Device and method for continuous laser sharpening resin binder grinding wheel

A technology of bonding agent and grinding wheel, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems of difficult precise control and many parameters, and achieves low cost, simple device structure, and exposed height increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

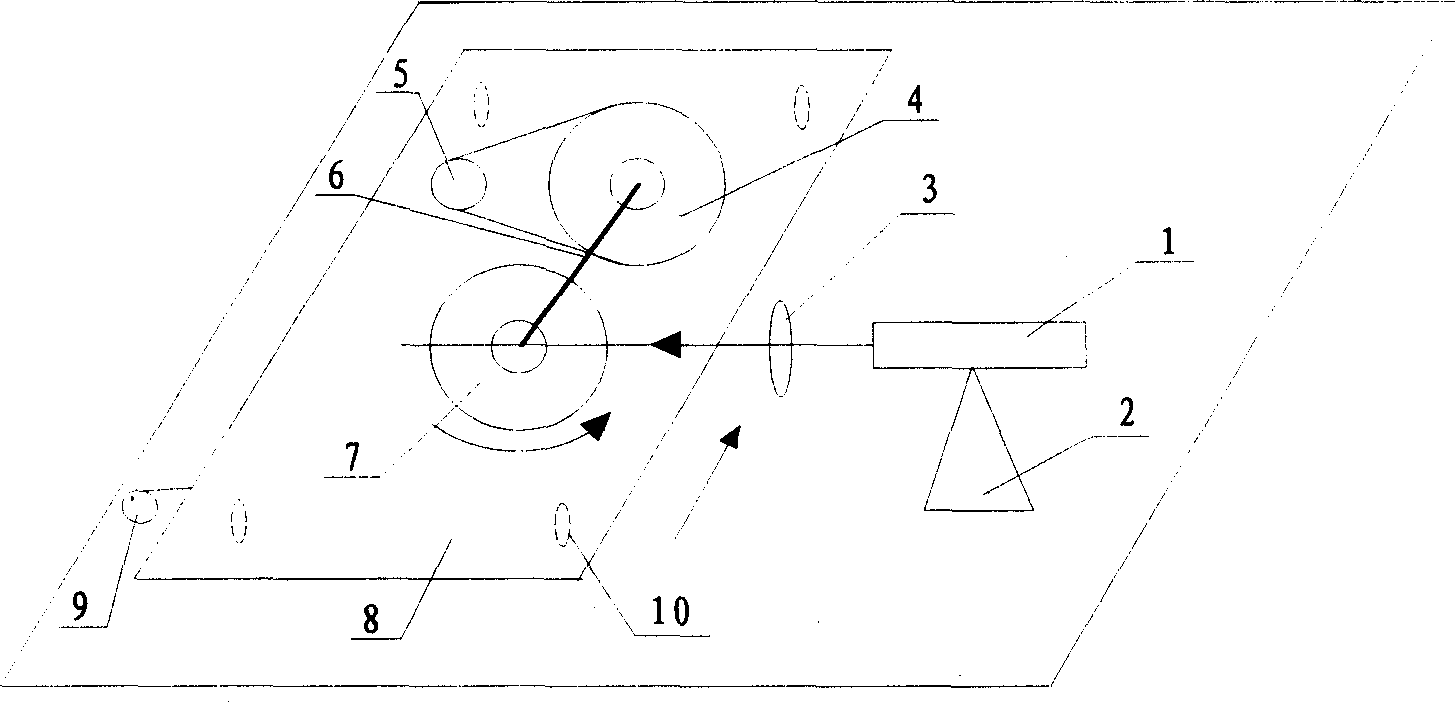

[0022] like figure 1 As shown, the sharpening device of the present invention includes CO 2 Laser 1, fixed bracket 2, focusing lens 3, pulley 4, frequency modulation motor 5, spindle 6, grinding wheel frame 8 and three-phase asynchronous motor 9. CO 2 Laser 1 adopts the sealed CO produced by Shanghai Laser Research Institute. 2 laser. Wheel frame 8 is a flat car with 4 small wheels 10, and three-phase asynchronous motor 9 is connected with two small wheel shafts arranged side by side in 4 small wheels 10. Resin bond grinding wheel 7 adopts resin bond Al with a particle size of 100 2 o 3 Grinding wheel. The main shaft 6 is supported on the grinding wheel frame 8 by two bearings, and the resin bond grinding wheel 7 and the belt pulley 4 are installed at the two ends of the main shaft 6 respectively. The four small wheels 10 are driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com