Novel material crushing device for preparation of inorganic nonmetal advanced material

An inorganic non-metal, raw material pulverization technology, applied in application, cocoa, grain processing and other directions, can solve the problems of poor device versatility, inability to adjust particle size, inability to change the grinding and grinding force, etc., to improve the effect and increase the grinding force. , Improve the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

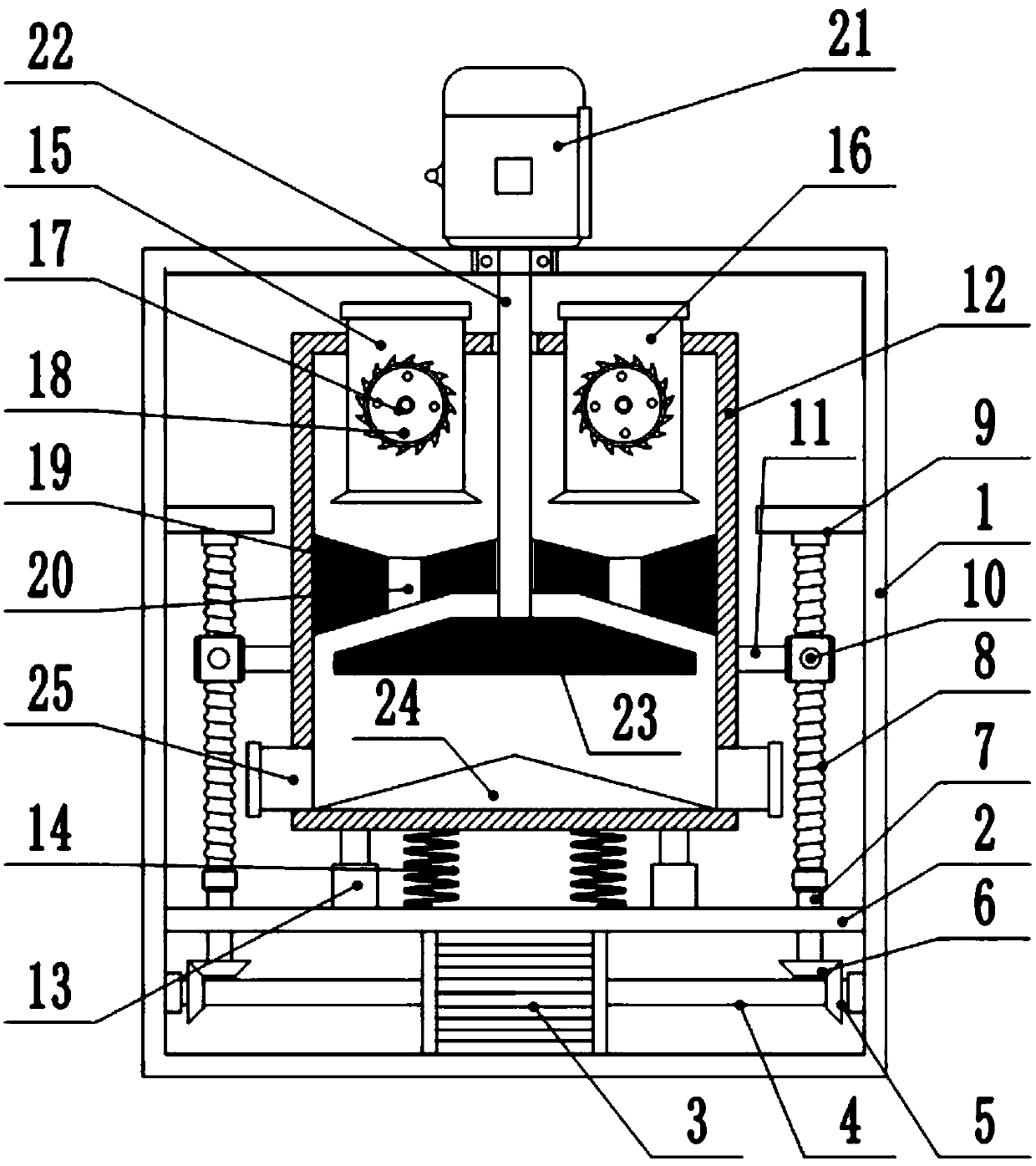

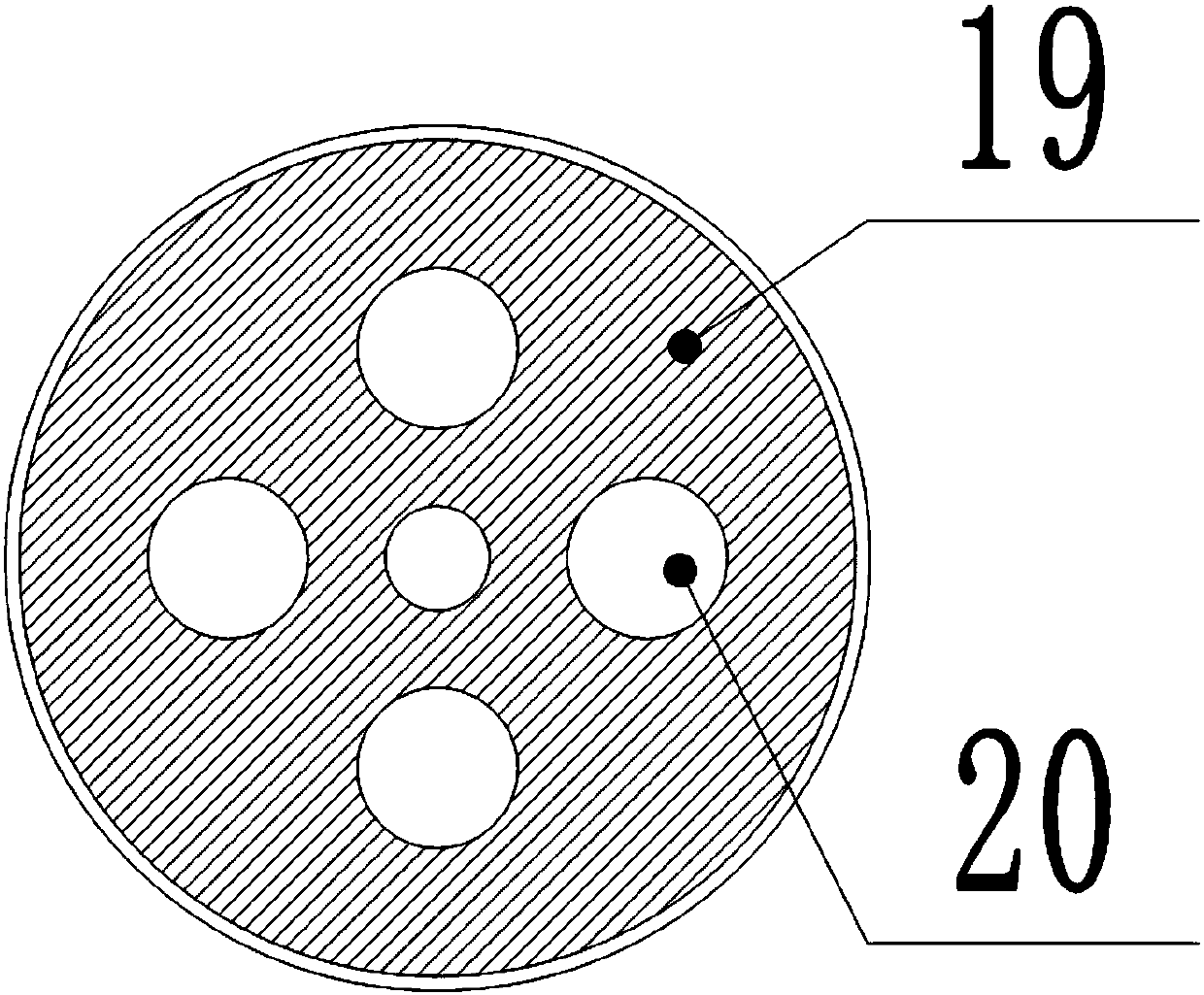

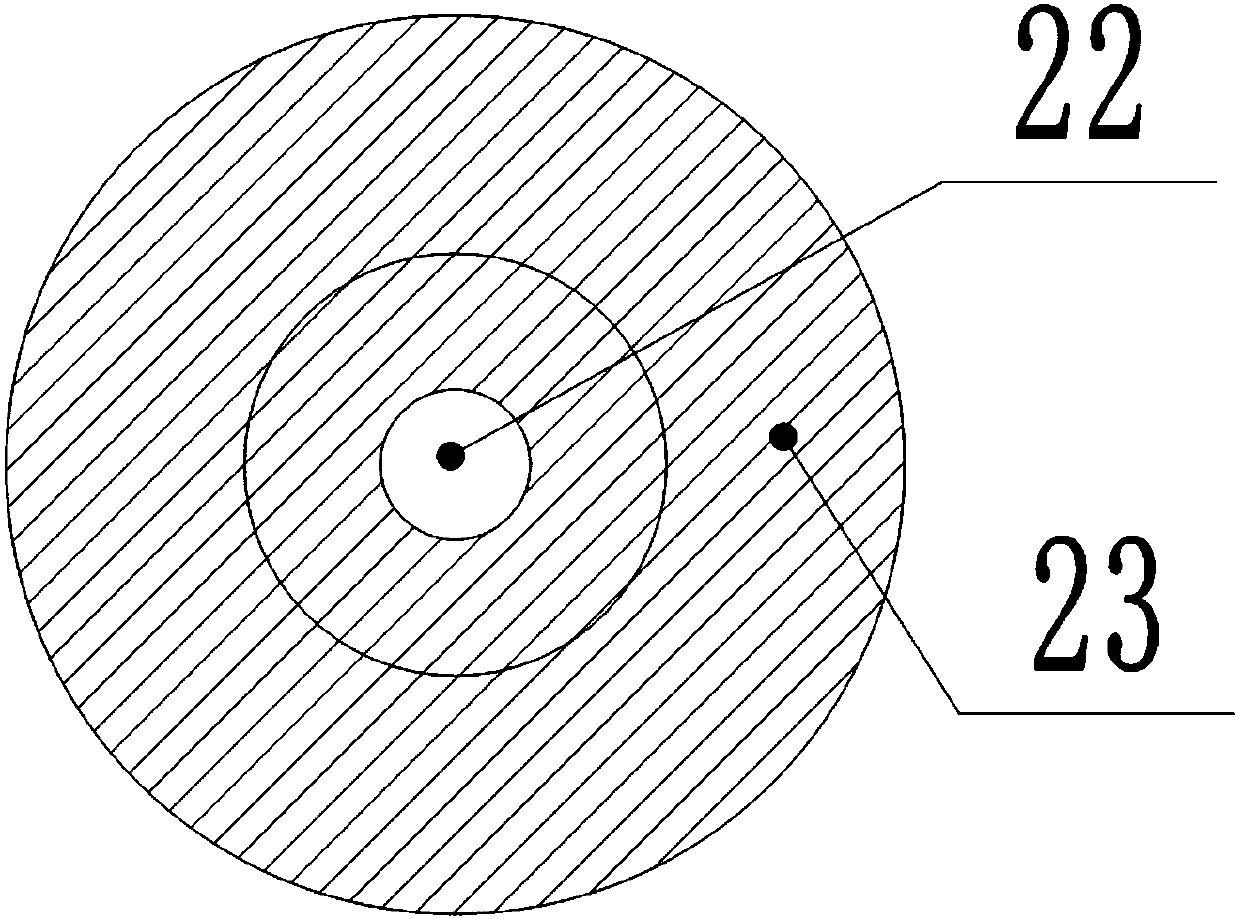

[0019] see Figure 1-3 , a raw material crushing device for the preparation of new inorganic non-metallic materials, comprising an outsourcing tail box 1, a biaxial motor 3, a crushing box 12, a crushing wheel 18, a fixed upper grinding disc 19 and a conical movable grinding disc 23, the outsourcing tail box The two sides of 1 are hinged with open and close doors, and the inside of the outsourcing tail box 1 is horizontally installed with a partition plate 2, and a double-axis motor 3 is fixedly installed in the middle of the lower area of the partition plate 2, and the double-axis motor 3 is a servo motor and is Single-phase asynchronous motor, the output shafts at both ends of the double-shaft motor 3 are fixedly connected with an extension shaft 4 through a coupling, and the other ends of the extension shaft 4 are respectively installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com