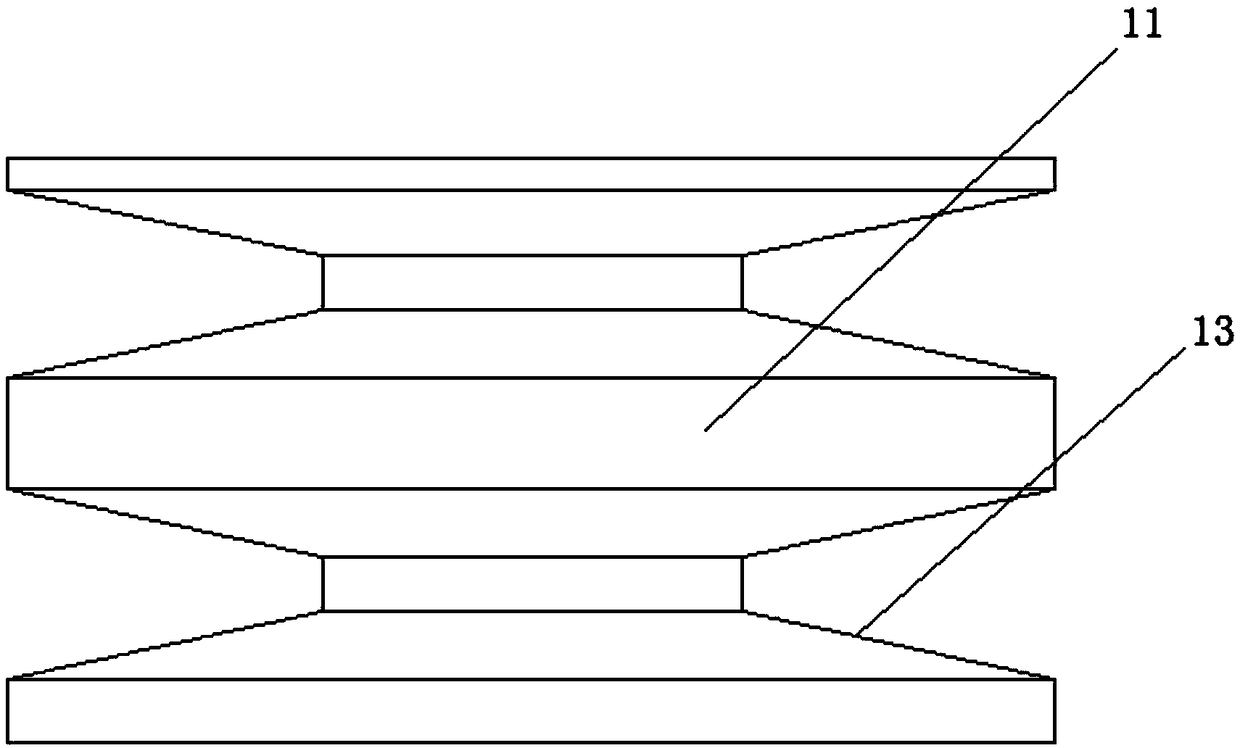

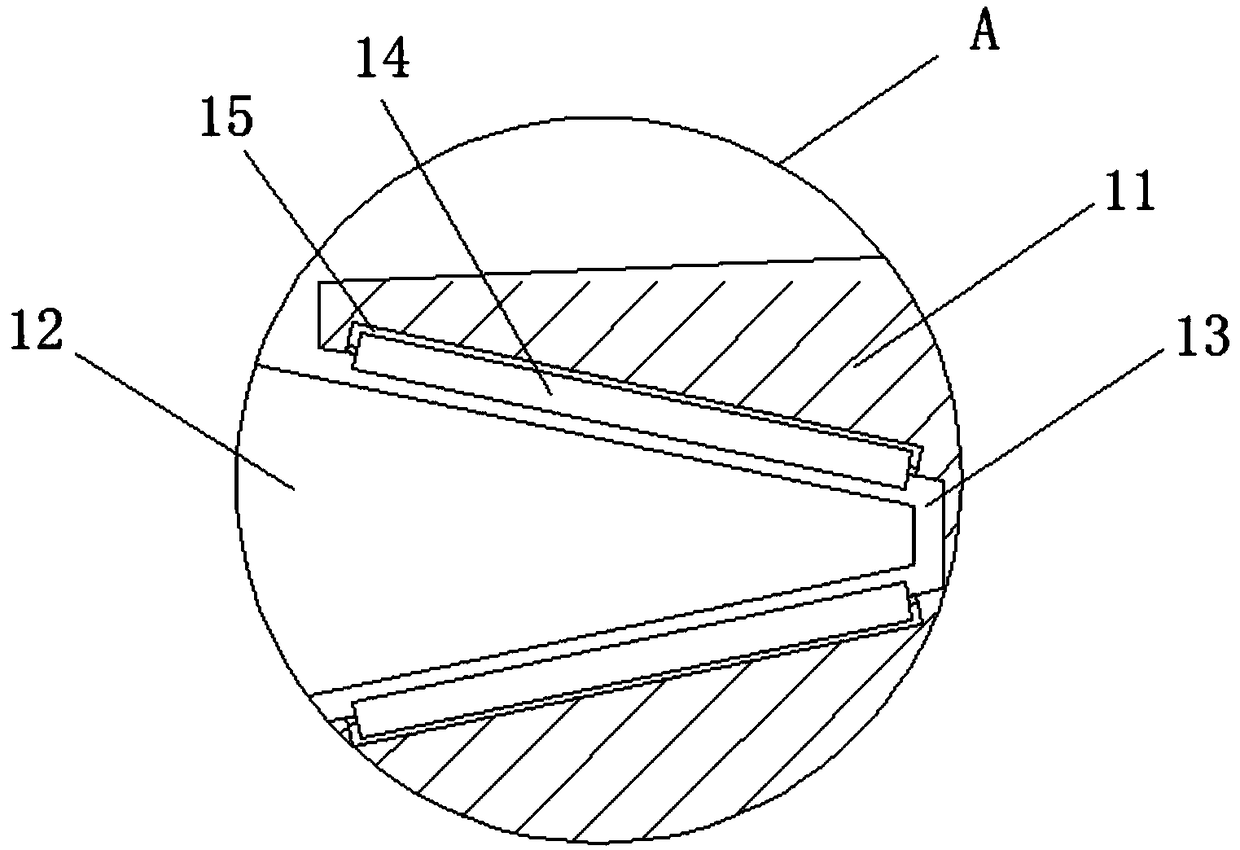

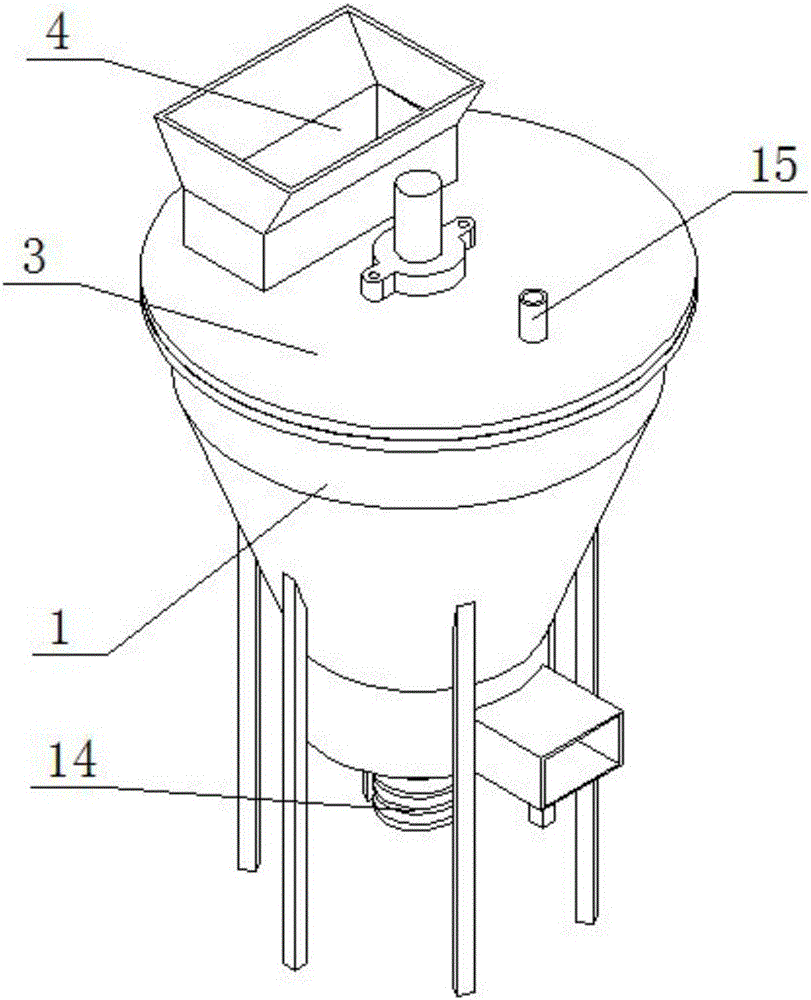

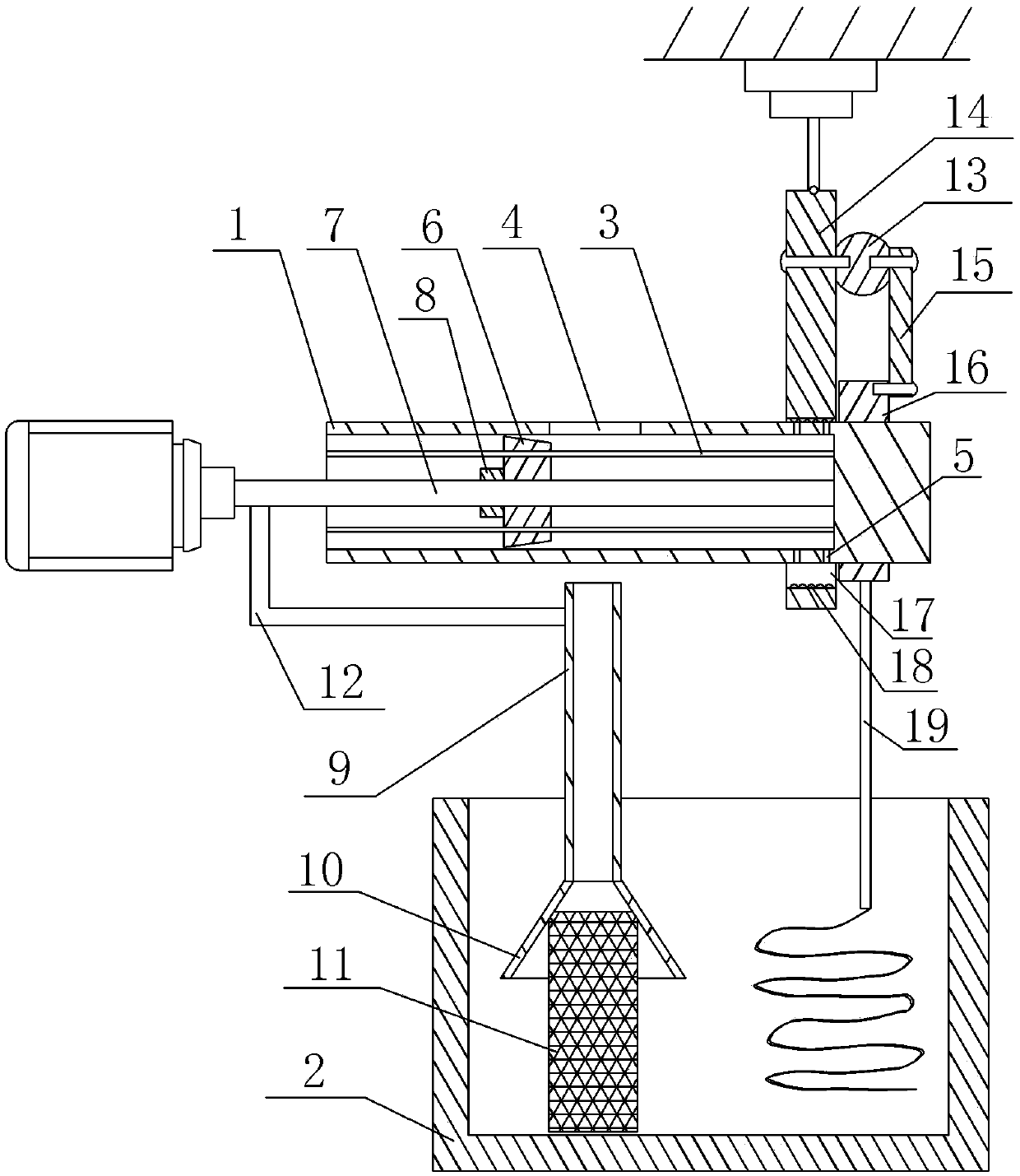

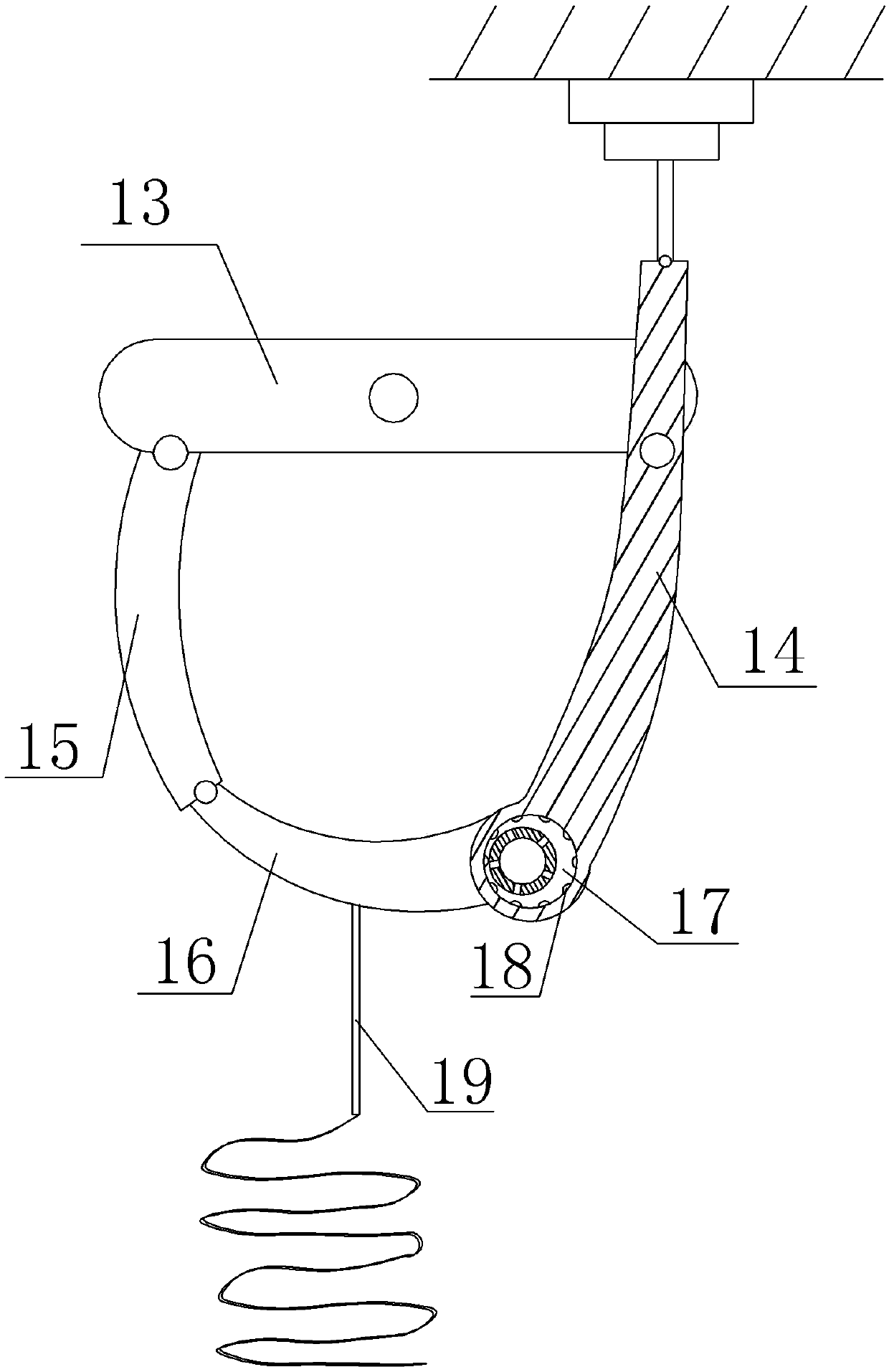

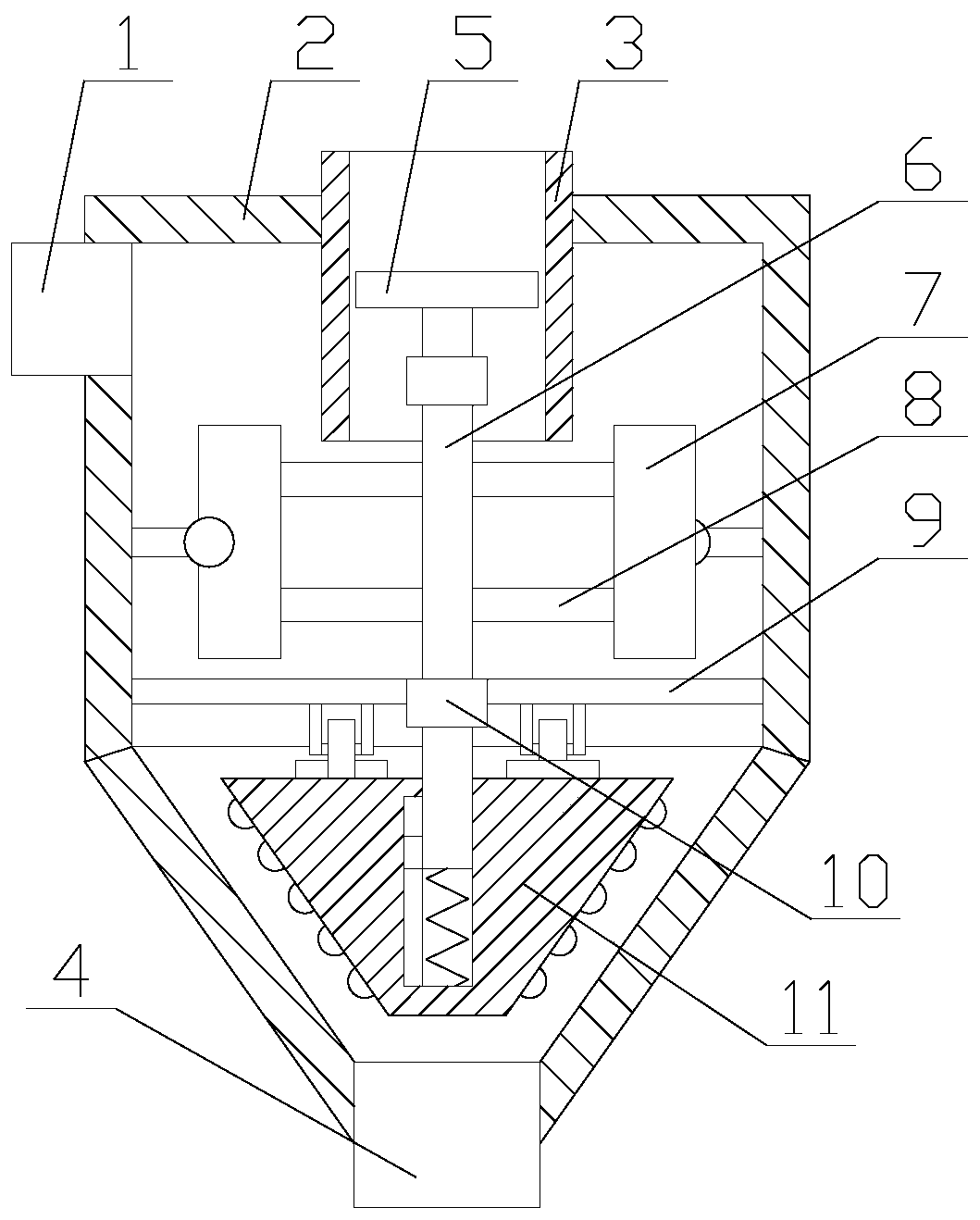

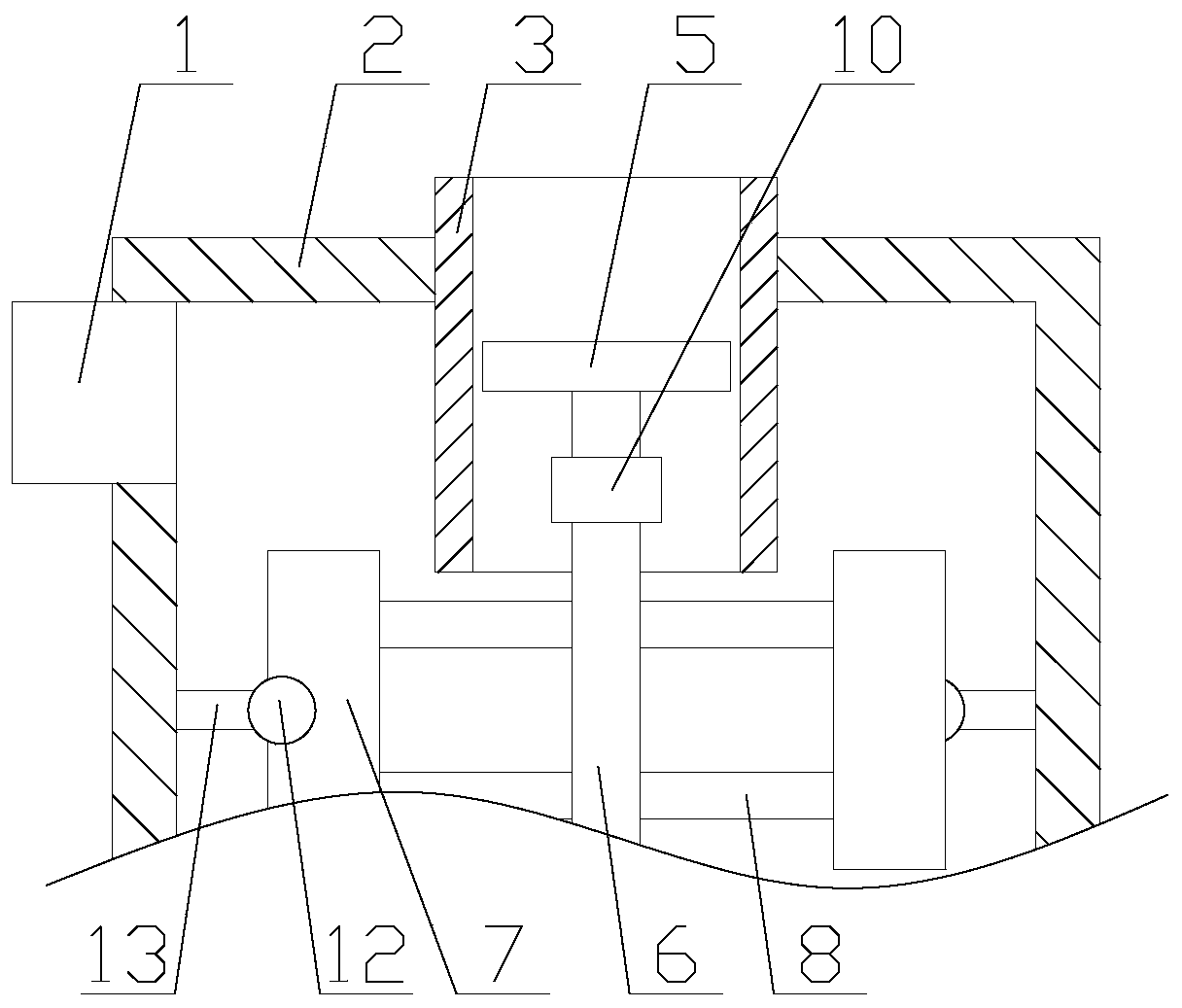

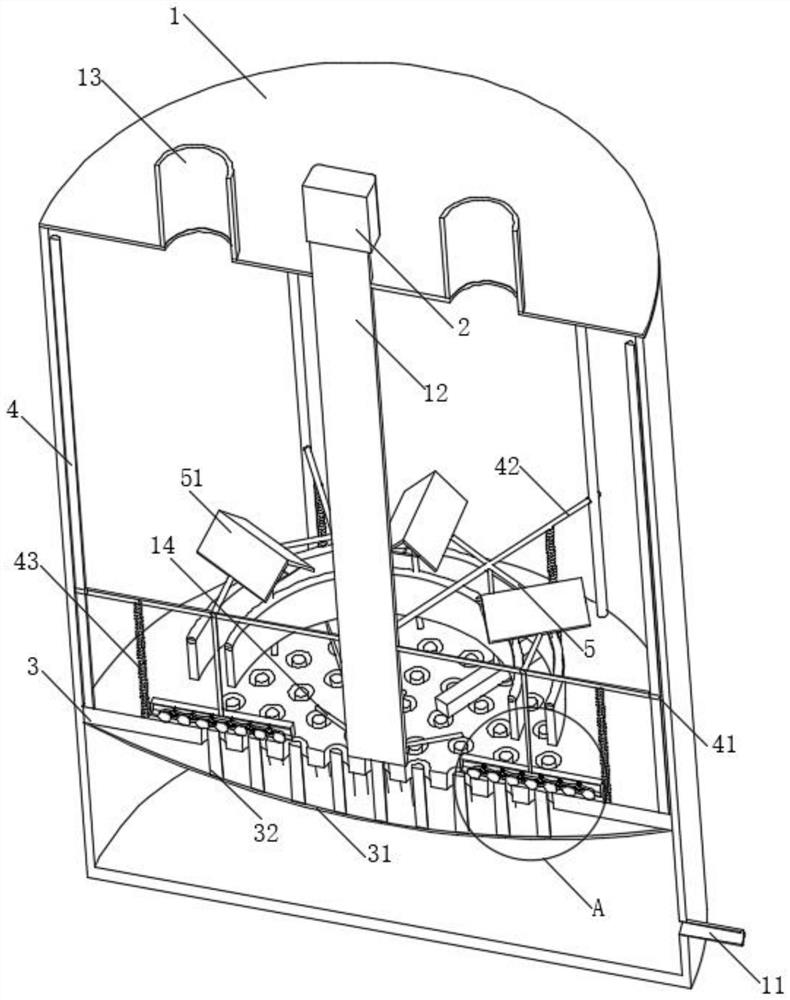

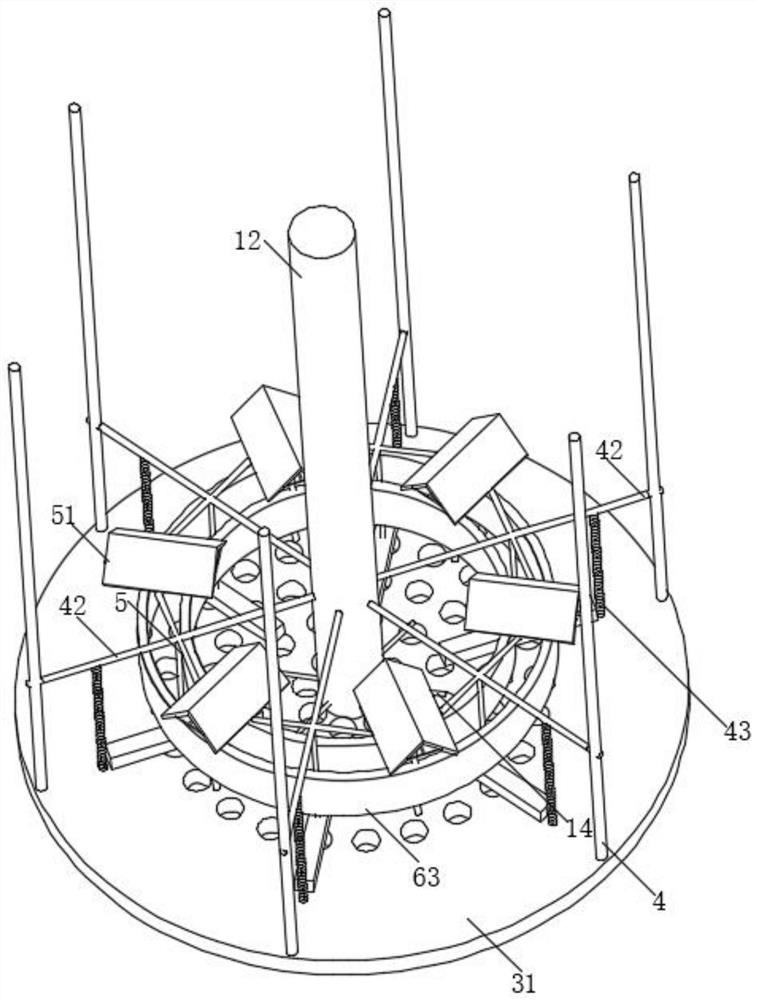

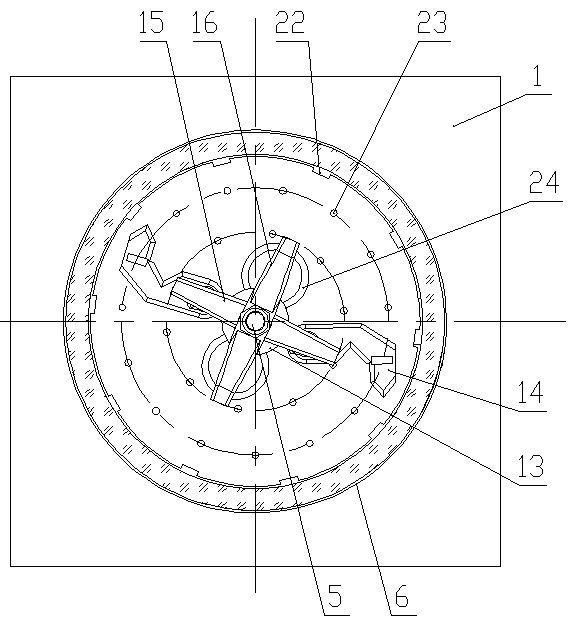

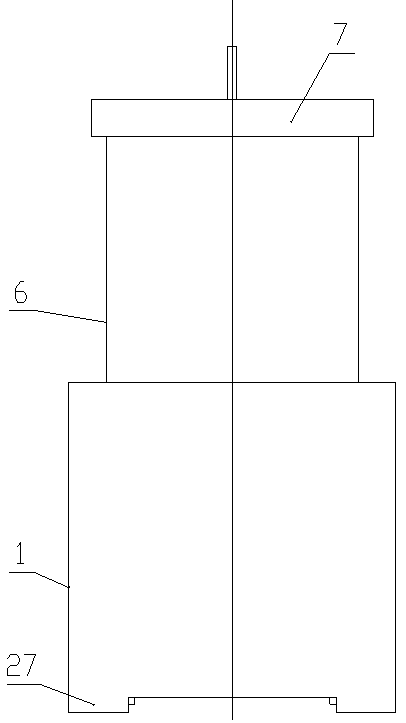

Agricultural shock-absorbing integrated crushing-dissolving device for fertilizer particles

InactiveCN108607662AImprove the crushing and grinding effectImprove efficiencyRotary stirring mixersTransportation and packagingAgricultural engineeringDrive motor

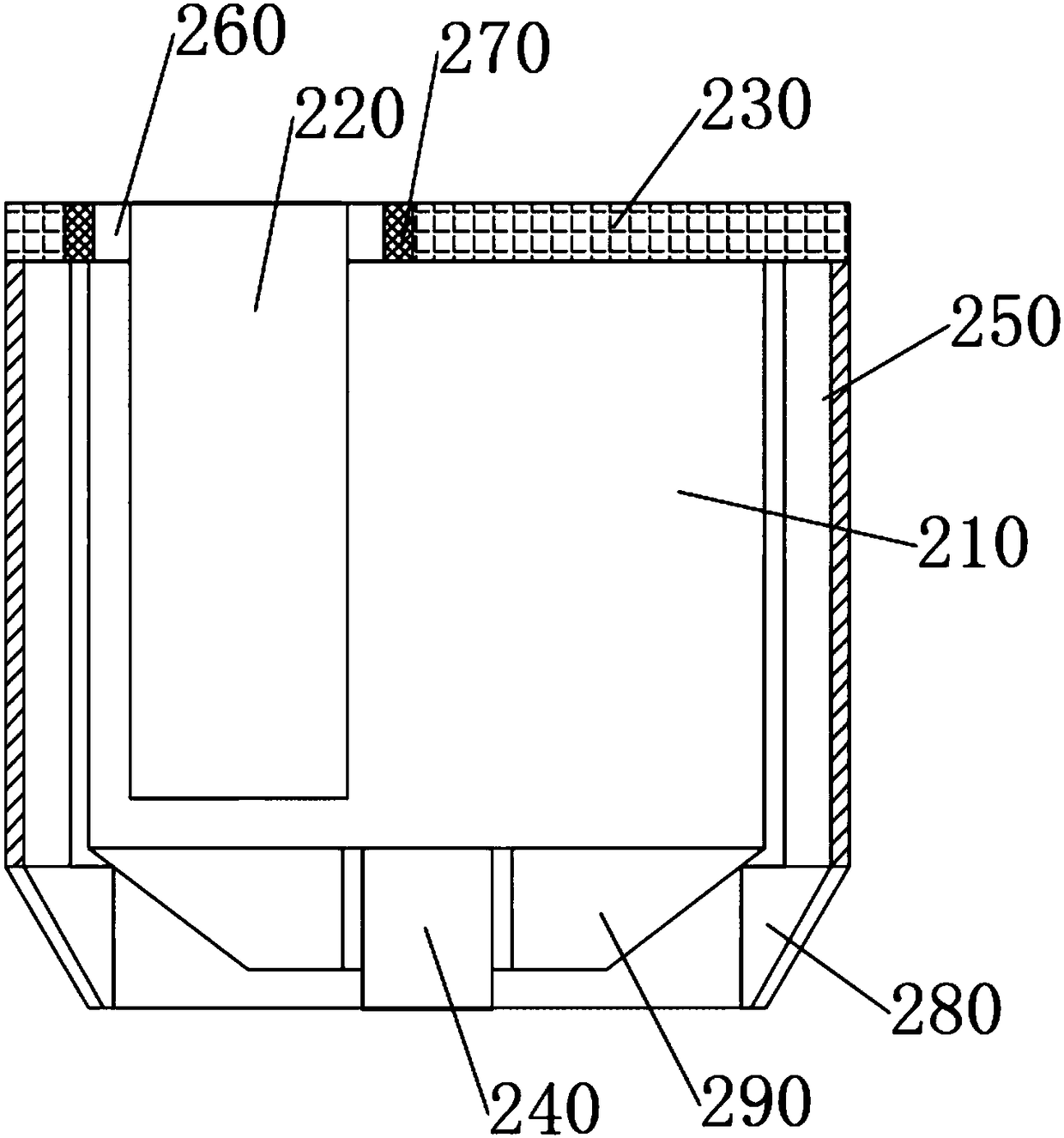

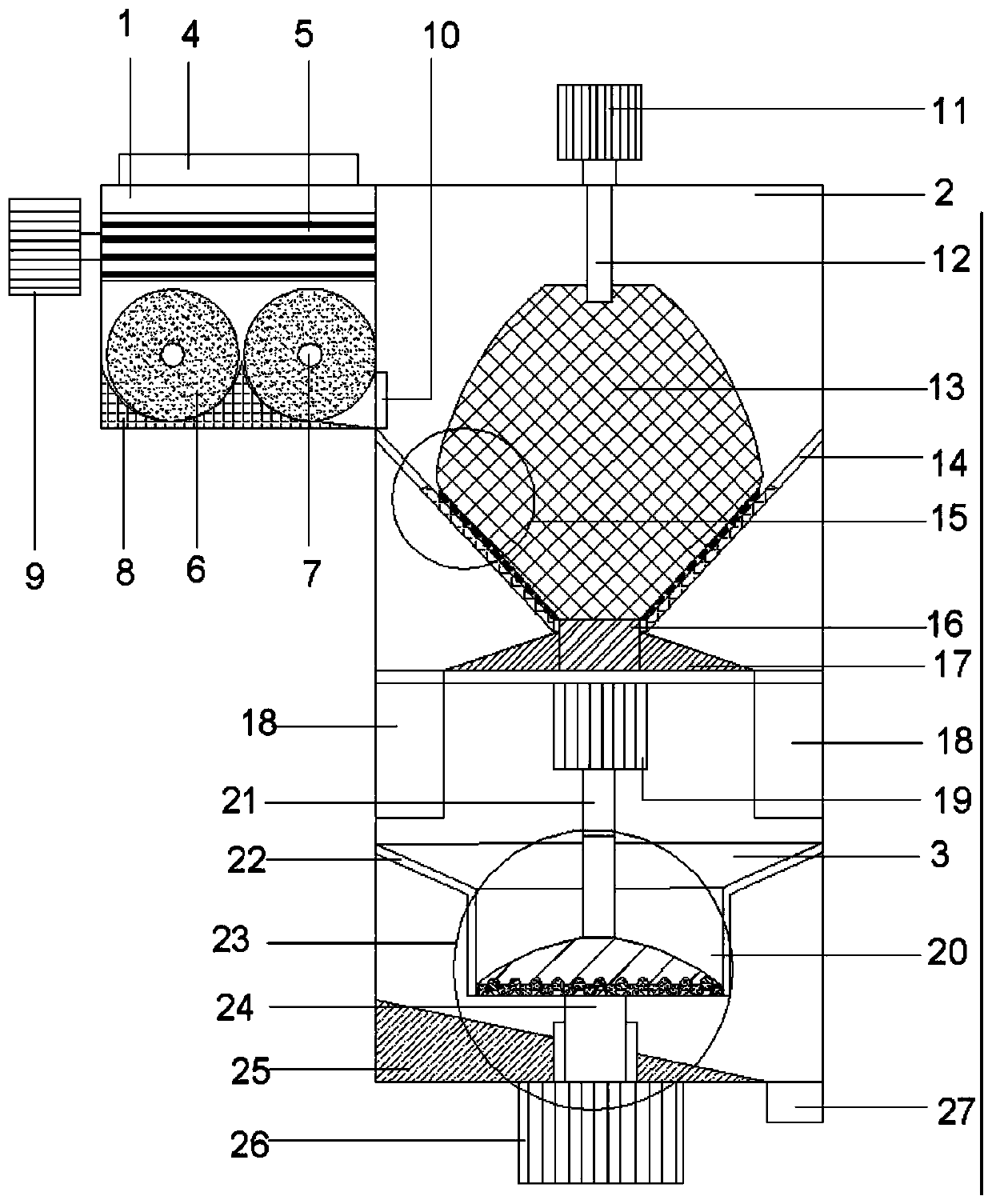

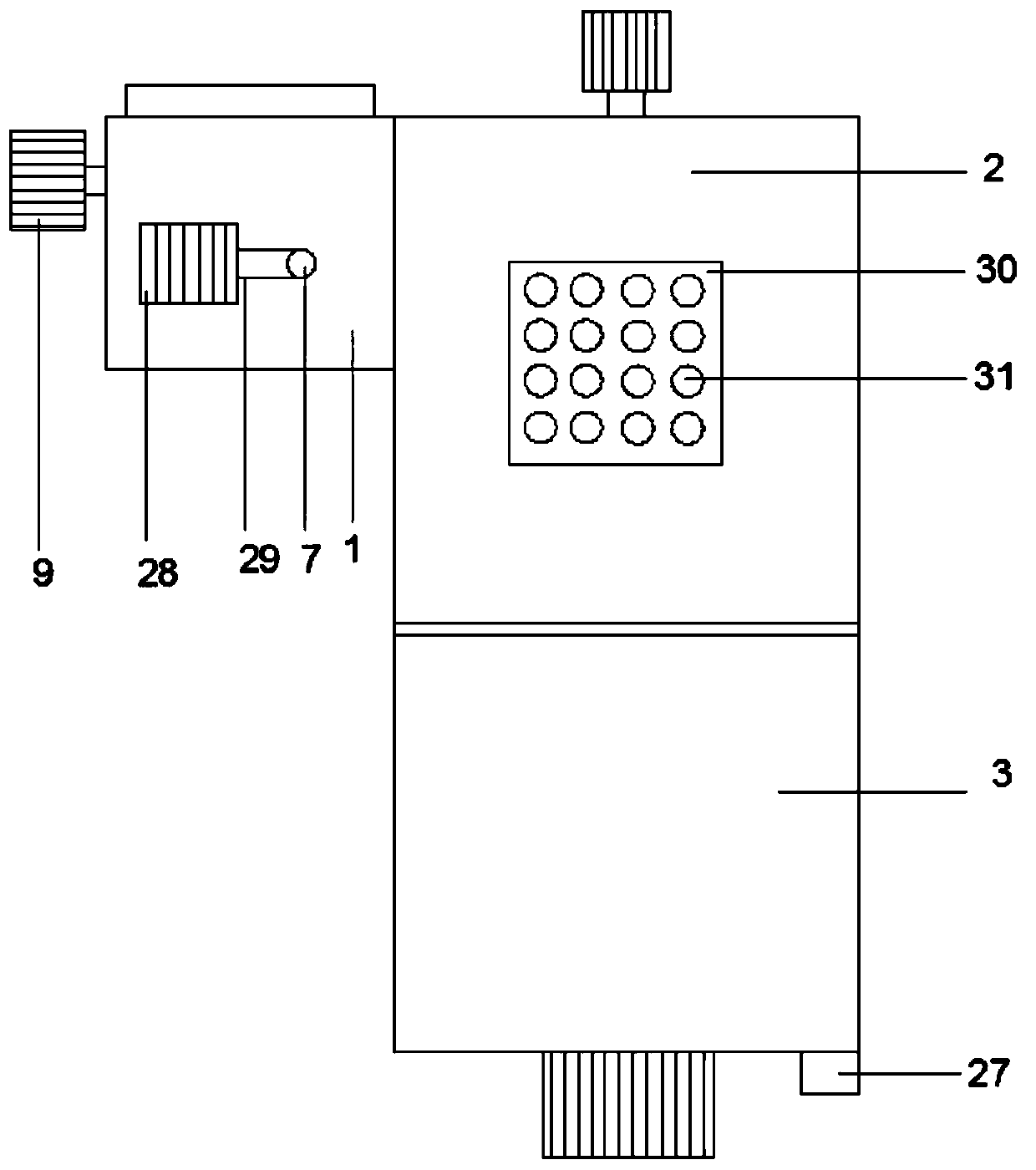

The invention discloses an agricultural shock-absorbing integrated crushing-dissolving device for fertilizer particles. The agricultural shock-absorbing integrated crushing-dissolving device comprisesa crushing-dissolving barrel, wherein two feed inlets are formed in the top wall of the crushing-dissolving barrel; a rotating vertical shaft is arranged in the crushing-dissolving barrel, and the axis of the rotating vertical shaft is superposed with the axis of the crushing-dissolving barrel; the lower end of the rotating vertical shaft is connected with a driving motor arranged on the bottom wall of the crushing-dissolving barrel; the outer side wall of the upper end part of the rotating vertical shaft is provided with a rotating cylinder; a liquid inlet pipe is located at the lower side of a screening web plate; the lower side of the crushing-dissolving barrel is provided with a pedestal plate; two support arms of an arc supporting seat is connected with the bottom wall of the crushing-dissolving barrel via a limited sliding mechanism; the arc supporting seat is supported by an elastomeric material; and the inside wall of the arc supporting seat is connected with the bottom wall of the crushing-dissolving barrel via damping springs. The agricultural shock-absorbing integrated crushing-dissolving device provided by the invention has simple structure, realizes multiple crushing,can improve crushing effect and avoid blockage, is high in dissolution efficiency, sufficient in dissolution, simple and fast to operate and good in practicability.

Owner:苏天平

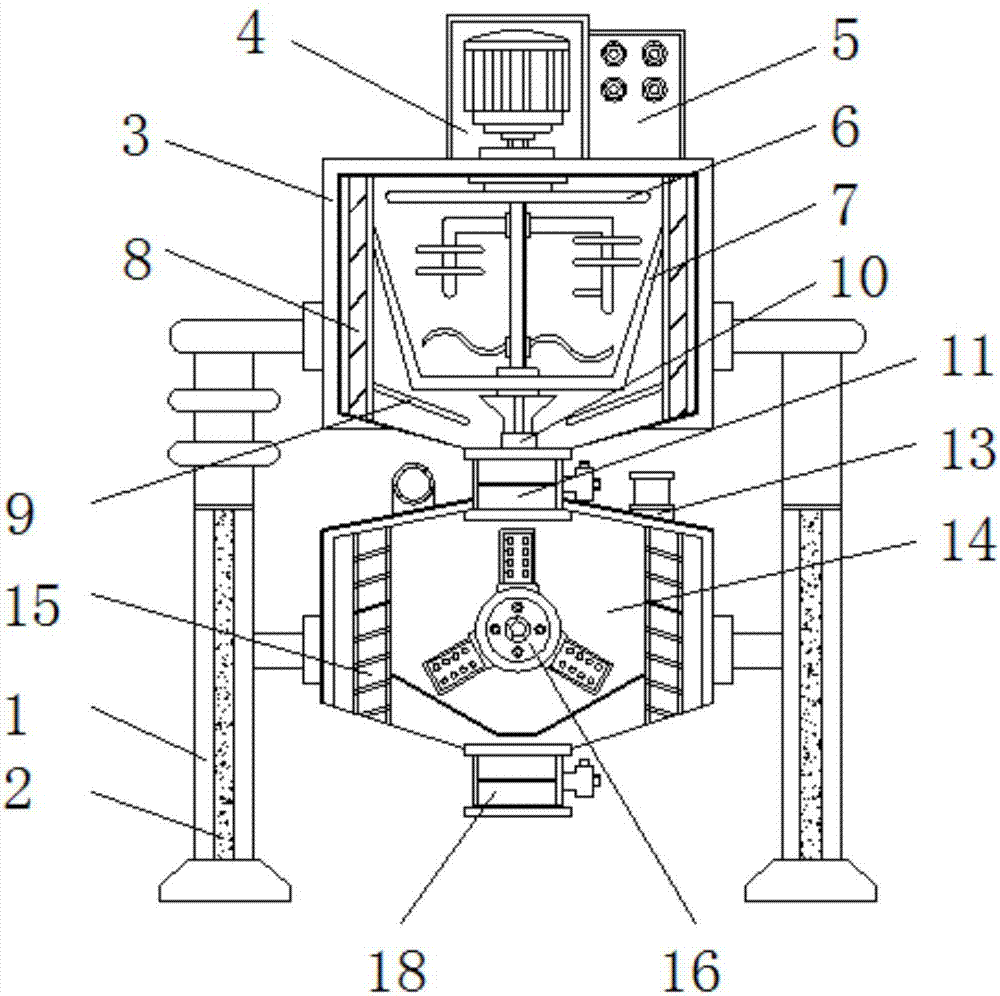

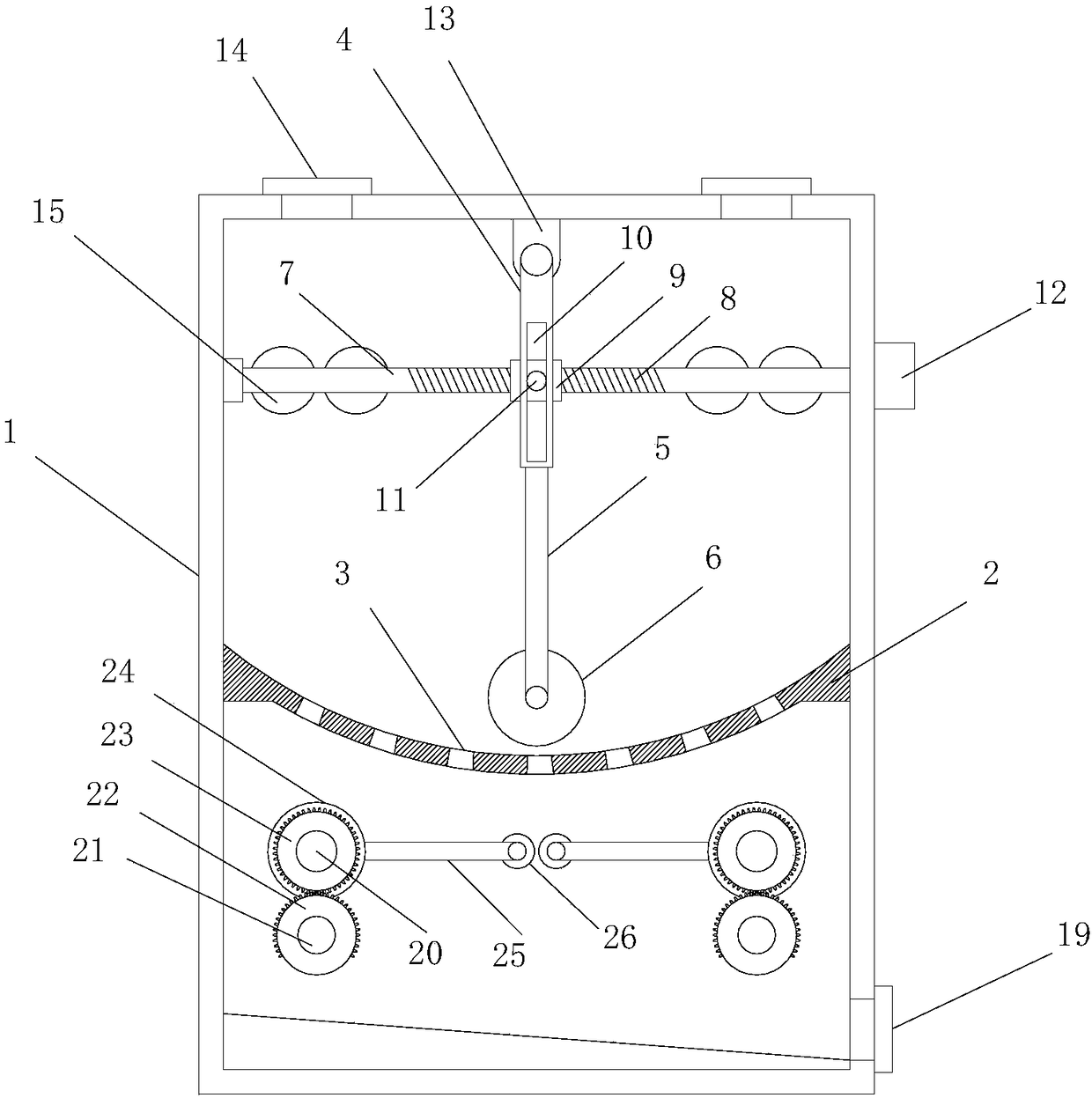

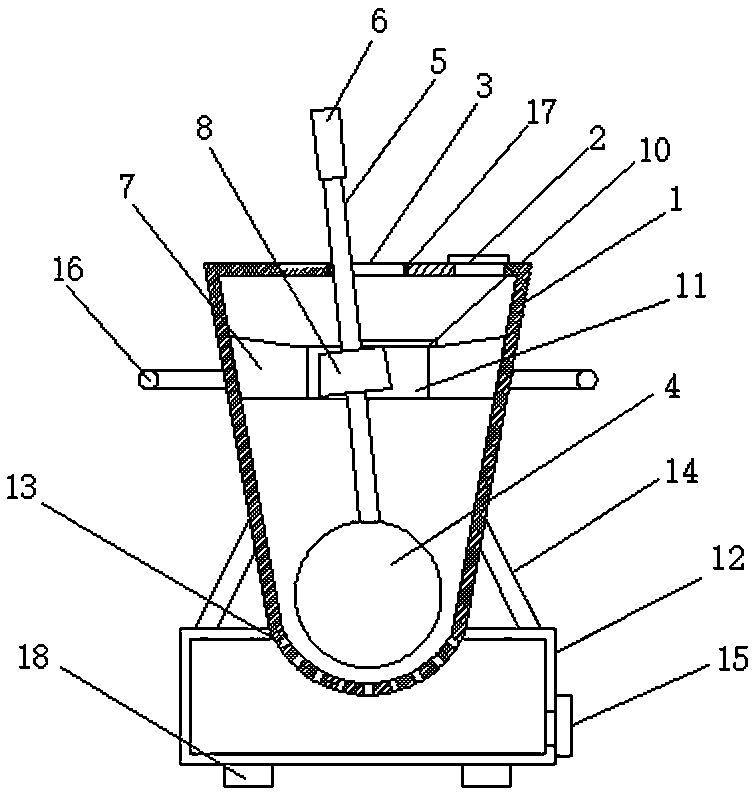

Grinding and filtering integrated device of soybeans

InactiveCN107455474AFine powderImprove the effectGrain treatmentsStationary filtering element filtersCushionEngineering

The invention relates to a grinding and filtering integrated device of soybeans. The grinding and filtering integrated device comprises a fixed machine frame, a grinding disk, a heater and a No.2 filter screen, wherein a damping cushion is fixed in the fixed machine frame; a grinding cabin is arranged at the upper part of the inner part of the fixed machine frame; a No.1 motor is fixed to the grinding cabin; a control box is mounted on the right side of the No.1 motor; a No.1 filter screen is arranged under the grinding disk; a sound insulation layer is connected to the inner part of the grinding cabin; a heating cavity is formed in a stirring cabin; a heater is located in the heating cavity; a stirring shaft is located in the heating cavity; a sealed hatch is mounted on the rear surface of the stirring cabin, and a water line is arranged on the right side of the sealed hatch; and the No.2 filter screen is located in the heating cavity. According to the grinding and filtering integrated device of soybeans disclosed by the invention, a reversing hopper and the No.1 filter screen are designed, so that the soybeans in the grinding cabin are sufficiently ground into soybean powder; and after the soybeans are cooked, bean dregs are convenient to separate by the No.2 filter screen.

Owner:WUHU TAIQING ELECTRONICS TECH CO LTD

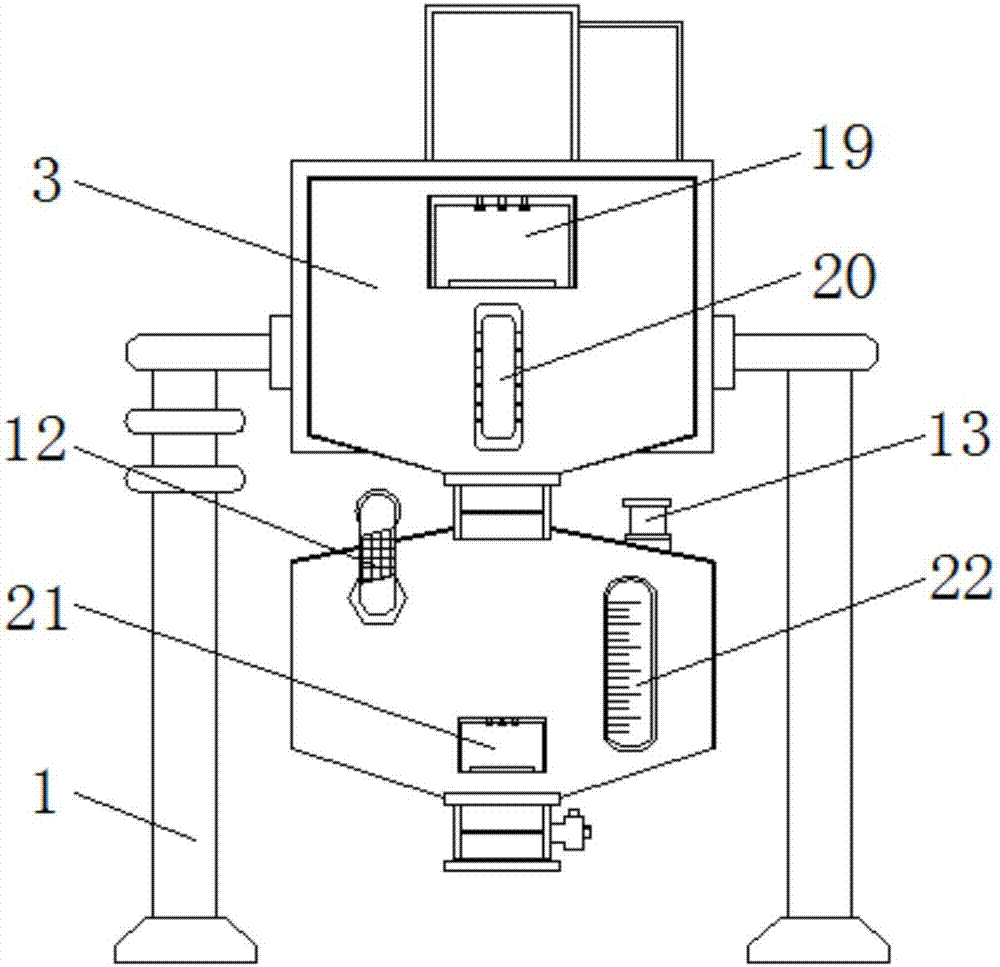

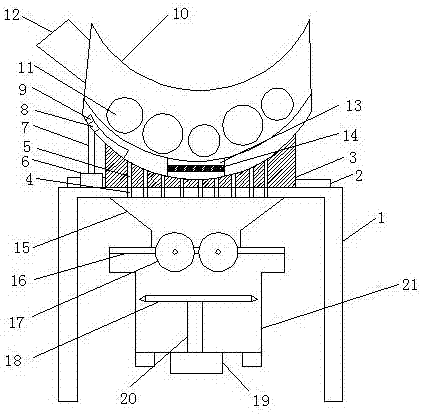

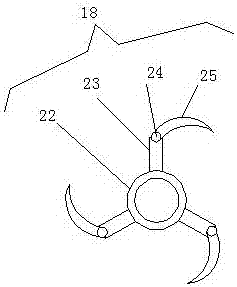

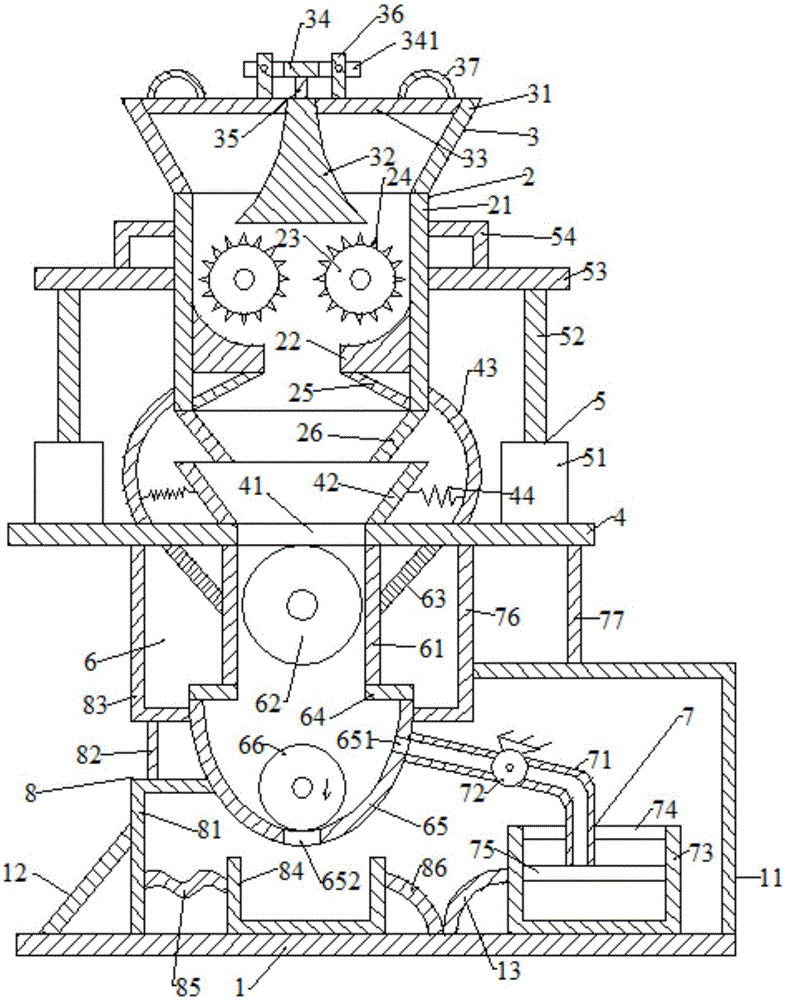

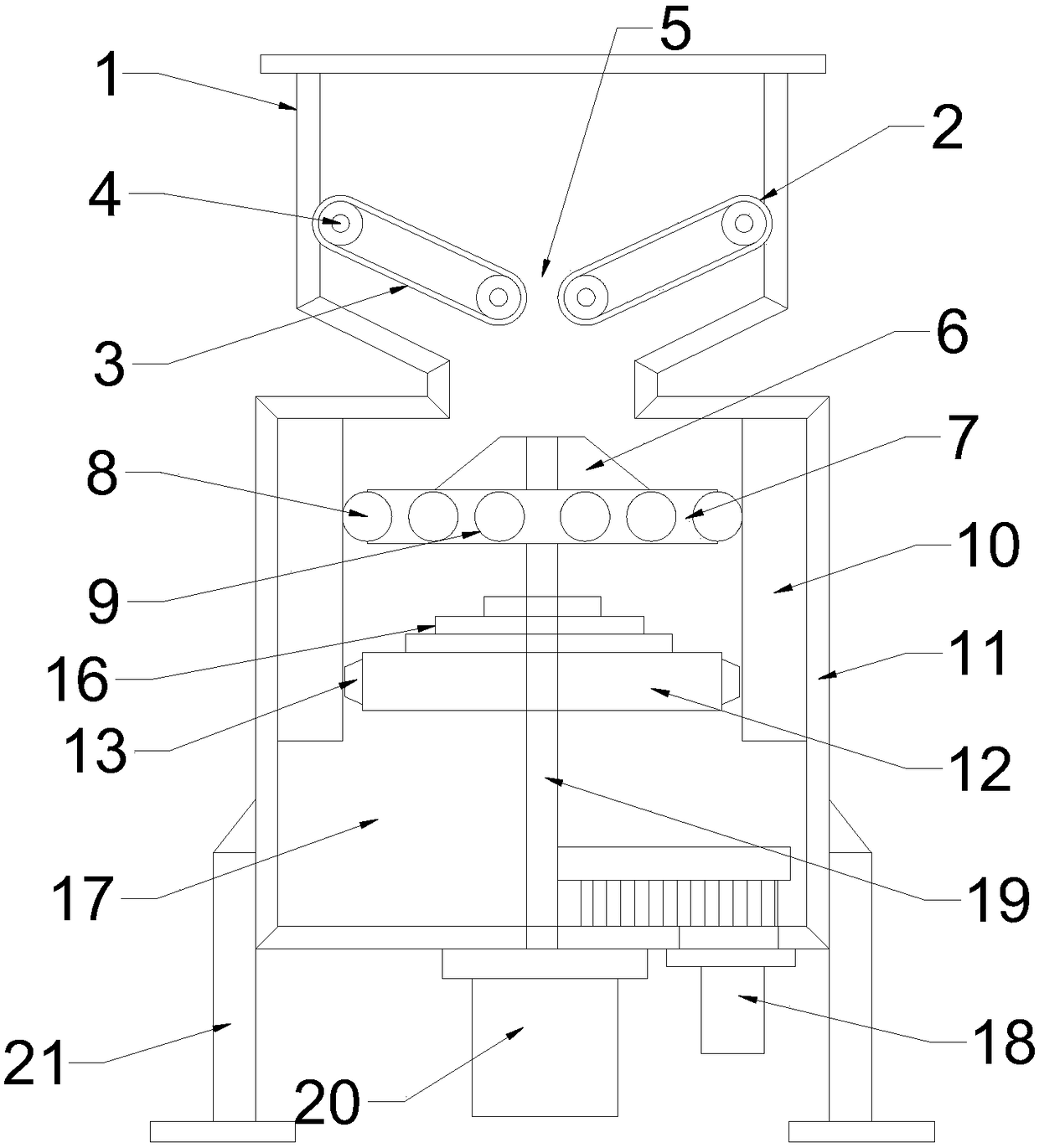

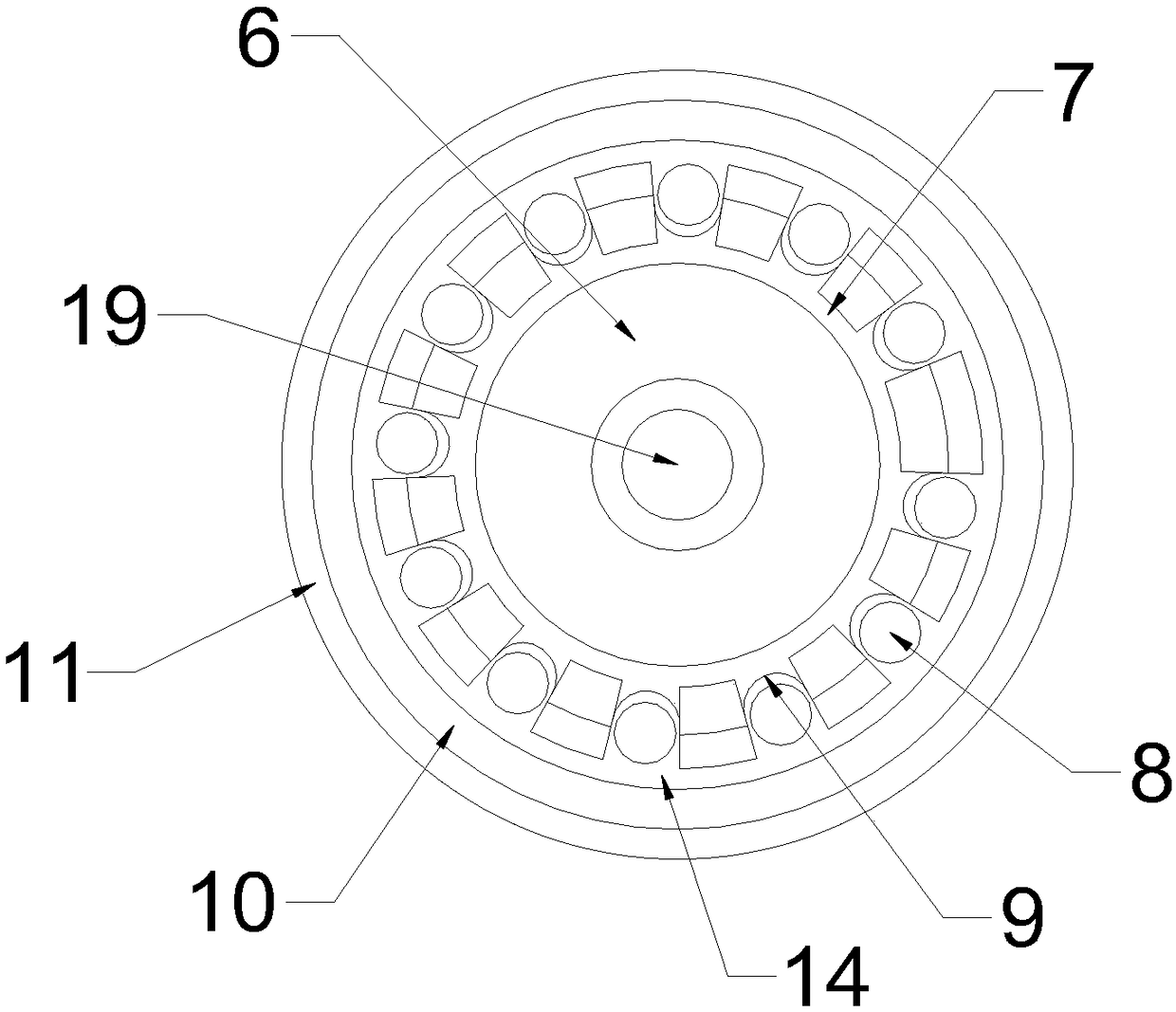

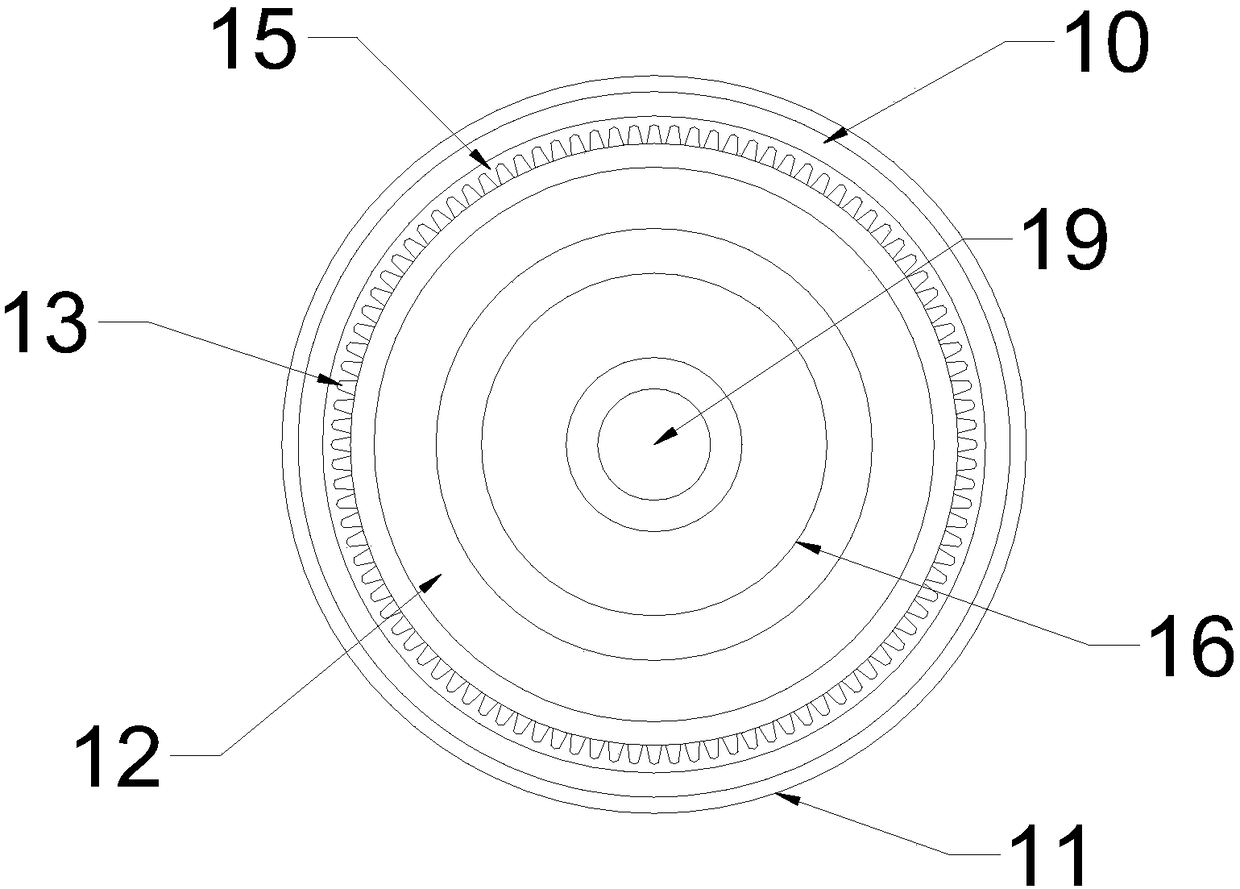

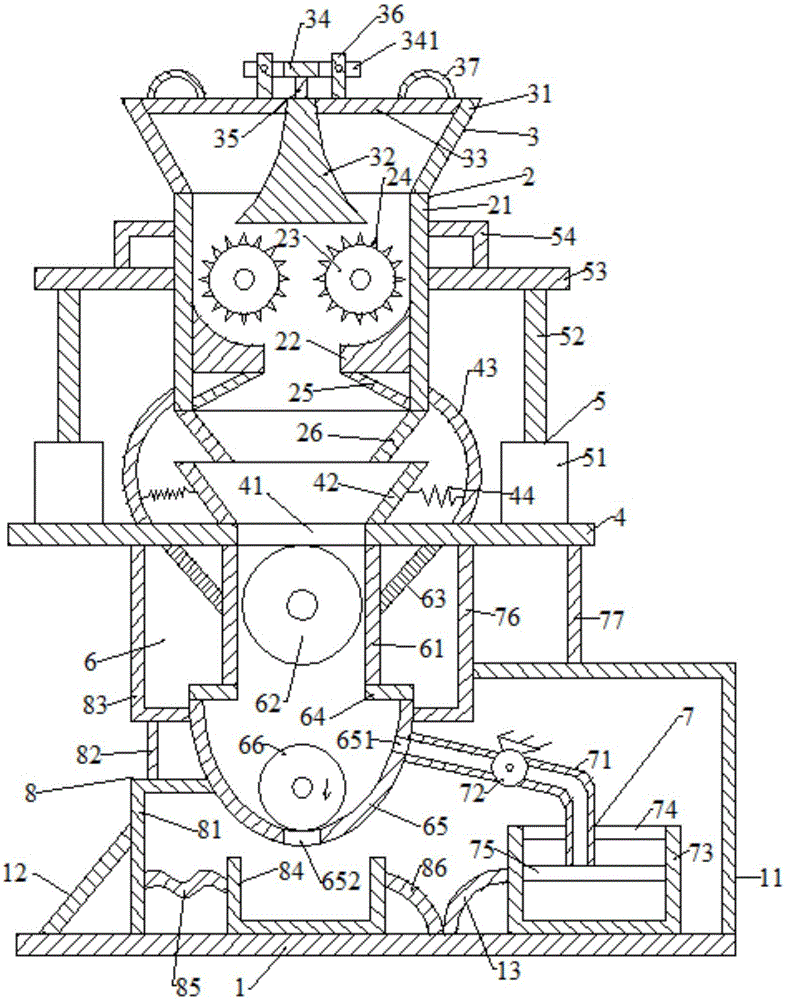

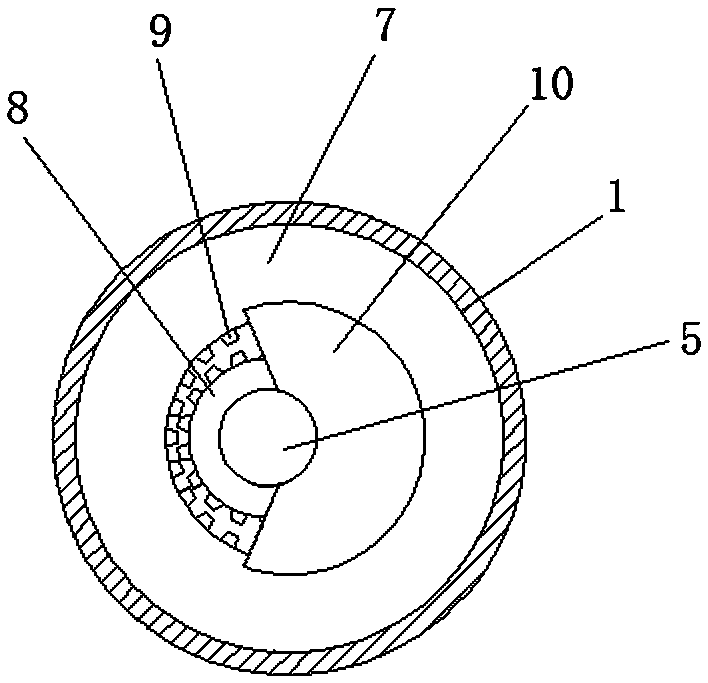

Kitchen waste treatment equipment

PendingCN108356051ASmooth rotationDoes not affect grinding actionTransportation and packagingSolid waste disposalElectricityEngineering

The invention relates to kitchen waste treatment equipment. The kitchen waste treatment equipment comprises a support, a crushing and grinding device, a solid-liquid separation device, a drying and deodorizing device, a first stock bin and a control device, wherein the crushing and grinding device, the solid-liquid separation device, the drying and deodorizing device, the first stock bin and the control device are arranged in the support and are sequentially arranged from top to bottom; the solid-liquid separation device is provided with a first discharge port and a second discharge port; thefirst discharge port is connected to a liquid discharge pipe; the second discharge port is connected to a feed port of the drying and deodorizing device; and the control device is electrically connected to the crushing and grinding device, the drying and deodorizing device and the solid-liquid separation device. The kitchen waste treatment equipment has the advantages that the structure is simple,the full-automatic operation is realized, the use is convenient, the environmental pollution caused by kitchen waste can be avoided from the source, and the kitchen waste can be conveniently recycled.

Owner:深圳市富利臻环保科技有限公司

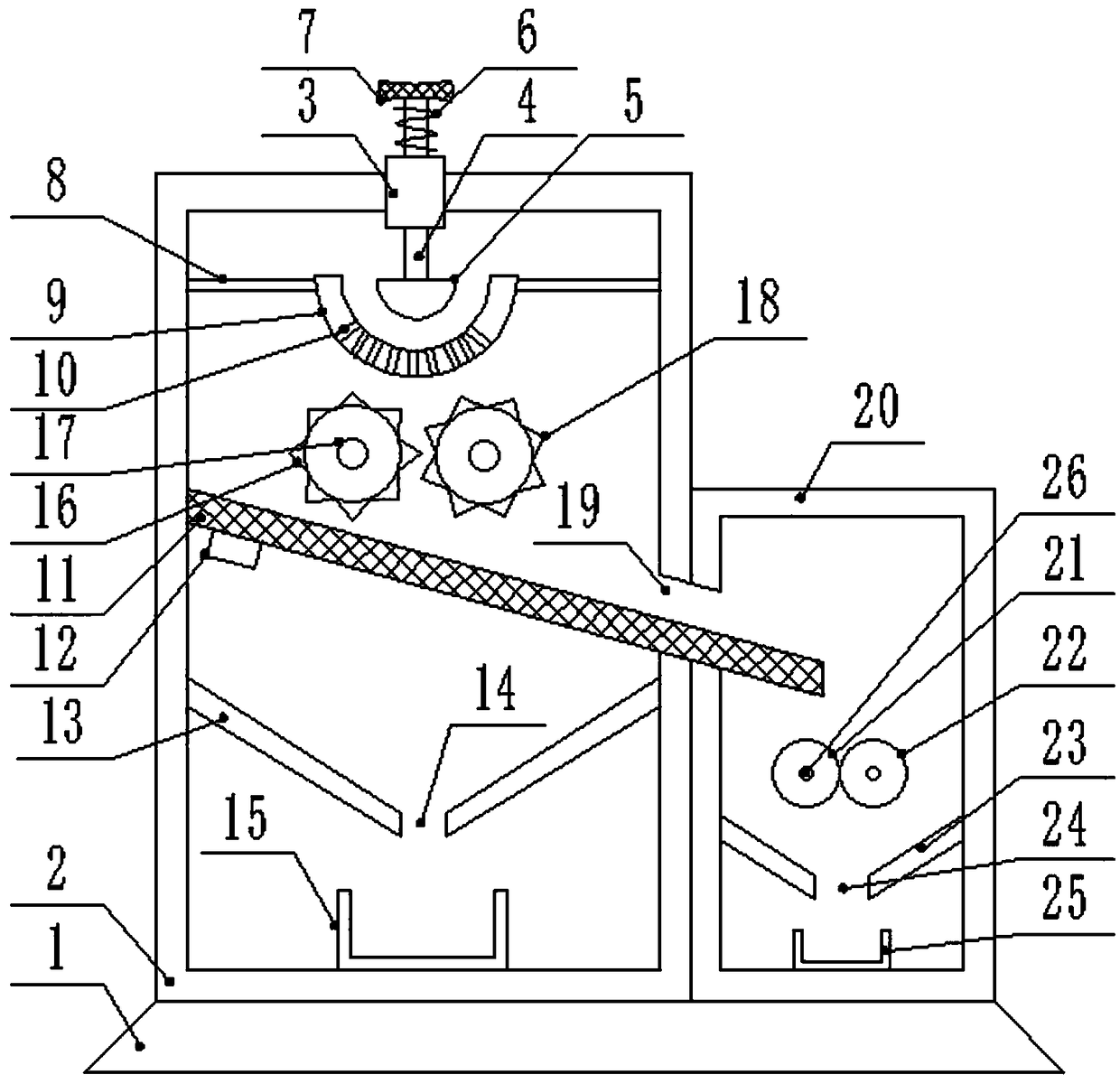

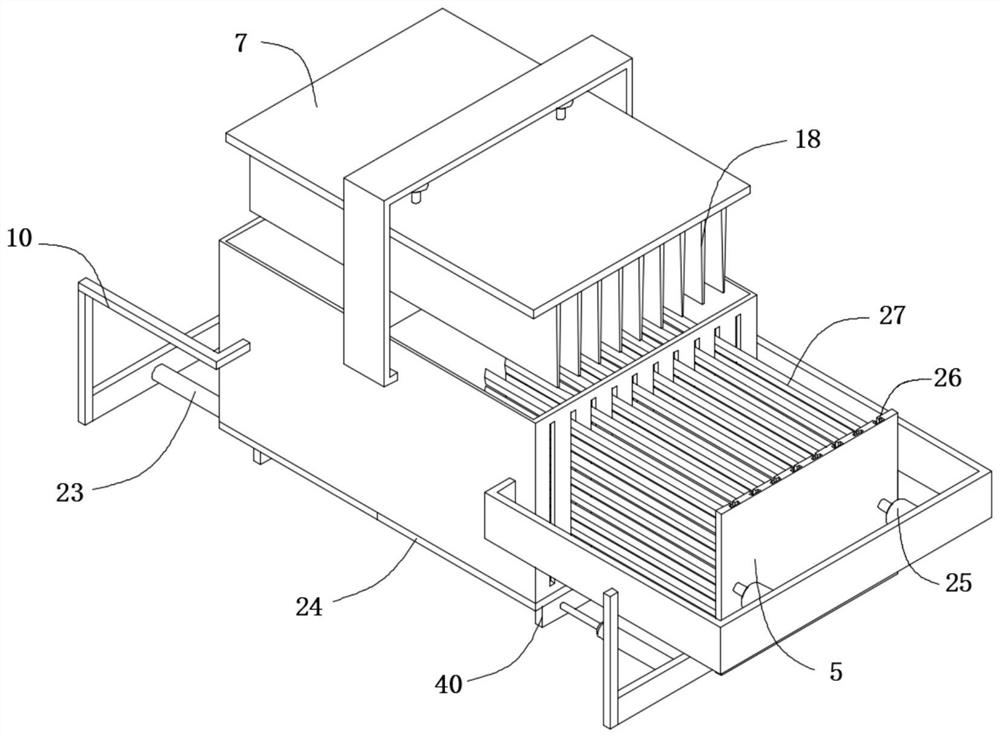

Soft magnetic ferrite raw material grinding and crushing device

ActiveCN111068883AEfficient crushingConvenient post-processing fine grindingGrain treatmentsPlate pressureSoft magnet

The invention discloses a soft magnetic ferrite raw material grinding and crushing device and relates to the technical field of soft magnetic ferrite processing. The soft magnetic ferrite raw materialgrinding and crushing device comprises a feeding hopper, a grinding box and a finish grinding box. Two first grinding rollers are arranged at the top end of the feeding hopper, two second grinding rollers are arranged below the first grinding rollers, a grinding plate is arranged below the second grinding rollers, a supporting column is arranged at the center of the bottom of the grinding box, aring of grinding side plate surrounds the periphery of the supporting column, a first rotating shaft is rotatably connected to the top of the grinding box, a grinding block is fixed to the lower end of the first rotating shaft, an air cylinder is arranged at the upper end of the finish grinding box, the lower end of the air cylinder is connected to a telescopic rod, pressure plates are fixed to the bottom of the telescopic rod, and the pressure plates are located right above a screening plate and are same in size. The soft magnetic ferrite raw material grinding and crushing device overcomes defects in the prior art, is reasonable in design and convenient to use and can grind and crush a ferrite raw material continuously effectively, so that the grinding and crushing effect and efficiency are improved, production and processing of the ferrite are promoted, and raw materials are prevented from being wasted.

Owner:天长市华磁磁电有限公司

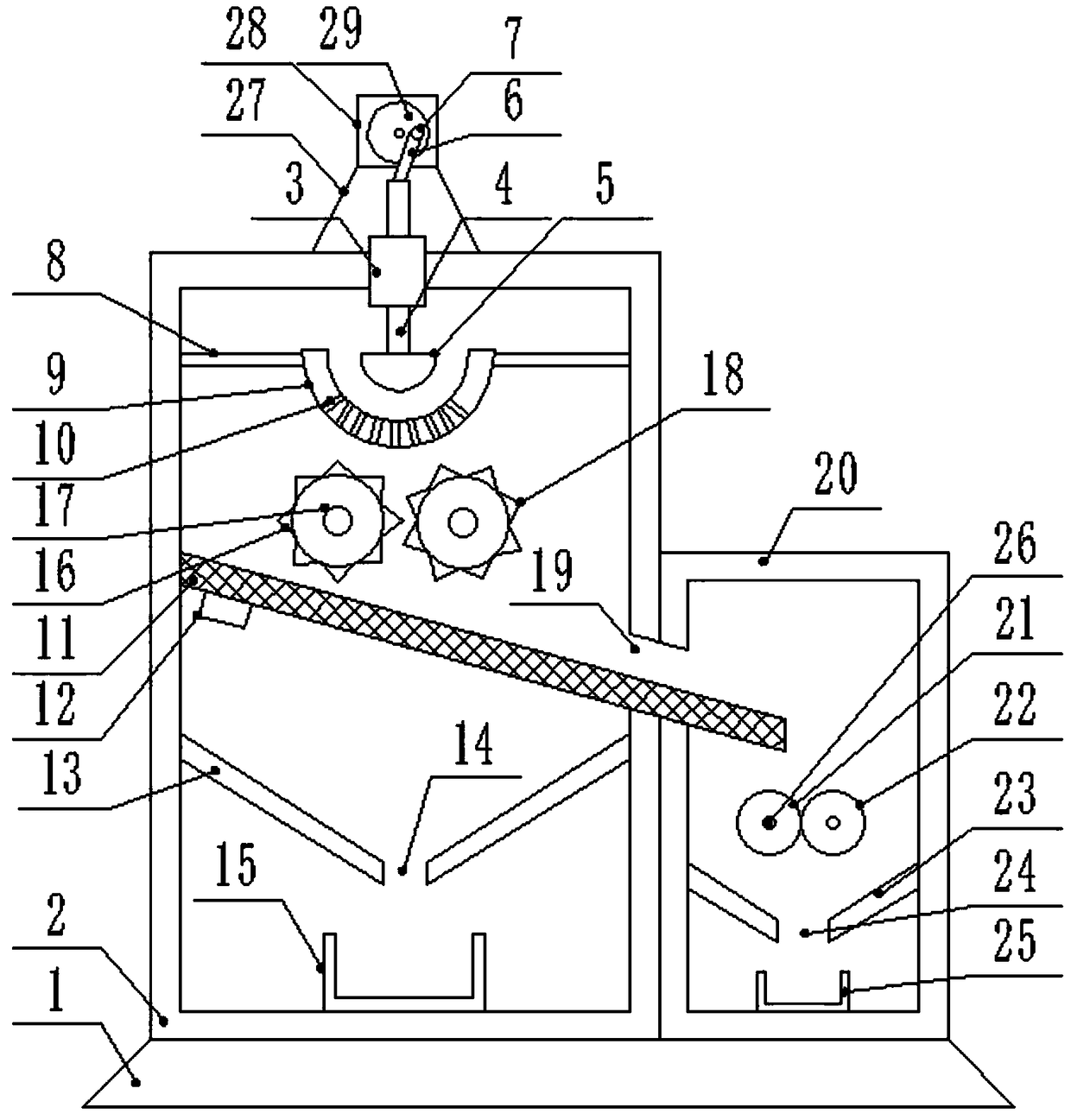

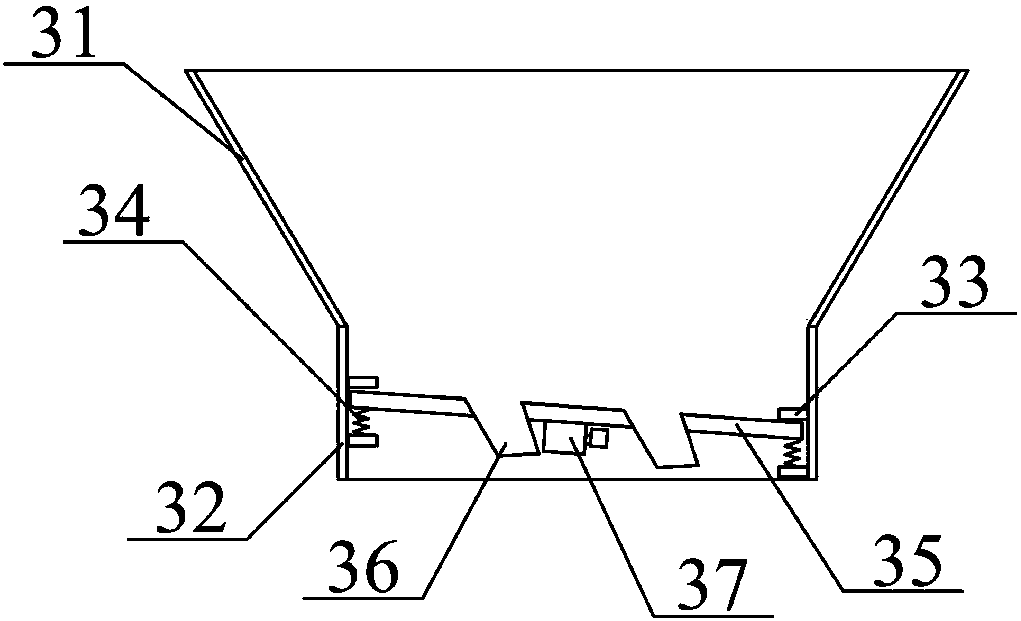

High-efficiency and environment-friendly medicinal material smashing and grinding device

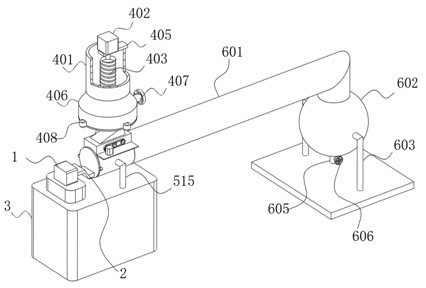

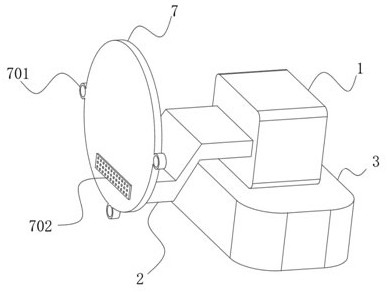

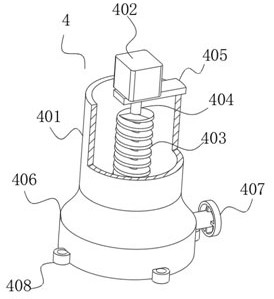

ActiveCN106000529ASimple structureEasy to useDispersed particle filtrationTransportation and packagingEnvironmental resistanceMechanical engineering

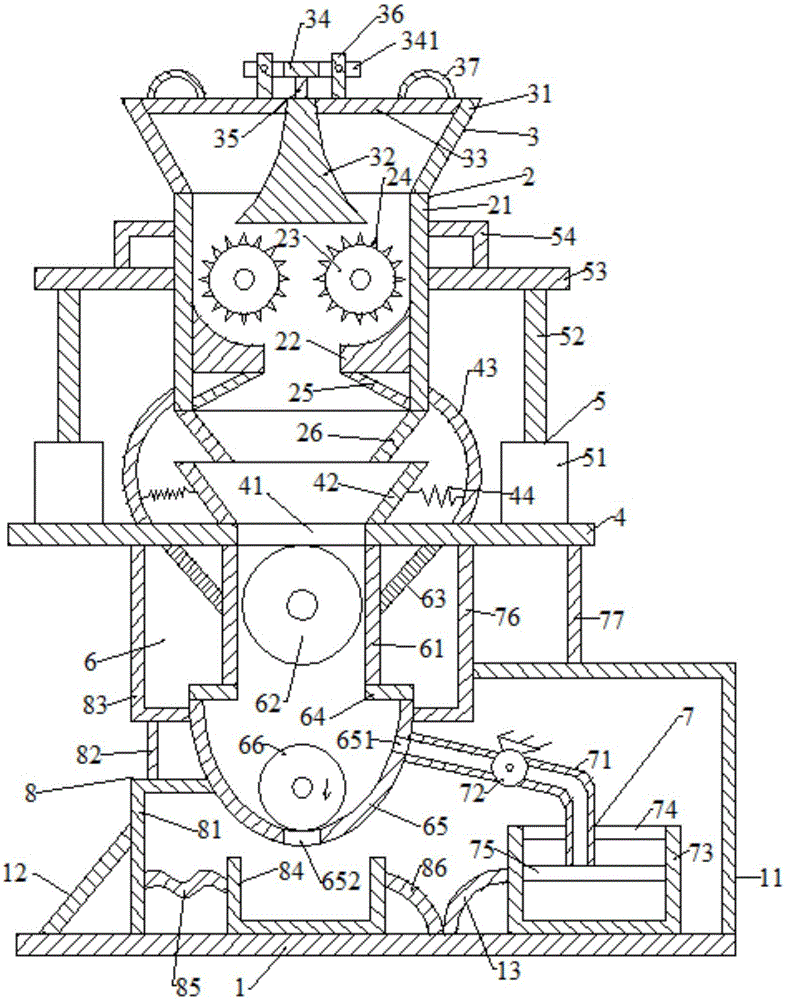

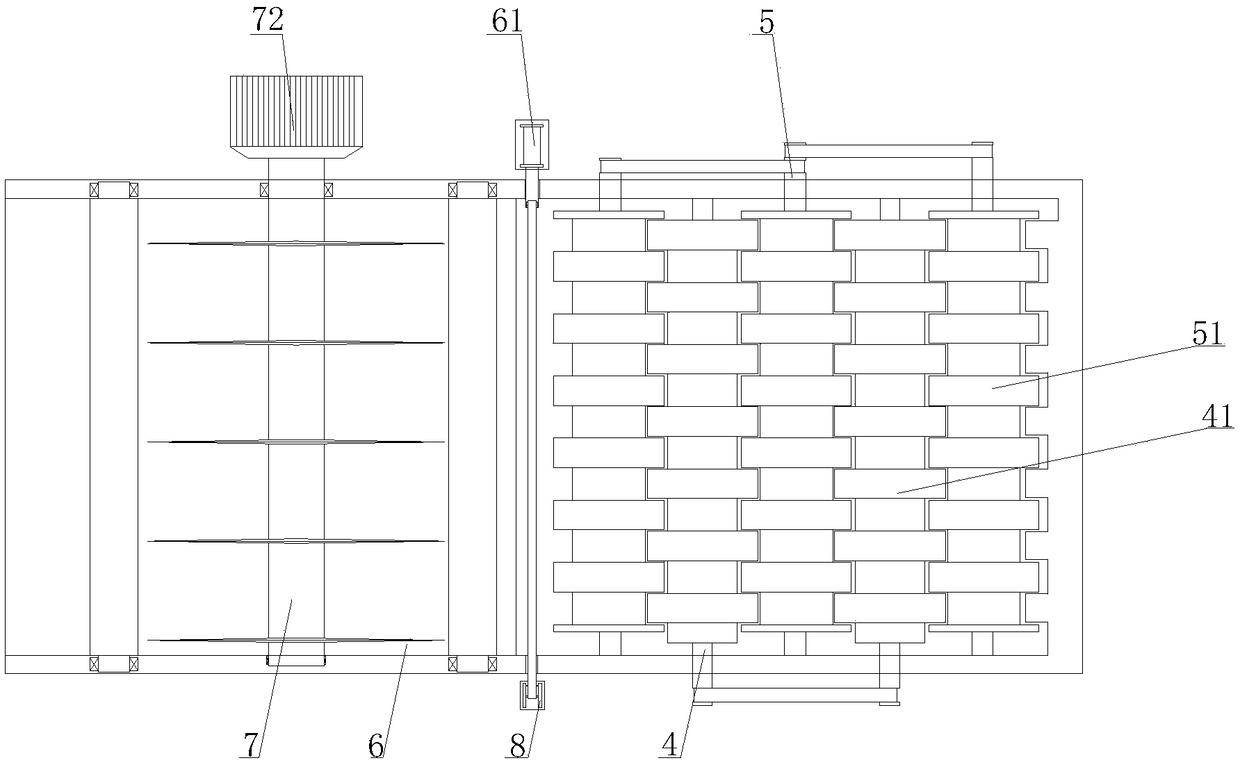

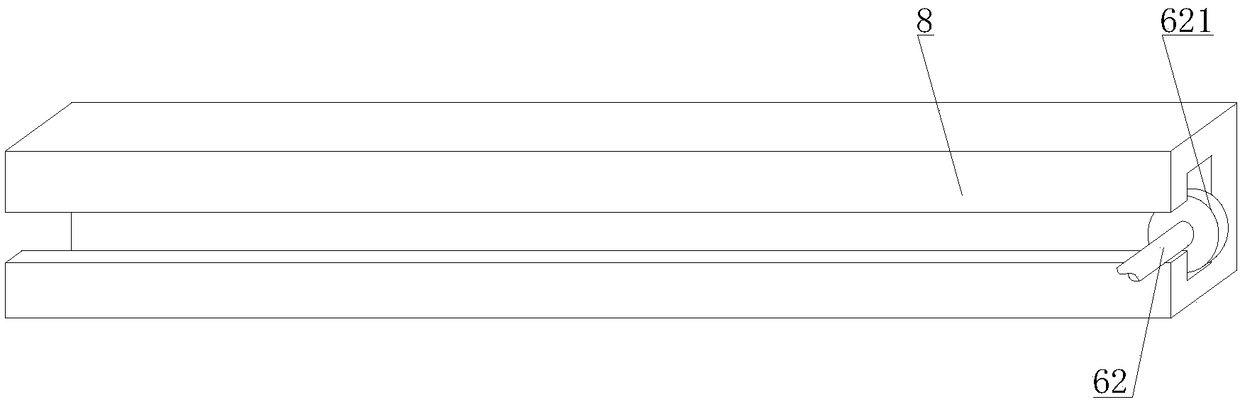

The invention discloses a high-efficiency and environment-friendly medicinal material smashing and grinding device. The device comprises a baseplate (1), a frame body device (2), a cover plate device (3), a first transverse plate (4), a cylinder device (5), a grinding device (6), a dust collecting device (7) and a collecting device (8); a first bracket (11), a first bent rod (13) and a first inclined plate (12) are arranged on the baseplate (1); the frame body device (2) includes a first frame body (21), a first fixed block (22), a first roller (23) and first smashing teeth (24); the cover plate device (3) includes a feed hopper (31), a diversion block (32), a cover plate (33), a first vertical bar (35), a first cross bar (34), a first connecting rod (36) and a holding ring (37); and a first through hole (41) and a third frame body (42) are arranged on the first transverse plate (4). The device directly puts medicinal materials into use of the next step after smashing and dual grinding, and is high in smashing efficiency.

Owner:浙江贝尼菲特药业有限公司

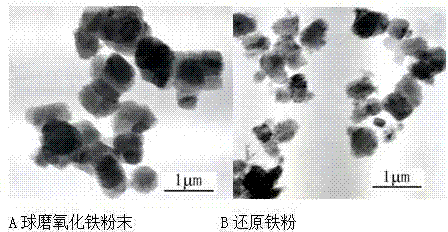

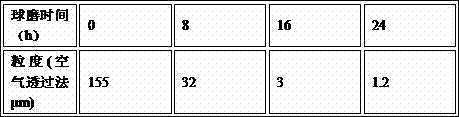

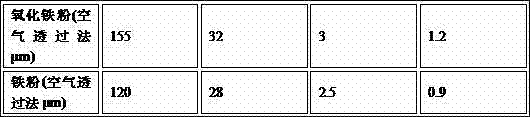

Micron-sized ultrafine iron powder preparation method

Owner:上海寰保渣业处置有限公司 +1

Coating smashing and grinding device

InactiveCN107138262AImprove the crushing and grinding effectReasonable structural designGrain treatmentsPulp and paper industryControl switch

The invention relates to the technical field of grinding devices, in particular to a coating smashing and grinding device. The coating smashing and grinding device comprises a support. An air cylinder is mounted on the side, close to a groove, of the upper end of the support. The air cylinder is connected with a fixed block through a supporting rod, wherein the fixed block is matched with the groove. A collection hopper is arranged at the lower end of the support and located under first through holes. The lower end of the collection hopper is connected with a smashing bin. A cross rod is arranged at the upper end of the smashing bin and provided with extrusion rolls. The extrusion rolls are located at an outlet of the collection hopper. A motor is arranged at the lower end of the smashing bin and connected with a smashing device through a rotary shaft. Discharging openings are formed in the two sides of the lower end of the smashing bin. The air cylinder, an electromagnetic valve and the motor are externally connected with a control switch. The device is high in grinding and smashing effect, reasonable in structural design, simple in operation, better in effect and high in practicality and has certain application and popularization value.

Owner:CHENGDU YALIAN TECH CO LTD

Manual-control crushing and grinding device for salt production

InactiveCN108579866AImprove the crushing and grinding effectEasy to eatGrain treatmentsElectric machineryEngineering

The invention discloses a manual-control crushing and grinding device for salt production. The manual-control crushing and grinding device for salt production comprise a base, wherein a crushing and grinding tank is fixedly arranged on the left side of the upper surface of the base; a fixed sliding block is fixedly connected to the middle of a tank body above the crushing and grinding tank; a crushing rod is connected into the middle in the vertical direction of the fixed sliding block in a contacting way; a crushing hammer is fixedly arranged at the lower end of the crushing rod; a handle isfixedly connected to the upper end of the crushing rod; a spring is fixedly connected to the lower surface of the handle; the crushing rod penetrates through the inner part of the middle of the spring; fixing rods are fixedly connected to positions on the upper left side and the upper right side of the tank body in the crushing and grinding tank; crushing grooves are fixedly arranged in the middleparts of the fixing rods; through holes are formed in the lower part of the crushing grooves; first crushing teeth and second crushing teeth are arranged on the left side and the right side of the lower part of the crushing groove; crushing motors are connected to the right rear parts of the first crushing teeth and the second crushing teeth; and a screen mesh is arranged under the first crushingteeth and the second crushing teeth. The manual-control crushing and grinding device for salt production provided by the invention has a good crushing and grinding effect on crude salt, and can be used for fine crushing and grinding the crude salt, so that the salt can be favorably eaten by people.

Owner:赵锦山 +2

Material grinding and smashing device

ActiveCN106003473ASimple structureEasy to usePlastic recyclingDirt cleaningWaste rubberMechanical engineering

The invention discloses a material grinding and smashing device. The material grinding and smashing device comprises a baseplate (1), a frame body device (2), a cover plate device (3), a first transverse plate (4), a cylinder device (5), a grinding device (6), a dust collecting device (7) and a recovery device (8); a first bracket (11), a first bent rod (13) and a first inclined plate (12) are arranged on the baseplate (1); the frame body device (2) includes a first frame body (21), a first fixed block (22), a first roller (23) and first smashing teeth (24); the cover plate device (3) includes a feed hopper (31), a diversion block (32), a cover plate (33), a first vertical bar (35), a first cross bar (34), a first connecting rod (36) and a holding ring (37); and a first through hole (41) and a third frame body (42) are arranged on the first transverse plate (4). The material grinding and smashing device directly recovers waste rubber after smashing and dual grinding, and is high in smashing efficiency.

Owner:泰州市新滨江开发有限责任公司

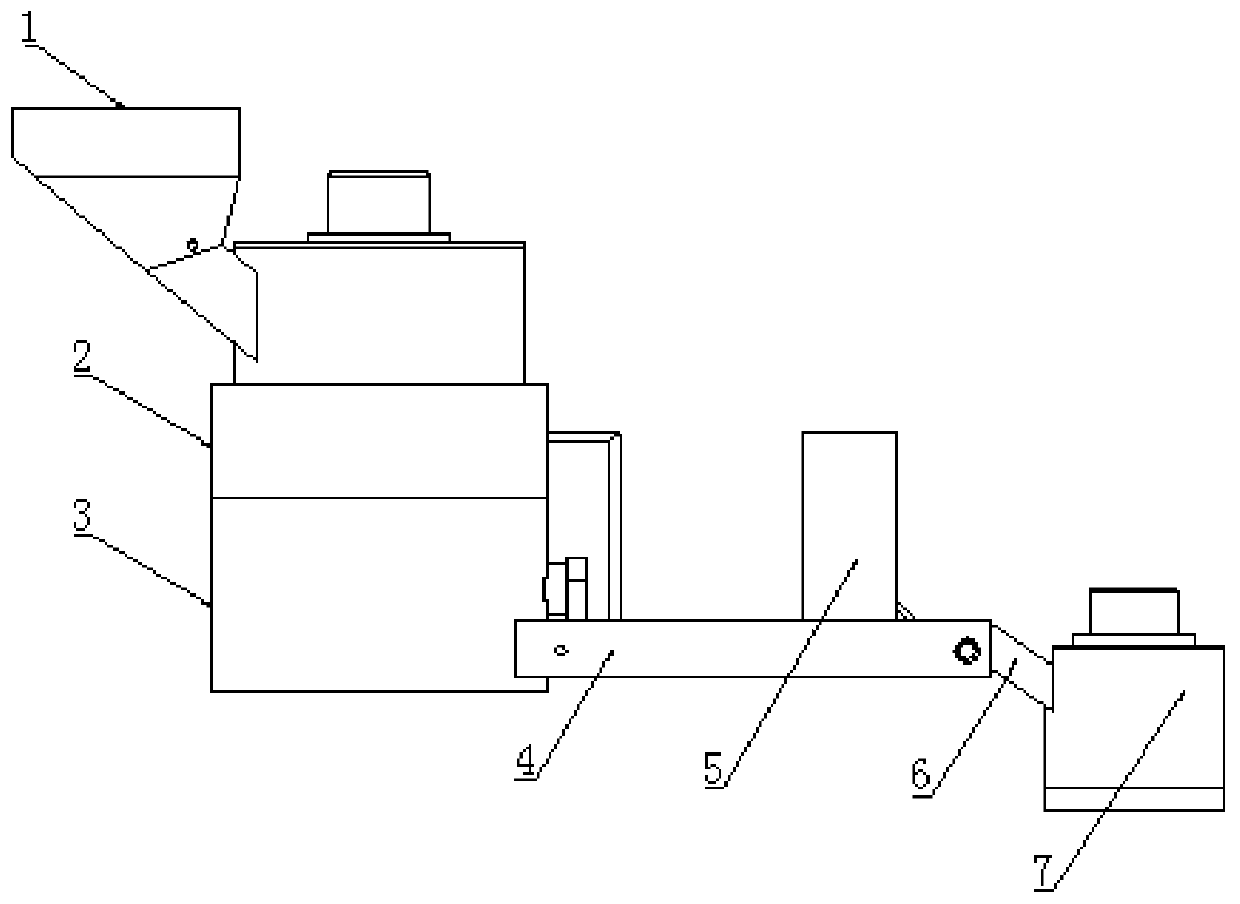

Smashing and grinding device used in garbage fertilizer making system

InactiveCN106607136AExtended service lifeStable crushing qualityGrain treatmentsPressure inorganic powder coatingEngineeringEvening

The invention discloses a smashing and grinding device used in a garbage fertilizer making system. The smashing and grinding device comprises a horizontally placed machine seat. The section of the machine seat is in a V shape. A smashing roller is vertically arranged in the machine seat. The shape of the smashing roller is matched with the machine seat. An end cover used for fixing the smashing roller is arranged at the upper end of the machine seat and is provided with a feed inlet. A cavity is arranged in the smashing roller. A material evening plate is horizontally arranged on the upper end face of the smashing roller. A discharge face and a smashing face are arranged on the outer surface of the smashing roller sequentially from top to bottom. The discharge face and the smashing face are both arranged obliquely. The discharge face is provided with a first crushing cutter. A smashing cutter set, a rough grinding cutter set and a fine grinding cutter set are arranged on the discharge face sequentially from top to bottom. The smashing cutter set comprises a plurality of smashing cutters. The smashing and grinding device is simple in structure, long in service life, convenient to operate, low in cost, safe, reliable, capable of fast and effectively smashing and grinding garbage, particularly some garbage difficult to smash, high in structural strength and wide in usage range.

Owner:JIANGSU QINGSHI TECH

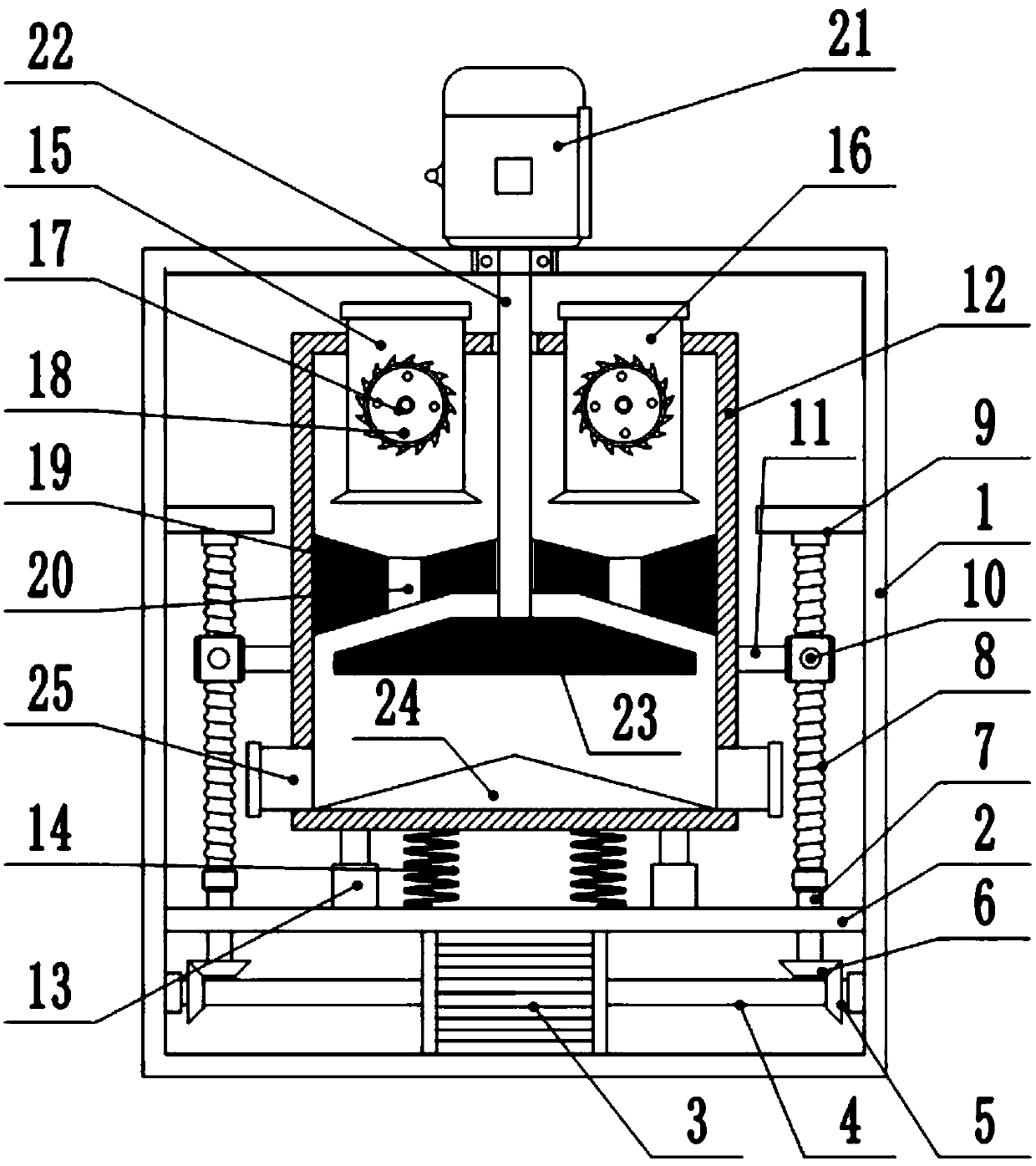

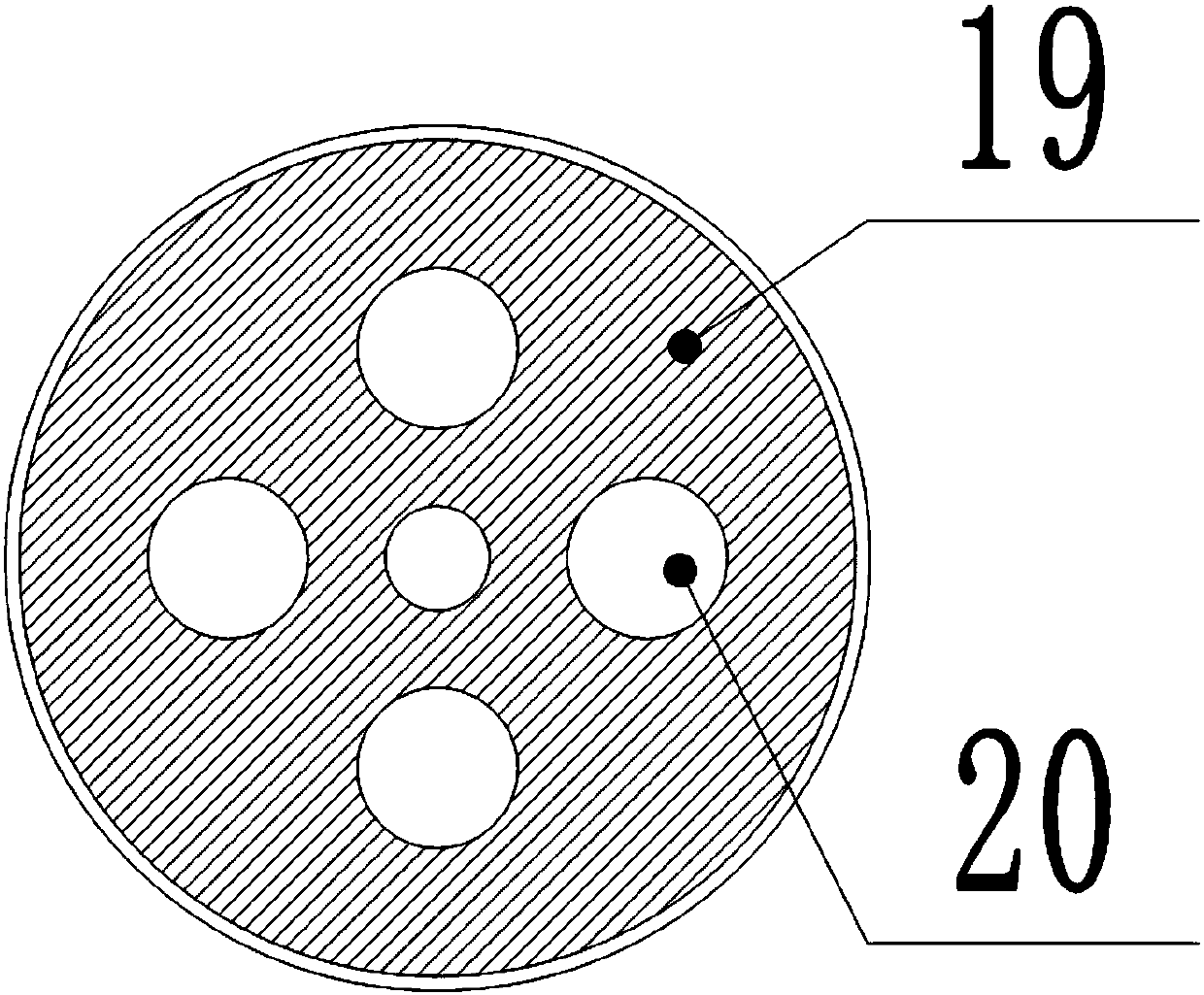

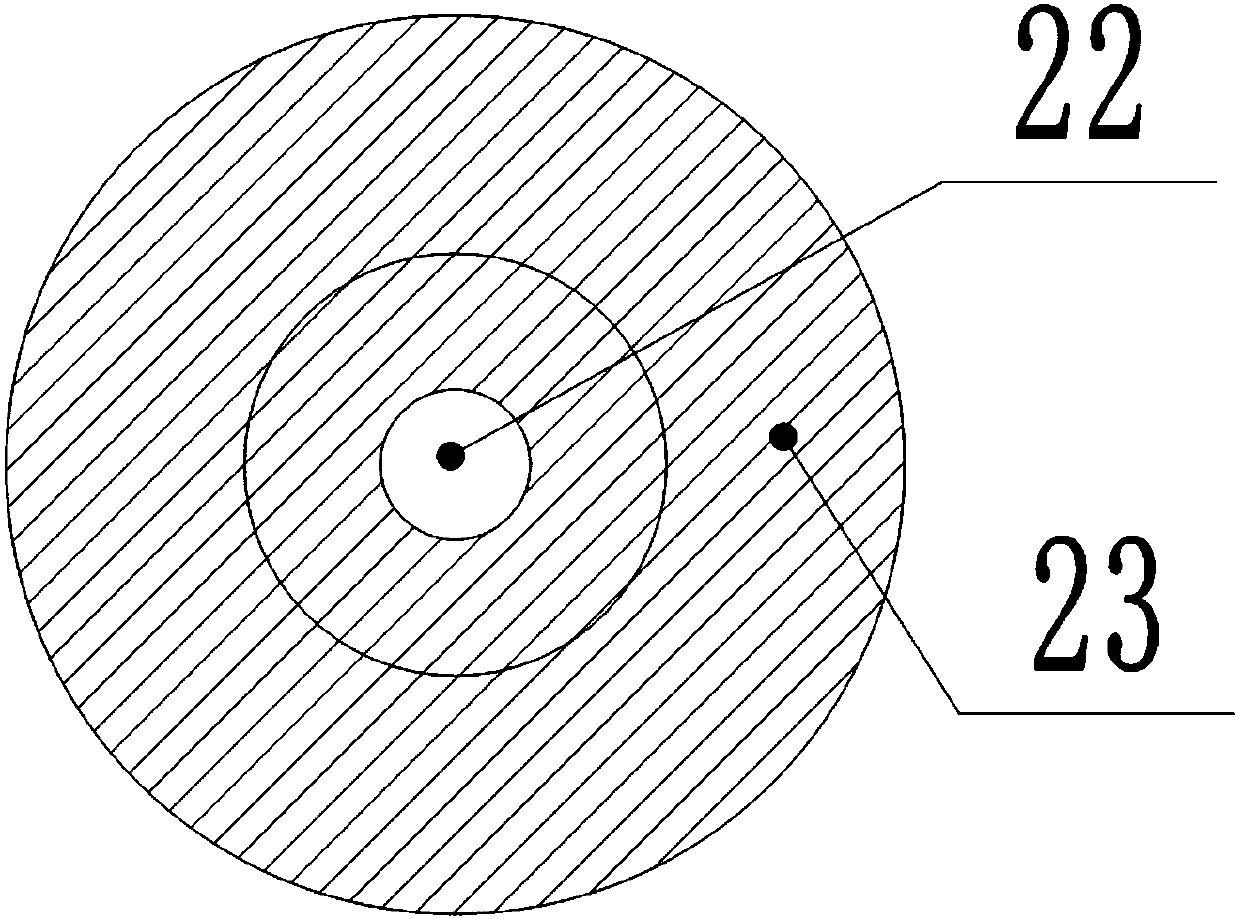

Novel material crushing device for preparation of inorganic nonmetal advanced material

ActiveCN110152781AImprove the crushing and grinding effectIncrease grinding powerCocoaGrain treatmentsFixed frameElectric machinery

The invention discloses a novel material crushing device for preparation of an inorganic nonmetal advanced material. The novel material crushing device for the preparation of the inorganic nonmetal advanced material comprises an outer encircling box, a double shaft motor, a crushing box, a crushing wheel, a fixed upper grinding disk and a tapered movable grinding disk, wherein fixing frames are fixedly welded to the inner sides of lifting sliding blocks located on the left side and the right side, the crushing box is arranged between the fixing frames, a main shaft passes out of the fixed upper grinding disk, the tapered movable grinding disk is installed at the lower end of the main shaft in a threaded mode, and the main shaft is in clearance fit with the fixed upper grinding disk. By enabling the crushing wheel and the tapered movable grinding disk to start rotating, raw materials can be ground for the second time, and therefore grinding and crushing effects are greatly improved, andsimultaneously the lifting sliding blocks can move up and down by enabling screw rods to be in threaded fit with the lifting sliding blocks, and therefore the crushing box is indirectly driven to move up and down, then an interval between the fixed upper grinding disk and the tapered movable grinding disk can be changed so as to increase grinding force and improve grinding effect, and simultaneously the material crushing device can adapt to grinding the raw materials different in particle size, and furthermore is simple and effective.

Owner:南通太洋高新材料科技有限公司

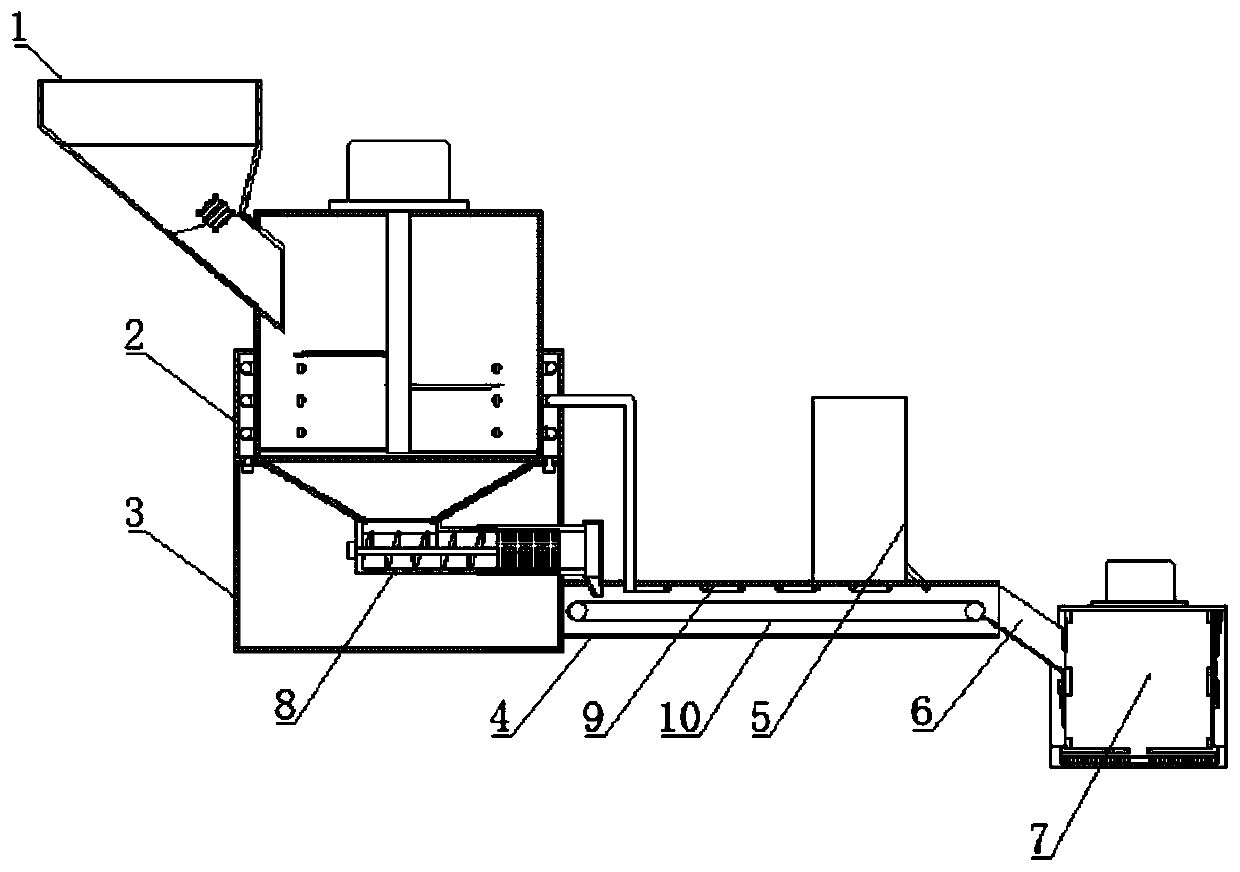

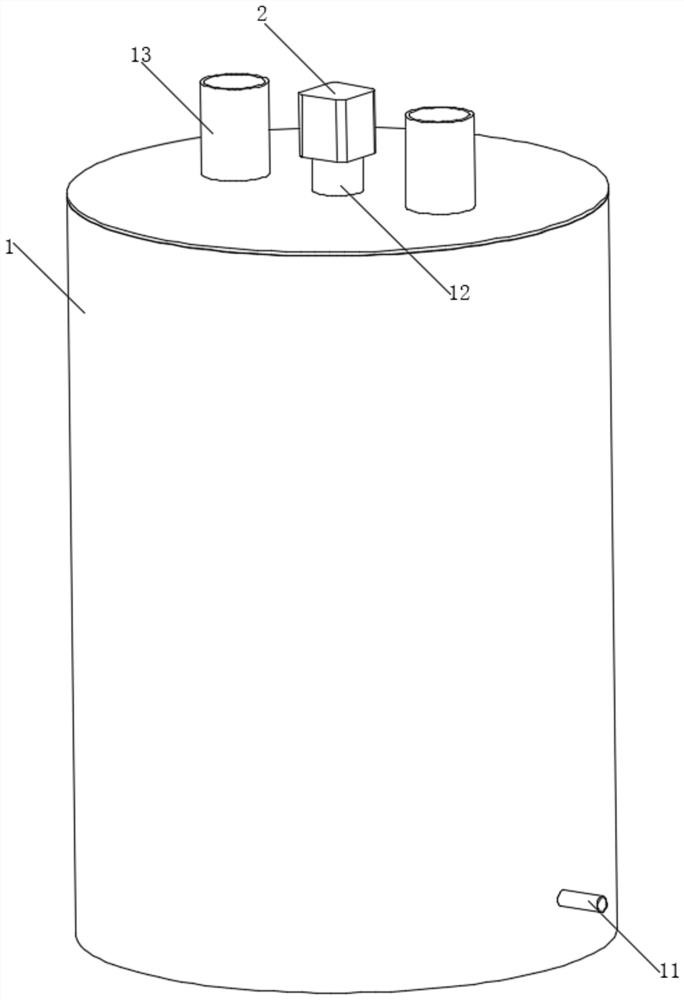

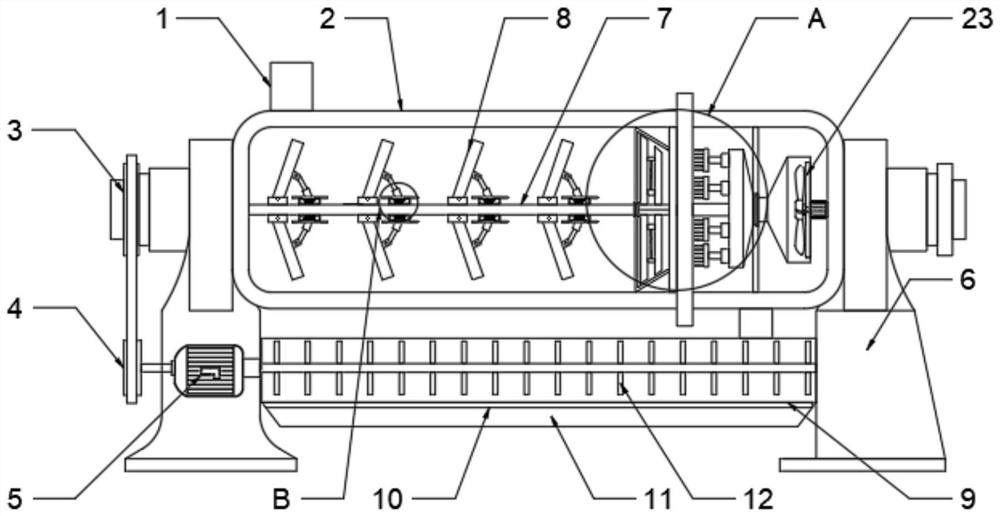

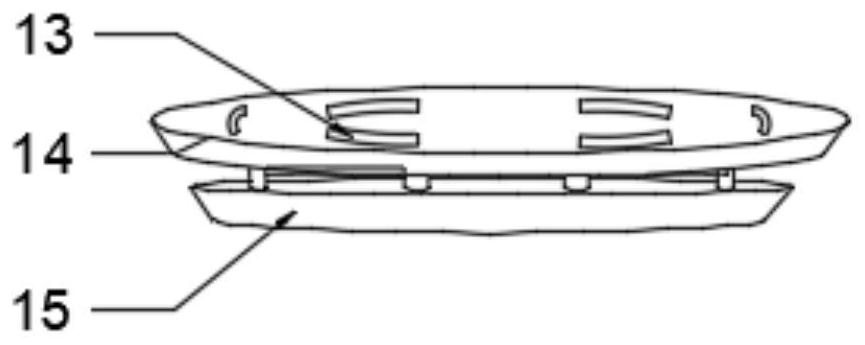

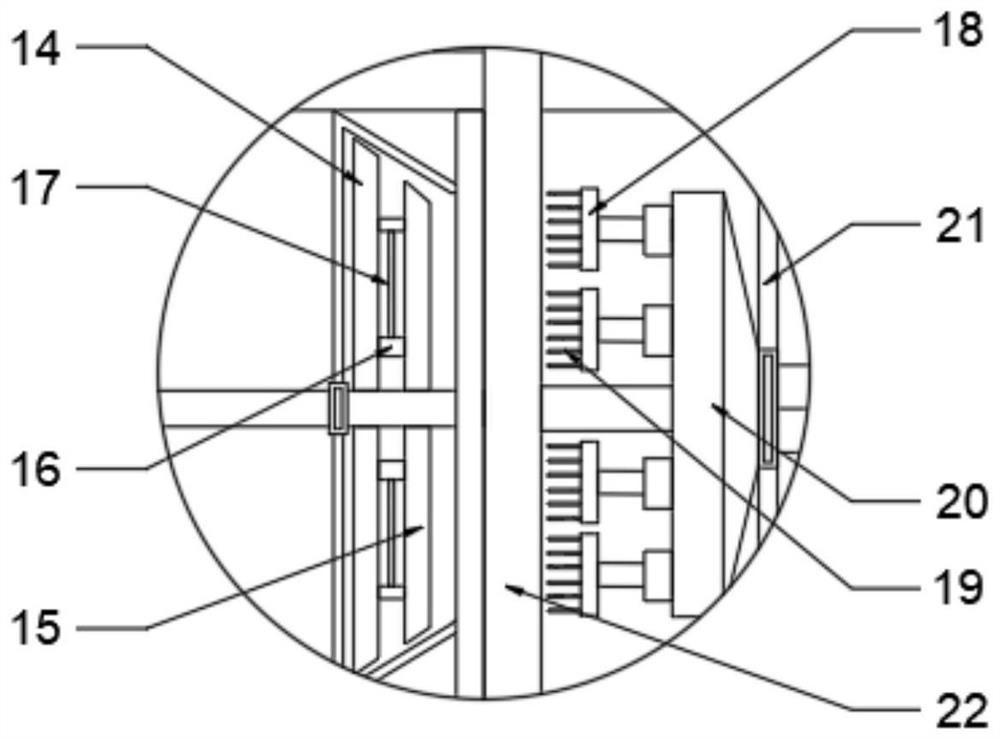

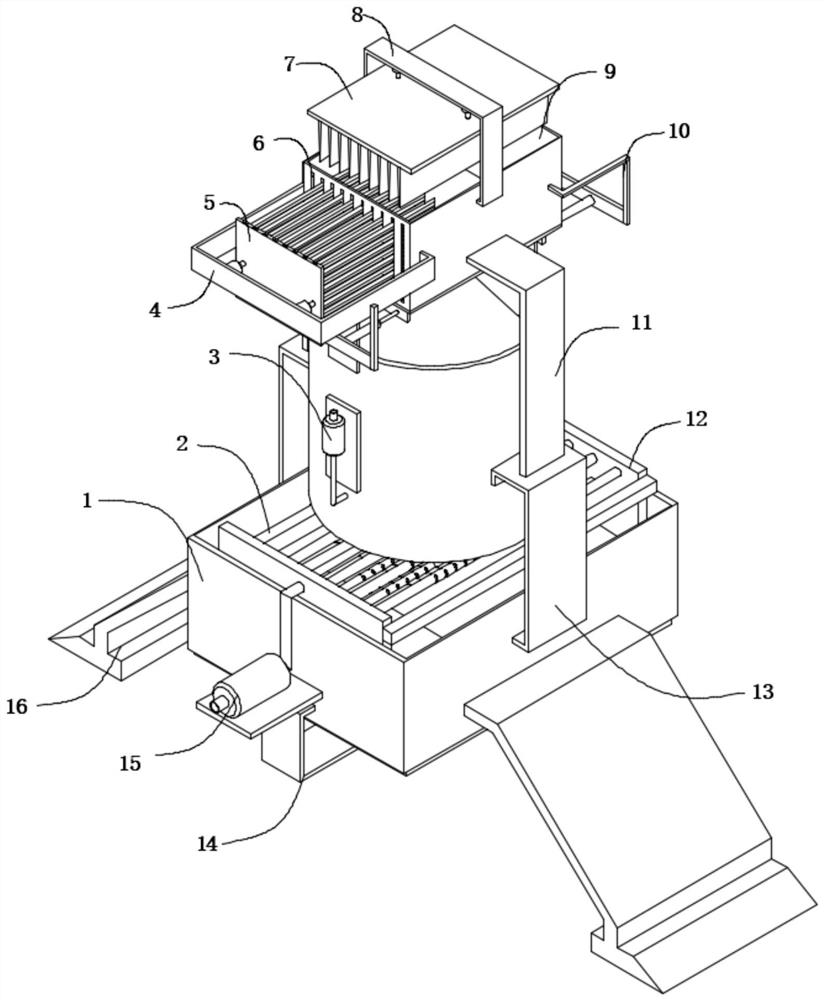

Minced fillet production waste recovery device

InactiveCN110420719AImprove crushing effectQuality assuranceDrying solid materials with heatDrying solid materials without heatWater contentWaste recovery

The invention discloses a minced fillet production waste recovery device. The minced fillet production waste recovery device comprises a feeding mechanism, a crushing mechanism and a steam generator,wherein the feeding mechanism is arranged above the left of the crushing mechanism; the feeding mechanism communicates with the crushing mechanism; a waste liquid collecting cylinder is arranged underthe crushing mechanism; and an upper port of the waste liquid collecting cylinder is connected with the crushing mechanism in a sleeving mode. According to the minced fillet production waste recoverydevice, after being crushed by the crushing mechanism, the minced fillet production waste can be conveniently extruded and dehydrated by a subsequent discharging mechanism, and therefore the water content of the minced fillet production waste can be greatly reduced; the minced fillet production waste is uniformly spread on a conveying belt through a strip-shaped discharging opening formed in a discharging box for drying treatment, so that the drying efficiency and the drying effect of the minced fillet production waste are greatly improved; and a jet nozzle on an annular pipe sprays high-temperature steam conveyed by the steam generator to the crushing waste to achieve high-temperature sterilization and disinfection.

Owner:陈佳涵

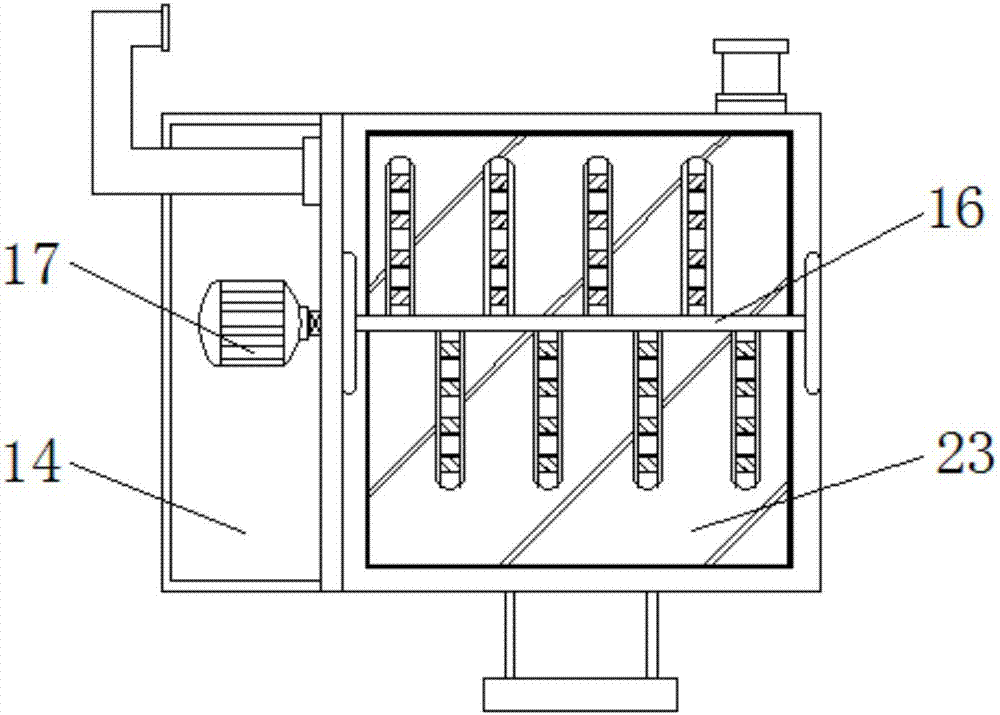

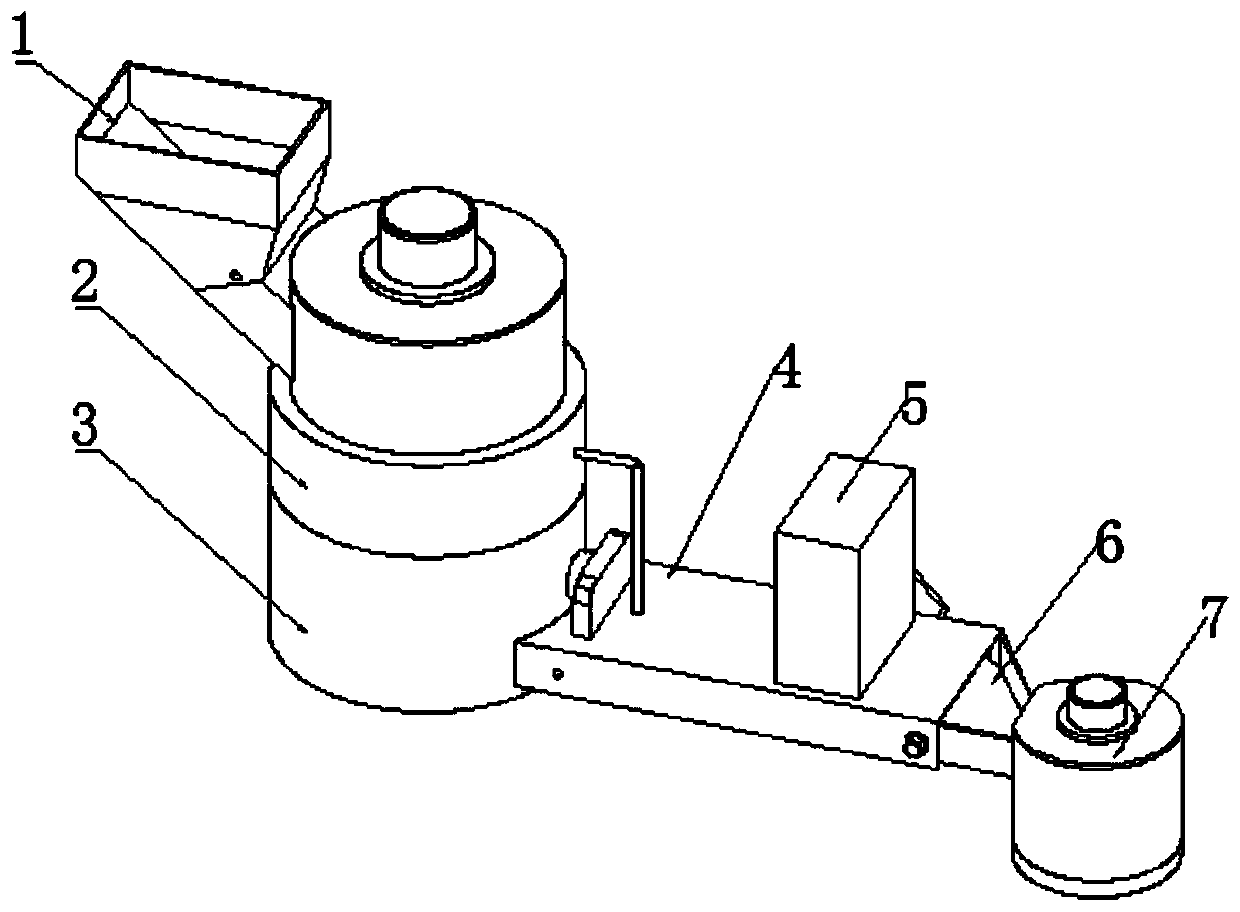

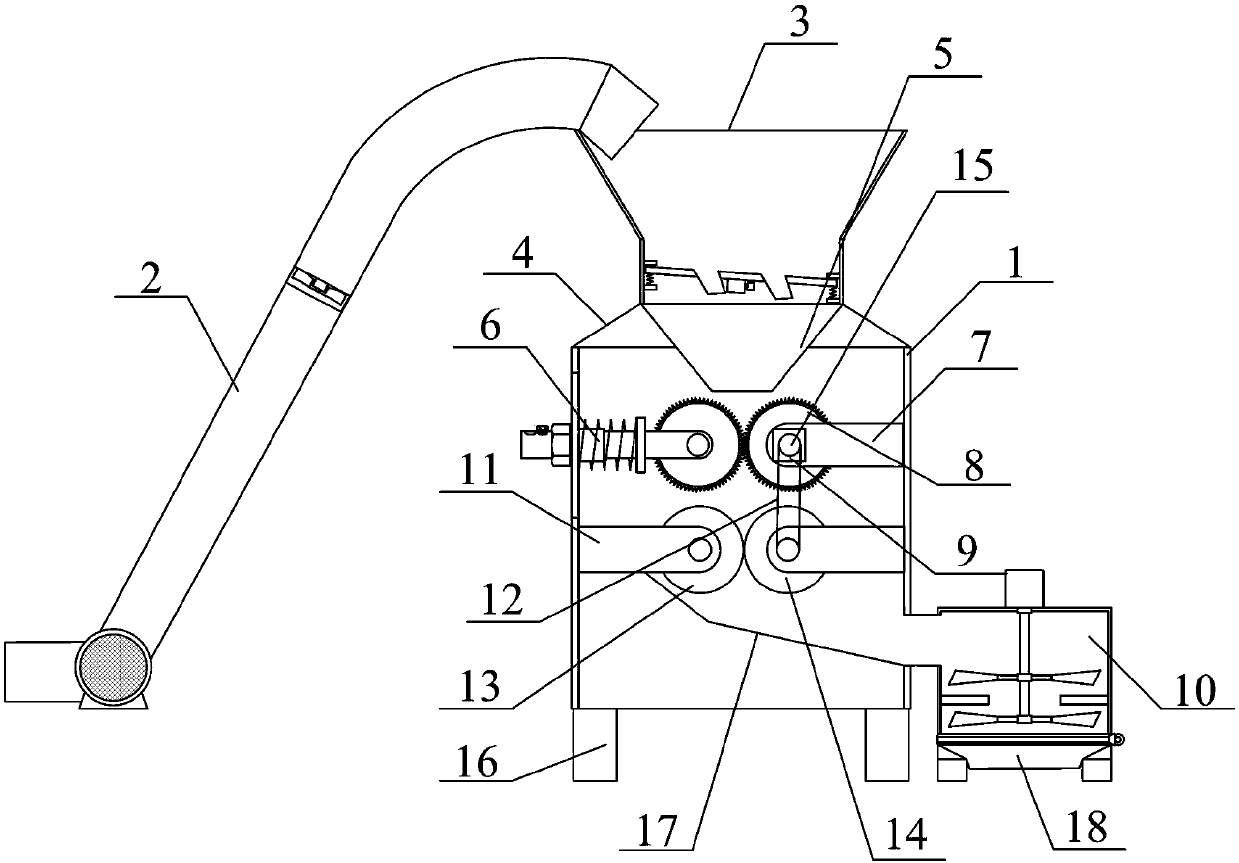

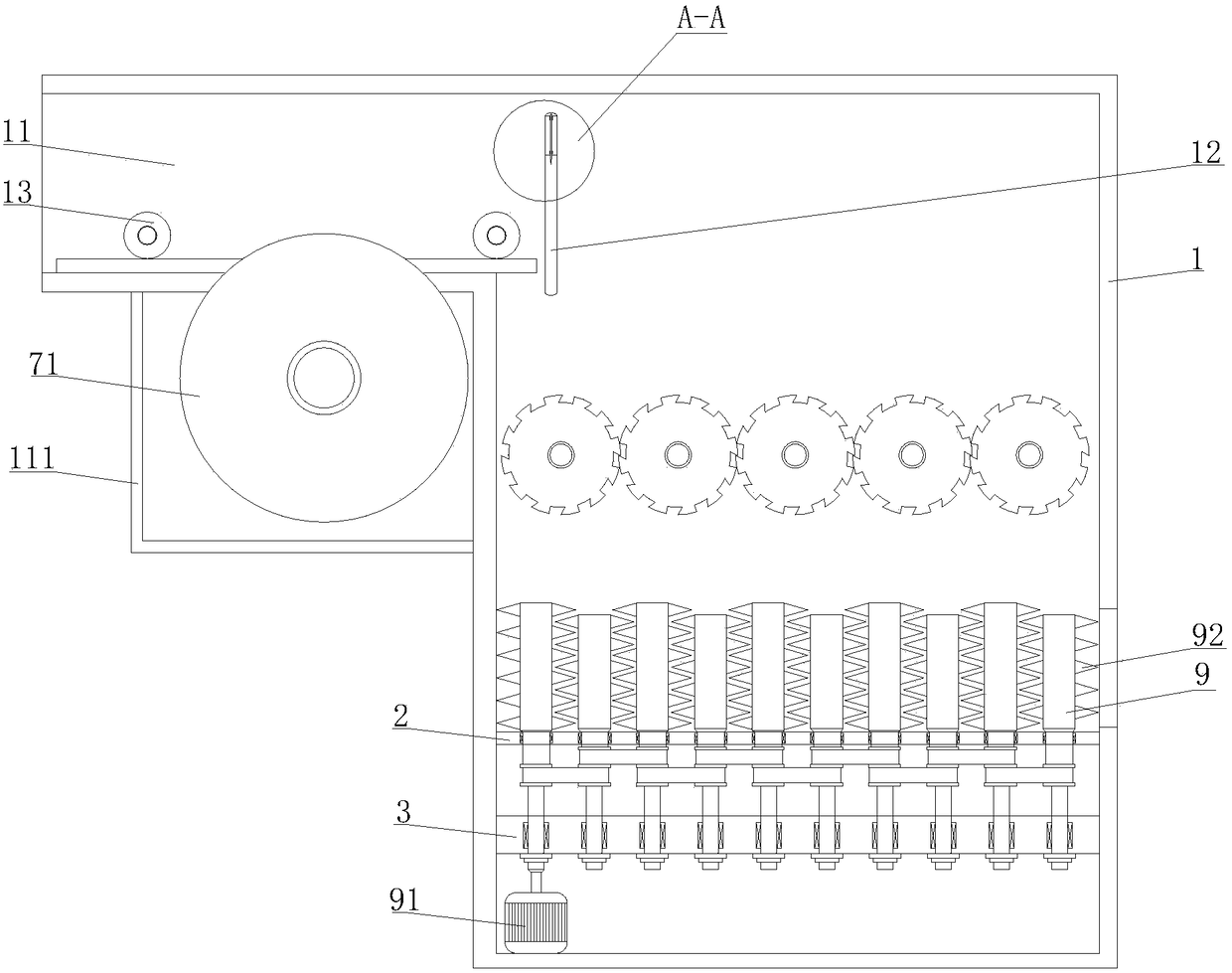

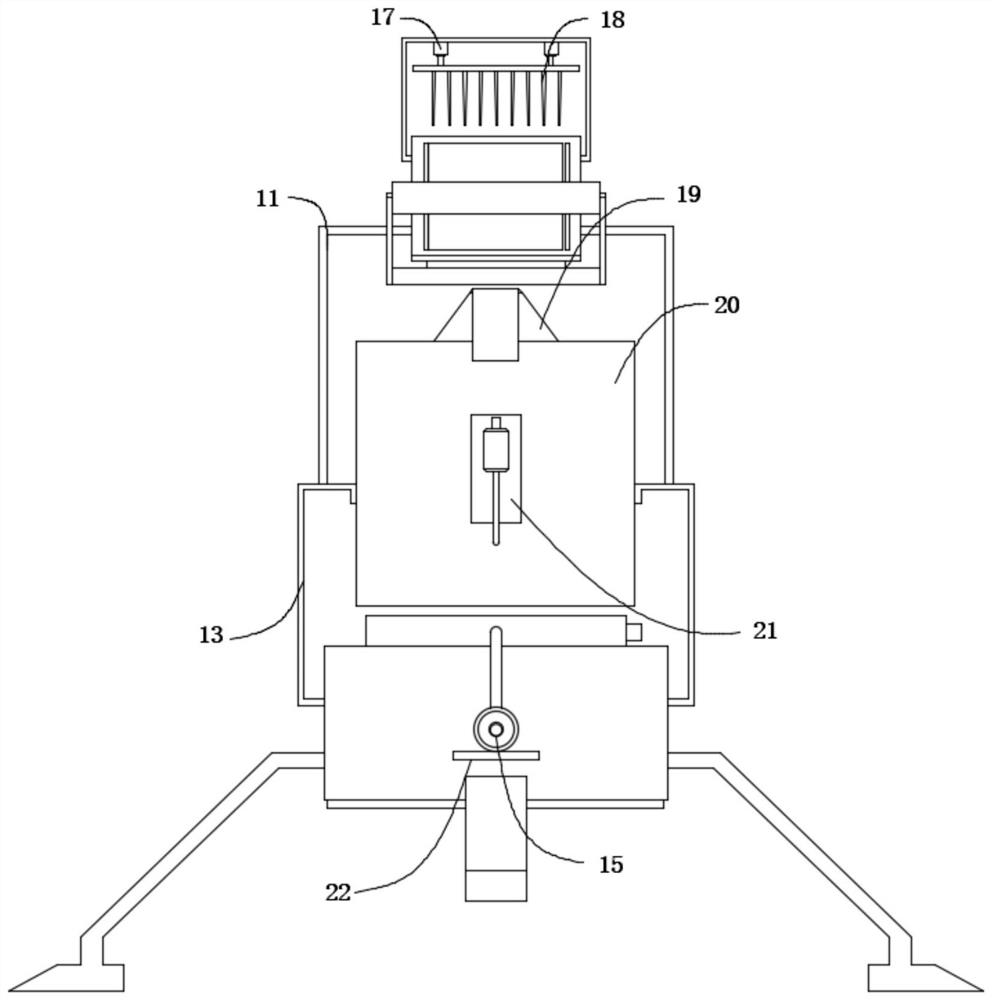

Wood chip processing production system

PendingCN107415011AResolve implicated issuesGood crushing and grinding effectWood working apparatusGrain treatmentsElectric machineryDrive motor

The invention discloses a wood chip processing production system and relates to the field of wood processing equipment. The wood chip processing production system comprises a rolling cavity, a crushing cavity and a ball-milling barrel; two rolling rolls rolling oppositely are arranged in the rolling cavity and arranged in a mutually reversed mode; spiral blades are arranged on the surfaces of the rolling rolls; the blades on the two rolling rolls are arranged in a mutual penetrating mode; an outlet of the rolling cavity is guided to the crushing cavity; a crushing cutter shaft is arranged in the crushing cavity; a slope protruding downwards is arranged on the inner wall of the crushing cavity; a plurality of vertical open grooves are formed in the slope; cutter bits matched with the open grooves are arranged on the crushing cutter shaft; broken wood slides down along the slope and shot down from the interiors of the open grooves through the rotating crushing cutter shaft; a horizontal outlet communicating with the ball-milling barrel is formed in the bottom of the crushing cavity; an air duct facing the horizontal outlet directly is further formed in the bottom of the crushing cavity; an air blower is connected with the air duct externally; abrasion-resistant tiles are arranged on the inner wall of the ball-milling barrel; a circle of transmission teeth are arranged on the rotation surface of the ball-milling barrel; and the transmission teeth are in engaging transmission with a straight gear on a driving motor rotary shaft.

Owner:浙江浔园家居股份有限公司

Automatic control crushing and grinding device with crankshaft and slider for salt production

InactiveCN108636567AImprove the crushing and grinding effectEasy to eatGrain treatmentsAutomatic controlElectric machinery

The invention discloses an automatic control crushing and grinding device with a crankshaft and a slider for salt production. The automatic control crushing and grinding device comprises a base, wherein a crushing and grinding box is fixedly mounted on the left side of the upper surface of the base; a fixed slider is fixedly connected to the upper middle of the crushing and grinding box; a crushing rod is connected to the interior of the middle of the fixed slider in a contact manner in a vertical direction; a crushing hammer is fixedly mounted at the lower end of the crushing rod; a motor support is fixedly connected to the outer middle of the crushing and grinding box; a motor is fixedly mounted at the upper end of the motor support; a round wheel is connected to the front of the middleof the motor; a slider is fixedly connected to the right side of the central surface of the round wheel; a crankshaft is connected to the lower part of the surface of the slider; the lower end of thecrankshaft is fixedly connected to the middle of the upper end of the crushing rod; fixed rods are fixedly connected to the left side and the right side of the internal upper part of the crushing andgrinding box; a crushing trough is fixedly mounted in the middle of the fixed rod; and through holes are formed in the lower part of the crushing trough. The automatic control crushing and grinding device has a very good crushing and grinding effect on coarse salt and can perform fine crushing and grinding to facilitate eating by people.

Owner:赵锦山 +2

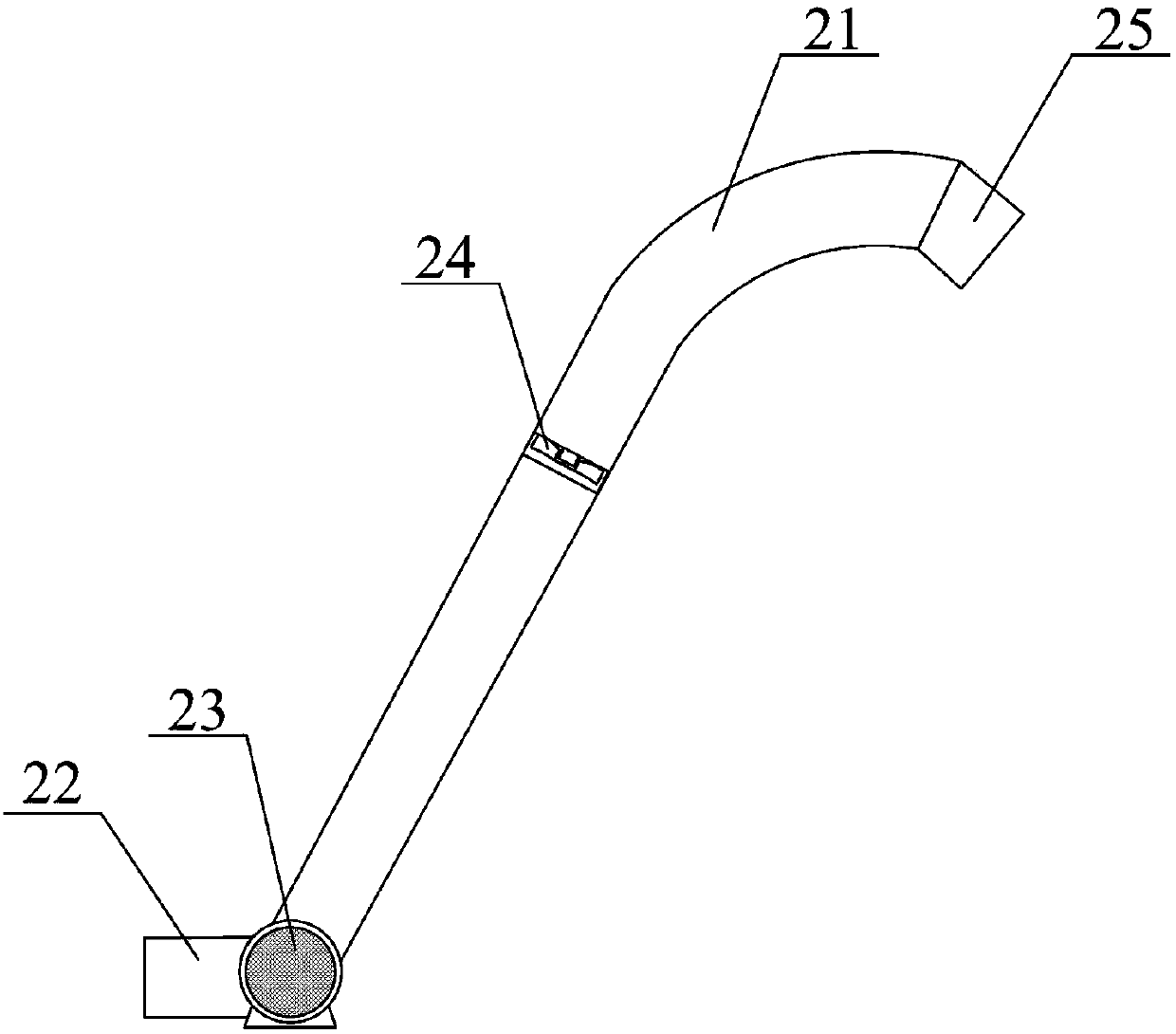

Pneumatic conveying device for bulk materials

ActiveCN112973864ALarge volumeLong conveying distanceFeeding-stuffGrain treatmentsGrindingElectric machinery

The invention discloses a pneumatic conveying device for bulk materials, and relates to the technical field of pneumatic conveying. The pneumatic conveying device comprises a pneumatic pump, an air supply pipeline, a supporting table, a stirring assembly, a grinding assembly and a conveying assembly; the pneumatic pump is fixedly connected with the grinding assembly through the air supply pipeline; the stirring assembly is fixedly installed on the grinding assembly; the conveying assembly is fixedly connected to the grinding assembly through welding; and the pneumatic pump is fixedly installed on the supporting table. According to the pneumatic conveying device, granular feed is poured into a feeding cylinder, a first motor is started to drive spiral stirring blades to stir the granular feed, a first discharging valve is opened, the stirred feed enters a grinding box through a spiral feeding pipe, a second motor drives grinding rollers to grind and crush the feed, the crushed feed is blown to an L-shaped conveying pipeline through the pneumatic pump to enter a spherical collecting box, so that the granular feed is stirred, ground, crushed and conveyed, the conveying amount is large, the conveying distance is long, and the conveying speed is high.

Owner:合肥品卓科技有限公司

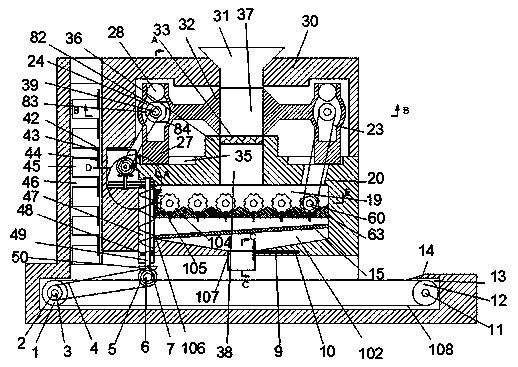

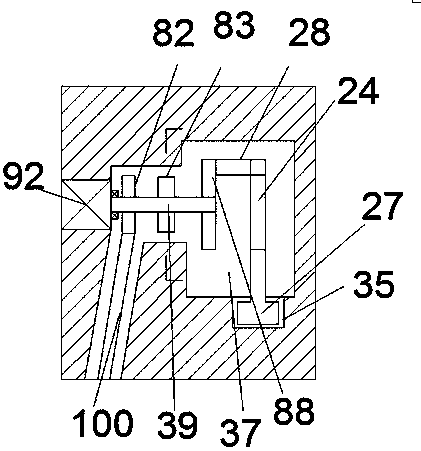

Textile processing device

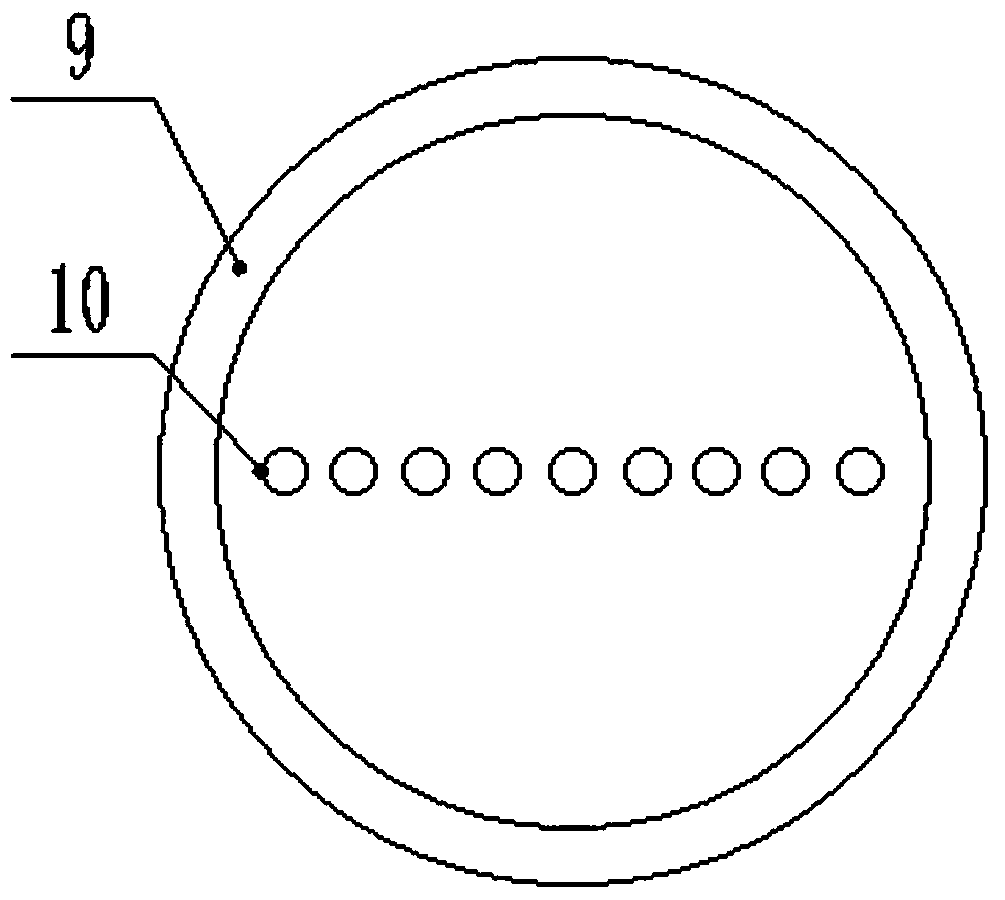

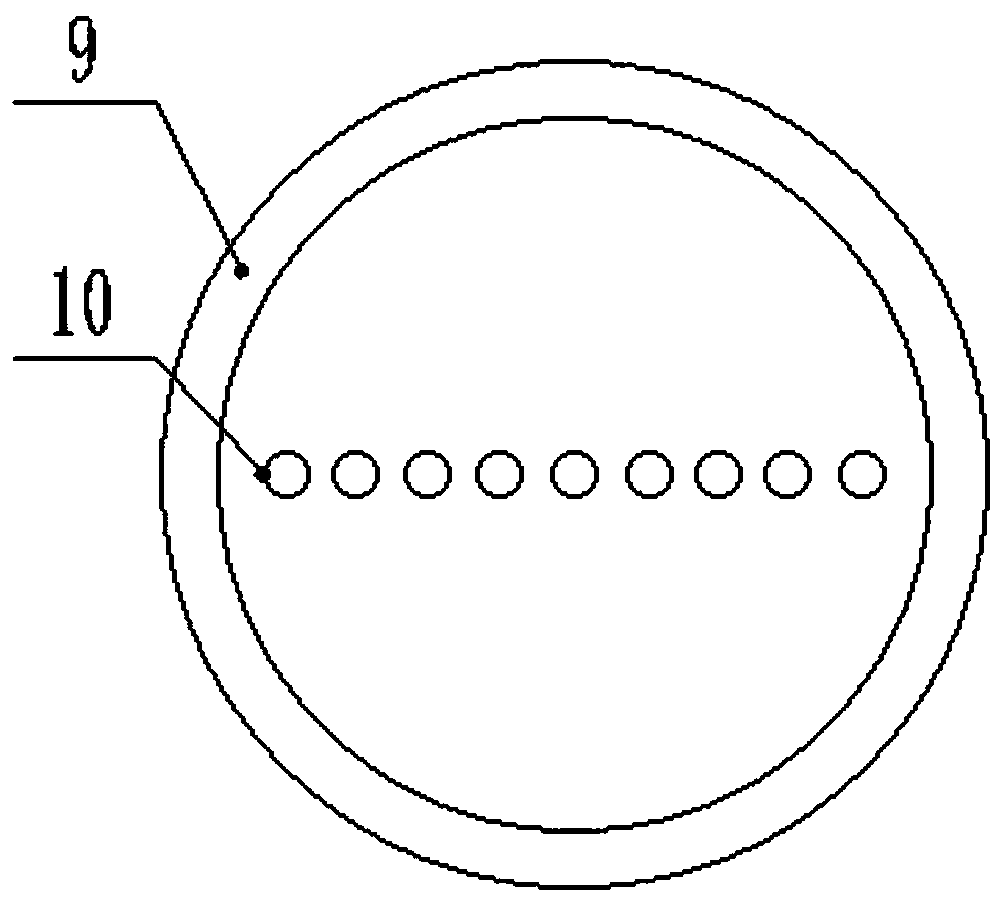

InactiveCN108035095AImprove dyeing effectReduce the possibility of re-precipitationTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentEngineeringMechanical engineering

The invention relates to the field of textile processing, in particular to a textile processing device. The textile processing device is characterized in that the textile processing device comprises apositioning grinding tube, a dyeing tank, a pushing and salvaging mechanism and a jitter grinding mechanism; a limit bar is arranged on a sealing end of the positioning grinding tube along the axialdirection; a feed hole and a plurality of discharge holes are arranged on the tube wall of the positioning and grinding tube; the pushing and salvaging mechanism comprises a servo motor, a pushing unit and a salvaging unit; the pushing unit comprises a lead screw pair and an extruded disc, wherein the lead screw pair comprises a lead screw and a nut seat; the salvaging mechanism comprises a bending bar, a feed pipe, a funnel and a filter plate; the jitter grinding mechanism comprises a cylinder, a support rod, a grinding rod, an adjusting rod and a jitter bar. With the technical scheme, the textile processing device has the advantages of conducting jitter and dip dyeing of textile fabrics, and performing multiple grinding of paint color particles.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Crushing device for biological medical material machining

InactiveCN110841754AImprove qualityImprove the crushing and grinding effectGrain treatmentsBiotechnologyMaterials processing

The invention discloses a crushing device for biological medical material preparation. The device comprises an outer box body; a crushing cavity is formed in the outer box body, and a feeding port isformed in the upper portion of the crushing cavity; an upper sieve plate is arranged below the feeding port, fixing plates are fixedly mounted on the left side and the right side of the upper sieve plate, and the fixing plates are fixedly mounted on the front end wall and the rear end wall of the crushing cavity; a T-shaped sliding groove is formed in the lower end wall of the crushing cavity, andcrushing assemblies are symmetrically arranged in the crushing cavity left and right; and a falling cavity is formed below the upper sieve plate, a grinding cavity is formed below the falling cavity,and a circulating inlet is formed in the left upper part of the grinding cavity. Through adding the crushing assemblies, the material quality is higher, and a plurality of grinding crushing wheels are arranged, so that the crushing and grinding effect of raw materials is greatly improved; the action of the upper sieve plate effectively avoids blockage at the blanking channel, and the action of the lower sieve plate can enable the machined non-qualified material to be machined again until qualified; and the device is high in machining quality and high in practicability.

Owner:孙丽宏

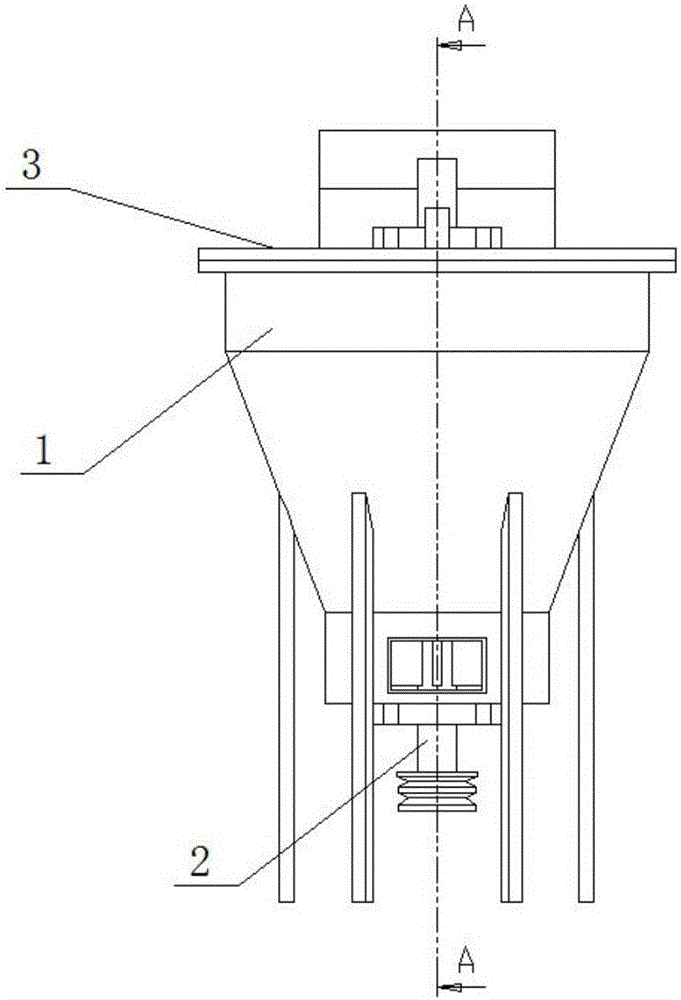

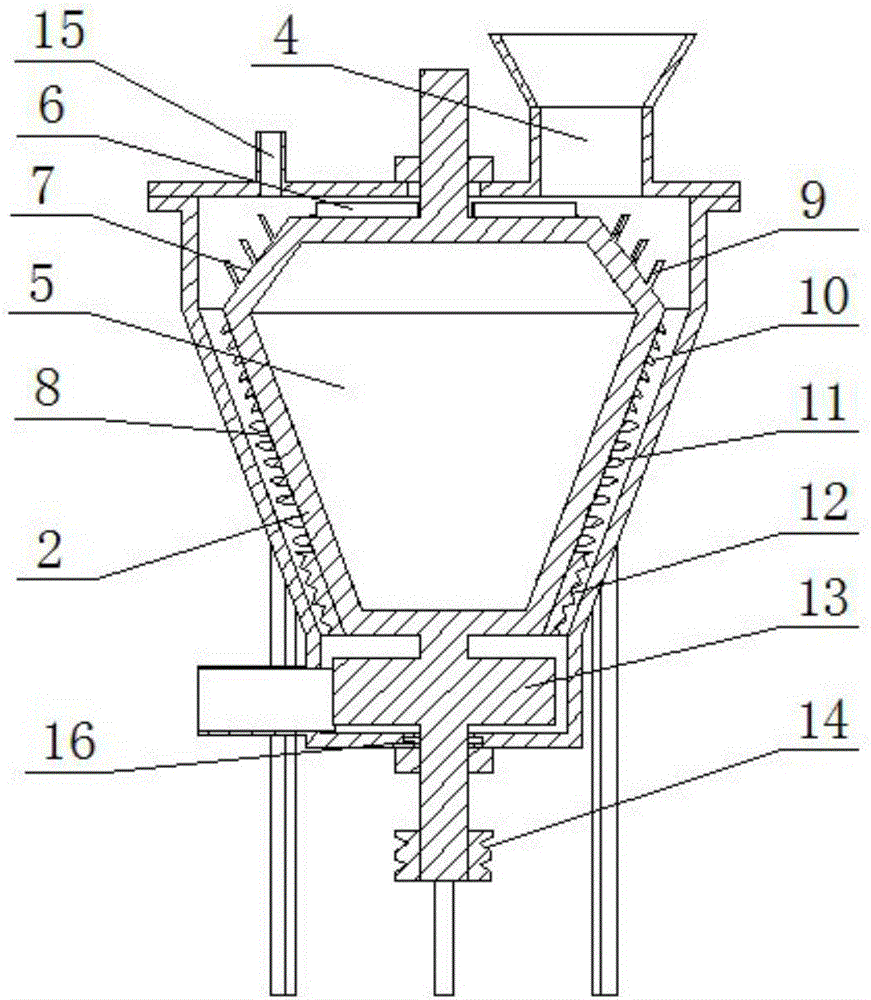

Intelligent circulation combustion system for large hearth coal

ActiveCN110986028AImprove practicalityImprove energy saving performanceSolid fuel combustionGrain treatmentsAutomotive engineeringHearth

The invention relates to an intelligent circulation combustion system for large hearth coal. The intelligent circulation combustion system comprises a gas-solid separator. The gas-solid separator comprises a gas inlet pipe, an exhaust pipe, a body and a return pipe. The system further comprises an anti-blocking mechanism and a grinding mechanism. The anti-blocking mechanism comprises a drive shaft, a supporting rod, a fan blade, two mounting bearings and two knocking assemblies. The grinding mechanism comprises a grinding block, a columnar concave opening, a locating assembly, a spring, two supporting wheels and at least two convex strips. Each knocking assembly comprises a rotating plate, a rubber column, a knocking block and two connecting rods. The locating assembly comprises a limitinggroove and a limiting block. In the intelligent circulation combustion system for large hearth coal, the body can be knocked by the anti-blocking mechanism, coal particles in the body are loosened, the probability that the coal particles are blocked in the body is reduced, and practicality of the gas-solid separator is improved; and the coal particles of the grinding mechanism can be ground, thesizes of the coal particles are reduced, and combustion efficiency of the coal particles is improved.

Owner:泰州金泰环保热电有限公司

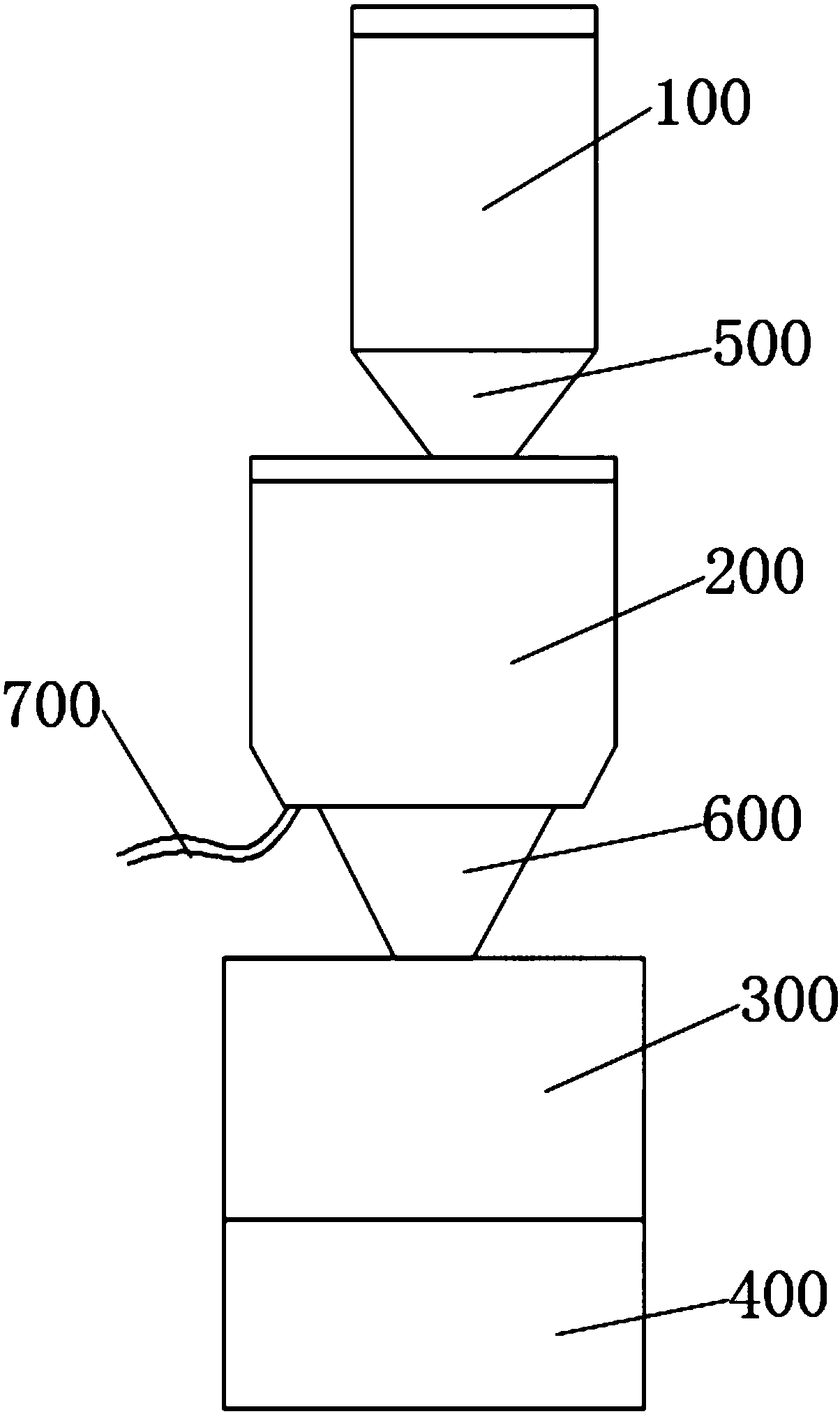

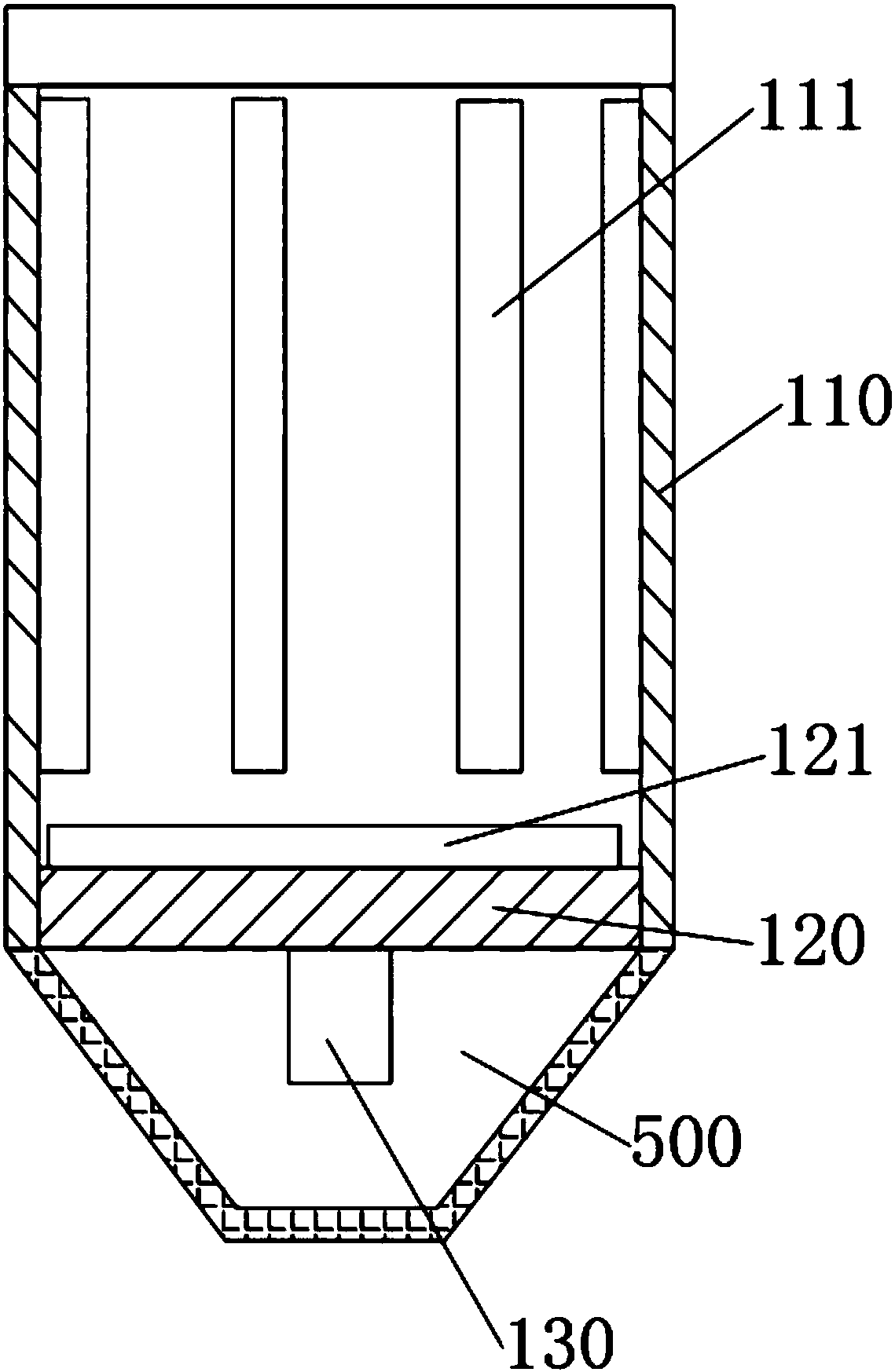

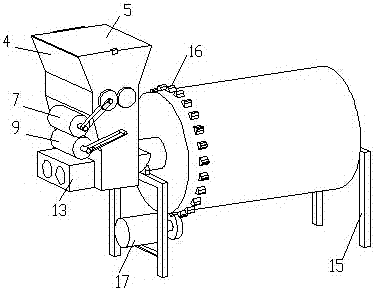

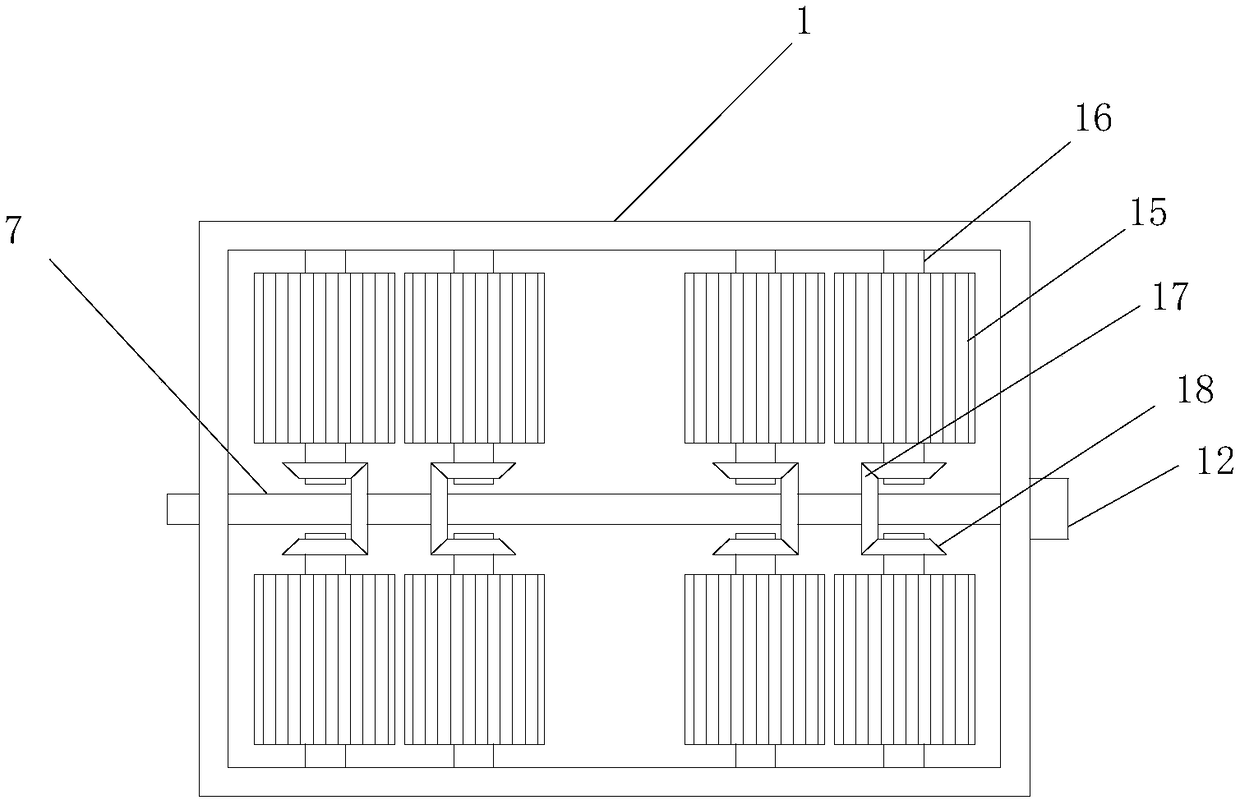

Ball type vertical efficient multistage grinding device

InactiveCN108405155AUniform particlesImprove the crushing and grinding effectGrain treatmentsElectric machineryBall type

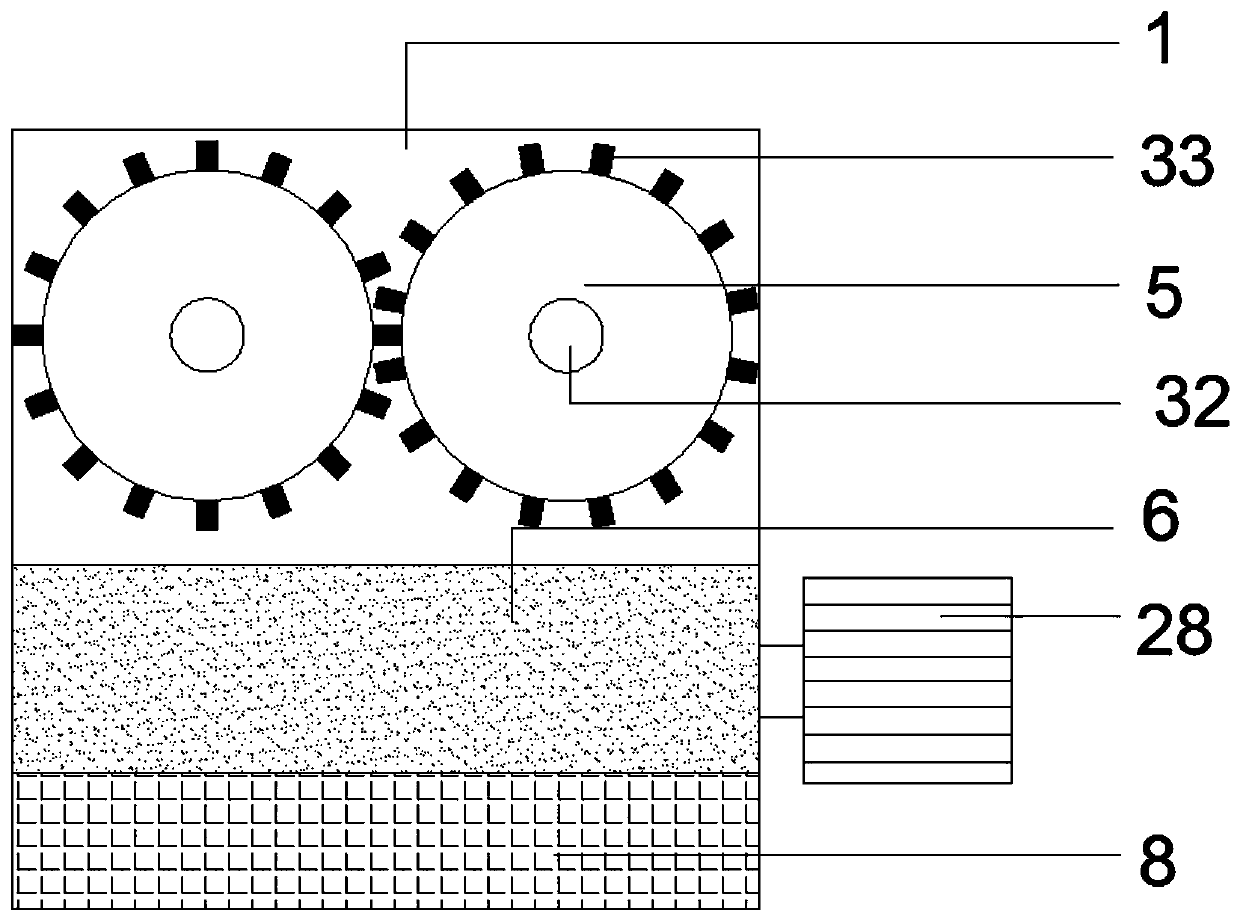

The invention discloses a ball type vertical efficient multistage grinding device which comprises a feed hopper, a pre-crushing chain wheel set, a primary grinding wheel disc, a grinding barrel, a main case, a secondary grinding disc and a motor. The main case is fixed onto a framework, the grinding barrel is fixed onto the inner wall of the main case, a collecting cavity is arranged in the main case and is positioned below the grinding barrel, a discharge pipe is connected onto the main case and is positioned at the bottom of the collecting cavity, the feed hopper is connected with the top ofthe main case, the pre-crushing chain wheel set is mounted inside the bottom of the feed hopper, the primary grinding wheel disc and the secondary grinding disc are mounted in the grinding barrel andare fixed onto a rotary shaft, a plurality of ball grooves are formed in the outer side of the primary grinding wheel disc, grinding balls are embedded in the ball grooves, and a plurality of grinding teeth are arranged on the outer side of the secondary grinding disc. The ball type vertical efficient multistage grinding device has the advantages that material granules are uniform under the condition of pre-crushing and grinding treatment carried out by the pre-crushing chain wheel set, the grinding balls of the primary grinding wheel disc and the grinding teeth of the secondary grinding disc, good crushing and grinding effects can be realized, and the efficiency can be improved.

Owner:HUNAN KUANGCHU TECH CO LTD

Pulverizing device used for new material processing

The invention provides a pulverizing device used for new material processing. The pulverizing device used for new material processing comprises an outer grinding frame, an adjustable exhaust tube structure, a vibrating collection hopper structure, a hopper frame, a feed hopper, a buffering auxiliary pressing wheel structure, a thorn roller fixing frame, a new material grinding thorn roller, a double-shaft motor, a new material secondary pulverizing and grinding box structure, a fixed cross rod, a transmission V-belt, a left pressing roller, a right pressing roller, a driving wheel, supportinglegs, a new material guiding plate and an adjustable discharge hopper structure, wherein the adjustable exhaust tube structure is arranged on the left side of the outer grinding frame. According to the pulverizing device used for new material processing, a new material suction tube, an exhaust fan and an auxiliary exhaust fan are arranged so that the angle of a feed tube can be flexibly adjusted,and accordingly, new materials on the ground can be pumped conveniently; and an eccentric-axis vibrating motor, a vibrating plate, a limiting plate and a buffer spring are arranged so that the new materials can be vibrated and screened, and the situation that a large quantity of new materials are guided into the feed hopper, and consequentially blockage is caused is avoided.

Owner:SHEN ZHEN SQUARE BOTTLE CO LTD

Acid electrolyte equipment and method for preparing electrolytic manganese and method thereof

ActiveCN113529136AIncrease contact areaImprove responseElectrolysis componentsPhotography auxillary processesElectrolytic agentManganese

The invention relates to the technical field of electrolysis equipment, and discloses acid electrolyte equipment for preparing electrolytic manganese and a method thereof. The acid electrolyte equipment comprises an electrolysis tank, a liquid outlet pipe is arranged on the bottom side of the outer wall of the right side of the electrolysis tank, the liquid outlet pipe communicates with the side wall of the electrolysis tank, a rotating shaft is arranged at the center axis of the top of the electrolysis tank, and the rotating shaft penetrates through the top of the electrolysis tank and extends into the electrolysis tank. According to the acid electrolyte equipment for preparing electrolytic manganese and the method thereof, when a large amount of electrolyte needs to be prepared, reactants can generate a large amount of gas, the gas can push a flow guide plate to move up and down, so that a grinding plate can slide up and down along the outer wall of a supporting rod under the action of a cross rod and an auxiliary connecting rod, so that solid reactants on a screening plate can be knocked, extruded and crushed, the contact area of the solid reactants and liquid reactants can be increased, and the reaction effect is improved.

Owner:云南江南锰业股份有限公司

Material crushing device with dust removal function

The invention discloses a material crushing device with a dust removal function. The material crushing device comprises a bottom plate (1), a frame body device (2), a cover plate device (3), a first transversal plate (4), a cylinder device (5), a grinding device (6), a dust absorption device (7) and a recovery device (8), wherein a first support (11), a first bent rod (13) and a first inclined plate (12) are arranged on the bottom plate (1); the frame body device (2) comprises a first frame body (21), first fixing blocks (22), first rolling wheels (23) and first crushing teeth (24); the cover plate device (3) comprises a charge hopper (31), a flow distribution block (32), cover plates (33), a first vertical rod (35), a first transversal rod (34), first connection rods (36) and holding rings (37); and the first transversal plate (4) is provided with a first through hole (41) and a third frame body (42). The material crushing device disclosed by the invention is used for directly recovering waste rubber after crushing and double grinding, and high in crushing efficiency.

Owner:天津企程科技有限公司

Ganoderma lucidum spore powder crushing and refining device

InactiveCN108339603ABroken refinement effectImprove broken rateSievingScreeningSporeGanoderma lucidum

The invention discloses a ganoderma lucidum spore powder crushing and refining device. The device comprises a crushing and refining box body, wherein a grinding and refining plate is arranged inside the crushing and refining box body, the grinding and refining plate is arranged in an arc shape, and a feeding port is formed in the top wall of the crushing and refining box body; the top wall of theinterior of the crushing and refining box body is provided with a hinging seat, a hanging rod hinged to the hinged seat is arranged on the hinged seat, and a mounting fixing frame is arranged at the lower end of the hanging rod; a grinding roller is installed on the mounting fixing frame, and the outer side wall of the grinding roller abuts against the upper side surface of the crushing and refining box body; and opposite crushing rollers are arranged on each pair of supporting rotating shafts, and a discharging port is formed in the side wall of the bottom of the crushing and refining box body. According to the ganoderma lucidum spore powder crushing and refining device, the prepared ganoderma lucidum spore powder is high in efficiency of fragmentation, moreover, the structure is simple,the crushing effect is obvious, blockage of sieve holes is avoided, operation is simple, use is convenient, and practicability is high.

Owner:苏州高新区鼎正精密机电有限公司

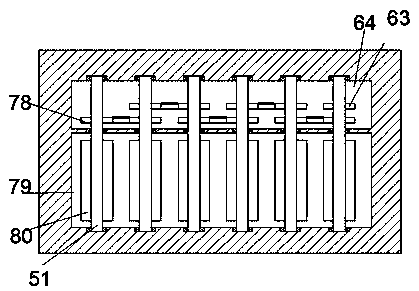

Stirring type ball mill

The invention discloses a stirring type ball mill. The stirring type ball mill comprises a stirring sleeve; the stirring sleeve is fixedly mounted on mounting tables; the number of the mounting tablesis two; a primary crushing mechanism is arranged in the stirring sleeve; a dust removal mechanism corresponding to the primary crushing mechanism is arranged in the stirring sleeve; a feeding openingis formed in the top of the stirring sleeve; the bottom of the stirring sleeve communicates with a secondary crushing box through a discharging opening; a secondary crusher is arranged in the secondary crushing box; a driving mechanism corresponding to the primary crushing mechanism and the secondary crusher is arranged on the corresponding mounting table; and a discharging box is arranged belowthe secondary crushing box. The stirring type ball mill is good in crushing and grinding effect, sieve holes in a sieve plate can be effectively cleaned, and the sieve plate is prevented from being blocked to reduce the grinding and crushing efficiency.

Owner:ZHUZHOU LIANXIN METAL CO LTD

Cutting grinder for waste wood boards and using method of cutting grinder

InactiveCN108297236AAvoid liftingIncrease elasticityProfiling/shaping machinesHydraulic cylinderPulp and paper industry

The invention discloses a cutting grinder for waste wood boards and a using method of the cutting grinder. The cutting grinder comprises a shell and a limiting plate. A feeding opening is formed in one side of the shell. A support plate, a positioning plate, a crushing shaft A and a crushing shaft B are arranged on the inner wall of the shell. A cutting frame is fixed on the lower surface of the portion, at one side of the feeding opening, of the shell. A cutting knife is arranged on an end opening, positioned inside the shell, of the feeding opening. A rotating shaft is movably connected to the inner wall of the cutting frame. Dividing knifes are evenly distributed on the outer wall of the rotating shaft. The dividing knifes cut the waste wood boards into multiple long wood bars quickly.When the wood bars reach the lower part of the cutting knife, a hydraulic cylinder simultaneously controls an air cylinder and the limiting plate to descend, the cutting knife descends as well, the cutting knife cuts the wood bars short like a saw while descending, crushing rollers A and crushing rollers B crush the wood bars, the crushed wood bars are further ground into chips and discharged, thewaste wood boards are crushed and milled stage by stage through multi-stage operation, and the crushing and milling effects are improved.

Owner:MAANSHAN ZENGRUN MACHINERY MFG

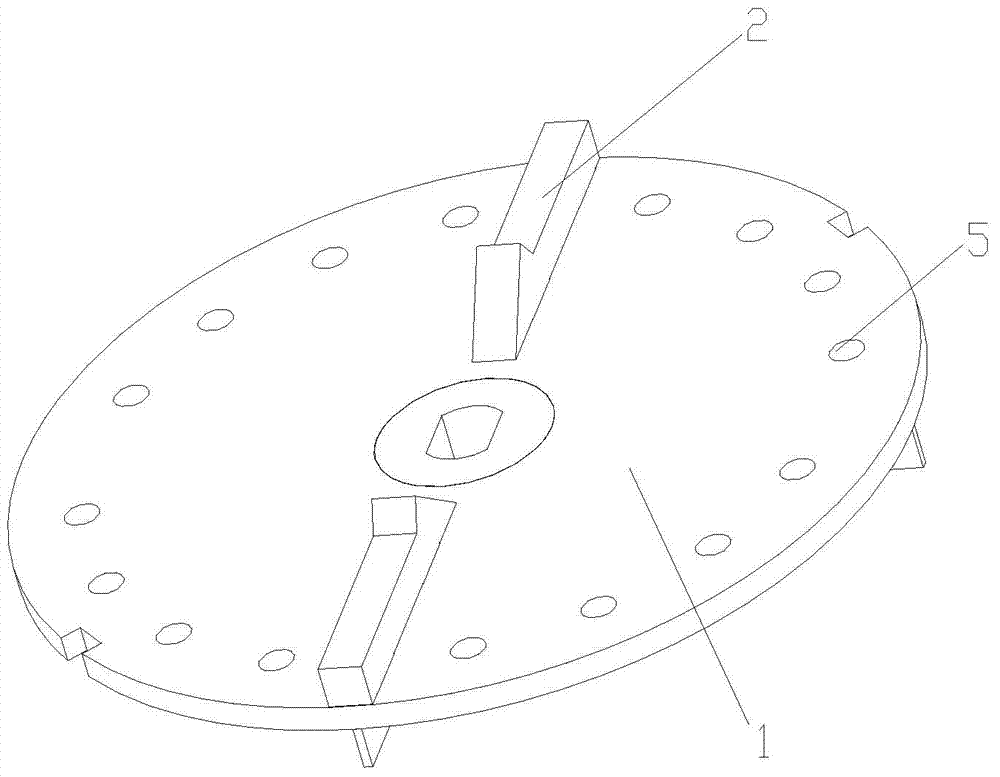

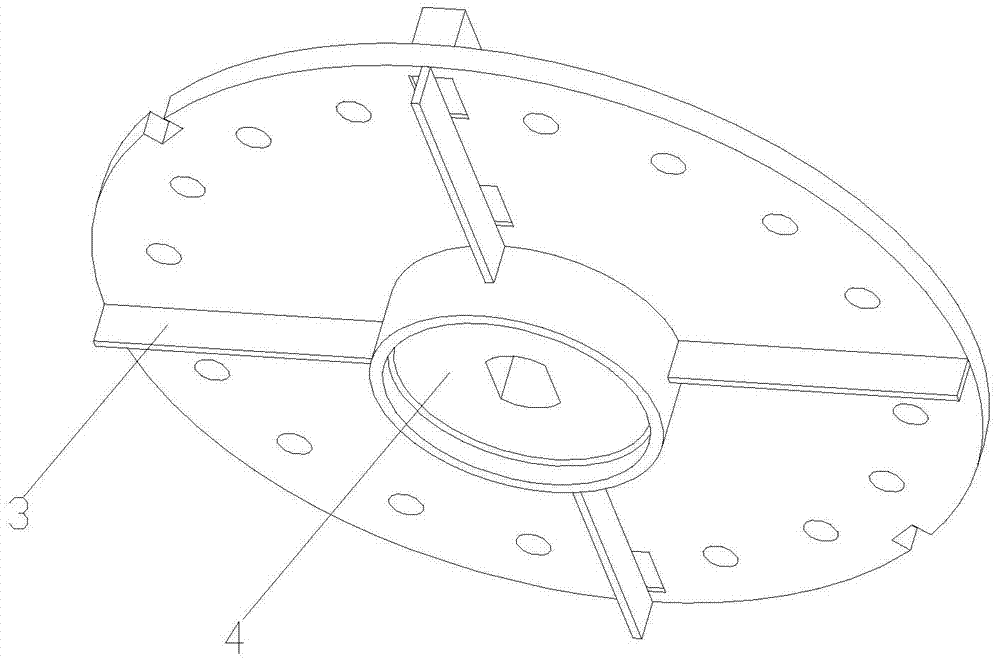

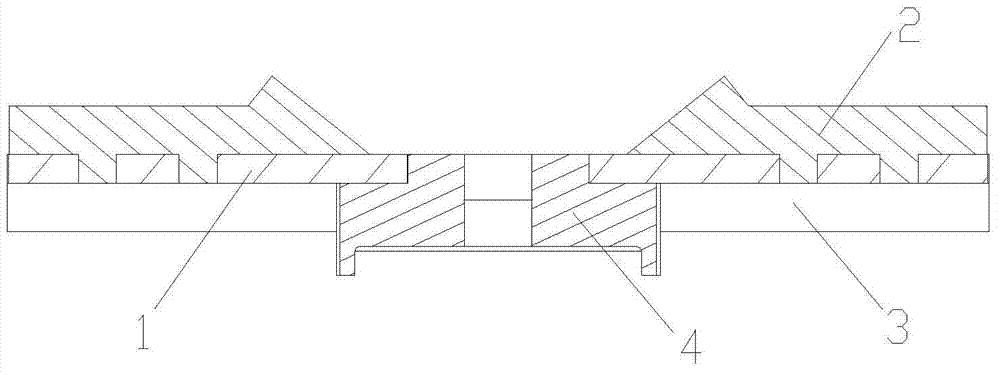

Grinding cutter for garbage crusher

InactiveCN104226438AImprove the crushing and grinding effectEasy to makeGrain treatmentsInterference fitManufacturing engineering

The invention relates to a grinding cutter for a garbage crusher. The grinding cutter for the garbage crusher comprises a cutterhead, a cutter block, a scraper and a coupling sleeve. The cutterhead is in a disc shape, the center of the cutterhead is provided with a central hole in interference fit with the coupling sleeve, and one end surface of the cutterhead is provided with a slot for wedging the cutter block; one end of the cutter block is aligned to the radial edge of the cutterhead, the other end of the cutter block extends towards the central hole; the other end surface of the cutterhead is provided with the scraper; one end of the scraper is connected with the coupling sleeve, and the other end of the scraper is aligned to the radial edge of the cutterhead. The grinding cutter for the garbage crusher achieves large amounts of improvement on shortcomings of existing cutters and enhances the crushing and grinding capacity. Meanwhile, the grinding cutter for the garbage crusher is simple in manufacture and reduces and saves the manufacturing costs.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

Seven-ingredient pomegranate peel powder for treating swine colibacillosis

PendingCN113995785AIncrease the degree of mixingImprove the mixing effectAntibacterial agentsGrain treatmentsEngineeringBiology

The invention belongs to the technical field of preparation of seven-ingredient pomegranate peel powder, and particularly relates to seven-ingredient pomegranate peel powder for treating swine colibacillosis. According to the scheme, the seven-ingredient pomegranate peel powder comprises a collecting frame and a mixing and extruding frame, the outer walls of the two sides of the mixing and extruding frame are fixedly connected with the same top frame, and the inner wall of the top of the top frame is fixedly connected with two first air cylinders; and the outer walls of the bottoms of the two first air cylinders are fixedly connected with the same squeezing plate, and the outer wall of the bottom of the squeezing plate is fixedly connected with squeezing parts at equal intervals. By arranging a wind power dispersing and mixing assembly, in the process that medicine powder falls down from screen holes in a screen, an air pump is started, the air pump blows a large amount of air into all hollow rods, the air is exhausted through air holes, the medicine powder in the falling process is blown away by wind power, and the medicine powder located in all spaces is dispersed and recombined through the hollow rods distributed in disorder; and the mixing degree of the medicine powder is further improved, and the medicine effect of the prepared seven-ingredient pomegranate peel powder is ensured.

Owner:江西利德菲生物药业有限公司

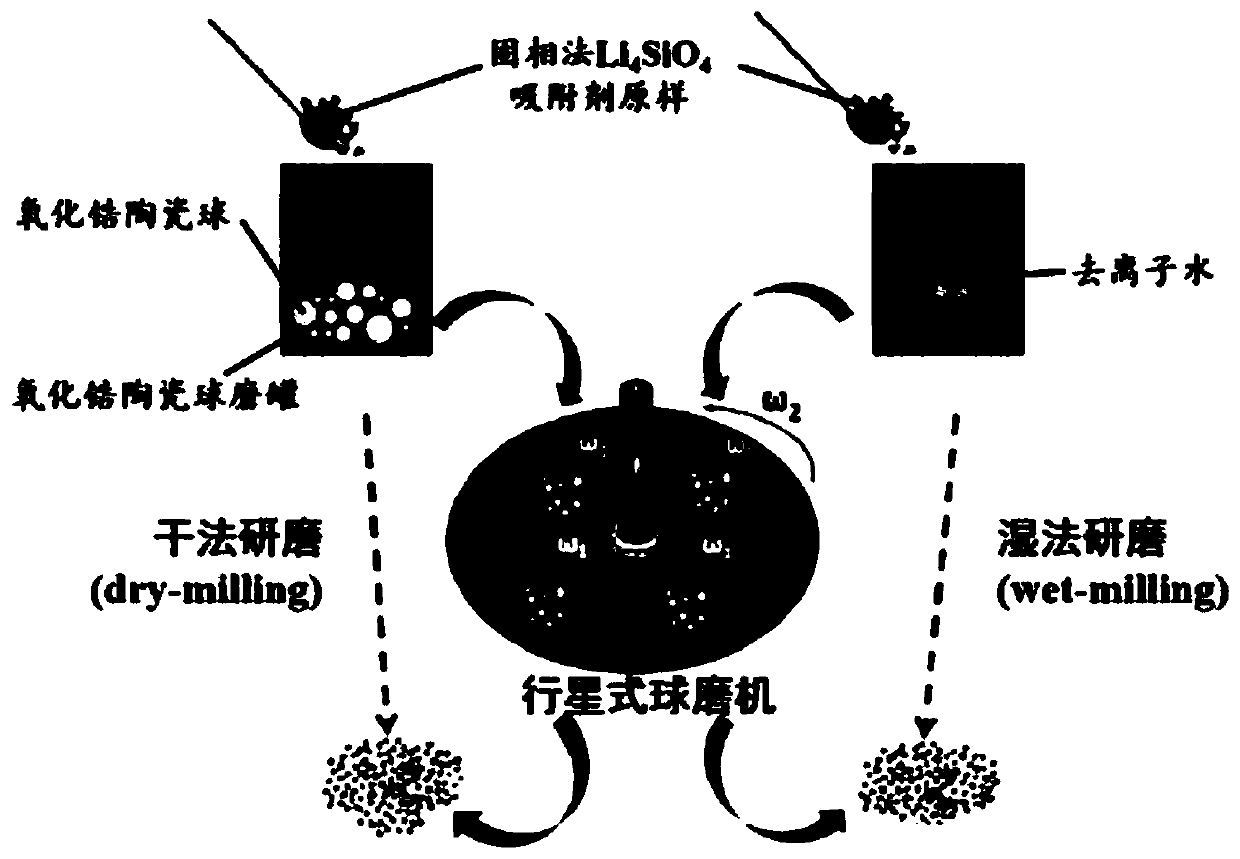

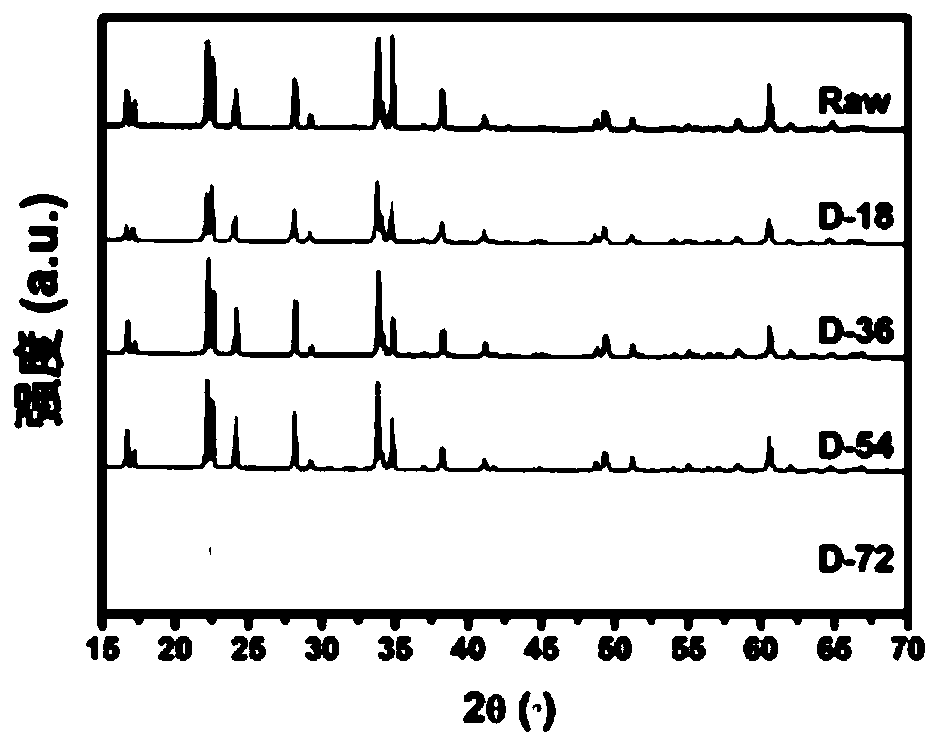

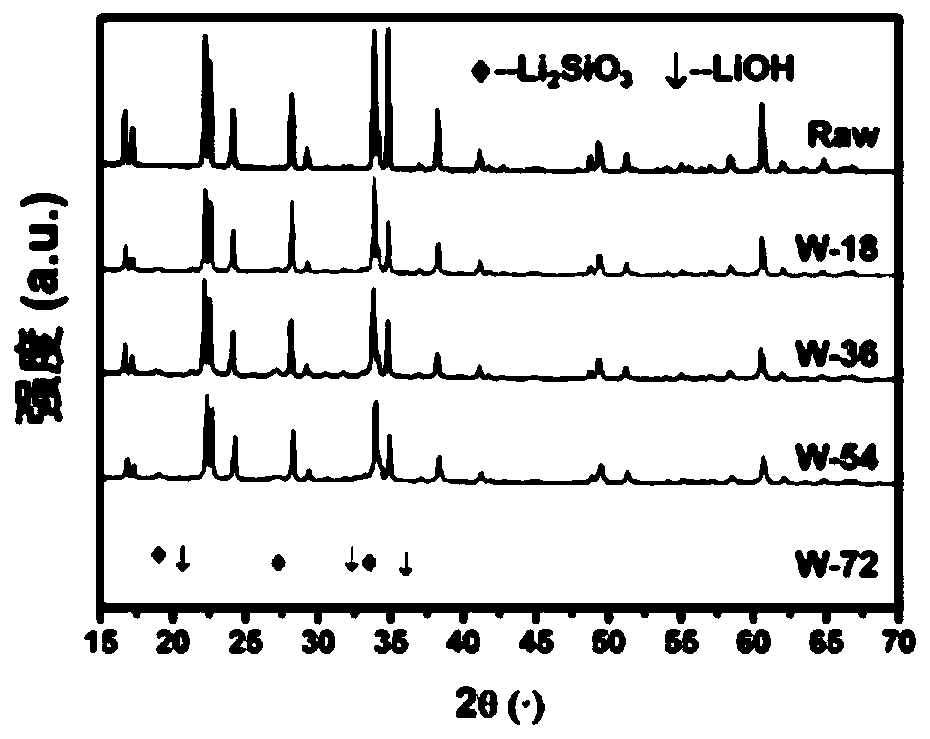

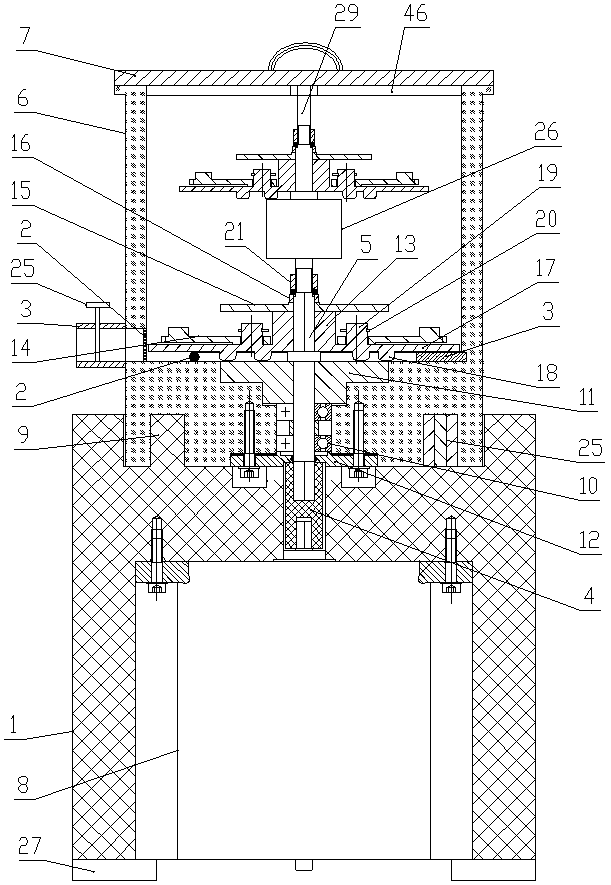

Wet-grinding modified lithium metasilicate, preparation method thereof and application of wet-grinding modified lithium metasilicate used as adsorbent

ActiveCN110292906AImprove surface topographyImprove adsorption performanceGas treatmentOther chemical processesChemistryCarbon dioxide

The invention relates to wet-grinding modified lithium metasilicate, a preparation method thereof and application of the wet-grinding modified lithium metasilicate used as an adsorbent and belongs tothe technical field of preparation and improvement of the adsorbent. The preparation method comprises the steps that a silicon source and a lithium source are calcined to obtain lithium metasilicate,the lithium metasilicate is placed in a grinding tank, deionized water is added, the lithium metasilicate is subjected to wet-grinding, and the surface of the lithium metasilicate is subjected to a water activity reaction to generate lithium hydroxide; after wet-grinding is ended, a ground product is dried, so that the lithium hydroxide is separated out in a nano sheet shape and attached and stacked to the surfaces of lithium metasilicate particles, and the wet-grinding modified lithium metasilicate is obtained. According to the modification method, the cost and feasibility are guaranteed, thegrinding modification effect is greatly improved, when applied to adsorption for carbon dioxide, the wet-grinding modified lithium metasilicate has the adsorption performance superior than that of atraditional dry-method grinding modified adsorbent, and a good prospect and basis are provided for industrial application in modification of the lithium-based adsorbent.

Owner:HUAZHONG UNIV OF SCI & TECH

Household single-motor processor for rotating food waste forwardly and reversely and crushing food waste

PendingCN110777894AImprove crushing efficiency and crushing effectImprove crushing effectDomestic plumbingElectric machineryMunicipal sewage

A household single-motor processor for rotating food waste forwardly and reversely and crushing the food waste comprises a base, a rotating shaft, a cup body, a motor, an upper cutter crushing assembly and a lower cutter crushing assembly, wherein the upper cutter crushing assembly and the lower cutter crushing assembly are sequentially and coaxially arranged in the cup body from top to bottom, and a discharge hole is formed in the lower portion of the cup body; the lower end of the upper cutter crushing assembly is in transmission connection with the upper end of the lower cutter crushing assembly through a reversing device. The processor has reasonable design and a compact structure, high-speed cutting, crushing and grinding are carried out up and down in the forward direction and the reverse direction, the crushing assemblies are designed into four-level high-speed rotating cutters, the crushing and grinding effects are good, and the processor has the advantages of good damping effects, strong stability and low noise; after crushing, granular residues with very small diameters are directly discharged into a sewer pipe and an urban sewage pipeline along with the wastewater, and finally are sent to a municipal sewage treatment plant, so that a new treatment method is opened for food waste, and the processor has great social benefits, environmental protection benefits and economic benefits.

Owner:郑州天之济信息科技有限公司

Western medicine grinder

InactiveCN109420557AImprove grinding efficiencyImprove the effectGrain treatmentsCoaxial lineEngineering

The invention discloses a western medicine grinder. The grinder comprises a grinding cylinder, wherein a material collecting tank is arranged at the lower end of the grinding cylinder, the grinding cylinder is in a cone shape, the bottom of the grinding cylinder is in an arc shape, a plurality of screen holes communicating with the material collecting tank are formed in the bottom end of the grinding cylinder, a grinding ball is arranged inside the bottom end of the grinding cylinder, a swing rod is arranged on the upper end wall of the grinding ball, a feeding port and a limiting through holeare formed in the top wall of the grinding cylinder, an annular block coaxial with the grinding cylinder is further arranged inside the grinding cylinder, a crushing through hole is formed in the center of the annular block, the swing rod penetrates through the crushing through hole and the limiting through hole, a sleeve is further arranged on the outer side wall of the swing rod, crushing teethare arranged on both the outer side wall of the sleeve and the side wall of the crushing through hole, and two symmetric handle frames are arranged on the side wall of the grinding cylinder. The grinder has the advantages that the structure is simple, parts are small, carrying is facilitated, the grinding efficiency is high, the crushing effect is good, and the practicability is high.

Owner:陈奇坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com