Wet-grinding modified lithium metasilicate, preparation method thereof and application of wet-grinding modified lithium metasilicate used as adsorbent

A technology of wet grinding and lithium silicate, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as poor cycle stability and low adsorption efficiency of carbon dioxide adsorbents, and achieve optimized surface morphology , enhance the effect, eliminate the effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The invention provides a modification method based on wet grinding that can obtain a high-performance lithium silicate adsorbent, comprising the following steps:

[0047] (1) Take a certain amount of lithium carbonate and silica sol (30% SiO 2 Aqueous solution) after wet mixing, put it into a constant temperature water bath and continue to stir until it is completely evaporated to dryness. Put the obtained solid into a corundum boat and calcinate it in a muffle furnace at 900°C for 4 hours. After taking it out, it is ground and sieved to obtain Li 4 SiO 4 The original powder of the adsorbent is ready for use;

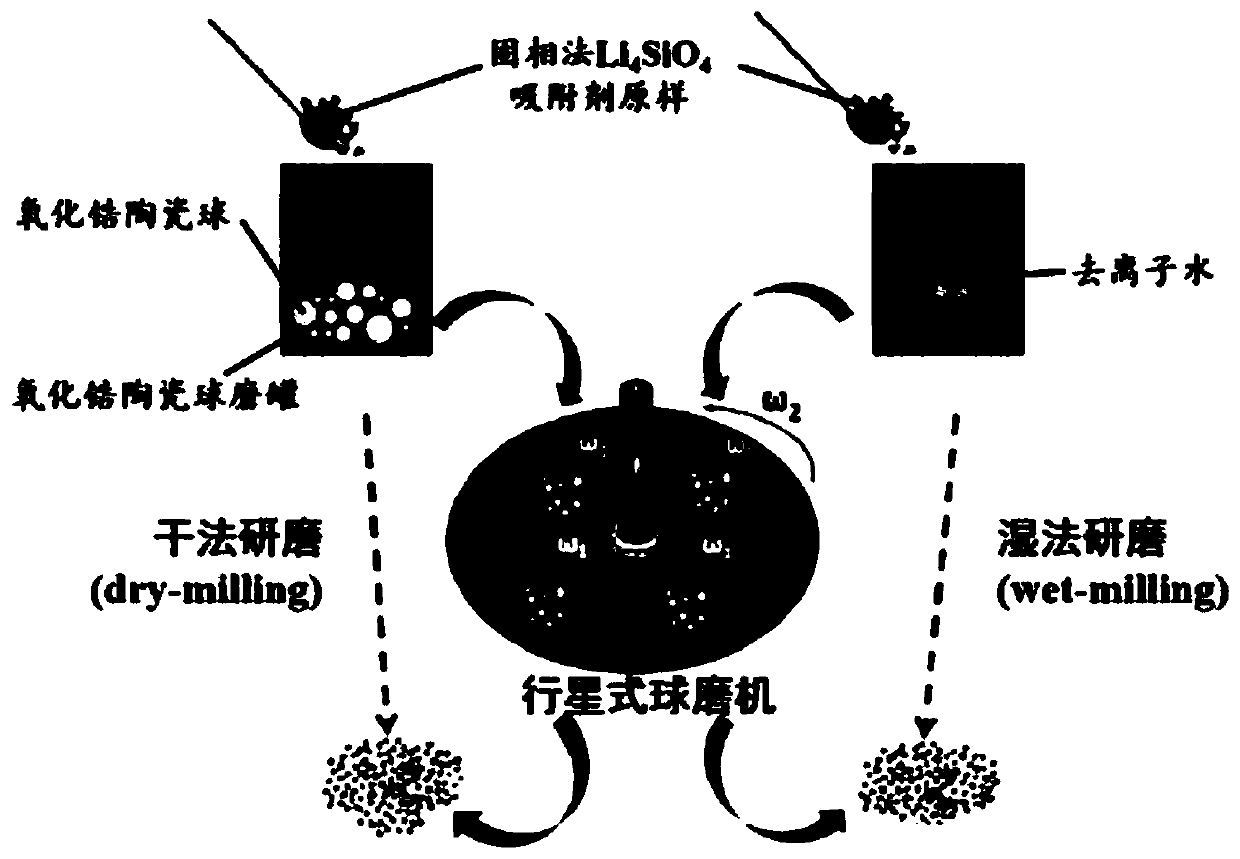

[0048] (2) if figure 1 As shown, weigh 4g and add it into the ball mill tank as it is, and add quantitative deionized water to the tank according to the solid-liquid ratio of 1:1, and finally add grinding balls according to the ball-to-material ratio of 12:1; Grinding modification method for comparison, at the same time weigh the same amount of the original an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com