Patents

Literature

41results about How to "Increase grinding power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flour processing technology

InactiveCN104646087AIncrease powder yieldImprove completenessGrain treatmentsMaterials preparationWheat Brans

The invention relates to the field of food, in particular to a flour processing technology. The flour processing technology comprises the following steps of (1) material preparation; (2) clean wheat proportion; (3) wheat wetting; (4) grinding; (5) powder purification; (6) flour blending. According to the flour processing technology, the problem that some smaller particles in materials, which are processed by 9 reduction roller mills, 6 shelling mills and a purifier, are difficultly grinded sufficiently in a tail mill in the grinding process is solved. The flour processing technology has the advantages that the smaller particles are grinded more sufficiently by utilization of impact mills, so that the flour yield is improved, the integrity rate of wheat bran is improved at the same time, and the quality of flour and by-products are guaranteed.

Owner:山东津宜润德面业有限公司

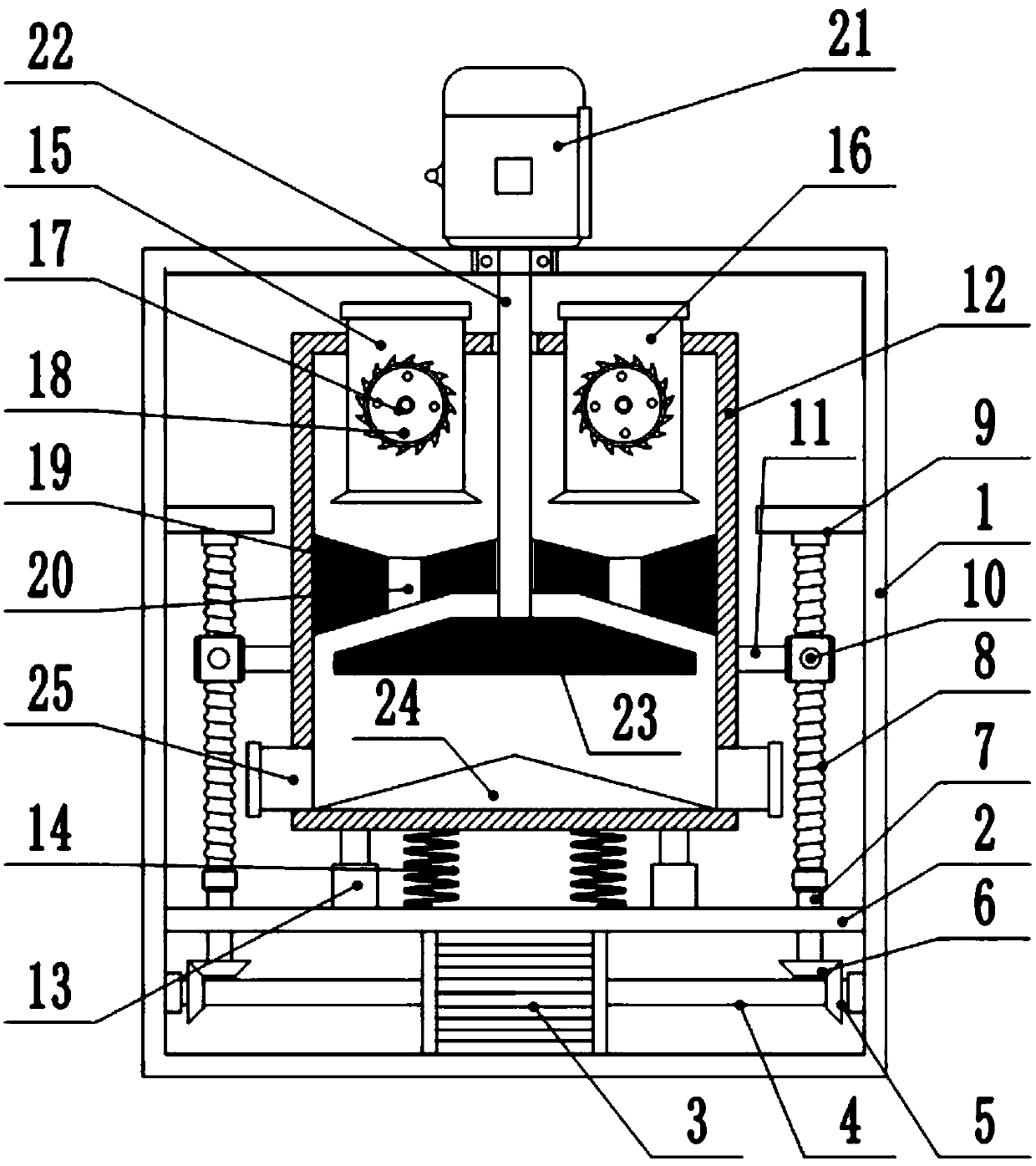

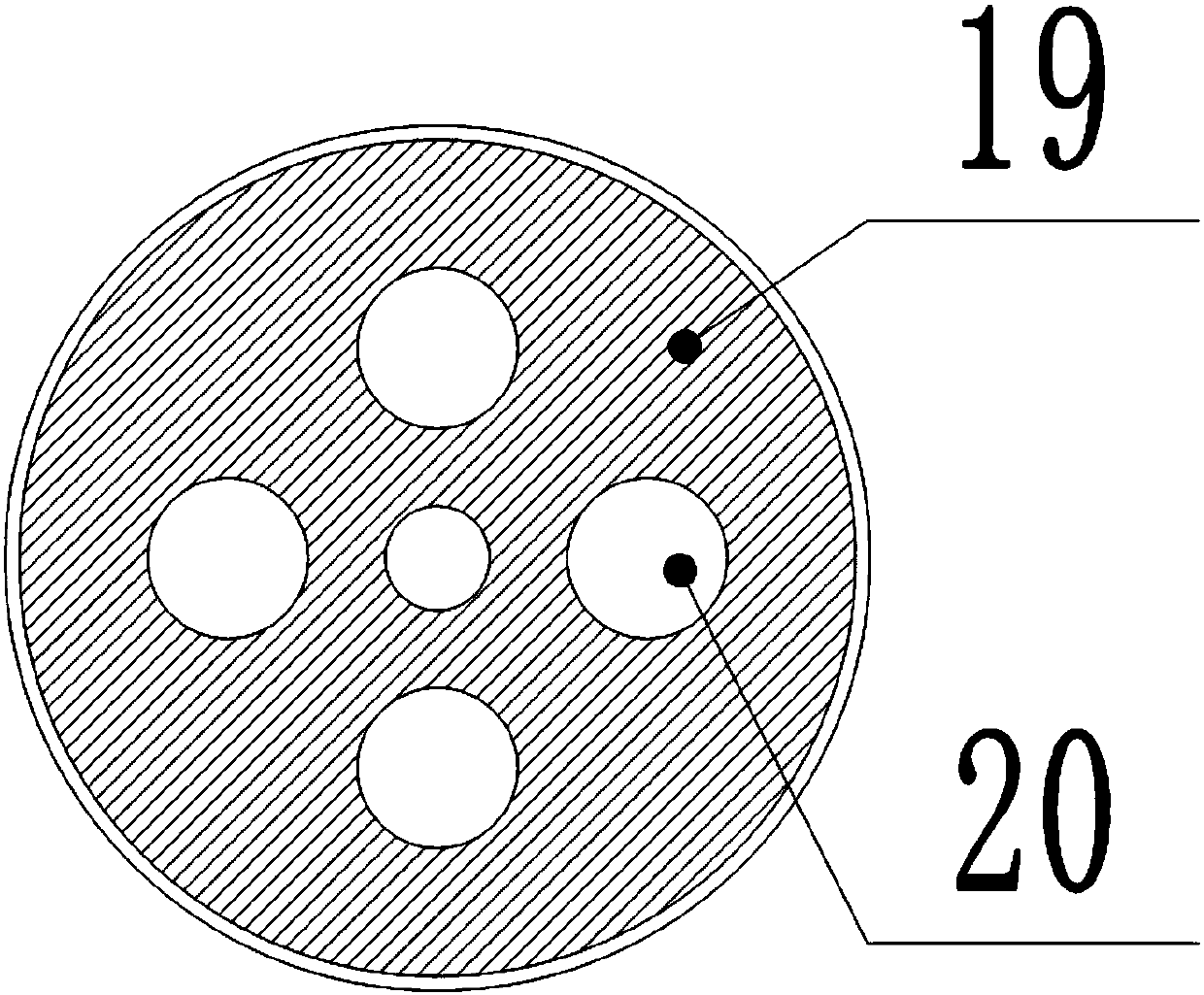

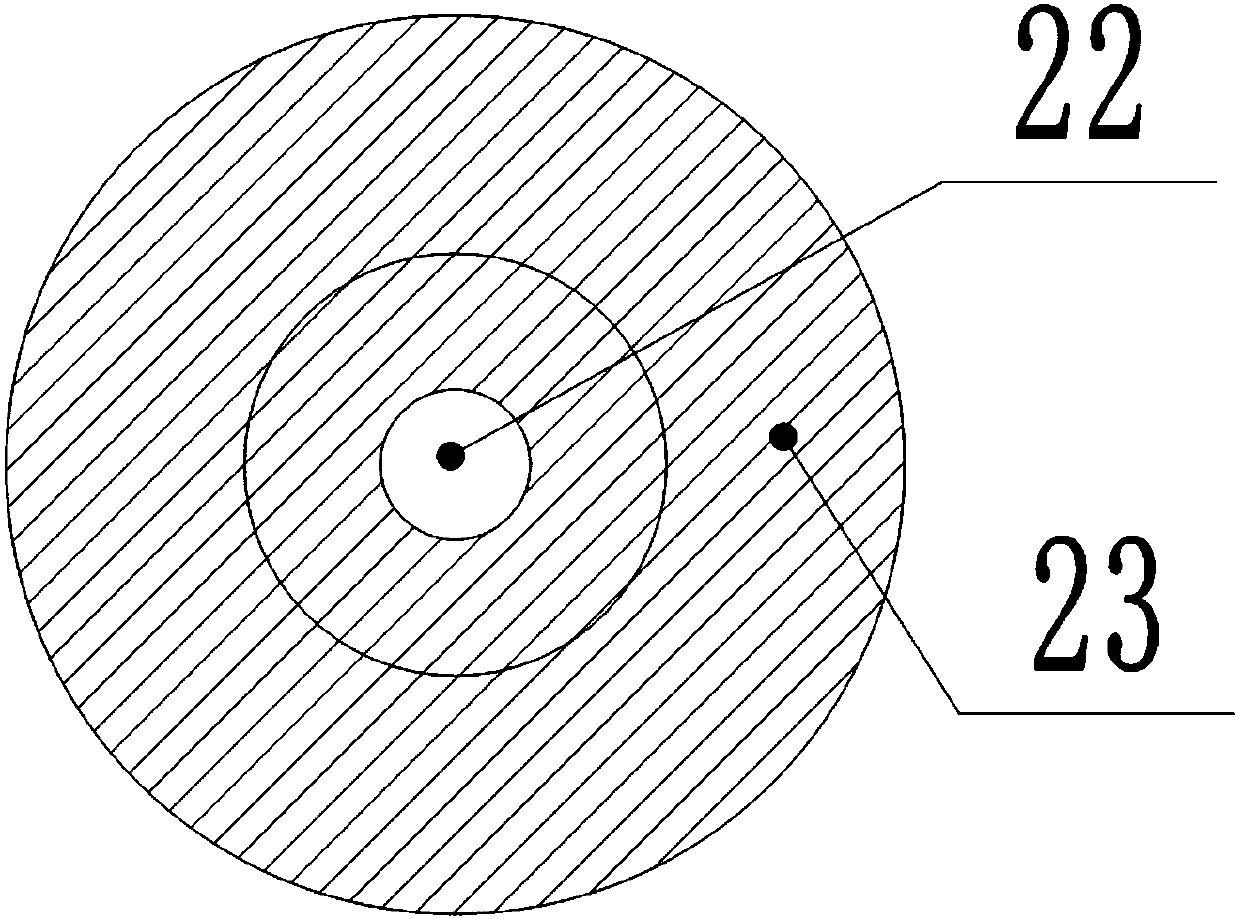

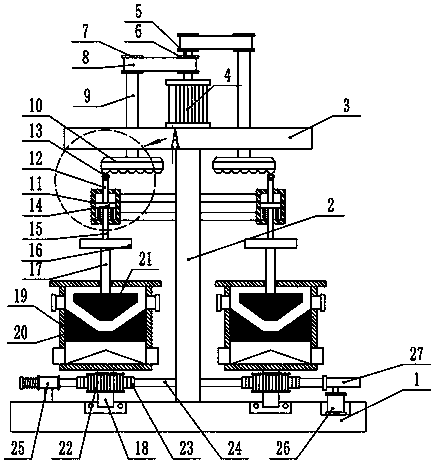

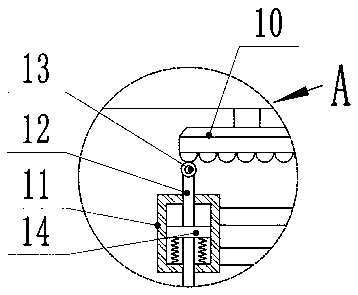

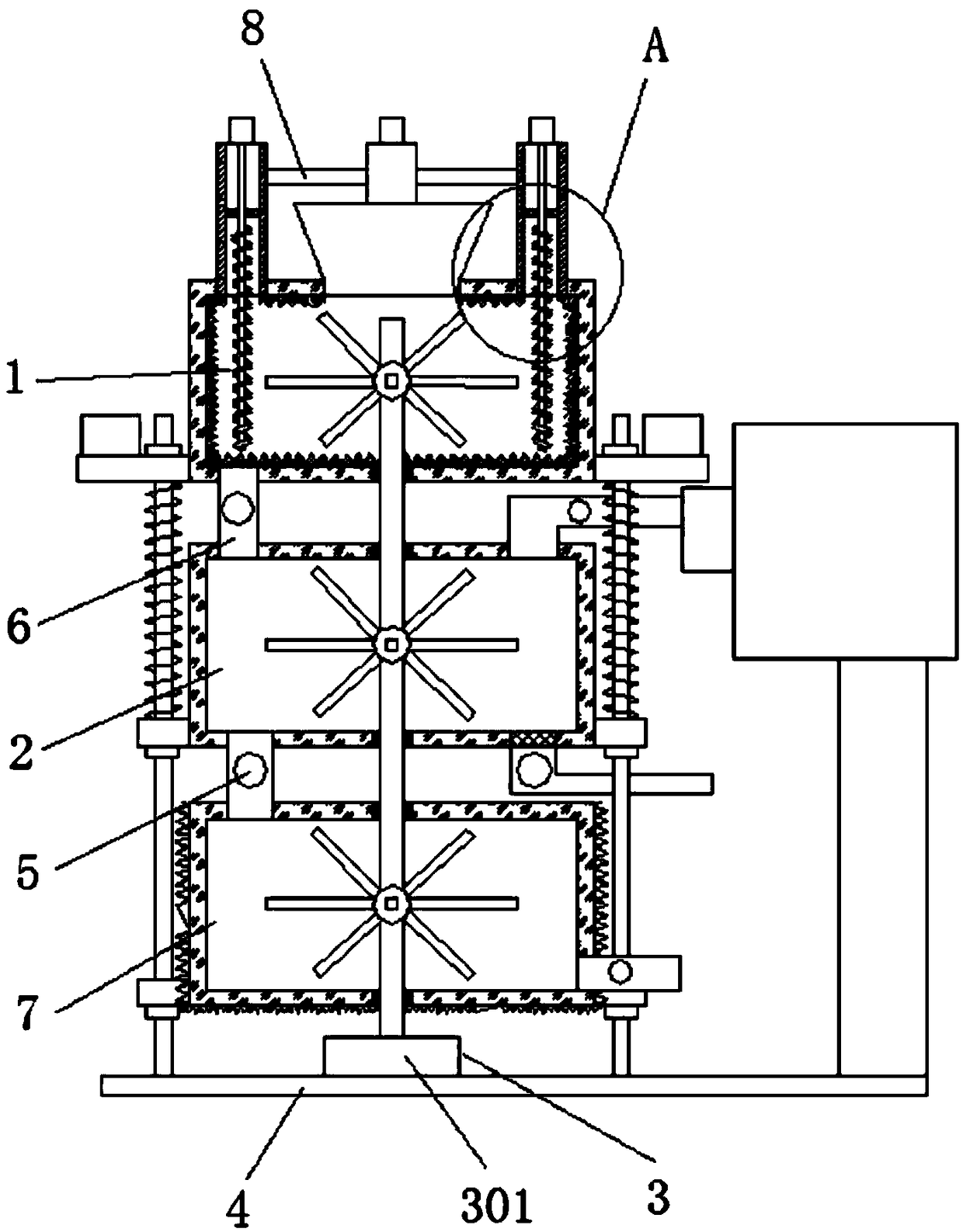

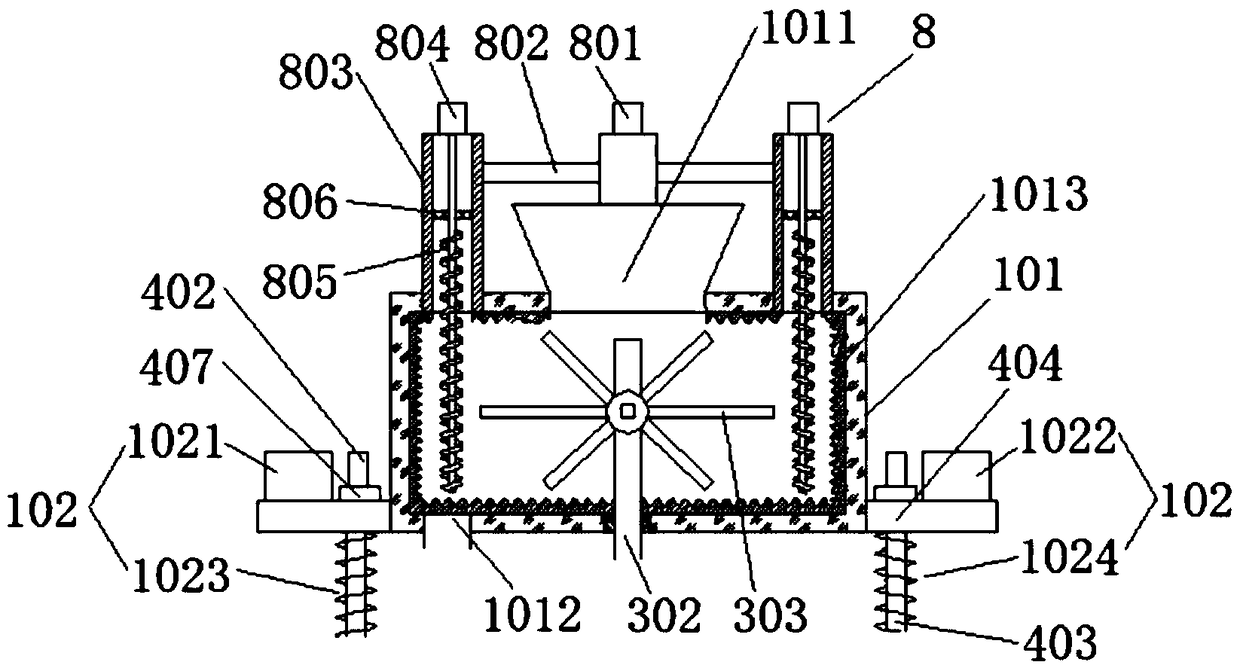

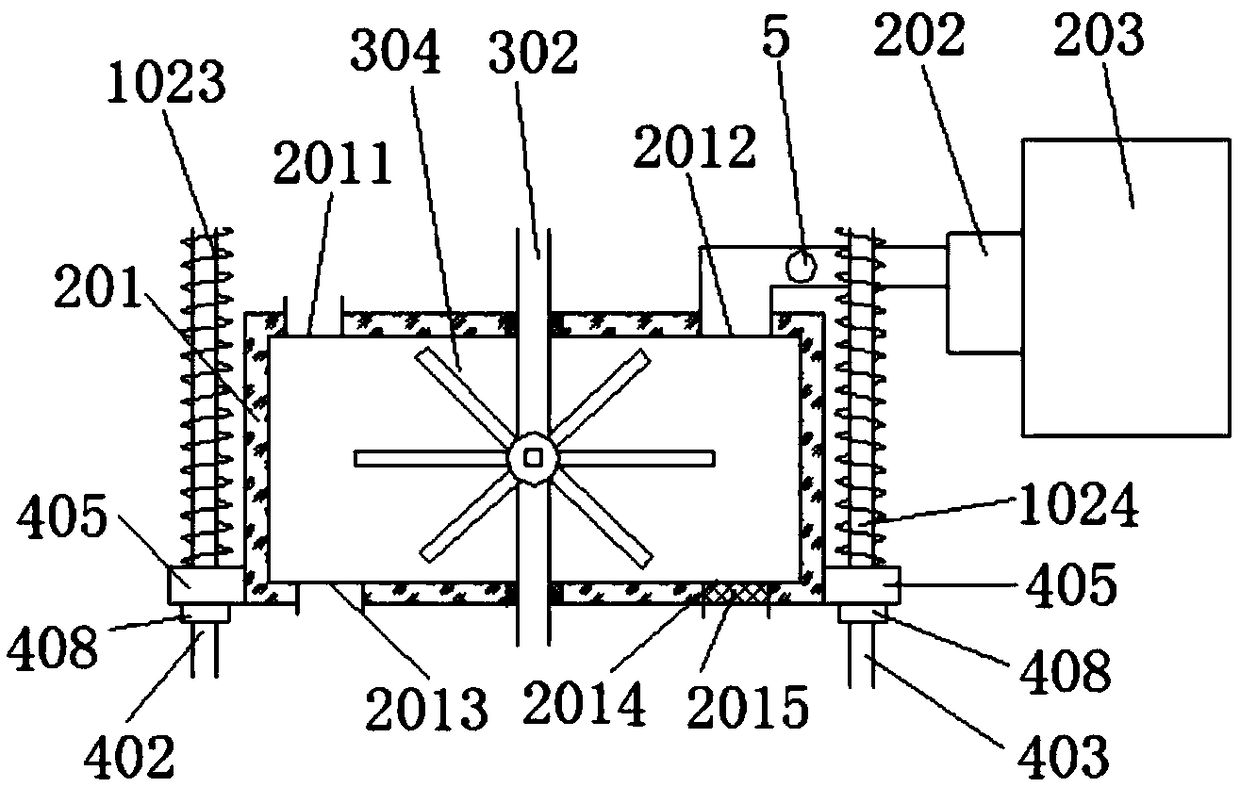

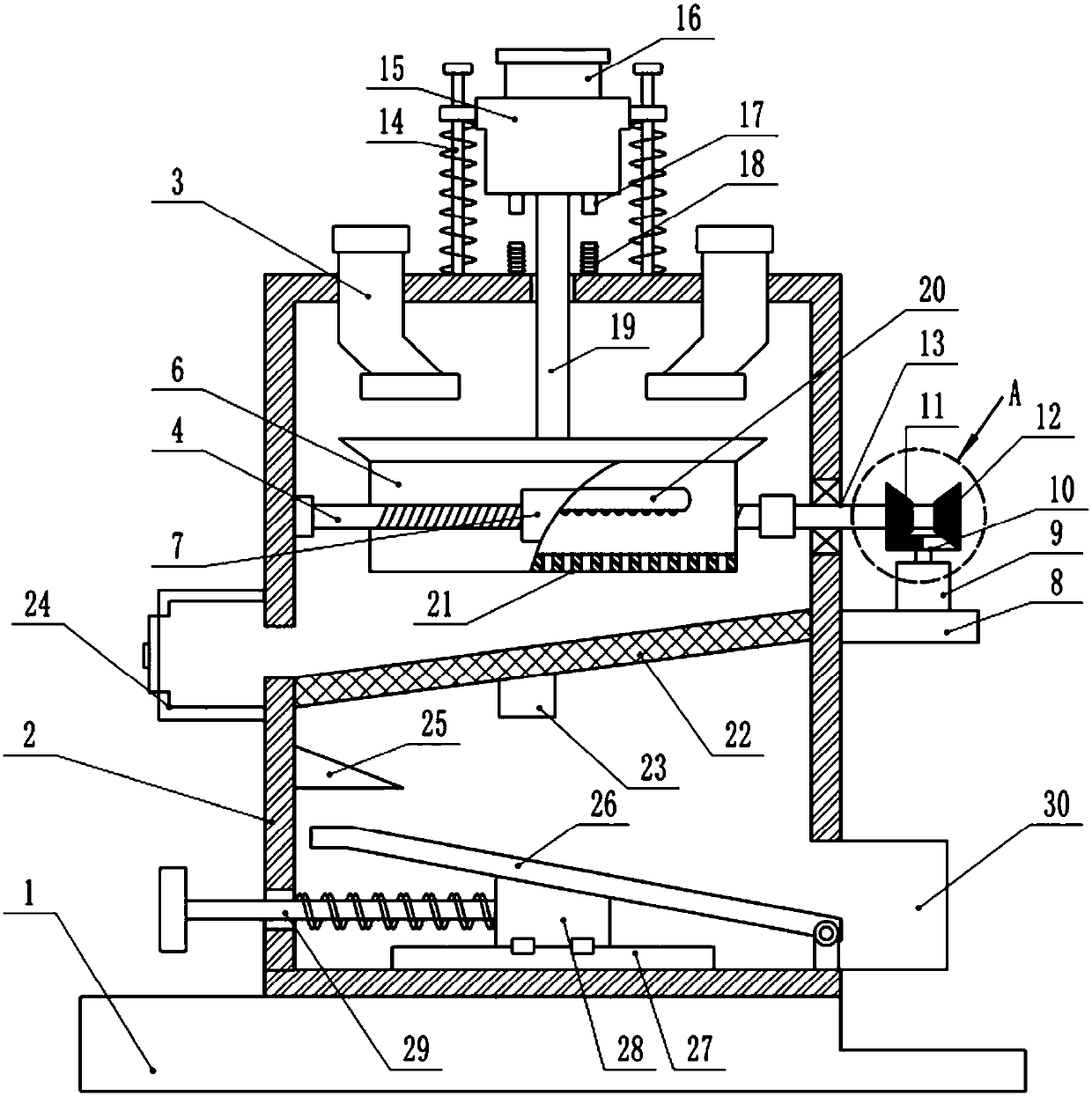

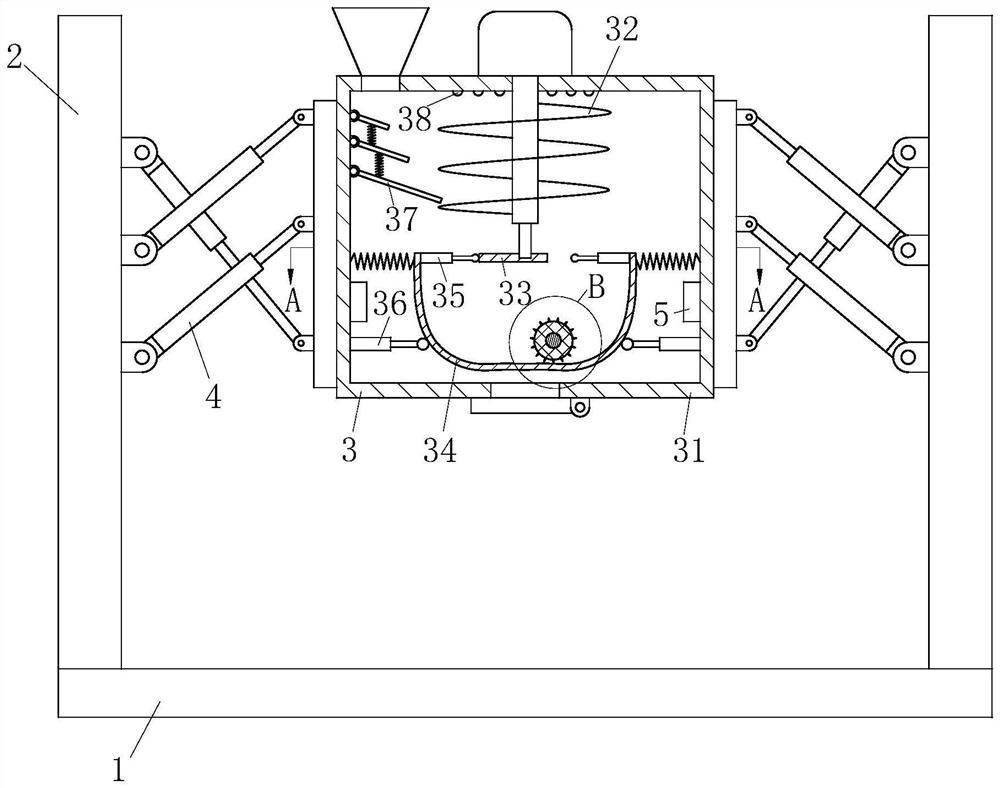

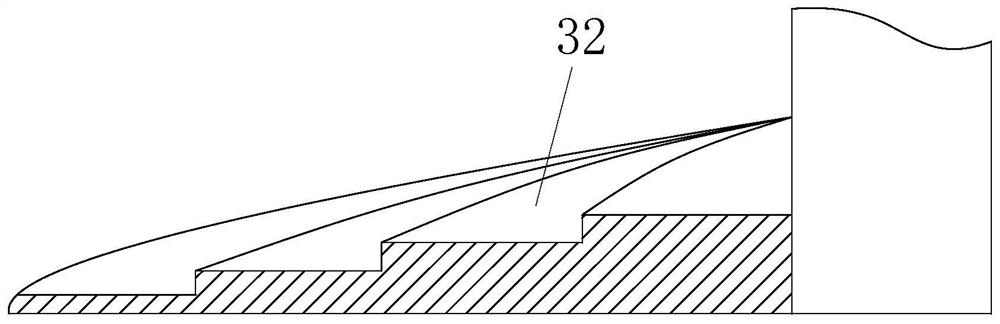

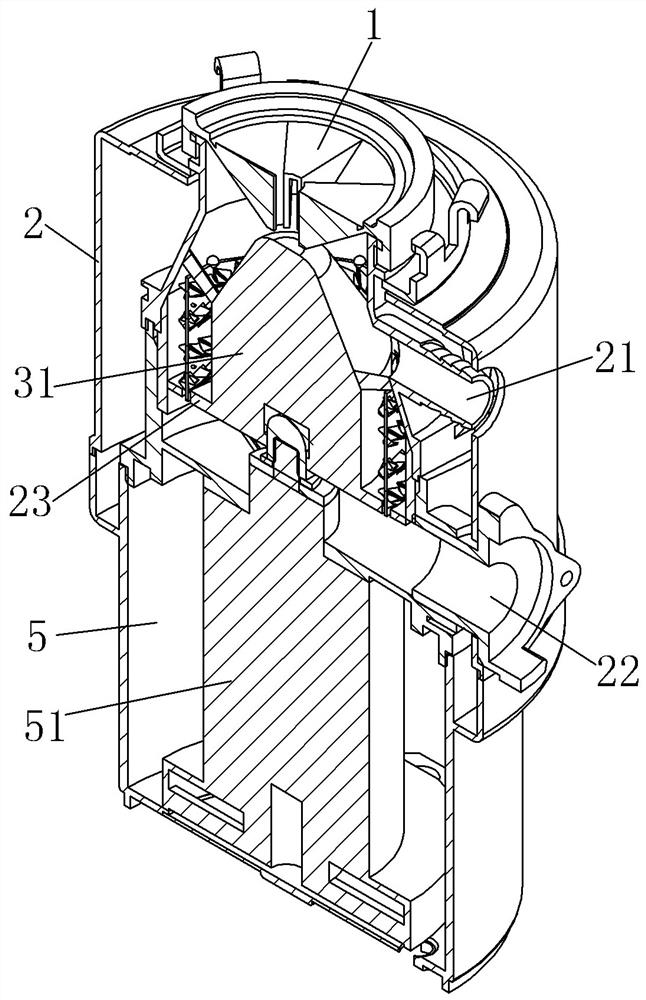

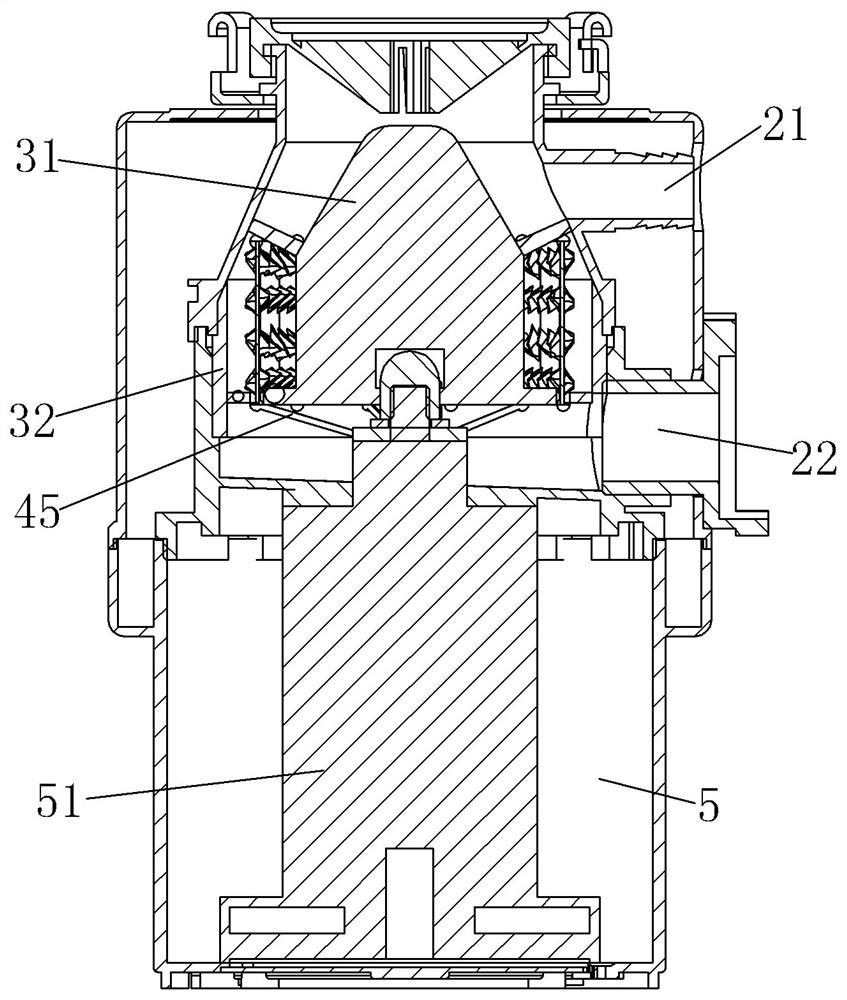

Novel material crushing device for preparation of inorganic nonmetal advanced material

ActiveCN110152781AImprove the crushing and grinding effectIncrease grinding powerCocoaGrain treatmentsFixed frameElectric machinery

The invention discloses a novel material crushing device for preparation of an inorganic nonmetal advanced material. The novel material crushing device for the preparation of the inorganic nonmetal advanced material comprises an outer encircling box, a double shaft motor, a crushing box, a crushing wheel, a fixed upper grinding disk and a tapered movable grinding disk, wherein fixing frames are fixedly welded to the inner sides of lifting sliding blocks located on the left side and the right side, the crushing box is arranged between the fixing frames, a main shaft passes out of the fixed upper grinding disk, the tapered movable grinding disk is installed at the lower end of the main shaft in a threaded mode, and the main shaft is in clearance fit with the fixed upper grinding disk. By enabling the crushing wheel and the tapered movable grinding disk to start rotating, raw materials can be ground for the second time, and therefore grinding and crushing effects are greatly improved, andsimultaneously the lifting sliding blocks can move up and down by enabling screw rods to be in threaded fit with the lifting sliding blocks, and therefore the crushing box is indirectly driven to move up and down, then an interval between the fixed upper grinding disk and the tapered movable grinding disk can be changed so as to increase grinding force and improve grinding effect, and simultaneously the material crushing device can adapt to grinding the raw materials different in particle size, and furthermore is simple and effective.

Owner:南通太洋高新材料科技有限公司

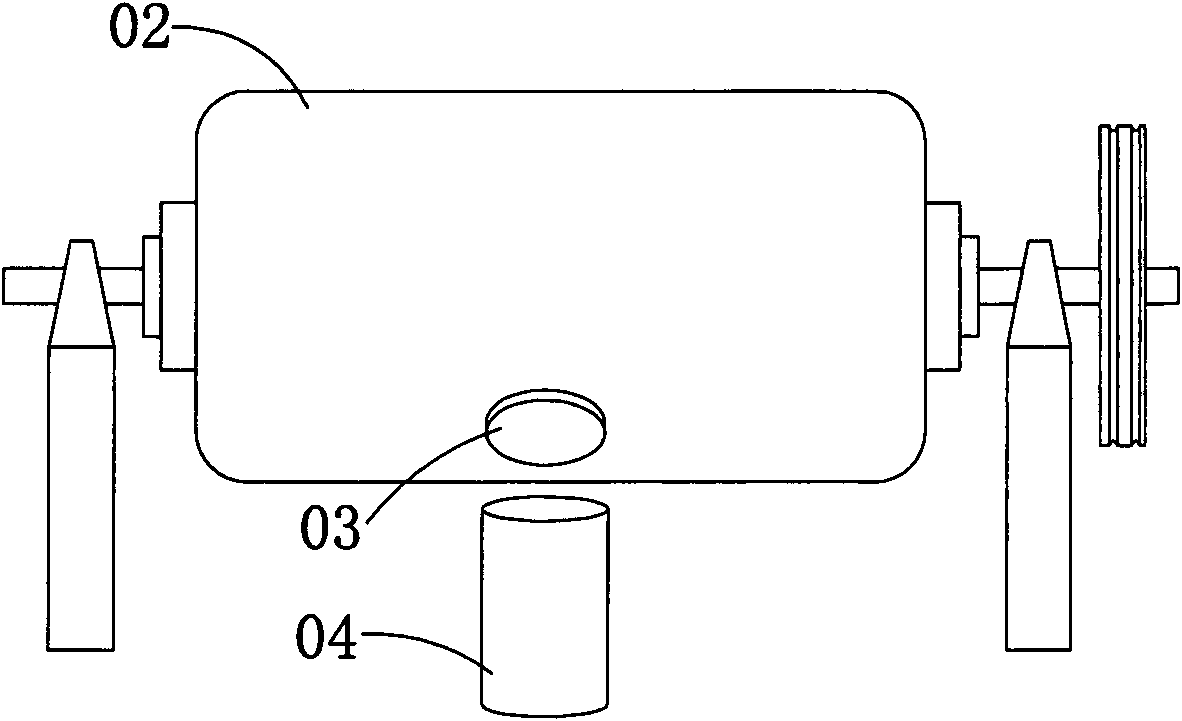

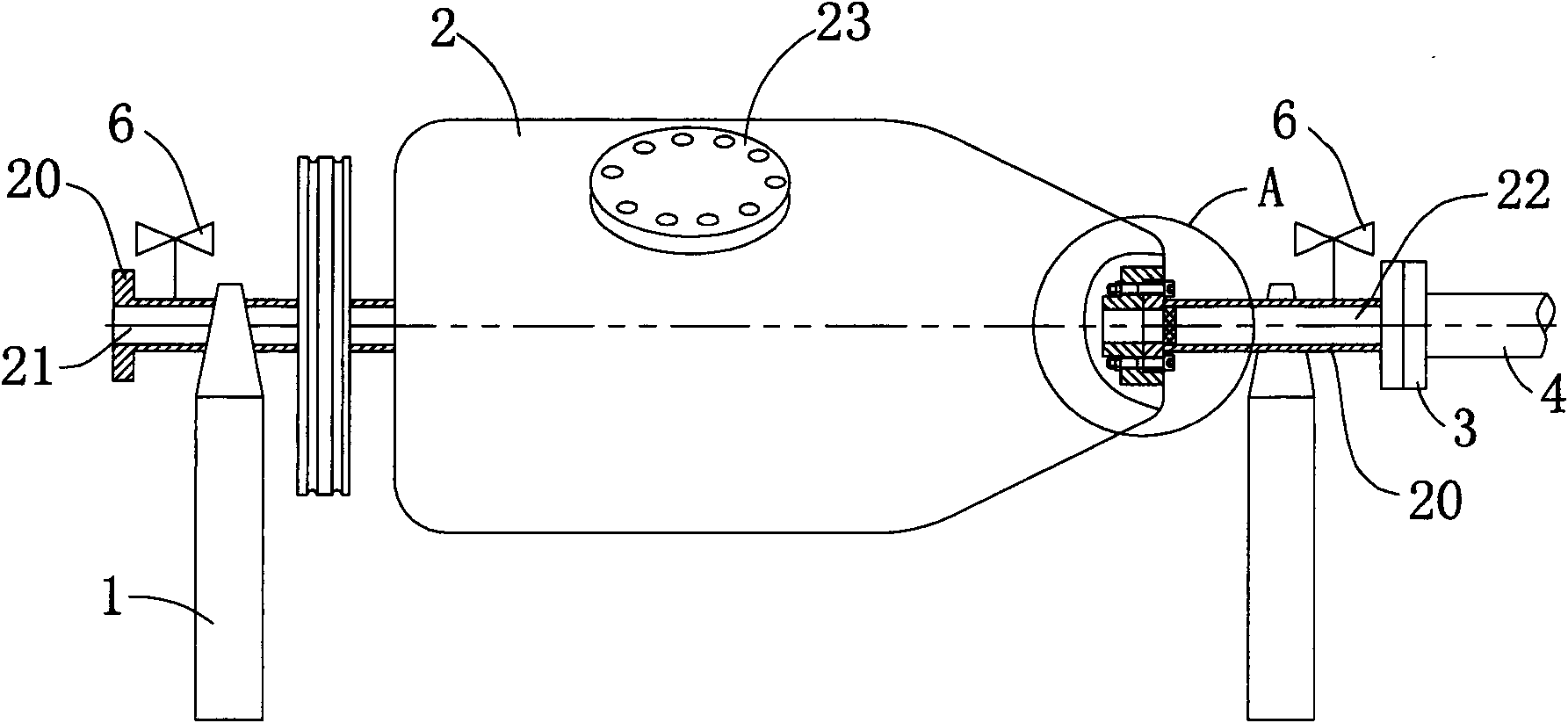

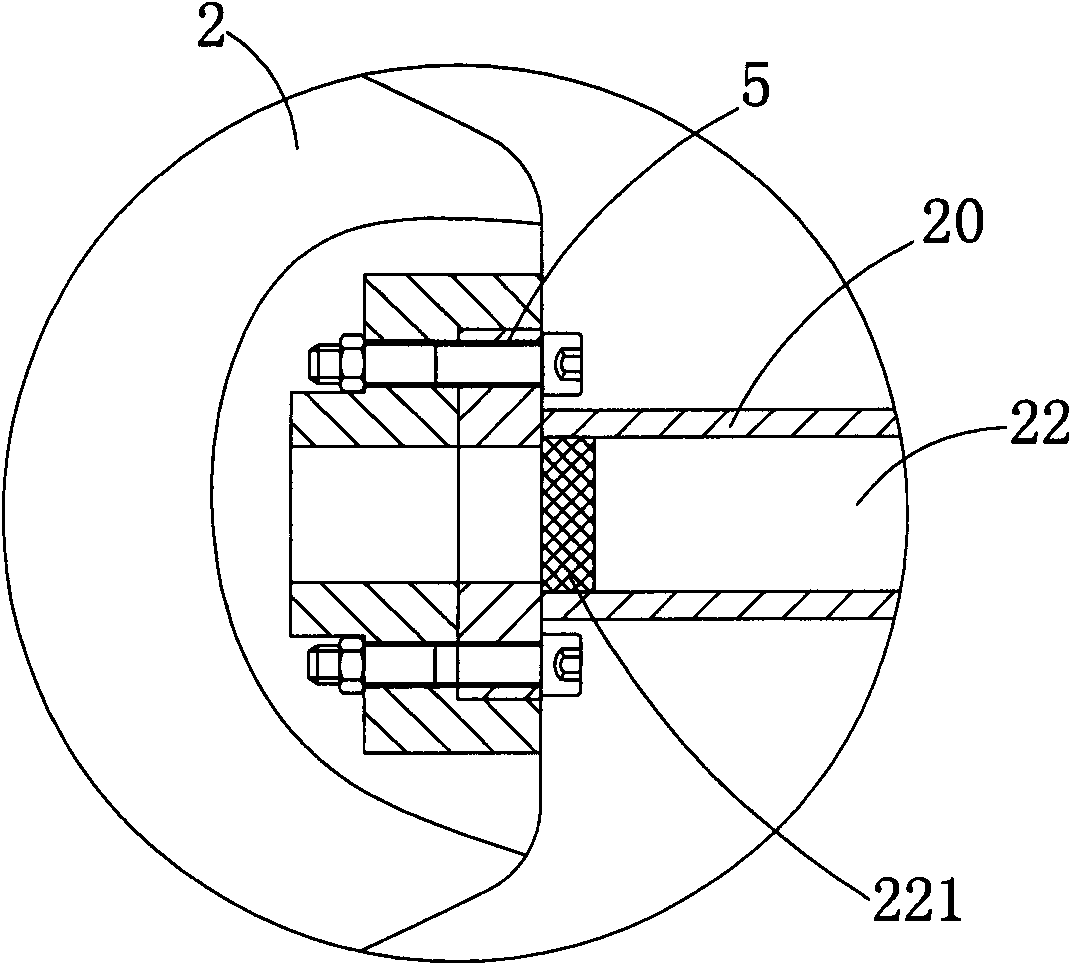

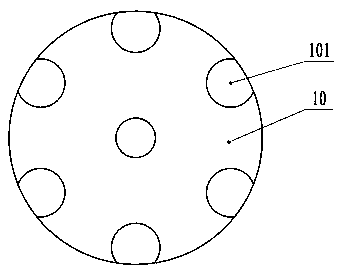

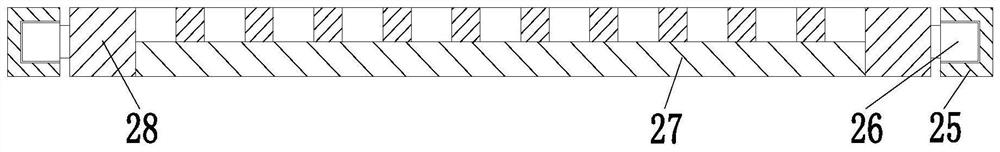

Improved structure of ball grinder

The invention discloses an improved structure of a ball grinder, comprising a support, a roller and rotating shafts arranged at the two ends of the roller, wherein one end of the roller is conical, a discharging hole is arranged in the rotating shaft close to the conical end of the roller, and the rotating shaft at the other end of the roller is internally provided with a feeding hole. In the invention, the operating mode of the traditional ball grinder that discharging is carried out after shutting down is changed, continuous processing is realized without shutting down, namely a material enters into the roller from the feeding hole, the density is increased and the grinding intensity is increased while the material enters into the conical end of the roller, and finally the refined material is extruded from the discharging hole, the ball grinder continuously operates in the period, the continuous feeding and discharging are realized, and the production efficiency is improved.

Owner:朱海良

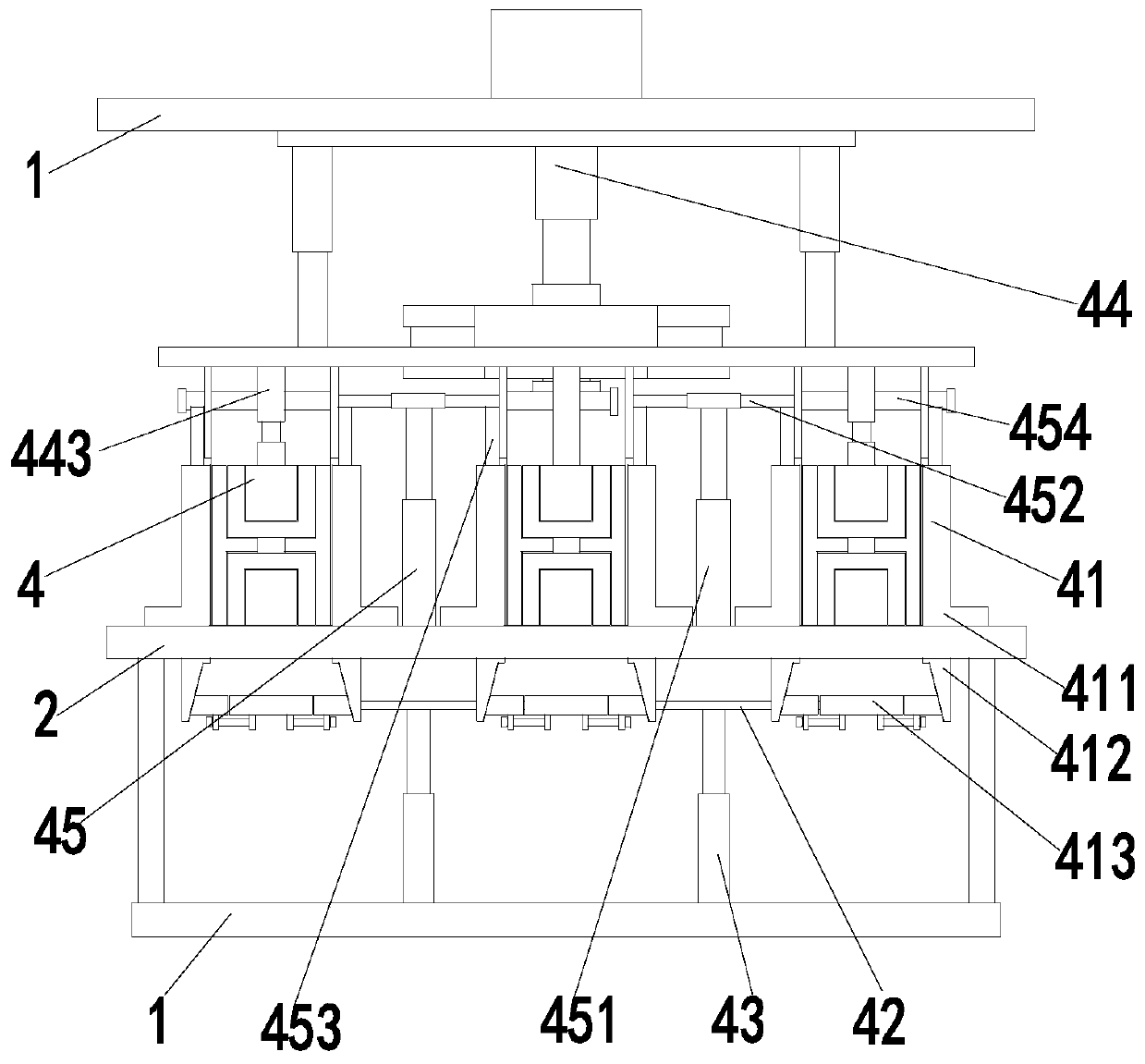

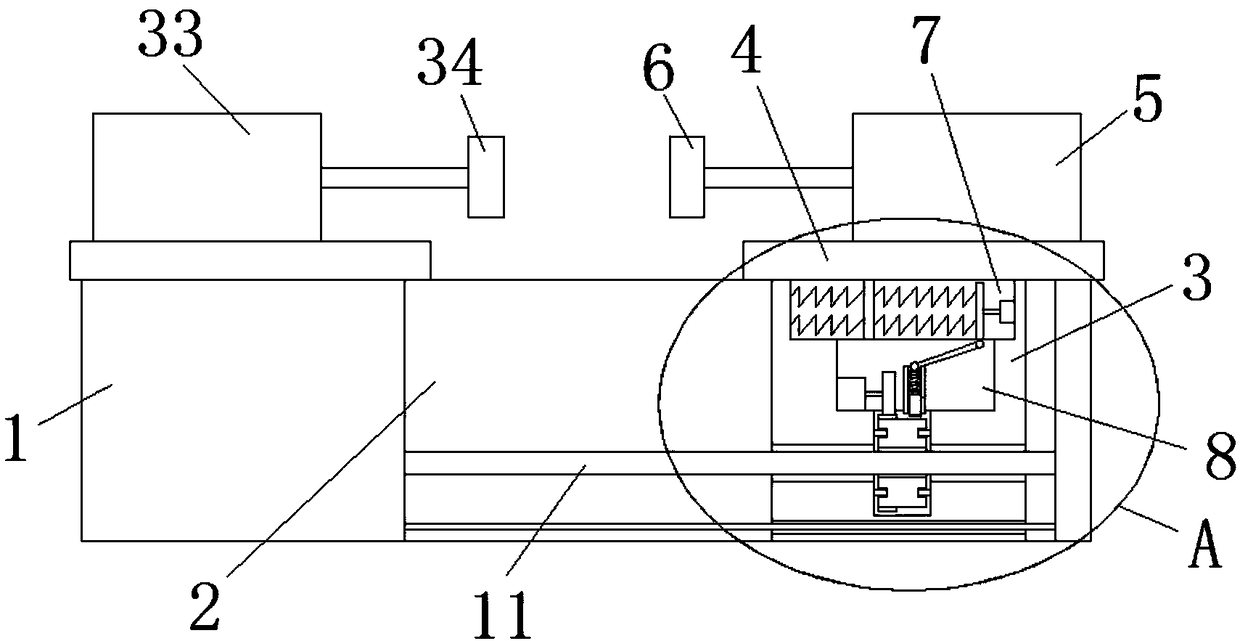

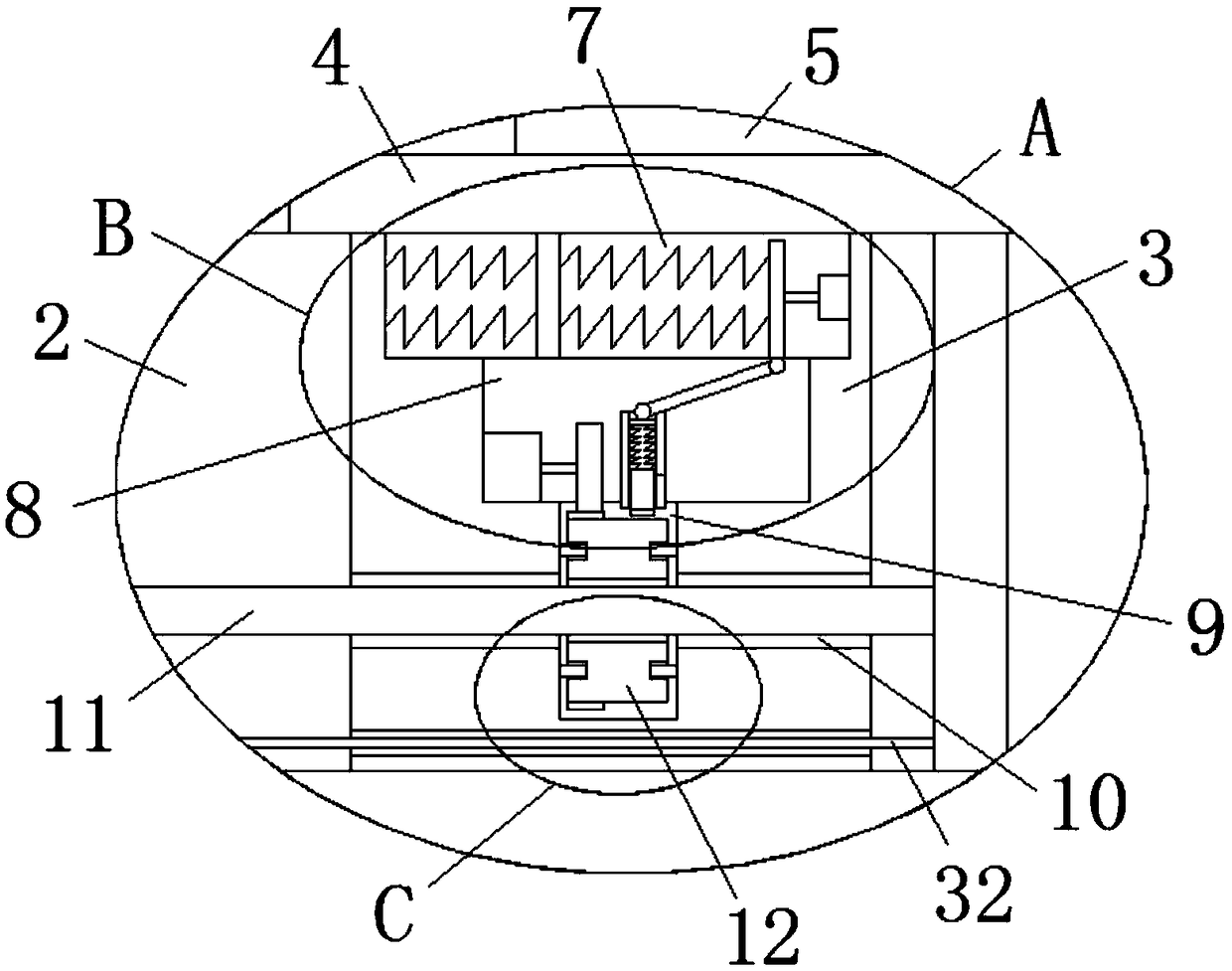

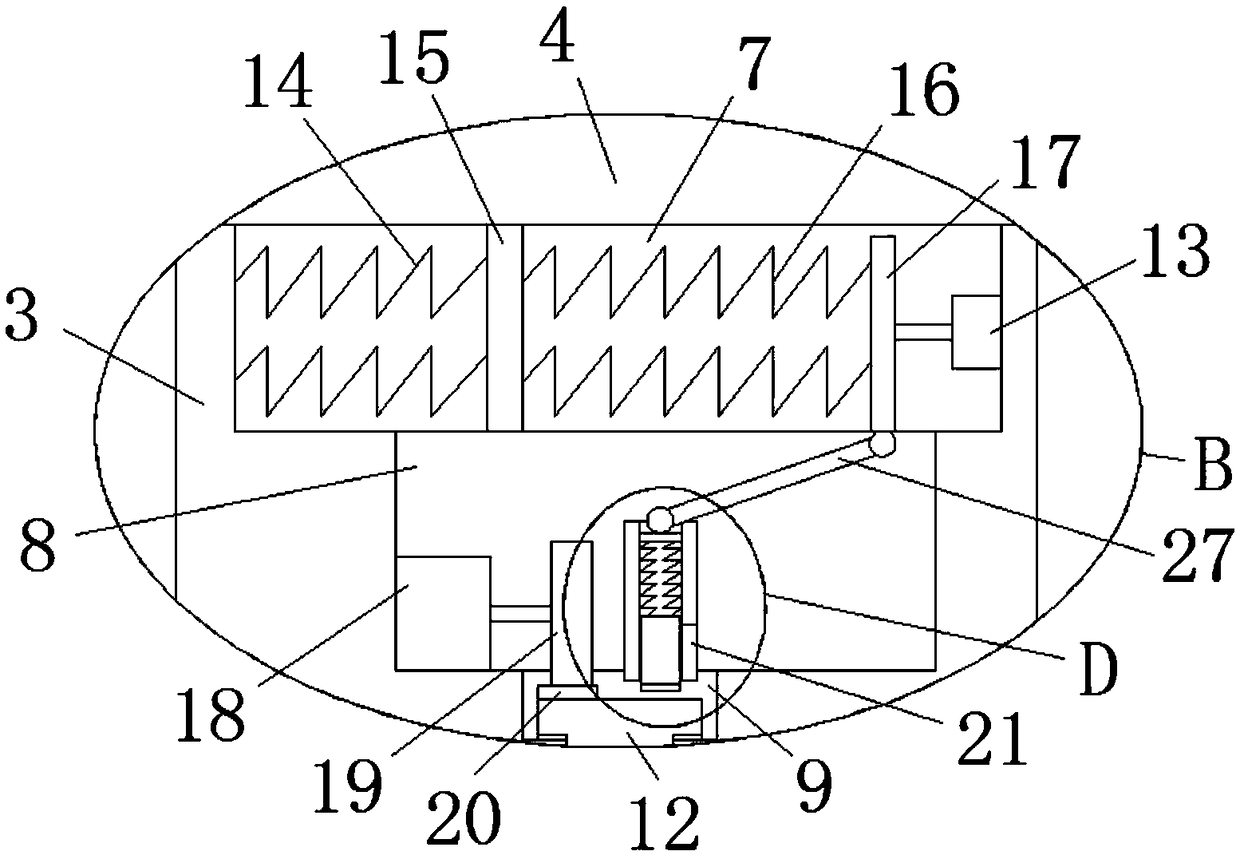

Fertilizer granule intermittent compression type grinding device for agriculture

The invention discloses a fertilizer granule intermittent compression type grinding device for agriculture. The fertilizer granule intermittent compression type grinding device comprises a base, a first driving motor, a cylinder body, a grinding rotating tube, a grinding head and a second driving motor, wherein the cylinder body is arranged under a moving rod A; a piston is glidingly arranged inside the cylinder body; the moving rod A is fixedly welded at the upper surface of the piston; a rolling wheel is rotationally arranged at the upper end of the moving rod A; a moving rod B is fixedly welded at the lower side of the piston; a connecting plate is arranged at the lower end of the moving rod B; a grinding shaft is arranged on the lower surface of the connecting plate through screw threads; the grinding head is fixedly arranged at the lower end of the grinding shaft. During the grinding, the grinding head at the lower end of the grinding shaft vertically moves; a pressurization effect is achieved; the grinding intensity is improved; the grinding effect is greatly improved, so that the fertilizer granule is more exquisite; the fertilizer dissolution is facilitated; the grinding rotating tube intermittently performs positive rotation and reverse rotation; compared with that of the single-direction rotation, the grinding effect is better; the condition of incomplete grinding iseffectively avoided.

Owner:倪为勇

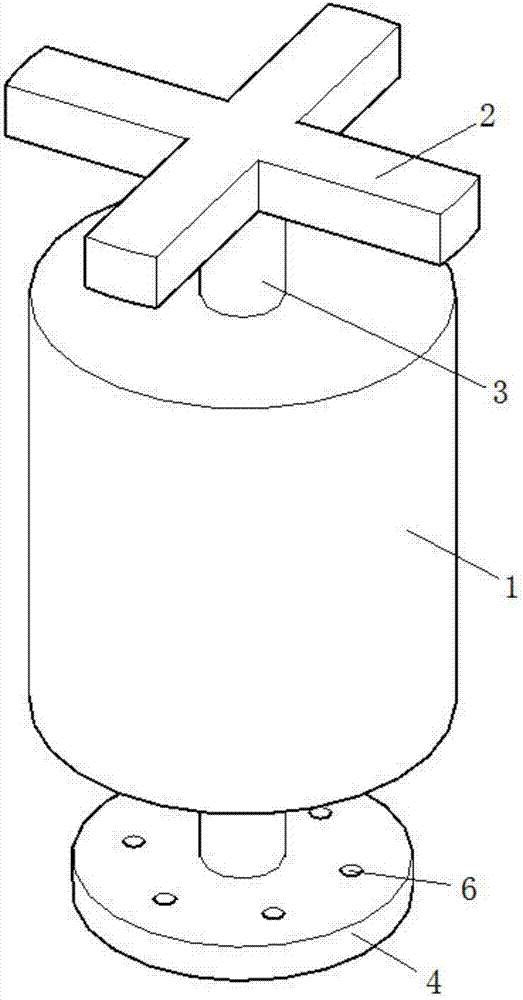

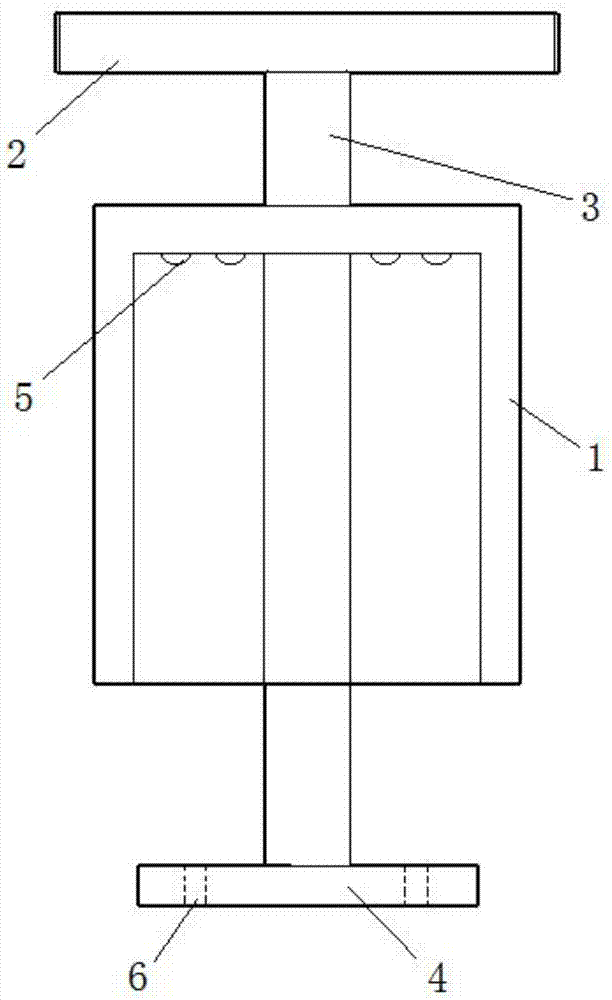

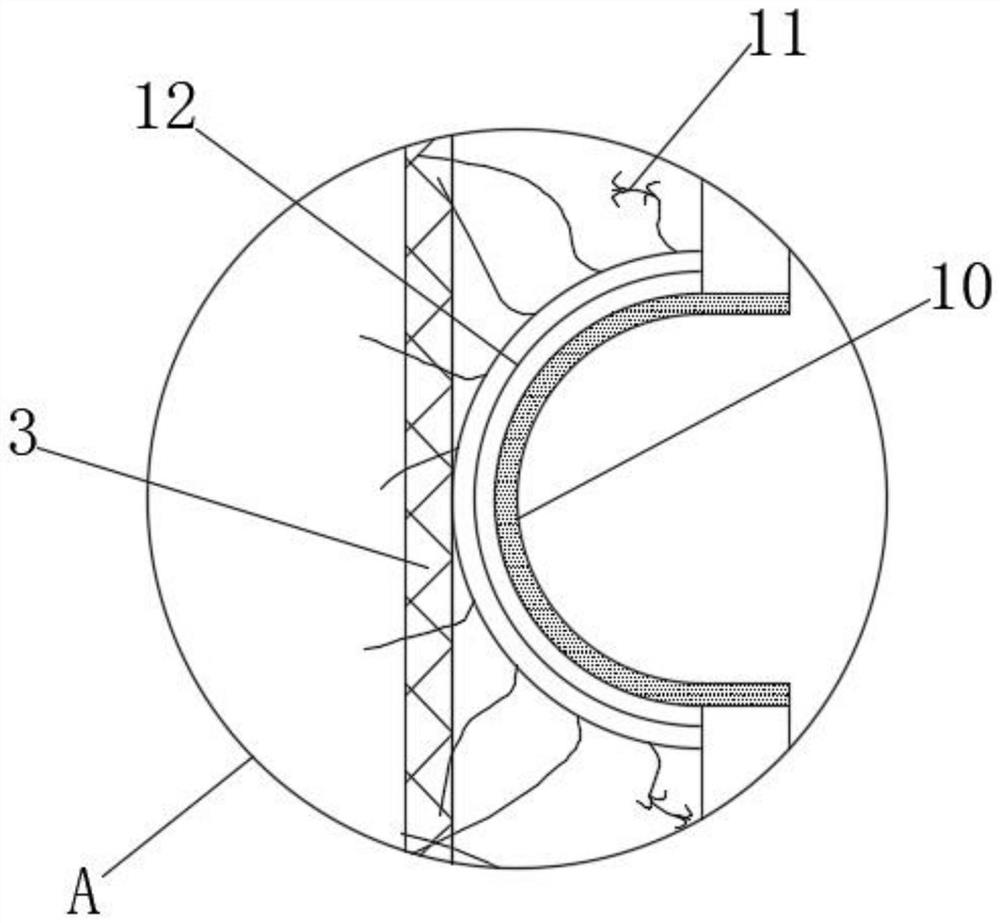

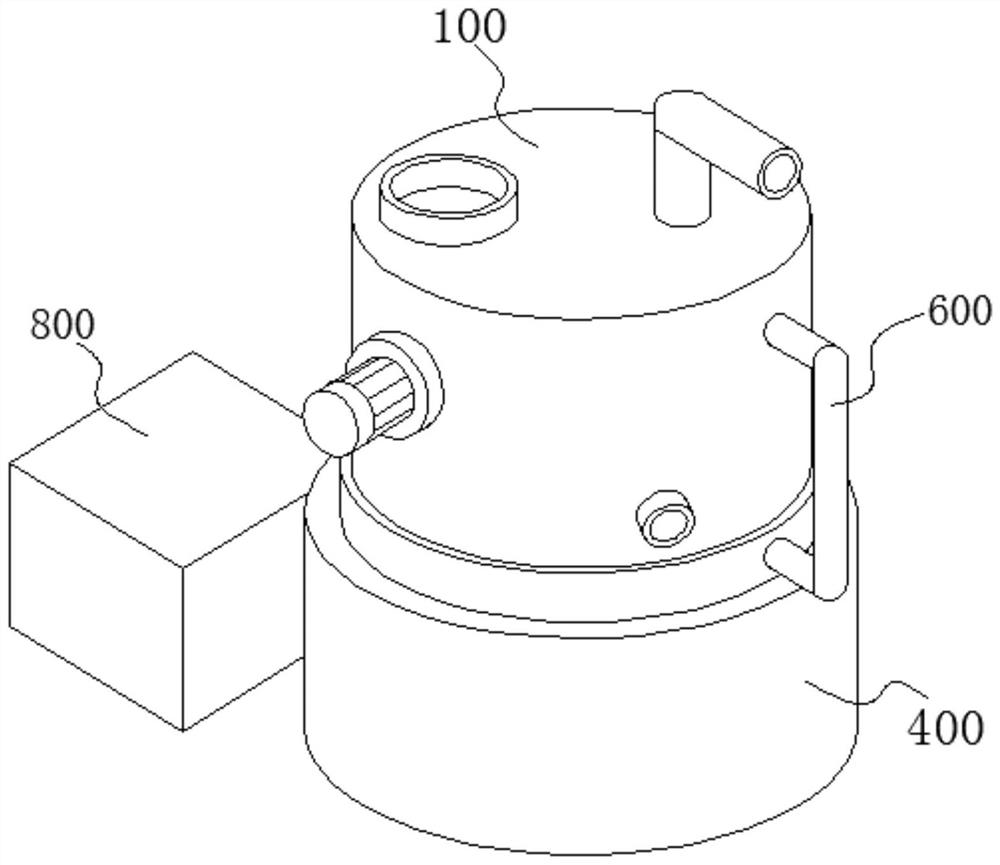

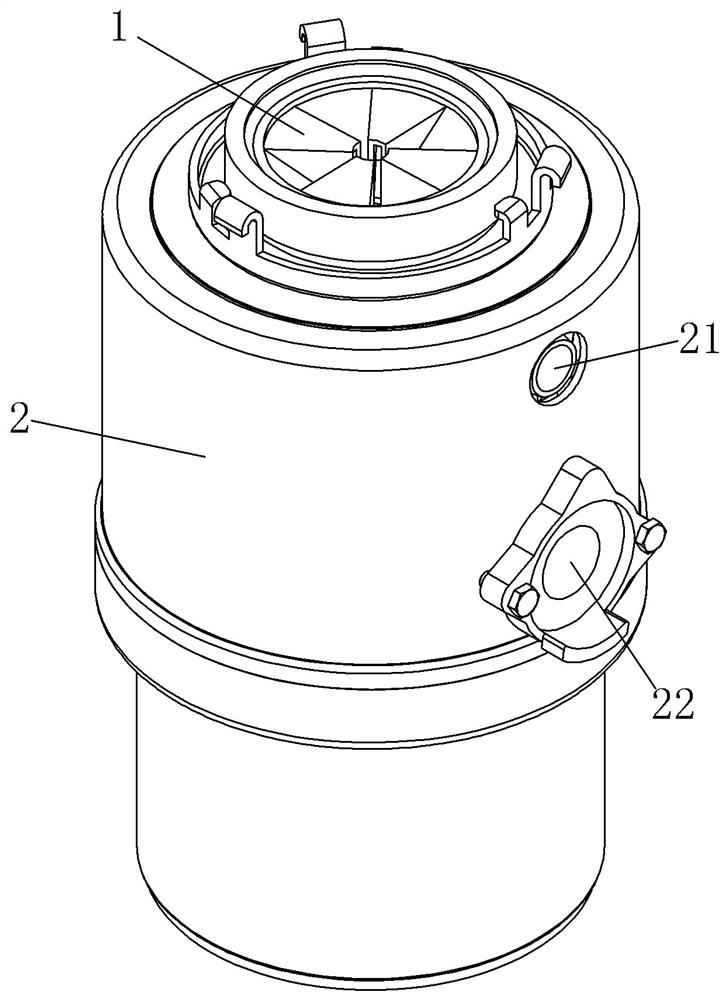

Novel waste sand regenerative device

PendingCN108687302ASave resourcesIncrease grinding powerMould handling/dressing devicesSolid waste managementImpurityPulp and paper industry

The invention relates to the technical field of waste sand regeneration, and particularly discloses a novel waste sand regenerative device. The waste sand regenerative device comprises a polishing mechanism, a washing mechanism, a stirring mechanism and a mounting bracket. The polishing mechanism, the washing mechanism and the stirring mechanism are installed on the mounting bracket. The stirringmechanism is mounted on the polishing mechanism and the washing mechanism, and synchronously stirs sand material in the polishing mechanism and the washing mechanism, wherein the polishing mechanism comprises a polishing cylinder body and the washing mechanism comprises a washing cylinder body. The stirring mechanism comprises a coaxial motor, a rotary shaft, a first stirring frame and a second stirring frame, wherein the first stirring frame and the second stirring frame are correspondingly located in the polishing cylinder body and the washing cylinder body. The coaxial motor rotates to drive the first stirring frame and the second stirring frame on the rotary shaft to stir correspondingly the sand material in the polishing cylinder body and the washing cylinder body. According to the novel waste sand regenerative device, the sand material is processed from congealed and clumpy waste sand to nearly inclusion-free, clean and reusable new sand, the whole processing procedure is high-efficient and energy-saving, and a large number of sand materials are saved.

Owner:柳晶(溧阳)环保科技有限公司

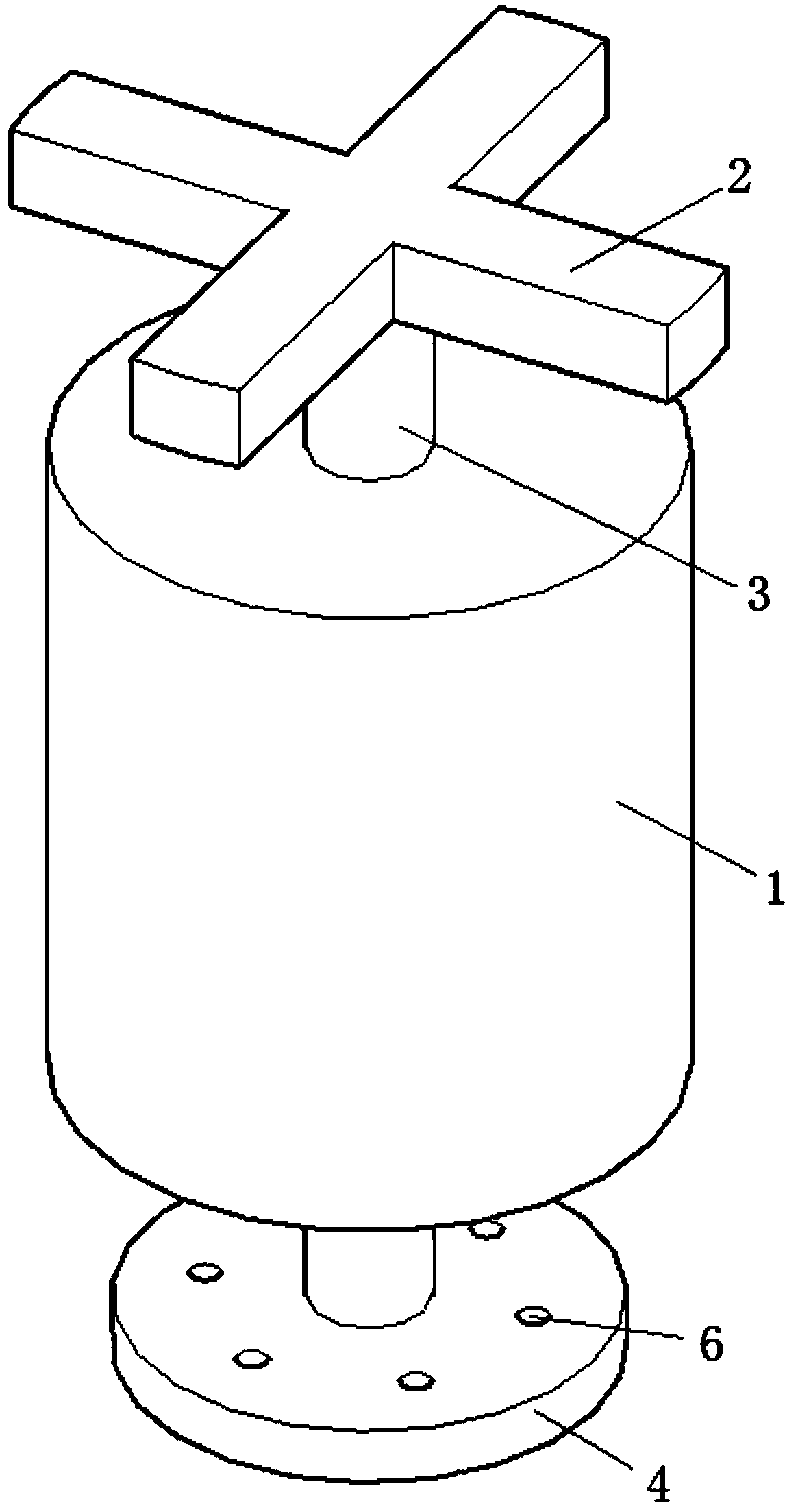

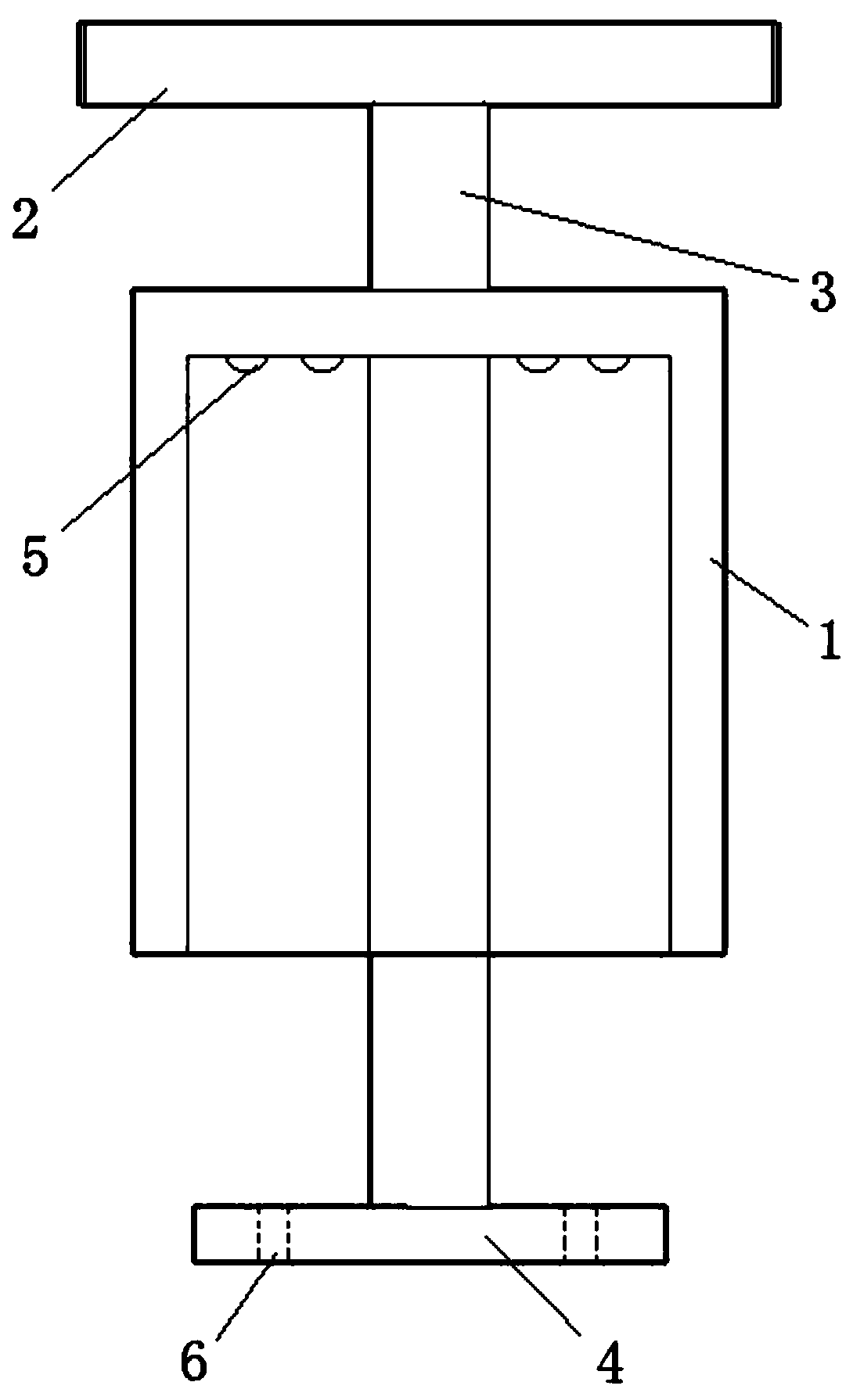

Batch smashing device for tablets

The invention relates to the field of medical apparatuses and instruments, in particular to a batch smashing device for tablets. The batch smashing device comprises a tablet barrel, a cross knob, a connecting rod, a pressure plate, a bump and a powder outlet, wherein the connecting rod passes through the tablet barrel and is in spiral rotation connection with the tablet drum; the cross knob is arranged at the top end of the connecting rod; the pressure plate is arranged at the bottom end of the connecting rod; the powder outlet is formed in the pressure plate; and the bump is arranged inside the bump. The batch smashing device is easily combined and dismounted; and the pressure plate of the batch smashing device cooperates with the tablet barrel for extruding, so that the tablets are smashed in batch, and therefore, the batch smashing device is wide in scope of application, is convenient to use, saves integral space, is low in cost and has creativity.

Owner:林舒怀

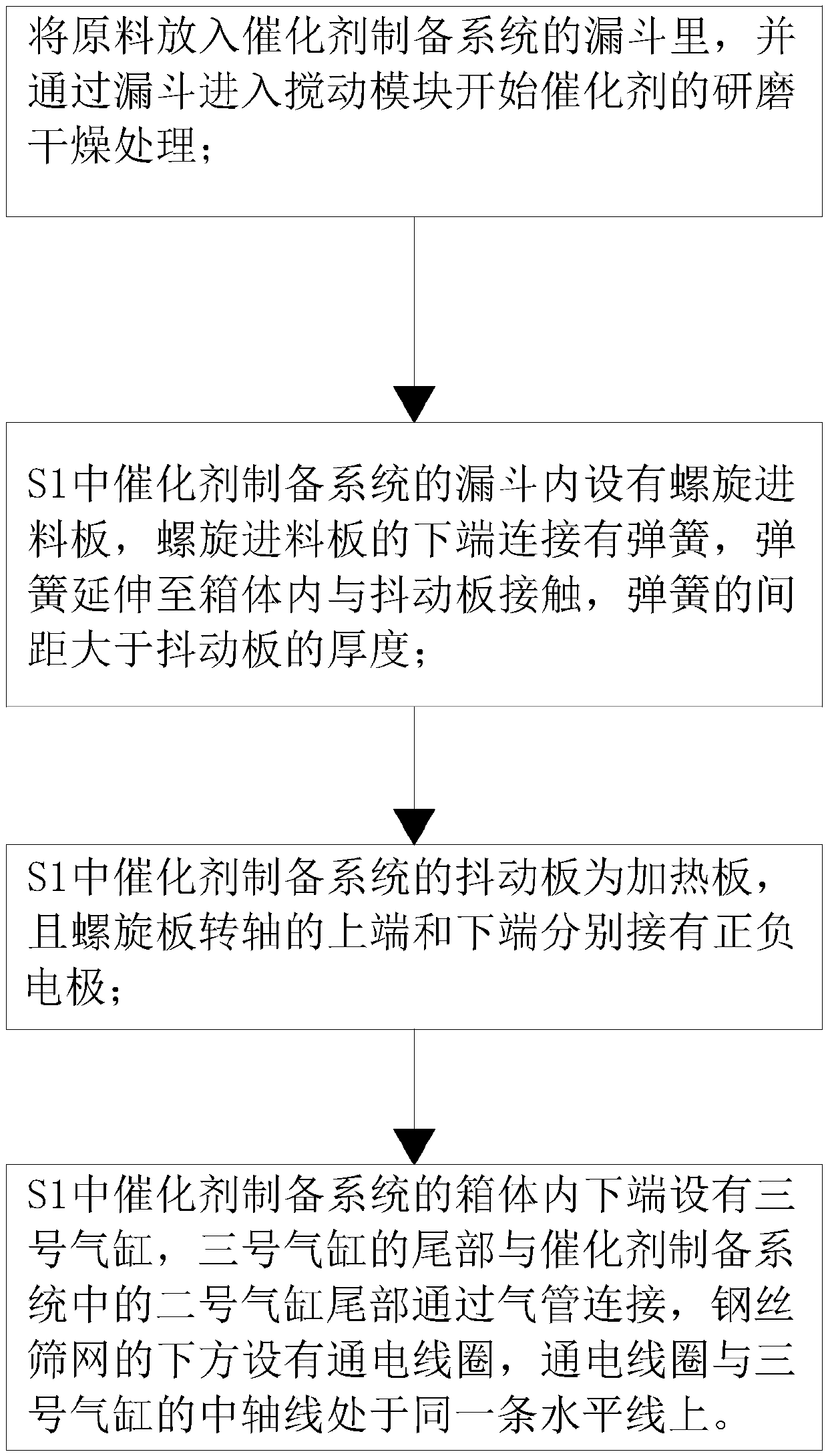

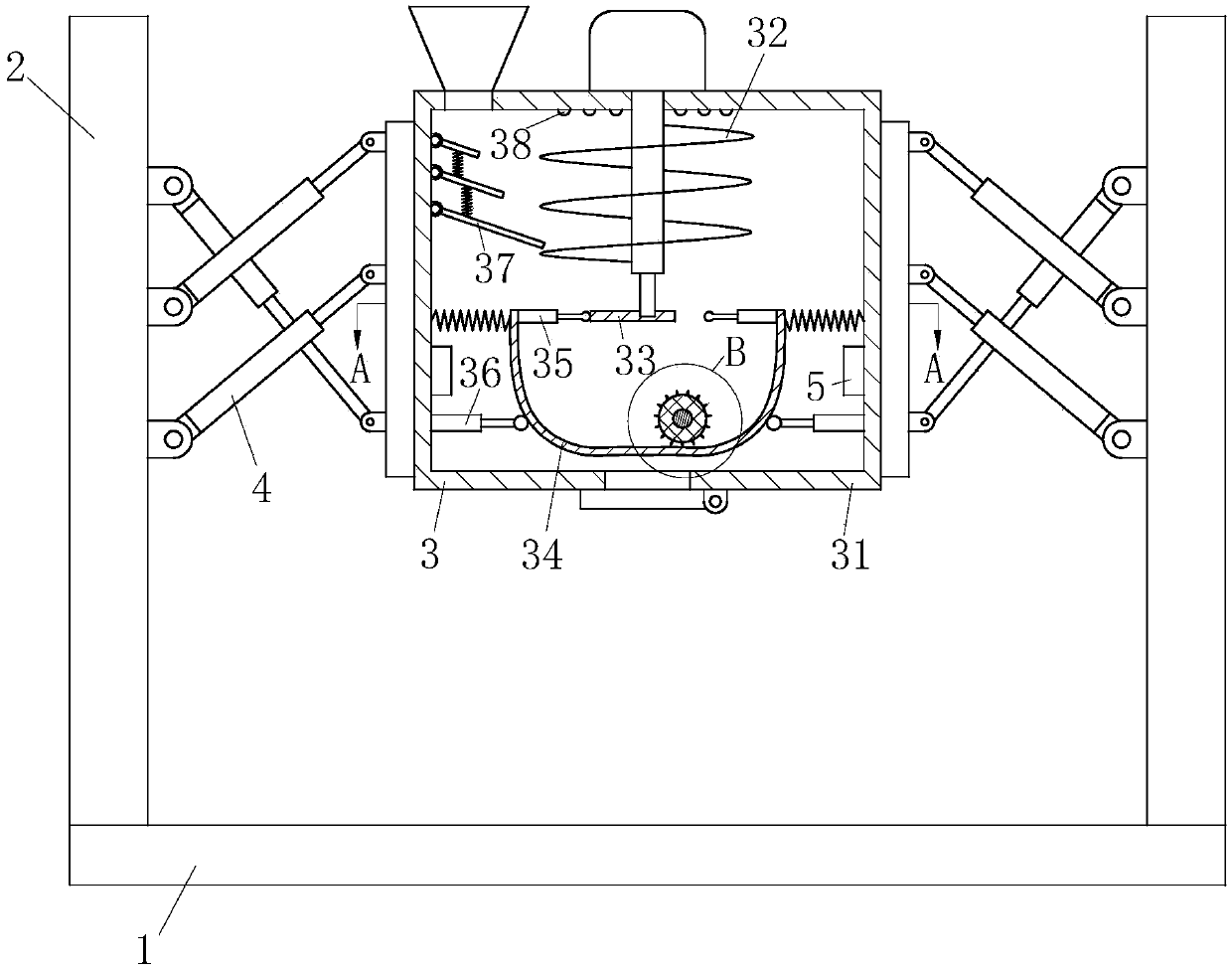

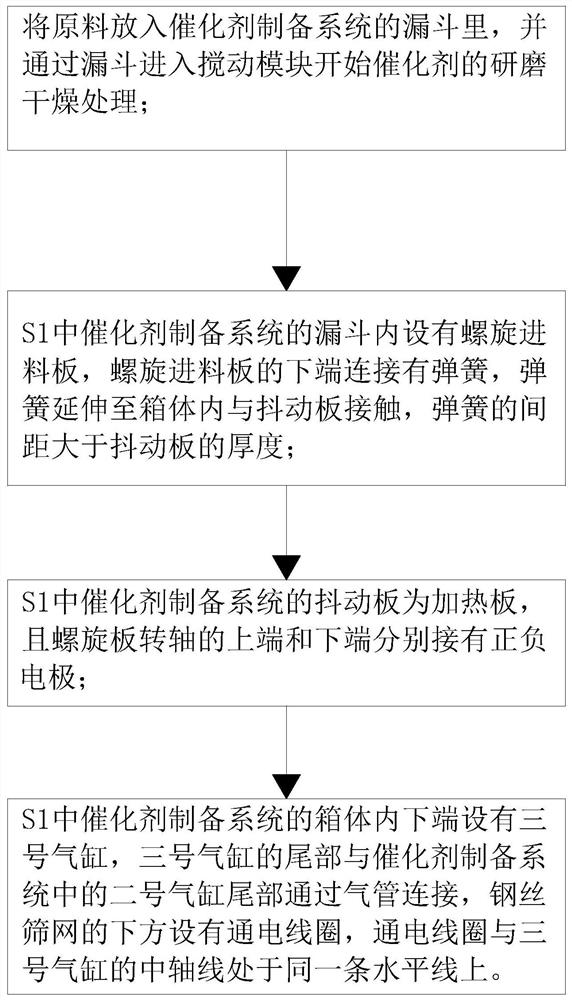

Grinding and drying technology for catalyst

ActiveCN109569829AAvoid damageImprove refinement efficiencySievingGranular material dryingPulp and paper industryRaw material

The invention belongs to the technical field of catalyst preparation, and particularly relates to a grinding and drying technology for a catalyst. The grinding and drying technology for the catalyst comprises the following steps that raw materials are putted into a funnel of a catalyst preparation system and then into a stirring module through the funnel to start the catalyst grinding and drying treatment; a spiral feeding plate is arranged in the funnel, springs are connected to the lower end of the spiral feeding plate, the springs extend into a box body so as to be in contact with shaking plates, and the distance between the springs is larger than the thickness of the shaking plates; the shaking plates are heating plates and the upper end and the lower end of a spiral plate rotary shaftare connected with a positive electrode and a negative electrode respectively; and a third air cylinder is arranged at the lower end of the box body, the tail part of the third air cylinder is connected with the tail parts of second air cylinders in the catalyst preparation system through air pipes, a power-on coil is arranged below a steel wire screen, and the central axis of power-on coil and the central axis of the third air cylinder are located on a same horizontal line. According to the grinding and drying technology for the catalyst, the springs are in contact with the shaking plates, the shaking amplitude and frequency of the shaking plates increase in the rotating process of the springs and the refining efficiency of the raw materials of the catalyst is improved.

Owner:江苏上阳金属新材料有限公司

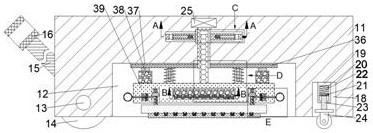

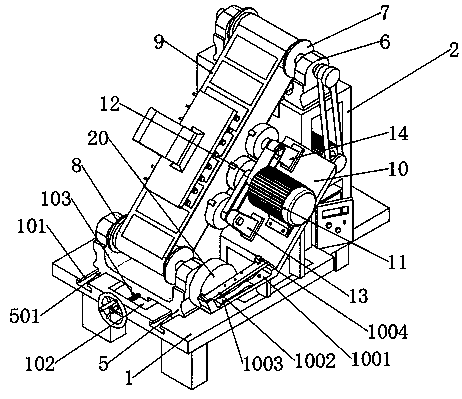

An automatic control grinding integrated device based on shaft side processing

ActiveCN109968134BEasy to adjustImprove functionalityEdge grinding machinesGrinding drivesAutomatic controlEngineering

The invention provides an automatic control grinding integrated device based on shaft side processing, which includes a pressing arm, a pressing plate, a rotating shaft, a rotating sleeve and a grinding disc; the bottom frame is used for the bottom support of the device, and the right side of the top surface is welded There is a right stand, and the first motor is installed in the top cavity of the frame structure of the right stand, and the top surface of the bottom frame and the top surface of the right stand are respectively equipped with a first swivel seat and a second swivel seat, wherein the first The second swivel seat realizes the belt drive connection with the first motor at the bottom through the pulley on one side; the first and second swivel seats are respectively fitted with a first connecting wheel and a second connecting wheel through splines. Press on the outer circle of the shaft parts to be polished to increase the grinding force. There is a circular grinding disc on the left front side. The grinding disc rotates synchronously with the rotation of the first turntable shaft, which can be used for grinding the outer surface of shaft parts. terminal, so the functionality is improved again, and the comprehensive structure design is reasonable.

Owner:杭州龙砺智能科技有限公司

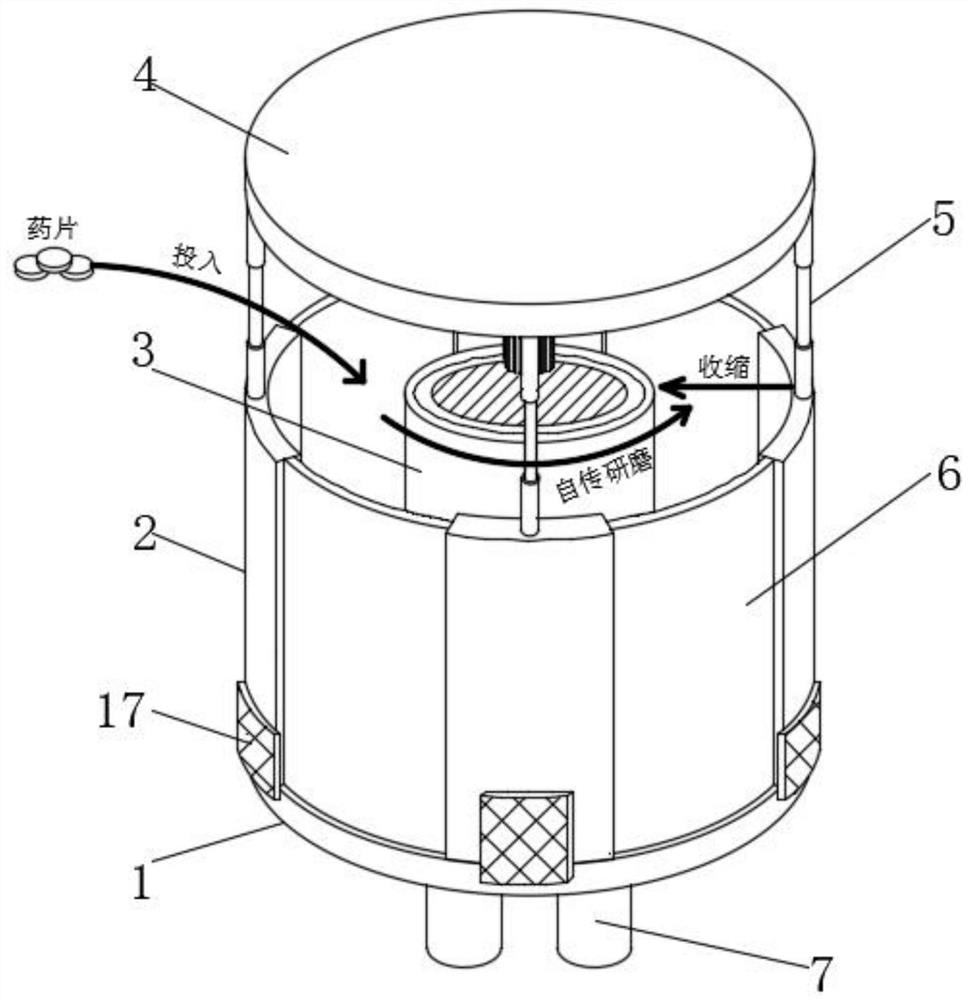

Tablet grinding device for edible medicines

InactiveCN113413984ARealize automatic grinding functionReduce workloadGrain treatmentsEngineeringDrug product

The invention discloses a tablet grinding device for edible medicines, and belongs to the field of tablet processing. According to the tablet grinding device for the edible medicines, a grinding net can be driven to rotate by utilizing a motor, meanwhile, an automatic tablet grinding function is achieved through cooperation with pushing and extruding of moving plates, the grinding net can rub adsorption lines in the rotating process, so that the adsorption lines have static electricity and can adsorb medicine powder generated by grinding, packaging films can be automatically sealed under the action of the adsorption lines after the packaging films are reset, the automatic packaging function to the medicine powder is achieved, the workload of monitoring personnel can be greatly reduced, after the packaging films enter water, the water can penetrate through the adsorption lines to dissolve the medicine powder on the surfaces of the adsorption lines, meanwhile, water-soluble sealing blocks are dissolved, so that gas in hollow balls are exhausted, the adsorption lines are driven to shake, the medicine powder dissolving rate is increased, after the medicine powder is completely dissolved, the packaging films automatically float upwards and are adsorbed together through the magnetic powder, and a guardian can conveniently carry out uniform recovery.

Owner:淮北悯农生物科技有限公司

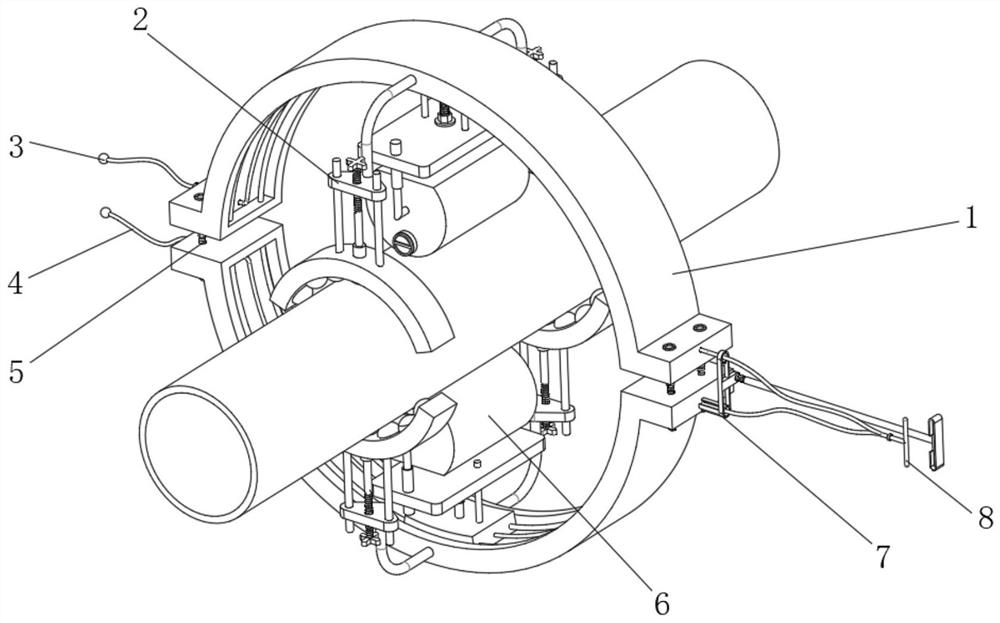

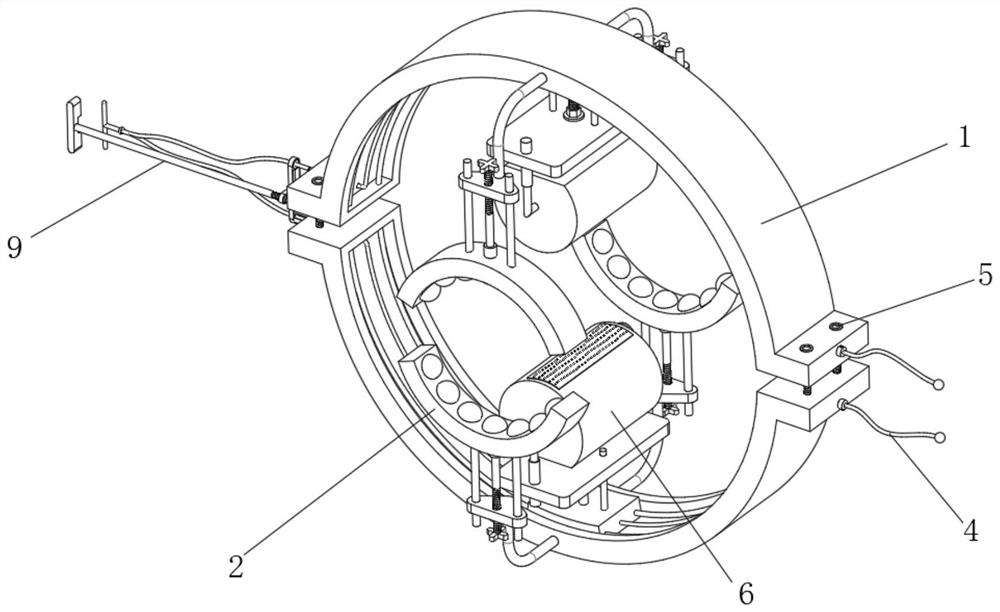

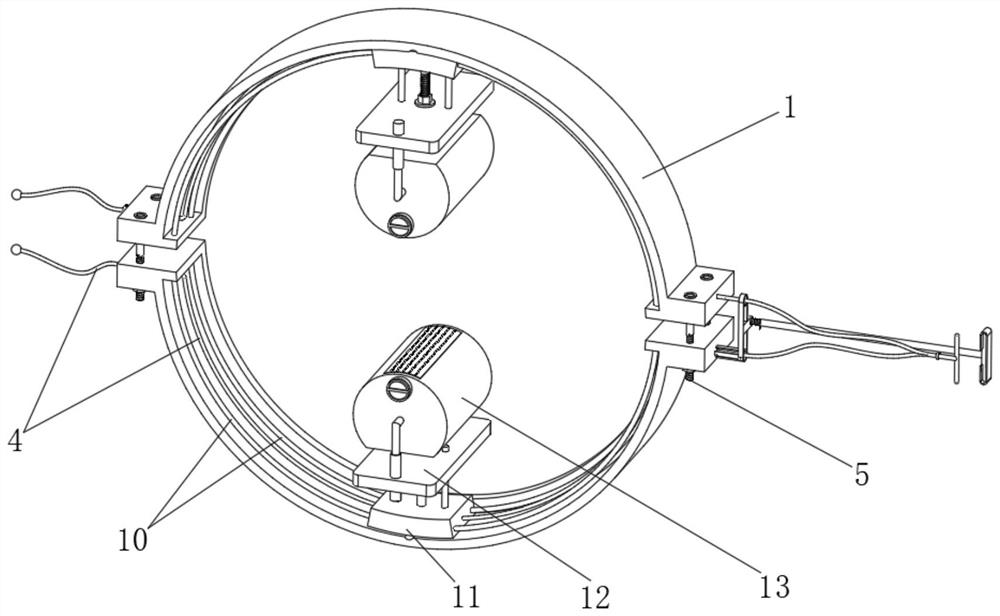

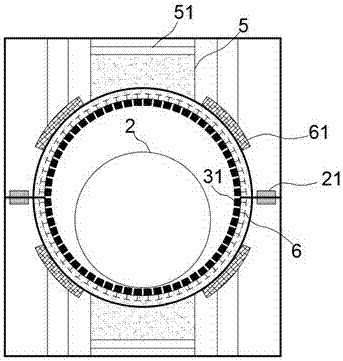

Water conservancy construction pipeline outer surface rust removal device and using method thereof

ActiveCN114083414AEasy to adaptImprove grinding efficiencyGrinding machinesGrinding work supportsCylindrical grindingBolt connection

The invention discloses a water conservancy construction pipeline outer surface rust removal device and a using method thereof, and relates to the technical field of pipeline outer surface rust removal devices. The grinding effect is improved. The device comprises two hoop-shaped mounting frames which are symmetrically arranged, the two hoop-shaped mounting frames are mounted and fixed through connecting bolts, supporting mechanisms are arranged on the two sides of each hoop-shaped mounting frame, and a grinding mechanism is arranged on the inner side of each hoop-shaped mounting frame. The method comprises the following steps that a user places the two hoop-shaped mounting frames on the outer side of a pipeline, and the two hoop-shaped mounting frames are connected and fixed through connecting bolts. Through arrangement of the hoop-shaped mounting frames, the cylindrical polishing part, the elastic rope, the handle and other structures, the elastic rope can be repeatedly dragged through the handle, the sliding base is pulled to slide back and forth along the surface of the arc-shaped guide rod under the elastic cooperation of the elastic rope, and the pipeline is polished through the cylindrical polishing part; and since thegrinding track of the cylindrical grinding part is curved, the device can better adapt to the pipeline surface, and the grinding efficiency and the grinding effect are improved.

Owner:沧州昊海水利工程质量检测有限公司

A tablet batch crushing device

The invention relates to the field of medical apparatuses and instruments, in particular to a batch smashing device for tablets. The batch smashing device comprises a tablet barrel, a cross knob, a connecting rod, a pressure plate, a bump and a powder outlet, wherein the connecting rod passes through the tablet barrel and is in spiral rotation connection with the tablet drum; the cross knob is arranged at the top end of the connecting rod; the pressure plate is arranged at the bottom end of the connecting rod; the powder outlet is formed in the pressure plate; and the bump is arranged inside the bump. The batch smashing device is easily combined and dismounted; and the pressure plate of the batch smashing device cooperates with the tablet barrel for extruding, so that the tablets are smashed in batch, and therefore, the batch smashing device is wide in scope of application, is convenient to use, saves integral space, is low in cost and has creativity.

Owner:林舒怀

Hand-push type wooden floor polishing and waxing equipment

ActiveCN112545372AEvenly distributedAchieving Broken RepairCarpet cleanersFloor cleanersParaffin waxPolishing

The invention discloses hand-push type wooden floor polishing and waxing equipment, which comprises a machine body, a containing cavity with a downward opening is formed in the lower end face of the machine body, a centrifugal cavity is formed in the upper side of the containing cavity, and a heating trigger device is arranged in the centrifugal cavity. By utilizing a lifting paraffin placing plate, constant-pressure abutting of a polishing disc and a wooden floor is completed, the polishing and grinding strength can be improved, the damaged surface of the floor can be effectively repaired, meanwhile, solid paraffin is placed in the equipment, is liquefied by high temperature, and is delivered into the polishing disc, and thus uniform dyeing is realized. Paraffin is evenly distributed, meanwhile, opening and closing of a paraffin conveying channel can be achieved through rotation energy of the equipment, pipeline blockage caused by paraffin cooling and solidification is prevented, meanwhile, the equipment can roll on the ground, the control strength of an operator on the equipment is reduced, and the physical strength of operating the device is saved.

Owner:石家庄泽裕科技有限公司

Stable stainless steel pipe welding device

PendingCN114654159AIncrease contactAvoid fixationEdge grinding machinesGrinding drivesSS - Stainless steelPipe welding

The invention discloses a stable stainless steel pipe welding device. The stable stainless steel pipe welding device comprises a base, a welding seat, a welding head, a base, a limiting rotating device and an auxiliary processing device. The limiting rotating devices are arranged between the base and the base, the limiting rotating devices comprise the left limiting rotating device and the right limiting rotating device, steel pipes entering from the two ends pass through the limiting rotating devices, the clamping mechanisms and the guide mechanisms are arranged in the limiting rotating devices, the guide mechanisms can conduct position adjustment on the adjusting boxes at the bottoms, and rotating rollers in the guide mechanisms can make contact with the steel pipes conveniently; the clamping mechanism can conveniently limit the steel pipe in the rotating process of the steel pipe, the situation that the welding position is fixed, the steel pipe needs to be manually rotated is avoided, the two ends synchronously rotate, and the welding effect and precision are improved; and the auxiliary processing device is installed at the left end of the top of the base, efficient rotating grinding can be conducted on the welding position of the welded steel pipe, and the steel pipe is rotated in the opposite direction in cooperation with the limiting rotating device, so that the grinding strength and uniformity are improved.

Owner:金保莱管道系统江苏有限公司

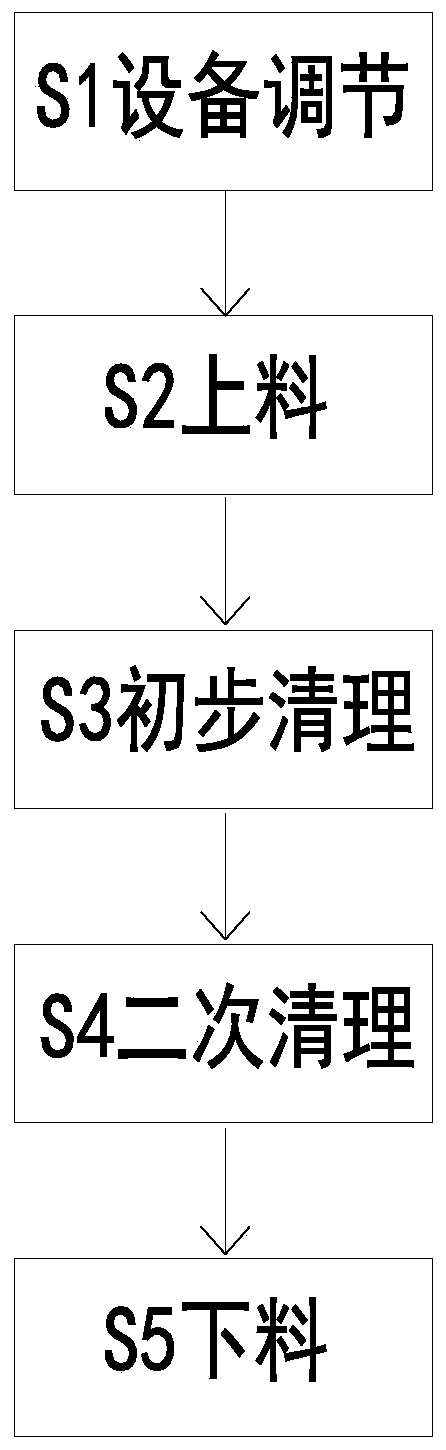

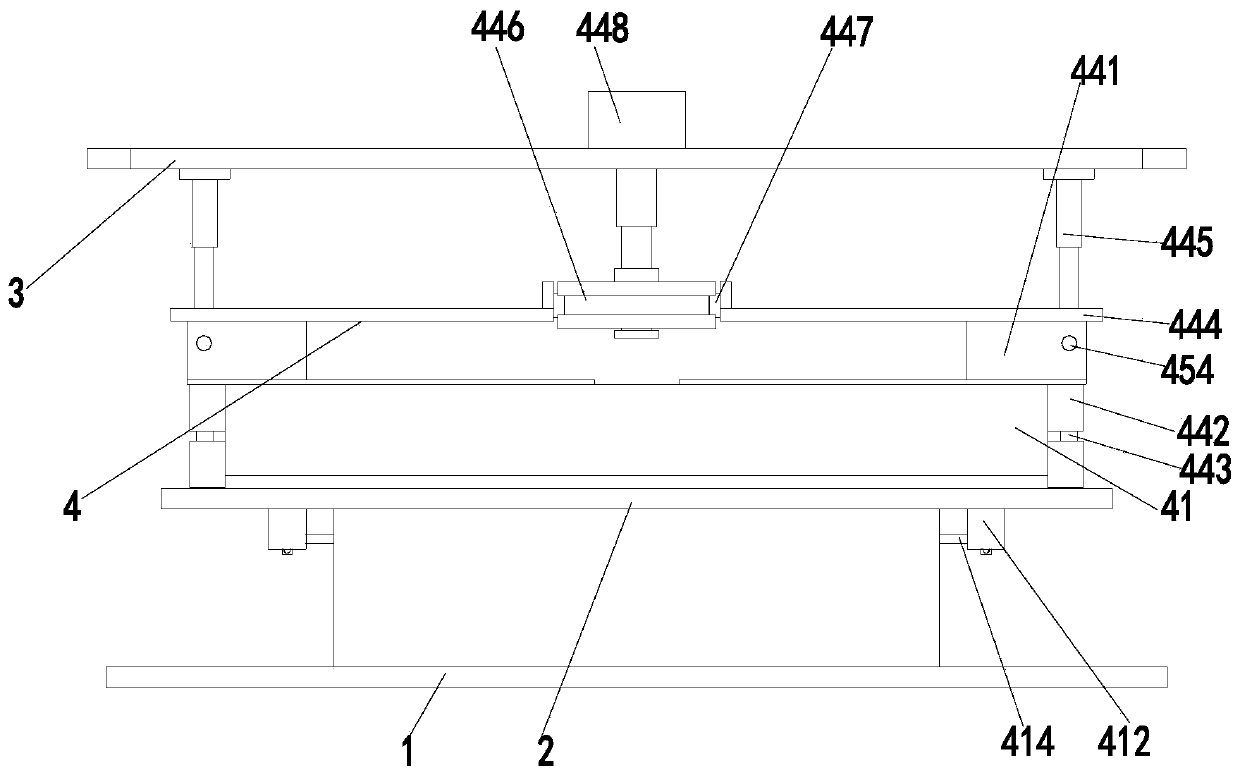

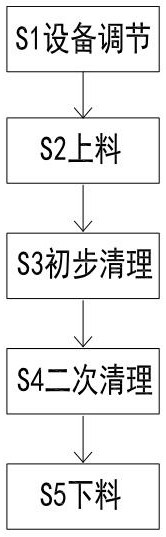

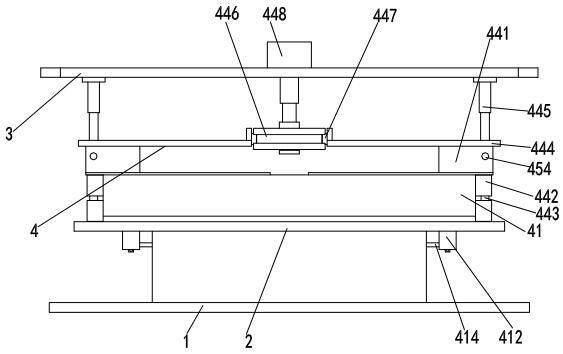

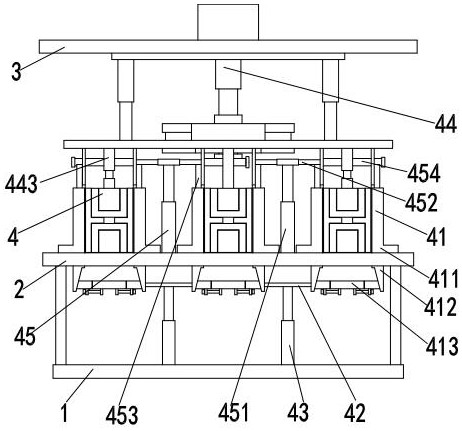

Hot-rolled casting surface oxide scale treatment method

ActiveCN111360666AResidue reductionEasy to cleanGrinding carriagesGrinding drivesSurface cleaningElectric machine

The invention relates to a hot-rolled casting surface oxide scale treatment method. The method uses surface cleaning equipment. The surface cleaning equipment comprises a bottom plate, a workbench, amounting rack and a cleaning mechanism; the specific method flow for cleaning the oxide scale on the hot-rolled casting surface by adopting the surface cleaning equipment comprises the following stepsof equipment regulation, material loading, preliminary cleaning, secondary cleaning and blanking; the cleaning mechanism comprises a limiting seat, a connector, a lifting cylinder, a cleaning branchchain, and an adjusting branch chain; the cleaning branch chain comprises a cleaning plate, a cleaning block, a butt-joint pole, a movable plate, a butt-joint cylinder, a rotating cam, a connecting sliding block and a rotating motor. By adopting a multi-statin design mode, a plurality of casting surface can be cleaned at the same time, the polishing degree can be adjusted as actual working requirement during the cleaning process, thereby improving the cleaning effect, and reducing the residue of the oxide scale on the recasting surface.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

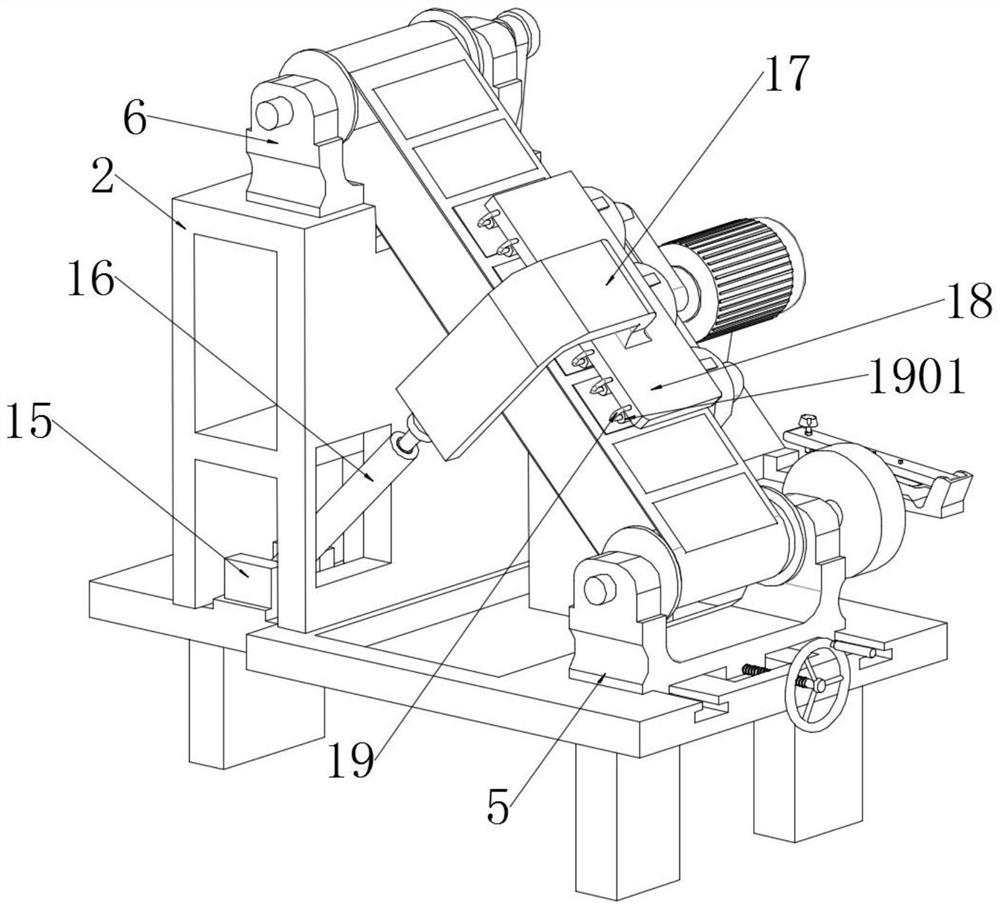

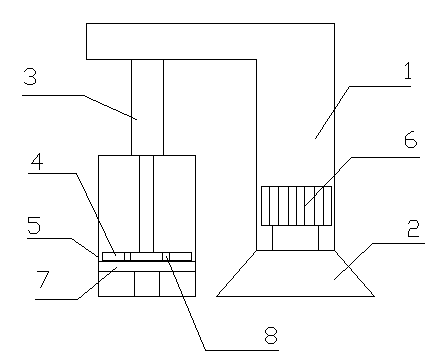

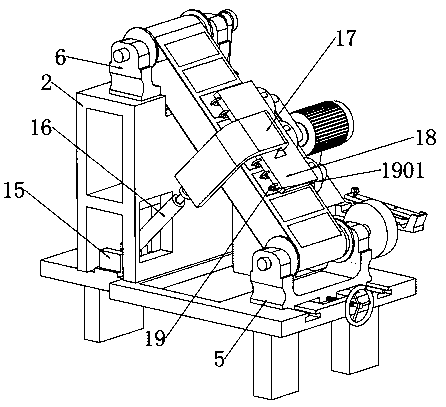

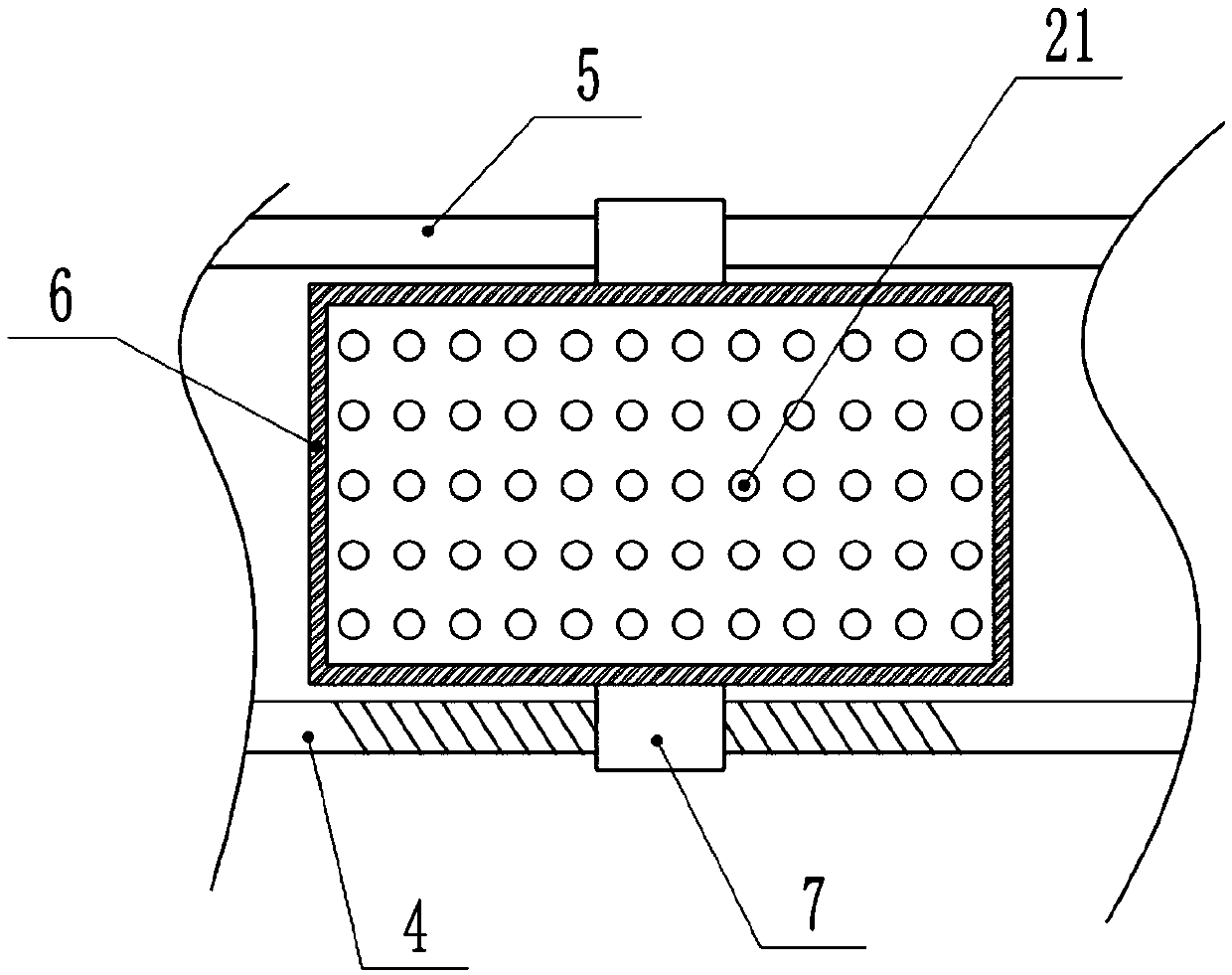

Vertical sanding machine

InactiveCN103567016AIncrease grinding powerImprove work efficiencyCocoaGrain treatmentsSanderArchitectural engineering

The invention relates to grinding equipment, in particular to a vertical sanding machine. The sanding machine comprises a rack, a base, a lifting rod, a dispersing disk, a grinding cylinder and a motor, wherein the motor is fixed in the rack; the bottom of the rack is fixed with the base; the top of the rack is fixed with the lifting rod; the dispersing disk is fixed to the top of the lifting rod and is placed in the grinding cylinder; a grinding disk is fixed to the bottom of the grinding cylinder; through holes are formed in the dispersing disk. By the sanding machine, the grinding force of materials can be greatly improved, and the work efficiency is improved.

Owner:CHANGZHOU AISEN PLASTIC TECH

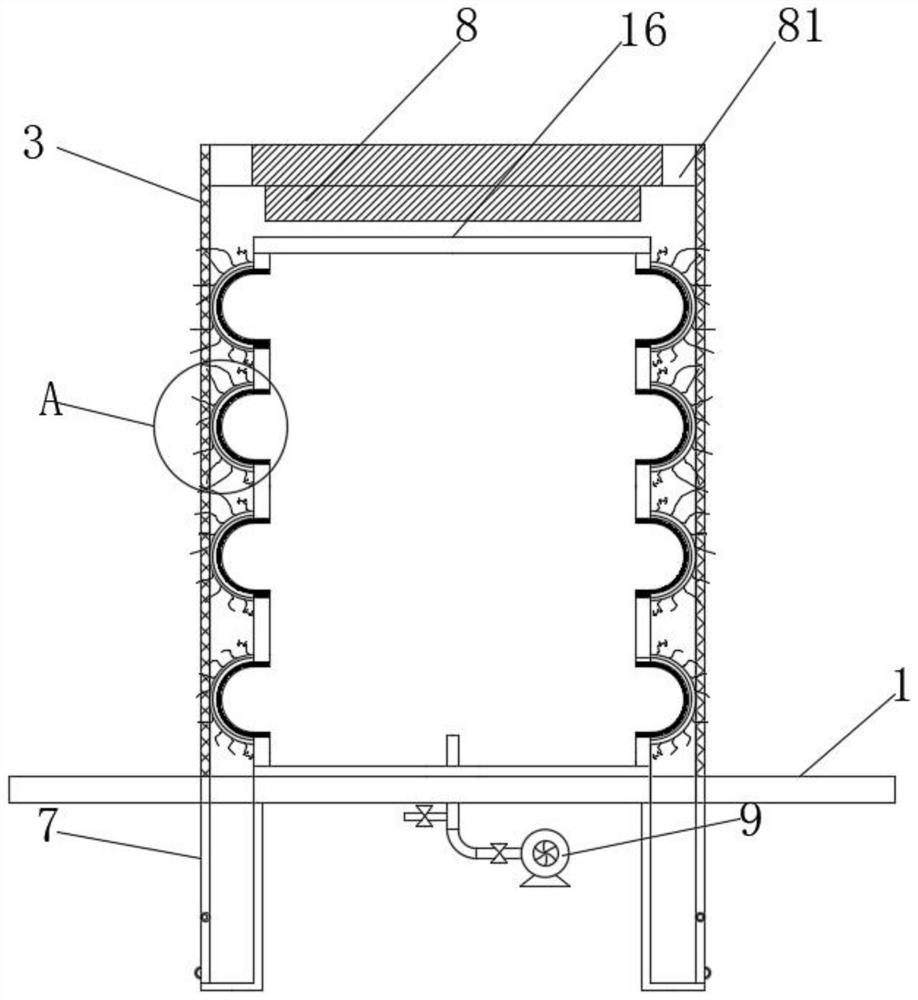

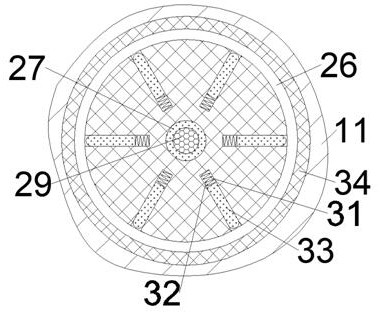

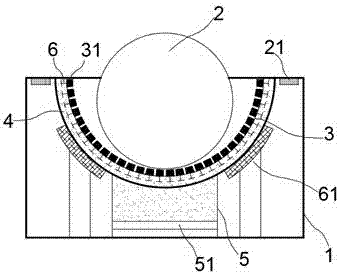

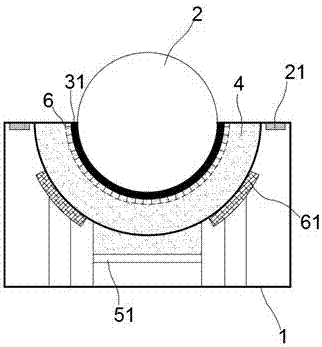

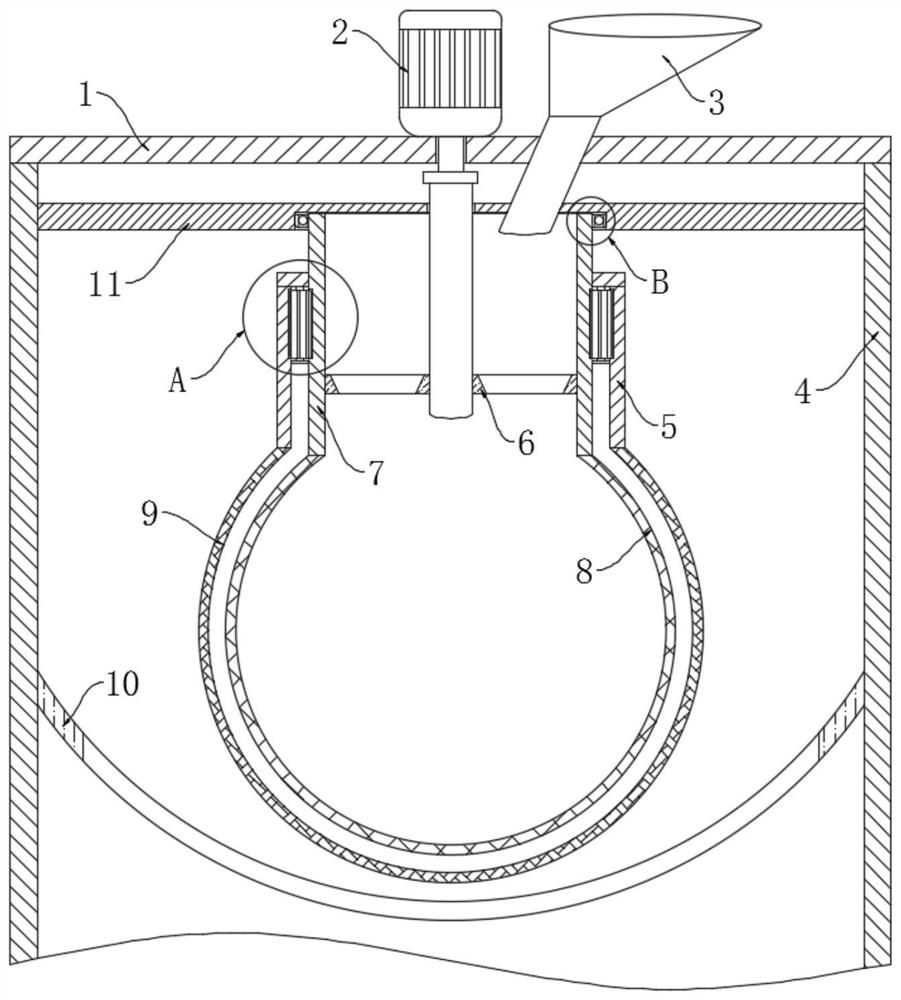

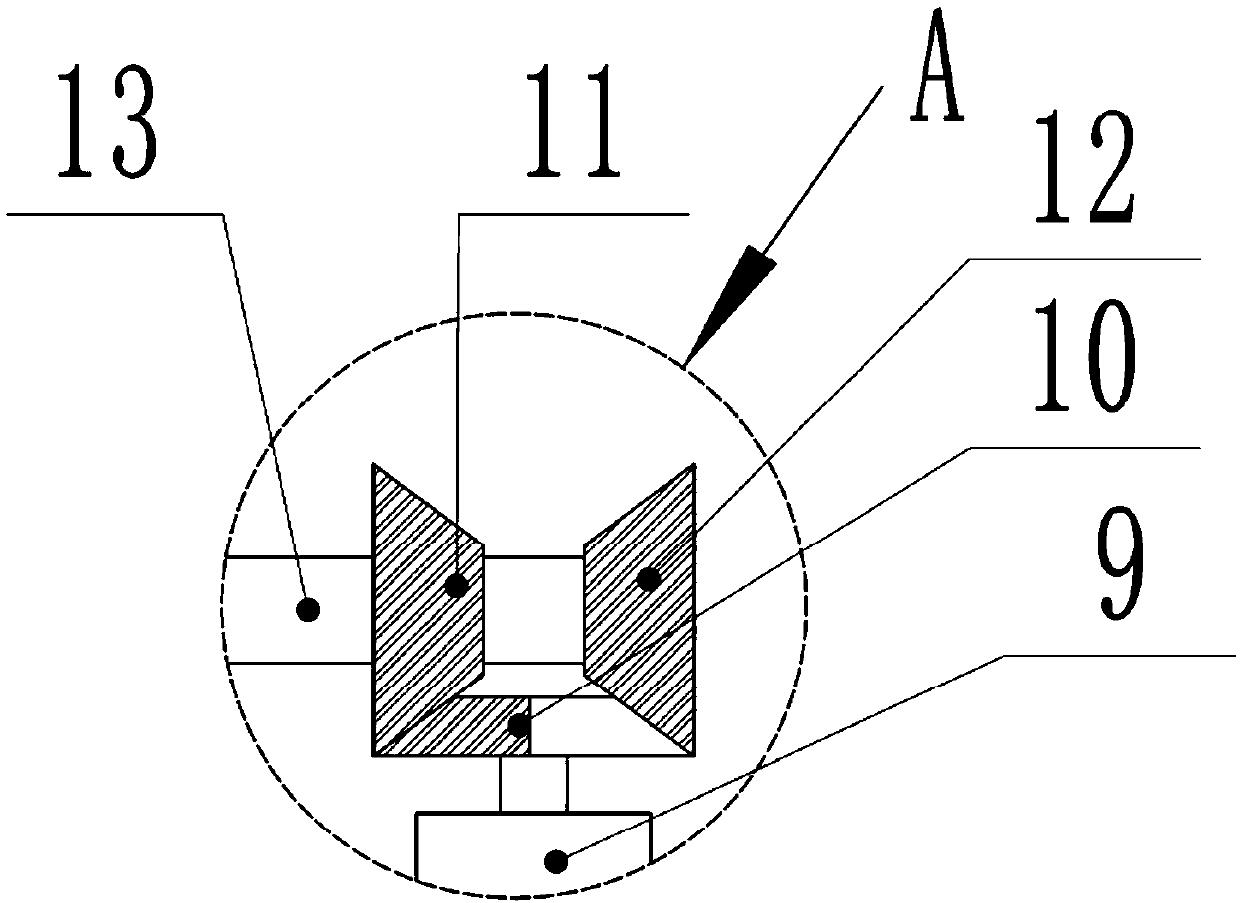

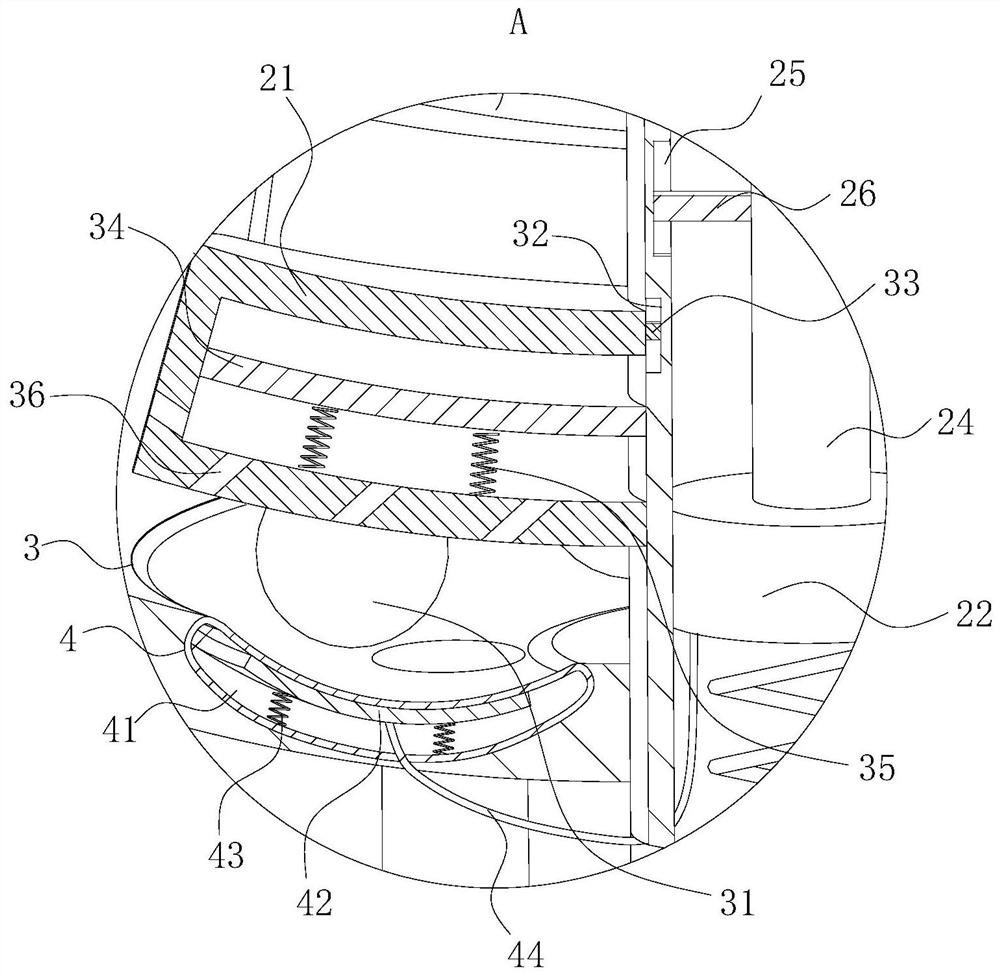

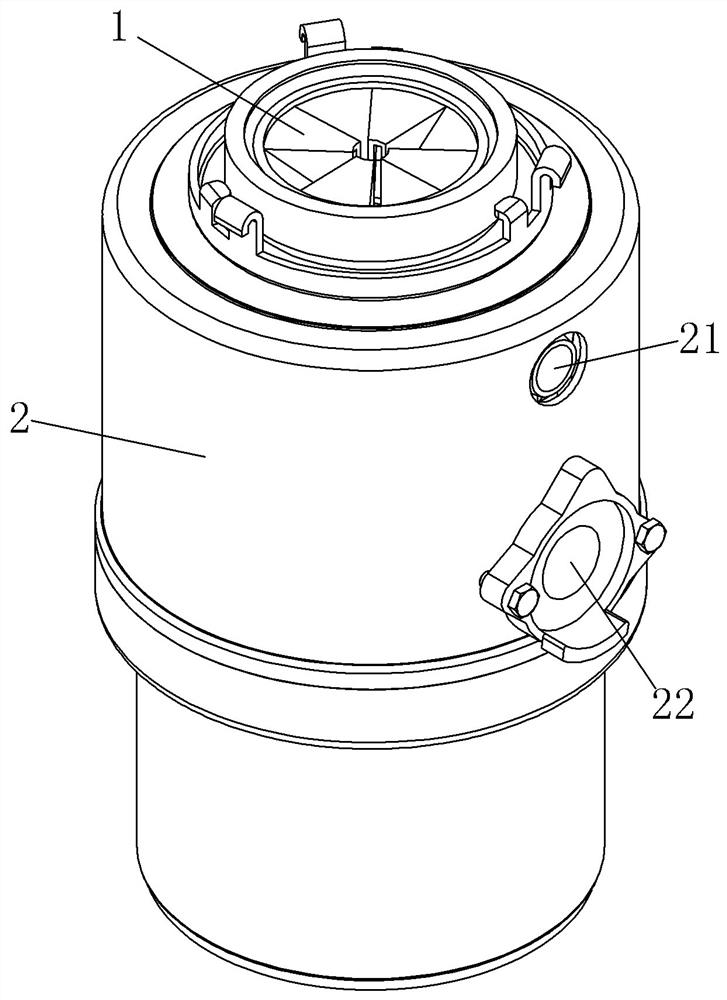

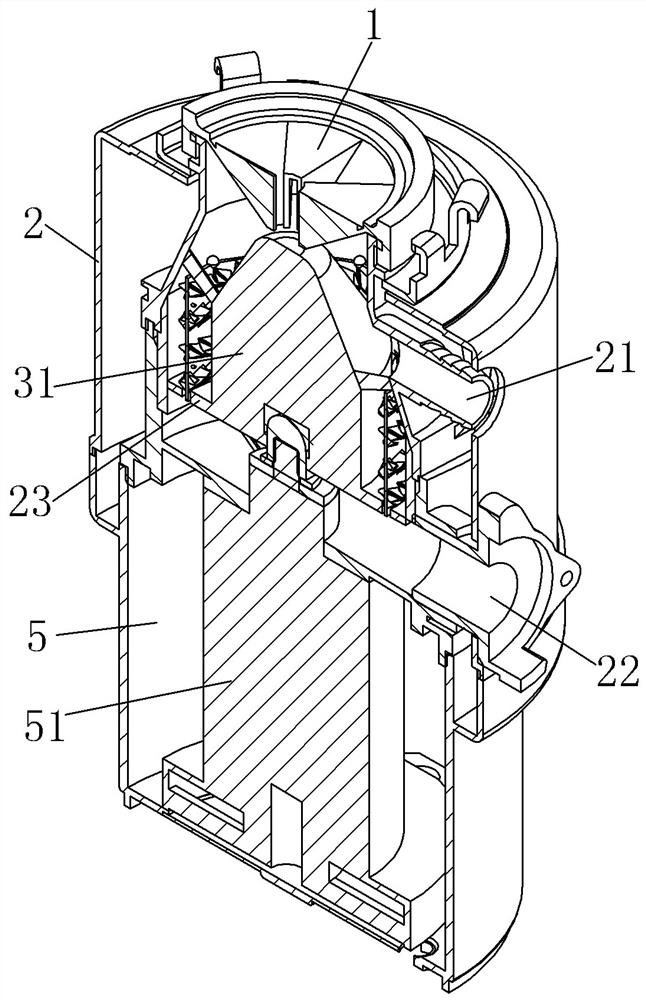

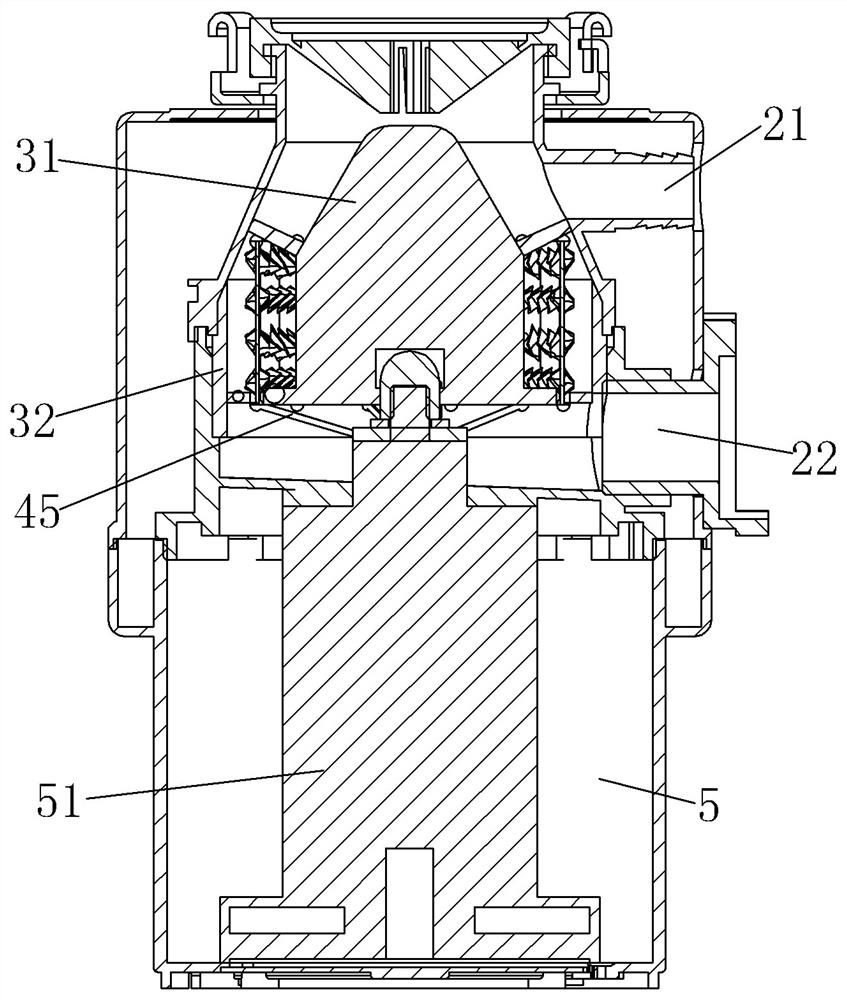

Spherical medical treatment grinding device

InactiveCN107138236AImprove grinding efficiencyIncrease grinding powerGrain treatmentsPolymer chemistryMedical treatment

The invention relates to a spherical medical treatment grinding device. The spherical medical treatment grinding device comprises a grinding body and a grinding ball; a grinding groove sinking inwards is formed in the grinding body, an elastic layer is arranged on the grinding groove, an airtight liquid storage cavity is defined by the elastic layer and the grinding groove, and the liquid storage cavity is filled with adjusting liquid; an adjusting cavity is further arranged on the grinding body, the adjusting cavity and the liquid storage cavity are in airtight communication, and a controller is arranged on the adjusting cavity; grinding sheets arranged in an arrayed manner at equal intervals are arranged on the outer surface of the elastic layer, the cross section of the grinding sheets are in sector shape, and the grinding sheets can be spliced into half chapping spherical surfaces with coincident radius of curvature; and the radius of curvature of the chapping spherical surfaces is matched with the radius of curvature of the grinding ball. By means of the spherical medical treatment grinding device, the grinding speed and grinding effect can be effectively improved, medicine particle outburst is effectively prevented, the grinding safety degree is improved, and medicine waste is prevented.

Owner:嘉兴嘉湖骨科医院管理有限公司

Grinding device for wormwood extraction

The invention discloses a grinding device for wormwood extraction. The grinding device comprises a grinding box, a first connecting block, a second connecting block and a third connecting block are arranged at the edge of the grinding box, and the lower end of the first connecting block, the lower end of the second connecting block and the lower end of the third connecting block are each providedwith a bracket; a first rotation shaft is arranged at the upper end of the first connecting block in a penetrating mode, a first connecting rod is arranged at the upper end of the first rotation shaft, a motor is arranged at the lower end of the first rotation shaft and located at the lower end of the first connecting block, an output shaft of the motor is connected with the first rotation shaft,and the end, far away from the first rotation shaft, of the first connecting rod is movably connected with one end of a first movable rod; a second rotation shaft is arranged at the upper end of the second connecting block in a penetrating mode, a second connecting rod is arranged at the upper end of the second rotation shaft, and the end, far away from the second rotation shaft, of the second connecting rod is movably connected with one end of a second movable rod; and a third rotation shaft is arranged at the upper end of the third connecting block, and a third connecting rod is arranged atthe upper end of the third rotation shaft. The grinding device for wormwood extraction has the beneficial effects that a grinding block is adjusted downwards, therefore, the wormwood grinding intensity is improved, and grinding can be fuller.

Owner:安徽清山艾草制品有限公司

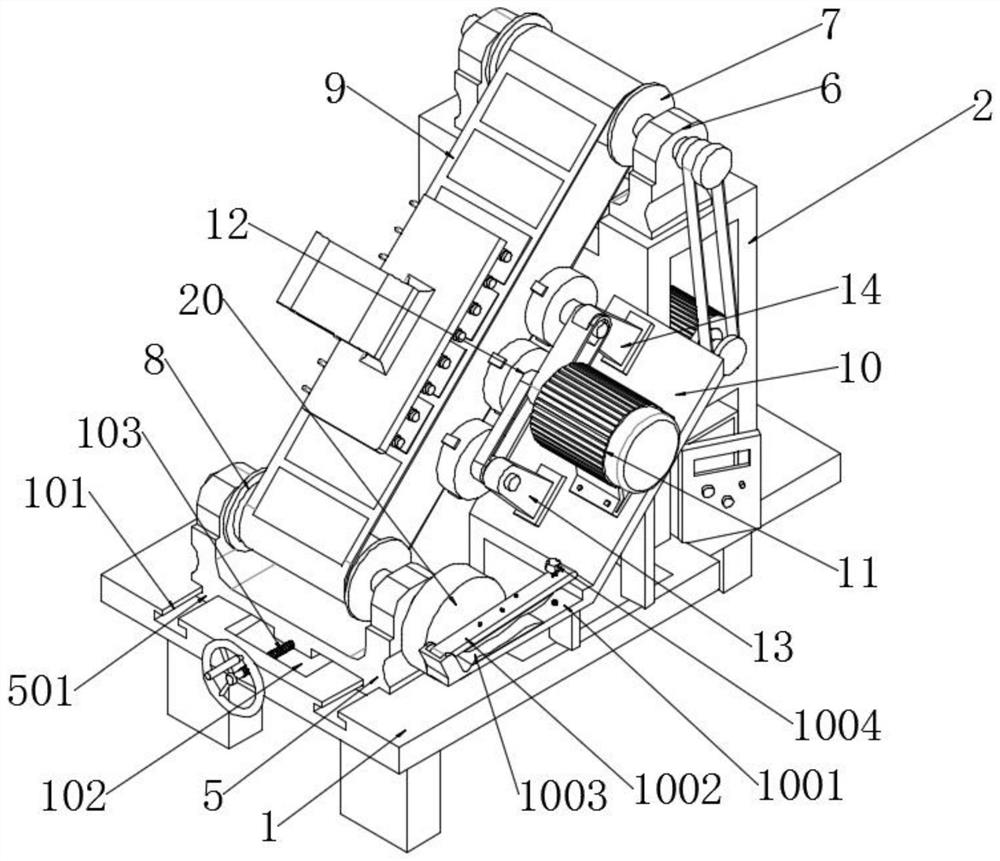

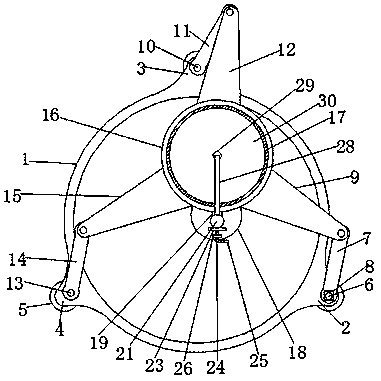

Automatic control type grinding integrated device based on shaft side machining

ActiveCN109968134AEasy to adjustImprove functionalityEdge grinding machinesGrinding drivesStanding frameAutomatic control

The invention provides an automatic control type grinding integrated device based on shaft side machining. The automatic control type grinding integrated device comprises a pressing arm, a pressing plate, a rotating shaft, a rotating sleeve and a grinding disc. A bottom frame is used for bottom supporting of the integrated device, a right stand frame is welded to the right side of the top face ofthe bottom frame, a first motor is mounted in a top cavity of a frame body structure of the right stand frame, a first rotating seat and a second rotating seat are further mounted on the top face of the bottom frame and the top face of the right stand frame separately, and the second rotating seat is in belt-transmission connection with the first motor at the bottom through a belt wheel on one side; and a first connecting wheel and a second connecting wheel fixedly sleeve the first rotating seat and the second rotating seat through splines. The integrated device is pressed to the outer circleof a to-be-grinded shaft type part, so that grinding force is increased; a circular grinding disc is arranged on the front left side, the grinding disc synchronously rotates with a first rotating seatshaft and can right grind the outer end of the shaft type part, and thus functionality is further improved and the comprehensive structure design is reasonable.

Owner:杭州龙砺智能科技有限公司

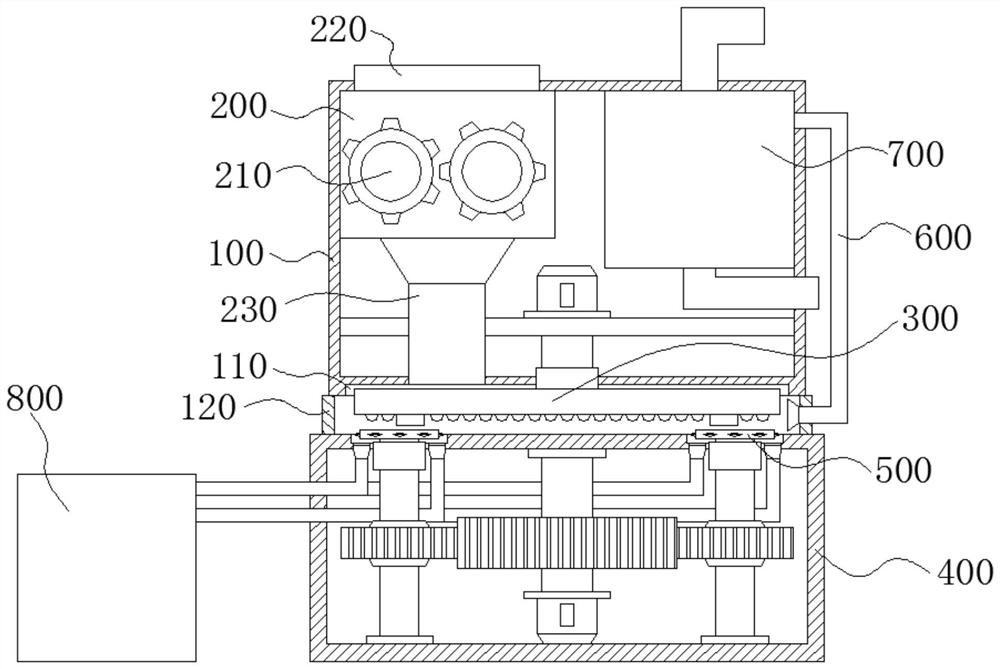

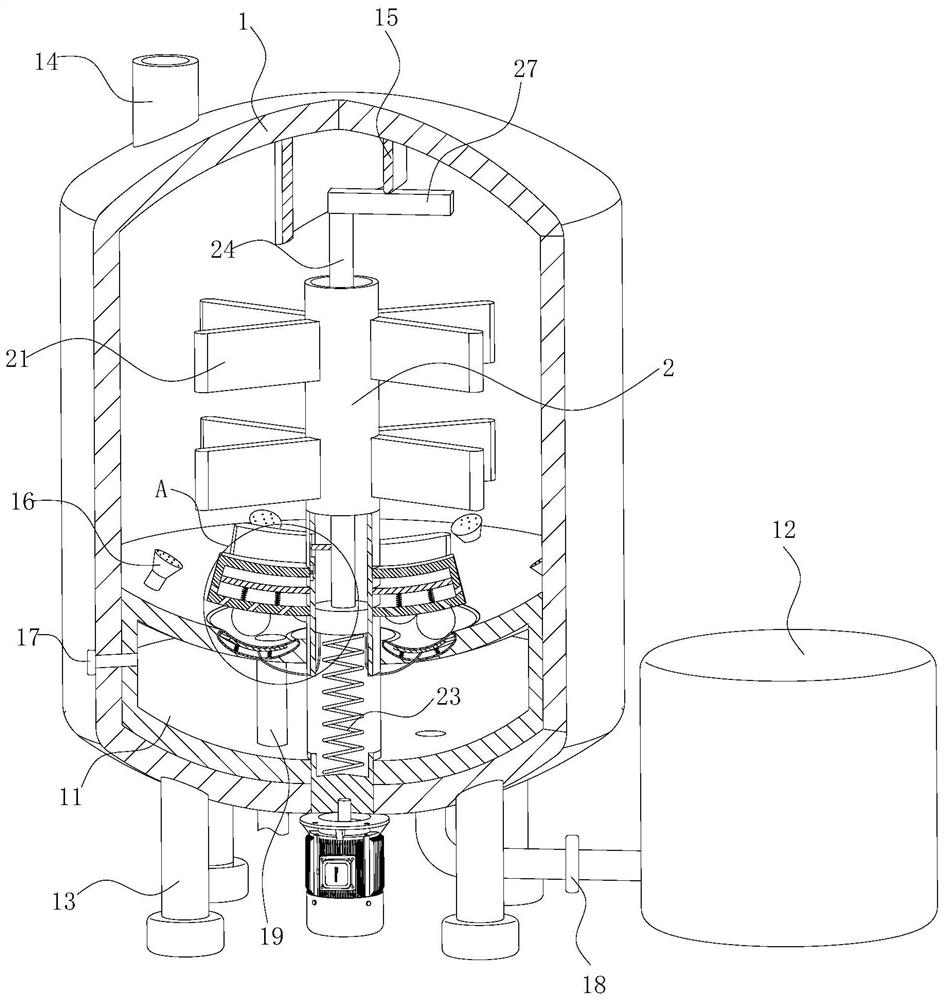

A slurry device for preparing bio-organic water fertilizer and its preparation method

ActiveCN111773819BImprove crushing efficiencyAct as a secondary filterClimate change adaptationGrain treatmentsGear wheelCoupling

The invention discloses a slurry device for preparing bio-organic water and fertilizer and a preparation method thereof, which comprises a casing and a cover plate fixed above the casing, and a first connecting cylinder and a second connecting cylinder are arranged coaxially inside the casing. barrel, and the inner diameter of the first connecting barrel is larger than the outer diameter of the second connecting barrel, and tooth grooves are opened on the inner side wall of the first connecting barrel and the outer side wall of the second connecting barrel, and between the two tooth grooves A plurality of reversing gears are meshed together, the lower ends of the first connecting cylinder and the second connecting cylinder are respectively fixedly connected with an outer crushing layer and an inner crushing layer, and a drive motor is fixedly installed on the cover plate, and the drive motor The output shaft passes through the cover plate and is fixedly connected with a vertical shaft through a coupling, and a circular hollow plate is interference-fitted on the vertical shaft. When processing the slurry, the present invention can subject the solid block to multiple grinding actions, so that the solid block can be crushed more thoroughly, and the obtained slurry has less precipitation, thereby greatly improving the quality of water and fertilizer.

Owner:WUHAN NATURES JOY PLANT NUTRI TECH

A kind of preparation method of lost foam casting coating

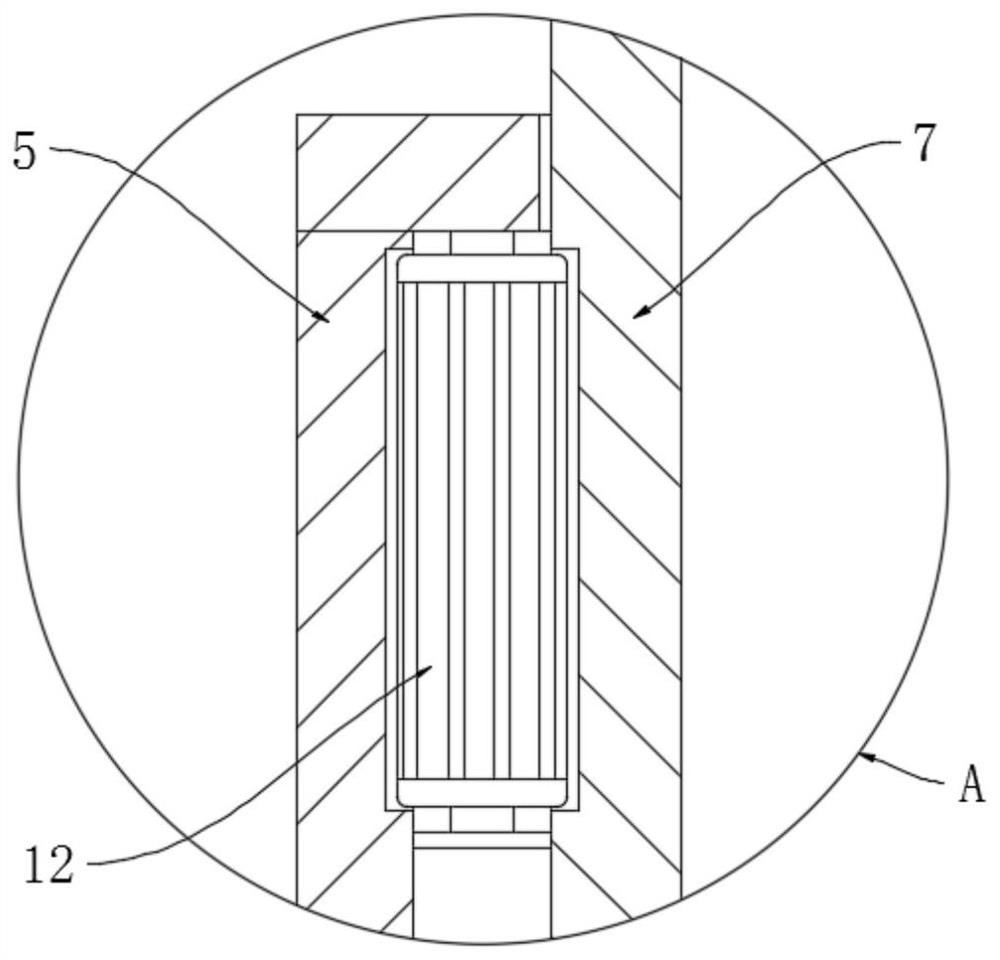

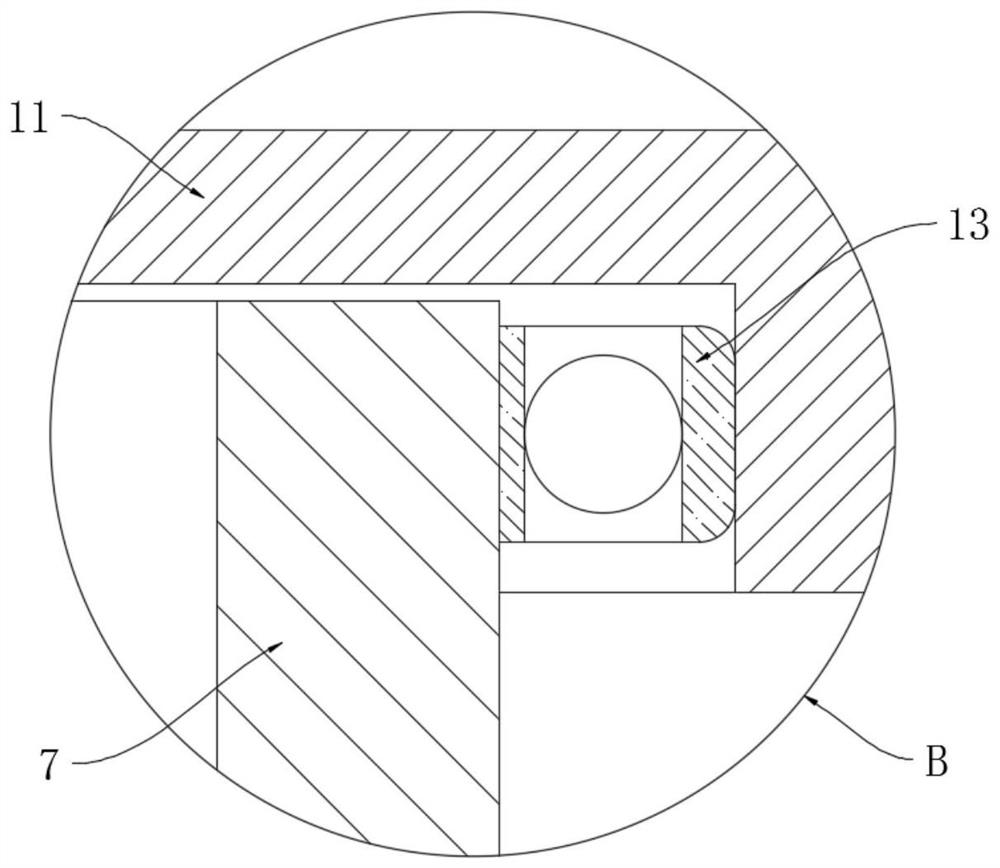

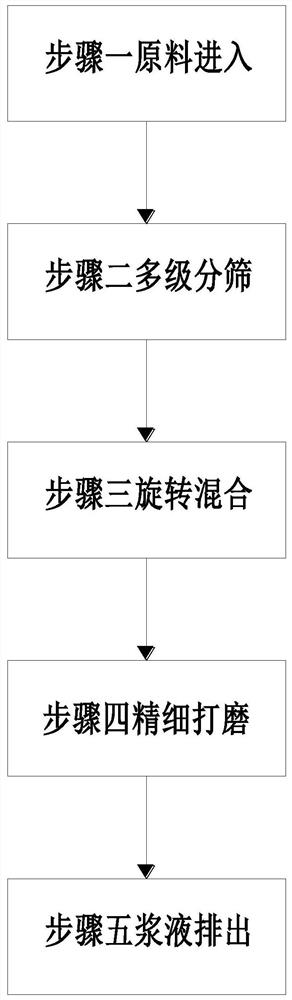

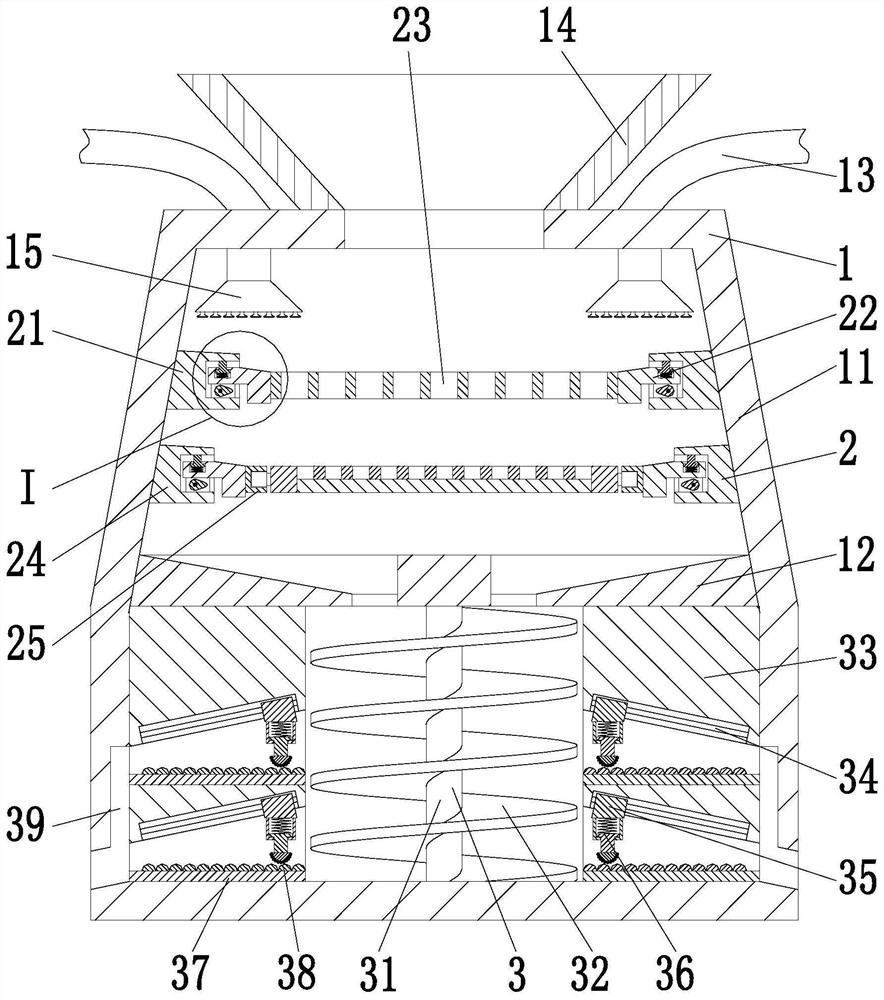

ActiveCN111185570BAdjust Gap SizeImprove screening efficiencyFoundry mouldsFoundry coresLost-foam castingMaterials science

The present invention relates to a preparation method of lost foam casting paint, the preparation method of lost foam casting paint adopts the following paint processing equipment, the paint processing equipment includes a support spray device, a multi-stage vibrating screen device and a rotary grinding device; the described The supporting spraying device has a hollow structure, a multi-stage vibrating screen device is installed on the upper side of the supporting spraying device, and a rotary grinding device is installed on the lower side of the supporting spraying device. The invention can solve the problem that the existing equipment only performs one screening process when preparing the lost foam casting coating, the screening efficiency is low, and the size of the screen holes is fixed, which cannot meet the requirements for different screening particle sizes, and the existing When the equipment is used to prepare the coating for lost foam casting, it uses one-time grinding treatment, and the grinding fineness is not high, which leads to problems such as the decline in the quality of subsequent coatings.

Owner:徐州卓越新材料科技有限公司

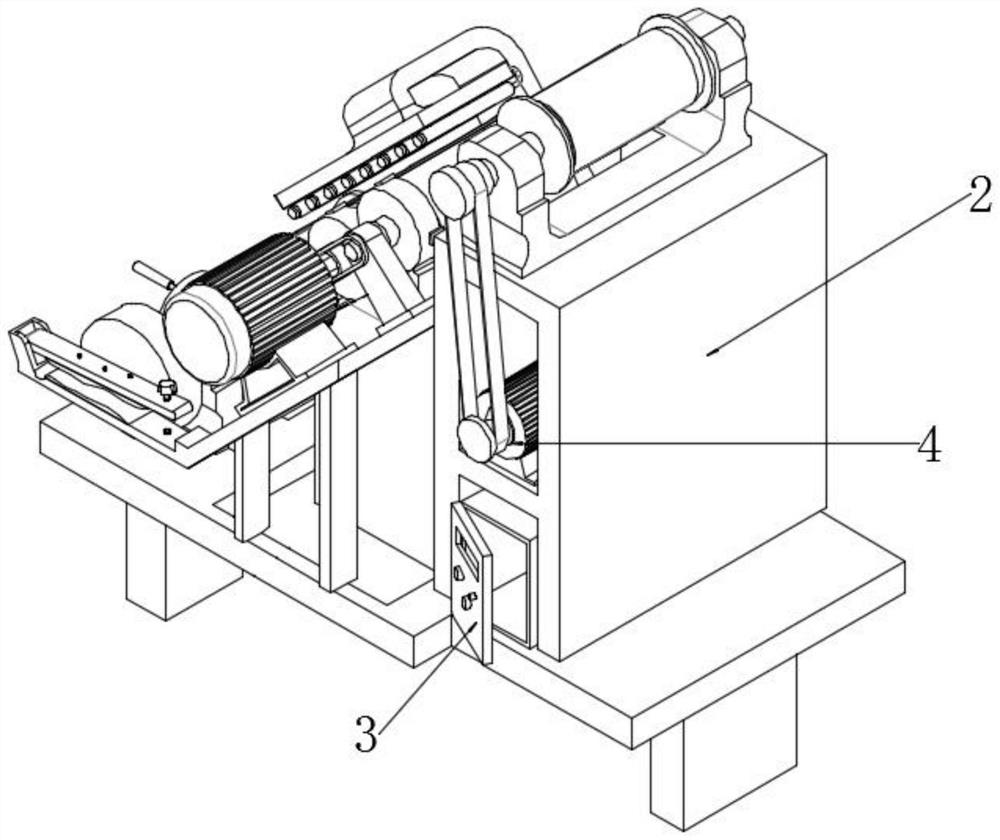

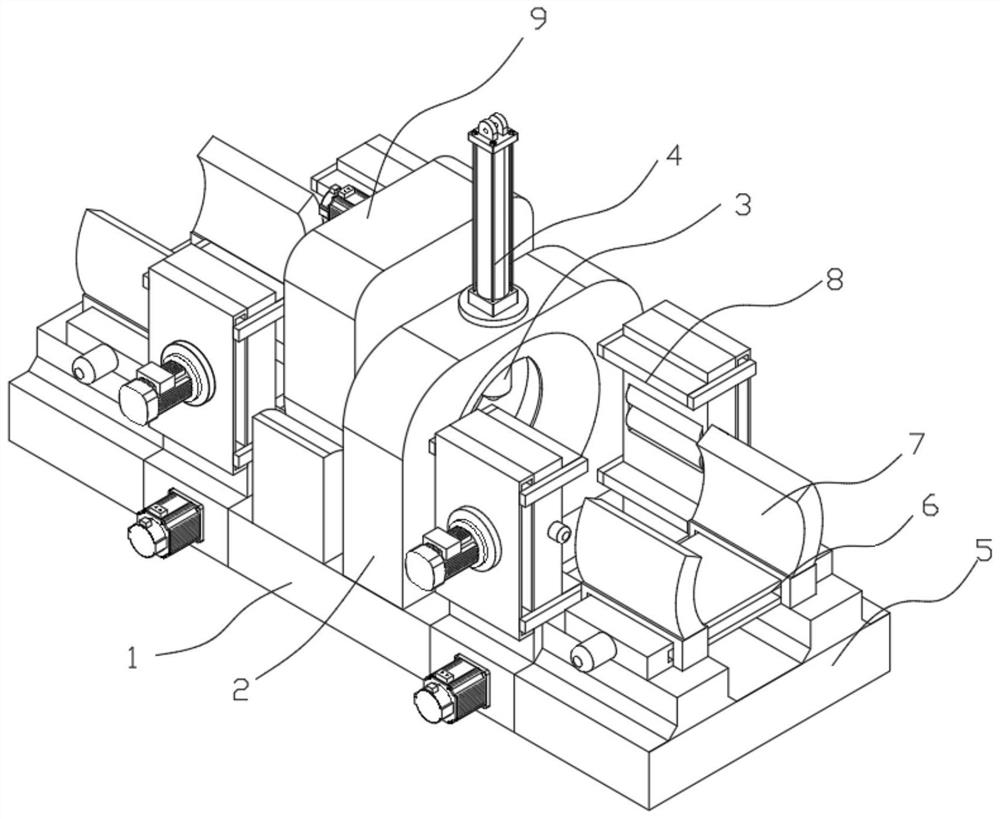

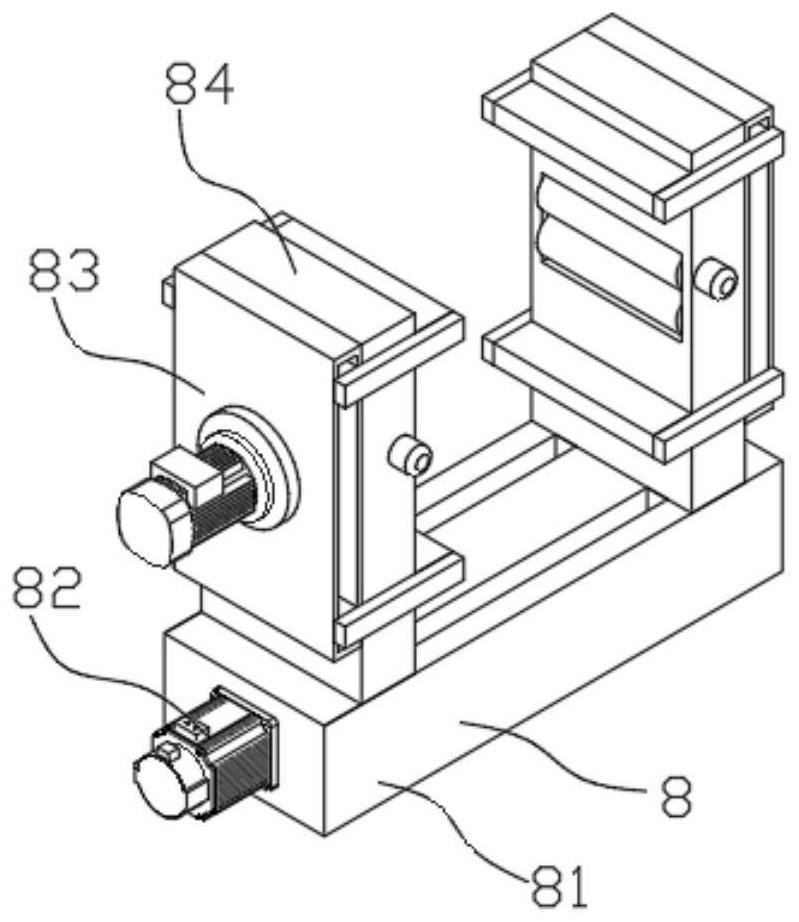

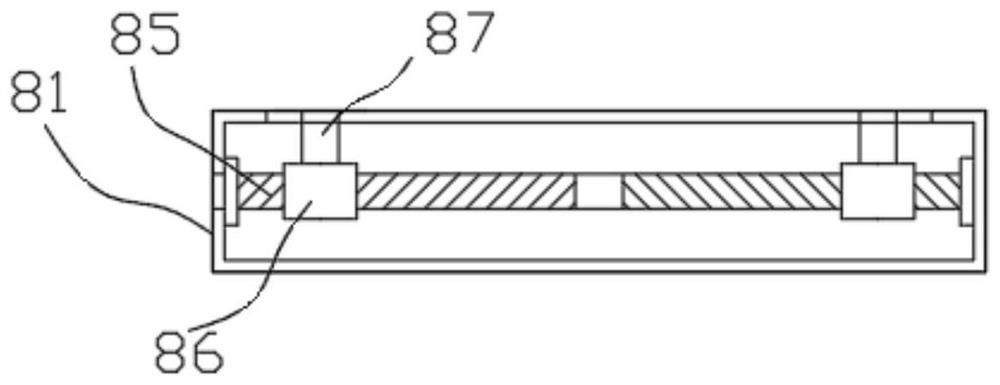

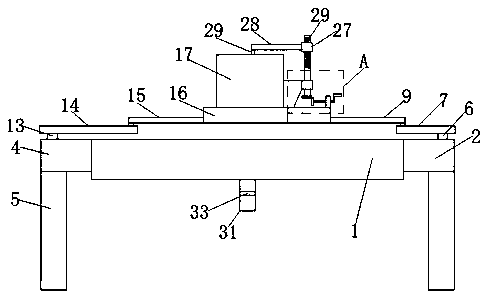

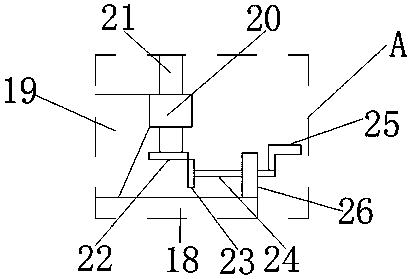

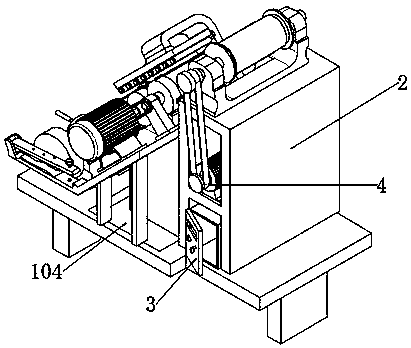

Dual-driving grinding machine

InactiveCN108422300AIncrease grinding powerConvenient grinding operationGrinding carriagesGrinding drivesEngineeringSlide plate

The invention discloses a dual-driving grinding machine. The dual-driving grinding machine comprises a workbench, a sliding hole is formed in the workbench, a sliding plate is slidably installed in the sliding hole, a first plate is slidably installed on the top of the workbench, a first motor is fixedly installed on the top of the first plate, a first grinding head is fixedly installed on an output shaft of the first motor, a first groove is formed in the top of the sliding plate, a second groove is formed in the inner wall of the bottom of the first groove, a rotating groove is formed in theinner wall of the bottom of the second groove, the inner walls of the two sides of the rotating groove are each provided with a through hole, a same lead screw is arranged in the two through holes, the two ends of the lead screw are welded to the inner walls of the two sides of the sliding hole, and a rotating disc is installed on the lead screw in a threaded mode and rotatably installed in the rotating groove. According to the dual-driving grinding machine, the practical performance is high, the structure is simple, operation is convenient, the grinding power between the first grinding headand the second grinding head can be conveniently increased, the position of the sliding plate can be conveniently fixed, grinding operation can be conveniently conducted on a ground part, and use is convenient for people.

Owner:罗厚镇

A method for treating iron scale on the surface of hot-rolled castings

ActiveCN111360666BResidue reductionEasy to cleanGrinding carriagesGrinding drivesSurface cleaningElectric machine

The invention relates to a hot-rolled casting surface oxide scale treatment method. The method uses surface cleaning equipment. The surface cleaning equipment comprises a bottom plate, a workbench, amounting rack and a cleaning mechanism; the specific method flow for cleaning the oxide scale on the hot-rolled casting surface by adopting the surface cleaning equipment comprises the following stepsof equipment regulation, material loading, preliminary cleaning, secondary cleaning and blanking; the cleaning mechanism comprises a limiting seat, a connector, a lifting cylinder, a cleaning branchchain, and an adjusting branch chain; the cleaning branch chain comprises a cleaning plate, a cleaning block, a butt-joint pole, a movable plate, a butt-joint cylinder, a rotating cam, a connecting sliding block and a rotating motor. By adopting a multi-statin design mode, a plurality of casting surface can be cleaned at the same time, the polishing degree can be adjusted as actual working requirement during the cleaning process, thereby improving the cleaning effect, and reducing the residue of the oxide scale on the recasting surface.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

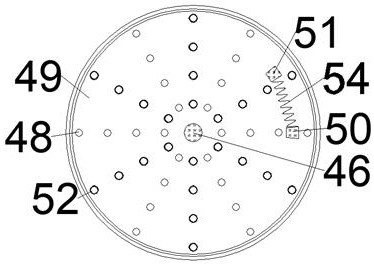

A high-efficiency grinding device for tablets used in the preparation of capsule western medicines

The invention discloses a tablet efficient grinding device for capsule type Western medicine preparation. The tablet efficient grinding device comprises a grinding box, a grinding groove, a drive motor, a grinding motor, magnets, electromagnets, a grinding rotary disc, a preliminary screening plate, a fine screen and a second guide plate. The grinding box is arranged on a base. The multiple sets of magnets are mounted on the lower side of a motor rack. The electromagnets are further arranged on the upper side of the grinding box. The grinding rotary disc is fixedly mounted at the lower end ofa grinding shaft. The fine screen is further obliquely mounted in the grinding box. The second guide plate is hinged to the bottom of the grinding box. In the grinding box, the grinding rotary disc isintermittently driven to move downwards to extrude tablets, and therefore the grinding force is increased, and tablet grinding is more sufficient; and during discharging, the oblique angle of the second guide plate is changed, the function of vibration is achieved, and powder blocking during discharging is effectively avoided.

Owner:浙江东日药业有限公司

Efficient activated carbon dust-free grinding device

InactiveCN113578445AIncrease contact areaImprove purification efficiencyHuman health protectionCombination devicesActivated carbonAir filter

The invention relates to the technical field of activated carbon production, in particular to an efficient activated carbon dust-free grinding device. The device comprises a shell, an upper grinding unit, a lower grinding unit and a purification unit, wherein the edge of the bottom of the shell is sleeved with a dustproof ring; the upper grinding unit is located in the dustproof ring, and the lower grinding unit is mounted at the bottom of the dustproof ring; the shell of the lower grinding unit, the dustproof ring and the shell can form a closed grinding cavity; one side wall of the grinding cavity communicates with an air outlet pipe; the purification unit comprises a purification box and a gas filtering plate; the purification box is mounted in the shell, and the other end of the air outlet pipe is communicated with an inner cavity of the purifying box; and the air filtering plate is mounted in the purifying box and is higher than the air outlet pipe connector. According to the invention, environmental pollution can be reduced, dust-free operation is realized, and the grinding effect is improved.

Owner:深圳市厚朴文化传媒有限公司

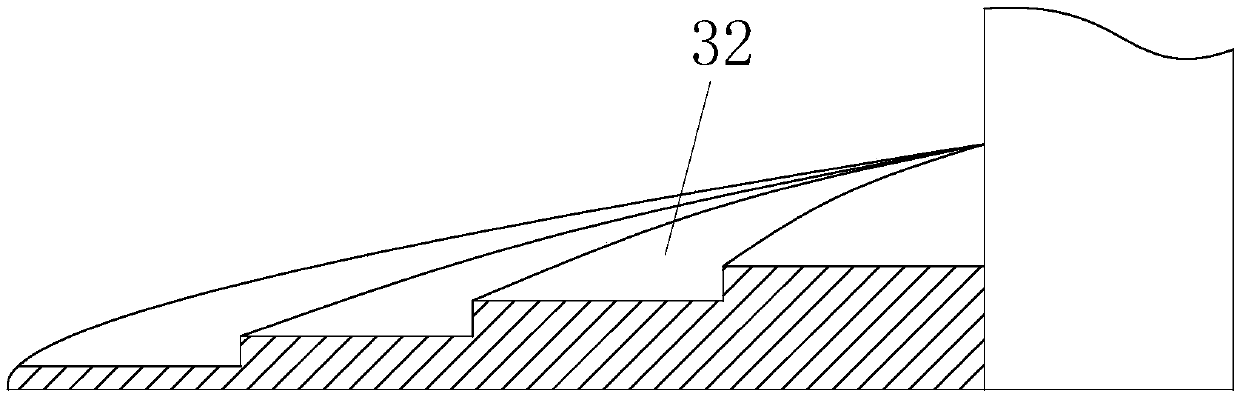

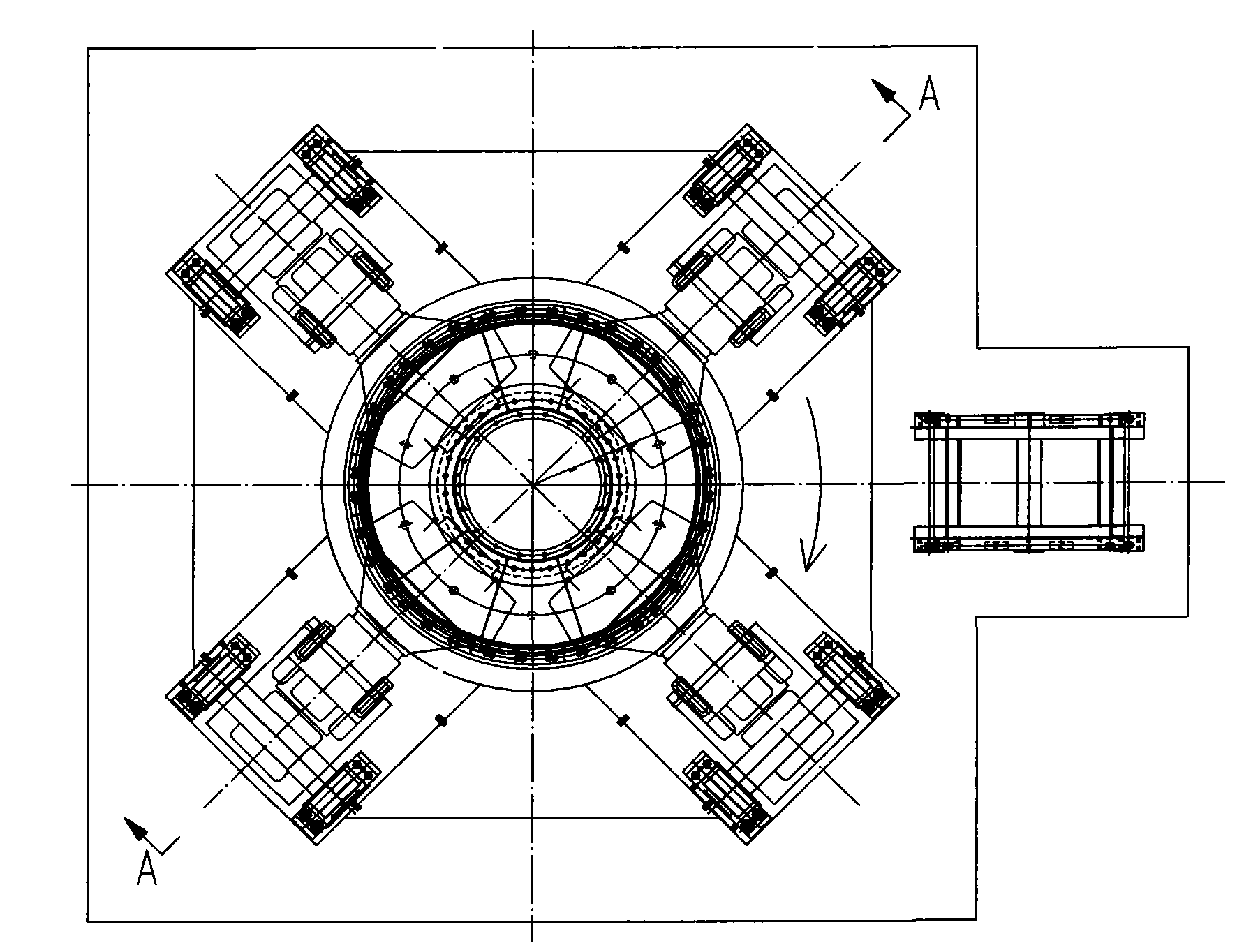

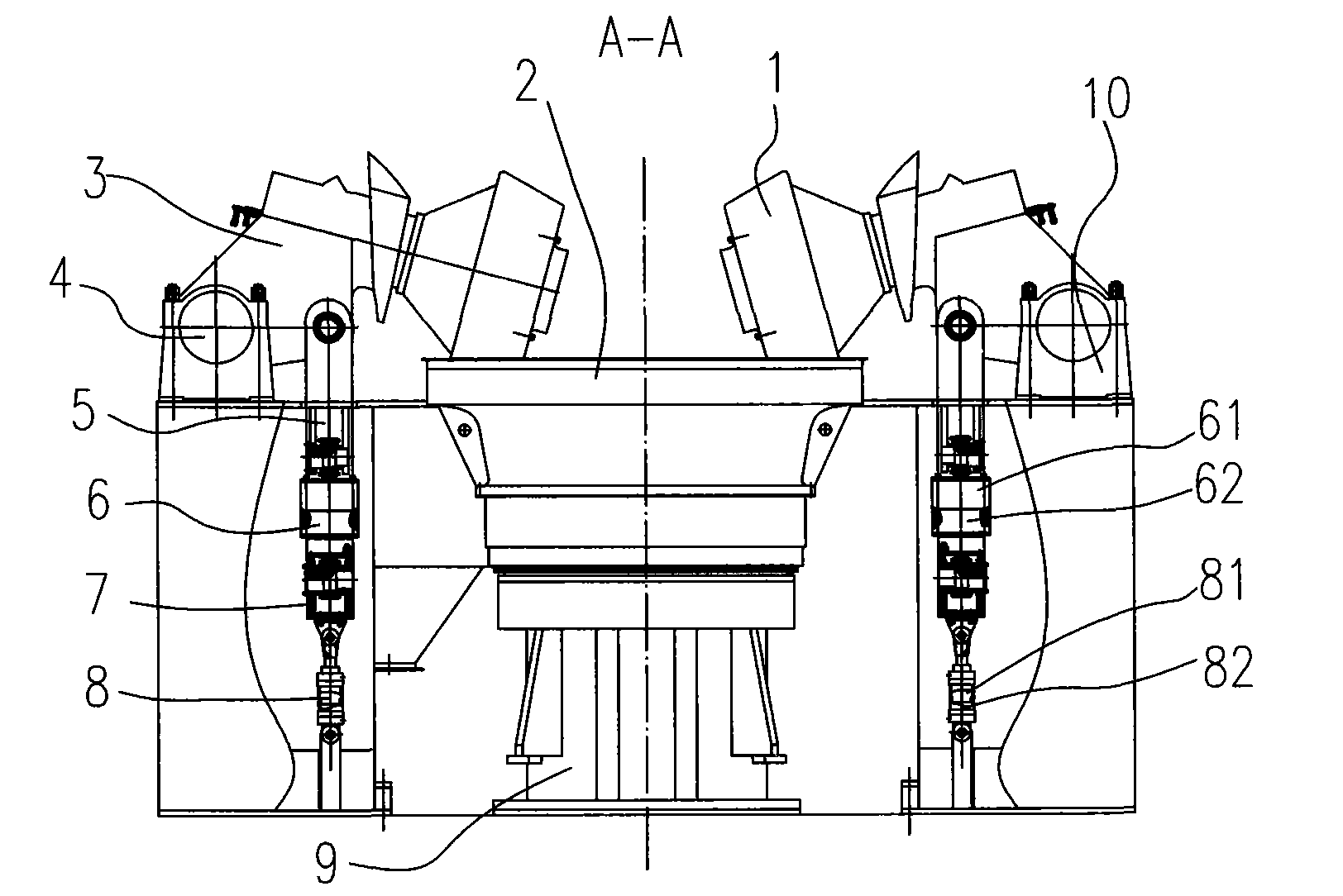

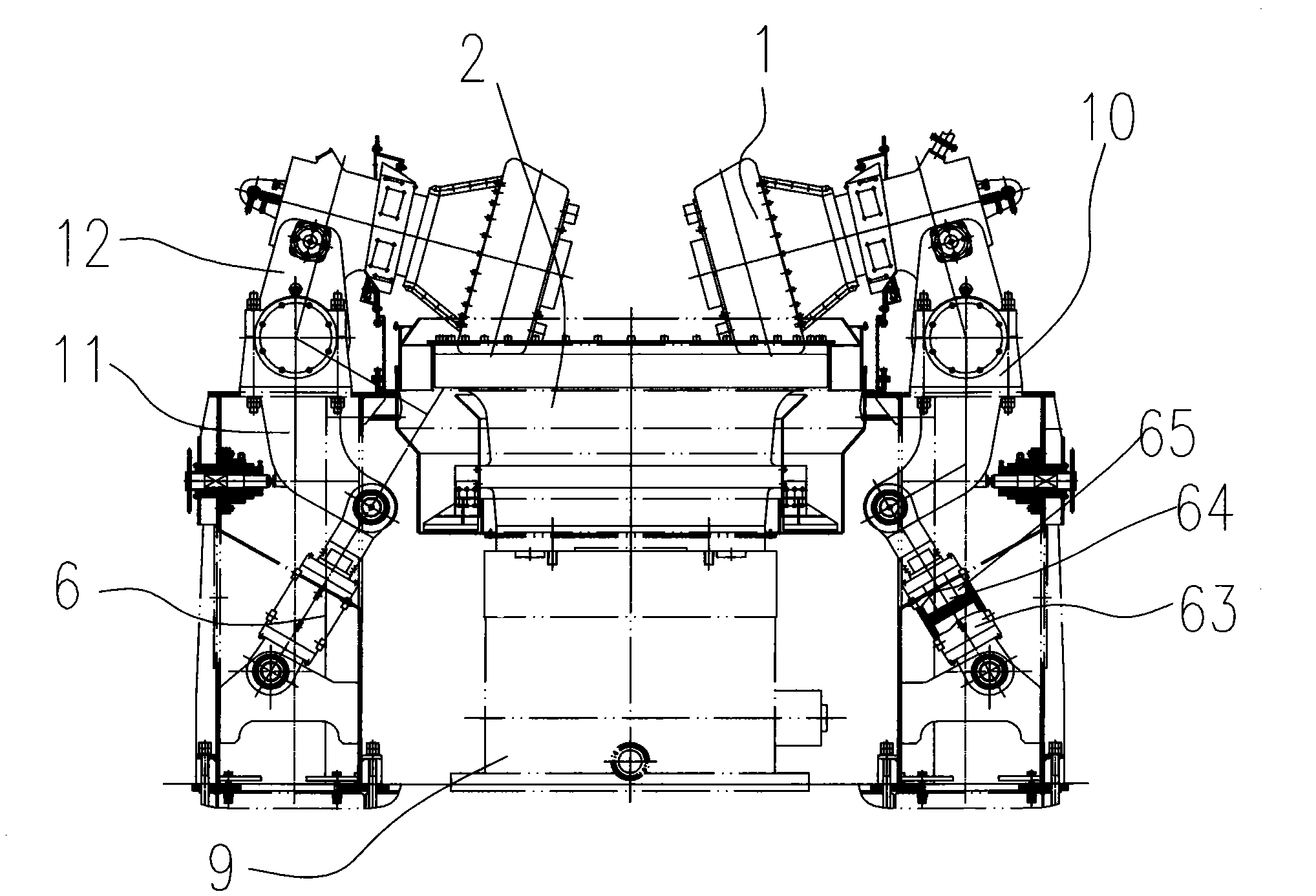

Hydraulic pressurization device of grinder roller of vertical grinding mill

The invention discloses a hydraulic pressurization device of a grinder roller of a vertical grinding mill, which relates to the improvement on the pressurization device of a grinder roller of a vertical grinding mill and has the advantages of high control precision, high energy conversion and utilization rate and lighter structure. The hydraulic pressurization device comprises a grinding head, a millstone and a double-feed hydraulic device; the grinder roller is in a circular truncated cone shape and movably connected to the front end face of the grinding head which is connected to a mill body through a rotation pin so as to ensure that the conical roller surface of the grinding roller is located above the millstone; the double-feed hydraulic device comprises a pressurization oil cylinder, a buffering oil cylinder, a bottom draw bar and a top draw bar, the pressurization oil cylinder and the buffering oil cylinder form a coaxial structure with the pressurization oil cylinder on the upper part and the buffering oil cylinder on the lower part through a connector, and the lower part of the buffering oil cylinder is connected onto the mill body through the bottom draw rod; the upper part of the pressurization oil cylinder is fixedly connected with the lower end of the top draw rod, and the upper end of the top draw rod is articulated with the bottom of the middle section of the grinding head; and the bottom of the rear section of the grinding head is connected onto the mill body through the rotation pin. Under the same pressure, the diameter of a hydraulic cylinder is decreased, or under the same diameter, the pressure is reduced.

Owner:JIANGSU HENGYUAN INT ENG CO LTD

A catalyst grinding and drying process

ActiveCN109569829BAvoid damageImprove refinement efficiencySievingGranular material dryingPtru catalystEngineering

The invention belongs to the technical field of catalyst preparation, and specifically relates to a catalyst grinding and drying process. The process includes the following steps: putting raw materials into a hopper of a catalyst preparation system, and entering the agitation module through the funnel to start the grinding and drying process of the catalyst; There is a spiral feeding plate inside the funnel, the lower end of the spiral feeding plate is connected with a spring, the spring extends to the box and contacts the shaking plate, the distance between the springs is greater than the thickness of the shaking plate; the shaking plate is a heating plate, and the upper end of the spiral plate shaft The positive and negative electrodes are respectively connected to the lower end of the box; the lower end of the box is equipped with a No. 3 cylinder, and the tail of the No. 3 cylinder is connected to the tail of the No. 2 cylinder in the catalyst preparation system through a gas pipe. The central axis of the No. 1 cylinder is on the same horizontal line; the present invention contacts the jitter plate through the spring, and increases the jitter amplitude and frequency of the jitter plate during the rotation of the spring, thereby improving the refinement efficiency of the catalyst raw material.

Owner:江苏上阳金属新材料有限公司

Modified organic silicon coating preparation equipment

InactiveCN113230991AReduce energy consumptionReduce manufacturing costChemical/physical/physico-chemical nozzle-type rreactorsGrain treatmentsOrganosiliconMechanical engineering

The invention belongs to the technical field of coatings, and particularly relates to modified organic silicon coating preparation equipment. The equipment comprises a reaction kettle, a liquid inlet bin and a storage tank; a fixed cylinder is fixedly connected to the center of the inner wall of the top of the reaction kettle, a rotating shaft is rotatably connected to the center of the reaction kettle, and stirring rods which are uniformly arranged are fixedly connected to the outer surface of the rotating shaft; a piston plate is slidably connected into the rotating shaft in a sealed mode, a first spring is fixedly connected to the side face of one side of the piston plate and the inner wall of the rotating shaft, a connecting rod is fixedly connected to the side face of the other side of the piston plate, and a horizontally-placed rotating rod is fixedly connected to the upper end of the connecting rod; a liquid inlet bin is arranged on the inner wall of the bottom of the reaction kettle, and spraying heads are uniformly arranged on the upper surface of the liquid inlet bin. According to the invention, the automatic liquid feeding and spraying of the liquid feeding bin can be achieved, energy consumption is reduced, and the production cost is reduced; meanwhile, the spraying head sprays liquid from different directions, so that the liquid in the reaction kettle is uniformly mixed, the liquid on the upper surface of the liquid inlet bin is impacted to accelerate liquid flowing, and materials are prevented from being deposited and attached to the inner wall of the reaction device.

Owner:付豪

Crushing and recycling equipment for optical cable waste

ActiveCN113427674ACrushing works smoothly and efficientlyImprove nesting efficiencyPlastic recyclingMechanical material recoveryFiberStructural engineering

The invention relates to the technical field of optical cable recycling, in particular to crushing and recycling equipment for optical cable waste. The crushing and recycling equipment for the optical cable waste comprises a shell, a plurality of grinding plates, a driving device and a plurality of grinding parts, wherein the grinding parts are rotatably arranged between two vertically adjacent material passing openings; each grinding part comprises two cutters which are located on the inner sides and outer sides of the grinding plates and can synchronously rotate; and each cutter is provided with structures such as a grinding face, a mounting face, a sharp edge end, a first transition face, a material gathering face, a blunt edge end and a material raising face. According to the crushing and recycling equipment for the optical cable waste, when the resistance borne by a first-stage grinding cavity or a second-stage grinding cavity is increased, the cutters deflect, the angles of the sharp edge ends and the blunt edge ends relative to the movement direction of the light-guide fiber are changed, so that the cutting strength of light-guide fibers is changed; and the positions of the material raising faces and the material gathering faces relative to the material passing openings are changed, the flow guide direction of the light-guide fibers is changed, and then the grinding force of the first-stage grinding cavity and the second-stage grinding cavity is automatically adjusted according to the change of the resistance of the grinding cavities, so that the stacking and jamming are avoided, and the grinding efficiency is improved.

Owner:南通安广美术图案设计有限公司

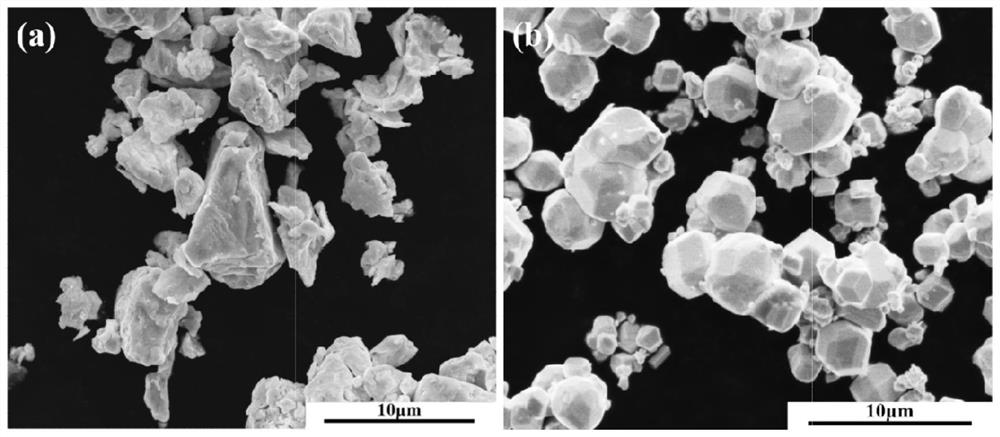

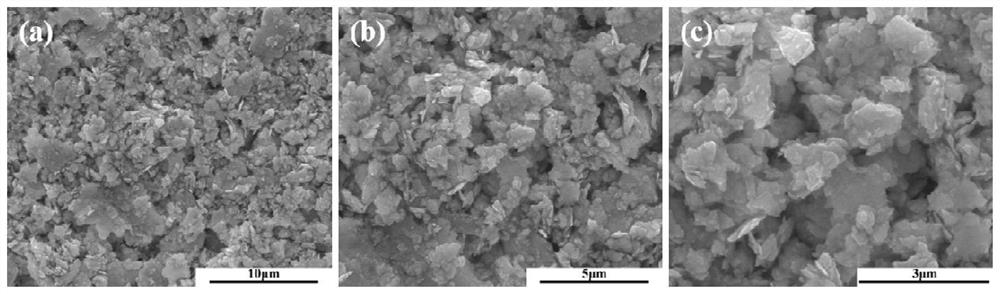

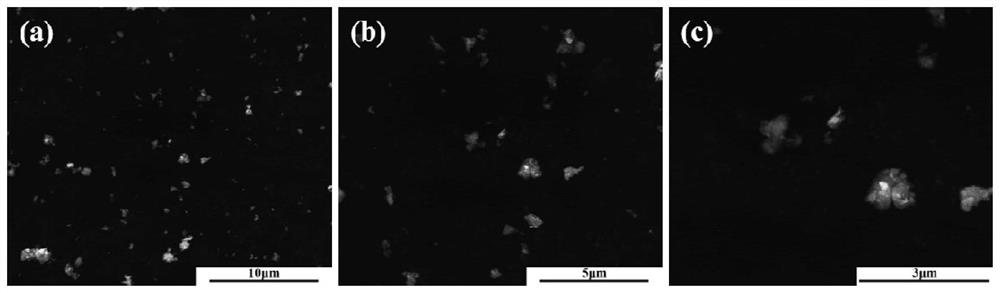

Tungsten-rhenium solid alloy powder with nanocrystalline structure as well as preparation method and application of tungsten-rhenium solid alloy powder

ActiveCN114769602AIncrease grinding powerGood dispersionTransportation and packagingMetal-working apparatusAlloyHigh activity

The invention discloses tungsten-rhenium solid alloy powder of a nanocrystalline structure and a preparation method and application of the tungsten-rhenium solid alloy powder. Tungsten powder and rhenium powder are subjected to ball milling under the protective atmosphere to obtain alloy powder, the alloy powder is subjected to ultrasonic dispersion and drying under the protective atmosphere to obtain dispersed alloy powder, then the dispersed alloy powder is subjected to heat treatment under the reducing atmosphere, and the tungsten-rhenium solid alloy powder is obtained. In the ball milling process, clockwise rotation ball milling and anticlockwise rotation ball milling are alternately carried out, the duration time of any clockwise rotation ball milling or anticlockwise rotation ball milling is 4-6 min, rotation is stopped for 1-2 min during alternation, and the total ball milling time is 50-70 h. The tungsten-rhenium solid alloy powder prepared through the method has the characteristics of low agglomeration degree and low oxygen content, meanwhile, the high activity of the tungsten-rhenium alloy powder prepared through the method is guaranteed through a large number of nanocrystalline structures, and the problems that the tungsten-rhenium alloy powder is low in activity and the like can be effectively solved.

Owner:CENT SOUTH UNIV

A crushing and recycling equipment for optical cable waste

ActiveCN113427674BCrushing works smoothly and efficientlyImprove nesting efficiencyPlastic recyclingMechanical material recoveryFiberStructural engineering

The invention relates to the technical field of optical cable recovery, in particular to equipment for crushing and recycling optical cable waste. It includes a shell, several grinding plates, a driving device and several grinding parts. The grinding part is rotatably arranged between the two upper and lower adjacent feed ports. Each grinding part includes two grinding parts located on both sides of the grinding plate. And the tool that can rotate synchronously has structures such as a grinding surface, a mounting surface, a sharp edge end, a first transition surface, a gathering surface, a blunt edge edge, and a lifting surface. In the present invention, when the resistance of the primary grinding cavity or the secondary grinding cavity increases, the tool deflects, and the angle between the sharp blade end and the blunt blade end relative to the moving direction of the optical fiber changes, so as to change the cutting force on the optical fiber and lift the material. The position of the surface and the aggregate surface relative to the material opening is changed to change the guiding direction of the optical fiber, so as to adjust the grinding force of the primary grinding chamber and the secondary grinding chamber according to the change of the resistance of the grinding chamber to avoid material stacking Jamming, improve grinding efficiency.

Owner:南通安广美术图案设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com