Hydraulic pressurization device of grinder roller of vertical grinding mill

A technology of a pressurizing device and a vertical mill, which is applied in grain processing and other directions, can solve the problems of difficulty in achieving precision control of feed rate, damage to mechanical parts and hydraulic valve blocks, overall weight of equipment, and large energy consumption, saving materials. The effect of consuming and arranging space, reducing the load, and reducing the difficulty of space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

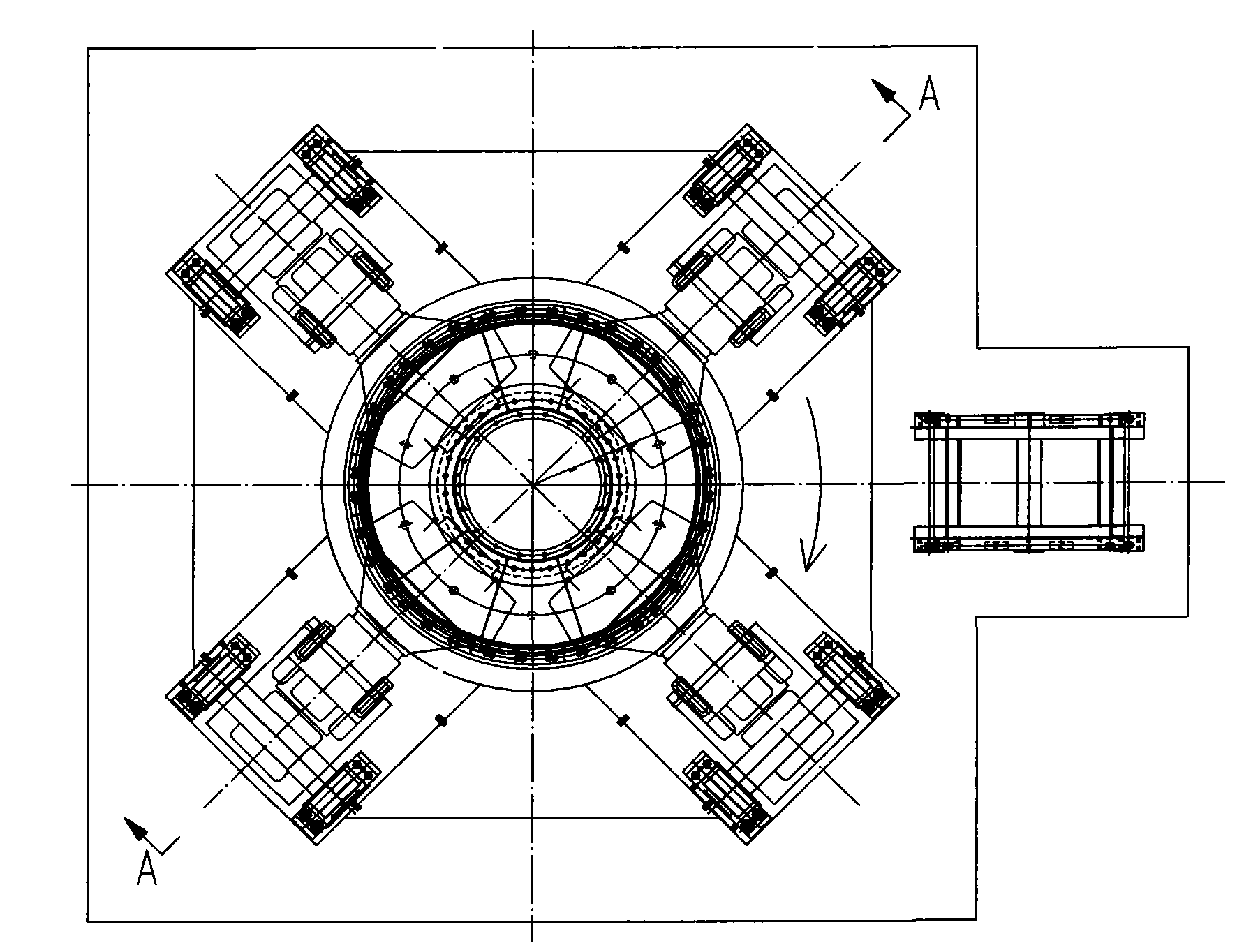

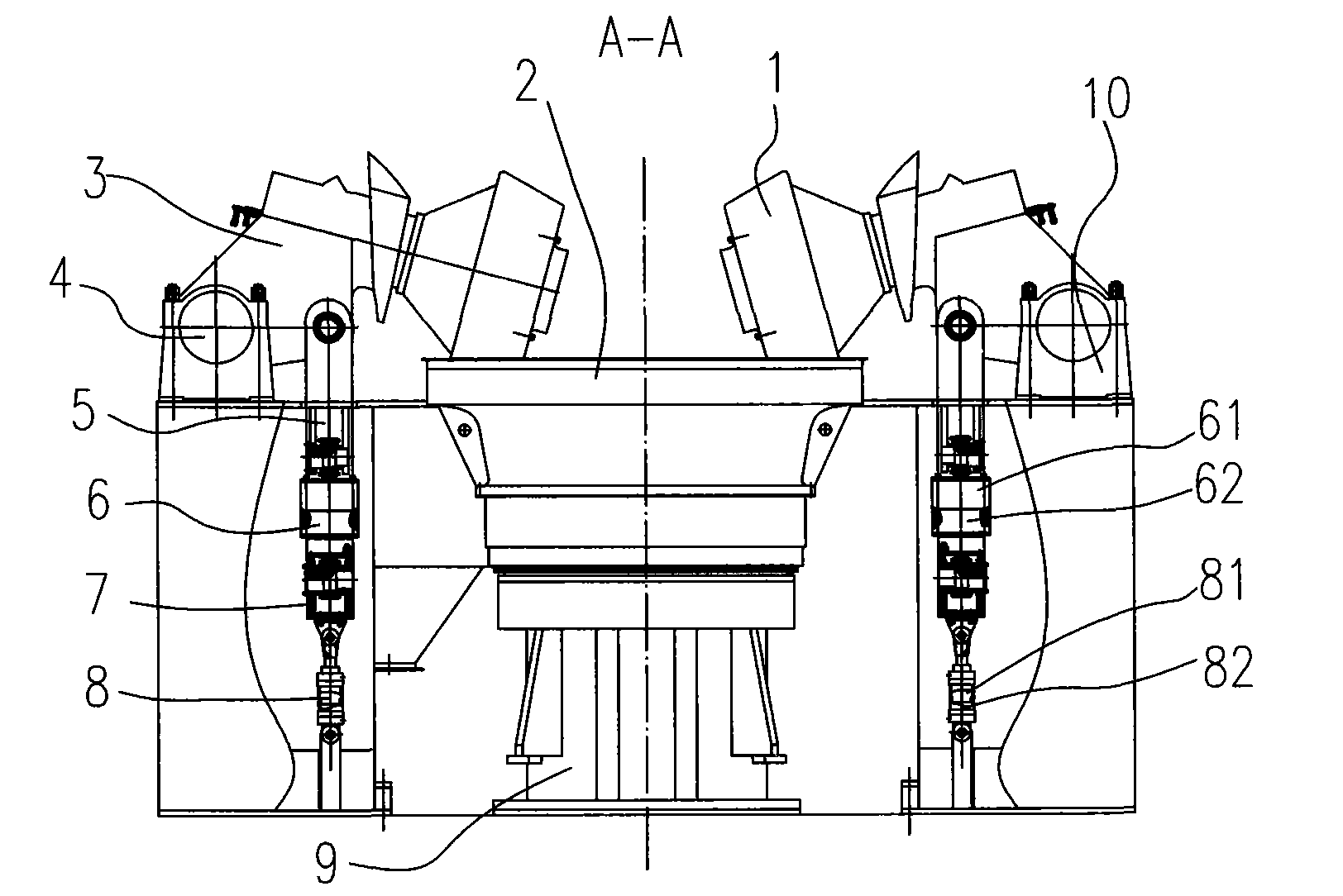

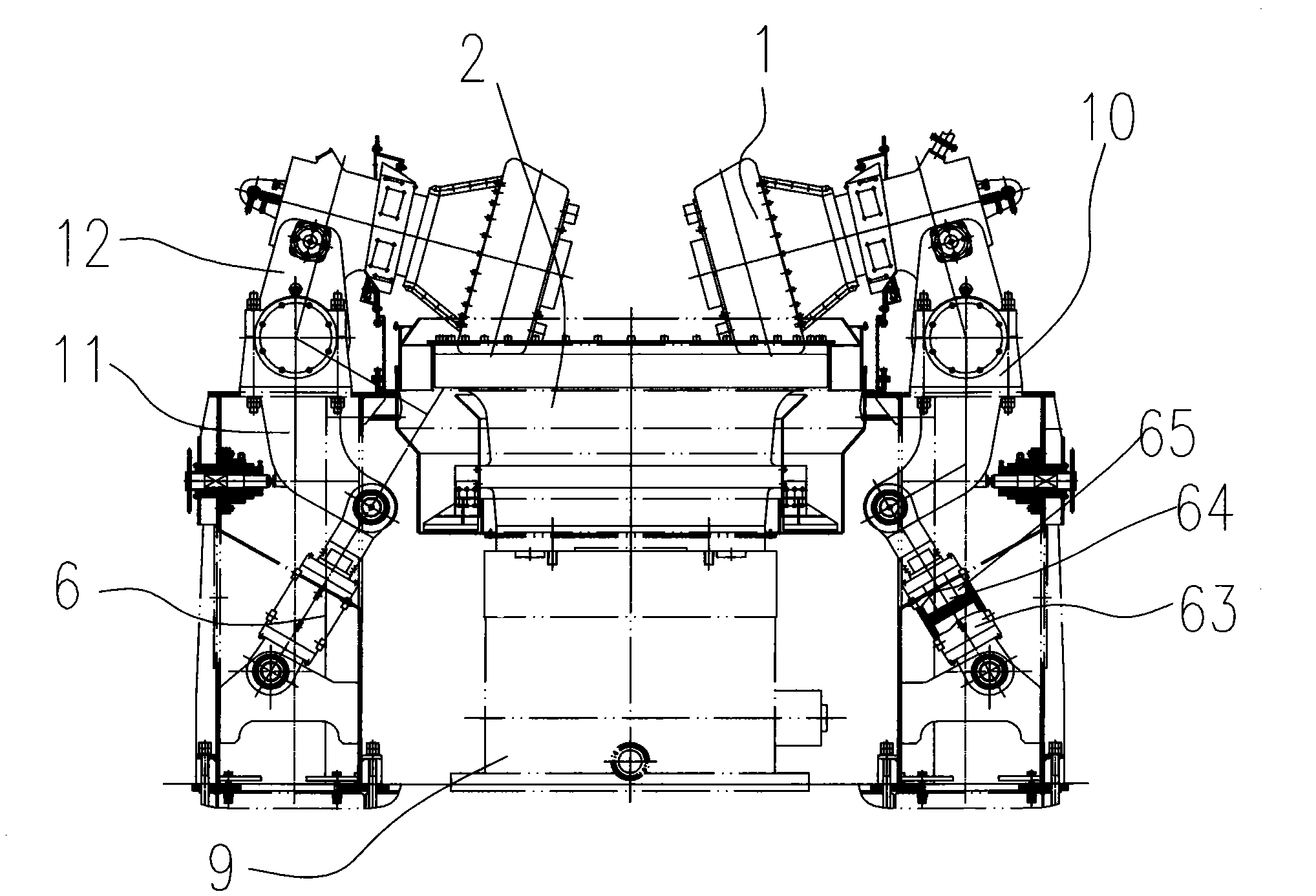

[0023] Such as figure 1 , 2 As shown, the vertical mill of the present invention includes a grinding head 3, a grinding disc 2 horizontally movably connected to a machine body 9; the grinding roller 1 is in the shape of a conical platform, and is movably connected to the front end surface of the grinding head 3. The grinding head 3 is rotated The pin 4 is connected to the machine body 9 so that the conical roller surface of the grinding roller 1 is located above the grinding disc 2.

[0024] It also includes a double-feed transmission device; the double-feed transmission device includes a pressurized cylinder 6, a buffer cylinder 8, a bottom tie rod, a top tie rod 5, and a coupling assembly 7. 7) A coaxial integrated structure is formed with the pressure cylinder 6 on top and the buffer cylinder 8 on the bottom. The lower part of the buffer cylinder 8 is connected to the body 9 through a bottom tie rod; the upper part of the pressure cylinder 6 is fixedly connected to the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com