Water conservancy construction pipeline outer surface rust removal device and using method thereof

An external surface and pipeline technology, which is applied in grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc., can solve the problems of poor grinding effect and difficult to fit the outer wall of the pipeline, so as to improve the grinding effect, improve the grinding efficiency, The effect of changing the grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

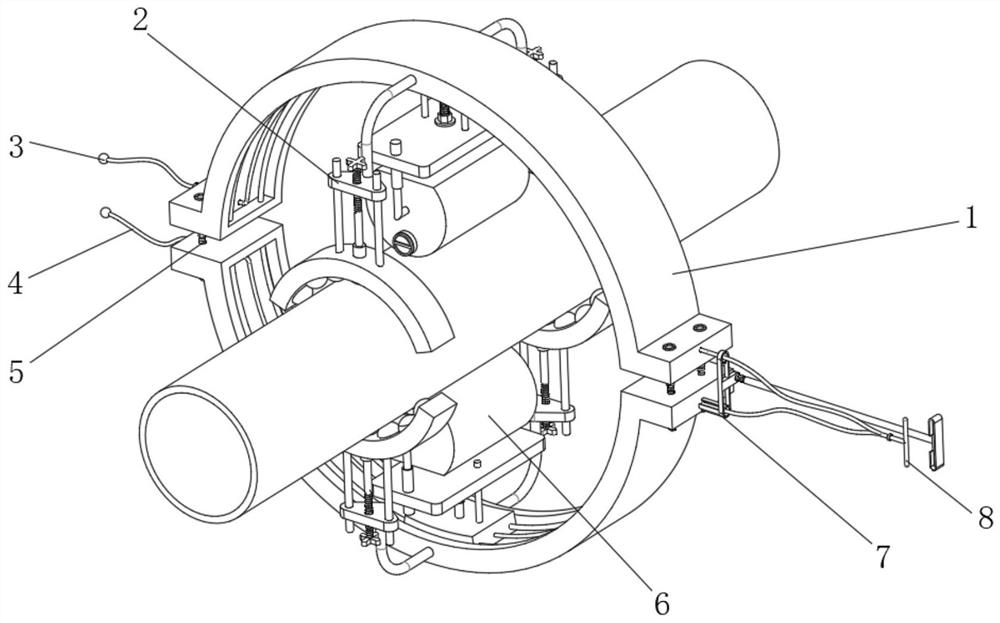

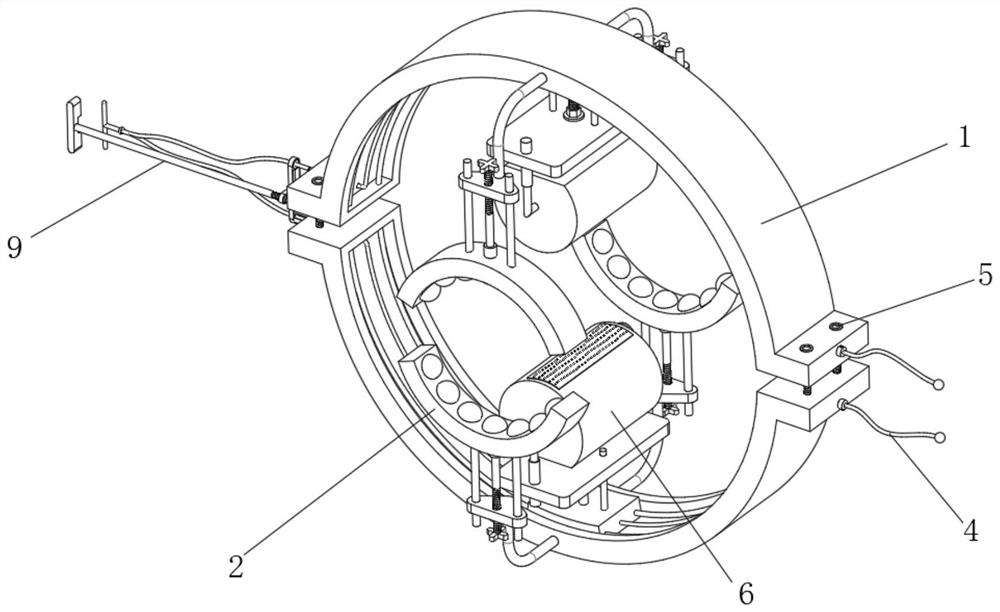

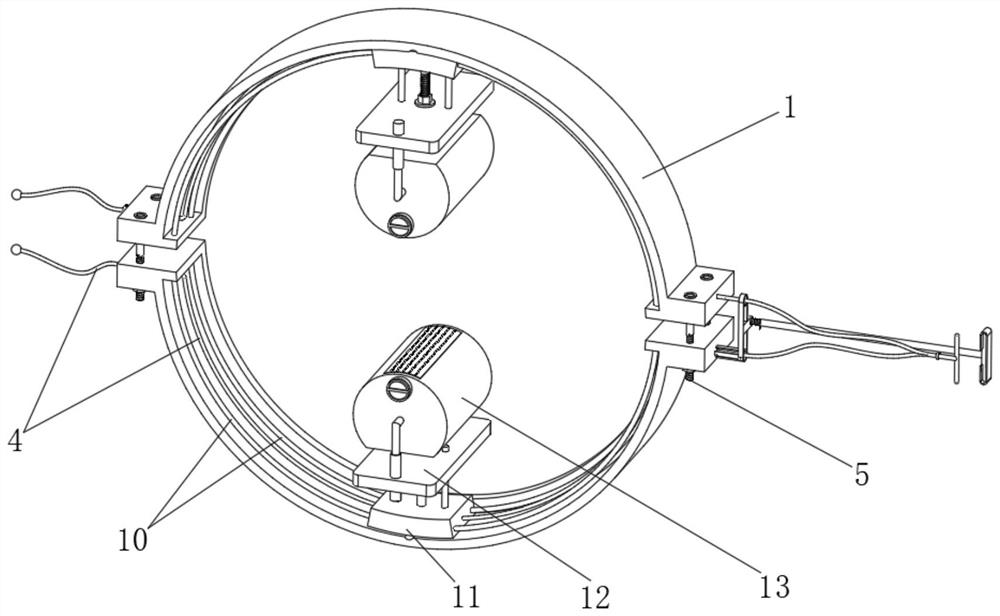

[0040] A kind of derusting device for the outer surface of water conservancy construction pipeline, such as Figure 1-7As shown, it includes two symmetrically arranged hoop-shaped mounting frames 1, and the two hoop-shaped mounting frames 1 are installed and fixed by connecting bolts 5. The two sides of the hoop-shaped mounting frame 1 are provided with support mechanisms 2, and the hoop-shaped mounting frames 1 are installed The inner side of frame 1 is provided with grinding mechanism 6, and described grinding mechanism 6 comprises cylindrical grinding piece 13 and slide seat 11, and cylindrical grinding piece 13 is installed on the side of slide base 11 away from hoop-shaped installation frame 1, and described hoop-shaped An arc-shaped guide rod 10 is installed on the inside of the mounting frame 1, and the arc-shaped guide rod 10 is an arc-shaped structure adapted to the hoop-shaped mounting frame 1. The sliding seat 11 is slidably connected to the outer wall of the arc-sha...

Embodiment 2

[0049] A kind of derusting device for the outer surface of water conservancy construction pipeline, such as Figure 6 As shown, in order to further improve the grinding effect; this embodiment makes the following improvements on the basis of Embodiment 1: a plurality of rolling balls 25 are arranged inside the cylindrical grinding member 13; one side of the outer wall of the cylindrical grinding member 13 is integrated There is a port 24, the size of the port 24 is adapted to the rolling ball 25, and the sealing cover 23 is connected through the thread in the port 24; by setting the rolling ball 25, in the process of the sliding seat 11 being repeatedly pulled, the rolling ball 25 can oscillate in the cylindrical grinding member 13, thereby improving the effect of applying force to the outer surface of the pipeline by the cylindrical grinding member 13, thereby improving the grinding effect.

Embodiment 3

[0051] A method for using a derusting device for the outer surface of a water conservancy construction pipeline, comprising the following steps:

[0052] S1: The user places two hoop-shaped mounting brackets 1 on the outside of the pipe, and connects and fixes them through connecting bolts 5;

[0053] S2: By screwing the adjusting screw 28, the sliding balls 29 on the two arc mounting seats 30 are in close contact with the pipe;

[0054] S3: Screw the threaded sleeve 27, and adjust the adjusting frame 12 to a proper position;

[0055] S4: pull the elastic rope 4 repeatedly through the handle 8, and use the cylindrical polishing part 13 to polish the outer wall of the pipeline;

[0056] S5: After the current position is polished, push the hoop-shaped mounting frame 1, adjust the position of the hoop-shaped mounting frame 1, and repeat step S4 until all the grinding is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com